Page 1

Product Name and Model Number User Manual

User Manual

InBio160/260/460 Pro Access Control Panel

Date: April 2021

Doc Version: 1.0

English

Thank you for choosing our product. Please read the instructions carefully

before operation. Follow these instructions to ensure that the product is

functioning properly. The images shown in this manual are for illustrative

purposes only.

For further details, please visit our Company’s website

www.zkteco.eu.

Page | 1 Copyright©2020 ZKTECO CO., LTD. All rights reserved.

Page 2

InBio160/260/460 Pro Access Control Panel User Manual

Copyright © 2021 ZKTECO CO., LTD. All rights reserved.

Without the prior written consent of ZKTeco, no portion of this manual can be copied or forwarded in any

way or form. All parts of this manual belong to ZKTeco and its subsidiaries (hereinafter the "Company" or

"ZKTeco").

Trademark

is a registered trademark of ZKTeco. Other trademarks involved in this manual are owned by

their respective owners.

Disclaimer

This manual contains information on the operation and maintenance of the ZKTeco equipment. The

copyright in all the documents, drawings, etc. in relation to the ZKTeco supplied equipment vests in and is

the property of ZKTeco. The contents hereof should not be used or shared by the receiver with any third

party without express written permission of ZKTeco.

The contents of this manual must be read as a whole before starting the operation and maintenance of

the supplied equipment. If any of the content(s) of the manual seems unclear or incomplete, please

contact ZKTeco before starting the operation and maintenance of the said equipment.

It is an essential pre-requisite for the satisfactory operation and maintenance that the operating and

maintenance personnel are fully familiar with the design and that the said personnel have received

thorough training in operating and maintaining the machine/unit/equipment. It is further essential for

the safe operation of the machine/unit/equipment that personnel has read, understood and followed the

safety instructions contained in the manual.

In case of any conflict between terms and conditions of this manual and the contract specifications,

drawings, instruction sheets or any other contract-related documents, the contract

conditions/documents shall prevail. The contract specific conditions/documents shall apply in priority.

ZKTeco offers no warranty, guarantee or representation regarding the completeness of any information

contained in this manual or any of the amendments made thereto. ZKTeco does not extend the warranty

of any kind, including, without limitation, any warranty of design, merchantability or fitness for a

particular purpose.

ZKTeco does not assume responsibility for any errors or omissions in the information or documents which

are referenced by or linked to this manual. The entire risk as to the results and performance obtained from

using the information is assumed by the user.

ZKTeco in no event shall be liable to the user or any third party for any incidental, consequential, indirect,

special, or exemplary damages, including, without limitation, loss of business, loss of profits, business

interruption, loss of business information or any pecuniary loss, arising out of, in connection with, or

Page | 1 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 3

InBio160/260/460 Pro Access Control Panel User Manual

relating to the use of the information contained in or referenced by this manual, even if ZKTeco has been

advised of the possibility of such damages.

This manual and the information contained therein may include technical, othe

r inaccuracies or

typographical errors. ZKTeco periodically changes the information herein which will be incorporated into

new additions/amendments to the manual. ZKTeco reserves the right to add, delete, amend or modify the

information contained in the manual from time to time in the form of circulars, letters, notes, etc. for

better operation and safety of the machine/unit/equipment. The said additions or amendments are

meant for improvement /better operations of the machine/unit/equipment and such amendments shall

not give any right to claim any compensation or damages under any circumstances.

ZKTeco shall in no way be responsible (i) in case the machine/unit/equipment malfunctions due to any

non-compliance of the instructions contained in this manual (ii) in case of operation of the

machine/unit/equipment beyond the rate limits (iii) in case of operation of the machine and equipment in

conditions different from the prescribed conditions of the manual.

The product will be updated from time to time without prior notice. The latest operation procedures

and relevant documents are available on http://www.zkteco.eu

If there is any issue related to the product, please contact us.

ZKTeco Europe

Address

Ctra. Fuencarral, 44. Ed. 1.

Alcobendas, Madrid. Spain

For business-related queries, please write to us at sales@zkteco.eu.

To know more abo

ut our global branches, visit www.zkteco.eu.

Page | 2 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 4

InBio160/260/460 Pro Access Control Panel User Manual

About the Company

ZKTeco is one of the world’s largest manufacturer of RFID and Biometric (Fingerprint, Facial, Finger-vein)

readers. Product offerings include Access Control readers and panels, Near & Far-range Facial Recognition

Cameras, Elevator/floor access controllers, Turnstiles, License Plate Recognition (LPR) gate controllers and

Consumer products including battery-operated fingerprint and face-reader Door Locks. Our security

solutions are multi-lingual and localized in over 18 different languages. At the ZKTeco state-of-the-art

700,000 square foot ISO9001-certified manufacturing facility, we control manufacturing, product design,

component assembly, and logistics/shipping, all under one roof.

The founders of ZKTeco have been determined for independent research and development of biometric

verification procedures and the productization of biometric verification SDK, which was initially widely

applied in PC security and identity authentication fields. With the continuous enhancement of the

development and plenty of market applications, the team has gradually constructed an identity

authentication ecosystem and smart security ecosystem, which are based on biometric verification

techniques. With years of experience in the industrialization of biometric verifications, ZKTeco was

officially established in 2007 and now has been one of the globally leading enterprises in the biometric

verification industry owning various patents and being selected as the National High-tech Enterprise for 6

consecutive years. Its products are protected by intellectual property rights.

About the Manual

This manual introduces the operations of the InBio160/260/460 Pro Access Control Panel.

All figures displayed are for illustration purposes only. Figures in this manual may not be exactly

onsistent with the actual products.

