Page 1

Zenith®Pumps

Installation,

Care and

Maintenance

Zenith

Polymer

Extrusion

Gear Pumps

PEP-II Series

Gear Pumps

Page 2

Zenith®Pumps

2

Thoroughly read and understand this entire manual

before installation and operation of pump.

Benefits

Specifications

Capacities: 0.16 to 750 cc/rev.

Operating Speed: 10 - 90 rpm on most extrusion processes depending upon

process parameters

Differential Pressure: Up to 5,000 psi (345 bar)

Body Pressure: 10,000 psi (690 bar).

Temperature: To 645° F (340° C),

(950° F maximum with special fasteners and seals).

In 1926, Zenith Pumps was approached

by the synthetic fiber industry to design a

pump to provide a precise, pulseless, and

repeatable flow and assure better quality

control.

Since then, Zenith has provided

pumps for virtually every polymer utilized

in the plastics extrusion industry. Over the

years, Zenith has continually developed

and improved its pump designs to meet

the stringent demands made by new

polymers and new processes.

Zenith Pumps' line of PEP-II polymer

extrusion pumps has a unique positive

displacement design, which provides consistent, accurate polymer delivery under

varying extruder output conditions of

pressure, temperature and viscosity.

These virtually pulseless gear pumps are

the ideal interface between the extruder

and the die of extrusion systems, and provide a homogeneous melt at increased

throughputs and tighter gauge tolerances.

For years, polymer processors have utilized

gear-pump-assisted extrusion to solve

critical issues in the diverse plastics

industry.

The Zenith gear pump optimizes the

extrusion process by allowing the screw

to melt and homogenize the polymer. As

the pump generates the needed pressure,

it relieves the extruder of work; therefore,

reducing heat from the shear, lowering the

torque required, and eliminating surging.

All this optimizes the performance of the

extruder and offers the following benefits:

• Improved Dimensional Stability—

Effectively isolates the die from

upstream fluctuations.

• Controlled Melt Quality—Regulates

the extruder back pressure while it

reduces residence time, stabilizes the

plasticating action, and lowers melt

temperature.

• Increased Production—Provides very

high efficiency regardless of its pres-

sure building requirement.

• Reduced Raw Material Usage—

Provides a narrower finished product

gauge variation.

• Eliminates Surging and Screw Beat—

Effectively handles problems caused

by melt density or extruder parameters.

• Increased Extruder Flexibility—

Allows varying process conditions

such as higher regrind levels, temperatures, pressures, etc.

• Crowned Root Gear Design—

Reduces shear internal to the pump,

lowering the temperature and increasing

the production rate per power required.

• Streamlined Operation and Start-up—

Closed-loop controls provide easy

operator interface.

• Extended Extruder Life—Reduces

work required by the extruder such as

pressure and torque.

• Lower Operational Costs—Provides

a more efficient method of conveying,

eliminating material giveaway, and

increasing production per pound of

extrudate, etc.

