Page 1

3Com® Switch 8800

Power Over Ethernet

Installation Guide

www.3Com.com

Part Number: 10015270 Rev. AA

Published: July 2006

Page 2

3Com Corporation

350 Campus Drive

Marlborough, MA

USA 01752-3064

Copyright © 2006, 3Com Corporation. All rights reserved. No part of this documentation may be reproduced in any form or

by any means or used to make any derivative work (such as translation, transformation, or adaptation) without written

permission from 3Com Corporation.

3Com Corporation reserves the right to revise this documentation and to make changes in content from time to time

without obligation on the part of 3Com Corporation to provide notification of such revision or change.

3Com Corporation provides this documentation without warranty, term, or condition of any kind, either implied or

expressed, including, but not limited to, the implied warranties, terms or conditions of merchantability, satisfactory quality,

and fitness for a particular purpose. 3Com may make improvements or changes in the product(s) and/or the program(s)

described in this documentation at any time.

If there is any software on removable media described in this documentation, it is furnished under a license agreement

included with the product as a separate document, in the hard copy documentation, or on the removable media in a

directory file named LICENSE.TXT or !LICENSE.TXT. If you are unable to locate a copy, please contact 3Com and a copy will

be provided to you.

UNITED STATES GOVERNMENT LEGEND

If you are a United States government agency, then this documentation and the software described herein are provided to

you subject to the following:

All technical data and computer software are commercial in nature and developed solely at private expense. Software is

delivered as “Commercial Computer Software” as defined in DFARS 252.227-7014 (June 1995) or as a “commercial item”

as defined in FAR

license for the Software. Technical data is provided with limited rights only as provided in DFAR 252.227-7015 (Nov

FAR 52.227-14 (June 1987), whichever is applicable. You agree not to remove or deface any portion of any legend provided

on any licensed program or documentation contained in, or delivered to you in conjunction with, this User Guide.

Unless otherwise indicated, 3Com registered trademarks are registered in the United States and may or may not be registered

in other countries.

3Com and the 3Com logo are registered trademarks of 3Com Corporation.

Cisco is a registered trademark of Cisco Systems, Inc.

Funk RADIUS is a registered trademark of Funk Software, Inc.

Aegis is a registered trademark of Aegis Group PLC.

Intel and Pentium are registered trademarks of Intel Corporation. Microsoft, MS-DOS, Windows, and Windows NT are

registered trademarks of Microsoft

registered trademark in the United States and other countries, licensed exclusively through X/Open Company, Ltd.

IEEE and 802 are registered trademarks of the Institute of Electrical and Electronics Engineers, Inc.

All other company and product names may be trademarks of the respective companies with which they are associated.

2.101(a) and as such is provided with only such rights as are provided in 3Com’s standard commercial

Corporation. Novell and NetWare are registered trademarks of Novell, Inc. UNIX is a

1995) or

ENVIRONMENTAL STATEMENT

It is the policy of 3Com Corporation to be environmentally-friendly in all operations. To uphold our policy, we are committed

to:

Establishing environmental performance standards that comply with national legislation and regulations.

Conserving energy, materials and natural resources in all operations.

Reducing the waste generated by all operations. Ensuring that all waste conforms to recognized environmental standards.

Maximizing the recyclable and reusable content of all products.

Ensuring that all products can be recycled, reused and disposed of safely.

Ensuring that all products are labelled according to recognized environmental standards.

Improving our environmental record on a continual basis.

End of Life Statement

3Com processes allow for the recovery, reclamation and safe disposal of all end-of-life electronic components.

Regulated Materials Statement

3Com products do not contain any hazardous or ozone-depleting material.

Environmental Statement about the Documentation

The documentation for this product is printed on paper that comes from sustainable, managed forests; it is fully

biodegradable and recyclable, and is completely chlorine-free. The varnish is environmentally-friendly, and the inks are

vegetable-based with a low heavy-metal content.

