Page 1

User’s Guide

For Models S-300 and S-500

Zebra Technologies Corporation

333 Corporate Woods Parkway

Vernon Hills, Illinois 60061-3109

Phone Number: (847) 634-6700

Telefax Number: (847) 913-8766

Customer order # 44870L Manufacturer part # 44870LB Rev. 2

Zebra Technologies Europe Limited

Zebra House, The Valley Centre

Gordon Road, High Wycombe

Buckinghamshire HP13 6EQ England

Phone Number: +44 (0) 1494 472872

Telefax Number: +44 (0) 1494 450103

Page 2

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation. It is

intended solely for the information and use of parties operating and maintaining the

equipment described herein. Such proprietary information may not be used, reproduced, or

disclosed to any other parties for any other purpose without the expressed written permission of Zebra Technologies Corporation.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies Corporation. All

specifications and signs are subject to change without notice.

FCC Compliance Statement

Note: This equipment has been tested and found to comply with the limits for a Class A

digital Device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

In order to insure compliance, this printer must be used with a Shielded Power Cord and

Shielded Communication Cables.

“The user is cautioned that any changes or modifications not expressly approved by Zebra

Technologies Corporation could void the user’s authority to operate the equipment.”

Canadian DOC Compliance Statement

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus as set out in the radio interference regulations of the Canadian Department

of Communications.

Liability Disclaimer

Zebra Technologies Corporation takes steps to assure that its published Engineering specifications and Manuals are correct; however, errors do occur. Zebra Technologies Corporation has

been advised of the possibility of such damages. Because some states do not allow the exclusion

or limitation of liability for consequential or incidental damages, the above limitation may not

apply to you.

Copyrights

This copyrighted manual and the label printer described herein are owned by Zebra

Technologies Corporation. All rights are reserved. Unauthorized reproduction of this manual or the software in the label printer may result in imprisonment of up to one year and

fines of up to $10,000 (17 U.S.C.506). Copyright violators may be subject to civil liability.

Centronics

IBM is a registered trademark of IBM Corporation

Zebra®, Stripe®, ZPL®, and ZPL II® are registered trademarks of Zebra Technologies

Corporation

© Zebra Technologies Corporation

is a registered trademark of Genicom Corporation

Page 3

Warranty Information

1. Printer Warranty

ZEBRA® printers, excluding thermal printheads which are warranted separately below, are warranted against

defects in material or workmanship for six (6) months from the date of original shipment by ZEBRA Technologies Corporation. This warranty does not cover normal wear and tear and shall be null and void if the equipment

is modified, improperly installed or used, damaged by accident or neglect, or in the event any parts are improperly

installed or replaced by the user.

Since printhead wear is part of normal operations, the original printhead and replacement printheads are

covered by a limited warranty of six (6) months from the date of original shipment by ZEBRA Technologies. To qualify for this warranty, the printer must be returned to the factory or other authorized service

center. Although the user is not required to purchase ZEBRA brand supplies (media and/or ribbons), to the

extent it is determined that the use of other supplies (media and/or ribbons) shall have caused any defect

in the thermal printhead for which a warranty claim is made, the user shall be responsible for ZEBRA

Technologies’ customary charges for labor and materials to repair such defect. To the extent that it is

determined that failure to follow the preventive maintenance schedule and procedures listed in the

Operator’s Guide shall have caused any defect in the thermal printhead for which a warranty claim is made,

this limited warranty shall be void.

ZEBRA TECHNOLOGIES’ SOLE OBLIGATION UNDER THIS WARRANTY SHALL BE TO

FURNISH PARTS AND LABOR FOR THE REPAIR OR REPLACEMENT OF PRODUCTS

FOUND TO BE DEFECTIVE IN MATERIAL OR WORKMANSHIP DURING THE

WARRANTY PERIOD.

As a condition of this warranty, the user must: (a) obtain a ZEBRA Return Authorization for the printer, or

subassembly(s); (b) ship the printer or subassembly(s), transportation prepaid to the authorized service

location; and (c) include with the Product or subassembly(s) a written description of the claimed defect. Unless

ZEBRA Technologies authorizes return of the entire Product, the user shall return only the subassembly(s).

Products returned shall be packaged in the original packing and shipping container or comparable container.

In the event equipment is not so packaged or if shipping damage is evident, it will not be accepted for service

under warranty. Surface transportation charges for the return of the printer to the customer shall be paid by

ZEBRA Technologies within the 48 contiguous states and the District of Columbia. Customer shall pay

shipping costs, customs clearance, and other related charges outside the designated area. If ZEBRA

Technologies determines that the Product returned to it for warranty service or replacement is not

defective as herein defined, BUYER shall pay all costs of handling and transportation.

2. Supplies Warranty

ZEBRA supplies are warranted to be free from defects in materials or workmanship for a period of either

the stated material shelf life or 6 months from date of shipment, whichever occurs first, provided that the

BUYER has complied with ZEBRA Technologies’ guidelines on storage, handling, and usage of the

labeling supplies in ZEBRA printers. ZEBRA Technologies does not warrant the performance of ZEBRA

labeling supplies on non-ZEBRA printers.

Any supplies product shown to the satisfaction of ZEBRA Technologies, within the time provided, to

be so defective shall be replaced without charge, or ZEBRA Technologies may issue a credit in such an

amount as it deems reasonable.

3. Warranty Exclusions and Conditions

The above warranties are in lieu of all other warranties, expressed or implied, oral or written, statutory or

otherwise, including any

ZEBRA Technologies shall not be responsible for the specific application to which any Products are

applied, including but not limited to compatibility with other equipment.

implied warranty of merchant-ability or fitness for a particular purpose.

i

Page 4

Warranty Information

All statements, technical information and recommendations relating to ZEBRA Products are based

upon tests believed to be reliable but do not constitute a guarantee or warranty.

ZEBRA TECHNOLOGIES SHALL NOT, UNDER ANY CIRCUMSTANCES WHATSOEVER,

BE LIABLE TO BUYER OR ANY OTHER PARTY FOR LOST PROFITS, DIMINUTION OF

GOOD WILL OR ANY OTHER SPECIAL OR CONSEQUENTIAL DAMAGES

WHATSOEVER WITH RESPECT TO ANY CLAIM HEREUNDER. IN ADDITION, ZEBRA

TECHNOLOGIES’ LIABILITY FOR WARRANTY CLAIMS SHALL NOT, IN ANY EVENT,

EXCEED THE INVOICE PRICE OF THE PRODUCT CLAIMED DEFECTIVE, NOR SHALL

ZEBRA TECHNOLOGIES BE LIABLE FOR DELAYS IN REPLACEMENT OR REPAIR OF

PRODUCTS.

No salesperson, representative or agent of ZEBRA Technologies is authorized to make any guarantee,

warranty, or representation in addition to the foregoing warranty.

NO WAIVER, ALTERATION, ADDITION, OR MODIFICATION OF THE FOREGOING

WARRANTIES SHALL BE VALID UNLESS MADE IN WRITING AND SIGNED BY AN

EXECUTIVE OFFICER OF ZEBRA TECHNOLOGIES.

Zebra Software License Agreement

The enclosed software and documentation are protected by the United States copyright law and

international treaty, and therefore you must treat them like a book, with the exception that you may

make copies to protect yourself against loss of the original.

Your right to use the enclosed software and documentation as described below is non-exclusive and

non-transferable. Zebra retains ownership in the software and documentation and all other right, title

and interest. The enclosed software and documentation may be used by any number of people and may

be freely moved from one computer to another as long as there is no possibility of their being used by

more than one person on more than one computer at the same time.

Machine readable files representing graphics or fonts which you have created independently may be

converted to ZPL format files using the enclosed software and such files may be used, copied onto

diskettes or font cards, given away, or sold without paying license fees to Zebra.

Pictorial or graphic images and machine readable files representing them may be protected by United

States copyright law and international treaty provisions which prohibits you from transcribing or

scanning such images or using copying, or converting such files without permission of the copyright

owner. You may not use this software in violation of U.S. copyright law or international treaty. By

using this software, you agree to be bound by these terms.

Zebra Technologies Corporation (“ Zebra” ) warrants the enclosed diskette to be free of defects in

material and workmanship for a period of 60 days from the date of purchase. In the event of notification

within the warranty period of defects in material and workmanship, Zebra will replace the defective

diskette or documentation. Zebra specifically disclaims all other warranties, expressed or implied,

including but not limited to implied warranties of merchantability and fitness for a particular purpose.

IN NO EVENT WILL ZEBRA TECHNOLOGIES BE LIABLE FOR LOST PROFITS, LOST DATA,

OR ANY OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES CAUSED BY ABUSE OR

MISAPPLICATION OF THE SOFTWARE OR BY ITS USE IN VIOLATION OF THE U.S. COPYRIGHT LAW OR INTERNATIONAL TREATY.

ii

Page 5

Table of Contents

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Zebra Software License Agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

1

1 Gettin g St arted

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Reporting Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Storage and Res hipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Site Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Printer Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

AC Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cutter Module Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Media and Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Loading Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Tear-Off Mo de Medi a Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Roll Media Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Fa nfold Med ia Lo ading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cutter Mode Media Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

External Rewind Mode Me dia L oading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Peel-Off Mode Media Loadin g. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Removing the Label Backing M aterial . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Adjusting the Media Senso r. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Non-Continuou s Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Continuous Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ribbon Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Adjusting the Rib bon Suppl y Spi ndle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ribbon Supply Spindle : Normal Positi on . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ribbon Supply Spindle : Low-Te nsio n Positio n. . . . . . . . . . . . . . . . . . . . . . . 11

Loading the Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Ribbon Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Initial Printer Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Configuration and Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Option Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Configuration Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Media Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adjust the Print Darkness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2

3

4

5

6

x

i

d

n

e

p

p

A

y

r

a

s

s

o

l

G

x

e

d

n

I

iii

Page 6

Table of Contents

Adjust the Media Rest Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Adjust the Positi on of the Top of the Label. . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 Operatio n

Operating Your Zebra Stripe Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Printer Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Tear-Off Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Peel-Off Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cutter Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

External Rewind Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operator Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

AC Power ON/OFF Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Front Panel Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Front Panel Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Printer Status Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Sample ZPL II Label Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Format 1: Simple Text and a Barcode . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Format 2: Saving a Label Format As a Graphic Image . . . . . . . . . . . . . . 24

