Page 1

ZD500 Series™

User’s Guide

Thermal Transfer Printer

P1062653-002 Rev. A

Page 2

ii

© 2013 ZIH Corp. The copyrights in this manual and the software and/or firmware in the

label printer and accessories described therein are owned by ZIH Corp. Unauthorized

reproduction of this manual or the software and/or firmware in the label printer may result in

imprisonment of up to one year and fines of up to $10,000 (17 U.S.C.506). Copyright violators

may be subject to civil liability.

®

This product may contain ZPL

®

Equalizer

Circuit; E3®; and Monotype Imaging fonts. Software © ZIH Corp. All rights

reserved worldwide.

, ZPL II®, and ZebraLink™ programs; Element Energy

ZD500 Series, ZD500R, ZebraLink and all product names and numbers are trademarks, and

3

Zebra, the Zebra logo, ZPL, ZPL II, Element Energy Equalizer Circuit, and E

Circuit are

registered trademarks of ZIH Corp. All rights reserved worldwide.

All other brand names, product names, or trademarks belong to their respective holders.

For additional copyright and trademark information, please see “Copyright” on the Zebra

website.

www.zebra.com/copyright

Proprietary Statement This manual contains proprietary information of Zebra

Technologies Corporation and its subsidiaries (“Zebra Technologies”). It is intended solely for

the information and use of parties operating and maintaining the equipment described herein.

Such proprietary information may not be used, reproduced, or disclosed to any other parties

for any other purpose without the express, written permission of Zebra Technologies.

Product Improvements Continuous improvement of products is a policy of Zebra

Technologies. All specifications and designs are subject to change without notice.

Liability Disclaimer Zebra Technologies takes steps to ensure that its published

Engineering specifications and manuals are correct; however, errors do occur. Zebra

Technologies reserves the right to correct any such errors and disclaims liability resulting

therefrom.

Limitation of Liability In no event shall Zebra Technologies or anyone else involved in the

creation, production, or delivery of the accompanying product (including hardware and

software) be liable for any damages whatsoever (including, without limitation, consequential

damages including loss of business profits, business interruption, or loss of business

information) arising out of the use of, the results of use of, or inability to use such product,

even if Zebra Technologies has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply to you.

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 3

Compliance and Regulatory Statements

FCC Compliance Statement (USA)

This device complies with Part 15 rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause

undesired operation.

This equipment has been tested and found to comply with the limits for Class B Digital

Devices, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a residential

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the product manuals, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television

reception, the user is encouraged to do one or more of the following measures:

• Reorient or relocate the receiving antenna.

iii

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced RF service technician for help.

Important •

1. The radio must be installed with a minimum 20 cm separation between the user and the

antenna.

2. The radio must not be co-located or used in simultaneous transmitting condition with

another radio.

3. The host system shall have a label to indicate that the system contains a certified module.

An example is “Contains FCC ID : I28MD-EXLAN11N , IC ID: 3798B-EXLAN11N”.

4. The radio is for indoor use only in the 5150-5250 GHz frequency range.

The user is cautioned that any changes or modifications not expressly approved by Zebra

Technologies could void the user’s authority to operate the equipment. To ensure compliance,

this printer must be used with fully shielded communication cables.

Mexico — NOM-121-SCT1-2009

Este equipo ha sido diseñado para operar con las antenas que enseguida se enlistan y para una

ganancia máxima de antena de [x] dB. El uso con este equipo de antenas no incluidas en esta

lista o que tengan una ganancia mayor que [x] dB quedan prohibidas. La impedancia requerida

de la antena es de [y] ohms.

auden - p/n 220370-09

• Gain = 2.77dbi @ 2.4 GHz

• Gain = 2.69 - 3.19dBi @ 5 GHz

• Impedance = 50 ohms

1/16/2014 ZD500 Series™ TThermal Transfer Printer User’s Guide P1062653-002Rev. A

Page 4

iv

Canadian DOC Compliance Statement

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

This Class B digital apparatus complies with Canadian ICES-003.

Industry Canada (IC) Warning

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio

exempts de licence. L’exploitation est autorisée aux deux conditions suivantes : (1) l’appareil

ne doit pas produire de brouillage, et (2) l’utilisateur de l’appareil doit accepter tout brouillage

radioélectrique subi, même si le brouillage est susceptible d’en compromettre le

fonctionnement.

This device complies with Industry Canada license-exempt RSS standard(s). Operation is

subject to the following two conditions: 1) This device may not cause interference., 2) This

device must accept any interference, including interference that may cause undesired operation

of the device.

Brasil — Aviso da Anatel

Este equipamento opera em caráter secundário, isto é, não tem direito a proteção contra

interferência prejudicial, mesmo de estações do mesmo tipo, e não pode causar interferência a

sistemas operando em caráter primário.

“Este produto está homologado pela ANATEL, de acordo com os procedimentos

regulamentados pela Resolução 242/2000, e atende aos requisitos técnicos aplicados”

Para maiores informações, consulte o site da ANATEL www.anatel.gov.br

This equipment's operation is of a secondary character; that is, it doesn't have the right to

protection against damaging interference, even from stations of the same type, nor can it cause

interference to systems with a primary operating character.

Este produto utiliza internamente o modulo de RF M6E- micro numero de homologação pela

ANATEL 3059-13-8108 e o modulo WYSBMVGXB numero de homologação pela ANATEL

3825-13-9965

Este equipamento opera em caráter secundário, isto é, não tem direito a proteção contra

interferência prejudicial, mesmo de estações do mesmo tipo, e não pode causar interferência a

sistemas operando em caráter primário.

Japan Restricted Frequencies

この周波数帯は 5.725 5.825 GHz の日本で利用できるされません。

For 5.725 - 5.825 GHz, this frequency band will not be available in Japan.

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer PrinterUser’s Guide 1/16/2014

Page 5

Taiwan Restricted Frequencies

5.15-5.25 GHz, 該頻段將在臺灣不可用。

For 5.15 - 5.25 GHz, this frequency band will not be available in Taiwan.

Korean Compliance Statement

이 기기는 가정용 (B 급 ) 전자파 적합기기 로서 주로 가정에서 사용하는 것을 목적으로

하며 , 모든 지역에서 사용할 수 있습니다 .

The equipment is for home use (Class B) and has acquired electromagnetic conformity

registration, so it can be used not only in residential area but other areas as well.

This radio device is not allowed to be used for human safety since it has possibility of radio

interference during operation.

European Regulatory Information

v

Note • Member states in the EU with restrictive use for this device are crossed out. This

device is also authorized for use in all EFTA member states (CH, IS, LI, NO).

1/16/2014 ZD500 Series™ TThermal Transfer Printer User’s Guide P1062653-002Rev. A

Page 6

vi

NCC

經型式認證合格之低功率射頻電機,非經許可,公司、商號或使用者均不得擅自變

更頻率、加大功率或變更原設計之特性及功能。低功率射頻電機之使用不得影響飛

航安全及干擾合法通信;經發現有干擾現象時,應立即停用,並改善至無干擾時方

得繼續使用。前項合法通信,指依電信法規定作業之無線電通信。低功率射頻電機

須忍受合法通信或工業、科學及醫療用電波輻射性電機設備之干擾。

According to "Administrative Regulations on Low Power Radio Waves Radiated Devices"

Without permission granted by the NCC, any company, enterprise, or user is not allowed to

change frequency, enhance transmitting power or alter original characteristic as well as

performance to an approved low power radio-frequency devices. The low power radiofrequency devices shall not influence aircraft security and interfere legal communications; If

found, the user shall cease operating immediately until no interference is achieved. The said

legal communications means radio communications is operated in compliance with the

Telecommunications Act.

The low power radio-frequency devices must be susceptible with the interference from legal

communications or ISM radio wave radiated devices.

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer PrinterUser’s Guide 1/16/2014

Page 7

WLAN Radio Specification

802.11 b

•2.4 GHz

• DSSS (DBPSK, DQPSK and CCK)

• RF power 63 mW (ZebraNet n Print Server)

802.11 g

•2.4 GHz

• OFDM (16-QAM and 64-QAM with BPSK and QPSK)

• RF power 63 mW (ZebraNet n Print Server)

802.11 n

•2.4 GHz

• OFDM (16-QAM and 64-QAM with BPSK and QPSK)

• RF power 63 mW (ZebraNet n Print Server)

vii

802.11 a/n

• 5.15-5.25 GHz, 5.25-5.35 GHz, 5.47-5.725 GHz, 5.725-5.825 GHz

• OFDM (16-QAM and 64-QAM with BPSK and QPSK)

• RF power 50 mW (ZebraNet n Print Server)

Bluetooth 2.1 + EDR

•2.4 GHz

•FHSS

• RF power 0.4 mW

RFID Radio Specification

• 902 - 928 MHz (US); 865 - 868 MHz (EU)

• ISO-18000 - 6B; ISO 18000-6C

• RF power <30 dBm ERP

1/16/2014 ZD500 Series™ TThermal Transfer Printer User’s Guide P1062653-002Rev. A

Page 8

viii

Environmental Management

Environmental Management

Do not dispose of this product in unsorted municipal waste. This product is recyclable, and

should be recycled according to your local standards.

For more information, please see our website at:

Web address: www.zebra.com/environment

Document Conventions

Alternate Color

If you are viewing this guide on-line, you can click the blue text used for cross-references or

hyper-links to jump directly to other sections in the guide or to web sites on the Internet.

Command Line Examples, File Names, and Directories

Table 1 • Document Conventions

Command line examples, file names, and directories appear in a Typewriter style

(Courier) mono-spaced font. For example:

ZTools to get to the Post-Install scripts in the /bin directory.

Type

Open the

Icons and Advisory Words

The following icons and advisory words are used to draw your attention to certain areas of text.

Caution • Warns you of the potential for electrostatic discharge.

Caution • Warns you of a potential electric shock situation.

Caution • Warns you of a situation where excessive heat could cause a burn.

Caution • Advises you that failure to take or avoid a specific action could result in physical

harm to you.

(No icon)

Caution • Advises you that failure to take or avoid a specific action could result in physical

harm to the hardware.

Zebra<version number>.tar file in the /root directory.

Important • Advises you of information that is essential to complete a task.

Note • Indicates neutral or positive information that emphasizes or supplements important

points of the main text.

Tools • Tells you what tools you need to complete a given task.

