Page 1

Hardware Development Guide of

Version V1.0, 2015-09-28

Module Product

MW3650

Page 2

Hardware Development Guide of Module Products

Legal Information

By receiving the document from Shenzhen ZTEWelink Technology Co., Ltd (shortly referred to as

ZTEWelink), you are deemed to have agreed to the following terms. If you don’t agree to the

following terms, please stop using the document.

Copyright © 2015 Shenzhen ZTEWelink Technology Co., Ltd. All rights reserved. The document

contains ZTEWelink’s proprietary information. Without the prior written permission of

ZTEWelink, no entity or individual is allowed to reproduce, transfer, distribute, use and disclose

this document or any image, table, data or other information contained in this document.

is the registered trademark of ZTEWelink. The name and logo of ZTEWelink are

ZTEWelink’s trademark or registered trademark. Meanwhile, ZTEWelink is granted to use ZTE

Corporation’s registered trademark. The other products or company names mentioned in this

document are the trademark or registered trademark of their respective owner. Without the prior

written permission of ZTEWelink or the third-party oblige, no one is allowed to read this

document.

The product meets the design requirements of environmental protection and personal security. The

storage, use or disposal of products should abide by the product manual, relevant contract or the

laws and regulations of relevant country.

ZTEWelink reserves the right to make modifications on the product described in this document

without prior notice, and keeps the right to revise or retrieve the document any time.

If you have any question about the manual, please consult the company or its distributors promptly.

MW3650

All Rights reserved, No Spreading abroad without Permission of ZTEWelink II

Page 3

Revision History

Version Date Description

1.0 2015-09-28 1st released version

MW3650

Hardware Development Guide of Module Products

All Rights reserved, No Spreading abroad without Permission of ZTEWelink III

Page 4

Hardware Development Guide of Module Products

Contents

Figures ................................................................................................................................................. VII

Tables ................................................................................................................................................. VIII

1 About This Document .................................................................................................................. 10

1.1 Application Range ......................................................................................................... 10

1.2 Purpose .......................................................................................................................... 10

1.3 Supported & Reference Documents List ....................................................................... 11

1.4 Abbreviations ................................................................................................................ 11

2 Product Overview ......................................................................................................................... 13

MW3650

2.1 Technical Parameters ..................................................................................................... 14

2.2 Function Overview ........................................................................................................ 16

2.2.1 Baseband Function ................................................................................................ 16

2.2.2 Radio Frequency Function .................................................................................... 16

3 Mechanic Features ....................................................................................................................... 18

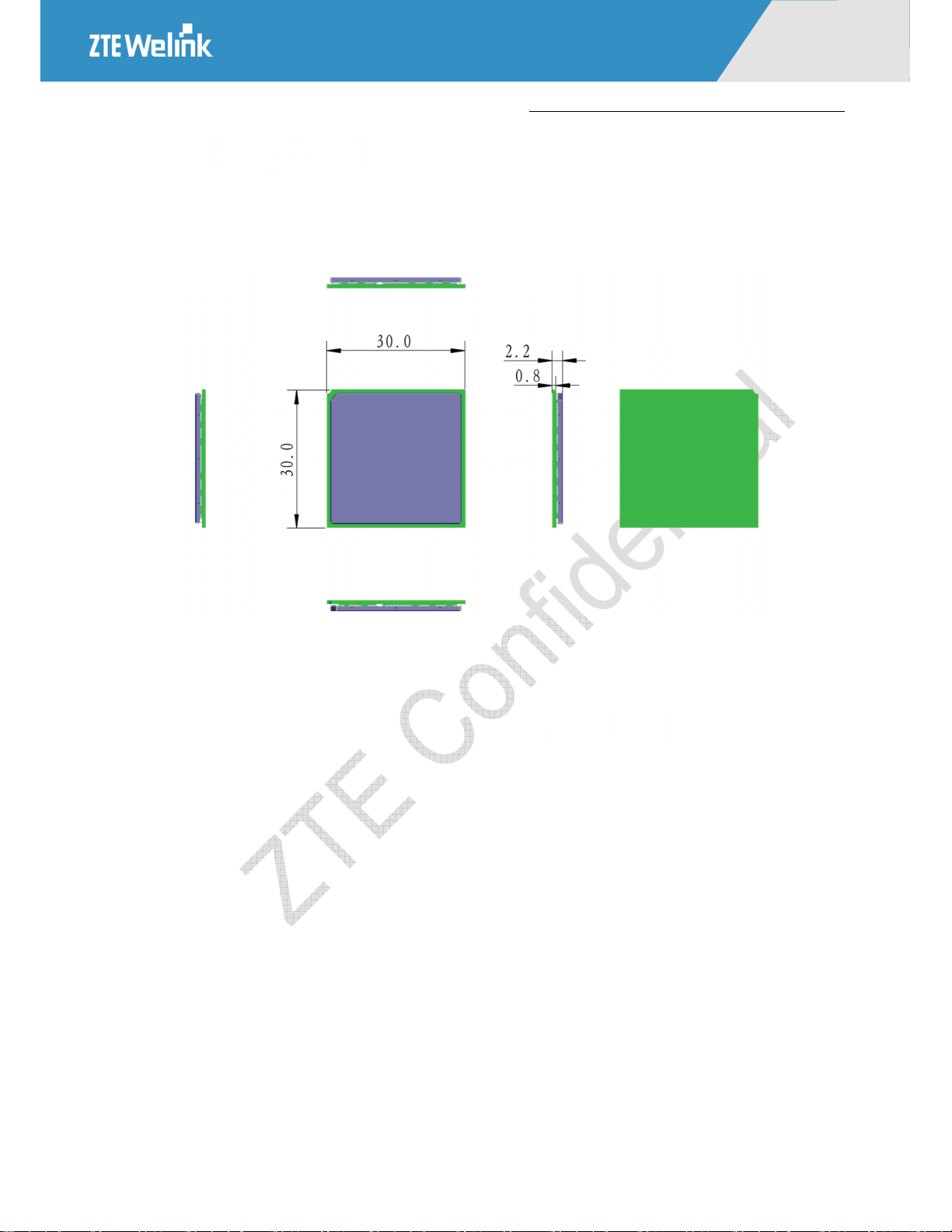

3.1 Module Illustration ........................................................................................................ 18

3.2 Module hex-vision images ............................................................................................ 19

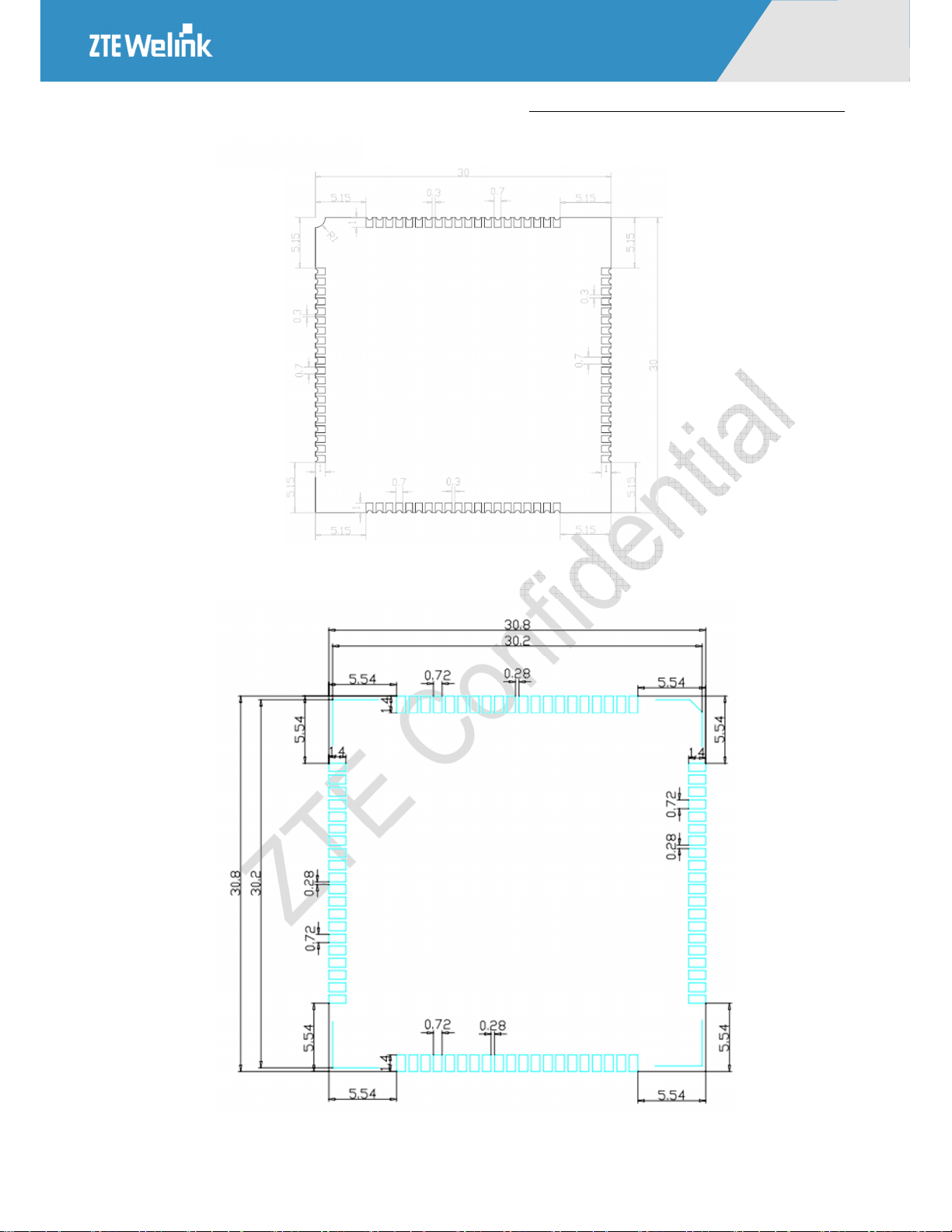

3.3 Module Main Board PCB Encapsulation Dimension Diagram ..................................... 19

3.4 PCB Design Guidelines ................................................................................................. 21

