Page 1

Model 2100 (4100)

Overhead Projector

Service Manual

(Order the M2100 Illustrated Parts Breakdown separately - Stock # 78-6970-4936-5)

78-6970-1335-3 9/92

Visual Systems Division

3M Austin CenterBuilding

A145-5N-01

Austin, TX 78726-9000

Page 2

MODEL 2100 OVERHEAD PROJECTOR

TABLE OF CONTENTS

Technical Support Hotline - 1-800-328-1371 (U.S. & Canada)

TITLE PAGE NUMBER

Section 1 - Introduction.................................................................................1-1

Specifications..............................................................................1-1

Principles of Operation................................................................1-3

- Optics.......................................................................................1-3

- Cooling.....................................................................................1-3

Section 2 - Operation and Maintenance........................................................2-1

Set Up Procedure.......................................................................2-1

Lamp Management System........................................................2-3

Cleaning......................................................................................2-4

- Cleaning Stage and Fresnel Lens.............................................2-4

- Mirrors......................................................................................2-4

Lubrication..................................................................................2-5

Section 3 - Troubleshooting...........................................................................3-1

Section 4 - Adjustments................................................................................4-1

General.......................................................................................4-1

Tools Required............................................................................4-1

Projector Check-out Facilities......................................................4-1

Optical Alignment........................................................................4-3

- Square Image...........................................................................4-3

- Focus Mechanism.....................................................................4-4

- Aligning the Fresnel Lens.........................................................4-4

Color Tuning Cable......................................................................4-5

Post (Folding)..............................................................................4-6

Lampchanger Cable....................................................................4-6

Section 5 - Electrical Diagrams.....................................................................5-1

Section 6 - Disassembly/Re-assembly..........................................................6-1

Projection Head Assembly (Doublet)..........................................6-1

Projection Head Assembly (Triplet).............................................6-1

Top Cover Assembly...................................................................6-1

Fresnel Lens...............................................................................6-1

Stage Glass................................................................................6-2

Focusing Assembly.....................................................................6-2

Condenser Lens.........................................................................6-3

Section 7 - Illustrated Parts Breakdown.........................................................7-1

(Published separately - Stock # 78-6970-4936-5)

9/92

Page 3

MODEL 2100 OVERHEAD PROJECTOR

SECTION 1 INTRODUCTION

This service manual contains servicing instruction, troubleshooting guide,

adjustments, electrical diagrams, assembly/dis-assembly of parts and the

illustrated parts list.

ANGULAR BODY

(2130/4130, 2140/4140, 2160, 2170)

ROUND BODY

(2150/4150, 2180)

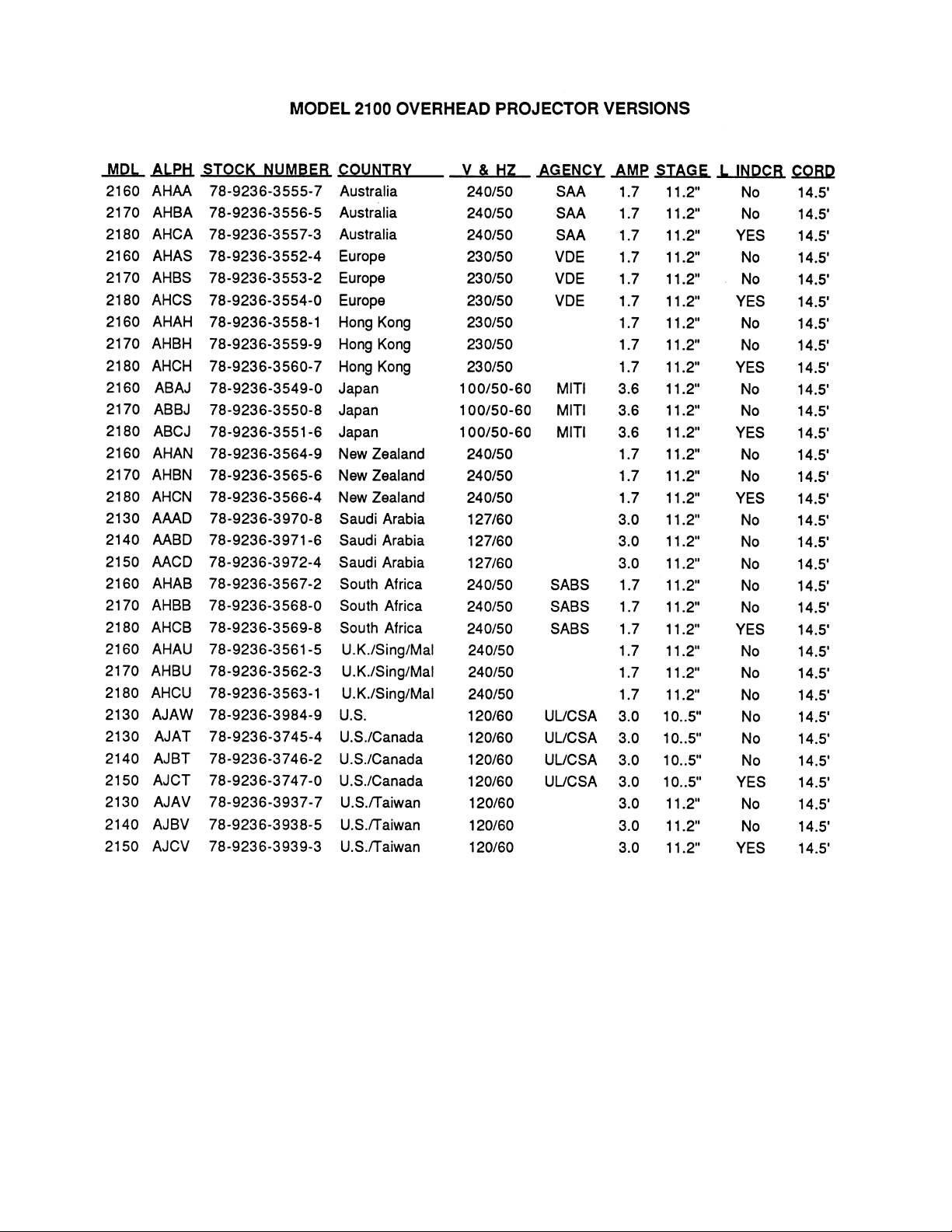

SPECIFICATIONS

Physical

Width - 15.25" (387mm)

