3M 08362, 08365, 08367, 08368 User Manual

Urethane Seam Sealer is a premium one-part moisture-curing

310 mL Metal Cartridge

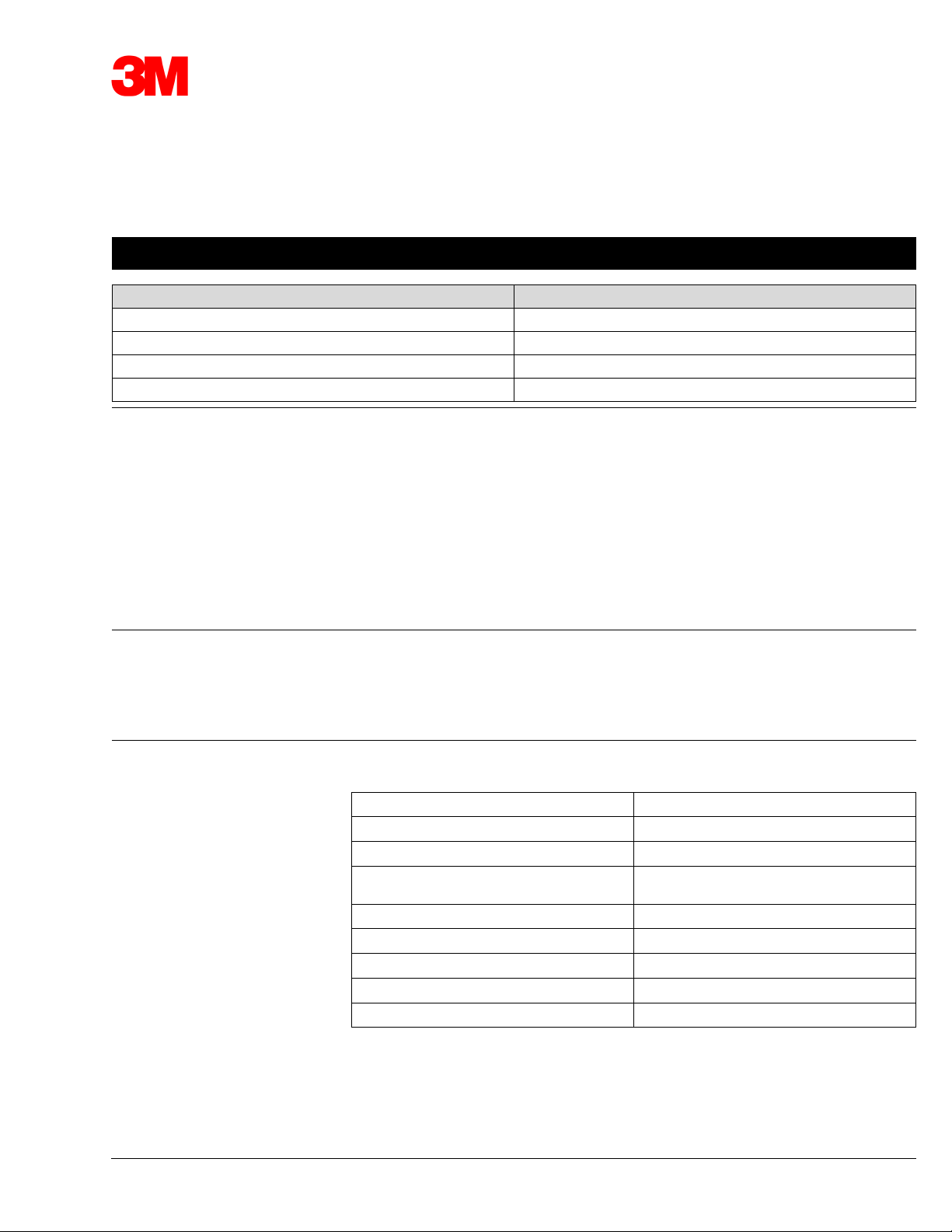

Container

310mL Aluminum Cartridge

Base

Moisture Curing Urethane

Density lbs./Gallon (Approx.)

9.8

White (08368)

Flash Point

Solids Content (Approx.)

95%

Consistency

Viscous Paste

Service Temperature

Solvent

Minimal Xylene

Urethane Seam Sealer

08362 • 08365 • 08367 • 08368

Technical Data June 2020

3M Part Numbers 3M Part Descriptor

08362 3M™ Urethane Seam Sealer (gray)

08365 3M™ Urethane Seam Sealer (beige)

08367 3M™ Urethane Seam Sealer (black)

08368 3M™ Urethane Seam Sealer (white)

Product Description

Features

Typical Physical Properties

3M™

automotive seam sealer designed for application to exterior and interior body

seams. 3M™ Urethane Seam Sealer may be applied to properly prepared

primer/paint coated surfaces or properly prepared bare metal surfaces. 3M™

Urethane Seam Sealer also functions as a weld through sealer when used in

conjunction with squeeze type resistance spot welding (STRSW) operations.

3M™ Urethane Seam Sealer may be painted with common automotive type

paint systems (water and solvent borne systems) in thirty minutes and up to

twenty four hours later (scuff after 24 hours).

Moisture Cure Technology

Weld Through Capability

Direct to Metal Application

NOTE: The following technical information and data should be considered representative or typical

only and should not be used for specification purposes.