Page 3

CONTENTS

1 INTRODUCTION

Switch 8800 PoE Power Rack 5

Features 5

Architecture and Configurations 5

2 SYSTEM DESCRIPTION

Overview 9

Power Supply Modules 9

PoE Power Rack 9

Power Supply Module Visual indicators 10

System Controller 10

Distribution Panel 12

CONTENTS 3

3 SAFETY

Safety Statements 13

Warning Statements and Safety Symbols 13

Precautions 13

4 INSTALLATION AND TESTING

Introduction 15

Guidelines 15

EMI Considerations 15

Safety 15

Installation Sequence 15

Install the PoE DIMM Module 16

Technical Specifications 16

Install the PoE DIMM Module 16

Mount Chassis 16

Install Power Supply Modules 18

Ground PoE Power Rack 18

Connecting to AC utility/ AC grounding 19

Initial Start-up 19

Powering on the Device 19

5 ENGINEERING, MAINTENANCE AND TROUBLESHOOTING

Maintenance and Troubleshooting 21

LED Indication 21

Page 4

4 CONTENTS

Page 5

1

INTRODUCTION

Switch 8800 PoE Power Rack

The 3Com Switch 8800 PoE power rack is a modular, stand-alone Power over

Ethernet (PoE) power source. The PoE Power Rack provides a total of 4500 Watts of

DC power with 2+1 power redundancy for PoE powered devices connected to the

Switch 8800 chassis.

Features The PoE Power Rack has the following features:

■ Compatible with a wide range of input voltages from 90 V to 264 V and uses 20

A/250 VAC EN60320 C20 appliance coupler connectors and connector plugs.

■ Power factor is above 0.99

■ Efficiency is over 88%

■ Maximum device output is (N + 1) 90A @ 54V

■ Power supply modules are hot-swappable for uninterrupted operation

■ The PoE Power Rack power status may be monitored by an RS232 or RS485

interface

■ Advanced EMC (Electro Magnetic Compatibility) design

■ High safety and reliability

Architecture and Configurations

The PoE Power Rack architecture integrates DC power supply modules (3 maximum),

a system controller, and the distribution module, in a four rack-unit-high (4U) chassis.

The system controller provides local monitoring and control of the device. The general

configuration is shown in

Ta bl e 1 The PoE Power Rack Configuration

Description Standard Configuration

4U high chassis D x W x H- 320.5 x 482.6 x 177mm (12.62 x 19.00 x 6.97 in)

System controller One

SWITCH 8800 PoE

Power Supply Module

AC distribution

components

Ta bl e 1.

One installed (3 maximum for power redundancy)