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer PrinterUser’s Guide 1/16/2014

Page 9

Contents

Compliance and Regulatory Statements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Environmental Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Document Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

• Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

1 • Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

ZD500 Series™ Thermal Printers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

The ZD500 Series™ printer features:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

The ZD500 Series™ printer options: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

What’s in the Box? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpack and Inspect the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Printer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Control Panel Display Menu and Status Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Printer Control Panel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Navigating through Screens in the Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Control Panel Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 • Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Select a Location for the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Attaching Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Preparing and Handling Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Media Storage Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Setting the Printer Menu and Report Display Language. . . . . . . . . . . . . . . . . . . . . . . . . . 19

Loading Roll Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Loading Transfer Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Test Printing with Configuration Report Printouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1/16/2014 ZD500 Series™ User’s Guide P1062653-002 Rev. A

Page 10

Contents

x

Connecting your Printer to a Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Interface Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wired (Ethernet) Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

ZebraNet® Internal Wireless Print Server Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Configure Using the Connectivity Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Bluetooth Option Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Connecting to a Windows Vista® SP2 or Windows 7® Master Device . . . . . . . . . . . 45

After Your Printer is Connected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3 • Printer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Changing Printer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

SETTINGS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

TOOLS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

NETWORK Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

RFID Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

LANGUAGE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

SENSOR Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

PORTS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

BLUETOOTH Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Manual Calibration - Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

RFID Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4 • Print Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Determining Printer Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Thermal Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Modes of Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Setting the Thermal Print Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Types of Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Determining Thermal Media Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Media Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Attaching the 3 inch Core Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Loading 3 inch I.D. Media rolls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Removing the 3 inch Core Adapters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Ribbon Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

When to Use Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Coated Side of Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Ribbon Test with Adhesive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Ribbon Scratch Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Replacing Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Adding a New Transfer Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Replacing a Partially Used Transfer Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

P1062653-002 Rev. A ZD500 Series™ User’s Guide 1/16/2014

Page 11

Contents

Adjusting the Print Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Adjusting the Print Quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Media Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Using the Movable Black Mark Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Adjusting the Movable Sensor for Black Marks or Notches . . . . . . . . . . . . . . . . . . . . 90

Adjusting the Movable Sensor for Web (Gap) Sensing . . . . . . . . . . . . . . . . . . . . . . . 92

Printing on Fan-Fold Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Printing with Externally Mounted Roll Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Sending Files to the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Fonts and Your Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Identifying Fonts in Your Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Localizing the Printer with Code Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Asian fonts and Other Large Font Sets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Getting Asian Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

5 • Printer Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Label Dispenser Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Cutter Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Loading Media with the Cutter Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

ZebraNet® Internal Wireless Print Server Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Bluetooth Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Printer Network Configuration Status Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

xi

6 • Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

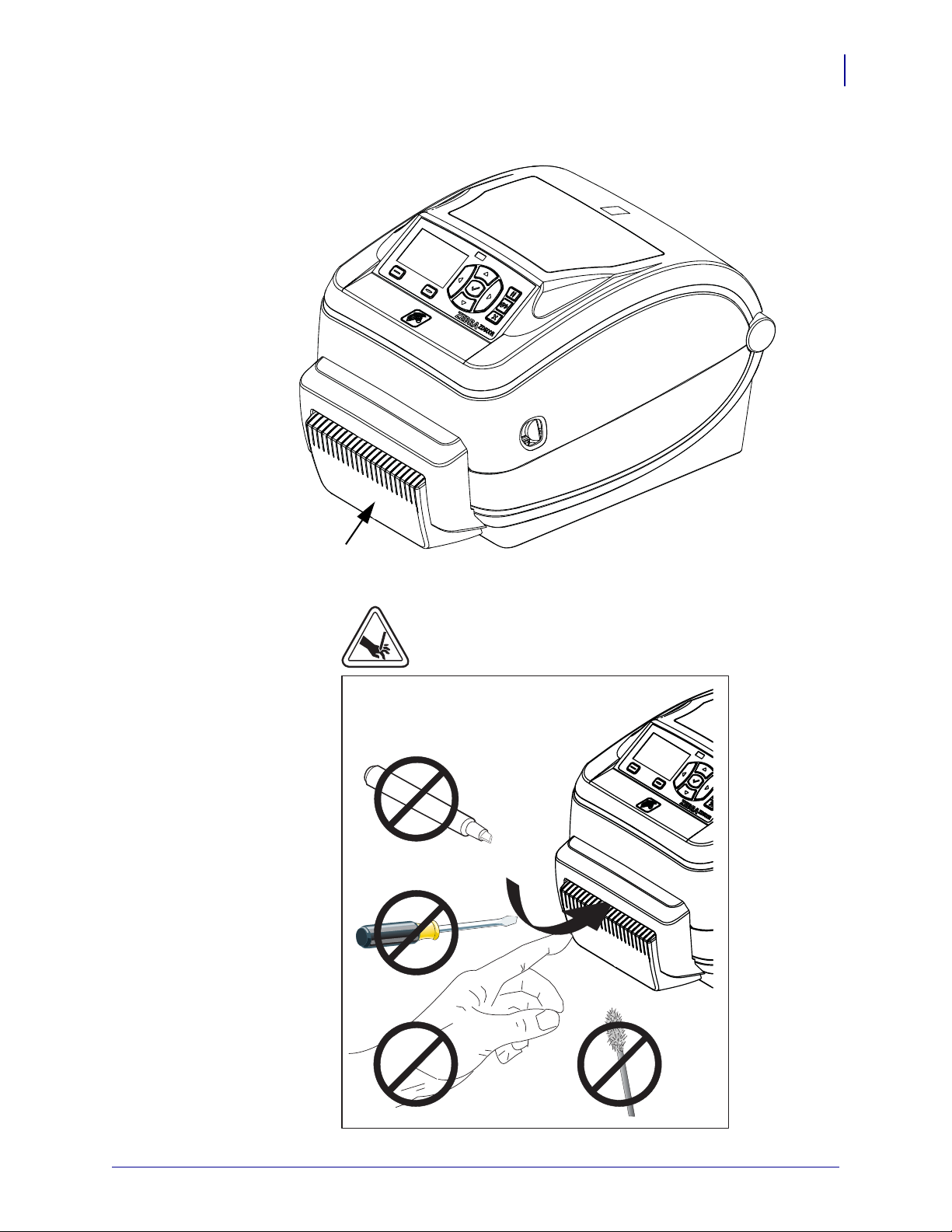

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Cleaning the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Media Path Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Sensor Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Platen Cleaning and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Other Printer Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

RTC Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Replacing the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

7 • Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Printing Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Ribbon Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Communications Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Miscellaneous Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

RFID Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

1/16/2014 ZD500 Series™ User’s Guide P1062653-002Rev. A

Page 12

Contents

xii

Printer Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Power-On Self Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Configuration Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Print Quality Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Reset Printer Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Reset Network Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Communication Diagnostics Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Sensor Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

A • Appendix: Interface Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Serial Port Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Connecting the Printer to a DTE Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

B • Appendix: Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

External ZD500 Series™ Printer Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Label Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

P1062653-002 Rev. A ZD500 Series™ User’s Guide 1/16/2014

Page 13

1

Introduction

This section introduces you to your new Zebra® ZD500 Series™ desktop thermal label

printer. It describes what you get in your shipping box and provides an overview of printer

features. It also includes procedures that describe how to open and close the printer and

report any problems.

Your printer, when connected to a host computer, functions as a complete system for

printing labels, receipts, forms, and tags.

This users guide provides all the information you need to operate your printer on a daily

basis.

ZD500 Series™ Thermal Printers

The Zebra® ZD500 Series™ models are desktop thermal label printers with the widest

range of features and options including an internal UHF RFID encoder option.

• The 203 dpi (dots per inch print density) version printer provides thermal transfer and

direct thermal printing at speeds up to 6 ips (inches per second).

• The 300 dpi version printer provides thermal transfer and direct thermal printing at

speeds up to 4 ips.

• These printers support ZPL™ Zebra printer programming language and a wide variety

of interface and feature options.

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 14

Introduction

2

ZD500 Series™ Thermal Printers

The ZD500 Series™ printer features:

• A user display and control panel for easier installation and direct access feature

• OpenAccess™ design for simplified media loading.

• Color-coded operator controls and media guides.

• Zebra™ Global Printing Solution – supports Microsoft Windows keyboard encoding

• On–The –Fly OpenType and TrueType font scaling and import, Unicode, resident

• XML-Enabled printing—allows XML communications for bar code label printing,

controls typically found only in premium printers.

(and ANSI), Unicode UTF-8 and UTF 16 (Unicode Transformation Formats), XML,

ASCII (7 and 8 bit used by legacy programs and systems), basic single and double

byte font encoding, JIS and Shift-JIS (Japanese International Standards), Hexadecimal

encoding, and custom character mapping (DAT table creation, font linking, and

character remapping).

scalable font, and a selection of resident bitmap fonts.

eliminating license fees and print server hardware and lowering customization and

programming costs.

• Movable Sensor: A full width movable black mark or notch sensor, and multi center

position transmissive (label gap/web) sensor.

• 56 MB of user accessible flash memory for storing forms, fonts, and graphics.

• USB 2.0, Serial RS-232 and bi-directional parallel ports.

• Internal ZebraNet10/100 Print Server—supports 10Base-T, 100Base-TX and fast

Ethernet 10/100 auto-switching networks.

• On-board RTC (Real Time Clock).

• Printhead maintenance reporting enabled and customizable by the user.

The ZD500 Series™ printer options:

• Internal UHF RFID Encoder (See the RFID Programmimg Guide 3 for details)

• Label Dispense (Peel-Off Liner and Present Label for Operator).

• General purpose media cutter.

• Wi-Fi (802.11a/b/g/n)

• Bluetooth 3.0

• Pre-loaded Swiss 721 Latin 1 font (for EU zone printers). Font is available for

download.

• Asian Language support with printer configuration options for the large Simplified

and Traditional Chinese, Japanese, or Korean character sets. Printers sold in China

have the Simplified Chinese SimSun font pre-installed.

• Zebra® ZBI 2.0™ (Zebra BASIC Interpreter) programming language. ZBI allows you

to create custom printer operations that can automate processes, use peripherals (i.e.

scanners, scales, keyboards, Zebra® ZKDU™, etc.) all without being attached to a PC

or network.

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 15

Introduction

ZD500 Series™ Thermal Printers

Your printer, when connected to a host computer, functions as a complete system for

printing labels, receipts, forms, and tags. Many printer settings may also be controlled by

your printer’s driver or label design software. Refer to the driver or software

documentation for more information.

To create label formats, refer to your programming guides or label design applications

such as the free label and form design software: ZebraDesigner™.

The printer includes a complete suite of free Link-OS software applications and drivers to

configure printer settings, design and print labels and receipts, get printer status, import

graphics and fonts, send programming commands, update firmware, and download files.

Clone printer settings and send graphics, files, fonts, and firmware (updates) to one or

more Zebra® Ethernet and locally connected printers with ZebraNet™ Bridge.

3

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 16

Introduction

Power Cord

varies by locale or region

Documentation

and Software

Power

Supply

USB Cable

Printer

Ribbon Core

3in (76.2 mm) I.D.

Media Roll Adapters

4

What’s in the Box?

What’s in the Box?

Save the carton and all packing materials in case you need to ship or store the printer later.

After unpacking, make sure you have all parts. Follow the procedures for inspecting the

printer to familiarize yourself with printer parts so you can follow the instructions in this

book.

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Unpack and Inspect the Printer

When you receive the printer, immediately unpack it and inspect for shipping damage.

• Save all packing materials.

• Check all exterior surfaces for damage.

• Open the printer and inspect the media compartment for damage to components.

If you discover shipping damage upon inspection:

• Immediately notify the shipping company and file a damage report. Zebra

Technologies Corporation is not responsible for any damage to the printer

incurred during shipment, and will not cover the repair of this damage under its

warranty policy.

• Keep all packaging material for shipping company inspection.

• Notify your authorized Zebra

®

reseller.