Page 3

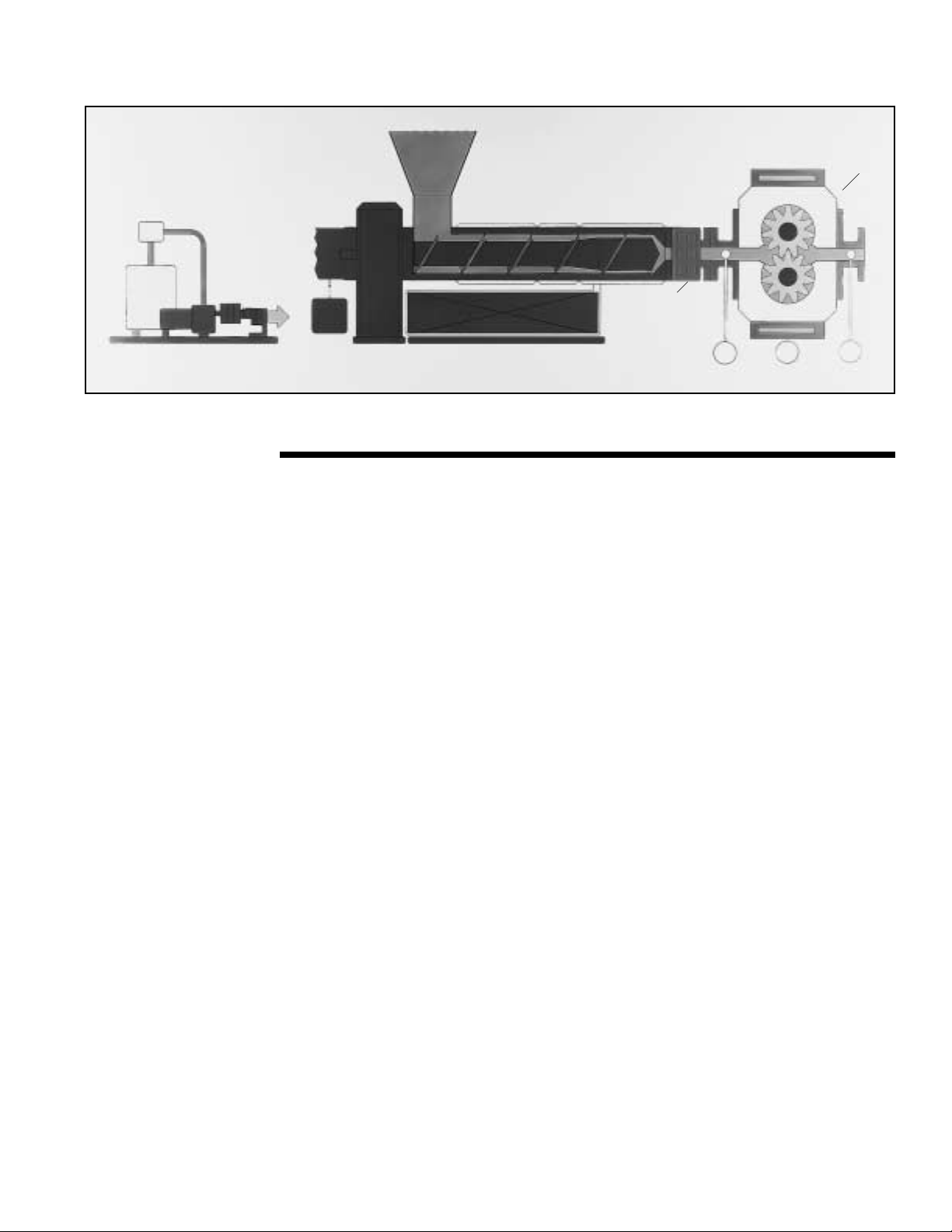

Zenith®Pumps and The Extrusion Process

Design

Zenith Pumps can handle all your extrusion pumping applications including

additive injection for on-line compounding of tackifiers, colorants, stabilizers, etc.

3

ZENITH

ADDITIVE

INJECTION

SYSTEM

ELECTRIC

HEAT PLATE

PUMP

TEMPERATURE

INLET

PRESSURE

DISCHARGE

PRESSURE

ZENITH

PEP-II

PUMP

CHANGER

P

P

T

EXTRUDER

The PEP-II pump is constructed of two

gears rotating in mesh within a closely fitted housing that is comprised of three

plates. The center, or gear plate, fits

closely around the outside diameter of the

metering gears and bearings. The front

and rear, or cover plates, sandwich the

center plate and restrict axial movement

of the gears and bearings. In capacities

of 5 cc/rev and larger, the driving gear is

manufactured integral with the drive shaft,

and the driven gear is machined integral

with its shaft. In capacities of 3.0 cc/rev

and below, the gears are keyed to their

respective shafts. In all capacities the

shafts are supported by “D” shaped

bearings which fit into the center plate. In

capacities of 40 cc/rev and above, these

bearings are located by two screws which

pass through the cover plates. In capacities

of 20 cc/rev and below, the bearings are

keyed to each other for accurate location.

Each cover plate is secured to the

center plate by 10 screws (6 screws for

below 5 cc/rev). Each side of the center

plate has a circular port in the center of a

bolt circle for the mounting of adapter

flanges that fit the pump to your equiment.

Threaded holes are provided on the top

and bottom of the center plate for the

mounting of heat plates and for the

mounting of the pump to its stand.

Thermocouple wells (1/8-27 NPT) are

located on the body of the pump.

A Zenith Rheoseal assembly secured

to each cover plate (front cover plate only

on 3.0 cc/rev and below) prevents leakage

around the shaft, using both dynamic and

static types of sealing mechanisms. A

Rheoseal consists of a helical groove on

the inner diameter, a cooling jacket and a

static, backup seal counter bore and

gland. These spiral grooves allow the

Rheoseal to act as a screw-type pump.

As the fluid attempts to leave the gear

pump, the shaft's rotary motion forces the

fluid into the grooves. This creates a pressure greater than the pressure forcing

polymer out of the pump, thus returning

the polymer back towards the pump.