Format 3: Using a Serialized Data Field. . . . . . . . . . . . . . . . . . . . . . . . . . 24

3 Routin e Care and Adjustmen t

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Cleaning the Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Cleaning the Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Cleaning the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Cleaning the Cutter Modu le . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

AC Power Fuse Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Mechanical Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Print Quality Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Toggle Pressure Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Media Sensor Positio n Adjus tment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Backing Rewind Power Roller Adjustment . . . . . . . . . . . . . . . . . . . . . . . 35

Battery Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4 Troubleshooting and Diagnostics

Troubleshooting Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Printer Diagnosti cs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Power-On Self Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Additional Printer Self Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

iv

Page 7

Table of Contents

CANCEL Key Self Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

PAUSE Key Self Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

FE ED Ke y Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

MODE Key Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

FEED Key and PAUSE Ke y. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Extended Printer Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

1

5 Specifica tio ns

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Printing Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Media Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Ribbon Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Media Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Operator Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

®

Zebra Programming Language (ZPL II

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Bar Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Standard Printer Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Standard Printer Font Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Optional Print e r Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Optional Printer Font Exam ples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6 Support Services

How to Reach Us . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Zebra Technical Support Bulletin Board Service . . . . . . . . . . . . . . . . . . . 53

Technical Support Service via Telephone . . . . . . . . . . . . . . . . . . . . . . . . . 54

Technical Support via Mail or Fax. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Product Service and Support Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Select The Program That Fits Your Busines s . . . . . . . . . . . . . . . . . . . . . . 56

Extended Factory Service Agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Third Party Support And Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Zebra Sol ution Cente r an d Nat io nal Sales and S er vic e

Center Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Wang Custom e r Se rvi ces Div isi on. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Zebra Factory Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

User Self Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

International Service and Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Zebra Training Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Operations and Maintenance Courses . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2

3

4

5

6

x

i

d

n

e

p

p

A

y

r

a

s

s

o

l

G

x

e

d

n

I

v

Page 8

Table of Contents

Bar Codes at Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Labeling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Appendix

Adjusting the Print he ad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Printer Interface Technical Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

RS-232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Signal Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Hardware Control Signal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

RS-232 Cabling Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Interconnect T o DTE Dev i ces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Interconnect To DCE Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Parallel Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Parallel Cabling Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Signal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Glossary

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

vi

Page 9

1 Getting Started

Congratulations! You have just purchased a high-quality thermal demand printer

manufactured by the industry leader in quality, service, and value–Zebra Technologies

Corporation. For over 25 years, Zebra has provided customers with the highest caliber

of products and support.

This manual provides all of the information you will need to operate your printer on a

daily basis. To create label formats, refer to the ZPL II Programming Guide (part #

46469L–if you did not order one with your printer, it is available free by sending in the

postcard at the front of this manual).

There is also a two-volume maintenance manual for this printer.

Maintenance (part # 44868L) contains the information you may need in order to

maintain your printer, and

(part # 44869L) contains information necessary for repairing the circuit boards at the

component level. You may order both volumes by specifying part # 44452L.

Volume 2: Circuit Descriptions and Electrical Schematics

Unpacking

Save the carton and all packing materials in case shipping is ever required.

Inspect the printer for possible damage incurred during shipment.

Check all exterior surfaces for damage.

•

Raise the Media Access Door and inspect the Media Compartment for

•

damage to components.

Volume 1: General

1

Reporting Damage

If you discover shipping damage upon inspection:

Immediately notify the shipping company of the damage.

•

Retain all packaging material for shipping company inspection.

•

File a damage report with the shipping company and notify your local

•

distributor and Zebra Technologies Corporation of the damage.

Zebra Technologies Corporation is not responsible for any damage incurred during

shipment of the equipment and will not repair this damage under warranty. Immediate

notification of damage to the shipping company or its insuring agency will generally

result in ensuring any damage claim validity and ultimate monetary compensation.

1

Page 10

Getting Started

Storage and Reshipping

If you are not placing the Zebra Stripe Printer into operation immediately, repackage it

using the original packing materials. The Zebra Stripe Printer may be stored under the

following conditions.

Temperature: -40° to 140° F (-20 to 60° C)

•

Relative humidity: 5% to 85% non-condensing

•

To ship the Zebra Stripe Printer, carefully pack it in a suitable container to avoid

damage during transit. Whenever possible, use the original container from the factory.

A shipping container can be purchased from Zebra Technologies Corporation, if the

original one is lost or destroyed.

If you use a different container, package the printer carefully to avoid damage.

CAUTION: When packaging the printer in a rigid container, use shock

mounts or shock-absorbing packing material. A rigid container will allow

shock on the outside to be transmitted undamped to the printer which may

cause damage. Also, before packing, remove all ribbon and media from

the supply and take-up spindles to prevent damage to the printer.

Site Requirements

CAUTION: To insure that the printer has proper ventilation and cooling, do

not place any padding or cushioning material under the unit, because this

restricts air flow.

The Zebra Stripe Printer may be installed on any solid, level surface of sufficient size

and strength to accommodate the physical dimensions and weight of the unit. The area

enclosure in which the printer will operate must meet the environmental conditions

specified. Electrical power must be available and in close proximity to the printer.

Since the Zebra Stripe Printer was designed and is fabricated as an industrial-type unit,

it will function satisfactorily in areas such as warehouses, factory floors, and office

environments that conform to specified environmental and electrical conditions.

Printer Power Up

WARNING!! Check the AC voltage requirements for the printer before

connecting it to a source of electrical power.

Follow the instructions in this section to connect this printer to a source of electrical

power and a data communication cable.

2

Page 11

Getting Started

Voltage Selection

The Stripe is available from the factory preset for either 100-120 VAC electrical power

or 220-240 VAC electrical power. Refer to the product label on the back of the

printer and make sure that the unit is properly configured for your power

requirements.

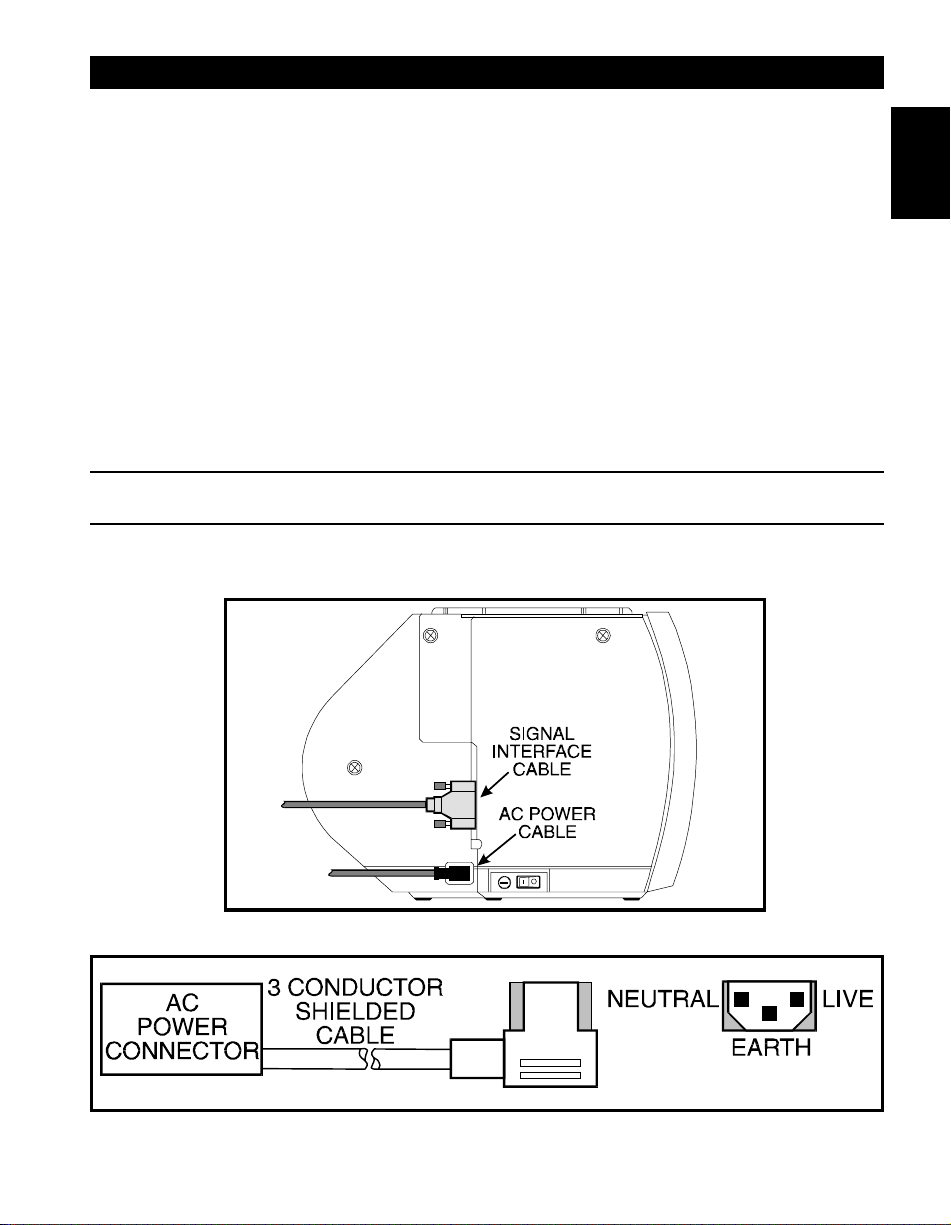

AC Power Cable

The AC Power Cable has a three-prong female connector on one end. See Figure 2. This

connector must be plugged into the mating connector on the left side of the printer. See

Figure 1.

The electrical connection at the other end of the AC Power Cable will be one of the

following:

US Standard 110 VAC three-prong plug

•

Great Britain Standard 220 VAC three-prong plug

•

European Standard 220 VAC three-prong plug

•

WARNING!! For personnel and equipment safety, always use a three-prong

plug with an earth ground connection.

Insure that the AC Power ON/OFF Switch is in the OFF (0) position before connecting

the AC Power Cable to a nearby electrical outlet.

1

Figure 1 Cable Connections

Figure 2 AC Power Cable

3

Page 12

Getting Started

Communications

The Stripe comes with either an Electronics Industries Association (EIA) RS-232 serial

data interface or a factory-installed parallel interface. In both cases, you must supply

the required interface cable for your application. See the Appendix for specific cable

requirements.

