Page 1

Operations

Load Media in Rewind Mode

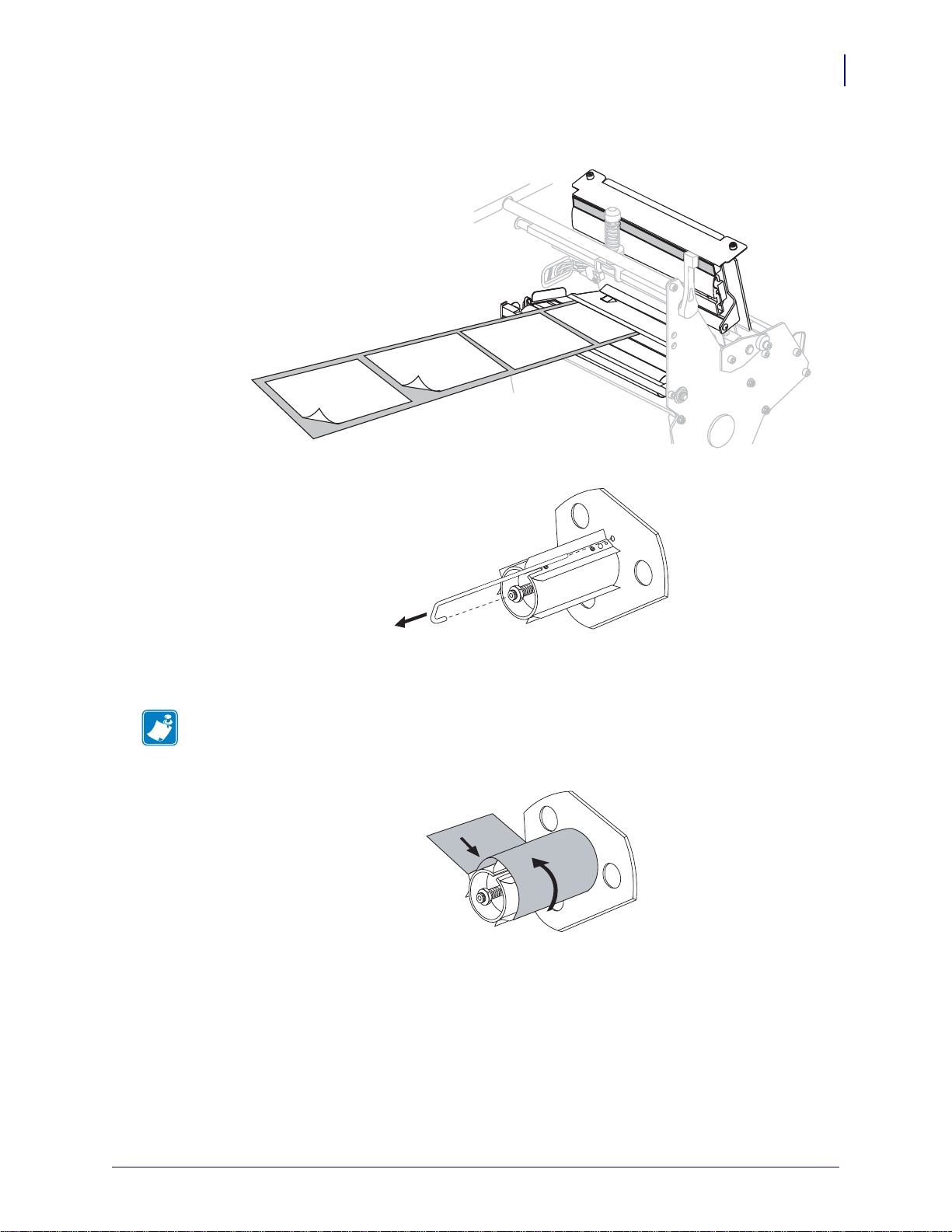

13. Extend approximately 36 in. (920 mm) of media out of the printer. Remove and discard

the labels from this exposed media.

