Page 1

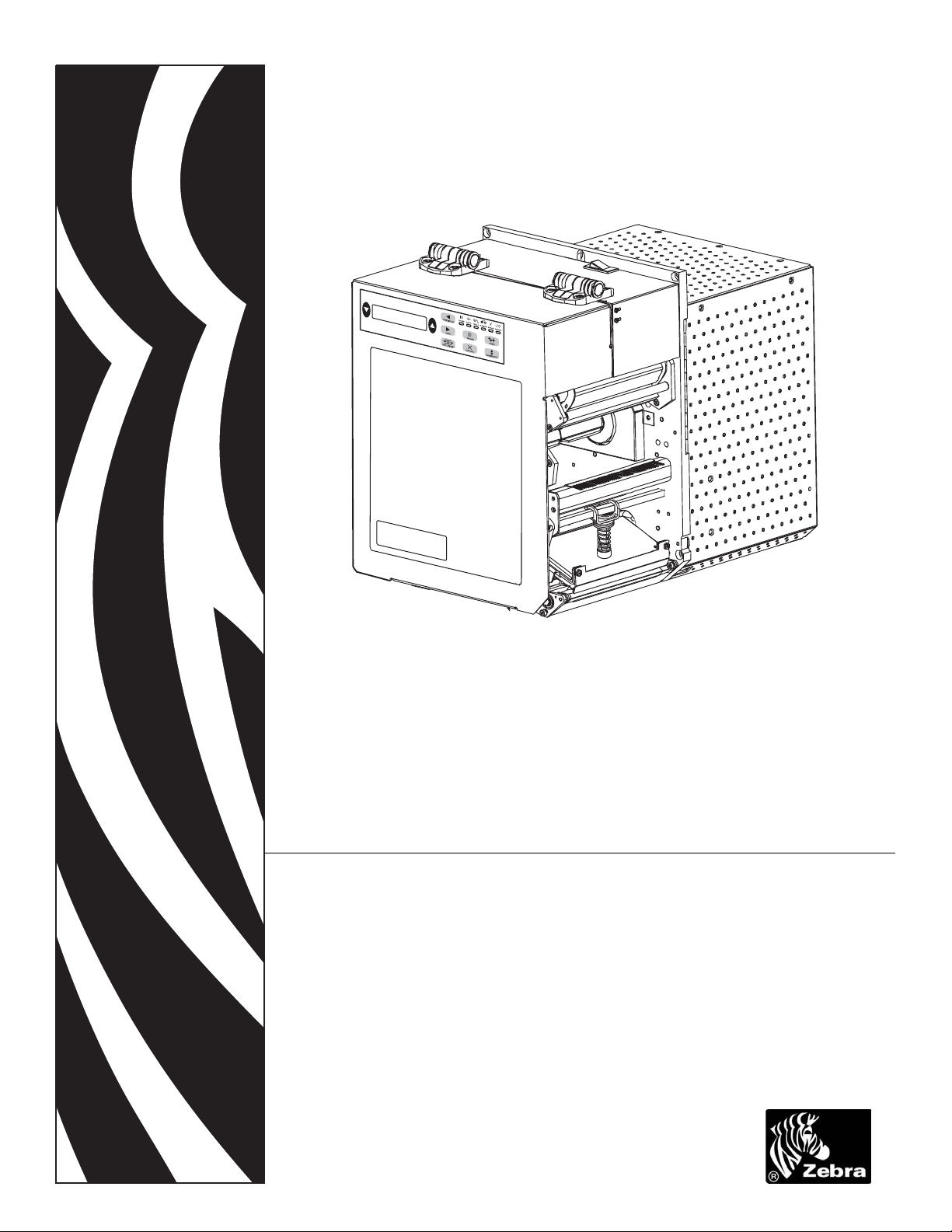

Zebra® R110PAX4™

Print Engine

User Guide

Page 2

© 2005 ZIH Corp.

The copyrights in this manual and the label print engine described therein are

owned by Zebra Technologies. Unauthorized reproduction of this manual or the

software in the label print engine may result in imprisonment of up to one year

and fines of up to $10,000 (17 U.S.C.506). Copyright violators may be subject to

civil liability.

All product names and numbers are Zebra trademarks, and Zebra, the Zebra logo,

ZPL, ZPL II, ZebraNet, ZebraLink, are registered trademarks of ZIH Corp. All

rights reserved.

All other brand names, product names, or trademarks belong to their respective

holders.

