Page 1

MESA

DME-M90ASSX

DME-M90AMBX

DME-M90ASGX

www.zephyronline.com

RANGE HOOD - Installation instructions

ENGLISH..........................3

FRANÇAIS.......................27

Page 2

Page 3

Table of Contents

SAFETY INSTRUCTIONS..................................................................................................pag. 4

LIST OF MATERIALS...........................................................................................................pag. 8

DUCTING CALCULATION SHEETS.......................................................................................pag. 9

HOOD SPECIFICATION..................................................................................................pag. 10

INSTALLATION

- INTERNAL BLOWER.....................................................................................pag. 11

- EXTERNAL & IN-LINE BLOWER PREPARATION...............................pag. 14

- DUCTING OPTIONS.....................................................................................pag. 17

- MOUNTING THE RANGE HOOD.............................................................pag. 18

- POWER SUPPLY CONNECTION..............................................................pag. 19

TOUCH CONTROL............................................................................................................pag. 20

OPTIONAL REMOTE CONTROL..................................................................................pag. 21

MAINTENANCE ................................................................................................................pag. 22

WIRING DIAGRAMS........................................................................................................pag. 23

LIST OF PARTS AND ACCESSORIES ........................................................................pag. 25

WARRANTY .......................................................................................................................pag. 26

- 3 -

Page 4

Safety instructions 1/4

IMPORTANT SAFETY INSTRUCTIONS

FOR RESIDENTIAL USE ONLY

READ AND SAVE THESE INSTRUCTIONS

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

IMPORTANT: Save these Instructions for the Local Electrical Inspectors use.

INSTALLER: Please leave these Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

Take care when using cleaning agents or detergents.

Suitable for use in household cooking area.

WARNING - To reduce the risk of fire or electric shock, do not use this fan with

any Solid-State Speed Control Device.

CAUTION - To reduce risk of fire and to properly exhaust air, be sure to duct

air outside – Do not vent exhaust air into spaces within walls or ceilings or into

attics, crawl spaces, or garages.

CAUTION - For general ventilating use only. Do not use to exhaust hazardous

or explosive materials and vapors.

CAUTION - To avoid motor bearing damage and noisy and/or unbalanced im-

pellers, keep drywall spray, construction dust, etc. off power unit.

CAUTION - Please read specification label on product for further information

and requirements.

WARNING – TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended by the manufacturer. If you have

questions, contact the manufacturer.

B. Before servicing or cleaning unit, switch power off at service panel and lock

the service disconnecting means to prevent power from being switched on

accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

WARNING - TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

A. Never leave surface units unattended at high settings. Boilovers cause smok

- 4 -

Page 5

Safety instructions 2/4

ing and greasy spillovers that may ignite. Heat oils slowly on low or medium

settings.

B. Always turn hood ON when cooking at high heat or when flambeing foods

( i.e. Crepes Suzette, Cherries Jubilee, Peppercorn Beef Flambè ).

C. Clean ventilating fans frequently. Grease should not be allowed to accumulate

on fan or filter.

D. Use proper pan size. Always use cookware appropriate for the size of the

surface element.

E. Keep fan, filters and grease laden surface clean.

F. Use high range setting on range only when necessary. Heat oil slowly on low

to medium setting.

G. Don’ t leave range unattended when cooking.

H. Always use cookware and utensils appropriate for the type and amount off

food being prepared.

WARNING – TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A

RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWINGa:

A. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then

turn off the burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go

out immediately, EVACUATE AND CALL THE FIRE DEPARTMENT.

B. NEVER PICK UP A FLAMING PAN – You may be burned.

C. DO NOT USE WATER, including wet dishcloths or towels – a violent steam ex-

plosion will result.

D. Use an extinguisher ONLY if:

1. You know you have a Class ABC extinguisher, and you already know how to

operate it.

2. The fire is small and contained in the area where it started.

3. The fire department is being called.

4. You can fight the fire with your back to an exit.

a

Based on “kitchen firesafety tips” published by NFPA

Proper maintenance of the Range Hood will assure proper performance of

the unit.

INSTALLATION INSTRUCTIONS

WARNING – TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

A. Installation work and electrical wiring must be done by qualified person(s) in

accordance with all applicable codes and standards, including fire-rated construction.

- 5 -

Page 6

Safety instructions 3/4

B. Sufficient air is needed for proper combustion and exhausting of gases through

the flue (chimney) of fuel burning equipment to prevent back drafting. Follow

the heating equipment manufacturer’s guideline and safety standards such as

those published by the National Fire Protection Association (NFPA), and the

American Society for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

C. When cutting or drilling into wall or ceiling, do not damage electrical wir-

ing and other hidden utilities.

D. Ducted fans must always be vented to the outdoors.

E. This unit must be grounded.

WARNING - TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

WARNING - UNDER CERTAIN CIRCUMSTANCES DOMESTIC APPLIANCES MAY

BE DANGEROUS.

A. Do not check filters with hood working.

B. Do not touch the lamps after a prolonged use of the appliance.

C. No food must be cooked flambè underneath the hood.

D. The use of an unprotected flame is dangerous for the filters and could cause

fires.

E. Watch constantly the fried food in order to avoid the cooking oil flares up.

F. Before performing any mainteinance operation, disconnect the hood from

the electrical service.

The manufacturers will not to accept any responsibility for eventual damages,

because of failure to observe the above instructions.

Electrical Requirements

Important:

- Observe all governing codes and ordinances.

- It is the customer’s responsibility to be aware of these below:

- To contact a qualified electrical installer.

- To assure that the electrical installation is adequate and in conformance with

National Electrical Code, ANSI/NFPA 70 latest edition* or CSA standards C22.194, Canadian Electrical Code, Part 1 and C22.2 No.0-M91 - latest edition** and

all local codes and ordinances.

- If codes permit and a separate ground wire is used, it is recommended that a

qualified electrician determine that the ground path is adequate.

- Do not ground to a gas pipe.

- Check with a qualified electrician if you are not sure the range hood is properly grounded.

- 6 -

Page 7

Safety instructions 4/4

- Do not have a fuse in the neutral or ground circuit.

- This appliance requires a 120V 60Hz electrical supply and connected to an

individual properly grounded branch circuit protected by a 15 or 20 ampere

circuit breaker or time delay fuse. Wiring must be 2 wire with ground. Please

also refer to Electrical Diagram on product.

- A cable locking connector (not supplied) might also be required by local codes. Check with local requirements, purchase and install appropriate connector

if necessary.

* National Fire Protection Association Batterymarch Park, Quincy, Massachusetts

02269

** CSA International 8501 East Pleasant Valley Road, Cleveland, Ohio 44131-5575

Federal Communication Commission Interface Statement

- This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation.

- This equipment generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined

by turning the equipment off and on, the user is encouraged to try to correct

the interference by one of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

WARNING Prop. 65 Warning for California Residents: This product may

contain chemicals known to the State of California to cause cancer, birth defects,

or other reproductive harm.

- 7 -

Page 8

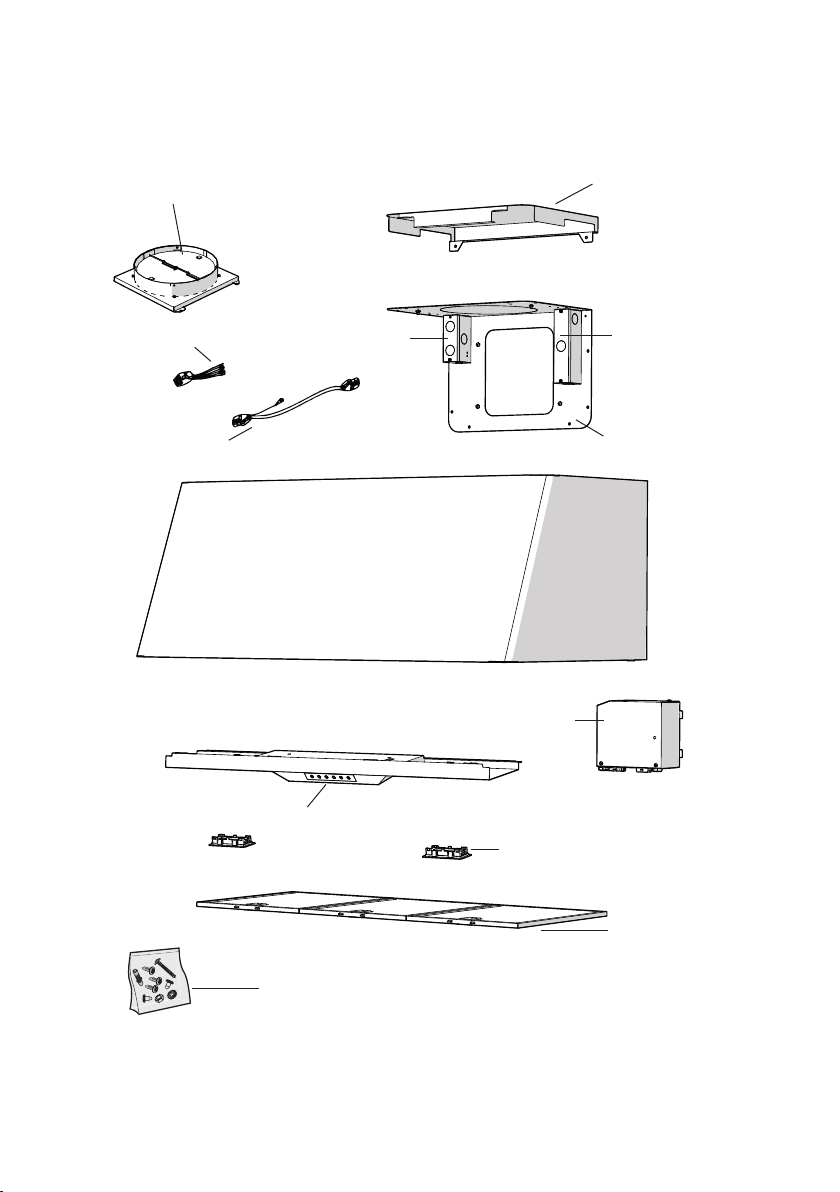

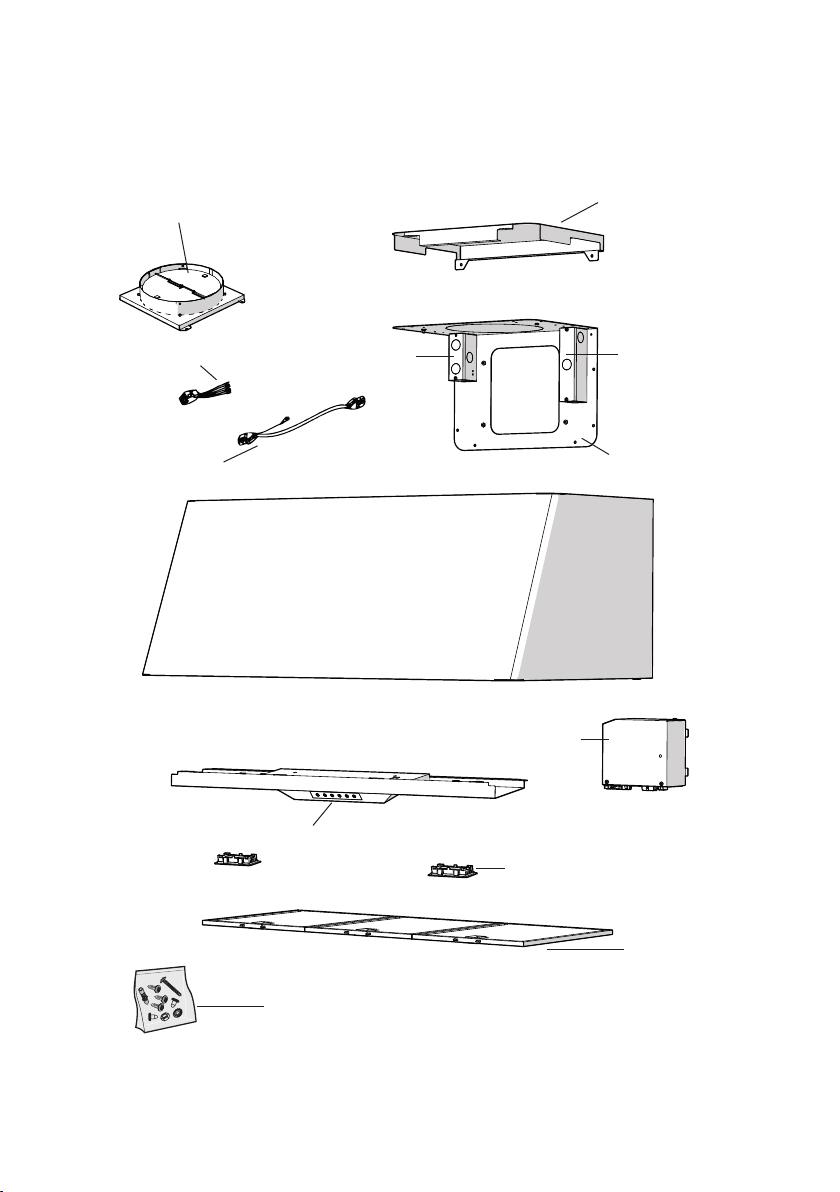

List of Materials

Remote Blower

Collar with Damper

Remote Blower

Wiring Harness

Remote Blower

Wiring Extension

Box marked

'120 VAC input'

Top Cover

Remote Blower

Box

Blower Bracket

Electrical

System Box

Control

Hardware

Led Light

Hybrid Baffle Filters

- 8 -

Page 9

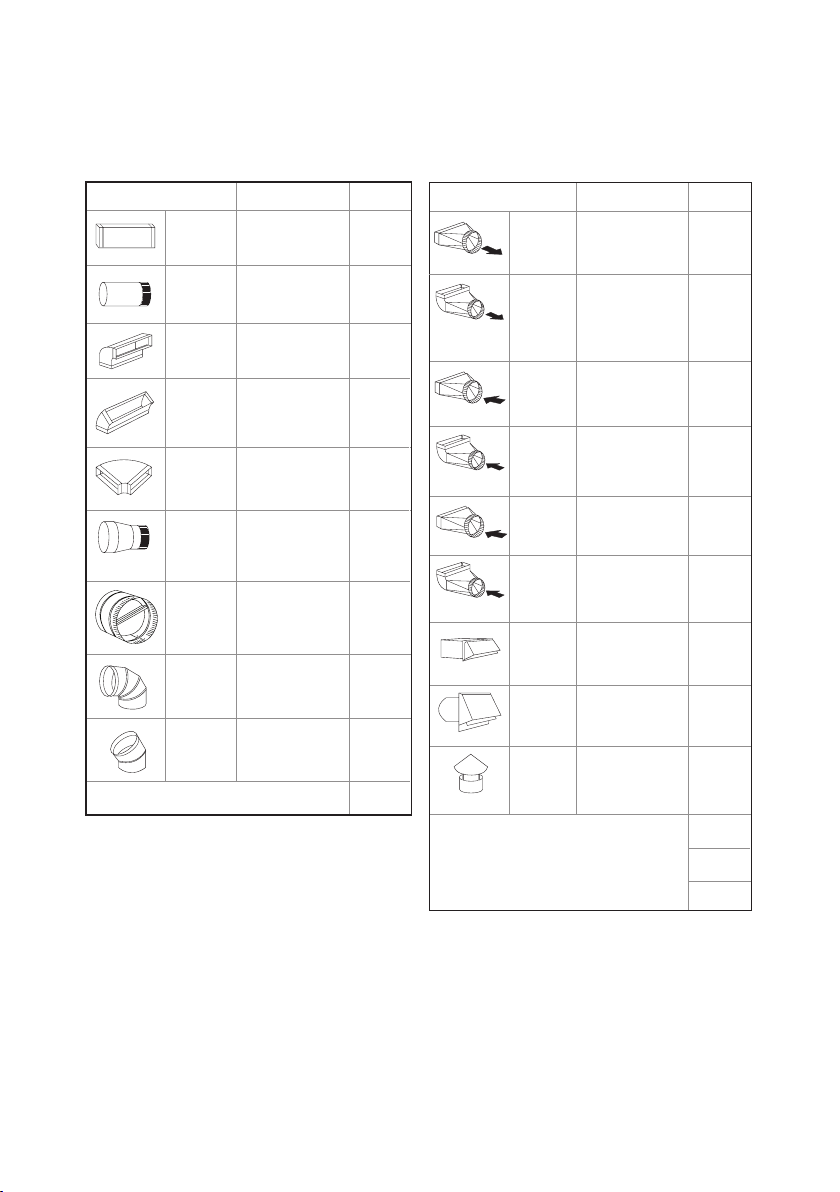

Ducting Calculation Sheet

Equivalent number

Duct pieces

3- 1/ 4” x 10”