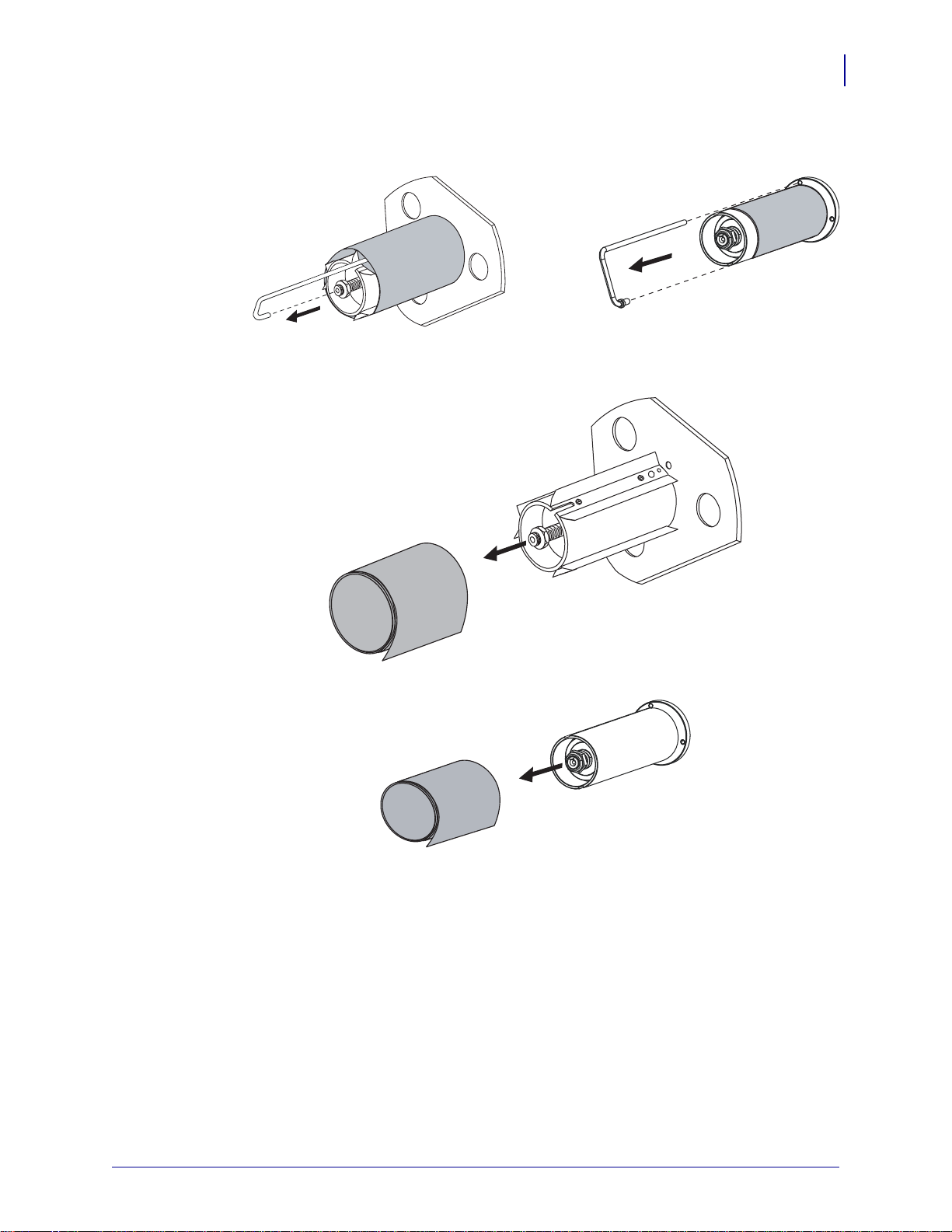

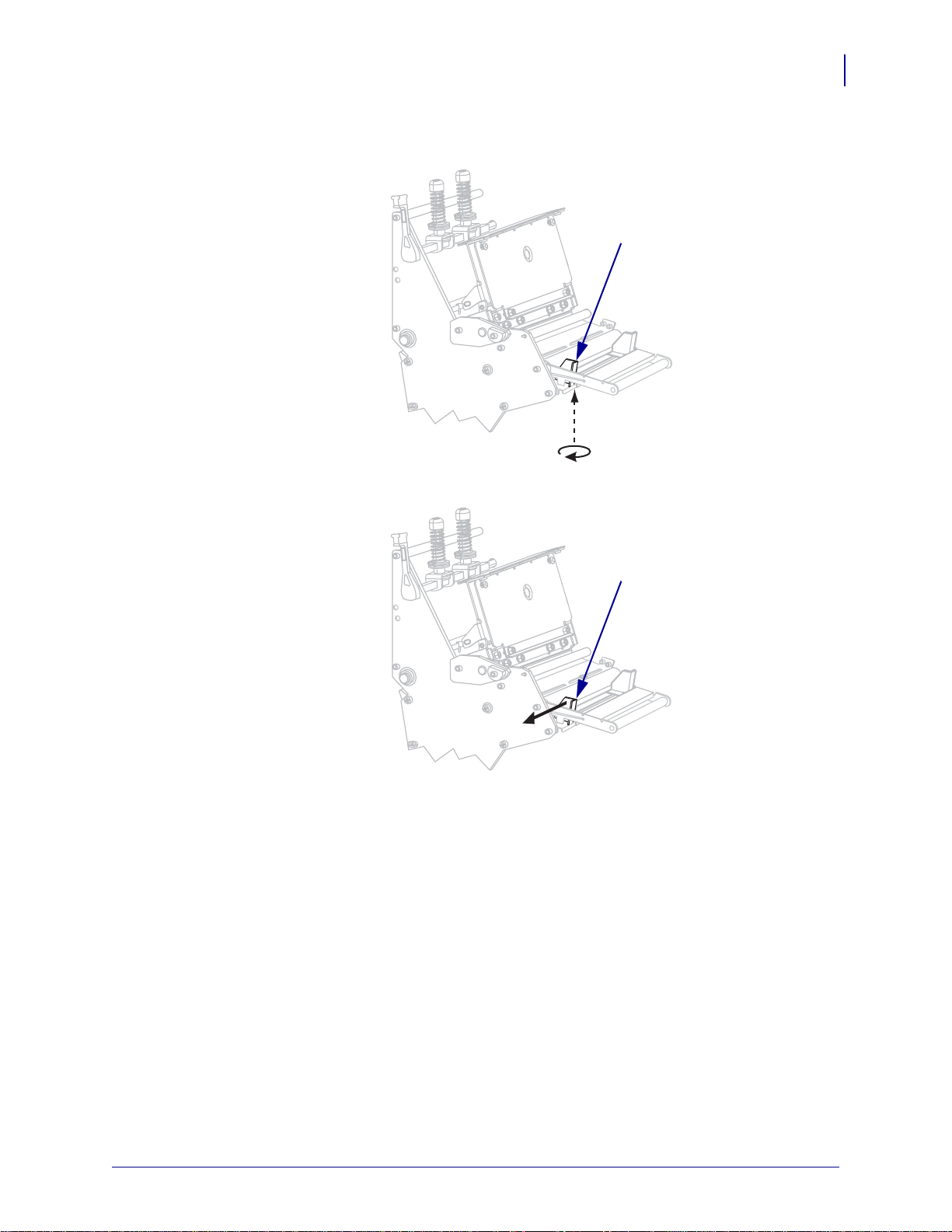

14. Remove the hook from the rewind spindle.

61

15. If you are using a core, slide it onto the rewind spindle until it is flush against the guide

plate.

Note • A core is not required.

16. Wind the media liner counterclockwise around the rewind spindle.

17. Reinstall the hook. Insert the short end of the hook into the hole in the center of the

adjusting nut (

1). Insert the long end of the hook into the small hole o n the guide p late ( 2).

2/23/09 Xi4 User Guide P1009874-001

Page 2

Operations

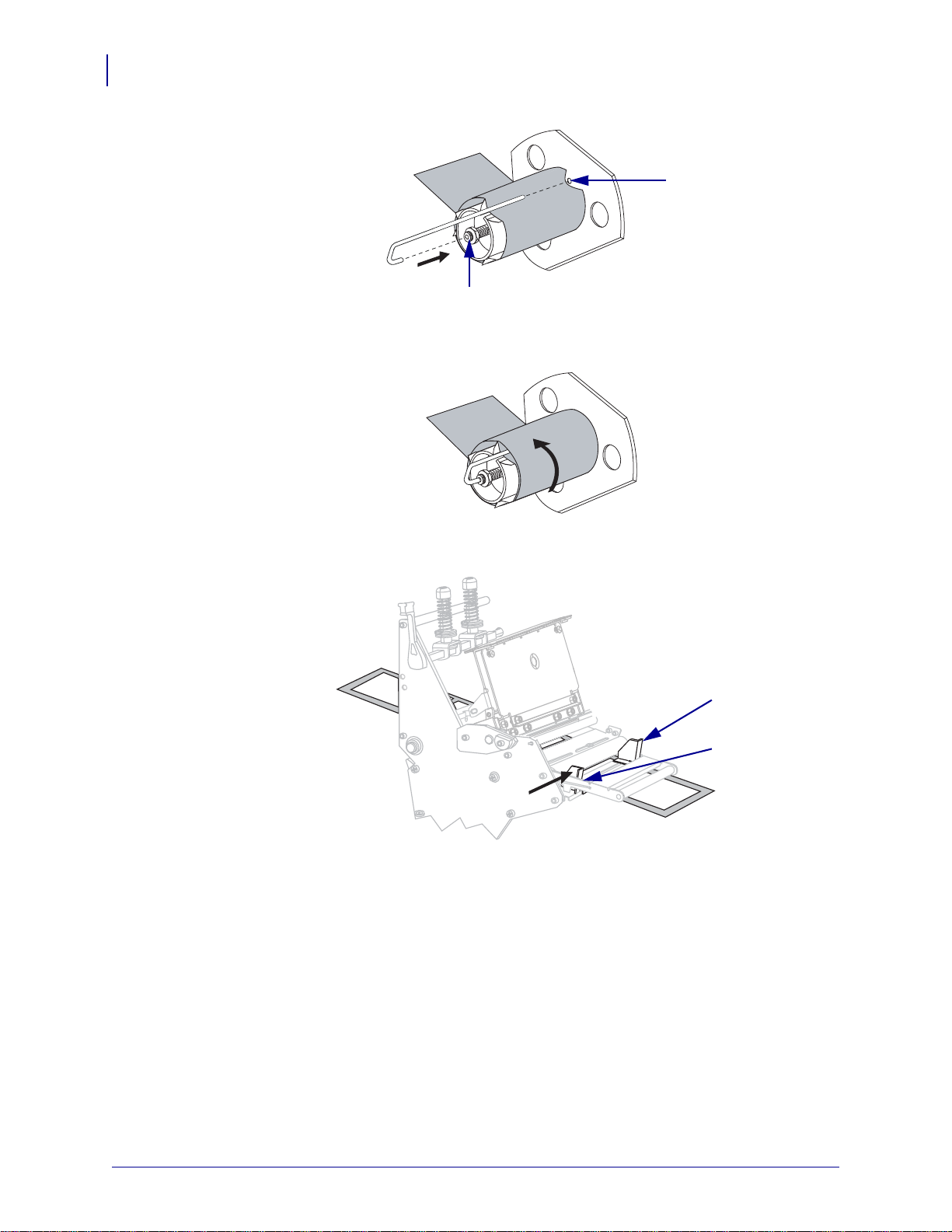

2

1

1

2

62

Load Media in Rewind Mode

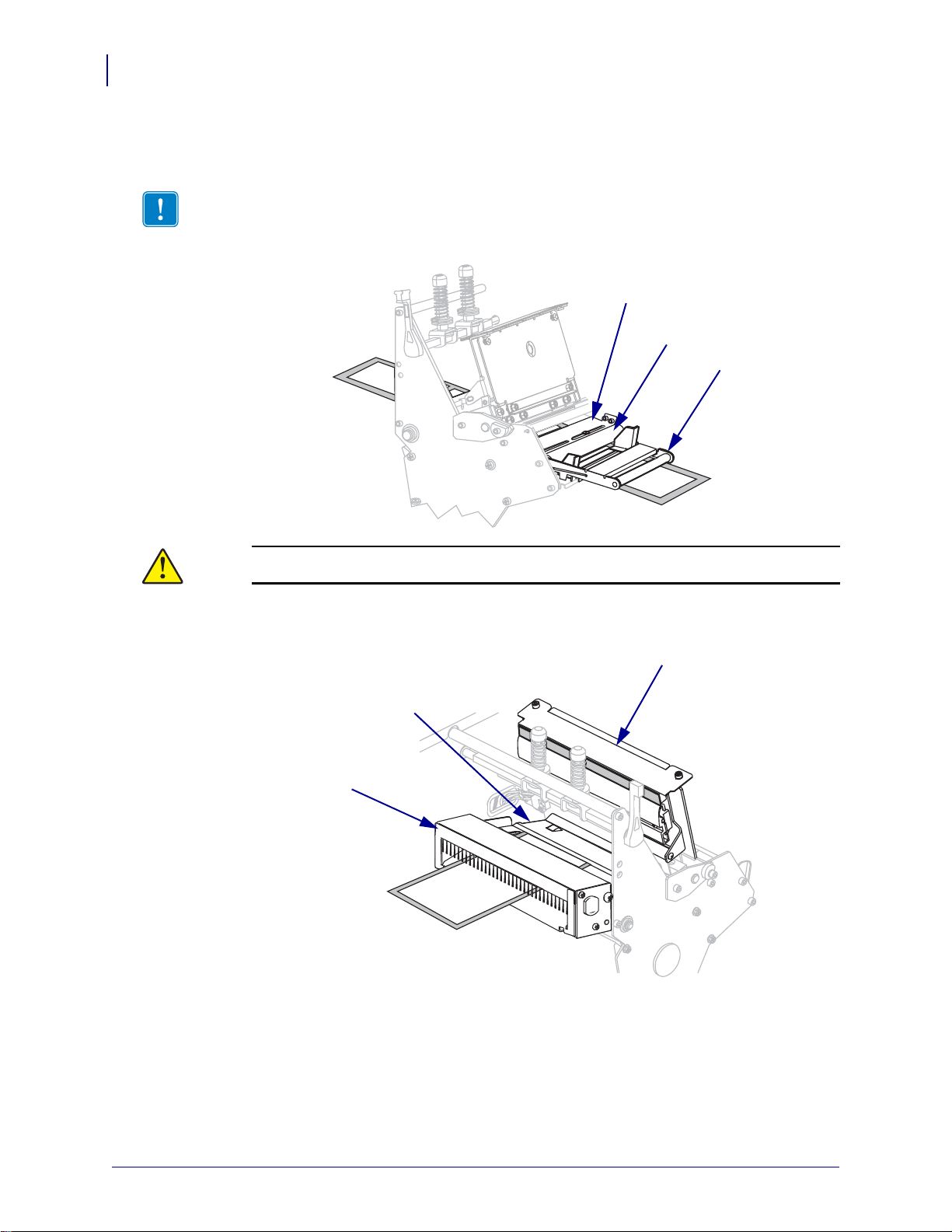

18. Rotate the spindle counterclockwise several turns to wind the media liner over the hook

and remove any slack.

