Page 1

Zebra XiIII-Series

User's Guide

Customer order # 48025L

Manufacturer part # 48025LB Rev. 1

Page 2

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation. It is intended solely for the

information and use of parties operating and maintaining the equipment described herein. Such proprietary

information may not be used, reproduced, or disclosed to any other parties for any other purpose without the

expressed written permission of Zebra Technologies Corporation.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies Corporation. All specifications and signs are

subject to change without notice.

FCC Compliance Statement

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital Device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

In order to insure compliance, this printer must be used with a Shielded Power Cord and Shielded Communication

Cables.

"The user is cautioned that any changes or modifications not expressly approved by Zebra Technologies Corporation

could void the user's authority to operate the equipment."

Canadian DOC Compliance Statement

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus as set out in

the radio interference regulations of the Canadian Department of Communications.

CE Compliance

If the accompanying printer displays the CE mark, it also meets EMC directive 89/336/EEC, with amendments

effective at the time of manufacture.

Liability Disclaimer

Zebra Technologies Corporation takes steps to assure that its published Engineering Specifications and Manuals are

correct; however, errors do occur. Zebra Technologies Corporation reserves the right to correct any such errors and

disclaims liability resulting therefrom.

No Liability for Consequential Damage

In no event shall Zebra Technologies Corporation or anyone else involved in the creation, production, or delivery of

the accompanying product (including hardware and software) be liable for any damages whatsoever (including,

without limitation, damages for loss of business profits, business interruption, loss of business information, or other

pecuniary loss) arising out of the use of or the results of use of or inability to use such product, even if Zebra

Technologies Corporation has been advised of the possibility of such damages. Because some states do not allow the

exclusion or limitation of liability for consequential or incidental damages, the above limitation may not apply to

you.

Copyrights

This copyrighted manual and the label printer described herein are owned by Zebra Technologies Corporation. All

rights are reserved. Unauthorized reproduction of this manual or the software in the label printer may result in

imprisonment of up to one year and fines of up to $10,000 (17 U.S.C.506). Copyright violators may be subject to

civil liability.

All products and brand names are trademarks of their respective companies. All rights reserved.

2000 Zebra Technologies Corporation. All rights reserved.

ii Zebra XiIII-Series User’s Guide

Page 3

TableofContents

Introduction

Hello!........................................1

UnpackingandInspection..............................2

ReportingDamage................................2

Storage......................................2

MediaandRibbonRequirements..........................3

PowerCord.....................................3

PrinterAnatomy101.................................4

CalibratingthePrinter

Purpose.......................................5

TypesofMedia...................................6

Non-ContinuousWebMedia...........................6

Non-ContinuousBlackMarkMedia.......................7

ContinuousMedia................................7

ChoosingthePrintMode..............................8

LoadingtheMedia..................................9

PositioningtheMediaSensors...........................10

TransmissiveSensor..............................10

BlackMarkSensor...............................12

LoadingtheRibbon................................13

OperatorControls.................................14

POWERSwitch.................................14

FrontPanel...................................14

ConfiguringthePrinter...............................15

ConfiguringtheSoftwareorPrinterDriver....................16

MediaandRibbonCalibration...........................17

PrintingaTestLabel................................19

ZebraXiIII-SeriesUser’sGuide iii

Page 4

EstablishingCommunication

SystemConsiderations...............................21

Interfaces....................................21

DataSpecifications...............................21

CablingRequirements...............................22

PrinterBasics

OperatorControls.................................23

POWERSwitch.................................23

FrontPanelDisplay...............................24

FrontPanelKeys................................25

FrontPanelLights...............................26

RollMediaLoading................................27

Tear-OffMode.................................27

Peel-OffMode.................................28

RewindMode(forPrintersWithouttheCutterOption)..............30

CutterMode...................................32

RewindMode(forPrintersWiththeCutterOption)..............34

FanfoldMediaLoading..............................36

RemovingtheLabelBackingMaterial.......................38

RibbonLoading..................................39

RibbonRemoval..................................41

Configuration

EnteringtheSetupMode..............................43

ChangingPassword-ProtectedParameters.....................44

LeavingtheSetupMode..............................45

ConfigurationandCalibrationSequence......................46

iv ZebraXiIII-SeriesUser’sGuide

Page 5

RoutineCareandAdjustment

Cleaning......................................65

CleaningtheExterior..............................66

CleaningtheInterior..............................66

CleaningthePrintheadandPlatenRoller....................66

CleaningtheSensors..............................67

CleaningtheSnapPlate.............................68

CleaningtheCutterModule..........................70

Lubrication.....................................70

FuseReplacement.................................70

Adjustments....................................72

TogglePositioning...............................72

PrintheadPressureAdjustment.........................73

MediaSensorPositionAdjustment.......................73

Troubleshooting

LEDErrorConditionsandWarnings.......................75

PrintQualityProblems...............................78

WrinkledRibbon..................................79

Communications..................................79

PrinterDiagnostics.................................81

Power-OnSelfTest...............................81

AdditionalPrinterSelfTests..........................81

ZebraXiIII-SeriesUser’sGuide v

Page 6

Specifications

MediaHandling..................................87

Options.......................................87

®

ZebraProgrammingLanguage(ZPLII

BarCodes......................................88

GeneralSpecifications...............................89

PrintingSpecifications...............................90

RibbonSpecification................................90

MediaSpecifications................................91

PowerLineCordSpecifications..........................92

).....................88

Appendix

PrinterInterfaceTechnicalInformation......................93

RS-232/RS-422/RS-485SerialDataPort....................93

ParallelDataPort................................97

Index

vi ZebraXiIII-SeriesUser’sGuide

Page 7

Hello!

Introduction

Thankyouforpurchasingthishigh-qualityZebraXiIII-Seriesprinter,

manufacturedbytheindustryleaderinquality,service,andvalue--Zebra

TechnologiesCorporation.Forover25years,Zebrahasprovided

customerswiththehighestcaliberofproductsandsupport.

n

Thismanualprovidesalloftheinformationyouwillneedtooperate

yourprinter.

n

TheZPLIIProgrammingReferenceVolumesIandII

(part#45540L)showyouhowtocreatetheperfectlabelformatforyour

application.Thesebooksalsoexplainhow,throughZBI

extendthepowerofZPLIIbyallowingcustomprogramstobewritten

thatoperatewithintheprinter,directlyinterfacingwith,forexample,bar

codescannersandkeyboarddisplaydevices.Inaddition,thebooks

containinformationabouttheenhancedoperatingsystemfeaturesof

yourprinter.Therearethreewaystoobtainthesebooks:onthe

accessoryCD-ROM(suppliedwiththeprinter),onourwebsite

(www.zebra.com),andprintedmanualscanbeorderedfromyour

distributor.

,youcan

n

TheZebraNetâNetworking:PrintServerIIäInstallationandUser’s

Guide(part#45537L)explainshowyoucanquicklysetupyourprinter

onanIPnetwork(optionalZebraNetPrintServerIIrequired).

n

Thereisalsoamaintenancemanualforthisprinter.Thismanual

(part#48152L)containstheinformationyouwillneedtomaintainyour

printer.

ZebraXiIII-SeriesUser’sGuide 1

Page 8

Unpacking and Inspection

Inspect the printer for possible damage incurred during shipment.

n

Check all exterior surfaces.

n

Raise the media access door and inspect the media compartment.

In case shipping is required, save the carton and all packing material.

Contact your authorized Zebra reseller for instructions.

Reporting Damage

If you discover shipping damage:

n

Immediately notify and file a damage report with the shipping company.

Zebra Technologies Corporation is not responsible for any damage

incurred during shipment of the equipment and will not repair this

damage under warranty.

n

Keep the carton and all packing material for inspection.

n

Notify your authorized Zebra reseller.

Storage

If you are not placing the printer into operation immediately, repackage it

using the original packing materials. The printer may be stored under the

following conditions:

n

Temperature: -4° to +140° F (-20° to +60° C)

n

Relative humidity: 5 to 85% non-condensing

2 Zebra XiIII-Series User’s Guide

Page 9

MediaandRibbonRequirements

Sinceprintqualityisaffectedbymediaandribbon,printingspeeds,and

printeroperatingmodes,itisveryimportanttoruntestsforyour

applications.

WeSTRONGLYRECOMMENDtheuseofZebraTechnologies

Corporation-brandsuppliesforcontinuoushigh-qualityprinting.Awide

rangeofpaper,polypropylene,polyester,andvinylstockhasbeen

specificallyengineeredtoenhancetheprintingcapabilitiesoftheprinter

andtoensureagainstprematureprintheadwear.

n

Continuousrollmedia,fanfoldmedia,orcardstockwithoptional

perforationsandregistrationholesmaybeused.

n

Printheadlifemaybereducedbytheabrasionofexposedpaperfibers

whenusingperforatedmedia.

n

TheribbonMUSTbeaswideasorwiderthanthemediabeingused.If

theribbonisnarrowerthanthemedia,areasoftheprintheadwillbe

unprotectedandsubjecttoprematurewear.(Whenprintingindirect

thermalmode,ribbonisnotusedandshouldnotbeloadedinthe

printer.)

PowerCord

WARNING!Forpersonnelandequipmentsafety,alwaysusea

three-prongplugwithaground(earth)connection.

NOTE:Dependingonhowyourprinterwasordered,apowercordmayor

maynotbeincluded.Ifoneisnotincluded,oriftheoneincluded

isnotsuitableforyourrequirements,referto“PowerLineCord

Specifications”onpage92.

Thepowercordconnectormustbepluggedintothematingconnectoron

therearoftheprinter.

MakesurethatthePOWERon/offswitch(locatedatthebackoftheprinter)

isintheoffpositionbeforeconnectingthepowercabletoanelectrical

outlet.

ZebraXiIII-SeriesUser’sGuide 3

Page 10

Printer Anatomy 101

Depending on the options you have selected, your printer may look slightly

different.

Tear-off/

peel-off

bar

Printhead

lever

Platen

roller

Snap

plate

Lower

roller

Spindle

hook

Ribbon take-up

spindle

Ribbon supply

spindle

Dancer

roller

assembly

Media

guide

Rewind

spindle

(optional)

Only on select models

Media

supply

guide

Media

supply

hanger

Figure 1

4 Zebra XiIII-Series User’s Guide

Page 11

This chapter of the user’s guide is so important that we’ve printed it on a

different color paper! That way, it will be easy for you to find when you

must calibrate (set up) the printer for your particular application.

Purpose

n

n

NOTE: This procedure must be performed when the printer is first

To calibrate the printer, you must do the following (all of the instructions

are contained in this chapter):

Calibrating the Printer

To calibrate the printer.

To verify that the printer is properly set up by printing a test label.

installed or when it cannot properly detect the top of the label.

n

Determine the type of media (labels) being used.

n

Choose the print method.

n

Position the media sensors (if necessary).

n

Configure the printer and software or driver based on the label being

used.

n

Perform a media and ribbon calibration.

n

Print a test label.

Zebra XiIII-Series User’s Guide 5

Page 12

Types of Media

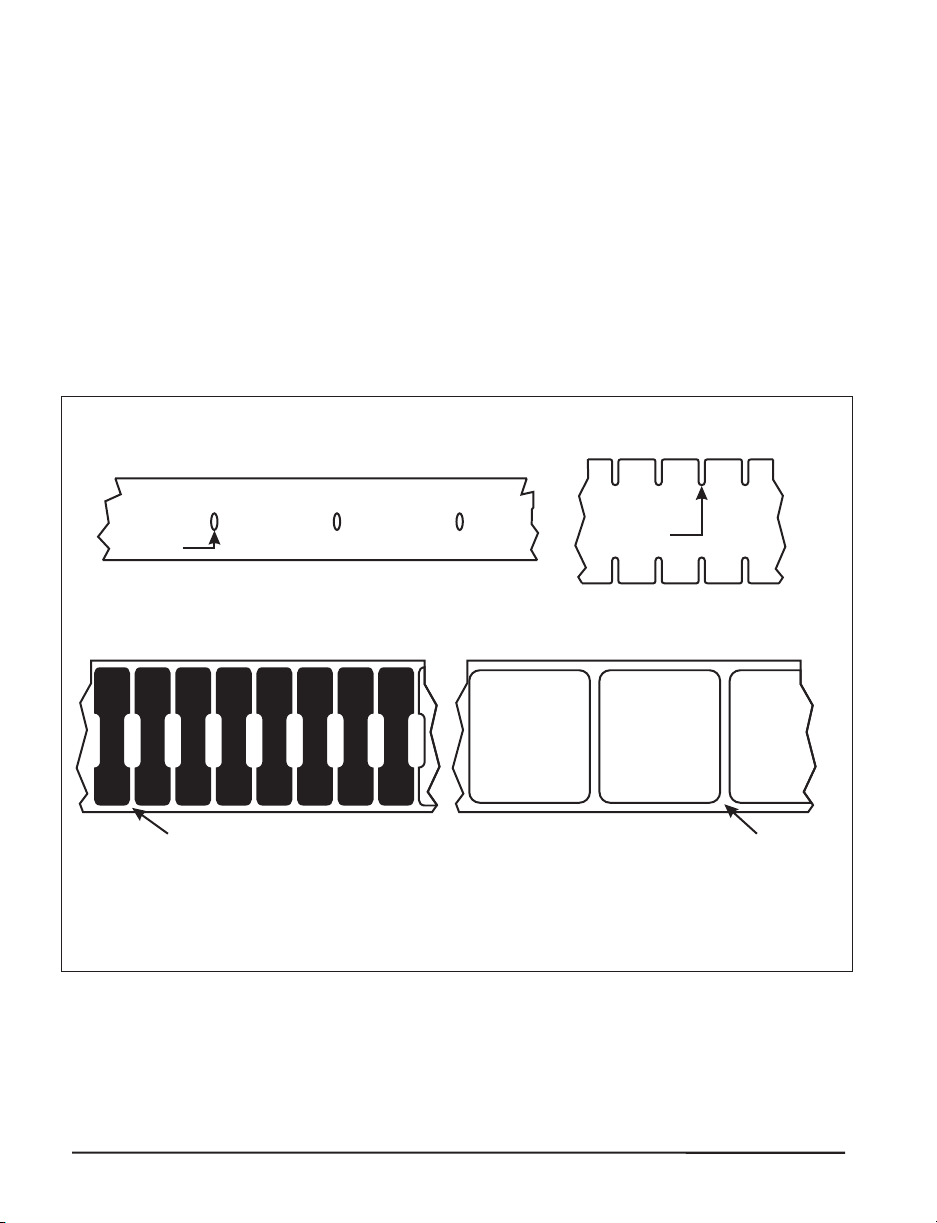

Non-Continuous Web Media

Non-continuous web media (refer to Figure 2) refers to individual labels

that are separated by a gap, notch, or hole. When you look at the media,

you can tell where one label ends and the next one begins.