Customer Order # 58981L-002

Manufacturer Part # 58981L-002 Rev. 1

Page 3

Contents

About This Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Who Should Use This Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

How This Document Is Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Document Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 • Print Engine Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Print Engine Exterior View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Front Panel Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Front Panel Indicator Lights (LEDs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power On/Off Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 • Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Unpack and Inspect the Print Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Inspect the Print Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Report Shipping Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Store the Print Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Print Engine Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Install the Print Engine in an Applicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Connect the Print Engine to a Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Power Cord Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide iii

Page 4

Contents

Select a Communication Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Standard Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Optional Print Servers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

DB-15 Applicator Interface Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

System Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Interface Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Data Cable Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Types of Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

When to Use Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Coated Side of Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3 • Print Engine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Load Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Load Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Remove Used Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Calibrate the Print Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Adjust Media Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Reflective Media Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Transmissive Media Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4 • Print Engine Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Enter Setup Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Exit Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Print a Configuration Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Print a Network Configuration Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Changing Password-Protected Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Default Password Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Disable the Password Protection Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Front Panel LCD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

ZebraNet

RFID LCD Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

®

Wired and Wireless Print Server LCD Displays . . . . . . . . . . . . . . . . . . . . 74

5 • RFID Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Transponder Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

ZPL Commands for RFID Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Electronic Product Code (EPC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

EPC Structure in RFID Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

XML-Enabled Printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Getting Started with RFID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

iv R110PAX4 User Guide 58981L-002 Rev. 1 2/11/05

Page 5

Contents

Creating Basic RFID Label Formats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

RFID Label Format 1—Write a 96-bit Tag in Hexadecimal. . . . . . . . . . . . . . . . . . . . . 87

RFID Label Format 2—Write a 64-bit Tag in Hexadecimal. . . . . . . . . . . . . . . . . . . . . 88

RFID Label Format 3—Write a 96-bit Tag in ASCII . . . . . . . . . . . . . . . . . . . . . . . . . . 89

RFID Label Format 4—Read Data from Tag and Print on Label . . . . . . . . . . . . . . . . 90

RFID Label Format 5—Write Tag, Read Tag, and Print Data on Label . . . . . . . . . . . 91

RFID Label Format 6—Write Tag, Read Tag, and Return Results to Host. . . . . . . . . 93

ZPL II Commands for RFID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

^HR Calibrate RFID Transponder Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

^HV Host Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

^RB Define EPC Data Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

^RF Read or Write RFID Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

^RM Enable RFID Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

^RN Detect Multiple RFID Tags in Encoding Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

~RO Reset Advanced Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

^RR Specify RFID Retries for a Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

^RS RFID Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

^RT Read RFID Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

^RW Set RFID Read and Write Power Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

^RZ Set RFID Tag Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

^WT Write Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

^WV Verify RFID Write Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

6 • Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Cleaning Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Clean Exterior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Clean Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Clean the Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Clean the Printhead and Platen Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Toggle Positioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Printhead Pressure Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Power Fuse Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

7 • Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Troubleshooting Checklists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

LCD Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Memory Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Print Quality Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Communications Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Miscellaneous Print Engine Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide v

Page 6

Contents

Print Engine Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Power-On Self Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Additional Print Engine Self Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Communications Diagnostics Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

A • Print Engine Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Environmental Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Agency Approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Zebra Programming Language (ZPL II) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Bar Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Printing Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Media Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Ribbon Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

B • Data Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Parallel Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Serial Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Serial Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

RS-232 Interface Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Applicator Interface Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Applicator Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Applicator Interface Connector Pin Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Jumper Configurations for +5 V I/O Applicator Interface Board . . . . . . . . . . . . . . . . 170

Proprietary Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Printer Software and Firmware License Agreement . . . . . . . . . . . . . . . . . . . . 179

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

vi R110PAX4 User Guide 58981L-002 Rev. 1 2/11/05

Page 7

About This Document

This section provides you with contact information, docu men t struc ture and organization, and

additional reference documents.

Contents

Who Should Use This Document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

How This Document Is Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide 1

Page 8

About This Document

Who Should Use This Document

Who Should Use This Document

This User Guide is intended for use by any person who needs to operate or troubleshoot

problems with the print engine.

