Zebra Technologies ZT400 User Manual

P1066582-002 Rev. B

Zebra® ZT400 Series™

User Guide

© 2014 ZIH Corp. The copyrights in this manual and the software and/or firmware in the printer described

therein are owned by ZIH Corp. and Zebra’s licensors. Unauthorized reproduction of this manual or the software

and/or firmware in the printer may result in imprisonment of up to one year and fines of up to $10,000

(17 U.S.C.506). Copyright violators may be subject to civil liability.

This product may contain ZPL

Monotype Imaging fonts. Software © ZIH Corp. All rights reserved worldwide.

Zebra, the Zebra head graphic, Link-OS, ZPL, and ZPL II are trademarks of ZIH Corp., registered in many

jurisdictions worldwide. All rights reserved.

Bluetooth

All other brand names, product names, or trademarks belong to their respective holders. For additional trademark

information, please see “Trademarks” on the product CD.

®

is a registered trademark of the Bluetooth SIG.

®

, ZPL II®, and ZebraLink™ programs; Element Energy Equalizer® Circuit; E3®; and

Proprietary Statement This manual contains proprietary information of Zebra Technologies Corporation and its

subsidiaries (“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced, or disclosed

to any other parties for any other purpose without the express, written permission of Zebra Technologies.

Product Improvements Continuous improvement of products is a policy of Zebra Technologies. All

specifications and designs are subject to change without notice.

Liability Disclaimer Zebra Technologies takes steps to ensure that its published Engineering specifications and

manuals are correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

Limitation of Liability In no event shall Zebra Technologies or anyone else involved in the creation, production,

or delivery of the accompanying product (including hardware and software) be liable for any damages whatsoever

(including, without limitation, consequential damages including loss of business profits, business interruption, or loss

of business information) arising out of the use of, the results of use of, or inability to use such product, even if Zebra

Technologies has been advised of the possibility of such damages. Some jurisdictions do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

Part Number: P1066582-002 Rev. A

Declaration of Conformity

Declaration of Conformity

We have determined that the Zebra printers identified as the

3

ZT410™ and ZT420™

manufactured by:

Zebra Technologies Corporation

475 Half Day Road, Suite 500

Lincolnshire, Illinois 60069 U.S.A.

Have been shown to comply with the applicable technical standards of the FCC

For Home, Office, Commercial, and Industrial use

If no unauthorized change is made in the equipment,

and if the equipment is properly maintained and operated.

4/8/14 ZT400 Series™ User Guide P1066582-002

Declaration of Conformity

4

Compliance Information

Compliance Information

FCC Compliance Statement

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause

undesired operation.

Note • This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio/TV technician for help.

FCC Radiation Exposure Statement

(for printers with RFID encoders)

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed and operated with minimum distance 20cm

between the radiator and your body.

This transmitter must not be co-located or operating in conjunction with any other antenna or

transmitter.

Canadian DOC Compliance Statement

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

P1066582-002 ZT400 Series™ User Guide 4/8/14

Contents

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Compliance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

About This Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Who Should Use This Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

How This Document Is Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1 • Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Printer Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Printer Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Near Field Communication (NFC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Types of Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Ribbon Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

When to Use Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Coated Side of Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2 • Printer Setup and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Handling the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Unpack and Inspect the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Store the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Ship the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Select a Location for the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Select a Communication Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Data Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connect the Printer to a Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Power Cord Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Select a Print Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4/8/14 P1066582-002

Contents

6

Load the Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Final Steps for Tear-Off Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Final Steps for Peel-Off Mode

(with or without Liner Take-Up) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Final Steps for Rewind Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Final Steps for Cutter Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Load the Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3 • Printer Configuration and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Adjust Printer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Print Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Calibration and Diagnostic Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Network Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

RFID Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Language Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Sensor Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Port Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

BlueTooth Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

User Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Navigating through Screens in the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

SETTINGS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

TOOLS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

NETWORK Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

RFID Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

LANGUAGE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

SENSORS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

PORTS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

BLUETOOTH Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Calibrate the Ribbon and Media Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Adjust the Printhead Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Remove Used Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

4 • Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Cleaning Schedule and Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Clean the Exterior, the Media Compartment, and the Sensors . . . . . . . . . . . . . . . . 131

Clean the Printhead and Platen Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Clean the Peel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Clean the Cutter Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Replacing Printer Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Ordering Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Recycling Printer Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

P1066582-002 ZT400 Series™ User Guide 4/8/14

Contents

5 • Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Meaning of Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Printing Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Ribbon Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

RFID Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Communications Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Miscellaneous Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Printer Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Power-On Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

CANCEL Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

PAUSE Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

FEED Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

FEED + PAUSE Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

CANCEL + PAUSE Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Communication Diagnostics Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Sensor Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

7

6 • Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Printing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Media Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Ribbon Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

4/8/14 ZT400 Series™ User Guide P1066582-002

Contents

Notes • ___________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

8

P1066582-002 ZT400 Series™ User Guide 4/8/14

About This Document

This section provides you with contact information, document structure and organization, and

additional reference documents.

Contents

Who Should Use This Document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

How This Document Is Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4/8/14 P1066582-002

About This Document

10

Who Should Use This Document

Who Should Use This Document

This User Guide is intended for use by any person who needs to perform routine maintenance,

upgrade, or troubleshoot problems with the printer.

How This Document Is Organized

The User Guide is set up as follows:

Section Description

Introduction on page 11 This section provides a high-level overview of the

printer and its components.

Printer Setup and Operation

on page 21

Printer Configuration and Adjustment

on page 65

Routine Maintenance on page 129 This section provides routine cleaning and

Troubleshooting on page 145 This section provides information about errors that

Specifications on page 173 This section lists general printer specifications,

Glossary on page 179 The glossary provides a list of common terms.

This section assists the technician with initial setup

and operation of the printer.

This section assists you with configuration of and

adjustments to the printer.

maintenance procedures.

you might need to troubleshoot. Assorted

diagnostic tests are included.

printing specifications, ribbon specifications, and

media specifications.

P1066582-002 ZT400 Series™ User Guide 4/8/14

Introduction

This section provides a high-level overview of the printer and its components.

1

Contents

Printer Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Types of Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Ribbon Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

When to Use Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Coated Side of Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4/8/14 P1066582-002

Introduction

12

34

12

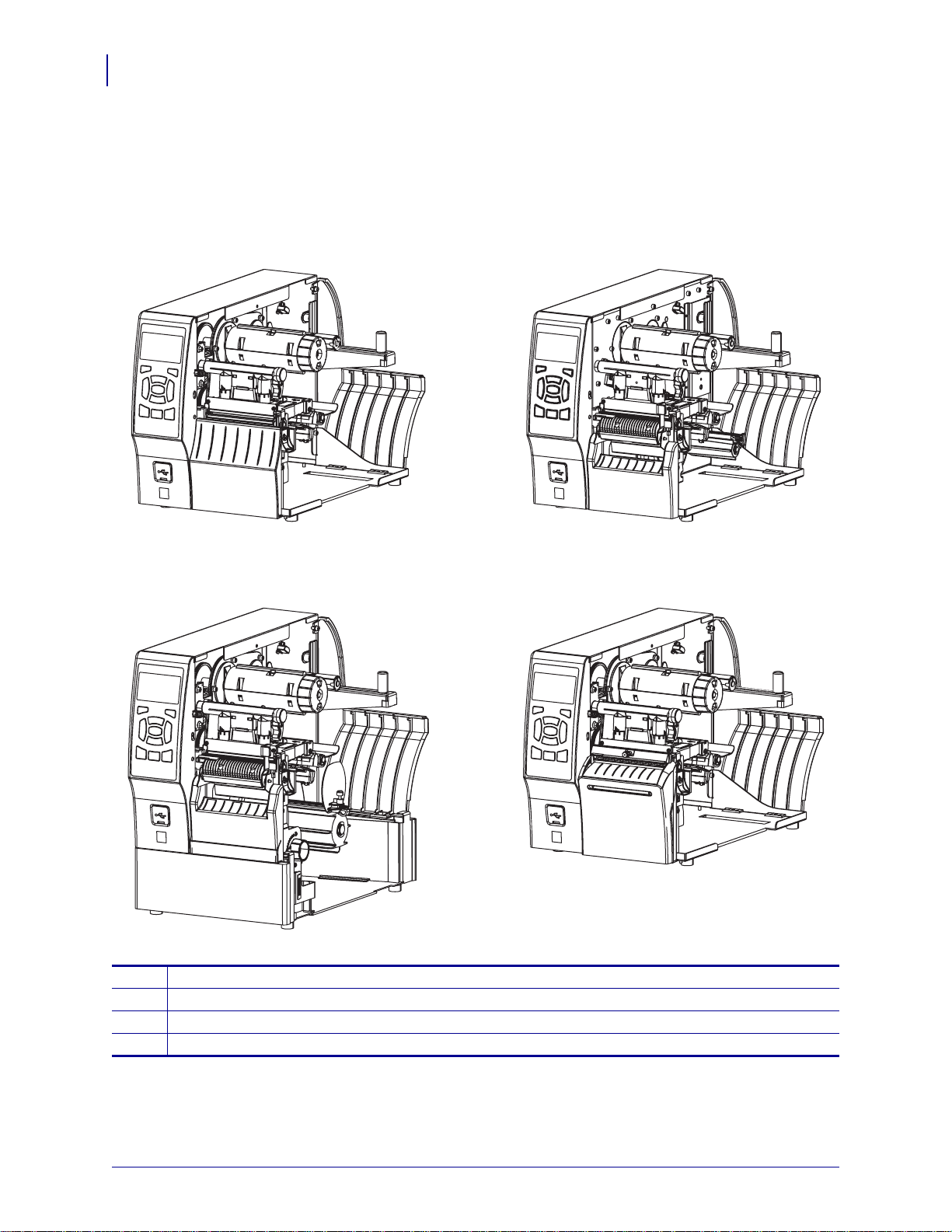

Printer Options

Printer Options

The available printer options are shown in Figure 1. For information about the print modes that

can be used with the printer options, see Select a Print Mode on page 30.

