Zibro S2041, S2053, S2035 user manual

S2035 - S2041 - S2053

4

SERVICE MANUAL

2

Unit

SPECIFICATION

INDOOR OUTDOOR

TAN-A28EWI TAG-A28EWI

Moisture Removal

Power source

Airflow Method

Air circulation (at High)

Input

Electrical Data

Piping Connection Port (Flare piping)

Pipe Size (Flare piping)

Drain hose

Power Cord

Dimensions

Net Weight

Running Current

Starting Current

Inner diameter

Length

Length

Number of core-wire

Height

Width

Depth

BTU/hCooling Capacity

BTU/hHeating Capacity –

L/h

phase

V

Hz

OUTLET

INTAKE

3

m/min

W

A

A

inch

inch

inch

inch

mm

m–

m–

mm

mm

mm

kg

10,000(2,700-12,000)

13,200(2,400-18,000)

1.6

Single

230

50

SIDE VIEW

Cooling ;

Heating ;

Cooling ;

Heating ;

Cooling ;

Heating ;

; Half Union 1/4''

L L

; Half Union 3/8''

G G

L (liquid side) ; 1/4''

G (gas side) ; 3/8''

core-wire/ 1 mm –

9.0

11.0

660

765

2.9

3.4

3.4

; 2-way valve 1/4''

; 3-way valve 3/8''

L (liquid side) ; 1/4''

G (gas side) ; 3/8''

14

0.6

1.4

2

295

799

210

9.1

–

–

TOP VIEW

–

–

–

–

–

550

780

278

35

– 1 –

Unit

SPECIFICATION

INDOOR OUTDOOR

TAN-A28EWI TAG-A28EWI

Type

Air Circulation

Heat Exchanger

Refrigerant Control Device

Refrigerant (R410A )

Thermostat

Timer

Air Filter

Parts Provided

Motor Type

Rated Output

W

g (oz)

Cross-flow Fan Propeller Fan

DC brushless(8-pole) DC brushless (8-pole)

30 40

Plate fin configuration,forced draft

21.2FPI 18.1 FPI

–

–

Electronic Control

Real time dual ON/OFF

7-hour OFF

Mold-proof

1 Mounting plate

2 Remote controller

3 Battery (2 pcs.)

4 Remote controller holder

5 Screw cap (2 pcs.)

6 Drain elbow

7 Gum Bushing (2 pcs.)

8 Vibration proof rubber (4 pcs.)

Expansion Valve

1,100(38.8)

–

–

–

Specifications are subject to change without notice.

– 2 –

Unit

SPECIFICATION

INDOOR OUTDOOR

TAN-A32EWI TAG-A32EWI

Moisture Removal

Power source

Airflow Method

Air circulation (at High)

Input

Electrical Data

Piping Connection Port (Flare piping)

Pipe Size (Flare piping)

Drain hose

Power Cord

Dimensions

Net Weight

Running Current

Starting Current

Inner diameter

Length

Length

Number of core-wire

Height

Width

Depth

BTU/hCooling Capacity

BTU/hHeating Capacity –

L/h

phase

V

Hz

OUTLET

INTAKE

3

m/min

W

A

A

inch

inch

inch

inch

mm

m–

m–

mm

mm

mm

kg

12,500(2,700-14,100)

17,100(2,400-20,700)

1.7

Single

230

50

SIDE VIEW

Cooling ;

Heating ;

Cooling ;

Heating ;

Cooling ;

Heating ;

; Half Union 1/4''

L L

; Half Union 3/8''

G G

L (liquid side) ; 1/4''

G (gas side) ; 3/8''

core-wire/ 1 mm –

9.5

12.5

885

1,130

3.9

5.0

5.0

; 2-way valve 1/4''

; 3-way valve 3/8''

L (liquid side) ; 1/4''

G (gas side) ; 3/8''

14

0.6

1.4

2

295

799

210

9.1

–

–

TOP VIEW

–

–

–

–

–

550

780

278

35

– 3 –

Unit

SPECIFICATION

INDOOR OUTDOOR

TAN-A32EWI TAG-A32EWI

Type

Air Circulation

Heat Exchanger

Refrigerant Control Device

Refrigerant (R410A )

