Page 1

f

-

3B SCIENTIFIC

NMR Supplementary Set 1000642

Instruction manual

06/12 ALF

®

PHYSICS

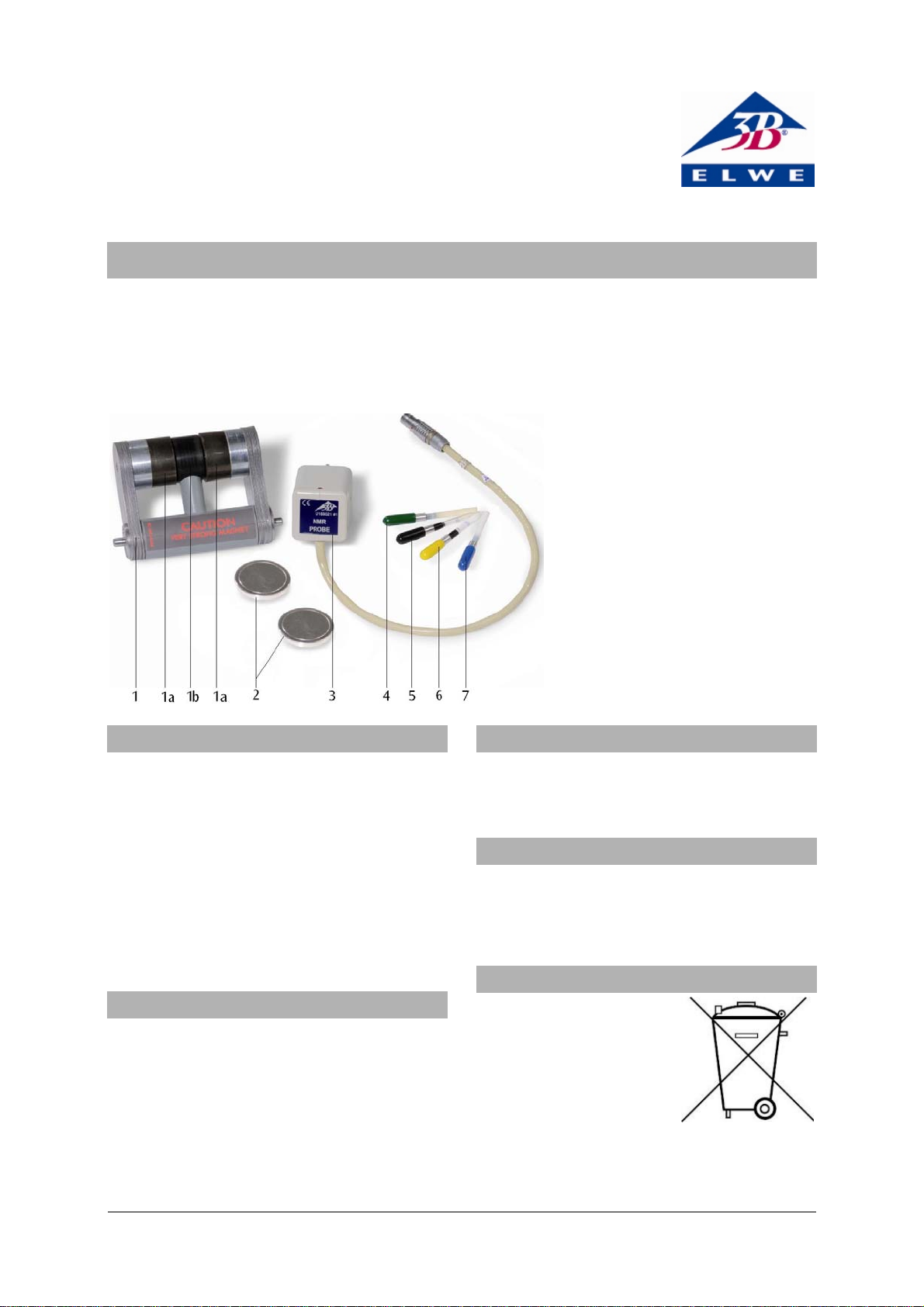

1 Magnet unit

1a Magnet

1b Yoke

2 Discs for assembly

3 NMR probe

4 Polystyrene sample

5 Comparison sample

6 Glycerine sample

7 Teflon sample

1. Safety instructions

The permanent magnets can generate considerable forces of attraction and repulsion with the

result that there is a risk of squashing or splintering.