Since the rotary motion is required of the

shaft, two other static types of seals are

employed on the Rheoseal—a spring

energized lip-seal or a packing seal

secured by the gland. Also a flushing

cooling jacket surrounds a portion of the

grooved seal. Use of the cooling jacket

may be required for effective sealing if the

viscosity is below 1,000 poise at process

conditions. If used, water passing through

the housing cools the polymer, increasing

the effectiveness of the seal's pumping

action. A thermocouple well is provided

in the seal housing to allow for measuring

the temperature close to the region where

sealing actually occurs.

A complete line of accessories is

available and includes heating plates

(electric, oil and steam), adapter flanges,

mounting blocks and pump drive systems

complete with power package controls

and process controls. Please contact

Zenith or your local Zenith representative

for further information.

Page 4

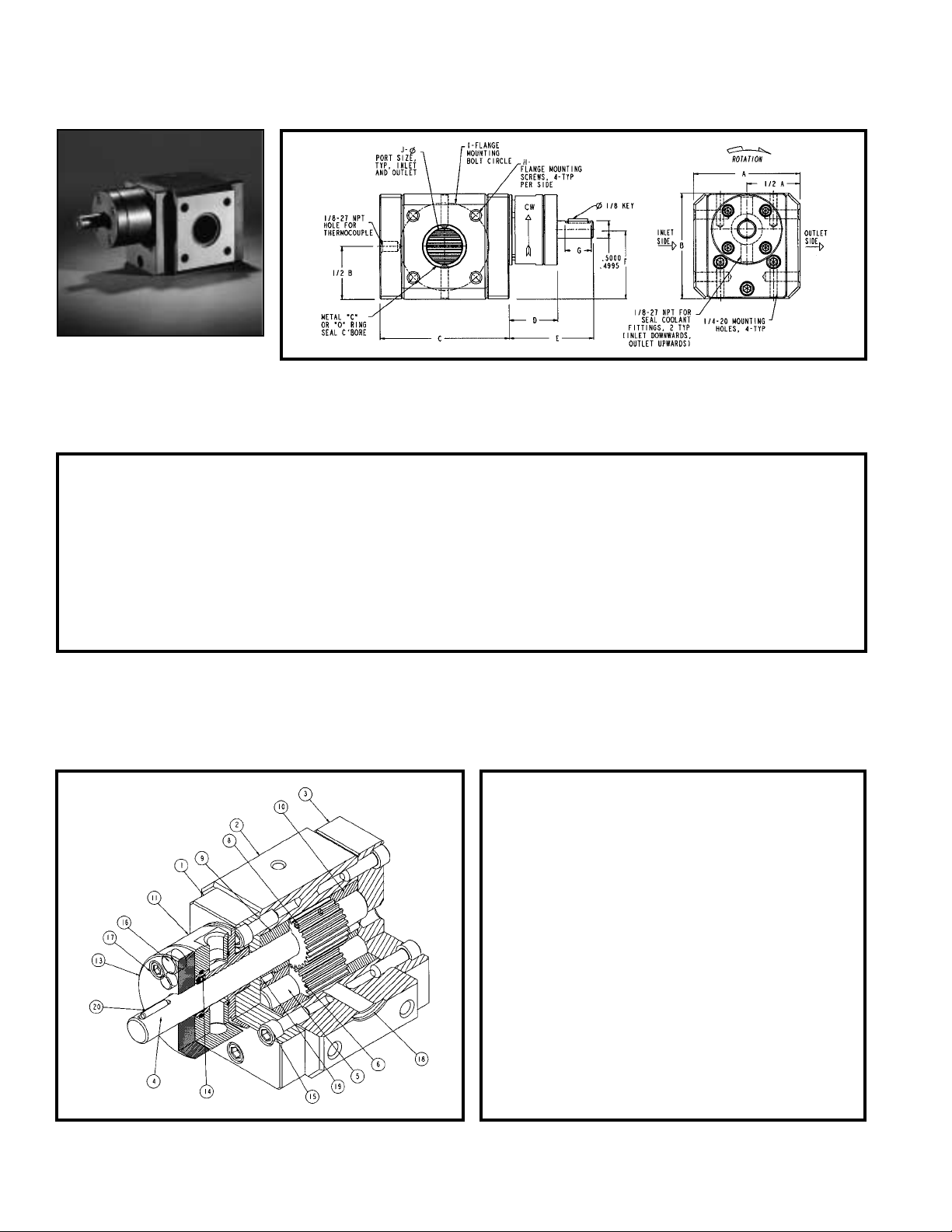

PEP-II Pump

0.16-3 cc/rev

ITEM QTY PART MATERIAL

1 1 FRONT PLATE TOOL STEEL

2 1 CENTER PLATE TOOL STEEL

3 1 REAR PLATE TOOL STEEL

4 1 DRIVE SHAFT TOOL STEEL

5 1 ARBOR TOOL STEEL

6 2 METERING GEAR TOOL STEEL

8 2 KEY, GEAR

9 2 BEARING TOOL STEEL

10 2 BEARING TOOL STEEL

11 1 RHEOSEAL STAINLESS

13 1 SEAL PLATE STAINLESS

14 1 LIP SEAL FILLED PTFE

15 6 SOCKET HEAD BOLT ALLOY

16 4 SOCKET HEAD BOLT ALLOY

17 4 SOCKET HEAD BOLT ALLOY

18 2 METAL C-RING, PORTS

19 2 KEY, D-BEARING

20 1 KEY, EXTERNAL

PUMP PUMP DIMENSIONS MAX APPROX

CAPACITY A B C D E F G H I J TORQUE WEIGHT

0.16 3.000 3.000 2.860 1.400 2.400 1.960 0.750 1/4 1.500 0.125 80 9

0.3 3.000 3.000 2.860 1.400 2.400 1.960 0.750 1/4 1.500 0.125 80 9

0.6 3.000 3.000 2.860 1.400 2.400 1.960 0.750 1/4 1.500 0.250 195 9

1.2 3.000 3.000 3.650 1.400 2.400 1.960 0.750 5/16 2.500 0.750 410 9

1.8 3.000 3.000 3.650 1.400 2.400 1.960 0.750 5/16 2.500 0.750 410 9

3.0 3.000 3.000 3.650 1.400 2.400 1.960 0.750 5/16 2.500 1.000 600 9