19. Align the media with the inner media guide (1). Slide in the outer media guide (2) until i t

just touches the edge of the media.

P1009874-001 Xi4 User Guide 2/23/09

Page 3

Operations

1

12

Load Media in Rewind Mode

20. Tighten the thumb screw (not visible from this angle) that is located on the bottom of the

outer media guide (

21. Push down the printhead assembly (1), and then rotate the printhead-open lever (2)

1).

clockwise until it locks into place.

63

The labels wind on the rewind spindle or core.

2/23/09 Xi4 User Guide P1009874-001

Page 4

Operations

Rewind

Peel

Rewind

Peel

64

Load Media in Rewind Mode

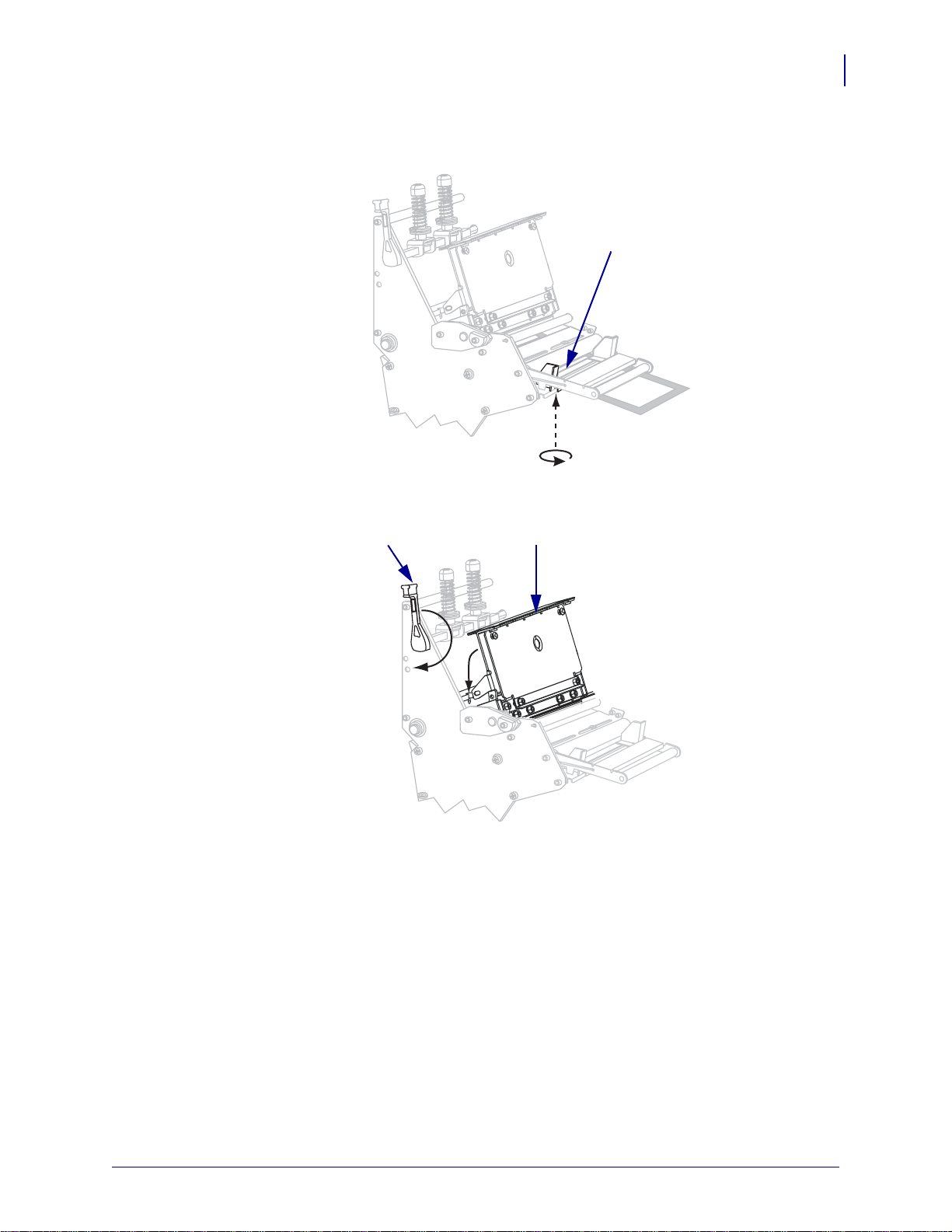

Remove Media Liner from the Rewind or Peel Spindle

To remove media liner from the rewind or peel spindle, complete these steps:

Rewind mode and Peel-Off mode each use spindles to wind used media liner. Remove the

media liner from the spindle each time that you change labels.

Important • It is not necessary to turn off the power to remove media liner from the spindle.

If power is turned off, all label formats and images, as well as any temporarily saved

parameter settings stored in the printer’s internal memory, are lost. When power is turned

back on, these items must be reloaded.

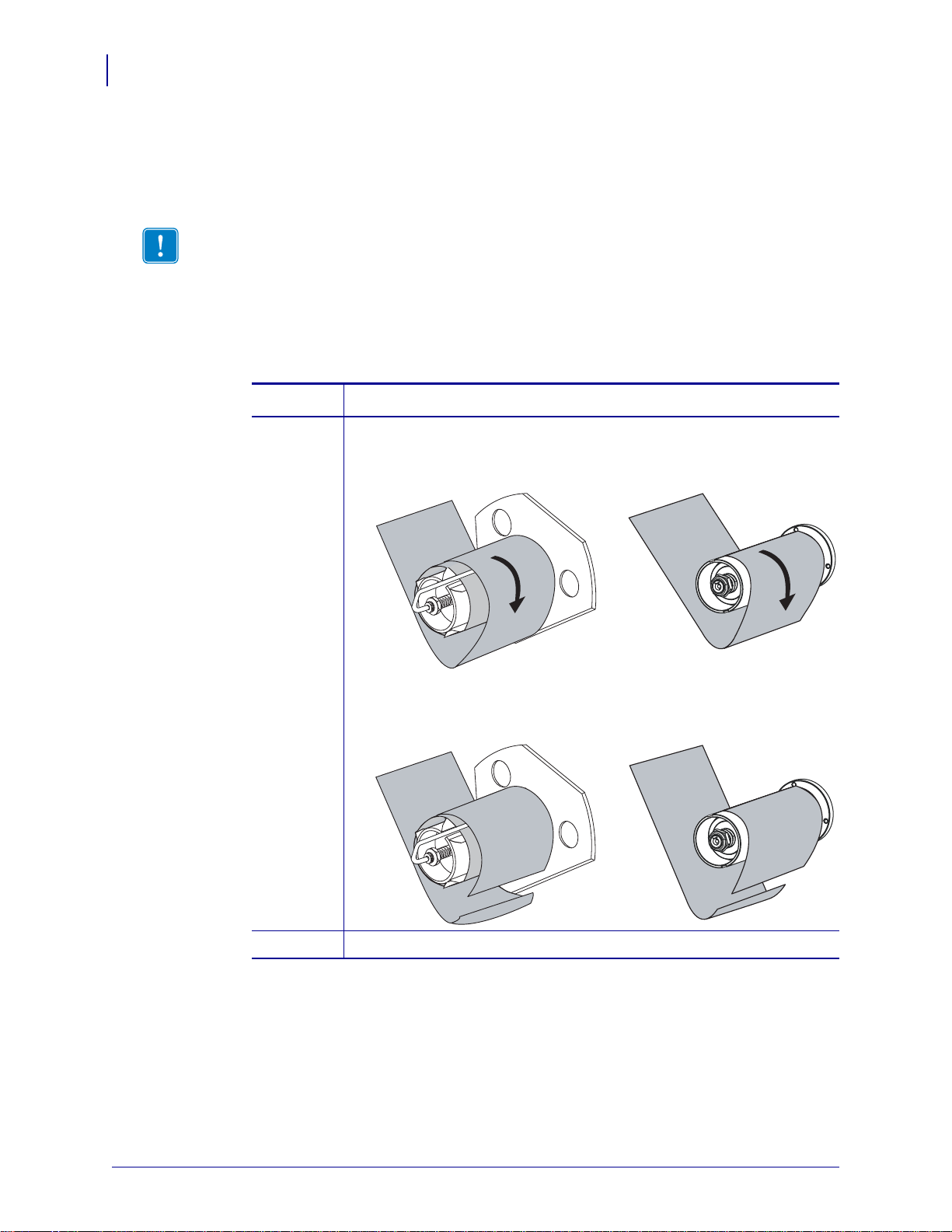

1. Has the media run out?

If... Then...