Depth - 20.25" (514mm) (Post in upright position)

- 26.25" (667mm) (Post in folded position)

Height - 7.75" (197mm) (Body)

- 30.75" (781mm) (Maximum, top of head)

Weight - 22 lbs. (10.0 Kg) 2180

- 25 lbs. (11.3 Kg) 2130, 2140, 2150, 2160, 2170, 4130, 4140, 4150

9/92

1-1

Page 4

MODEL 2100 OVERHEAD PROJECTOR

1-2

9/92

Page 5

MODEL 2100 OVERHEAD PROJECTOR

Electrical

2130/2140/2150

2160/2170/2180 2160/2170/2180

4130/4140/41 50

Voltage

Frequency

Current Rating

Power Cord

Agency Approval

120/127/VAC

60HZ

3.0 Amps

14-1/2' (4.4mm)

UL, CSA

100VAC

50/60HZ

3.6 Amps

14-1/2' (4.4mm)

-------

220/230/240VAC

50HZ

1.7 Amps

14-1 /2' (4.4mm)

VDE, NEMKO,

SETI

Fuse

-------

F4 Amp - 250 Volt

SEMKO, SEV

F4 Amp - 250 Volt

Mechanical

Safety interlock: Shuts off power to the projector when the top cover assembly is opened.

Safety thermostat: Cuts power to the lamp if the projector exceeds safe operating

temperature.

Color tuning knob: Allows projector to be easily color tuned for any screen size

1.0m x 1.0m (40" x 40") to 2.8m x 2.8m (110" x 110").

Projection Head Tilt - 0° - 20° (All Heads)

Lamp Changer - when lamp burns out, switch to standby lamp.

Optical

Lamp: ANSI Code FNT, 24 Volt, 275 Watt

Lamp Life: 75 Hours

2130/2140/2150 2160/2170/2180

4130/41 40/4150

Illumination: 2000 lumens typical; 2100 lumens typical;

1800 lumens minimum;1900 lumens minimum;

Mirrors: Chassis mirror is second surface high reflective type. (After serial no. 435242)

Projection mirror is front surface high reflective type.

2130, 2140, 2160, 2170 2150, 2180

4130/4140 4150

Head, Projection: 355mm (14.0" F.L.) 327mm (12.9" F.L.)

Doublet Triplet - w/focus

293mm (11.5" F.L.) correction

Singlet 330mm (13" F.L.)

After serial no. 411964

2130/21 40/2150 2160/2170/2180

4130/41 40/4150

Stage: 267mm x 267mm 285mm x 285mm

Transmissive (10.5" x 10.5") (11.2" x 11.2")

Aperture

9/92

1-2

Page 6

MODEL 2100 OVERHEAD PROJECTOR

PRINCIPLES OF OPERATION

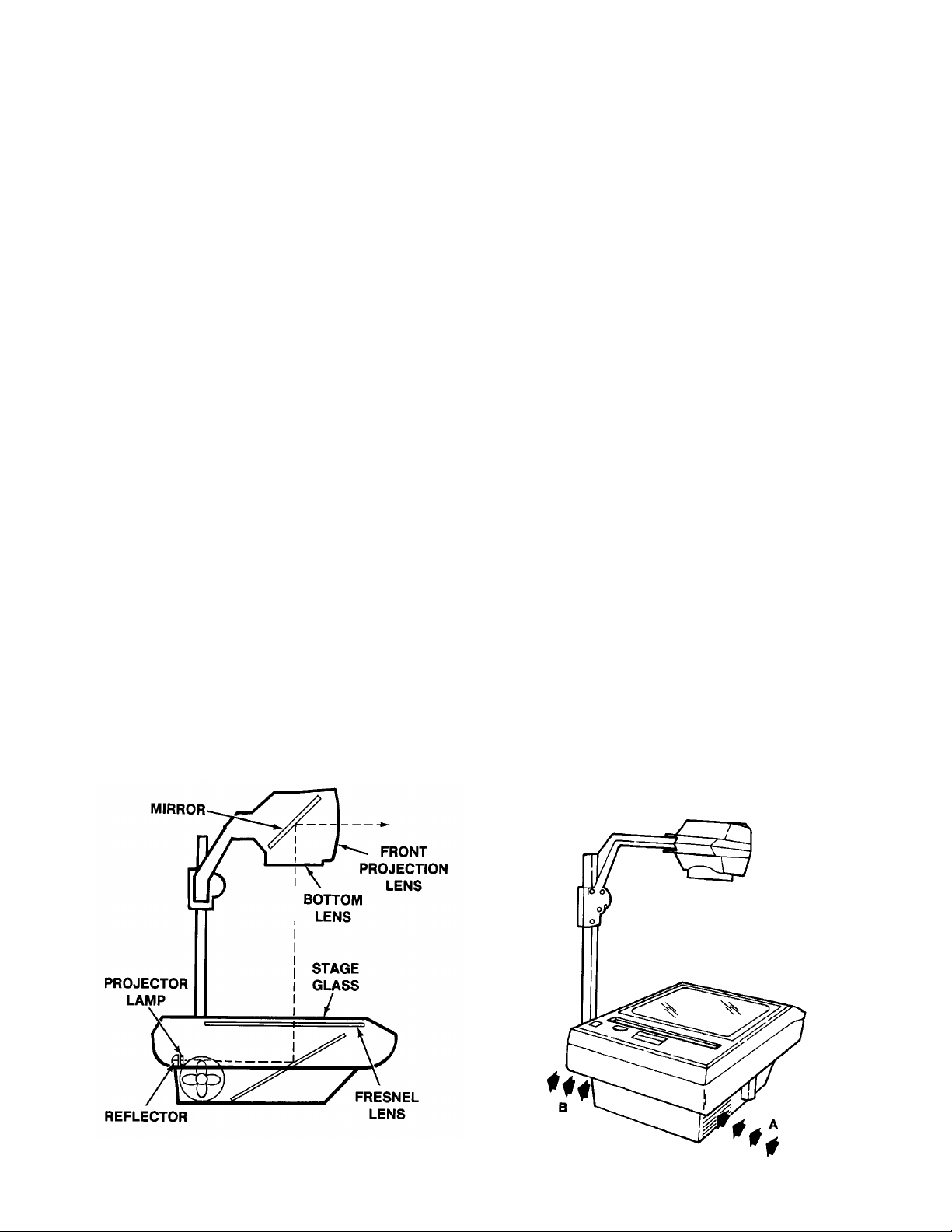

Optics (See Figure 1-2)

The light source for the Overhead Projector

is 275 watt, 24 volt, Tungsten Lamp listed

as ANSI Code FNT and rated at 75 hours.