CAUTION: Zebra printers comply with FCC “Rules and Regulations”, Part 15, Subpart

J, for Class A Equipment, using fully shielded six-foot data cables. Use of longer cables

or unshielded cables may increase radiated emissions above the Class A limits.

Cutter Module Interface

The Cutter Module connects to the printer via a standard 8-pin connector.

The cable on the front of the printer plugs into the connector on the bottom of the Cutter

Module once the Cutter Module has been installed.

(For Stripes with the Factory-Installed Cutter Option)

4

Page 13

Getting Started

HEAD

OPEN

LEVER

PRINTHEAD

SHOWN

OPEN

OPEN

MEDIA

SENSOR

ASSEMBLY

RIBBON RELEASE

BUTTON

PRINTHEAD

ASSEMBLY

MEDIA

GUIDE

RIBBON

SUPPLY

MEDIA

SUPPLY

GUIDE

MEDIA

SUPPLY

MEDIA

SUPPLY

HANGER

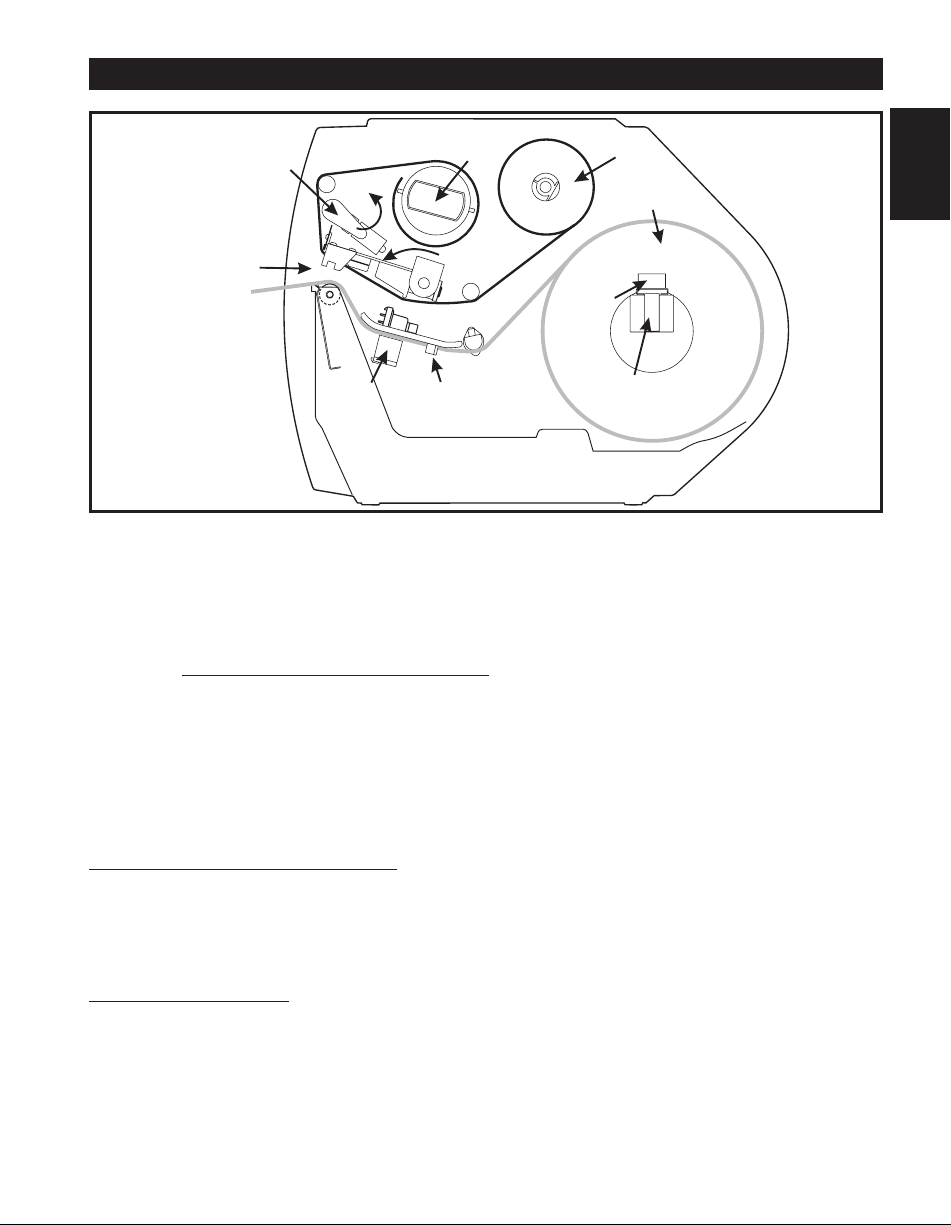

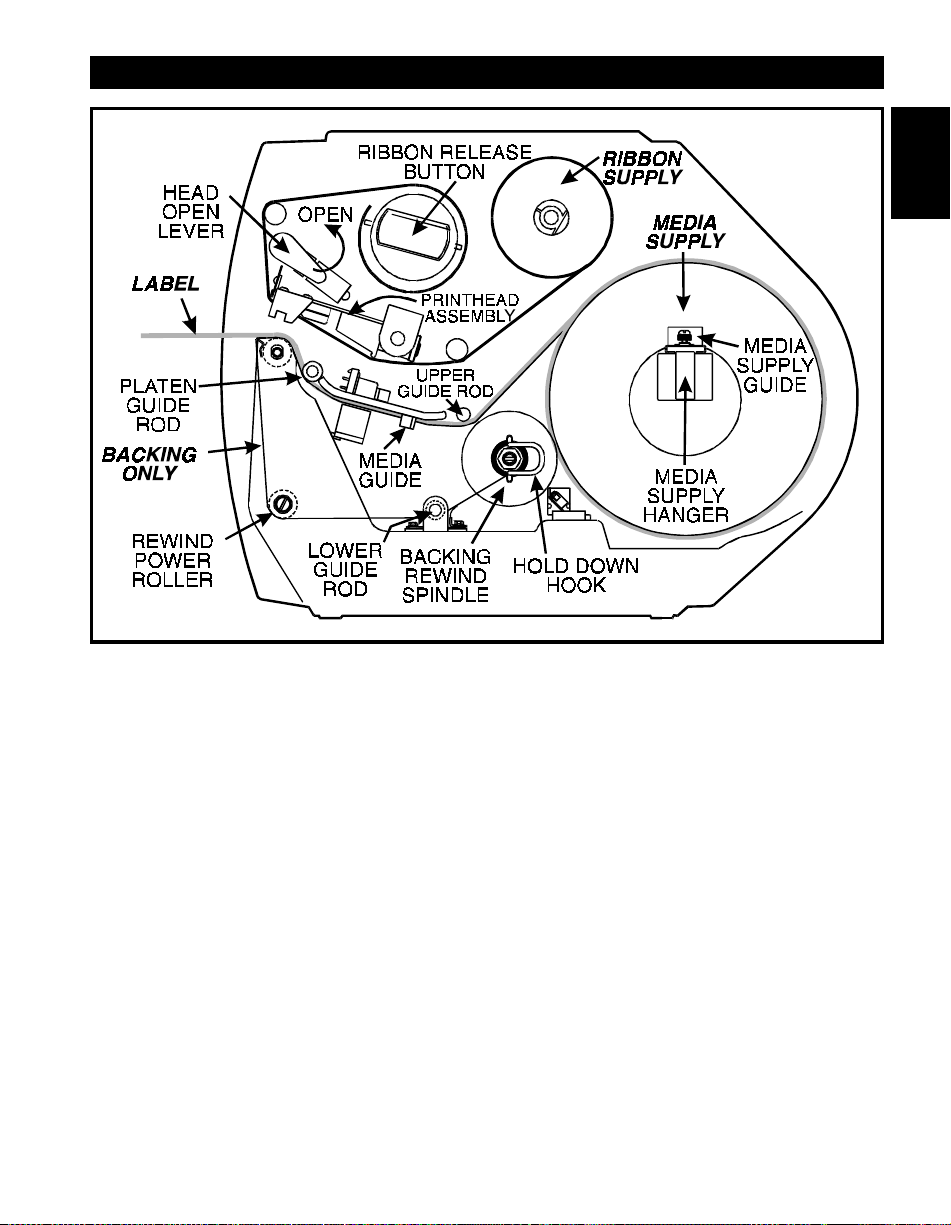

Figure 3 Roll Media Loading in Tear-Off Mode

Media and Ribbon

Loading Media

NOTE: A Media Calibration must be performed when media and ribbon (if used) are first installed in the printer, or when a different type of media or ribbon is installed. See page 14.

1

Media widths and thicknesses vary between applications. To maintain print quality from one

application to another, refer to the Print Quality Adjustments section starting on page 33.

To load media, see Figures 3 through 6 and follow the loading procedure for your

application.This section details the media and ribbon loading instructions for the

printer. For detailed descriptions of the operating modes, see Chapter 2.

Tear-Off Mode Media Loading

Figures 3 and 4 illustrate the method of loading media for operation in Tear-Off Mode.

First, move the Head Open Lever counterclockwise to the OPEN position and raise the

Printhead. Slide the Media Guide and the Media Supply Guide as far out from the

printer frame as possible.

Roll Media Loading

Place the media roll on the Media Supply Hanger, and thread the media through the

Printhead Assembly as shown in Figure 3. Adjust the Media Supply Guide and the

Media Guide against the outer edge of the media. These guides must not cause pressure

or excessive drag on the media. CLOSE the Head Open Lever, and see page 10 to adjust

the Media Sensor position.

5

Page 14

Getting Started

Fanfold Media Loading

Fanfold media, from outside the printer, feeds through either the bottom or rear access

slot.

To load fanfold media, thread the media through the Printhead Assembly as shown in

Figure 4. Adjust the Media Supply Guide and the Media Guide against the outer edge of

the media. These Guides must not cause pressure or excessive drag on the media.

CLOSE the Head Open Lever, and see page 10 to adjust the Media Sensor position.