■ Three independent AC power input sockets with three AC Power

switches

■ 3-phase AC voltage sensor

The standard PoE Power Rack is configured with one power supply module. The

power rack may be configured with up to 3 power supplies based on the power and

power redundancy requirements. Refer to

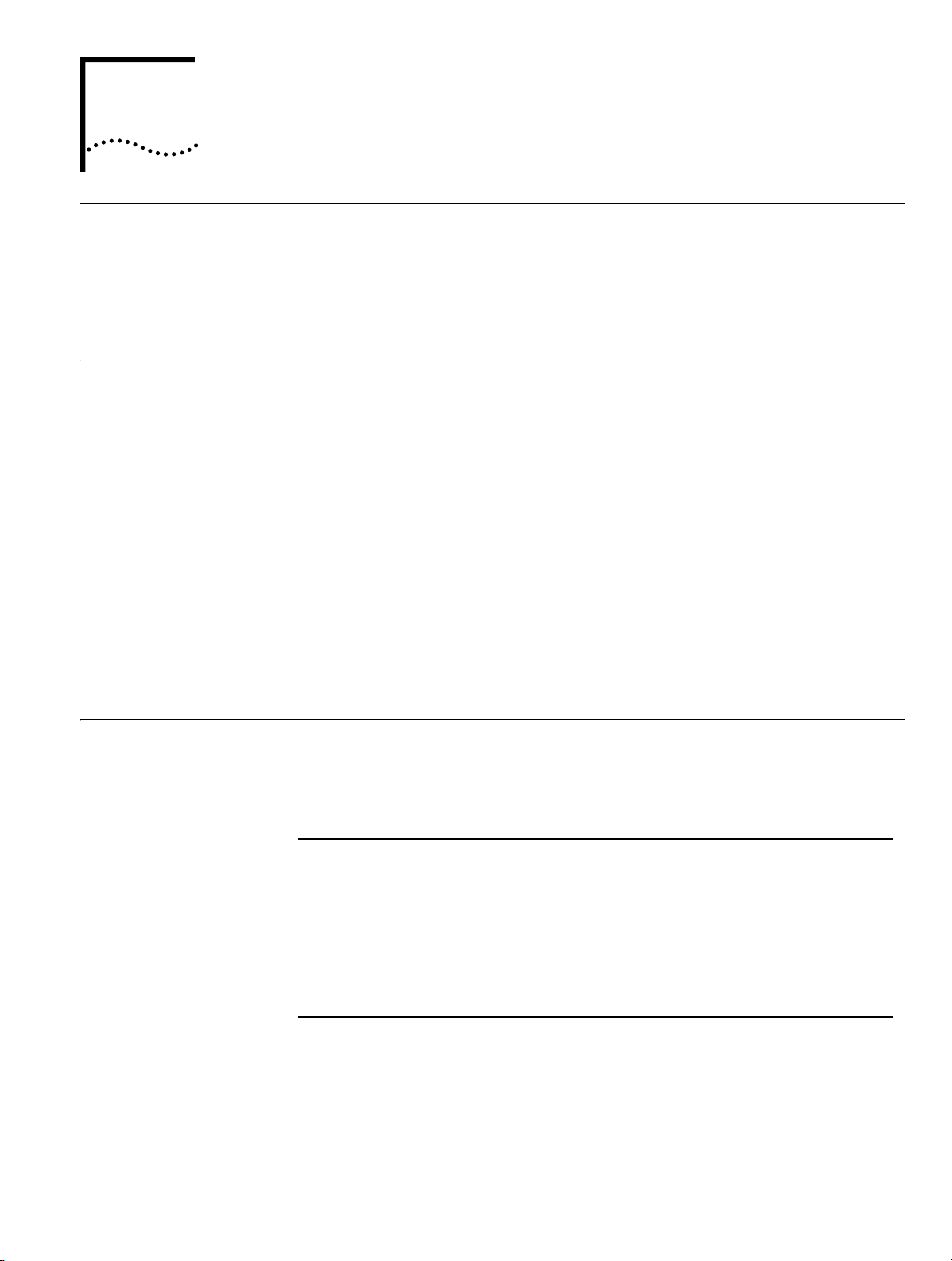

Figure 1 for overall dimensions. Refer to

Figure 2 for the rear view of the PoE power rack.

Page 6

6 CHAPTER 1: INTRODUCTION

Figure 1 The PoE Power Rack

Figure 2 The PoE Power Rack (Rear View)

