Page 1

3B SCIENTIFIC® PHYSICS

Ultrasonic CW generator U10006

Laser diode for Debye-Sears effect U10007

Test vessel U10008

Instruction sheet

8/03 ALF

®

3

2

1

Ultrasound generator with accessories for the DebyeSears experiment and for demonstrating standing ultrasonic waves.

Safety instructions

Before switching on the ultrasound generator and accessories, carefully read the following instructions for

the sake of your safety and for the safety of the equipment.

• The slits in the device are for ventilation and must

be kept clear to avoid overheating the equipment.

It is recommended that the device be placed on its

own stand (also included).

• Before switching on the device make sure that it is

adjusted to the mains voltage you intend to use.

Make sure that you keep within the operating specifications.

• Never try to push objects through the slits in the

device since this could cause short circuits or electric shocks.

• Only use 3B’s own ultrasound transducer with the

“PROBE” connection. Be careful, voltages may be

as high as 70 V.

• Do not use the ultrasound transducer for a lengthy

period without contact to fluids. Otherwise the

transducer may overheat and be destroyed.

• Do not turn on the U10007 laser diode if there are

1 Laser diode

2 Test vessel

3 Ultrasonic transducer

people standing in the beam. This is a class II laser

with power < 1 mW. Do not look into the beam or

aim it at other people or animals.

• Beware: high-powered ultrasound! Do not use the

probe on people or animals.

Contents

1. Introduction ............................................ 7

2. Components ............................................ 7

2.1 Ultrasound generator - operating elements 7

2.2 Set-up for test container 8

2.3 Lens on glass slide 8

2.4 Laser diode (U10008) 8

3. Experiment procedure .............................. 8

3.1 General instructions for experiments 8

3.2 Debye-Sears effect 9

3.3 Projection of standing ultrasonic waves 9

4. Technical details ..................................... 10

1.1. Ultrasound generator 10

4.2. Ultrasonic transducer 10

4.3. Test vessel 10

6

Page 2

1. Introduction

In 1932 Debye and Sears demonstrated for the first time

how light is refracted when passing through a fluid excited to high-frequency oscillation. The maxima and

minima in density act here like the grid elements of

an optical diffraction grating. The grating constant

corresponds to the ultrasonic wavelength and is thus

dependent on the frequency of the ultrasound and the

speed of sound in the medium through which the

sound is travelling.

The CW (continuous wave) generator with its accompanying broad-band ultrasound transducer, along with

an adjustable test vesseland its integrated laser holder,

mean that it is possible for the first time to demonstrate this phenomenon to schoolchildren and college

students alike using simple and compact equipment.

The equipment can demonstrate both frequency dependence (with four different frequencies) and the ultrasonic wavelength in various fluids, allowing the

speed of sound in the medium to be calculated.

It is also possible to project standing ultrasonic waves

by inserting an optical lens between the laser source

and the ultrasonic waves. The waves are then projected

by the diverging laser beam.