Figure 1 • Printer Options

Tear-Off (standard)

1

Peel with Liner Take-Up option

2

Rewind option

3

Cutter option

4

P1066582-002 ZT400 Series™ User Guide 4/8/14

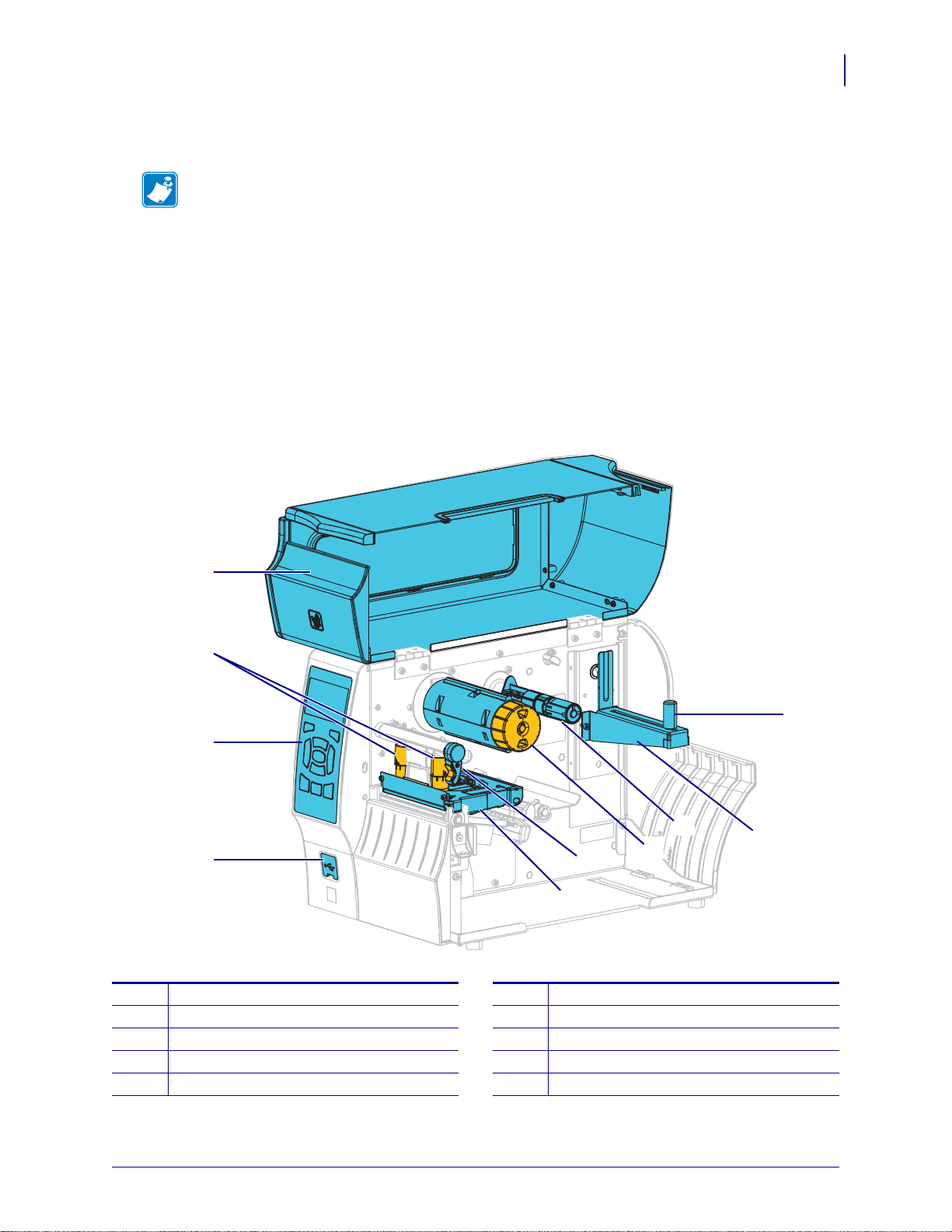

Printer Components

1

3

4

2

10

9

8

7

6

5

Note • The components inside your printer are color-coded.

• The touch points that you will need to handle are colored gold inside the printers and are

highlighted in gold in the illustrations in this manual.

• The components associated with the ribbon system are made of black plastic, while the

components associated with media are made of gray plastic. Those components and

others are highlighted in light blue in the illustrations in this manual as needed.

Figure 2 shows the components inside the media compartment of a standard printer.

Depending on the printer model and the installed options, your printer may look slightly

different. The components that are labeled are mentioned in procedures throughout this

manual.

Figure 2 • Printer Components

Introduction

Printer Components

13

Media door

1

Printhead pressure adjustment toggles

2

Control panel

3

USB host port

4

Printhead assembly

5

* This component appears only in printers that have the Thermal Transfer option installed.

4/8/14 ZT400 Series™ User Guide P1066582-002

Printhead-open lever

6

Ribbon take-up spindle*

7

Ribbon supply spindle*

8

Media supply hanger

9

Media supply guide

10

Introduction

6

13

12

9

8

11

10

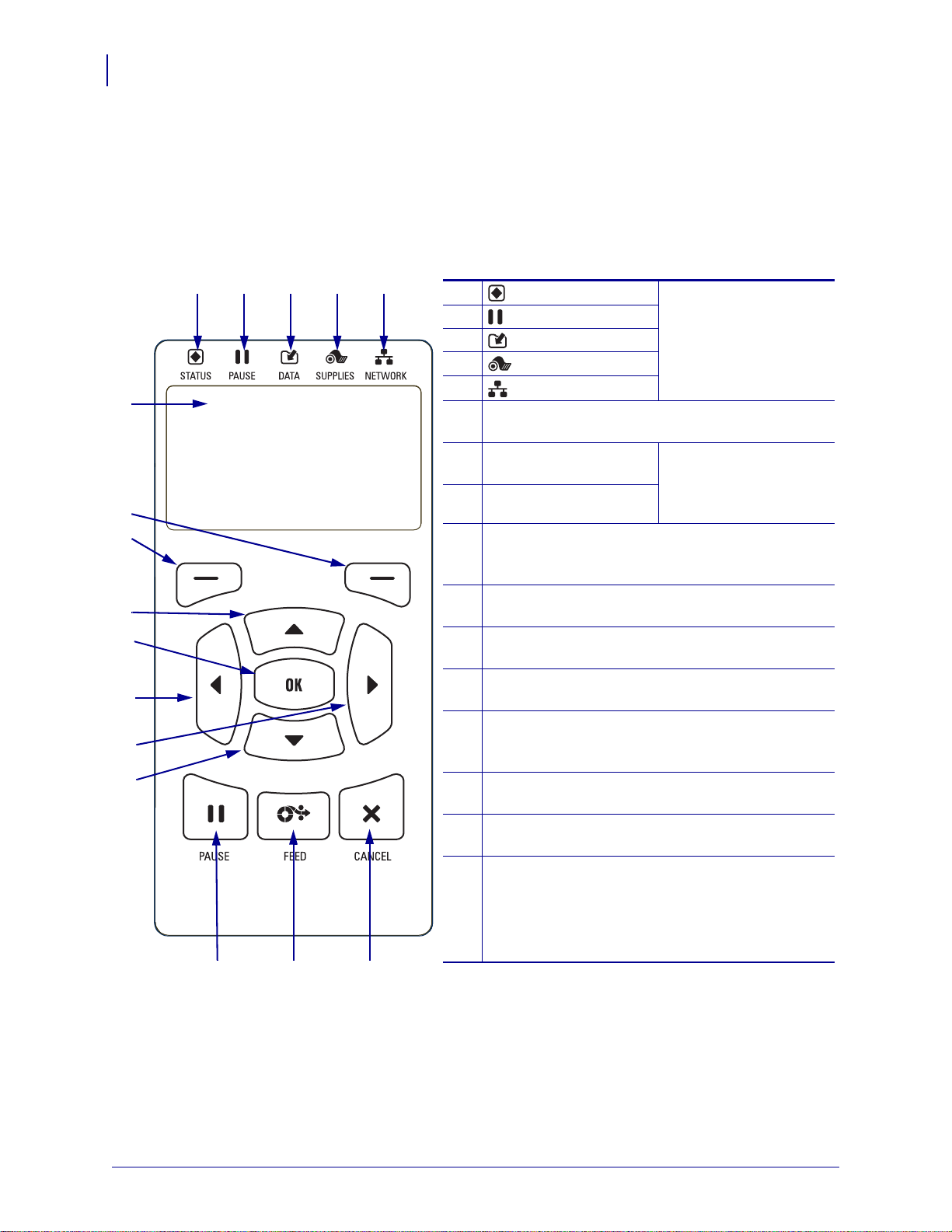

1 2 3 4 5

14 15 16

Figure 3 • Control Panel

7

1

STATUS light These indicator lights

show the current status

of the printer. For more

information, see Table 1

on page 146.

2

PAUSE light

3

DATA light

4

SUPPLIES light

5

NETWORK light

6

The display shows the printer’s current status and

allows the user to navigate the menu system.

7

RIGHT SELECT

button

These buttons execute

the commands shown

directly above them in

the display.

8

LEFT SELECT button

9

The UP ARROW button changes the parameter

values. Common uses are to increase a value or to

scroll through choices.