Hole

Label gap (2-4 mm)

Notch

Non-continuous media with a hole or notch

Label gap (2-4 mm)

Non-continuous media with gaps between the labels

(individual labels on a continuous liner)

Figure 2

6 Zebra XiIII-Series User’s Guide

Page 13

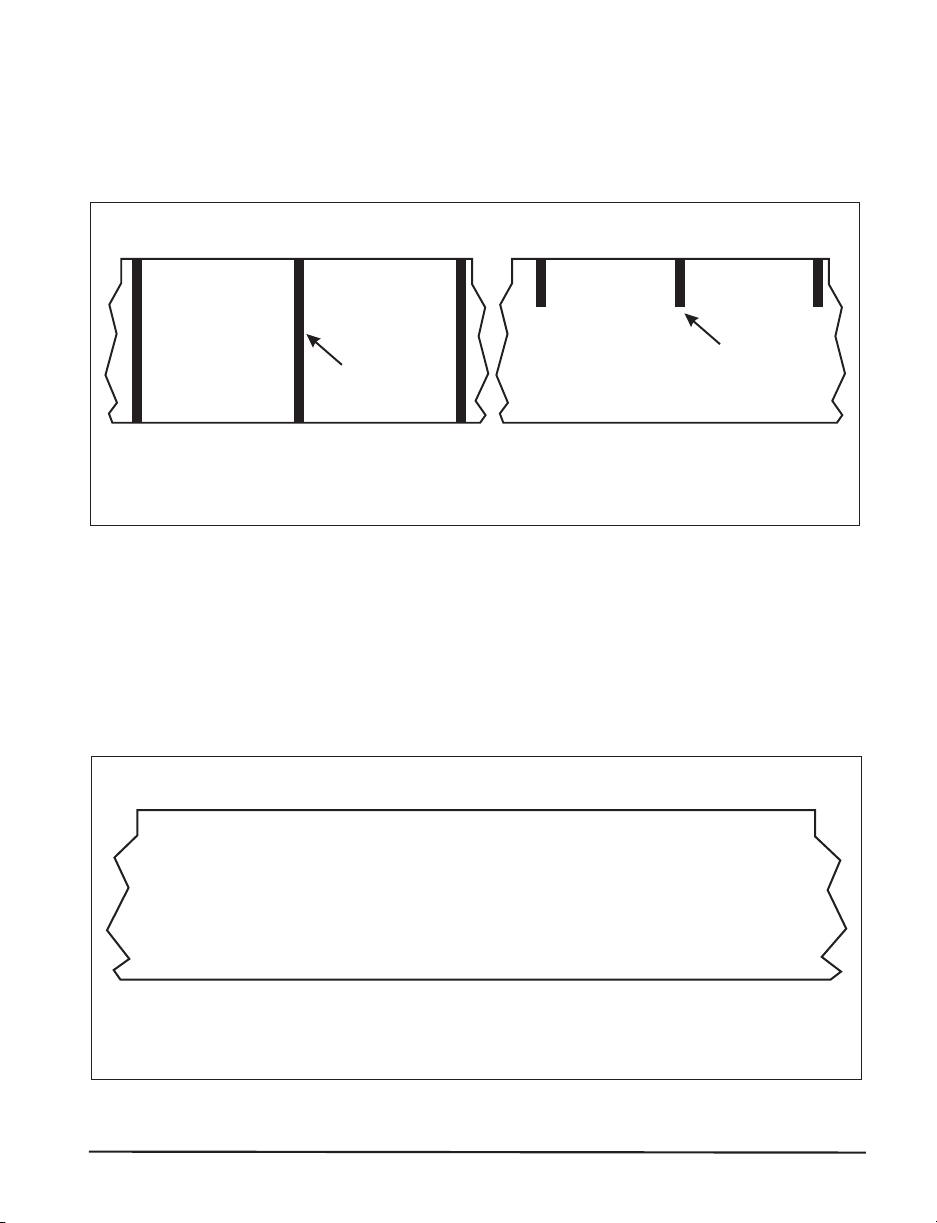

Non-Continuous Black Mark Media

Non-continuous black mark media has black marks printed on the back that

indicate the start and end of each label (refer to Figure 3).

Black mark

Non-continuous media for black mark sensing

Figure 3

Continuous Media

Black mark

Continuous media (refer to Figure 4) is one uninterrupted roll of material

that allows the image to be printed anywhere on the label.

Continuous media (no gaps, holes, notches, or black marks)

Figure 4

Zebra XiIII-Series User’s Guide 7

Page 14

Choosing the Print Mode

n

Tear-off mode allows you to tear off each label, or a strip of labels, after

it is printed.

n

In Peel-off mode, backing material is peeled away from the label as it is

printed. After this label is removed from the printer, the next one is

printed.

n

When in cutter mode, the printer automatically cuts the label after it is

printed.

n

In rewind mode, the media and backing are rewound onto a core as the

labels are printed.

8 Zebra XiIII-Series User’s Guide

Page 15

LoadingtheMedia

Figure5illustratesonemethodofmedialoading.Formoredetailed

instructions,aswellasinformationabouthowtoloadthedifferenttypesof

mediaandthevariousprintingmodes,refertotheinstructionsthatbeginon

page27.

Printheadlever

Open

Closed

Tear-off/

peel-off

bar

Media

guide

Figure5

Media

supply

guide

Media

ZebraXiIII-SeriesUser’sGuide 9

Page 16

Positioning the Media Sensors

The correct positioning of the media sensors is important. It can make the

difference between a perfect label and a call to Technical Support!

Transmissive Sensor

The web or gap sensor, better known as the “transmissive sensor,” detects

the gap between labels.

The transmissive sensor actually consists of two sections: a light source

(the lower media sensor) and a light sensor (the upper media sensor). The

media passes between the two.

The upper media sensor must be positioned:

n

Directly over the hole or notch, or

n

Anywhere along the width of the media if there is a gap between labels.

NOTE: If you are using continuous media, position the upper media sensor

over the media so that the printer can detect an out-of-paper

condition.

10 Zebra XiIII-Series User’s Guide

Page 17

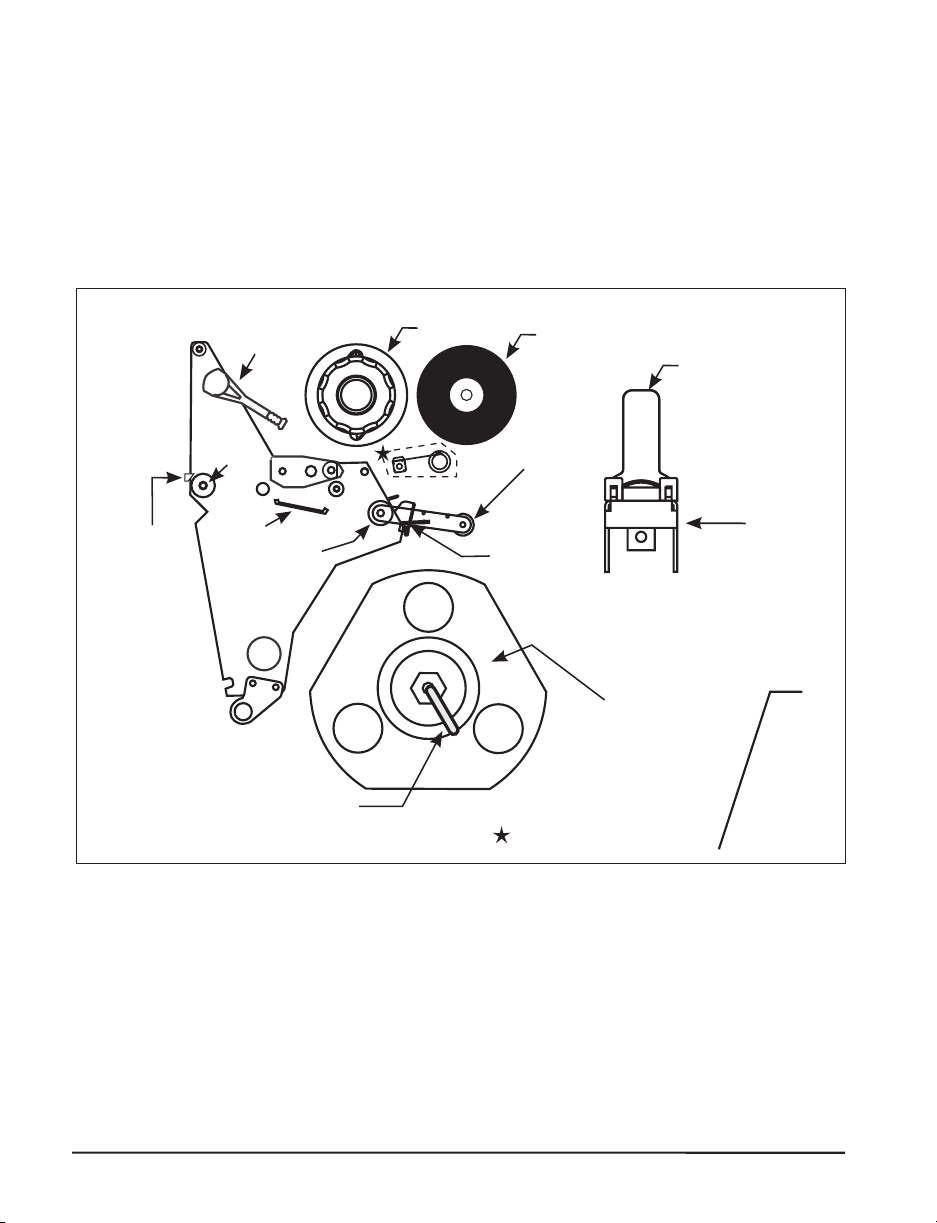

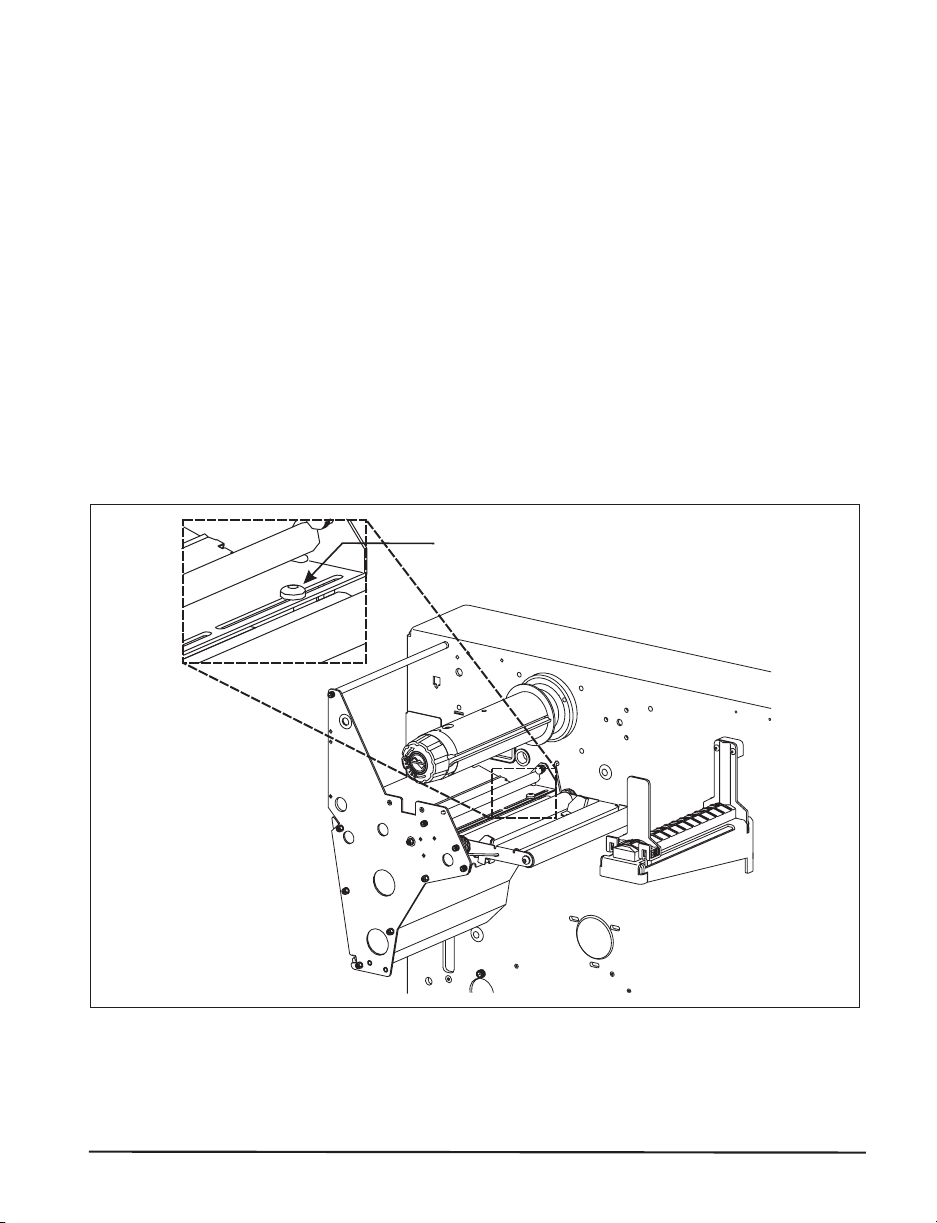

Adjusting the Upper Media Sensor

Refer to Figure 6. (For clarity, not all printer parts are shown.)

1. Remove the ribbon (if it is installed).

2. Locate the upper media sensor. The upper media sensor “eye” is

directly below the adjustment screw head.

3. Slightly loosen the upper media sensor adjustment screw (Phillips

head).

