Page 1

Instructions and Parts List

TM

3M-Matic

200a Type 39600

Adjustable

Case Sealer

with

TM

Important Safety

Information

Read "Important Safeguards",

pages 3-5 and also

operating "Warnings",

page 14 BEFORE

INSTALLING OR

OPERATING THIS

EQUIPMENT.

AccuGlide

Taping Heads

Serial No.

For reference, record machine serial number here.

Spare Parts

It is recommended you

immediately order the spare

parts listed on page 31,

Section I and page 17,

Section II. These parts are

expected to wear through

normal use and should be

kept on hand to minimize

production delays.

3M Packaging Systems Division

3M Center, Building 220-8W-01

St. Paul, MN 55144-1000

"3M-Matic"and "AccuGlide" are Trademarks

of 3M, St. Paul, MN 55144-1000

Litho in U.S.A.

© 3M 1999 44-0009-1894-4 (F69.0)

Page 2

Replacement Parts and Service Information

To Our Customers:

This is the 3M-Matic/AccuGlide/Scotch brand equipment you

ordered. It has been set up and tested in the factory with "Scotch" brand

tapes. If technical assistance or replacement parts are needed, call or Fax

the appropriate number listed below.

Included with each machine is an Instructions and Parts List manual.

Technical Assistance:

3M-Matic Helpline 1-800/328 1390. Please provide the customer support

coordinator with the machine number, machine type/model and serial number.

If you have a technical question that does not require an immediate response,

you may Fax it to 715/381 0248.

Replacement Parts and Additional Manuals

Order parts by part number, part description and quantity required. Also,

when ordering parts and/or additional manuals, include machine name,

number and type. A parts order form is provided at the back of this manual.

3M/Tape Dispenser Parts

241 Venture Drive 1-800/344 9883

Amery, WI 54001-1325 FAX# 715/268 8153

Minimum billing on parts orders will be $25.00. Replacement part prices available on request.

$10.00 restocking charge per invoice on returned parts.

Note : Outside the U.S., contact the local 3M subsidiary for parts ordering information.

3

3M Packaging Systems Division

3M Center, Building 220-8W-01

St. Paul, MN 55144-1000

"3M-Matic", "AccuGlide" and Scotch are trademarks of

3M, St. Paul, Minnesota 55144-1000

Printed in U.S.A.

© 3M 1999 44-0009-1851-4(E79.0)

Page 3

Replacement Parts And Service Information

To Our Customers:

This is the 3M-Matic/AccuGlide/Scotch brand equipment you

ordered. It has been set up and tested in the factory with "Scotch" brand

tapes. If any problems occur when operating this equipment, and you

desire a service call, or phone consultation, call, write or Fax the

appropriate number listed below.

Included with each machine is an Instructions and Parts List manual.

SERVICE, REPLACEMENT PARTS AND ADDITIONAL MANUALS

AVAILABLE DIRECT FROM:

Order parts by part number, part description and quantity required. Also, when

ordering parts and/or additional manuals, include machine name, number and

type.

3

3M Packaging Systems Division

3M Center, Building 220-8W-01

St. Paul, MN 55144-1000

1-800/328 1390

"3M-Matic", "AccuGlide" and Scotch are trademarks of

3M, St. Paul, Minnesota 55144-1000

Printed in U.S.A.

© 3M 1999 44-0009-1852-2(D79.0)

Page 4

Instruction Manual

200a, Adjustable Case Sealer, Type 39600

This instruction manual is divided into two sections as follows:

Section

Section II Includes specific information regarding the AccuGlide II STD 2 Inch Taping Heads.

I Includes all information related to installation, operation and parts for the case sealer.

Table of Contents Page

Section

Description ...................................................................................................................................... 1

Equipment Warranty and Limited Remedy ...................................................................................... 2

200a Contents ................................................................................................................................. 2

Important Safeguards ...................................................................................................................... 3 - 5

Specifications .................................................................................................................................. 6 - 8

Installation and Set-Up .................................................................................................................... 9 - 11

I 200a Adjustable Case Sealer

Receiving and Handling ..................................................................................... 9

Machine Set-Up .................................................................................................. 9 - 11

Packaging and Separate Parts ................................................................. 9 -10

Machine Bed Height ................................................................................. 11

Outboard Tape Roll Mounting ................................................................... 11

Tape Leg Length....................................................................................... 11

Box Size Capacity of Case Sealer ............................................................ 12

Electrical Connection and Controls ........................................................... 12

Initial Start-Up of Case Sealer .................................................................. 12

Operation ........................................................................................................................................ 13 - 16

Electrical On/Off Switch ...................................................................................... 14

Tape Loading/Threading .................................................................................... 14

Box Size Set-Up ................................................................................................. 15 - 16

Box Sealing ........................................................................................................ 16

Maintenance .................................................................................................................................... 17 - 18

Cleaning ............................................................................................................. 17

Lubrication .......................................................................................................... 17

Circuit Breaker .................................................................................................... 18

Knife Replacement, Taping Head ....................................................................... 18

Box Drive Belt Replacement............................................................................... 18

(Table of Contents continued on next page)

i

Page 5

Table of Contents (Continued) Page

Adjustments ................................................................................................................................... 19 - 21

Drive Belt Tension ...................................................................................................... 19 - 20

Taping Head Adjustments .......................................................................................... 21

Special Set-Up Procedure ............................................................................................................... 23 - 25

Changing Tape Leg Length ................................................................................ 23 - 24

Box and Machine Bed Height Range ................................................................. 24 - 25

Troubleshooting............................................................................................................................... 27

Electrical Diagram ........................................................................................................................... 29

Parts and Service Information ......................................................................................................... 31

Options/Accessories........................................................................................................................ 32

Replacement Parts Illustrations and Parts Lists ..................................................... (Yellow Section) 33 - 57

Section II AccuGlide II STD 2 Inch Taping Heads

(See Section II for Table of Contents)

ii

Page 6

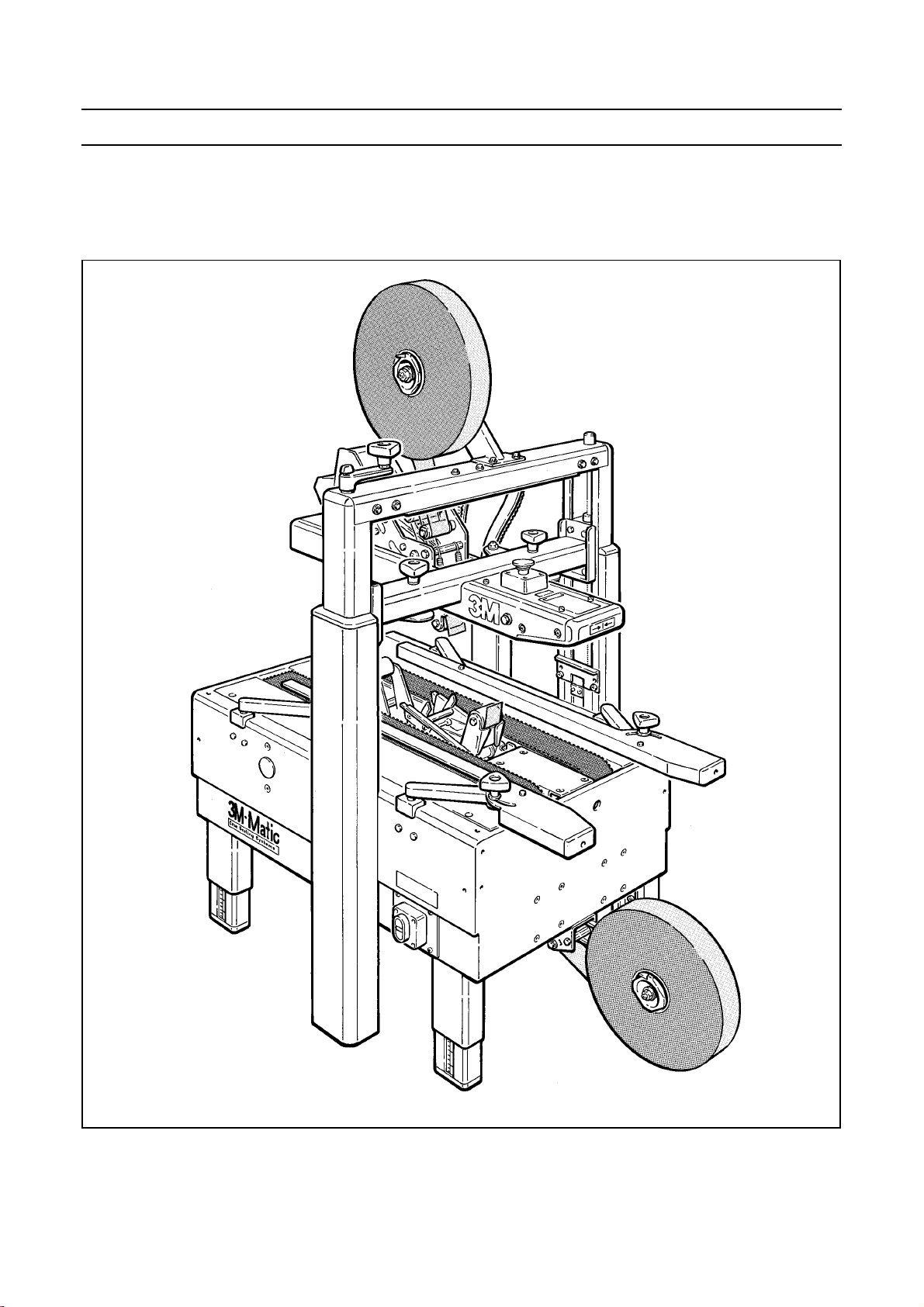

Description

The 3M-MaticTM 200a Adjustable Case Sealer with AccuGlide II Taping Heads is designed to apply a C clip

of Scotch brand pressure-sensitive film box sealing tape to the top and bottom center seam of regular slotted

containers. The 200a is manually adjustable to a wide range of box sizes (see "Specifications Box Weight and

Size Capacities", Page 7).

3M-Matic

TM

200a Adjustable Case Sealer, Type 39600 (Note Lower tape supply roll and bracket assembly are

shown in the alternate location)

Page 7

Equipment Warranty and Limited Remedy: THE FOLLOWING WARRANTY IS MADE IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTY OF MERCHANTABILITY, THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE AND ANY IMPLIED WARRANTY ARISING OUT OF A COURSE OF DEALING, A CUSTOM OR

USAGE OF TRADE:

TM

3M sells its 3M-Matic

200a Adjustable Case Sealer, Type 39600 with the following warranties:

1. The Taping Head knife, springs and rollers will be free from all defects for ninety

(90) days after delivery.

2. All other Taping Head parts will be free from all defects for three (3) years after delivery.

3. The gearmotor will be free from all defects for one (1) year after delivery.

4. All other parts will be free from all defects for ninety (90) days after delivery.

If any part is proved to be defective within its warranty period, then the exclusive remedy and 3Ms and sellers

sole obligation shall be, at 3Ms option, to repair or replace the part, provided the defective part is returned

immediately to 3Ms factory or an authorized service station designated by 3M. A part will be presumed to have

become defective after its warranty period unless the part is received or 3M is notified of the problem no later

than five (5) calendar days after the warranty period. If 3M is unable to repair or replace the part within a

reasonable time, then 3M, at its option, will replace the equipment or refund the purchase price. 3M shall have

no obligation to provide or pay for the labor required to install the repaired or replacement part. 3M shall have

no obligation to repair or replace (1) those parts failing due to operator misuse, carelessness, or due to any

accidental cause other than equipment failure, or (2) parts failing due to non-lubrication, inadequate cleaning,

improper operating environment, improper utilities or operator error.

Limitation of Liability: 3M and seller shall not be liable for direct, indirect, special, incidental or consequential

damages based upon breach of warranty, breach of contract, negligence, strict liability or any other legal

theory.

The foregoing Equipment Warranty and Limited Remedy and Limitation of Liability may be changed only by a

written agreement signed by authorized officers of 3M and seller.