10

The OK button selects or confirms what is shown

on the display.

11

The LEFT ARROW button, which is active only

in the menu system, navigates to the left.

12

The RIGHT ARROW button, which is active only

in the menu system, navigates to the right.

13

The DOWN ARROW button changes the

parameter values. Common uses are to decrease a

value or to scroll through choices.

14

The PAUSE button starts or stops printer operation

when pressed.

15

The FEED button forces the printer to feed one

blank label each time the button is pressed.

16

The CANCEL button cancels label formats when

the printer is paused.

• Press once to cancel the next label format.

• Press and hold for 2 seconds to cancel all label

formats.

14

Control Panel

Control Panel

The control panel indicates the printer’s current status and allows the user to control basic

printer operation.

P1066582-002 ZT400 Series™ User Guide 4/8/14

Near Field Communication (NFC)

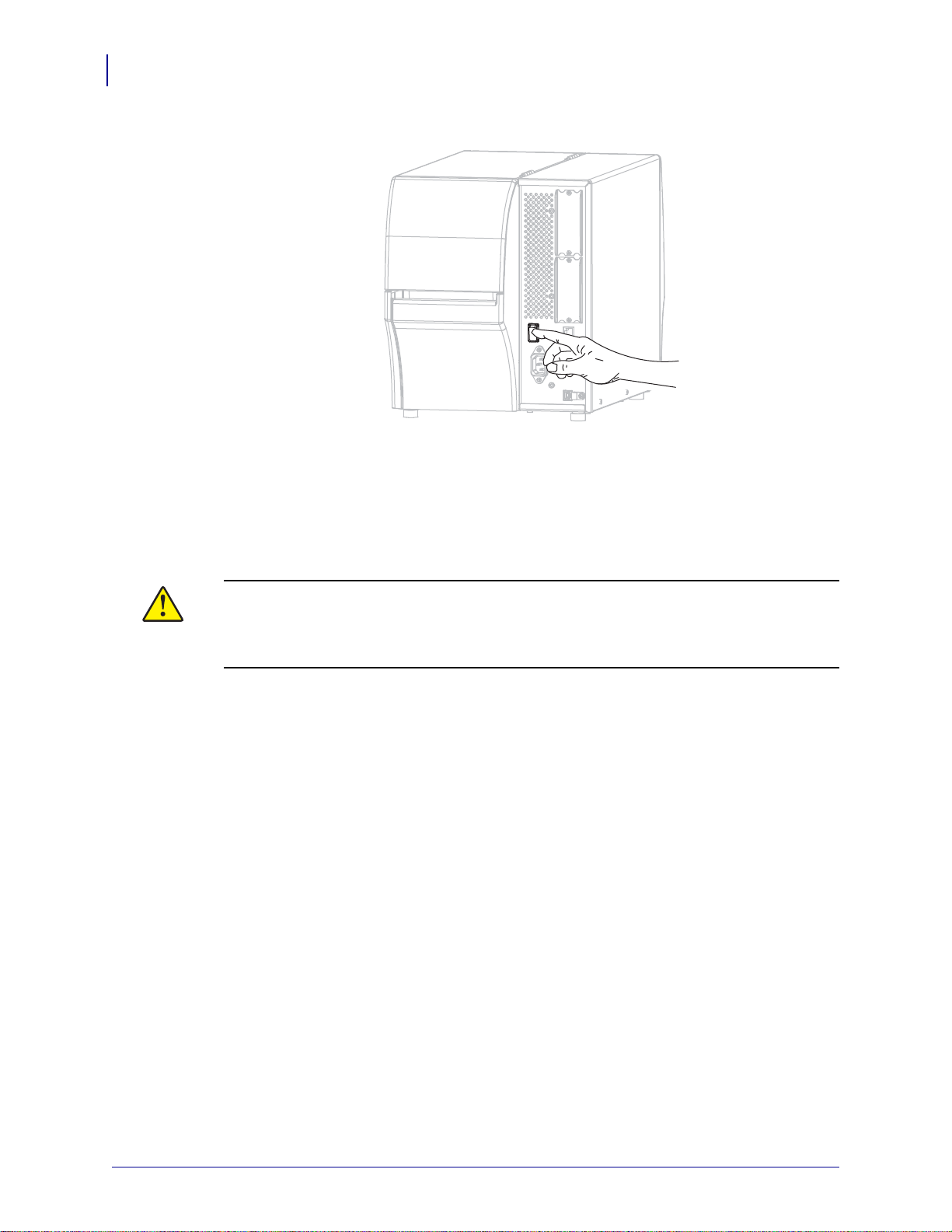

The Zebra Print Touch™ feature allows you to touch an Android™-based, NFC-enabled

smartphone or tablet to the Zebra Print Touch logo (Figure 4) to pair the device to the printer.

Your device then launches an app that displays a menu of choices that are specific to your

Zebra printer.

Figure 4 • Print Touch Logo Location

Introduction

Near Field Communication (NFC)

15

4/8/14 ZT400 Series™ User Guide P1066582-002

Printer Setup and Operation

16

Types of Media

Types of Media

Important • Zebra strongly recommends the use of Zebra-brand supplies for continuous

high-quality printing. A wide range of paper, polypropylene, polyester, and vinyl stock has

been specifically engineered to enhance the printing capabilities of the printer and to prevent

premature printhead wear. To purchase supplies, go to http://www.zebra.com/howtobuy.

Your printer can use various types of media:

• Standard media—Most standard media uses an adhesive backing that sticks individual

labels or a continuous length of labels to a liner. Standard media can come on rolls or in a

fanfold stack (Table 1).

• Tag stock—Tags are usually made from a heavy paper. Tag stock does not have adhesive

or a liner, and it is typically perforated between tags. Tag stock can come on rolls or in a

fanfold stack (Table 1).

• Radio frequency identification (RFID) “smart” media—RFID

media can be used in a printer that is equipped with an RFID

reader/encoder. RFID labels are made from the same materials and

adhesives as non-RFID labels. Each label has an RFID transponder

(sometimes called an “inlay”), made of a chip and an antenna,

embedded between the label and the liner. The shape of the transponder varies by

manufacturer and is visible through the label. All “smart” labels have memory that can be

read, and many have memory that can be encoded.

Important • Transponder placement within a label depends on the transponder type and

the printer model. Make sure that you are using the correct “smart” media for your printer.

For more information, refer to the RFID Programming Guide 3. A copy of the manual is

available at http://www.zebra.com/manuals or on the user CD that came with your printer.

For transponder placement details, go to http://www.zebra.com/transponders.

P1066582-002 ZT400 Series™ User Guide 4/8/14

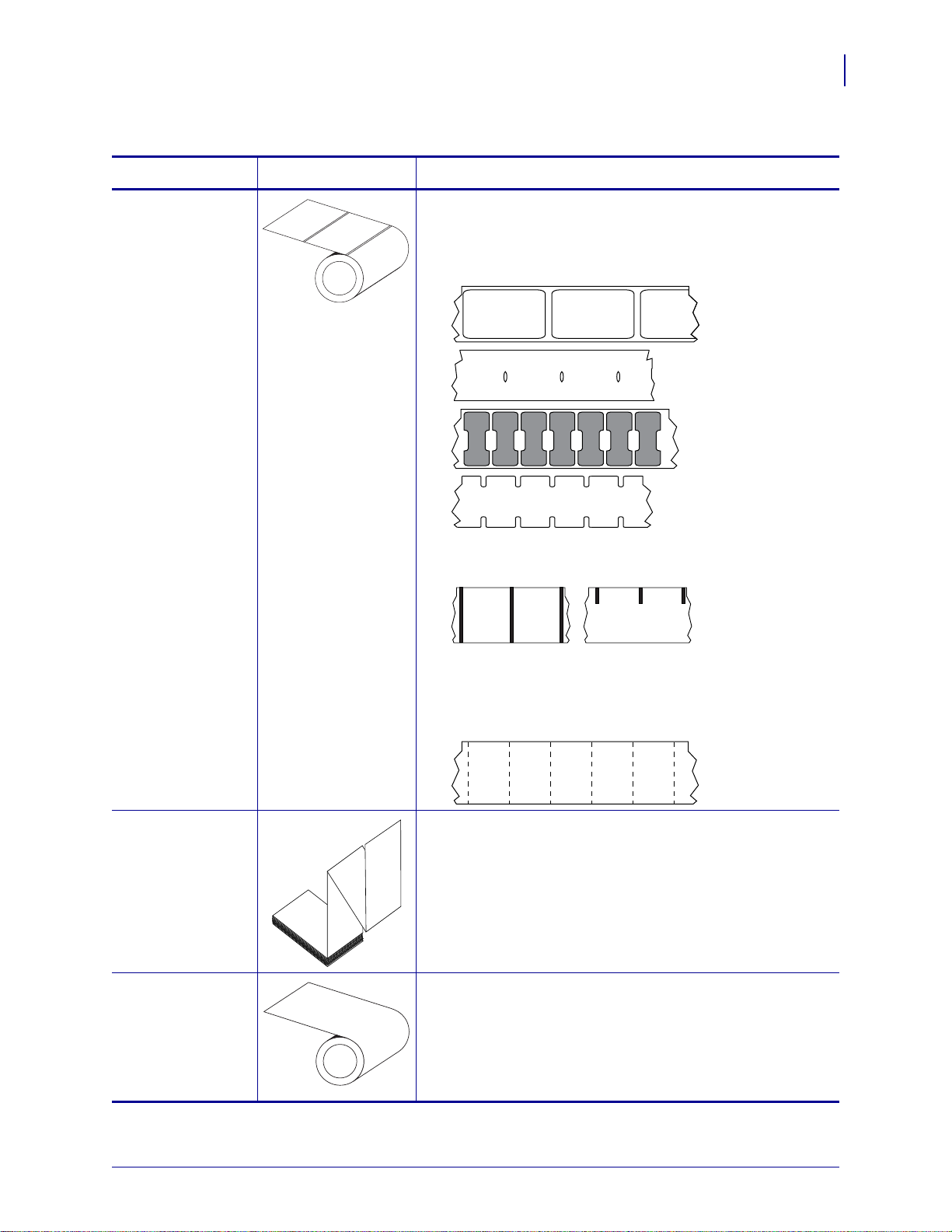

Table 1 • Roll and Fanfold Media

Media Type How It Looks Description

Printer Setup and Operation

Types of Media

17

Non-Continuous

Roll Media

Roll media is wound on a core that can be 1 in. to 3 in. (25 to

76 mm) in diameter. Individual labels or tags are separated by

one or more of the following methods:

• Web media separates labels by gaps, holes, or notches.

