Page 1

5

RFID Guidelines

This chapter provides an overview of how RFID works and the ZPL commands used to create

RFID labels.

Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Transponder Placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

ZPL II Commands for RFID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Sample of RFID Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 61

Page 2

RFID Guidelines

Overview

Overview

The R110XiIIIplus “smart” label printer-encoders serve as dynamic tools for both printing and

encoding RFID labels, tickets, and tags. The printer encodes information on ultra-thin UHF

RFID transponders embedded in “smart” labels. It then immediately verifies proper encoding

and prints bar codes, graphics, and/or text on the label’s surface. For more information about

RFID media, see RFID “Smart” Labels on page 16.

Function of an encoded “smart” label depends on factors such as where the label is placed on

an item as well as on the contents of the item (such as metals or liquids). Contact the supplier

of your RFID transponders for assistance with these types of issues.

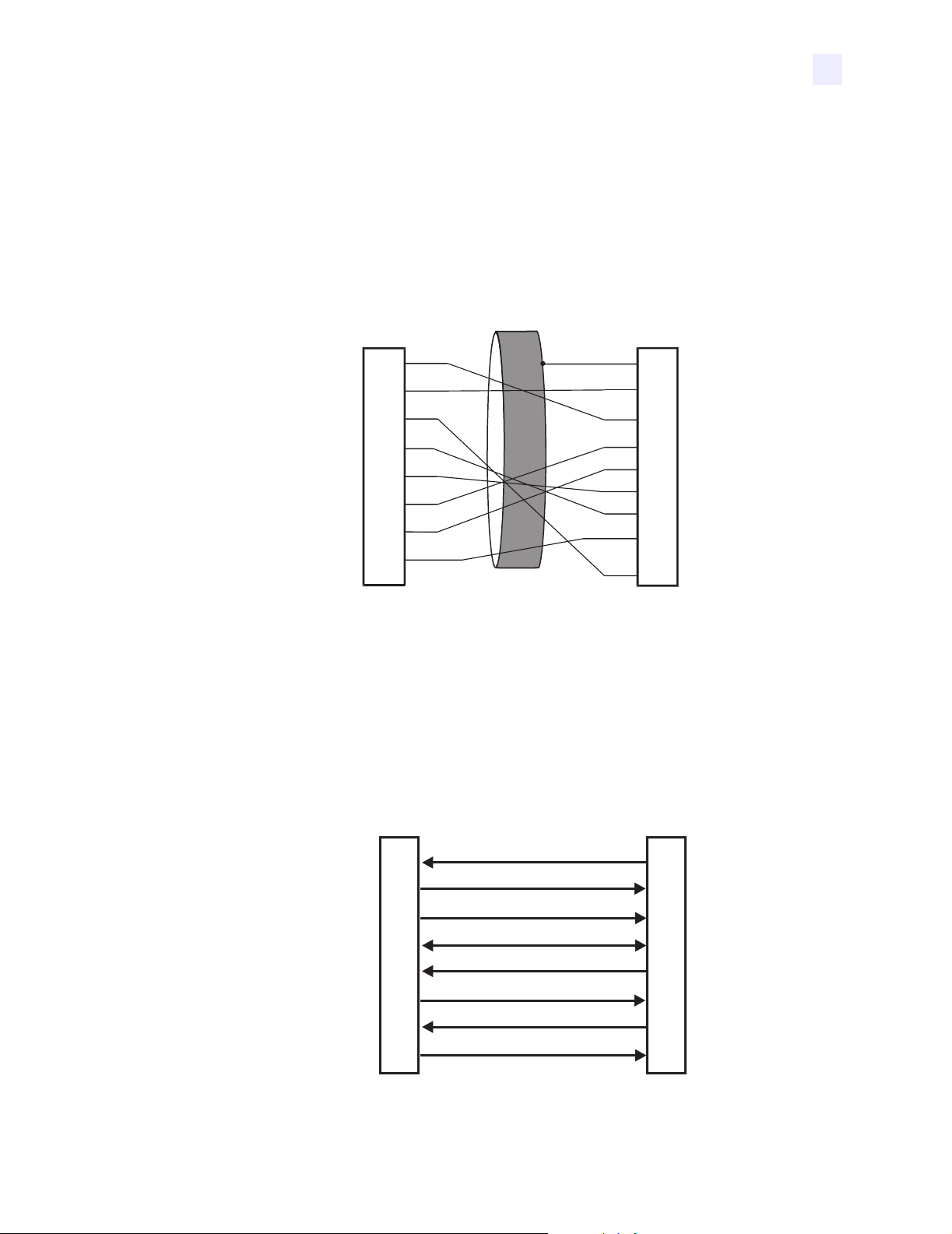

Transponder Placement

Communication between the “smart” label and the printer is established when the transponder

lines up with the printer’s antenna. The optimal transponder position varies with the

transponder size, its configuration, and the type of RFID IC chip used.

Print quality may be affected by printing directly over the transponder. In particular, there is an

area on each label immediately around the location of the IC chip where the printer may print

with low quality. Design your printed label around the location of the chip in the type of

approved “smart” label that you select. For the list of approved transponders and related

placement specifications, go to http://www.rfid.zebra.com/r110.htm.

Important • It is important to use transponders that have been specifically approved for use in

this RFID printer. Failure to do so may result in the inability to read or write to the embedded

RFID tags. As new transponders become commercially available, Zebra will evaluate them for

compatibility with this printer. For the list of approved transponders, go to

http://www.rfid.zebra.com/r110.htm.

62 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 3

ZPL II Commands for RFID

Printing and encoding (writing) of “smart” labels is handled through the use of Zebra

Programming Language (ZPL). Each transponder has memory that can be read from through

ZPL commands, and most transponders have memory that can be written to. The printer

divides the ZPL commands that it receives into two categories: RFID and non-RFID (such as

the printing commands for bar codes or human-readable text). The RFID commands are

executed first.

ZPL commands also provide for exception handling, such as setting the number of read/write

retries before declaring a transponder defective. For example, if an RFID transponder fails to

program correctly or cannot be detected, the printer ejects it and prints the word “VOID”

across the label. This process continues for the number of RFID tags specified by the

command using the same data and format.

The following pages provide the ZPL II commands that can be used for RFID applications.

Important • If a parameter is designated as not applicable, any value entered for the parameter

will be ignored, but the place holder for the field is required.

RFID Guidelines

ZPL II Commands for RFID

^RS

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 63

Page 4

RFID Guidelines

^HV

^HV

Host Verification

Description This command is used to return data from specified fields, along with an

optional ASCII header, to the host. It can be used with any field that has been assigned a

number with the

^RT command.

Format

The following table identifies the parameters for this format.

Parameters Details

# = field number

specified with another

command

n = number of bytes to be

returned

h = header Header (in uppercase ASCII characters) to be returned with the data.

^HV#,n,h

The value assigned to this parameter should be the same as the one used in the

^RT command.

Accepted values: 0 to 9999

Default value: 0

Accepted values: 1 to 256

Default value: 64

Acceptable values: 0 to 3072 characters

Default value: none

64 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 5

^RS

RFID Setup

RFID Guidelines

^RS

Important • Use care when using this command in combination with ^RT (reading tag data).

Problems can occur if the data read from the tag is going to be printed on the label. Any data

read from the transponder must be positioned to be printed above the read/write position.

Failure to do this will prevent read data from being printed on the label.

Description The ^RS command moves the RFID tag into the effective area for reading or

writing or for possible error handling if there is an error.

Format

The following table identifies the parameters for this format.

Parameters Details

^RSt,p,v,n,e

t =tag type Accepted values:

• 1 = Auto detect (automatically determine the tag type by querying the tag)

Default value: 1

p = read/write position of

the transponder in the

vertical (Y axis) in

dot rows from the top

of the label

v = length of void

printout in vertical (Y

axis) dot rows

n = number of labels to

try in case of

read/encode failure

Set to 0 (no movement) if the transponder is already in the effective area

without moving the media.

Accepted values: 0 to label length

Default value: label length minus 8 dot rows

Default value: label length

Accepted values: 0 to label length

Default value: 3

Accepted values: 1 to 10 (number of labels)

e = error handling If an error persists after the specified number of labels are tried, perform this

error handling action.

Accepted values:

• N = No action (printer drops the label format causing the error and moves to

the next queued label)

• P = Place printer in Pause mode (label format stays in the queue until the user

cancels)

• E = Place printer in Error mode (label format stays in the queue until the user

cancels)

Default value: N

Note • You can set the printer to send an error message to the host as an

unsolicited message for each failure. To enable or disable the unsolicited error

message, refer to the

RFID error in these commands is

^SX and ^SQ ZPL commands. The parameter for the

V.