4. Using the tip of the screwdriver, slide the upper sensor along the slot to

the desired position.

5. Secure the upper media sensor adjustment screw.

Upper media sensor

adjustment screw

Figure 6

Zebra XiIII-Series User’s Guide 11

Page 18

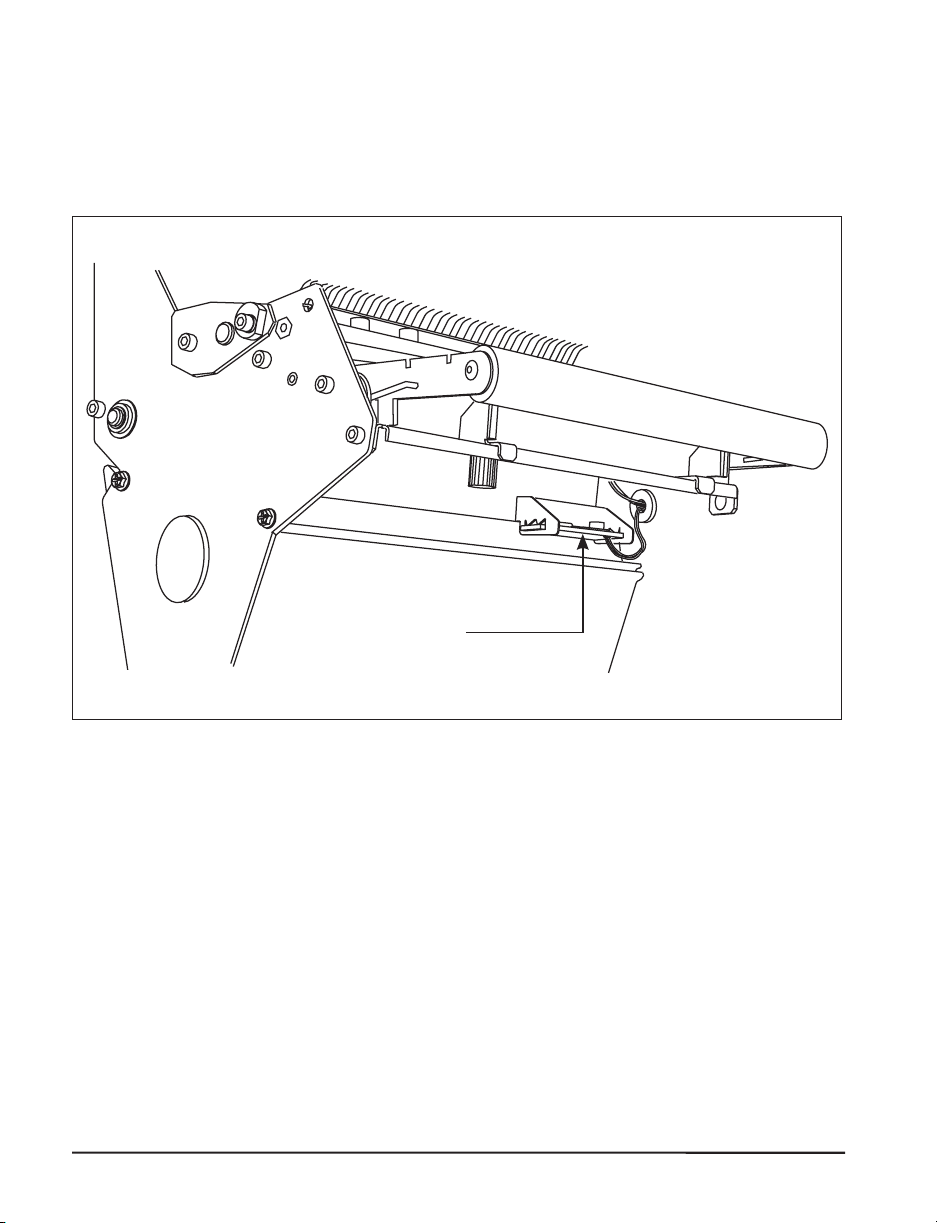

AdjustingtheLowerMediaSensor

Positionthelowermediasensor(refertoFigure7)byslidingitinitsslot

untilitispositionedundertheuppermediasensor.

Lower

mediasensor

Figure7

BlackMarkSensor

Theblackmarksensorisinafixedpositionandenabledviathefrontpanel

(detailsin“ConfiguringthePrinter”onpage15).

12 ZebraXiIII-SeriesUser’sGuide

Page 19

LoadingtheRibbon

Toloadribbon,refertoFigure8(forthe90XiIII,96XiIII,and140XiIII)and

Figure9(forthe170XiIIIand220XiIII).Formoredetailedinformation,

refertotheinstructionsthatbeginonpage39.

Printhead

Closed

lever

Open

Printhead

lever

Open

Ribbon

take-up

spindle

Figure8

Ribbon

take-up

spindle

Ribbon

supply

spindle

Ribbon

supply

spindle

Closed

Figure9

ZebraXiIII-SeriesUser’sGuide 13

Page 20

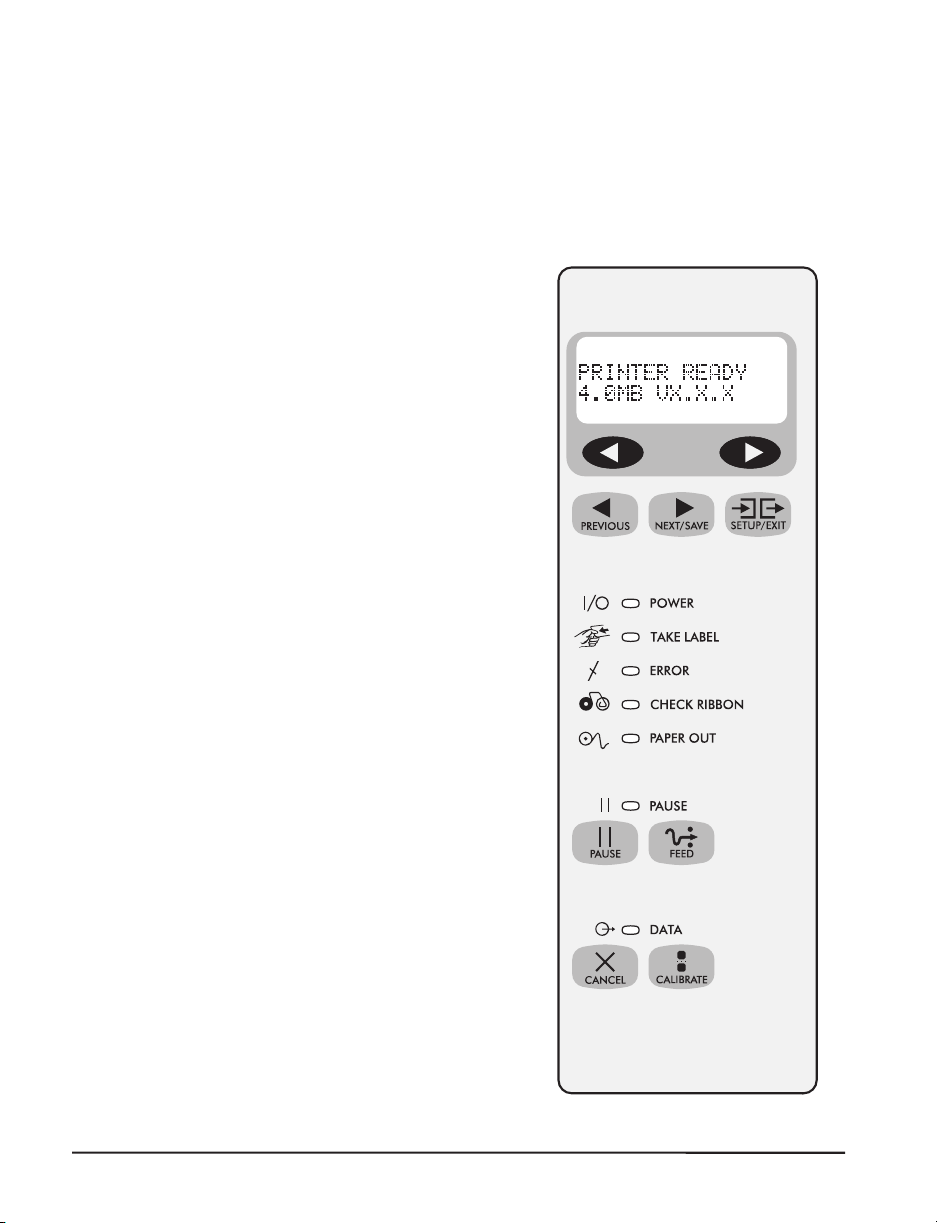

OperatorControls

POWERSwitch

ThePOWERswitchislocatedatthebackoftheprinterabovethepower

cordandfuse.Turnontheprinter.

FrontPanel

Thestep-by-stepinstructionsinthis

sectiontellyouwhichkeystopress

andwhatappearsontheliquidcrystal

display(LCD)duringthecalibration

procedure.

Foramoredetailedexplanationofthe

frontpanelkeysandlights(asshown

inFigure10),refertotheinstructions

thatbeginonpage24.

Figure10

14 ZebraXiIII-SeriesUser’sGuide

Page 21

ConfiguringthePrinter

Theconfigurationprocedureinthenexttablecontainstheinformationyou

needtogetyourprinterupandrunning,butitisnotcomprehensive.Refer

topage43formoreinformation.

n

EntertheconfigurationmodebypressingtheSETUP/EXITkeyatthe

“PRINTERREADY”display.

NOTE:YouwillneedtopresstheNEXT/SAVEkeymorethanonceto

advancetosomeofthedisplays.

n

Toincreasethevalue,answer“yes,”indicate“on,”ormovetothenext

selection,usetheRIGHTBLACKOVALkey.

n

Todecreasethevalue,answer“no,”indicate“off,”orreturntothe

previousselection,usetheLEFTBLACKOVALkey.

NOTE:Whenchangingparameters,anasterisk(*)intheupperleft-hand

cornerofthedisplayindicatesthatyouhavechangedthissetting

fromwhatiscurrentlystoredinmemory.

ZebraXiIII-SeriesUser’sGuide 15

Page 22

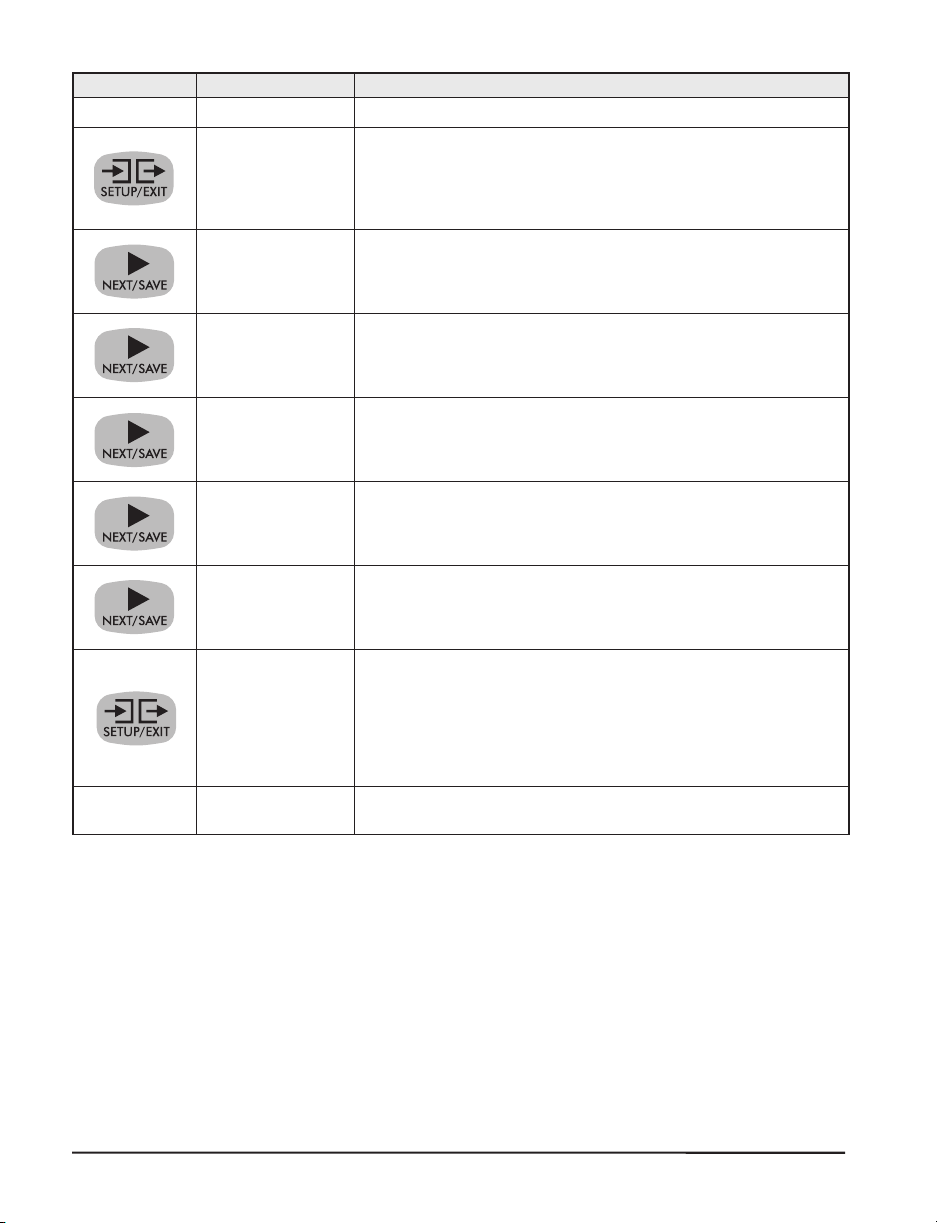

Press Display Shows Action/Explanation

- PRINTER READY Normal printer operation.

DARKNESS

PRINT MODE

MEDIA TYPE

SENSOR TYPE

PRINT METHOD

MAXIMUM

LENGTH

SAVE SETTINGS

Press the BLACK OVAL keys to increase or decrease the print

darkness setting. (You may need to change this setting when

you print your label.)

Press the BLACK OVAL keys to select tear-off, peel-off, cutter,

or rewind mode.