Contents 200a Adjustable Case Sealer

(1) 200a Adjustable Case Sealer, Type 39600

(1) Upper Assembly Height Adjustment Crank/Hardware

(1) Upper Tape Drum/Bracket/Hardware

(2) Column Stop Bracket/Hardware

(1) Tool/Spare Parts Kit

(1) Instruction and Parts Manual

Scotch, AccuGlide, and 3M-MaticTM are Trademarks of 3M, St. Paul, Minnesota 55144-1000

2

Page 8

Important Safeguards

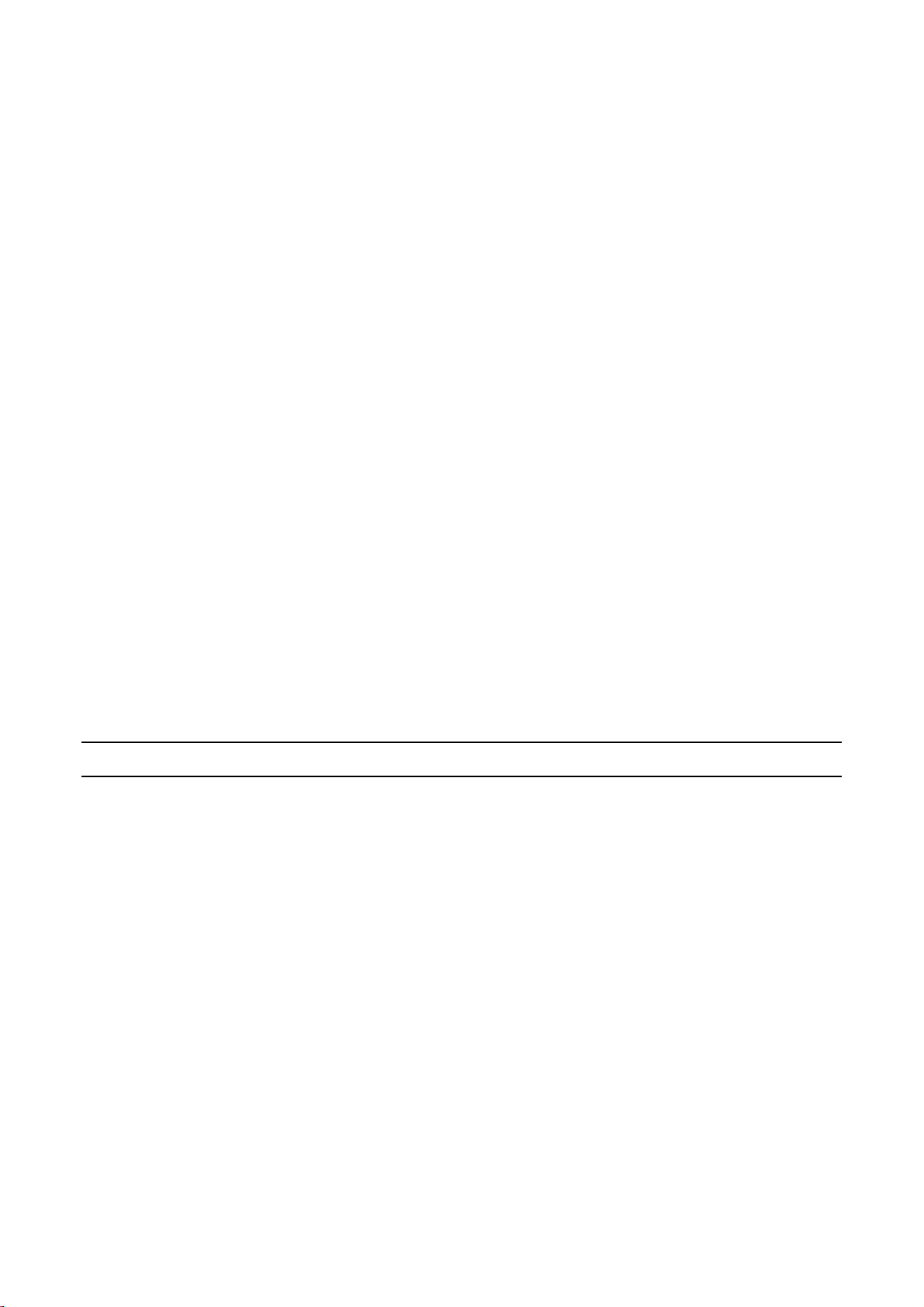

This safety alert symbol identifies

important messages in this manual.

READ AND UNDERSTAND THEM BEFORE

INSTALLING OR OPERATING THIS

EQUIPMENT.

Important In the event the following safety

labels are damaged or destroyed, they must be

replaced to ensure operator safety. A label

kit, part number 78-8113-6714-9 is available as

a stock item or individual labels can be ordered.

See Parts Illustration/List, Section I, pages 56

and 57.

The "Warning Hazardous Voltage" label, shown

in Figure 1-2, is attached to the electrical enclosure

on the lower left side of the machine frame. The

label warns service personnel to unplug the power

supply before attempting any service work on the

case sealer.

The "Warning Sharp Knife" label, shown in

Figure 1-1, is attached to both sides of the upper ski

assembly at the location of the cut-off knife on the

upper taping head. The labels warn operators and

service personnel of the very sharp knife used to cut

the tape at the end of the tape application.

Figure 1-2 Electrical Warning Label

The "Caution Pinch Point" label, shown in

Figure 1-3, is attached to the center plate at the exit

end of the machine bed. The label warns the

operator to keep hands out of this area when the

drive belts are running.

Figure 1-1 Knife Warning Label

Figure 1-3 Pinch Point Caution Label

3

Page 9

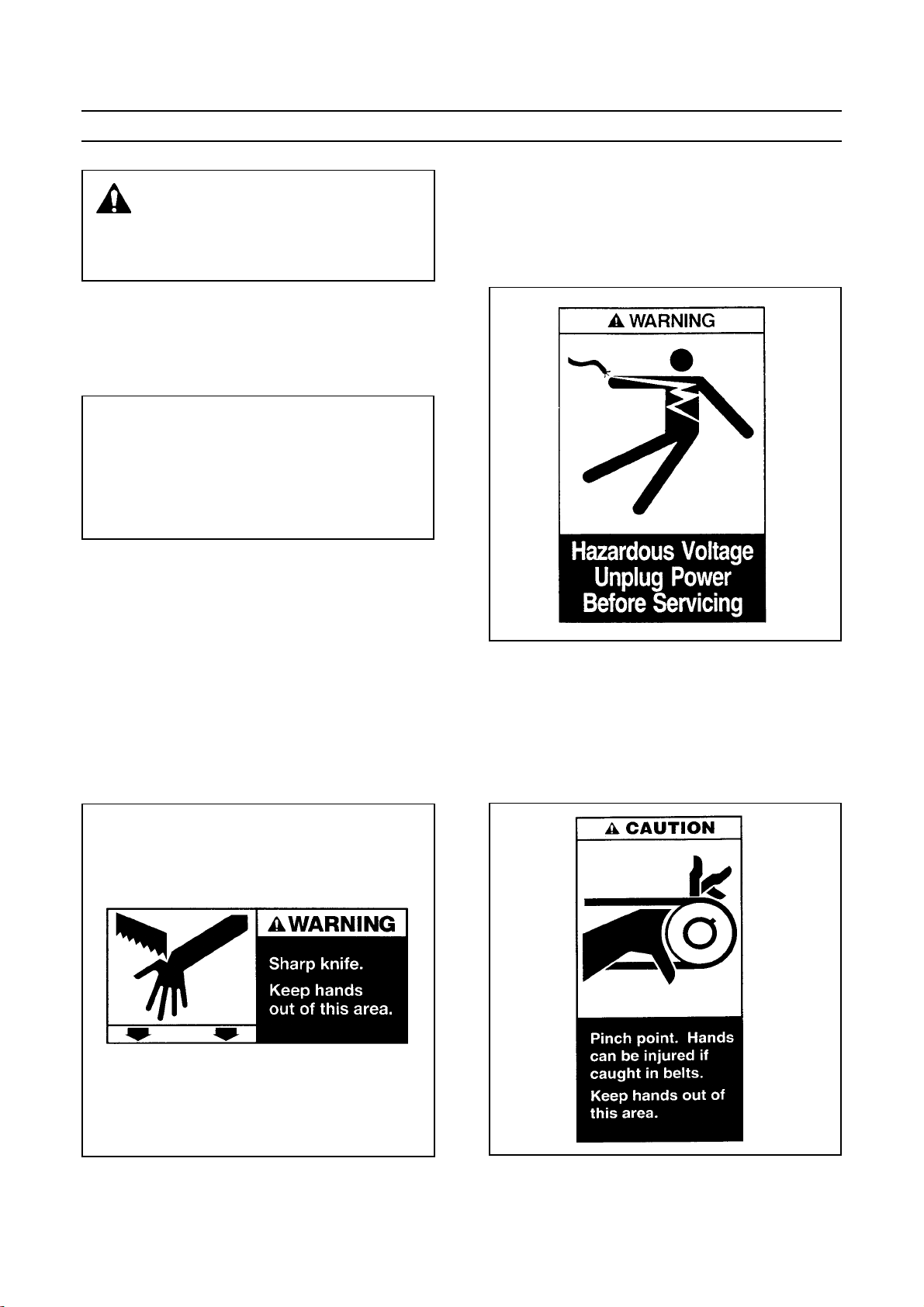

Important Safeguards (Continued)

The "Caution Pinch Point" label, shown in

Figure 1-4, is attached to the top of the upper

assembly crossbar on both sides of the machine.

The label reminds operator to keep hands away from

compression rollers when machine is running.

The "Safety Instructions" label, shown in

Figure 1-6, is attached to the top/front of the upper

ski assembly. The label provides convenient

safeguard instructions for the operator and service

personnel.

Figure 1-4 Pinch Point Caution Label

The 200a is equipped with a "Red" emergency stop

switch located on the top/front of the upper ski

assembly. The "Stop" label, shown in Figure 1-5,

is located near the switch and reminds operators

and casual personnel of the function of this switch.

Figure 1-6 Safety Instruction Label

The "Center Box Here" label, shown in Figure 1-7,

is attached to the front of the upper frame to remind

the operator of the proper box placement procedure.

Figure 1-5 Stop Label

Figure 1-7 Center Box Label

4

Page 10

Important Safeguards (Continued)