3.5 Suggestions for Heat-dissipation Design ....................................................................... 22

4 Interfaces....................................................................................................................................... 23

4.1 Definition of PINs ......................................................................................................... 23

4.2 Hardware interface description ...................................................................................... 27

4.3 Ground ........................................................................................................................... 28

4.4 Power Interface .............................................................................................................. 28

4.4.1 V_MAIN PINS ..................................................................................................... 28

4.4.2 VREF PINS ........................................................................................................... 30

4.4.3 Power interface PCB Layout and Wiring Guidance .............................................. 30

4.5 Power-on/Power-off & Reset......................................................................................... 31

4.5.1 Power On .............................................................................................................. 31

All Rights reserved, No Spreading abroad without Permission of ZTEWelink IV

Page 5

Hardware Development Guide of Module Products

4.5.2 Power Off .............................................................................................................. 31

4.5.3 Reset ...................................................................................................................... 32

4.5.4 Power-on/Power-off Flow ..................................................................................... 32

4.6 UART Interface ............................................................................................................. 34

4.7 (U)SIM Card Interface .................................................................................................. 36

4.8 USB Interface ................................................................................................................ 38

4.9 Working Status Indicator Interface ................................................................................ 39

4.10 SPI Bus Interface ........................................................................................................... 40

4.11 I2C Bus .......................................................................................................................... 41

4.12 User Interface ................................................................................................................ 42

5 Antenna ......................................................................................................................................... 43

MW3650

5.1 Preliminary Antenna Evaluation .................................................................................... 43

5.2 Antenna Design Guidance ............................................................................................. 43

5.3 Suggested Antenna Location ......................................................................................... 44

5.4 RF PCB wire guidelines ................................................................................................ 45

5.5 EMC Requirements ....................................................................................................... 45

5.6 Index Requirement of Antenna ...................................................................................... 46

5.6.1 Passive Index of Antenna ...................................................................................... 46

5.6.2 Active Index of Antenna ....................................................................................... 47

5.6.3 OTA Test method of Whole Machine Antenna ...................................................... 48

6 Electric Feature ............................................................................................................................ 49

6.1 Interface PWL ............................................................................................................... 49

6.2 Power Supply ................................................................................................................ 49

6.3 Working Current ............................................................................................................ 49

7 Technical Index of Radio Frequency .......................................................................................... 51

7.1 Index of RF under UMTS Mode ................................................................................... 51

7.1.1 Maximum Transmission Power ............................................................................. 51

7.1.2 Receiving Sensibility ............................................................................................ 52

7.1.3 Spurious Emission Index ....................................................................................... 52

7.2 Index of RF under GPRS/GSM/EDGE Mode ............................................................... 52

7.2.1 Maximum Transmission Power ............................................................................. 53

7.2.2 Receiving Sensibility ............................................................................................ 53

All Rights reserved, No Spreading abroad without Permission of ZTEWelink V

Page 6

Hardware Development Guide of Module Products

7.2.3 Spurious Emission Index ....................................................................................... 53

8 Related Test & Test Standard ...................................................................................................... 55

8.1 Testing Reference .......................................................................................................... 55

8.2 Description of Testing Environment .............................................................................. 56

8.3 Reliability Testing Environment .................................................................................... 56

8.4 Reliability Testing Result .............................................................................................. 57

8.5 ESD Characteristic ........................................................................................................ 58

9 SMT Process and Baking Guide ................................................................................................. 59

9.1 Storage Requirements .................................................................................................... 59

9.2 Module’s Position Requirements on Main board .......................................................... 59

9.3 Module Planeness Standard ........................................................................................... 60

MW3650

9.3.1 Process Routing Selection ..................................................................................... 60

9.3.2 Solder Paste Selection ........................................................................................... 60

9.3.3 Design of module PAD’s steel mesh opening on main board................................ 61

9.3.4 Module Board’s SMT process ............................................................................... 62

9.3.5 Module Soldering Reflow Curve .......................................................................... 63

9.3.6 Reflow method ...................................................................................................... 64

9.3.7 Maintenance of defects ......................................................................................... 64

9.4 Module’s Baking Requirements .................................................................................... 64

9.4.1 Module’s Baking Environment ............................................................................. 64

9.4.2 Baking device and operation procedure ................................................................ 65

9.4.3 Module Baking Conditions ................................................................................... 65

10 Safety Warnings and Notes .......................................................................................................... 66

All Rights reserved, No Spreading abroad without Permission of ZTEWelink VI

Page 7

Hardware Development Guide of Module Products

Figures

Figure 2-1 System Connection Structure ............................................................................. 16

Figure 4-1 PIN Configuration Diagram ............................................................................... 23

Figure 4-2 Wakeup Waveform .............................................................................................. 26

Figure 4-3 LDO Power Supply ............................................................................................ 29

Figure 4-4 DC/DC Switching Power Supply ....................................................................... 30

Figure 4-5 Power On & Reseting Circuit Reference Diagram ............................................. 31

Figure 4-6 Power-on Sequence Chart of Module ................................................................. 33

Figure 4-7 Power-off Sequence Chart of Module ................................................................ 33

Figure 4-8 UART Interface PWL Conversion Reference Design ........................................ 35

Figure 4-9 Module Serial Port & AP Application Processor ............................................... 35

Figure 4-10 The Connection of UART and Standard RS-232-C Interface .......................... 36

Figure 4-11 (U)SIM Card Console Circuit Reference Design ............................................. 37

Figure 4-12 USB Interface Circuit Reference Design Schematic Diagram ......................... 39

Figure 5-1 Translation Circuit Diagram ............................................................................... 44

Figure 5-2 OTA Test System ............................................................................................... 48

Figure 9-1 Green oil and white oil at module’s position on main board .............................. 60

Figure 9-2 Module Board’s Steel Mesh Diagram ................................................................ 62

Figure 9-3 Material Module Pallet ....................................................................................... 62

Figure 9-4 Module Furnace Temperature Curve Diagram ................................................... 63

MW3650

All Rights reserved, No Spreading abroad without Permission of ZTEWelink VII

Page 8

Hardware Development Guide of Module Products

Tables

Table 1-1 Support Documents List ...................................................................................... 11

Table 1-2 Abbreviation List ................................................................................................. 11

Table 2-1 Module Frequency band configuration ................................................................ 13

Table 2-2 Major Technical Parameters ................................................................................ 14

Table 2-3 Working Frequency Band .................................................................................... 17

Table 3-1 Product Illustration .............................................................................................. 18

Table 4-1 PIN Interface Definition ...................................................................................... 23

Table 4-2 Voltage Current Characteristic ............................................................................ 29

Table 4-3 Power-on/Power-off Time ................................................................................... 33

Table 4-4 The Definition of UART Signal .......................................................................... 34

Table 4-5 The Definition of USIM Card Interface............................................................... 36

Table 4-6 The Definition of USB PINS ............................................................................... 38

Table 4-7 The Correspondence of Port Map ........................................................................ 39

Table 4-8 Indicator Light Reference Design Schematic Diagram ....................................... 40

Table 4-9 The Description of Working Status Indicator Light ............................................ 40

Table 4-10 The Definition of SPI Interface ......................................................................... 40

Table 4-11 I2C Reference Circuit Design ............................................................................ 41

Table 5-1 The Passive Index Reference of Main Antenna about PAD product ................... 46

Table 5-2 The Passive Index Reference of Diversity Antenna about PAD product ............ 46

Table 5-3 Recommended Product OTA Index Requirement ............................................... 47

Table 6-1 Main Out ward Interface PWL of Module ........................................................... 49

Table 6-2 Input Voltage ....................................................................................................... 49

Table 6-3 The Current Consumption under Sleep Mode ..................................................... 50

Table 6-4 The Working Current of MODULE .................................................................... 50

Table 7-1 Maximum Transmission Power ........................................................................... 51

Table 7-2 Reference of Receiving Sensitivity ...................................................................... 52

Table 7-3 Spurious Emission Index ..................................................................................... 52

Table 7-4 Maximum Transmission Power of GSM850/900/1800/1900 (GMSK/8PSK) .... 53

Table 7-5 Receiving Sensitivity ........................................................................................... 53

Table 8-1 Testing Standard .................................................................................................. 55

Table 8-2 Testing Environment ........................................................................................... 56

Table 8-3 Testing Instrument & Device ............................................................................... 56

Table 8-4 Reliability Features .............................................................................................. 56

Table 8-5 The Temperature Testing Result Under Windless Condition .............................. 57

Table 8-6 The High/low Temperature Running and Storage Testing Result ....................... 57

Table 8-7 Module ESD Features .......................................................................................... 58

Table 9-1 Baking parameters ............................................................................................... 59

Table 9-2 LCC module PAD’s steel mesh opening ............................................................. 61

MW3650

All Rights reserved, No Spreading abroad without Permission of ZTEWelink VIII

Page 9

Hardware Development Guide of Module Products

R&TTE Regulation:

In all cases assessment of the final product must be mass against the Essential requirements of

the R&TTE Directive Articles 3.1(a) and (b), safety and EMC respectively, as well as any relevant

Article 3.2 requirements.

Hereby, ZTE CORPORATION declares that this product is in complies with the essential

requirements of Article 3 of the R&TTE 1999/5/EC Directive.

MW3650

All Rights reserved, No Spreading abroad without Permission of ZTEWelink IX

Page 10

MW3650

Hardware Development Guide of Module Products

1

About This Document

1.1 Application Range

This document is applicable as the hardware development guide of MW3650 module produce. Users need to design

products according to the requirement and guide of this document. This document only can be applied to the hardware

application development of MW3650 module product.

1.2 Purpose

This document provides the hardware solutions and development fundamentals for a product with the module. By

reading this document, the user can have an overall knowledge of the module and a clear understanding of the

technical parameters. With this document, the user can successfully fulfill the application and development of 3G

wireless Internet product or equipment.

Besides the product function features and technical parameters, this document also provides the product reliability

tests and related testing standards, business function realization process, RF performance indexes and a guide on the

design of user circuits, to provide the user with a complete design reference.