Press the BLACK OVAL keys to select continuous or

non-continuous media type. (If you choose continuous

media, you must also include a label length instruction in

your label format.)

Press the BLACK OVAL keys to select transmissive or black

mark sensing mode. Unless your media has black marks on

the back, leave your printer at the default setting (web).

Press the BLACK OVAL keys to select thermal transfer (if you

are using ribbon) or direct thermal (no ribbon).

Press the BLACK OVAL keys to set the value that is closest to,

but not less than, the length of the label you are using.

Press the BLACK OVAL keys to select:

PERMANENT -- saves the changes when the power is turned

off.

Press NEXT/SAVE to accept the selection.

- PRINTER READY

You have exited the configuration mode and are now ready

to calibrate the printer.

Configuring the Software or Printer Driver

Many printer settings may also be controlled by your printer’s driver or

label preparation software. Refer to the driver or software documentation

for more information.

16 Zebra XiIII-Series User’s Guide

Page 23

Media and Ribbon Calibration

NOTE: All steps must be performed in the following procedure, even if

only one sensor needs to be adjusted.

1. Press the SETUP/EXIT key.

2. Press the NEXT/SAVE key until “MEDIA AND RIBBON

CALIBRATE” displays.

3. To start the calibration procedure, press the RIGHT BLACK OVAL

key. “LOAD BACKING CANCEL CONTINUE” displays.

4. Open the printhead. Remove approximately 8” (203 mm) of labels

from the media roll, enough so that only the backing material is

threaded between the media sensors when the media is loaded

(refer to Figure 11).

Remove

labels

Figure 11

Zebra XiIII-Series User’s Guide 17

Page 24

5. Press the RIGHT BLACK OVAL key. The front panel display will

show “REMOVE RIBBON CANCEL CONTINUE.”

6. Either remove the ribbon or slide it as far from the printer frame as

possible.

7. Close the printhead, trapping the ribbon in this position.

8. Press the RIGHT BLACK OVAL key. The front panel will show

“CALIBRATING PLEASE WAIT.”

9. When this part of the calibration process is completed, the display will

read “RELOAD ALL CONTINUE.”

10. Open the printhead. Pull the backing material until a label is positioned

between the media sensors.

11. Either load the ribbon or return the ribbon to its proper position.

12. Close the printhead. Press the RIGHT BLACK OVAL key to perform

the next part of the calibration sequence. “MEDIA AND RIBBON

CALIBRATE” displays. The printer is calibrated when the media stops

feeding.

13. Press the SETUP/EXIT key to leave the programming mode. Choose

“permanent” when SAVE CHANGES displays.

18 Zebra XiIII-Series User’s Guide

Page 25

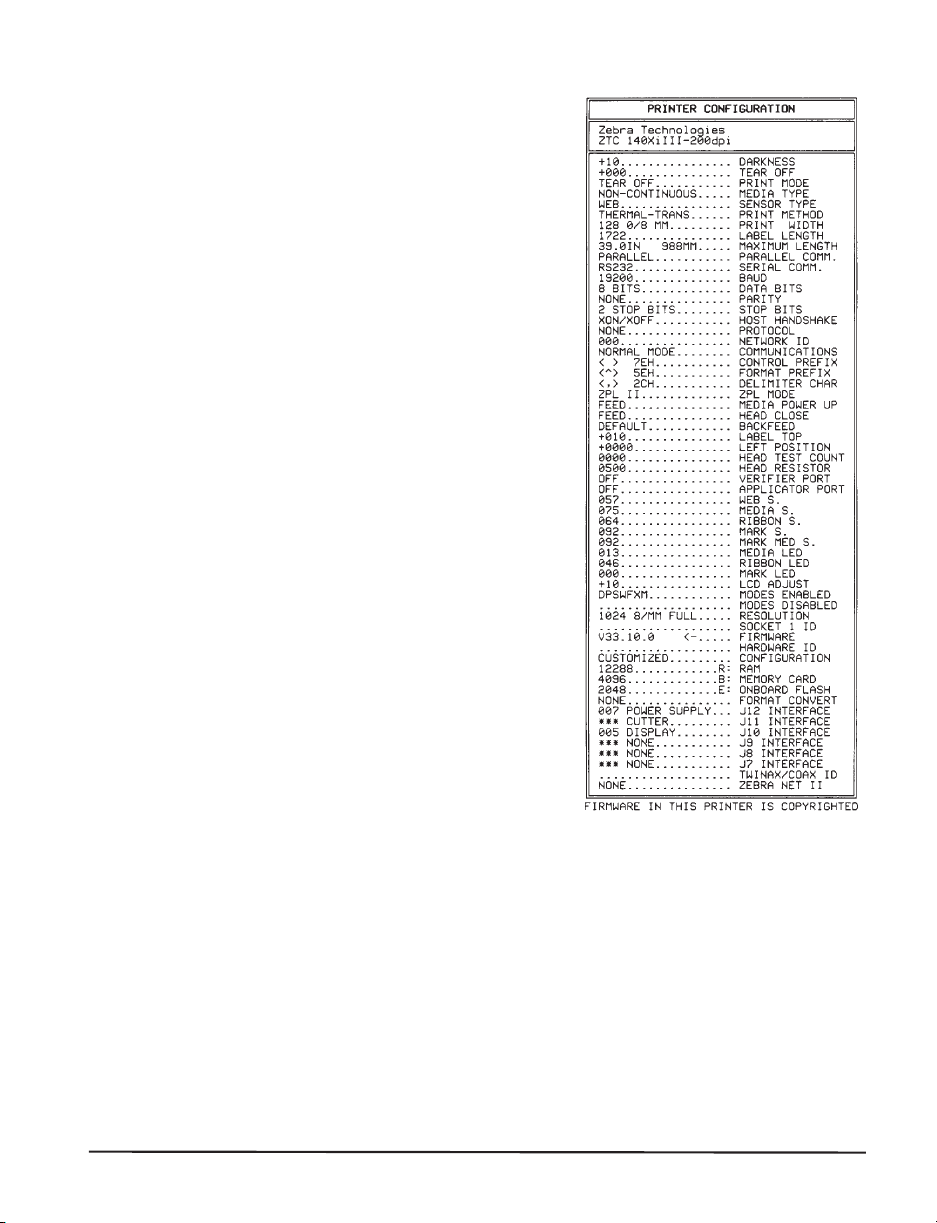

PrintingaTestLabel

Toprintatestlabel:

1.Turnofftheprinter.

2.PressandholdtheCANCELkey

whileturningontheprinter.

Aconfigurationlabel,whichshowsthe

printer’scurrentlystoredparameters,

willprint(similartotheoneshownin

Figure12).

Figure12

Ifyouencounteranyproblemswhileyouareconfiguringorcalibratingthe

printerorprintingatestlabel,refertoTroubleshooting,whichstartson

page75.Otherwise,refertoEstablishingCommunicationonpage21toset

upthecommunicationparameters.

ZebraXiIII-SeriesUser’sGuide 19

Page 26

20 Zebra XiIII-Series User’s Guide

Page 27

Establishing Communication

System Considerations

Interfaces

The method of interfacing this printer to a data source depends on the

communication options installed in the printer. The standard interfaces are

an RS-232/RS-422/RS-485 serial data port and a bi-directional parallel port.

The optional ZebraNet PrintServer II enables printers to be connected to 10

BaseT Ethernet networks. In addition, the IBM

option is available for those applications that require them.

Data Specifications

®

Twinax or IBM Coax

When communicating via an

asynchronous serial data port (refer

to Figure 13), the baud rate, number

of data and stop bits, parity, and

handshaking are user selectable.

Parity only applies to data

transmitted by the printer since the

parity of received data is ignored.

Printer

25

Male

25

Null modem adapter

(if using a standard

modem cable)

50’ maximum

Figure 13

Male

Computer

25

Female

9

Zebra XiIII-Series User’s Guide 21

Page 28

Whencommunicatingviatheparallel

port(refertoFigure14),the

previouslymentionedparametersare

notconsidered.Refertopage53to

configurethecommunication

parametersfortheprinter.The

valuesselectedmustbethesameas

thoseusedbythehostequipment

connectedtotheprinter.

Forserialandparallelpinoutand

technicalinformation,refertothe

Appendixonpage93.

ComputerPrinter

36-pin

male

PC

25-pin

female

25-pin

male

10’maximum

CablingRequirements

Datacablesmustbefullyshieldedandfittedwithmetalormetalized

connectorshells.Shieldedcablesandconnectorsarerequiredtoprevent

radiationandreceptionofelectricalnoise.

Tominimizeelectricalnoisepickupinthecable:

n

Keepdatacablesasshortaspossible.

n

Donotbundlethedatacablestightlywiththepowercords.

n

Donottiethedatacablestopowerwireconduits.

NOTES:ZebraprinterscomplywithFCC“RulesandRegulations”,

Part15,SubpartJ,forClassAEquipment,usingfullyshielded

6’datacables.Useoflongercablesorunshieldedcablesmay

increaseradiatedemissionsabovetheClassAlimits.

RS-422andRS-485applicationsshouldusetwistedshielded

pairsasrecommendedintheAppendixoftheTA/EA.-485

Specification.

Figure14

22 ZebraXiIII-SeriesUser’sGuide

Page 29

Operator Controls

This section discusses the functions of the various controls and indicators

on the printer. The operator should become familiar with each of these

functions.

POWER Switch

This switch is located at the back of the printer above the power cord and

fuse. The POWER switch should be turned off before connecting or

disconnecting any cables.

External influences, such as lightning storms or noise on the power or data

cables, may cause erratic printer behavior. Turning the printer’s power off

and back on may re-establish proper printer operation.

Printer Basics

Zebra XiIII-Series User’s Guide 23

Page 30

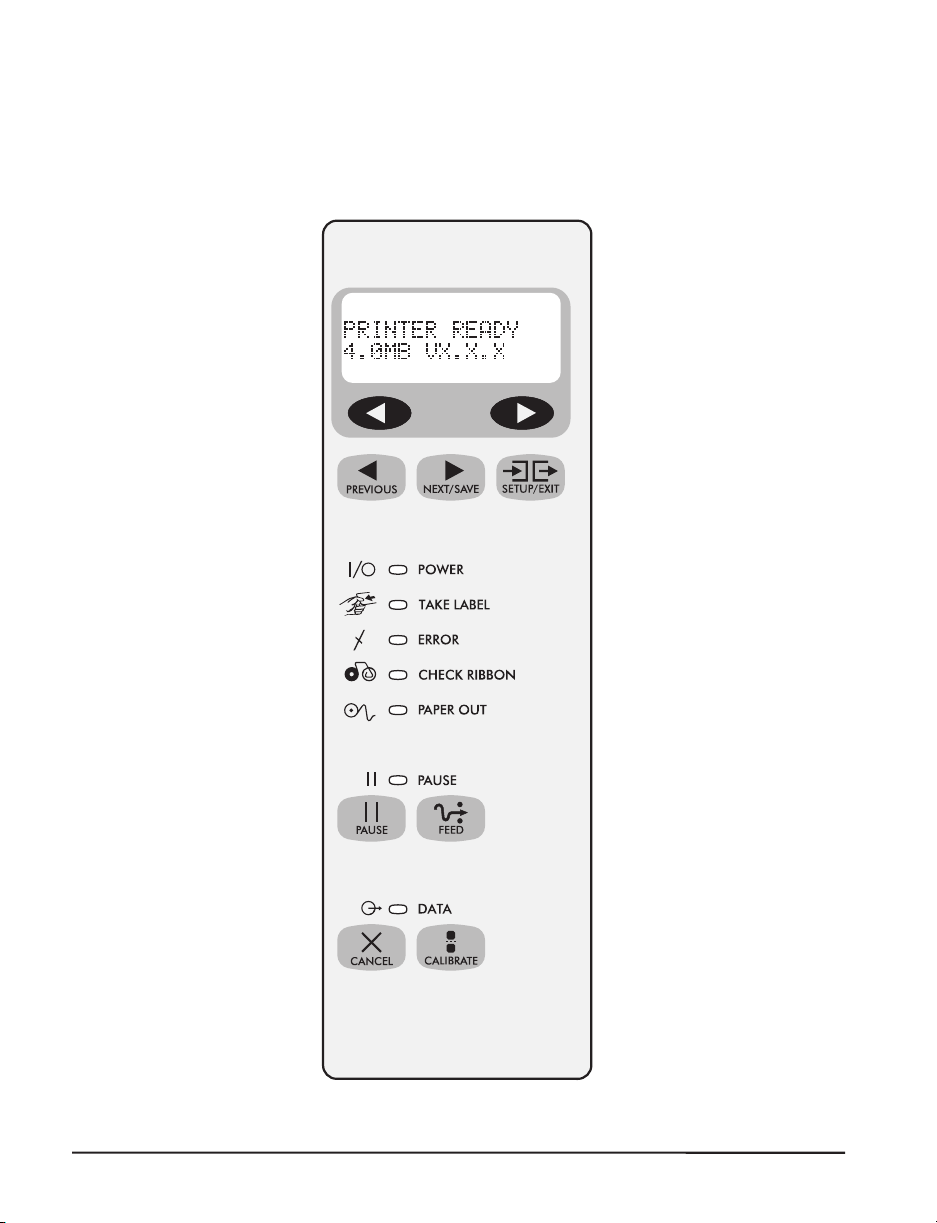

Front Panel Display

The front panel display communicates operational status and programming

modes and parameters.

Figure 15

24 Zebra XiIII-Series User’s Guide

Page 31

FrontPanelKeys

Key Function

Startsandstopstheprintingprocess.

•Iftheprinterisnotprinting:noprintingcanoccur.

•Iftheprinterisprinting:printingstopsoncethecurrentlabeliscomplete.

Presstoremoveerrormessagesfromthedisplay.

NOTE:PausemodecanalsobeactivatedviaZPLII(~PP,^PP).

Forcestheprintertofeedoneblanklabeleachtimethekeyispressed.

•Printernotprinting:oneblanklabelimmediatelyfeeds.

•Printing:oneblanklabelfeedsafterthecurrentbatchoflabelsiscomplete.

NOTE:EquivalenttotheSlewtoHomePosition(~PH,^PH)ZPLIIinstruction.