CC/REV PUMP DIMENSIONS ARE IN INCHES IN-LBS LBS

Materials Of Construction Diagram And Chart

Diagram 2 Chart 2

Chart 1

Dimensional Data Chart

Diagram 1

Dimensional Diagram

4

Page 5

ITEM QTY PART MATERIAL

1 1 DRIVING GEAR SHAFT TOOL STEEL

2 1 DRIVEN GEAR SHAFT TOOL STEEL

3 1 CENTER PLATE TOOL STEEL

4 2 COVER PLATE 4140

6 2 BEARING TOOL STEEL

7 2 BEARING TOOL STEEL

14 2 SEAL PLATE STAINLESS

16 2 LIP SEAL FILLED PTFE

17 20 SOCKET HEAD BOLT ALLOY

18 8 SOCKET HEAD BOLT ALLOY

20 2 RHEOSEAL STAINLESS

21 8 SOCKET HEAD CAP SCREW ALLOY

22 2 METAL C-RING, SEALS

23 2 METAL C-RING, PORTS NOT SHOWN

Materials Of Construction Diagram And Chart

Dimensional Diagram

PUMP PUMP DIMENSIONS MAX APPROX

CAPACITY ABCDE FGH IJTORQUE WEIGHT

5 3.250 3.250 3.250 1.125 2.875 2.125 0.500 1/4 1.875 0.750 1225 10

10 4.000 4.000 4.000 1.188 3.375 2.615 0.625 5/16 2.344 1.000 2085 18

20 4.750 5.000 5.000 1.188 3.750 3.300 0.750 3/8 2.813 1.250 3250 34

40 5.750 6.000 6.250 1.188 4.438 4.000 1.000 7/16 3.531 1.500 6750 61

100 8.000 8.250 8.250 1.750 5.438 5.458 1.250 5/8 4.688 2.188 12100 150

175 9.500 9.750 9.880 1.813 6.375 6.475 1.500 3/4 5.750 2.625 22400 260

300 11.250 12.000 12.500 2.375 8.063 8.000 2.000 7/8 7.063 3.000 50600 480

750 14.750 15.750 16.500 3.000 10.000 10.542 2.500 1 1/8 9.688 4.250 116600 1100

CC/REV PUMP DIMENSIONS ARE IN INCHES IN-LBS LBS

Dimensional Data Chart

Diagram 3

5

Chart 3

PEP-II Pump

5-750 cc/rev

Chart 4Diagram 4

Page 6

Operation

6

Installation

Polymer enters the PEP-II pump on the

suction side where shaft rotation exposes

gear tooth volumes between the gear

teeth. Polymer fills these spaces and is

transported to the discharge side where

the gear teeth mesh together, decreasing

the gear tooth volumes and displacing the

polymer. Due to the precision tolerances

and close clearances within the rotating

spaces, very high pressures can be

achieved at the pump discharge with

extremely high volumetric efficiencies.