Page 17

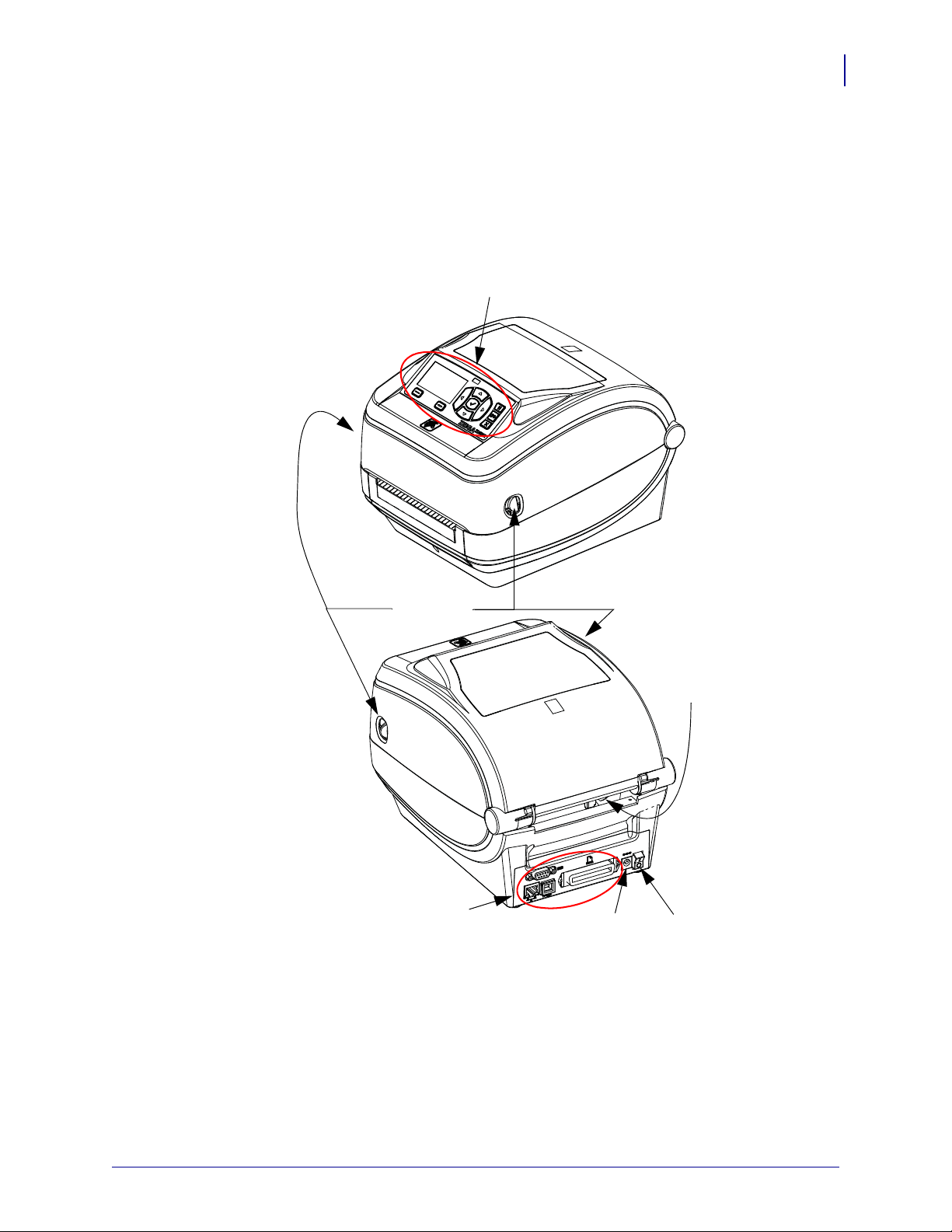

Printer Features

Interface

Connectors

Control Panel

Release

Latches

Release

Latches

DC Power

Receptacle

Power

Switch

Fan-Fold Media

Entry Slot

Figure 1 shows features on the outside and Figure 2 shows features inside the media

compartment of your printer. Depending on the printer model and the installed options,

your printer may look slightly different.

Figure 1 • Printer Features

Introduction

Printer Features

5

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 18

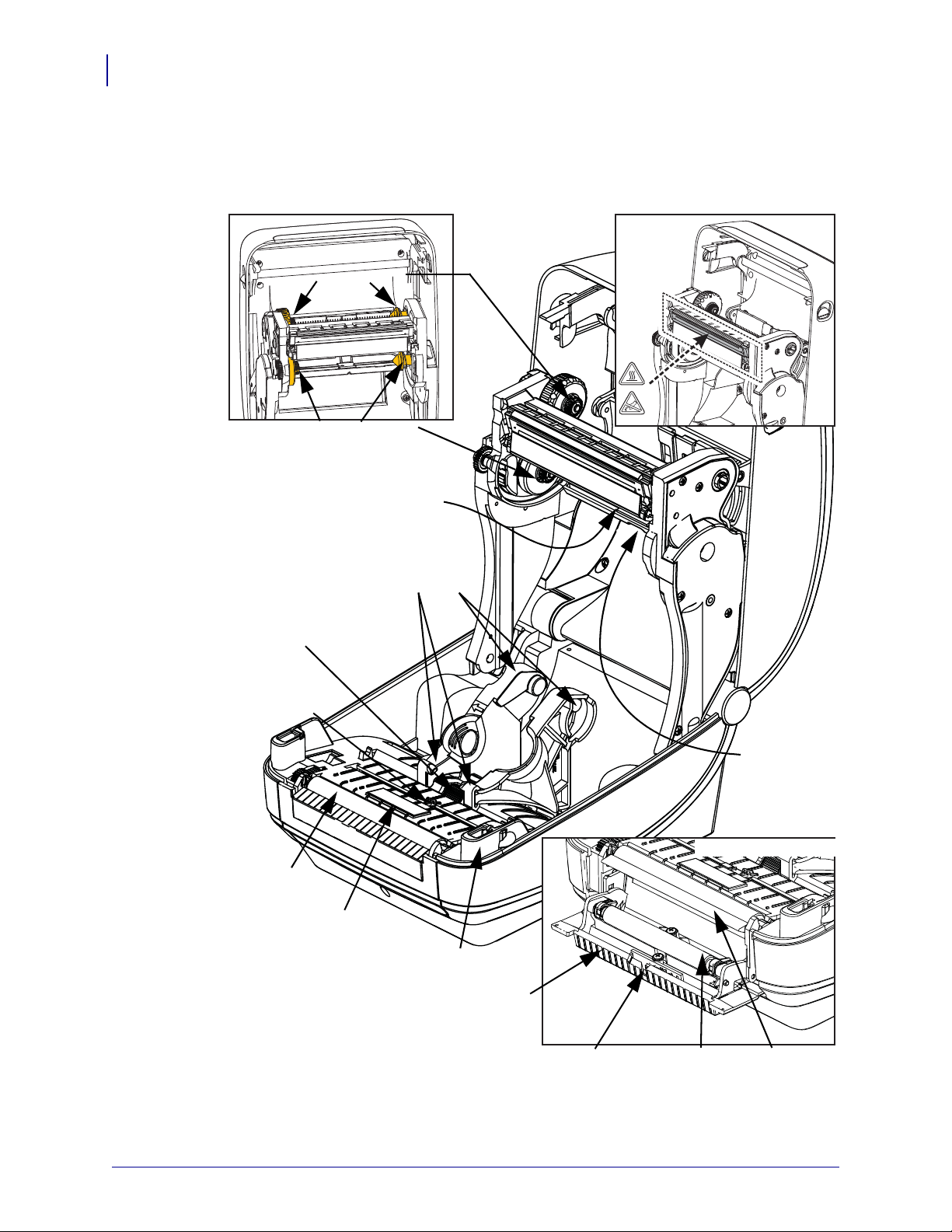

Introduction

Label Taken

Sensor

Peel Bar

Platen

Roller

Printhead

Movable

Black Mark

Sensor

Ribbon Trailer Sensor

(hidden from view)

Roll Holders and

Media Guides

Head-Up Sensor

(inside)

Pinch

Roller

Dispenser Door

(open)

Take Up Spindles

Supply Spindles

Ribbon Roll Holders

Dispenser Option

Web (Gap)

Sensor

Media Guide Stop

Adjustment

RFID Antenna

(inside)

6

Printer Features

Figure 2 • Printer Features Continued

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 19

Figure 3 • Printer Features - Cutter Option

Media Cutter

(Option)

Introduction

Printer Features

7

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 20

Introduction

12

6 5811 9 7

1

2

3

4

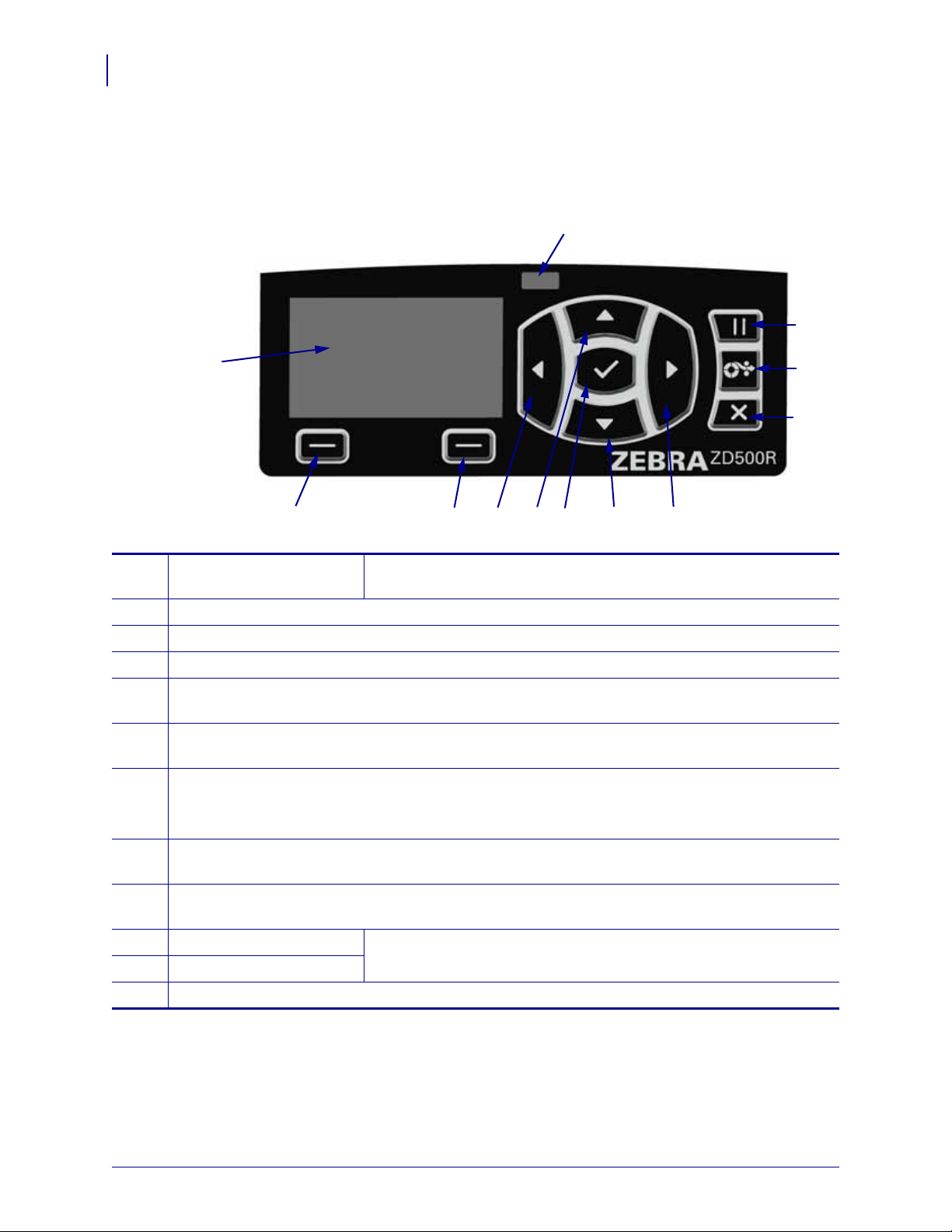

Figure 4 • ZD500 Series™ Control Panel

10

8

Control Panel

Control Panel

The control panel indicates the printer’s operating status and allows the user to control

basic printer operation.

STATUS light Shows the current status of the printer. For more information, see

1

The PAUSE button starts or stops printer operation when pressed.

2

The FEED button forces the printer to feed one blank label each time the button is pressed.

3

The CANCEL button cancels print jobs when the printer is paused.

4

The RIGHT ARROW button, which is active only in the menu system, navigates to the right

5

through the main menu and to previous items in sub-menus.

The DOWN ARROW button changes the parameter values. Common uses are to decrease a value

6

or to scroll through choices.

The SELECT () button operates as follows:

7

• When on the Home screen, pressing enters the menu system.

• When in the menu system, pressing accepts the values shown.

The UP ARROW button changes the parameter values. Common uses are to increase a value or to

8

scroll through choices.

The LEFT ARROW button, which is active only in the menu system, navigates to the left through

9

the main menu and to the next item in sub-menus.

RIGHT OPTION button These buttons execute the actions or commands shown directly above

10

LEFT OPTION button

11

The display shows the printer’s operating status and allows the user to navigate the menu system.

12

Table 1 on page 9.

them in the display.