• Black mark media uses pre-printed black marks on the

back side of the media to indicate label separations.

Non-Continuous

Fanfold Media

Continuous

Roll Media

• Perforated media has perforations that allow the labels or

tags to be separated from each other easily. The media may

also have black marks or other separations between labels

or tags.

Fanfold media is folded in a zigzag pattern. Fanfold media can

have the same label separations as non-continuous roll media.

The separations would fall on or near the folds.

Roll media is wound on a core that can be 1 in. to 3 in. (25 to

76 mm) in diameter.

Continuous roll media does not have gaps, holes, notches, or

black marks to indicate label separations. This allows the

image to be printed anywhere on the label. Sometimes a cutter

is used to cut apart individual labels.

4/8/14 ZT400 Series™ User Guide P1066582-002

Printer Setup and Operation

Outside Inside

18

Ribbon Overview

Ribbon Overview

Ribbon is a thin film that is coated on one side with wax, resin, or wax resin, which is

transferred to the media during the thermal transfer process. The media determines whether

you need to use ribbon and how wide the ribbon must be.

When ribbon is used, it must be as wide as or wider than the media being used. If the ribbon is

narrower than the media, areas of the printhead are unprotected and subject to premature wear.

When to Use Ribbon

Thermal transfer media requires ribbon for printing while direct thermal media does not.

To determine if ribbon must be used with a particular media, perform a media scratch test.

To perform a media scratch test, complete these steps:

1. Scratch the print surface of the media rapidly with your fingernail.

2. Did a black mark appear on the media?

If a black mark... Then the media is...

Does not appear on the media Thermal transfer. A ribbon is required.

Appears on the media Direct thermal. No ribbon is required.

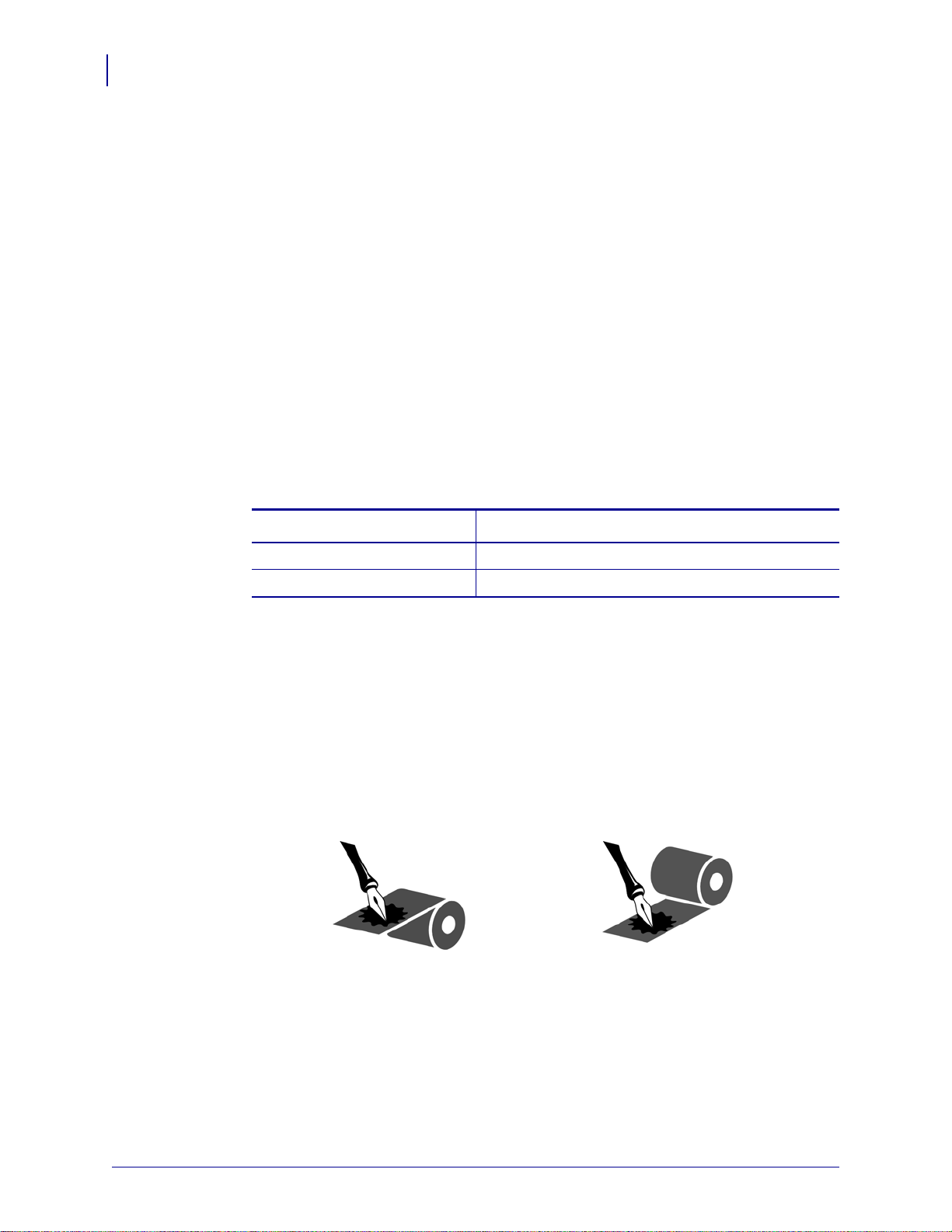

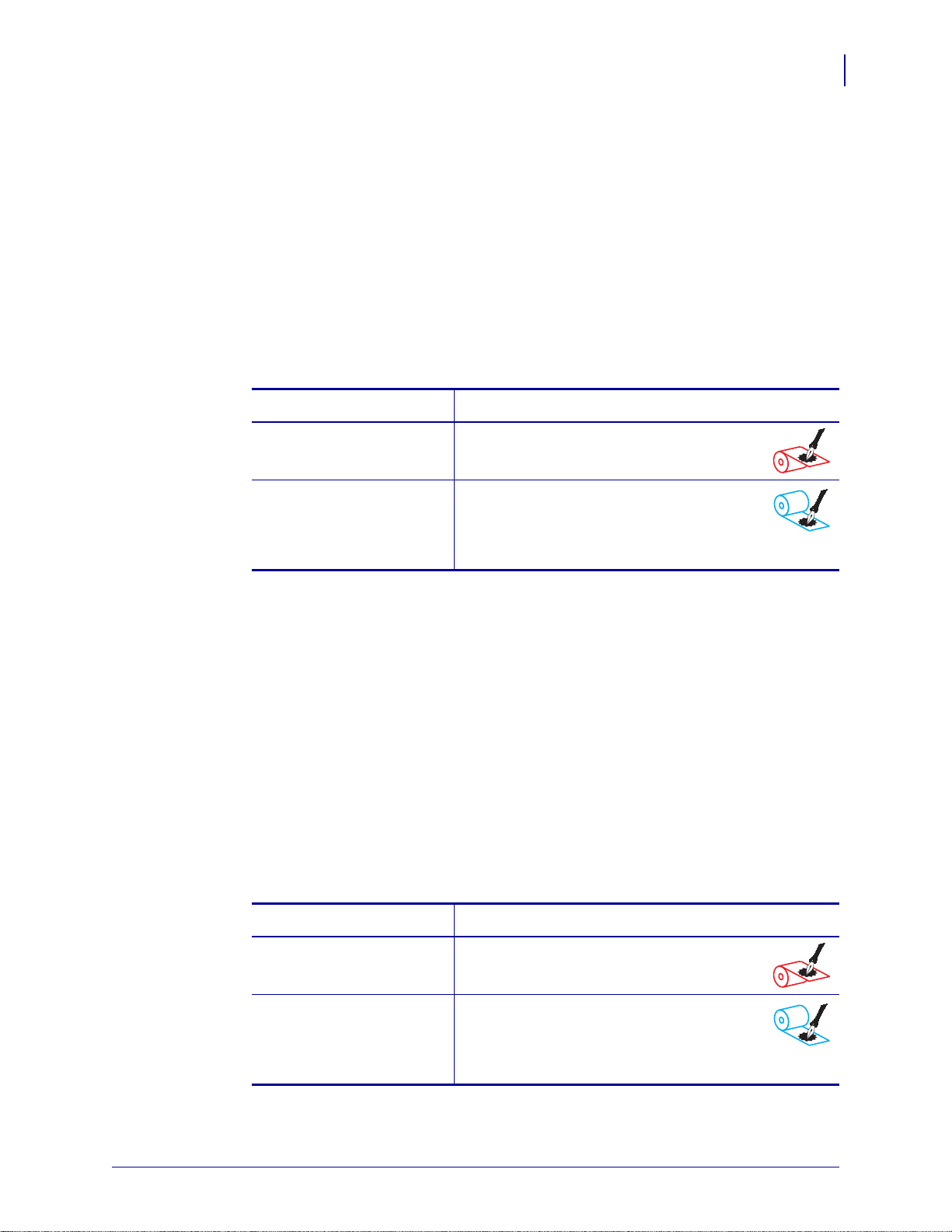

Coated Side of Ribbon

Ribbon can be wound with the coated side on the inside or outside (Figure 5). This printer can

only use ribbon that is coated on the outside. If you are unsure which side of a particular roll of

ribbon is coated, perform an adhesive test or a ribbon scratch test to determine which side is

coated.