Rect.,

straight

6”, 7”, 8”, 10”

Round,

straight

3- 1/ 4” x 10”

0

Rect. 90

elbow

3- 1/ 4” x 10”

0

Rect. 45

elbow

3- 1/ 4” x 10”

0

Rect. 90

flat elbow

7” to 6” or

8” to 7” Round

tapered

reducer

6”, 7“, 8”

Round

in-line

damper

6”, 7”, 8”, 10”

Round,

0

90

elbow

6”, 7”, 8”, 10”

Round,

0

45

elbow

Subtotal column 1 =

length x used =

1 Ft. x ( ) =

1 Ft. x ( ) =

15 Ft. x ( ) =

9 Ft. x ( ) =

24 Ft. x ( ) =

25 Ft. x ( ) =

15

Ft. x ( ) =

15 Ft.

x ( ) =

9 Ft. x ( ) =

To tal

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Duct pieces

3- 1/ 4” x 10”

Rect. to

6” round

transition

3- 1/ 4” x 10”

Rect. to

6” round

transition

0

elbow

90

6” round to

3- 1/ 4” x 10”

rect.

transition

6” round to

3- 1/ 4” x 10”

rect.

transition

0

elbow

90

7” round to

3 1/ 4” x 10”

rect.

transition

7” round to

3- 1/ 4” x 10”

rect.

transition

0

elbow

90

3- 1/ 4” x 10”

Rect.

wall cap

with damper

6”, 7”, 8”, 10”

Round, wall

cap with

damper

6”, 7”, 8”, 10”

Round

roof cap

Equivalent number

length x used =

5 Ft. x ( ) =

20 Ft. x ( ) =

1 Ft. x ( ) =

16 Ft. x ( ) =

8 Ft. x ( ) =

23 Ft. x ( ) =

30 Ft. x ( ) =

30 Ft. x ( ) =

30 Ft. x ( ) =

To tal

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Maximum Duct Length: For satisfactory air movement,

the total duct length

should not exceed 150 equivalent feet.

- 9 -

Subtotal column 2 =

Subtotal column 1 =

Totalductwork =

Ft.

Ft.

Ft.

Page 10

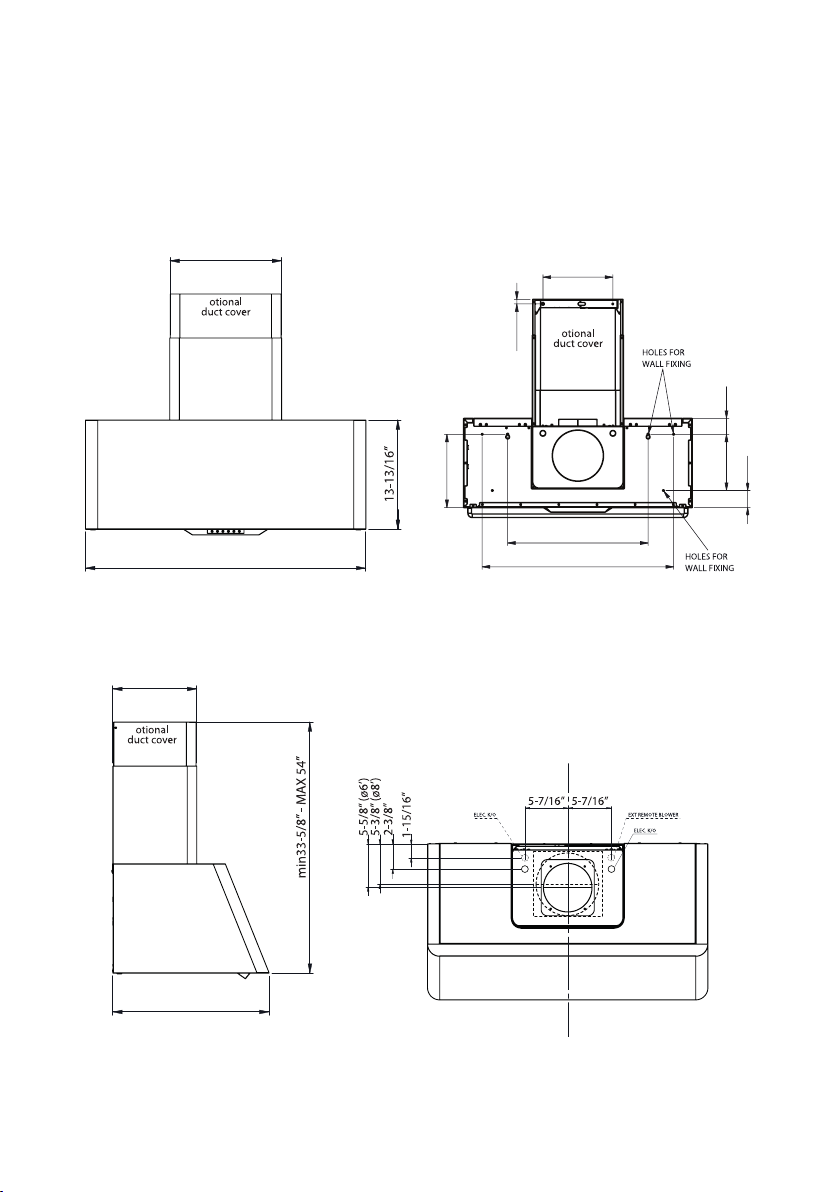

14-1/16”

Hood Specifications

10-9/16”

front of hood

35-5/16”

side of hood

11-5/16”

back of hood

10-13/16”

11/16”

21-3/4”

29-5/8”

top of hood

2-7/16”

2-5/8”

8-11/16”

19-11/16”

- 10 -

Page 11

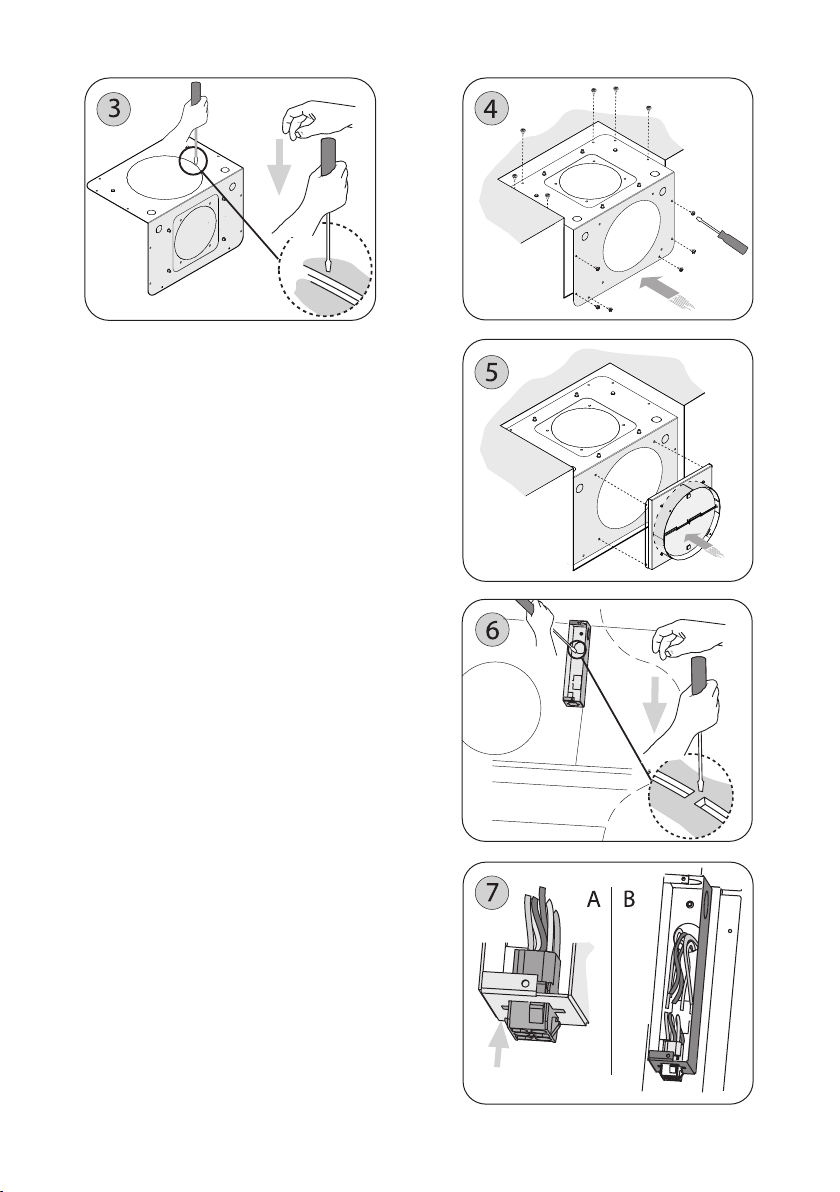

Installation - Internal Blower

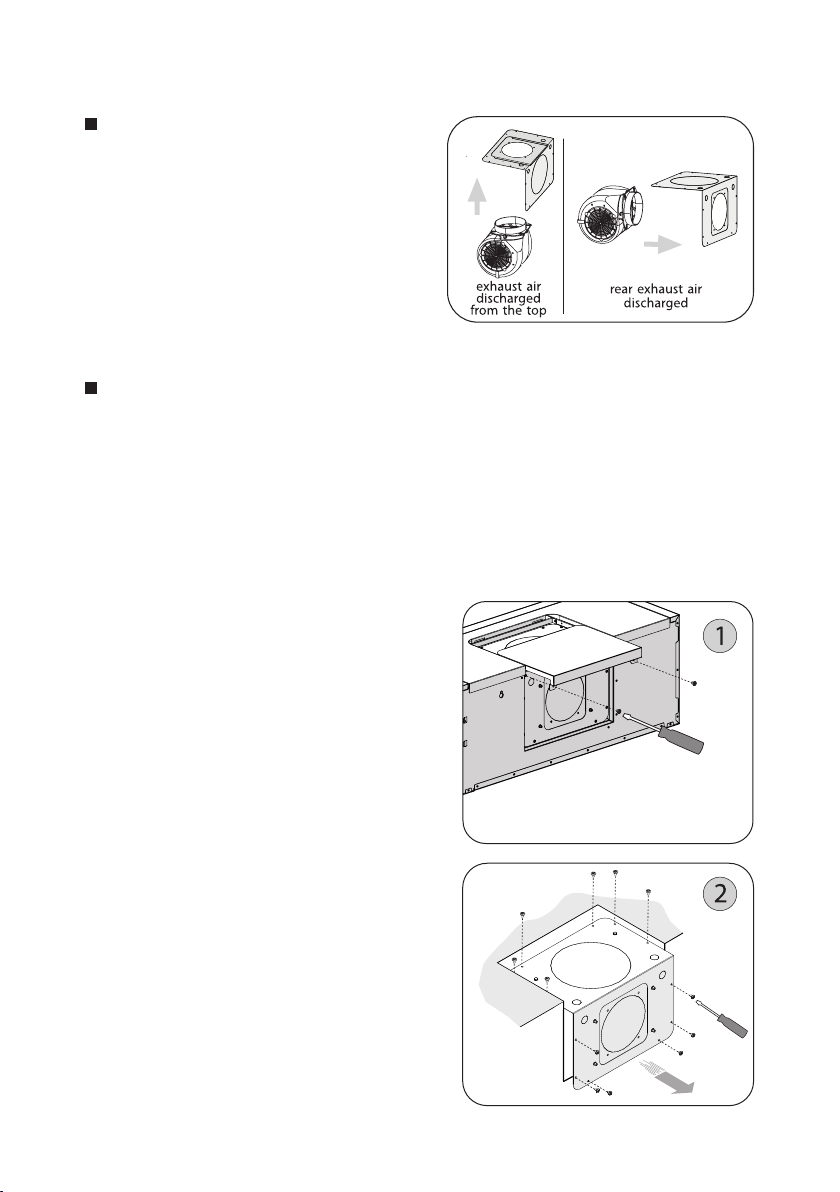

NOTE! The device in this version (with

internal suction blower) is equipped for

rear discharge of exhaust air. However,

if required, it is possible to have the

exhaust air discharged from the top.

This can be accomplished by carrying

out the steps indicated in the following paragraphs; upon reaching step 8,

the motor plate must not be rotated.

The following instructions are for installing the internal blower.

CAUTION: To reduce the risk of fire and electric shock, install this rangehood

only with internal blower models CBI-290A or CBI-600A.

For external and in-line blower preparation please turn to page 14.

