Page 1

Urethane Seam Sealer is a premium one-part moisture-curing

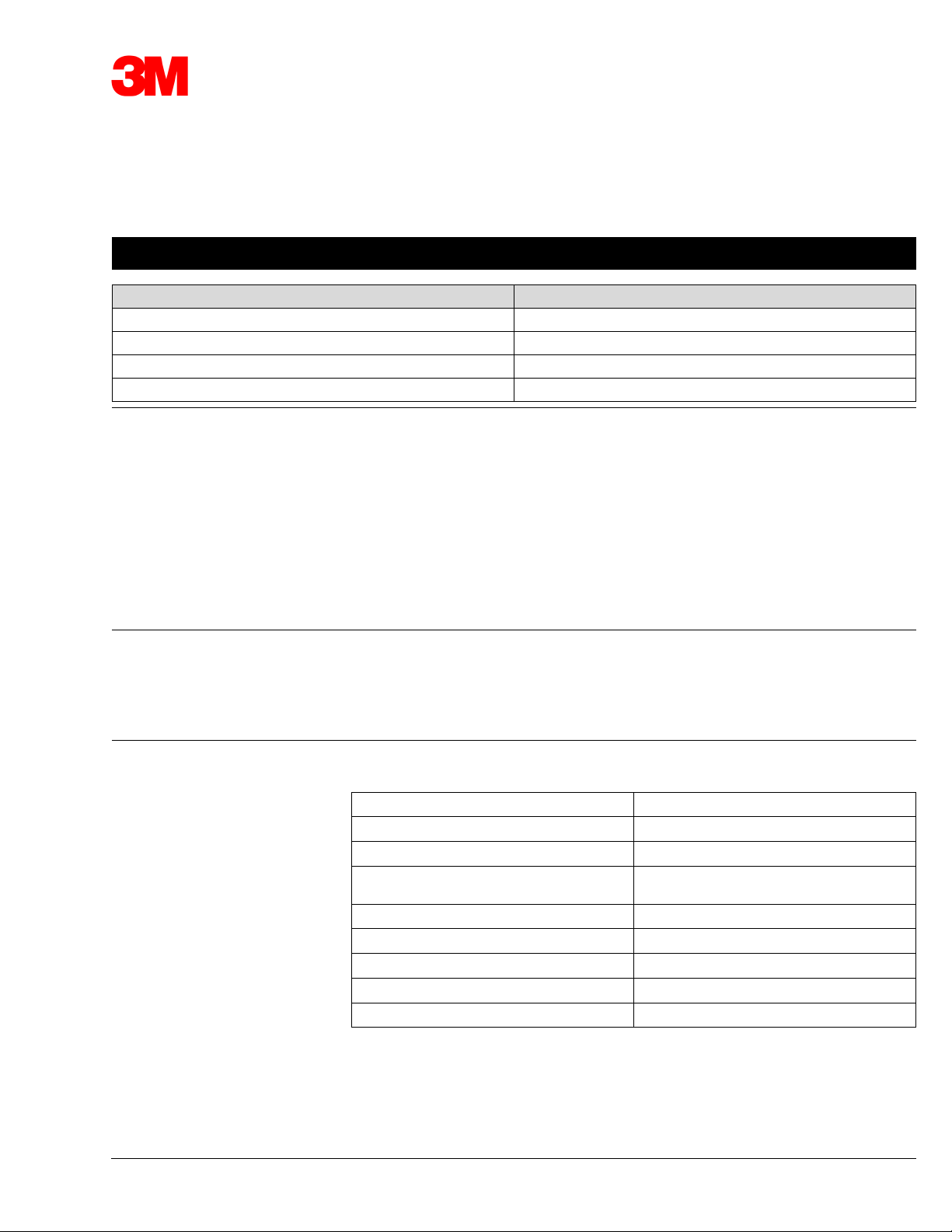

310 mL Metal Cartridge

Container

310mL Aluminum Cartridge

Base

Moisture Curing Urethane

Density lbs./Gallon (Approx.)

9.8

White (08368)

Flash Point

Solids Content (Approx.)