As PEP-II pumps rely on the metered

polymer for lubrication of internal bearing

surfaces, the operating speed is designed

to be from 10 to 90 rpm on most extrusion

processes depending on process parameters. Do not allow the pump to run dry

or attempt to pump poor lubricating

fluids such as water or solvent. When

high-viscosity fluids are used, more time

is required to fill the tooth volumes. As a

result, the inlet pressure must be

increased or the gears must rotate at a

slower speed to ensure complete volume

filling. Proper speed and inlet pressure

must always be maintained to prevent

cavitation and to ensure proper lubrication.

Slip can occur across the sides

of the gears from the high-pressure side

to the low-pressure side. The amount of

slip depends on four factors: polymer

viscosity, speed, differential pressure

and pump clearances. Under reasonably

stable operating conditions, slip is repeatable and predictable, and pump operation

can be adjusted to compensate.

Pumps should be carefully unpacked to

make sure that the shipment is complete.

If any items are missing or damaged, the

freight carrier and Zenith should be notified immediately.

To prepare the pump for use:

1) Where required, install the heat

plates as follows. Zenith-supplied heat

plates are machined to tolerances that

eliminate the need for heat transfer cement.

All bolts used should be lubricated with

high-temperature thread lubricant such

as DAG Dispersion 154, Felpro C-100 or

equivalent.

2) Place the top heat plate on the

pump, then place the insulation jacket on

top of the heat plate. Install and tighten

the bolts, taking care not to crack the

insulation block.

3) Repeat for the bottom plate, noting

that bottom heat plate mounting bolts are

typically used to mount the pump to its

mounting block.

4) Place the supplied metal O-rings

into the counterbores in the pump ports,

and attach the inlet and discharge porting

flanges with lubricated screws. Replace

the O-rings after each use. Torque down

the screws in a crisscross pattern, taking

them first to 1/4 the recommended torque

value, then to 1/2, to 3/4 and finally to

their full recommended torque value as

shown on the table on page 10. If the

flanges are not supplied by Zenith, make

certain that their mating faces are flat,

with no pilots that protrude into the pump.

Check that the pump rotates freely by

turning the shaft with your hand.

5) The pump drive shaft should be

connected to the motor drive assembly

with a flexible coupling, a double universal

joint shaft or an appropriate Zenith SJMC

coupling. Side loading on the pump shaft

is to be avoided at all costs.

6) If water is used for sealing, connect

either 1/8-27 or 1/4-18 NPT fittings to the

Rheoseal and turn on the water. Be sure

to avoid excessive cooling, or damage to

the pump may occur.

7) Turn on the pump heaters. A 250° F

temperature rise per hour is recommended

for cold starts. No attempt should be

made to start the pump until the entire

pump is at operating temperature. Cold

starts are the most common cause of

pump failure.

On start-up, a small amount of molten

polymer should be introduced into the

pump by slowly rotating (less than 5 rpm)

the pump by hand to ensure that the

pump is free turning and well lubricated.

With sufficient inlet pressure, the pump

can then be started at a very slow speed,

with discharge pressure low enough to

maintain low loading. When operating

satisfactorily, the pump and system may

now be gradually brought up to normal

process speeds and pressures.

Page 7

Cleaning,

Inspection,

Repair and

Service

7

Disassembly

After removal from the system, the assembled pump can be cleaned by placing it

in a suitable furnace (i.e. vacuum oven,

fluidized bed, etc.) and slowly increasing

the temperature to 800-850° F in no less

than two hours. Special care should be

taken to avoid flashing of the polymer.

Control of temperature is essential as it is

possible to draw back the hardness of the

steel and affect dimensional stability if the

pump is overheated. The time to completely carbonize the polymer is three to

twelve hours, depending on the polymer,

temperature, pump size and furnace load.

The pump must be gradually cooled

to room temperature (no forced cooling

or quenching), then disassembled and

cleaned as instructed in the following

section. Close adherence to these instructions should be maintained for maximum

pump life and performance.

It is recommended that pump users

institute a program of dimensional inspection of critical parts in order to keep maintenance and operating costs at a minimum.