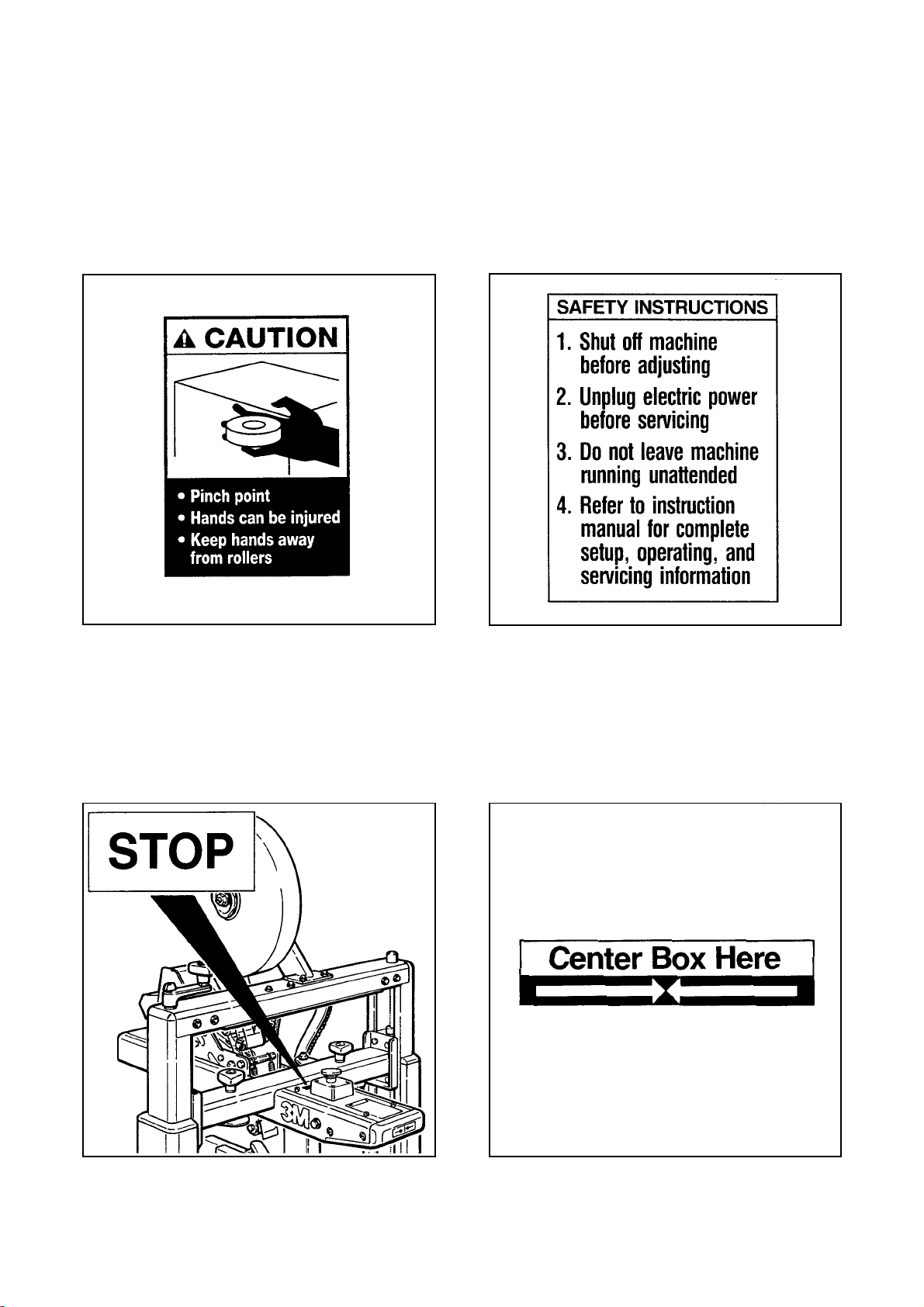

The "Up/Down/Lock" label, shown in Figure 1-8, is

located on the top surface, on each side, of the

upper column assembly. The label reminds the

operator of the direction to turn the height

adjustment crank to raise and lower the upper

ski/taping head and the locking feature.

Figure 1-8 Up/Down/Lock Label

The following two labels are located on the upper

and lower taping heads. Replacement part numbers

for these labels are listed in Section II.

The "Tape Threading Label", shown in Figure 1-9,

is attached to the left side of both the upper and

lower taping heads.

The "Warning Sharp Knife" label warns

operators and service personnel of the extremely

sharp knife used to cut the tape at the end of the

box sealing operation. The label, shown in

Figure 1-10, is located on the orange knife guard

between the applying roller assembly and the

buffing roller assembly. Never operate taping

head with knife guard removed.

Before working with the taping heads or loading/

threading tape, refer to Figures 3-1 and 3-2 in

Section II to identify the knife location. Keep hands

out of these areas except as necessary to

service the taping heads or to load/thread tape.

Figure 1-9 Tape Threading Label

Figure 1-10 Knife Warning Label

5

Page 11

Specifications

1. Power Requirements:

Electrical - 115 VAC, 60 Hz, 1.9 A (220 watts)

The machine is equipped with a 1/6 HP gearmotor and comes with a standard neoprene covered power cord

and a grounded plug. Contact your 3M Representative for power requirements not listed above.

2. Operating Rate:

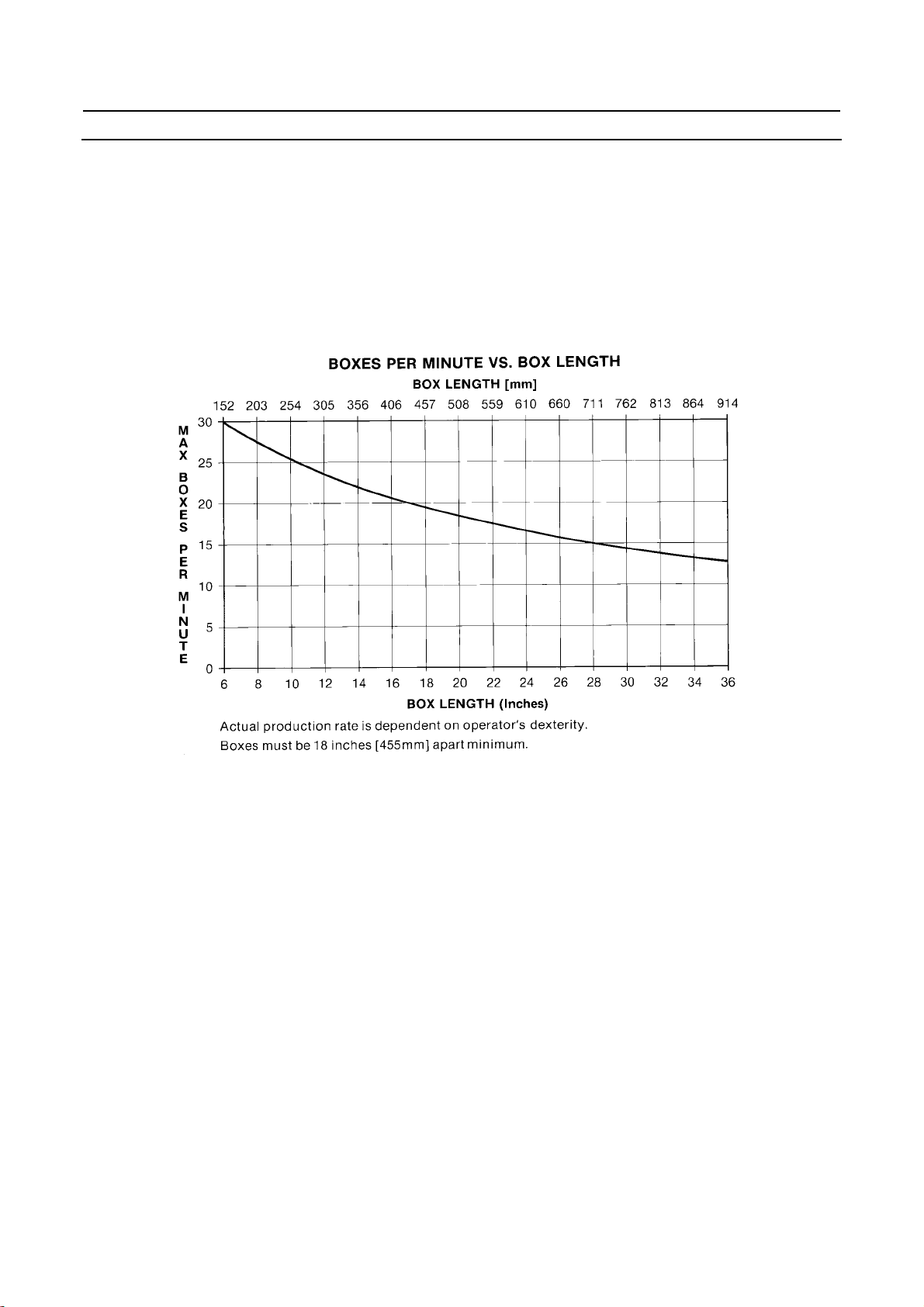

Box drive belt speed is approximately 0.4 m/s [78 feet per minute].

IMPORTANT SAFEGUARD

3. Operating Conditions:

Use in dry, relatively clean environments at 5

Note: Machine should not be washed down or subjected to conditions causing moisture condensation

on components.

IMPORTANT SAFEGUARD

4. Tape:

Scotch brand pressure-sensitive film box sealing tapes.

5. Tape Width:

36 mm [1 1/2 inch] minimum to 48 mm [2 inch] maximum.

(Specifications continued on next page)

o

to 40o C [40o to 105o F] with clean, dry boxes.

6

Page 12

Specifications (Continued)

6. Tape Roll Diameter:

Up to 405 mm [16 inch] maximum on a 76.2 mm [3 inch] diameter core.

(Accommodates all system roll lengths of Scotch

brand film tapes.)

7. Tape Application Leg Length Standard:

70 mm ± 6 mm [2 .75 inch ±.25 inch ]

Tape Application Leg Length Optional:

50 mm ± 6 mm [2 inch ±.25 inch]

(See "Special Set-Up Procedure Changing the Tape Leg Length", Page 23.)

8. Box Board:

Style regular slotted containers RSC

125 to 275 P.S.I. bursting test, single wall or double wall B or C flute.

9. Box Weight and Size Capacities:

A. Box Weight, filled 2.3 kg [5 lbs.] minimum, 38.6 kg [85 lbs.] maximum.

B. Box Size: Minimum Maximum

Length 150 mm [6.0 inch] Unlimited

Width 150 mm [6.0 inch]* 550 mm [21.5 inch]

Height 120 mm [4.75 inch]** *** 620 mm [24.5 inch] ***

* Cartons narrower than 250 mm [10 inch] in width may require more frequent belt replacement

because of limited contact area.

** 90 mm [3.5 inch] height with heads adjusted to apply 50 mm [2 inch] tape leg lengths. (See "Special

Set-Up Procedure Changing the Tape Leg Length", Page 23.)

*** 165 mm [6.5 inch] minimum to 725 mm [28.5 inch] maximum height with columns adjusted to upper

position. (See "Special Set-Up Procedure Box and Machine Bed Height Range", Page 24.)

Special modifications may be available for carton sizes not listed above.

Contact your 3M Representative for information.

Note: The case sealer can accommodate most boxes within the size range listed above. However, if

the box length (in direction of seal) to box height ratio is .75 or less, then several boxes should be test run

to assure proper machine performance.

DETERMINE THE BOX LIMITATIONS BY COMPLETING THIS FORMULA:

BOX LENGTH IN DIRECTION OF SEAL MUST BE GREATER THAN .75

BOX HEIGHT

Any box ratio approaching this limitation should be test run to assure performance.

(Specifications continued on next page.)

7

Page 13

Specifications (Continued)