An external reflector is needed with this

lamp.

Care should be exercised to prevent

excessive vibration or jarring of the

projector when the lamp is on. The lamp

filament becomes more brittle at the

operating temperature of the projector and

shocks may cause premature failure of the

lamp.

The glass envelope should not be touched

by the fingers when inserting the lamp in

the lampholder. Oils on the skin may

combine with the glass to form blisters

which also will shorten the life of the lamp.

The Fresnel lens, located above the lamp

and directly beneath the projection stage, is

a condensing lens which consists of a

series of concentric rings, each of which

has a surface curvature similar to that of a

thick smooth lens. The Fresnel lens is made

of plastic and may be severely damaged if

the fan is stopped or the paths of cooling air

blocked. Proper alignment and direction of

the Fresnel lens is essential in order to

maintain the resolution and brightness

specifications for the projector.

The stage glass provides a convenient flat

surface for placing transparencies and other

materials to be projected. Because the light

passes through the stage, these projection

materials must be transparent.

There are two (2) different projection head

assemblies available for the projector. One

is an Open Triplet Head with focus

correction which has a triplet lens and front

surface mirror and the second a closed

Doublet Head which has one or two

condensing lens(es) and a front surface

mirror. The projection head is located

directly over the center of the Fresnel Lens.

The projector is focused by raising or

lowering the projection head.

Proper alignment of the optical components

and a clean machine are essential if the

maximum operating capabilities of the

overhead projector are to be realized.

Cleaning and alignment procedures are

discussed in Sections 2 and 4 inclusive.

Cooling (See Figure 1-3)

Cooling of the overhead projector is

accomplished by a motor-driven fan located

next to the lamp housing. The cooling air

enters the projector through opening “A”

and exits through opening “B.” (See Figure

1-3) It’s important that the flow of cooling air

not be restricted either by placing projector

too close to a wall (about one foot

clearance is necessary) or by leaving

foreign objects inside the projector.

1-3

9/92

Page 7

SECTION 2 - OPERATION AND MAINTENANCE

SET UP PROCEDURE

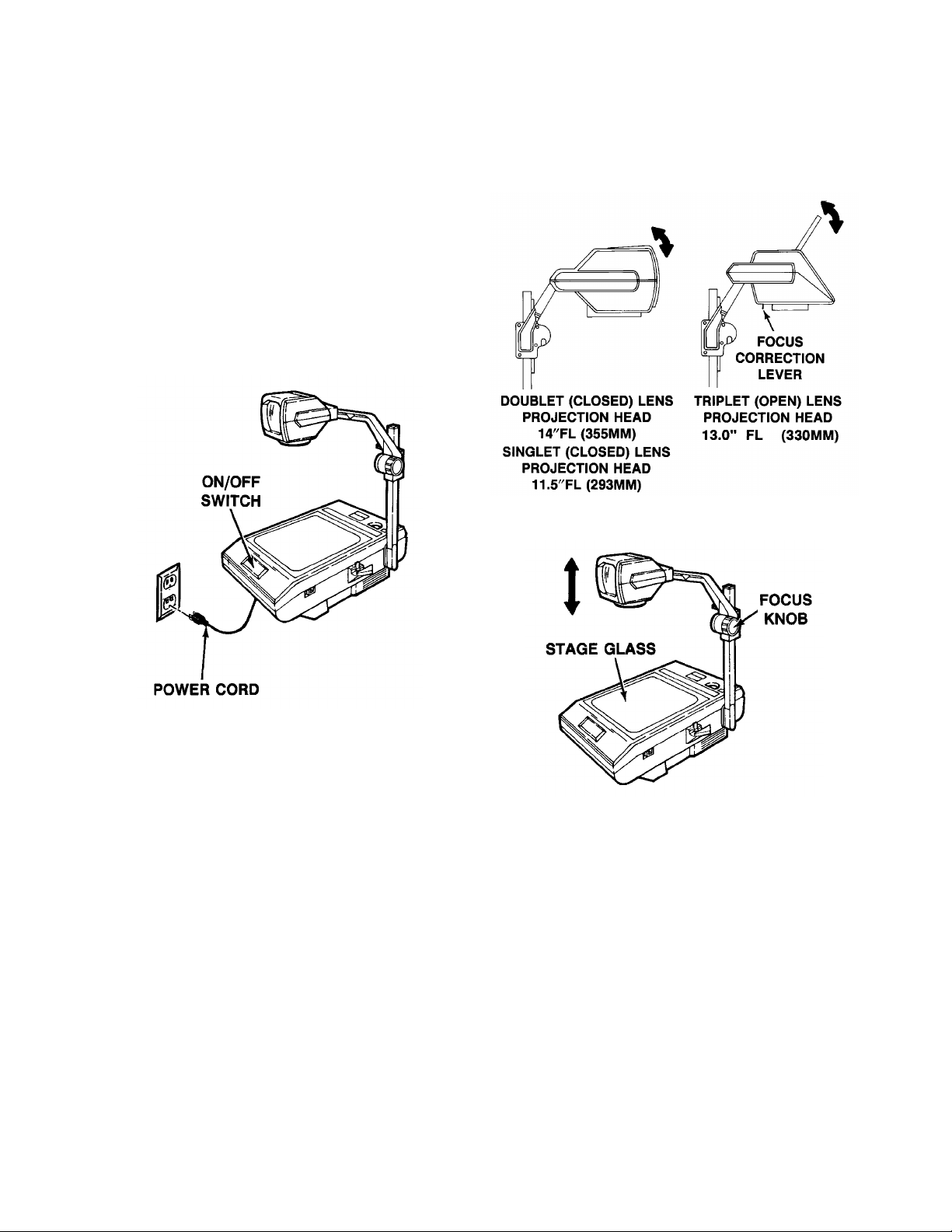

1 . Connect the power cord to a properly

grounded electrical outlet. (Electrical

requirements are listed on the serial plate

located under the base of the projector.)