Figure 5 • Ribbon Coated on Outside or Inside

P1066582-002 ZT400 Series™ User Guide 4/8/14

Adhesive Test

If you have labels available, perform the adhesive test to determine which side of a ribbon is

coated. This method works well for ribbon that is already installed.

To perform an adhesive test, complete these steps:

1. Peel a label from its liner.

2. Press a corner of the sticky side of the label to the outer surface of the roll of ribbon.

3. Peel the label off of the ribbon.

4. Observe the results. Did flakes or particles of ink from the ribbon adhere to the label?

If ink from the ribbon... Then...

Adhered to the label The ribbon is coated on the outside and can be

used in this printer.

Did not adhere to the label The ribbon is coated on the inside and cannot

be used in this printer.

To verify this, repeat the test on the other

surface of the roll of ribbon.

Printer Setup and Operation

Ribbon Overview

19

Ribbon Scratch Test

Perform the ribbon scratch test when labels are unavailable.

To perform a ribbon scratch test, complete these steps:

1. Unroll a short length of ribbon.

2. Place the unrolled section of ribbon on a piece of paper with the outer surface of the

ribbon in contact with the paper.

3. Scratch the inner surface of the unrolled ribbon with your fingernail.

4. Lift the ribbon from the paper.

5. Observe the results. Did the ribbon leave a mark on the paper?

If the ribbon... Then...

Left a mark on the paper The ribbon is coated on the outside and can be

used in this printer.

Did not leave a mark on the

paper

The ribbon is coated on the inside and cannot

be used in this printer.

To verify this, repeat the test on the other

surface of the roll of ribbon.

4/8/14 ZT400 Series™ User Guide P1066582-002

Printer Setup and Operation

Notes • ___________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

20

Ribbon Overview

P1066582-002 ZT400 Series™ User Guide 4/8/14

Printer Setup and

Operation

This section assists the technician with initial setup and operation of the printer.

2

Contents

Handling the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Unpack and Inspect the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Store the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Ship the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Select a Location for the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Select a Communication Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Data Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connect the Printer to a Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Power Cord Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Select a Print Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Load the Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Load the Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4/8/14 P1066582-002

Printer Setup and Operation

22

Handling the Printer

Handling the Printer

This section describes how to handle your printer.

Unpack and Inspect the Printer

When you receive the printer, immediately unpack it and inspect for shipping damage.

• Save all packing materials.

• Check all exterior surfaces for damage.

• Raise the media door, and inspect the media compartment for damage to components.

If you discover shipping damage upon inspection:

• Immediately notify the shipping company and file a damage report.

• Keep all packaging material for shipping company inspection.

• Notify your authorized Zebra reseller

Important • Zebra Technologies is not responsible for any damage incurred during the

shipment of the equipment and will not repair this damage under warranty.

Store the Printer

If you are not placing the printer into immediate operation, repackage it using the original

packing materials. You may store the printer under the following conditions:

• Temperature: –40°F to 140°F (–40° to 60°C)

• Relative humidity: 5% to 85% non-condensing

Ship the Printer

If you must ship the printer:

• Turn off (

• Remove any media, ribbon, or loose objects from the printer interior.

• Close the printhead.

• Carefully pack the printer into the original container or a suitable alternate container to

avoid damage during transit. A shipping container can be purchased from Zebra if the

original packaging has been lost or destroyed.

O) the printer, and disconnect all cables.

P1066582-002 ZT400 Series™ User Guide 4/8/14

Select a Location for the Printer

Select a location for the printer that meets these conditions:

• Surface: The surface where the printer will be located must be solid, level, and of

sufficient size and strength to hold the printer.

• Space: The area where the printer will be located must include enough space for

ventilation and for accessing the printer components and connectors. To allow for proper

ventilation and cooling, leave open space on all sides of the printer.

Caution • Do not place any padding or cushioning material behind or under the printer

because this restricts air flow and could cause the printer to overheat.

• Power: The printer should be within a short distance of an appropriate power outlet that is

easily accessible.

• Data communication interfaces: The printer must be within range of your WLAN radio

(if applicable) or within an acceptable range for other connectors to reach your data source

(usually a computer). For more information on maximum cable lengths and configuration,

see Table 2 on page 25.

Printer Setup and Operation

Select a Location for the Printer

23

• Operating conditions: Your printer is designed to function in a wide range of

environmental and electrical conditions, including a warehouse or factory floor. Table 1

shows the temperature and relative humidity requirements for the printer when it is

operating.

Table 1 • Operating Temperature and Humidity

Mode Temperature Relative Humidity

Thermal Transfer 40° to 104°F (5° to 40°C) 20 to 85% non-condensing

Direct Thermal 32° to 104°F (0° to 40°C)

4/8/14 ZT400 Series™ User Guide P1066582-002

Printer Setup and Operation

24

Select a Communication Interface

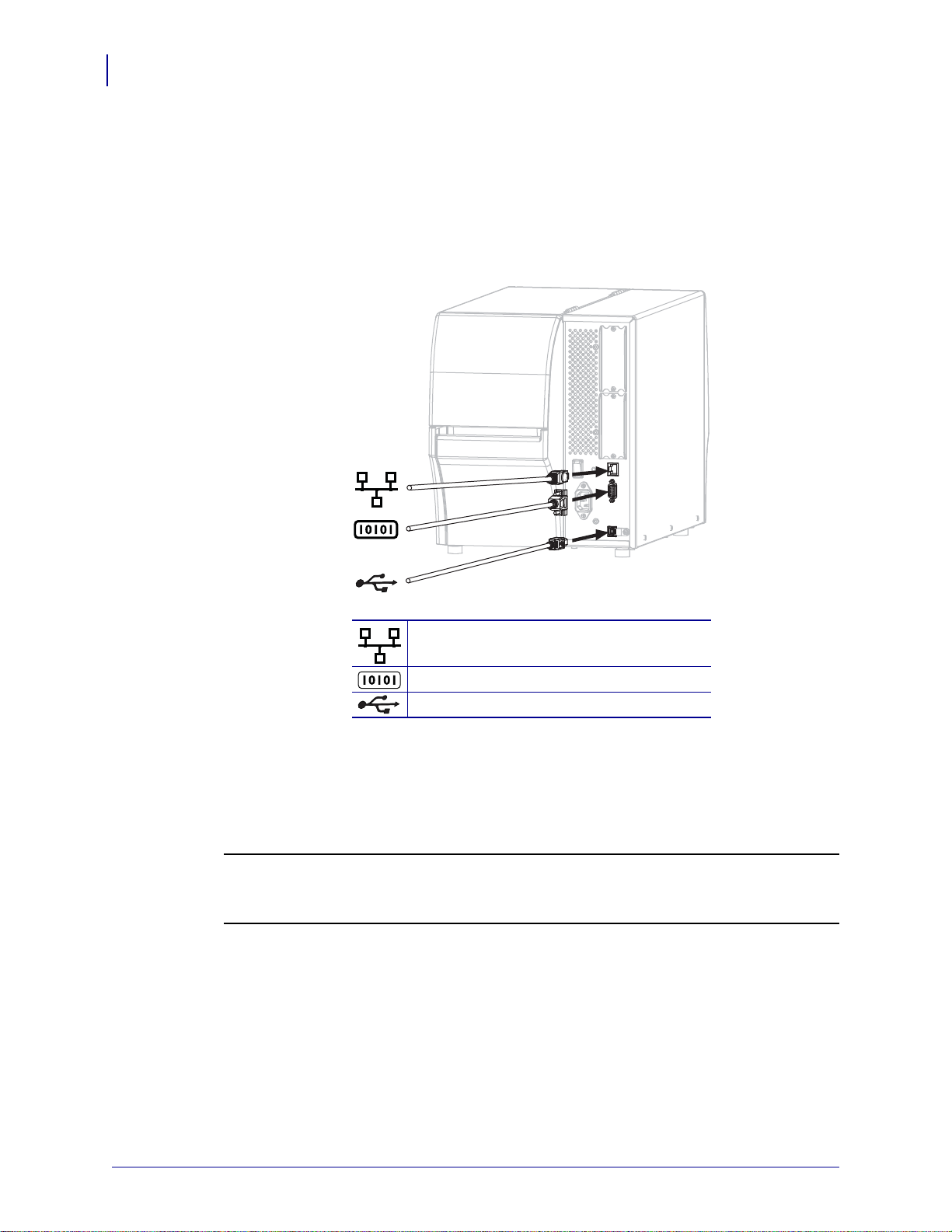

Select a Communication Interface

You may connect your printer to a computer using one or more of the available connections.

The standard connections are shown in Figure 1. A ZebraNet wired or wireless print server

option or a parallel port may also be present on your printer.

Figure 1 • Communication Interfaces

Internal wired Ethernet print server

Serial port

USB port

Table 2 on page 25 provides basic information about communication interfaces that you can

use to connect your printer to a computer. You may send label formats to the printer through

any communication interface that is available. Select an interface that is supported by both

your printer and your computer or your Local Area Network (LAN).