2. Components

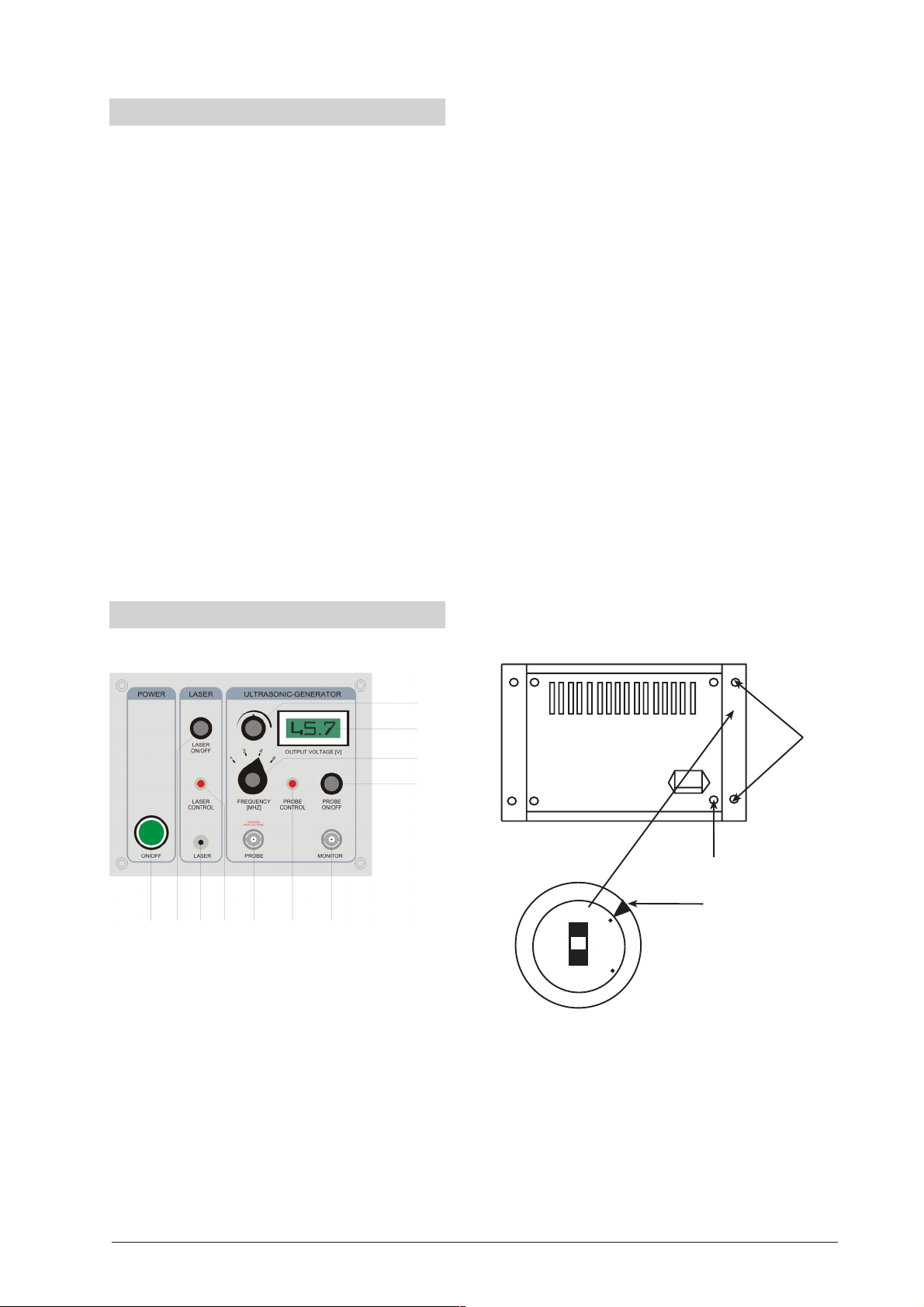

2.1 Ultrasound generator - operating elements

The ultrasound generator generates continuous highpower ultrasonic waves (CW = continuous wave). The

voltage bmcan be adjusted between 5 and 65 V. There

is an LCD display for the voltage output bl. The transmitted voltage can be switched off separately 8. The

frequency can be set to one of four frequencies (1, 2, 4

or 8 MHz) 9. An additional monitor output 7 allows

the output frequency to be determined precisely with

the aid of an oscilloscope or a frequency counter. A

suitable output 3is provided to supply power to a

laser diode. This can also be switched off separately

2.

Adjustment of mains voltage

The ultrasound generator can operate with 230 V or

115 V mains voltage. A voltage selector switch is situated on the rear of the casing and is hidden beneath

the covering to the right of the rear panel. A screwdriver is used to alter the switch setting (see illustration). If the mains voltage is altered, the fuse needs to

be changed to suit the mains voltage. A T630 mA fuse

should be used with 115 V mains voltage and a T315

mA fuse for 230 V mains.

Warning:

Unplug from the mains before altering the mains setting.