2. Place the projector on a level surface and

turn the projector on by pushing down on

the ON/OFF switch.

MODEL 2100 OVERHEAD PROJECTOR

CAUTION!

Do not look in the front projection

lens when lamp is on.

3. Adjust the image to the screen

elevation by moving the front

projection lens upward or downward

on the DOUBLET HEAD

ASSEMBLY and the mirror on the

TRIPLET HEAD ASSEMBLY. (See

Figure 2-2)

4. Place a transparency on the stage glass

and focus the projected image by rotating

the Focus Knob. (See Figure 2-3)

5. To maintain top to bottom focus when the

screen is not perpendicular to the

projected image, engage the FOCUS

CORRECTION LEVER located on the

under side of the TRIPLET HEAD

ASSEMBLY using the following

procedure:

NOTE

THE PROJECTION SCREEN

MUST BE IN THE VERTICAL

9/92

POSITION.

2-1

Page 8

MODEL 2100 OVERHEAD PROJECTOR

A. Pull the mirror down as the FOCUS

CORRECTION LEVER is pushed to

the rear of the head assembly.

B. Raise the mirror back to the original

position and refocus using the FOCUS KNOB.

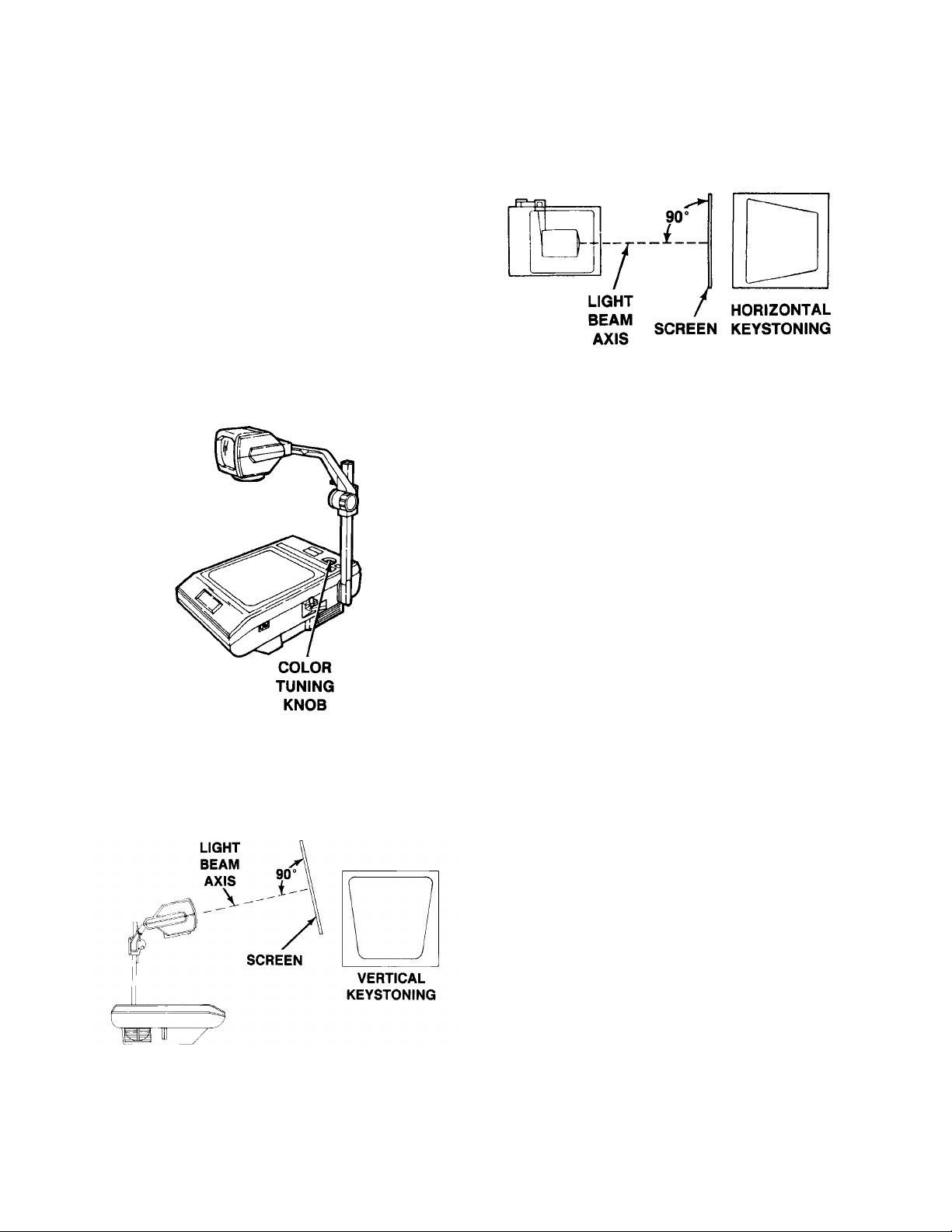

6. Rotate the Color Tuning Knob until

the projected image is free of any

yellow or blue corners.

- To remove blue corners, rotate the

dial counterclockwise.

- To remove yellow corners, rotate the

dial clockwise.

Correct any horizontal keystoning by

moving the projector until it is perpen dicular with the screen.

7. Correct any vertical keystoning by

tilting the screen until it is perpendicular to the light beam axis.

2-2

9/92

Page 9

LAMP MANAGEMENT SYSTEM

(Lamp Indicator)

Pertains only to models equipped with lamp

indicators. (2130/4130 - No holes, opaque)

NOTE

When the projector is turned on, the

red X will momentarily light. This is a

characteristic of the projector.

The Lamp Indicator indicates status of

projection lamp as defined on the following

labels:

MODEL 2100 OVERHEAD PROJECTOR

METHOD 1

A red X will appear on the lamp symbol

when that lamp is burned out. Switch to the

standby lamp. The X will continue to light

until the defective lamp is changed.