NOTE:

At present, our company has a large number of module products. Users may come across many module board

welding problems when using the module. To ensure the module board welding first pass yield and guarantee the

module manufacturing and welding quality in the following integration process, please do as the chapter 9 of

Manufacturing Guide in this document.

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 10

Page 11

MW3650

Hardware Development Guide of Module Products

1.3 Supported & Reference Documents List

Besides this hardware development guide, we also provide the Datasheet document, software development guide and

AT command reference guide. Table 1-1 is the support document list.

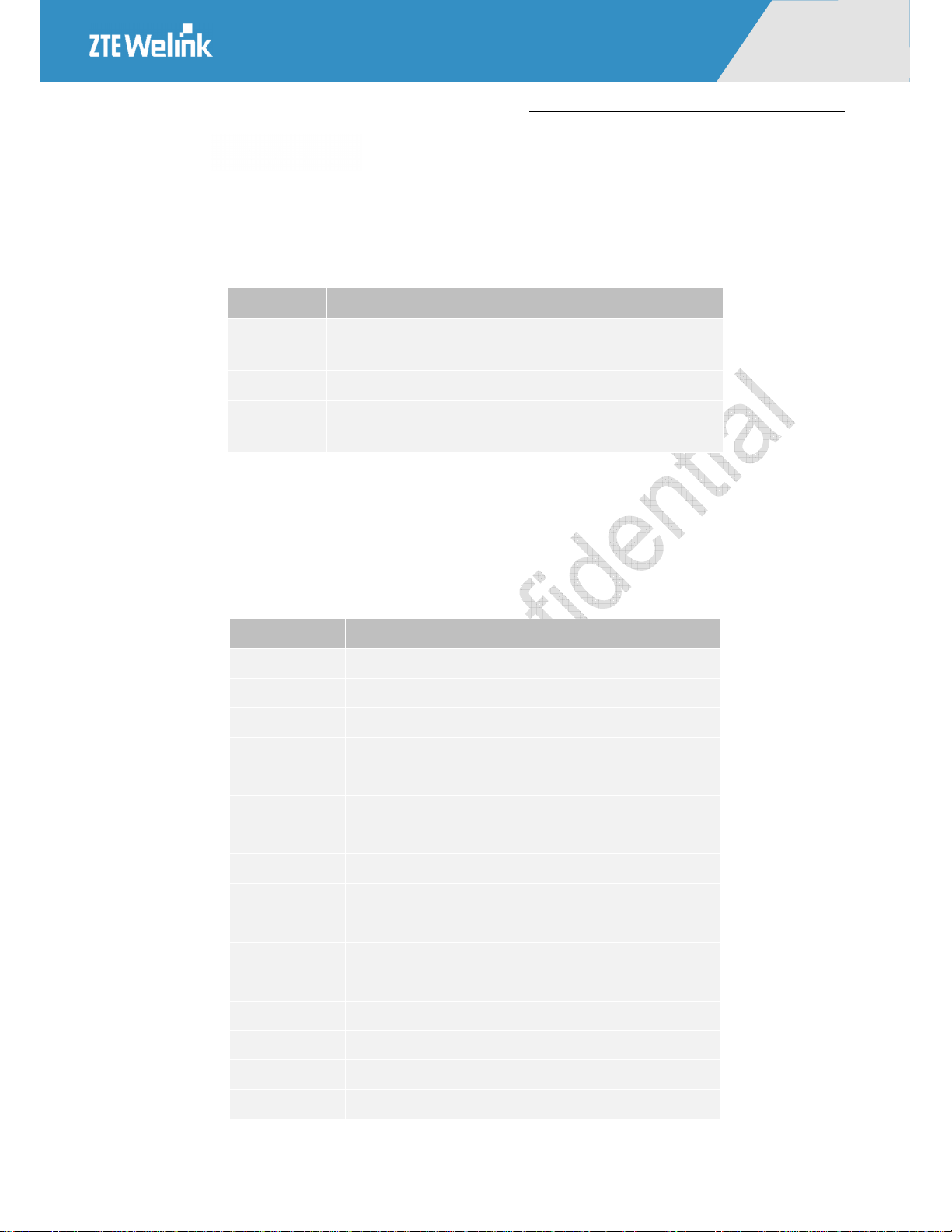

Table 1-1 Support Documents List

Document NO. Document Name

1 ZTEWelink Software Development Guide of Module

Product(MG3732_V2A&MW3650).pdf

2 ZTEWelink MW3650 Datasheet.pdf

3 AT Command reference guide for ZTEWelink

MG3732_V2A,MW3650 Module.pdf

1.4 Abbreviations

Table 1-2 is a list of abbreviations involved in this document, as well as the English full names.

Table 1-2 Abbreviation List

Abbreviations Full Name

ADC Analog-Digital Converter

ARP Antenna Reference Point

BER Bit Error Rate

BTS Base Transceiver Station

CDMA Code Division Multiple Access

CS Coding Scheme

CSD Circuit Switched Data

CPU Central Processing Unit

DAC Digital-to-Analog Converter

DCE Data Communication Equipment

DSP Digital Signal Processor

DTE Data Terminal Equipment

DTMF Dual Tone Multi-Frequency

DTR Data Terminal Ready

EGSM Enhanced GSM

EMC Electromagnetic Compatibility

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 11

Page 12

Hardware Development Guide of Module Products

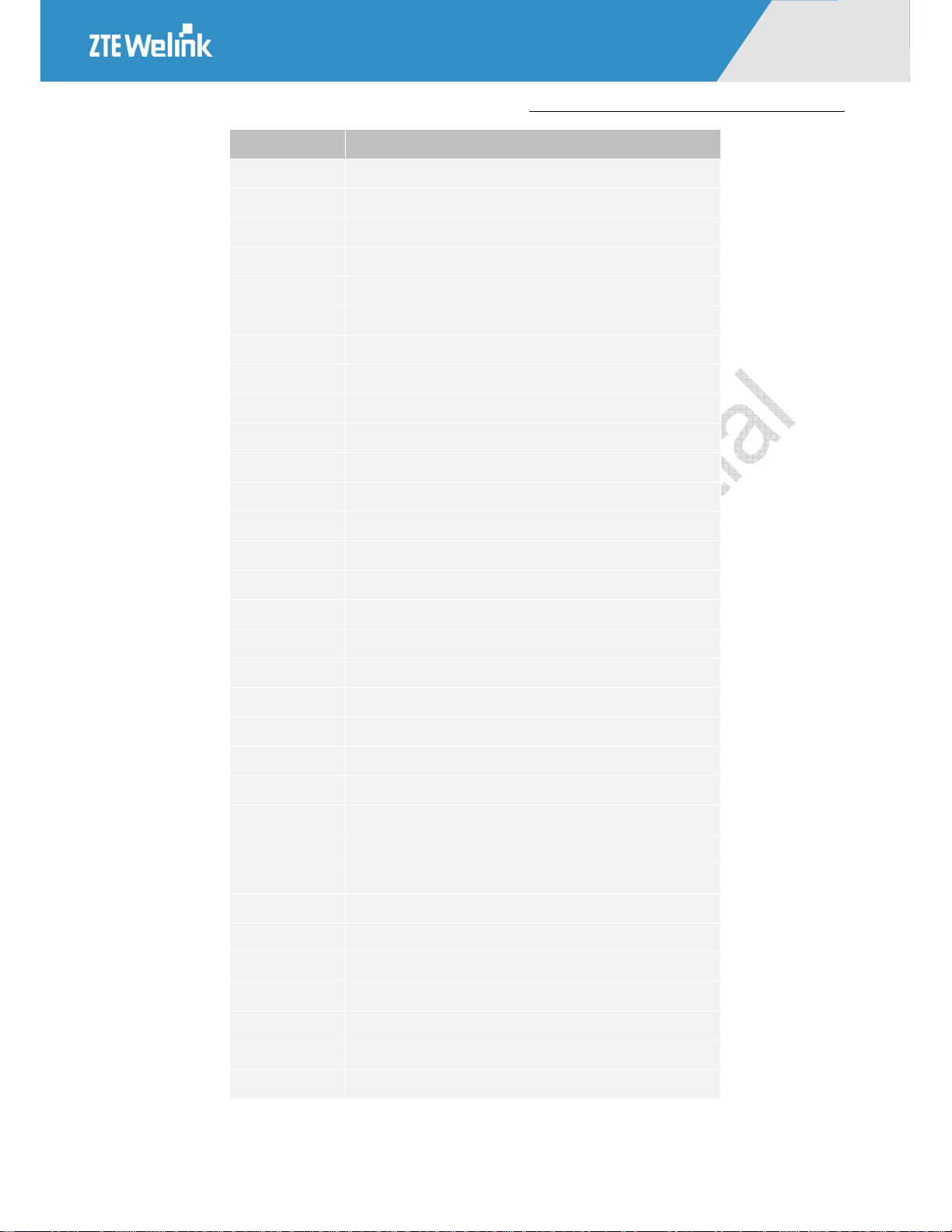

Abbreviations Full Name

EMI Electro Magnetic Interference

ESD Electronic Static Discharge

ETS European Telecommunication Standard

FDMA Frequency Division Multiple Access

FR Full Rate

GPRS General Packet Radio Service

GSM Global Standard for Mobile Communications

IC Integrated Circuit

IMEI International Mobile Equipment Identity

ISO International Standards Organization

MW3650

ITU International Telecommunications Union

LCD Liquid Crystal Display

LED Light Emitting Diode

MCU Machine Control Unit

PCB Printed Circuit Board

PCL Power Control Level

PCS Personal Communication System

PDU Protocol Data Unit

PPP Point-to-point protocol

RAM Random Access Memory

RF Radio Frequency

ROM Read-only Memory

RTC Real Time Clock

SIM Subscriber Identification Module

SMS Short Message Service

SPI Serial Peripheral Interface

TE Terminal Equipment also referred it as DTE

UART Universal asynchronous receiver-transmitter

UIM User Identifier Management

USB Universal Serial Bus

UMTS Universal Mobile Telecommunication System

WCDMA Wideband Code Division Multi Access

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 12

Page 13

MW3650

Hardware Development Guide of Module Products

2

MW3650 is a WCDMA/HSDPA/GSM/GPRS/EDGE industry module developed by our company, and it is a wireless

Internet module with LCC interface. The module has voice(optional), short message and data service functions. The

downlink peak data rate is 3.6Mbps and the uplink peak data rate is 384Kbps, so it can supply the users with

economical high speed internet access business, wireless data business and so on. It is widely applied to but not

limited to the various products and equipment such as modem, embedded module, wireless phone, multimedia phone

and touch screen communication device, PAD, vehicle-mounted terminals and electric consumed devices, using the

MW3650 module.

