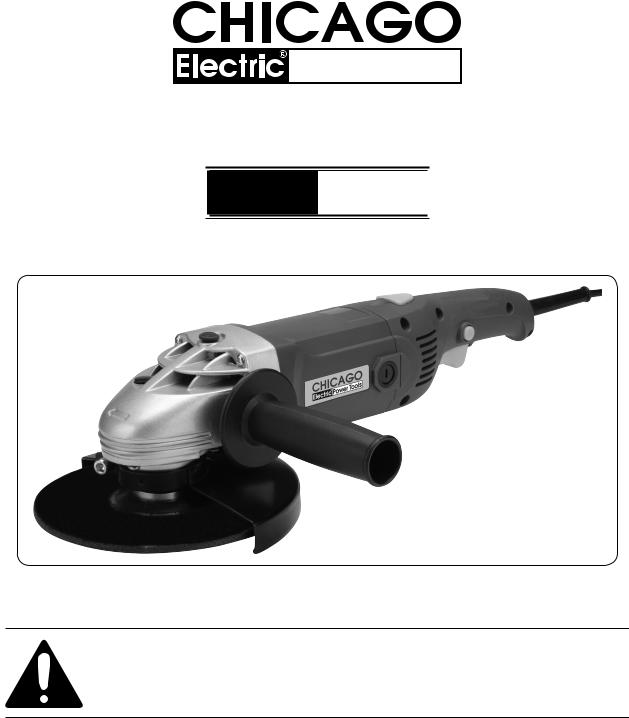

Chicago Electric 67648 User Manual

7” Angle Grinder

Model 67648

Model 67648

Set up and Operating Instructions

(Grinding Wheel Sold Separately)

Visit our website at: http://www.harborfreight.com

Read this material before using this product. Failure to do so can result in serious injury. Save this manual.

Copyright© 2010 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork contained herein may be reproduced in any shape or form without the express written consent of Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing improvements, actual product may differ slightly from the product described herein.

For technical questions or replacement parts, please call 1-800-444-3353.

Contents

Important SAFETY Information 3

General Power Tool Safety Warnings 3

Safety Warnings Common for Grinding, Sanding, and

Wirebrushing Operations 5 Kickback and Related Warnings7

Safety Warnings Specific for Grinding Operations 8

Safety Warnings Specific for Sanding Operations 9

Safety Warnings Specific for Wire Brushing Operations 9

Vibration Safety 9

Grounding 9

Grounded Tools: Tools with Three Prong Plugs 10

Double Insulated Tools:

Tools with Two Prong Plugs 10 Extension Cords 10 Symbology 11

Specifications 12

Unpacking 12

Components 12

Instructions for putting

into use 12

Assembly 13

Operating Instructions 14

Tool Set Up 14

Work Piece and Work Area

Set Up 15

General Operating Instructions 15

Maintenance And Servicing 16

Cleaning, Maintenance, and

Lubrication 16

Carbon Brush (40)

Replacement 17

Accessory Storage and

Handling 17

Troubleshooting 18

Parts List 19

ASSEMBLY DIAGRAM 20

LIMITED 90 DAY WARRANTY 21

Page 2 |

For technical questions, please call 1-800-444-3353. |

SKU 67648 |

Save This Manual

Keep this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the back of the manual near the assembly diagram (or month and year of purchase if product has no number). Keep this manual and the receipt in a safe and dry place for future reference.

Important SAFETY

Information

In this manual, on the labeling, and all other information provided with this product:

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING indicates a hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION, used with the safety alert

symbol, indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE is used to address practices not

related to personal injury.

CAUTION, without the safety alert symbol, is

used to address practices not related to personal injury.

General Power Tool Safety Warnings

WARNING Read all safety warnings and instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term ″power tool″ in the warnings refers to your mains-operated (corded) power tool.

1.Work area safety

a.Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b.Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c.Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2.Electrical safety

a.Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with grounded power tools.

Unmodified plugs and matching outlets will reduce risk of electric shock.

b.Avoid body contact with grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an

SKU 67648 |

For technical questions, please call 1-800-444-3353. |

Page 3 |

increased risk of electric shock if your body is grounded.

c.Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

d.Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

e.When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f.If operating a power tool in a damp location is unavoidable, use a Ground Fault Circuit Interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

3.Personal safety

a.Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol

or medication. A moment of inattention while operating power tools may result in serious personal injury.

b.Use safety equipment. Always wear eye protection. Safety equipment such as a dust mask, non-skid safety shoes, a hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

c.Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source, picking up or carrying the tool. Carrying power tools with your finger on the switch or

energizing power tools that have the switch on invites accidents.

d.Remove any adjusting key or wrench before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

e.Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

f.Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

g.If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of these devices can reduce dust-related hazards.

h.Only use safety equipment that has been approved by an appropriate standards agency. Unapproved safety equipment may not provide adequate protection. Eye protection must be

ANSI-approved and breathing protection must be NIOSH-approved for the specific hazards in the work area.

4.Power tool use and care

a.Do not force the power tool. Use the correct power tool for your application. The correct power tool will

do the job better and safer at the rate for which it was designed.

b.Do not use the power tool if the switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

c.Disconnect the plug from the power source and/or the battery pack from

Page 4 |

For technical questions, please call 1-800-444-3353. |

SKU 67648 |

the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

d.Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

e.Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power tools.

f.Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

5.Service

a.Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Safety Warnings Common for Grinding, Sanding, and Wirebrushing Operations

1.This power tool is intended to function as a grinder, sander, or wire brushing tool. Read all safety warnings, instructions, illustrations and specifications provided with this power tool. Failure to follow all

instructions listed below may result in electric shock, fire and/or serious injury.