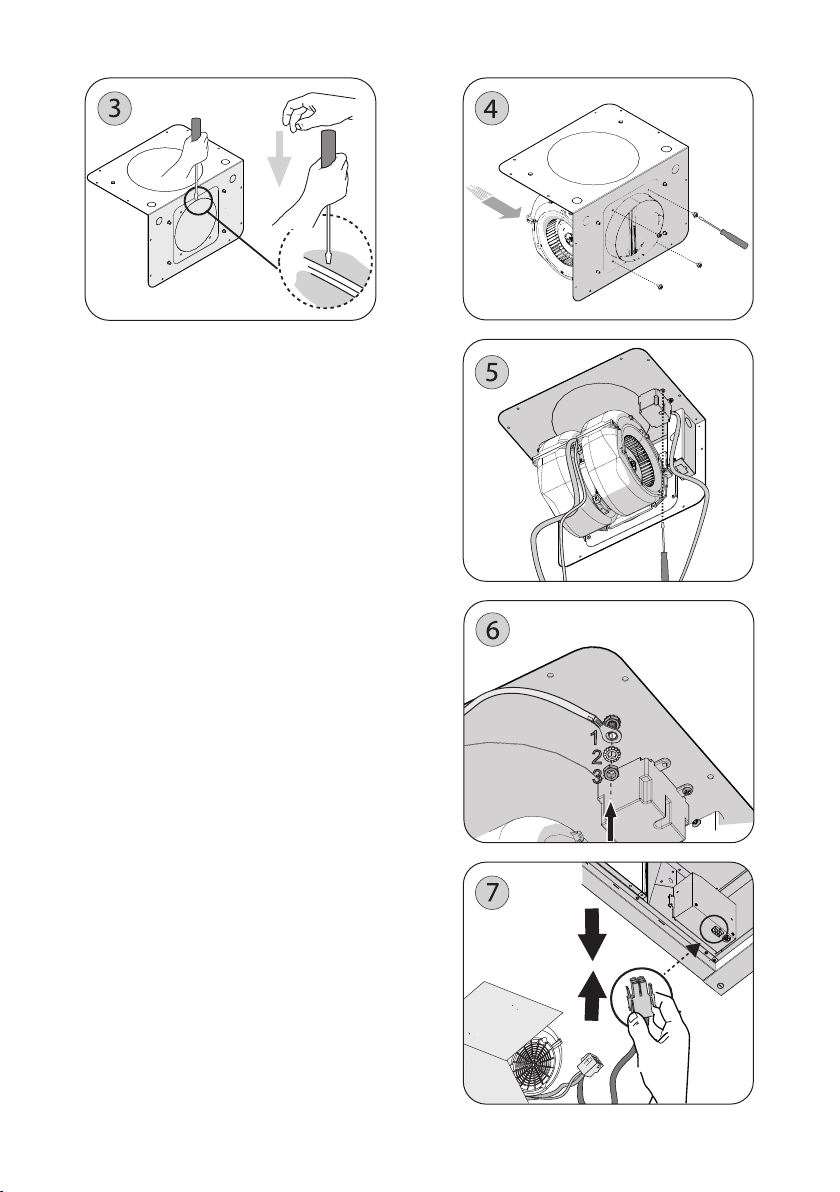

1. Remove the (2) screws securing the top

cover. See Fig.1

2. Remove the 6” round metal knockout

plate from the blower plate by using a

flat head screwdriver. See Fig.2

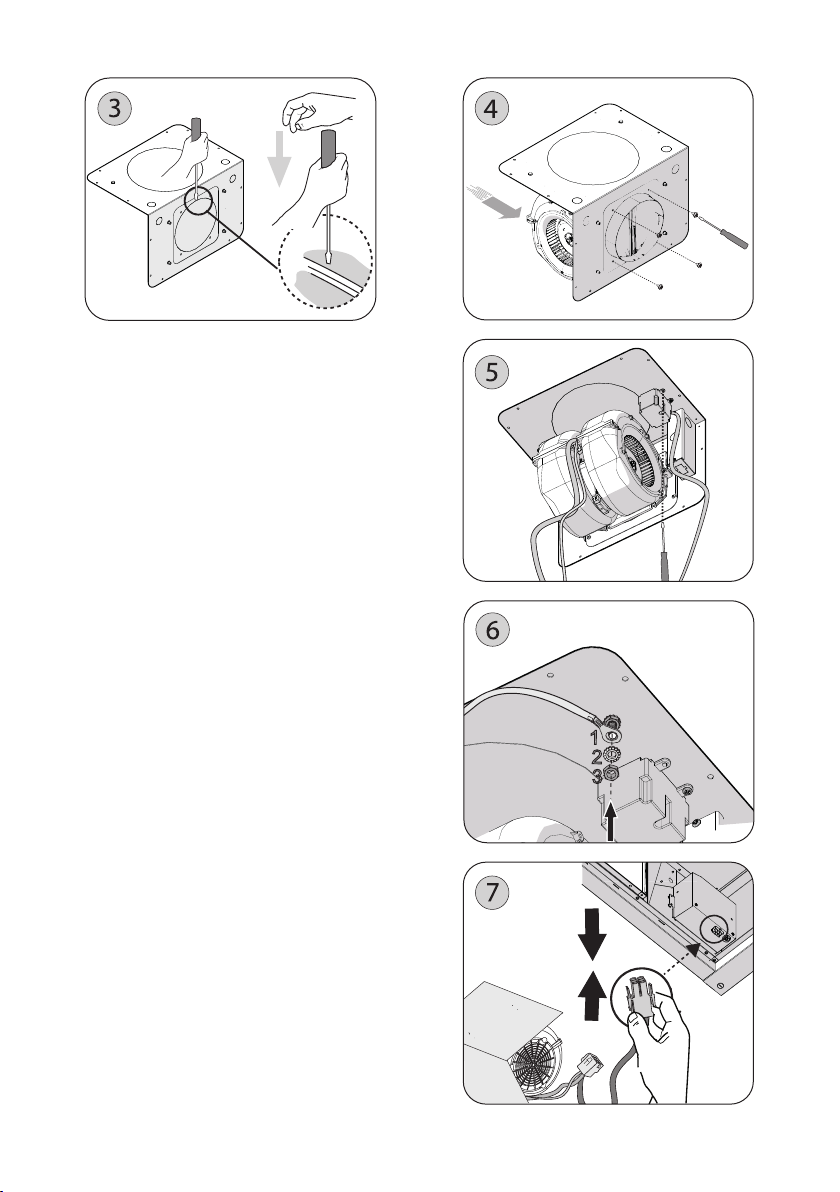

3. Remove the (6) screws securing the blo-

wer plate to the blower housing and remove blower plate. See Fig.3

4. Install internal blower into blower plate

and secure using (4) screws included

with the blower. See Fig.4

- 11 -

Page 12

5. Secure capacitor box connected to the

provided cable to the blower plate using

(2) screws included with the blower. See

Fig.5

6. Secure Green/Yellow ground wire con-

nected to the cable to the provided capacitor to blower plate. Fig.6

7. Attach the 6 pin male molex connector

from blower wire to the 6 pin female molex connector located inside the blower

housing. See Fig.7

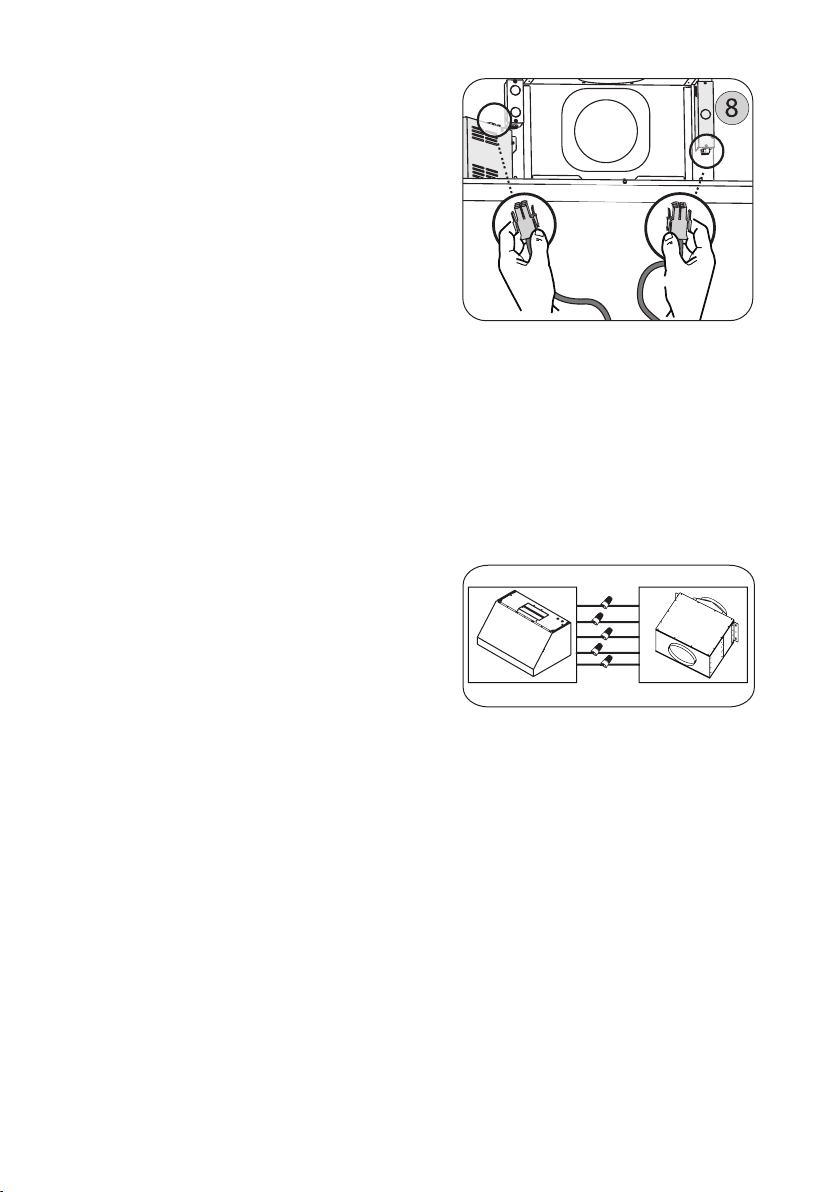

8. Install the blower and plate on the inside

of the blower housing: carry out the instructions at step 2 in reverse order then

use the screws provided to complete installation. (Tot. 12). Fig.8

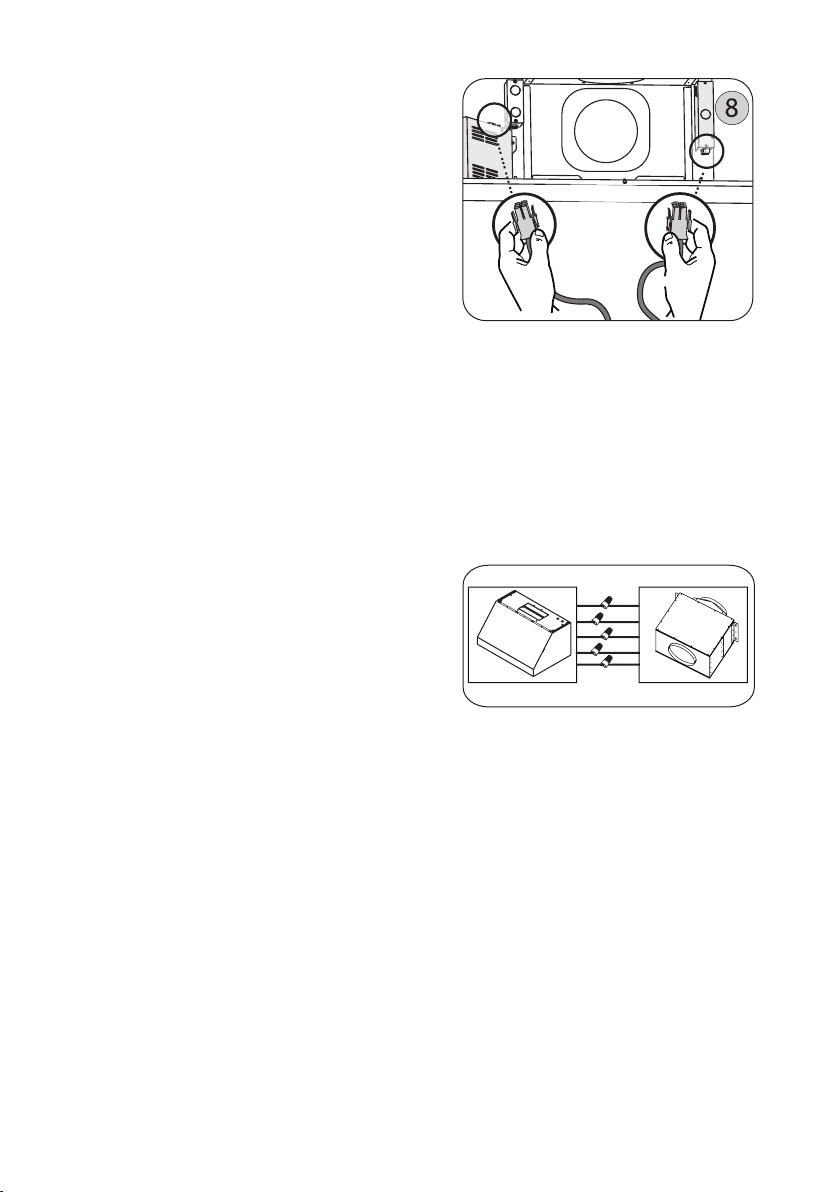

9. Connect 9 pin male molex connector

from blower wire to 9 pin female molex

connector on the capacitor wire. See

Fig.9

- 12 -

Page 13

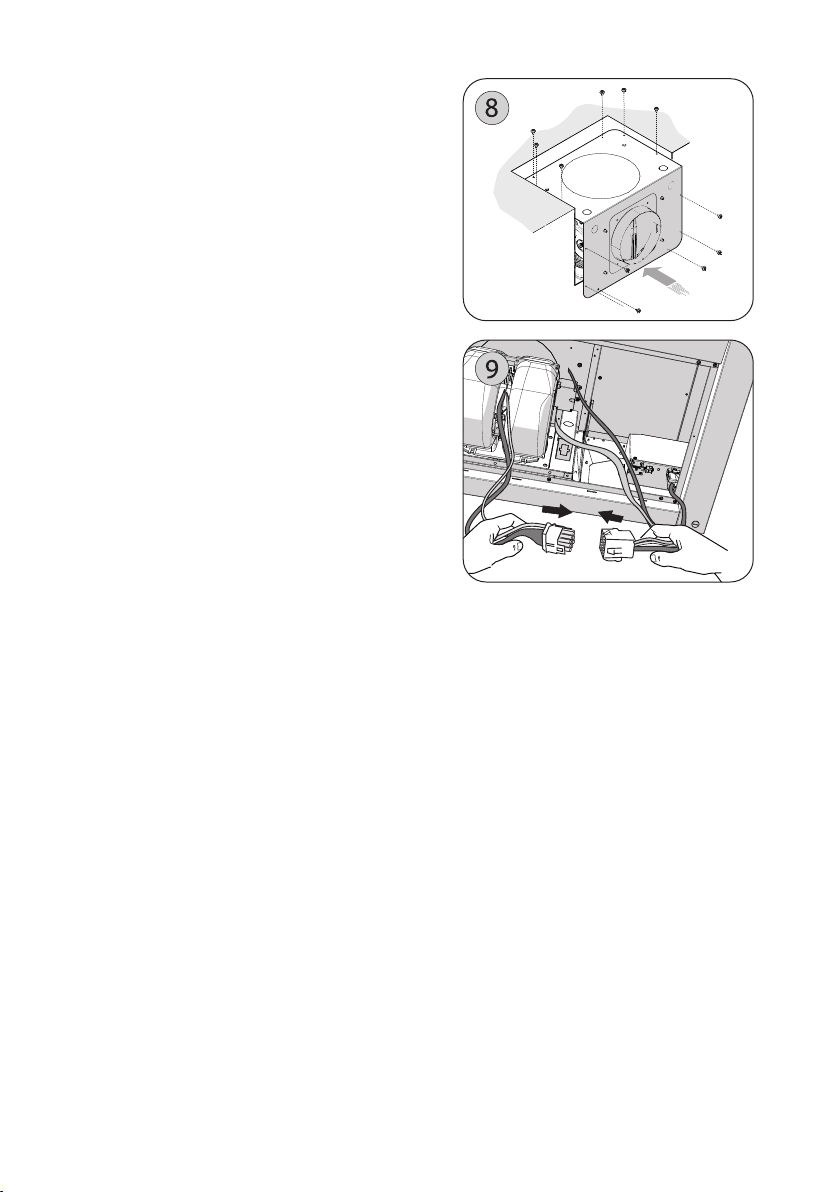

WARNING! Place electrical wiring inside

the blower housing.

10. Put the top cover back on.

The hood is now ready to be installed on

the wall.

- 13 -

Page 14

Installation - External & In-Line Blower

Preparation

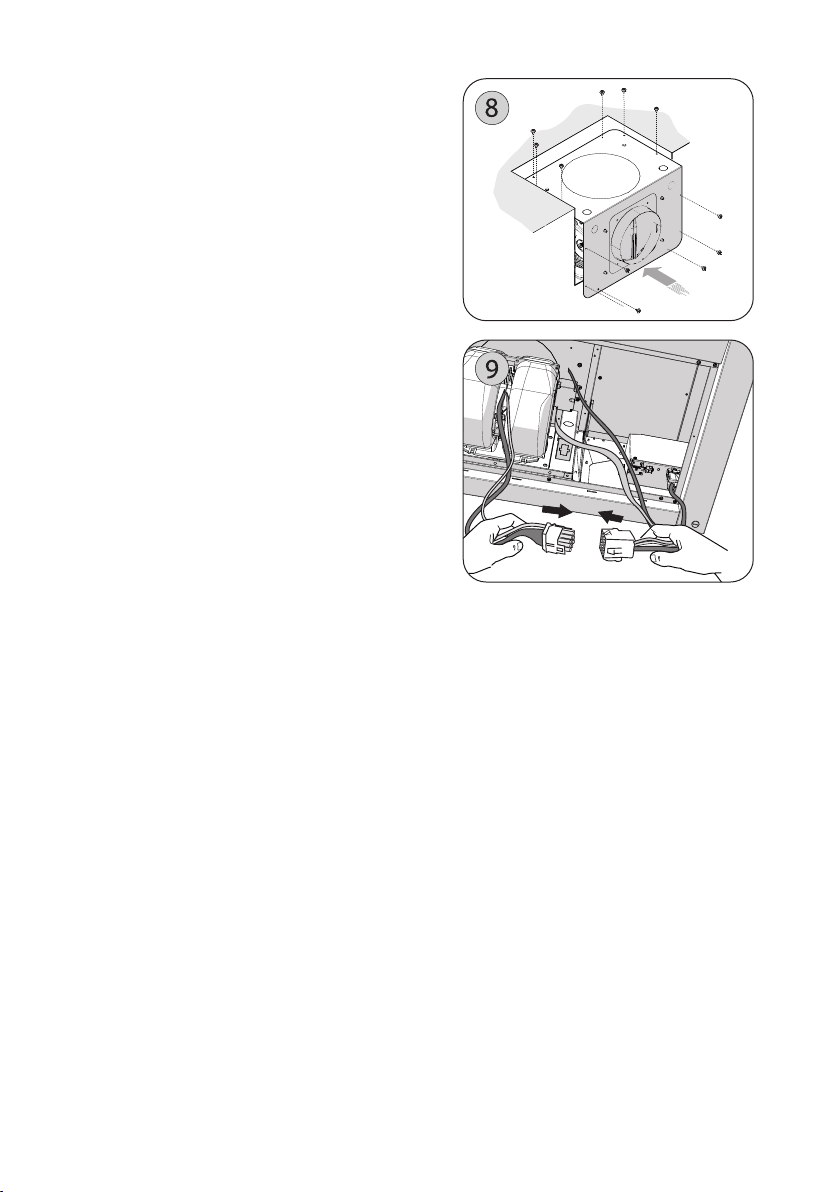

NOTE! The device in this version

(with external blower) is equipped for

rear discharge of exhaust air. However,

if required, it is possible to have the

exhaust air discharged from the top.