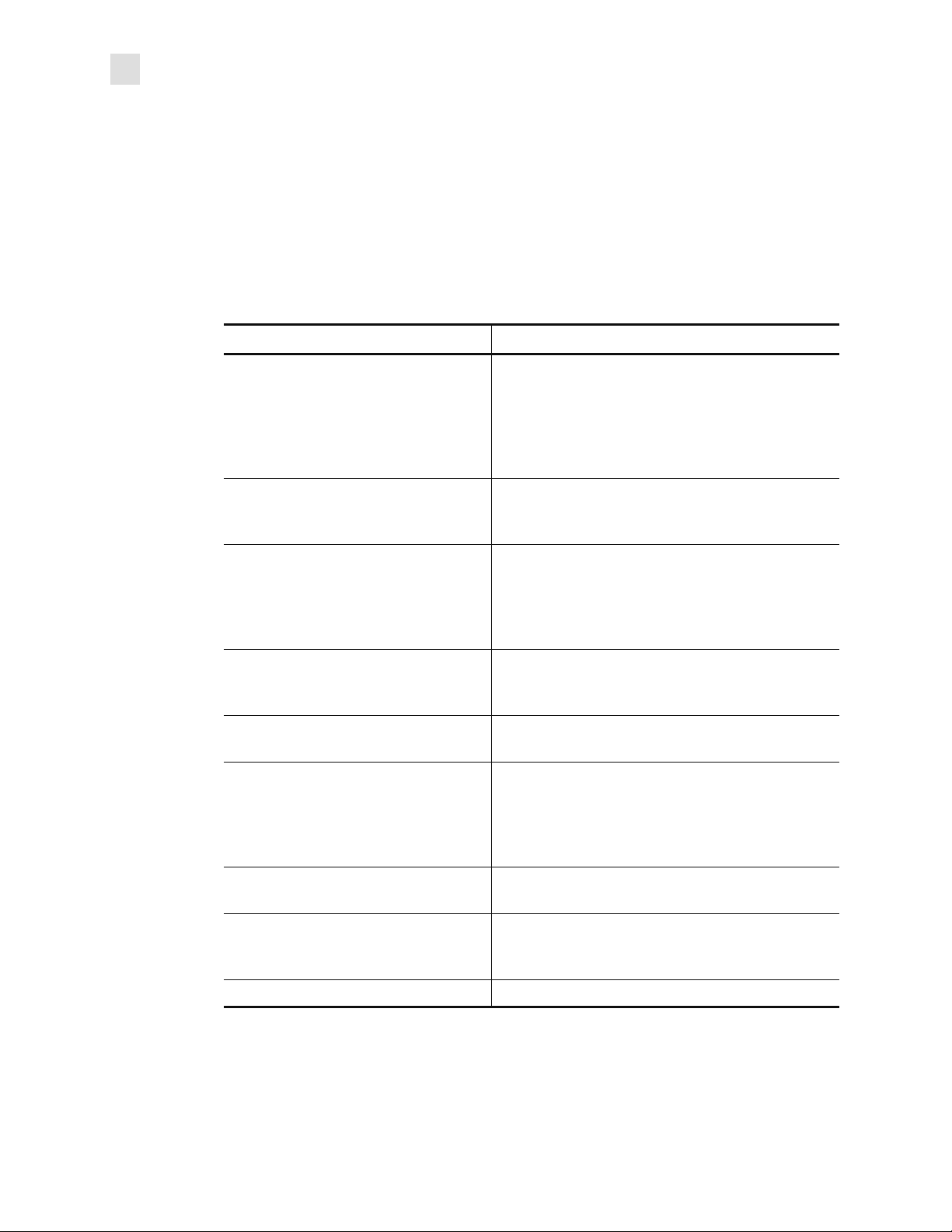

How This Document Is Organized

The User Guide is set up as follows:

Section Description

Print Engine Basics on page 7

Getting Started on page 13

Print Engine Operation on page 31

Print Engine Configuration on page 49

Routine Maintenance on page 121

Troubleshooting on page 131

Print Engine Specifications

on page 149

Data Ports on page 157

This chapter provides a high-level overview of the

print engine and its components. A print engine is

a printer that is part of a labeling system. The print

engine is mounted in a applicator, which includes

components to apply labels automatically as they

are printed.

This chapter provides the tasks that you must

complete and the issues that you must consider

before you load and configure your print en gine.

If you have completed the tasks and resolved

issues in the checklist in Before You Begin

on page 14, use this chapter to load the print

engine, to calibrate the print engine, and to print

configuration labels.

This chapter describes the front panel parameters

that are used to configure the print engine for

operation.

This chapter provides routine cleaning and

maintenance procedures.

This chapter provides you with information about

LCD, print quality, communications, and other

errors that you might need to troubleshoot. If you

need technical assistance, contact your equipment

supplier.

This appendix provides the features of and

specifications for the print engine.

This appendix describes the standard

communication ports available to connect the print

engine to your computer or network.

Glossary on page 193

2R110PAX4 User Guide 58981L-002 Rev. 1 2/1 1/05

The glossary provides a list of common terms.

Page 9

Contacts

About This Document

Contacts

You can contact Zebra Technologies at any of the following:

Visit us at: http://www.zebra.com

Our Mailing Addresses:

Zebra Technologies Corporation

333 Corporate Woods Parkway

Vernon Hills, Illinois 60061.3109 U.S.A

Telephone: +1 847.634.6700

Fax: +1 847.913.8766

Zebra Technologies Europe Limited

Zebra House

The Valley Centre, Gordon Road

High Wycombe

Buckinghamshire HP13 6EQ, UK

Telephone: +44 (0)1494 472872

Fax: +44 (0)1494 450103

Support

You can contact Zebra support at:

Web Address: www.zebra.com/SS/service_support.htm

Note • The web address is case-sensitive.