95%

Consistency

Viscous Paste

Service Temperature

Solvent

Minimal Xylene

Urethane Seam Sealer

08362 • 08365 • 08367 • 08368

Technical Data June 2020

3M Part Numbers 3M Part Descriptor

08362 3M™ Urethane Seam Sealer (gray)

08365 3M™ Urethane Seam Sealer (beige)

08367 3M™ Urethane Seam Sealer (black)

08368 3M™ Urethane Seam Sealer (white)

Product Description

Features

Typical Physical Properties

3M™

automotive seam sealer designed for application to exterior and interior body

seams. 3M™ Urethane Seam Sealer may be applied to properly prepared

primer/paint coated surfaces or properly prepared bare metal surfaces. 3M™

Urethane Seam Sealer also functions as a weld through sealer when used in

conjunction with squeeze type resistance spot welding (STRSW) operations.

3M™ Urethane Seam Sealer may be painted with common automotive type

paint systems (water and solvent borne systems) in thirty minutes and up to

twenty four hours later (scuff after 24 hours).

Moisture Cure Technology

Weld Through Capability

Direct to Metal Application

NOTE: The following technical information and data should be considered representative or typical

only and should not be used for specification purposes.

Color

Gray (08362), Beige (08365), Black (08367),

>200°F (93.3°C) (closed cup method)

-20°F to 180°F (-28°C to 82°C)