This can be accomplished by carrying

out the steps indicated in the following paragraphs; upon reaching step 4,

the blower plate must be rotated and

installed in the opposite direction.

The following instructions are for preparing the hood for use with an external or in-line blowers models CBE-1000 or PBN-1000A.

CAUTION: To reduce the risk of fire and electric shock, install this rangehood

only with remote blowers rated maximum 6.2 A.

For internal blower instructions please turn to page 11.

1. Remove the (2) screws securing the top

cover. See Fig.1

2. Remove the (6) screws securing the blo-

wer plate to the blower housing and

remove blower plate. See Fig.2

3. Remove the 8” round metal knockout

plate from the blower plate by using a

flat head screwdriver. See Fig.3

4. Install the plate with the outlet facing

the wall, inside the motor casing: carry

out the instructions at stage 2 in reverse order then use the screws provided

to complete installation. (Tot. 12). See

Fig.4

- 14 -

Page 15

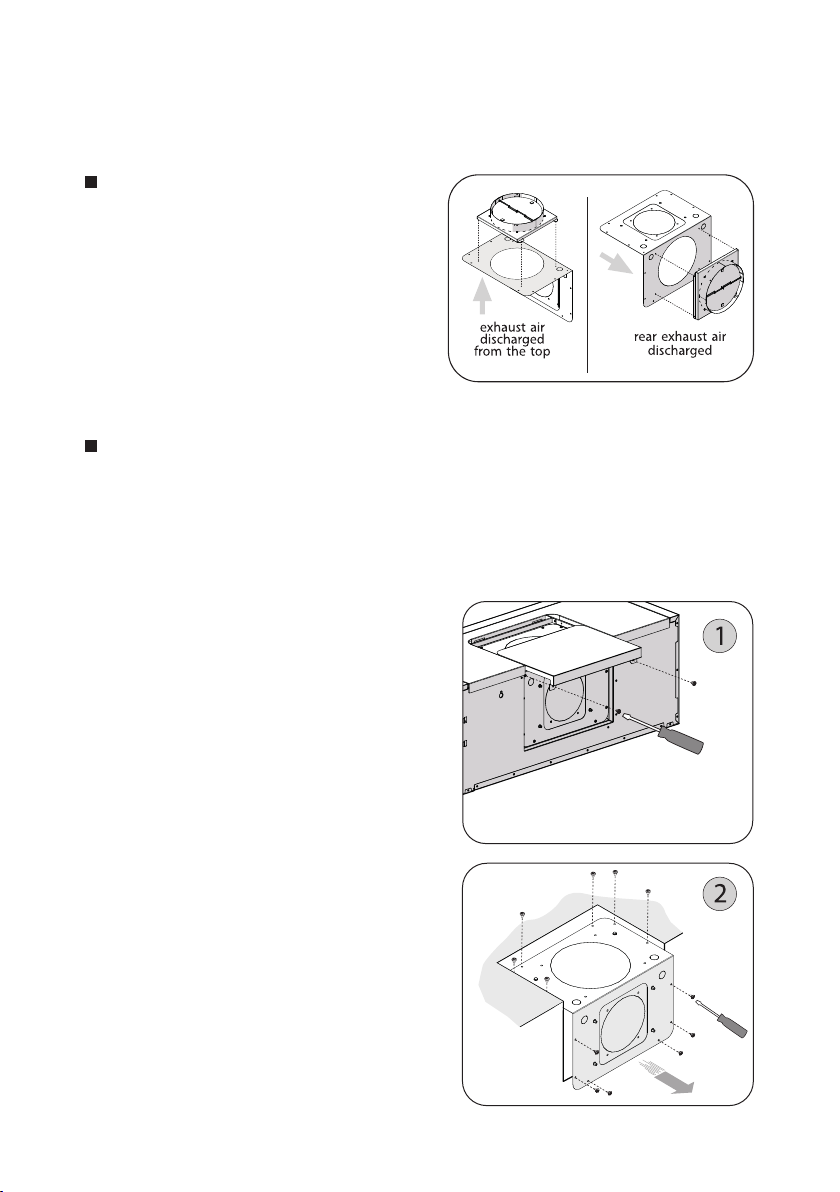

5. Install the flange and fix it to the blower

plate with the (4) screws. Fig. 5

6. Put the top cover back on.

7. With the aid of a slotted screwdriver, bre-

ak the grommet of circular hole through

which the wires pass. Fig. 6

8. Insert the female connector in the ter-

minal box already attached to the hood.

Fig. 7A

Pass the wires of the remote motor throu-

gh the terminal box hole and connect

them to the connector wires. Fig.7B

Note: Carry out the power supplly con-

nection in accordance with the national

electric code, ANSI/NFPA 70-1999.

Note1: A cable lock (not included) may be

required by local codes. Please review

local codes for more information.

- 15 -

Page 16

9. Attach 6 pin male molex connectors to 6

pin female molex connectors inside blower housing. See Fig. 8

Note2: Check local codes to determine

minimum wire gauge.

See manual included with external and

in-line blower for instructions on installing the blower.

- 16 -

Page 17

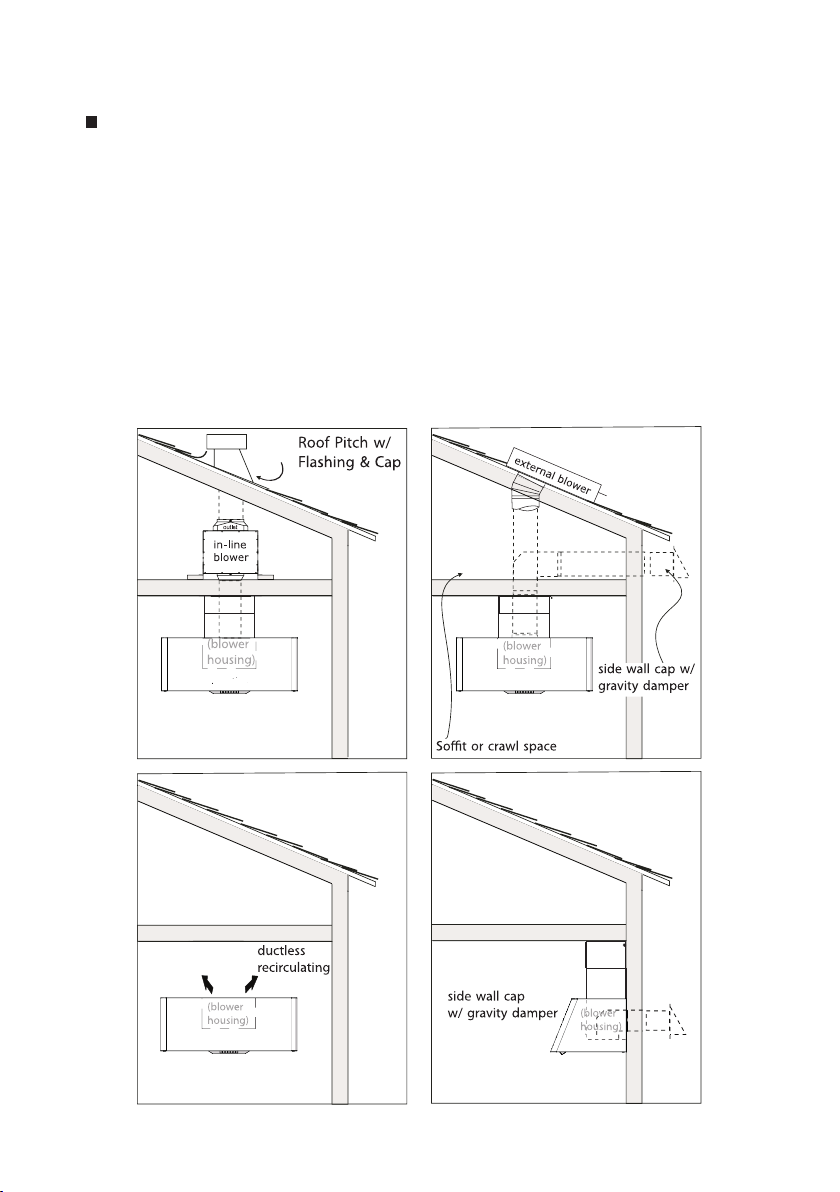

Installation - Ducting Options

WARNING FIRE HAZARD

NEVER exhaust air or terminate duct work into spaces between walls, crawl

spaces, ceiling, attics or garages.

All exhaust must be ducted to the outside, unless using the recirculating option.

Use single wall rigid Metal ductwork only.

Fasten all connections with sheet metal screws and tape all joints w/ certified

Silver Tape or Duct Tape.

Some Ducting Options

- 17 -

Page 18

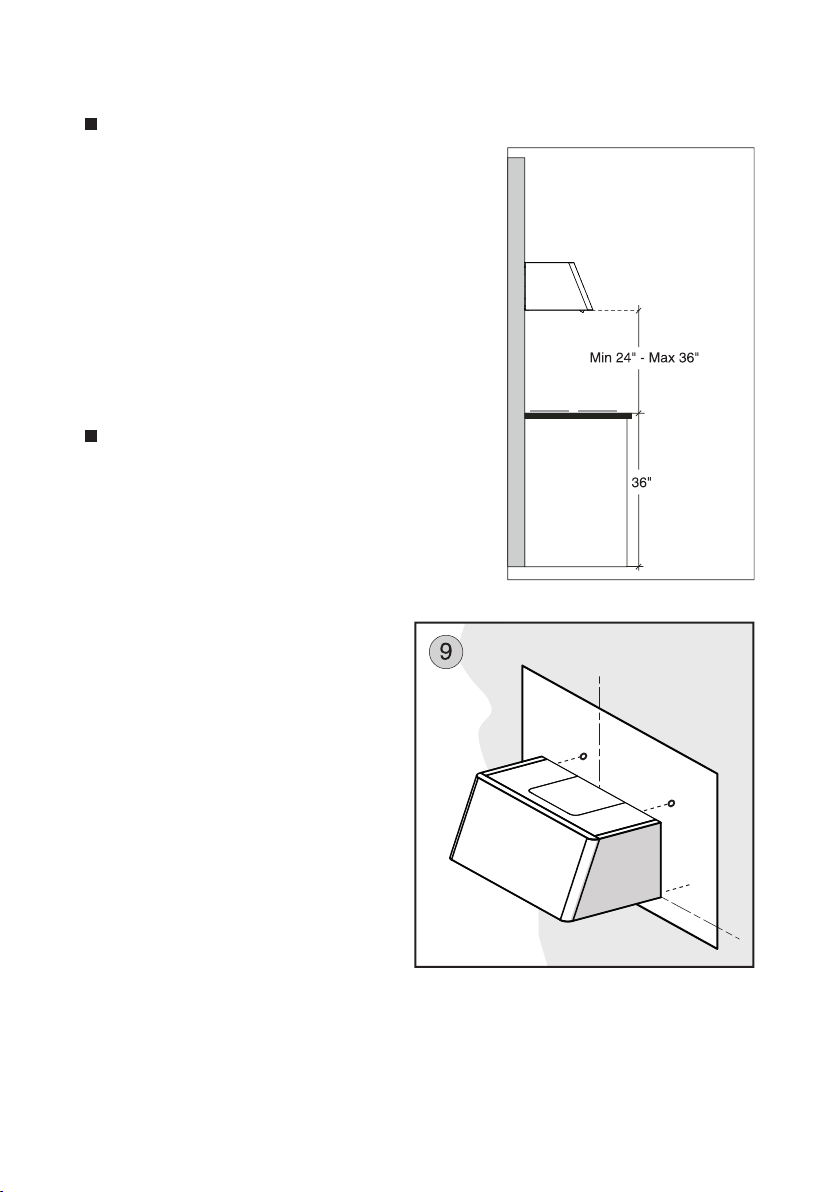

Installation - Mounting the Range Hood

MOUNTING HEIGHTS

The range hood must be installed at a minimum

height of 24 inches (61cm) from the cooking

surface. If a connecting duct work composed

of two parts is used, the upper part must be

placed outside the lower part. Do not connect

the range hood duct to the same duct used to

exhaust hot air or fumes from another appliance.

Before proceeding with the assembly instructions

remove the decorative mesh filters so that the

range hood is easier to handle.

MOUNTING TO THE WALL

1. Place the paper template included with your

hood on the wall to determine where to add

the screws for mounting the hood. Make sure

the bottom of the template aligns with the

bottom of where the hood will be located.

See Fig. 9

2. Lift the hood onto the screws and

adjust to make sure the hood is

level.

3. When the hood has been adjusted

tighten the screws to secure the

hood in place.

NOTE: Screws must be fastened into

wooden studs so wood blocking may

be necessary. If using wall anchors

make sure to check your local codes

for suitability and type of anchors

to use.

NOTE1: For the various installations use screws and screw anchors suited to the

type of wall (minimum screw size: 1/4" diameter x 2-3/4" length).

- 18 -

Page 19

Installation - Power Supply Connection

GENERAL

• Carefully read the following important information regarding installation

safety and maintenance. Keep this information booklet accessible for further

consultations.

POWER SUPPLY CONNECTION

For connection to the power supply refer to

the following:

1. Remove the power supply cover by un-

doing the (2) screws Fig. 1.

2. Connect the wires of the hood to those

of the power supply as described. Fig. 2 :

BLACK = L line

WHITE = N neutral

GREEN / YELLOW = G ground

- A double-pole switch properly rated must

be installed to provide the range hood power supply disconnection.

- Connect the electrical conduit to the Field

Wiring Compartment using listed conduit

fittings.

- Carry out the power supplly connection in

accordance with the national electric code,

ANSI/NFPA 70-1999.

3. Insert the wires into the box, then close

the box cover, securing it using the screws

that were previously removed.

- 19 -

Page 20

Touch Control

ABCDEF

A – Lights Button: Lights are three level (high, medium, low). From stand-by-on mode,

touch once for high, twice for medium, three times for low, four times to cycle back.

B - Delay Off Button: Press the Delay Off Button to enable the ten-minute delay-off

function, no matter at what speed the fan is running at. B button will start blinking

indicating the delay off function is enabled. After ten minutes the fan and lights will

turn off. Delay off function can be disabled by pressing B button, changing the speed,

or pressing the Power Button C.

C - Power Button: Press once to activate all button stand by mode allowing control of

other button functions. All buttons will illuminate indicating stand by mode. Press the

Power Button again to turn the hood off (fan and lights). The stand by mode will remain

active for 30 seconds.

D - Low Speed Button: In stand-by mode: Press once for low speed.

E - Medium Speed Button: In stand-by mode: Press once for medium speed.

F - High Speed Button: In stand-by mode: Press once for high speed.

MESH FILTER CLEAN REMINDER (always enabled): after 60 hours of fan usage, button

A blinks when the hood is in stand-by, indicating it is time to clean the mesh filters. To

Reset the function: with the hood in stand-by, press and hold the B button for 4 to 5

seconds, the A button will stop blinking, and the 60-hour timer will reset.