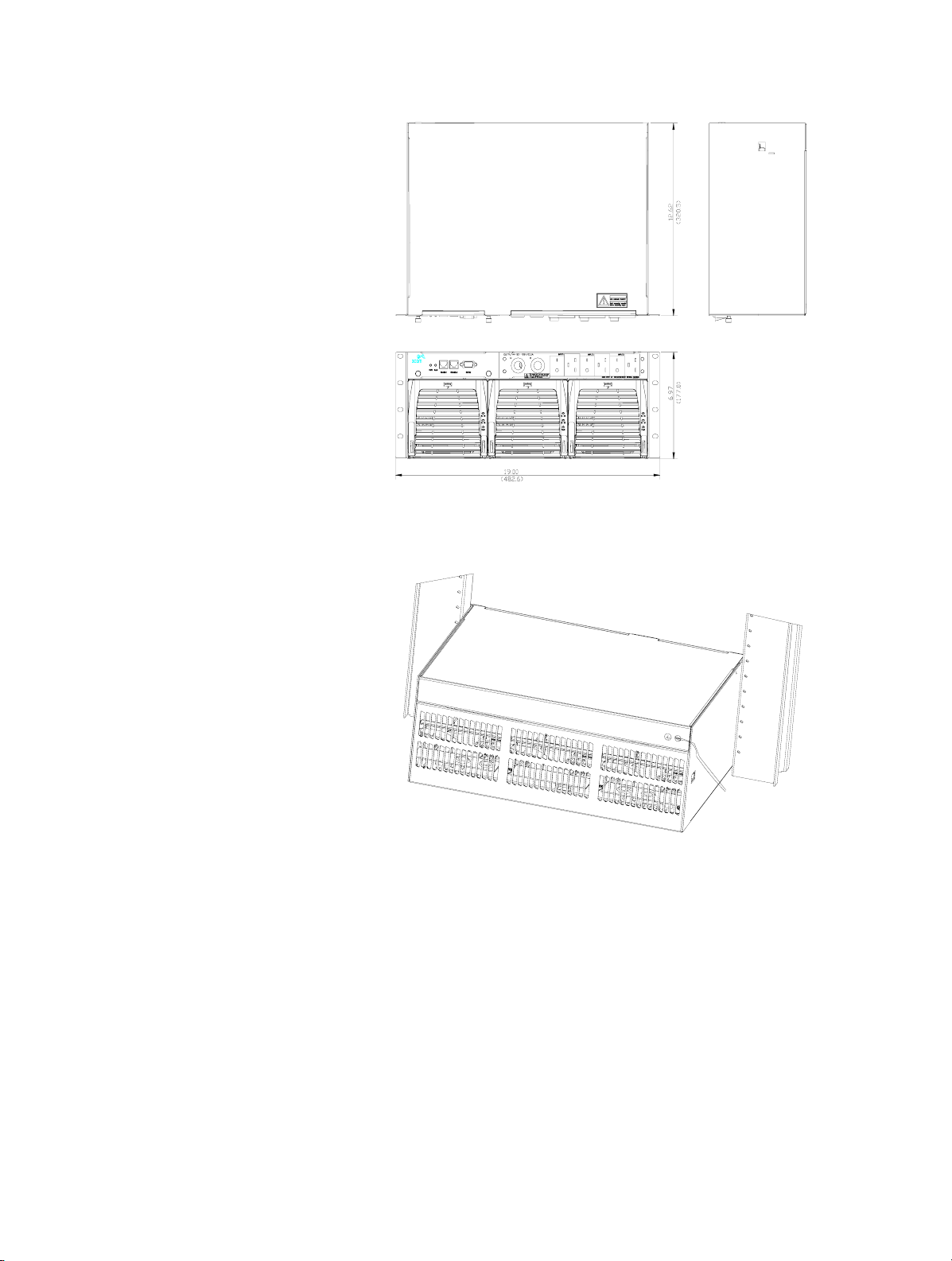

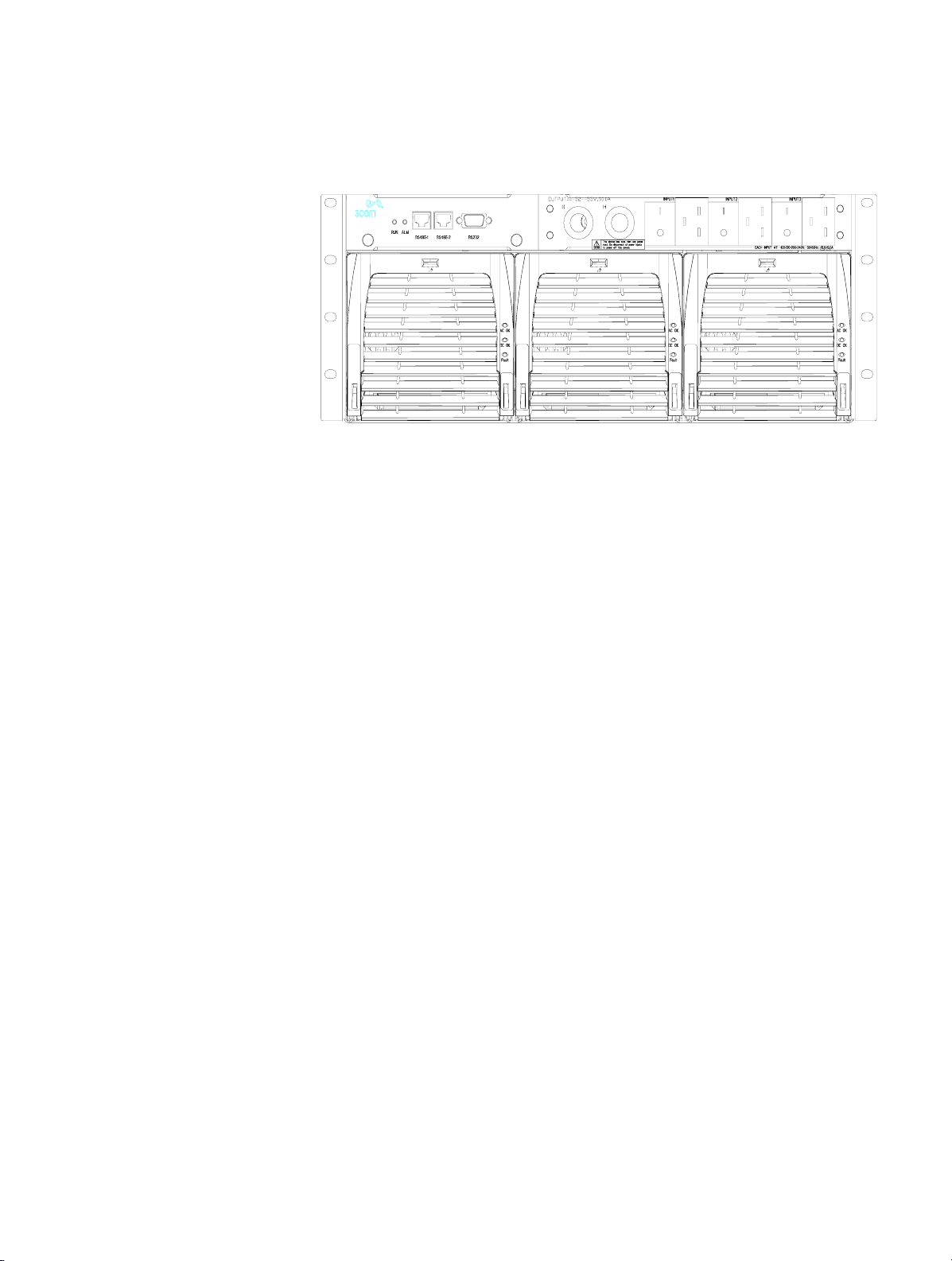

Refer to Figure 3 for the front view of a fully equipped PoE power rack. It consists of:

■ System controller with 2 LEDs and 3 connectors

■ Distribution panel with DC output sockets and three AC input sockets

■ Power supply modules (3 modules are shown in Figure 3)

The three AC input sockets correspond to the three power supply modules

(numbered from left to right).

Page 7

Architecture and Configurations 7

Figure 3 The PoE Power Rack Configured with Three Power Supply Modules (Front VIew)

Page 8

8 CHAPTER 1: INTRODUCTION

Page 9

SYSTEM DESCRIPTION

2

Overview Figure 4 shows the schematic diagram of the PoE Power Rack power system,

showing the interconnections and signal flow through the power supply modules

and internal components.

Figure 4 Schematic Diagram of the PoE Power Rack

Power Supply Modules

PoE Power Rack Up to three power supply modules can be mounted in each PoE Power Rack. Each

DC power is supplied to the power bus by the power supply modules.

The PoE Power Supply Module is interchangeable between the Switch Rack and the

Switch 8800 PoE Power Rack. NO other components are interchangeable.

power supply module in the PoE Power Rack receives AC power from the AC

distribution panel.

Page 10

10 CHAPTER 2: SYSTEM DESCRIPTION

Power Supply Module Visual indicators

The front panel of the power supply module has three LEDs (Figure 5). Their

descriptions, colors, and functions are shown in Ta bl e 2.

Figure 5 Power Supply Module Front Panel

Ta bl e 2 LED State Description

Condition AC OK (green) DC OK (green) Fault (Red)

All OK Lighted Lighted Off

Thermal alarm

(Ambient)

Thermal alarm (fan fail) Lighted Off Lighted

Blown AC fuse in unit Lighted Off Lighted

Low or no AC > 15mS

(single unit)

AC not present in any

power supply module

Over Voltage Latched

shutdown

Any internal failure Lighted Off Lighted

Lighted Off Off

Off Off Off

Off Off Off

Lighted Off Lighted

System Controller The PoE Power Rack has a system controller at the front of the chassis. Refer to

Figure 6.

Figure 6 Front Panel of the Controller

To indicate operational and alarm status, a green LED (RUN) and red LED (ALM) are

located on the front panel of the PoE system controller. When the system has an

alarm, such as input failure, input over-voltage or under-voltage, output over-voltage

or under-voltage, power supply failure, or power supply self-protection, the red (ALM)

LED will light. Once the alarm status is cleared, the LED goes off.

The system controller of the PoE Power Rack has two major functions:

Page 11

System Controller 11

■ Monitor system operation status - An AC sensor card inside the PoE Power Rack

samples the AC input voltage. The sampled signal is sent to the controller for

processing. If the AC input voltage is lower than the pre-set alarm level, the

controller reports an AC input under-voltage alarm. Likewise, if the input voltage is

higher than the pre-set alarm level, the controller reports an AC input over-voltage

alarm. The DC output voltage is also sampled and sent to the controller. If the

output voltage is lower than the pre-set alarm level, the controller will report a DC

Low alarm. Likewise, if the DC output voltage is higher than the pre-set alarm, the

controller reports a DC output High alarm. The power supply module status

communicates with the controller via an internal RS485 bus. If the power supply

modules issues an alarm, the alarm is passed to the controller. Power supply

module failure alarms include: AC input failure, DC output failure, fan failure, high

output voltage, current limit, over temperature, and module shut-down.

■ Communicate with deamon systems - The controller supports interface to the

Switch 8800 chassis through RS232 or RS485 cable connection. A cable is

provided with the PoE Power Rack for attachment to the Switch 8800 (connect the

RS232 connector end to the PoE Power Rack and connect the RJ45 cable end to

the port labeled "Com" next to the PoE DC terminal block on the back of the

Switch 8800). Using CLI commands, the user can receive and read system

information or command the operation of the PoE Power Rack. The RS485-1 and

RS485-2 have the same function. The customer can choose only one port for

communication. The RS485/RS232 can not work at same time, so do not connect

them both at the same time.