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 65

Page 6

RFID Guidelines

^RS

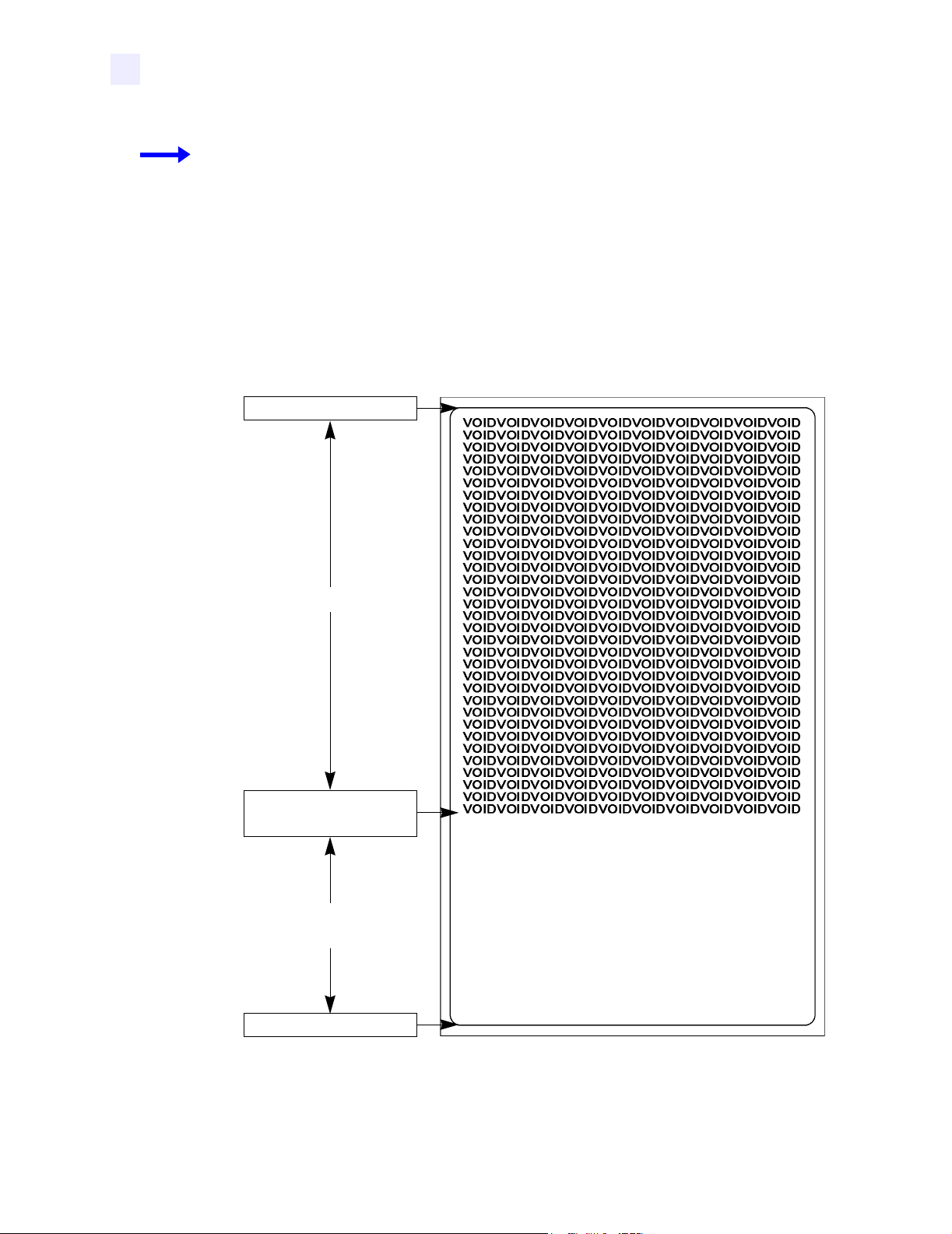

Example 1 • This example sets the printer to move the media to 800 dots from the top of the

media [or label length minus 800 from the bottom (leading edge) of the media] and voids the

rest of the media in case of an error. The printer will try to print two labels, then will pause the

printer if printing and encoding fail.

^XA

^RS,800,,2,P^FS

^XZ

The following illustration shows the resulting voided label. Note where the void starts. The

media has been moved 800 dot rows from the top of the label (label length minus 800 dot rows

from the bottom (leading edge) of a label) to bring the transponder into the effective area to

read/write a tag. If the printer fails the operation, the rest of the media is voided.

Top of label

800 dot rows

Start of RFID

operation

Label length minus

800 dot rows

Bottom of label

66 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 7

RFID Guidelines

^RS

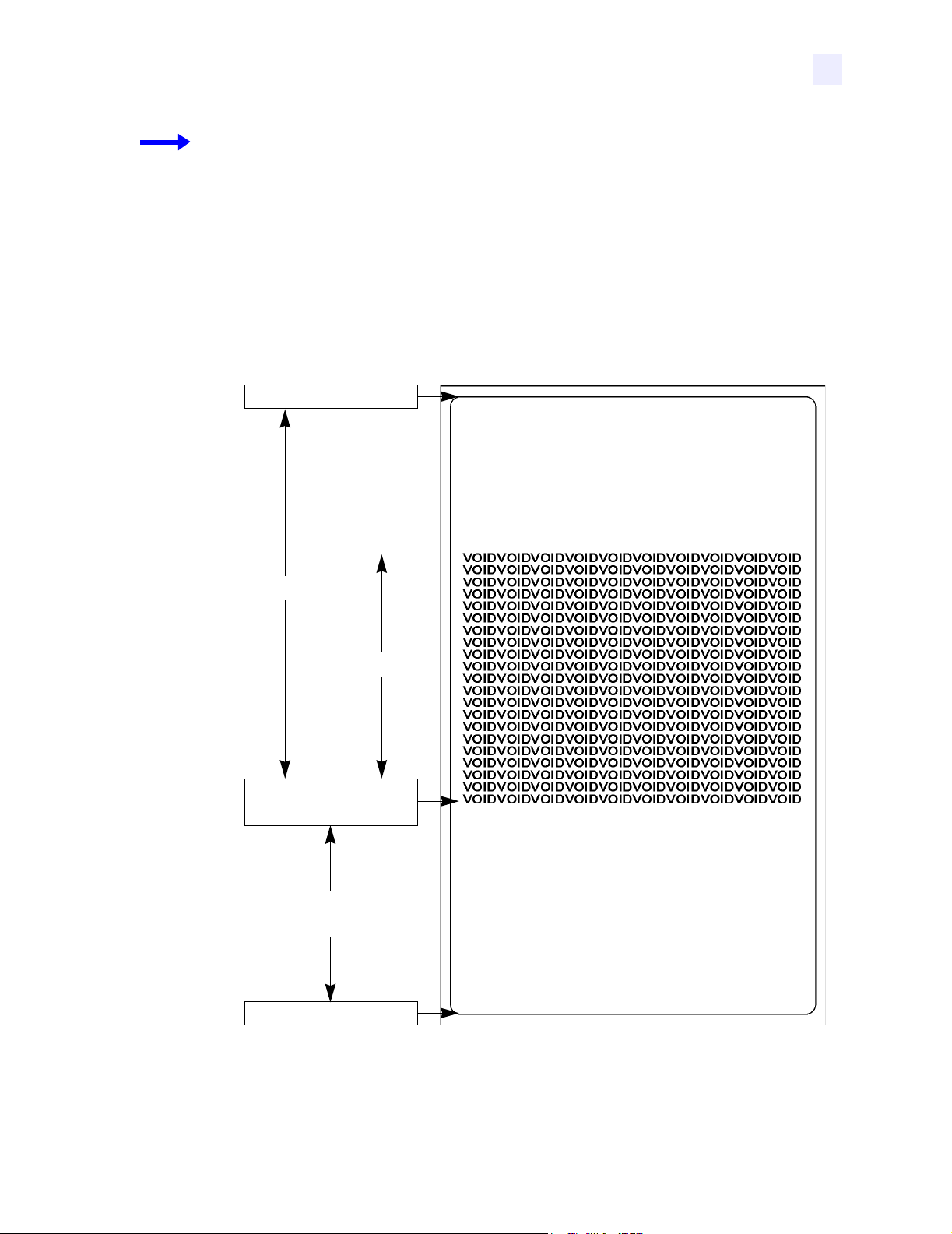

Example 2 • This example sets the printer to move the media to 800 dots from the top of the

media [or label length - 500 from the bottom (leading edge) of the media] and prints “void”

500 dots in vertical length (Y axis) in case of an error.

^XA

^RS,800,500,2,P^FS

^XZ

The following illustration shows the resulting voided label. Note where the void starts. The

media has been moved 800 dot rows from the top of the label [label length minus 800 dot rows

from the bottom (leading edge) of a label] to bring the transponder into the effective area to

read/write a tag. If the printer fails the operation, an area that is 500 dot rows of the media is

voided instead of the entire rest of the media.

Top of label

800 dot rows

500 dot rows

Start of RFID

operation

Label length minus

800 dot rows

Bottom of label

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 67

Page 8

RFID Guidelines

^RT

^RT

Read Tag

Description The ^RT command tells the printer to read the current RFID tag data. The data

can be sent back to the host via the

^HV command.

Format

The following table identifies the parameters for this format.

Parameters Details

# = number to be

assigned to the field

b = starting block

number*

n = number of blocks

to read*

^RT#,b,n,f,r,m,s

Accepted values: 0 to 9999

Default value: 0

Accepted values: 0 to n, where n is the maximum number of blocks for the tag.

Default value: 0

Accepted values: 1 to n, where n is the maximum number of blocks minus the

starting block number. For example, if the tag has 8 blocks (starting with

block 0) and you start with block 6, n can be 2. This would give you block 6 and

block 7 information.

Default value: 1

f =format Accepted values:

•0 (ASCII)

• 1 (Hexadecimal)

Default value: 0

r = number of retries Accepted values: 0 to 10

Default value: 0

m =motion Accepted values:

• 0 (Feed label after writing.)

• 1 (No Feed after writing. Other ZPL may cause a feed.)

Default value: 0

s = special mode For EPC Class 1 (Alien reader) only. Not applicable for EPC class 0.

Default value: 0 (Do not read if mismatched checksum.)

Accepted values: 1 (Read even if mismatched checksum.)

*Not applicable for R110XiIIIplus

Example • This sample reads a tag, prints the data on a label, and sends the string

Tag Data:xxxxxxxx back to the host. The data read will go into the ^FN1 location of the

format. The printer will retry the command five times, if necessary.

^XA

^FO20,120^A0N,60^FN1^FS

^RT1,,,,5^FS

^HV1,,Tag Data:^FS

^XZ

68 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 9

^WT

Write Tag

RFID Guidelines

^WT

Note • Check the amount of data memory available for the tag that you will be using. If more is

sent than the memory can hold, the data will be truncated.

Description The ^WT command allows you to program the current RFID tag.

Format

The following table identifies the parameters for this format.

Parameters Details

^WTb,r,m,w,f,v

b =block number Accepted values:

• 0 (ID data/EPC)

• 1 (User data)

Default value: 0

r = number of

retries

Accepted values: 0 to 10

Default value: 0

m =motion Accepted values:

• 0 (Feed label after writing.)

• 1 (No Feed after writing. Other ZPL may cause a feed.)

Default value: 0

w = write protect Accepted values:

• 0 (Not write protected.)

• 1 (Write protect.)

Default value: 0

f = data format Accepted values:

• 0 (ASCII)

• 1 (Hexadecimal)

Default value: 0

v = verify valid

data*

*Not applicable for R110XiIIIplus

Default value: y

Accepted values:

• n (Do not verify)

• y (Verify valid data [Hex A5A5 in the first two bytes] before writing)

Example • This sample encodes data “RFIDRFID” and will try writing up to five times, if

necessary.

^XA

^WT,5^FDRFIDRFID^FS

^XZ

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 69

Page 10

RFID Guidelines

Sample of RFID Programming

Sample of RFID Programming

ZPL II is Zebra’s label design language. ZPL II lets you create a wide variety of labels from

the simple to the very complex, including text, bar codes, and graphics.