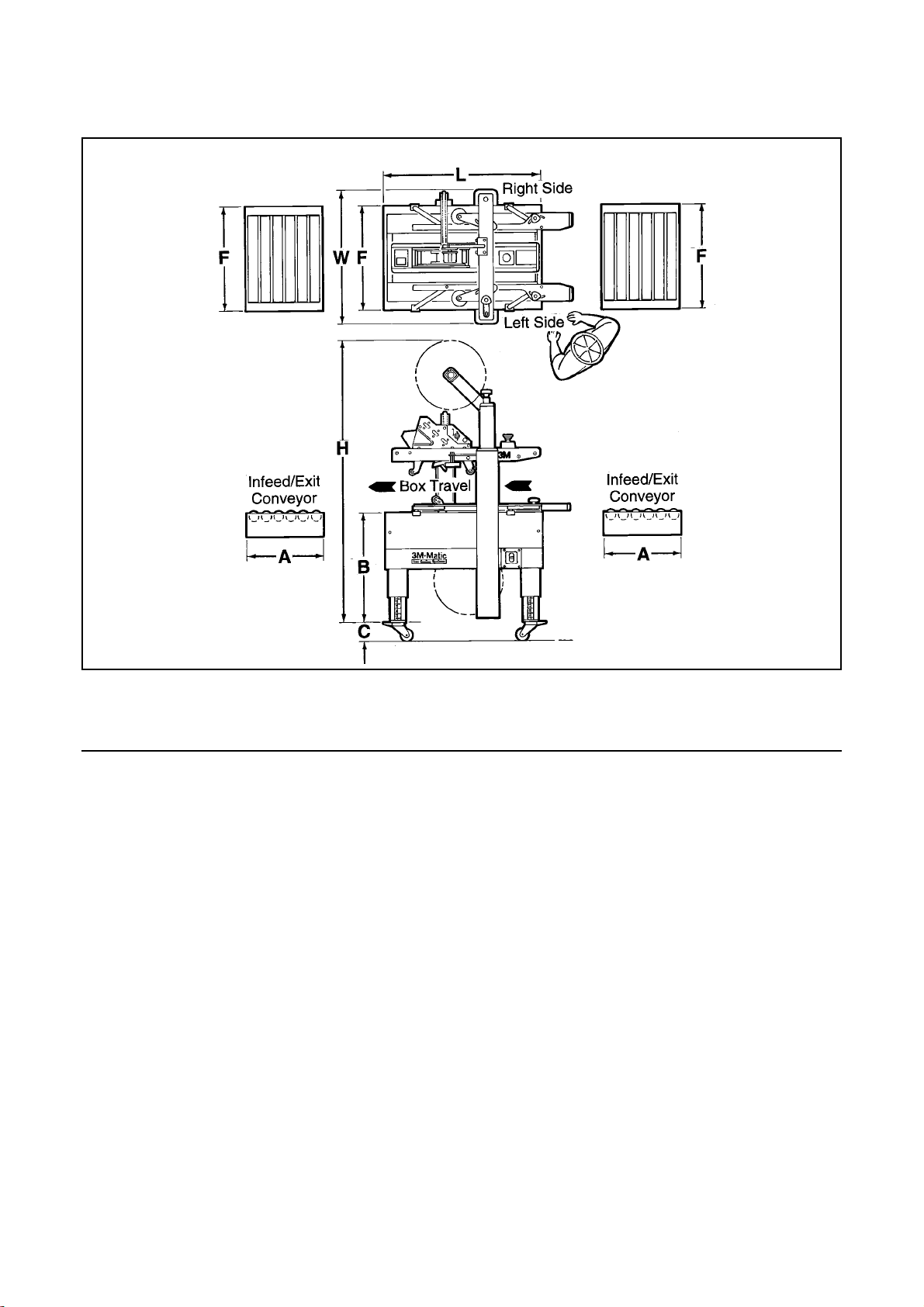

10. Machine Dimensions:

W L H A* B C** F

Minimum

mm 790 930 1350 460 610 100 620

[Inches] [31] [36 1/2] [53] [18] [24***] [4] [24 1/2]

Maximum

mm 2185 890

* Infeed/Exit conveyors are optional

** Casters are optional

*** When columns are adjusted to upper position, "B" minimum/maximum dimension decreases by 90 mm

[3 1/2 inches] and "H" maximum dimension increases by 100 mm [4 inch]. (See "Special Set-Up Procedure

Box and Machine Bed Height Range", Page 24.)

Weight 145.6 kg [320 lbs] crated (approximate)

123.4 kg [280 lbs] uncrated (approximate)

11. Set-Up Recommendations:

Machine must be level.

Customer supplied infeed and exit conveyors (if used) should provide straight and level box entry and exit.

Exit conveyors (powered or gravity) must convey sealed boxes away from machine.

8

Page 14

Installation and Set-Up

Receiving And Handling

After the machine has been uncrated, examine the

case sealer for damage that might have occurred

during transit. If damage is evident, file a damage

claim immediately with the transportation company

and also notify your 3M Representative.

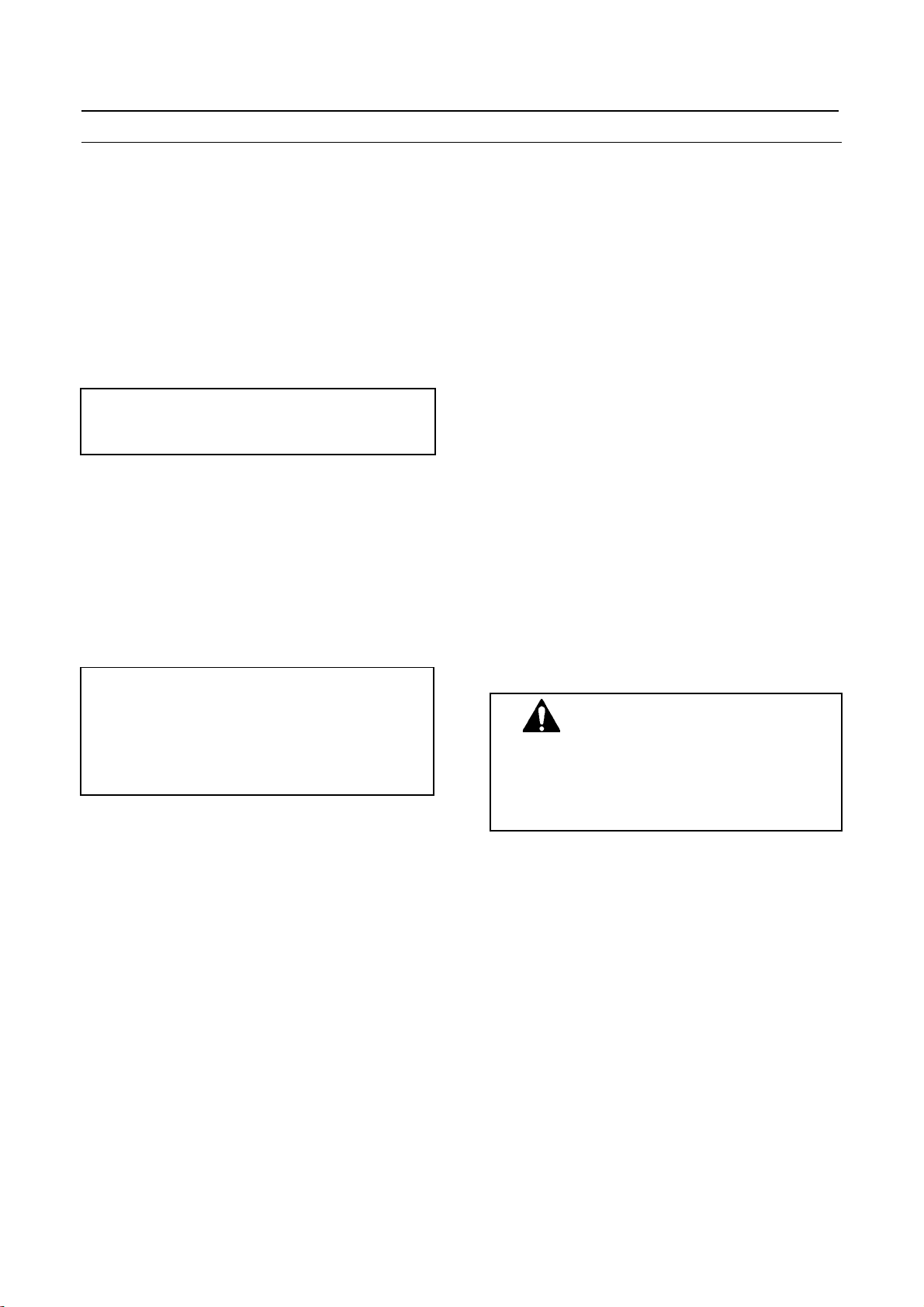

Machine Set-Up

Important Read "Warnings", on page

14, before attempting to set-up the case

sealer for operation.

The following instructions are presented in the order

recommended for setting up and installing the case

sealer, as well as for learning the operating

functions and adjustments. Following them step

by step will result in your thorough understanding of

the machine and an installation in your production

line that best utilizes the many features built into the

case sealer. Refer to Figure 3-1 to identify the

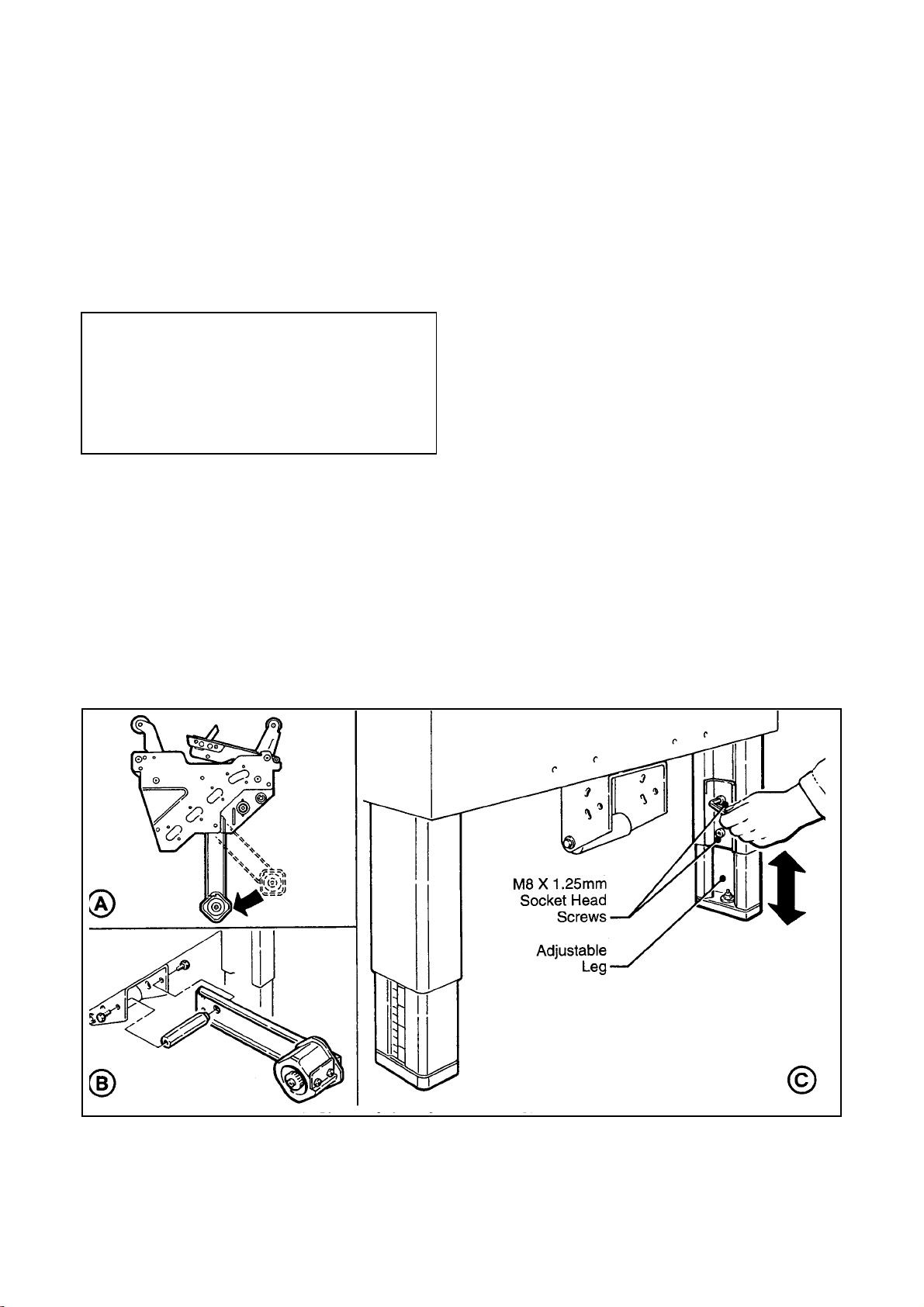

various components of the case sealer.

5. Cut cable ties that secure upper assembly to

machine bed on each side of machine. Remove

and discard cable ties and protective foam

sheeting.

6. Remove tape drum bracket bolts (4) from top

crossbar and install tape drum bracket from

parts box on top crossbar as shown in

Figure 2-1A.

7. Install height adjustment crank handle on top of

left column as shown in Figure 2-1B. Crank

upper assembly up high enough to allow clear

access to lower taping head. Remove and

discard the two cushion shipping blocks.

8. Loosen both side guides, pivot to full open

position and re-tighten locking knobs.

9. Wipe protective shipping oil off stainless steel

covers on machine bed.

10. Cut and remove cable ties on both upper and

lower taping heads. (Applying/buffing rollers are

held retracted for shipment.)

Note A tool kit consisting of metric open

end and hex socket wrenches is provided

with the machine. These tools should be

adequate to set-up the machine, however,

other tools supplied by the customer will be

required for machine maintenance.

PACKAGING AND SEPARATE PARTS

1. Lift fiberboard cover off pallet after removing

staples at bottom.

2. Remove protective wrapping around machine.

3. Remove hardware that secures case sealer legs

to pallet.