Color

Gray (08362), Beige (08365), Black (08367),

>200°F (93.3°C) (closed cup method)

-20°F to 180°F (-28°C to 82°C)

Page 1 of 4

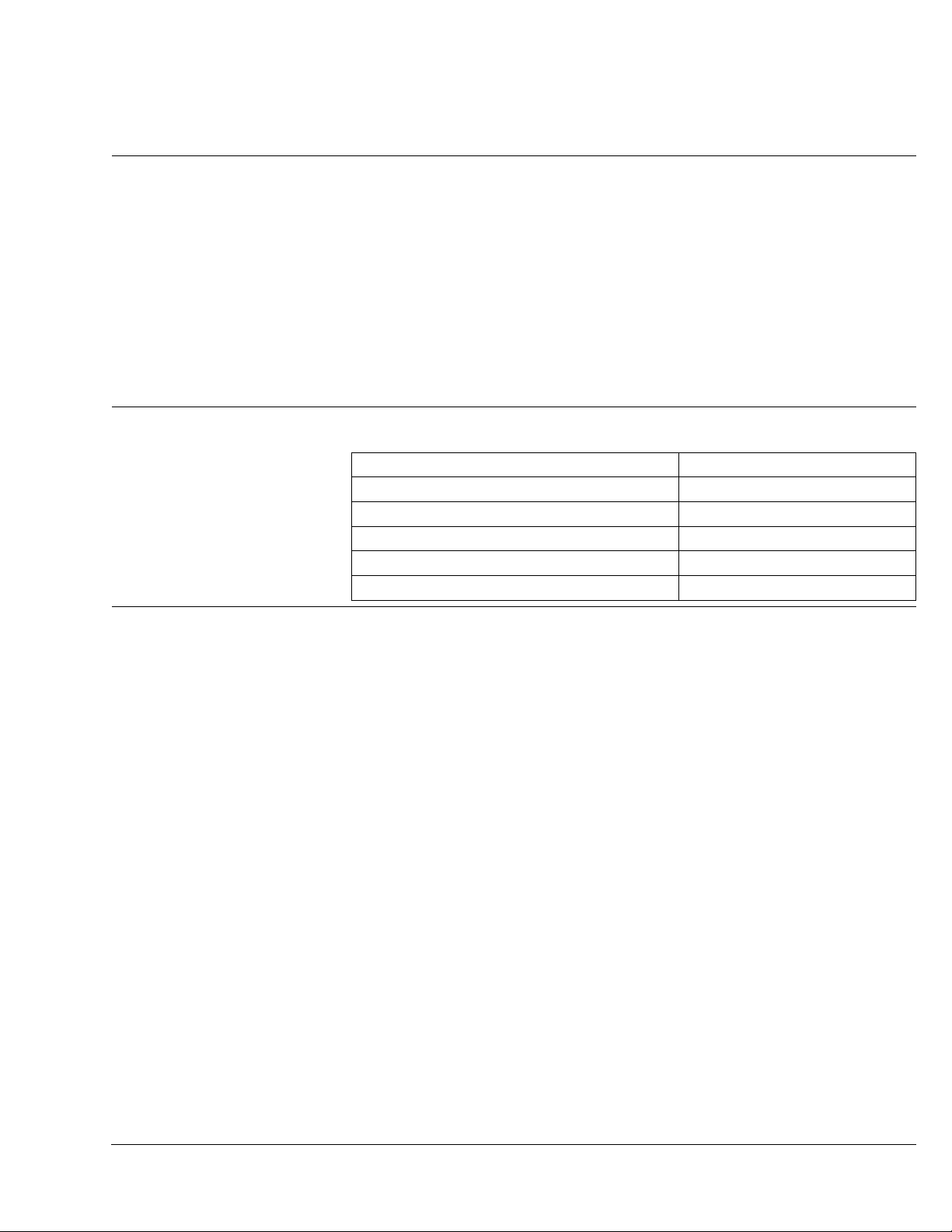

3M™ Urethane Seam Sealer

Cold Temperature Resistance at -20°F (-29°C)

Remains flexible

Heat Resistance: 8 Weeks at 200°F (93°C)

Remains flexible

Adhesion: Primed Metal: Excellent

Cohesive failure

Bare Metal: Excellent

Cohesive failure

Tensile Strength: Good

Flexibility: Excellent

600% Elongation

08362 • 08365 • 08362 • 08365

Product Uses

General sealing of interior and exterior automotive seams including floor pans,

hem flanges, frame rails, rear body panels, aprons and other seams including

those requiring weld through applications using squeeze type resistance spot

welding.

Use with the following accessories:

• 3M™ Single Component Cartridge Applicator – Pneumatic (PN 08990)

• 3M™ Professional Caulk Applicator – Manual (PN 08993)

• 3M™ Threaded Cartridge Nozzles (PN 08187 box/50)

For professional use only. Not intended for retail sale.

Performance Properties

NOTE: The following technical information and data should be considered representative or typical

only and should not be used for specification purposes.

Directions for Use PRIMER OR PAINT SURFACE

1. Clean the surface with a VOC compliant surface cleaner to remove any

contaminates.

2. Scuff the surface using a Scotch-Brite™ Scuff Pad or grade P180 to P320

abrasive.

3. Blow off and re-clean the surface to ensure proper adhesion.

4. Perforate the seal at the cartridge outlet and install the nozzle. Use the pull

tab to remove the metal seal at the cartridge base. Install the cartridge in a

suitable caulking gun (see reference in “Product Uses” section).

5. Cut nozzle to provide desired bead size.

6. Apply seam sealer and tool (if necessary) to desired finished appearance.

(230 psi)

7. Allow 30 minutes before painting, after 24 hours scuff with a 3M™

Scotch-Brite scuff pad.

Page 2 of 4

Loading...

Loading...