Thermostat

Timer

Air Filter

Parts Provided

Motor Type

Rated Output

W

g (oz)

Cross-flow Fan Propeller Fan

DC brushless(8-pole) DC brushless (8-pole)

30 40

Plate fin configuration,forced draft

21.2FPI 18.1 FPI

–

–

Electronic Control

Real time dual ON/OFF

7-hour OFF

Mold-proof

1 Mounting plate

2 Remote controller

3 Battery (2 pcs.)

4 Remote controller holder

5 Screw cap (2 pcs.)

6 Drain elbow

7 Gum Bushing (2 pcs.)

8 Vibration proof rubber (4 pcs.)

Expansion Valve

1,100(38.8)

–

–

–

Specifications are subject to change without notice.

– 4 –

Unit

SPECIFICATION

INDOOR OUTDOOR

TAN-A53EWI TAG-A53EWI

Moisture Removal

Power source

Airflow Method

Air circulation (at High)

Input

Electrical Data

Piping Connection Port (Flare piping)

Pipe Size (Flare piping)

Drain hose

Power Cord

Dimensions

Net Weight

Running Current

Starting Current

Inner diameter

Length

Length

Number of core-wire

Height

Width

Depth

BTU/hCooling Capacity

BTU/hHeating Capacity –

L/h

phase

V

Hz

OUTLET

INTAKE

3

m/min

W

A

A

inch

inch

inch

inch

mm

m–

m–

mm

mm

mm

kg

17,700(1,700-18,800)

23,800(1,700-33,400)

2.8

Single

230

50

SIDE VIEW

Cooling ;

Heating ;

Cooling ;

Heating ;

Cooling ;

Heating ;

; Half Union 1/4''

L L

; Half Union 3/8''

G G

L (liquid side) ; 1/4''

G (gas side) ; 3/8''

core-wire/ 2 mm –

14.0

15.0

1,845

1,800

8.1

7.9

8.1

; 2-way valve 1/4''

; 3-way valve 3/8''

L (liquid side) ; 1/4''

G (gas side) ; 3/8''

14

0.6

2.3

2

295

799

210

9.5

–

–

TOP VIEW

–

–

–

–

–

550

780

278

35

– 5 –

Unit

SPECIFICATION

INDOOR OUTDOOR

TAN-A53EWI TAG-A53EWI

Type

Air Circulation

Heat Exchanger

Refrigerant Control Device

Refrigerant (R410A )

Thermostat

Timer

Air Filter

Parts Provided

Motor Type

Rated Output

W

g (oz)

Cross-flow Fan Propeller Fan

DC brushless(8-pole) DC brushless (8-pole)

30 40

Plate fin configuration,forced draft

21.2FPI 18.1 FPI

–

–

Electronic Control

Real time dual ON/OFF

7-hour OFF

Mold-proof

1 Mounting plate

2 Remote controller

3 Battery (2 pcs.)

4 Remote controller holder

5 Screw cap (2 pcs.)

6 Drain elbow

7 Photo-Catalytic Anti-Odor filter (2 pcs.)

8 Static,Catechin filter (2 pcs.)

9 Gum Bushing (2 pcs.)

Expansion Valve

1,100(38.8)

–

–

–

Specifications are subject to change without notice.