There is one RS485 port and one RS232 interface on the rear panel of the PoE Power

Rack (the cable provided with the PoE Power Rack is a RS232 cable type).

The RS485 and RS232 signals are described in Table 3 and Table 4. :

Ta bl e 3 RS485 Pin Definitions

Pin Definition

1 Transmit, +

2 Transmit, -

3 Receive, +

4 Ground

5 Not used

6 Receive, -

7 Ground

8 Not used

Ta bl e 4 RS232 Pin Definitions

Pin Definition

1 Not used

2 Receive

3 Transmit

4 Not used

5 Ground

6 - 9 Not used

Page 12

12 CHAPTER 2: SYSTEM DESCRIPTION

Distribution Panel The distribution panel consists of DC output sockets and three AC input sockets.

Refer to

Figure 7 Distribution Panel

The three EN60320 C20 AC input sockets on the front panel of the device are rated

at 20A@250VAC. Each socket supplies power to one power supply module. There is

an AC power ON/OFF switch beside each AC input socket for individual power

switching.

The DC distribution panel has Copper bus bars and two 4 AWG/570mm cables with

OT25-8 terminals to provide 54VDC output of the device. Use the two cables to

connect the power rack and the Switch 8800 chassis. The output socket on the left is

marked “-” (negative). The output socket on the right is marked “+” (positive).

Figure 7.

Page 13

SAFETY

3

Safety Statements Please read and follow all safety instructions and warnings before servicing the PoE

Power Rack. Refer to the individual module product manuals for additional safety

statements specific to the modules.

■ The device must be in a restricted access area (dedicated equipment rooms,

equipment closets, etc.) where the applicable requirements of the device are met.

■ The equipment must be in a controlled environment (an area where the humidity

is maintained at levels that cannot cause condensation on the equipment, the

contaminating dust and irritant gases controlled, and the steady-state ambient

temperature is within the range specified).

■ Do not install this equipment at a combustible place.

■ This equipment has been evaluated for use in a continuous ambient temperature

of up to 50°C.

■ Torque electrical connections, conforming to the values specified on labels or in

the product documentation.

Warning Statements and Safety Symbols

■ Refer to the product documentation for the proper hardware. Use only the parts

specified in the equipment documentation.

■ Improper fuses/circuit breakers may cause body injury or equipment damages.

■ External circuit breakers must be sized as required by the applicable local codes.

Refer to the equipment ratings to assure the equipment rating will not exceed

80% of the value of the breaker chosen.

The symbols may sometimes be accompanied by some types of statement, for

example, "Hazardous voltage/energy inside" or "Risk of injury". "This device must

be accessed only by qualified personnel."

These symbols are used to identify the presence of hazardous AC/DC main voltage

and also can be used to alarm the level of danger.

Precautions When working on this type of equipment, the following precautions must be noted:

■ This unit must be installed, serviced, and operated only by skilled and qualified

personnel who have the necessary knowledge and practical experience with

Page 14

14 CHAPTER 3: SAFETY

electrical equipment and who understand the hazards that can arise when

working on this equipment.

■ The PoE Power Rack can be powered by multiple AC inputs, ensure that the

appropriate circuit protection device for each AC input being serviced is

disconnected before changing or servicing a Power Supply Module. If servicing the

PoE Power Rack, all the AC power cords must be removed from the equipment.

■ High leakage currents may be possible on this type of equipment. Make sure the

equipment is properly grounded before connecting AC input power. Use only

properly grounded AC power cords.

■ Hazardous energy and voltages are present in the device and on the DC output

cables that can shock or cause serious injury. Follow all safety warnings and

practices when servicing this equipment. Insure that the PoE Power Rack AC

power cords are unplugged from the PoE Power Rack before connecting the DC

output cables to the PoE Power Rack and the Switch 8800.

■ Exercise care when servicing this area.

In addition to proper job training and safety procedures, the following are some basic

precautions that should always be used:

■ Use only properly insulated tools.

■ Remove all metallic objects (key chains, glasses, rings, watches, or jewelry).

■ Wear safety glasses.

■ Test circuits before touching.

■ Lock out and tag any circuit breakers/fuses when possible to prevent accidental

turn on.

■ Be aware of potential hazards before servicing equipment.

■ Identify exposed hazardous electrical potentials on connectors or, wirings. (Note

the condition of these circuits, especially any wiring).

■ Be careful when removing or replacing any covers - avoid contacting any circuits.