The function features of this module are described as bellow:

1) Support UMTS/HSDPA 850(900)/1900/2100MHz frequency band,

1800/1900MHz frequency band.

2)

Can supply GSM/GPRS/EDGE and UMTS/HSDPA high speed data access service in a mobile

environment.

3)

Support SMS and voice functions.

Product Overview

GSM/GPRS/EDGE 850/900/

4)

Supply (U)SIM card interface (3.0V/1.8V), USB2.0 interface, 8-wire UART (compatible with

2-wire UART), power on/off, reset and so on.

Taking MW3650 module as an example, this document introduces the logical structure, hardware interfaces and main

function in detail. It also supplies the corresponding design reference of hardware and structure.

NOTE:

At present,

according to the corresponding requirement of customers as is shown blow.

the frequency band of MW3650 module in UMTS mode can take proper tailoring or configuration

Table 2-1 Module Frequency band configuration

Configuration GSM Bands WCDMA Bands

MW3650V1A 850/1900MHz 1900/850MHz

MW3650V1B 900/1800MHz 2100/900MHz

MW3650V1C 900/1800MHz 2100MHz

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 13

Page 14

MW3650

Hardware Development Guide of Module Products

2.1 Technical Parameters

The major features of the module can be described from the aspects of mechanic feature, base band, radio frequency,

technical standard, environment features and so on. Table below is a list of the major technical parameters and

features supported by module.

Table 2-2 Major Technical Parameters

Type Item Specifications

Dimensions (L × W × H) 30.0mm × 30..0mm × 2.3mm

Mechanical

Feature

Weight About 5g

Encapsulation type LCC with 80 pins

Baseband

RF

(U)SIM/SIM

USB interface USB 2.0 HIGH SPEED

UART interface 8-wire UART

Max Power Dissipation About 2.2W

Power Supply DC 3.3~4.2V, typical value is 3.8V

Working Current2

GSM Frequency Band

UMTS Frequency Band

Diversity Reception

Frequency Band

Max. Transmitter Power

Standard SIM card interface

3V SIM card and 1.8V SIM card

Peak current About 0.6A

The average

current in

normal working

Standby current

EDGE/GPRS/GSM:1900/1800/900/850MHz

HSDPA/WCDMA:2100/1900/850(900)MHz;

NA1

UMTS2100/1900/900/850: Power Class 3 (+24dBm

+2.5/-1.5dBm)

GSM/GPRS 850MHz/900MHz: Power Class 4 (+33dBm +

2.5/-0.5 dBm)

GSM/GPRS 1800MHz/1900MHz: Power Class 1 (+30dBm

+2.5/-0.5 dBm)

EDGE 850MHz/900MHz: Power Class E2 (+27dBm

+4.5/-1.5dBm)

EDGE 1800MHz/1900MHz: Power Class E2 (+26dBm

+4.5/-2.5dBm)

About 540mA@UMTS 2100

About 239mA@GSM 900

About 5mA@UMTS

About 5mA@GSM

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 14

Page 15

Type Item Specifications

WCDMA2100 : ≤-108dBm

WCDMA1900 : ≤-109dBm

Receiving sensitivity

Main Antenna External, Provide Antenna PAD

Data Rate

WCDMA900 : ≤-109dBm

WCDMA850 : ≤-109 dBm

GSM850/900/1800/1900 : ≤-107dBm

GSM CS: UL 9.6kbps/DL 9.6kbps

GPRS: Multi-slot Class 10

EDGE: Multi-slot Class 12

WCDMA CS: UL 64kbps/DL 64kbps

WCDMA PS: UL 384kbps/DL 384kbps

MW3650

Hardware Development Guide of Module Products

Technical

Standard

Environmen

t Feature3

HSDPA HSDPA: DL 3.6Mb/s(Category 6)

Protocol HSDPA/WCDMA/EDGE/GPRS/GSM

3GPP Protocol R5, R4, R99

Windows XP (SP2 and later)

Windows Vista & 7

OS

Working Temperature -30 ~ 75° C

Storage Temperature -40 ~ 85° C

Humidity 5%~ 95%

DATA Support

SMS

Voice Support

WinCE

Linux

Android

Support ultra-long SMS

Support Text and PDU mode

Point to point MO and MT

Application

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 15

MMS

TCP/IP Support

UDP/IP Support

Phonebook Support

Upgrade Support

Support (Not support built-in MMS protocol stack

temporarily)

Page 16

MW3650

Hardware Development Guide of Module Products

NOTE:

“NA” indicates nonsupport.

Working current value is the average value tested under the max transmitter power. The value may be different in

different condition and environment. Please take the actual measurement as the reference.

Please make sure that the module is started up in the recommended working current range and working

temperature to avoid the damage or the abnormal working of the module.

2.2 Function Overview

2.2.1 Baseband Function

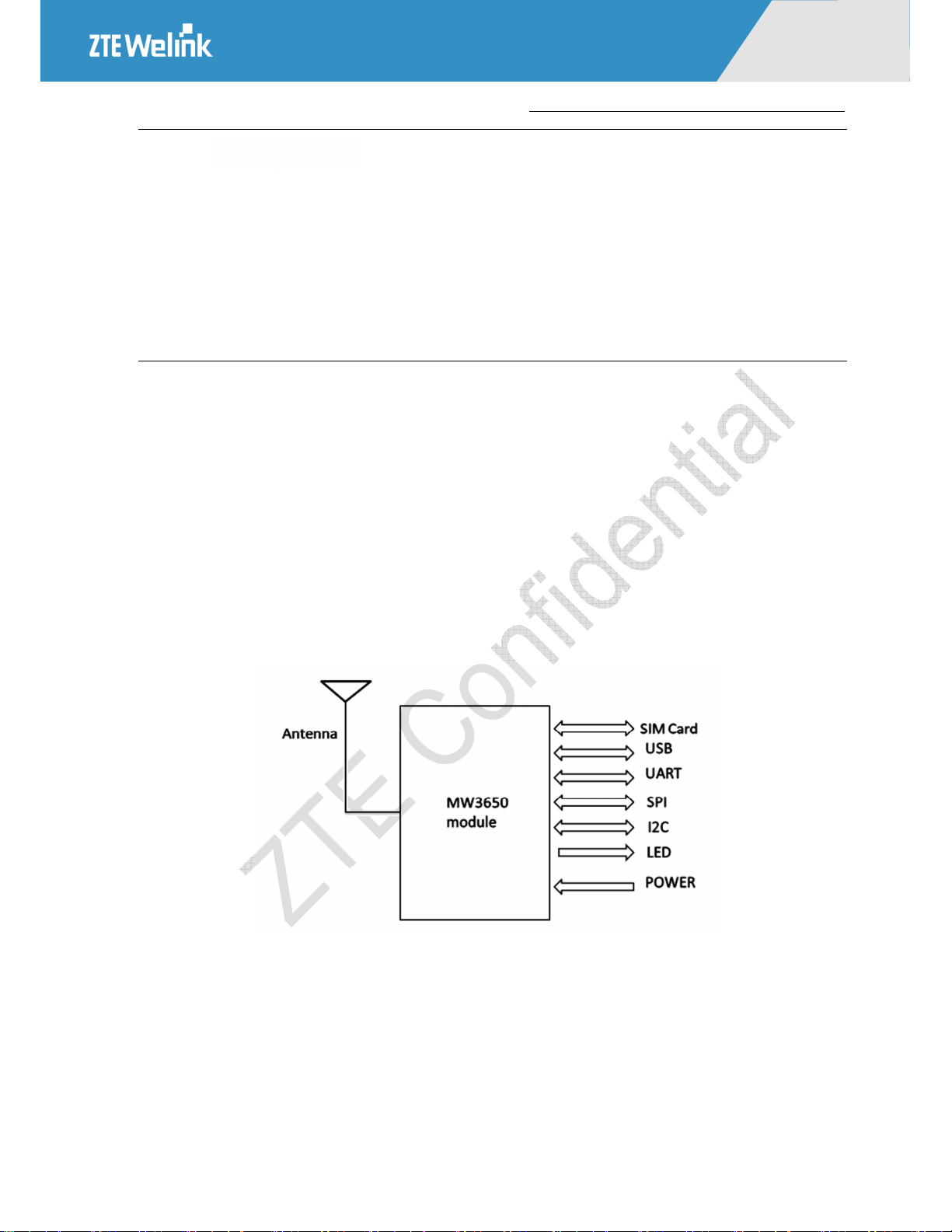

When connected with the system board, the module mainly includes the following signal groups: USB signal, (U)SIM

card signal, status querying signal, UART signal, module power-on/resetting signal, main antenna interface and

power-supply interface. Figure below is the system connection structure.

Figure 2-1 System Connection Structure

2.2.2 Radio Frequency Function

The working frequency band of module is shown in the table below.

a) Support HSDPA/WCDMA 850(900)/1900/2100MHz.

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 16

Page 17

Hardware Development Guide of Module Products

b) Support GSM/EDGE/GPRS 850/900/1800/1900MHz.

c) The highest downlink rate supported by HSDPA is 3.6Mbit/s.

d) PS domain supports EDGE CLASS12/GPRS CLASS10 bearer service.

e) CS domain supports 64Kbit/s data service in WCDMA mode.