Add

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 21

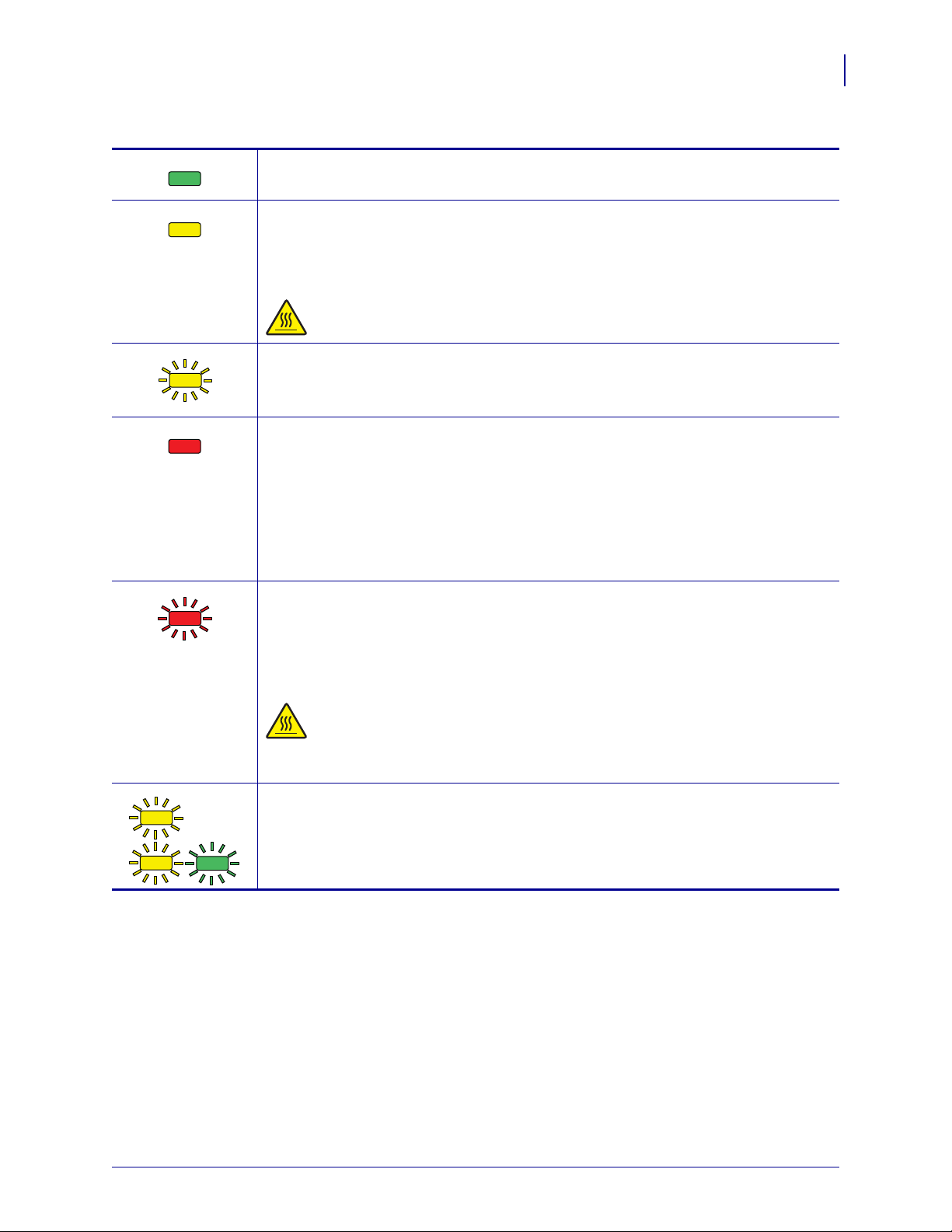

Table 1 • Printer Status Indicator Light

STATUS light steady green

The printer is ready.

STATUS light steady amber

This indicator light on steady indicates one of the following:

• The printer is not ready.

• The printhead is over temperature.

Caution • The printhead may be hot and could cause severe burns. Allow

the printhead to cool.

STATUS light flashing amber

This indicator light flashing indicates one of the following:

• The printhead is under temperature.

STATUS light steady red

This indicator light on steady indicates one of the following:

• The media supply is out.

• The ribbon supply is out.

• The printhead is open.

• Cutter malfunction.

The printer needs attention and cannot continue without user intervention.

Introduction

Control Panel

9

STATUS light flashing red

This indicator light flashing indicates one of the following:

• The printer is unable to correctly identify the printhead type.

• The main logic board (MLB) is over temperature.

• The printhead is extremely over temperature.

Caution • The printhead may be hot and could cause severe burns. Allow

the printhead to cool.

The printer needs attention and cannot continue without user intervention.

STATUS light flashing amber followed by alternating amber/ green

This status light condition indicates the printer is in Forced Download Mode.

Forced Download Mode is used to download new firmware to the printer. This

mode should only be used by trained personnel.

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 22

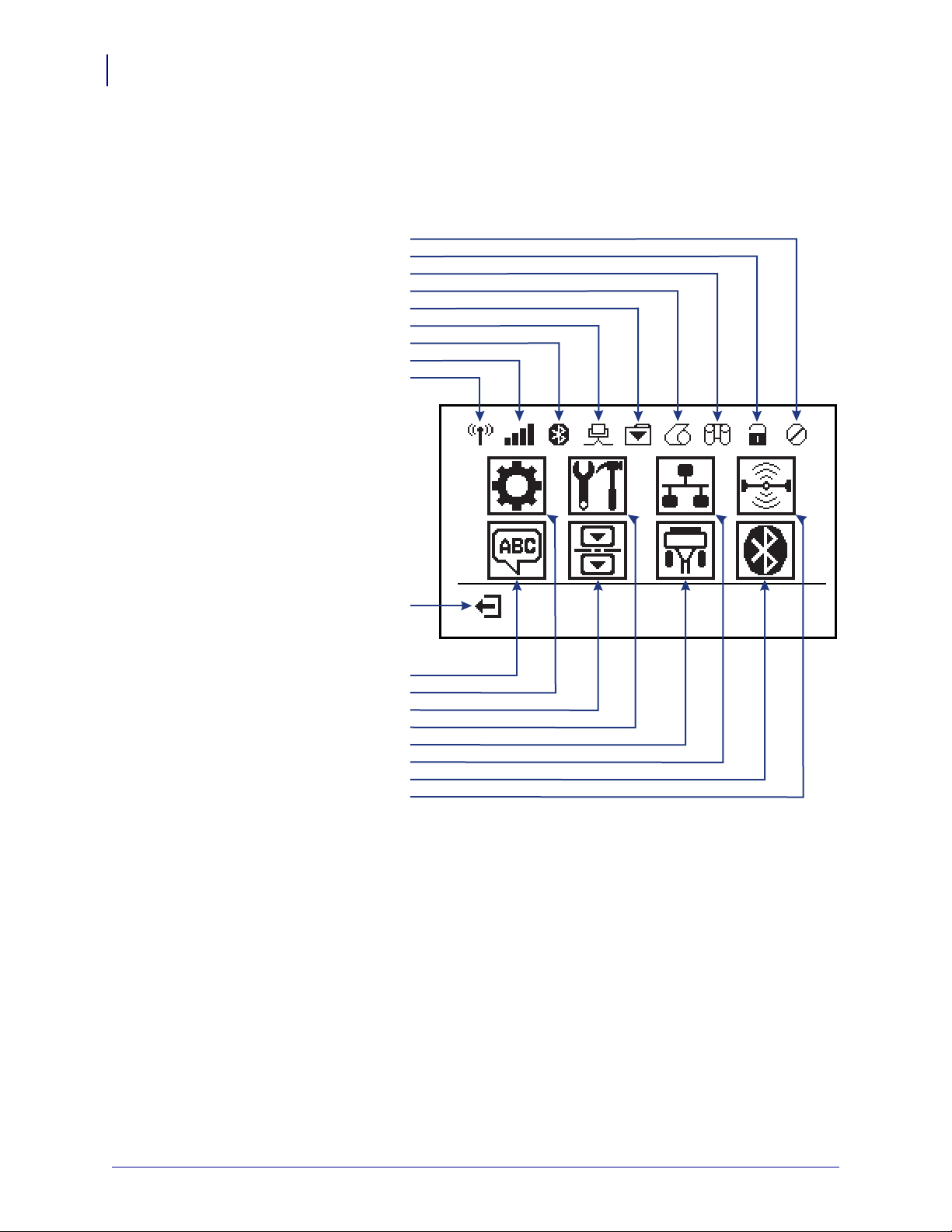

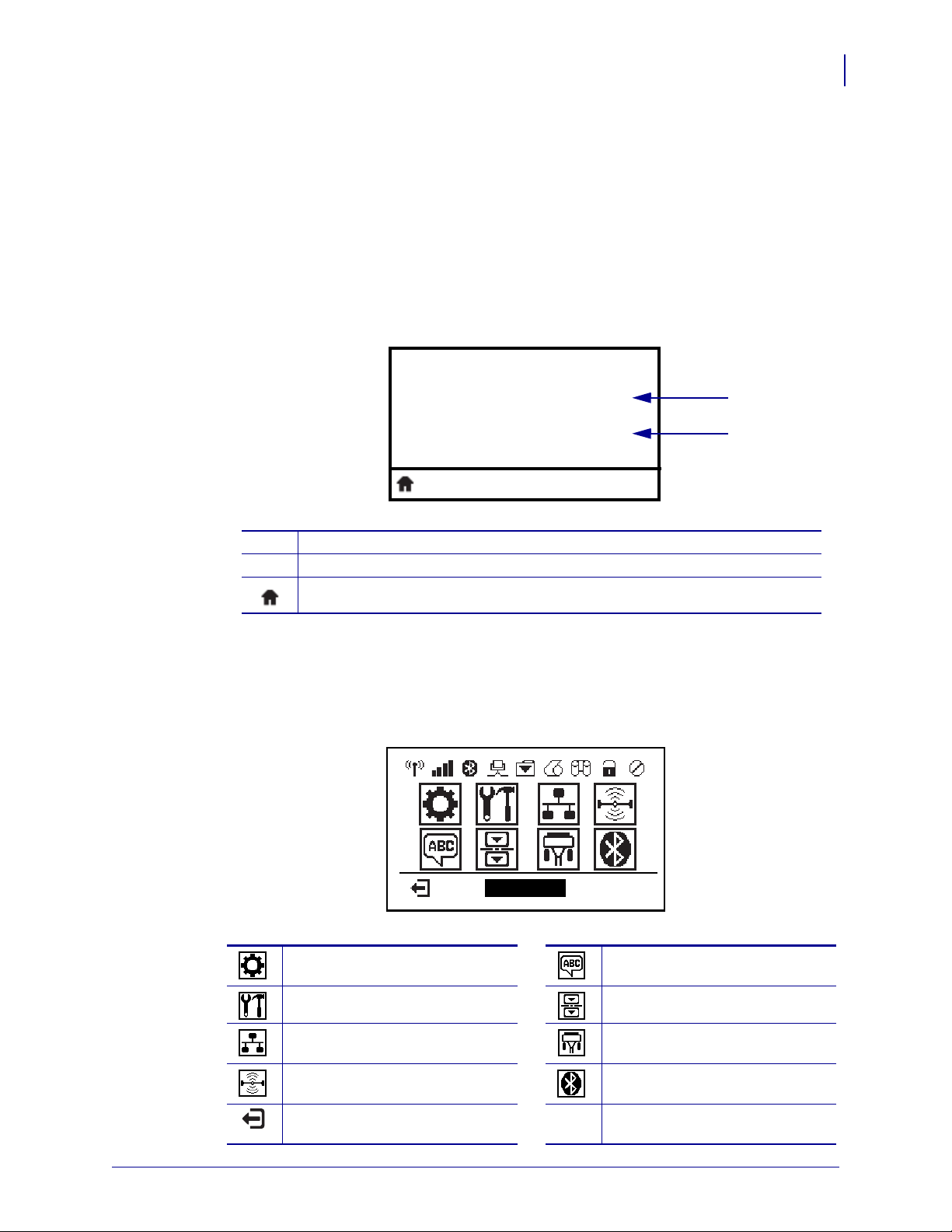

Introduction

Error

Cover Unlocked

Ribbon In

Media In

Data

Ethernet

Bluetooth

Signal Strength

WiFi

Previous Menu Shortcut

Language Menu

Settings Menu

Sensors Menu

Tools Menu

Ports Menu

Network Menu

Bluetooth Menu

RFID Menu

10

Control Panel Display Menu and Status Icons

Control Panel Display Menu and Status Icons

Figure 5 • Typical Home Menu

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 23

Printer Control Panel Display

PRINTER READY

V74.19.1Z

1

2

SETTINGS

The printer’s control panel includes a display, where you can view the printer’s status or

change its operating parameters. In this section, you will learn how to navigate through the

printer’s menu system and change values for menu items.