4. Cut and remove cable tie that secures black

electrical conduit to the electrical mast on top of

machine.

WARNING Follow this step

carefully as spring pressure is

applied to applying and buffing arms when

cable tie is removed. Keep hands/fingers

AWAY from tape cut-off knife under orange

knife guard. Knife is extremely sharp and

can cause severe injury.

Hold taping head BUFFING ROLLER and cut

and remove cable tie that holds applying/buffing

arms retracted. See Figure 2-1C. Allow buffing/

applying arms to extend slowly.

9

Page 15

Figure 2-1 200a Frame Set-Up

11. Check for free action of both upper and lower

taping heads.

WARNING Keep hands/fingers

away from tape cut-off knife under

orange knife guard. Knife is extremely

sharp and can cause severe injury.

Push buffing roller into head to check for free,

smooth action of taping heads.

12. Loosen lock knobs and pivot side guides to

center position. Install machine stops (from

parts box) as shown in Figure 2-1D. Use the

lowest hole position and bolt into the lowest

threaded insert on the column. (The upper hole

position in the stops are only used when the

taping heads are adjusted to apply 50 mm

[2 inch] tape legs.)

13. Ensure that the tape drum bracket assembly,

located on the lower taping head, is mounted

straight down, as shown in Figure 2-2A. The

tape drum bracket assembly can be pivoted to

provide tape roll clearance in certain cases.

14. Use appropriate material handling equipment

to remove the machine from the pallet and

move it into position.

Whenever the machine is lifted with a fork

truck, insure that the forks span completely

across the machine frame and do not contact

any wiring or mechanism under the machine

frame. In some cases the lower taping head

may need to be removed to avoid damage.

CAUTION Machine weighs

approximately 123 kg [280 pounds]

uncrated.

15. Continue with the remainder of the Installation

and Set-Up procedure through page 12.

10

Page 16

Installation and Set-Up (Continued)

MACHINE BED HEIGHT

Adjust machine bed height. The case sealer is

equipped with four adjustable legs that are

located at the corners of the machine frame.

The legs can be adjusted to obtain different

machine bed heights from 610 mm [24 in]

minimum to 890 mm [35 in] maximum.

Note Minimum machine bed height can be

reduced to 520 mm [20.5 in] by moving outer

columns up one set of mounting holes.

However, this change also reduces minimum

box height of 120 mm [4.75 in] to 165 mm

[6.5 in]. (See "Special Set-Up Procedure

Box/Machine Bed Height Range", page 24.)

Refer to Figure 2-2C and set the machine bed

height as follows:

1. Use appropriate material handling

equipment and blocking techniques to raise

the machine frame to allow adequate leg

adjustment.

2. Loosen, but do not remove, two M8 x 16

socket head screws in one leg (use M6 hex

wrench). Adjust the leg length for the

desired machine bed height. Retighten the

two screws to secure the leg. Adjust all four

legs equally.

OUTBOARD TAPE ROLL MOUNTING

(Lower Taping Head Alternate Position)

Remove the tape drum bracket assembly,

spacer and fasteners from the lower taping

head. Install and secure on the infeed end of

the lower frame, as shown in Figure 2-2B.

TAPE LEG LENGTH

Taping heads are pre-set to apply 70 mm

[2.75 in] long tape legs. To change tape leg

length to 50 mm [2.0 in], see "Special Set-Up

Procedure Changing the Tape Leg Length",

page 23.

Figure 2-2 Machine Bed Height Adjustment and Lower Tape Drum Bracket Position

11

Page 17

Installation and Set-Up (Continued)

BOX SIZE CAPACITY OF CASE SEALER

At its factory setting, the case sealer handles

box sizes up to 620 mm [24.5 in] maximum

height. If larger capacity is needed, the machine

can be adjusted to accommodate boxes up to

725 mm [28.5 in] high. Refer to "Special Set-Up

Procedure Box and Machine Bed Height

Range", page 24. Note Adjusting machine

to accommodate 725 mm [28.5 in] high boxes

also increases minimum box size to 165 mm

[6.5 in].

ELECTRICAL CONNECTION AND CONTROLS

The electrical control box, located on the lower

right side of the machine frame, contains the

pre-set circuit breaker. The control box can be

located on the opposite side of the machine

frame if desired.

A standard three conductor power cord with plug

is provided at the back of the electrical control

box for 115 Volt, 60 Hz., 1.9 Amp electrical

service. The receptacle providing this service

shall be properly grounded. Before the power

cord is plugged into 115 Volt, 60 Hz outlet make

sure that all packaging materials and tools are

removed from the machine. Do not plug

electrical cord into outlet until ready to run

machine.

Use of an extension cord is not recommended.

However, if one is needed for temporary use, it

must have a wire size of AWG 16 [1.5 mm dia],

have a maximum length of 30.5 m [100 ft], and

must be properly grounded.

WARNING To prevent shock and

fire hazard: Position extension cord

where it will be out of the way of foot or

vehicle traffic. Extension cord is only for

temporary use do not use for a

permanent installation.

Note Machines outside the U.S. may be

equipped with 220/240 Volt, 50 Hz systems or

other electrical requirements compatible with

local practice.

INITIAL START-UP OF CASE SEALER

After completing the "Installation and Set-Up"

procedure, continue through "Operation" for tape

loading and start-up to be sure case sealer is

properly adjusted to run boxes

12

Page 18

Operation

IMPORTANT Before operating the case sealer, read the "Important Safeguards", pages 3-5 and

"Warnings" on page 14 as well as all of the "Operation" instructions.

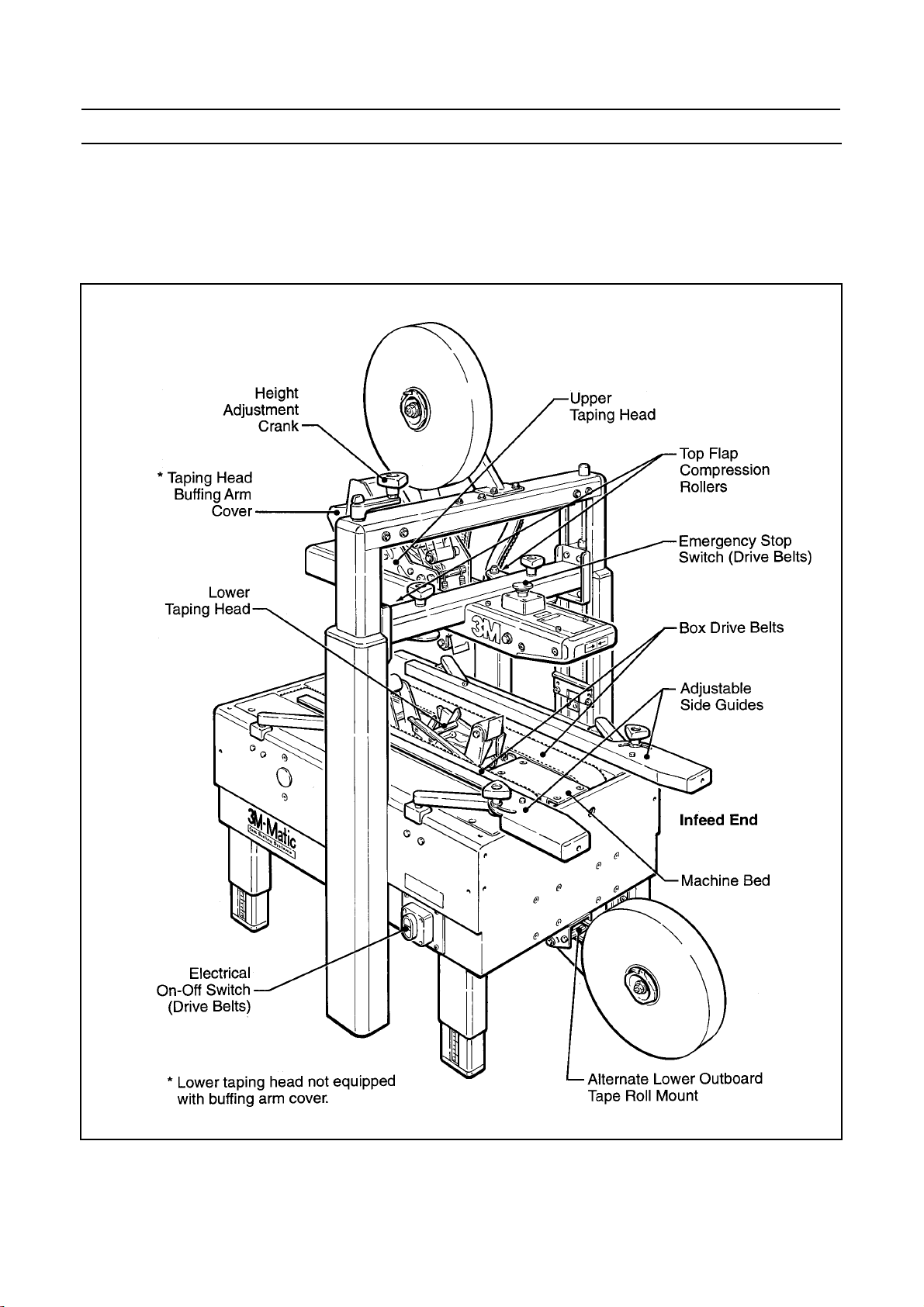

Refer to Figure 3-1 below to acquaint yourself with the various components and controls of the case sealer. Also

see Figures 3-1 and 3-2 in Section II for taping head components.

Figure 3-1 200a Case Sealer Components (Left Front View)

13

Page 19

Operation (Continued)

WARNINGS

1. Turn electrical supply off and disconnect before servicing taping heads or performing any

adjustments or maintenance on the machine.

2. Do not leave machine running unattended.

3. Before turning drive belts on, be sure no tools or other objects are on the machine bed.

4. Keep hands and loose clothing away from moving belts.

5. Keep hands and clothing away from taping heads when machine is running. A box traveling

through the machine causes taping head rollers to retract when box enters and extend as box

leaves taping head.

6. Never attempt to work on any part of the machine, load tape or remove jammed boxes from the

machine while machine is running.

7. When feeding boxes to the machine by hand, push box in from end only DO NOT PUSH WITH

HANDS ON ANY CORNER OF THE BOX.

8. Both the upper and lower taping heads utilize extremely sharp knives. The knives are located

under the orange knife guard which has the 'WARNING SHARP KNIFE" label. Before loading

tape, refer to Figures 3-1 and 3-2 in Section II to identify the knife location. Keep hands out of

these areas except as necessary to service the taping heads.

9. Turn drive belts "Off" when machine is not in use.

10. Failure to comply with these warnings could result in severe personal injury and/or equipment

damage.

Electrical "On/Off" Switch

The box drive belts are turned on and off ("Off"

button is red) with the electrical switch on the side of

the machine frame.

Note The case sealer has a circuit breaker

located in the electrical control box on the

lower right side of the machine frame. If circuit

becomes overloaded and circuit breaker trips,

see "Maintenance Circuit Breaker", page 18.

Emergency Stop Switch

The machine electrical supply can be turned off by

pressing the latching emergency stop switch. To

restart machine, rotate emergency stop switch

(releases switch latch) and then restart machine by

pressing "I" (On) button on side of machine frame.

Tape Loading/Threading

See Section II, Pages 7 and 8

Note If lower tape drum is mounted in

alternate lower outboard position, remove

taping head from machine bed by pulling

straight up, insert threading needle in taping

head and replace taping head. Install tape

roll on drum (adhesive on tape leg up), thread

tape under knurled roller on outboard mount,

then attach tape to threading needle and pull

tape through taping head with threading

needle.

CAUTION Taping head weighs

approximately 7.2 kg [16 pounds]

without tape. Use proper body mechanics

when removing or installing taping head.

14

Page 20

Operation (Continued)

Box Size Set-Up

1. ADJUST UPPER TAPING HEAD

The upper taping head is positioned for the box

height by means of the height adjustment crank

shown in Figure 3-2. Turn crank clockwise to

lower head, counterclockwise to raise head.