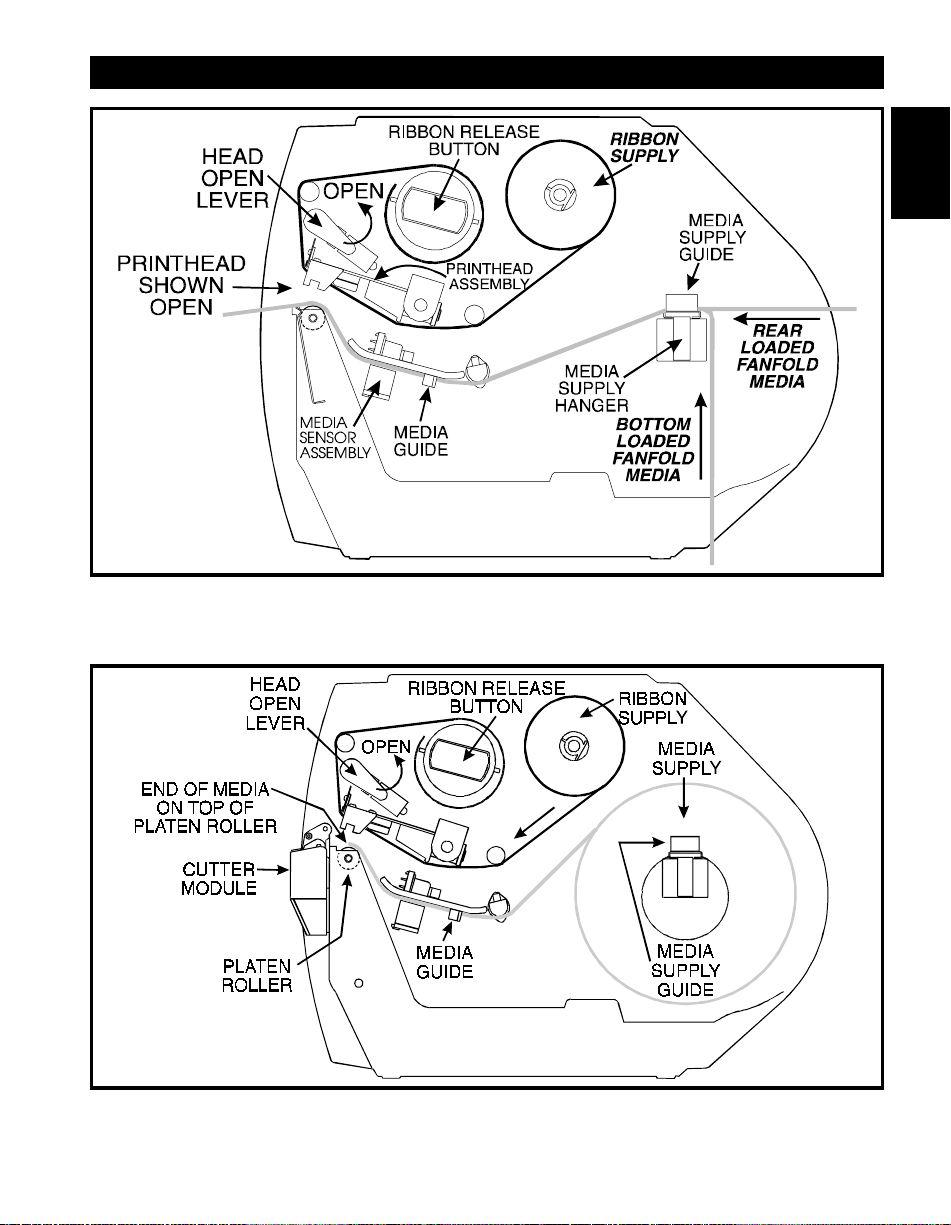

Cutter Mode Media Loading

Figure 5 illustrates a Stripe printer equipped with the Cutter Option.

To ensure proper media loading, follow the directions for the Tear-Off Mode with the

exception that the end of the media must be positioned on top of the Platen Roller. See

Figure 5.

With the end of the media positioned directly on top of the platen roller, CLOSE the

Head Open Lever. The printer will automatically feed out and cut one label when the

printer is powered on.

External Rewind Mode Media Loading

NOTE: The Peel-Off Option is designed for the Peel-Off Mode only. It is not designed as an

internal media rewind feature.

This operating mode requires an External Rewinder. Media loading is the same as for

the Tear-Off Mode of operation. If an External Rewinder is used, follow the

manufacturer’s operating instructions for that unit.

(Cutter Option Required)

6

Page 15

Getting Started

Figure 4 Fanfold Media Loading in Tear-Off Mode

1

Figure 5 Cutter Mode Media Loading

7

Page 16

Getting Started

Peel-Off Mode Media Loading

Figure 6 illustrates an S-500 printer with the Peel-Off Option.

To insure proper media loading, see Figure 6 and follow the procedure below.

1. Slide the Media Supply Guide, Media Guide, and the Outer Edge Guides on both

the Platen Guide Rod and the Lower Guide Rod as far out from the Printer Frame

as possible.

2. Open the Head Open Lever and raise the Printhead Assembly.

3. Remove the Hold Down Hook.

4. Thread the media through the printhead as shown in Figure 6.

5. From the front of the printer, pull the media through the Printhead Assembly until

approximately 24" of media extends out from the printer. Remove the labels from

the backing of the 24" of media that extends from the front of the printer.

6. Align the inside edge of the media with the Edge Guide Mark near the left side of

the Tear-Off/Peel-Off Plate, then close the Head Open Lever. (See Figure 15 on

page 22 for a detailed illustration.)

7. Thread the backing behind the Lower Label Available Sensor, through the slot

under the Rewind Power Roller, and below the Lower Guide Rod to the Backing

Rewind Spindle. Then wind the backing material around the Backing Rewind

Spindle 3 or 4 times in a counter-clockwise direction. To insure proper winding,

press the edge of the backing material against the round plate at the far end of the

Spindle.

8. To hold the media against the Spindle, place the Hold Down Hook over the

backing and insert both ends into the small slots in the round plate at the far end

of the Spindle. Again, rotate the Backing Rewind Spindle counterclockwise to

remove any slack in the backing material.

9. Adjust all of the Guides:

Push the Media Supply Guide inward until it is just touching the outer

•

side of the Media Supply Roll, then lock the guide in place with its

locking screw. (The Guide must not cause pressure or excessive drag on

the Media Supply Roll.)

Adjust the Outer Edge Guides on both the Lower Guide Rod and the

•

Platen Guide Rod until they just touch the outer edge of the media and

backing without causing the material to buckle.

Adjust the Media Guide until it just touches the outer edge of the media

•

without causing the material to buckle.

10. See page 10 to adjust the Media Sensor.

(Peel-Off Option Required)

In the Peel-Off Mode, proper media tracking is critical. Refer to the Backing Rewind

Power Roller Adjustment on page 35 to make sure that the media tracks properly

through the printer.

8

Page 17

Getting Started

1

Figure 6 Peel-Off Mode Media Loading

Removing the Label Backing Material

When the amount of backing wound on the Backing Rewind Spindle reaches full

capacity, the Backing Rewind Spindle Full Sensor activates, the Paper/Ribbon light

flashes, and printing pauses.

To remove the backing material, follow these steps (you don’t need to turn the printer

Power OFF for this procedure):

1. Unwind about 24" of backing from the Backing Rewind Spindle and cut it off at

the spindle.

2. Pull out the Hold Down Hook and slide the backing material off of the Spindle and

discard.

3. Feed the new starting edge of the backing through the mechanism and attach it to

the Backing Rewind Spindle as described in the loading procedure.

4. While holding the media in position against the Tear-Off/Peel-Off Plate, Open and

Close the Printhead without disturbing the media position. The printer is now

ready to print more labels.

(Peel Off Option Required)

9

Page 18

Getting Started

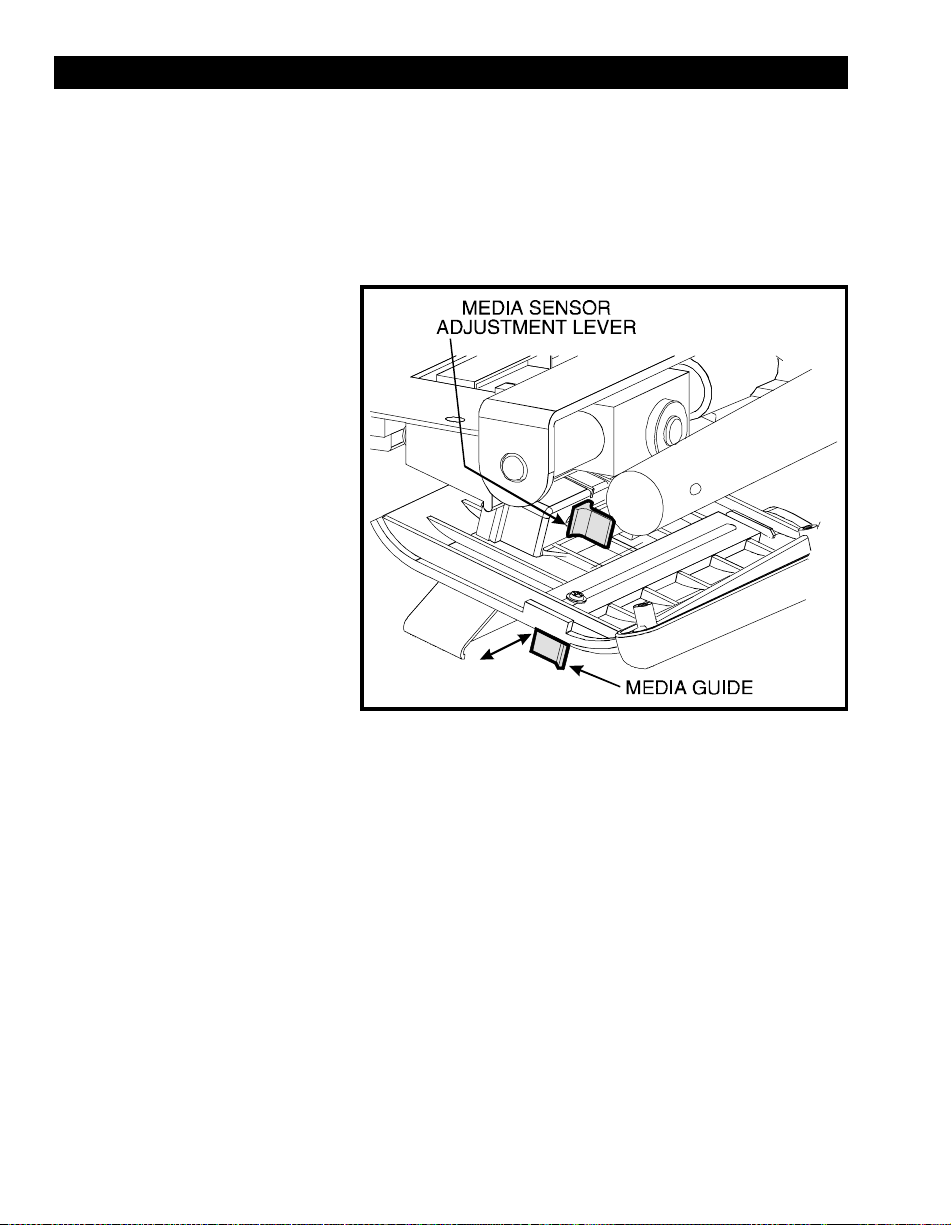

Adjusting the Media Sensor

When the Stripe printer is powered ON, it performs a self test and configures its

operating characteristics. Some of these characteristics are determined by the position of

the Media Sensor. See Figure 7.