After the printer completes the power-up sequence, it moves to the Idle Display (Figure 6).

If a print server is installed, the printer cycles through the information shown and the

printer’s IP address.

Figure 6 • Idle Display

Introduction

Printer Control Panel Display

11

The printer’s current status

1

Information that you set through TOOLS Menu on page 56 - IDLE DISPLAY

2

Home menu shortcut

The printer’s operating parameters are organized into several user menus, which you can

access through the printer’s Home menu (Figure 7). For detailed information about

changing the printer settings, see Printer Configuration on page 51.

Figure 7 • Home Menu

See SETTINGS Menu on page 52.See LANGUAGE Menu

on page 69.

See TOOLS Menu on page 56.See SENSOR Menu on page 71.

See NETWORK Menu

on page 61.

See RFID Menu on page 65 See BLUETOOTH Menu

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Exit and return to the Idle Display

(Figure 6).

See PORTS Menu on page 72.

on page 74

Page 24

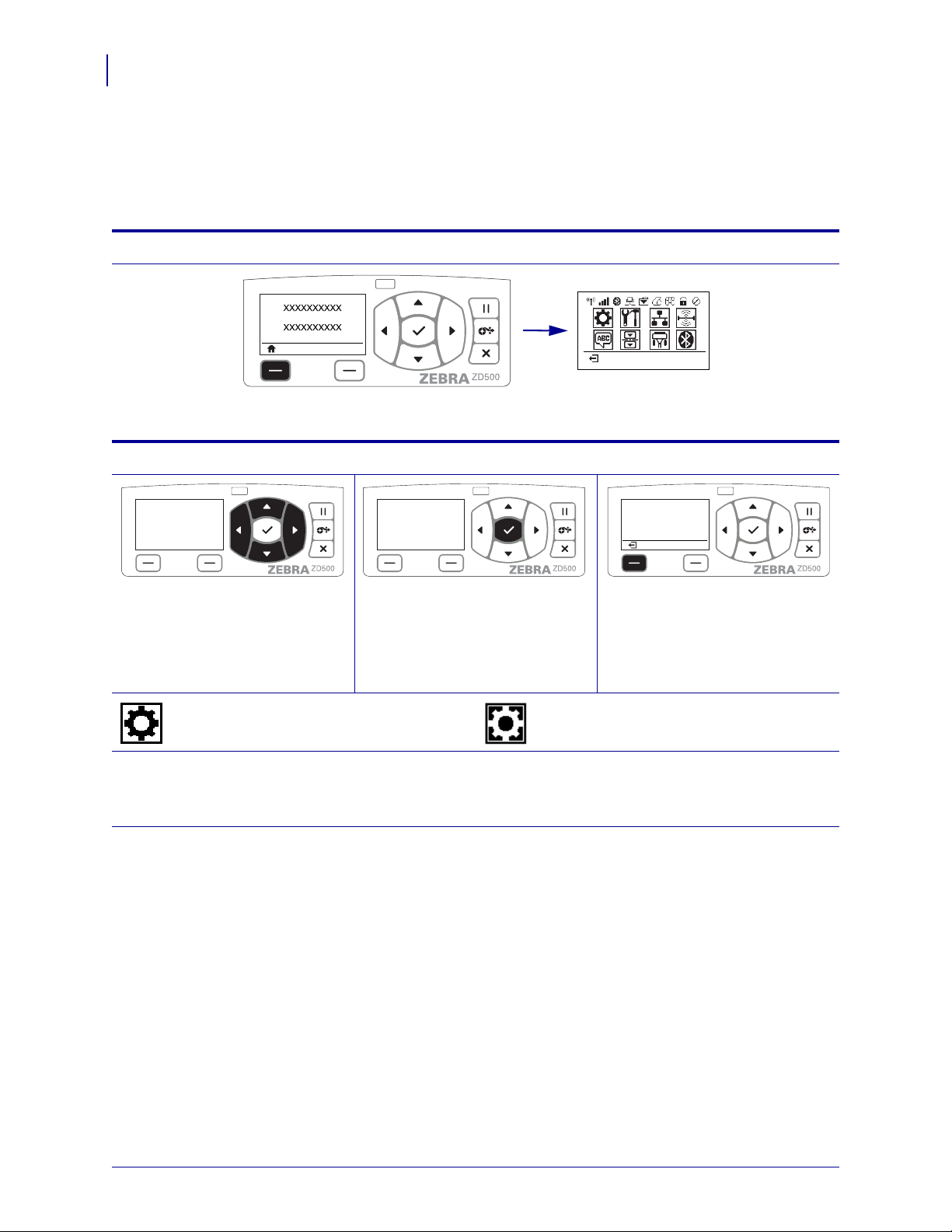

Introduction

SETTINGS menu icon

SETTINGS menu icon highlighted

and active for selection.

12

Printer Control Panel Display

Navigating through Screens in the Menu

Idle Display

Home Menu

Table 2 shows navigating through the screens in the control panel display.

Table 2 • Navigation

At the Idle Display (Figure 6 on page 11), press LEFT SELECT to go

to the printer’s Home menu (Figure 7 on page 11).

To move from icon to icon in the

Home menu, press the ARROW

buttons.

To select the highlighted menu

icon and enter the menu, press

SELECT (

) button.

Press LEFT SELECT to exit the

Home menu and return to the Idle

Display.

When an icon is selected, its

image reverses to highlight it.

Note • The printer automatically returns to the Idle Display after 15 seconds of inactivity in the Home menu.

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 25

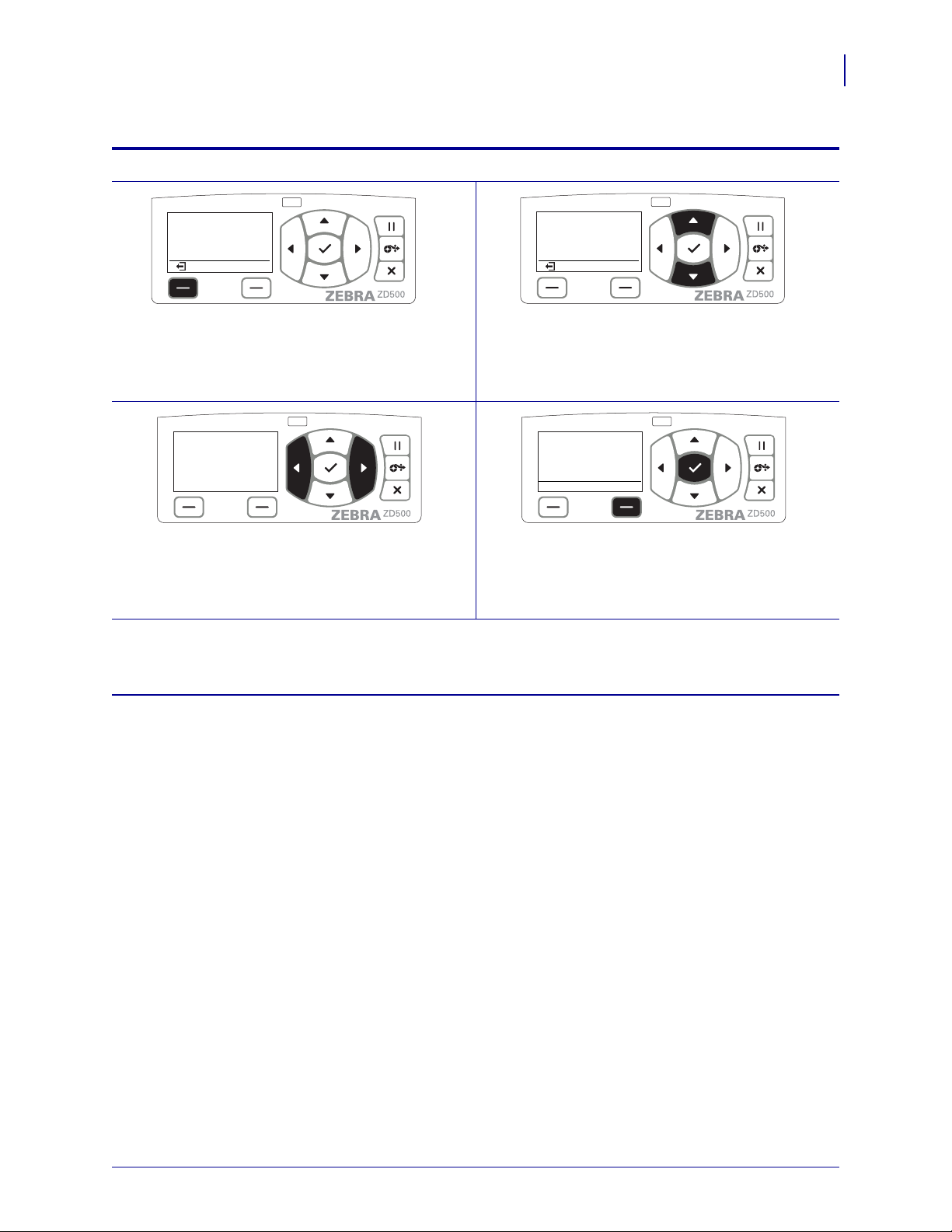

Introduction

XXXXXXX

XXX

Printer Control Panel Display

Table 2 • Navigation

User Menus

Press LEFT SELECT to return to the Home menu. ▼and ▲ indicate that a value can be changed. Any

changes that you make are saved immediately.

Press the UP ARROW or DOWN ARROW to

scroll through accepted values.

13

To scroll through the items in a User menu, press the

LEFT ARROW or RIGHT ARROW.

A word in the bottom-right corner of the display

indicates an available action.

Press SELECT (

) button or press RIGHT

SELECT to perform the action shown.

Note • The printer automatically returns to the Home menu after 15 seconds of inactivity in a User menu.