c

Page | 3 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 5

InBio160/260/460 Pro Access Control Panel User Manual

Window names, menu items, data table, and field names are inside square

level menus are separated by forwarding slashes. For example,

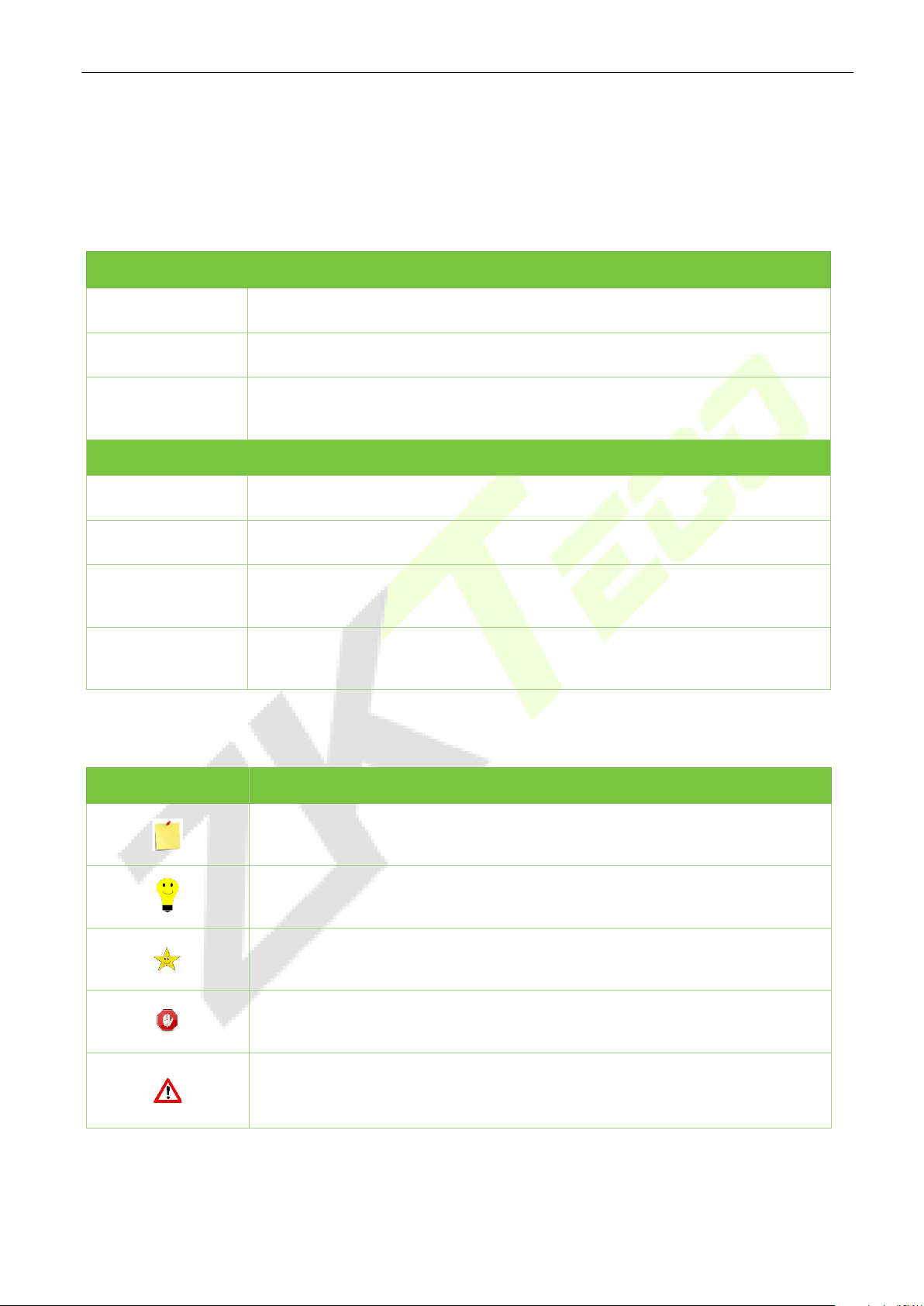

Document Conventions

Conventions used in this manual are listed below:

GUI Conventions

For Software

Convention Description

Bold font Used to identify software interface names e.g. OK, Confirm, Cancel

>

Folder.

For Device

Convention Description

Multi-level menus are separated by these brackets. For example, File > Create >

< >

[ ]

Button or key names for devices. For example, press <OK>

brackets. For example, pop up the [New User] window

Multi-

/

[File/Create/Folder].

Symbols

Convention Description

his implies about the notice or pays attention to, in the manual

T

The general information which helps in performing the operations faster

he information which is significant

T

are taken to avoid danger or mistakes

C

The statement or event that warns of something or that serves as a cautionary

example.

Page | 4 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 6

InBio160/260/460 Pro Access Control Panel User Manual

Table of Contents

1 SAFETY INSTRUCTIONS ........................................................................................................................... 6

IMPORTANT SECURITY INSTRUCTIONS ............................................................................................................... 6

INSTALLATION INSTRUCTIONS ........................................................................................................................... 7

2 SYSTEM INTRODUCTION ......................................................................................................................... 9

SYSTEM FUNCTIONAL PARAMETERS .................................................................................................................. 9

PRODUCT TECHNICAL PARAMETERS ................................................................................................................. 9

CONTROL PANEL INDICATORS ......................................................................................................................... 10

3 INSTALLATION AND CONNECTION ....................................................................................................... 11

INSTALLATION PROCEDURE ............................................................................................................................ 11

INSTALLATION OF ACCESS CONTROL PANEL WIRES .......................................................................................... 12

CONTROL PANEL SYSTEM INSTALLATION ......................................................................................................... 13

CONTROL PANEL CONNECTION TERMINALS .................................................................................................... 14

CONNECTION WITH DOOR SENSORS, EXIT SWITCHES, AUXILIARY INPUT DEVICES, AND PC485 EXTENSION

COMMUNICATION ....................................................................................................................................................... 17

CONNECTION WITH READERS ......................................................................................................................... 20

RELAY OUTPUT CONNECTION ......................................................................................................................... 22

ACCESS CONTROL OPE R ATOR PANEL SYSTEM POWER SUPPLY STRUCTURE ...................................................... 24

4 EQUIPMENT COMMUNICATION ............................................................................................................ 26

ACCESS CONTROL NETWORKING WIRES AND WIRING ..................................................................................... 26

TCP/IP COMMUNICATION .............................................................................................................................. 27

RS485 COMMUNICATION .............................................................................................................................. 27

DIP SWITCH SETTINGS ................................................................................................................................... 28

ZKPANELWEB ............................................................................................................................................... 31

5 STATEMENT ON THE RIGHT TO PRIVACY ............................................................................................... 38

6 ECO-FRIENDLY OPERATION ................................................................................................................... 39

Page | 5 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 7

InBio160/260/460 Pro Access Control Panel User Manual

1 Safety Instructions

Important Security Instructions

1. Read and follow the instructions carefully before operation. Please keep the instructions for future

reference.

2. Accessories: Please use the accessories recommended by the manufacturer or delivered with the

product. Other accessories are not recommended, including major alarming systems and

monitoring systems. The primary alarming and monitoring system should comply with the local

applicable fire-prevention and security standards.

3. Installation cautions: Do not place this equipment on an unstable table, tripod mount, support, or

base, lest the equipment falls and get damaged or any other undesirable outcome resulting in

severe personal injuries. Therefore, it is essential to install the equipment as instructed by the

manufacturer.

4. All peripheral devices must be grounded.

5. No external connection wires can be exposed. All the connections and idle wire ends must be

wrapped with insulating tapes to prevent any damage to the equipment by accidental contact of

the exposed wires.

6. Repair: Do not attempt to have an unauthorized repair of the equipment. Disassembly or

detachment is risky and likely to cause shock. All repairs should be done by a qualified technician.

7. If any of the following cases arise, disconnect the power supply from the equipment first and

intimate the technician immediately.

The power cord or connector is damaged.

Any liquid or material spilled into the equipment.

The equipment is wet or exposed to bad weather (rain, snow, etc.).

If the equipment cannot work properly, even if it is operated as instructed, please be sure to adjust

only the control components specified in the operating instructions. Incorrect adjustments on

other control components may cause damage to the equipment; even the equipment may fail to

operate permanently.

The equipment falls, or its performance changes dramatically.

8. Replacing components: If it is necessary to replace a component, only the authorized technician

can replace the accessories specified by the manufacturer.

9. Security inspection: After the equipment is repaired, the technician must conduct security

inspection to ensure proper working of the equipment.