The Media Sensor Assembly consists of two sections. The media passes between a

stationary light source and a movable light sensor. The light source is positioned below

the media, while the light sensor

is positioned above the media.

This adjustment aligns the

position of the light sensor with

the notch or edge of the label.

With the Printhead OPEN, look

through the front of the print

mechanism and locate the Media

Sensor Adjustment Lever.

Reposition the sensor until the

top of the adjustment lever is in

line with the notch in the media.

CLOSE the printhead by moving

the Head Open Lever to the

CLOSED position.

When continuous media (no

notch or opening to sense) is

used, position the Media Sensor

anywhere over the media so that

an “Out-of-Media” condition

will still be sensed.

Non-Continuous Media

This type of media has some type of physical characteristic (web, notch, perforation,

etc.) which indicates the start/end of each label.

The Media Sensor must be properly positioned to sense these indicators. See “Adjusting the

Media Sensor” (above).

Continuous Media

Since continuous media does not contain label start/end indicators, you must tell the

printer via software how long each label is. If you are using ZPL or ZPL II, include a

Label Length (^LL) instruction in each label format you send to the printer (refer to

your ZPL II Programming Guide). If you are using other software to drive your printer,

refer to the instructions provided with that software.

Even with continuous media, you still need to position the Media Sensor in the middle

of the media to sense when you run out of media.

Figure 7 Media Sensor Adjustment

10

Page 19

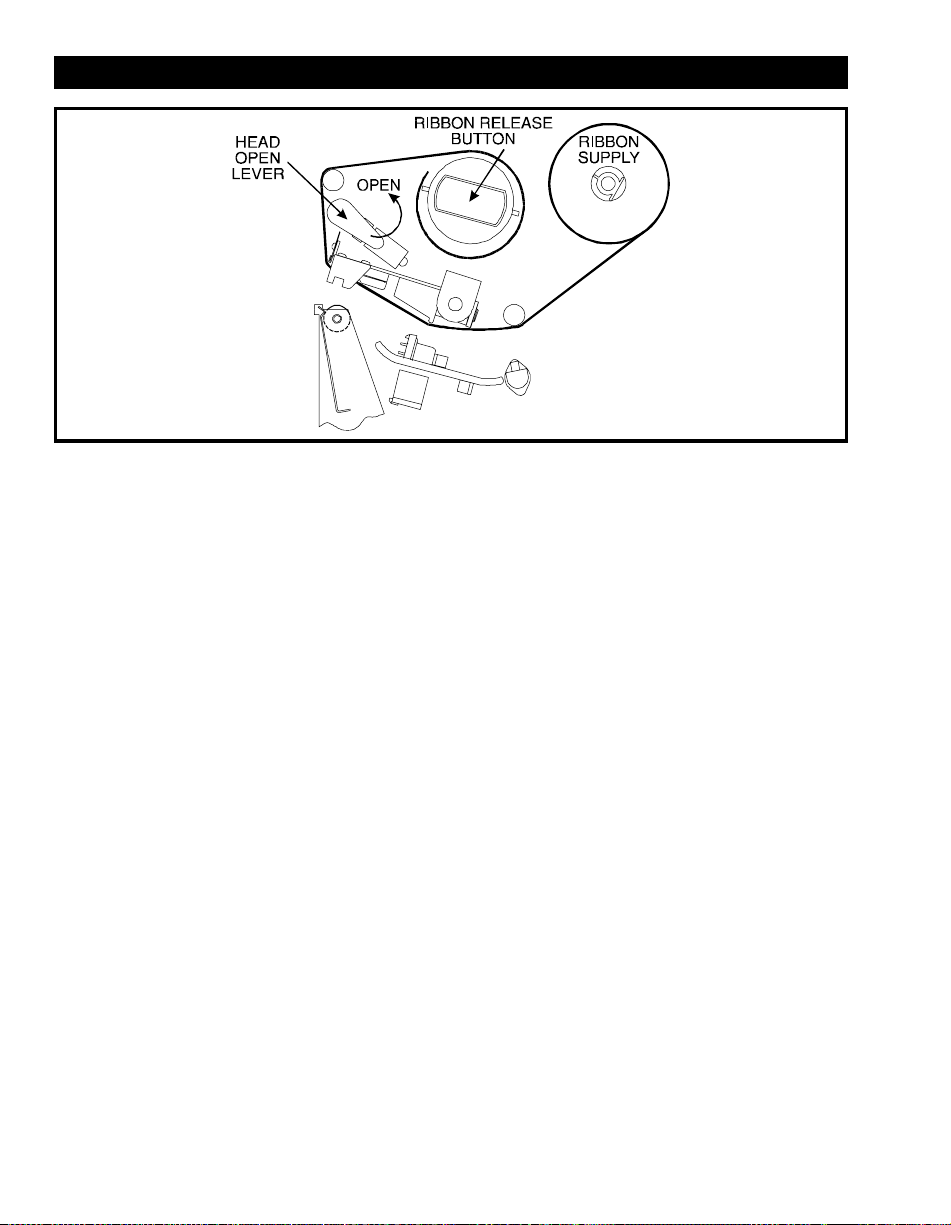

Ribbon Loading

Getting Started

Adjusting the Ribbon Supply Spindle

Ribbon Supply Spindle: Normal Position

In the Normal Position, the “Dual-Tension” Ribbon Supply Spindle provides the

desired amount of ribbon back-tension for different ribbon widths.

To place the Spindle in the Normal Position, firmly pull the Spindle End-Cap until it

clicks into place, as shown in Figure 8.

Ribbon Supply Spindle: Low-Tension Position

Low-Tension Position is used in

(60 mm) to provide lower ribbon back-tension. Low-Tension Position is only

recommended when normal tension hampers the ribbon movement.

To put the Spindle in the Low-Tension Position, firmly push the Spindle End-Cap until

it clicks into place, as shown in Figure 8.

limited applications

with ribbons wider than 2.4"

1

Normal Position Low-Tension Position

Figure 8 Ribbon Supply Spindle Adjustment

11

Page 20

Getting Started

Figure 9 Ribbon Loading Diagram

Loading the Ribbon

To load ribbon, see Figure 9 and follow the procedure below.

Use ribbon that is wider than the media. The smooth backing of the ribbon protects the

Note:

printhead from wear and premature failure due to excessive abrasion.

For Direct Thermal Print Method, ribbon is not used and should not be loaded in the printer

when performing the Media Calibration.

1. Adjust the Ribbon Supply Spindle position for normal or low tension. (see

page 11).

2. Align the blades on the two sections of the spindle as shown in Figure 8. (You do

not need to do this if your ribbon width is 2.4" (60 mm) or less.)

3. Place the ribbon roll on the Ribbon Supply Spindle.

4. Open the Printhead by moving the Head Open Lever counterclockwise to the

OPEN position.

5. Thread the ribbon as shown without creasing or wrinkling it. Wind the ribbon onto

the Ribbon Takeup Spindle for several turns in a clockwise direction.

6. Close the Printhead by moving the lever clockwise to the CLOSED position.

Ribbon Removal

Cut the ribbon where it is stretched between the Upper Ribbon Guide Arm and the

Takeup Spindle. To remove ribbon from the Takeup Spindle, press the Release Button

and slide the ribbon off the Spindle.

12

Page 21

Getting Started

Initial Printer Test

To insure proper sensing of the media and ribbon, perform a Media Calibration. This

procedure establishes the media parameters for the printer. If loading the printer with

media and ribbon for the first time, or changing the type of media, perform the Media

Calibration on page 14.