METHOD 2

A red X will appear between the two lamp

symbols when a lamp is burned out. Switch

to the standby lamp. The X will continue to

light until the defective lamp is changed.

NOTE

The Overhead Projector must remain

on for 2 to 3 minutes after a lamp

burns out. This will allow the fan to

cool the burned-out lamp and

prevent burned fingers. Unplug the

unit before replacing the lamp.

9/92

2-3

Page 10

MODEL 2100 OVERHEAD PROJECTOR

CLEANING

The optical components of the overhead projector require occasional cleaning to remove

the dust and oil which tends to accumulate

and absorb light. 3M Brand Lens Cleaner

(Part No. 78-6969-7086-6) is recommended.

A small amount of mild detergent in water will

serve as a substitute. Use soft, lint-free cloths,

one to apply the solution and another for

drying.

NOTE

Never use paper lens tissues on

projection lenses as they may damage the lens.

Cleaning Stage Glass and Fresnel Lens

When cleaning the underside of the stage

glass and the top side of the Fresnel Lens,

observe the following steps.

1. Pull the Release Latch and lift the top

cover Top Cover Assembly (See Figure).

2. Remove the Top Cover Assembly by pull-

ing either one of two hinges outward until

the hinge pin is out of the hole. Slide the

complete Top Cover Assembly in the opposite direction to release the second hinge

and lift up and out (See Figure).

3. Loosen the four screws holding the Fresnel

Lens in place.

NOTE: Do not remove the

screws.

4. Turn the retaining clips off to one side.

5. Remove the Fresnel Lens.

6. All surfaces can now be cleaned.

7. Replace all components in reverse order.

Mirrors

2-4

The mirror in the Open Lens Projection

Head of all Model 2100 (4100) projectors

are front surface mirrors and must

cleaned with a cloth and lens cleaner.

Remove any surface dirt on this mirror with

a Camel Hair Brush only.

Prior to serial number 435242 a front surface type Chassis Mirror was used (clean

as above). After serial number 435242, a

second surface high reflective type is used

and may be cleaned with a soft cloth and

lens cleaner.

9/92

NOT

be

Page 11

LUBRICATION

As needed and upon new parts installation,

lubricate lightly the following area with

Anderol No. 757 Grease (3M Part No. 788000-8079-4).

For reference on the lubricating points, see

the three blow-up parts lists.

MODEL 2100 OVERHEAD PROJECTOR

Focus Assembly

Folding Post Assembly

Lamp Changer Assembly

Before S/N 439180

9/92

Lamp Changer Assembly

After S/N 439180

2-5

Page 12

MODEL 2100 OVERHEAD PROJECTOR

SECTION 3 - TROUBLESHOOTING

SYMPTOM CHECK CAUSE/SOLUTIONS

Projected image is:

a. Corners of projected image

appear red (brown) or blue.

b. Top, bottom, or sides of

projected image are not

focused.

c. Not as bright as it should

be.

Focus mechanism slips or is

too tight.

- Is lamp of proper type? (See

label on underside of top cover)

- Is lamp properly seated down in

its socket and vertical?

- If unit is equipped with a lamp

changer, is changer lever fully

seated in the number one

position?

- Is lamp of proper type? (See

label on underside of Top

Cover)

- Is lamp properly seated down in

its socket and vertical?

- If unit is equipped with a lamp

changer, is changer lever fully

seated in the number one

position?

- Are any of the optics

components noticeably

"knocked" out of alignment?

- Is lamp of proper type? (See

label on underside of Top

Cover)

- Is lamp properly seated down in

its socket and vertical?

- If unit is equipped with a lamp

changer, is changer lever fully

seated in the number one

position?

- Has another FNT lamp been

tried?

- Focus tension screw needs

adjustment

- Damaged or misadjusted optics

components (requires

realignment of optics).

- Head "knocked" out of

alignment.

- Adjust Color Tuning

- Adjust optics components

(requires realignment of

optics).

- Lamp not seated.

- Reflector

- Condenser

- Replace lamp.

- Damaged or misadjusted optics

components (requires

realignment of optics).

- Corroded wiring connection.

- Wrong lamp on

- Reflector broken/missing

- To tighten, turn screw

counterclockwise. To loosen,

turn clockwise. Add update kit

if required. (see next page)

Lamp does not energize, but

fan motor does energize.

Neither lamp nor fan motor

energizes.

- Is lamp burned out?

- Is lamp of proper type? (See

label on underside of top cover)

- Is lamp properly seated down in

its socket and vertical?

- If unit is equipped with a lamp

changer, is changer lever fully

seated in the number one

position?

- Is power cord plugged into

electrical outlet?

- Is outlet supplying power to

projector?

9/92

- Replace lamp.

- Replace overheat thermostat.

- Replace lamp sensing switch

(only on projectors equipped

with lamp changer).

- Loose or broken wire

connection.

- Defective power supply.

- On-off switch defective.

- Defective interlock switch.

- Loose or broken wire

connection.

- On-off switch out of

adjustment.

- Replace Fuse (if equipped)

3-1

Page 13

MODEL 2100 OVERHEAD PROJECTOR

TROUBLESHOOTING (continued)

SYMPTOM CHECK CAUSE/SOLUTIONS

Fan motor does not rotate, but

lamp does energize.

Both lamps of units with lamp

changer energize at once.

Projector does not operate

when power switch is

depressed.

On dual lamp projectors,

position of lamp socket does

not change when lamp

changer control is moved.

Top Cover Assembly does not

close completely.

Lamps burn out.

- Is anything blocking rotation of

fan motor?

- Wires crossed and touching?

- Lamp changer switch?

- Projector plugged in?

- Top Cover all the way down?

- Interlock Switch functioning?

- Fuse (if so equipped).

- Loose tension cable.

- Interlock switch out of

alignment?

- Cover latch movement is

restricted?

- High voltage

- Loose or broken wire

connection to motor.

- Defective fan motor.

- Defective lamp sensing switch.

- Defective power cord.

- Defective Interlock Switch.

- Replace Fuse.

- Broken Wire

- Tighten cable. (See Section 4,

adjustments)

- Align interlock switch.

- Disconnected or broken latch

return spring.