Place box on infeed end of machine bed with

both top and bottom flaps folded and insert

under upper head ski approximately 150 mm

[6 inch] as shown in Figure 3-3. Lower the head

until all flaps are fully closed.

Figure 3-2 Upper Taping Head

2. ADJUST SIDE GUIDES (Figure 3-4)

Align box top flap center seam with arrows on

front of ski.

Move side guides against each side of box to

hold box in position, centered on arrows on front

of ski.

Tighten hand knobs to secure side guides.

Figure 3-3 Upper Taping Head

Figure 3-4 Side Guides

15

Page 21

Operation (Continued)

3. RUN BOXES TO CHECK ADJUSTMENT

(Figure 3-5)

Turn electrical switch to "On" to start drive belts.

Move box forward under upper taping head until

it is taken away by drive belts. If box is hard to

move under head or is crushed, raise head

slightly. If box movement is jerky or stops under

upper head, lower upper head slightly to add

more pressure between box and drive belts.

Note Upper head has unique feature for

overstuffed boxes. The head will raise up to

13 mm [1/2 inch] to compensate for this type

of condition.

CAUTION If drive belts are allowed

to slip on box, excessive belt wear

will occur.

Figure 3-5 Check Adjustments

4. POSITION COMPRESSION ROLLERS

(Figure 3-6)

Push box into machine and alternately turn

"On/Of" switch "On" and "Off" until box is

positioned where flap compression rollers can

be adjusted against top edge of box.

Pivot both flap compression rollers against top

edge of box and lock in place with hand knobs.

Turn electrical switch "On" and run box through

machine.

Box Sealing

1. Feed boxes to machine at minimum 455 mm

[18 inch] intervals.

2. Turn electrical supply "Off" when machine is not

in use.

3. Reload and thread tape as necessary.

4. Be sure machine is cleaned and lubricated

according to recommendations in "Maintenance"

section of this manual.

Figure 3-6 Compression Rollers

Notes

1. Machine or taping head adjustments are

described in "Adjustments" Section I for

machine or Section II for taping heads.

2. Box drive motors are designed to run at a

moderate temperature of 40°C [104°F].

In some cases, they may feel hot to the

touch.

16

Page 22

Maintenance

The case sealer has been designed for long, trouble

free service. The machine will perform best when it

receives routine maintenance and cleaning.

Machine components that fail or wear excessively

should be promptly repaired or replaced to prevent

damage to other portions of the machine or to the

product.

WARNING Turn off electrical

power supply and disconnect power

cord from electrical supply before

beginning maintenance. If electrical

power is not disconnected, severe injury

to personnel could result.

Cleaning

Note Never attempt to remove dirt from

taping heads by blowing it out with

compressed air. This can cause the dirt to

be blown inside the motor and onto sliding

surfaces which may cause premature

equipment wear. Never wash down or

subject equipment to conditions causing

moisture condensation on components.

Serious equipment damage could result.

Lubrication

Most of the machine bearings, including the drive

motor, are permanently lubricated and sealed and

do not require additional lubricant.

Figure 4-1 illustrates the machine points that do

require lubrication every 250 hours of operation.

Lubricate the points indicated by arrows ( ) with

a small amount of multi-purpose grease.

Note Wipe off excess oil and grease. It will

attract dust which can cause premature

equipment wear and jamming. Take care

that oil and grease are not left on the surface

of rollers around which tape is threaded, as it

can contaminate the tape's adhesive.

TAPING HEAD LUBRICATION See Section II,

"Maintenance Lubrication", page 10.

Regular slotted containers produce a great deal of

dust and paper chips when processed or handled in

equipment. If this dust is allowed to build-up on

machine components, it can cause component wear

and overheating of drive motor. The dust build-up

can best be removed from the machine by a shop

vacuum. Depending on the number and type of

boxes sealed in the case sealer, this cleaning should

be done approximately once per month. If the boxes

sealed are dirty, or if the environment in which the

machine operates is dusty, cleaning on a more

frequent basis may be necessary. Excessive dirt

build-up that cannot be removed by vacuuming

should be wiped off with a damp cloth.

Figure 4-1 Lubrication Points Frame

17

Page 23

Maintenance (Continued)

WARNING Turn off electrical power supply and disconnect power cord from electrical

supply before beginning maintenance. If power cord is not disconnected, severe injury to

personnel could result.

Circuit Breaker

The case sealer is equipped with a circuit breaker

which trips if the motor is overloaded. The circuit

breaker is located inside the electrical control box on

the side of machine frame just below the machine

bed.

WARNING The following procedure

must be performed by trained service

personnel because of the high voltage

electrical hazard within the control box.

If circuit is overloaded and circuit breaker trips,

unplug machine from electrical power:

1. Determine cause of overload and correct.

2. Remove electrical enclosure cover.

3. Lift circuit breaker switch to reset. If circuit

breaker will not reset, wait 2 minutes and

retry.

4. Replace cover.

5. Plug in machine.

6. Press machine "On" button to resume case

sealing.

Figure 4-2 Box Drive Belt Replacement

Knife Replacement, Taping Head

See Section II, "Maintenance Knife

Replacement", page 9.

Box Drive Belt Replacement

Figure 4-2

Note 3M recommends the replacement of

drive belts in pairs, especially if belts are

unevenly worn.

To remove old belt:

1. Remove and retain center plate (A) and four

screws.

2. Remove and retain side cover (B) and fasteners.

3. Loosen, but do not remove lock nut (C).

4. Loosen tension screw (D) until all belt tension is

removed.

5. Pull belt splicing pin (E) out and remove belt.

6. Place new belt over pulleys with laced splice at

top. Insert splicing pin. Note - Pin must not

extend beyond edge of belt.

7. Adjust belt tension as explained in "Adjustments

- Box Drive Belt Tension", Page 19.

8. Replace side cover and center plate and secure

with original fasteners.

18

Page 24

Adjustments

WARNING Turn off electrical power supply and disconnect power cord from electrical supply

before beginning adjustments. If power cord is not disconnected, severe injury to personnel

could result.

Box Drive Belt Tension

The two continuously moving drive belts convey boxes through the tape applying mechanism. The box drive

belts are powered by an electric gear motor.

Tension adjustment of these belts may be required during normal operation. Belt tension must be adequate to

positively move the box through the machine and the belts should run fully on the surface of the pulleys at each

end of the frame. The idler pulleys on the infeed end are adjusted in or out to provide proper belt tension. Each

belt is adjusted separately.

Belt tension is obtained by tightening the adjustment screw so that a moderate pulling force of 3.5 kg [7.5 lbs.]

applied at the midspan, as shown in Figure 5-1, will deflect the belt 25 mm [1 inch]. This will assure positive

contact between the belt and the drive pulley on the discharge end of the taping head.

Figure 5-1 Box Drive Belt Tension Adjustment

19

Page 25

Adjustments (Continued)

WARNING Turn off electrical power supply and disconnect power cord from electrical supply

before beginning adjustments. If power cord is not disconnected, severe injury to personnel

could result.

Refer to Figure 5-2 and adjust belt tension as follows:

1. Remove and retain center plate and four screws.

2. Loosen, but do not remove, M10 lock nut with a 17 mm open end wrench.

3. Reset the tension on the drive belt as needed. Use M6 hex wrench and adjust the M8 socket head tension

screws in (clockwise) to increase tension or out (counterclockwise) to decrease tension. Tighten lock nut to

secure tension setting.

4. Replace center plate and secure with original screws.

Figure 5-2 Box Drive Belt Tension Adjustment (Machine Bed Infeed End)

20

Page 26

Adjustments (Continued)

WARNING Turn off electrical power supply and disconnect power cord from electrical

supply before beginning adjustments. If power cord is not disconnected, severe injury to

personnel could result.

Taping Head Adjustments Refer to Section II

WARNING Use care when working near tape cut-off knives on taping heads as knives are

extremely sharp. If care is not taken, severe injury to personnel could result.

TAPE WEB ALIGNMENT Section II, Page 11

TAPE DRUM FRICTION BRAKE Section II, Page 11

APPLYING MECHANISM SPRING Section II, Page 12

ONE-WAY TENSION ROLLER Section II, Page 12

21

Page 27

THIS PAGE IS BLANK

22

Page 28

Special Set-Up Procedure

WARNING Turn off electrical power and disconnect power cord from electrical supply before

beginning Special Set-Up Procedure. If power cord is not disconnected, severe injury to

personnel could result.

Changing the Tape Leg Length

(From 70 to 50 mm [2-3/4 to 2 inch])

The following changes to the case sealer frame and upper/lower taping heads will allow the taping of boxes

90 mm [3.5 inch] minimum height.

CASE SEALER FRAME

(Refer to Figure 6-1A)

1. Raise the upper head assembly by turning crank handle counterclockwise. Remove and retain the two stop

bracket screws and washers from the normal position holes "A-A".

2. Move stop bracket down and secure with original fasteners through upper holes "A" in stop bracket. Relocate

both right and left stop brackets.

Figure 6-1 Case Sealer Frame Changes

23

Page 29

Special Set-Up Procedure (Continued)

WARNING Turn off electrical power and disconnect power cord from electrical supply

before beginning Special Set-Up Procedure. If power cord is not disconnected, severe injury

to personnel could result.

TAPING HEADS

WARNING Use care when working near knives as knives are extremely sharp. If care is not

taken, severe injury to personnel could result.

1. Loosen, but do not remove, the two retaining screws that secure the upper taping head shown in

Figure 6-1B.

2. Slide the head forward and lift straight up to remove it from the case sealer.

CAUTION Taping head weighs approximately 7.2 kg [16 lbs]. Use proper body

mechanics when lifting upper or lower taping heads.

3. Lift the lower taping head, shown in Figure 6-1C, straight up to remove it from the case sealer bed.

4. Refer to Section II, "Adjustments Changing Tape Leg Length", page 13 for taping head set-up.

Box and Machine Bed Height Range Refer to Figure 6-2

Moving the outer columns up one set of mounting holed increases the maximum box size handled by the

200a case sealer and decreases the minimum machine bed height.

Note This also increases the minimum box height from 120 mm [4.75 inch] to 165 mm [6.5 inch].

To move the outer columns up one set of mounting holes:

1. Place minimum 305 mm [12 inch] high blocks at the front and rear of the upper taping head assembly as

shown in Figure 6-2A. Important Blocks (front and rear) must be same height in order to keep upper

taping head assembly parallel with machine bed/drive belts. Crank the upper taping head assembly

down until it touches these blocks.

2. Remove and retain the six screws and plain washers that fasten each column to the frame. Figure 6-2B.

3. Turn the height adjustment crank clockwise to raise the outer columns up one set of mounting holes

(100 mm [4 inch]).

WARNING Blocks and spacers must be capable of supporting the 34 Kg [75 pound] weight

of the outer columns and upper taping head assembly.

4. Install and tighten the six screws and plain washers in each column that were removed in Step 2. Crank

upper taping head assembly up and remove blocks.

If desired, the bed height can now be decreased to 520 mm [20.5 inch] by adjusting legs upward. (See

"Installation and Set-Up Machine Bed Height", Page 11.)

24

Page 30

Special Set-Up Procedure (Continued)

Figure 6-2 Box and Machine Bed Height Range

25

Page 31

THIS PAGE IS BLANK

26

Page 32

Troubleshooting

The Troubleshooting Guide lists some possible machine problems, causes and corrections. Also see Section II

"Troubleshooting", pages 15 and 16 for taping head problems.

Troubleshooting Guide

Problem

Cause

Correction

Drive belts do not convey boxes

Drive belts do not turn

Narrow boxes

Worn drive belts

Top taping head does not apply

enough pressure

Top flap compression rollers in too

tight

Taping head applying spring

holder missing

Taping head applying spring set

too high

Worn or missing friction rings

Drive belt tension too low

Electrical disconnect

Circuit breaker not at correct

setting

Check machine specifications.

Boxes are narrower than

recommended, causing slippage

and premature belt wear.