Page | 6 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 8

InBio160/260/460 Pro Access Control Panel User Manual

10. Power supply: Operate the equipment with only the type of power supply indicated on the label.

Contact the technician for any uncertainty about the type of power supply.

Violation of any of the following cautions is likely to result in personal injury or equipment

failure. We will not be responsible for the damages or injuries caused thereby.

Before installation, switch off the external circuit (that supplies power to the system), including

locks.

Before connecting the equipment to the power supply, ensure the output voltage is within the

specified range.

Never connect the power before completion of installation.

Installation Instructions

1. The conduits of wires under relay must match with the metal conduits; other wires can use PVC

conduits, to prevent failure caused by rodent damage. The Control panel is designed with proper

antistatic, lightning-proof, and leakage-proof functions, ensure its chassis and the AC ground wire

are correctly connected and the AC ground wire is grounded physically.

2. It is recommended not to plug/unplug connection terminals frequently when the system is

powered on. Be sure to unplug the connection terminals before starting any relevant welding job.

3. Do not detach or replace any control panel chip without permission, and an unpermitted

operation may cause damage to the control panel.

4. It is recommended not to connect any other auxiliary devices without permission. All non-routine

operations must be communicated to our engineers in advance.

5. A control panel should not share the same power socket with any other large-current device.

6. It is preferable to install card readers and buttons at the height of 1.4 to 1.5m above the ground

or subject to customers’ usual practice for proper adjustment.

7. It is advised to install control panels at places where maintenance is easy, like a weak electric

well.

8. It is strongly recommended that the exposed part of any connection terminal should not be

longer than 4mm, and specialized clamping tools may be used to avoid short-circuit or

communication failure resulting from accidental contact with excessively exposed wires.

9. To save access control event records, export the data periodically from control panels.

10. Prepare countermeasures according to application scenarios for unexpected power failure, like

selecting power supply with UPS.

11. To protect the access control system against the self-induced electromotive force generated by an

electronic lock at the instant of switching off/on, it is necessary to connect a diode in parallel

Page | 7 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 9

InBio160/260/460 Pro Access Control Panel User Manual

(please use the FR107 delivered with the system) with the electronic lock to release the

self-induced electromotive force during onsite connection for application of the access control

system.

12. It is recommended that an electronic lock and a control panel should use separate power supplies.

13. It is recommended to use the power supply delivered with the system as the control panel power

supply.

14. In a place with substantial magnetic interference, galvanized steel pipes or shielded cables are

recommended, and proper grounding is required.

Page | 8 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 10

InBio160/260/460 Pro Access Control Panel User Manual

2 System Introduction

The Access Control management system is a new modernized security management system, which is an

effective measure of security and protection management. It is mainly used to manage the entrances and

exits of highly secured places, such as banks, hotels, equipment rooms, offices, smart communities, and

factories.

System Functional Parameters

High-speed 32-bit 1.2GHz CPU, 128M RAM, and 256M Flash.

Embedded LINUX operating system.

One-door/two-door two-way access or four-door one-way access.

Fingerprint capacity: 20,000.

A maximum of 60,000 cardholders and 100,000 offline event records.

Support of multiple Wiegand card formats and a password keypad, compatible with various types

of cards.

Use Ethernet and RS485 industrial bus dual communication technology, for reliable communications.

Control Panel with a watchdog (hardware) built in to prevent a crash.

Over-current, over-voltage, and inverse-voltage protection for the input of the power supply to

the control panel.

Over-current protection for the power supply to card readers.

Instant over-voltage protection for all input/output ports.

Instant over-voltage protection for communication ports.

Product Technical Parameters

Working Power supply: Rated voltage 12V (±20%) DC, rated current is 2A.

Working environment: Temperature 0°C to 45°C; Humidity 20% to 80%.

Electronic lock relay output: The maximum switching voltage is 12V(DC); The maximum switching

current is 2A.

Auxiliary relay output: The maximum switching voltage is 12V(DC); The maximum switching

current is 1.25A.

The detachable connection terminals are made of alloy-steel non-magnetic flange materials.

Outline dimensions of the control PCB: 181mm(length) × 106mm (width) for InBio160/260 Pro;

226mm (length) × 106mm (width) for InBio460 Pro.

External box dimensions: 350(L)mm × 300(W)mm × 90(H)mm.

Valve regulated lead-acid battery:

Constant voltage charge voltage regulation

Page | 9 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 11

InBio160/260/460 Pro Access Control Panel User Manual

Cycle use : 14.5V~14.9V(25)

Initial current: less than 2.88A1

Standby use: 13.6V~13.8V(25)

Capacity: 12V, 7.2Ah/20hr

Battery Type: LC-RA127R2T1

Battery Caution:

Do not charge in a gas tight container.

Do not short the battery terminals.

Do not incinerate.

Flush with water at once if contact is made with electrolyte (Acid).

Do not attempt to disassemble the battery.