Wheninthepausemode,thiskeywillcancelprintjobs.

•Printjobinqueue:pressonceforeachprintjobtobedeleted.

•Pressandholdforseveralsecondstocancelallprintjobsintheprinter’s

memory.TheDATAlightwillturnoff.

WheninPausemode,thiskeywillcalibratetheprinterfor:

•Medialength.

•Mediatype(continuousornon-continuous).

•Printmode(directthermalorthermaltransfer).

•Sensorvalues.

NOTE:Thekeysbelowareusedonlywhenconfiguringtheprinter.Specificusesofthesekeys

areexplainedinConfiguration,startingonpage43.

•Scrollsbacktothepreviousparameter.

•Pressandholdtoquicklygobackwardthroughparametersets.

•Scrollsforwardtothenextparameter.(Savesanychangesyou’vemadeinthe

configurationandcalibrationsequence.)

•Pressandholdtoquicklyadvancethroughparametersets.

Entersandexitstheconfigurationmode.

Thesekeyschangetheparametervalues.Theyareusedindifferentways

dependingontheparameterdisplayed.Commonusesare:toincrease/decrease

avalue,answer“yes”or“no,”indicate“on”or“off,”scrollthroughseveral

choices,inputthepassword,orsetuptheprinterforafirmwaredownload.

ZebraXiIII-SeriesUser’sGuide 25

Page 32

Front Panel Lights

NOTE: If two operating conditions occur simultaneously (for example,

one that causes a light to be on constantly and one that causes the

same light to flash), the light will flash.

Light Status Indication

POWER

TAKE LABEL

ERROR

CHECK

RIBBON

PAPER OUT

PAUSE

DATA

Off The printer is off or power is not applied.

On The printer is on.

Off Normal operation.

Flashing

Off Normal operation — no printer errors.

Flashing

Off Normal operation — ribbon (if used) is properly loaded.

On

Off Normal operation — media is properly loaded.

On

Off Normal operation.

On

Off Normal operation. No data being received or processed.

On

Flashing

(Peel-off mode only.) The label is available. Printing is paused until

the label is removed.

A printer error exists. Check the display screen for more

information.

Printing is paused, the front panel displays a warning message, and

the PAUSE light is on.

• If the printer is in direct thermal mode: Ribbon is loaded.

• If the printer is in thermal transfer mode: No ribbon is loaded.

No media is under the media sensor. Printing is paused, the display

shows an error message, and the PAUSE light is on.

The printer has stopped all printing operations. Either the PAUSE

key was pressed, a pause command was included in the label

format, the on-line verifier detected an error, or a printer error was

detected. Refer to the display screen for more information.

Data processing or printing is taking place. No data is being

received.

The printer is receiving data from or sending status information to

the host computer. Flashing slows when the printer cannot accept

more data, but returns to normal once data is again being received.

26 Zebra XiIII-Series User’s Guide

Page 33

Roll Media Loading

NOTE: A calibration must be performed when media and ribbon (if used)

are first installed in the printer, or when a different type of media

or ribbon is being used.

Tear-Off Mode

Refer to Figure 16.

1. Open the printhead.

2. Slide the media guide and media supply guide as far from the printer

frame as possible. Flip down the media supply guide.

3. Load media as shown.

4. Flip up the media supply guide. Slide in the media guide and media

supply guide so they just touch, but not restrict, the edge of the roll.

5. Close the printhead.

Printhead lever

Open

Closed

Media

guide

Figure 16

Media

supply

guide

Media

Zebra XiIII-Series User’s Guide 27

Page 34

Peel-OffMode

NOTE:Rewindoptionrequired.

RefertoFigure17.

1.Removetherewindplatefromthefrontoftheprinter(ifinstalled).

Storeitonthetwomountingscrewsontheinsideofthefrontpanel.

2.Opentheprinthead.

3.Slidethemediaguideandmediasupplyguideasfarfromtheprinter

frameaspossible.Flipdownthemediasupplyguide.

4.Loadmediaasshown.

5.Whenloadingmedia,allowapproximately36”(914mm)ofmediato

extendpastthetear-off/peel-offbar.Removealllabelsfromthis

portiontocreatealeader.

6.Removethehookfromtherewindspindle.Ifyouareusingacore,

slideitontotherewindspindleuntilitisflushagainsttheguideplate.

7.Windthelabelbackingaroundeitherthe3”(76mm)coreortherewind

spindleandreinstallthehook.

8.Flipupthemediasupplyguide.Slideinthemediaguideandmedia

supplyguidesotheyjusttouch,butnotrestrict,theedgeoftheroll.

Beforeclosingtheprinthead,makesure:

n

Themediaispositionedagainsttheinsideguides.

n

Themediaistautandparallelwithitselfandthepathwaywhenwound

ontotherewindspindle/core.

9.Closetheprinthead.

10.Todiscardthelabelbackingfromtherewindspindle,referto

“RemovingtheLabelBackingMaterial”onpage38.

28 ZebraXiIII-SeriesUser’sGuide

Page 35

Label

Printhead lever

Open

Media

supply

guide

Media

Label

backing

Rewind

Closed

Tear-off/

peel-off

plate

bar

Hook

Media

guide

Figure 17

Rewind

spindle

Guide

plate

Zebra XiIII-Series User’s Guide 29

Page 36

RewindMode(forPrintersWithouttheCutterOption)

NOTE:Rewindoptionrequired.

RefertoFigure18.

1.Removetherewindplatefromitsstoragelocationinfrontoftheprint

mechanisminsidethemediacompartment.

2.Inverttherewindplatesothatthelipontheattachedhookplatepoints

down.

3.Insertthehookplatelipashortdistance(½"/13mm)intothelower

openinginthesideplate.

4.Aligntheupperendoftherewindplatewiththecorrespondingopening

inthesideplate.Slideintherewindplatesothatitstopsagainstthe

printer’smainframe.

5.Opentheprinthead.

6.Slidethemediaguideandmediasupplyguideasfarfromtheprinter

frameaspossible.Flipdownthemediasupplyguide.

7.Loadmediaasshown.

8.Whenloadingmedia,allowapproximately36”(914mm)ofmediato

extendpasttheprinthead.Removealllabelsfromthisportiontocreate

aleader.

9.Removethehookfromtherewindspindle.Ifyouareusingacore,

slideitontotherewindspindleuntilitisflushagainsttheguideplate.

10.Windthelabelbackingaroundeitherthe3”(76mm)coreortherewind

spindleandreinstallthehook.

11.Flipupthemediasupplyguide.Slideinthemediaguideandmedia

supplyguidesotheyjusttouch,butnotrestrict,theedgeoftheroll.

30 ZebraXiIII-SeriesUser’sGuide

Page 37

Before closing the printhead, make sure:

n

The media is positioned against the inside guides.

n

The media is taut and parallel with itself and the pathway when wound

onto the rewind spindle/core.

12. Close the printhead.

Printhead lever

Closed

Side

plate

Rewind

plate

Open

Hook

Media

guide

Figure 18

Media

supply

guide

Media

Guide

plate

Zebra XiIII-Series User’s Guide 31

Page 38

CutterMode

NOTE:Cutteroptionrequired.

RefertoFigure19.

1.Opentheprinthead.

2.Slidethemediaguideandmediasupplyguideasfarfromtheprinter

3.Loadmediaasshown.

4.Flipupthemediasupplyguide.Slideinthemediaguideandmedia

5.Closetheprinthead.

6.Theprinterwillautomaticallyfeedoutandcutonelabelwhenthe

frameaspossible.Flipdownthemediasupplyguide.

supplyguidesotheyjusttouch,butnotrestrict,theedgeoftheroll.

printeristurnedon.

32 ZebraXiIII-SeriesUser’sGuide

Page 39

Printhead lever

Open

Media

supply

guide

Media

Cutter

Closed

Media

guide

Figure 19

Zebra XiIII-Series User’s Guide 33

Page 40

RewindMode(forPrintersWiththeCutterOption)

NOTE:Cutterandrewindoptionsrequired.

RefertoFigure20.

1.Removetherewindplatefromitsstoragelocationinfrontoftheprint

mechanisminsidethemediacompartment.

2.Inverttherewindplatesothatthelipontheattachedhookplatepoints

down.

3.Insertthehookplatelipashortdistance(½"/13mm)intothelower

openinginthesideplate.Slideintherewindplatesothatitstops

againsttheprinter’smainframe.

4.Insertthetwosmalltabsontherewindplateintothecorresponding

slotsinthecuttersupportbracket.(Therewindplateshouldspringinto

theproperposition.)

5.Opentheprinthead.

6.Slidethemediaguideandmediasupplyguideasfarfromtheprinter

frameaspossible.Flipdownthemediasupplyguide.

7.Loadmediaasshown.

8.Whenloadingmedia,allowapproximately36”(914mm)ofmediato

extendpasttheprinthead.Removealllabelsfromthisportiontocreate

aleader.

9.Removethehookfromtherewindspindle.Ifyouareusingacore,

slideitontotherewindspindleuntilitisflushagainsttheguideplate.

10.Windthelabelbackingaroundeitherthe3”(76mm)coreortherewind

spindleandreinstallthehook.

11.Flipupthemediasupplyguide.Slideinthemediaguideandmedia

supplyguidesotheyjusttouch,butnotrestrict,theedgeoftheroll.

34 ZebraXiIII-SeriesUser’sGuide

Page 41

Before closing the printhead, make sure:

n

The media is positioned against the inside guides.

n

The media is taut and parallel with itself and the pathway when wound

onto the rewind spindle/core.

12. Close the printhead.

Cutter

Printhead lever

Closed

plate

Rewind

plate

Open

Side

Hook

Media

guide

Figure 20

Media

supply

guide

Media

Rewind

spindle

Guide

plate

Zebra XiIII-Series User’s Guide 35

Page 42

FanfoldMediaLoading

NOTE:Acalibrationmustbeperformedwhenmediaandribbon(ifused)

arefirstinstalledintheprinter,orwhenadifferenttypeofmedia

orribbonisbeingused.

Fanfoldmediafeedsthrougheitherthebottomorrearaccessslotfrom

outsidetheprinter.

RefertoFigures21and22.

1.Opentheprinthead.

2.Slidethemediaguideasfarfromtheprinterframeaspossible.

3.Loadmediaasshown.Ifincuttermode,routemediathroughthe

cutter.

4.Slideinthemediaguidesoitjusttouches,butnotrestricts,theedgeof

theroll.

5.Closetheprinthead.

36 ZebraXiIII-SeriesUser’sGuide

Page 43

Printhead lever

Open

Bottom supply

Closed

Printhead lever

Open

Closed

Media

Media

guide

Figure 21

Rear supply

Media

guide

Media

Figure 22

Zebra XiIII-Series User’s Guide 37

Page 44

Removing the Label Backing Material

Since the rewind spindle holds the backing from a standard-size media roll,

we recommend that you perform this procedure whenever you change the

media.

To remove the backing material from the rewind spindle, follow these steps

(you don’t need to turn off the printer for this procedure).

1. Unwind approximately 36” (914 mm) of backing from the rewind

spindle. Cut it off at the spindle.

2. Pull out the hook. Slide the backing material off of the rewind spindle

and discard.

3. Wind the media around the rewind spindle once or twice and reinstall

the hook. Continue winding to remove any slack in the media.

38 Zebra XiIII-Series User’s Guide

Page 45

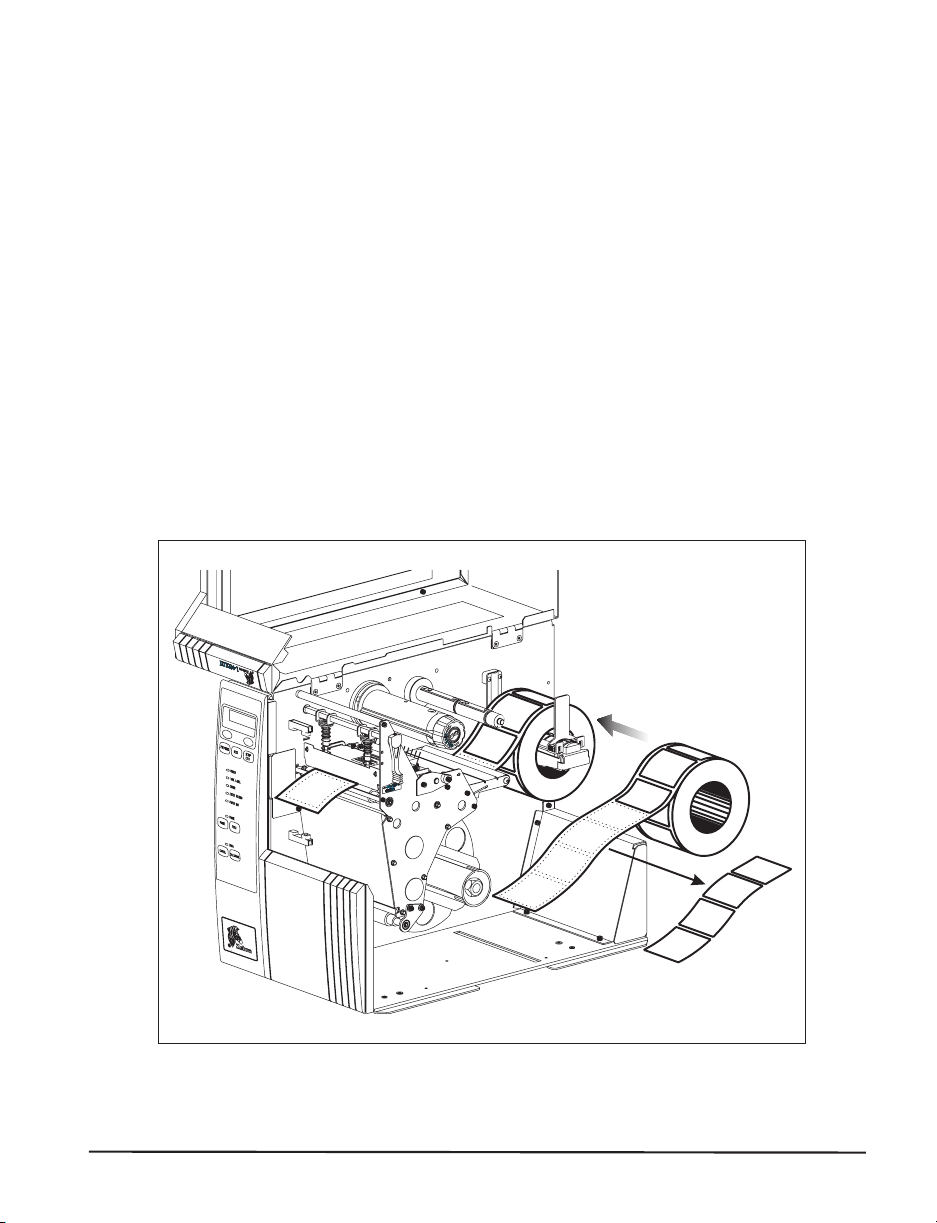

RibbonLoading

Toloadribbon,refertoFigure23(forthe90XiIII,96XiIII,and140XiIII)

andFigure24(forthe170XiIIIand220XiIII)andfollowtheprocedure

below.