No a. Create slack in the media liner by rotating the spindle slightly

clockwise.

b. Cut or tear the media liner at the spindle.

Yes Continue with the next step.

P1009874-001 Xi4 User Guide 2/23/09

Page 5

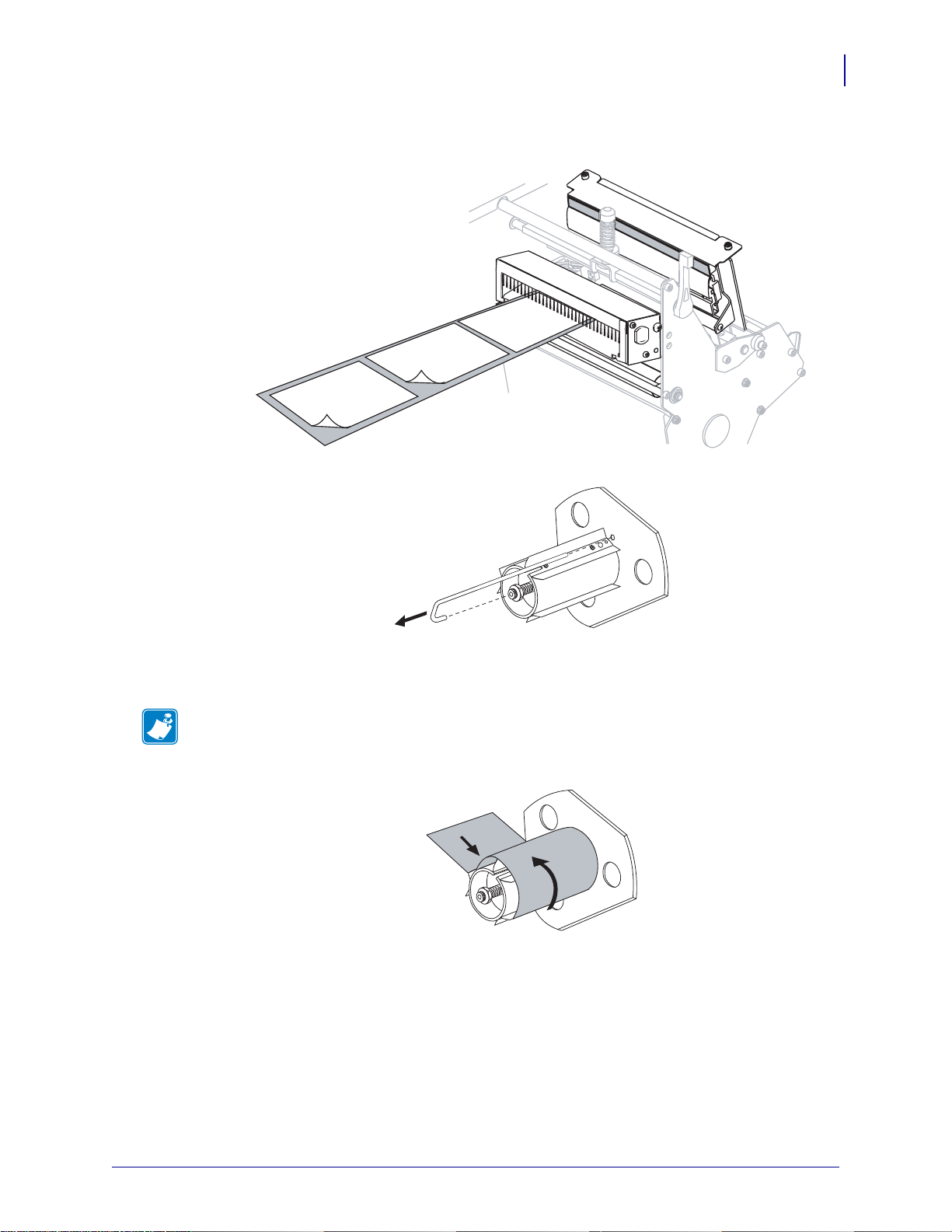

2. Pull out the spindle hook.

Rewind Peel

Rewind

Peel

3. Slide the media liner off of the spindle and discard.

Operations

Load Media in Rewind Mode

65

2/23/09 Xi4 User Guide P1009874-001

Page 6

Operations

1

2 4

5

8 7

6

9

10

3

66

Load Media in Rewind Mode (with Cutter Option)

Load Media in Rewind Mode (with Cutter Option)

Some printers with the Cutter option can use Rewind mode to print and save a roll of labels

(Figure 10). This section shows how to load media for Rewind mode in printers that have a

Cutter option.

Note • Rewind mode cannot be used with the Cutter option on 110Xi4 printers.

Figure 10 • Media Loaded in Rewind Mode with Cutter Option

Printhead-open lever

1

Media guide

2

Media guide roller

3

Media supply guide

4

Labels

5

Guide plate

6

Spindle hook

7

Rewind spindle

8

Rewind plate for Rewind mode with Cutter option*

9

10

11

* In new printers, remove the protective plastic covering from the rewind

plate before using.

Printed label

Cutter

P1009874-001 Xi4 User Guide 2/23/09

Page 7

Operations

3

4

2

1

Load Media in Rewind Mode (with Cutter Option)

Caution • While performing any tasks near an open printhead, remove all rings, watches,

hanging necklaces, identification badges, or other metallic objects that could touch the

printhead. You are not required to turn off the printer power when working near an open

printhead, but Zebra recommends it as a precaution. If you turn off the power, you will lose

all temporary settings, such as label formats, and you must reload them before you resume

printing.