By noting the performance of a pump

immediately before removing it from service

and correlating the performance to measured component wear, the user can

establish the maximum wear limits for the

pump’s critical components. Further, he

can predict the service life of the pump,

and schedule his downtime accordingly.

After a pump has been disassembled,

all parts should be carefully inspected for

nicks, burrs, scoring or other signs of

wear. The side plates, D-bearings (and

sides of the gears on the 3.0 cc/rev and

smaller pumps) can be hand blocked on

600 grit paper, and any nick or burrs and

other sharp edges very lightly touched

with an Arkansas stone.

Note: After cleaning, all seals, O-rings

and fasteners must be discarded.

CAUTION: As the thickness relation-

ship between metering gears, center

plate and D-bearings is critical to metering

performance, care should be taken that

these parts are only polished and that

no metal is removed. Lapping of these

components should not be done under

any circumstances.

As with any other Zenith pumps, PEP-II

pumps may be returned to Zenith for

complete rehabilitation as necessary. This

procedure may be desirable if only a few

pumps are involved. If a large number of

pumps are to be maintained at the user’s

plant, it may be worthwhile to have key

maintenance personnel attend a maintenance seminar at the Zenith factory to view

the manufacturing, gauging and assembly

techniques involved in producing the

PEP-II pump. In addition, Zenith also

offers a contract service program. Please

contact Zenith for further information on

these services.

These instructions should be thoroughly

read and understood before starting disassembly.

General instructions that should be

observed to ensure correct disassembly

of the pump are as follows:

• If the pump is to be disassembled

on a regular basis, set up a room with a

separate clean area with all the tools

required for disassembly, reassembly and

storage.

• During disassembly, note the location and orientation of all parts to ensure

proper reassembly.

• Use a soft-jawed vise to hold the

pump during disassembly.

When maintenance is required, refer

to the exploded view and disassemble the

pump as follows:

CAUTION: Careful handling of the parts

is imperative. Do not drop or allow parts

to strike each other. The slightest nick or

burr can cause difficulty in reassembly and

may cause further damage to the pump.

1) Clearly mark which side of the

pump is the inlet port and drive input side.

2) Remove the screws securing the

Rheoseal seal plate cover to the seal

housing and remove the cover.

3) Remove the screws securing the

Rheoseal seal housing to the cover plate

and withdraw the housing from the cover

plate and shaft, taking care not to damage the drive shaft. After removal of the

seal housing, disassemble and clean the

Rheoseal housings either mechanically or

chemically (always replace the O-rings).

4) Carefully pry out and discard the

lipseals at this time, taking care not to

damage the seal countersink in the housing, as damage here could cause polymer

leakage at start-up.

5) Loosen and remove the D-bearing

retainer screws (40 cc/rev and above

only).

6) Loosen all cover plate screws one

turn, then back them out and remove

them from the pump. Remove each cover

Page 8

Disassembly

continued

8

D-Bearing

Orientation

Schematic

plate and set aside in a safe place to prevent damage. At this point, make certain

to note the orientation of the groove on the

rear of each bearing with respect to the

inlet port. They MUST be reassembled in

the same way as disassembled; that is,

they must point toward the inlet port, or

severe pump damage may result when

the pump is started.

WARNING: (Read before steps 7 & 8)

Extreme caution must be exercised when

removing the gear shafts and bearing. For

the 40 cc/rev and above capacity pumps,

which have two (2) tapped holes in the Dbearing faces, an optional disassembly

method is possible. If the gear shaft and

two D-bearings will not slide out as a

complete assembly after tapping with a

soft-faced hammer, it is recommended

that a gear puller tool be used to extract

the individual D-bearings from each side

of the gear shafts. If these still exhibit

force, soaking in a lubricating (penetrating) oil will help the disassembly.

For 20 cc/rev and smaller capacities, there are no tapped holes in the

D-bearing faces to be utilized. The gear

shaft and D-bearings must be removed

as a complete assembly. Again, soaking

the parts in lubricating (penetrating) oil

or other non-damaging solution will help

ease the disassembly. Do not force the

parts out one side with a hammer or

arbor press.

7) Slide the gear shafts and bearings

out of the center plate. They will not come

out separately as the gear teeth will not

clear the bearings. Take extreme care not

to nick or ding the gear teeth or the edges

of the bearings. If they will not slide out

easily, use a hammer with a plastic or soft

brass head to gently tap them out. DO

NOT use a steel-headed hammer.

Alternate taps on the shafts until the parts

slide clear. Separate the two shaft/bearing

assemblies, taking care not to lose the

keys in the 10 cc/rev and smaller pumps.