Caution • Ensure that the printer power is off (O) before connecting data communications

cables. Connecting a data communications cable while the power is on (

printer.

I) may damage the

P1066582-002 ZT400 Series™ User Guide 4/8/14

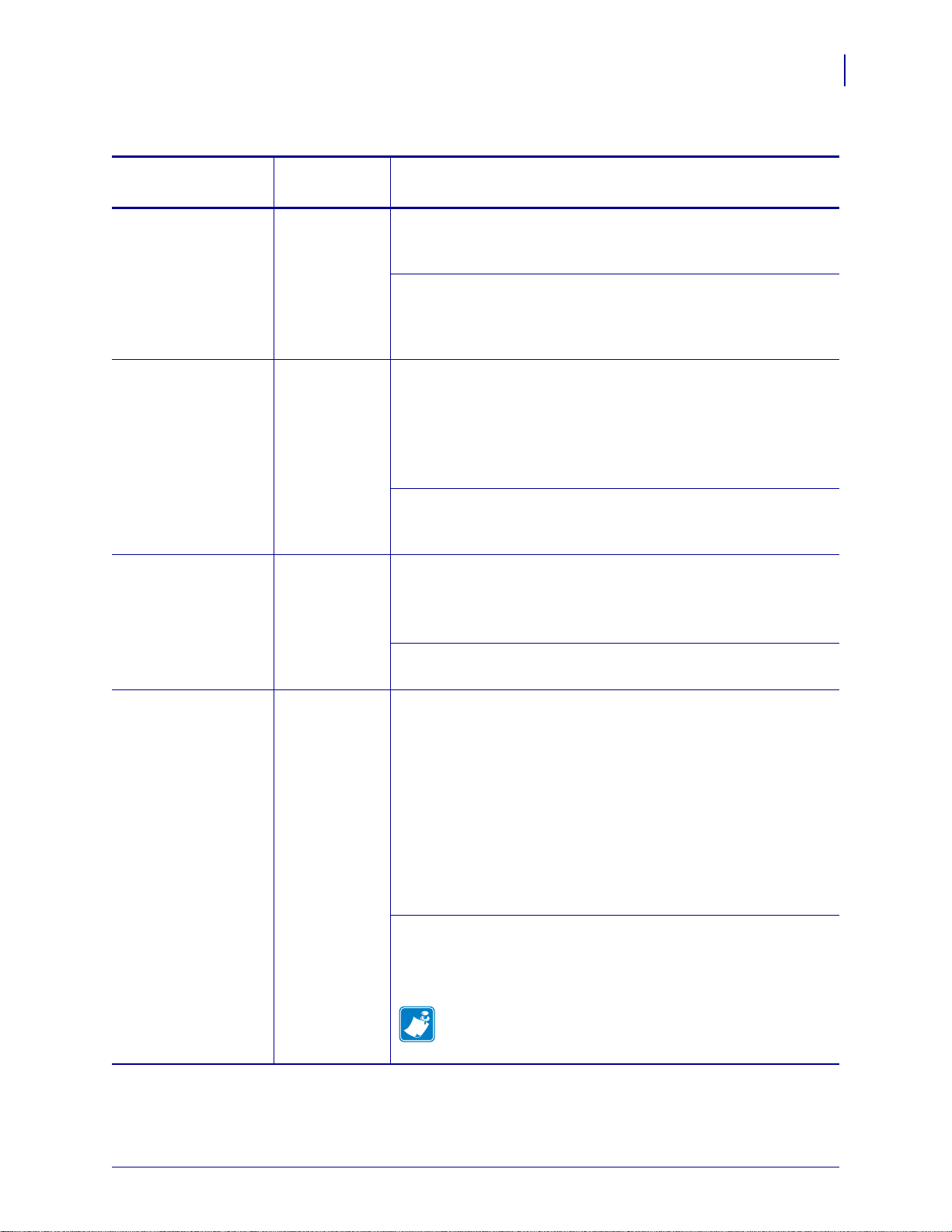

Table 2 • Communication Interfaces

Printer Setup and Operation

Select a Communication Interface

25

Interface

Bluetooth

®

Standard or

Option

Description

Standard Limitations and Requirements Many mobile devices can

communicate with the printer within a 10-foot radius of the

printer.

Connections and Configuration Refer to the Zebra

Bluetooth User Guide for specific instructions for configuring

your printer to use a Bluetooth interface. A copy of this manual is

available at http://www.zebra.com/manuals.

RS-232 Serial Standard Limitations and Requirements

• Maximum cable length of 50 ft (15.24 m).

• You may need to change printer parameters to match the host

computer.

• You need to use a null-modem adaptor to connect to the printer

if using a standard modem cable.

Connections and Configuration The baud rate, number of

data and stop bits, the parity, and the XON/XOFF or DTR control

must match those of the host computer.

USB Standard Limitations and Requirements

• Maximum cable length of 16.4 ft (5 m).

• No printer parameter changes required to match the host

computer.

Wired Ethernet print

server

Connections and Configuration No additional

configuration is necessary.

Standard Limitations and Requirements

• Can print to the printer from any computer on your LAN.

• Can communicate with the printer through the printer’s web

pages.

• The printer must be configured to use your LAN.

• A parallel connection or a wireless print server (if installed)

takes up this port on the printer.

Caution • Be careful not to plug a USB cable into a wired

Ethernet print server connector on the printer because doing so

will damage the Ethernet connector.

Connections and Configuration Refer to the ZebraNet

Wired and Wireless Print Servers User Guide for configuration

instructions. A copy of this manual is available at

http://www.zebra.com/manuals.

Note • To use this connection, you may need to remove a

factory-installed plug that is designed to keep someone

from accidentally plugging a USB connector into this port.

4/8/14 ZT400 Series™ User Guide P1066582-002

Printer Setup and Operation

26

Select a Communication Interface

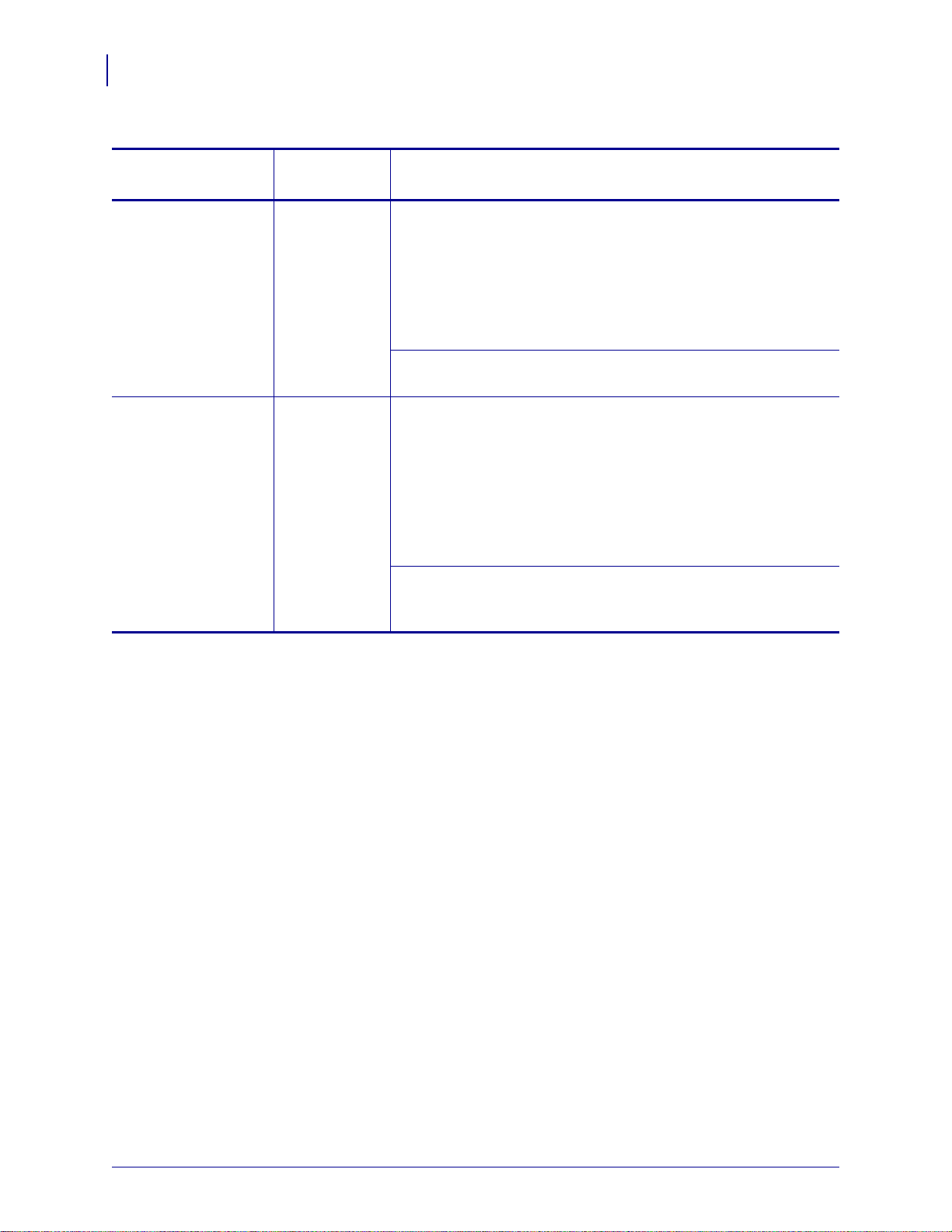

Table 2 • Communication Interfaces (Continued)

Interface

8-bit Parallel data

interface

Standard or

Option

Description

Option Limitations and Requirements

• Maximum cable length of 10 ft (3 m).