- Install Resistor Kit or replace

transformer or change

transformer tap.

Field Kits Available

Focus Knob Slipping

If the projector is below

SN401987, the knob must

also be replaced.

Resistor Kit (120V)

Base Rail Kit (for broken

base rails on lamp module)

Technical Support Hotline - 1-800-328-1371

78-8054-1613-4

78-8054-1614-2

78-8054-1315-6

78-8054-1443-6

78-8054-1615-9

In the U.S & Canada

7:30 - 5:30 CST

Lt. Grey

Charcoal

Tech Service

3-2

9/92

Page 14

SECTION 4 ADJUSTMENTS

GENERAL

The following section describes the

adjustments that will be necessary to service

the Model 2100 (4100) Overhead Projectors.

TOOLS REQUIRED

A. Screwdriver (standard & phillips)

B. Wrench, open end

C. Pliers, standard

D. Pliers, grip ring

E. Square

F. Torx Driver, #T-15 (for removal of stage

glass) 3M Part Number 26-1005-8317-3

MODEL 2100 OVERHEAD PROJECTOR

PROJECTOR CHECK-OUT FACILITIES

Reliable check-out and optical alignment of the

overhead projectors can be accomplished only

if proper facilities are available. (see Figure)

This requires a permanent viewing screen and

test stand in the dealer’s shop, thus enabling

high check-out standards to be established and

maintained. Service personnel will also find that

the use of permanent test facilities will assure a

better check-out job in considerably less time

than otherwise would be required.

Only two low-cost items are required to provide

proper check-out facilities: a test viewing

screen, 60 by 60 inches, with a flat (nonreflective) white surface; and a bench or test

stand permanently located about 8 feet from

the screen.

The screen should be vertical and can most

easily be provided by applying a flat white paint

to a 60 by 60 inch area of a smooth wall. If a

smooth wall is not available, a piece of

wallboard painted flat white, or a white window

shade of the proper size, can be mounted in

the selected area.

The test stand should be high enough to

provide easy access to all parts of the

Overhead Projector when the projector is

placed on the stand for check-out. An electrical

outlet and a switch should be built into the test

stand to facilitate making electrical connections

to the projector.

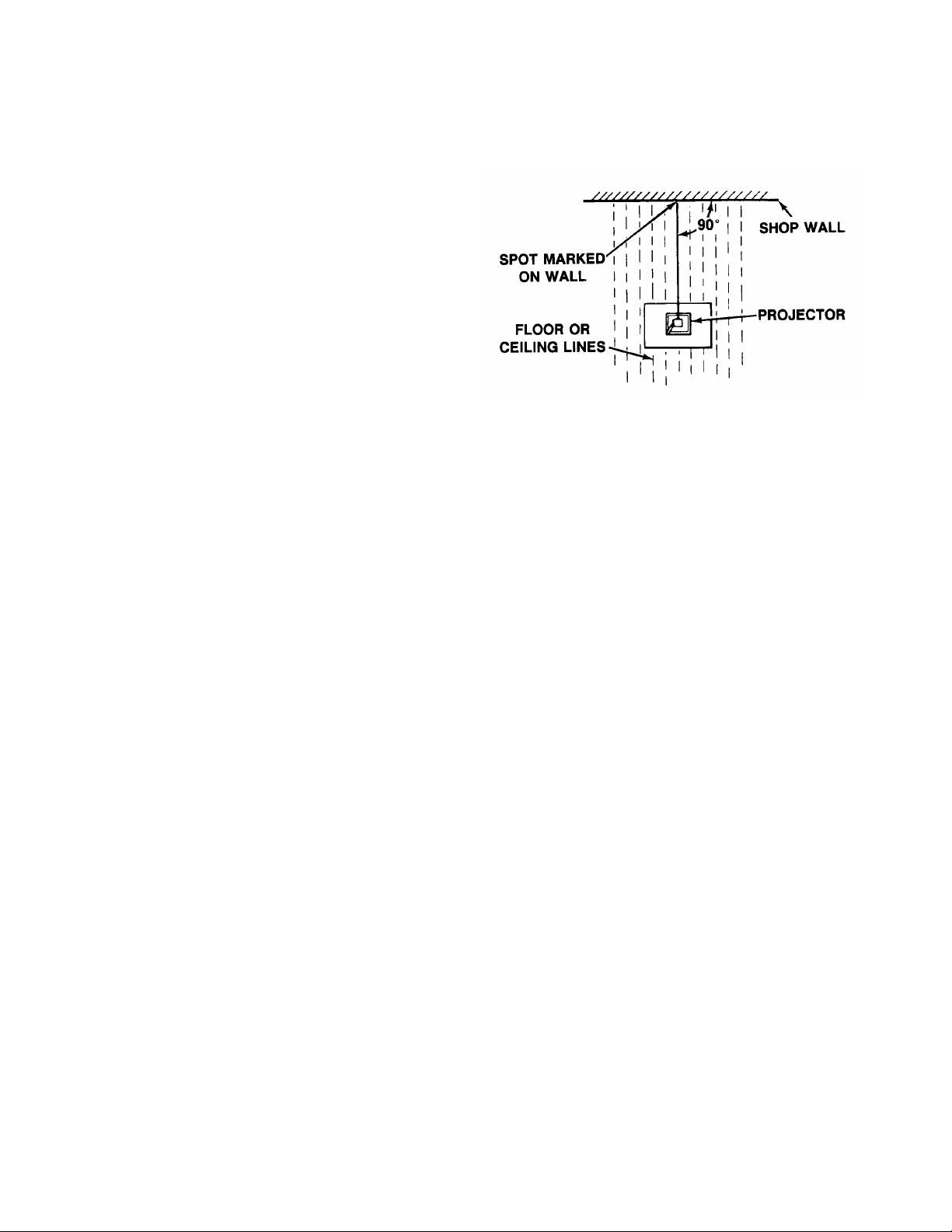

Arrangement of Check-out Area

The following steps provide a simple procedure

for setting up the permanent test facilities. It is

particularly important that the projector be

perfectly square with the viewing screen in

order to eliminate the possibility of vertical or

horizontal keystoning. Even the slightest

keystoning will result in unequal focusing of the

projected image at the four corners, and will

especially affect resolution readings.