US Phone Number +1 847.913.2259

UK/International Phone Number +44 (0) 1494 768289

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide 3

Page 10

About This Document

Document Conventions

Document Conventions

The following conventions are used throughout this document to convey certain information:

Alternate Color (online only) Cross-references contain links to other sections in this guide.

If you are viewing this guide online, click the blue text to jump to its location.

Command Line Examples All command line examples appear in Courier New font.

For example, type the following to get to the Post-Install scripts in the

Ztools

Files and Directories All file names and directories appear in Courier New font. For

example, the

Cautions, Important, Note, and Example

Electrostatic Discharge Cautio n • Warns you of the potential for electrostatic discharge.

Zebra<version number>.tar file and the /root directory.

bin directory:

Electric Shock Caution • Warns you of a potential electric shock situation.

Caution • Warns you of a situation where excessive heat could cause a burn.

Caution • Advises you that failure to take or avoid a specific action could result in physical

harm to you.

Caution • Advises you that failure to take or avoid a specific action could result in physical

harm to the hardware.

Caution • Advises you need to wear protective eyeware.

Important •

Advises you of information that is essential to complete a task.

Note • Indicates neutral or positive information that emphasizes or supplements important

points of the main text.

Example • Provides an example, often a scenario, to better clarify a section of text.

4R110PAX4 User Guide 58981L-002 Rev. 1 2/1 1/05

Page 11

About This Document

Related Documents

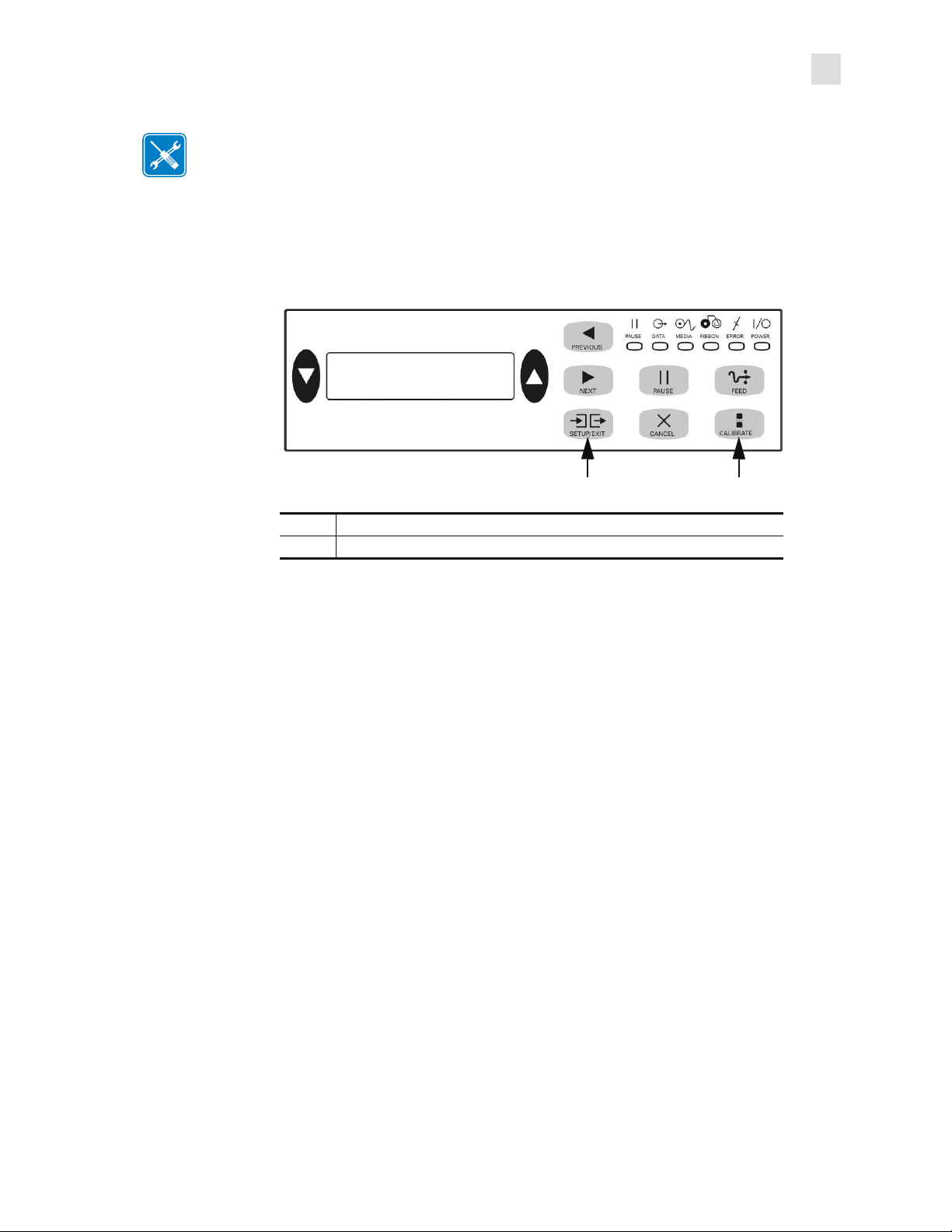

Tools • Tells you what tools you need to complete a given task.