• Recommended cable length of 6 ft (1.83 m).

• No printer parameter changes required to match the host

computer.

• A wired or wireless print server (if installed) takes up this port

on the printer.

Connections and Configuration No additional

configuration is necessary.

Wireless print server Option Limitations and Requirements

• Can print to the printer from any computer on your Wireless

Local Area Network (WLAN).

• Can communicate with the printer through the printer’s web

pages.

• The printer must be configured to use your WLAN.

• A parallel connection or a wired print server (if installed) takes

up this port on the printer.

Configuration Refer to the ZebraNet Wired and Wireless Print

Servers User Guide for configuration instructions. A copy of this

manual is available at http://www.zebra.com/manuals.

Data Cables

You must supply all data cables for your application.

Ethernet cables do not require shielding, but all other data cables must be fully shielded and

fitted with metal or metallized connector shells. Unshielded data cables may increase radiated

emissions above the regulated limits.

To minimize electrical noise pickup in the cable:

• Keep data cables as short as possible.

• Do not bundle the data cables tightly with the power cords.

• Do not tie the data cables to power wire conduits.

P1066582-002 ZT400 Series™ User Guide 4/8/14

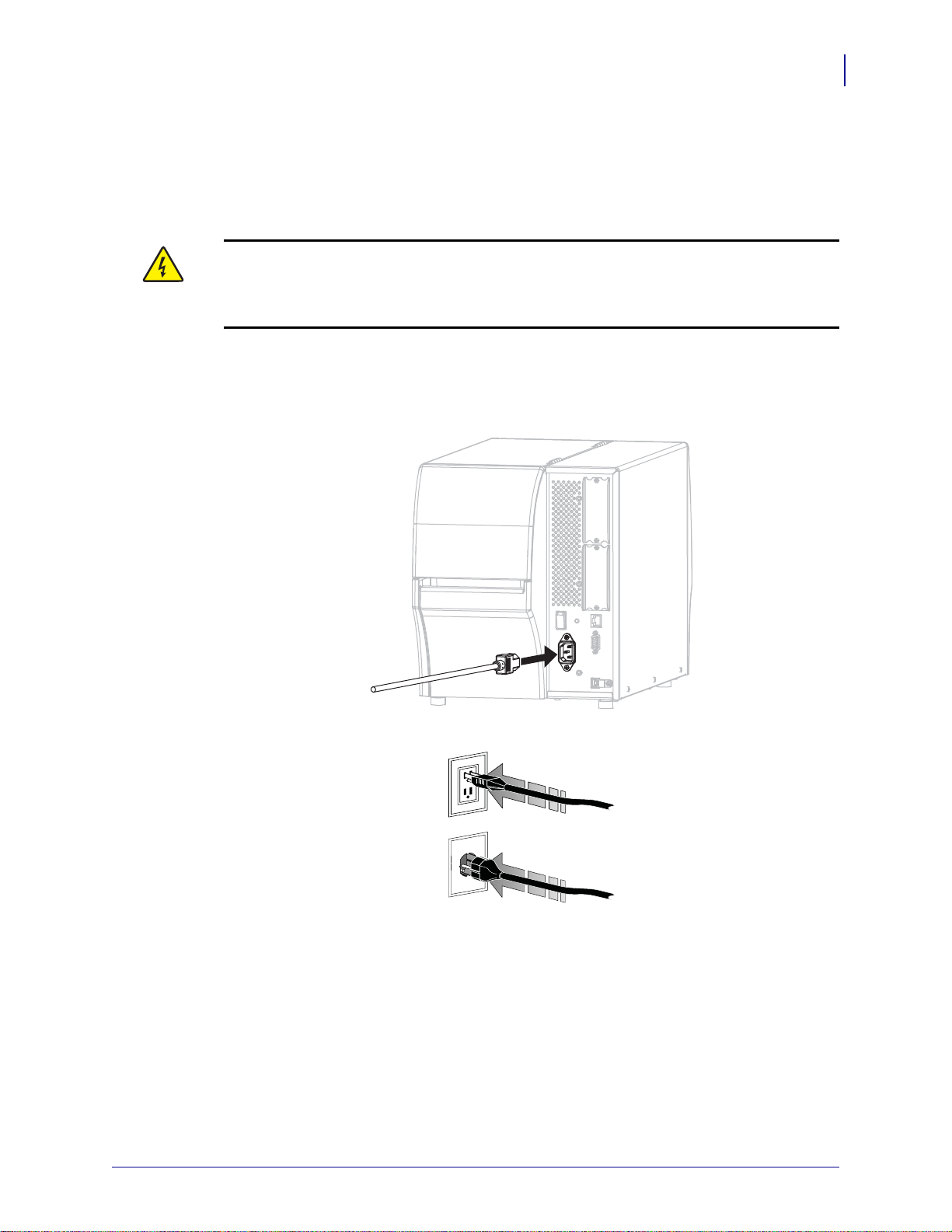

Connect the Printer to a Power Source

115 V AC

230 V AC

The AC power cord must have a three-prong female connector on one end that plugs into the

mating AC power connector at the rear of the printer. If a power cable was not included with

your printer, refer to Power Cord Specifications on page 28.

Caution • For personnel and equipment safety, always use an approved three-conductor

power cord specific to the region or country intended for installation. This cord must use an

IEC 320 female connector and the appropriate region-specific three-conductor grounded

plug configuration.

To connect the printer to a power source, complete these steps:

1. Plug the female end of the A/C power cord into the A/C power connector on the back of

the printer.

Printer Setup and Operation

Connect the Printer to a Power Source

27

2. Plug the male end of the A/C power cord into an appropriate power outlet.

4/8/14 ZT400 Series™ User Guide P1066582-002

Printer Setup and Operation

28

Connect the Printer to a Power Source

3. Turn on (I) the printer.

The printer boots up and performs a self-test. The printer reports its status through the

indicator lights on the control panel (see Table 1 on page 146 for the meaning of the light

colors and combinations).

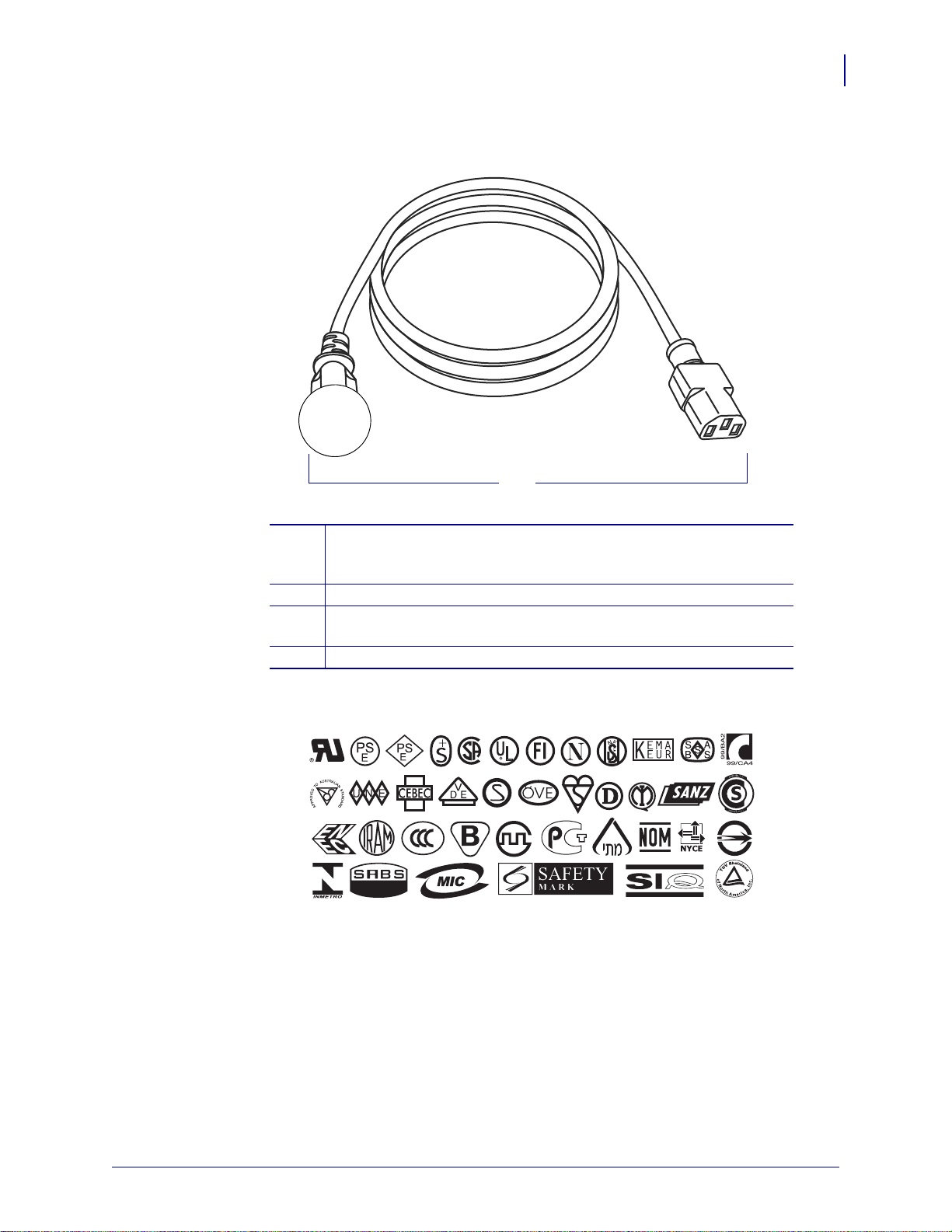

Power Cord Specifications

Caution • For personnel and equipment safety, always use an approved three-conductor

power cord specific to the region or country intended for installation. This cord must use an

IEC 320 female connector and the appropriate region-specific, three-conductor grounded

plug configuration.