This section is not intended as an introduction to ZPL II. If you are a new ZPL II user, order

the ZPL II Programming Guide (part number 46530L) or go to

download the guide.

For your programming, do the following:

1. Set up the printer and turn the power On (I).

http://support.zebra.com to

2. Use any word processor or text editor capable of creating ASCII-only files (for example,

use Microsoft

®

Word and save as a .txt file) and type in the label format exactly as shown

in the sample label format shown in Table 7.

3. Save the file in a directory for future use. Use the “.zpl” extension.

4. Copy the file to the printer.

From the DOS command window, use the “COPY” command to send a file to the Zebra

printer. For example, if your file name is format1.zpl then type,

COPY FORMAT 1.ZPL XXXX

where XXXX is the port to which your Zebra printer is connected (such as LPT1).

5. Compare your results with those shown. If your printout does not look like the one shown,

confirm that the file you created is identical to the format shown, then repeat the printing

procedure. If nothing prints, refer to

• Printer Setup on page 7

• Printer Operation on page 21

• Front Panel Controls on page 41

• Troubleshooting on page 99

to make sure that your system is set up correctly.

70 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 11

RFID Guidelines

Sample of RFID Programming

Table 7 • Sample ZPL Code and Results

Line Number Type This Label Format Resulting Printout

1 ^XA ZEBRA

2^RS,0^FS

5A65627261000000

3 ^WT^FDZebra^FS

4 ^FO100,100^A0n,60^FN0^FS

5 ^FO100,200^A0n,40^FN1^FS

6^RT0^FS

7 ^RT1,,,1^FS

8^XZ

Line 1 Indicates start of label format.

Line 2 Indicates no movement for media.

Line 3 Writes the data “Zebra” to the tag.

Line 4 Print field number ‘0’ at location 100,100.^FN0 is replaced by what we read on line 6.

Line 5 Print field number ‘1’ at location 100,200. ^FN1 is replaced by what we read on line 7.

Line 6 Read Tag into field number 0 in ASCII format (default).

Line 7 Read Tag into field number 1 in hexadecimal format.

Line 8 End of label format.

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 71

Page 12

RFID Guidelines

Sample of RFID Programming

Notes • ___________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

To provide feedback on this document, please send your comments to techpubs@zebra.com, or

write your comments on this page and fax to the following:

Fax: 1.847.821.1795 Attention: TechPubs — CTC

72 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 13

6

Data Ports

This chapter describes the standard communication ports available to connect the printer to your

computer or network.

Contents

Parallel Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Serial Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

RS-232 Interface Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

RS-422/RS-485 Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

USB 2.0 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 73

Page 14

Data Ports

Parallel Port

Parallel Port

When communicating via the parallel port, the values selected must be the same as those used

by the host equipment connected to the printer. Port selection for status information is

determined by the channel sending the request. The parallel port can be set for bidirectional or

unidirectional communication. The default setting is bidirectional.

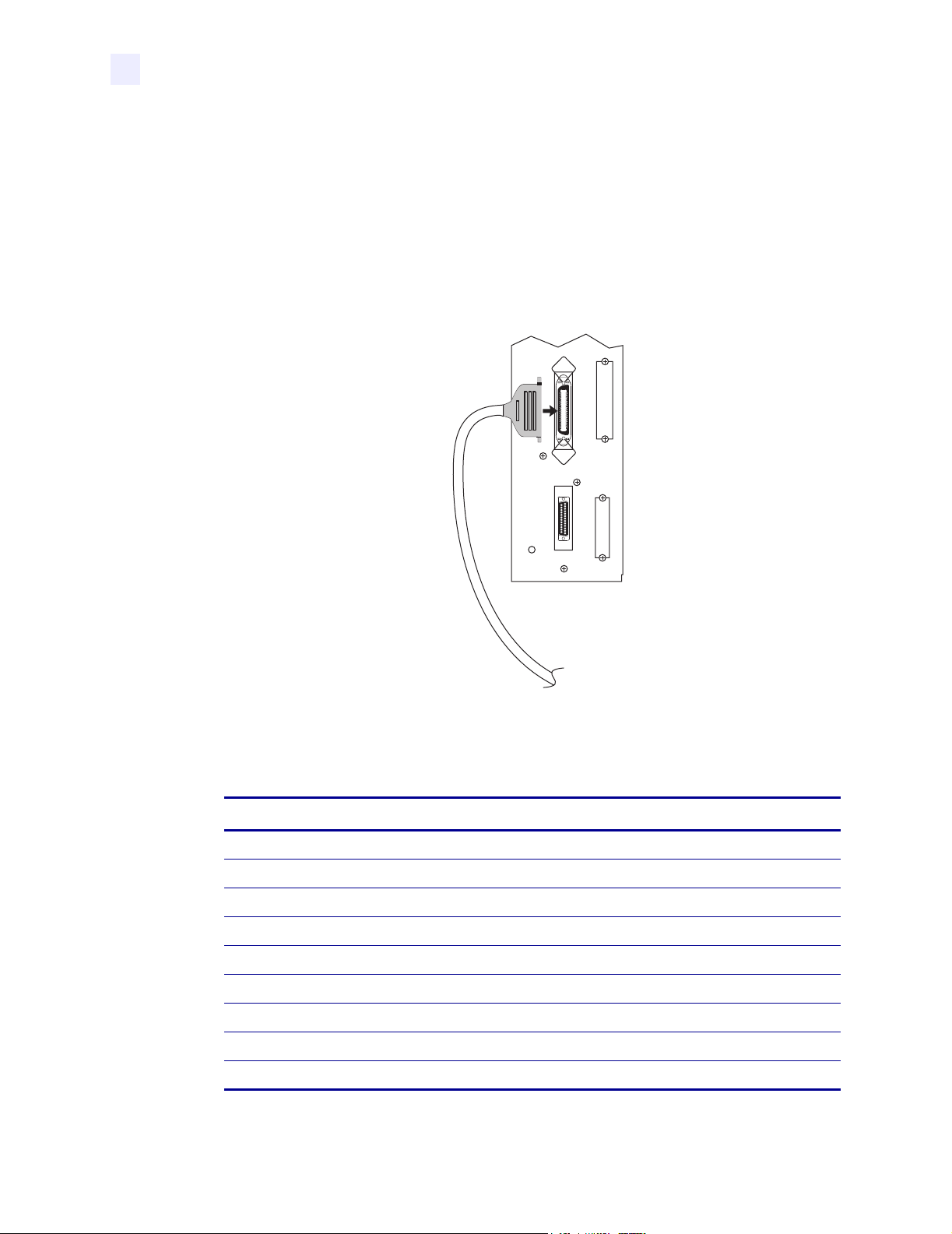

A standard 36-pin parallel connector (Figure 30) is available on the back of the printer for

connection to the data source.

Figure 30 • Parallel Connector

Table 8 shows the pin configuration and function of a standard computer-to-printer parallel

cable.

Table 8 • Parallel Cable Pin Configuration

36-Pin Connectors Description

1 nStrobe/HostClk

2–9 Data Bits 1–8

10 nACK/PtrClk

11 Busy/PtrBusy

12 PError/ACKDataReq

13 Select/Xflag

14 nAutoFd/HostBusy

15 Not used

16, 17 Ground

74 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 15

Table 8 • Parallel Cable Pin Configuration (Continued)

36-Pin Connectors Description

18 +5 V at 750 mA

The maximum current draw may be limited by option

configuration.

19–30 Ground

31 ninit

32 nFault/NDataAvail

33, 34 Not used

35 +5 V through a 1.8 KΩ Resistor

36 NSelectin/1284 active

Data Ports

Parallel Port

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 75

Page 16

Data Ports

Serial Port

Serial Port

To communicate using the serial data port of the printer, you must choose the number of data

and stop bits, parity, and handshaking. Parity applies only to data transmitted by the printer

because the parity of received data is ignored.

The values selected must be the same as those used by the host equipment connected to the

printer. Default settings are 9600 baud, 8 data bits, 1 stop bit, no parity, and XON/XOFF.

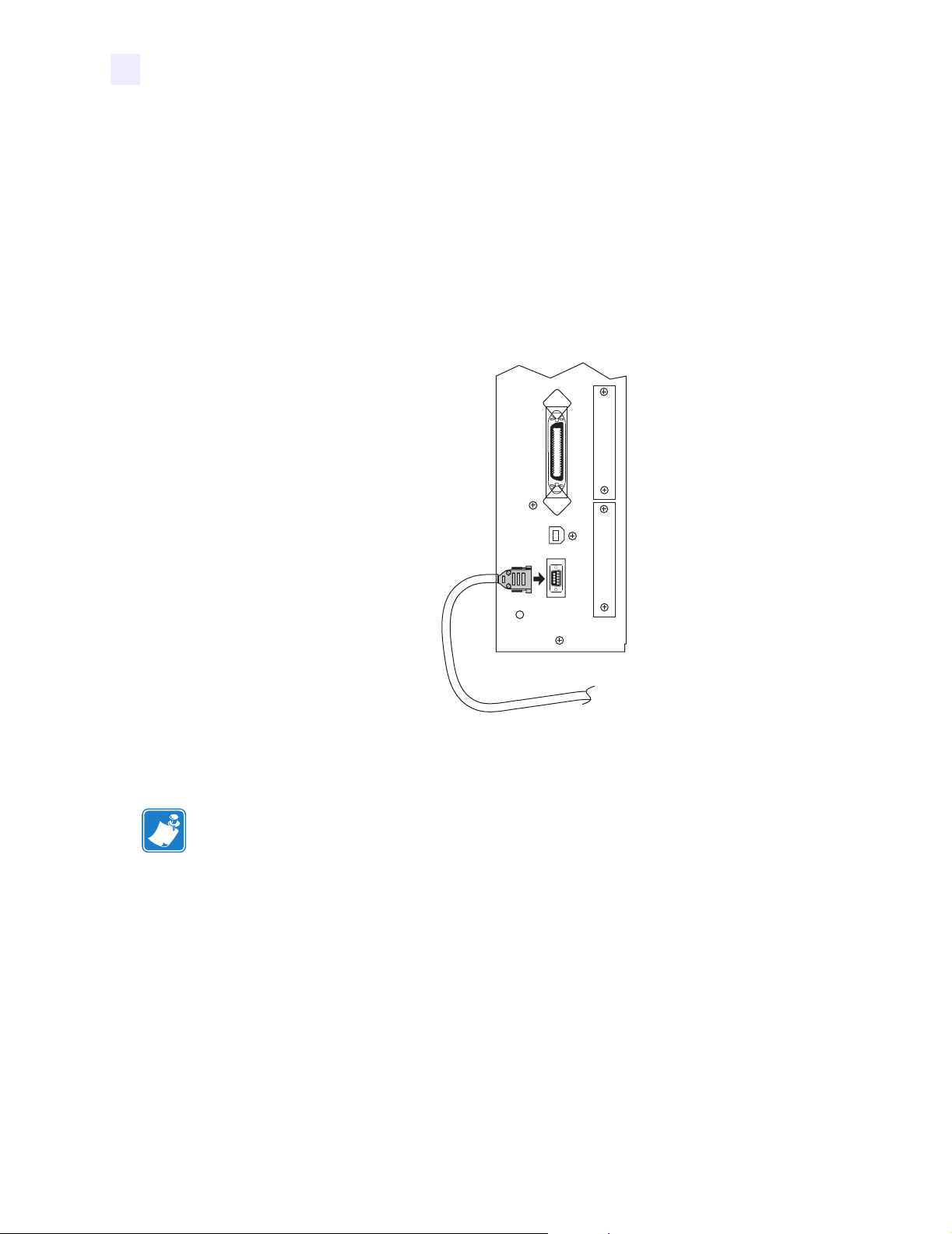

Connect the serial data cable to the female DB-9 connector (Figure 31) on the back panel of

the printer.