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 26

Introduction

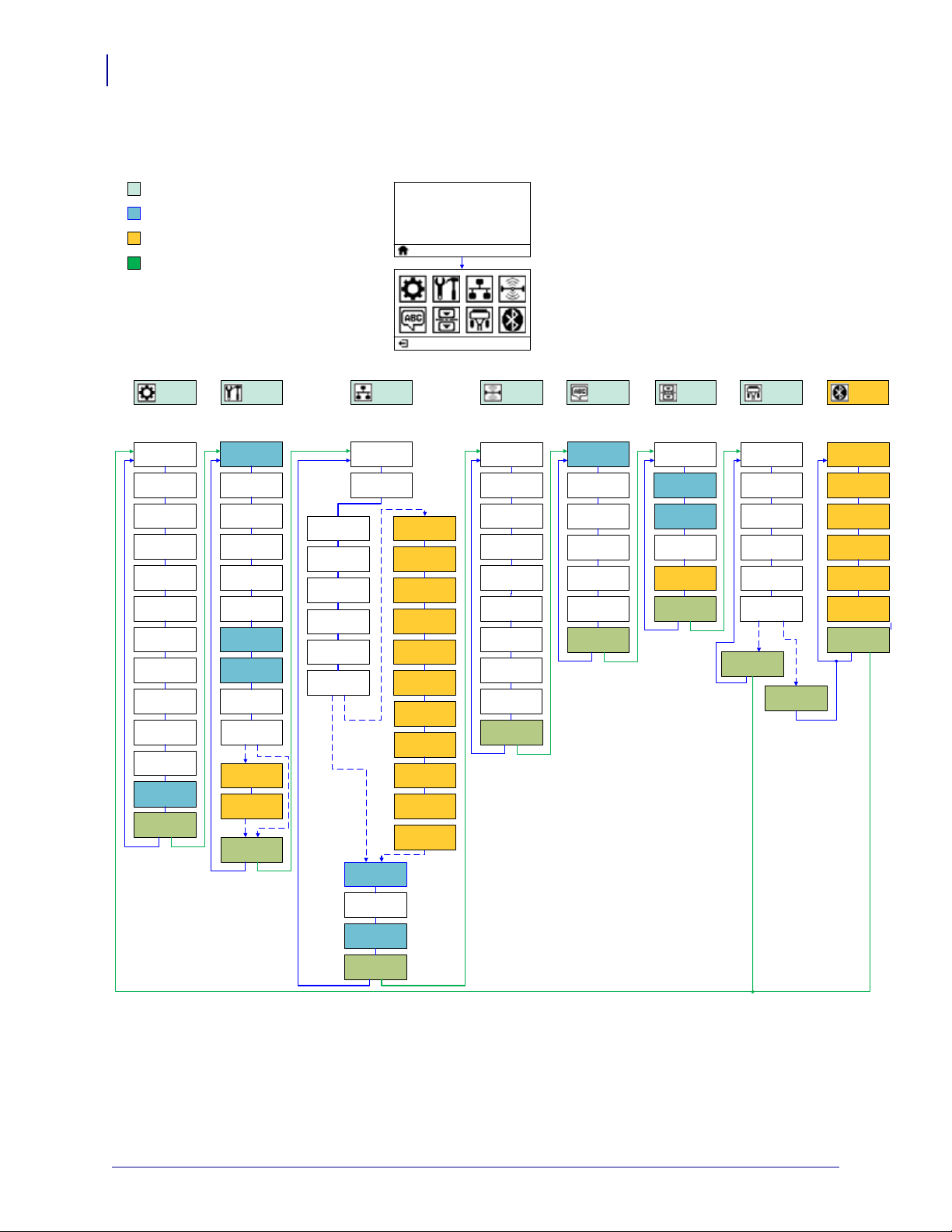

14

Control Panel Menu Map

Control Panel Menu Map

Home Menu Items

Menu Item also in other Menus

Printer Option. May not be present.

Go to next Menu group

Printer Ready

V74.xx.xxZ

Darkness

Print Speed

Media Type

Print Method

Tear Off

Print Width

Print Mode

Label Top

Left Position

Reprint Mode

Label Length

Max

Language

Tools Menu

Print

Information

LCD Contrast

LCD Backlight

Idle Display

Power Up

Action

Head Close

Action

Load Defaults

Manual

Calibration

Diagnostic

Mode

ZBI Enabled?

Yes No

Run ZBI

Program

Stop ZBI

Program

Network Menu

Wired IP

Address

Wired Subnet

Mask

Wired

Gateway

Wired IP

Protocol

Wired MAC

Address

Wired Port

WLAN

Installed

No

WLAN

Reset Network

Active Print

Server

Primary

Network

Print

Information

WLAN IP

Address

WLAN Subnet

Mask

WLAN

Gateway

WLAN IP

Protocol

WLAN MAC

Address

WLAN Port

ESSID

Channel

Signal

IP Port

IP Alternate

Port

RFID Status

RFID Calibrate

RFID Read

Data

RFID Test

RFID Program

Position

RFID Read

Power

RFID Write

Power

RFID Valid

Count

RFID Void

Count

Language

Menu

Language

(Menu)

Language

ZPL Override

Command

Character

Control

Character

Delimiter Char

ZPL Mode

Sensors Menu

Sensor Type

Manual

Calibration

Print

Information

Label Sensor

Take Label

Ports Menu

Baud Rate

Data Bits

Parity

Host

Handshake

Parallel Mode

WML Version

Settings

Menu

Bluetooth

Menu

Bluetooth

Address

Mode

Discovery

Connected

BT Spec

Version

Min Security

Mode

Settings Menu

htooteulBstroPsrosneSDIFRkrowteNslooTsgnitteS

Load Defaults

RFID Menu

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 27

This section assists you in setting up and operating your printer for the first time.

Basic Printer Setup (Overview)

The setup process to can be broken down to two (2) phases: hardware setup and host system

(software/driver) setup.

2

Setup

• Place the printer in a safe location with access to power and where cable or the

wireless option communications can access your printer.

• Attach the printer to a grounded AC power source.

• Select and prepare media for your printer.

• Load the media.

• Load the transfer ribbon if you are using thermal transfer media.

• Turn the printer ON. Print a ‘Configuration Report’ to verify basic printer operation.

• Turn the printer OFF.

• Choose method to communicate to your printer - Local connection via USB, Serial, or

Parallel ports; Local network via Ethernet (LAN); or using the printer’s wireless

option that supports Wi-Fi (802.11 a/b/g/n WLAN) and Bluetooth 3.0.

• Attach the printer to the network or host system, and configure the printer as required

for communicating to the print system host/network.

For supported Windows Operating systems (most common) with a Local (cabled) connection:

• ‘Run’ the Zebra Setup Utilities for systems from the User’s CD.

• Click on ‘Install New Printer’ and run the install wizard. Select ‘Install Printer’ and

select the ZD500R from the list of ZDesigner printers.

• Select the port (USB, Serial or Parallel) that you connected to the PC.

• Turn the printer ON and configure printer communications for your interface type.

• Print a Windows driver ‘Test Print’ to verify operation with Windows.

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 28

Setup

16

Select a Location for the Printer

Select a Location for the Printer

The printer and media need a clean safe area with moderate temperatures to have optimal print

operations.

Select a location for the printer that meets these conditions:

• Surface: The surface where the printer will be located must be solid, level, and of

sufficient size and strength to hold the printer.

• Space: The area where the printer will be located must include enough space for

ventilation, opening the printer (media access and cleaning), and for accessing the printer

components and connectors. To allow for proper ventilation and cooling, leave open space

on all sides of the printer.

Caution • Do not place any padding or cushioning material under or around the base

of the printer because this restricts air flow and could cause the printer to overheat.

• Power: The printer should be within a short distance of an appropriate power outlet that is

easily accessible.

• Data communication interfaces: The printer must be within range of your WLAN or

Bluetooth radio (if applicable) or within an acceptable range for other connectors to reach

your data source (usually a computer).

Data cables should not be routed with or near power cords or conduits, fluorescent

lighting, transformers, microwave ovens, motors or other electrical noise and interference

sources. These interference sources may interfere with communications, host system

operation, and printer functionality.

• Operating conditions: Your printer is designed to function in a wide range of

environmental and electrical conditions, including a warehouse or factory floor. Table 4

shows the temperature and relative humidity requirements for the printer when it is

operating.

Table 3 • Operating Temperature and Humidity

Mode Temperature Relative Humidity

Thermal Transfer 41° to 104°F (5° to 40°C) 20 to 85% non-condensing

Direct Thermal 32° to 104°F (0° to 40°C)

Table 4 • Non-Operating and Storage Temperature and Humidity

Mode Temperature Relative Humidity

Both -40° to 140°F (-40° to 60°C) 5 to 85% non-condensing

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 29

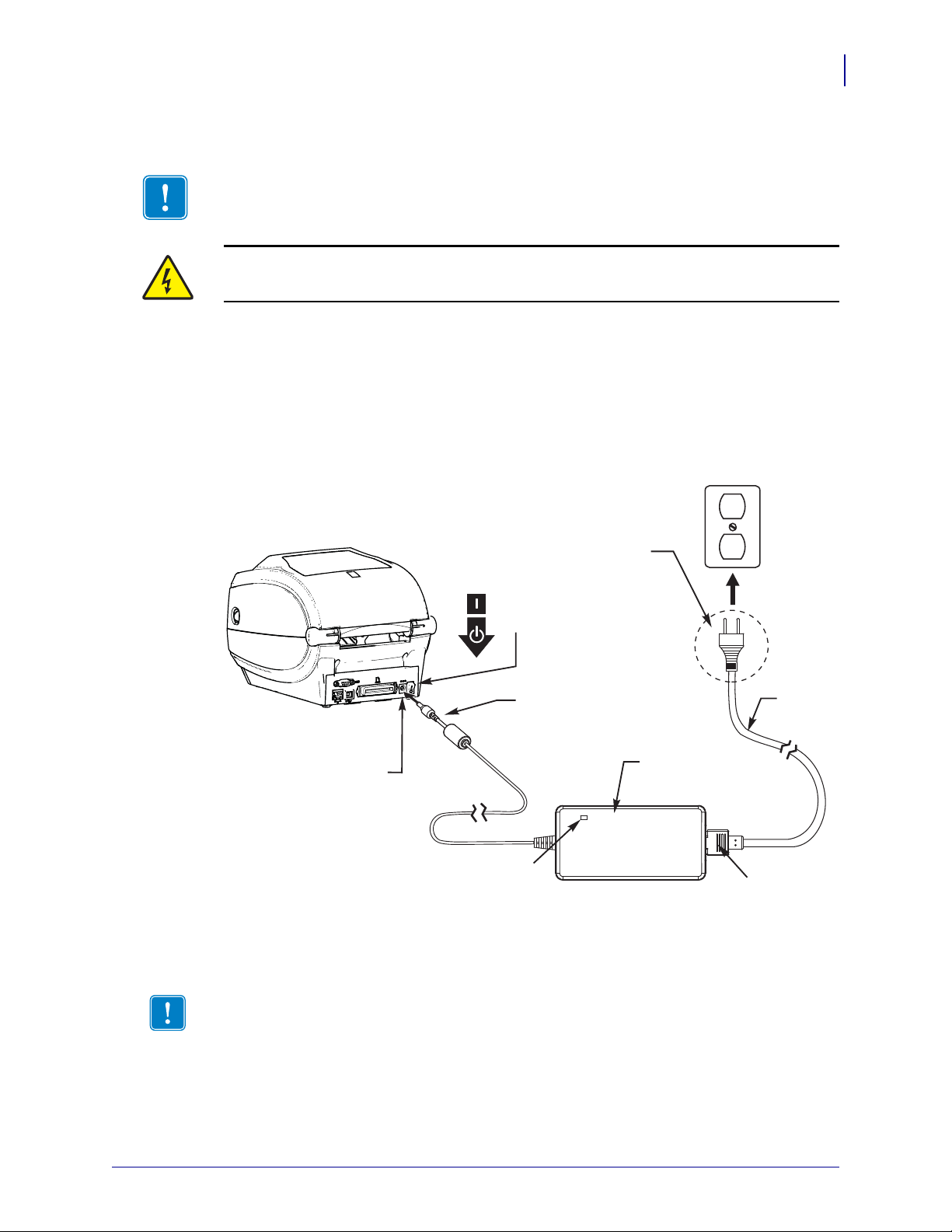

Attaching Power

Power

Connector

Power

Switch

Plug Varies

by Country

Active Power Light

Power

Receptacle

AC

Power

Cord

Printer

Power

Supply

IEC 60320

C-13

Important • Set up your printer so that you can handle the power cord easily if needed. To

make certain the printer cannot carry electrical current, you must separate the power cord

from the power supply receptacle or AC electrical outlet.

Caution • Never operate the printer and power supply in an area where they can get wet.

Serious personal injury could result!