Table 2-3 Working Frequency Band

Working Frequency Band Uplink Frequency Band Downlink Frequency Band

UMTS850 (band V) 824 MHz — 849 MHz 869 MHz — 894 MHz

UMTS900 (band VIII) 880 MHz — 915 MHz 925 MHz — 960 MHz

UMTS1900 (band II) 1850 MHz — 1910 MHz 1930 MHz — 1990 MHz

MW3650

UMTS2100 (band I) 1920 MHz — 1980 MHz 2110 MHz — 2170 MHz

GSM850 824 MHz — 849MHz 869 MHz — 894 MHz

GSM900 890 MHz — 915MHz 925 MHz — 960MHz

GSM1800 1710 MHz — 1785MHz 1805 MHz — 1880MHz

GSM1900 1850 MHz — 1910MHz 1930 MHz — 1990MHz

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 17

Page 18

MW3650

Hardware Development Guide of Module Products

3

Mechanic Features

3.1 Module Illustration

The Product Illustration of module is shown in the Figure 3-1.

Table 3-1 Product Illustration

NOTE:

The picture above is just for reference; please take the actual products as the reference.

Dimensions (L × W × H): 30.0 mm × 30.0mm ×2.3mm

Weight: about 5g

.

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 18

Page 19

3.2 Module hex-vision images

The module hex-vision images are shown in figure 3-2 (units: mm).

Figure 3-2 module hex-vision images

MW3650

Hardware Development Guide of Module Products

Note: the height in the figure above is without the module label, so it is 2.2mm.

3.3 Module Main Board PCB Encapsulation

Dimension Diagram

The detailed dimension of PCB welding panel is shown in figure 3-3 (units: mm).

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 19

Page 20

Hardware Development Guide of Module Products

Figure 3-3 The detailed dimension of PCB welding panel

MW3650

Figure 3-4 Recommended Welding Panel Design Dimension of Customer Interface Board

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 20

Page 21

Hardware Development Guide of Module Products

Figure 3-5 PCB Bottom Welding Panel

MW3650

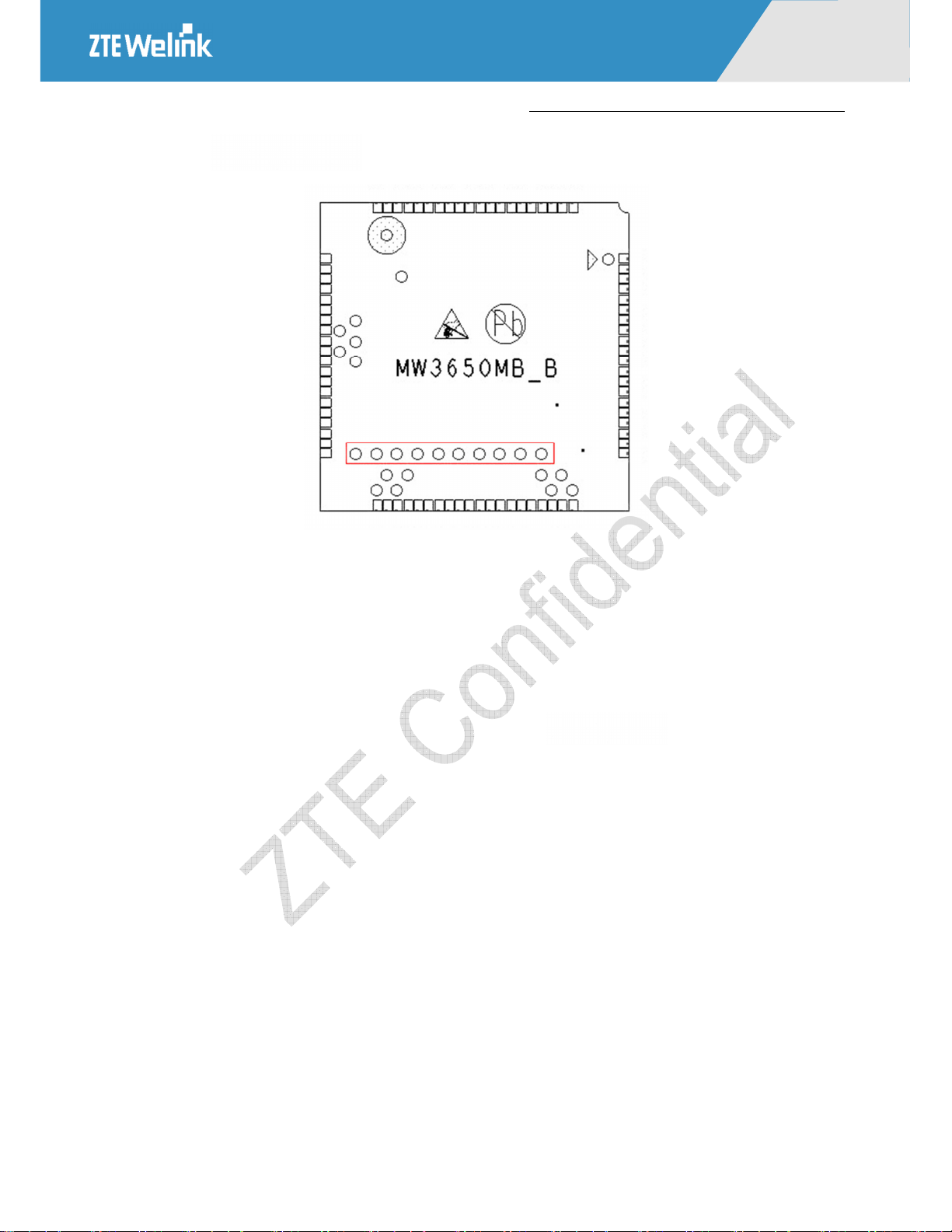

3.4 PCB Design Guidelines

To ensure the module has good performance in the application process, the users of modules should do

as the following guidelines in the process of PCB wire designing:

1) For testing and maintenance convenience, the customer dev board PCB should be hollowed out to

show the test pionts as is shown in the red box in figure 3-5 so as to do JTAG installation and

debugging.

2) The rest round test points are used for module power supply and calibration in SMT production

process. Do not short out these test points when connect the module to main board.

3) In the design process, the strongly disturbing signals such as clock signal, high-frequency digital

signal and switching signal of switch power supply should be placed far away from the module.

4) Please pay attention to the protection of RF and audio analog signal. If condition permits, it is

better to separate the analog ground and digital ground. After the separation, the signal line or

power line should not pass over the separation channel.

5) To ensure the integrity and circulation ability, if condition permits, it is better to adopt planar form.

6) Please ensure the integrity of the module ground to reduce the leak of disturbing signal.

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 21

Page 22

Hardware Development Guide of Module Products

3.5 Suggestions for Heat-dissipation Design

The module will dissipate heat during the working process, and might also be affected by other

high-temperature devices. When do the heat-dissipation design, please pay attention to the following items:

1) Place this product far away from the switch power supply and high speed signal line, and protect the

wiring of these interference sources.

2) Place the antenna and coaxial-cable connecting the network card and antenna far away from these

interference sources.

3) Place the module far away from the devices that have high calorific power such as CPU and

Southbridge to avoid the influencing the RF performance because of the temperature rise.

MW3650

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 22

Page 23

MW3650

Hardware Development Guide of Module Products

4

Interfaces

4.1 Definition of PINs

The definition of interface PINs on module is shown in figure 4-1.

Figure 4-1 PIN Configuration Diagram

Table 4-1 PIN Interface Definition

PIN Classification Signal Definition I/O Description Remark

1 POWER_ON ON/OFF I Power on/off

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 23

Pull-up internally, low

pulse active

Page 24

Hardware Development Guide of Module Products

PIN Classification Signal Definition I/O Description Remark

2 RESET PON_RESET_N I Reset signal 1.8V low level active

3

4

5

6 NC -- -- -7 GPIO I/O GPIO -8 GPIO I/O GPIO -9 GND -- GND -10 NC -- -- -11 GND -- GND -12

13 Reserved -- -- -14 Reserved -- -- -15 Reserved -- -- -16 Reserved -- -- -17 Reserved -- -- -18 Reserved -- -- -19 Reserved -- -- -20 GND -- GND -21 GND -- GND -22

23 USB_DM I/O USB data- -24 USB_DP I/O USB data + -25 NC -- -- -26 NC -- -- -27 NC -- -- -28 NC -- -- -29 NC -- -- -30 NC -- -- -31 GND -- GND --

32

33 SPI_MOSI_DATA --

34 SPI_CLK I/O

35 SPI_CS_N I/O SPI strobe signal 1.8V

36 GND -- GND --

37 USIM USIM_CLK O

Reserved

USB

SPI

GND -- GND -VREF_2V8 O Voltage output 2.85V

VREF_1V8 O Voltage output 1.8V

Reserved -- -- --

VBUS I USB power 5V

SPI_MISO_DATA --

Main input, slave

output 1.8V

Main input, slave

output 1.8V

SPI interface clock

signal 1.8V

USIM card clock

line 1.8V/3.0V

MW3650

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 24

Page 25

Hardware Development Guide of Module Products

PIN Classification Signal Definition I/O Description Remark

38 USIM_DATA I/O

39 USIM_RST O

40 VREG_USIM O

41 USIM_DETECT I

42

43

44

45

46 GND -- GND -47

48 ADC1 I ADC 0-VCC

49 GND -- GND --

50

51 V_MAIN I

52 GND -- GND --

53

54 UART_RXD I

55 UART_RTS O Ready for sending

56 UART_CTS I

57 UART_DSR O

58 UART_DTR I

59 UART_DCD O

60 UART_RI O

61 GND -- GND -62 ANT RF_ANT I/O Antenna interface -63 GND -- GND -64 GPIO I/O GPIO --

Reserved

ADC

UART

Reserved

Reserved

Reserved

Reserved

ADC2 I ADC 0-VCC

V_MAIN I

UART_TXD O

USIM card data

line 1.8V/3.0V

USIM card reset

signal 1.8V/3.0V

USIM 1.8/3V

power supply 1.8V/3.0V

USIM card detect

signal 1.8V

-- -- --

-- -- --

-- -- --

-- -- --

Module main

power supply

Module main

power supply

UART Transmit

Data DTE receive serial data

UART Receive

Data DTE transmit serial data

Ready for

receiving -UART DCE get

ready

UART DTE get

ready

UART Carrier

detects

UART Ring

Indicator

3.3V-4.2V

3.3V-4.2V

DCE Request to send

DCE get ready

DTE get ready

Notify DTE the remote

call

MW3650

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 25

Page 26

Hardware Development Guide of Module Products

PIN Classification Signal Definition I/O Description Remark

65 GPIO I/O GPIO -66 GPIO I/O GPIO -67 NC -- -- -68 NC -- -- --

69 WWAN_STATE O

70 SIG_LED O

71 WAKEUP_OUT O

72 WAKEUP_IN I

73

74 I2C_SDA I/O I2C data line 1.8V

75 GPIO I/O GPIO -76 GPIO I/O GPIO -77 GPIO I/O GPIO -78 GND -- GND -79 NC -- -- -80 GND -- GND --

I2C

I2C_SCL I I2C clock line 1.8V

Network status

index signal

Module status

indicator light

output wakeup

signal

Input wakeup

signal

1. Power-on status:

indicator light off;

2. network searching

status: indicator light

flickers with the frequency

of 3Hz;

3.Standyby status:

indicator light flickers with

the frequency of 1Hz;

4.Service status: indicator

light flickers with the

frequency of 5Hz.