– 6 –

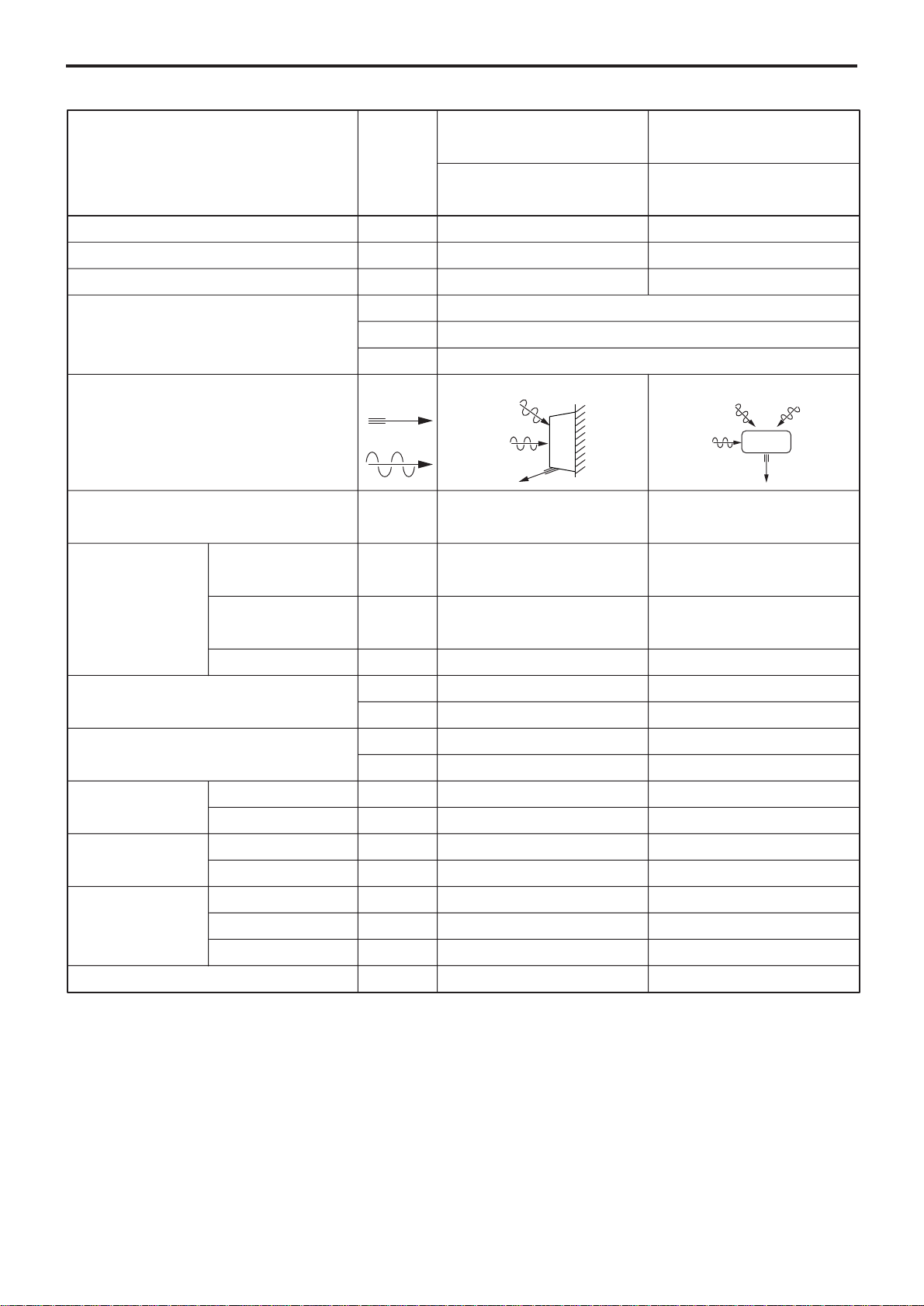

FUNCTIONS

REMOTE-CONTROL TRANSMITTER

ON/OFF

Operation mode selection

COOL

DRY

HEAT

AUTOMATIC

INDOOR UNIT

Sensing the room temperature

Room temperature sensor (thermistor)

Time delay safety control

Restarting is inhibited for approximately

3 minutes.

Indoor fan speed control

High, Med, Low

Air flow selection

AUTOMATIC

HIGH

MEDIUM

LOW

Room temperature setting

16°C 〜30°C

Timer operation selection

CONTINUOUS operation

OFF

ON

Sleep

Timer / time setting

Operation stops at the set time

(OFF timer)

Operation starts at the set time

(ON timer)

0.5〜 7.0hours(Sleep timer)

Operation indication lamps (LED)

(GREEN).......Light up in operation

(YELLOW) .... Timer in operation

(GREEN).......Outdoor unit operate

Dry operation mode

AUTOMATIC

Room temperature control

Maintains the room temperature in

accordance with the setting temperature.

Deice (defrost) control

Deicing operation automatically starts

when the heating efficiency is declined by

the ice formed in the outdoor unit.