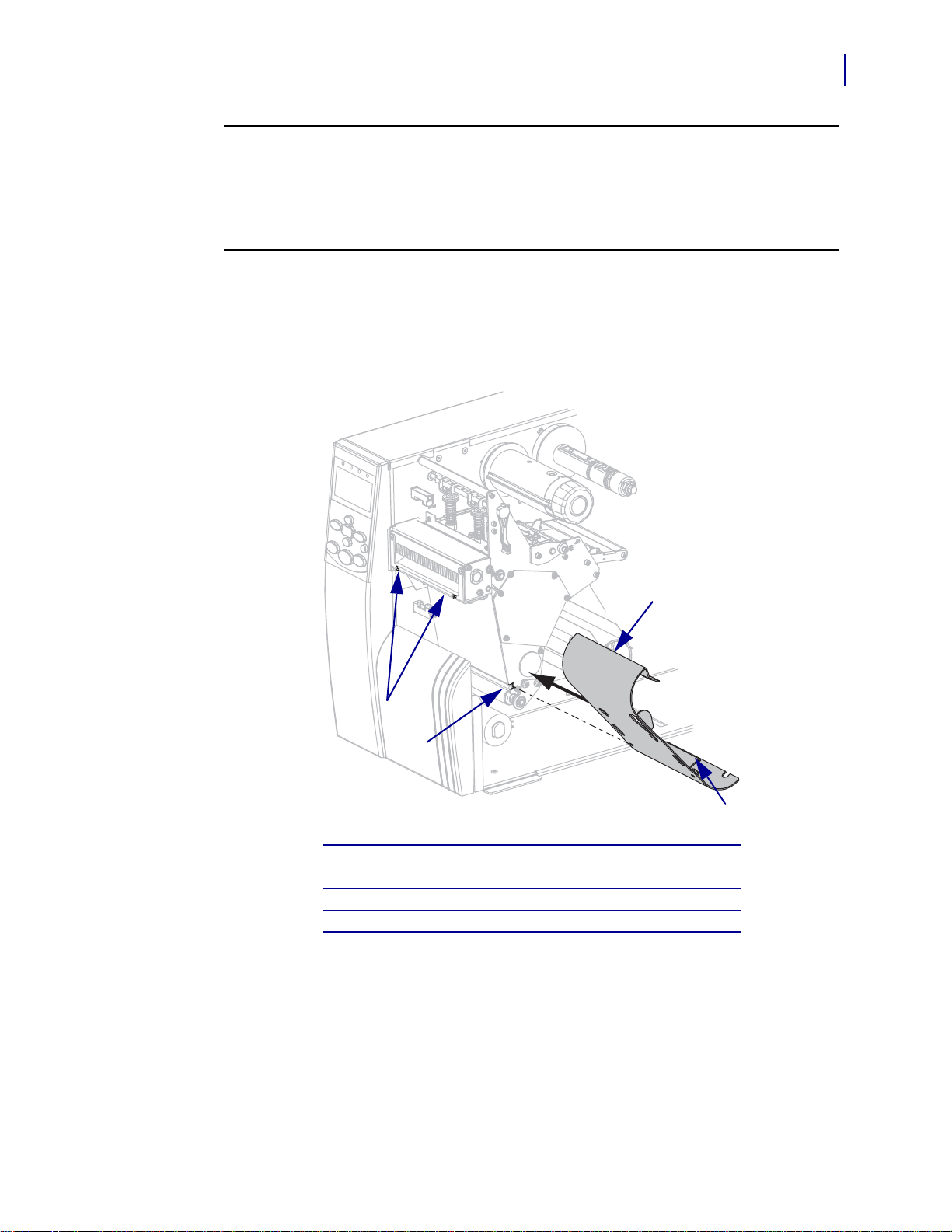

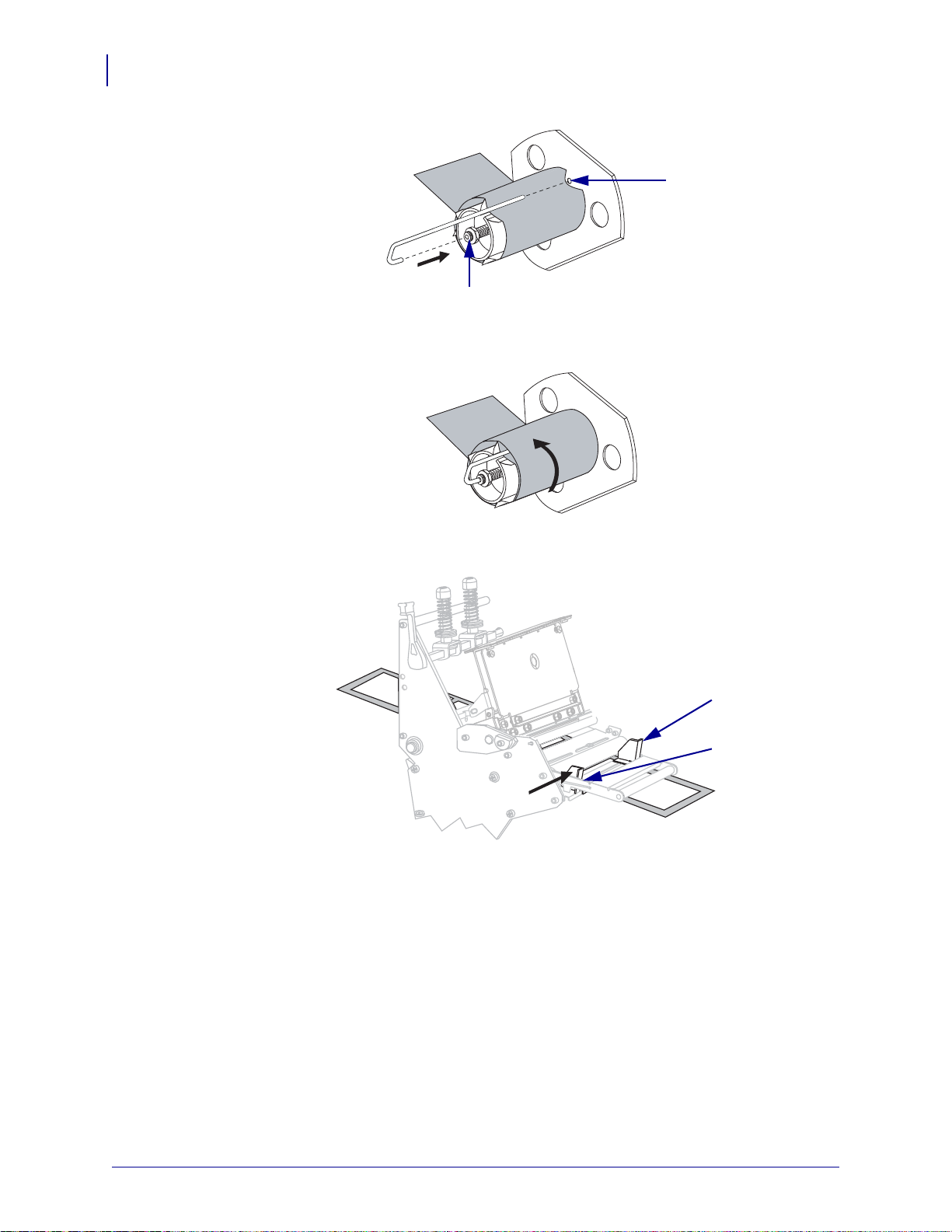

To set up the Rewind mode for printers with the cutter option, complete

these steps:

1. Remove the rewind plate from its storage location inside the printer.

2. Position the rewind plate so that the lip on the attached hook plate points down.

67

Slots on cutter

1

Lower slot

2

Rewind plate

3

Lip

4

3. Insert the hook plate lip 1/2 in. (13 mm) into the lower slot in the side plate.

4. Slide in the rewind plate until it stops against the printer’s main frame.

2/23/09 Xi4 User Guide P1009874-001

Page 8

Operations

1

68

Load Media in Rewind Mode (with Cutter Option)

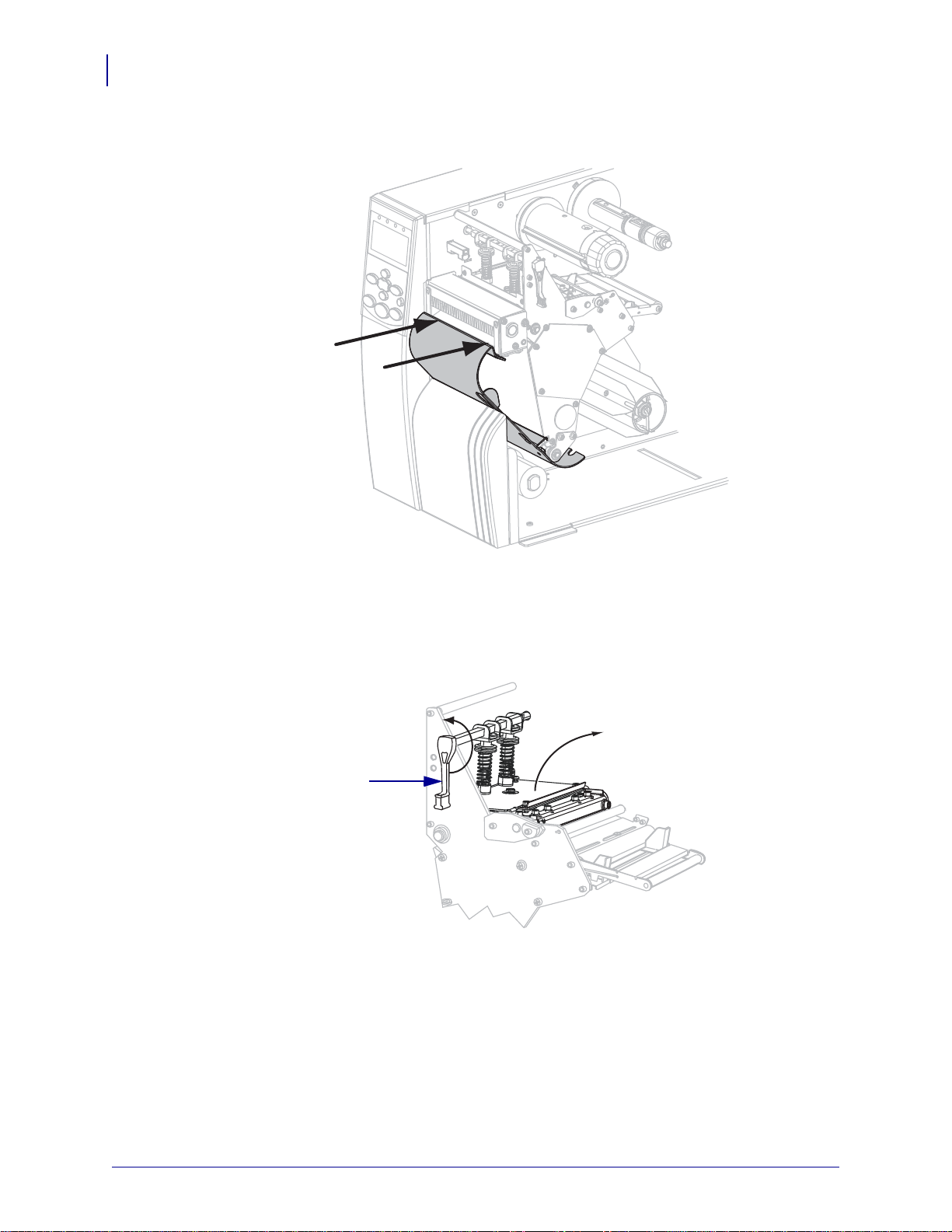

5. Push the top edges of the rewind plate until the rewind plate snaps into place in the slots

on the cutter.

6. Set the printer to Rewind mode. See Select Print Mode on page 101 for instructions.

7. Insert media into the printer. See Prepare the Media for Loading on page 37 for

instructions.

8. Open the printhead assembly by rotating the printhead-open lever (1) counter-clockwise.

P1009874-001 Xi4 User Guide 2/23/09

Page 9

Operations

1

1

Load Media in Rewind Mode (with Cutter Option)

9. Loosen the thumb screw (not visible from this angle) that is located on the bo ttom of the

outer media guide (

10. Slide the outer media guide (1) all the way out.

1).