--

--

MW3650

NOTE:

WAKEUP is USB wake-up PIN in default. If the main controller needs to be waked up after a trigger event (such

as SMS arrive) happens, a “low-high-low” PWL change is generated and each state lasts 1s. Then the level of this

pin changes to high level. Then main controller needs to issues USB wake-up command to wake up the module.

Figure 4-2 Wakeup Waveform

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 26

Page 27

Hardware Development Guide of Module Products

4.2 Hardware interface description

The interfaces and peripheral circuit should be designed reasonably in the process of hardware

MW3650

development. The interface voltages of peripheral circuit must match with voltages of product pins.,

otherwise the performance may be influenced or the module cannot work normally or even be

damaged.

This section mainly describes related interfaces of the module including interface logic function,

interface description, design example and match circuit. According to the interfaces description in this

section, customers can make secondary developments about embedded system and consumer

electronics.

Interfaces of MW3650 module includes as following aspects.

UART interface

(U)SIM card (compatible with 1.8V/3.0V)

USB2.0 full-speed interface

External power supply

Power on/off and RESET control

I2C interface

SPI interface

ADC

Module status indicator

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 27

Page 28

4.3 Ground

MW3650

Hardware Development Guide of Module Products

GND is the Ground signal of this product, and needs to be well connected to the ground on system board.

the GND signal is not connected completely, the performance of module will be affected.

handing is important to module performance guarantee such as guaranteeing signal integrity, improving RF

performance, reducing EMI interference and heat dissipation.

In module ground handing process:

1. The module ground welding panel should have full access to mainboard welding panel;

2. All GND pins must be accessed to ground panel with shortest ground wire. All GND pins should be

connected together effectively using plenty of vias;

3. For RF signal, please pay attention to the resistance wire structure (micro strip line, strip line) and

ensure the integrity of reference ground;

4.

It is wise to surround (on both sides) the PCB transmission line such as audio and clock signal

with Ground, and isolate the interference source from sensitive source;

5. Line geometry should have uniform characteristics, constant cross section, avoid meanders and

Well ground

If

abrupt curves.

4.4 Power Interface

4.4.1 V_MAIN PINS

According to the definition, power supply pins of module are described as V_MAIN signal group including

pin50&51. Power supply pins V_MAIN are positive poles and input signals.

When design the external circuit, firstly, ensure external power supply circuit has sufficient power supply

ability and the power voltage range is strictly controlled between 3.4V and 4.2V (typical value 3.8V). If the

voltage is higher than the voltage range, the main chip will be damaged while if the voltage is lower than the

voltage range, the working of RF circuit will be influenced or shutdown/restart phenomenon will happen.

When the network signal is weak, RF transmit power and module transient current will increase and

transient peak current value will reach about 2A. So when design the power supply circuit, choose DC/DC

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 28

Page 29

Hardware Development Guide of Module Products

or LDO of that lager than 2A. In addition, considering that the transient current needed by high-power

transmit is large under GSM model, so in the circuit design process, please add a large capability (lager than

470uF) in the output of DC/DC or LDO to avoid voltage decline abruptly. Sufficient line width of power line

on system board should be guaranteed, and at the same time, the power line should form a well

circumfluence with ground panel. Moreover, in the power supply circuit design process, large capacitance at

kilo uF level should be added to guarantee the transient power supply ability. It is recommended that on

system side DC/DC power supply is adopted and power ripple is controlled within 100mV.

Table 4-2 Voltage Current Characteristic

Type Minimum value Typical value Maximum value (transient)

Input voltage 3.3 V 3.8 V 4.2 V

MW3650

As is shown in the following figure, using LDO power supply circuit as a reference,

of LDO

needs to be above 3A.

As the poor transient response of linear regulator, large capacitors should

over-current capability

be placed at the input and output of LDO to avoid resetting or power off resulted from that too large

voltage fluctuation in high-power transmitting process under GSM mode. The reference power supply

circuit design with LDO is as shown in Figure below.

Figure 4-3 LDO Power Supply

As is shown in the following figure, use DC/DC switch power and large capacitors (lager than 1000uF) to

ensure the normal working of RF PA (power amplifier) and sufficient transient current under GSM Burst

mode.

The advantage of this reference design is that it can provide well transient current under 2G weak signal

environment to satisfy modules requirements, to prevent device shutdown and Ports re-enumeration as a

consequence of the supply voltage drop.

The over-current ability of DC/DC switch power should be larger than 3A such as ZI1153, AAT2138 and so

on. The input voltage range of ZI1153 is 2.5V~5.5V and the output voltage range is 0.6V to VIN (input).

The input voltage range is 2.7V~5.5V and the output voltage range is 3.3V~5.5V.

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 29

Page 30

Hardware Development Guide of Module Products

As shown in the Figure below, use DC/DC switching power supply ZI1153 as the buck chip. Place a

tantalum capacitor of 330UF at the input of the chip. Place a 2200UF capacitor or place several 330UF

tantalum capacitors in parallel. This circuit fully meets the module power requirements. (If the user’s PCB

size is limited, the output of buck chip can place three more 330UF tantalum capacitors of which the total

capacity is more than 1000uF)

Figure 4-4 DC/DC Switching Power Supply

MW3650

Vin=5V

Vout=3.8V

4.4.2 VREF PINS

MW3650 module has 2 power output pins used to supply power for external circuit on the mainboard. The voltages of

these pins and the voltages of baseband processor and storage come from the same internal voltage regulator. They

output voltage only when the module is powered on. The normal output voltage is PIN5 (VREF_1V8,1.8V) and

PIN4(VREF_2V8,2.85V). Users should draw current as less as possible from these pins. Generally, users are

suggested that these power pins are only used for pulling up chip pins in level matching process.

4.4.3 PCB Layout Guideline of Power Supply

When design the power supply of module, the layout and wiring of related components in power supply part is very

important. If they are not designed appropriately, it will have effects on many aspects, such as the EMC performance ,

the transmission modulation spectrum, receive sensitivity and so on.

The users of Modules should do as the following guidelines in the process of power supply PCB line designing:

The use of a good common ground plane is suggested.

Because the power switch has strong EMC interference, place the circuit lines far away from antenna.

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 30

Page 31

MW3650

Hardware Development Guide of Module Products

Considering the module power supply requirements, the PCB traces from the input connector to the power regulator

IC must be wide enough to ensure no voltage drops occur when the 2A current peaks are absorbed. The recommended

power wiring width is more than 100mil.

The wiring of power supply should be far away from the circuit which is sensitive for noise such as

microphone/earphone, RF cable and so on.

The PCB wiring between module and bypass capacitor should be wide enough and as short as possible to ensure there

is no significant voltage decline abruptly when the current is peak 2A.

4.5 Power-on/Power-off & Reset

4.5.1 Power On

After the module been normally electrified, it is in power-off status.

To turn on the module, the ON/OFF pin must be tied low for at least 3 seconds and then released.

4.5.2 Power Off

To turn off the module the ON/OFF pin must be tied low for at least 3 seconds and then released.

The power on/off part circuit reference design is shown in the following figure.

Figure 4-5 Power On & Reseting Circuit Reference Diagram

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 31

Page 32

MW3650

Hardware Development Guide of Module Products

4.5.3 Reset

You can reset the module by driving the PON_RESET_N to a low level voltage for more than 100ms and then

releasing. After resetting, the module will shut down first and then enter power-on status automatically.

Other advises

To ensure that the data of module is well saved a, please do not cut off the module power during the module runtime.

It is strongly recommended that use AT command (+ZPWROFF) to shut down the module in application.

The PON_RESET_N and ON/OFF signals are sensitive. When designing a circuit on the PCB of the main board, it is

recommended that the circuit length not exceed 20 mm and the circuit be kept at a distance of 2.54 mm (100 mil) at

least from the PCB edge. Furthermore, you need to surround (on both sides) the signals with Ground. Otherwise, the

module may be reset due to interference.

4.5.4 Power-on/Power-off Flow

To guarantee the user can power on and power off stably, you can refer to the power-on sequence chart as shown in

Figure 4-6 and the power-off sequence chart as shown in Figure 4-7. Table 4-3 shows the power-on and power-off

time. During the process of power on the module, pay attention to the following items:

1) The power on time that the module supplies to external interfaces cannot be earlier than the module power on

time.

2) Once the V_MAIN is powered on, the ON/OFF signal will be synchronized and established as the high PWL.

3) The time interval between the V_MAIN is electrified normally and ON/OFF signal is valid could not be too short.

For details see T2 parameter. It is recommended not to disconnect the power supply after V_MAIN is powered

off.

4) The failing edge of ON/OFF is the start of power-on time. ON/OFF should be released after being kept at low

PWL for a period of time.

5) VBUS supplies power for USB PHY. It is not recommended to connect VBUS to power supply before V_MAIN.

During the process of power-off, pay attention to the following items:

1) To power off by the ON/OFF signal, the T4 period needs to be designed as required.

2) After VPH_PWR and USB_VBUS are powered off, it is recommended not to disconnect the power supply.