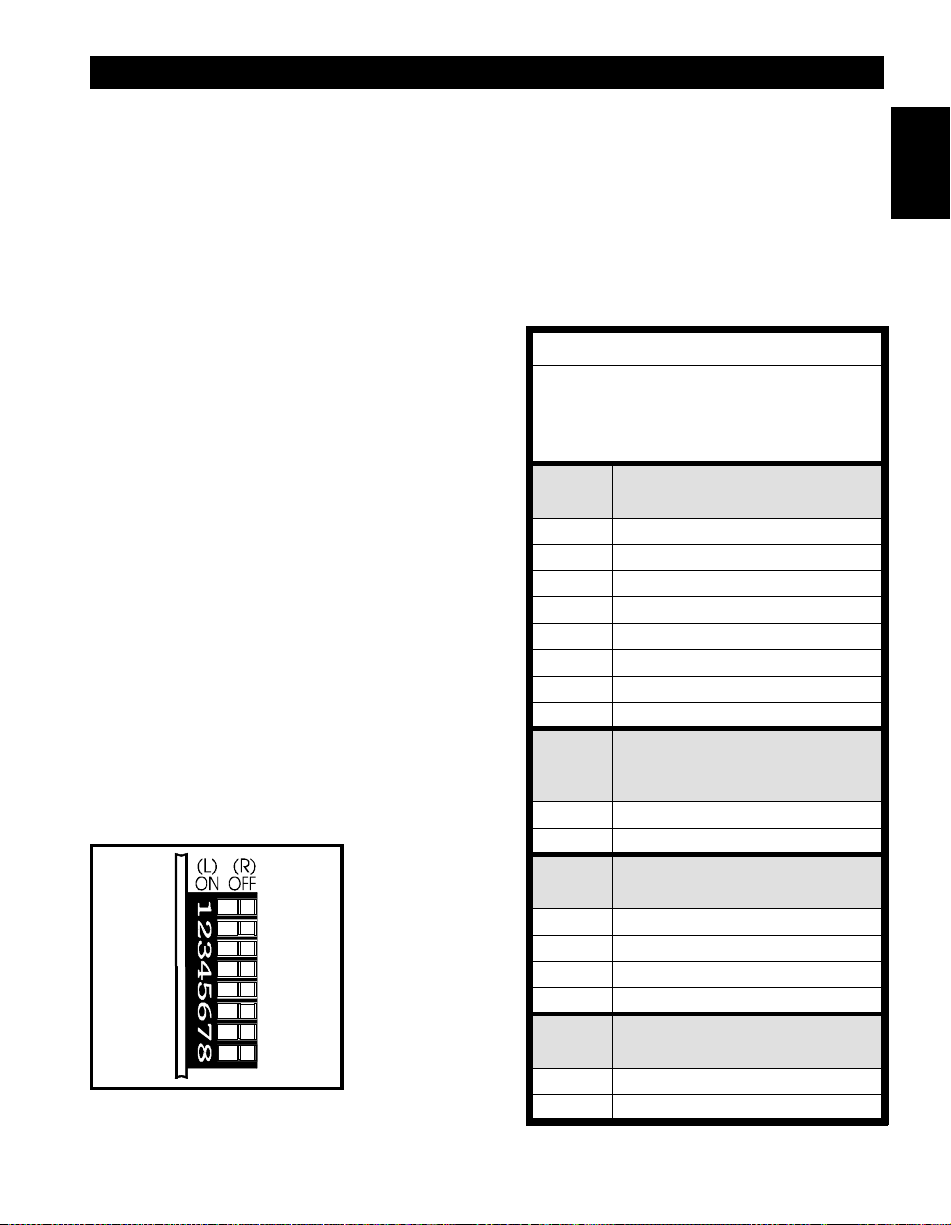

Configuration and Calibration

1

Option Switches

(Only for Serial-Interface

Printers)

A printer with a parallel interface does

Note:

not require these configuration parameters and

therefore has no switches.

A printer with the RS-232 serial interface has

eight miniature switches, which are located

inside the rear access opening above the Signal

Interface Cable Connector.

You need to position these switches to match

the settings of your host computer in order to

establish communications between the two

devices. If you do not know how to determine

the settings on your host computer, refer to the

directions in the instruction manual provided

with the computer.

If these switches are in the proper position to

match the communication configuration of the

host computer, and the printer is not receiving

data, see the Appendix to make sure you are

using the correct interface cable.

Figure 10 Option Switches

Option Switch Settings

An “R” means the switch is OFF (positioned

to the right), while an “L” means the switch

is ON (positioned to the left). Zebra sets all

switches to OFF when the printer is

manufactured.

Switch

3 2 1

R R R 9600 Baud

R R L 19200 Baud

R L R 110 Baud

R L L 300 Baud

L R R 600 Baud

L R L 1200 Baud

L L R 2400 Baud

L L L 4800 Baud

Switch

4

R 7 Data bits

L 8 Data bits

Switch

6 5

R R Even parity

R L Parity disabled

L R Odd parity

L L Parity disabled

Switch

7

R XON/XOFF control

L DTR/DSR control

(Must be set to 8 data bits for

Communication Handshake

Baud Rate

Data Bits

Code Page 850.)

Parity

Control

13

Page 22

Getting Started

Configuration Mode

The Configuration Mode allows you to fine-tune the internal printer configuration

settings for your application. In this mode, you can change the following parameters:

Printing darkness

•

Rest position of the media with respect to the “ web” or “ interlabel gap”

•

Position of printing relative to the top of the label

•

Media and Ribbon Sensor values

•

Label length

•

Printing method

•

Media type (continuous or non-continuous)

•

You can get a printout of the printer configuration (the values for each of these

parameters) at any time by performing the CANCEL Key Self Test (see Chapter 4).

If it is ever necessary to reset the printer configuration to the factory defaults, refer to the

“FEED Key and PAUSE Key” Self Test description in Chapter 4.

The ZPL II Programming Guide contains information on instructions which may be sent

to the printer to disable the MODE key and set specific label format values for each of

these parameters. If you are not using ZPL II, refer to the instructions provided with the

software you are using to determine if your software also allows you to change these

parameters.

Media Calibration

IMPORTANT:

when a different type of media or ribbon is installed, or when print mode is changed.

Perform the Media Calibration Procedure when media is first installed,

During this procedure, the printer automatically determines the media type, label length,

media and ribbon sensor settings, and printing method. Media type is determined by

sensing either continuous or non-continuous media as blank labels move through the

printer. If non-continuous media is sensed, Label Length is also calibrated. If ribbon is

sensed, the Thermal Transfer Print Method is configured; otherwise, the Direct Thermal

Print Method is configured.

The results of this calibration are stored in the printer’s memory and are retained even if

printer power is removed. These parameters remain in effect until the next calibration is

performed.

NOTE:

are peeled away from the backing during this procedure.

1. Load media and ribbon (if used). Make sure the Media Sensor is properly posi-

2. Place the Head Open Lever in the OPEN position.

14

If the printer is in the Peel-Off Mode, the operator must “catch” the labels as they

tioned.

Page 23

Getting Started

3. Turn the power switch ON. When the Power ON Self Test is complete, the

POWER and PAUSE lights will be ON and the PRINTHEAD light will FLASH.

4. Press the MODE key 3 times briefly. PAUSE and CALIBRATE lights turn ON.

5. Close the Head Open Lever.

6. Press UP to calibrate. The printer feeds some media. The MODE lights will flash

ON and OFF to indicate that the settings have been saved in memory.

7. Press PAUSE to exit the PAUSE mode. The PAUSE light turns OFF.

Adjust the Print Darkness

This procedure sets the darkness of the printing on the label. To maximize the life of the

printhead, use the lowest setting which provides the necessary print quality.

1. Press the MODE key. PAUSE and DARKEN lights turn ON.

2. Press UP or DOWN to adjust the current setting.

3. Press the MODE key 3 times briefly. The MODE lights will flash ON and OFF to

indicate that the settings have been saved in memory.

4. Press PAUSE to exit the PAUSE mode. The PAUSE light turns OFF.

Adjust the Media Rest Position

This procedure sets the end-of-label position relative to the Tear-Off Plate or Cutter.

Adjust this if your label is not being torn or cut at the correct point.

1

1. Press the MODE key twice briefly. PAUSE and POSITION lights turn ON.

2. Press UP or DOWN to adjust the current setting.

3. Press the MODE key twice briefly. The MODE lights will flash ON and OFF to

indicate that the settings have been saved in memory.

4. Press PAUSE to exit the PAUSE mode. The PAUSE light turns OFF.

Adjust the Position of the Top of the Label

This procedure positions the printing on the label relative to the top edge of the label.

Adjust this if your printing is too close or too far away from the top or bottom edge of

the label.

1. Press the MODE Key twice briefly then press and hold it for about 5 seconds until

the lights change. The PAUSE, DARKEN, and CALIBRATE lights turn ON.

2. Press UP or DOWN to adjust the current setting.

3. Press the MODE key twice briefly. The MODE lights will flash ON and OFF to

indicate that the settings have been saved in memory.

4. Press PAUSE to exit the PAUSE mode. The PAUSE light turns OFF.

15

Page 24

Getting Started

16

Page 25

2 Operation

Operating Your Zebra Stripe Printer

Now that your printer is ready for operation, how does it work? The Zebra Stripe Printer

is designed to receive instructions from a host computer, such as an IBM-compatible

PC. To create a label, you will either need to write a format in ZPL II, which is a

programming language for creating label formats, or you will need to use a software

program designed to format labels for the Zebra Stripe Printer. If you are using label

design software, refer to the instructions provided with your software package to

determine how to proceed.

If you are using, or plan to use, ZPL II programming language to format your labels,

make sure you have a copy of the ZPL II Programming Guide. This free guide was

available at the time you ordered your printer, but if you do not have a copy then refer

to the mail- or fax-in card in the front of this book to get a copy. For some sample

ZPL II label formats, refer to the section at the end of this chapter. But first, we’ll

describe the different operating modes.

Printer Operating Modes

The Stripe printer can be configured in several different operating modes by sending the

proper commands from the host computer.

Tear-Off Mode

When the media is in the rest (idle) position, the webbing between labels is over the

Tear-Off/Peel-Off Plate. To print a label, the printer first backfeeds the media until the

start of the label is directly under the printhead then prints the entire label.

To print a large quantity of labels, send a format for printing a batch of labels to the

printer; the printing will continue until all labels have been printed.

Peel-Off Mode

When the media is in the rest (idle) position, the start of the label to be printed is

slightly in front of the printhead. To print a label, the printer first backfeeds the

media until the start of the label is directly under the printhead, then prints the entire

label.

In this mode, once the label is printed, the media passes over the Tear-Off/Peel-Off

Plate at a sharp angle. The backing material is peeled away from the label and winds

around the Backing Rewind Spindle. The media feeds forward until most of the label

hangs loose from the backing. The Label Available Sensor detects this label and pauses

printing until the operator removes the label, then the next label prints.

The Backing Rewind Spindle will hold one-half of the backing from a standard-size

media roll. The Rewind Spindle Full Sensor detects when the spindle is full and pauses

(Factory-Installed Peel-Off Option Required)

2

17

Page 26

Operation

printing. The PAPER/RIBBON light flashes to indicate this condition. To remove the

backing from the Rewind Spindle, see page 9.

Cutter Mode

When the media is in the rest (idle) position, the start of the label to be printed is

directly under the printhead. The printer prints the entire label and automatically cuts

the label after it is printed. The Cutter Catch Tray “ catches” the completed labels.

The Cutter automatically cycles through one cutting motion when the printer’s power is

turned ON. When printing labels, the Cutter activation is determined by a command sent

to the printer by the host computer, either a ZPL II command or a command from a

different software driver. To disable the cutter, turn the printer’s Power Switch OFF and

simply unplug the connecting cable from the bottom of the Cutter Module.