There are no keys in the 20 cc/rev and

larger pumps.

8) Slide the bearings from the shafts,

again taking extreme care not to damage

the gear teeth, bearing edges or the

shafts. If the bearings will not slide easily

from the shaft (due to residual polymer),

use a plastic or soft brass-headed hammer and a soft drift (NOT steel) to gently

tap the bearings free. Do not pry them off

with a screwdriver or other tool as this

may damage the gear teeth. Identify

which shaft the bearings came from, and

set them aside in a safe place.

9) On the 3 cc/rev and smaller, slide

the gears from their shafts and remove

the keys from the shaft.

Page 9

Reassembly

9

These instructions should be thoroughly

read and understood before starting

reassembly.

General instructions that should be

observed to ensure correct reassembly

of the pump are as follows:

• Using a solvent such as

trichloroethane or chloroethene Nu,

clean all parts that are to be used in the

reassembled pump.

WARNING: Use extreme care when using

any solvent. Prolonged contact with the

liquid or inhalation of the vapor can cause

serious health problems.

• During and between each of the

assembly steps, manually turn the

metering gears to ensure that they are

free turning. If binding occurs at any time

during assembly, determine the cause

and correct it before proceeding further.

A tiny nick, burr or foreign particle can

extensively damage a valuable part if

allowed to remain. Never use excessive

force in assembling or turning a pump. If

properly aligned, the pieces will fit easily

into the plate, and the drive shaft will turn

freely. All seals, O-rings and fasteners

must be replaced with new parts prior

to assembly.

• Use a soft-jawed vise to hold the

pump during reassembly.

• Before installing screws, lubricate

their threads with DAG Dispersion 154,

Felpro C-100, or similar heat-resistant

lubricant, and torque to prescribed values

as shown on the table on page 10.

1) On 3.0 cc/rev and smaller pumps,

place a gear key on each shaft and slide

each gear onto its shaft, engaging the key.

2) Slide the gear shafts into the center

plate, taking care not to damage the gear

teeth. On 3.0 cc/rev and smaller pumps,

note that each shaft has a larger diameter

end. These larger ends must be on opposite sides of the pump for the bearing

grooves to align properly.

3) Gently slide the gear shafts so that

the rear ends of the shafts protrude from

the rear of the center plate. On the 3.0

cc/rev and smaller pumps, take care not

to slide the shafts out of the gears and

allow the keys to drop out of the shafts.

4) Slide a bearing onto the drive shaft,

taking special care to select a bearing

with the proper groove configuration (and

with the proper ID on the 3.0 cc/rev and

smaller pumps). Slide the matching bearing onto the driven shaft, taking care to

select a bearing with the proper groove

configuration. Set the flats on the circumference of the bearings against each

other, and gently slide the bearings and

shafts into the center plate. Slide them far

enough through the center plate to allow

the drive shaft to protrude out on the front

side and allow the front bearings to be

installed. See D-bearing orientation

schematic on page 8.

5) Install the front bearings in the

same manner as the rear bearings, and

slide the bearings and shafts back into

the center plate so that the gears are

roughly in the center of the center plate.

6) For the 20 cc/rev and smaller

pumps, the bearings should be allowed to

protrude very slightly above the face of

the center plate before the cover plates

are installed. This will allow the bearings

to fit flush against the cover plates as

there are no bearing screws on these

smaller pumps. For 20 cc/rev and smaller

pumps, insert the bearing locating keys

on each side.

7) At this point make certain again

that there is no foreign matter on the faces

of the cover plates or on the faces of the

center plate. An accidental smudge of

thread lubricant can cause the small

pumps to bind.

8) Place the front cover plate on the

pump (and center on pump), checking

one more time that the configuration of the

bearing grooves is correctly oriented for

the inlet and discharge ports of the pump.

Insert the lubricated cover plate screws

into the pump and tighten them finger

tight only. Repeat for the rear cover plate.

9) On the 40 cc/rev and larger pumps,

insert the bearing retainer screws and

tighten them finger tight at this time.

10 Torque down the cover plate

screws in a crisscross pattern, taking

them first to 1/4 the recommended torque

value, then to 1/2, to 3/4 and finally to

their full recommended torque value.

11) Torque down the bearing retainer

screws in the same manner as the cover

plate screws. (Install C-Rings if applicable.)

12) Fit the Rheoseal seal housing to

the shaft. Loosely install but do not torque

down the seal housing screws, as this will

allow the lip seal to properly center the

housing.