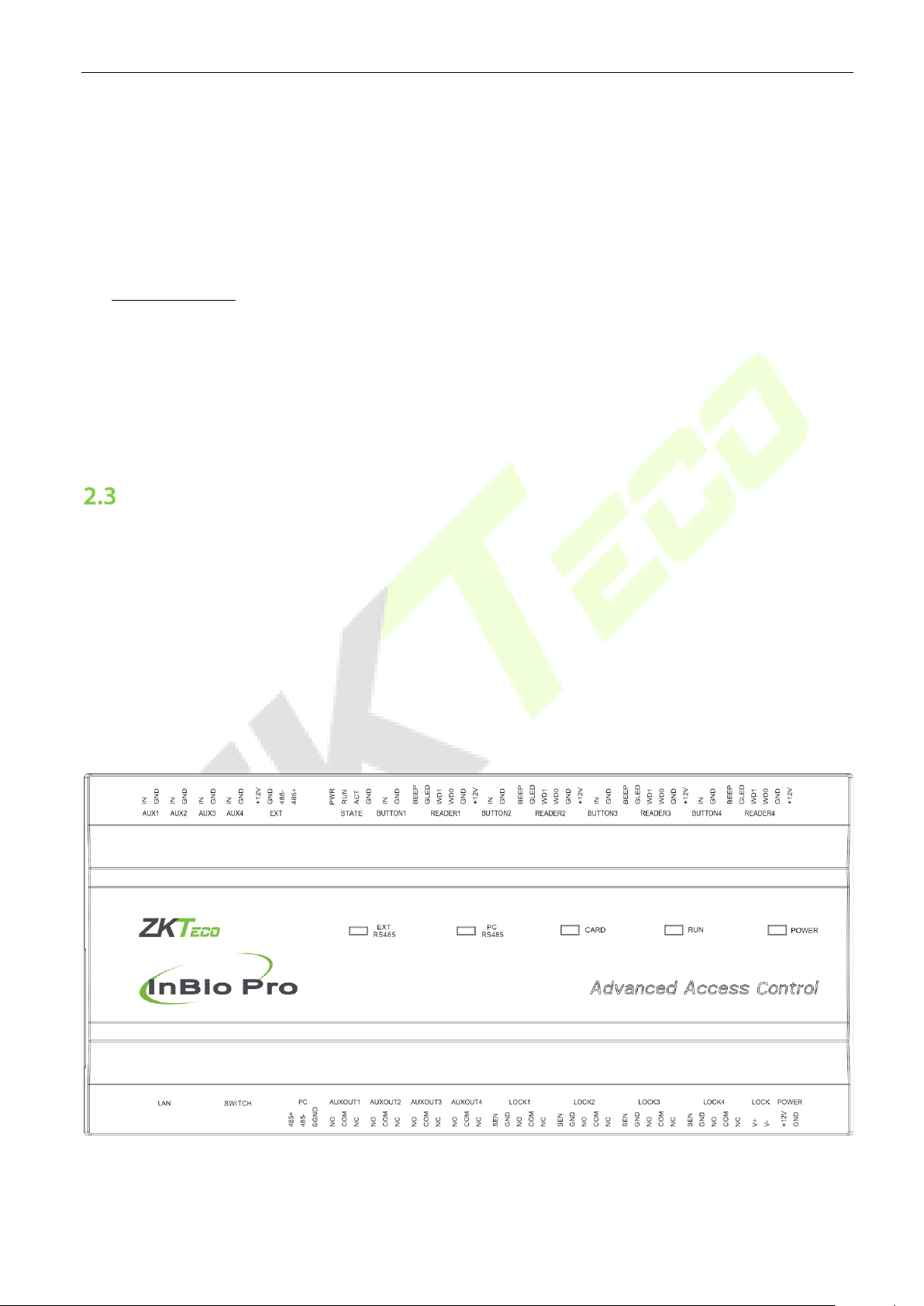

Control Panel Indicators

When the InBio160/260/460 Pro is powered on, normally the POWER indicator (red) is lit constantly, the

RUN indicator (green) shall flash slowly (indicating the system is normal), and other indicators are all off.

LINK indicator (green): indicates proper TCP/IP connection if it is lit constantly;

ACT indicator (yellow): indicates transmission of TCP/IP data if it flashes;

EXT RS485 (TX) indicator (yellow): indicates sending of 485 data if it flashes;

EXT RS485 (RX) indicator (green): indicates receiving of 485 data if it flashes;

CARD indicator (yellow): indicates input of Wiegand signal if it is lit.

Indicator Diagram:

Figure 2-1 Indicators in the InBio460 Pro

Page | 10 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 12

InBio160/260/460 Pro Access Control Panel User Manual

3 Installation and Connection

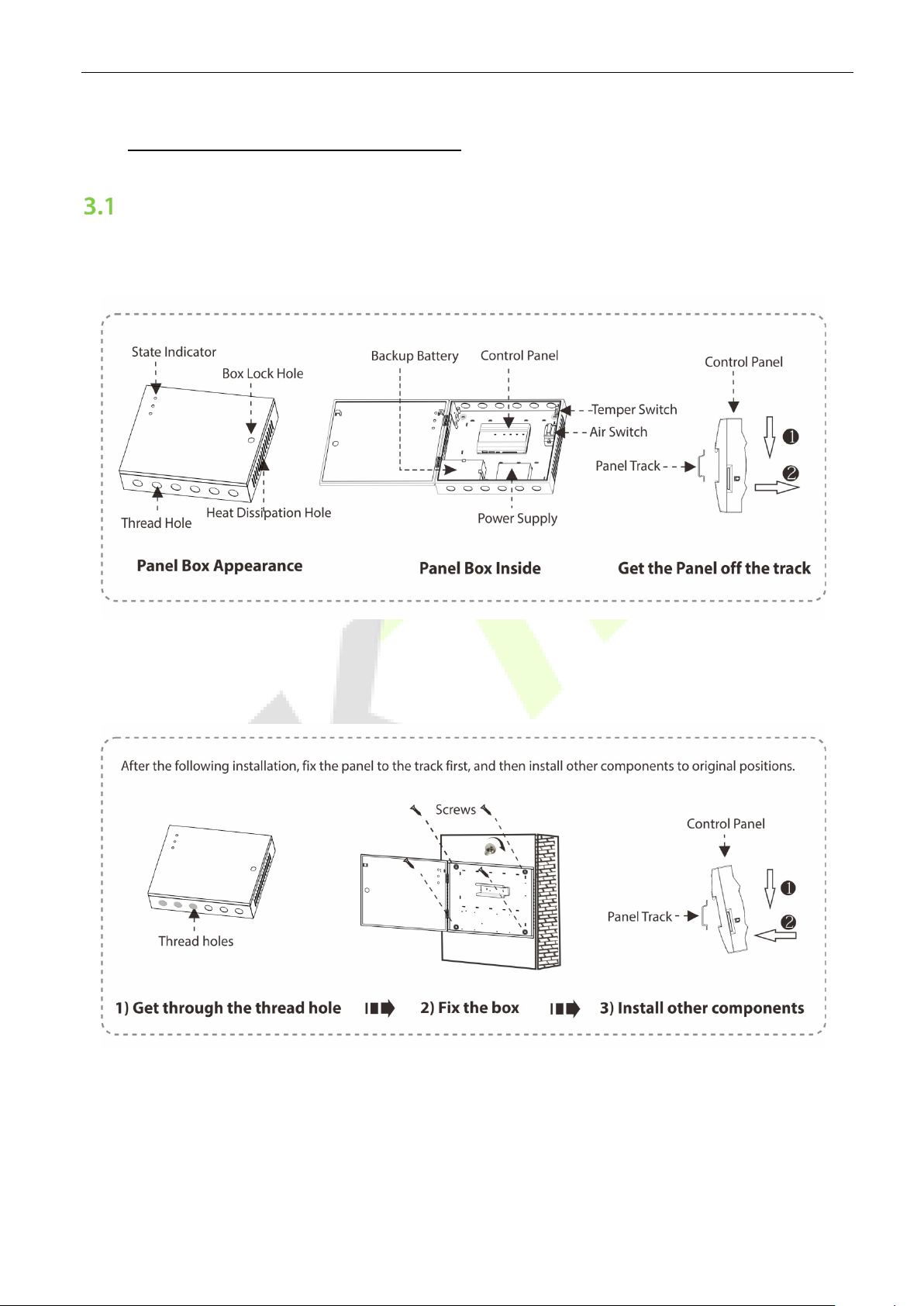

Installation Procedure

Appearance and Internal of the panel box:

Installation steps for the control panel:

Page | 11 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 13

InBio160/260/460 Pro Access Control Panel User Manual

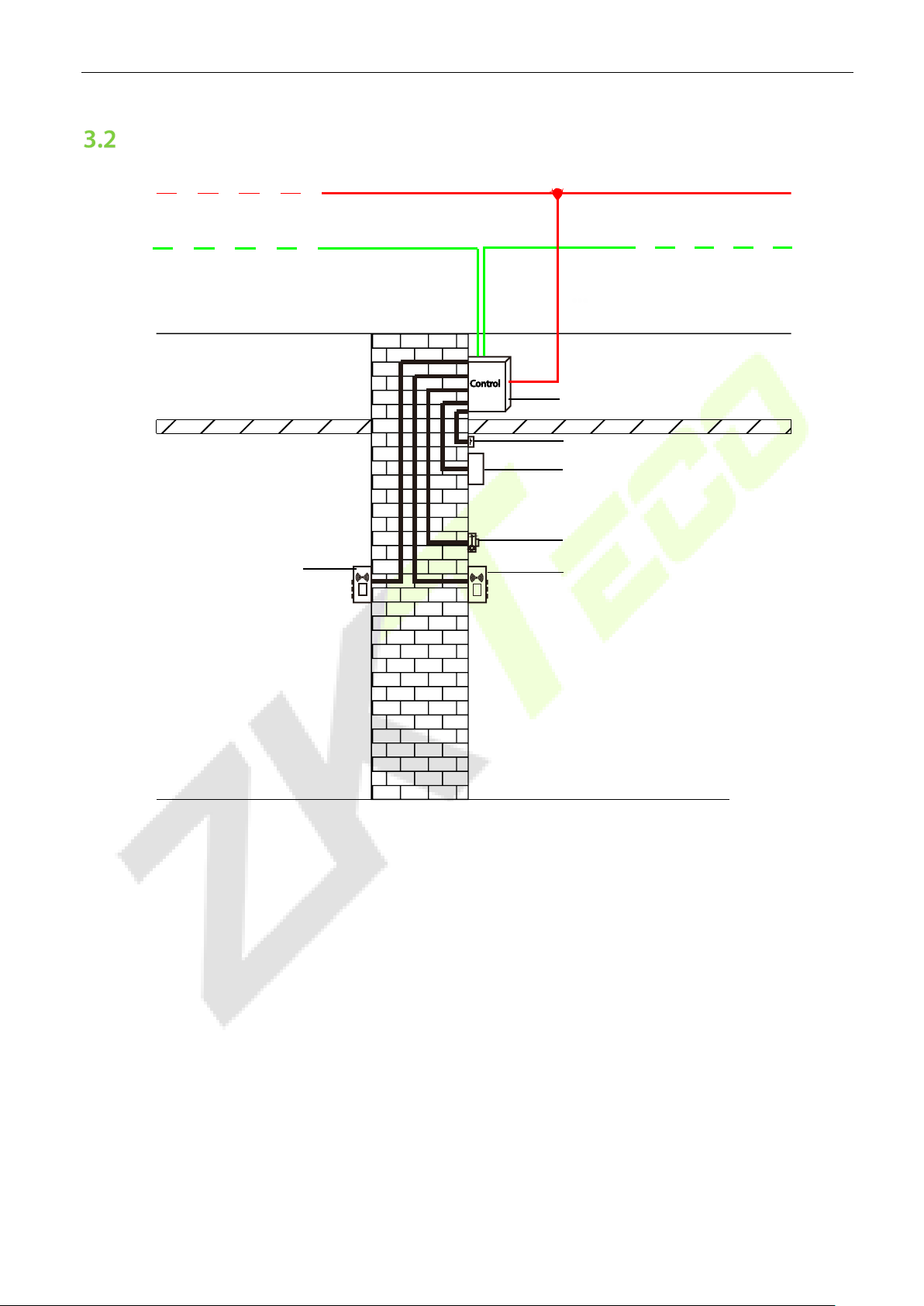

Electronic lock

Outdoor

Ceiling

Installation of Access Control Panel Wires

+12V Power line

TCP/IP Network communication wire

RS485 Network communication wire

Control Panel

Door sensor

Exit button

wiegand

card reader

Outdoor

Figure 3-1 Access Control Panel Wire Installation Diagram

Remarks:

• Ensure the power supply is disconnected before connecting the wires; otherwise, it may cause

severe damage to the equipment.

• The access control wires must be separated according to heavy and light current; the control

panel wires, electronic lock wires, and exit button wires must run through their casing pipes,

respectively.

Indoor

Indoor wiegand card reader

Page | 12 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 14

InBio160/260/460 Pro Access Control Panel User Manual

Control Panel System Installation

Figure 3-2 Schematic Diagram of System Installation

Page | 13 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 15

InBio160/260/460 Pro Access Control Panel User Manual

Note: The diagram above takes the InBio460 Pro for example. By contrast, only one-door two-way

access is applicable to the InBio160 Pro system; only two-door one-way or two-door two-way access is

applicable to the InBio460 Pro system.

The access control management system consists of two parts: Management Workstation (PC) and Control

panel. The management workstation and control panel communicate through TCP/IP and RS485 network.

On a 485 bus, each management workstation can be connected with up to 63 InBio Pro control operator

panels (preferably fewer than 32). The communication wires should be kept away from high-voltage wires

as far as possible and should be neither routed in parallel with nor bundled with power wires.

A management workstation is a PC connected with the network. By running the access control

management software installed in the PC, access control management personnel can remotely perform

various management functions, like adding/deleting a user, viewing event records, opening/closing doors,

and monitoring the status of each door in real-time.

Control Panel Connection Terminals

InBio160 Pro Terminal connection diagram

Page | 14 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 16

InBio160/260/460 Pro Access Control Panel User Manual

InBio260 Pro Terminal connection diagram

Page | 15 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 17

InBio160/260/460 Pro Access Control Panel User Manual

InBio460 Pro Terminal connection diagram

Page | 16 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 18

InBio160/260/460 Pro Access Control Panel User Manual

Description of the terminals:

1. The auxiliary input may connect to infrared body detectors, fire alarms, or smoke detectors.

2. The auxiliary output may connect to alarms, cameras or doorbells, etc.

3. The RS485 Reader port can be connected externally to RS485 reader.

4. The terminals above are set through the relevant access control software. Please see the respective

software manual for further details.

SD card function:

1. Backup event records of access control for client.

Ports of InBio160/260/460 Pro Control Panel:

No. Functional Port

Wiegand card

1

reader interface

2 Exit button 1 2 4

3 Control lock relay 1 2 4

4 Door sensor 1 2 4

5 Extension input 1 2 4

6 Extension output 1 2 4

RS485 & PC

7

communication

RS485 extension

8

communication

9 TCP/IP

InBio160 Pro

(One-Door Two-Way)

2 4 4

InBio260 Pro

(Two-Door Two-Way)

InBio460 Pro

(Four-Door One-Way/

Two -Door Two Way)

Connection with Door Sensors, Exit Switches, Auxiliary Input

Devices, and PC485 Extension Communication

1. Door sensor

A Door Sensor is used to sense the open/close status of a door. With a door sensor switch, an access

control panel can detect the unauthorized opening of a door and will trigger the output of alarm.

Page | 17 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 19

InBio160/260/460 Pro Access Control Panel User Manual

Moreover, if a door is not closed within a specified period after it is opened, the door control panel will

2

also raise the alarm. It is recommended to select two-core wires with a gauge over 0.22 mm

. A door

sensor can be omitted if it is unnecessary to monitor the open/closed status of a door, raise the alarm

when the door is not closed for a long time, monitor if there is unauthorized access, and use the interlock

function.

2. Exit switch

An exit switch is a switch installed indoor to open a door. When it is switched on, the door will be opened.