Figure 31 • Serial Connector

Use a DB-9 to DB-25 interface module for all RS-232 connections through a DB-25 cable. An

interface module is required for RS-422/RS-485 interface support (see RS-422/RS-485

Interconnections on page 80).

Note • For all RS-232 input and output signals, the printer follows the specifications of the

Electronics Industries Association (EIA) RS-232 and the Consultative Committee for

International Telegraph and Telephone (CCITT) V.24.

76 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 17

Serial Pin Configuration

Table 9 shows the pin configuration and function of the rear panel serial data connector on

the printer.

Table 9 • Serial Connector Pin Configuration

Pin No. Name Description

1 — Not connected

2 RXD Receive data—data input to printer

3 TXD Transmit data—data output from printer

4 DTR Data terminal ready—output from printer

5 SG Signal ground

6 DSR Data set ready—input to printer

7 RTS Request to send—output from printer

8 CTS Clear to send—input to printer

Data Ports

Serial Port

\

9 +5 VDC +5 VDC at 750 mA

The maximum current draw may be limited by option

configuration.

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 77

Page 18

Data Ports

Serial Port

RS-232 Interface Connections

Note • Adapters are available from Zebra Technologies LLC.

• RS-422/RS-485 adapter, Zebra part number 33114M

• RS-232 DB-9 to DB-25 adapter, Zebra part number 33109M

Direct Connection to a Computer

The printer is configured as Data Terminal Equipment (DTE).

Note • Use a null modem (crossover) cable to connect the printer to a computer or any other

DTE device.

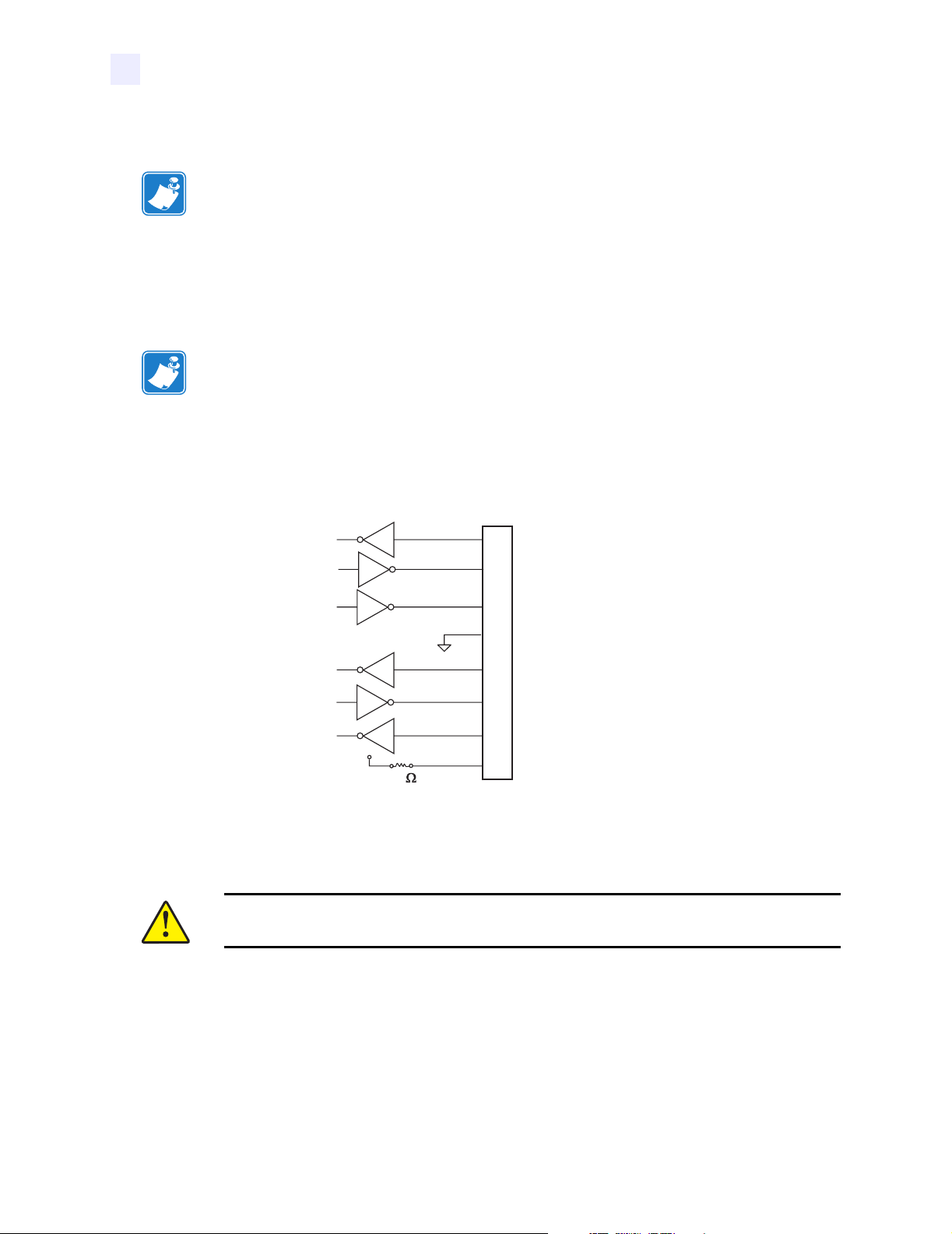

Figure 32 shows the internal connections of the printer’s RS-232 connector.

Figure 32 • RS-232 Connections

RS-232 Connector (DTE)

Rear Panel Female DB-9

2

RXD (receive data) input

3

TXD (transmit data) output

4

DTR (data terminal ready) output

5

SG (signal ground)

6

DSR (data set ready) input

7

RTS (request to send) output

8

+5 VDC

R1

1K

NOTE: Pin 1 is unused and unterminated.

CTS (clear to send) input

9

+5 VDC signal source

Pin 9 is also available as a +5 VDC signal source at 750 mA. The maximum current draw may

be limited by option configuration.

Caution • To enable this capability, a qualified service technician must install a jumper on

the printer’s main logic board on JP1, pins 2 and 3.

78 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 19

Data Ports

Serial Port

DB-9 to DB-25 Connections

An interface adapter is required (Zebra part number 33109M) to connect the printer’s DB-9

interface to a DB-25 connector. A generic DB-25 adapter CAN be used, although the +5 VDC

signal source would not be passed through the adapter.

Figure 33 shows the connections required for the DB-9 to DB-25 interface.

Figure 33 • DB-9 to DB-25 Connections

Male DB-9 Adapter

Connector

(plugs into printer)

RXD

2

TXD

3

DTR

4

SG

5

DSR

6

RTS

7

CTS

8

+5 VDC

9

SIGNAL

NOTE: Pin 1 of DB-9 connector is unused and unterminated.

Female DB-25 Adapter

Connector

(plugs into cable)

FG

1

TXD

RXD

RTS

CTS

DSR

+5 VDC

SIGNAL

DTR

SG

2

3

4

5

6

7

9

20

Modem Connection

When the printer is connected via its RS-232 interface to Data Communication Equipment

(DCE) such as a modem, use a standard RS-232 (straight-through) interface cable.

Figure 34 shows the connections required for this cable.

Figure 34 • RS-232 Connections

DTE

(Printer)

2

3

4

5

6

7

8

9

NOTE: Pin 1 is unused and unterminated at the printer.

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 79

RXD (receive data)

TXD (transmit data)

DTR (data terminal ready)

SG (signal ground)

DSR (data set ready)

RTS (request to send)

CTS (clear to send)

+5 VDC signal source

DCE

(Modem, etc.)