69

2/23/09 Xi4 User Guide P1009874-001

Page 10

Operations

2

3

1

1

2

3

70

Load Media in Rewind Mode (with Cutter Option)

11. If your printer includes a media dancer assembly (1), thread the media under the media

dancer assembly roller. For all printers, thread the media under the media guide roller (

and then the upper media sensor (

Important • Make sure that you thread the media under these components. If you thread

the media over the them, the media obstructs the ribbon sensor and causes a false

RIBBON OUT error.

2)

3).

12.

Caution • The cutter blade is sharp. Do not touch or rub the blade with your fingers.

Thread the media forward until it passes under the printhead assembly (1), under the

snap plate (

2), and through the cutter assembly (3).

P1009874-001 Xi4 User Guide 2/23/09

Page 11

Operations

Load Media in Rewind Mode (with Cutter Option)

13. Extend approximately 36 in. (920 mm) of media out of the printer. Remove and discard

the labels from this exposed media.

14. Remove the hook from the rewind spindle.

71

15. If you are using a core, slide it onto the rewind spindle until it is flush against the guide

plate.

Note • A core is not required.

16. Wind the media liner counterclockwise around the rewind spindle.

17. Reinstall the hook. Insert the short end of the hook into the hole in the center of the

adjusting nut (

1). Insert the long end of the hook into the small hole o n the guide p late ( 2).

2/23/09 Xi4 User Guide P1009874-001

Page 12

Operations

2

1

1

2

72

Load Media in Rewind Mode (with Cutter Option)

18. Rotate the spindle counterclockwise several turns to wind the media liner over the hook

and remove any slack.

19. Align the media with the inner media guide (1). Slide in the outer media guide (2) until i t

just touches the edge of the media.

P1009874-001 Xi4 User Guide 2/23/09

Page 13

Operations

1

12

Load Media in Rewind Mode (with Cutter Option)

20. Tighten the thumb screw (not visible from this angle) that is located on the bottom of the

outer media guide (

21. Push down the printhead assembly (1), and then rotate the printhead-open lever (2)

1).

clockwise until it locks into place.

73

The labels wind on the rewind spindle or core.

22. For instructions for removing the labels from the rewind spindle, see Remove Media Liner

from the Rewind or Peel Spindle on page 64.

2/23/09 Xi4 User Guide P1009874-001

Page 14

Operations

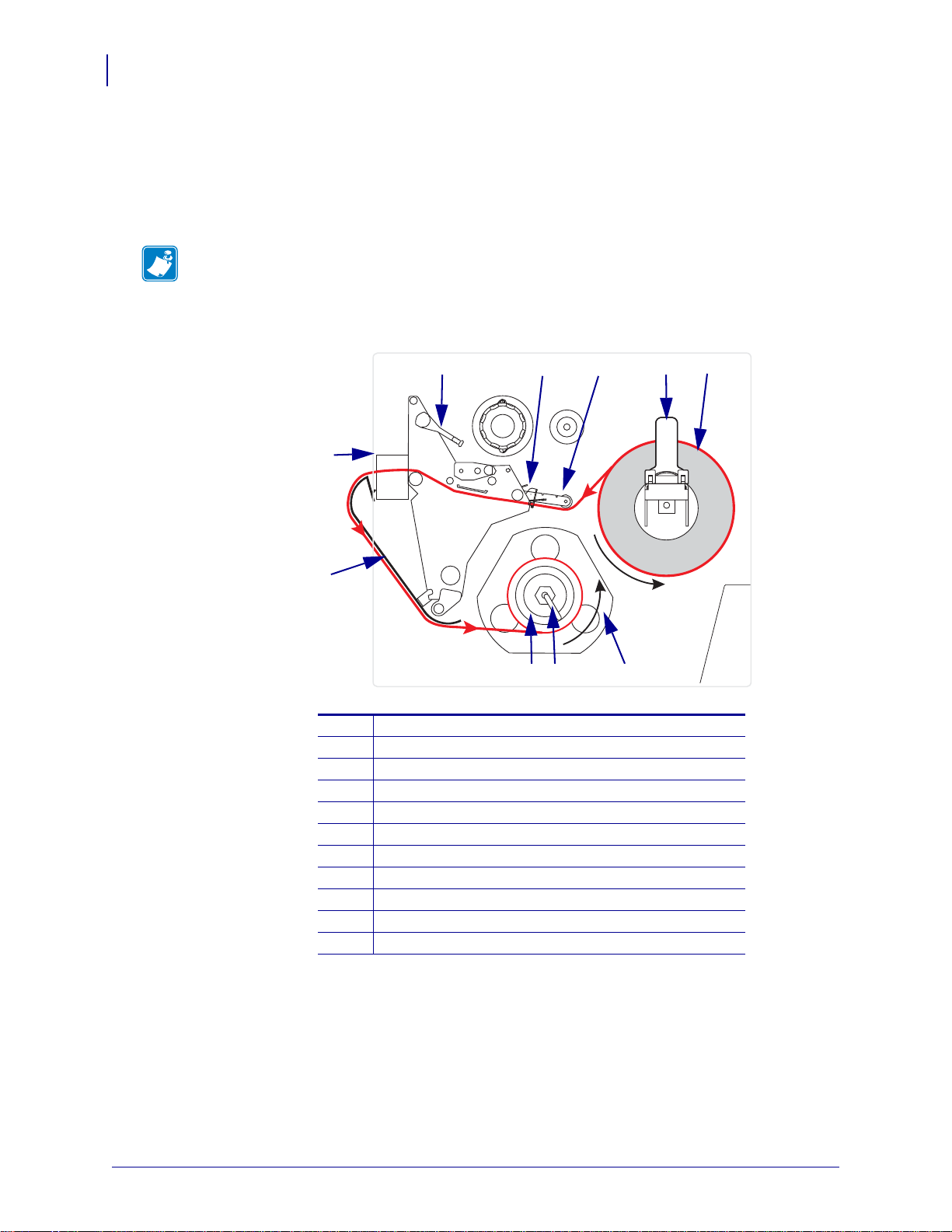

Without Ribbon Dancer With Ribbon Dancer

12

74

Load Ribbon

Load Ribbon

Use the instructions in this section to load ribbon for use with thermal transfer labels. For

direct thermal labels, do not load rib bo n in th e printer. The ribbon path is slightly d ifferent for

printers with ribbon dancers (Figure 11).

Important • Use ribbon that is wider than the media to protect the printhead from wear.

Ribbon must be coated on the outside.

Figure 11 • Ribbon Path

Caution • While performing any tasks near an open printhead, remove all rings, watches,

hanging necklaces, identification badges, or other metallic objects that could touch the

printhead. You are not required to turn off the printer power when working near an open

printhead, but Zebra recommends it as a precaution. If you turn off the power, you will lose

all temporary settings, such as label formats, and you must reload them before you resume

printing.

To load ribbon, complete these steps:

1. Align the arrow (1) on the ribbon take-up spindle knob with the notch (2) in the ribbon

take-up spindle.

P1009874-001 Xi4 User Guide 2/23/09

Page 15

Operations

23 1

Load Ribbon

2. Align the segments of the ribbon supply spindle.

3. Orient the ribbon with the loose end unrolling clockwise.

4. Place the roll of ribbon on the ribbon supply spindle. Push the roll back as far as it will go.

75

5. A ribbon leader makes ribbon loa ding an d unloa ding ea sier. Does yo ur roll of rib bon ha ve

paper or something else attached to the end to serve as a ribbon leader?

If… Then…

Yes Continue with the next step.

No

a. Tear off a strip of media (labels and liner) about 6–12 in. (150–305 mm)

long from the roll.

b. Peel a label from the media strip.

c. Use this label (1) to attach the end of the ribbon (2) to the media strip (3).

The media strip acts as a leader.

2/23/09 Xi4 User Guide P1009874-001

Page 16

76

2

1

Operations

Load Ribbon

6. Open the printhead assembly by rotating the printhead-open lever counter-clockwise.

7. Does your printer contain a ribbon dancer assembly? (See Figure 11 on page 74 for the

ribbon dancer location.)

If... Then...

No Thread the ribbon over the media dancer assembly (1) and under the

ribbon guide roller (

2).

P1009874-001 Xi4 User Guide 2/23/09

Page 17

If... Then...

3

2

1

1

3

2

Operations

Load Ribbon

77

Yes

8. Push the ribbon leader forward until it passes under the printhead assembly (1), over the

a. Thread the ribbon through the ribbon dancer. The ribbon must go

under the upper roller (

b. Thread the ribbon under the ribbon guide roller (3).

1) and then over the lower roller (2).

snap plate (2), and then over the platen roller (3).

2/23/09 Xi4 User Guide P1009874-001

Page 18

78

21

Operations

Load Ribbon

9. Bring the ribbon leader over the upper ribbon roller (1) and then toward the ribbon take-up

spindle (

10. Wind the ribbon leader and attached ribbon counterclockwise around the ribbon take-up

2).

spindle.

11. Rotate the spindle counterclockwise several turns to wind the ribbon and remove any

slack.

P1009874-001 Xi4 User Guide 2/23/09

Page 19

Operations

12

Load Ribbon

12. Push down the printhead assembly (1), and then rotate the printhead-open lever (2)

clockwise until it locks into place.