CHARCOAL FILTER REPLACE REMINDER (disabled by default, must be enabled by user

if recirculating hood): To enable Charcoal Filter Replacement Function hold buttons D

and F simultaneously for four seconds. The A button will quickly flash 3 times indicating

the Charcoal Filter Replacement Function is enabled. After 200 hours of fan usage, the B

button will blink while the hood is on, indicating it is time to replace the charcoal filters.

To Reset the Charcoal Filter Replace Reminder function: Hold the B button for 4 to 5

seconds until it stops flashing, and the 200-hour timer will reset.

Order replacement charcoal filter kit number Z0F-C010 through your local dealer, www.

zephyronline.com, or the Zephyr customer service department.

To disable the Charcoal Filter Replacement function, repeat the enable procedure, the A

button will illuminate for 3 seconds then turn off indicating the Charcoal Filter Replacement Function is disabled.

CLEAN AIR FUNCTIOn (disabled by default, must be enabled by the user). To enable

Clean Air function, with hood in stand by, press and hold button E for 4 to 5 seconds.

The E button will start blinking, the fan will turn on low speed for 10 minutes. After

10 minutes the fan will turn off and the 4-hour timer will begin. The E button led will

continue blinking when Clean Air Function is enabled, even if fan is not on. When Clean

Air function is enabled, every 4 hours of non-fan usage the fan will automatically turn

on at low speed for 10 minutes. After 10 minutes the fan will turn off and the 4-hour

timer will reset.

- 20 -

Page 21

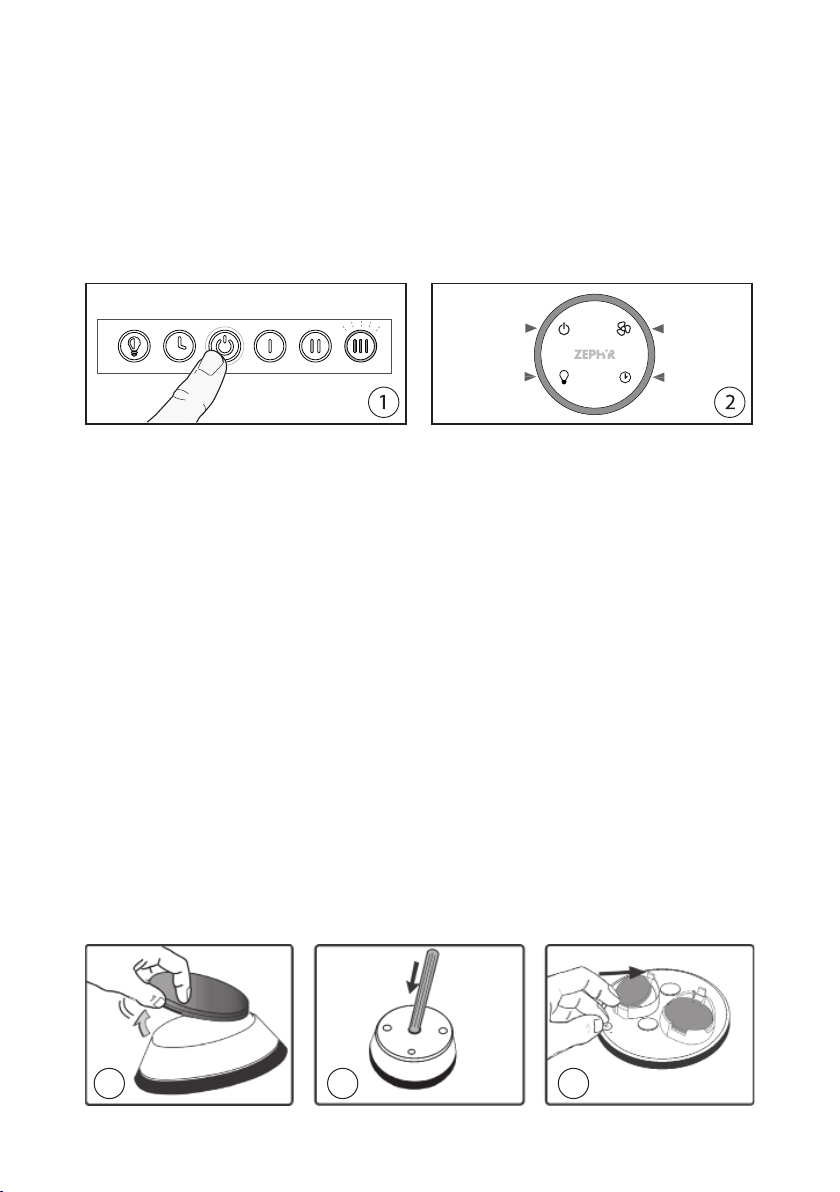

Optional Remote Control

SYNCHRONIZATION:

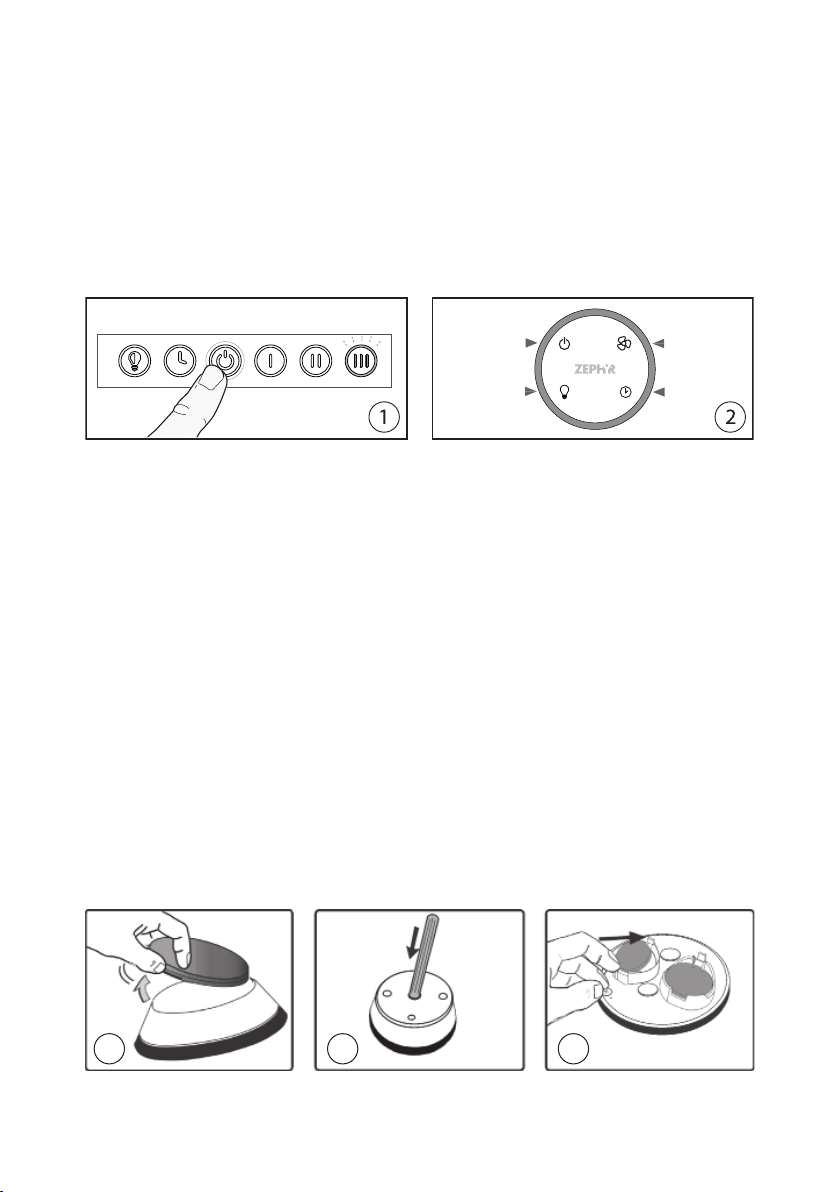

To synchronize the remote control with the range hood for the first time, proceed as follows:

1. With the range hood off, press and hold the “Power” on the hood for 4 seconds (Fig.1) until the

“3rd speed” indicator on the hood flashes for 3 times.

2. Press any button on the remote control within 4 seconds to confirm the link (Fig.2). If successful,

the lights of the hood will turn on. The range hood is now syncrhonized with the remote control.

If you experience anyproblems, repeat the procedure.

FCC Caution: To assure continued compliance, any changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate this equipment. (Example - use only shielded interface cables when connecting to computer or

peripheral device. This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions. (1) This device

may not cause harmful interference, and (2) This device must accept any interference received, including interference that may cause

undesired operation.

GENERAL INFORMATION:

- Remove any protective film from the remote surface prior to using it.

- The remote control has a range of approximately 10-15 feet.

- The remote control is equipped with a magnetic base and may be attached to ferrous surface

for easy storage.

- The remote top is made of a plastic material and is prone to scratches.

Use care when handling and cleaning the remote; we suggest using a microfiber cloth toclean it.

- The remote control will enter a sleep mode after 20 seconds of inactivity to conserve batterylife.

Press any button for one second to wake the remote.

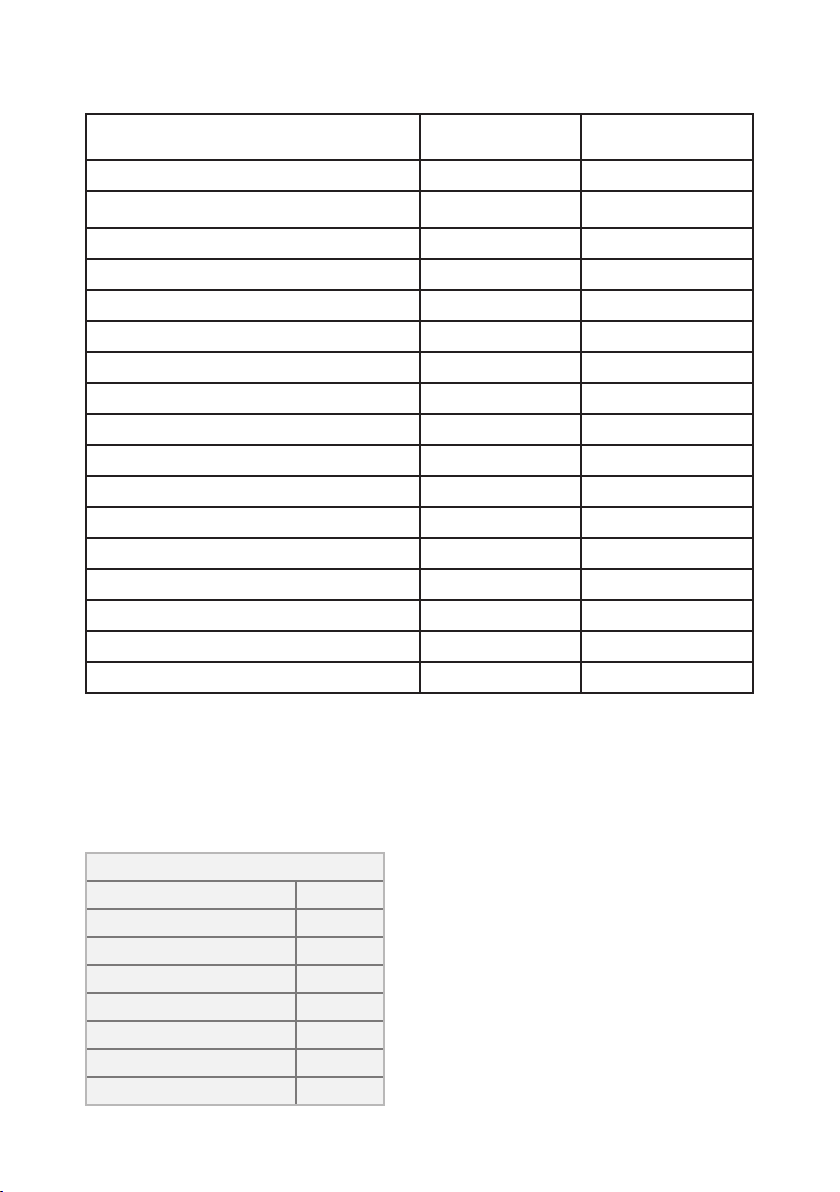

BATTERY REPLACEMENT:

The batteries will last approximately 8 months, depending on usage.

1. Remove rubber cover from bottom (Fig.3).

2. Using an object such as a screwdriver or pen, gently place it in the center opening in the bottom

of the remote and push inwards to dislodge the top touch panel from the remote body. (Fig. 4)

3. Press on the metal spring located in the battery tray to dislodge battery. Replace both batteries

with type 3V CR2450 (Fig.5). Re-assemble by following instructions in reverse.

3 54

- 21 -

Page 22

Maintenance

• It is recommended to operate the appliance prior to cooking. It is recommended

to leave the appliance in operation for 5 minutes after cooking is completed in

order to completely eliminate cooking vapors and odors. The proper function

of the range hood is conditioned by the regularity of maintenance.

• The decorative mesh filters capture the grease particles suspended in the

air and are therefore subject to clogging because of frequent use. In order to

prevent a fire hazard, it is recommended to clean the filter a minimum of every

2 months or when instructed by the Metal Filter Clean indicator on the range

hood controls. Clean the range hood by carrying out the following instructions:

- Remove the filters from the range hood and wash them in a solution of water

and neutral liquid detergent, leaving to soak.

- Rinse thoroughly with warm water and leave to dry.

- Filters may also be washed in the dishwasher at the lowest setting.

The filters may alter in color after several washes but is not cause for replacement.

• Clean the blower and other surfaces of the range hood regularly using a cloth

moistened with denatured alcohol or non abrasive liquid detergent.

- 22 -

Page 23

Wiring Diagram

INTERNAL BLOWER CIRCUIT DIAGRAM

- 23 -

Page 24

Wiring Diagram

REMOTE BLOWER CIRCUIT DIAGRAM

- 24 -

Page 25

List of Parts and Accessories

DESCRIPTION HOOD PART#

REPLACEMENT PARTS

LED Light 1.3W (each)

DME

Z0B0051

OPTIONAL ACCESSORIES

Recirculating Kit

Replacement Charcoal Filters (2x)

DME

DME

ZRC-01ME

Z0F-C010

Duct Cover Extension, Stainless Steel DME-M90ASSX Z1C-00MESS

Duct Cover Extension, Matte Black DME-M90AMBX Z1C-00MEMB

Duct Cover Extension, Satin Gold DME-M90ASGX Z1C-00MESG

Accent Rail, Mesa, SS

Accent Rail, Mesa, Gold

Remote Control

Internal Blower, 290 CFM

Internal Blower, 600 CFM

External Blower, 1000 CFM

In-Line Blower, 1000 CFM

To order parts, visit us online at http://store.zephyronline.com or call us at 1.888.880.8368

DME

DME

DME

DME

DME

DME

DME

MERAIL-00SS

MERAIL-00SG

14000010

CBI-290A

CBI-600A

CBE-1000

PBN-1000A

UL References

LED Light 1.3W (each) SPK8148

Recirculating Kit KIT0I0518

Replacement Charcoal Filters ACK00061

Duct Cover Extension Inox KIT0I0519

Duct Cover Extension MBlack KIT0I0520

Duct Cover Extension Gold KIT0I0521

Accent Rail Inox KIT0I0516

Accent Rail Gold KIT0I0516

- 25 -

Page 26

Limited Warranty

TO OBTAIN SERVICE UNDER WARRANTY OR FOR ANY SERVICE RELATED QUESTIONS:

United States Customers please call: 1-888-880-8368 or contact us at: zephyronline.com/contact

Canada Customers please call: 1-800-361-0799 or Email: service@distinctive-online.com

Zephyr Ventilation, LLC (referred to herein as “we” or “us”) warrants to the original consumer purchaser (referred

to herein as “you” or “your”) of Zephyr products (the “Products”) that such Products will be free from defects in

materials or workmanship as follows:

Two Year Limited Warranty for Parts: For two years from the date of your original purchase of the Products,

we will provide, free of charge, Products or parts (including LED light bulbs, if applicable) to replace those that

failed due to manufacturing defects subject to the exclusions and limitations below. We may choose, in our sole

discretion, to repair or replace parts before we elect to replace the Products.