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 32

Page 33

V_MAIN

MW3650

Hardware Development Guide of Module Products

Figure 4-6 Power-on Sequence Chart of Module

T1

VBUS

ON/OFF

V_MAIN

VBUS

ON/OFF

T3

T

2

Figure 4-7 Power-off Sequence Chart of Module

T5

T4

Table 4-3 Power-on/Power-off Time

Parameter Description Min Typical Max Unit

T1

T2

T3

T4

T5

The time from power-on issue to VBUS

ready

From powering on V_MAIN to ON/OFF

ready

The time of active low level impulse of

ON/OFF pin to power on module

The time of active low level impulse of

ON/OFF pin to power off module

The time from power-off issue to

V_MAIN and VBUS off

0 0.5 1 second

1 1.5 -- second

-- 3 -- second

-- 3 -- second

1 2 -- second

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 33

Page 34

MW3650

Hardware Development Guide of Module Products

4.6 UART Interface

The module provides a series of UART interfaces. The highest speed is 230.4Kbps and the typical speed is 115.2Kbps.

The external interface PWL is 1.8V CMOS PWL signal used for UART communication.

The definition and interface mode of UART are shown as followed.

Table 4-4 The Definition of UART Signal

PIN No. Type Definition I/O Description

53

54 UART_RXD I UART Receive

55 UART_RTS O Send get ready

56 UART_CTS I Receive get ready

UART(1.8V)

57 UART_DSR O Data equipment get ready

58 UART_DTR I Data terminal get ready

59 UART_DCD O Data carrier wave detect

60 UART_RI O Ring indication

NOTE:

1) When the module communicates with PC or MCU trough UART, please pay attention to the direction of TX and

RX. TX and RX is named in the reference direction of module.

2) The sleep of UART is realized through UART_DTR pin. When the module needs sleep, please set this pin as

high PWL while when the module needs to be waked-up, please set this pin as low PWL.

3) When there is SMS, the RI pin will generate low PWL interrupt.

UART_TXD O UART Send

4) MW3650 UART interface supports 1.8V voltage, so the external UART interface which is not 1.8V needs PWL

conversion. As is shown in the following figure, audion can be used to realize the PWL conversion. The

resistance is only an example in the figure. Please recount it during designing. The diode in the figure is Schottky

diode (whose forward voltage drop is 0.3V). If other diodes are chosen, please choose the one whose forward

voltage drop is small to ensure the PWL of RXD_1V8 is below the low PWL input threshold when the low PWL

is input.

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 34

Page 35

Hardware Development Guide of Module Products

Figure 4-8 UART Interface PWL Conversion Reference Design

MW3650

Figure 4-9 Module Serial Port & AP Application Processor

TXD

RXDTXD

RFR

DTR

DSRDSR

DCD

AP

Module

RXD

CTS

RFR CTS

DTR

DCD

RI RI

GND GND

To catch LOG during the software debugging process, it is recommended for users to keep this interface and reserve

testing points. If the module is connected with the application processor whose PWL is 1.8V, the connection way is as

shown in figure 4-9. 8-line or 2-line connection way can be adopted. The PWL of module interface is 1.8V. If it does

not match with the AP interface, the PWL switching circuit is suggested to be added. MW3650 module can connected

with standard RS-232-C interface through chips of 232 type. If the design is related to the interconverting between

TTL PWL and EIA PWL, the NLSX5014MUTAG chip is recommended to be used. For example, when 2-line UART

is used, the MAX3232 chip is recommended and when 8-line UART is used, SP3238 or MAX3238 chip is

recommended to design the interface. The connection way is shown in the following figure.

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 35

Page 36

Hardware Development Guide of Module Products

Figure 4-10 The Connection of UART and Standard RS-232-C Interface

MW3650

The module support standard 8-wire UART interfaces and transfer digital signals, please isolate them from sensitive

signals to avoid influencing other analog signal and RF signal.

4.7 (U)SIM Card Interface

Module baseband processor integrates the (U)SIM card interface to compliance with ISO 7816-3 standards, and

supports 3.0V/1.8V (U)SIM cards. The signals on SIM card interface is as shown in Table below.

Table 4-5 The Definition of USIM Card Interface

PIN No. Type Definition I/O Description

37

38 USIM_DATA I/O USIM card data line

39 USIM_RST O USIM card reset signal

40 VREG_USIM O USIM 1.8/3V power supply

Notes about designing SIM card:

USIM

USIM_CLK O USIM card clock line

1) Because the typical speed of (U)SIM card interface is about 3.25MHz, it is recommended to place (U)SIM card

console close to the (U)SIM card interface, to prevent the wiring from being too long (the wiring is recommended

not to be longer than 100mm) to influence the normal communication of (U)SIM signal.

2) The wiring of SIM card signal wire should be placed far away from RF wire and V_MAIN power supply line.

3) The GND of SIM card console wiring and the module GND wiring should be short and thick, meanwhile the

electric potential of them should be the same. The line width of SIM_VDD and GND should be ensured not less

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 36

Page 37

MW3650

Hardware Development Guide of Module Products

than 0.5mm. The bypass circuit between VREG_USIM and SIM_GND should not be bigger than 1uF, and be

placed near the SIM card console.

4) To avoid the potential interference between USIM_CLK and USIM_DATA signal, please do not place the wiring

of them too near, and USIM_CLK and USIM_DATA signal need to be surrounded by Ground. USIM_RST

signal also needs ground protection. Add a 0.1uF or 0.22uF capacitance of 0402 encapsulation on VREG_USIM,

and cascade a 0Ω resistance and parallel a 33pF capacitance with USIM_CLK, USIM_DATA and USIM_RST

for the convenience of matching of latter electrical performance and to avoid the interference because of too long

wiring. Besides, USIM_DATA signal should be pulled up to VREG_USIM. The pull-up resistor value is about

10K to avoid the identification problem of SIM card.

5) Besides, these four signal wires should parallel TVS to avoid electrostatic discharge. The recommended reference

design circuit of ESD protection of wireless module SIM card interface is shown in the following figure.

6) The wiring related to (U)SIM card need to be put together. The wiring width of VREG_USIM is related to its

length. The recommended value is 10 mil wiring width. The wiring of (U)SIM card can refer the wiring of BUS.

Please pay attention to the wiring protection to avoid the interference of high-speed signal and strong reference

signal of clock to (U)SIM card signal. Otherwise the restart of (U)SIM card may be caused. The ESD protection

components of (U)SIM card should be placed near (U)SIM card console to avoid the electrostatic interference to

module.

Figure 4-11 (U)SIM Card Console Circuit Reference Design

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 37

Page 38

MW3650

Hardware Development Guide of Module Products

4.8 USB Interface

MW3650 module has the high-speed USB2.0 interface. It is connected to the system board side by LCC interface,

which is the path for communication between the processor on the system board side and module of which the pins

are PIN23(USB_DM) and PIN24(USB_DP). The definition of USB pins is shown in table 4-6.

Table 4-6 The Definition of USB PINS

PIN NO. Type Definition I/O Description Remark

22

23 USB_DM I/O USB data- -24 USB_DP I/O USB data+ --

VBUS is the module USB power supply pin. The working current of USB is 4.75V~5.25V and typical value is

USB

VBUS I USB power 5V

5V.This power supply can supply the module with 3.8V voltage after transition by the power supply circuit mentioned

in the previous section. USB_DM/USB_DP is differential data line. During PCB wiring, it should meets the

requirements of differential line and surrounded by Ground. If it is too close to antenna, to avoid the influence of

antenna radiation, high-speed common mode suppression filter can be concatenated on the USB differential signal

wiring circuit.

USB interface needs to add TVS components to avoid damage of module components because of static electricity.

The load capacitance value of TVS should be less than 3pF, to satisfy the transmission of USB2.0 high-speed signal.

In the following figure, D1 is USB2.0 anti-static protective components.

Meanwhile, USB_VBUS pin is vulnerable to voltage shock which can damage the pin. It is recommended to adopt

appropriate OVP measure to avid the voltage higher than 5.25V. Besides, the power-off leakage current exists on

USB_VBUS. It is suggested to add power switch on power supply branch circuit or cascade a resistance with the

resistance value between 200kΩ and 400kΩ to reduce the leakage current when the module is powered off but does

not cut off the power.

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 38

Page 39

Hardware Development Guide of Module Products

Figure 4-12 USB Interface Circuit Reference Design Schematic Diagram

MW3650

Usually, USB interface of module can be enumerated to several ports, such as AT port, DIAG port, Modem port and

so on. These ports are enumerated in order during the load process. For example, during the load process of module

under Linux system, if the enumeration of DIAG port is ttyUSB0, the ports maps on PC are shown in the following

table.

Table 4-7 The Correspondence of Port Map

Module VID&PID

MW3650

USB Modem port, bearing AT commands, is mainly used for initiating data business.

Service Port, bearing AT commands, is mainly used for AT command operation when MODEM port is occupied by

data business.

VID_19D2&

PID_FFEB

Dial-up port AT Command Port DIAG Port Audio Port

USB Modem Service Port Diagnostics Port Voice Port

Windows: 03

/Linux: ttyUSB3

Windows: 02

/Linux: ttyUSB2

Windows: 00

/Linux: ttyUSB0

Windows: 01

/Linux: ttyUSB1

Diagnostics Port, bearing DIAG task, can be connected to the tool for catching LOG or updating to catch software

LOG information or update the firmware.

4.9 Working Status Indicator Interface

The SIG_LED pin is constant current output interface whose current driver capability is 20mA. It is connected with

LED to indicate the working status of module.

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 39

Page 40

MW3650

Hardware Development Guide of Module Products

The indicator light reference design is shown in the following figure. The luminance of LED can be regulated by the

value of resistance. The indicator status of network is as defined in table below

Table 4-8 Indicator Light Reference Design Schematic Diagram

Table 4-9 The Description of Working Status Indicator Light

Module status Indicator light status Frequency

Power-on status Indicator light off

Network searching status Standard flicker 3Hz

Free status Slow flicker 1Hz

Data business status Fast flicker 5Hz

4.10 SPI Bus Interface

The SPI interface signal definition of this product is shown in the following table.