Note: Do not exchange Cutter Modules between different printers. The Cutter Module

adjustments are optimized during installation to work with a particular printer, and may not

perform correctly if the Module is placed on a different unit.

(Factory-Installed Cutter Option Required)

External Rewind Mode

(External Rewinder Required)

Some applications call for the media to be rewound onto a core as the labels are printed.

The Stripe printer, however,

Backing Rewind Spindle

does not

is not

have an internal Media Rewind capability–the

designed to rewind label stock. You will need an

external rewinder for this application.

When the media is in the rest (idle) position, the start of the next label is directly under

the printhead. After the label is printed, the media feeds forward until the start of the next

label is under the printhead. The media never backfeeds in this mode. When the printer

completes a batch of labels, printing will stop. The speed and tension of the rewind

operation is strictly a function of the external rewind unit.

Operator Controls

This section discusses the functions of the various controls and indicators on the Stripe

printer. The operator should become familiar with each of these functions.

AC Power ON/OFF Switch

This switch is located on the left side of the printer near the AC Power Cord and Fuse.

See Figure 1. The AC Power Switch should be turned OFF (0) before connecting or

disconnecting any cables.

Turning the switch ON (1) activates the printer and causes it to perform a Power ON

Self Test as it begins operation. Turning the printer power ON while holding down

certain front panel keys will launch additional Printer Self Tests following the Power

ON Self Test. See Chapter 4.

External influences such as lightning storms or unwanted noise on the power or data

cables may cause erratic printer behavior. Turning the AC Power OFF and back ON may

re-establish proper printer operation.

18

Page 27

Operation

Figure 11 AC Power ON/OFF Switch

2

Figure 12 Zebra Stripe Printer Front Panel

19

Page 28

Operation

Front Panel Keys

PAUSE Key Starts and stops the printing process.

FEED Key Forces the printer to feed one blank label.

CANCEL

Key

MODE Key - Puts printer in Configuration Mode.

- If the printer is not printing: no printing can occur

- Printing: printing stops once the current label is complete

- Printer not printing: one blank label feeds immediately

- Printing: one blank label feeds after the current batch of labels is complete

When in the PAUSE mode, this key will cancel print jobs.

- No print jobs in queue: press to cancel the next print job to be sent to printer

- Print job in queue: press once to cancel current print job

- Press and hold for several seconds (3) to cancel all print jobs in the printer’s

memory. The Data Light will turn OFF.

- Activates automatic Media Calibration procedure.

Front Panel Lights

NOTE:

which causes the same light to flash occur at the same time, the light will flash.

POWER

PRINTHEAD

PAP E R/

RIBBON

PAU SE

DATA

DARKEN

POSITION

CALIBRATE

If an operating condition which causes a light to be ON constantly and one

Light Status Indication

OFF Printer is OFF, or not receiving power.

ON Printer is ON.

OFF Normal operation.

ON Head Over Temperature condition. Printing stops until the printhead

Flashing Printhead Open.

OFF Media and ribbon (if used) are properly loaded.

ON Paper out.

Flashing In Thermal Transfer Mode: Ribbon is out.

OFF Normal operation.

ON Printer has stopped all printing operations.

OFF Normal operation, no data being received.

ON Labels are printing.

Single flash The CANCEL key was pressed and a format was successfully deleted

Flashing Receiving data from host computer.

Slow flashing Printer sent a “stop transmitting” command to the host computer.

ON Printer is in the Configuration Mode. See Chapter 1 for more

ON

ON

cools down. Printing resumes automatically.

Printhead Under Temperature condition. Printing continues.

In Direct Thermal Mode: Ribbon is in printer.

In Peel-Off Mode: backing rewind spindle is full.

from the print queue.

information.

20

Page 29

Operation

Printer Status Sensors

The Zebra Stripe Printer contains several status sensors. These sensors alert the operator to

various conditions by either stopping the printing or turning on a light.

Sensor What it monitors How it works

Printhead Sensor Checks the open/closed status

Media Sensor

(See Chapter 1 to adjust this

sensor.)

Ribbon Sensor Monitors the presence of

Label Available Sensor (Peel-Off

Option Required. See Fig. 15.)

Backing Rewind Spindle Full

Sensor (Peel-Off Option

Required. See Fig. 14.)

of the Printhead lever.

Checks for proper media

loading.

If non-continuous media is

used: Sets label length for

individual labels.

ribbon.

In Peel-Off Mode, it checks to

see if a label is available.

Senses when the Backing

Rewind Spindle is full of used

backing material.

If the printhead is open, the

Printhead Light flashes.

If you run out of paper, the

Paper/Ribbon Light will turn ON.

If you run out of ribbon, the

Paper/Ribbon Light flashes.

Once a label prints, it will pass

between the two parts of this

Sensor and cause the printer to

pause. When the label is

removed, printing resumes.

When the Spindle is full, the

Paper/Ribbon Light flashes.

2

Figure 13 Printhead Position

21

Page 30

Operation

Figure 14 Backing Rewind Spindle Full Sensor Position

22

Figure 15 Label Available Sensor Position

Page 31

Operation

Sample ZPL II Label Formats

ZPL II® is Zebra Technologies Corporation’s Zebra Programming Language II label

design language. ZPL II lets you create a wide variety of labels from the simple to the

very complex, including text, bar codes, and graphics.

This section contains three sample label formats for you to begin experimenting with. It

is not intended as an introduction to ZPL II. To learn about ZPL II, send in the request

card at the beginning of this book for a free copy of the ZPL II Programming Guide.

For each format, do the following:

1. Save the file.

2. Copy the file to the printer.

Set-up the printer and turn the Power ON.

•

Use a text editing program (ex: Windows Write or DOS Editor) and type

•

in the label format exactly as shown in the sample label format shown

below.

Save the file in a directory for future use. Use the extension “ . zpl”.

•

Copy the file to the Zebra Stripe Printer.

•

Typically, computers running DOS use the “COPY” command to send a file to the

Note:

Zebra printer. For example, if your file name is “format1.zpl” then type, “

MAT1.ZPL COM1

”.

3. Compare your results with those shown. If your printout does not look like the one

shown, confirm that the file you created is identical to the format shown, then

repeat the printing procedure. If nothing prints, refer to Chapter 1 to make sure

your system is set up correctly, otherwise refer to Chapter 4, “Troubleshooting

and Diagnostics” .

COPY FOR-

2

Format 1: Simple Text and a Barcode

Line

#

1

^XA

2

^LH30,30

3

^FO20,10^AD^FDZEBRA^FS

4

^FO20,60^B3N,Y,20,N^FDAAA001^FS

5

^XZ

Line #1: Indicates start of label format.

Line #2: Sets label home position (in dots) from the upper left-hand corner of the label.

Line #3: Sets field origin, selects font “D”, defines field data as “ZEBRA”.

Line #4: Sets field origin, selects bar code Code 39, sets barcode height at 20 dot rows,

defines field data for bar code as “AAA001".

Line #5: End of label format.

Type this label format: You’ll get this printout:

23

Page 32

Operation

Format 2: Saving a Label Format As a Graphic Image

Line

#

1

^XA

2

^LH30,30

3

^FO20,10^AD^FDZEBRA^FS

4

^FO20,60^B3N,Y,20,N^FDAAA001^FS

5

^ISFORMAT2,N

6

^XZ

7

^XA

8

^ILFORMAT2

9

^XZ

Line #1-4: These commands were described in Format 1.

Line #5: Saves the format in the printer’s memory as a graphic image named “FORMAT2",

the ”N" indicates “do not print after saving”.

Line #6-7: (See Format 1)

Line #8: Load and print the graphic image saved as “FORMAT2".

Line #9: (See Format 1)

Type this label format: You’ll get this printout:

(Same as Format 1, but this format

was also saved in the printer’s

memory as a graphic image named

“FORMAT2".)

Format 3: Using a Serialized Data Field

Line

#

1

^XA

2

^LH30,30

3

^FO20,10^AD^FDZEBRA^FS

4

^FO20,60^B3,,40,,^FDAAA001^FS

5

^FO20,180^AF^SNSERIAL NUMBER 00000000111,1,Y^FS

6

^PQ10

7

^XZ

Type this label format: You’ll get this printout:

Ten labels should print. The

first and last are shown here.

Line #1 - 3: These commands were described in Format 1.

Line #4: Defines field data for bar code as “AAA001".

Line #5: Defines serialized field, starting value of 111, increment by 1, insert leading zeros.

Line #6: Sets print quantity to 10

Line #7: (See Format 1)

24

Page 33

3 Routine Care and Adjustment

Cleaning

CAUTION: Use only the cleaning agents indicated below. Zebra Technologies

Corporation will not be responsible for any other fluids being used on this

printer. No lubricants are needed.

Table 1 provides a brief cleaning schedule. Specific cleaning procedures are provided

on the following pages.A Preventive Maintenance Kit (part # 01429) is available from

Zebra. Kit items are also sold separately by the part numbers shown.

Preventive Maintenance Kit

Solvent (Alcohol), 4 oz. bottle (part # 01426)

Applicators, bag of 100 (part # 01427)

Cleaning the Exterior

The exterior surfaces of the Zebra Stripe Printer may be cleaned with a lint-free cloth. Do not

use harsh or abrasive cleaning agents or solvents. If necessary, a mild detergent solution or

desktop cleaner may be used sparingly.

Cleaning the Interior

Remove any accumulated dirt and lint from the interior of the printer using a soft bristle

brush and/or vacuum cleaner. Inspect this area after every roll of media.

AREA METHOD INTERVAL

Printhead Alcohol After every roll of media (or

Platen Roller Alcohol

Media Sensor Air Blow

Media Path Alcohol

Ribbon Path Air Blow

Upper Guide Rod (Peel-Off) Alcohol After every roll of media.

Platen Guide Rod (Peel-Off) Alcohol After every roll of media.

Rewind Power Roller (Peel-Off) Alcohol After every roll of media.

Lower Guide Rod (Peel-Off) Alcohol After every roll of media.

Cutter

assembly (if

used)

Tear-Off/Peel-Off Plate Alcohol Once Per Month.

Label Available Sensor Air Blow Once Per Six Months.

If using continuous

pressure-sensitive media

If using tagstock or label

backing material only

Adhesive remover,

such as “Goo-

Gone”

Alcohol and air

blow

500 feet of fanfold media)

when printing direct thermal.