2

3

4

5

6

7

8

9

Page 20

Data Ports

Serial Port

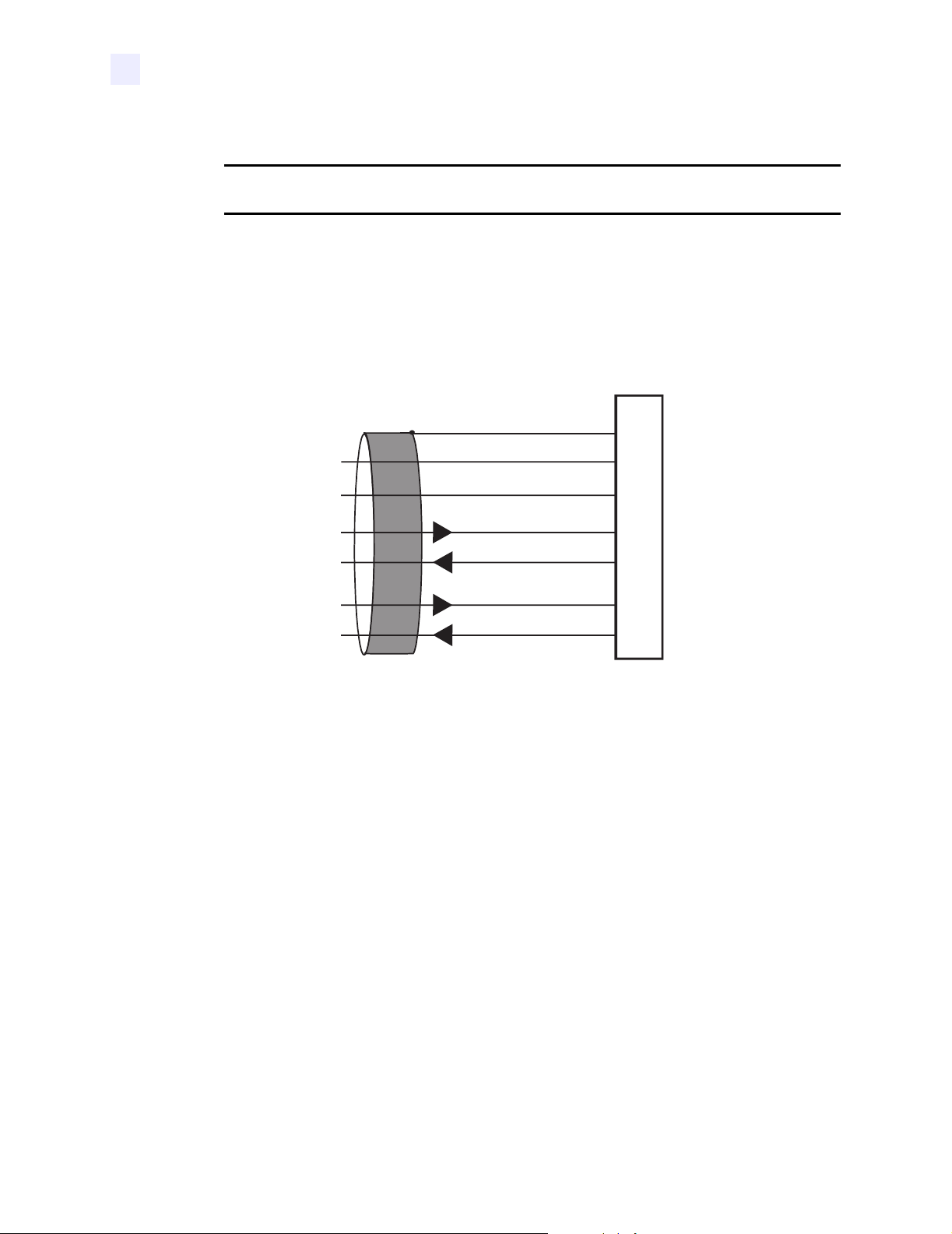

RS-422/RS-485 Interconnections

Caution • A qualified service technician must install a jumper on the printer’s main logic

board at JP1, pins 2 and 3, for the RS-422/RS-485 interface adapter to function properly.

An interface adapter (Zebra part number 33114M) is required to connect the printer’s RS-232

DB-9 interface to a host computer through an RS-422 or RS-485 interface. A generic DB-25

adapter can be used. Figure 35 shows the cable wiring for interconnecting the DB-9 to the

interface adapter’s DB-25 female connector.

Figure 35 • DB-9 to DB-25 Connections

Frame ground

+5 VDC 725 mA source

Signal ground ref.

Data input B (–)

Data output B (–)

Data input A (+)

Data output A (+)

NOTE: Pins 2–8, 10, 12, 15, 17, 18, and 20–25 are unused and unterminated.

Female DB-25 Connector on

RS-422/RS-485 Adapter

1

9

11

13

14

16

19

80 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 21

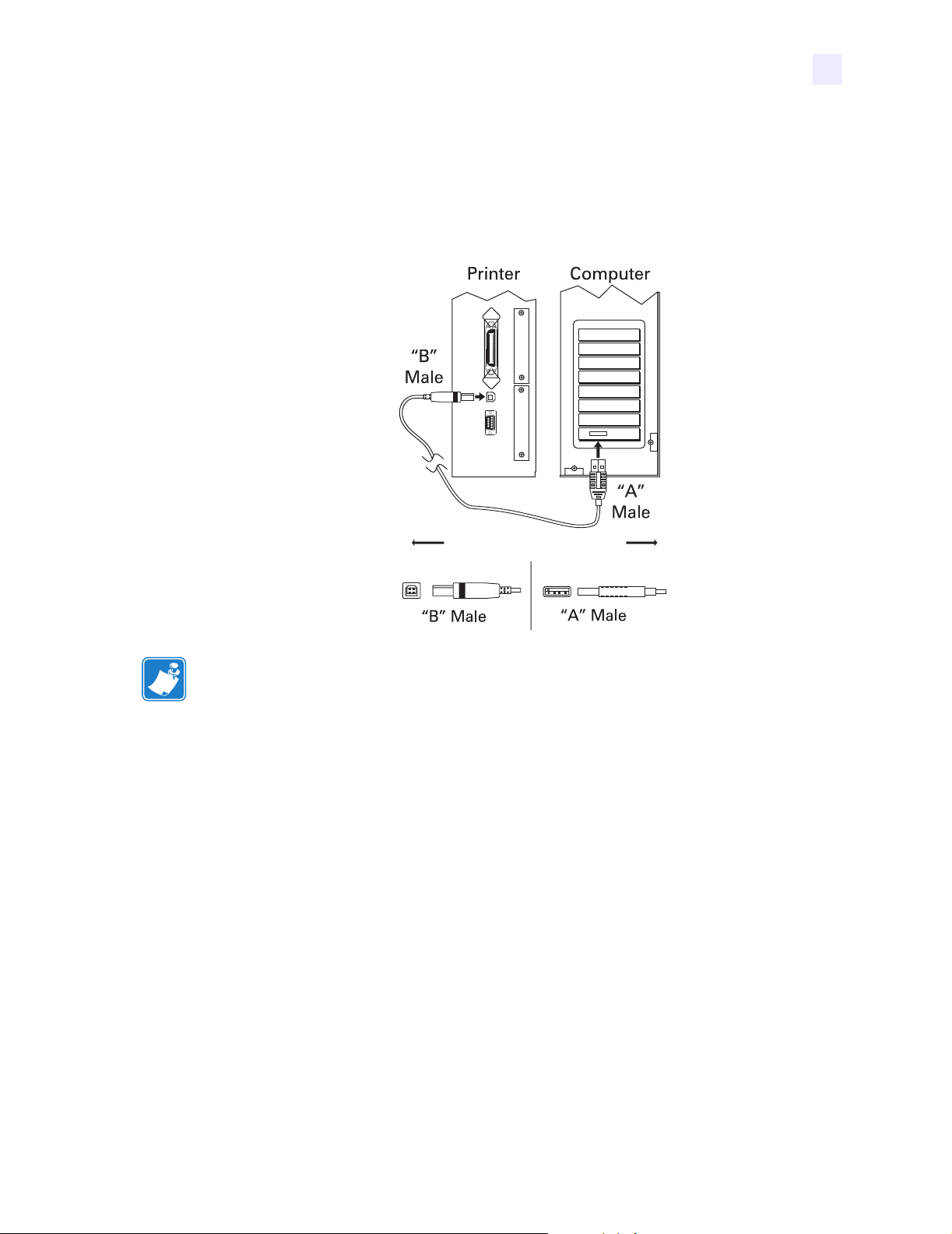

USB 2.0 Port

A USB 2.0 port (which is USB 1.1 and 1.0 compatible) is available to connect your printer to

the host equipment. The industry-standard USB cable has an A-male connector on one end and

a B-male connector on the other end as shown in Figure 36.

Data Ports

USB 2.0 Port

Figure 36 • USB Connectors

=

16.4 ft (5 m) maximum

Note • Use a USB 2.0-certified compliant cable no longer than 16.4 ft (5 m) long. A cable that

meets these requirements is available from Zebra (part number 33011).

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 81

Page 22

Data Ports

USB 2.0 Port

Notes • ___________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

To provide feedback on this document, please send your comments to techpubs@zebra.com, or

write your comments on this page and fax to the following:

Fax: 1.847.821.1795 Attention: TechPubs — CTC

82 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 23

7

Memory Cards

This chapter describes the optional cards that can be used with the printer and gives instructions for

installation.

Contents

PCMCIA Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

CompactFlash Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 83

Page 24

Memory Cards

PCMCIA Memory Card

PCMCIA Memory Card

A Type 1- or Type II-compliant PCMCIA memory card holds extra memory or font options for

the printer. The card is hot-swappable (it can be installed while the printer is on).

Electrostatic Discharge Caution • Observe proper electrostatic safety precautions when

handling any static-sensitive components such as circuit boards and printheads.

To install the PCMCIA card, complete these steps:

1. Remove the PCMCIA card shield from the rear of the printer (Figure 37).

Figure 37 • PCMCIA Card Installation

1 2 3 4

PCMCIA card shield

1

PCMCIA card

2

Notch

3

Card-eject button

4

2. Insert the PCMCIA card, with the notch up, into the card slot as shown. Insert it far

enough to make the eject button pop out.

84 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 25

Memory Cards

PCMCIA Memory Card

3. Reinstall the PCMCIA card shield over the PCMCIA card and card slot.

Note • The PCMCIA card may take a few minutes to initialize. The PAU SE light

flashes while the card initializes. If the card is already initialized, the PAUSE light

flashes only once or twice after the card is installed.

The printer is ready to operate with the additional memory or font option. To be sure that

the card has successfully initialized, print a configuration label as instructed in Print a

Printer Configuration Label on page 31 and review it to see whether the new memory

card information is listed.

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 85

Page 26

Memory Cards

CompactFlash Card

CompactFlash Card

A CompactFlash card is a nonvolatile memory card that stores data even when the power to

the printer is turned off. A Type I-compliant CompactFlash card holds extra memory or

optional fonts for your printer.

Caution • This procedure should only be performed by qualified service technicians.

Electrostatic Discharge Caution • Observe proper electrostatic safety precautions when

handling any static-sensitive components such as circuit boards and printheads.

To install a CompactFlash card, complete these steps:

1. Turn the AC power Off (O).

2. Disconnect the AC power cord from the printer.

3. Remove the two screws near the bottom of the electronics cover (Figure 38).

Figure 38 • Printer Exterior

1

3

4

Electronics cover

1

Screws

2

Channel

3

Lip of cover

4

4. Lift the electronics cover at the rear top corner. Pull the corner forward and up, then lift the

2

cover up and away from the printer.

86 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 27

Memory Cards

CompactFlash Card

5. Insert the CompactFlash card into the card slot on the upper portion of the option board.

Insert the card with the back (unlabeled) side of the card facing out. The card can be

inserted only one way and should snap into place.