Table 4-10 The Definition of SPI Interface

PIN NO. Type Definition I/O Description

32

33 SPI_MOSI_DATA -- Main output, slave input

34 SPI_CLK I/O SPI interface clock signal

35 SPI_CS_N I/O SPI gating signal

SPI

SPI interface electric features:

The SPI bus of this product is configured as the main equipment, which has three modes:

Running mode—basic running mode;

SPI_MISO_DATA -- Main input, slave output

Waiting mode— The waiting mode of SPI is a configurable low-power mode, enabled by the byte of the control

registered. In the waiting mode, if the waiting byte is cleared, SPI works under the similar running mode. However, if

SPI waits for the position byte, SPI clock stops and enters the low-power status.

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 40

Page 41

MW3650

Hardware Development Guide of Module Products

Stop mode—Under the stop mode, SPI is not available, so the power consumption is reduced. If SPI is configured as

the master equipment, any transmission process will be stopped, but it can enter the running mode when the waiting

mode stops.

4.11 I2C Bus

I2C is the two-wire bus for the communication between ICs, which supports any IC process (NMOS, CMOS,

dual-polarity). The two signal wires, serial data (I2C_SDA) and serial clock (I2C_SCL), can transmit information

between the connected equipment. Each equipment is identified by the unique address (such as the micro controller,

storage, LCD driver or keyboard interface). Due to the different functions of the equipment, it can be used as both the

sender and the receiver.

The I2C interface has the following electric features:

1) The two-wire bus is used for the communication between chips.

2) It supports any external equipment of any manufacturing technology (1.8V).

3) It supports the external functions, such as the image sensor, micro controller, LCD driver and

keyboard interface.

The I2C interface has two working modes with different transmission ratios: standard mode with a speed as high as

100kbps; high-speed mode with a speed as high as 400kbps. Figure 4-11 is the I2C reference circuit design diagram.

Table 4-11 I2C Reference Circuit Design

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 41

Page 42

MW3650

Hardware Development Guide of Module Products

4.12 User Interface

AT commands are mainly used for communication between users and the module. AT commands comply with ITU-T

V.250, 3GPP 27.007 and 3GPP 27.005 standards. Moreover, the module also supports ZETWelink expanding AT

commands.

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 42

Page 43

MW3650

Hardware Development Guide of Module Products

5

Antenna

5.1 Preliminary Antenna Evaluation

The antenna is a sensitive device and its performance is greatly affected by external environments. The radiation

performance of the antenna is affected by the mainboard dimensions, antenna position, occupied space size of the

antenna, and the grounding of surrounding components of the antenna. Besides, the fixed assembly of the antenna, the

wiring of RF cables on the antenna, and the fixed position of the antenna all are related to the problem whether the

antenna exists the interference problem with structure. Thus, during the preliminary design phase of an antenna, it is

critical that antenna engineers, RF engineers, baseband engineers, structure engineers, and ID engineers work together

to make estimation for both 2D and 3D design.

5.2 Antenna Design Guidance

Well shielding measure should be added between external antenna and RF PAD of module, and external cables should

be far away from all interference source, especially high-speed digital signal, DC/DC power and so on.

According to mobile equipment standard, the standing-wave ratio of antenna the module uses should be between 1.1

and 1.5. Input resistance is 50Ω. Under different environments, the requirements of antenna gain are different. Usually,

antenna performance is better if intraband gain is larger and out-of-band gain is smaller. When using the multi-ports

antenna, the isolation between the ports should be larger than 30dB. For example, the isolations between the two

different polarization ports on polarization antenna, the two different frequency ports on dual-frequency antenna and

the four ports on dual-frequency dual-polarization antenna should be larger than 30dB.

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 43

Page 44

Hardware Development Guide of Module Products

Figure 5-1 Translation Circuit Diagram

MW3650

Anten

Microstrip line or

stripline with a

natural impedance of

50 ohm

Dual-L matching

network

Microstrip line or

stripline with a

natural impedance of

50 ohm

na

RF interface on the

antenna RF cable

and RF interface on

the mainboard

RF coaxial cable of

the antenna

RF interface on

the module

PIN62 is antenna pin. The following items should be noticed when this pin is used an antenna feed pin.

1) The feed cable connected with PIN 62 is microstrip line or strip line with resistance value of 50Ω. Near the

module, π-shaped or inverted-F-shaped matching network should be added for latter tuning.

2) The RF wiring should be kept certain distance with GND. Usually the distance is 3 times the line width of RF

wiring.

3) Do not pile the interference sources near the RF wiring or RF ports, such as DCDC, WIFI module and so on.

5.3 Suggested Antenna Location

Mainboard area has serious interference. The experiments result shows that the module performance will be poor If

the module is placed in these interference regions. During the laptop design, it is better to separate the module from

the mainboard PCB, instead of installing the module on the mainboard. If they cannot be separated, the module should

be far from modules and components that might generate EMI, such as chip and memory, power interface, and data

cable interface.

For Internet laptops products, the ideal position of antennas is on the top left corner or top right corner of the LCD,

which is relatively far from the mainboard, so the electromagnetic interference is relatively small. Besides, because it

is far from human bodies, it is easy to satisfy SAR indexes. The other choice is on the left or right of LCD. Other

products such as router, e-book and so on should be evaluated specifically according to the features of product itself.

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 44

Page 45

MW3650

Hardware Development Guide of Module Products

Because different antenna manufacturers may adopt different antenna modes and different terminal products have

different external dimension and different requirements for antenna performance, the reserved spaces as well as

antenna dimension and location are all different. Take the 3G internet laptops as an example, the recommended

antenna space dimension is larger than 7mm*10mm*100mm, and it is recommended to place the antenna at the top of

LCD screen.

5.4 RF PCB wire guidelines

The RF wiring of antenna should be kept as short as possible. It is suggested to choose thicker RF cables considering

the transmission consumption. Meanwhile, RF cables should be far away from modules and components that might

generate EMI, such as chip and memory, power interface, and data cable interface. The RF wiring connecting the

antenna and 3G module should not be right angle, squeezing and abraded.

Keep, if possible, at least one layer of the PCB used only for the Ground plane; If possible, use this layer as reference

Ground plane for the transmission line;

5.5 EMC Requirements

Electronic communications have more EMC requirements than non-communication products. It is very important that

baseband engineer, RF engineer and antenna engineer must fully communicate during the design process of circuit

and wiring to reduce the electromagnetic interference of produces. The following items are common problems and

solutions that can be referred during the product design process.

1) During the product design, it is better to separate the module from the mainboard PCB, instead of installing the

module on the ground of the mainboard. If they cannot be separated, the module should be far from modules and

components that might generate EMI, such as chip and memory, power interface, and data cable interface.

2) Because the mainboard of PAD, CPE, and Internet laptops does not have a shielding cover, as that of mobile

terminals, to shield most circuits to avoid overflow of electromagnetic interference, you can spray conductive

paint on the surface on non-antenna areas within the structural components above and below the mainboard, and

the conductive paint should be connected to the ground on the mainboard by several points to shield

electromagnetic interference.

3) Besides, data cables of the LCD and the camera might introduce interference signals, which affect the receiving

performance of the antenna. Thus, it is necessary to wrap conductive cloth around the two data cables and

connected them to the ground.

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 45

Page 46

MW3650

Hardware Development Guide of Module Products

4) RF cables of the antenna should be far from modules and components that might generate EMI, such as chip and

memory, power interface, and data cable interface. The wiring of RF cables should be close to the ground of the

mainboard.

5.6 Index Requirement of Antenna

Module supported electronic communications pay more and more attention to collect radiation performance test. At

present there are two methods to investigate the radiation performance: one method is investigating the radiation

performance of antenna which is a traditional antenna test method, i.e. passive test; the other method is testing the

radiation power and receiving sensitivity in a specific microwave darkroom, i.e. active test.

The index requirement of antenna involves passive index requirement and active index requirement. Passive indexes

include S11, antenna efficiency, antenna gain, antenna pattern and so on which can used as parameters weighing the

performance of antenna itself. Active indexes usually mean OTA indexes, including TPR (all-round radiation power),

TIS (all-round receiving sensitivity), radiation pattern and so on which are important indexes weighing the whole

device (including antenna, module, circuit main board) radiation performance.

5.6.1 Passive Index of Antenna

Different products have different requirements about antenna performance. The following is the passive reference

index about PAD products while the antenna radiation performance is weighed by the active index. The passive index

requirements are only for the main antenna as is shown in table below.

Table 5-1 The Passive Index Reference of Main Antenna about PAD product

Frequency band 824-960MHz 1710-2170MHz

VSWR <3.5:1 <3.5:1

Maximum gain >0dBi >0dBi

Average gain >-3.5dBi >-3.5dBi

Efficiency >40% >40%

It is recommended that the passive index reference of diversity antenna should be decided by the requirements of its

performance. If it is required that the performance of diversity antenna is the same as the performance of main antenna,

the requirement about passive index of diversity antenna is shown in table above. If it is required that the performance

of diversity antenna reach half of performance of main antenna, see table below for passive index.

Table 5-2 The Passive Index Reference of Diversity Antenna about PAD product

Frequency band 824-960MHz 1710-2170MHz

All Rights reserved, No Spreading abroad without Permission of ZTEWelink 46

Page 47

MW3650

Hardware Development Guide of Module Products

VSWR <3.5:1 <3.5:1

Maximum gain >-3dBi >-3dBi

Average gain >-6.5dBi >-6.5dBi

Efficiency >20% >20%

NOTE:

MW3650 module does not support diversity reception.

5.6.2 Active Index of Antenna

Active index is an important index weighing the radiation performance of whole device (including antenna, module

and circuit main board), so the active index decides the final radiation performance of product. Because different

products have different active index and different operators have different requirements about active index, it is

suggested that antenna engineer, RF engineer, baseband engineer, structure engineer and ID engineer evaluate the

performance the whole device can achieve according to the requirements customer provides about the product

performance in the beginning of a project to decide the active index. For mobile terminal product, there is no

international general standard. The standards are all customized according to the requirements of operator. Table 5-4

is the active index provided by our company for mobile terminal products for reference.