One Year Limited Warranty for Labor: For one year from the date of your original purchase of the Products, we

will provide, free of charge, the labor cost associated with repairing the Products or parts to replace those that

failed due to manufacturing defects subject to the exclusions and limitations below. After the first year from the

date of your original purchase, you are responsible for all labor costs associated with this warranty.

Warranty Exclusions: This warranty covers only repair or replacement, at our option, of defective Products or parts

and does not cover any other costs related to the Products including but not limited to: (a) normal maintenance

and service required for the Products and consumable parts such as fluorescent, incandescent or halogen light

bulbs, mesh and charcoal filters and fuses; (b) any Products or parts which have been subject to freight damage,

misuse, negligence, accident, faulty installation or installation contrary to recommended installation instructions,

improper maintenance or repair (other than by us); (c) commercial or government use of the Products or use

otherwise inconsistent with its intended purpose; (d) natural wear of the finish of the Products or wear caused

by improper maintenance, use of corrosive and abrasive cleaning products, pads, and oven cleaner products; (e)

chips, dents or cracks caused by abuse or misuse of the Products; (f) service trips to your home to teach you

how to use the Products; (g) damage to the Products caused by accident, fire, floods, acts of God; or (h) Custom

installations or alterations that impact serviceability of the Products. If you are outside our service area, additional

charges may apply for shipping costs for warranty repair at our designated service locations and for the travel cost

to have a service technician come to your home to repair, remove or reinstall the Products. After the first year

from the date of your original purchase, you are also responsible for all labor costs associated with this warranty.

All Products must be installed by a qualified professional installer to be eligible for warranty repairs or service.

Limitations of Warranty. OUR OBLIGATION TO REPAIR OR REPLACE, AT OUR OPTION, SHALL BE YOUR SOLE

AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. WE SHALL NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH THE USE OR PERFORMANCE OF THE

PRODUCTS. THE EXPRESS WARRANTIES IN THE PRECEDING SECTION ARE EXCLUSIVE AND IN LIEU OF ALL

OTHER EXPRESS WARRANTIES. WE HEREBY DISCLAIM AND EXCLUDE ALL OTHER EXPRESS WARRANTIES FOR

THE PRODUCTS, AND DISCLAIM AND EXCLUDE ALL WARRANTIES IMPLIED BY LAW, INCLUDING THOSE OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Some states or provinces do not allow limitations on the duration of an implied warranty or the exclusion or

limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to you.

To the extent that applicable law prohibits the exclusion of implied warranties, the duration of any applicable

implied warranty is limited to the same two-year and one-year periods described above if permitted by applicable

law. Any oral or written description of the Products is for the sole purpose of identifying the Products and shall

not be construed as an express warranty. Prior to using, implementing or permitting use of the Products, you

shall determine the suitability of the Products for the intended use, and you shall assume all risk and liability

whatsoever in connection with such determination. We reserve the right to use functionally equivalent refurbished or reconditioned parts or Products as warranty replacements or as part of warranty service. This warranty is

not transferable from the original purchaser and only applies to the consumer residence where the Product was

originally installed located in the United States and Canada. This warranty is not extended to resellers.

To Obtain Service Under Limited Warranty: To qualify for warranty service, you must: (a) notify us at the address

or telephone number stated below within 60 days of the discovery of the defect; (b) give the model number and

serial number; and (c) describe the nature of any defect in the Product or part. At the time of the request for

warranty service, you must present evidence of your proof of purchase and proof of the original purchase date. If

we determine that the warranty exclusions listed above apply or if you fail to provide the necessary documentation

to obtain service, you will be responsible for all shipping, travel, labor and other costs related to the services. This

warranty is not extended or restarted upon warranty repair or replacements.

Please check our website for any additional Product information, www.zephyronline.com.

Zephyr, 2277 Harbor Bay Parkway, Alameda, CA 94502

JAN21.0401

- 26 -

Page 27

Page 28

MESA

DME-M90ASSX

DME-M90AMBX

DME-M90ASGX

www.zephyronline.com

HOTTE PER CUISINE - Notice d’utilisation

ENGLISH..........................3

FRANÇAIS.......................27

Page 29

Sommaire

INSTRUCTIONS DE SECURITE...................................................................................pag. 30

LISTE DES MATERIAUX.................................................................................................pag. 35

FEUILLE POUR CALCULER LES CONDUITS.........................................................pag. 36

SPECIFICATIONS TECHNIQUES.................................................................................pag. 37

INSTALLATION

- MOTEUR INTERIEUR...................................................................................pag. 38

- PREPARATION MOTEUR EXTERIEUR ET IN-LINE...........................pag. 41

- OPTIONS D’ASPIRATION..........................................................................pag. 44

- FIXATION DE LA HOTTE............................................................................pag. 45

- RACCORDEMENT AU RESEAU ELECTRIQUE....................................pag. 46

CONTRÔLE TACTILEE........................................................................................pag. 47

TÉLÉCOMMANDE EN OPTION..................................................................pag. 48

ENTRETIEN.........................................................................................................................pag. 49

SCHEMAS DE CABLAGE................................................................................................pag. 50

LISTE DE PIÈCES DÉTACHÉES ET ACCESSOIRES.............................................pag. 52

GARANTIE...........................................................................................................................pag. 53

- 29 -

Page 30

Instructions De Securite 1/5

INSTRUCTIONS DE SECURITE IMPORTANTES

POUR UN USAGE DOMESTIQUE EXCLUSIVEMENT

LIRE ET CONSERVER LES INSTRUCTIONS

COMMENCER PAR LIRE ENTIEREMENT LES INSTRUCTIONS.

IMPORTANT: Conserver les Instructions à usage des Inspecteurs Electriques

Locaux.

A L’ATTENTION DE L’INSTALLATEUR: Laisser les Instructions dans l’unité à

usage du propriétaire.

A L’ATTENTION DU PROPRIETAIRE: Conserver les Instructions pour des

consultations ultérieures.

N’utiliser des produits de nettoyage ou des détergents qu’avec la plus grande

prudence.

Cet appareil est propre à une utilisation domestique et culinaire.

AVERTISSEMENT – Afin de réduire les risques d’incendie ou d’électrocution,

ne pas utiliser le moteur avec un Dispositif de Contrôle de la Vitesse à Semiconducteurs quel qu’il soit.

ATTENTION – Afin de réduire les risques d’incendie et de permettre une

aspiration correcte de l’air, s’assurer que celui-ci est bien transporté à

l’extérieur à travers un conduit d’évacuation. – Ne pas évacuer l’air dans des

interstices tels qu’entre des cloisons ou des plafonds, dans des greniers, des

espaces confinés ou des garages.

ATTENTION – N’utiliser que pour une ventilation générique. Cet appareil n’est

pas propre à l’aspiration de matières ou de vapeurs dangereuses ou explosives.

ATTENTION – Afin d’éviter des bruits et des dommages au niveau du

moteur, et/ou un déséquilibre au niveau des hélices, veiller à ce que l’unité

d’alimentation n’entre pas en contact avec du spray, de la poussière etc.

ATTENTION – Pour obtenir des compléments d’informations, consulter

l’étiquette de spécification sur le produit.

AVERTISSEMENT – AFIN DE RÉDUIRE LES RISQUES D’INCENDIE,

D’ÉLECTROCUTION OU DE DOMMAGES AUX PERSONNES, RESPECTER LES

REGLES SUIVANTES:

A. N’utiliser l’unité que pour les opérations prévues par le fabricant. Pour toute

question éventuelle, contacter le fabricant.

B. Avant d’effectuer des opérations de maintenance ou de nettoyage sur

- 30 -

Page 31

Instructions De Securite 2/5

l’unité, débrancher le panneau de service et fermer à clef les commandes de

déconnection afin d’éviter toute mise sous tension accidentelle.

Au cas où les commandes de déconnection ne pourraient être fermées à clef, fixer

sur lepanneau de service un message avertissant du danger, par exemple une

plaque.

AVERTISSEMENT – AFIN DE RÉDUIRE LES RISQUES D’INCENDIE PAR

INFLAMMATION DES GRAISSES PRESENTES SUR LA GAZINIERE:

A. Ne jamais laisser de casseroles sur feu vif sans surveillance. D’éventuels

débordements dus à une forte ébullition peuvent provoquer de la fumée

et des dépôts de graisses susceptibles de prendre feu. Réchauffer l’huile

lentement, à petit feu ou moyen.

B. ALLUMER systématiquement la hotte pour cuisiner à des températures élevées

ou pour flamber des aliments (ex. : Crêpes Suzette, Cherries Jubilee – cerises

flambées au brandy et glace -, Boeuf flambé au poivre).

C. Nettoyer souvent le moteur. Eviter que les graisses ne s’accumulent sur le

moteur ou sur le filtre.

D. Utiliser des plats aux dimensions adaptées. Toujours utiliser des ustensiles de

cuisine adaptés à la taille de la casserole qui se trouve sur la cuisinière.

E. Veiller à ce que le moteur, les filtres et la surface où viennent s’accumuler les

graisses restent propres.

F. N’utiliser une flamme élevée que lorsque cela est nécessaire. Réchauffer l’huile

lentement, à faible ou moyenne température.

G. Ne jamais laisser la cuisinière sans surveillance pendant la cuisson.

H. Utiliser systématiquement des ustensiles de cuisine adaptés au type et à la

quantité d’aliments que l’on prépare.

AVERTISSEMENT – AFIN DE RÉDUIRE LES RISQUES DE DOMMAGES AUX

PERSONNES EN CAS D’INCENDIE PAR INFLAMMATION DES GRAISSES

PRESENTES SUR LA CUISINIERE, RESPECTER LES REGLES SUIVANTES a:

A. ETOUFFER LA FLAMME à l’aide d’un couvercle hermétique, une plaque à four ou

un plateau en métal et éteindre le brûleur. PROCEDER AVEC LA PLUS GRANDE

PRUDENCE AFIN D’EVITER TOUTE BRULURE. Si les flammes ne s’éteignent pas

immédiatement, EVACUER LA PIECE ET APPELER LES POMPIERS.

B. NE JAMAIS TOUCHER UN PLAT EN FEU – on risque de se brûler.

C. NE PAS UTILISER D’EAU, ni de chiffons ou de serviettes humides – cela pourrait

provoquer une violente explosion de vapeur.

D. Utiliser un extincteur UNIQUEMENT dans les cas suivants:

1. On dispose d’un extincteur de Classe ABC que l’on sait faire fonctionner.

2. L’incendie est peu important et il est confiné à la zone où il a éclaté.

3. On a déjà appelé les pompiers.

4. On peut affronter les flammes tout en ayant une issue de secours derrière soi.

aBasé sur les « mesures de sécurité incendie dans la cuisine « publiées par

- 31 -

Page 32

Instructions De Securite 3/5

l’organisme NFPA.

Une bonne maintenance de la hotte garantit le parfait fonctionnement de

l’unité.

INSTRUCTIONS D’INSTALLATION

AVERTISSEMENT – AFIN DE RÉDUIRE LES RISQUES D’INCENDIE,

D’ÉLECTROCUTION OU DE DOMMAGES AUX PERSONNES, RESPECTER LES

REGLES SUIVANTES:

A. Les opérations d’installation et de branchement électrique doivent être

effectuées par du personnel qualifié, conformément aux lois et aux normes en

vigueur, y compris celles relatives aux appareils à feu.

B. Il est nécessaire de disposer d’une quantité d’air suffisante pour une bonne

combustion et aspiration des gaz à travers le conduit de fumée de l’installation

de combustion du carburant, afin d’éviter un appel d’air de l’arrière. Suivre

les indications du fabricant de l’installation de chauffage et les normes de

sécurité correspondantes telles que celles émises par l’Association Nationale

de Protection contre les Incendies (National Fire Protection Association -

NFPA), la Société Américaine des Techniciens de Chauffage, Réfrigération

et Climatisation de l’Air (American Society for Heating, Refrigeration and Air

Conditioning Engineers - ASHRAE), et par les autorités locales préposées.

C. Au cours des opérations de découpage ou de perforation du mur ou du

plafond, veiller à ne pas endommager les câbles électriques ou d’autres

canalisations cachées.

D. L’appareil doit toujours être relié à un trou d’évacuation vers l’extérieur.

E. L’unité doit être reliée à la terre.

AVERTISSEMENT – AFIN DE RÉDUIRE LES RISQUES D’INCENDIE, N’UTILISER

QUE DESCONDUITS METALLIQUES

AVERTISSEMENT – LES APPAREILS ELECTROMENAGERS PEUVENT PARFOIS

S’AVERER DANGEREUX.

A. Ne pas contrôler les filtres lorsque la hotte est en état de marche.

B. Ne pas toucher les lampes après une utilisation prolongée de l’appareil.

C. Ne jamais faire flamber d’aliments sous la hotte.

D. L’usage de flammes libres est dangereux pour les filtres et peut générer des

incendies.

E. Contrôler constamment les fritures pour éviter que des éclaboussures d’huile

ne prennent feu.

F. Avant d’effectuer toute opération de maintenance, débrancher la hotte du

réseau d’alimentation électrique.

Le fabricant ne pourra être retenu responsable d’éventuels dommages causés

par le non respect des instructions susmentionnées.

- 32 -

Page 33

Instructions De Securite 4/5

Exigences électriques

Important:

- Respectez tous les codes et ordonnances en vigueur.

- Il est de la responsabilité du client d’en prendre connaissance ci-dessous:

- Pour contacter un installateur électrique qualifié.

- Pour garantir que l’installation électrique est adéquate et conforme au National

Electrical Code, ANSI / NFPA 70 dernière édition * ou aux normes CSA C22.1-94,

Code canadien de l’électricité, partie 1 et C22.2 No.0-M91 - dernière édition **

et tous les codes et ordonnances locaux.

- Si les codes le permettent et qu’un fil de terre séparé est utilisé, il est recommandé qu’un électricien qualifié détermine que le chemin de terre est adéquat.

- Ne pas mettre à la terre un tuyau de gaz.

- Vérifiez auprès d’un électricien qualifié si vous n’êtes pas sûr que la hotte est

correctement mise à la terre.

- Ne pas avoir de fusible dans le circuit neutre ou de terre.

- Cet appareil nécessite une alimentation électrique de 120 V à 60 Hz et est connecté à un circuit de dérivation individuel correctement mis à la terre protégé

par un disjoncteur de 15 ou 20 ampères ou un fusible temporisé. Le câblage

doit être à 2 fils avec mise à la terre. Veuillez également vous référer au schéma

électrique du produit.

- Un connecteur de verrouillage de câble (non fourni) peut également être

requis par les codes locaux. Vérifiez les exigences locales, achetez et installez le

connecteur approprié si nécessaire.

* National Fire Protection Association Batterymarch Park, Quincy, Massachusetts

02269

** CSA International 8501 East Pleasant Valley Road, Cleveland, Ohio 44131-5575

Déclaration d’interface de la Federal Communication Commission

- Cet équipement a été testé et déclaré conforme aux limites d’un appareil

numérique de classe B, conformément à la partie 15 des règles FCC. Ces limites

sont conçues pour fournir une protection raisonnable contre les interférences

nuisibles dans une installation résidentielle.

- Cet équipement génère, utilise et peut émettre de l’énergie radiofréquence et,

s’il n’est pas installé et utilisé conformément aux instructions, peut provoquer

des interférences nuisibles aux communications radio. Cependant, il n’y a aucune garantie que des interférences ne se produiront pas dans une installation

particulière. Si cet équipement cause des interférences nuisibles à la réception

de la radio ou de la télévision, ce qui peut être déterminé en éteignant et en

- 33 -

Page 34

Instructions De Securite 5/5

rallumant l’équipement, l’utilisateur est encouragé à essayer de corriger les

interférences par l’une des mesures suivantes:

- Réorientez ou déplacez l’antenne de réception.

- Augmentez la séparation entre l’équipement et le récepteur.

- Connectez l’équipement à une prise sur un circuit différent de celui sur lequel

le récepteur est connecté.

- Consultez le revendeur ou un technicien radio / TV expérimenté pour obtenir

de l’aide.

AVERTISSEMENT Prop. 65 Avertissement pour les résidents de Californie:

Ce produit peut contenir des produits chimiques reconnus par l’État de Californie

comme pouvant provoquer le cancer, des malformations congénitales ou d’autres

troubles de la reproduction.