1. Make sure the printer’s power switch is in the off position (down).

2. Insert the AC power cord into the power supply.

3. Plug the other end of the cord into an appropriate AC electrical outlet. Note: The active

power light will go on if power is on at the AC outlet.

4. Insert the power supply’s power connector into the printer’s power receptacle.

Setup

Attaching Power

17

Note • Ensure the appropriate power cord with a three (3) prong plug and an IEC 60320-C13

connector are used at all times. These power cords must bear the relevant certification mark of

the country in which the product is being used.

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 30

Setup

18

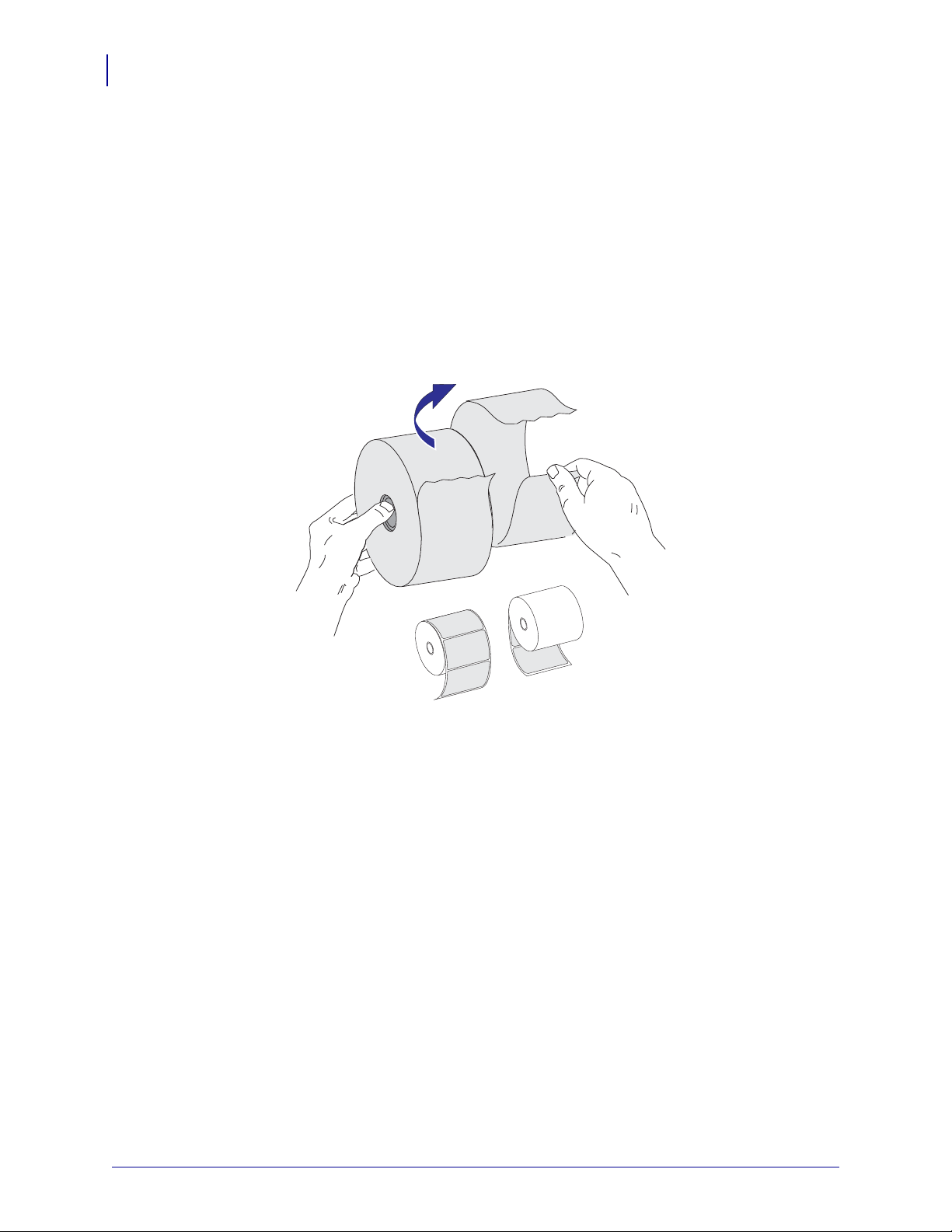

Preparing and Handling Media

Preparing and Handling Media

Carefully handling and storing media is important for the print quality in addition to using the

right media (such as Genuine Zebra™ Supplies) and the right printer, your Zebra ZD500

Series™ printer. If the media becomes contaminated or dirty, it can damage or degrade the

printhead or the printer, as well as, cause defects in the printed image (voids, streaks,

discoloration, compromise the adhesive, etc.).

During manufacturing, packaging, handling and storage, the outside length of media may

become dirty or contaminated when handled or dusty when stored. To prevent this type of

contamination, we ask you to remove the outside layer of the media roll or stack. This will

remove any contaminates or adhesive from labels or tape used to secure the media to the roll

that may transfer to the printer or printhead.

Media Storage Tips

• Store media in a clean, dry, cool, dark area.

• Direct thermal media is chemically treated to be heat sensitive. Direct sunlight or heat

sources may ‘expose’ the media.

• Do not store media with chemicals or cleaning products.

• Leave media in its protective packaging until it is to be placed in the printer for use.

• Many media types and label adhesives have a ‘shelf life’ or expiration date. Always

use the oldest, viable (non-expired) media first.

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 31

Setting the Printer Menu and Report Display Language

Setting the Printer Menu and Report Display Language

The printer supports many languages for menu display, time and date format, and

configuration reports.

The primary method used to configure language is the control panels menu. Use the following

procedure to set your printer’s language when the printer is turned on and in the ‘Ready’ state.

1. Press the menus ‘Home’ ( ) button.

2. Navigate to the ‘LANGUAGE’ ( ) menu button and press the ‘Select’ () button.

3. Use the ‘Up’ () and ‘Down’ () navigation arrows to browse the languages.

4. Stop browsing when you have found the language you wish to use for operating the

printer. The language displayed will be your selected language.

Set Media Print Method

Set the printer’s PRINT METHOD using the printer control panel. See SETTINGS Menu

on page 52 - PRINT METHOD for the full procedure.

Setup

19

The ZD500 Series™ printer has been designed to print with DIRECT THERMAL (direct

thermal media which uses heat sensitive media to print) or THERMAL TRANS (thermal

transfer printing which uses ribbon to heat transfer print to the media).

The direct thermal and thermal transfer settings each have optimized Darkness control

characteristics to allow similar visual Darkness and Print Quality at the same DARKNESS and

PRINT SPEED settings.

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 32

Setup

20

Loading Roll Media

Loading Roll Media

Use the instructions in this section to load roll media in Tear-Off mode and Gap/Web media

sensing set by default. This mode also works for most full width black mark (black line)

media.

For other common media and setting variations see one of the following:

• Using the Movable Black Mark Sensor on page 89

• Printing on Fan-Fold Media on page 93

• Cutter Option on page 103

• Label Dispenser Option on page 100 after you have loaded media using this

procedure.

Instructions for media loading:

1. Open the printer. Pull the release latch levers toward the front of the printer.

2. Open the media roll holders. Pull the media guides open with your free hand and place the

media roll on the roll holders and release the guides. Orient the media roll so that its

printing surface will face up as it passes over the platen (drive) roller.

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 33

Movable

Black Mark Sensor

Off Center

Black Mark Sensing Only

Default - Web (Gap) Sensing

Standard Operating Position

Setup

Loading Roll Media

3. Verify that the movable black mark sensor is aligned in the center default position. This is

the standard operating position for media sensing. When the sensor is moved from the

default label web (gap) sensing area, the printer will only detect black mark and die-cut

notched media.

21

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 34

Setup

Under Media

Guides

22

Loading Roll Media

4. Pull the media so that it extends out of the front of the printer. Verify the roll turns freely.

The roll must not sit in the bottom of the media compartment. Verify that the media’s

printing surface is facing up.

5. Push the media under both of the media guides.

6. Close the printer. Press down until the cover snaps closed.

Your media may need a ‘Manual Calibration’ to adjust the printer’s sensors and label length

setting to operate properly. See the Manual Calibration - Media on page 75. If you are using

RFID media, run a RFID Calibration procedure, see the RFID Menu on page 65 - RFID

CALIBRATE for details.

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 35

Loading Transfer Ribbon

Notch

Adhesive Strip

Right Side

(printer and roll)

Setup

Loading Transfer Ribbon

23

Transfer ribbons come in several varieties and in some cases colors to match your application

®

needs. Genuine Zebra

brand media. Using non-Zebra media or ribbons not approved for use in your Zebra

transfer ribbons are specifically designed for your printer and Zebra

®

printer

may damage your printer or printhead.

• The media and ribbon types should be matched to provide you with optimal print results.

• Always use ribbon that is wider than the media to protect the printhead from wear.

• For direct thermal printing, do not load ribbon in the printer.

Before following these steps, prepare the ribbon by removing its wrapping and pulling its

adhesive strip free.

Important • DO NOT USE early model desktop printer ribbon cores! The older ribbon cores

can be identified by notches on only one side of the ribbon core. These older cores are too large

and will cause take-up spool to bind.

Note • DO NOT USE ribbon cores with damaged notches - rounded, frayed, smashed, etc. The

core notches should be square to lock the core on the spindle or the core may slip causing

ribbon wrinkle, poor end of ribbon sensing or other intermittent failures.

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 36

Setup

24

Loading Transfer Ribbon

1. With the printer open, place a new ribbon roll on printer’s lower ribbon supply spindles.

Rotate the roll until the notches align and lock into the left side of the supply hub.

2. Place an empty ribbon core on printer’s take-up spindles. Rotate the ribbon core until the

notches align and lock into the left side of the take-up hub.

You can find your first ribbon take-up core in the packing box. Subsequently, use the

empty supply core to take up the next roll of ribbon.

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 37

Setup

Loading Transfer Ribbon

3. Pull the transfer ribbon’s leader off the roll and attach it with the adhesive strip on the

leader to the empty ribbon core on the take-up spindle. Center the ribbon on the ribbon

core.

25

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 38

Setup

26

Loading Transfer Ribbon

4. Rotate the thumb wheel on the left side of the supply spindle towards the rear of the

printer until the ribbon is pulled tight across the printhead.

5. Verify that the media is loaded and ready to print and then close the printer cover.

6. Press the Feed button to have the printer feed a minimum of 10 cm (4 inches) of media to

remove slack and ribbon wrinkle, and to align the ribbon on the spindles.

7. Change the print mode setting from direct thermal printing to thermal transfer to set the

printer’s temperature profiles for thermal transfer media. This can be done with the printer

driver, application software, or printer programming commands.

• When controlling printer operations with ZPL programming, refer to the Media Type

(^MT) ZPL II command (follow the instructions in the ZPL Programming Guide).

8. To verify the mode change from direct thermal printing to thermal transfer printing, use

the Test Printing with Configuration Report Printouts on page 27 to print a configuration

label. The ‘PRINT METHOD’ should read ‘THERMAL-TRANS’ on the printer

configuration status label.

Your printer is now ready to print.

Your media may need a ‘Manual Calibration’ to adjust the printer’s sensors and label length

setting to operate properly. See the Manual Calibration - Media on page 75. If you are using

RFID media, run a RFID Calibration procedure, see the RFID Menu on page 65 - RFID

CALIBRATE for details.

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 39

Test Printing with Configuration Report Printouts

Test Printing with Configuration Report Printouts

Before you connect the printer to your computer, make sure that the printer is in proper

working order. You can do this by printing a configuration status report.

1. Make sure the media is properly loaded and the top cover of the printer is closed.

2. Press and hold CANCEL button while setting the printer power switch to on (I).

3. Hold CANCEL button down until the printer status light turns green for the first time and

release.

4. The Printer and Network Configuration Reports (below) will be printed a couple of

seconds after the printer’s display reports ‘PRINTER READY’.