After every roll of ribbon

when printing in the thermal

transfer mode.

After every roll of media or

more often depending upon

your application and media.

After every 2 or 3 rolls of

media.

3

Table 1 Cleaning Schedule

25

Page 34

Routine Care and Adjustment

Cleaning the Printhead

Inconsistent print quality, such as voids in the bar code or graphics, may indicate a dirty

printhead. For optimum performance, Zebra recommends performing the following

cleaning procedure after every roll of ribbon.

NOTE: It is not necessary to turn the printer OFF before cleaning the printhead. If power is

turned OFF, all label formats and images, as well as any temporarily saved parameter

settings stored in the printer’s internal memory, will be lost. When power is turned back ON,

it will be necessary to reload these items.

To clean the printhead, refer to Figure 16 and follow these steps:

1. Open the Media Compartment Door and the Front Panel.

2. Open the Printhead by moving the Printhead Open Lever to the OPEN position.

3. Remove the media and ribbon (if present).

4. Moisten an applicator tip with Zebra Technologies Corporation recommended

solvent and wipe along the print elements from end to end. (The print elements are

the grayish/black strip just behind the chrome strip. See Figure 16). Allow a few

seconds for the solvent to evaporate.

5. Rotate the platen roller and clean thoroughly with solvent.

6. Brush/vacuum any accumulated paper lint and dust away from the rollers and

media sensors.

7. Reload ribbon and/or media, close and latch the printhead, close the Front Panel

and the Media Compartment Door, and continue printing.

26

Figure 16 Printhead Cleaning

Page 35

Routine Care and Adjustment

Cleaning the Cutter Module

(For Printers Equipped with the Optional Cutter)

The Cutter Module requires periodic cleaning to remove paper dust and gummed label

residue. The procedure on the following pages should be performed by the operator

according to the schedule on page 25. However, depending on your application and

media type you may need to clean the cutter more or less frequently.

NOTE: In the figures shown, media and ribbon have been removed for clarity. It is not

necessary to remove media or ribbon before performing the maintenance procedures described.

IMPORTANT: Do not exchange Cutter Modules between different printers. The Cutter

Module adjustments are optimized during installation to work with a particular printer and

may not perform correctly if the module is placed on a different printer.

3

Figure 17 Cutter Module and Catch Tray Location

27

Page 36

Routine Care and Adjustment

I. Remove the Cutter Module from the printer.

1. Turn the printer’s AC power OFF.

2. Raise the printer’s Media Access Door and lower the printer’s Front Door. See Figure 17.

3. Remove the Label Catch Tray by lifting it up and away from the front of the Cutter Module.

4. See Figure 18. Gently pull straight down on the Cutter Cable Connector to remove it from the

mating socket on the Cutter Module.

5. Turn the Cutter Mounting Screw (by hand or with a screwdriver) in a counter-clockwise

direction until it is loose.

6. See Figure 19. Hold the Cutter Module as shown. Apply gentle upward pressure to the left and

right ends while raising the Cutter Module up and away from the Mounting Posts. If necessary,

rock the Module side-to-side to loosen it.

This procedure is continued on the next page.

28

Figure 18 Cutter Connector and Mounting Screw

Figure 19 Cutter Module Removal

Page 37

Routine Care and Adjustment

Figure 20 Cutter Module Disassembly

II. Disassemble the C utter Module.

1. See Figure 20. Hold the Cutter Module as illustrated. Put your thumbs on the two Wire Spring

Loops and your index fingers on the top of the Rear Cutter Blade Guard. It may help to lay the

Cutter Module on a table or other surface throughout this process.

2. To remove the Rear Cutter Blade Guard, first press down simultaneously on the two Wire

Spring Loops. While pressing down on the loops, press the Rear Cutter Guard back toward

you and over top of the Loops. (You’re trying to tuck the Loops underneath the Blade Guard in

this process.)

3. Continue pressing the Rear Cutter Guard toward you and allow the back edge of the Guard to

pop up as the Guard comes free from its holders. You may now remove the Rear Cutter Guard

by lifting it off of the module.

NOTE:

The Wire Springs may flip up out of position during this process. Springs will be

repositioned during reassembly.

4. Observe the ends of the Rear Cutter Blade Guard and note the small metal pins protruding

toward the inside. During the Reassembly Procedure, these pins will be mounted into the

corresponding mounting slots in the Cutter Side Panels.

5. To provide complete access to the area to be cleaned, raise the Upper Cutter Blade Guard as

shown in Figure 20.

3

III. Clean the Cutter Module.

1. Remove any label material which has adhered to the Cutter parts and use a small brush to

remove any paper dust from the Cutter Module.

2. If you use pressure-sensitive media, use a lint-free cloth soaked in an adhesive remover to

remove all gum and label residue from the Cutting Blades and Guards.

If you use tag stock, use alcohol (part # 01426) to remove any dirt.

This procedure is continued on the next page.

29

Page 38

Routine Care and Adjustment

IV. Reassemble the Cutter Module.

1. See Figure 22. Position the two Wire Springs down against the Lower Cutter Blade.

2. Place the Rear Cutter Blade Guard over the Wire Springs, perpendicular to its final position.

Place your thumbs on the top (flat) part of the Guard.

NOTE:

Insure that the ends of the Rear Cutter Blade Guard are positioned on the outside of

the Cutter Side Panels.

3. See Figure 22. Press the Rear Cutter Blade Guard down and forward, rotating the Guard as

you proceed, to lock the mounting pins into position in the Cutter Side Panel mounting slots.

Slide the Guard forward until the two Wire Spring Loops pop up on the back side of the Guard.

NOTE:

Insure that the Wire Springs remain positioned under the Rear Cutter Blade Guard

when assembly is completed.

4. Lower the Upper Cutter Blade Guard back to its normal position. When reassembled, the back

of the Cutter Module should look like the one shown in Figure 23.

This procedure is continued on page 32.

30

Figure 21 Cutter Module Reassembly

Figure 22 Side View of Cutter Module Reassembly

Page 39

Routine Care and Adjustment

3

Figure 23 Reassembled Cutter Module

Figure 24 Cutter Module Reinstallation

31

Page 40

Routine Care and Adjustment

V. Reinstall the Cutter Module.

1. See Figure 19. Position the Cutter Module above the Cutter Mounting Posts. Press down on

the Cutter Module until the Mounting Slots engage the Mounting Posts on the printer.

2. See Figure 18. Tighten the Mounting Screw in a clockwise direction to hold the Cutter Module

in Position.

3. See Figure 18. Position the Cutter Cable Connector so the flat side of the connector faces

away from the printer, then insert it up into the mating connector on the Cutter Module.

4. Replace the Cutter Catch Tray onto the two mounting posts located on the front of the Cutter

Module.

VI. Test the Cutter Operation.

1. If necessary, reload ribbon and label stock into the printer, then close the printer’s Front Door

and Media Access Door.

NOTE:

When loading media, make sure the end of the label is positioned on top of the Platen

Roller, then close the Printhead Latch.

2. When the printer is turned ON, the Cutter Module will cycle through one cutting operation and

be ready to print labels.

3. OPTIONAL: Hold in the PAUSE key while turning the printer’s AC power ON. When the Power

ON Self Test begins (all lights ON), release the PAUSE key. When the Power ON Self Test ends,

the printer will automatically print test labels which the Cutter Module will automatically cut.

End of Cutter Cleaning Procedure.

Lubrication

No lubricating agents of any kind are required on this printer.

Some commercially available lubricants will damage the finish if used.

AC Power Fuse Replacement

A user-replaceable AC Power Fuse is located just to the left of the Power ON/OFF

Switch. (See Figure 11 on page 19.) For a 110 VAC installation, the replacement Fuse is

a 3AG Fast Blow style rated at 5 Amp/250VAC. For a 220 VAC installation, the Fuse is

the same style but rated at 3 Amp/250VAC .

Before replacing the Fuse, turn the AC Power Switch OFF and unplug the AC Power

Cable.

To replace the Fuse, insert the tip of a flathead screwdriver into the slot in the end of

the Fuse Holder End Cap. Press in slightly on the End Cap and turn the screwdriver

slightly counterclockwise. This will disengage the End Cap from the Fuse Holder and

permit removal of the Fuse. To install a new fuse, reverse the sequence.

32

Page 41

Routine Care and Adjustment

Mechanical Adjustments

The Stripe printer has been designed with minimal operator adjustments required.

Print Quality Adjustments

In the factory, the Stripe printer is aligned and tested using Zebra’s 5319 ribbon and

Zebra’s Z-Trans 6A full width, non-continuous media to print thermal transfer labels at

Speed C (4"/sec). For other media/ribbon combinations, the user may need to adjust

Print Darkness, Toggle Pressure, or possibly the Printhead Position.

When changing from one media/ribbon combination to another, only slight changes in

Print Darkness or Toggle Pressure may be required. For these situations, refer to the

Toggle Pressure Adjustment on page 34. However, to achieve optimum print quality,

perform the adjustment procedure which follows. A #2 Phillips screwdriver and a

flathead screwdriver will be required.

I. Check the initial print quality.

1. Open the Media Compartment Door and Front Panel on the printer.

2. Load the recommended media and ribbon for your application and adjust

the Media Sensor Position.

3. Send a label format to the printer or activate the PAUSE Key Self Test (see

Chapter 4), print a few labels, and press the PAUSE key to stop printing.

4. Observe the print quality of the test labels. If it is satisfactory, complete the

process by turning the AC Power OFF. Otherwise, continue to Step II.

3

II. Adjust the print darkness.

1. Press the MODE key (DARKEN light and PAUSE light turn ON) to permit

darkness adjustment.

2. Press the PAUSE key to begin printing test labels.

3. While observing the print darkness, repeatedly press the UP (FEED) key to

make the printing DARKER, or the DOWN (CANCEL) key to make the

printing LIGHTER, until the desired darkness is achieved.

4. Once proper print darkness is achieved, press the PAUSE key to stop

printing.

If you are still experiencing poor print quality, perform the Toggle Pressure Adjustment

34. If that doesn’t correct your print problem, turn to the Appendix to adjust the

printhead position.

Note: Adjusting the position of the printhead should be done only after all of the above

attempts have been made to correct the situation.

33

Page 42

Routine Care and Adjustment

Toggle Pressure Adjustment