An exit button is fixed at the height of about 1.4m above the ground. Ensure it is located in the right

position without slant, and its connection is correct and secure. (Cut off the exposed end of any unused

wire and wrap it with insulating tape.) Make sure to avoid electromagnetic interference (such as light

2

switches and computers). It is recommended to use two-core wires with a gauge over 0.3mm

as the

connection wire between an exit switch and the Control panel.

3. Auxiliary input

TheInBio160 Pro provides one auxiliary input interface; the InBio260 Pro provides two and theInBio460

Pro provides four, which may connect to infrared body detectors, smoke detectors, gas detectors, window

magnetic alarms, wireless exit switches, etc. Auxiliary inputs are set through the relevant access control

software. Please see the ZKAccess 4.0 user manual for further details.

Figure 3-3 Connections between InBio460 Pro and Door Sensors, Exit Switches, and Auxiliary Input Devices

Page | 18 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 20

InBio160/260/460 Pro Access Control Panel User Manual

4. PC485 extension communication

The Control panel supports extensive modules which like EX0808, through PC485. An inBioX60 Pro can

connect eight EX0808 at most. As shown in the following figure.

Figure 3-4

Connection between inBio460 Pro and EX0808 through PC485

Notes:

1. A maximum of eight EX0808 extended boards can be connected to an inBio460 Pro controller.

2. Each EX0808 can connect a maximum of eight auxiliary input devices and eight auxiliary output

devices.

3. A separate power supply is required for each EX0808.

4. Set the RS485/OSDP addresses of each EX0808 by the DIP switch before power is supplied.

DIP Switch Setting for RS485/OSDP Communication

Page | 19 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 21

InBio160/260/460 Pro Access Control Panel User Manual

Connection with Readers

The Control panel supports RS485 reader and Wiegand reader.

Connection with RS485 readers

The InBio160 Pro can connect two RS485 readers in the one-door two-way mode. The InBio260 Pro

provides four readers, which can be connected in the two-door two-way mode. The InBio460 Pro provides

four readers, which can be connected in the two-door two-way or four-door two-way mode.

RS485 reader connection: Set the RS485 address (device number) of the reader by DIP switch or other ways.

RS485

address

Control Panel

1 2 3 4 5 6 7 8

InBio160 Pro

InBio260 Pro

InBio460 Pro

#1Door

IN

#1Door

IN

#1Door

IN

#1Door

OUT

#1Door

OUT

#1Door

OUT

#2Door

#2Door

IN

#2Door

IN

OUT

#2Door

OUT

#3Door

IN

#3Door

OUT

#4Door

IN

#5Door

OUT

Figure 3-5

A single EXT RS485 interface can supply for maximum 750 mA (12V) current. So the entire current consumption

should be less than this max value when the readers share power with the panel. For calculation, please use

max current of the reader, and starting current is usually more than twice of the normal work current, please

consider this situation.

Using the KR502M-RS card reader as an example, the standby current is less than 80mA, the max current is less

than 90mA. When starting the device, Instantaneous current can reach for 180 mA. For RS485 reader,

Connection between inBio460 Pro and RS485 Readers

Page | 20 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 22

InBio160/260/460 Pro Access Control Panel User Manual

considered that the starting current is bigger, there are only four readers can connect for power supply

through the EXT RS485 interface. So the power of control panel can only connect up to 4 readers.

If RS485 reader is connected externally and shares the power supply with the device, it is recommended that

the connection between the EXT RS485 port and the reader be no longer than 100m. Otherwise, it is

recommended that using a separate power supply for the reader.

For some of the devices with much greater consumption, we suggest to use the separately power supplies, to

make sure the steady operation.

Connection with Wiegand Readers

The InBio160 Pro can connect two Wiegand readers in the one-door two-way mode. The InBio260 Pro

provides four readers, which can be connected in the two-door two-way mode. The InBio460 Pro provides

four readers, which can be connected in the two-door two-way or four-door one-way mode.

The Wiegand interfaces provided by the InBio160/260/460 Pro series can be connected to different types

of readers. If your card reader does not use the voltage of DC 12V, an external power supply is needed. A

reader should be installed at a height of about 1.4m above the ground and at a distance of 30-50mm

away from a door frame.

Figure 3-6 The connection between the Control Panel and Wiegand Readers

Page | 21 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 23

InBio160/260/460 Pro Access Control Panel User Manual

Relay Output Connection

InBio160 Pro has two relays (one used as control lock by default, and the other one used as auxiliary

output); InBio260 Pro has four relays (two used as control locks by default, and the other two used as

auxiliary outputs); InBio460 Pro has eight relays (four used as control locks by default, and the other four

used as auxiliary outputs).

The relays for auxiliary outputs may connect to monitors, alarms, doorbells, etc. Auxiliary outputs are set

through the relevant access control software. Please refer to the respective software manual for details.

1. The default connection mode of the door lock is “dry mode.” In general, the electronic lock uses an

external power supply separately. The wiring mode of the door lock relay cannot be changed, except

that the auxiliary output relay. The diagram below uses the example of a door lock connection to

demonstrate the output relay connection.

2. An access control panel provides multiple electronic lock outputs. The COM and NO terminals apply

to the locks that are unlocked when power is connected and locked when power is disconnected.

The COM and NC terminals use the locks that are locked when power is connected and unlocked

when power is disconnected.

3. To protect the access control system against the self-induced electromotive force generated by an

electronic lock at the instant of switching off/on, it is necessary to connect a diode in parallel (please

use FR107 delivered with the system) with the electronic lock to release the self-induced

electromotive force during the onsite connection for application of the access control system.

4. By setting the jumper terminal beside the lock relay, you can select the device power supply or lock

power supply for the lock (that is, the wet mode or dry mode).

Dry mode jumper setting: short 1-2 and 3-4 , and the device power supply will be

used for the relay output.

Wet mode jumper setting: short 2-3 and 4-5 , and the lock power supply will be

used for the relay output.

Note: The default connection mode of the door lock is “Dry mode”.

Take the InBio160 Pro as an example here, as shown in the following figure.

Page | 22 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 24

InBio160/260/460 Pro Access Control Panel User Manual

Figure 3-7 “Dry mode” wiring diagram of lock connecting with external power supply(recommend)

Figure 3-8 ”Wet mode” wiring diagram of lock and controller common power supply

Page | 23 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 25

InBio160/260/460 Pro Access Control Panel User Manual

Access Control Operator Panel System Power Supply Structure

Page | 24 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 26

InBio160/260/460 Pro Access Control Panel User Manual

An access control operator panel is powered by +12V DC. Generally, to reduce power interference

between control panels, each control operator panel should be powered separately. When high reliability

is required, control panels and electronic locks should be powered respectively.

To prevent power failure of a control operator panel from making the whole system unable to work

normally, the access control management system is usually required to have one UPS at least, and access

control locks are powered externally to guarantee the access control management system can still work

normally during power failure.

Page | 25 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 27

InBio160/260/460 Pro Access Control Panel User Manual

4 Equipment Communication

The background PC software can communicate with the system according to two protocols (TCP/IP and

RS485) for data exchange and remote management.

Access Control Networking Wires and Wiring

1. The power supply is 12V DC converted from 220V.

2. As an electronic lock has a large current, it generates a strong interference signal while functioning.

2

To reduce such an effect, 4-core wires (RVVP 4×0.75mm

door sensor) are recommended.