Depending on how your printer was ordered, a power cord may or may not be included. If one

is not included or if the one included is not suitable for your requirements, see Figure 2 and

refer to the following guidelines:

• The overall cord length must be less than 9.8 ft. (3 m).

• The cord must be rated for at least 10 A, 250 V.

• The chassis ground (earth) must be connected to ensure safety and reduce electromagnetic

interference.

P1066582-002 ZT400 Series™ User Guide 4/8/14

Printer Setup and Operation

3

1

2

4

Connect the Printer to a Power Source

Figure 2 • Power Cord Specifications

29

AC power plug for your country—This should bear the certification

1

mark of at least one of the known international safety organizations

(Figure 3).

3-conductor HAR cable or other cable approved for your country.

2

IEC 320 connector—This should bear the certification mark of at

3

least one of the known international safety organizations (Figure 3).

Length ≤ 9.8 ft. (3 m). Rating 10 Amp, 250 VAC.

4

Figure 3 • International Safety Organization Certification Symbols

4/8/14 ZT400 Series™ User Guide P1066582-002

Printer Setup and Operation

30

Select a Print Mode

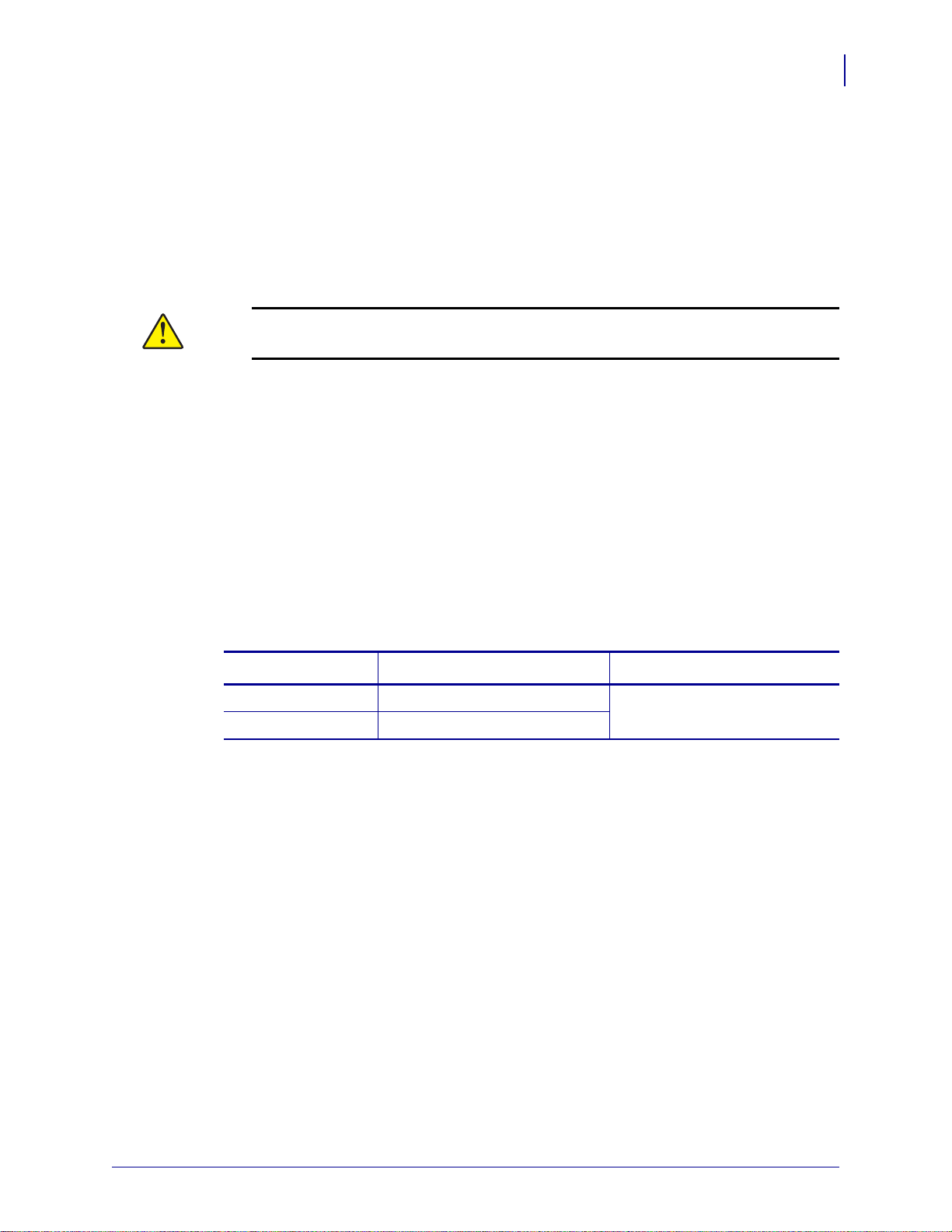

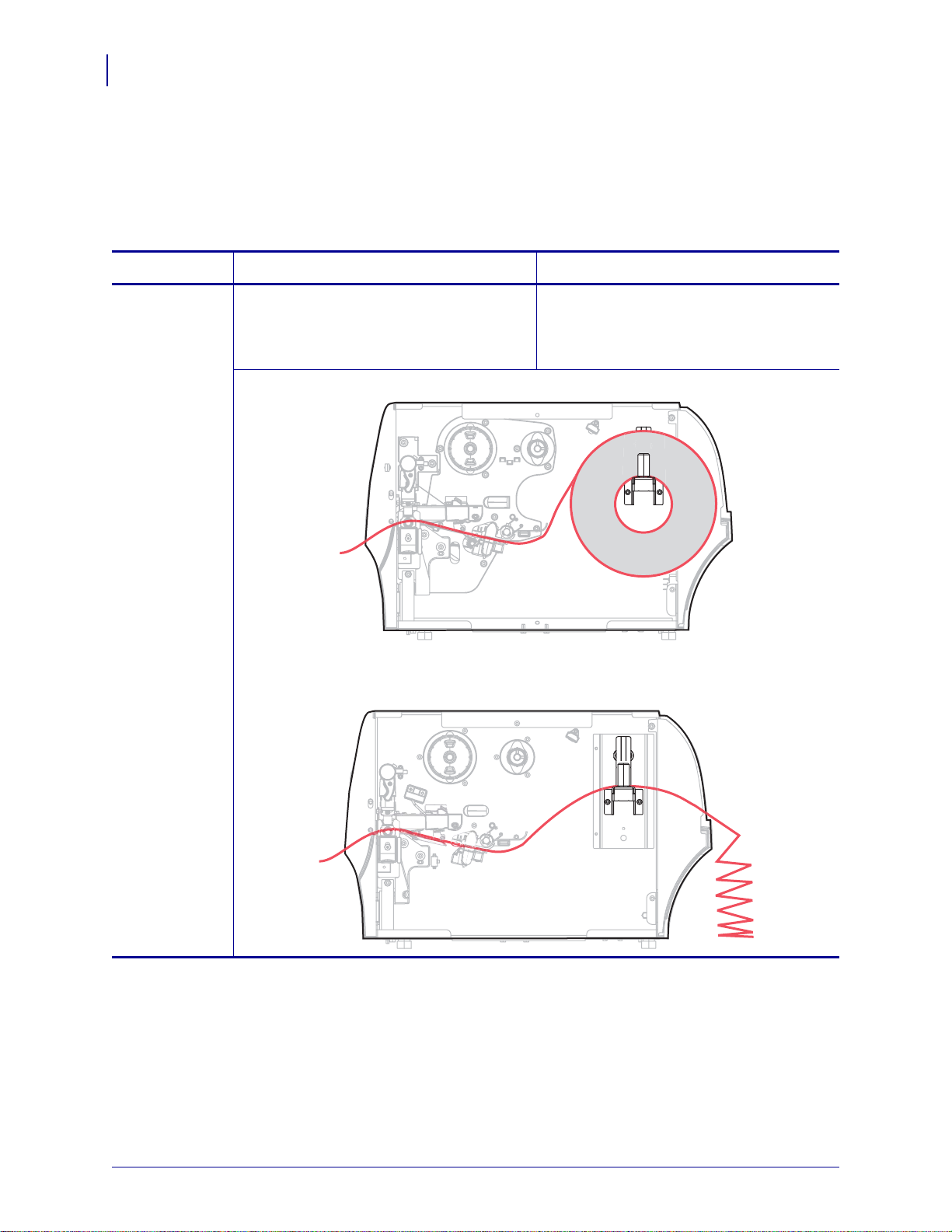

Select a Print Mode

Use a print mode that matches the media being used and the printer options available

(Tab le 3 ). The media path is the same for roll and fanfold media.

Table 3 • Print Modes and Printer Options

Print Mode When to Use/Printer Options Required Printer Actions

Tear-Off

(default setting)

Use for most applications. This mode can

be used with any printer options and most

media types.

Roll media in Tear-Off mode

Fanfold media in Tear-Off mode

(shown fed through the rear access slot)

The printer prints label formats as it

receives them. The printer operator can tear

off the printed labels any time after they

print.

Red solid lines = media, Blue dotted lines = backing only

P1066582-002 ZT400 Series™ User Guide 4/8/14

Loading...

Loading...