79

Remove Used Ribbon

Remove used ribbon from the ribbon take-up spindle each time you change the roll of ribbon.

To remove used ribbon, complete these steps:

1. Has the ribbon run out?

If the ribbon... Then

Ran out Continue with the next step.

Did not run out Cut or break the ribbon before the ribbon take-up spindle.

2/23/09 Xi4 User Guide P1009874-001

Page 20

80

Operations

Load Ribbon

2. While holding the ribbon take-up spindle, turn the ribbon release knob clockwise until it

stops.

The ribbon release bars pivot down, easing the spindle’s grip on the used ribbon.

3. Slide the used ribbon off of the ribbon take-up spindle and discard.

P1009874-001 Xi4 User Guide 2/23/09

Page 21

Calibrate the Printer

Calibrate the printer when it is first put into service. Calib ra tio n al lows the pr int er to esta bl ish

the proper settings for the specific media and ribbon used in your application. You may

calibrate the printer at other times as needed. Table 8 shows the different methods for

calibration.

Table 8 • Types of Calibration

Type of Calibration Description When/How It Occurs

Operations

Calibrate the Printer

81

Auto-calibration The printer automatically sets the

value it detects for the spaces between

labels.

Long (Standard)

Calibration

The printer does the following:

• feeds media and ribbon

• sets the values it detects for media

length, media type (continuous or

non-continuous), and print mode

(thermal transfer or direct thermal)

• updates the sensor values

Occurs at the following times:

• When the printer is first turned on if

CALIBRATION is selected for

MEDIA POWER UP (see Select

Media Power-Up Option

on page 113).

• When the printer feeds media after

the printhead is closed if

CALIBRATION is selected for

HEAD CLOSE (see Select Head

Close Option on page 114).

• As part of both the sensor profile

and media and ribbon sensor

calibration procedures.

To perform a long calibration, do one

of the following:

• Press

• Select CALIBRATION for the

PAUSE on the control panel

to pause the printer, and then press

CALIBRATE.

MEDIA POWER UP or HEAD

CLOSE parameter (see Select

Media Power-Up Option

on page 113 or Select Head Close

Option on page 1 14 ).

Short Calibration The printer calibrates using the

current sensor values rather than

detecting the spaces between labels

and resetting the sensors. This

calibration sequence uses fewer labels

than the long calibration sequence, but

it is less reliable because the values

that are stored in the sensors could be

incorrect.

2/23/09 Xi4 User Guide P1009874-001

Select SHORT CAL for the

POWER UP or HEAD CLOSE

parameter (see Select Media

Power-Up Option on page 113 or

Select Head Close Option

on page 114.

MEDIA

Page 22

Operations

82

Calibrate the Printer

Table 8 • Types of Calibration (Continued)

Type of Calibration Description When/How It Occurs

Sensor Profile

Calibration

Media and Ribbon

Sensor Sensitivity

Calibration

The printer auto-calibrates and prints

a media sensor profile.

One of the most common adjustments

to printer settings. The printer resets

the sensitivity of the sensors to detect

correctly the media and ribbon that

you are using. If you change the type

of ribbon and/or media, you might

need to reset the sensitivity of the

media and ribbon sensors. When the

sensors are at their new sensitivity, the

printer performs an auto-calibration.

Select the SENSOR PROFILE

option on the control panel. See Print

Sensor Profile on page 108 for

instructions.

Select the

CALIBRATE

MEDIA AND RIBBON

option on the control

panel. See Calibrate Media and

Ribbon Sensor Sensitivity on page 109

for instructions.

P1009874-001 Xi4 User Guide 2/23/09

Page 23

Adjust Media Sensors

XX

YY

ZZ

1

The transmissive sensor consists of two sections: a light source (the lower media sensor) and a

light sensor (the upper media sensor). The media passes between the two.

Adjust these sensors only when the printer cannot detect the top of the label. The con trol panel

LCD displays

the printer.

Note • For most models of Xi4, the upper media sensor can be positioned along the inside

half of the media (the side closest to the back frame of the printer) or the outside half of the

media (the side farthest from the back frame of the printer). However, for the 220Xi4, you

cannot move the sensors to the outside half of the media.

Upper Media Sensor—Inside Half of Media

To adjust the upper media sensor for the inside half of the media, complete

these steps:

ERROR CONDITION PAPER OUT, even though there are labels loaded in

Operations

Adjust Media Sensors

83

1. Remove the ribbon (if ribbon is used).

2. Locate the upper media sensor adjustment screw (1). The upper media sensor eye is

directly below the adjustment screw head.

2/23/09 Xi4 User Guide P1009874-001

Page 24

Operations

XX

YY

ZZ

XX

YY

ZZ

XX

YY

ZZ

84

Adjust Media Sensors

3. Using a thin, flat-blade screwdriver, loosen the upper media sensor adjustment screw.

4. Slide the upper media sensor along the slot to the desired position (for non-continuous

media with a notch or hole in the media, the sensor must be directly above the notch or

hole).

5. Tighten the adjustment screw to secure the upper media sensor.

P1009874-001 Xi4 User Guide 2/23/09

6. Adjust the lower media sensor to match the new position of the upper media sensor. See

Lower Media Sensor on page 87.

Page 25

Upper Media Sensor—Outside Half of Media

XX

YY

ZZ

1

XX

YY

ZZ

To adjust the upper media sensor for the outside half of the media, complete

these steps (all models except the 220Xi4):

1. Remove the ribbon (if ribbon is used).

2. Locate the upper media sensor adjustment screw (1). The upper media sensor eye is

directly below the adjustment screw head.

Operations

Adjust Media Sensors

85

3. Using a thin, flat-blade screwdriver, loosen and then remove the upper media sensor

adjustment screw.

4. Lift the upper media sensor assembly from the slot, and move it and the wire cover to the

outside slot. Carefully pull the wires through the cable tie. You may need to set aside the

sensor wire cover if the adjustment is too far to the outside.

5. Replace and slightly tighten the adjustment screw.

2/23/09 Xi4 User Guide P1009874-001

Page 26

Operations

XX

YY

ZZ

XX

YY

ZZ

86

Adjust Media Sensors

6. Slide the upper media sensor along the slot to the desired position (for non-continuous

media with a notch or hole in the media, the sensor must be directly above the notch or

hole).

7. Tighten the adjustment screw.

8. Make sure that the wires are routed back into the groove of the media sensor bracket.

9. Adjust the lower media sensor to match the new position of the upper media sensor. See

Lower Media Sensor on page 87.

P1009874-001 Xi4 User Guide 2/23/09

Page 27

Lower Media Sensor

After you adjust the upper media sensor, adjust the lower media sensor to match its new

position.

To adjust the lower media sensor, complete these steps:

1. Locate the lower media sensor assembly under the rear roller. The sensor is a spring clip

holding a circuit board.

Operations

Adjust Media Sensors

87

2. Slide the lower sensor until it is under the upper media sensor. Use the light that shines

from the sensor to help align it with the upper sensor. Gently pull wires out as needed

(wires should have a little slack).

2/23/09 Xi4 User Guide P1009874-001

Page 28

Operations

1

88

Adjust Printhead Pressure and Toggle Position

Adjust Printhead Pressure and Toggle Position

Print quality depends on the labels and ribbon used as well as the toggle pressure and position.

Make sure that your labels and ribbon are acceptable for your application. If they are, check

the toggle position and then the printhead pressure.

Toggle Position Adjustment

You may need to adjust the toggles if printing is too light on one si de or if thick labe ls are used.

If the toggle pressure is too light or uneven, the labels and ribbon may slip.

To position the toggles, complete these steps:

1. Loosen the locking nuts (1) at the top of the toggle assemblies.

2. Slide the toggles until they provide even pressure on the media. For extremely narrow

media, position one toggle over the center of the labels, and decrease the pressure on the

unused toggle.

3. Tighten the locking nuts.

P1009874-001 Xi4 User Guide 2/23/09

Page 29

Printhead Pressure Adjustment

1

If positioning the toggles properly does not solve a print quality problem, try adjusting the

printhead pressure. Maximize printhead life by using the lowest pressure that produces the

desired print quality.

Caution • Observe proper electrostatic safety precautions when handling any

static-sensitive components such as circuit boards and printheads.

To adjust printhead pressure, complete these steps:

1. Print some labels at 2.4 in. (61 mm) per second by running the PAU SE Sel f Tes t

on page 154.

2. While printing labels, use the control panel contro ls to lower the darkness set ting unt il the

labels are printing gray instead of black.

3. Loosen the upper knurled nuts on the toggle assemblies (1).

Operations

Adjust Printhead Pressure and Toggle Positi on

89

2/23/09 Xi4 User Guide P1009874-001

Page 30

Operations

1

90

Adjust Printhead Pressure and Toggle Position

4. Some media types require higher pressure to print well. For these media types, inc rease or

decrease pressure using the lower knurled nuts (

printed area are equally dark.

5. Increase the darkness level using the control panel controls until the printing is clear.

1) until the left and right edges of the

6. Tighten the upper knurled nuts.

P1009874-001 Xi4 User Guide 2/23/09

Page 31

Adjust Printhead Pressure and Toggle Positi on

Notes • ___________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

Operations

91

2/23/09 Xi4 User Guide P1009874-001

Page 32

Operations

92

Adjust Printhead Pressure and Toggle Position

P1009874-001 Xi4 User Guide 2/23/09

Page 33

4

Configuration

This section describes the control panel parameters that are used to configure the printer for

operation.