- 34 -

Page 35

Liste Des Materiaux

Raccord avec clapêt

du ventilateur extérieur

Harnais Câblage

Ventilateur exterieur

Exstension Câblage

Ventilateur exterieur

Boîte portant inscrip-

tion “120 VAC Input”

Chapeau

Boîte du ventilateur

exterieur

Support

du ventilateur

Ensemble tableau

electrique

Commandes

Matériel

Lampes

Filtres à chicane

hybrides

- 35 -

Page 36

Feuille Pour Calculer Les Conduits

Longueur x

Nombre utilisé

1 pi x ( ) =

1 pi x ( ) =

15 pi x ( ) =

9 pi x ( ) =

24 pi x ( ) =

25 pi x ( ) =

15

pi x ( ) =

15 pi

9 pi x ( ) =

=

x ( ) =

To tal

Pièces de conduit

3- 1/ 4 po

x 10 po

rect., droit

6 po, 7 po,

8 po, 10 po

circ., droit

3- 1/ 4 po

x 10 po

rect.,

coude à 90º

3- 1/ 4 po

x 10 po

rect.,

coude à 45º

3- 1/ 4 po

x 10 po

rect., coude

plat à 90º

7 po to 6 po or

8 po to 7 po

circ. reducteur

conique

6 po, 7 po,

8 po circ.

bouchone de

l’air

6 po, 7 po,

8 po, 10 po

circ.,

coude à 90º

6 po, 7 po,

8 po, 10 po

coude à 45º

Sous-total - colonne 1=

Longueur maximale du conduit d’aération :

Pour un mouvement d’air convenable, la longueur totale d’un conduit

d’aération ne devrait pas compter plus que l’équivalent de 150 pieds.

pi

pi

pi

pi

pi

pi

pi

pi

pi

pi

Pièces de conduit

Longueur x

Nombre utilisé

6 po circ. à

rect. de

3-1/4 po

x 10 po

6 po circ. à

rect. de

3-1/4 po x

10 po,

coude à 90º

6 po circ. à

rect. de

3-1/4 po

x 10 po

6 po circ. à

rect. de

3-1/4 po

x 10 po,

coude à 90º

7 po circ. à

rect. de

3-1/4 po

x 10 po

7 po circ. à

rect. de

3-1/4 po

x 10 po,

coude à 90º

3-1/ 4 po

x 10 po

embout mural

rect./registre

6 po, 7 po,

8 po, 10 po

embout

mural

circ./registre

6 po, 7 po,

8 po, 10 po

chapeau de

toiture circ.

5 pi x ( ) =

20 pi x ( ) =

1 pi x ( ) =

16 pi x ( ) =

8 pi x ( ) =

23 pi x ( ) =

30 pi x ( ) =

30 pi x ( ) =

30 pi x ( ) =

Sous-total - colonne 2 =

Sous-total - colonne 1 =

Total du conduit =

=

To tal

pi

pi

pi

pi

pi

pi

pi

pi

pi

pi

pi

pi

- 36 -

Page 37

14-1/16”

Specifications Techniques

Partie avant de la hotte

Arrière de la hotte

10-13/16”

35-5/16”

Partie latérale de la hotte

10-9/16”

11/16”

11-5/16”

21-3/4”

29-5/8”

Partie supérieure de la hotte

2-7/16”

2-5/8”

8-11/16”

19-11/16”

- 37 -

Page 38

Installation – Moteur Interieur

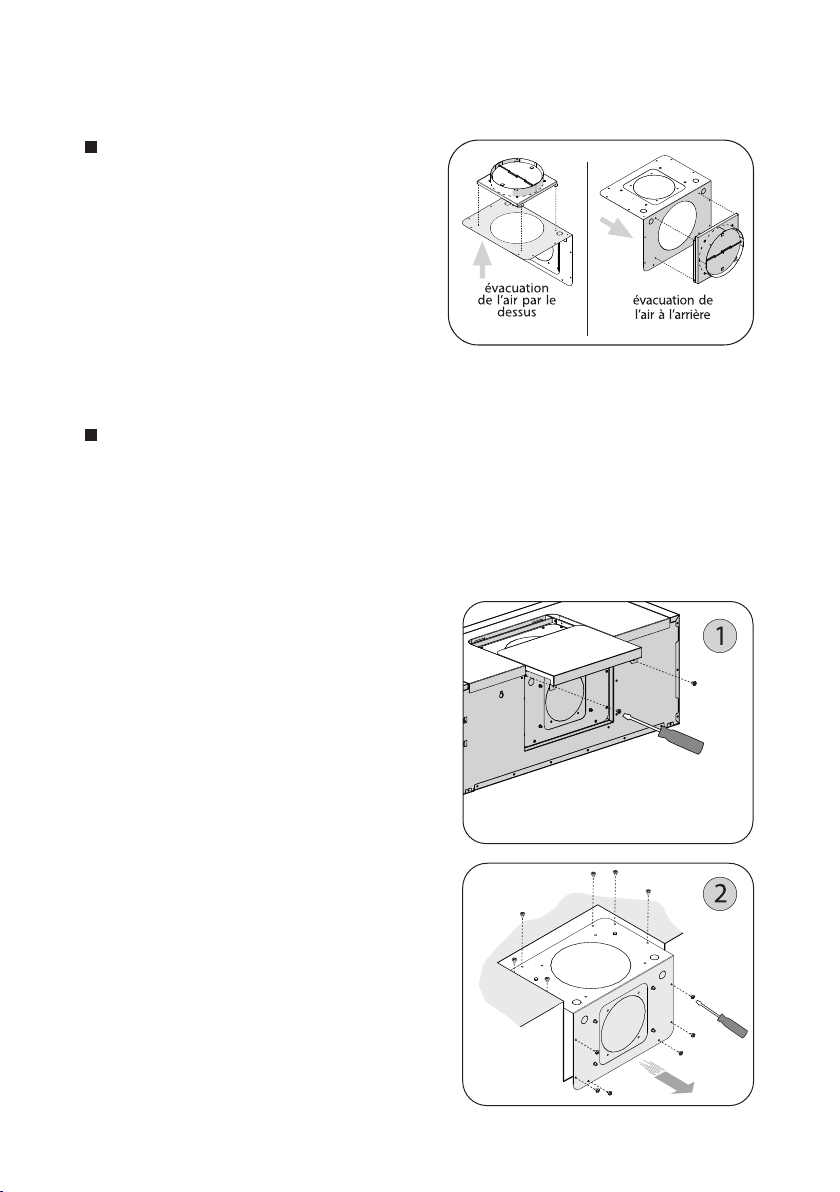

NOTE! Dans cette version (moteur

interne avec évacuation), l’appareil est

doté d’un orifice d’évacuation de l’air

à l’arrière. Il est toutefois possible, en

fonction des exigences du client, de

prévoir l’évacuation par le dessus. Cette

transformation est possible grâce à la

procédure décrite dans les paragraphes

suivants. Une fois la phase 8 atteinte,

il n’est pas nécessaire de pivoter la

plaque du moteur.

Les instructions qui suivent concernent l’installation du moteur intérieur.

AVERTISSEMENT: à fin de reduire le risque de incendie et de shock éléctrique il faut installer la hotte seulement avec le moteur a l’intèrieur modèles

CBI-290A ou CBI-600A.

Pour la préparation du moteur extérieur et in-line, allez à la page 41.

1. Détacher les (2) vis fixant le chapeau.

Fig.1

2. Dévissez les (6) vis fixant la plaque du

moteur au corps moteur et enlevez la

plaque. Fig. 2

3. Enlevez la plaque métallique circulaire

de 6” à l’aide d’un tournevis plat. Fig. 3

4. Installez le moteur intérieur dans la pla-

que du moteur et fixez l’ensemble en

utilisant les (4) vis. Fig. 4

- 38 -

Page 39

5. Placez à la plaque du moteur le con-

denseur relié câble en dotation en utilisant les (2) vis. Fig. 5

6. Fixez le câble de la terre vert/jaune con-

necte au câble avec le condensateur en

dotation dans la vis se trouvant sur la

plaque du moteur. Fig. 6

7. Raccordez le connecteur mâle à 6 voies

du moteur au connecteur femelle à 6

voies, relié à l’intérieur du corps moteur.

Fig. 7

8. Installer le moteur et la plaque à

l’intérieur du corps moteur en respectant les instructions de la phase 2 dans

l’ordre inverse et en fixant les éléments

à l’aide des vis fournies. (Tot. 12). Fig. 8

9. Reliez le connecteur mâle à 9 voies du

moteur au connecteur femelle à 9 voies

du condenseur. Fig. 9

- 39 -

Page 40

AVERTISSEMENT! Placez les câbles électriques à l’intérieur du corps moteur.

10. Réintroduire le chapeau.

A ce point, la hotte est prête pour être

installée au mur.

- 40 -

Page 41

Installation – Preparation Moteur Exterieur

Et In-Line

NOTE! Dans cette version (moteur

externe), l’appareil est doté d’un

orifice d’évacuation de l’air à l’arrière.

Il est toutefois possible, en fonction

des exigences du client, de prévoir

l’évacuation par le dessus. Cette transformation est possible grâce à la procédure décrite dans les paragraphes

suivants. Une fois la phase 4 atteinte,

il est nécessaire de pivoter la plaque

du moteur dans le sens inverse.

Les phases suivantes concernent la préparation de la hotte avec moteur

extérieur ou moteur In-Line. CBE-1000, PBN-1000A.

AVERTISSEMENT: à fin de reduire le risque de incendie et de shock éléctrique il faut installer la hotte seulement avec le moteur a l'extèrieur regleé au

maximum 6.2A.

Pour les instructions du moteur intérieur, revenez à la page 38.

1. Détacher les (2) vis fixant le chapeau.

Fig.1

2 . Dévissez les (6) vis fixant la plaque du

moteur au corps moteur et enlevez la

plaque. Fig.2

3. Enlevez la plaque métallique circulaire

de 8” à l’aide d’un tournevis plat. Fig. 3

4. Installer la plaque en orientant la sortie

vers le mur et à l’intérieur du corps moteur en respectant les instructions de la

phase 2 dans l’ordre inverse et en fixant

les éléments à l’aide des vis fournies.

(Tot. 12). Fig.4

- 41 -

Page 42

5. Installer la bride en la fixant à la plaque

du moteur à l’aide des (4). Fig. 5

6. Réintroduire le chapeau.

7. Retirer la partie prédécoupée du passa-

ge de câbles à l’aide d’un tournevis plat.

Fig. 6

8. Insérer le connecteur femelle dans la

boîte des connexions déjà fixée à la hotte. Fig. 7A

Faire passer les fils du moteur au travers du

couvercle de la boîte des connexions et

les relier à ceux se trouvant à l’intérieur

de la boîte. Fig.7B

Remarque: Réalisez la connexion élec-

trique conformément aux dispositions

de la norme nationale (ANSI/NFPA 70-

1999).

Remarque1: Le bloque-câble (fourni)

pourrait être requis par les réglementa-

- 42 -

Page 43

tions locales. Pour de plus amples informations, prière de consulter les réglementations locales.

9. Raccordes les deux connecteurs mâles à

6 voies aux deux connecteurs femelles à

6 voies se trouvant à l’intérieur du corps

moteur. Fig 8

Remarque2: Consultez les réglementations locales pour déterminer le diamètre

minimum prescrit du câble.

Suivez les instructions pour l’installation

se trouvant dans le manuel annexé au

moteur extérieur et au moteur In-Line.

- 43 -

Page 44

Installation – Options D’aspiration

AVERTISSEMENT : DANGER D’INCENDIE

N’installez JAMAIS le conduit d’évacuation de l’air dans les interstices des murs,

vides sanitaires, attiques ou garages.

L’air doit toujours être évacué à l’extérieur sauf si on opte pour l’option de la

recirculation. .

Utilisez exclusivement des conduits en métal rigide à simple paroi.

Procédez à toutes les connexions en vous servant des vis auto-taraudeuses et

appliquez du ruban adhésif américain certifié sur toutes les jonctions.

Voici quelques possibilités d’installation des conduits

- 44 -

Page 45

Installation – Fixation De La Hotte

INSTALLATION

L’appareil doit être installé à une hauteur minimum de 24 pouces (61 cm) de plaque. Si l’on

utilise un conduit composé de deux éléments, la

partie supérieure doit alors être reliée à l’extérieur

de la partie inférieure.

Ne pas relier le conduit d’aspiration d’air de

la hotte à celui utilisé pour aspirer l’air chaud

ou les fumées provenant de d’autres appareils

électroménagers non électriques. Avant de procéder aux opérations d’assemblage, retirer le(s)

filtre(s) anti-graisses. L’unité sera ainsi plus facile

à manoeuvrer.

FIXATION AU MUR

1. Positionnez le gabarit de fixation fourni avec

la hotte sur la paroi pour déterminer l’emplacement des vis pour le montage de la hotte.

Assurez-vous que la ligne au fond

du gabarit est alignée avec la partie

inférieure de la hotte à l’endroit

où celle-ci devra être positionnée.

Fig. 9

2. Soulevez la hotte sur les vis et

réglez-la pour vous assurer que

la hotte est bien alignée horizontalement.

3. Quand la hotte aura été réglée,

serrez les vis pour fixer la hotte.

Remarque: Durant l’installation, veuillez fixer les vis sur les montants en

bois. Si vous utilisez une agrafeuse,

consultez la réglementation locale

pour déterminer le type et la conformité des crampons à utiliser.

Remarque1: Pour les différentes installations utiliser les vis et les supports

correspondants adaptés au type de mur sur lequel on entend fixer l’appareil

(mesure minimum de la vis 1/4" avec un diamètre X 2-3/4" de longueur).

- 45 -

Page 46

Installation – Raccordement Au Reseau

Electrique

GENERALITES

• Lire attentivement les informations suivantes, relatives à la sécurité dans les

opérations d’installation et de manutention. Conserver ce fascicule d’informations

pour des consultations ultérieures.

BRANCHEMENT ÉLECTRIQUE

Pour brancher l’appareil au réseau d’alimentation électrique, suivre les indications

reportées sur la figure:

1. Enlevez le couvercle d’alimentation en

dévissant les (2) vis. Fig. 1

2. Reliez les fils du hotte à ceux de l’ali-

mentation électrique en procédant aux

raccordements suivants. Fig.2 :

NOIR = L ligne

BLANC = N neutre

VERT / JAUNE = G terre

- Un interrupteur bipolaire approprié doit

être installé afin de permettre à la hotte de

se débrancher du réseau électrique.

- Raccordez le conduit électrique au boîtier

de connexion en n’utilisant que des composants homologués.

- Réalisez la connexion électrique conformément aux dispositions de la norme

nationale (ANSI/NFPA 70-1999).

3. Insérez les câbles à l’intérieur de la boîte

et ensuite fermez-la en fixant le couvercle avec les vis précédemment enlevées.

- 46 -

Page 47

Contrôle tactile

ABCDEF

A - Bouton d'éclairage: Les lumières sont à trois niveaux (haut, moyen, bas). En mode veille, touchez

une fois pour le haut, deux fois pour le moyen, trois fois pour le bas, quatre fois pour revenir en arrière.

B - Bouton de désactivation de la temporisation: Appuyez sur le bouton de désactivation de la

temporisation pour activer la fonction de désactivation de la temporisation de dix minutes, quelle

que soit la vitesse de fonctionnement du ventilateur. Le bouton B se met à clignoter, indiquant que

la fonction de désactivation de la temporisation est activée. Au bout de dix minutes, le ventilateur

et les lumières s'éteignent. La fonction de désactivation de la temporisation peut être désactivée en

appuyant sur le bouton B, en changeant la vitesse ou en appuyant sur le bouton d'alimentation C.

C - Bouton d'alimentation : Appuyez une fois pour activer tous les boutons en mode veille, ce qui

permet de contrôler les autres fonctions des boutons. Tous les boutons s'allument pour indiquer le

mode veille. Appuyez à nouveau sur le bouton d'alimentation pour éteindre la hotte (ventilateur

et lumières). Le mode veille reste actif pendant 30 secondes.