• Be especially cautious when inserting magnets into the basic unit.

• Never use the magnets except as specified.

Magnetic fields can erase data from magnetic

media and affect or destroy electronic or mechanical components like heart pacemakers.

• People with pacemakers should not conduct

this experiment.

2. Description

The NMR supplement set is to be used with the

ESR/NMR basic set (1000637 resp. 1000638) for

investigating nuclear spin resonance in glycerine,

polystyrene and Teflon.

The set consists of an NMR probe with a highfrequency coil, a strong and uniform permanent

magnet, a glycerine sample, a polystyrene sample, a Teflon sample, an empty comparison sample and two discs for assembling the apparatus.

3. Technical data

Magnetic flux of

permanent magnets: 300 mT approx.

Frequency range: 11 − 15 MHz approx.

4. Maintenance and storage

• Remove any debris from the surfaces of the

permanent magnet poles and of the assembly discs using a cloth with some isopropanol.

• Keep permanent magnets in a dry place.

5. Disposal

• The packaging should

be disposed of at local

recycling points.

• If the equipment itsel

needs to be scrapped, it is

safe to dispose of all com

ponents other than the

probe in domestic waste.

The probe should be disposed of in containers

dedicated to the disposal of electrical refuse.

1

Page 2

6. Equipment required in addition

1 ESR/NMR basic set (230 V, 50/60 Hz) 1000638

or

1 ESR/NMR basic set (115 V, 50/60 Hz) 1000637

1 Analogue oscilloscope, 2x30 MHz 1002727

2 High-frequency cables 1002746

alternatively

1 3B NETlog™ unit (230 V, 50/60 Hz) 1000540

or

1 3B NETlog™ unit (115, 50/60 Hz) 1000539

assembly discs (see Fig. 4).

• Push back the two discs with your thumbs and

pull on the coils to move the magnet supports

into their end positions (see Fig. 5).

• Tighten both knurled screws by hand at the

same time. Make sure that the magnets are

accurately aligned on top of the assembly

discs. If necessary, slot the discs all the way

back into the probe chamber and then push

the magnet supports into their end positions.

1 3B NETlab™ 1000544

2 High-frequency cables, BNC/4-mm plug 1002748

1 PC

7. Operation

7.1 Assembly of the basic unit

The discs, the pole surfaces of the magnets and

the probe chamber in the basic unit must all be

free of grease, dust and debris.

• If necessary they should be cleaned using

isopropanol.