Contents

Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Enter and Use Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Exit Setup Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Change Password-Protected Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Default Password Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Disable the Password Protection Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Print a Configuration Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Print a Network Configuration Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Standard Control Panel Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Additional Control Panel Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

2/23/09 Xi4 User Guide P1009874-001

Page 34

Configuration

94

Setup Mode

Setup Mode

After you have installed the media and ribbon and the Power-O n Self T est (PO ST) is complete,

the control panel displays

application using the control panel display and the buttons directly below it. If it becomes

necessary to restore the initial printer defaults, see FEED and PAUSE Self Test on page 158.

Important • Certain printing conditions may require that you adjust printing parameters,

such as print speed, darkness, or print mode. These conditions include (but are not

limited to):

• printing at high speeds

• peeling the media

• the use of extremely thin, small, synthetic, or coated labels

Because these and other factors affect print quality, run tests to determine the best

combination of printer settings and media for your applic ation. A po or match may li mit print

quality or print rate, or the printer may not function properly in the desired print mode.

Note • If the printer is operating on an IP network and you have a ZebraNet 10/100 Print

Server or Wireless Plus Print Server, you can change the printer’s parameters in these

additional ways:

• with ZebraLink™ WebView. For information, see the appropriate print server user guide.

• with ZebraNet Bridge. For information, see the ZebraNet Bridge Enterprise Printer

Management User Guide.

PRINTER READY. You may now set printer parameters for your

Enter and Use Setup Mode

Use the LCD on the control panel to view and adjust printer settings through Setup mode.

When a parameter is changed, an asterisk (*) appears in the upper left corner of the display to

indicate that the value is different from the one currently active in the printer.

Press this key... To do the following...

SETUP/EXIT

SELECT select or deselect a parameter.

PLUS (+) continue to the next parameter.

MINUS (-) return to the previous parameter in the cycle.

enter or exit Setup mode.

P1009874-001 Xi4 User Guide 2/23/09

Page 35

Exit Setup Mode

When you exit setup mode, you have several options for saving, changing, or not changing

parameters.

To leave Setup mode, complete these steps:

1. Press SETUP/EXIT.

The LCD displays

2. Press PLUS (+) or MINUS (-) to display the save options:

LCD Description

SAVE CHANGES.

Configuration

Setup Mode

95

PERMANENT

TEMPORARY

CANCEL

LOAD DEFAULTS

LOAD LAST SAVE

DEFAULT NET

3. Press NEXT/SAVE to select the displayed choice.

When the configuration and calibration sequence is done,

Stores values in the printer even when power is turned off.

Saves the changes until power is turned off.

Cancels all changes made since you entered Setup mode,

except for changes made to the darkness and tear-off settings,

which go into effect as soon as they are made.

Restores all parameters other than the network settings b ack to

the factory defaults. Use care when loading defaults because

you will need to reload all settings that you changed manually.

Note • On non-RFID printers, loading factory defaults

causes the printer to auto-calibrate.

Loads values from the last permanent sav e.

Restores the wired and wireless network settings back to

factory defaults.

PRINTER READY displays.

2/23/09 Xi4 User Guide P1009874-001

Page 36

Configuration

96

Change Password-Protected Parameters

Change Password-Protected Parameters

Certain parameters, including the communication parameters, are password-protected by

factory default.

Caution • Do not change password-protected parameters unless you have a complete

understanding of the parameters’ functions. If the parameters are set incorrectly, the printer

may function unpredictably.

The first time that you attempt to change a password-protected parameter, the printer displays

ENTER PASSWORD. Before you can change the parameter, you must enter the four-digit

numeric password. After you have entered the password correctly, you do not have to enter it

again unless you leave Setup mode by pressing

To enter a password for a password-protected parameter, complete

these steps:

1. At the password prompt, use MINUS (-) to change the selected digit position.

2. When you have selected the digit that you wish to change, use PLUS (+) to increase the

selected digit value. Repeat these two steps for each digit of the password.

SETUP/EXIT or by turning off (O) the printer.

3. After entering the password, press NEXT/SAVE.

The parameter you selected to change is displayed. If the password was entered correctly,

you can change the value.

Default Password Value

The default password value is 1234. The password can be changed using the Zebra

Programming Language (ZPL) command

pages (ZebraNet

®

10/100 Print Server or Wireless Plus Print Server required).

^KP (Define Password) or using the printer’s web

Disable the Password Protection Feature

You can disable the password prot ection feature so that it no longer prompts you for a

password by setting the password to 0000 via the

password-protection feature, send the ZPL comma nd

1 to 9999.

^KP ZPL command. To re-enable the

^KPx, where x can be any number from

P1009874-001 Xi4 User Guide 2/23/09

Page 37

Print a Configuration Label

A configuration label lists the printer settings that are stored in configuration memory. After

you load the media and ribbon (if necessary), print a configuration label as a record of your

printer’s current settings. Keep the label to use when troubleshooting printing problems.

To print a configuration label, complete these steps:

1. On the control panel, press SETUP/EXIT.

2. Press NEXT/SAVE or PREVIOUS to scroll through the parameters until you reach

LIST SETUP.

3. Press PLUS (+) to confirm printing.

A configuration label prints (Figure 12).

Figure 12 • Sample Configuration Label

Configuration

Print a Configuration Label

97

2/23/09 Xi4 User Guide P1009874-001

Page 38

Configuration

asterisk

indicating the

active print

server

98

Print a Network Configuration Label

Print a Network Configuration Label

If you are using a print server, you can print a network configuration label after the printer is

connected to the network.

To print a network configuration label, complete these steps:

1. On the control panel, press SETUP/EXIT.

2. Press NEXT/SAVE or PREVIOUS to scroll through the parameters until you reach

LIST NETWORK.

3. Press PLUS (+) to confirm printing.

A network configuration label prints (Figure 13). An asterisk designates whether the

wired or wireless print server is active. If n o wireless print server is installed, the wireless

portion of the label does not print.

Figure 13 • Network Configuration Label (With a Wireless Print Server Installed)

P1009874-001 Xi4 User Guide 2/23/09

Page 39

Standard Control Panel Parameters

Table 9 shows parameters in the order in which they are displayed when you press

NEXT/SAVE after entering Setup mode. For parameters that do not appear in this table, see

Additional Contr ol Pan el Para me ters on page 121.

Note • Your label preparation software or the printer driver may override adjustments made

through the control panel. Refer to the software or driver documentation for more

information.

Table 9 • Printer Parameters (Continued, page 1 of 22)

Configuration

Standard Control Panel Parameters

99

Language/Parameter

Action/Explanation

Adjust Print Darkness

Darkness (burn duration) settings depend on a variety of factors, including

ribbon type, media type, and the cond ition of the printhead . You may adjust

the darkness for consistent high-quality printing.

Important • Set the darkness to the lowest setting that provides

good print quality. If the darkness is set too high, the ink may

smear, the ribbon may burn through, or the printhead may wear

prematurely.

If printing is too light or if there are voids in printed areas, increase the

darkness. If printing is too dark or if there is spreading or bleeding of

printed areas, decrease the darkness.

The FEED Self Test on page 155 can be used to determine the best darkness

setting. You may want to adjust darkness while performing the PAUSE Self

Test on page 154. Because the darkness setting takes effect immediately,

you can see the results on labels that are currently printing. Darkness

settings also may be changed by the driver or software settings.

Default Value: +10

Range: 00 to +30

To change the value shown:

1. Press PLUS (+) to increase darkness.

2. Press MINUS (-) to decrease darkness.

2/23/09 Xi4 User Guide P1009874-001

Page 40

100

1

Media direction

2

Factory-set tear line location at position 00

1

2

Configuration

Standard Control Panel Parameters

Table 9 • Printer Parameters (Continued, page 2 of 22)

Language/Parameter

Action/Explanation

Adjust Print Speed

Adjusts the speed for printing a label (given in inches per second). Slower

print speeds typically yield better print quality. Print speed changes take

effect upon exiting Setup mode.

Default Value: 2 IPS

Range:

• 200 dpi: 2 to 10 IPS

• 300 dpi: 2 to 8 IPS

• 600 dpi: 1 to 4 IPS

To change the value shown:

1. Press PLUS (+) to increase the value.

2. Press MINUS (-) to decrease the value.

Adjust the Tear-Off Position

This parameter establishes the position of the media over the

tear-off/peel-off bar after printing.

See Figure 14. Higher numbers mov e the media out (the tear line moves

closer to the leading edge of the next label), and lower numbers move the

media in (the tear line moves closer to the edge of the label just printed).

Figure 14 • Tear-Off Position Adjustment

Default Value: 0

Range: -120 to +120

To change the value shown:

1. Press PLUS (+) to increase the value. Each press adjusts the tear-off

position by four dot rows.

2. Press MINUS (-) to decrease the value. Each press adjusts the tear-off

position by four dot rows.

P1009874-001 Xi4 User Guide 2/23/09

Loading...

Loading...