Figure 39 shows where to insert the CompactFlash card.

Figure 39 • Compact Flash Card Insertion

1 2 3

Option board

1

Card slot

2

Compact flash card

3

6. Reinstall the electronics cover by lowering the cover so the lip of the cover goes into the

channel on the top of the printer.

7. Secure the cover by reinstalling the two screws near the bottom of the cover.

8. Reconnect the printer AC power cord.

9. Press and hold CANCEL while turning the printer On (I).

The printer prints a configuration label.

10. Check for the presence of additional memory or optional fonts by looking at the

information on the configuration label.

Note • The CompactFlash card may take a few minutes to initialize. If the process is not

successfully completed within 10 minutes, contact Technical Support at

http://www.zebra.com/SS/service_support.htmfor assistance.

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 87

Page 28

Memory Cards

CompactFlash Card

Notes • ___________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

To provide feedback on this document, please send your comments to techpubs@zebra.com, or

write your comments on this page and fax to the following:

Fax: 1.847.821.1795 Attention: TechPubs — CTC

88 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 29

8

Routine Maintenance

Cleaning your printer regularly maintains print quality and may extend the life of the printer. This

section provides routine cleaning and maintenance procedures.

Contents

Cleaning Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Clean Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Clean Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Printhead and Platen Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Snap Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Replace Fuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 89

Page 30

Routine Maintenance

Cleaning Schedule

Cleaning Schedule

The recommended cleaning schedule is shown in Tab le 10. See the following pages for

specific procedures.

Caution • Use only the cleaning agents indicated. Zebra is not responsible for damage

caused by any other fluids being used on this printer.

Table 10 • Recommended Printer Cleaning Schedule

Area Method Interval

Printhead Solvent*† Perform these procedures at the following times:

Platen roller Solvent*

Transmissive (media) sensor Air blow

Media path Solvent*

Ribbon sensor Air blow

•When

• Direct Thermal Print Mode: After every roll of labels

• Thermal Transfer Print Mode: After every roll

CLEAN HEAD NOW

or 500 ft (150 m) of fanfold labels.

(1500 ft or 450 m) of ribbon.

appears.

Label-available sensors Air blow Monthly

Tear-off bar Solvent*

Snap plate Solvent* As needed

* Use Zebra’s Preventative Maintenance kit, part number 47362, or a solution of 90% isopropyl alcohol and

10% deionized water.

Clean Exterior

Clean the outside surfaces of the printer with a lint-free cloth. Use a mild detergent solution or

desktop cleaner sparingly, as needed.

Caution • Do not use harsh or abrasive cleaning agents or solvents.

90 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 31

Clean Interior

After every four rolls of media, inspect the inside of the printer. Use a soft bristle brush or a

vacuum cleaner to remove any dirt and lint from the interior of the printer.

Printhead and Platen Roller

After every roll of ribbon, clean the printhead. Clean the printhead more often if you see

inconsistent print quality, such as voids in the bar code or graphics.

Clean after every roll (1500 feet or 450 m) of thermal transfer ribbon or after every roll

(500 feet or 150 m) of direct thermal labels or when

the LCD.

Note • You do not need to turn off the printer before cleaning the printhead. If power is turned

off, all label formats and images, as well as any temporarily saved parameter settings stored in

the printer’s internal memory, are lost. When power is turned back on, these items must be

reloaded.

If print quality does not improve after you perform this procedure, clean the printhead with

Save-a-Printhead cleaning film. This specially coated material removes contamination

buildup without damaging the printhead. Call your authorized Zebra reseller or distributor for

more information.

Routine Maintenance

CLEAN HEAD NOW

Clean Interior

appears on

Caution • The printhead is hot and can cause severe burns. Allow the printhead to cool.

Caution • Observe proper electrostatic safety precautions when handling any static-

sensitive components such as circuit boards and printheads.

To clean the printhead and platen roller, complete these steps:

1. Open the printhead.

2. Remove the media and ribbon (if loaded).

3. Use Zebra’s Preventative Maintenance kit, part number 47362, or a solution of

90% isopropyl alcohol and 10% deionized water on an applicator to wipe along the print

elements from end to end, as shown in Figure 40. (The print elements are on the brown

strip on the printhead.) Allow a few seconds for the solvent to evaporate.

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 91

Page 32

Routine Maintenance

Clean Interior

Figure 40 • Cleaning the Printhead

3

4

1

2

Applicator

1

Platen roller

2

Printhead print elements

3

Printhead lever

4

4. Rotate the platen roller and clean thoroughly with solvent and an applicator.

5. Brush or vacuum any accumulated paper lint and dust away from the rollers.

6. Reload the media and the ribbon (if required).

7. Close the printhead.

92 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 33

Sensors

Brush or vacuum any accumulated paper lint and dust off the sensors whenever the sensors are

blocked. At minimum, clean the sensors according to the recommendations in Cleaning

Schedule on page 90.

Ribbon and Label-Available Sensor Locations

The ribbon sensor and optional label-available sensor are shown in Figure 41.

Figure 41 • Sensor Locations

1

Routine Maintenance

Clean Interior

Label-available sensors

1

Ribbon sensor

2

2

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 93

Page 34

Routine Maintenance

Clean Interior

Transmissive (Media) Sensor Locations

The locations of the upper and lower transmissive (media) sensors are shown in Figure 42 and

Figure 43.

Figure 42 • Upper Media Sensor

1

Upper media sensor

1

Figure 43 • Lower Media Sensor

Lower media sensor

1

1

94 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 35

Snap Plate

Clean the snap plate when label adhesive or a label is stuck to the underside. Figure 44 shows

the location of the snap plate.

Figure 44 • Snap Plate

1

Routine Maintenance

Clean Interior

2

6

1

2

5

4

3

Antenna support screws

Location of right-side snap plate screw

(screw not shown)

Snap plate

3

Antenna support

4

Antenna support frame

5

Left-side snap plate screw

6

To clean the snap plate, complete these steps:

1. Remove the two screws that secure the snap plate to the antenna support frame.

Important • Do not remove the antenna support screws.

2. Remove the snap plate from the printer.

3. Clean the snap plate with cleaning solvent and a soft cloth.

4. To reinstall the snap plate, slide it back into place until the screw holes on the snap plate

line up with the screw holes in the antenna support frame.

5. Reinstall the two snap plate screws to secure the snap plate to the antenna support frame.

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 95

Page 36

Routine Maintenance

Replace Fuse

Replace Fuse

The R110XiIIIPlus fuse must be replaced only by an authorized service technician.

Caution • Turn the AC power switch Off (O) and remove the power cord before performing

this procedure.

The printer uses a metric-style fuse (5 × 20 mm IEC) rated at F5A, 250 V. The AC power entry

module comes with two approved fuses in the fuse holder: one is in-circuit, and the second is

provided as a spare. The end caps of the fuse must bear the certification mark of a known

international safety organization.

To replace a faulty fuse, complete these steps:

1. Use a small-blade screwdriver or similar tool to remove the fuse holder.

The fuse holder is part of the AC power entry module at the rear of the printer (Figure 45).

Figure 45 • AC Power Entry Module

1

2

3

4

Power switch

1

Fuse holder

2

AC power entry module

3

Small-blade screwdriver

4

2. Remove the faulty fuse and install a new fuse in the in-circuit position (Figure 46).

Important • If you use the spare fuse, be sure to order a replacement fuse from your

authorized Zebra distributor. The spare fuse should be the exact type and rating as the

original in-circuit fuse.

96 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 37

Routine Maintenance

Replace Fuse

Figure 46 • Fuse Locations

1

2

3

In-circuit fuse

1

Fuse holder

2

Spare fuse

3

3. Snap the fuse holder back into the AC power entry module.

4. Reconnect the power cord, and turn the printer On (I).

Note • If the printer does not power on, an internal component failure may have occurred,

and the printer requires servicing by an authorized service technician.

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 97

Page 38

Routine Maintenance

Replace Fuse

Notes • ___________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

To provide feedback on this document, please send your comments to techpubs@zebra.com, or

write your comments on this page and fax to the following:

Fax: 1.847.821.1795 Attention: TechPubs — CTC

98 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 39

9

Troubleshooting

This chapter provides you with information about LCD, print quality, communications, and other

errors that you might need to troubleshoot.

Contents

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

LCD Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Print Quality Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Communications Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Printer Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Power-On Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Additional Printer Self Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Communications Diagnostics Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Additional Printer Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 99

Page 40

Troubleshooting

Troubleshooting

Troubleshooting

If an error condition exists with the printer, review this checklist:

Is there an error message on the LCD? If yes, see LCD Error Messages on page 101 for

more information.

Is the CHECK RIBBON light on when ribbon is loaded properly, or are non-continuous

labels being treated as continuous labels? If yes, see Media and Ribbon Sensor

Calibration on page 34.

Are you experiencing problems with print quality? If yes, see Print Quality Problems

on page 104.

Are you experiencing communications problems? If yes, see Communications Problems

on page 106.

If the labels are not printing or advancing correctly, review this checklist:

Are you using the correct type of labels? Review the types of label in Types of Media

on page 14.

Review the label- and ribbon-loading illustrations, starting with Load the Printer

on page 22.

Check the position of the media sensor and move if necessary, as shown in Adjust and

Calibrate Sensors on page 34.

Does the printhead need to be adjusted? See Adjust Printhead Pressure and Toggle

Position on page 38 for more information.

Do the sensors need to be calibrated? See Media and Ribbon Sensor Calibration

on page 34 for more information.

If none of the above suggestions correct the problem, review this checklist:

Perform one or more of the self-tests given in Printer Diagnostics on page 108. Use the

results to help identify the problem.

If you are still having problems, see Support on page xviii for customer support

information.

100 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 41

LCD Error Messages

The LCD displays messages when there is an error. See Table 11 for LCD errors, the possible

causes, and the recommended solutions.

Table 11 • LCD Error Messages

LCD Possible Cause Recommended Solution

Troubleshooting

LCD Error Messages

RIBBON OUT

PAPER OUT

Thermal Transfer Mode—

Ribbon is not loaded or is loaded

incorrectly.

Thermal Transfer Mode—

Ribbon is loaded but the ribbon

sensor is not sensing the ribbon.

Direct Thermal Mode—

Ribbon is loaded.

Direct Thermal Mode—

Settings are incorrect.

Labels are not loaded or are

loaded incorrectly.

Media Sensor is not adjusted

correctly.