Therefore, several of the following steps involve

squaring the projected light with the screen.

Permanently locating the test stand and

viewing screen will assure that the proper

relationship, once established, does not

change.

(Continued on the next page)

9/92

4-1

Page 15

MODEL 2100 OVERHEAD PROJECTOR

1. Select a 60 by 60 inch, smooth area on

one wall. Place a sturdy bench or test

stand about 8 feet from this wall area.

Position the Overhead Projector on the

test stand so that it points toward the

wall.

2. Measure the vertical distance from the

floor to the center of the front projection

lens. Following a floor or ceiling line from

the projector to the wall, make a mark on

the wall the same distance from the floor.

4. Using the mark on the wall as a base

point, measure 30 inches up, down, to

the left and to the right. Mark the edges

of the resultant 60-inch square, and paint

the enclosed area a flat white, or cover

the area with a window shade, wallboard

or other substitute viewing screen.

5. Turn the projector on and focus an image

on the screen. Move the projector

forward or backward, maintaining the

image in focus at all times, until the

projected light just fills the 60 by 60 inch

screen. Be sure the image is in focus.

Locating Center of Projection Area

NOTE

If floor or ceiling lines are not

available, stretch a cord or string

from the projection lens to the wall,

and use a carpenter’s square or

other square object to find the point

at which the cord is perfectly

perpendicular to the wall.

3. Mark the position of the stand on the floor

and the projector on the stand so that the

perpendicular relationship of the line from

the projection lens to the wall is not lost

while making subsequent adjustments .

Correct Tilt of Projector

4-2

9/92

Page 16

OPTICAL ALIGNMENT

Proper alignment of the optical system is

essential for good resolution and uniform

illumination. Poor resolution in one corner and

either red or blue in the corners of the projected

image are indications of poor alignment. The

following components should be checked and

adjusted if necessary before aligning the

overhead projector.

SQUARE IMAGE

A. Set projector on a level table. Project an

image onto a screen or wall. Axis of

beam must be perpendicular to projection

surface.

B. Check to see that side of projected image

are vertical.

C. If the image is not square, remove CAP

and loosen the three (3) Head Fastening

Screws (Doublet Head), and move the

projection head either to the left or right,

forward or backward. When image is

square, tighten the center top screw first,

then the two bottom screws. (See Figure)

MODEL 2100 OVERHEAD PROJECTOR

D. To square the image on the Triplet Head,

remove the two Top Shroud screws and lift

off the Top Shroud. Follow the same

procedure as used on the Doublet Head to

complete adjustment. Replace the Top

Shroud.

9/92

4-3

Page 17

MODEL 2100 OVERHEAD PROJECTOR

FOCUS MECHANISM

If the projection head does not hold its focus

position, you must adjust focus knob tension or

add focus kit (78-8054-1613-4 (gray), 78-80541614-2 (charcoal).

To adjust:

Turn the Tension Screw counterclockwise to

tighten focus assembly. Turn clockwise if

binding occurs.

ALIGNING THE FRESNEL LENS

When replacing the Fresnel Lens, use the

following procedure:

A. Remove the Top Cover Assembly. (See

Section 2 - Cleaning Stage Glass and

Fresnel Lens, page 2-3)

B. Place the Top Cover Assembly upside

down on a flat, clean surface.

C. With the four (4) corner screws loosened,

stretch two rubber bands between

diagonally opposite screws, forming an

"X" pattern. (See Figure)

D. Center circle of Fresnel Lens should

exactly coincide with center of "X".

E. After centering, remove rubber bands one

at a time and retighten corner screws.

NOTE

Refocus the projector each time an

adjustment is made.

Aligning the Fresnel Lens

4-4

9/92

Page 18

MODEL 2100 OVERHEAD PROJECTOR

COLOR TUNING CABLE

(Before Serial Number 422868)

NOTE

Tension in cable should be 3/16"

maximum.

A. Raise the Top Cover Assembly by pulling

the Release Latch and lift up. (See

Figure)

COLOR TUNING CABLE

(After Serial Number 422868)

No adjustment.

B. Turn the Color Tuning Knob clockwise to

the maximum.

C. While holding the Cable Screw, loosen

the Cable Nut. Using pliers, pull the slack

out of the cable.

D. Retighten Cable Nut and Screw. (See

Figure)

9/92

4-5

Page 19

MODEL 2100 OVERHEAD PROJECTOR

POST (FOLDING)

If POST is not perpendicular to the body of the

projector, proceed with the following steps

using Figures below as reference:

1. Loosen SET SCREW.

2. Put a square on the body of the

projector and against the POST>

3. Turn the CAM clockwise to adjust

POST.

4. Re-tighten SET SCREW.

NOTE

POST SHOULD FOLD DOWN

WITHOUT TOO MUCH FORCE.

3. Bend down the appropriate LOCKING

TAB.

LAMPCHANGER CABLE

NOTE

Tension on cable should be a maximum

of 3/16".

A. Hold the Cable Nuts (2) with wrench and

loosen the Cable Screws (2).

B. Move the screws with nuts outward to

tighten cable.

C. Retighten screws with nuts after

adjustment is made. (See Figure)

4-6

Before Serial Number 422868

On projectors after serial number 422868, there

is no cable adjustment.