After deicing operation, heating operation

automatically starts with “Hot start

function.”

Air flow direction control

Auto angle selection

Auto swing mode

Manual mode

– 7 –

Hot-start control (heating)

The indoor fan stops until the evaporator

piping temperature will be reached.

Anti-freezing control for the

evaporator

Compressor will be stopped when the

evapolator’s piping temperature is below

2℃ for one minute.

Compressor will be restarted when the

evaporator’s piping temperature is above

2℃.

Airflow direction control

Automatic airflow direction control

The louver automatically swings up and

down (cooling, dry)...horizontal and 35°

downward.

The louver is set at 70° downward

during heating operation.

FUNCTIONS

OUTDOOR UNIT

Inverter control

Inverter control reduce the ON/OF times

of compressor,so can keep the room

temperature changeless during

operation.

Auto recovery function

If there is any power failure during

operation, operation status before power

failure is memorized.

3〜 4 minutes after power recovery, the

unit restarts automatically with previous

operation status memorized.

(3〜 4 minutes is protective time for

compressor.)

Attention

Because of Auto recovery function, if

shutting off the power supply during

operation, the unit may restart

irrespective your intention when turning

on the power supply next time.

If the unit is not to be used for a long

time, shut off the power supply after

terminating all operation with remote

controller.

Electricity consumption

Inverter control can operate with less

electricity consumption than normal air

conditioner.

Deice(Defrost) control

(for outdoor unit panel)

Deice operation automatically starts

when the outdoor temperature is lower

than 2℃ and the ice is formed on the

bottom of outdoor unit.