13) Install the lip seals, using the

special Zenith installation tools as follows

to prevent damaging the seal. Install the

lip seals with the open face toward the

body of the pump. Slide the installation

Page 10

Size (UNC Recommended

Alloy Steel) Torque (in-lbs)

1/2-13 922

9/16-12 1,331

5/8-11 1,836

3/4-10 3,257

7/8-9 5,800

1-8 8,000

1 1/8-7 12,000

10

Reassembly

continued

Bolt Torque

Size (UNC Recommended

Alloy Steel) Torque (in-lbs)

#8-32 30

#10-24 43

#10-32 49 (UNF thread)

1/4-20 103

5/16-18 213

3/8-18 378

7/16-14 605

PEP-II

ISO View

Clockwise rotation, pressure building pump shown (standard).

ring on the shaft with the ID tapering

toward the pump. On the drive shaft ends,

fit the bullnose on the end of the shaft.

Work the seal gently over the end of the

bullnose and down the shaft, as any damage could cause polymer leakage after

start-up. Ease the seal into the wide end

of the installation ring and, using the

pressing tool, gently press the lip seal into

the Rheoseal housing. Do not attempt to

press on the lip seal with screwdriver or

other pointed object, as this will damage

the seal. Do not press the lip seal all the

way into its cavity. Instead, allow it to

protrude slightly so that it will be correctly

seated by the seal cover. Carefully

remove the special Zenith tools.

14) Slide the seal cover over the shaft

until it rests on the protruding lip seal.

Align the screw holes in the cover with

those in the housing and insert the

screws. Tighten them evenly in a crisscross pattern so that the seal is slowly

pressed into the seal housing. When the

cover is touching the housing all the way

around, remove the seal cover and torque

the seal housing bolts down. Reinstall the

seal cover on the shaft and torque it

down. In reinstalling the pump, be certain

to follow the instructions given in the

Installation section of this manual.

Page 11

11

Troubleshooting

Parts

Replacement

When ordering replacement parts, please be sure to include the following information:

1) Pump model number

2) Part number (12-digit) and description

3) Quantity

4) Shipping instructions

Order parts from your local Zenith representative or direct from Zenith.

Trouble Probable Cause Remedy

Pump will not turn 1) Low pump Check thermocouple and control

temperature loop for proper setting/operation.

Allow sufficient heat-up time.

2) Drive malfunction Verify drive is powered. Check to

assure all alarm circuits are clear.

Check drive motor current and

speed settings. Check all drive

couplings.

3) Process

conditions changed Check process conditions for

proper melt temperature, pressures, viscosities and materials.

4) Entrained particle Disassemble and clean pump;

replace any damaged parts.

5) Possible

internal damages Disassemble and clean pump;

replace damaged parts.

Consult factory.

Excessive seal

assembly leakage 1) Worn lip seal Replace lip seals.

2) Incorrect water flow Monitor and adjust water flow

to provide correct sealing

temperature.

3) Clogged Rheoseal Disassemble two-piece seal

channel housing and inspect.

Reduced pump

efficiency 1) Worn gear(s) Replace worn gear.

2) Worn bearings Replace worn bearings.

3) Process conditions Consult factory for clearance

changed recommendations on new

process conditions.

Page 12

FAILURE, IMPROPER SELECTION OR IMPROPER USE

OF THE PRODUCTS AND/OR SYSTEMS DESCRIBED

HEREIN OR RELATED ITEMS CAN CAUSE DEATH,

PERSONAL INJURY AND PROPERTY DAMAGE.

This document and other information from Zenith Pumps, its

subsidiaries and authorized distributors provide product and/or

system options for further investigation by users having technical

expertise. It is important that you analyze all

aspects of your application and review the information concerning

the product or system in the current product catalog. Due to the

variety of operating conditions and applications for these products

or systems, the user, through its own analysis and testing, is solely

responsible for making the nal selection of the products and

systems and assuring that all performance, safety and warning

requirements of the application are met.

The products described herein, including without limitation,

product features, specications, designs, availability and pricing,

are subject to change by Zenith Pumps and its subsidiaries at

any time without notice.

WARNING

A Colfax Buisiness Unit

ISO 9001: 2000 Registered

Zenith®Pumps

1710 Airport Road

Monroe, NC 28110

Phone: 704-289-6511 • Fax: 704-289-9273

zenithpumps@colfaxcorp.com • www.zenithpumps.com

© Copyright 1992 Zenith Pumps PEP C&M 10/04

Loading...

Loading...