2.Operations such as polishing or cutting off are not recommended to be performed with this power tool.

Operations for which the power tool was not designed may create a hazard and cause personal injury.

3.Do not use accessories which are not specifically designed and recommended by the tool manufacturer. Just because the

accessory can be attached to your power tool, it does not assure safe operation.

4.The rated speed of the accessory must be at least equal to the maximum speed marked on the power tool. Accessories running faster than their RATED SPEED can break and fly apart.

5.The outside diameter and the thickness of your accessory must be within the capacity rating of your power tool. Incorrectly sized accessories cannot be adequately guarded or controlled.

6.The arbor size of wheels, flanges, backing pads or any other accessory must properly fit the spindle of the power tool. Accessories with arbor holes that do not match the mounting hardware of the power tool will run out of balance, vibrate excessively and may cause loss of control.

7.Do not use a damaged accessory. Before each use inspect the accessory such as abrasive wheels for chips and cracks, backing pad for cracks, tear or excess wear, wire brush for loose or cracked wires. If power tool or accessory is dropped, inspect for damage or

SKU 67648 |

For technical questions, please call 1-800-444-3353. |

Page 5 |

install an undamaged accessory. After inspecting and installing an accessory, position yourself and bystanders away from the plane of the rotating accessory and run the power tool at maximum no-load speed for one minute. Damaged accessories will normally break apart during this test time.

8.Wear personal protective equipment. Depending on application, use face shield, safety goggles or safety glasses. As appropriate, wear dust mask, hearing protectors, gloves and workshop apron capable of

stopping small abrasive or work piece fragments. The eye protection must be capable of stopping flying debris generated by various operations.

The eye protection must be capable of stopping flying debris generated by various operations. The dust mask or

respirator must be capable of filtering out particles generated by your operation. Prolonged exposure to high intensity noise may cause hearing loss.

9.Keep bystanders a safe distance away from work area. Anyone entering

the work area must wear personal protective equipment. Fragments of work piece or of a broken accessory may fly away and cause injury beyond immediate area of operation.

10.Hold power tool by insulated gripping surfaces only, when performing an operation where the accessory may contact hidden wiring or its own cord.

An accessory contacting a ″live″ wire may make exposed metal parts of the power tool ″live″ and shock the operator.

11.Position the cord clear of the spinning accessory. If you lose control, the cord may be cut or snagged and your hand

or arm may be pulled into the spinning accessory.

12.Never lay the power tool down until the accessory has come to a complete stop. The spinning accessory may grab the surface and pull the power tool out of your control.

13.Do not run the power tool while carrying it at your side. Accidental contact with the spinning accessory could snag your clothing, pulling the accessory into your body.

14.Regularly clean the power tool’s air vents. The motor’s fan will draw the dust inside the housing and excessive accumulation of powdered metal may cause electrical hazards.

15.Do not operate the power tool near flammable materials. Sparks could ignite these materials.

16.Do not use accessories that require liquid coolants. Using water or other liquid coolants may result in electrocution or shock.

17.Maintain labels and nameplates on the tool. These carry important safety information. If unreadable or missing, contact Harbor Freight Tools for a replacement.

18.Avoid unintentional starting. Prepare to begin work before turning on the tool.

19.Do not lay the tool down until it has come to a complete stop. Moving parts can grab the surface and pull the tool out of your control.

20.Do not leave the tool unattended when it is plugged into an electrical outlet. Turn off the tool, and unplug it from its electrical outlet before leaving.

Page 6 |

For technical questions, please call 1-800-444-3353. |

SKU 67648 |

21.This product is not a toy. Keep it out of reach of children.

22.People with pacemakers should consult their physician(s) before use.

Electromagnetic fields in close proximity to heart pacemaker could cause pacemaker interference or pacemaker failure. In addition, people with pacemakers should:

•Avoid operating alone.

•Do not use with power switch locked on.

•Properly maintain and inspect to avoid electrical shock.

•Any power cord must be properly grounded. Ground Fault Circuit Interrupter (GFCI) should also be implemented – it prevents sustained electrical shock.

23.WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities, contains chemicals known [to the State of

California] to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•Lead from lead-based paints

•Crystalline silica from bricks and cement or other masonry products

•Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles. (California Health

& Safety Code § 25249.5, et seq.)

24.WARNING: Handling the cord on this product will expose you to lead, a chemical known to the State of California to cause cancer, and birth defects or

other reproductive harm. Wash hands after handling. (California Health & Safety Code § 25249.5, et seq.)

25.The warnings, precautions, and instructions discussed in this instruction manual cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be built into this product, but must be supplied by the operator.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad, brush or any other accessory. Pinching or snagging causes rapid stalling of the rotating accessory which in turn causes the uncontrolled power tool to be forced in the direction opposite of the accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched by the workpiece, the edge of the wheel that is entering into the pinch point can dig into the surface of the material causing the wheel to climb out or kick out. The wheel may either jump toward or away from the operator, depending on direction of the wheel’s movement at the point of pinching. Abrasive wheels may also break under these conditions.

Kickback is the result of power tool misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions as given below.

1.Maintain a firm grip on the power tool and position your body and arm to allow you to resist kickback

forces. Always use auxiliary handle, if provided, for maximum control over kickback or torque reaction during start-up. The operator can control

SKU 67648 |

For technical questions, please call 1-800-444-3353. |

Page 7 |

Loading...

Loading...