Illustration Callouts Callouts are used when an illustration contains information that needs

to be labeled and described. A table that contains the labels and descriptions follows the

graphic. Figure 1 provides an example.

Figure 1 • Sample Figure with Callouts

21

1

2

Related Documents

The following documents might be helpful references:

• ZPL II

®

Programming Guide Volume I (part number 45541L) and Volume II (part

number 45542L).

SETUP/EXIT

CALIBRATE

button

button

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide 5

Page 12

About This Document

Related Documents

Notes • ___________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

6R110PAX4 User Guide 58981L-002 Rev. 1 2/1 1/05

Page 13

1

Print Engine Basics

This chapter provides a high-level overview of the print engine and its components. A print

engine is a printer that is part of a label ing system. The prin t engine i s mounted in a applic ator,

which includes components to apply labels automatically as they are printed.

Contents

Print Engine Exterior View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Front Panel Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Front Panel Indicator Lights (LEDs). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power On/Off Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide 7

Page 14

Print Engine Basics

Print Engine Exterior View

Print Engine Exterior View

Print engines are available in a right-hand configuration (media moves from left to right,

Figure 2) and a left-hand configuration (media moves from right to left, Figure 3).

Figure 2 • Right-Hand (RH) Print Engine

1

2

3

4

Figure 3 • Left-Hand (LH) Print Engine

1

2

4

3

Power on/off switch

1

Front panel

2

Media door

3

Electronics cover

4

8R110PAX4 User Guide 58981L-002 Rev. 1 2/1 1/05

Page 15

Front Panel

All controls and indicators for the print engine are located on the front panel (Figure 4). The

Liquid Crystal Display (LCD) shows operating status and feature parameters. The front panel

buttons are used to control the print engine operations and to set parameters. The front panel

lights (LEDs) indicate the print engine’s status.

Print Engine Basics

Front Panel

Figure 4 • Front Panel

2 1 31

Buttons

1

LCD

2

Lights/LEDs

3

Front Panel Buttons

The front panel buttons are described in Table 1.

Table 1 • Front Panel Buttons

Button Description/Function

BLACK OVALS The two black ovals are used to change values for the parameter displayed on the

LCD. Common uses include increasing or decreasing a value, answering YES or

NO, indicating ON or OFF, and scrolling through choices.

PREVIOUS Scrolls the LCD to the previous parameter.

NEXT Scrolls the LCD to the next parameter.

SETUP/EXIT Enters and exits Setup mode.

PAUSE Stops and restarts the printing process or removes error messages and clears the

LCD. When the print engine is paused, the PAUSE light is on.

• If the print engine is idle, it enters Pause mode immediately.

• If the print engine is printing, the label is completed before the printing process

stops.

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide 9

Page 16

Print Engine Basics

Front Panel

Table 1 • Front Panel Buttons (Continued)

Button Description/Function

CANCEL CANCEL functions only in Pause mode. Pressing CANCEL has these effects:

• Cancels the label format that is currently printing.

• If no label format is printing, the next one to be printed is canceled.

• If no label formats are waiting to be printed, CANCEL is ignored.

To clear the print engine’s entire label format memory, press and hold CANCEL

until the DATA light turns off.

FEED Feeds a blank label.

• If the print engine is idle or paused, the label is fed immediately.

• If the print engine is printing, the label is fed after the current batch finishes

printing.

CALIBRA TE CALIBRATE functions only in Pause mode. Press CALIBRATE to recalibrate for

proper media length, to set media type (continuous/non-continuous), and to set print

method (direct thermal/thermal transfer).

Front Panel Indicator Lights (LEDs)

The front panel lights are described in Table 2.

Table 2 • Front Panel Lights

LED OFF Indicates ON Indicates FLASHING Indicates

POWER

(Green)

PAUSE

(Yellow)

Power switch is off, or

no power to print

engine.

Power switch is on, and power

is being supplied to print

engine.

Normal operation. One of the following:

• Print engine paused because

of an error condition

(printhead, ribbon, or paper

error). Usually occurs in

conjunction with another

LED.

• PAUSE was pressed.

• A pause was requested from

the applicator port.