Replace drive belts

Adjust the box height adjustment

with the crank

Readjust compression rollers

Replace spring holder

Reduce spring pressure

Replace friction rings

Adjust belt tension

Check power and electrical plug

Set to correct current value

Upper and lower applying

mechanisms interfere with each

other

Drive belts break

Light boxes tip back on exit

Squeaking noise as boxes pass

through machine

Motor not turning

Machine's minimum height stop

does not match tape head leg

length setting

Worn belt

Upper ski down too far

Dry compression rollers

Dry column bearings

Defective column bearings

27

Evaluate problem and correct

Check manual to make sure

taping heads match machine

setting

Replace belt

Carefully adjust upper ski

Lubricate compression rollers

Lubricate column bearings

Replace column bearings

Page 33

28

Page 34

Electrical Diagrams (Continued)

Figure 7-2

29

Page 35

Electrical Diagrams (Continued)

Figure 7-3

30

Page 36

Replacement Parts and Service Information

Spare Parts

It is suggested that the following spare parts be ordered and kept on hand:

Qty. Ref. No. Part Number Description

2 2795-39 78-8070-1531-4 Belt - Drive W/Pin

Label Kit

In the event that any labels are damaged or destroyed, they must be replaced to ensure operator safety. A

label kit, part number 78-8113-6714-9, is available as a stock item. It contains all the safety labels used on the

200a Adjustable Case Sealer.

Tool Kit

A tool kit, part number 78-8060-8476-6, is available as a stock item. The kit contains the necessary open end and

hex socket wrenches for use with the metric fasteners on the case sealer. The threading tool, part number

78-8076-4726-4, contained in above kit is also available as a replacement stock item.

Replacement Parts Ordering Information and Service

Refer to the first page of this instruction manual "Replacement Parts and Service Information.

31

Page 37

Options/Accessories

For additional information on the options/accessories listed below, contact your 3M Representative.

Part Number Option/Accessory

78-8052-6553-1 Box Hold Down Attachment, Model 18500

78-8069-3983-7 Caster Kit Attachment

78-8069-3924-1 Conveyor Extension Attachment

78-8069-3926-6 Low Tape Sensor Kit

78-8114-0828-1 AccuGlide II STD 2 Inch Upper Taping Head, Type 39600

78-8114-0829-9 AccuGlide II STD 2 Inch Lower Taping Head, Type 39600

78-8079-5505-5 Three Flap Folder Kit

32

Page 38

Replacement Parts Illustrations and Parts Lists

200a Adjustable Case Sealer, Type 39600

Frame Assemblies

To Order Parts:

1. Refer to first illustration, Frame Assemblies, page 35 for the Figure Number that identifies a specific

portion of the machine.

2. Refer to the appropriate Figure or Figures to determine the parts required and the parts reference number.

3. The Parts List that follows each illustration, includes the Reference Number, Part Number and Part

Description for the parts on that illustration.

Note The complete description has been included for standard fasteners and some commercially

available components. This has been done to allow obtaining these standard parts locally, if desired.

4. Order parts by Part Number, Part Description and Quantity required. Also include machine name,

number and type.

5.. Refer to the first page of this instruction manual Replacement Parts and Service Information for

replacement parts ordering information.

IMPORTANT Not all the parts listed are normally stocked items. Some parts or assemblies shown are

available only on special order. Contact 3M/Tape Dispenser Parts to confirm item availability.

33

Page 39

THIS PAGE IS BLANK

34

Page 40

200a Adjustable Case Sealer

Frame Assemblies

35

Page 41

200a Adjustable Case Sealer

Figure 2795/1 of 2

36

Page 42

Figure 2795 (Page 1 of 2)

Ref. No. 3M Part No. Description

2795-1 78-8070-1513-2 Frame Drive

2795-2 78-8070-1514-0 Spacer

2795-3 78-8070-1515-7 Spacer

2795-4 26-1003-5829-5 Screw Hex Hd, M6 x 12

2795-7 78-8052-6710-7 Roller Idler

2795-8 78-8052-6709-9 Washer Special

2795-9 78-8010-7435-8 Washer Lock, M6

2795-10 26-1003-7957-2 Screw Soc Hd Hex Hd, M6 x 16

2795-11 78-8070-1518-1 Spacer Shaft

2795-12 26-1003-6918-5 Nut Hex Flange, M10, Plastic Insert

2795-13 78-8070-1519-9 Screw Soc Hd Hex Hd, M8 x 70

2795-14 78-8017-9318-9 Washer Plain 8 mm

2795-15 78-8070-1520-7 Guide Drive Belt

2795-16 26-1005-4757-4 Screw Flat Hd M5 x 20

2795-17 78-8070-1521-5 Support Gearbox

2795-18 26-1003-7964-8 Screw Soc Hd Hex Soc Dr, M8 x 20

2795-19 78-8070-1522-3 Gear Motor 115V, 60HZ

2795-20 78-8076-4715-7 Cord Grip

2795-21 78-8070-1523-1 Screw 1/4-28 x 1/2 SHCS

2795-22 78-8070-1524-9 Sprocket 3/8 inch

2795-23 78-8023-2479-4 Screw Set M6 x 10, W/End Cup

2795-24 78-8070-1525-6 Chain 3/8 inch, 54 Links

37

Page 43

200a Adjustable Case Sealer

Figure 2795/2 of 2

38

Page 44

Figure 2795 (Page 2 of 2)