– 8 –

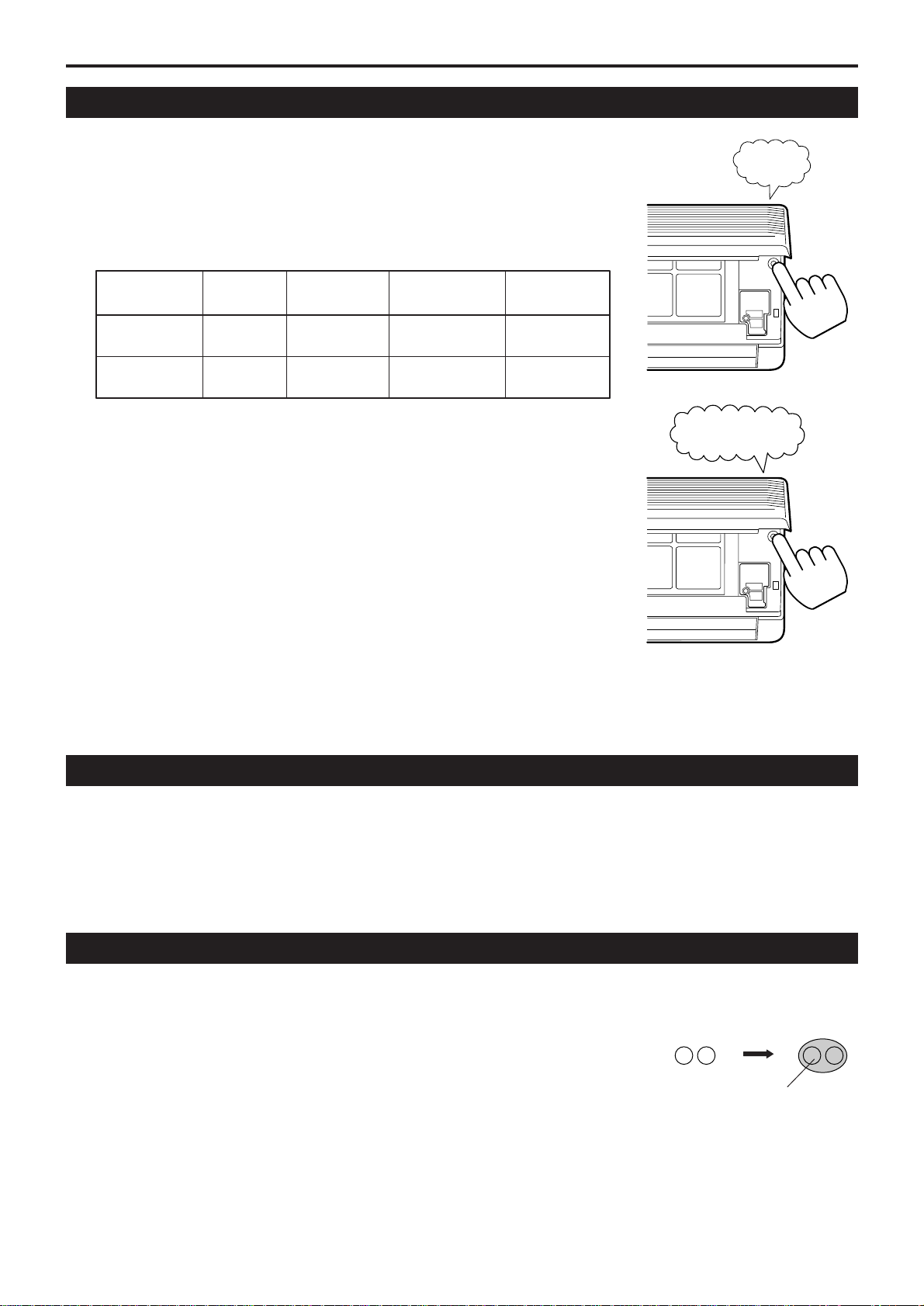

SERVICE FUNCTION EXPLANATION

EMERGENCY AND TEST OPERATION

Emergency Operation

•

Use this operation only when the remote controller is out of order or lost.

•

When the emergency operation switch is pressed, beep starts once, which

means the start of this operation.

•

In this operation, the system automatically selects the operation modes, cooling

(or heating when available) according to the room temperature, as follows.

Beep

Temperature

ABOVE 23℃

BELOW 23℃

•

It is not possible to operate in dry mode.

Operation

mode

COOLING

HEATING

Designated

temperature

26℃

23℃

Timer mode Air flow

CONTINUOUS

CONTINUOUS

AUTOMATIC

AUTOMATIC

Test Operation

Test operation switch is same as emergency one.

•

Use this operation only for testing the performance of the machine in

the condition where the room temperature is less than 16°C.

•

Continue to press the test operation switch for more than 5 seconds.

After you hear twice beep, release your finger from the switch

: the cooling operation starts with the air flow speed “HI.”

•

If the test operation switch is pressed more than 10 seconds, it doesn’t

work.

•

After 30 minutes, test operation ends automatically.

Twice beep

HOW TO RELEASE EMERGENCY AND TEST OPERA TION

• In case of releasing during those operations, you can either push emergency operation switch once more or

apply operation using remote control.

You will hear a beep sound and emergency/ test operation is released.

• If you release the operation by remote control, operation will continue as setting of the remote control

automatically.

INTERFERENCE PREVENTION OF SIGNALS FROM THE REMOTE CONTROLLER

When two indoor units used in the same room, interference of the signals may happen. To avoid this, alternative

signal model B can be selected by the following. (Ex-factory setting is mode A)

J1

• Remote controller side : Have “J1” on the PC board short-circuited by soldering.

• Indoor unit side : Cut “R13” on the PC board.

Soldering

J1

– 9 –

OPERATION DETAILS

TIMER OPERATION

ON Timer operation

•

Press the ON/OFF switch. Right after replacing new batteries, set the present time in advance.

•

Set the “ON T ime” : Press the “TIME ADJ” button twice.

Adjust the time with the “ , ” button.

Press the “TIME ADJ” button twice.The setting of “ON Time” is completed and the present time appears on the LCD.

•

Set the “ON Timer” : Press the Timer fixing button “ON”.

OFF Timer operation

•

Press the ON/OFF switch. Right after replacing new batteries, set the present time in advance.

•

Set the “OFF T ime” : Press the “TIME ADJ” button 3 times.

Adjust the time with the “ , ” button.

Press the “TIME ADJ” button once.The setting of “OFF Time” is completed and the present time appears on the LCD.

•

Set the “OFF Timer” : Press the Timer fixing button “OFF”.