9/92

Page 20

9/92

Page 21

9/92

Page 22

9/92

Page 23

9/92

Page 24

9/92

Page 25

9/92

Page 26

9/92

Page 27

9/92

Page 28

MODEL 2100 OVERHEAD PROJECTOR

SECTION 6 DISASSEMBLY/RE-ASSEMBLY

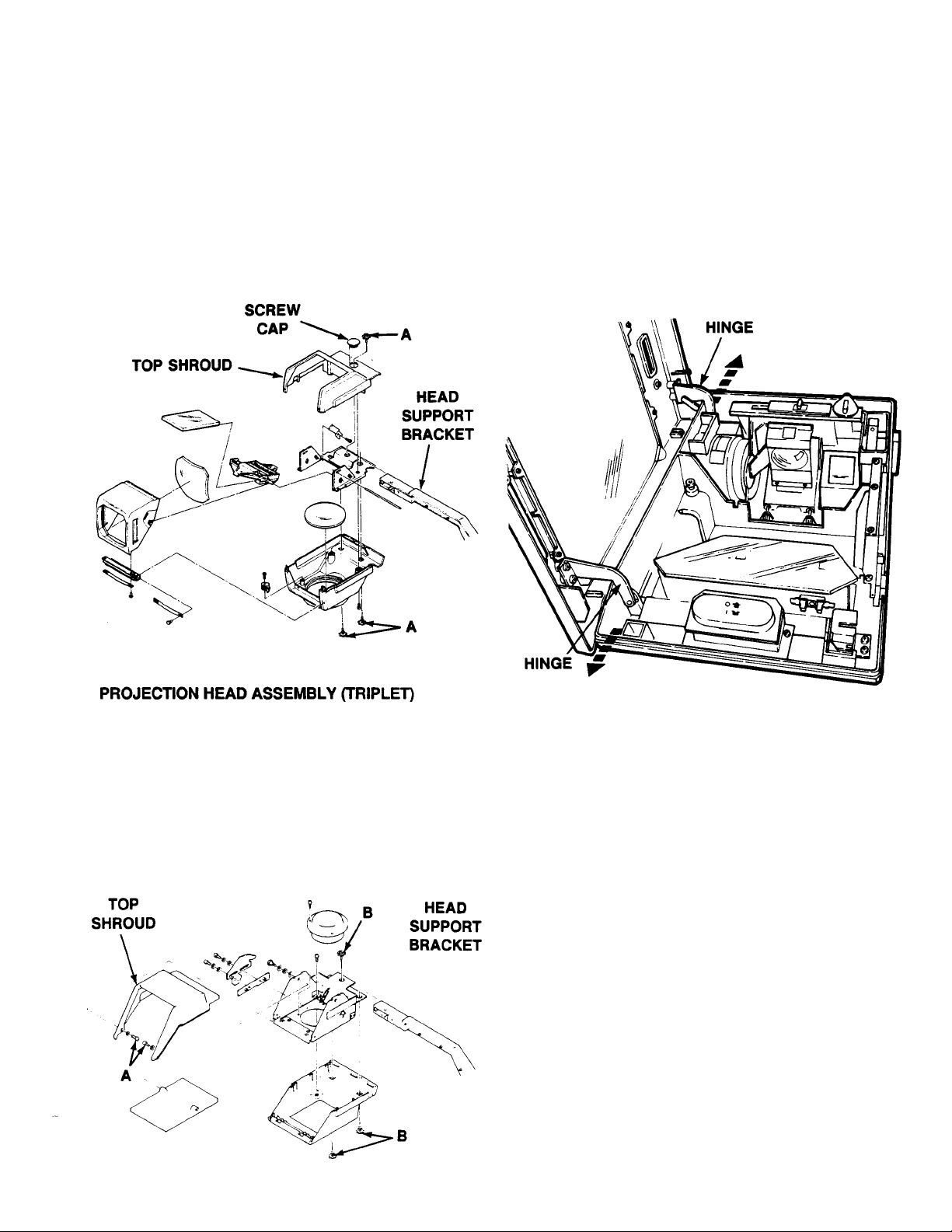

PROJECTION HEAD ASSEMBLY (DOUBLET)

1. To disassemble Head Assembly from Head

Support Bracket:

A. Remove Screw Cap from Top Shroud.

B. Remove the three screws (“A”).

C. Slide the Head Assembly off Support

Bracket.

TOP COVER ASSEMBLY

1. Raise the Top Cover Assembly by pulling the

Release Lever and lifting up.

2. Using both hands, pull either one of the two

hinges outward until the hinge pin is out of

the hole. Slide the complete TOP COVER

ASSEMBLY in the opposite direction to

release the second hinge and lift up and out.

2. To disassemble Head Assembly from Head

Support Bracket:

A. Remove the two screws (“A”).

B. Lift the Top Shroud off assembly.

C. Remove the three screws (“B”).

D. Slide the Head Assembly off Support

Bracket.

FRESNEL LENS

1. Remove Top Cover Assembly. (See Figure

above)

2. Loosen the four (4) screws holding the four

(4) corner clips and lens. DO NOT REMOVE

SCREWS. Turn clips to side and remove

lens.

NOTE

When replacing the Fresnel Lens, make

certain the bow in the lens is in the

convex (upward) position when

projector is upright.

See Section 4, page 4-4, for proper alignment

of Fresnel Lens.

9/92

6-1

Page 29

MODEL 2100 OVERHEAD PROJECTOR

STAGE GLASS

1. Remove Top Cover Assembly.(See page 6-

1)

2. Remove the Fresnel Lens. (See page 6-1)

3. Remove the six (6) tamper proof screws

using a T15 Torx Driver. (3M Part Number

26-1005-8317-3)

4. Remove the MASK (black frame) and Stage

Glass.

5. To reassemble, make certain the beveled

edges on the Stage Glass are facing down

and the 3M logo is in the lower left front

corner. (2140/2150 only, 2130 does not

have logo)

NOTE

This drawing of Stage is up side down.

FOCUSING ASSEMBLY

1 Remove knob.

2. Before disassembling, turn Adjusting Screw

clockwise to loosen assembly.

3. Remove the four “A” screws and cover. (All

internal parts are now exposed.)

4. Before re-assembling, turn adjusting screw

counterclockwise. (This procedure makes

re-assembly easier.)

5. After re-assembly is completed, readjust the

focus tension.

6. Reassemble MASK and Fresnel Lens in

reverse order as noted above.

6-2

9/92

Page 30

MODEL 2100 OVERHEAD PROJECTOR

How to remove and install the condenser lens (when equipped)

Caution! Wear safety glasses when removing lens.

.020 Feeler Gage

.020 to .030 Gap after installation

Tab

Illustration A Illustration B

1. Insert a Pin Punch or Drill Rod into the hole in the Tab (see illustration A)

2. Release the lens by bending the Tab.

3. Install the new lens and bend the Tab back into place.

Caution! Do not overtighten the tab. The lens must have enough clearance

for expansion. There should be a .20 to .30 gap between the lens and

lens bracket (Illustration B).

Caution! Be careful not to scratch or chip the lens while installing.

9/92

6-3

Loading...

Loading...