• A pause was received as part

of the label format.

—

—

DATA

(Green)

No data being received

or processed.

Data is processing or printing is

taking place. No data is being

received.

Print engine is receiving data

from or sending status

information to the host

computer.

10 R110PAX4 User Guide 58981L-002 Rev . 1 2/11/05

Page 17

Print Engine Basics

Front Panel

Table 2 • Front Panel Lights (Continued)

LED OFF Indicates ON Indicates FLASHING Indicates

MEDIA

(Yellow)

RIBBON

(Yellow)

ERROR

(Orange)

Normal operation.

Media properly loaded.

Out of media. (Print engine is

paused, LCD displays error

—

message, and PAUSE light is

ON).

Normal operation.

Ribbon properly

loaded.

Ribbon in while print engine is

in direct thermal mode, or no

ribbon loaded while print engine

—

is in thermal transfer mode.

Print engine is paused, LCD

displays error message, and

PAUSE light is ON.

No print engine errors. — Print engine error exists. Check

the LCD for status.

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide 11

Page 18

Print Engine Basics

Power On/Off Switch

Power On/Off Switch

The power on/off switch is located on the top of the print engine housing, as shown in

Figure 5. When this switch is p laced in t he On (

print engine automatically performs a Power-On Self Test (POST). For more information, see

Power-On Self Test on page 142.

I) position, the POWER light turns on, an d the

Figure 5 • Print Engine Power Switch

12 R110PAX4 User Guide 58981L-002 Rev . 1 2/11/05

Page 19

2

Getting Started

This chapter provides the tasks that you must complete and the issues that you must consider

before you load and configure your print engine.

Contents

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Unpack and Inspect the Print Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Inspect the Print Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Report Shipping Damage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Store the Print Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Shipping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Print Engine Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Install the Print Engine in an Applicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Connect the Print Engine to a Power Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Power Cord Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Select a Communication Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Standard Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Optional Print Servers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

DB-15 Applicator Interface Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

System Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Interface Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Data Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Types of Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

When to Use Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Coated Side of Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide 13

Page 20

Getting Started

Before You Begin

Before You Begin

Review this checklist, and resolve any issues before you begin setting up your print engine.

When you are ready, continue with Print Engine Operation on page 31.

Unpack and Inspect the Print Engine Have you unpacked the print engine and

inspected it for damage? If you have not, see Unpack and Inspect the Print Engine

on page 15.

Install the Print Engine Have you considered what factors will affect how the print

engine is installed into an applicator? Is the print engine mounted in an applicator? For

information, see Print Engine Installation on page 16.

Attach a Power Cord Do you have the correct power cord for your print engine? If

you are unsure, see Power Cord Specifications on page 23. To attach the power cord and

connect the print engine to a power source, see Connect the Print Engine to a Power

Source on page 22.

Connect to a Data Source Have you determined how the print engine will connect to

a data source (usually a computer)? For more information, see Select a Communication

Interface on page 24.

Select Media Do you have the correct media for your application? If you are unsure,

see Types of Media on page 27.

Select Ribbon Do you need to use ribbon, and is the appropriate ribbon available, if

needed? If you are unsure, see Ribbon on page 29.

14 R110PAX4 User Guide 58981L-002 Rev . 1 2/11/05

Page 21

Unpack and Inspect the Print Engine

When you receive the print engine, immediately unpack and inspect it for shipping damage.

Save all packing materials.

Inspect the Print Engine

Inspect the print engine for possible damage incurred during shipment:

• Check all exterior surfaces for damage.

• Raise the media door, and inspect the media compartment for damage to components.

Report Shipping Damage

If you discover shipping damage upon inspection:

• Immediately notify the shipping company of the damage, and file a damage report with

them. Zebra is not responsible for any damage incurred during shipment of the equipment

and does not repair this damage under warranty.

• Keep all packaging material for shipping company inspection.

• Notify your authorized Zebra reseller.

Getting Started

Unpack and Inspect the Print Engine

Store the Print Engine

If you are not placing the print engine into immediate operat ion, repackage it usin g the original

packing materials. You may store the print engine under the following conditions:

• Temperature: –40° to 160°F (–40° to 71°C)

• Relative humidity: 5% to 95% non-condensing

Shipping

If you must ship the print engine:

• Remove any ribbon from the spindles to avoid damaging the print engine.

• Carefully pack the print engine into the origi na l container or a suitable alternate container

to avoid damage during transit. A shipping container can be purchased from Zebra if the

original packaging has been lost or destroyed.

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide 15

Page 22

Getting Started

Print Engine Installation

Print Engine Installation

This section provides basic information for mounting the print engine into an applicator. The

illustrations in this section show the print engine from different angles and include

measurements and clearance needs.