Sleep Timer operation

•

Press the “SLEEP” button during the operation.

•

Set the operating period by pressing the “SLEEP” button until the period designated appears on the LCD.

Timer Cancellation

•

ON/OFF Timer : Press the Timer fixing button “ON”(On Timer) and/or “OFF”(Off Timer) once again.

•

Sleep Timer : Press the “SLEEP” button until the operating period on the LCD disappears.

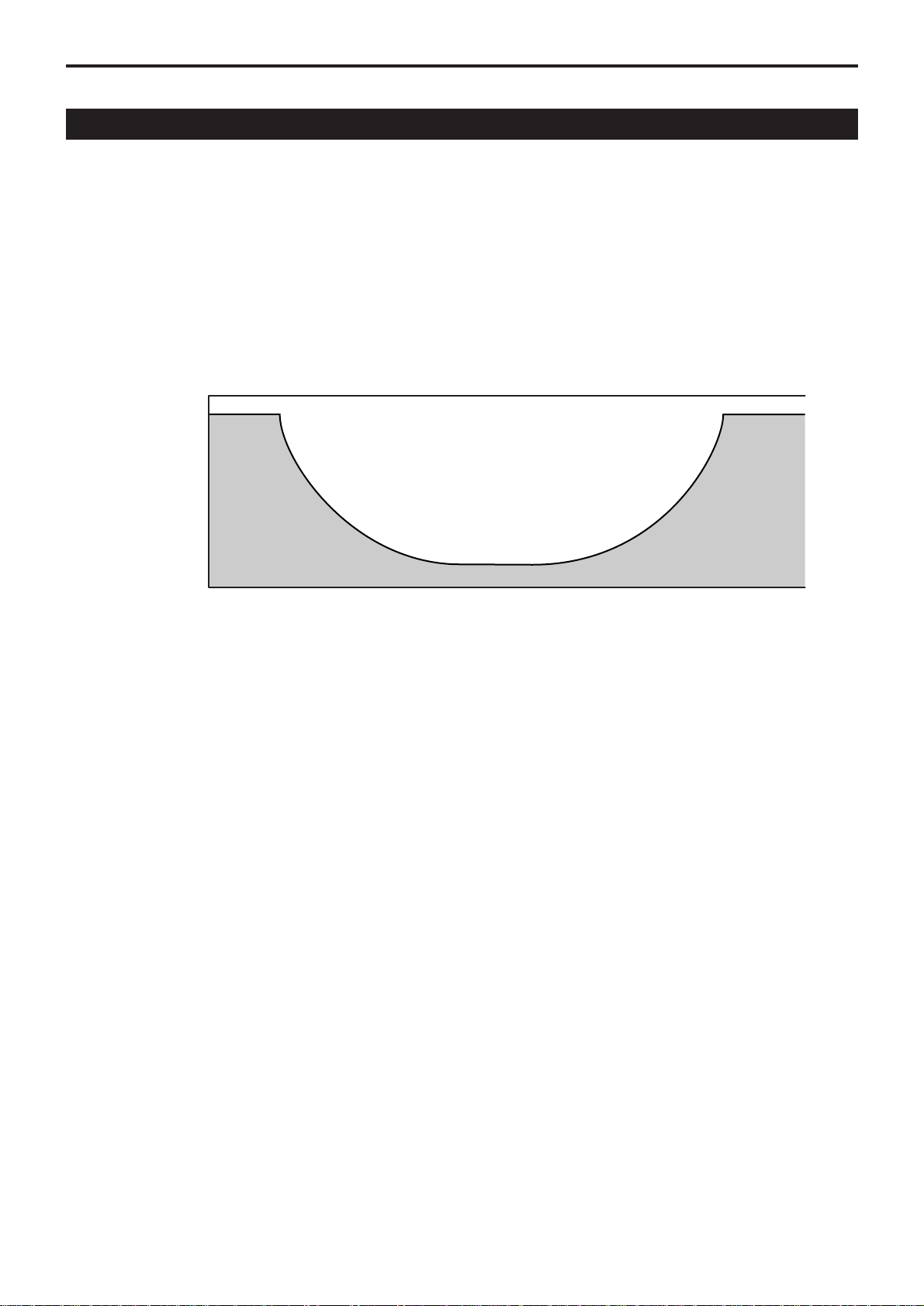

AIRFLOW DIRECTION CONTROL

Vertical adjustment

When ON/OFF switch is pressed, the vertical louver will move to the adequate positions for each operation

automatically.