Page 1 of 4

Page 2

3M™ Urethane Seam Sealer

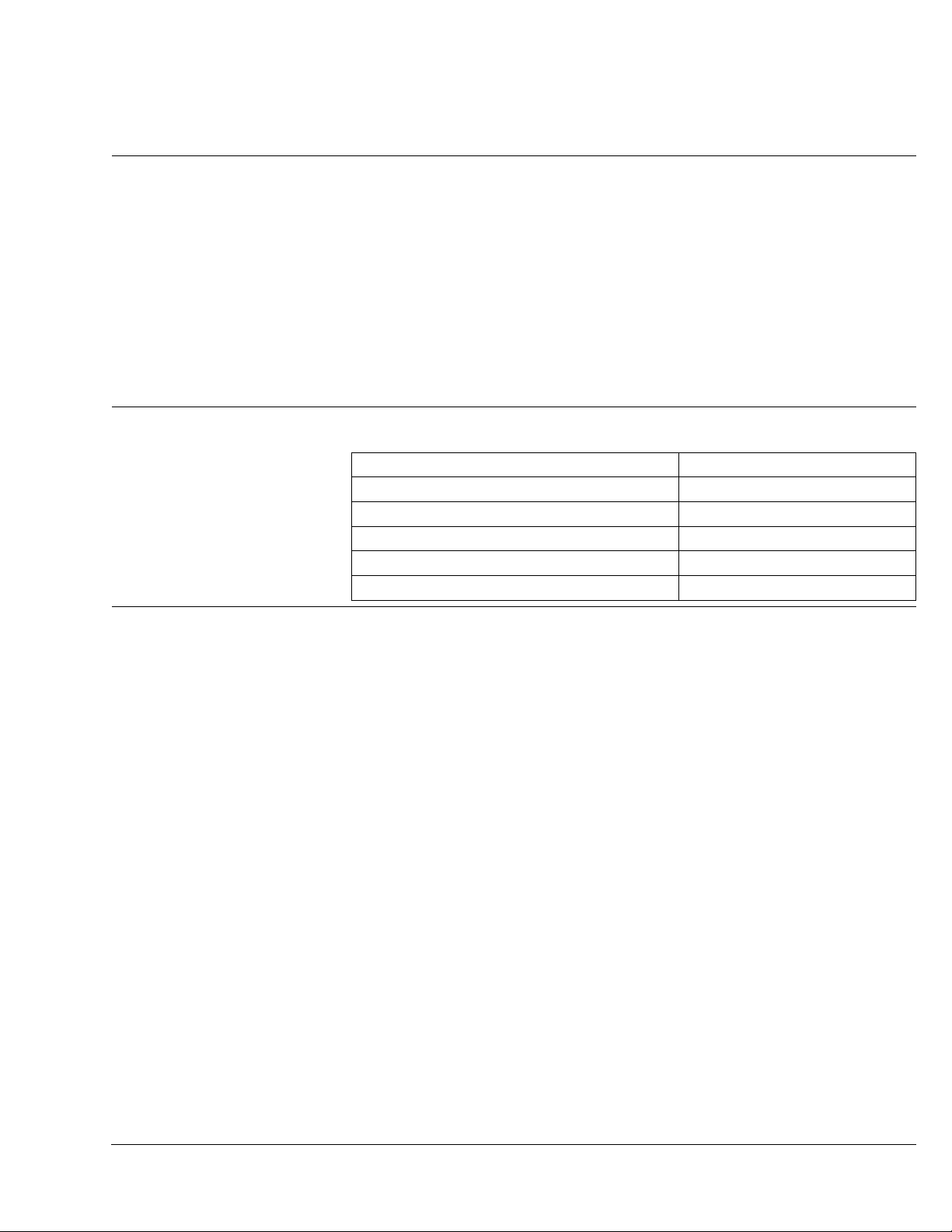

Cold Temperature Resistance at -20°F (-29°C)

Remains flexible

Heat Resistance: 8 Weeks at 200°F (93°C)

Remains flexible

Adhesion: Primed Metal: Excellent

Cohesive failure

Bare Metal: Excellent

Cohesive failure

Tensile Strength: Good

Flexibility: Excellent

600% Elongation

08362 • 08365 • 08362 • 08365

Product Uses

General sealing of interior and exterior automotive seams including floor pans,

hem flanges, frame rails, rear body panels, aprons and other seams including

those requiring weld through applications using squeeze type resistance spot

welding.

Use with the following accessories:

• 3M™ Single Component Cartridge Applicator – Pneumatic (PN 08990)

• 3M™ Professional Caulk Applicator – Manual (PN 08993)

• 3M™ Threaded Cartridge Nozzles (PN 08187 box/50)

For professional use only. Not intended for retail sale.

Performance Properties

NOTE: The following technical information and data should be considered representative or typical

only and should not be used for specification purposes.

Directions for Use PRIMER OR PAINT SURFACE

1. Clean the surface with a VOC compliant surface cleaner to remove any

contaminates.

2. Scuff the surface using a Scotch-Brite™ Scuff Pad or grade P180 to P320

abrasive.

3. Blow off and re-clean the surface to ensure proper adhesion.

4. Perforate the seal at the cartridge outlet and install the nozzle. Use the pull

tab to remove the metal seal at the cartridge base. Install the cartridge in a

suitable caulking gun (see reference in “Product Uses” section).

5. Cut nozzle to provide desired bead size.

6. Apply seam sealer and tool (if necessary) to desired finished appearance.

(230 psi)

7. Allow 30 minutes before painting, after 24 hours scuff with a 3M™

Scotch-Brite scuff pad.

Page 2 of 4

Page 3

3M™ Urethane Seam Sealer

08362 • 08365 • 08362 • 08365

Directions for Use, cont.

WELD THROUGH

NOTE: For weld through operations (prior to welding the panel(s) make test welds on scrap parts

to assure proper welding machine settings).

1. Remove coatings on all sides of weld flanges.

2. Apply seam sealer to all bare metal between weld flanges (brush to cover all

bare metal).

3. Mate parts together and clamp in place.

4. Be sure to use a shunt clamp and start welds near the clamp.

BARE METAL

1. Clean the surface with a VOC compliant surface cleaner to remove any

contaminates.

2. Grind any weld nuggets (grade 50 to 80) or scuff spot weld locations using a

non-woven coarse grade surface conditioning disc or belt.

3. Blow off and re-clean the surface to ensure proper adhesion.

4. Perforate the seal at the cartridge outlet and install the nozzle. Use the pull

tab to remove the metal seal at the cartridge base. Install the cartridge in a

suitable caulking gun (see reference in “Product Uses” section).

Applications

Storage and Handling

Precautionary Information

5. Cut nozzle to provide desired bead size.

6. Apply seam sealer and tool (if necessary) to desired finished appearance.

7. Allow 30 minutes before painting, after 24 hours scuff with a 3M™

Scotch-Brite scuff pad.