Page 15

INSTALLATION AND TESTING

4

Introduction This section outlines the sequence for installing the PoE Power Rack, including plug-in

modules. Test procedures for verifying the integrity of the installation are also

included.

Guidelines The device must be installed to allow sufficient front and rear access. All cables must

be routed through insulated conduit openings. All service operations can be

completed on the front of the power rack.

EMI Considerations When running the DC output cables, ensure that the positive and negative cables are

routed so as no loops are created.

Safety WARNING:

■ Only qualified personnel can install and service the PoE Power Rack.

■ Hazardous energy is present in the device and on the interface cables, which can

cause electric shock, serious injury, or death if safety precautions are ignored.

Follow all safety warnings and practices when servicing this equipment.

Installation Sequence Review all safety warnings in Section 3 before beginning the installation process.

Observe all warnings and labels on the equipment.

The PoE Power Rack consists of a chassis which includes AC and DC distribution

modules, one system controller, one power supply module and one power supply

module bracket. Refer to

Note that the PoE Power Rack is shipped mostly pre-assembled so as to minimize the

overall installation process. The following installation sequence is recommended:

1 Mount chassis

2 Install power supply modules

3 Ground frame

4 Connect to Switch 8800 Chassis

5 Connect to loads

6 Connect to AC utility/AC grounding

7 Initialize the system

Figure 2 and Figure 3 for relationship of components.

Page 16

16 CHAPTER 4: INSTALLATION AND TESTING

Install the PoE DIMM

Module

If you are installing the optional PoE DIMM module, use the following instructions.

Technical Specifications

The technical specifications of PoE DIMM (Dual In-line Memory Module) are listed in

Ta bl e 5.

Ta bl e 5 Technical specifications of PoE DIMM module

Number of

Model

PD67024MUAC 24 Master AC Powered devices

PD67024S 24 Slave AC/DC According to Master

ports

Type Disconnect Detection

compliant with IEEE

802.3af or the

legacy standard

Install the PoE DIMM Module

Wear an ESD-protective wrist strap when installing the PoE DIMM modules.

Insert the Master and Slave DIMM modules in the right sockets. The silk screens on

the interface card must be consistent with those on the PoE DIMM modules. If the

modules are wrongly seated, cooling problems may occur, though the PoE module

can operate normally.

Note:

■ With the reverse insertion prevention design, you can only insert the module in the

right direction.

■ The PoE DIMM module is only supported on the PoE I/O module.

■ If no PoE SIMM module is in place, or the module is not fully seated, the interface

card cannot supply power, even if other functions go well.

The Master and Slave DIMM modules must be used at the same time.

Follow these steps to install the PoE DIMM:

1 Check the position of the module.

2 Insert the Master DIMM module into the J15 socket of the interface card and the

Slave DIMM module into the J16 socket.

3 Close the locking spring clips until the pins at both ends of the clip snap into the

notches in the module.

Mount Chassis All items required for installation are contained within the packaging. Additional

power supply modules are shipped separately. Check the packing list. Rack or frame

mounting screws are not included.

1 Place unit box in a vertical position near the installation site (equipment cabinet or

rack).

2 Carefully remove the crate top, crate sides, and the packing material. If possible,

recycle the packing crate and the packing material. If not, dispose of properly

according to local codes and regulations.

Page 17

Installation Sequence 17

3 The following items are included in the unit packaging: PoE Power Rack, power

supply module, dummy faceplates and cables. Remove all this material and place

aside.

Mounting screws are NOT supplied with the PoE Power Rack. Mounting screws may

be obtained from the equipment rack/cabinet supplier.

4 It is your option to remove power supply module and dummy faceplates or before

installation. Removing them makes the next step easier. Refer to

Figure 8.

5 Install the chassis into the 19-inch equipment rack or cabinet, using at least four

screws. See

Figure 9.

At least four screws must be used to ensure the PoE Power Rack is securely mounted

in the equipment rack or cabinet. Failure to use four screws may cause damage to the

PoE Power Rack.

When using an electric screwdriver, the correct torque setting recommended is 6.2 to

6.5 Newton meters. Do not over tighten the mounting screws.

Figure 8 Removing Power Supply Module and Dummy Faceplate

Then hold the handle to

slide out from chassis

Figure 9 Physical installation

First put screwdriver accessory

into rectangle hole, and give slight

strength upward to open the

handle

Page 18

18 CHAPTER 4: INSTALLATION AND TESTING

Install Power Supply

Modules

Power Supply Modules are installed by sliding into the power rack, pushing until the

power supply module is fully inserted, and closing the handle on the power supply

module. Refer to

Figure 10.