No voltage may be applied to the device while making

the adjustment,

1 2 3 4 5 6 7

1 Mains switch

2 On/off switch for laser

3 Connector socket for laser

4 Control light for laser

5 Connector socket for ultrasonic transducer

6 Control light for ultrasonic transducer

7 Monitor output

8 On/off switch for ultrasound

9 Frequency selection switch

bl Voltage display

bm Voltage setting

bm

bl

9

8

1

2

115

230

1 Remove the two screws from the rear panelling and take off

the panel. The voltage selector switch is revealed.

2 Fuse

115 V 630 mA

230 V 315 mA

3 An arrow indicates the voltage that is currently set. Adjust using

a screwdriver inserted into the slit.

3

7

Page 3

2.2 Set-up for U10008 test container

1 Adjustment screw for changing the angle of the transducer

2 Lid

3 Transducer holder

4 Ultrasonic transducer (supplied with U10006)

5 Securing screw for laser diode

6 Slot for lens holder

7 Laser holder

8 Securing screw for ultrasonic transducer

9 Glass vessel

The following illustration shows how the lens should

be properly placed in the test container.

1

2

3

4

5

6

7

8

9

2.4 Laser diode (U10007)

Standing ultrasonic waves are generated in a special

container. It allows the angle of incidence of the waves

to be set precisely to the perpendicular by means of a

special holder for the ultrasound transducer.

The test vessel consists of a glass vessel with a lid and a

holder for the transducer, three adjustment screws to

set the alignment for the standing wave and a laser

holder perpendicular to the axis of the waves which also

has a holder for a lens so that the ultrasonic waves and

the Debye-Sears effect can be projected.

2.3 Lens on a glass slide

A plane-convex lens is attached to a rectangular slide.

This is inserted into the slot in the laser holder of the

test container for experiments involving projection.

1 2 3

1 Plano-convex lens (f=100 cm)

2 Glass slide

3 Grip

1 2 3 4

1 Laser beam window

2 Laser module jacket

3 Plug for connecting to ultrasound generator

4 Connecting lead

Class II laser diode for demonstrating the Debye-Sears

effect and projecting ultrasonic waves for use with the

ultrasound generator and test container.

3. Experiment procedure

3.1 General instructions for experiments

Pay attention to the following instructions if the experiment is to work:

• Use water that contains as little air as possible since

air bubbles disturb both the ultrasound field and

the refraction of the laser beam.

• Any air bubbles around the probe should be re-

moved.

• Allow for the maximum distance between the test

container and the projection screen.

• When no measurements are being made, the ul-

trasound should be switched off so that the test

fluid does not heat up.

8

Page 4

• For precise measurements, also measure the tem-

perature and include this in the comparison.

• When using high voltage at any frequency and when

the transducer is properly aligned, at least 3 orders

of diffraction should be visible.

• The projection experiment is much more sensitive

to the angle of the transducer than the refraction

experiment. Thus for this experiment the conditions

for generating standing waves need to be adhered

to more precisely.

3.2 Debye-Sears effect

The wavelength of the ultrasonic waves in the Debye-Sears

experiment (photo left, 4 MHz

in water) can be determined

for various different test fluids

(water, glycerine, cooking oil).

This means measuring the distance s between the ultrasound transducer and the refracted image. Then the number of orders of refraction N

and distance between the -nth

and +nth bands x can be de-

termined. Since the wavelength of the laser light

λ

L

known then:

λ

2N s

(1)

λ

s

gives the ultrasonic wavelength

L

=

x

λ

. The individual vari-

s

ables can be calculated as in the following diagram.

λ

L

λ

s

s

N = 3

N = 2

N = 1

N = 0

N = -1

N = -2

N = -3

The ultrasonic frequency n is measured at the monitor

socket. Then the speed of sound c in the fluid is given

by:

is

2. Glycerine

v = 4 MHz, s = 2.90 m, N = 2, x = 1.6 cm,

λ

= 650 nm

L

therefore: λ = 471.2 µm, c = 1885 m/s

(Table: 1900 m/s at 25°C)

3.3 Projection of standing ultrasonic waves

Direct projection of ultrasonic waves can be an interesting extension to

the experiment. The

sound wave is projected by inserting a

convex lens into the

laser beam so that

the beam is diverged. The density

variations in the

standing wave then

appear as light and

dark regions on the

projection screen

(see photograph

right). To determine

the wavelength from

the diffraction image and the geometry involved, as well as the focal length

f of the lens in air (100 mm in this case), corrections due

to the glass walls of the vessel and the test fluid also

need to be considered.