NOTE:Useribbonthatisatleastaswideasthemedia.Thesmooth

backingoftheribbonprotectstheprintheadfromwearand

prematurefailureduetoexcessiveabrasion.(Fordirectthermal

printmode,ribbonisnotusedandshould

notbeloadedintheprinter.)

1.Alignthesegmentsoftheribbonsupplyspindle.

2.Placetheribbonrollontheribbonsupplyspindle.

NOTE:Makesurethatthecoreispushedupagainstthestopontheribbon

supplyspindleandthattheribbonisalignedsquarelywithitscore.

Ifthisisnotdone,theribbonmaynotcovertheprintheadentirely

ontheinside,exposingprintelementstopotentiallydamaging

contactwiththemedia.

3.Opentheprinthead.

4.(Optional)Tomakeribbonloadingand

unloadingeasier,makealeaderforyour

ribbonrollifitdoesn’talreadyhaveone.

Ribbon

Label

Stripofmedia

6-12”long

5.Tearoffastripofmedia(labelsand

backing)about6-12”(152-305mm)long

fromtheroll.Peeloffalabelfromthis

strip.Applyhalfofthislabeltotheend

ofthestripandtheotherhalftotheend

oftheribbon.Thisactsasaribbon

leader.

6.Threadtheribbon(withleader,ifused)asshownwithoutcreasingor

wrinklingit.

ZebraXiIII-SeriesUser’sGuide 39

Page 46

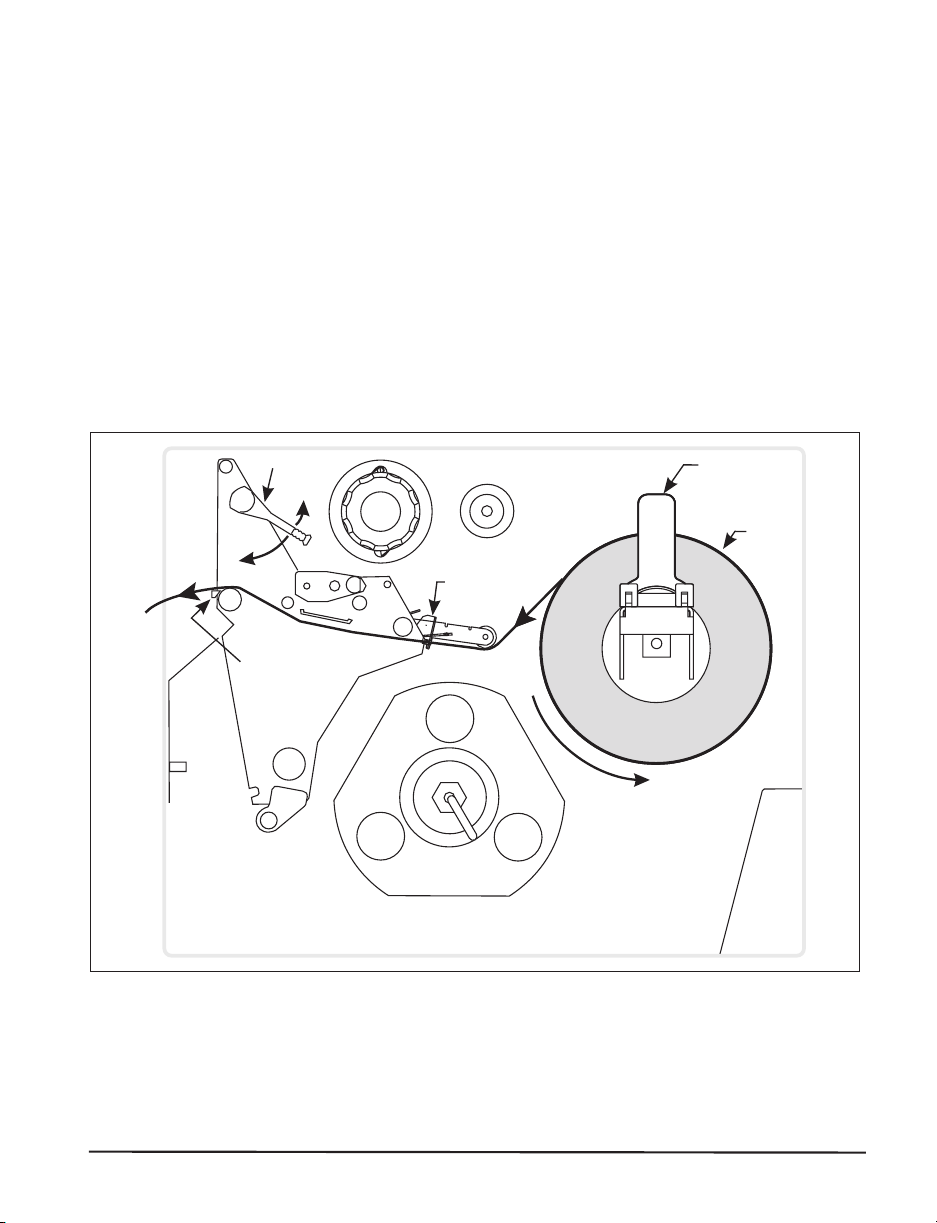

7.Beforewrappingtheribbonaroundtheribbontake-upspindle,ensurethat

thearrowontheknobalignswiththeindentednotch(seeFigure25

inset).

8.Placetheribbon(withleader,ifused)aroundtheribbontake-upspindle

andwindcounterclockwiseforseveralturns.

9.Closetheprinthead.

Closed

Printhead

Closed

Printhead

lever

Open

lever

Open

Ribbon

take-up

spindle

Figure23

Ribbon

take-up

spindle

Ribbon

supply

spindle

Ribbon

supply

spindle

Figure24

40 ZebraXiIII-SeriesUser’sGuide

Page 47

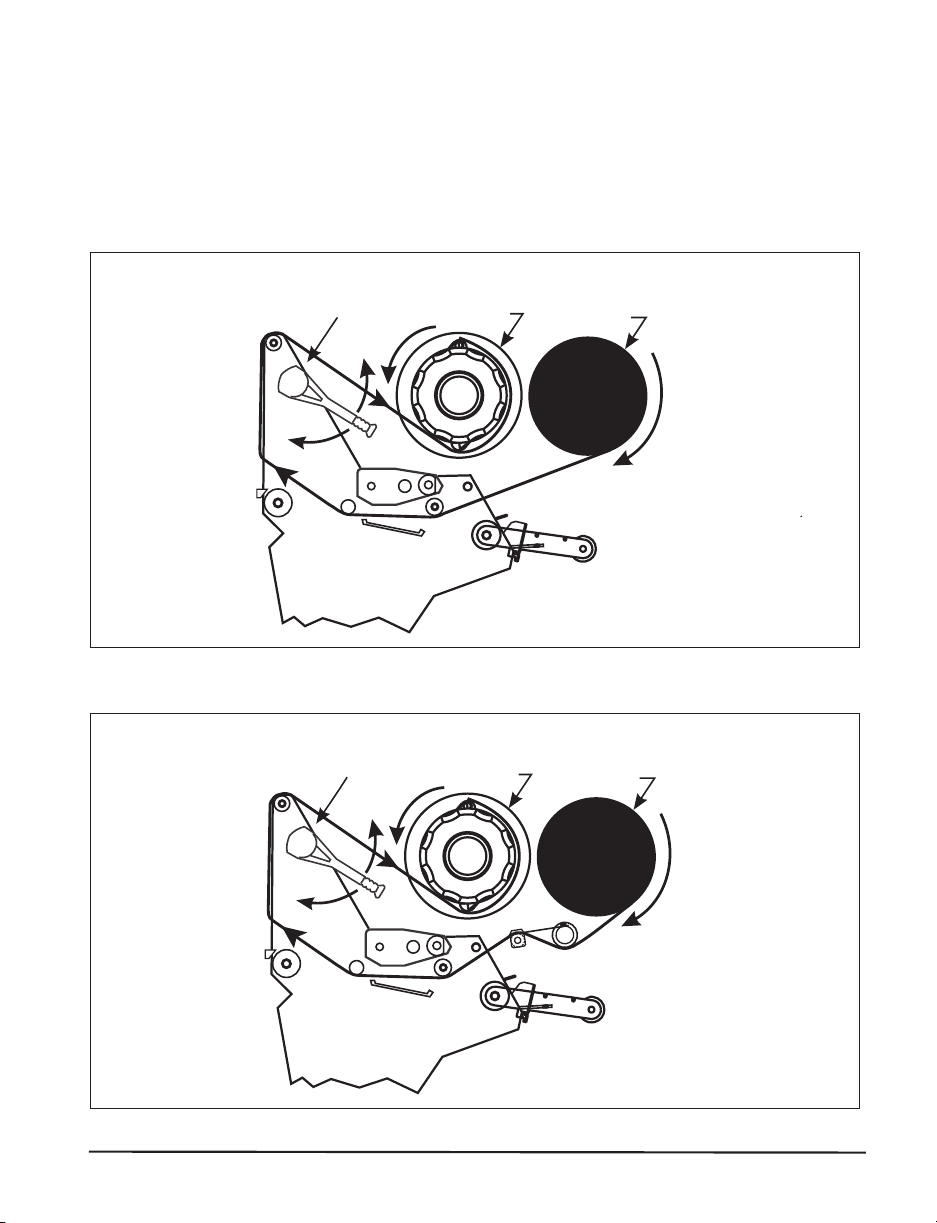

RibbonRemoval

1.Breaktheribbonasclosetotheribbontake-upspindleaspossible.

2.RefertoFigure25.Whileholdingtheribbontake-upspindle,turnthe

knob(1)clockwiseuntilitstops.Thiswillcausetheribbonreleasebars

topivotdown(2),easingthespindle’s“grip”onthewoundribbon.

3.Slidetheribbonoffoftheribbontake-upspindle.Oncethespent

ribbonhasbeenremoved,ensurethatthearrowontheknobalignswith

theindentednotchintheribbontake-upspindle(seeFigure25inset).

4.Removetheemptycorefromtheribbonsupplyspindle.

5.Followtheribbonloadingprocedureonpage39toloadthenewribbon.

2

1

Figure25

ZebraXiIII-SeriesUser’sGuide 41

Page 48

42 Zebra XiIII-Series User’s Guide

Page 49

Configuration

Afteryouhaveinstalledthemediaandribbonandthepower-onselftest

(POST)iscomplete,thefrontpaneldisplaywillshow“PRINTERREADY.”

(IftheprinterfailsitsPOST,refertopage81.)Youmaynowsetprinter

parametersforyourapplicationusingthefrontpaneldisplayandthefivekeys

directlybelowit.

NOTE:PrintersthatareoperatingonanIPnetworkcanbequickly

configuredviaZebraNet

PrintServerIIrequired).Forinformation,refertoZebraNet

Networking:PrintServerIIInstallationandUser’sGuide.

Ifitbecomesnecessarytorestoretheinitialprinterdefaults,see“FEED

KeyandPAUSEKeySelfTest”onpage85.

NOTE:Unlessotherwisenoted,allparametersarelistedintheorderthey

aredisplayed,startingwith“DARKNESS.”

EnteringtheSetupMode

Toentertheprogrammingmode,presstheSETUP/EXITkey.Presseither

theNEXT/SAVEkeyorPREVIOUSkeytoscrolltotheparameteryou

wishtoset.

NOTE:YoumayalsopressandholdtheNEXT/SAVEandPREVIOUS

keystoquicklyadvancethroughtheconfigurationparameters.

Parametersinthissectionareshownintheorderdisplayedwhenpressing

theNEXT/SAVEkey.Throughoutthisprocess,presstheNEXT/SAVE

keytocontinuetothenextparameter,orpressthePREVIOUSkeytoreturn

tothepreviousparameterinthecycle.

WebView(optionalZebraNet

Anasterisk(*)intheupperleft-handcornerofthedisplayindicatesthatthe

valuedisplayedisdifferentthanthecurrentlystoredvalue.

ZebraXiIII-SeriesUser’sGuide 43

Page 50

Changing Password-Protected Parameters

Certain parameters are password-protected by factory default.

CAUTION: Do not change password-protected parameters unless

you are sure you know what you are doing! If they are

set incorrectly, these parameters could cause the

printer to function in an unpredictable way.

The first attempt to change one of these parameters (pressing one of the

BLACK OVAL keys) will require you to enter a four-digit password. This

is done via the “ENTER PASSWORD” display. The LEFT BLACK

OVAL key changes the selected digit position. The RIGHT BLACK

OVAL key increases the selected digit value. After entering the password,

press the NEXT/SAVE key. The parameter you wish to change will be

displayed. If the password was entered correctly, you can now change the

value.

The default password value is 1234. The password can be changed using

the ^KP (Define Password) ZPL II instruction or through ZebraNet

WebView (optional ZebraNet PrintServer II required).

NOTE: Once the password has been entered correctly, it will not have to

be entered again unless you leave and re-enter the programming

mode using the SETUP/EXIT key.

NOTE: You can disable the password protection feature so that it no

longer prompts you for a password by setting the password to

ØØØØ via the ^KPØ ZPL/ZPL II command. To re-enable the

password-protection feature, send the ZPL/ZPL II command ^KPx,

where “x” can be any number, one to four digits in length,

except Ø.