Ref. No. 3M Part No. Description

2795-25 78-8070-1526-4 Cover Chain

2795-26 78-8010-7209-7 Screw Soc Hd, M6 x 12

2795-27 26-1000-0010-3 Washer Flat, M6

2795-28 78-8070-1527-2 Shaft W/Drive Pulleys

2795-29 78-8070-1528-0 Shaft Gearbox

2795-30 78-8057-5811-3 Key 6 x 6 x 20 mm

2795-31 78-8054-8986-7 Sprocket 3/8 inch Pitch, 28 teeth

2795-32 78-8054-8984-2 Bushing

2795-33 78-8070-1529-8 Support Shaft

2795-34 78-8070-1530-6 Bearing 6205-2RS

2795-35 78-8057-5739-6 Key M5 x 5 x 30 mm

2795-36 78-8076-5105-0 Pulley Assembly Drive

2795-37 78-8060-8416-2 Nut Special, M20 x 1

2795-38 78-8052-6713-1 Ring Polyurethane

2795-39 78-8070-1531-4 Belt Drive W/Hook

2795-40 78-8070-1532-2 Plate Front

2795-41 78-8113-6754-5 Cover Rear, W/English Language Label

2795-42 26-0001-5862-1 Screw Flat Hd Soc, M5 x 12

2795-43 26-1005-5316-8 Screw Flat Hd Hex Dr, M5 x 16

2795-44 78-8070-1534-8 Stud Side Plate

2795-45 78-8060-8488-1 Screw Hex Hd, M5 x 20

2795-46 26-1003-5841-0 Screw M8 x 16

2795-47 78-8070-1535-5 Bottom Drive Assembly

2795-48 26-1011-8828-7 Capacitor 115V Gearmotor

2795-51 78-8076-4500-3 Stud Mounting

2795-52 78-8094-6015-3 Spacer

2795-53 78-8076-5211-6 Set Nut GMP13.5

2795-54 78-8060-7885-9 End Cap /25X1,2

2795-55 78-8042-2919-9 Washer Triple, M6

2795-56 78-8100-1236-5 Belt Tensioning Assembly R/H

2795-57 78-8100-1237-3 Belt Tensioning Assembly L/H

2795-58 78-8100-1238-1 Belt Tensioner R/H

2795-59 78-8100-1239-9 Belt Tensioner L/H

39

Page 45

200a Adjustable Case Sealer

Figure 2796

40

Page 46

Figure 2796

Ref. No. 3M Part No. Description

2796-1 78-8070-1536-3 Support Guide Arm

2796-2 78-8010-7169-3 Screw Hex Hd, M6 x 12

2796-3 26-1000-0010-3 Washer Flat, M6

2796-4 78-8070-1537-1 Lever With Pivot

2796-5 78-8070-1538-9 Bushing

2796-6 26-1003-8816-9 Screw Set, M5 x 6

2796-7 78-8070-1539-7 Link Guide

2796-8 78-8017-9074-8 Washer 15 mm, Nylon

2796-9 78-8052-6733-9 Ring M10, Special

2796-10 78-8070-1540-5 Support Lever

2796-11 78-8032-0382-3 Screw Soc Hd, M5 x 16

2796-12 78-8070-1541-3 Guide Arm Front, Right

2796-13 78-8070-1542-1 Guide Arm Front, Left

2796-14 78-8070-1543-9 Guide Arm Rear

2796-15 78-8076-4505-2 Screw Set, M6 x 8

2796-16 78-8070-1544-7 Guide Right

2796-17 78-8070-1545-4 Guide Left

2796-19 78-8070-1546-2 Cap Guide

2796-20 26-1003-7953-1 Screw Soc Hd, M5 x 30

2796-21 78-8070-1547-0 Shaft - Guide

2796-22 78-8070-1548-8 Washer 20 x 12, 5 x 1 Nylon

2796-23 26-1003-5852-7 Screw Hex Hd, M10 x 40

2796-24 78-8052-6566-3 Washer Friction

2796-25 78-8070-1549-6 Knob VTR-B-M10

2796-26 78-8005-5735-3 Washer Lock, M5

2796-27 78-8032-0375-7 Screw Hex Hd, M6 x 16

2796-28 78-8079-5378-7 Tape Guide

41

Page 47

200a Adjustable Case Sealer

Figure 2798

42

Page 48

Figure 2798

Ref. No. 3M Part No. Description

2798-1 78-8070-1557-9 Compression Roller Assembly Right

2798-2 78-8070-1558-7 Compression Roller Assembly Left

2798-3 78-8070-1559-5 Support Compression Roller

2798-4 78-8054-8648-3 Pressure Roller

2798-5 78-8070-1560-3 Stud Roller Mounting

2798-6 78-8052-6566-3 Washer Friction

2798-7 78-8070-1561-1 Nut M10

2798-8 26-1004-5507-5 Washer M8

2798-9 26-1003-5841-0 Screw M8 x 16

2798-10 78-8017-9074-8 Washer 15 mm, Nylon

2798-11 78-8070-1562-9 Tube Roller Support

2798-12 12-7991-1752-3 Washer M14, Plain

2798-13 78-8070-1563-7 Screw M10 x 80

2798-14 78-8070-1549-6 Knob VTR-B-M10

2798-15 26-1003-6918-5 Nut Plastic Insert M10 Hex Flange

43

Page 49

200a Adjustable Case Sealer

Figure 2799

44

Page 50

Figure 2799

Ref. No. 3M Part No. Description

2799-1 78-8070-1564-5 Tape Drum Bracket Assembly

2799-2 78-8070-1565-2 Tape Drum Bracket Assembly

2799-3 78-8070-1566-0 Bracket Tape Drum

2799-4 78-8070-1395-4 Bracket Bushing Assembly

2799-5 78-8070-1568-6 Cap Bracket

2799-6 78-8076-4519-3 Shaft Tape Drum 2 Inch

2799-7 78-8017-9169-6 Nut M18 x 1

2799-8 78-8070-1569-4 Tape Drum Assembly

2799-9 78-8052-6749-5 Tape Drum Assembly

2799-10 78-8052-6268-6 Leaf Spring

2799-11 26-1002-5753-9 Screw Self Tapping

2799-12 78-8060-8172-1 Washer Friction

2799-13 78-8052-6271-0 Washer Tape Drum

2799-14 78-8100-1048-4 Spring Core Holder

2799-15 78-8017-9077-1 Nut Self-Locking, M10 x 1

2799-16 78-8032-0375-7 Screw Hex Hd M6 x 16

2799-17 78-8070-1215-4 Spacer Stud

2799-18 26-1000-0010-3 Washer Flat M6

2799-19 78-8010-7169-3 Screw Hex Hd M6 x 12, Metric

2799-20 78-8060-8474-1 Tape Drum Assembly 2 Inch Head

2799-21 26-1004-5510-9 Washer Plain, M10

45

Page 51

200a Adjustable Case Sealer

Figure 3430

46

Page 52

Figure 3430

Ref. No. 3M Part No. Description

3430-2 78-8091-0306-8 Bed Conveyor

3430-3 78-8091-0307-6 Support Drive

3430-4 26-1003-5842-8 Screw Hex Hd, M8 x 20

3430-5 78-8017-9318-9 Washer Plain, 8 mm

3430-6 78-8076-5381-7 Leg Assembly Inner W/Stop

3430-7 78-8076-5382-5 Leg Inner

3430-8 78-8060-8480-8 Pad Foot

3430-9 78-8055-0867-4 Screw Hex Hd, M8 x 30

3430-10 78-8017-9313-0 Nut Self Locking, M8

3430-11 78-8076-5383-3 Stop Leg

3430-12 26-1003-7963-0 Screw Soc Hd, M8 x 16

3430-13 78-8060-8481-6 Label Height

3430-14 78-8052-6677-8 Clamp Inner

3430-15 78-8052-6676-0 Clamp Outer

3430-16 78-8060-8482-4 Plate Protection

3430-17 26-1003-7948-1 Screw Soc Hd M5 x 10

3430-18 78-8076-5392-4 Support Tape Drum

3430-19 78-8060-8483-2 Support Outboard Roll

3430-20 78-8060-8484-0 Shaft Roller

3430-21 78-8060-8485-7 Roller

3430-22 78-8032-0375-7 Screw Hex Hd, M6 x 16

3430-23 26-1000-0010-3 Washer Flat, M6

3430-24 26-1003-7957-2 Screw Soc Hd, M6 x 16

3430-25 78-8070-1579-3 Plane Conveyor Bed

3430-26 78-8060-8486-5 Bushing

3430-27 78-8010-7211-3 Screw Soc Hd M6 x 25

3430-28 78-8060-8487-3 Cover Switch

3430-29 78-8060-8087-1 Screw M5 x 10

3430-30 78-8010-7417-6 Nut Hex, M5

3430-31 78-8060-8488-1 Screw Hex Hd, M5 x 20

3430-32 78-8046-8217-3 Washer Special

3430-33 78-8005-5741-1 Washer Plain, M5

3430-34 78-8076-4701-7 Cap /28

3430-35 78-8098-9076-3 Caster Assembly

3430-36 26-1009-9096-4 Caster Dual Locking

3430-37 26-1009-9094-9 Washer Spring, Helical, M12

3430-38 26-1009-9095-6 Nut M12

3430-41 78-8094-6013-8 Support Drive

3430-42 78-8094-6014-6 Bed Conveyor, W/Support

47

Page 53

200a Adjustable Case Sealer

Figure 3431

48

Page 54

Figure 3431

Ref. No. 3M Part No. Description

3431-1 78-8060-8489-9 Column Outer

3431-2 78-8060-8490-7 Plate Column Mounting

3431-3 26-1003-7964-8 Screw Soc Hd Hex Soc Dr, M8 x 20

3431-4 78-8017-9318-9 Washer Plain, 8 mm

3431-5 78-8060-8491-5 Cap Column

3431-6 26-1002-4955-1 Screw Self Tap, 8P x 13

3431-7 78-8005-5740-3 Washer Plain, 4 mm

3431-8 78-8060-8492-3 Stop Height

3431-9 78-8076-5482-3 Plate Nut Stop

3431-10 78-8060-8087-1 Screw M5 x 10

3431-11 78-8060-8494-9 Column Assembly Inner

3431-12 78-8060-8495-6 Column Inner

3431-13 78-8054-8617-8 Bearing Special

3431-14 78-8054-8589-9 Screw Special

3431-15 26-1003-6916-9 Nut Locking M6, Plastic Insert

3431-16 78-8060-8496-4 Lead Screw

3431-17 78-8054-8969-3 Spring

3431-18 78-8054-8970-1 Bed Plate Spring

3431-19 78-8054-8571-7 Nut Plastic

3431-20 78-8054-8968-5 Nut Special

3431-21 78-8054-8585-7 Collar

3431-22 78-8054-8586-5 Pin

3431-23 78-8054-8584-0 Spacer

3431-24 78-8054-8583-2 Bushing

3431-25 78-8060-8497-2 Bushing Lead Screw

3431-26 78-8059-5617-0 Screw Set, M6 x 8

3431-27 78-8060-8498-0 Bushing Inner Column

3431-28 78-8060-8499-8 Sprocket 3/8 inch

3431-29 26-1003-7946-5 Screw Soc Hd, M4 x 25

3431-30 78-8070-1501-7 Chain 3/8 inch, 156 Links

3431-31 78-8113-6755-2 Housing Chain, W/English Language Label

3431-32 78-8060-7878-4 Screw Idler

3431-33 78-8070-1503-3 Roller Chain Tensioning

3431-34 78-8042-2919-9 Washer M6

3431-35 26-1003-5829-5 Screw Hex Hd, M6 x 12

3431-36 26-1000-0010-3 Washer Flat, M6

3431-37 78-8070-1504-1 Cover

3431-38 78-8010-7157-8 Screw Hex Hd, M4 x 10

3431-39 78-8070-1505-8 Cap Inner Column

3431-40 78-8070-1506-6 Cover Screw

3431-41 78-8076-4807-2 Crank Assembly

3431-42 78-8076-5422-9 Crank

3431-43 78-8070-1509-0 Shaft Crank

3431-44 26-1005-5316-8 Screw Flat Hd, Hex Dr, M5 x 16

3431-45 78-8070-1510-8 Washer Nylon, 7 x 15 x 1

3431-46 78-8070-1511-6 Bushing

3431-47 78-8070-1512-4 Knob VTR-B-M12

3431-48 78-8076-4800-7 Washer Crank

3431-49 78-8076-4809-8 Washer Crank

3431-50 78-8076-4821-3 Key Stop

3431-51 78-8054-8821-6 Cap End

3431-52 26-1004-5507-5 Washer M8

49

Page 55

200a Adjustable Case Sealer

Figure 5592

50

Page 56

Figure 5592

Ref. No. 3M Part No. Description

5592-1 78-8091-0508-9 Bar Supporting

5592-2 26-1003-7957-2 Screw Soc Hd Hex Hd, M6 x 16

5592-3 78-8100-1042-7 Washer /15 x 6.35 x 2

5592-4 78-8113-6756-0 Side Plate Right, W/English Language Label

5592-5 78-8113-6757-8 Side Plate Left, W/English Language Label

5592-6 26-1003-5842-8 Screw Hex Hd, M8 x 20

5592-7 78-8017-9318-9 Washer Plain, 8 mm

5592-8 26-1000-1347-8 Nut Hex, M8

5592-9 78-8070-1574-4 Slide Front, Right

5592-10 78-8070-1575-1 Slide Front, Left

5592-11 78-8070-1576-9 Slide Rear, Right

5592-12 78-8070-1577-7 Slide Rear, Left

5592-13 78-8070-1553-8 Spacer

5592-14 78-8070-1554-6 Stud

5592-15 78-8060-7693-7 Roller 32 x 38

5592-16 26-1005-5316-8 Screw Flat Hd Hex Dr, M5 x 16

5592-17 78-8070-1555-3 Block Upper Head

5592-18 78-8060-7758-8 Fairlead /20

5592-19 78-8054-8955-2 Clamp Bracket

5592-20 26-1003-5820-4 Screw Hex Hd, M5 x 12

5592-21 78-8005-5741-1 Washer Flat, M5

5592-22 78-8076-4517-7 End Cap /22 x 1

5592-23 78-8113-6758-6 Cover Upper, W/English Language Labels

5592-24 78-8076-4500-3 Stud Mounting

5592-25 78-8070-1318-6 Label Box Centering

5592-26 78-8100-1234-0 Bezel

51

Page 57

Figure 5593

52

Page 58

Figure 5593

Ref. No. 3M Part No. Description

5593-1 78-8091-0660-8 Housing Wire

5593-2 78-8076-4702-5 Grommet /28

5593-3 26-1003-7963-0 Screw Soc Hd, M8 x 16

5593-4 78-8076-4636-5 Strap Wire

5593-5 78-8010-7163-6 Screw - Hex Hd, M5 x10

5593-6 78-8005-5741-1 Washer Flat, M5

5593-7 78-8010-7417-6 Nut Hex, M5

5593-8 78-8060-7631-7 Connector 3/8 Inch

5593-9 78-8060-8028-5 Sleeving /12, 0,93 M.

5593-10 78-8060-8029-3 Clamp 140 x 3, 5

5593-11 78-8076-4641-5 Cover

5593-12 78-8010-7157-8 Screw Hex Hd, M4 x 10

5594-13 78-8017-9018-5 Washer Plain, M4 SPEC.

5594-14 78-8060-7758-8 Fairlead /20

53

Page 59

200a Adjustable Case Sealer

Figure 5594

54

Page 60

Figure 5594

Ref. No. 3M Part No. Description

5594-1 78-8094-6379-3 Support Box

5594-2 78-8113-6759-4 Enclosure W/English Language Label

5594-3 78-8094-6381-9 Screw Soc Hd, M4 x 15

5594-4 78-8005-5740-3 Washer Plain, 4 mm

5594-5 26-1003-6914-4 Nut Plastic Insert, M4

5594-6 78-8076-4715-7 Cord Grip

5594-7 78-8076-5211-6 Set Nut GMP13.5

5594-8 78-8094-6382-7 Guide Mounting

5594-9 78-8028-8208-0 Screw 6P X 9,5

5594-10 78-8017-9018-5 Washer Plain, M4, SPEC

5594-11 78-8094-6383-5 Contactor Sprecher and Shuh CA4-5-10, 110V, 60Hz

5594-12 78-8076-5378-3 Circuit Breaker KTA-3-25

5594-13 78-8094-6384-3 Ground Clamp VGPE 4/6

5594-14 78-8076-4882-5 Terminal Board

5594-15 78-8028-7909-4 Power Cord W/Plug

5594-16 78-8100-1038-5 Cable 4 x 20 AWG, MT .5

5594-17 78-8060-8053-3 Wire 3-Pole, 5 Meters Length

5594-18 26-1003-7957-2 Screw Soc Hd Hex, M6 x 16

5594-19 26-1000-0010-3 Washer Flat, M6

5594-20 78-8113-6887-3 Support On/Off Switch, W/English Language Label

5594-21 78-8076-5194-4 Box E-Stop, Yellow, Allen Bradley 800E-1PY

5594-22 78-8094-6386-8 Switch On/Off

5594-25 78-8017-9257-9 Screw M4 x 10

5594-26 78-8060-8087-1 Screw M5 x 10

5594-27 78-8010-7417-6 Nut Hex, M5

5594-28 26-1014-5845-8 E-Stop Allen Bradley MTS-44-3LX01

5594-29 78-8076-4716-5 Star Washer M4

5594-30 78-8010-7416-8 Nut Hex, M4

5594-31 78-8091-0538-6 Screw Hex Hd, M4 x 20

5594-32 78-8100-1234-0 Collar

5594-33 78-8114-4896-4 Box On/Off, Grey

55

Page 61

200a Adjustable Case Sealer

Safety and Information Labels

56

Page 62

Safety and Information Labels

A label kit, part number 78-8113-6714-9, is available as a stock item. It contains all the safety and information

labels used on the case sealer, or labels can be ordered separately from the following list.

Ref. No. 3M Part No. Description Qty.

1 78-8070-1318-6 Label Box Centering 1

2 78-8070-1329-3 Label Warning, Hazardous Voltage 1

3 78-8070-1336-8 Label Warning, Sharp Knife 2

4 78-8070-1339-2 Information 3M Logo 2

5 78-8069-3852-6 Label Ground 2

6 78-8068-3859-1 Label Service and Spares 1

7 78-8062-4266-1 Label Product 1

8 78-8070-1628-8 Label Up and Down/Lock 2

9 78-8070-1366-5 Label Safety Instructions 1

10 78-8113-6775-0 Label, Electrical, On/Off 1

11 78-8060-8481-6 Label Leg 4

12 78-8095-1141-9 Label Stop 1

13 78-8113-6717-2 Label Caution, Pinch Point 1

14 78-8113-6912-9 Label Caution, Pinch Point 2

57

Loading...

Loading...