Requirements

Stability When the print engine is mounted, the complete assembly must be physically

stable. When the print engine is loaded with ribbon and media, the equipment must not

become physically unstable.

Ventilation and Temperature Provide ventilation for the print engine mounting enclosure

to remove heat and ensure uninterrupted, trouble-free operation of the print engine. Ambient

air temperature surrounding the print engine must not exceed the following:

• Temperature: 32° to 105°F (0° to 41°C)

• Relative humidity: 20% to 95% non-condensing

Power Requirements Consider the current rating of the print engine during installation.

When power is applied to the print engine and the enclosi ng equi pment, an overl oad condi tion

must not be created.

Grounding Requirements Maintain reliable g ro undi ng of the prin t en gin e. Pay part icu lar

attention to the AC power supply connections so that earth ground is maintained through the

AC power input connector.

Clearance for Cables and Connectors Allow ample space at the rear of the print engine

for electronic connectors and dressing of the following cables: IEC power cord, serial and/or

parallel host communication cable, optional host communication cable (Ethernet), and the

discrete signal (applicator) interface cable.

Power Cord Requirements The IEC power cord does not have a strain relief on the print

engine. If the operating characteristics of the applicator include vibration or strain on the

power cord, provide an appropriate clamping mechanism to avoid unintentional disconnection

of the power cord from the print engine.

16 R110PAX4 User Guide 58981L-002 Rev . 1 2/11/05

Page 23

Getting Started

Print Engine Installation

Figure 6 • Front View of Right-Hand Print Engine

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide 17

Page 24

Getting Started

Print Engine Installation

Figure 7 • Right Side View of Right-Hand Print Engine

18 R110PAX4 User Guide 58981L-002 Rev . 1 2/11/05

Page 25

Getting Started

Print Engine Installation

Figure 8 • Rear View of Right-Hand Print Engine

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide 19

Page 26

Getting Started

Print Engine Installation

Figure 9 • Top View of Right-Hand Print Engine

20 R110PAX4 User Guide 58981L-002 Rev . 1 2/11/05

Page 27

Install the Print Engine in an Applicator

3

This section provides the basic instructions for installing the print engine into an applicator.

Caution • If the print engine is installed improperly, it could fall out of the applicator and

cause injury. The center mounting bolt and four mounting screws must be installed and

secured. See Figure 10 for the location of the bolt and screws.

To install the print engine into an applicator, complete these steps:

1. See Figure 10. Install the center mounting bolt into the center hole on the applicator.

2. Carefully place the keyhole on the center mounting bolt.

Note • The keyhole and the center mounting bolt are designed to support the print engine

and assist in installing and removing the four mounting screws.

3. Install the four corner mounting screws to secure the print engine to the applicator.

Figure 10 • Front View of 110PAX4 Print Engine in Applicator

Getting Started

Print Engine Installation

2 1

1

1

1

Mounting screws (four total)

1

Keyhole

2

Center mounting bolt (shown inside hole on applicator)

3

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide 21

Page 28

Getting Started

Connect the Print Engine to a Power Source

Connect the Print Engine to a Power Source

The power supply in the print engine automati cally detects the applied line voltage and works

in the 90 to 264 VAC, 48 to 62 Hz range.

Refer to Figure 11. The AC power cord must have a three-prong female connector on one end

that plugs into the mating AC power connector at the rear o f the print en gine . If a pow er cable

was not included with your print engine, refer to Power Cord Sp eci fications on page 23.

Caution • For personnel and equipment safety, always use an approved three-conductor

power cord specific to the region or country intended for installation. This cord must use

an IEC 320 female connector and the appro pri at e re gion- sp ec i fic thr e e- co nd uc to r

grounded plug configuration.

To connect the print engine to a power source, complete these steps:

1. Turn Off (O) the print engine power switch (located on the top of the print engine

housing).

2. Plug th e power cord into the AC power connector on the rear of the print engine.

Figure 11 • Power Connection

Left-Hand Right-Hand

1

1

AC power connector

1

3. Plug the other end of the power cord into the power source.

22 R110PAX4 User Guide 58981L-002 Rev . 1 2/11/05

Page 29

Power Cord Specifications

Depending on how your print engine was ordered, a power cord may or may not be included.

If one is not included or if the one included is not suitable for your requirements, refer to the

following guidelines:

• The overall cord length must be less than 9.8 ft (3.0 m).

• The cord must be rated for at least 5 A, 250 V.

• The chassis ground (earth) must be connected t o ensure safety and re duce electromagnetic

interference. The third wire in the power cord grounds the connection (Figure 12).

Figure 12 • Power Cord Specifications

1 2 3 4

Getting Started

Connect the Print Engine to a Power Source

a

b

c

AC power plug for your country

1

3-conductor HAR cable

2

IEC 320 connector

3

Contact view of plug—(a) neutral, (b) earth, (c) live

4

• The AC power plug and the IEC 320 connector must bear the certification mark of at least

one of the known international safety organizations shown in Figure 13.