44 Zebra XiIII-Series User’s Guide

Page 51

Leaving the Setup Mode

You can leave the program mode at any time by pressing the SETUP/EXIT

key. The “SAVE CHANGES” display will appear. There are five choices,

described below. Pressing the LEFT or RIGHT BLACK OVAL key

displays other choices and pressing the NEXT/SAVE key selects the

displayed choice.

n

PERMANENT - Permanently saves the changes. Values are stored in

the printer even when power is turned off.

n

TEMPORARY - Saves the changes until changed again or until power is

turned off.

n

CANCEL - Cancels all changes since pressing the SETUP/EXIT key

except the darkness and tear-off settings (if they were changed).

n

LOAD DEFAULTS - Loads factory defaults. The factory defaults are

shown on the following pages.

NOTE: Loading factory defaults will require printer calibration.

n

LOAD LAST SAVE - Loads values from the last permanent save.

Zebra XiIII-Series User’s Guide 45

Page 52

ConfigurationandCalibrationSequence

Press DisplayShows Action/Explanation

---- PRINTERREADY Normalprinteroperation.

SettingPrintParameters

AdjustingPrintDarknessPresstheRIGHTBLACKOVALkeyto

increasedarkness.PresstheLEFTBLACKOVALkeytodecrease

darkness.

Default:+10

Range:0to+30

Darknesssettingsaredependentuponavarietyoffactors

includingribbontype,media,andtheconditionoftheprinthead.

Youmayadjustthedarknessforconsistenthigh-qualityprinting.

Ifprintingistoolight,oriftherearevoidsinprintedareas,you

DARKNESS

TEAROFF

PRINTMODE

shouldincreasethedarkness.Ifprintingistoodark,orifthereis

spreadingorbleedingofprintedareas,youshoulddecreasethe

darkness.

TheFEEDkeyselftestonpage84canalsobeusedtodetermine

thebestdarknesssetting.Sincethedarknesssettingtakeseffect

immediately,youcanseetheresultsonlabelsthatarecurrently

printing.

CAUTION:Setthedarknesstothelowestsettingthatprovides

goodprintquality.Darknesssettoohighmaycause

inksmearingand/oritmayburnthroughtheribbon.

Darknesssettingsalsomaybechangedbythedriverorsoftware

settings.

AdjustingtheTear-OffPositionPresstheRIGHTBLACKOVAL

keytoincreasethevalue,presstheLEFTBLACKOVALkeyto

decreasethevalue.Eachpressofthekeyadjuststhetear-off

positionbyfourdotrows.

Default:+0

Range:-120to+120

Thisparameterestablishesthepositionofthemediaoverthe

tear-off/peel-offbarafterprinting.Thelabelandbackingcanbe

tornofforcutbetweenlabels.

SelectingPrintModePresstheRIGHTorLEFTBLACKOVALkey

todisplayotherchoices.

Default:Tear-off

Selections:Tear-off,peel-off,cutter,rewind,applicator*

Printmodesettingstelltheprinterthemethodofmediadelivery

thatyouwishtouse.Besuretoselectaprintmodethatyour

hardwareconfigurationsupportssincesomeselectionsdisplayed

areforoptionalprinterfeatures.

*Optionrequired

46 ZebraXiIII-SeriesUser’sGuide

Page 53

Press Display Shows Action/Explanation

Setting Media Type Press the RIGHT or LEFT BLACK OVAL key

to display other choices.

Default: Continuous

Selections: Continuous, non-continuous

MEDIA TYPE

SENSOR TYPE

PRINT METHOD

This parameter tells the printer the type of media you are using.

Selecting continuous media requires that you include a label

length instruction in your label format (^LLxxxx if you are using

ZPL or ZPL II).

When non-continuous media is selected, the printer feeds media

to calculate label length (the distance between two detections of

the inter-label gap, webbing, or alignment notch or hole).

Setting the Sensor Type Press the RIGHT or LEFT BLACK OVAL

key to display other choices.

Default: Web

Selections: Web, mark

This parameter tells the printer whether you are using media with

a web (gap/space between labels, notch, or hole) to indicate the

separations between labels or if you are using media with a black

mark printed on the back. If your media does not have black

marks on the back, leave your printer at the default (web).

Selecting Print Method Press the RIGHT BLACK OVAL key for

the next value; press the LEFT BLACK OVAL key for the previous

value.

Default: Thermal transfer

Selections: Thermal transfer, direct thermal

The print method parameter tells the printer the method of

printing you wish to use: direct thermal (no ribbon) or thermal

transfer (using thermal transfer media and ribbon).

NOTE: Selecting direct thermal when using thermal transfer

media and ribbon creates a warning condition, but

printing will continue.

Zebra XiIII-Series User’s Guide 47

Page 54

Press DisplayShows Action/Explanation

SettingPrintWidthPresstheRIGHTBLACKOVALkeyto

increasethevalue,presstheLEFTBLACKOVALkeytodecrease

thevalue.Tochangetheunitofmeasurement,presstheLEFT

BLACKOVALkeyuntiltheunitofmeasurementisactive,then

presstheRIGHTBLACKOVALkeytotoggletoadifferentunitof

PRINTWIDTH

MAXIMUM

LENGTH

measure(inches,mm,ordots).

Default:,Range:Thedefaultandrangeofacceptablevaluesvary

dependingonwhatprinteryouhave.Referto“Printing

Specifications”onpage90forfurtherinformationaboutthe

rangesavailableforyourmodel.

Printwidthdeterminestheprintableareaacrossthewidthofthe

label.

SettingMaximumLengthPresstheLEFTBLACKOVALkeyto

decreasethevalue,presstheRIGHTBLACKOVALkeyto

increasethevalue.

Default:,Range:Thedefaultandrangeofacceptablevaluesvary

dependingonyourprinter’sconfiguration.Valuesareadjustable

in1”(25.4mm)increments.

Maximumlengthisusedinconjunctionwiththecalibration

procedure.Thevalueofthissettingdeterminesthemaximum

labellengththatwillbeusedduringthemediaportionofthe

calibrationprocess.Onlyafewlabelsarerequiredtosetmedia

sensors.Alwayssetthevaluethatisclosestto,butnotlower

than,thelengthofthelabelyouareusing.Forexample,ifthe

lengthofthelabelis14.5inches(368mm),settheparameterfor

15.0inches(381mm).

48 ZebraXiIII-SeriesUser’sGuide

Page 55

Listing Printer Information

Press Display Shows Action/Explanation

List Fonts Press the RIGHT BLACK OVAL key to print a label

listing all of the available fonts.

LIST FONTS

LIST BAR CODES

LIST IMAGES

LIST FORMATS

LIST SETUP

LIST ALL

This selection is used to print a label that lists all of the fonts

currently available in the printer, including standard printer fonts

plus any optional fonts. Fonts may be stored in RAM, FLASH

memory, font EPROMs, or font cards.

List Bar Codes Press the RIGHT BLACK OVAL key to print a label

listing all of the available bar codes.

This selection is used to print a label that lists all of the bar codes

currently available in the printer.

List Images Press the RIGHT BLACK OVAL key to print a label

listing all of the available images.

This selection is used to print a label that lists all of the images

currently stored in the printer’s RAM, FLASH memory, optional

EPROM, or optional memory card.

List Formats Press the RIGHT BLACK OVAL key to print a label

listing all of the available formats.

This selection is used to print a label that lists all of the formats

currently stored in the printer’s RAM, FLASH memory, optional

EPROM, or optional memory card.

List Setup Press the RIGHT BLACK OVAL key to print a label

listing the current printer configuration.

This selection is used to print a label that lists the current printer

configuration information. (Same as CANCEL key self test.)

List All Press the RIGHT BLACK OVAL key to print a label listing

all of the available fonts, bar codes, images, formats, and the

current printer configuration.

This selection is used to print a label that lists the five previous

selections, as described.

Zebra XiIII-Series User’s Guide 49

Page 56

Press Display Shows Action/Explanation

Initialize Memory Card

CAUTION: Perform this operation only when it is necessary to

erase all previously stored information from the optional memory

card. Press the NEXT//SAVE key to bypass this function.

1. Press the RIGHT BLACK OVAL key to select “YES.”

If your printer is set to require a password, you will

now be prompted to enter the password. Enter the

password and then press the NEXT/SAVE key.

2. The display will ask “INITIALIZE CARD?”. Press the RIGHT

BLACK OVAL key “YES.”

3. The front panel LCD will ask “ARE YOU SURE?”.

INITIALIZE CARD

INIT FLASH MEM

4. Press the RIGHT BLACK OVAL key “YES” to begin initialization.

or

Press the LEFT BLACK OVAL key “NO” to cancel the request

and return to the “INITIALIZE CARD” prompt.

5. Press the SETUP/EXIT key followed by the NEXT/SAVE key.

If initialization is still in process, the front panel display

will flash back and forth between the two phrases

“CHECKING B: MEMORY” and “PRINTER IDLE.”

When initialization is complete, the printer will

automatically exit the configuration mode and the

front panel will display “PRINTER READY.”

NOTE: Depending on the amount of memory in the memory

card, initialization may take up to five minutes to

complete.

Initialize Flash Memory

CAUTION: Perform this operation only when it is necessary to

erase all previously stored information from the FLASH memory.

Press the NEXT//SAVE key to bypass this function.

1. Press the RIGHT BLACK OVAL key to select “YES.”

If your printer is set to require a password, you will

now be prompted to enter the password. Enter the

password and then press the NEXT/SAVE key.

2. The display will ask “INITIALIZE FLASH?”. Press the RIGHT

BLACK OVAL key “YES.”

3. The front panel LCD will ask “ARE YOU SURE?”.

4. Press the RIGHT BLACK OVAL key “YES” to begin initialization.

or

Press the LEFT BLACK OVAL key “NO” to cancel the request

and return to the “INITIALIZE FLASH” prompt.

5. Press the SETUP/EXIT key followed by the NEXT/SAVE key.

If initialization is still in process, the front panel display

will flash back and forth between the two phrases

“CHECKING E: MEMORY” and “PRINTER IDLE.”

When initialization is complete, the printer will

automatically exit the configuration mode and the

front panel will display “PRINTER READY.”

NOTE: Depending on the amount of free FLASH memory,

initialization may take up to one minute to complete.

50 Zebra XiIII-Series User’s Guide

Page 57

MediaandRibbonSensorCalibration

NOTE:Beforeyoubeginthisprocedure,makesurethatthemaximumlengthissettoavalue

equaltoorgreaterthanthelengthofthelabelsyouareusing.Ifthemaximumlengthissettoa

lowervalue,thecalibrationprocesswillassumethatcontinuousmediaisintheprinter.See

page48formoreinformation.

Therearetwodifferenttypesofcalibrationthatcanbeperformedbytheprinter:

1)StandardCalibration.PressingtheCALIBRATEkeyontheprinter’sfrontpanelcausesthe

printertofeedmediaandribbonandsetthevaluesitdetectsformedia,mediabackingmaterial

(thespacesbetweenlabels),mediaout,andribbonornoribbon(whichdeterminestheprint

mode—thermaltransferordirectthermal).Thistypeofcalibrationalsooccursaspartofthe

sensorprofileandmediaandribboncalibrationprocedures.

2)MediaandRibbonSensorSensitivityCalibration.Performingthemediaandribbon

calibrationprocedurefirstresetsthesensitivityofthesensorstobetterdetectthemediaand

ribbonyouareusing.Withthesensorsattheirnewsensitivity,theprinterthenperformsthe

standardcalibrationdescribedabove.Changingthetypeofribbonand/ormediamayrequire

resettingthesensitivityofthemediaandribbonsensors.Indicationsthatthesensitivitymay

needtoberesetwouldbeaCHECKRIBBONlightonwiththeribbonproperlyinstalledor

non-continuousmediabeingtreatedascontinuousmedia.

Press DisplayShows Action/Explanation

SensorProfilePressNEXT/SAVEtoskipthisstandardcalibration

procedureandcontinuewiththemediaandribboncalibration

parameterwhichfollows.PresstheRIGHTBLACKOVALkeyto

initiatethisstandardcalibrationprocedureandprintamedia

sensorprofile.

SENSORPROFILE

SeeFigure26.Themediasensorprofilemaybeusedto

troubleshootregistrationproblemsthatmaybecausedwhenthe

mediasensordetectspreprintedareasonthemediaor

experiencesdifficultyindeterminingweblocation.Ifthe

sensitivityofthemediaand/orribbonsensorsMUSTbeadjusted,

usethemediaandribbonsensorsensitivityprocedure.

Figure26

ZebraXiIII-SeriesUser’sGuide 51

Page 58

Press Display Shows Action/Explanation

Media and Ribbon Sensor Sensitivity Press NEXT/SAVE to skip

the calibration procedure and continue with the host port

selection parameters that follow. Press the RIGHT BLACK OVAL

MEDIA AND

RIBBON

CALIBRATE

Media and Ribbon Calibration Procedure

LOAD BACKING

REMOVE RIBBON

CALIBRATING

PLEASE WAIT

---- RELOAD ALL

MEDIA AND

RIBBON

CALIBRATE

key to start the calibration procedure.

This procedure is used to adjust the sensitivity of the media and

ribbon sensors.

NOTE: The procedure must be followed exactly as presented.

All steps must be performed even if only one of the

sensors requires adjustment.

Press the LEFT BLACK OVAL key to cancel the operation, or do

the following:

1) Open the printhead.

2) Remove approximately 8” (203 mm) of labels from the media

roll, enough so that only the backing material is threaded

between the media sensors when the media is loaded.

Press the LEFT BLACK OVAL key to cancel the operation or do

the following:

1) Remove the ribbon (sliding it as far to the right as possible will

have the same effect as removing it).

2) Close the printhead.

The printer automatically adjusts the scale (gain) of the signals it

receives from the media and ribbon sensors based on the

specific media and ribbon combination you are using. On the

sensor profile, this essentially corresponds to moving the graph

up or down to optimize the readings for your application.

When “RELOAD ALL” is displayed:

1) Open the printhead and pull the media forward until a label is

positioned under the media sensor.

2) Move the ribbon back to its proper position.

3) Close the printhead.

Now that the scale has changed, the printer performs a

calibration equivalent to pressing the CALIBRATE key. During

this process, the printer checks the readings for the media and

ribbon based on the new scale you have established, determines

the label length, and determines whether you are in direct

thermal or thermal transfer print mode. The process is now

complete! To see the new readings on the new scale, print a

sensor profile.