Setup

27

If you cannot get these reports to print and you have checked your printer installation with this

document, then see the Troubleshooting section of the User’s Guide or the Zebra Website for

guidance.

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 40

Setup

28

Connecting your Printer to a Computer

Connecting your Printer to a Computer

The printer supports a variety of interface options and configurations. These include:

Universal Serial Bus (USB) interface, RS232 Serial, Parallel (IEEE 1284.4), 10/100 Wired

Ethernet, and an optional internal Wireless Ethernet (WiFi) and Bluetooth radio.

Pre-install Windows® Printer Drivers

Install the Zebra Setup Utilities before applying power to the printer connected to the PC

(running a Zebra driver supported Windows operating system). The Zebra Setup Utility will

prompt you to apply the printer power. Continue to follow the instructions to complete your

printer installation.

The Zebra Setup Utility is designed to assist you with installing these interfaces. The

cabling and unique parameters for each of these physical printer communication interfaces is

discussed in the following pages to assist you with making configuration setup choices prior to

and immediately following applying power. The Zebra Setup Utilities configuration wizards

will instruct you to turn the printer’s power on at the appropriate time to complete the

installation of your printer.

For more details on installing Ethernet (network) and Bluetooth interfaces:

•ZebraNet® Wired and Wireless Print Servers User Guide

Caution • Keep the power switch in the OFF position when attaching the interface cable.

The power cord must be inserted into the power supply and the power receptacle on the

back of the printer before connecting or disconnecting the communications cables.

Interface Cable Requirements

Data cables must be of fully shielded construction and fitted with metal or metallized

connector shells. Shielded cables and connectors are required to prevent radiation and

reception of electrical noise.

To minimize electrical noise pickup in the cable:

• Keep data cables as short as possible (6 foot [1.83 m] recommended).

• Do not tightly bundle the data cables with power cords.

• Do not tie the data cables to power wire conduits.

.

Important • This printer complies with FCC “Rules and Regulations,” Part 15, for Class B

Equipment, using fully shielded data cables. Use of un-shielded cables may increase radiated

emissions above the Class B limits.

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 41

USB Interface

USB Cable

Parallel Cable

Universal Serial Bus (version 2.0 compliant) provides a fast interface that is compatible with

your existing PC hardware. USB’s “plug and play” design makes installation easy. Multiple

printers can share a single USB port/hub.

When using a USB cable (not supplied with your printer), verify that the cable or cable

packaging bears the “Certified USB™” mark (see below) to guarantee USB 2.0 compliance.

Connecting your Printer to a Computer

.

Setup

29

Parallel Interface

The required cable must have a 25 pin “D” type (DB-25P) male connector on one and a

Centronics on the other end (IEEE 1284 A-B parallel interface specification).

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 42

Setup

Tighten

Serial Cable

30

Connecting your Printer to a Computer

Serial Interface

The printer uses a Null Modem (cross-over) cable for DTE communications. The required

cable must have a nine-pin “D” type (DB-9P) male connector on one end which plugs into the

mating (DB-9S) serial port located on the back of the printer. The other end of this signal

interface cable connects to a serial port on the host computer. For pinout information, refer to

Appendix A.

The serial port communication settings between the printer and host (typically a PC) must

match for reliable communication. The Bits per second (or Baud rate) and Flow control are the

most common settings that get changed.

Serial communications between the printer and the host computer can be set by:

• Using the printers Control Panel ‘PORTS’ menu.

• ZPL programming ^SC command

• Resetting the printer to its default printer configuration.

Factory defaults for serial communication settings are: 9600 baud, 8 bit word length, NO

parity, 1 stop bit, and XON/XOFF (‘Software’ data flow control in the Windows based host

system).

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 43

Wired (Ethernet) Interface

The printer requires UTP RJ45 Ethernet cable rated CAT-5 or better.

The printer has a built-in network print server. For more information on configuring your

printer to run on a compatible Ethernet based network, see the ZebraNet® Wired and Wireless

Print Server users guide. The printer must be configured to run on your LAN (local area

network) or WAN (wide area network). The print server on board your printer can be accessed

through the printer’s print server Web pages.

Assigning a IP Address for Network Access All devices on a Ethernet network

require a network IP (Internet Protocol) address. The printer’s IP address is needed to access

the printer for printing and printer configuration. The four different ways to assign an IP

address are:

• DHCP (Dynamic Host Connection Protocol) - Default setting

• ZebraNet Bridge

• Using the printer’s Control Panel ‘NETWORK’ menu

•Telnet

Setup

Connecting your Printer to a Computer

31

• Zebra Setup Utilities (includes the ZebraDesigner Windows printer driver)

DHCP for Personal Networks The printer by default is set to operate on LAN or WAN

with DHCP by default to aid end-user installations. This is intended primarily for personal

networks. The network automatically provides a new network IP address each time the printer

is turned on. The Windows printer driver uses a Static IP address to connect to the printer. The

IP address set in the printer driver will need to be changed to access the printer if its assigned

IP address has changed after the printer’s initial installation.

Managed Networks Using the printer in a structured network (LAN or WAN) requires a

network administrator to assign the printer a Static IP address and other settings needed to

operate on the network properly.

Viewing the Printer’s IP Address Use the printer’s control panel to access the Ethernet

settings in your printer.

1. Press the menus ‘Home’ ( ) button.

2. Navigate to the ‘NETWORK’ ( ) menu button and press the ‘Select’ () button.

3. Use the ‘Up’ () and ‘Down’ () navigation arrows to browse to the

‘WIRED IP ADDRESS’ setting. You can read the assigned IP address or set the IP

address. The printer’s default address (all 0’s - zeros) is not a valid address. With

assistance of your network administrator, you can set all of the ‘WIRED’ network setting

in this ‘NETWORK’ menu branch.

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 44

Setup

Ethernet Cable

(RJ45 Connector)

Green LED Amber LED

32

Connecting your Printer to a Computer

Ethernet Status/Activity Indicators

LED Status Description

Both OFF No Ethernet link detected

Green 100 Mbps link detected

Green with the Amber

flickering on and off

Amber 10 Mbps link detected

Amber with the Green

flickering on and off

100 Mbps link and Ethernet activity detected

10 Mbps link and Ethernet activity detected

Print Server - Default User ID and Password

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

There are some features that require the default User ID and/or default password to access

printer’s print server or if you have the Wi-Fi option in the printer. The Factory Default Values

are shown below:

• User ID: admin

• Password: 1234

Page 45

ZebraNet® Internal Wireless Print Server Option

ZebraNet® Internal Wireless Print Server Option

This section covers basic configuration of your ZebraNet Internal Wireless Print Server option

for operation. For more detailed information, refer to the ZebraNet Wired and Wireless Print

Servers User Guide.

Important • A wireless option board must be installed on your printer before you can

configure the printer to communicate using the wireless radio option.

You may configure your printer for wireless operation in the following ways. This basic guide

covers only the first option, the Connectivity Wizard.

• Through the Connectivity Wizard, which writes a ZPL script for you. On the last screen

of the utility, you may choose to send the command directly to your printer, or you may

choose to save the ZPL script to a file. The saved ZPL file has several purposes:

• The file can be sent to the printer through any available connection (serial, parallel,

USB, or wired print server).

• The file can be resent to the printer after the network settings have been restored to

factory defaults.

Setup

33

• The file can be sent to multiple printers that will use the same network settings.

• Through ZPL script that you write yourself. Use the ^WX command to set the basic

parameters for security type. You can send the command through any available connection

(serial, parallel, USB, or wired print server). Refer to the ZPL Programming Guide for

more information on this option.

• Through Set/Get/Do (SGD) commands that you send to the printer. Begin with

wlan.security to set the wireless security type. Depending on which security type

that you select, other SGD commands will be necessary to specify other parameters. You

can send the commands through any available connection (serial, parallel, USB, or wired

print server). Refer to the ZPL Programming Guide for more information on this option.

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 46

Setup

34

Configure Using the Connectivity Wizard

Configure Using the Connectivity Wizard

The ZebraNet Bridge Enterprise utility resides on the User CD for your printer and is available

through http://www.zebra.com/software. ZebraNet Bridge Enterprise version 1.2.5 or later is

required to configure the printer correctly for use.

The Connectivity Wizard, which is part of this software, allows you to configure your printer

easily for wireless operation by writing the appropriate ZPL script for you. Use this utility

when you are first installing the wireless print server or after you set the network options back

to factory defaults.

Note • You can only set up one print server at a time with the Connectivity Wizard. To

configure multiple print servers (wired and wireless), run the program once for each print

server.

To use the Connectivity Wizard, complete these steps:

1. If it is not already installed, install ZebraNet Bridge Enterprise on your computer.

You can get the program from the user CD that came with your printer, or you can

download it at http://www.zebra.com/software.

2. Launch the ZebraNet Bridge Enterprise program.

If you are prompted for a serial number, you may click

use the Connectivity Wizard.

3. From the Menu bar, select Tools > Connectivity Wizard.

The Connectivity Wizard opens.

Cancel. You will still be able to

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 47

Configure Using the Connectivity Wizard

4. From the Choose Port list, select the port to which your printer is connected.

• If you will save the file without sending it to the printer, you may select any available

port.

• If you select File:, you will be asked to browse to the location of the file you want to

save.

• If you select a serial port, the serial configuration information appears below the

Choose Port list. If necessary, change the serial communication settings to match your

printer’s settings.

Note • If a port is in use by another device, it will not be included in the drop-down

list.

5. Click Next.

The wizard prompts for the print server device to configure.

Setup

35

6. Select Wireless and then click Next.

The wizard prompts you for the type of printer you are using.

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 48

Setup

36

Configure Using the Connectivity Wizard

7. Select the type of printer you are using and then click Next.

The wizard prompts for the wireless IP information.

P1062653-002 Rev. A ZD500 Series™ Thermal Transfer Printer User’s Guide 1/16/2014

Page 49

Configure Using the Connectivity Wizard

8. Enable the DHCP (dynamic) or static IP option.

If you will be using... Complete the following steps...

DHCP a. Select DHCP and click Next.

b. Continue with step 9.

Static

a. Select Static.

The IP settings fields are activated.

a. Enter the IP Address, Default Gateway, and Subnet

Mask for the wireless print server. Contact your network

administrator for the correct values.

b. Continue with step 9.

9. Click Next.

The Wireless Settings window opens.

Setup

37

10. Enter the ESSID.

Important • The ESSID and pass phrase, if used, must be set at your access point before

completing these steps.

1/16/2014 ZD500 Series™ Thermal Transfer Printer User’s Guide P1062653-002 Rev. A

Page 50

Setup

38

Configure Using the Connectivity Wizard

11. From the drop-down, select your Security Mode.

If you select… Then…

None Continue with step 12.

WEP 40-Bit

WEP 128-Bit

EAP-TLS

EAP-TTLS

EAP-FAST

WPA-EAP-TLS

PEAP

LEAP

WPA-EAP-TTLS

WPA-PEAP

WPA-LEAP

WPA-PSK In the WPA section of the window:

WPA-EAP-FAST

KERBEROS

a. In the WEP Options section of the window, enter the

following values:

• Authentication type

• WEP Index

• Encryption Key Storage

• WEP Keys

b. Click Next and continue with step 12.

In the EAP section of the window, if necessary:

a. Enter the Optional Private Key.

b. Click Next and continue with step 12.

In the General Security section of the window:

a. Enter the Security Username and Password.

b. Click Next and continue with step 12.

a. Select the PSK Type.

b. Enter the PSK Name.

c. Click Next and continue with step 12.

a. In the General Security section of the window, enter the

Security Username and Password.

b. In the EAP section of the window, if necessary, enter the

Optional Private Key.

c. Click Next and continue with step 12.

a. In the Kerberos Settings section of the window, enter the

following values:

• Kerberos User

• Kerberos Password

• Kerberos Realm

• Kerberos KDC