Printer is set for non-continuous

labels but continuous labels are

loaded.

Load the ribbon correctly, following directions in

Load Ribbon on page 26

Adjust the media and ribbon sensors. See Media

and Ribbon Sensor Calibration on page 34.

Make sure that ribbon is not loaded and that the

printer is in Direct Thermal Print Mode. See

Selecting Print Method on page 45.

Make sure the printer driver and software settings

are compatible with Direct Thermal Print Mode.

Load the labels correctly. See Load the Printer

on page 22.

Check the position of the media sensors, and adjust

if necessary. See Media and Ribbon Sensor

Calibration on page 34.

• Make sure the labels and the Media Type settings

match. See Setting Media Type on page 45.

• Make sure the printer driver or software settings

match the label and Media Type settings.

• Calibrate the printer. For more information, see

Calibrate the Printer on page 33.

.

The MAX LENGTH setting is

set to a value that is shorter than

the actual length of the label.

HEAD OPEN

HEAD ELEMENT

BAD

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 101

The printhead is not fully closed. Close the printhead.

One or more of the printhead

elements failed the printhead

element test.

Change the MAX LENGTH setting to a value that is

at least 1 in. (25 mm) longer than the

• If the failed elements affect your printing

application, replace the printhead.

• To override this error, disable the head test count

feature on the front panel by defaulting the value

to 0000.

Page 42

Troubleshooting

LCD Error Messages

Table 11 • LCD Error Messages (Continued)

LCD Possible Cause Recommended Solution

RIBBON IN

HEAD TOO HOT

CLEAN HEAD NOW

Ribbon is loaded, but the printer

is set for Direct Thermal mode.

• To operate in Direct Thermal mode, remove the

ribbon.

• To operate in Thermal Transfer mode, leave the

ribbon loaded and change the print method to

Thermal Transfer. See Selecting Print Method

on page 45.

• Ensure that the printer driver and/or software

settings are correctly set (if applicable).

The printhead is over

temperature.

Printing automatically resumes when the printhead

elements cool to an acceptable operating

temperature.

Caution • The printhead is hot and can

cause severe burns. Allow the printhead

to cool.

Electrostatic Discharge Caution •

Observe proper electrostatic safety

precautions when handling any staticsensitive components such as circuit

boards and printheads.

The printhead requires cleaning. Clean the printhead according to the instructions in

Printhead and Platen Roller on page 91.

Caution • The printhead is hot and can

cause severe burns. Allow the printhead

to cool.

Electrostatic Discharge Caution •

Observe proper electrostatic safety

precautions when handling any staticsensitive components such as circuit

boards and printheads.

If the message does not go away after the printhead

is cleaned, open the printhead and then close it.

102 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 43

LCD Error Messages

Table 11 • LCD Error Messages (Continued)

LCD Possible Cause Recommended Solution

Troubleshooting

HEAD COLD

Caution • An improperly connected printhead data or power cable can

cause this error message. The printhead can still be hot enough to cause

severe burns. Allow the printhead to cool.

The printhead is under

temperature.

Printhead data cable is not

properly connected.

Continue printing while the printhead reaches the

correct operating temperature. If the error remains,

the environment may be too cold for proper

printing. Relocate the printer to a warmer area.

Caution • You must turn off the printer before

performing this procedure. Failure to do so can

damage the printhead.

1. Turn off (O) the printer.

2. Disconnect and reconnect the data cable to the

printhead.

3. Ensure that the cable connector is fully inserted

into the printhead connector.

4. Turn on (I) the printer.

Electrostatic Discharge Caution •

Observe proper electrostatic safety

precautions when handling any staticsensitive components such as circuit

boards and printheads.

OUT OF MEMORY

There is not enough memory to

perform the function shown on

the second line of the error

message.

Turn the printer off then back on to clear memory,

and try to print again. If the error recurs, there is

insufficient memory for the label length,

downloaded fonts or graphics, and images.

Ensure that the device, such as Flash memory or

PCMCIA card, is installed and not write-protected

or full. See Memory Cards on page 83.

Electrostatic Discharge Caution •

Observe proper electrostatic safety

precautions when handling any staticsensitive components such as circuit

boards and printheads.

Ensure that the data is not directed to a device that is

not installed or available.

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 103

Page 44

Troubleshooting

Print Quality Problems

Print Quality Problems

Table 12 identifies problems with print quality, the possible causes, and the recommended

solutions.

Table 12 • Print Quality Problems

Problem Possible Cause Recommended Solution

General print quality

issues

You are using an incorrect

combination of labels and ribbon

Consult your authorized Zebra reseller or distributor

for information and advice.

for your application.

The printer is set at the incorrect

print speed.

For optimal print quality, set the print speed to the

lowest possible setting for your application via

ZPL II, the driver, or the software. See Adjusting

Print Speed on page 44.

The printer is set at an incorrect

darkness level.

For optimal print quality, set the darkness to the

lowest possible setting for your application via the

front panel, the driver, or the software. See

Adjusting Print Darkness on page 44.

The printhead is dirty. Clean the printhead according to the instructions in

Printhead and Platen Roller on page 91.

Caution • The printhead is hot and can

cause severe burns. Allow the printhead

to cool.

Electrostatic Discharge Caution •

Observe proper electrostatic safety

precautions when handling any staticsensitive components such as circuit

boards and printheads.

There is light

printing (or no

The toggle pressure needs to be

adjusted.

Follow the instructions in Adjust Printhead

Pressure and Toggle Position on page 38.

printing) on the left

or right side of the

label or the printed

image is not sharp.

Gray lines on blank

labels with no

The printhead is dirty. Clean the printhead according to the instructions in

Printhead and Platen Roller on page 91.

consistent pattern

104 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Electrostatic Discharge Caution •

Observe proper electrostatic safety

precautions when handling any staticsensitive components such as circuit

boards and printheads.

Caution • The printhead is hot and can

cause severe burns. Allow the printhead

to cool.

Electrostatic Discharge Caution •

Observe proper electrostatic safety

precautions when handling any staticsensitive components such as circuit

boards and printheads.

Page 45

Print Quality Problems

Table 12 • Print Quality Problems (Continued)

Problem Possible Cause Recommended Solution

Troubleshooting

Light, consistent

vertical lines running

The printhead or platen roller is

dirty.

through the labels

Intermittent creases

on the left and right

There is too much toggle

pressure on the printhead.

edges of the labels

Wrinkled Ribbon The ribbon is not loaded

correctly.

The darkness setting is incorrect. Set the darkness to the lowest possible setting for

Clean the printhead and platen roller as instructed in

Printhead and Platen Roller on page 91.

Caution • The printhead is hot and can

cause severe burns. Allow the printhead

to cool.

Electrostatic Discharge Caution •

Observe proper electrostatic safety

precautions when handling any staticsensitive components such as circuit

boards and printheads.

Reduce the toggle pressure. See Adjust Printhead

Pressure and Toggle Position on page 38.

Electrostatic Discharge Caution •

Observe proper electrostatic safety

precautions when handling any staticsensitive components such as circuit

boards and printheads.

Load the ribbon correctly. See Load Ribbon

on page 26

.

good print quality. See Adjusting Print Darkness

on page 44.

Incorrect printhead pressure or

balance.

The labels are not feeding

correctly. They are shifting from

side to side.

Set the pressure to the minimum required for good

print quality. See Adjust Printhead Pressure and

Toggle Position on page 38.

Electrostatic Discharge Caution •

Observe proper electrostatic safety

precautions when handling any staticsensitive components such as circuit

boards and printheads.

Make sure that the media guide and media supply

guide touch the edge of the media.

Adjust the ribbon strip plate.

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 105

Page 46

Troubleshooting

Communications Problems

Communications Problems

Table 13 identifies problems with communications, the possible causes, and the recommended

solutions.

Table 13 • Communications Problems

Problem Possible Cause Recommended Solution

A label format was sent to

the printer but was not

recognized. The DATA light

does not flash.

A label format was sent to

the printer. Several labels

print, then the printer

skips, misplaces, misses, or

distorts the image on the

label.

The communication

parameters are incorrect.

The host is set to EPP parallel

communications.

The serial communication

settings are incorrect.

Check the printer driver or software

communications settings (if applicable).

If you are using serial communication, check the

serial port setting in the front panel menu. See

Setting Serial Communications on page 50.

Make sure you are using the correct

communication cable. See Data Cable

Requirements on page 13 for the requirements.

Using the front panel controls, check the

NONE

protocol setting. It should be set to

Setting Protocol on page 51.

If a driver is used, check the driver

communication settings for your connection.

Change the settings on the computer host to

standard parallel communications. See Setting

Parallel Communications on page 50.

Ensure that the flow control settings match.

Check the communication cable length. See

Data Cable Requirements on page 13 for

requirements.

. See

Check the printer driver or software

communications settings (if applicable).

A label format was sent to

the printer but was not

recognized. The DATA light

flashes but no printing

occurs.

106 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

The prefix and delimiter

characters set in the printer do

not match the ones in the

label format.

Incorrect data is being sent to

the printer.

Verify the prefix and delimiter characters. See

Format Prefix Character on page 53

Delimiter Character on page 53 for the

requirements.

Ensure that ZPL is being used.

Check the communication settings on the

computer. Ensure that they match the printer

settings.

and

Page 47

Troubleshooting

Communications Problems

Table 13 • Communications Problems (Continued)

Problem Possible Cause Recommended Solution

The printer fails to

calibrate or detect the top of

the label.

The printer was not calibrated

for the label being used.

The printer is configured for

continuous media.

The driver or software

configuration is not set

correctly.

Perform the calibration procedure in CANCEL

Self Test on page 109.

Set the media type to non-continuous media. See

Setting Media Type on page 45.

Driver or software settings produce ZPL

commands that can overwrite the printer

configuration. Check the driver or software

media-related setting.

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 107

Page 48

Troubleshooting

Printer Diagnostics

Printer Diagnostics

Self tests give information about the condition of the printer. The most commonly used are the

Power-On and the CANCEL self tests.

Caution • Be sure that the print width is set to match the label width you are using before

running any self tests. If the labels are not wide enough, the test may print on the platen

roller and damage it.

Power-On Self Test

The Power-On Self Test (POST) is performed automatically each time the printer is turned on.

During either test sequence, the front panel LEDs light up and the LCD monitors the progress

of the POST. If the printer fails any of these tests,

notify an authorized Zebra reseller.