3. RS485 communication wires are made of internationally accepted shielded twisted pairs, which

prove effective to prevent and shield interference.

4. The Wiegand readers use 6-core communication shielded wires (RVVP 6×0.5mm) (usually there are

6-core, 8-core, and 10-core types available for users to select according to the ports) to reduce

interference during transmission.

, two for a power supply, and two for a

2

5. Other control cables (like exit switches) are all made of 2-core wires (RVVSP 2×0.5mm

).

6. Notes for wiring:

Signal wires (like network cables) can neither run in parallel with nor share one casing pipe

with large-power electric wires (like electronic lock wires and power cables). If parallel wiring is

unavoidable for environmental reasons, the distance must be above 50cm.

Try to avoid using any conductor with a connector during distribution. When a connector is

indispensable, it must be crimped or welded. No mechanical force can be applied to the joint

or branch of conductors.

In a building, the distribution lines must be installed horizontally or vertically. They should be

protected in casing pipes (like plastic or iron water pipes, to be selected according to the

technical requirements of the indoor distribution). Metal hoses are applicable to ceiling wiring,

but they must be secure and good-looking.

Shielding measures and shielding connection: If the electromagnetic interference in the wiring

environment is found substantial in the survey before construction, it is necessary to consider

the shielding protection of data cables when designing a construction scheme. Overall,

shielding protection is required if there is a large radioactive interference source or wiring has

to be parallel with a large-current power supply on the construction site. Generally, shielding

measures includes keeping a maximum distance from any interference source, and using

metal wiring troughs or galvanized metal water pipes to ensure reliable grounding of the

connection between the shielding layers of data cables and the metal troughs or pipes. Noted

that a shielding enclosure can have a shielding effect only when it is grounded reliably.

Page | 26 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 28

InBio160/260/460 Pro Access Control Panel User Manual

Ground wire connection method: Reliable large-diameter ground wires in compliance with

applicable national standards are needed on the wiring site and should be connected in a tree

form to avoid DC loop. These ground wires must be kept far away from lightning fields. No

lightning conductor can serve as a ground wire and ensure there is no lightning current

through any ground wire when there is lightning. Metal wiring troughs and pipes must be

connected continuously and reliably and linked to ground wires through large-diameter

cables. The impedance of this section of wire cannot exceed 2 ohms. Also, the shielding layer

must be connected reliably and grounded at one end to guarantee a uniform current direction.

The ground wire of the shielding layer must be connected through a large-diameter wire (not

less than 2.5mm2).

TCP/IP Communication

The Ethernet 10/100Base-T Crossover Cable, a type of crossover network cable, is mainly used for

cascading hubs and switches or used to connect two Ethernet endpoints directly (without a hub). Both

10Base-T and 100Base-T are supported.

Figure 4-1 TCP/IP Communication System Networking

In Access software: Click Device > Search Device to search for access controllers in the network, and

directly add from the search result.

RS485 Communication

1. RS485 communication wires are made of internationally accepted RVSP wires (shielded twisted pairs),

which prove effective to prevent and shield interference. RS485 communication wires should be

Page | 27 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 29

InBio160/260/460 Pro Access Control Panel User Manual

connected by means of bus cascade instead of in a star form, to achieve a better shielding effect by

reducing signal reflection during communications.

2. A single 485 bus can be connected with 63 access control operator panels at most, but preferably

should be connected with less than 32.

3. To eliminate signal attenuation in communication cables and suppress interference, if the bus is

longer than 300 meters, one 120ohm resistance is usually inserted between the first and last access

control operator panels on the RS485 bus.

4. For this access control operator panel, putting place 8 of the DIP switch to the ON position is

equivalent to parallel connection of one 120ohm resistance between the 485+ and 485- lines. As

shown in the figure below, put place 8 of the DIP switches of the first and last control operator panels

to the ON position.

Figure 4-2 RS485 Communication System Networking

DIP Switch Settings

This part introduces how to set the RS485 address setting, factory setting and terminal resistance setting

of the control panel through the DIP switch.

Page | 28 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 30

InBio160/260/460 Pro Access Control Panel User Manual

485 address setting

Places 1-6 of the DIP switch are reserved to set device number for RS485 communication. The code is

binary, and the lower places are in the front. When the switch is set to the ON position, it indicates 1 (on);

when the switch is set downwards, it indicates 0 (off).

For example, to set a device number 39=1+2+4+32, which corresponds to the binary code 111001, put

places 1, 2, 3, and 6 to the ON position, as illustrated below.

485 address setting table:

Place Address

Address No.

01

02 OFF

03

04 OFF OFF

05

06 OFF

07

08 OFF OFF OFF

09

10 OFF

11

12 OFF OFF

13

14 OFF

15

16 OFF OFF OFF OFF

17

18 OFF

19

20 OFF OFF

21

22 OFF

23

24 OFF OFF OFF

25

26 OFF

27

1 2 3 4 5 6

1 2 4 8 16 32

ON

ON ON

ON

ON ON ON

ON

ON ON

ON

ON ON ON ON

ON

ON ON

ON

ON ON ON

ON

ON ON

OFF OFF OFF OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON

OFF OFF OFF

ON

OFF

ON ON

OFF OFF

ON

Switch Setting

OFF OFF OFF OFF

OFF OFF OFF OFF

ON

ON

OFF

OFF

ON ON

ON ON

OFF OFF

OFF OFF

ON

ON

OFF

OFF

OFF OFF OFF

OFF OFF OFF

OFF OFF OFF

OFF OFF OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON ON

ON ON

ON ON

ON ON

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Page | 29 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 31

InBio160/260/460 Pro Access Control Panel User Manual

Place Address

28 OFF OFF

29

30 OFF

31

32 OFF OFF OFF OFF OFF

33

34 OFF

35

36 OFF OFF

37

38 OFF

39

40 OFF OFF OFF

41

42 OFF

43

44 OFF OFF

45

46 OFF

47

48 OFF OFF OFF OFF

49

50 OFF

51

52 OFF OFF

53

54 OFF

55

56 OFF OFF OFF

57

58 OFF

59

60 OFF OFF

61

62 OFF

63

1 2 3 4 5 6

ON

ON ON ON ON ON

ON

ON ON

ON

ON ON ON

ON

ON ON

ON

ON ON ON ON

ON

ON ON

ON

ON ON ON

ON

ON ON

ON

ON ON ON ON ON ON

OFF

ON ON ON ON

OFF OFF OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON

OFF OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON ON ON

Switch Setting

ON ON ON

ON ON ON

OFF OFF OFF

OFF OFF OFF

ON

ON

OFF

OFF

ON ON

ON ON

OFF OFF

OFF OFF

ON

ON

OFF

OFF

ON ON ON ON

ON ON ON ON

OFF OFF

OFF OFF

OFF OFF

OFF OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON ON ON

ON ON ON

ON ON ON

ON ON ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

ON

ON

ON

ON

ON

ON

ON

ON

Restoring factory setting

The silk-screened 7 (place 7) of the DIP switch is the switch for restoration of system settings. The place is

set to OFF by default. When place 7 is moved upwards and downwards for three times within 10 seconds

Page | 30 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 32

InBio160/260/460 Pro Access Control Panel User Manual

and finally returned to the OFF position, the factory settings will be restored after the access control

operator panel is restarted.