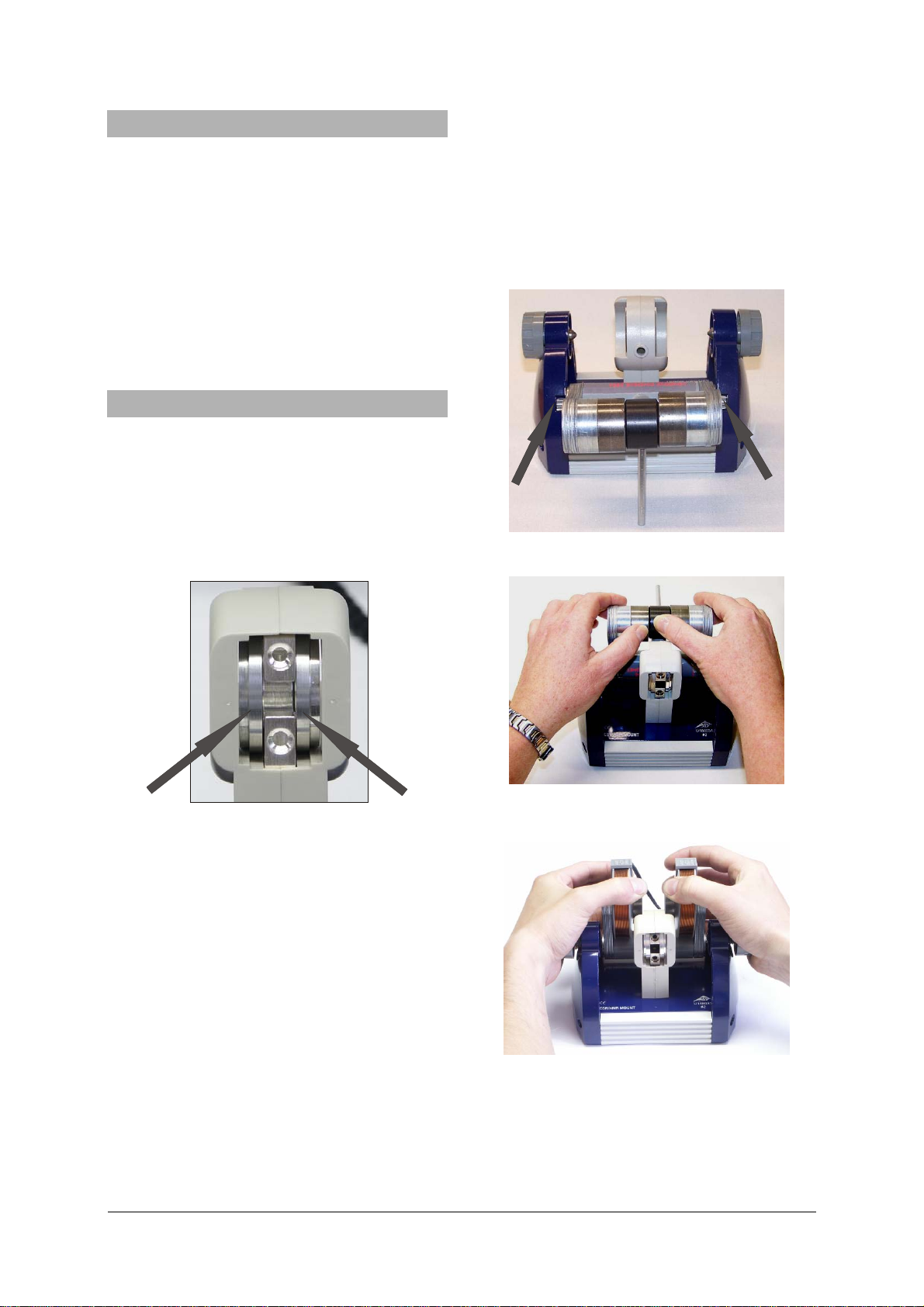

• Insert the discs into both sides of the sample

chamber (see Fig. 1).

Fig. 2 Permanent magnet inserted into basic unit

Fig. 1 Sample chamber with assembly discs inserted

• Twist the metal rod into the yoke of the

magnet unit. Place the magnet unit in the

clip on the basic unit as shown in Fig. 2.

• Take the magnet unit in both hands and push

the yoke downwards with your thumbs (see

Fig. 3).

• Push the coils over the magnets, making

sure the direction if the windings is the

same. The embossed arrows on the coils

must point in the same direction.

• Clean any grit or metal shavings off the two

magnets with a cloth.

• Move the completed magnetic unit onto the

assembly discs, making sure to carry out the

steps that follow: (see Fig. 4).

• Separate the two coils with your hands, pulling them outwards to increase the gap between them. You can rest your hands on the

knurled screws while doing this. Push the

magnets about a quarter of the way onto the

Fig. 3 Removing the yoke from the permanent magnet

Fig. 4 Pulling the two permanent magnets apart

2

Page 3

Fig. 5 Pulling the magnets onto the assembly discs

7.2 Connection to control console

• Insert the probe into the sample chamber in

such a way that it rests on the housing (see

Fig. 8).

• Connect the cable for the probe to the

“Probe In” socket of the control console, taking note of the socket's slot.

• Connect the coils to the “Coil” sockets on

the back of the control console.

• Connect the control console to its power

supply via the “12 VAC/1A“ socket.

Fig. 6 Basic unit completed with permanent magnets

and coils

7.1.1 Removing magnet unit

• Take the sample out of the sample chamber

in the basic unit.

• Disconnect the cables between the coils and

the control console.

• Loosen the knurled screws.

• Turn the basic unit so that the magnet unit is

pointing forwards.

• Lift up the yoke till it is on top of the sample.

• Hold the yoke in place with your thumbs and

use your fingers to pull the magnet unit towards the front till the yoke is between the

two magnets. Then take the entire unit out of

the basic unit (see Fig. 7).

• Take the discs out of the sample chamber.

Fig. 7 Removing the magnet unit from the basic unit

Fig. 8 Basic unit with probe

7.3 Calibration and settings

7.3.1 Using an oscilloscope

• Connect the “SIGNAL OUT” socket of the

control console to channel 1 of the oscilloscope and the “FIELD OUT” output to channel 2 (see Fig. 12).

• Set the oscilloscope as follows:

Channel 1: 0.5 V DC

Channel 2: 0.5 V DC

Time base: 5 ms

Trigger from a falling edge on channel 1.