N = 6

N = 5

N = 4

N = 3

x

N = 2

g

1

a1a

x

The light refraction method as described in 3.2 is thus

g

2

2

s

N = 1

N = 0

better suited for calculating the wavelength precisely.

The precise equation for

λ

in the projection experi-

s

ment is:

gna

1g1

f

−−

(3)

2

==

λ

s

N

x

sf

−−+−

n

FL

ggnaa

12g12

+

n

FL

(2) c =

λ

ν

s

Example results:

1. Water

v = 4 MHz, s = 2.90 m, N = 4, x = 4.1 cm,

therefore:

λ

= 367.8 µm, c = 1471 m/s

s

(Table: 1480 m/s at 20°C)

λ

= 650 nm

L

The distance a1 between the glass wall towards the lens

and the distance a2 can be approximated as half the

internal width of 9.6 cm. The thickness of the glass g

and g2 is about 4 or 5 mm. The refractive indices nFL for

the test fluid and ng for the glass may be measured or

taken from tables.

9

1

Page 5

N is the number of bright maxima and x the separation between them.

The speed of sound in the medium can now be calculated once again from the measured frequency n using equation (2).

Note:

With the U10008 test vessel it is only possible to set up

a good projection of the standing ultrasonic wave at a

frequency of 4 MHz. At 2 MHz and especially at 1 MHz

ultrasonic waves reflected from the bottom of the container are superimposed destructively on the impinging ultrasonic beam. Only for 4 MHz waves is the difference in the path length of the order of several wavelengths. At 8 MHz the amplitude of the emitted wave

is too small and also the absorption is much greater

(the absorption coefficient is proportional to the square

of the frequency). This means that no clear standing

waves are produced.

Example results:

Water:

a1 = a2 = 4.8 cm, f = 10 cm, nFL = 1.33, ng = 1.45,

s =3.03 m, n = 4 MHz, x = 8.9 cm, g1 = 5 mm, g2 = 4 mm

therefore: λ = 397 µm, c = 1590 m/s

(Table: 1480 m/s at 20°C)

4. Technical details

4.1 Ultrasound generator (U10006)

Frequency: 1, 2, 4, 8 MHz adjustable

Output signal: Sine wave, continuously adjustable

between 5 Vpp to approximately

65 Vpp. Can be switched off.

Red control light

Display: 3-digit LCD, one decimal place,

height of digits 10 mm

Monitor signal: TTL, Frequency signal

Laser output: 3 V DC, max. 300 mW at socket

5.5 mm outer Ø, 2.5 mm inner Ø,

Can be switched off.

Red control light

Dimensions: 256 x 86 x 156 mm

Mains voltage: 115/230 V, 50/60 Hz

Power consumption: max. 60 VA; 5 VA minimum power

(laser and ultrasound switched

off)

Fuse: T 315 mA (230 V) / T 630 mA (115 V)

Ultrasonic transducer

Probe diameter: 27 mm

Active surface area: 2 cm²

Cable length: 1 m with BNC socket

4.2 Test vessel (U10008)

Test vessel: 100 x 100 x 120 mm

Volume: 900 ml approx.

Laser holder: 17 mm internal diameter

Transducer holder: adjustable, designed for the

supplied transducer

Lens on glass slide

Lens slide: 76 mm x 26 mm Glass slide with

roughened gripping surface

Lens: Plano-convex, f = 100 mm

(in air), 16 mm Ø

4.3 Laser diode (U10007)

Beam spot: < 6 mm at 3 m

Wavelength: 650 nm

Power: < 1 mW, laser safety class II

Supply voltage: 3 V DC

Current consumption: max. 35 mA

Connecting plug: 1 m cable with plug of 5.5 mm

outer Ø, 2.5 mm inner Ø

Dimensions: 80 mm x 17 mm Ø

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com • Technical amendments are possible

10

Loading...

Loading...