Terminal resistance setting

Place 8 is for setting the RS485 termination resistance. Putting the switch to the ON position is equivalent

to parallel connection of a 120ohm termination resistance between 485+ and 485-.

ZKPanelWeb

To help users conveniently manage controllers, the built-in Web Server function is added to some models.

With this function, a user can connect to the controller through a PC, and enter the IP address of the

controller to access the web. Users can also use the Web Server function to perform other operations, such

as network configuration, Push communication configuration, time synchronization, and user account

management.

Log on to the Web Server

a. Connect the controller to the network or PC, start the browser, enter the IP address of the controller,

which is 192.168.1.201 by default. Then you can visit the Web Server.

b. When Web Server is used, “User Name“ and “Password“ should be set firstly. The default “user name” is

admin and the default “password” is zkteco@12345.

Page | 31 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 33

InBio160/260/460 Pro Access Control Panel User Manual

c. Click Sign In to access the ZKPanelWeb.

Note:

1) IP addresses of both the server (PC) and the controller must be in the same network segment.

2) IP address of the controller could be found by searching devices with the BioSecurity software

([Access - Access Device - Device - Search Device]).

Basic Operation Bar of the Web Server

1. Change of the Administrator's Password

a. Click . The following page is displayed:

b. Enter the old and new passwords, and click Confirm to change the administrator's login password.

2. Language Settings

Page | 32 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 34

InBio160/260/460 Pro Access Control Panel User Manual

Click , change the language in which the server interface is displayed, and click Confirm.

3. Use Conditions of the Server

Click , and you can view the version of the current server, as well as thebrowser and resolution

recommended for the server.

4. Online Help of the Server

If you met some problems when using the server, click to view or download the user help document.

Page | 33 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 35

InBio160/260/460 Pro Access Control Panel User Manual

5. Exit

Click , and then click Confirm to return to the server login page.

Network Settings

1. TCP/IP Settings

Function introduction:

Set the TCP/IP communication parameters, which are used in the communications between device and

PC.

Page | 34 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 36

InBio160/260/460 Pro Access Control Panel User Manual

Operating steps:

a. Click Network Setting > TCP/IP Settings.

b. Input the device’s IP address, Subnet Mask, Default Gateway.

IP address: the default IP is 192.168.1.201, and you can modify according to the actual.

Subnet Mask: the default subnet mask is 255.255.255.0, and you can modify according to the

actual.

Default Gateway: the default gateway is 0.0.0.0, and you can modify it according to the actual.

Primary DNS: the default value is null, and you can set its value.

c. Click Confirm to write parameters into the device. please restart the device by manual.

Communication Settings

1. PUSH Server Settings

PUSH Server: Indicates that the controller proactively pushes information to the server.

IP Mode: the default server IP is 0.0.0.0, and you can modify it according to the actual.

Port: the default Port is 80, and you can modify it according to the actual.

Domain Mode: the default value is null, and you can set its value.

2. Port Settings

Page | 35 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 37

InBio160/260/460 Pro Access Control Panel User Manual

Http Port: Indicates that the client initiates an HTTP request to a specified port on the server. the

default HTTP Port is 80, and you can modify it according to the actual.

3. Communication Password

Communication Password: Indicates that network communication is encrypted. The default value is null,

and you can set its value.

If you configure the communication password here, the same communication password must be

configured on the server before the connection can be set up.

System

1. User Settings

Click Edit to change the login password of an administrator or a user.

2. Time Settings

Page | 36 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 38

InBio160/260/460 Pro Access Control Panel User Manual

You can manually configure the controller time or synchronize the controller time with the PC time, and

click Confirm to complete the setting.

3. System Settings

Click Reboot. The device will be restarted.

4. Device Information

Page | 37 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 39

InBio160/260/460 Pro Access Control Panel User Manual

5 Statement on the Right to Privacy

Dear Customers,

Thank you for choosing this hybrid biometric recognition product that ZKTeco has developed and

manufactured. As a world-renowned provider of core biometric recognition technologies, we are

constantly researching and building new products, and strive to follow the privacy laws of each country in

which our products are sold.

We Declare That:

1. All of our civilian fingerprint recognition devices capture only features, not images of fingerprint, and do not

have protection of privacy.

2. None of the fingerprint characteristics that we capture can be used to reconstruct an image of the original

fingerprint, and do not involve privacy protection.

3. We would assume no direct or indirect responsibility as the provider of this device for any consequences that

might arise from your use of this device.

4. If you would like to dispute issues of human rights or privacy involving your use of our product, please

contact your dealer directly.

Our other law-enforcement fingerprint devices or development tools can capture the original images of

citizen's fingerprints. As to whether or not this constitutes a breach of your rights, please contact your

Government or the final supplier of the device. As the manufacturer of the device, we will not be legally

liable.

As a final point, we would like to emphasize further that biometric recognition is an emerging technology

that will inevitably be used in the future in e-commerce, banking, insurance, judiciary and other industries.

Every year, the world suffers major losses due to the unsafe nature of the passwords. Biometric products

serve protect your identity in high-security environments.

Page | 38 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 40

InBio160/260/460 Pro Access Control Panel User Manual

materials. The components which contain toxins or harmful elements are included due to the

6 Eco-friendly Operation

The product's "eco-friendly operational period" refers to the time period during which this

product will not discharge any toxic or hazardous substances when used in accordance

with the prerequisites in this manual.

The eco-friendly operational period specified for this product does not include batteries or

other components that are easily worn down, and must be periodically replaced. The

battery's eco-friendly operational period is 5 years.

Hazardous or Toxic substances and their quantities

Component

Name

Chip Resistor

Chip Capacitor

Chip Inductor

Diode

ESD

component

Buzzer

Adapter

(PBB)

Hazardous/Toxic Substance/Element

Lead (Pb)

Mercury

(Hg)

Cadmiu

m (Cd)

chromium

(Cr6+)

×

○ ○ ○ ○ ○

×

○ ○ ○ ○ ○

×

○ ○ ○ ○ ○

×

○ ○ ○ ○ ○

×

○ ○ ○ ○ ○

×

○ ○ ○ ○ ○

×

○ ○ ○ ○ ○

Hexavalent

Polybrominate

d Biphenyls

Polybrominated

Diphenyl Ethers

(PBDE)

○

Screws

○ ○ × ○ ○

○ indicates that the total amount of toxic content in all the homogeneous materials is below the

limit as specified in SJ/T 11363—2006.

× indicates that the total amount of toxic content in all the homogeneous materials exceeds the limit

as specified in SJ/T 11363—2006.

Note: 80% of this product’s components are manufactured using non-toxic and eco-friendly

current economic or technical limitations which prevent their replacement with non-toxic materials

or elements.

Page | 39 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

Page 41

www.zkteco.e

Copyright © 2021 ZKTECO CO., LTD. All Rights Reserved.

Page | 1 Copyright©2021 ZKTECO CO., LTD. All rights reserved.

u

Loading...

Loading...