7.3.2 Using 3B NETlog™

• Connect the “SIGNAL OUT” socket of the

control console to input

log™ unit and “FIELD OUT” to the input

• Connect the 3B NETlog™ unit to a computer

and run the 3BNETlab

IN

U on the 3B NET-

B

U .

TM

software

IN

A

• Create a new data record from the “Measurement lab” menu and define the following

parameters:

Input A: Field, Input mode VDC, Input range 2 V

Input B: Signal, Input mode VDC, Input

range 2 V

Measurement interval: 500 µs (2 kHz)

• Set to trigger from Input A with a falling edge

and a positive trigger point at about 10 to 20%.

• Activate the “Oscilloscope” button and start

measuring.

The oscilloscope window will open.

3

Page 4

7.4 Experiment procedure

ν=ν

• Insert the glycerine sample (yellow top) into

the sample chamber (see Fig. 9).

7.5.1 Use the two knurled screws to vary the

pressure on the assembly discs and observe the

signal as you do so. It may be necessary to

tighten the two screws to differing degrees.

7.5.2 Pull the probe out some of the way (up to

5 mm) and observe the signal.

7.5.3 Slightly loosen the two knurled screws and

move the magnets about 1 to 2 mm away from

their end positions. To do this, use your thumbs

to push back the two coils while resting your

fingers on the base unit (Fig. 10). Tighten the

knurled screws while observing the peak.

Fig. 9 Basic unit with glycerine sample inserted

• Set a frequency of about 13 MHz on the

control console (since the frequency knob is

a 10-turn potentiometer, it may need to be

turned by multiple revolutions).

• Set the sensitivity to medium and adjust if

necessary.

At the optimum setting, the LED can be seen to

flicker slightly. If the LED lights up fully, the signal is overloaded.

• Carefully adjust the fine setting using the

frequency selector knob seeking out a peak

in the signal between about 1 ms to 1.5 ms

in width.

Note:

When looking for the peak, it can be helpful to

loosen the knurled screws a bit to change the

strength of the magnetic field and thus the signal. In order to optimise the signal refer to section 7.5.

• Vary the frequency to bring it to the middle

of the peak and write down what that frequency is.

• Carry out the experiment again with different

material samples.

For the polystyrene sample (green top) the frequency will be in the same range as for the

glycerine sample. For the Teflon sample (blue

top) the frequency will be lower (see Figs. 13 to

15).

Another experiment can be carried out in which

the stalk of a plant can be inserted into the sample chamber for its resonant frequency to be

determined.

7.5 Optimisation of signal

If the signal is fuzzy (width of signal > 2ms),

there are several ways it can be improved. The

basic requirement for this is that some kind of

signal, no matter how poor its quality, needs to

be obtained for the glycerine sample. The objective is to obtain a signal with a median width of 1

ms.

Fig. 10 Moving the magnets

Fig. 11 Magnet moved out of its end position

7.5.4 Slightly loosen the two knurled screws and

move the magnets about 1 to 2 mm away from

their end positions, then move them back to the

ends. In doing so, move the two discs a little

further forward. Tighten the knurled screws

while observing the peak.

7.6 Evaluation

Resonant frequencies of material samples

Glycerine (

Polystyrene (

Teflon (

Plant stalk (

1

H) 42.58 MHz/T

1

H) 42.58 MHz/T

19

F) 40.06 MHz/T

1

H) 42.58 MHz/T

The following therefore applies:

ePolystyrenGlycerine

ν

Teflon

ν

Glycerine

06.40

=

58.42

4

Page 5

Fig. 12 Experiment set-up featuring NMR unit with an oscilloscope

Fig. 13 Screenshot from 3BNETlab

TM

(Glycerine ν = 12,854 MHz)

5

Page 6

Fig. 14 Screenshot from 3BNETlab

TM

(Polystyrene ν = 12,854 MHz)

Elwe Didactic GmbH ▪ Steinfelsstr. 5 ▪ 08248 Klingenthal ▪ Germany ▪ www.elwedidactic.com

3B Scientific GmbH ▪ Rudorffweg 8 ▪ 21031 Hamburg ▪ Germany ▪ www.3bscientific.com

Fig. 15 Screenshot from 3BNETlab

Subject to technical amendments

© Copyright 2012 3B Scientific GmbH

TM

(Teflon ν = 12,100 MHz)

Loading...

Loading...