D - Bouton de basse vitesse: En mode veille : Appuyez une fois pour une vitesse lente.

E - Bouton de vitesse moyenne: En mode veille : Appuyez une fois pour obtenir une vitesse moyenne.

F - Bouton de haute vitesse: En mode veille : Appuyez une fois sur le bouton de haute vitesse.

RAPPEL DE NETTOYAGE DES FILTRES A MAILLES (toujours activé): après 60 heures d'utilisation du

ventilateur, le bouton A clignote lorsque la hotte est en marche, indiquant qu'il est temps de nettoyer

les filtres à mailles. Pour réinitialiser la fonction : avec la hotte en marche, appuyez sur le bouton B

pendant 4 à 5 secondes, le bouton A cesse de clignoter et le minuteur de 60 heures est réinitialisé.

RAPPEL DE REMPLACEMENT DU FILTRE A CHARBON (désactivé par défaut, doit être activé par

l'utilisateur s'il s'agit d'une hotte à recirculation): Pour activer la fonction de remplacement du filtre

à charbon, maintenez les boutons D et F enfoncés simultanément pendant quatre secondes. Le

bouton A clignote rapidement 3 fois pour indiquer que la fonction de remplacement du filtre à

charbon est activée. Après 200 heures d'utilisation du ventilateur, le bouton B clignote lorsque la

hotte est en marche, indiquant qu'il est temps de remplacer les filtres à charbon.

Pour réinitialiser la fonction de rappel de remplacement du filtre à charbon : Maintenez le bouton

B enfoncé pendant 4 à 5 secondes jusqu'à ce qu'il cesse de clignoter, et le minuteur de 200 heures

se réinitialisera.

Commandez le kit de remplacement du filtre à charbon numéro Z0F-C010 auprès de votre revendeur

local, www.zephyronline.com, ou du service clientèle de Zephyr.

Pour désactiver la fonction de remplacement du filtre à charbon, répétez la procédure d'activation,

le bouton A s'allumera pendant 3 secondes puis s'éteindra, indiquant que la fonction de remplacement du filtre à charbon est désactivée.

FONCTION AIR PUR (désactivée par défaut, doit être activée par l'utilisateur). Pour activer la fonction

Air pur, lorsque la hotte est éteinte, appuyez sur le bouton E et maintenez-le enfoncé pendant 4 à 5

secondes. Le bouton E se met à clignoter, le ventilateur tourne à basse vitesse pendant 10 minutes.

Au bout de 10 minutes, le ventilateur s'éteint et le minuteur de 4 heures se met en marche. Le voyant du bouton E continue de clignoter lorsque la fonction Air pur est activée, même si le ventilateur

n'est pas en marche. Lorsque la fonction Air pur est activée, toutes les 4 heures d'utilisation sans

ventilateur, le ventilateur se met automatiquement en marche à basse vitesse pendant 10 minutes.

Au bout de 10 minutes, le ventilateur s'éteint et le minuteur de 4 heures se réinitialise.

- 47 -

Page 48

Télécommande en option

SYNCHRONISATION:

Pour synchroniser la télécommande avec la hotte de la cuisine, pour la première fois, rocéder en

suivant les indications suivantes:

1. En tenant arrêtée la hotte de la cuisine, appuyer et maintenir appuyée la touche “Power” sur la

hotte pendant 4 secondes (Fig.1) jusqu’à ce que l’indicateur “III” sur la hotte s’allume.

2. Appuyez sur n'importe quel bouton de la télécommande dans les 4 secondes pour confirmer

le lien (Fig.2). En cas de succès, l’indicateur “Delay Off” clignotera 3 fois. La hotte est maintenant

syncrhonized avec la télécommande. Si vous deviez rencontrer un problème répéter la procédure.

Avertissement FCC: Pour assurer une conformité continue, des changements ou modifications non expressément approuvés par la partie responsable de la conformité pourraient annuler l’autorité de l’utilisateur à utiliser cet équipement.

(Exemple - Utiliser seulement des câbles d’interface blindés lors de la connexion à l’ordinateur ou un périphérique. Cet

appareil est conforme à la partie 15 des règles de la FCC. L’opération est soumise aux deux conditions suivantes. (1) Ce

dispositif ne peut causer des interférences nuisibles, et (2 ) Ce dispositif doit accepter toute interférence reçue, y compris

les interférences qui peuvent provoquer un fonctionnement indésirable.

INFORMATIONS DE CARACTERE GENERAL:

- Retirer la pellicule protectrice de la surface à distance avant de l’utiliser.

- La télécommande est caractérisée par une portée d’environ 10-15’ (3-4,5 m)

- La télécommande est dotée d’une base magnétique et peut être apposée sur des surfaces métalliques pour un rangement pratique.

- La partie supérieure de la télécommande est réalisée en matière plastique anti-rayures. Apporter

le plus grand soin en manipulant et en nettoyant la télécommande; nous conseillons

d’utiliser un linge en microfibres pour son nettoyage.

- La télécommande passe en mode veille après 20 secondes d'inactivité pour économiser la batterie.

Appuyez sur un bouton pendant une seconde pour réveiller la télécommande.

REMPLACEMENT DES PILES:

Les piles ont un cycle de vie d’environ 8 mois, selon l’usage qu’on en fait.

1. Enlever le couvercle en caoutchouc de la partie inférieure de la télécommande (Fig.3).

2. Utiliser un objet tel qu'un tournevis ou un stylo, placer délicatement dans l'ouverture de centre

dans le bas de la télécommande et pousser vers l'intérieur pour déloger l'écran tactile haut du

corps à distance (Fig. 4).

3. Exercer une pression sur le ressort métallique situé dans le compartiment des piles pour les

extraire. Remplacer les deux piles avec le type 3V CR2450 (Fig.5). Remonter en répétant en sens

inverse la même procédure.

3 54

- 48 -

Page 49

Entretien

• Il est conseillé d’allumer l’appareil avant de commencer à cuisiner et de le laisser

fonctionner pendant 5 minutes après la fin de la cuisson afin d’éliminer complètement les vapeurs et les odeurs de cuisine. Le bon fonctionnement de la hotte est

déterminé par la régularité des opérations de maintenance.

• Les filtres anti-graisses capturent les particules de graisses en suspension dans l’air.

Ils se bouchent donc proportionnellement à l’utilisation que l’on fait de l’appareil.

Afin de prévenir tout risque d’incendie, il est conseillé de nettoyer le filtre au maximum tous les deux mois, en respectant les instructions suivantes :

- Retirer les filtres de la hotte et les mettre à tremper dans une solution composée

d’eau et de détergent liquide.

- Rincer soigneusement à l’eau tiède et laisser sécher.

- Les filtres peuvent être également lavés au lave-vaisselle.

Les panneaux en aluminium peuvent changer de couleur après un certain nombre

de lavages. Cela ne peut cependant représenter un motif de réclamation de la part

du client ou de demande de remplacement des panneaux.

• Nettoyer le ventilateur et les autres surfaces de la hotte avec un chiffon imbibé

d’alcool dénaturé ou de détergent liquide non abrasif.

- 49 -

Page 50

Schéma de câblage

SCHÉMA DU CIRCUIT DE MOTEUR INTERIEUR

- 50 -

Page 51

Schéma de câblage

SCHÉMA DU CIRCUIT DE MOTEUR EXTERIEUR

- 51 -

Page 52

Liste De Pièces Détachées Et Accessoires

DESCRIPTION HOTTE PARTIE#

PIÉCES DÉTACHÉES

Lampe LED 1.3W (chacun)

DME

Z0B0051

ACCESSOIRES EN OPTION

Kit Filtrant

Filtres à charbon (2x)

DME

DME

ZRC-01ME

Z0F-C010

Extension cheminée, Acier inoxydable DME-M90ASSX Z1C-00MESS

Extension cheminée, Noir mat DME-M90AMBX Z1C-00MEMB

Extension cheminée, Or satiné DME-M90ASGX Z1C-00MESG

Porte-louche, Mesa, SS

Porte-louche, Mesa, Gold

Télécommande

Moteur Interieur, 290 CFM

Moteur Interieur, 600 CFM

Moteur Exterieur, 1000 CFM

Moteur In-Line, 1000 CFM

Pour commander les pièces détachées, merci de visiter le sitehttp://store.zephyronline.com

ou de appeler au numero suivant: 1.888.880.8368

DME

DME

DME

DME

DME

DME

DME

MERAIL-00SS

MERAIL-00SG

14000010

CBI-290A

CBI-600A

CBE-1000

PBN-1000A

UL Reférences

Lampe LED 1.3W (chacun) SPK8148

Kit Filtrant KIT0I0518

Filtres à charbon ACK00061

Extension cheminée Inox KIT0I0519

Extension cheminée MNoir KIT0I0520

Extension cheminée Or KIT0I0521

Porte-louche Inox KIT0I0516

Porte-louche Or KIT0I0516

- 52 -

Page 53

Garantie limitée

POUR OBTENIR UN SERVICE SOUS GARANTIE OU POUR TOUTE QUESTIONS LIÉES AU SERVICE

Les clients des États-Unis doivent appeler le: 1-888-880-8368 ou nous contacter à: zephyronline.com/contact

Clients du Canada, veuillez appeler: 1-800-361-0799 ou par courriel: service@distinctive-online.com

Zephyr Ventilation, LLC (désigné aux présentes sous le nom de « nous ») garantit au premier acheteur (désigné

aux présentes sous le nom de « vous » ou « votre ») de produits Zephyr (les « Produits ») que lesdits produits sont

exempts de défauts de fabrication ou de main-d’oeuvre selon les conditions suivantes :

Garantie de deux ans sur les pièces: Garantie de deux ans à partir de la date d’achat originale du Produit. Nous

fournirons sans frais les Produits ou les pièces (y compris les ampoules LED, le cas échéant) de remplacement

qui comportaient des défauts de fabrication. Nous pourrions choisir, à notre seule discrétion, de réparer ou de

remplacer des pièces avant de prendre la décision de remplacer le Produit.

Garantie limitée d’un an sur la main-d’œuvre: Garantie d’un an à partir de la date d’achat originale du Produit.

Nous couvrirons sans frais les frais de main-d’oeuvre afférents à la réparation du Produit ou des pièces de remplacement qui comportaient des défauts de fabrication. Un an après la date d’achat originale, vous serez responsable

de tous les frais de main-d’oeuvre associés à la présente garantie.

Exclusions de la garantie: Cette garantie ne couvre que la réparation ou le remplacement, à notre gré, de pièces

ou de Produits défectueux et ne couvre aucun autre coût afférent aux Produits, dont, sans s’y limiter, les frais

liés : (a) à l’entretien normal des Produits et au remplacement des pièces consommables, comme les fluorescent,

incandescence ou halogèneampoules, les filtres métalliques, les filtres à charbon et les fusibles; (b) à tout Produit

ou pièce ayant été endommagé durant le transport ou étant le résultat d’un mauvais usage, d’une négligence, d’un

accident, d’une installation incorrecte ou ne respectant pas les notices d’installation recommandées, d’un entretien

ou d’une réparation inapproprié (dont ne nous sommes pas responsables); (c) à une utilisation commerciale ou

ne correspondant pas à l’utilisation pour laquelle les Produits sont conçus; (d) à l’usure naturelle du fini, à l’usure

due à un entretien inadéquat, à l’utilisation de produits nettoyants corrosifs ou abrasifs, de tampons nettoyeurs et

de produits de nettoyage pour le four; (e) aux éclats, entailles ou fissures résultant d’un abus ou d’une mauvaise

utilisation du Produit; (f) aux déplacement d’un technicien de service à votre domicile pour vous montrer comment

utiliser les Produits; (g) aux dommages causés par un accident, un incendie, une inondation, un cas fortuit; ou

(h) Les installations personnalisées ou modifications qui ont un impact maintenabilité du Produit. Si vous vous

trouvez à l’extérieur du territoire que nous desservons, des frais supplémentaires pourraient s’appliquer pour la

livraison des produits à nos points de service désignés pour une réparation sous garantie ou vous pourriez avoir

à débourser les frais de déplacement du technicien à votre domicile pour que le Produit soit réparé, enlevé ou

réinstallé. Un an après la date d’achat originale du Produit, vous êtes également responsable de tous les frais de

main-d’oeuvre associés à la présente garantie.

Restrictions de la garantie. NOTRE OBLIGATION DE RÉPARER OU DE REMPLACER, À NOTRE GRÉ, LE PRODUIT

CONSTITUE VOTRE SEUL ET UNIQUE RECOURS SOUS LA PRÉSENTE GARANTIE. NOUS NE NOUS PORTONS

PAS RESPONSABLES POUR TOUT DOMMAGE INDIRECT, ACCESSOIRE OU PARTICULIER RÉSULTANT OU AYANT

UN LIEN AVEC L’UTILISATION OU LE RENDEMENT DES PRODUITS. LES GARANTIES EXPRESSES DE LA SECTION PRÉCÉDENTE SONT EXCLUSIVES ET TIENNENT LIEU DE TOUTE AUTRE GARANTIE EXPRESSE. PAR LES

PRÉSENTES, NOUS REJETONS ET EXCLUONS TOUTE AUTRE GARANTIE EXPRESSE POUR LES PRODUITS ET

TOUTES LES GARANTIES TACITES PRÉVUES PAR LA LOI, DONT CELLES RELATIVES À LA QUALITÉ

MARCHANDE OU À L'ADÉQUATION DU PRODUIT POUR UNE UTILISATION PARTICULIÈRE. Certains États ou

provinces n’autorisent pas les restrictions sur la durée d’une garantie implicite ou l’exclusion ou la restriction des

dommages indirects ou accessoires; par conséquent, les exclusions et restrictions mentionnées ci-dessus pourraient

ne pas s’appliquer à votre cas. Dans la mesure où une loi applicable interdit l’exclusion de garanties implicites, la

durée de toute garantie implicite applicable se limite à la période de deux ans décrite ci-dessus. L’unique objectif

de toute description orale ou écrite est de présenter les Produits et celle-ci ne devrait pas être interprétée comme

une garantie expresse. Avant d’utiliser ou de permettre l’utilisation des Produits, vous devrez déterminer si les

Produits conviennent aux utilisations prévues et vous devrez assumer tout risque et toute responsabilité relatifs à

ces utilisations. Nous nous réservons le droit d’utiliser des pièces reconstruites ou remises à neuf pour remplacer

l’une des fonctionnalités dans le cadre de la présente garantie ou de l’une des parties de la présente garantie.

L’acheteur original ne peut transférer la présente garantie et celle-ci n’est valide qu’aux États-Unis et au Canada.

Pour obtenir du service sous la garantie: Pour avoir droit à du service sous garantie, vous devez : (a) nous avertir

en utilisant l’adresse ou le numéro de téléphone inscrit ci-dessous dans les soixante jours suivant la détection du

défaut; (b) donner le numéro du modèle, le numéro d’identification de la pièce ainsi que le numéro de série; et

(c) décrire la nature de tout défaut de la pièce ou du Produit. Au moment de faire la demande de service sous

garantie, vous devrez présenter votre preuve d’achat et la preuve de la date d’achat originale. Si nous déterminons

que les exclusions de la garantie énumérées ci-dessus s’appliquent ou si vous vous trouvez dans l’incapacité de

nous fournir la documentation nécessaire pour obtenir du service, vous serez responsable de tous les frais d’expédition, de déplacement, de main-d’oeuvre ou de tout autre coût afférent au service.

Veuillez consulter notre site Web au www.zephyronline.com pour savoir si des révisions ont été apportées à la garantie.

Zephyr, 2277 Harbor Bay Parkway, Alameda, CA 94502

JAN21.0201

- 53 -

Page 54

Page 55

Page 56

PRODUCT REGISTRATION

Congratulations on your Zephyr range

hood purchase! Please take a moment

to register your new range hood at

www.zephyronline.com/registration

IT'S IMPORTANT

Prompt registration helps in more ways

than one.

• Ensures warranty coverage should

you need service.

• Ownership verification for insurance

purposes.

• Notification of product changes or

recalls.

Zephyr Ventilation | 2277 Harbor Bay Pkwy. | Alameda, CA 94502 | 1.888.880.8368

3011000132500.00

Loading...

Loading...