Swing of air flow

If air flow direction switch is pressed once, the vertical louver will move within the range of figures.

Fixing the flow direction

If air flow direction switch is pressed again, the vertical louver will be fixed and that position is memorized.

From the next operation the louver will be set at previous position automatically.

Notes :

•

In Swing Mode, the louver automatically moves up and down within the certain range, as the illustration below .

•

There is two different ranges of louver swinging; one is of cooling & dry mode operation and the other is of

heating operation.

Standard Position

Approx.10 degrees

(Cooling/Dry)

Approx.70 degrees

(Heating)

Level

Swing of Air Flow

Level

Approx.10

degrees

Approx.40

degrees

Cooling

Dry

Heating

– 10 –

Approx.45

degrees

Approx.70

degrees

AIRFLOW DIRECTION CONTROL

OPERATION DETAILS

Horizontal Adjustment

Swing of Air Flow

The horizontal louver will keep moving steadly right and left if the horizontal louver button is pressed once.

Fixing the Flow Direction

The horizontal louver will come to a halt if the horizontal louver button is pressed once again.

NOTICE :

•

Dew drops may appear at the outlet under high humidity(e.g.during rainy season) if the system is operated

with the horizontal louver faced to the extreme right or left.

•

Use the wireless remote control unit without fail to change the angle of the horizontal louver. The horizontal

louver may move out of the normal range if forced by hands.

TAN/TAG-A53EWI

TIME DELAY SAFETY CONTROL FUNCTION - FOR PROTECTION OF COMPRESSOR

•

Compressor will not restart, in any operation modes, for 3 minutes after its stop.

•

Compressor does not stop during the first 6 minutes of its operation even if the room temperature reaches to

the designated temperature, except changing setting temperature.

COOLING MODE OPERATION

•

The compressor will stop when operational frequency reached the minimum frequency and that condition has

been kept for 6 minutes and the room temperature becomes 1℃ lower than it was set.

•

The compressor will re-start when room temperature becomes 0℃ higher than it was set.

•

The operational frequency will be set every ★1 seconds of operation.

The operational frequency setting will be calculated based on the deviation of the room temperature and the

set temperature on one end and the deviation factor at the time of previous setting on another.

Room temperature

Designated

temperature

0˚C

-1˚C

MAX

★2

Frequency of

compressor

MAX

★2

0

Hz

TAN/TAG-A28EWI, TAN/TAG-A32EWI

TAN/TAG-A53EWI

MIN★3

– 11 –

★1

40

120

MIN★3

★2

90Hz

100Hz

★3

24Hz

10Hz

OPERATION DETAILS

TAN/TAG-A28EWI, TAN/TAG-A32EWI

DRY MODE OPERATION

• Compressor stops when the room temperature fall to 0.3°C lower than the designated temperature

continuously for 2 minutes.

• Compressor restarts when room temperature rises to the designated temperature.

• The operating frequency of the compressor is determined according to the room temperature

(see the diagram below).

Indoor fan

Designated

temperature

+6.0

+5.3

+4.7

+4.0

+3.3

+2.7

+1.7

+1.0

+0.0

-0.7

Designated

Fan blow

Super

low

Stop

Room temperature

2min.

Super

low

Designated Fan blow

Operating

frequency of

compressor

Indoor fan

98Hz 90Hz

70

66

62

58

5252

4848

Selected

speed

Super

low

OFF

(3min.)

Super

low

Selected speed

– 12 –

OPERATION DETAILS

TAN/TAG-A53EWI

DRY MODE OPERATION

•

During dry mode operation, both motors (TAN,TAG) run proportionally according to the temperatures (indoor,

outdoor).

•

The compressor runs continuously while unit is operating. (see the diagram below)

MAX

30Hz

Operating

frequency of

compressor

MAX

30Hz

MIN15Hz

– 13 –

Loading...

Loading...