Additional Printer Self Tests

These self tests produce sample printouts and provide specific information that help determine

the operating conditions for the printer.

FAILED

shows on the LCD. If this occurs,

Each self test is enabled by pressing a specific front panel key or combination of keys while

turning the power On (I). Keep the key(s) depressed until the DATA light turns off. When the

POST is complete, the selected self test starts automatically.

Note • When performing a self test, do not send a label format to the printer. For remote hosts,

disconnect all data interface cables from the printer. For printers in Peel-Off Mode, remove the

labels as they come out of the printer.

108 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 49

CANCEL Self Test

The CANCEL self test prints a configuration label, which tells you the current settings for the

printer.

To perform the CANCEL Self Test, complete these steps:

1. Turn Off (O) the printer.

2. Press and hold CANCEL while turning the power On (I). Hold CANCEL until the DATA

light turns off.

A printer configuration label prints (Figure 47).

Figure 47 • Printer Configuration Label

Troubleshooting

Printer Diagnostics

The printer configuration can be changed by performing a calibration procedure. See Calibrate

the Printer on page 33 for more information.

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 109

Page 50

Troubleshooting

Printer Diagnostics

PAUSE Self Test

This self test can be used to provide the test labels required when making adjustments to the

printer’s mechanical assemblies. See the sample printout below.

To perform a PAUSE self test, complete these steps:

1. Turn Off (O) the printer.

2. Press and hold PAUSE while turning the power On (I). Hold PAUSE until the DATA light

turns off.

• The initial self test prints 15 labels at 2.4 in. (61 mm) per second, then automatically

pauses the printer. When PAUS E is pressed, an additional 15 labels print. Figure 48

shows a sample of the labels.

Figure 48 • PAUSE Test Label

• While the printer is paused, pressing CANCEL alters the self test. When PAU S E is

pressed, 15 labels print at 6 in. or 152 mm per second.

• While the printer is paused, pressing CANCEL again alters the self test a second time.

When PAUSE is pressed, 50 labels print at 2.4 in. (61 mm per second).

• While the printer is paused, pressing CANCEL again alters the self test a third time.

When PAUSE is pressed, 50 labels print at 6 in. (152 mm) per second.

• While the printer is paused, pressing CANCEL again alters the self test a fourth time.

When PAUSE is pressed, 15 labels print at the printer’s maximum speed.

• To exit this self test at any time, press and hold CANCEL.

110 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 51

FEED Self Test

This test helps you choose the best darkness setting for your printer.

To perform a FEED self test, complete these steps:

1. Turn Off (O) the printer.

2. Press and hold FEED while turning the power On (I). Hold FEED until the DATA light

turns off.

The printer prints a series of labels (Figure 49) at various speeds and at darkness settings

higher and lower than the darkness value shown on the configuration label.

Figure 49 • FEED Test Label

Troubleshooting

Printer Diagnostics

3. Inspect the labels and determine which one has the best print quality for your application.

The darkness value printed on that label is added to (plus) or subtracted from (minus) the

darkness value specified on the configuration label. The resulting numeric value (0 to 30)

is the best darkness value for that specific label/ribbon combination and print speed.

4. Enter the corresponding darkness and print speed values into the printer through the front

panel.

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 111

Page 52

Troubleshooting

Printer Diagnostics

FEED and PAUSE Self Test

Performing this self test temporarily resets the printer configuration to the factory default

values. These values are active only until power is turned off unless you save them

permanently in memory.

To perform a FEED and PAUSE self test, complete these steps:

1. Turn Off (O) the printer.

2. Press and hold FEED and PAUSE while turning the power On (I). Hold FEED and

PAUSE until the DATA light turns off.

No labels print at the end of this test.

Communications Diagnostics Test

This test is controlled from the front panel display. See Setting Communications Mode

on page 52. Figure 50 shows a typical printout from this test. Turn off the power to exit this

self test and return to normal operation.

Note • The communications test label prints upside-down.

Figure 50 • Communications Diagnostics Test Label

Additional Printer Diagnostics

Additional diagnostic tests are available for this printer. See the Maintenance Manual for

information about these additional tests.

112 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 53

A

Specifications

This appendix provides the features of and specifications for the RXiIIIPlus printers.

Contents

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Print Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Zebra Programming Language (ZPL II

Bar Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Agency Approvals for All Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Compliance for All Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Environmental Conditions for Operation and Storage . . . . . . . . . . . . . . . . . . . . . . . . 117

Print Specifications by Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Ribbon Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Label Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

®

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 113

Page 54

Specifications

Features

Features

This section lists the standard and optional features for the printer.

Standard Features

Note • Printer specifications are subject to change without notice.

• Thermal transfer and direct thermal printing

• DRAM 16 MB

•USB 2.0 Port

•Real-time Clock

• Advanced Counter

Print Modes

Five different print modes can be used, depending on the printer options purchased:

• Te ar -O ff Mode: Labels are produced in strips.

• Peel-Off Mode: Labels are dispensed and peeled from the backing as needed.

• Applicator Mode: The printer is part of a larger label application system.

Zebra Programming Language (ZPL II®)

ZPL features include:

• Downloadable graphics, scalable and bitmap fonts, and label formats

• Object copying between memory areas

• (RAM, memory card, and internal Flash)

• Code page 850 character set

• Data compression

• Automatic virtual input buffer management

• Format inversion

• Mirror image printing

• Four-position field rotation (0°, 90°, 180°, 270°)

• Slew command

• Controlled via mainframe, mini-computer, PC, portable data terminal

• Programmable quantity with print, pause, and cut control

• Communicates in printable ASCII characters

• Error-checking protocol

• Status message to host upon request

• Serialized fields

• In-spec OCR-A and OCR-B

•UPC/EAN

114 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 55

• User-programmable password

Bar Codes

Types of bar codes include:

• Bar code ratios—2:1, 7:3, 5:2, 3:1

• Codabar (supports ratios of 2:1 up to 3:1)

• CODABLOCK

•Code 11

• Code 39 (supports ratios of 2:1 up to 3:1)

• Code 49 (two-dimensional bar code)

• Code 93

• Code 128 (with subsets A, B, and C and UCC case codes)

• Check digit calculation where applicable

• Data Matrix

• EAN-8, EAN-13, EAN extensions

•ISBT-128

• Industrial 2 of 5

• Interleaved 2 of 5 (supports ratios of 2:1 up to 3:1, Modulus 10 Check Digit)

• LOGMARS

•MaxiCode

•Micro PDF

•MSI

• PDF-417 (2-dimensional bar code)

• PLANET code

•Plessey

• POSTNET

• QR-Code

• RSS code

• Standard 2 of 5

• TLC 39

• UPC-A, UPC-E, UPC extensions

Specifications

Features

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 115

Page 56

Specifications

Features

Agency Approvals for All Printers

Approvals include:

• Canadian ICES-003, Class B

• FCC class B

Compliance for All Printers

• Complies with FCC class B and Canadian Doc. class A rules

116 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 57

General Specifications

Dimensions R110Xi IIIPlus

Height 15.5 in (393.7 mm)

Width 10.37 in. (263.5 mm)

Depth 19.5 in. (495.3 mm)

Weight without options 51 lb. (25 kg)

Electrical Specifications

Power R110Xi IIIPlus

General 90 to 264 VAC; 48 to 62 Hz

Specifications

General Specifications

Power consumption printing

PAUSE test at slowest speed

Printer idle 20 W

180 W

Environmental Conditions for Operation and Storage

Environment Mode Temperature Relative Humidity

Operation Thermal Transfer 41° to 104°F

(5° to 40° C)

Direct Thermal 32° to 104°F

(0° to 40° C)

Storage Thermal Transfer or

Direct Thermal

–40° to 140°F

(–40° to 60° C)

20 to 85% non-condensing

5 to 85% non-condensing

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 117

Page 58

Specifications

Print Specifications by Model

Print Specifications by Model

Refer to the key and the table that follows for printer specifications.

Model Specifications Key

This table contains the key for print specifications for the table that follows.

Specification R110XiIIIPlus 200 dpi

Printhead resolution 203 dots/inch (8 dots/mm)

Dot size (width×length) 0.0049×0.0049 in. (0.125×0.125 mm)

First dot location (measured from inside

media edge)

Maximum print width 4.09 in. (104 mm)

Selectable print speeds (inches per second) 2.4, 3 through 10

Maximum Print length 39 in. (991 mm) 150 in. (3810 mm)

Bar code modulus (X) dimension 4.9 mil to 49 mil

Thin film printhead with Element Energy

Equalizer (E

Non-Continuous printing (gap, notch, or hole between labels).

Continuous printing (no gap, notch or hole).

Ladder (rotated) orientation.

Picket fence (nonrotated) orientation.

0.10 ± 0.035 in. (2.5 ± 0.89 mm)

4.9 mil to 49 mil

3)®

Ye s

118 RXiIIIPlus User Guide 6/7/2004 23063L-001 Rev. 1

Page 59

Ribbon Specifications

Refer to the table that follows for ribbon specifications.

Note • Match the ribbon to the label width and printhead width that you are using.

• Ribbon must be wound with the coated side out.

• Ribbon should be at least as wide as the labels to protect the printhead from excessive wear.

Specifications R110Xi IIIPlus 200 dpi

Printhead resolution 203 dots/inch

Ribbon width—Minimum* 0.79 in. (20 mm)

Specifications

Ribbon Specifications

(8 dots/mm)

Ribbon width—Maximum

4.33 in. (110 mm)

Standard length with 2:1 label to ribbon ratio 984 ft (300 m)

Standard length with 3:1 label to ribbon ratio 1476 ft (450 m)

Ribbon core inside diameter 1.0 in. (25.4 mm)

Maximum ribbon roll outside diameter 3.2 in. (81.3 mm)

* For RFID “smart” labels, the minimum ribbon width is determined by the minimum label width for the

transponder being used. For the list of approved transponders and related size and placement

specifications, go to http://www.rfid.zebra.com/r110.htm.

23063L-001 Rev. 1 6/7/2004 RXiIIIPlus User Guide 119

Page 60

Specifications

Label Specifications

Label Specifications

RXiIIIPlus printers need the correct size and type of labels for best performance. Refer to the

table that follows for the specifications.

Important • Media registration and minimum label length are affected by label type and

width, ribbon type, print speed, and printer mode of operation. Performance improves as these

factors are optimized. Zebra recommends qualifying any application with thorough testing.

Specifications

Minimum label length Tear-off 0.7 in. (18 mm)*

RFID “smart” labels **