1 Verify that the AC power switches on the AC distribution panel are in the "OFF"

position .

2 Insert the power supply module into the PoE Power Rack and slide it toward the

backplane until it contacts the backplane connectors.

3 Close the handle on the front of the power supply module and verify that the module

is firmly seated.

Figure 10 Install Power Supply Modules

Ground PoE Power Rack The PoE Power Rack must be electrically grounded before making any further

electrical connections. (Refer to the installation instructions for grounding the PoE

Power Rack).

1 It is recommended that the supplied green/yellow 16 mm 2 cable with a M6 single

hole terminal lug is securely connected to the PE grounding terminal on the rear panel

of the chassis, as shown in

Figure 11.

2 Terminate the other end of the conductor to a grounding plate or other acceptable

ground point. Follow local rules and codes regarding grounding requirements.

Figure 11 Frame Grounding

Page 19

Installation Sequence 19

Connecting to AC utility/

AC grounding

AC power input is accessed from the front of the unit. AC power cord connection is

made using power cords with IEC 60320 C-19 connector plugs. The AC power plugs

are labeled Input 1, Input 2, and Input 3, which correspond to the power supply

modules numbered from left to right. Refer to

Figure 12.

To connect AC power:

1 Turn the AC branch circuit breakers to the "OFF" position.

2 Ensure that the AC input switches are in the "OFF" position.

Plug the AC input power cord(s) into the AC socket(s) that correspond to the power

supply module slot location(s). For example, the C20 coupler labeled "Input1"

corresponds to the power supply module in the furthest left power supply module

slot, when viewing the PoE Power Rack from the front.

Figure 12 DC and AC Connections

Initial Start-up Verify that all AC branch circuit breakers and PoE Power Rack AC power switches are

Powering on the Device

in the "OFF" position.

1 Ensure that all power supply modules are seated and locked into position in the PoE

Power Rack.

2 Turn the AC branch circuit breakers to the "ON" position.

3 Turn the PoE Power Rack AC power switches to the "ON" position (corresponding to

the power supply modules installed).

4 Verify that the "AC OK", "DC OK", and green LEDs are on.

5 Verify the fan is operating on each power supply module.

6 Wait approximately 10-30 seconds to allow the switch system to go through its

start-up procedure.

7 Verify that the green LED on the controller panel is on.

8 Use a digital voltmeter to verify that the DC output voltage is approximately -54VDC.

9 For systems with more than one power supply module installed, turn one of the AC

power input switches to "OFF" to verify that the red alarm LED lights on the PoE

Power Rack controller.

10 For systems with more than one power supply module installed, turn the second AC

input switch off to verify that the FAULT LED lights on the controller. Clear the alarms

by turning on the AC input switch.

Page 20

20 CHAPTER 4: INSTALLATION AND TESTING

Page 21

ENGINEERING, MAINTENANCE AND

5

Maintenance and Troubleshooting

TROUBLESHOOTING

This section provides field maintenance information and troubleshooting procedures

for the PoE Power Rack and power supply modules. Review the safety information in

section 3 of this manual before performing maintenance procedures

All procedures described in this section must be performed by qualified maintenance

personnel only.

The power supply modules are not field serviceable and must be replaced in the event

of a failure.

LED Indication Use Table 6 to determine if there is a fault with PoE Power Rack.

When visual indicators do not identify a defective part, notify your authorized service

representative.

Ta bl e 6 Troubleshooting Guide

Controller alarm

status

RUNALM NONE ■ The AC power input

RUNALM AC OKFAULT ■ Power supply module

RUNALM AC OKDC

RUNALM AC OK ■ Power supply module has

Power supply

module

display Possible problems Possible solution

circuit breakers has

opened.

■ AC input voltage is too

low or power is lost

failure

■ Output beyond normal

range

OKFAULT

Communication error

between the power supply

module and the controller

no output and it is in

standby mode

■ Over load

■ Ambient temperature is

too high

■ Power supply module

failure;

1 Verify that AC

power input

circuit breaker is

closed; close

circuit breaker if

it is open.

2 Verify the AC

power is present

and in normal

range.

Replace the power

supply module

Replace the power

supply module

1 Initialize the

power supply

module or reset

the controller.

2 Check if the load

is over the

rating.

3 Check the

ambient

temperature.

4 Replace the

power supply

module

Page 22

22 CHAPTER 5: ENGINEERING, MAINTENANCE AND TROUBLESHOOTING

Table 6 Troubleshooting Guide

Controller alarm

status

ALM or None -- Controller failure Replace the

Power supply

module

display Possible problems Possible solution

controller

Loading...

Loading...