NOTE: 3M™ Urethane Seam Sealer may be applied to properly prepared bare metal and/or

primer/paint coated surfaces, and can be used as a “weld through” sealer when squeeze type

resistance spot welding equipment is used.

Acid etch primer is not recommended to be used in direct contact

with any 3M seam sealer. Residual acid can weaken the bond.

Store at room temperature. Rotate stock on a “first-in-first-out” basis. When

-ventilated area.

Before using this product, please reference Product Label and/or Safety Data Sheet for Health

and Safety Information. Note: Laws controlling the acceptable amounts of Volatile Organic

Compounds (VOCs) vary by state, and in some cases by locality. For surface preparation and

clean-up activities, consult federal, state and local regulations regarding use of products

containing VOCs in your area.

Page 3 of 4

Page 4

3M™ Urethane Seam Sealer

MITED

place use. Unless specifically stated otherwise on the

orting, or other uses not described in the applicable product packaging or literature),

product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness,

08362 • 08365 • 08362 • 08365

Technical Information

Product Selection and Use

Warranty, Limited Remedy

and Disclaimer

The technical information, guidance, and other statements contained in this document or

otherwise provided by 3M are based upon records, tests, or experience that 3M believes to be

reliable, but the accuracy, completeness, and representative nature of such information is not

guaranteed. Such information is intended for people with knowledge and technical skills

sufficient to assess and apply their own informed judgment to the information. No license under

any 3M or third party intellectual property rights is granted or implied with this information.

Many factors beyond 3M’s control and uniquely within user’s knowledge and control can affect the

use and performance of a 3M product in a particular application. As a result, customer is solely

responsible for evaluating the product and determining whether it is appropriate and suitable for

customer’s application, including conducting a workplace hazard assessment and reviewing all

applicable regulations and standards (e.g., OSHA, ANSI, etc.). Failure to properly evaluate, select,

and use a 3M product in accordance with all applicable instructions and with appropriate safety

equipment, or to meet all applicable safety regulations, may result in injury, sickness, death, and/or

harm to property.

Unless a different warranty is specifically stated on the applicable 3M product packaging or

product literature (in which case such warranty governs), 3M warrants that each 3M product

meets the applicable 3M product specification at the time 3M ships the product. 3M MAKES NO

OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LI

TO, ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, OR ARISING OUT OF A COURSE OF DEALING, CUSTOM, OR USAGE

OF TRADE. If a 3M product does not conform to this warranty, then the sole and exclusive

remedy is, at 3M’s option, replacement or repair of the 3M product or refund of the purchase

price. Warranty claims must be made within one (1) year from the date of 3M’s shipment.

Limitation of Liability

Disclaimer

Except for the limited remedy stated above, and except to the extent prohibited by applicable law,

3M will not be liable for any loss or damage arising from or related to the 3M product, whether

direct, indirect, special, incidental, or consequential (including, but not limited to, lost profits or

business opportunity), regardless of the legal or equitable theory asserted, including, but not limited

to, warranty, contract, negligence, or strict liability.

3M industrial and occupational products are intended, labeled, and packaged for sale to trained

industrial and occupational customers for work

applicable product packaging or literature, these products are not intended, labeled, or packaged

for sale to or use by consumers (e.g., for home, personal, primary or secondary school,

recreational/sp

and must be selected and used in compliance with applicable health and safety regulations and

standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and

other limitations, and the user must take any action required under any recall, field action or other

death, or property damage. For help with product selection and use, consult your on-site safety

professional, industrial hygienist, or other subject matter expert. For additional product information,

visit www.3M.com.[1]

Automotive Aftermarket Division

3M Center, Building 0223-6-S-07

St. Paul, MN 55144-1000

1-877-666-2277 (1-877-MMM-CARS)

3MCollsion.com

3M and Scotch-Brite are trademarks of 3M Company.

Printed in U.S.A. © 3M 2020 All rights reserved (06/20)

Page 4 of 4

Loading...

Loading...