52 Zebra XiIII-Series User’s Guide

Page 59

Setting Communication Parameters

Communication parameters must be set correctly for the printer to communicate with the host.

These parameters make sure that the printer and host are “speaking the same language.” All

communications parameters are password protected.

Press Display Shows Action/Explanation

Setting Parallel Communications Press the RIGHT or LEFT

BLACK OVAL key to display other choices.

PARALLEL

COMM

SERIAL COMM

BAUD

DATA BITS

Default: Parallel

Selections: Parallel, twinax/coax

Select the communications port that matches the one being used

by the host computer.

Setting Serial Communications Press the RIGHT or LEFT

BLACK OVAL key to display other choices.

Default: RS232

Selections: RS232, RS422/485, RS485 multidrop

Select the communications port that matches the one being used

by the host computer.

Setting Baud Press the RIGHT or LEFT BLACK OVAL key to

display other choices.

Default: 9600

Selections: 110, 300, 600, 1200, 2400, 4800, 9600, 14400, 19200,

28800, 38400, 57600

The baud setting of the printer must match the baud setting of

the host for accurate communications to take place. Select the

value that matches the one being used by the host.

Setting Data Bits Press the RIGHT or LEFT BLACK OVAL key

to display other choices.

Default: 7-bits

Selections: 7-bits, 8-bits

The data bits of the printer must match the data bits of the host

for accurate communications to take place. Set the data bits to

match the setting being used by the host.

NOTE: Must be set to 8 data bits to use Code Page 850.

Zebra XiIII-Series User’s Guide 53

Page 60

Press Display Shows Action/Explanation

Setting Parity Press the RIGHT or LEFT BLACK OVAL key to

display other choices.

Default: Even

PARITY

STOP BITS

HOST

HANDSHAKE

PROTOCOL

Selections: Even, odd, none

The parity of the printer must match the parity of the host for

accurate communications to take place. Select the parity that

matches the one being used by the host.

Setting Stop Bits Press the RIGHT or LEFT BLACK OVAL key

to display other choices.

Default: 1 stop bit

Selections: 1 stop bit, 2 stop bits

The stop bits of the printer must match the stop bits of the host

for accurate communications to take place. Select the stop bits

that match the one being used by the host.

Setting Host Handshake Press the RIGHT or LEFT BLACK

OVAL key to display other choices.

Default: XON/XOFF

Selections: XON/XOFF, DTR/DSR

The handshake protocol of the printer must match the handshake

protocol of the host for communications to take place. Select the

handshake protocol that matches the one being used by the host.

Setting Protocol Press the RIGHT or LEFT BLACK OVAL key

to display other choices.

Default: None

Selections: None, Zebra, ACK/NACK

Protocol is a type of error checking system. Depending on the

selection, an indicator may be sent from the printer to the host

signifying that data has been received. Select the protocol that is

requested by the host. Further details on protocol can be found

in the ZPL II Programming Reference Volumes I and II.

NOTE: Zebra is the same as ACK/NACK except that with Zebra

the response messages are sequenced.

NOTE: If Zebra is selected, printer must use “DTR/DSR” host

handshake protocol.

54 Zebra XiIII-Series User’s Guide

Page 61

Press DisplayShows Action/Explanation

SettingNetworkID PresstheLEFTBLACKOVALkeyto

movetothenextdigitposition,presstheRIGHTBLACKOVAL

keytoincreasethevalueofthedigit.

Default:000

NETWORKID

COMMUNICATIONS

Range:000-999

NetworkIDisusedtoassignauniquenumbertoaprinterusedin

anRS-422/RS-485network.Thisgivesthehostthemeansto

addressaspecificprinter.Iftheprinterisusedinanetwork,you

mustselectanetworkIDnumber.ThisdoesnotaffectTCP/IPor

IPXnetworks.

SettingCommunicationsMode PresstheRIGHTorLEFT

BLACKOVALkeytodisplayotherchoices.

Default:Normalmode

Selections:Normalmode,diagnostics

Thecommunicationdiagnosticsmodeisatroubleshootingtool

forcheckingtheinterconnectionbetweentheprinterandthe

host.When“diagnostics”isselected,alldatasentfromthehost

totheprinterwillbeprintedasstraightASCIIhexcharacters.The

printerprintsallcharactersreceivedincludingcontrolcodes,like

CR(carriagereturn).AsampleprintoutisshowninFigure36on

page85.

NOTESondiagnosticprintouts:

•AnFEindicatesaframingerror.

•AnOEindicatesanoverrunerror.

•APEindicatesaparityerror.

•AnNEindicatesnoise.

Foranyerrors,checkthatyourcommunicationparametersare

correct.Settheprintwidthequaltoorlessthanthelabelwidth

usedforthetest.Seepage48formoreinformation.

ZebraXiIII-SeriesUser’sGuide 55

Page 62

Selecting Prefix and Delimiter Characters

Prefix and delimiter characters are 2-digit hex values used within the ZPL/ZPL II formats sent to

the printer. The printer uses the last prefix and delimiter characters sent to it, whether from a

ZPL II instruction or from the front panel.

NOTE: DO NOT use the same hex value for the control, format, and delimiter character. The

printer needs to see different characters to function properly.

Press Display Shows Action/Explanation

Control Prefix Character Press the LEFT BLACK OVAL key to

move to the next digit position, press the RIGHT BLACK OVAL

key to increase the value of the digit.

CONTROL PREFIX

FORMAT

PREFIX

DELIMITER CHAR

Default: 7E (tilde - displayed as a black square)

Range: 00-FF

The printer looks for this 2-digit hex character to indicate the start

of a ZPL/ZPL II control instruction.

Format Prefix Character Press the LEFT BLACK OVAL key to

move to the next digit position, press the RIGHT BLACK OVAL

key to increase the value of the digit.

Default: 5E (caret)

Range: 00-FF

The printer looks for this 2-digit hex character to indicate the start

of a ZPL/ZPL II format instruction.

Delimiter Character Press the LEFT BLACK OVAL key to

move to the next digit position, press the RIGHT BLACK OVAL

key to increase the value of the digit.

Default: 2C (comma)

Range: 00-FF

The delimiter character is a 2-digit hex value used as a parameter

place marker in ZPL/ZPL II format instructions. Refer to the ZPL II

Programming Reference Volumes I and II for more information.

56 Zebra XiIII-Series User’s Guide

Page 63

Selecting ZPL Mode

Press Display Shows Action/Explanation

Selecting ZPL Mode Press the RIGHT or LEFT BLACK OVAL

key to display other choices.

Default: ZPL II

Selections: ZPL II, ZPL

ZPL MODE

Power-Up and Head Close Parameters

MEDIA POWER

UP

HEAD CLOSE

The printer will remain in the selected mode until it is changed by

this front panel instruction or by using a ZPL/ZPL II command. The

printer accepts label formats written in either ZPL or ZPL II. This

eliminates the need to rewrite any ZPL formats you already have.

Refer to the ZPL II Programming Reference Volumes I and II for

more information on the differences between ZPL and ZPL II .

Media Power-Up Press the RIGHT or LEFT BLACK OVAL key

to display other choices.

Default: Feed

Selections: Feed, calibration, length, and no motion

This parameter establishes the action of the media when the

printer is turned on.

• Calibration: Recalibrates the media and ribbon sensors.

• Feed: Feeds the label to the first web.

• Length: Determines the length of the label.

• No Motion: Media does not move.

Head Close Press the RIGHT or LEFT BLACK OVAL key to

display other choices.

Default: Feed

Selections: Feed, calibration, length, no motion

Determines the action of the media after the printhead has been

opened and then closed.

• Calibration: Recalibrates the media and ribbon sensors.

• Feed: Feeds the label to the first web.

• Length: Determines the length of the label.

• No Motion: Media does not move.

Zebra XiIII-Series User’s Guide 57

Page 64

Label Positioning Parameters

Press Display Shows Action/Explanation

Backfeed Sequence Press the RIGHT or LEFT BLACK OVAL

key to display other choices.

Default: Default (90%)

BACKFEED

LABEL TOP

LEFT POSITION

Selections: Default, after, before, 10%, 20%, 30%, 40%, 50%,

This parameter establishes when and how much label backfeed

occurs after a label is removed or cut in the peel-off, cutter, and

applicator modes. It has no effect in rewind or tear-off modes.

This parameter setting can be superseded by the ~JS instruction

when received as part of a label format (refer to the ZPL II

Programming Reference Volumes I and II).

NOTE: The difference between the value entered and 100%

Adjusting Label Top Position Press the RIGHT BLACK OVAL key

to increase the value, press the LEFT BLACK OVAL key to

decrease the value. The displayed value represents dots.

Default: +0

Range: -120 to +120 dot rows

The label top position adjusts the print position vertically on the

label. Positive numbers adjust the label top position further down

the label (away from the printhead), negative numbers adjust the

position up the label (toward the printhead).

Adjusting Left Position Press the LEFT BLACK OVAL key to

move to the next position, press the RIGHT BLACK OVAL key to

change between + and - and to increase the value of the digit.

The displayed value represents dots.

Default: 0000

Range: -9999 to +9999

NOTE: For a negative value, enter the value before changing to

This parameter establishes how far from the left edge of a label

the format will begin to print by adjusting horizontal positioning

on the label. Positive numbers adjust the printing to the left by

the number of dots selected, negative numbers shift printing to

the right.

60%, 70%, 80%, off

establishes how much backfeed occurs before the next

label is printed. For example, a value of 40 means that

40% of the backfeed takes place after the label is

removed or cut. The remaining 60% takes place before

the next label is printed. A value of “before” means that

all backfeed will take place before the next label is

printed.

the minus sign.

58 Zebra XiIII-Series User’s Guide

Page 65

Press Display Shows Action/Explanation

Setting the Head Test Count Press the LEFT BLACK OVAL

key to move to the next digit position, press the RIGHT BLACK

OVAL key to change the value of the digit.

HEAD TEST

COUNT

HEAD RESISTOR

VERIFIER PORT

Default: 0000 (disables the test)

Range: 0000 to 9999

The printer periodically performs a test of the printhead

functionality, called a “printhead test” or “head test.” This

parameter establishes how many labels are printed between

these internal tests.

Setting the Head Resistor Value Press the LEFT BLACK

OVAL key to move to the next digit position, press the RIGHT

BLACK OVAL key to increase the value of the digit.

CAUTION: This parameter should only be changed by qualified

personnel!

Initial Value: Factory-set to match the printhead shipped with

your printer.

Default Value: 0500

Range: 0500 to 1175

This value has been pre-set at the factory to match the resistance

value of the printhead. It will not need to be changed unless the

printhead is replaced.

CAUTION: DO NOT set the value higher than that shown on the

printhead. Setting a higher value may damage the

printhead!

Before replacing a printhead, look on the bottom of the printhead

element for the label that shows the resistance value (ohm value).

Setting the Verifier Port Press the RIGHT or LEFT BLACK

OVAL key to display other choices.

Default: Off

Selections: Off, 1 VER-RPRNT, 2 VER-THRUPUT

The auxiliary port is used to determine how the printer will react

to the Zebra on-line verifier. There are currently three operating

conditions for this port:

• Off: The verifier port is off.

• 1 VER-RPRNT ERR: Label reprinted if verifier detects an error.

If a bar code is near the upper edge of the label, the label will be

fed out far enough to be verified and then backfed to allow the

next label to be printed and verified.

• 2 VER-THRUPUT: Allows greatest throughput but may not

indicate a verification error immediately upon detection. May

print from one to three labels before an error is recognized and

printing stops.

For more information on the operation of the optional verifier,

refer to the documentation provided with that option.

Zebra XiIII-Series User’s Guide 59

Page 66

Press Display Shows Action/Explanation

Setting the Applicator Port Press the RIGHT or LEFT BLACK

OVAL key to display other choices.

Default: Off

Selections: Off, mode 1, mode 2, mode 3, mode 4

Determines the action of the verifier port.

• Off: The applicator port is off.

APPLICATOR

PORT

WEB S.

MEDIA S.

RIBBON S.

• Mode 1: Asserts the ~END_PRINT signal low while the printer

is moving the label forward.

• Mode 2: Asserts the ~END_PRINT signal high while the printer

is moving the label forward.

• Mode 3: Asserts the ~END_PRINT signal low for 20

milliseconds when a label has been completed and positioned.

Not asserted during continuous printing modes.

• Mode 4: Asserts the ~END_PRINT signal high for 20

milliseconds when a label has been completed and positioned.

Not asserted during continuous printing modes.

MARK S.

MARK MED S.

MEDIA LED

RIBBON LED

MARK LED

These parameters are automatically set during the calibration

procedure. They should only be changed by a qualified service

technician. Refer to the maintenance manual for more

information on these parameters.

Press the NEXT/SAVE key repeatedly to skip these parameters.

60 Zebra XiIII-Series User’s Guide

Page 67

Press Display Shows Action/Explanation

LCD Display Adjustment Press the LEFT BLACK OVAL key to

decrease the value (reduce brightness), press the RIGHT BLACK

LCD ADJUST

FORMAT

CONVERT

IDLE DISPLAY*

RTC DATE*

RTC TIME*

OVAL key to increase the value (increase brightness).

Range: 00 to 19

This parameter allows you to adjust the brightness of your

display if your display is difficult to read.

Format Convert Press the RIGHT or LEFT BLACK OVAL key to

display other choices.

Default: None

Selections: None, 150 → 300, 150 → 600, 200 → 600, 300 → 600

Selects the bitmap scaling factor. The first number is the original

dots per inch (d.p.i.) value; the second, the d.p.i. to which you

would like to scale.

Idle Display Press the RIGHT or LEFT BLACK OVAL key to

display other choices.

Default: Firmware version

Selections: mm/dd/yy (24 hour), mm/dd/yy (12 hour),

dd/mm/yy (24 hour), dd/mm/yy (12 hour)

This parameter selects the LCD display options for the real time

clock (if installed).

NOTE: If the default value is not selected, pressing either BLACK

OVAL key will briefly display the firmware version of the

printer.

RTC Date Press the LEFT BLACK OVAL key to move to the

next digit position, press the RIGHT BLACK OVAL key to increase