Figure 13 • International Safety Organization Marks

+

R

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide 23

Page 30

Getting Started

Select a Communication Interface

Select a Communication Interface

The way that you connect your print engine to a data source depends on the communication

options installed in the print engine. See Data Ports on page 157 for control signal

descriptions and other additional information.

Caution • Connecting a data communications cable while the power is ON may damage

the print engine.

Note • You must supply all interface cables for your application. Refer to Data Cable

Requirements on page 26 for specific cable requirements.

Standard Connections

Refer to Figure 14. The print engine comes standard with both an Electronics Industries

Association (EIA) RS-232 serial interface (DB-9 connector) and an IEEE 1284 bi-directional

parallel interface. You may use either of these interface methods to send commands and label

formats from a host to the print engine.

Figure 14 • Cable Connections

Left-Hand Right-Hand

3

1

2

2

1

3

DB-15 applicator interface port

1

Parallel interface connector

2

DB-9 serial interface connector

3

24 R110PAX4 User Guide 58981L-002 Rev . 1 2/11/05

Page 31

Optional Print Servers

• ZebraNet Wireless Print Server. For more information on this option, see the ZebraNet

Wireless Print Server User Guide (part number 13422L-001).

• ZebraNet 10/100 Print Server (10/100 PS). For more information on 10/100 PS, see the

ZebraNet 10/100 Print Server User and Reference Guide (part number 47619L-001).

DB-15 Applicator Interface Connector

A DB-15 Applicator Interface Connector provides communication between the print engine

and the associated applicator hardware. In some applications, control signal timing may be a

critical element in the performance of the print engine.

System Considerations

Communications Code The print engine sends and receives American Standard Code for

Information Interchange (ASCII). This code consists of 128 characters (256 for Code Page

850) including uppercase and lowercase letters, numbers, punctuation marks, and various

control codes.

Getting Started

Select a Communication Interface

Interfaces The method of interfacing the print engine to a data source depends on the

communication options installed in the print engine and the host. The standard interfaces are

an RS-232 serial data port and an IEEE 1284 bi-directional parallel port.

Communication Specifications When communicating via an asynchronous serial data

port (RS-232), the baud rate, number of data and stop bits, the parity, and the XON/XOFF or

DTR control are user-selectable and should be set to match those of the host computer. When

communicating via the IEEE 1284 bi-directional parallel port, the previously mentioned

parameters do not apply. Refer to Print Engine Configuration on page 49 to configure the

communication parameters for the print engine.

Interface Considerations

RS-232 A serial communication method consisting of data and control si gnals; available as a

standard feature on most PCs and other hosts.

• Advantages: Cables and connectors are readily available from computer equipment stores

and suppliers; easy to connect; two-way communication between the host and the print

engine.

• Disadvantages: Slower than the parallel connection; limited to 50 feet (15.24 m) of cable.

IEEE 1284 Bi-directional Parallel A common communication method available on most

PCs and other hosts.

• Advantages: Fastest of the four communication interfaces; cables and connectors are

readily available from computer equipment stores and suppliers; two-way communication

between the host and the print engine; easy to connect.

• Disadvantages: Shorter recommended cable length of 6 feet (1.83 m); man y comp uters

are equipped with only one parallel port, allowing only one IEEE 1284 bi-directional

device to be connected at a time.

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide 25

Page 32

Getting Started

Select a Communication Interface

Data Cable Requirements

Data cables must be fully shielded and fitted with metal or metallized connector shells.

Shielded cables and connectors are required to prevent radiation and reception of electrical

noise.

To minimize electrical noise pickup in the cable:

• Keep data cables as short as possible.

• Do not bundle the data cables tightly with the power cords.

• Do not tie the data cables to power wire conduits.

Note • Print engines comply with FCC Rules and Regula tio n s, Part 1 5, Su bp art J, for Cl ass A

equipment, using fully-shielded 6-foot (2-meter) data cables. Use of longer cables or

unshielded cables may increase radiated emissions above the Class A limits.

26 R110PAX4 User Guide 58981L-002 Rev . 1 2/11/05

Page 33

Types of Media

The print engine can use various types of media (Table 3). We strongly recommend the use of

Zebra-brand supplies for continuous high-quality printing. A wide range of paper,

polypropylene, polyester, and vinyl stock has been specifically engineered to enhance the

printing capabilities of the printer and to ensure against premature printhead wear.

Table 3 • Types of Media

Media Type How It Looks Description

Getting Started

Types of Media

Non-Continuous

Roll Media

The media is wound on a core. Individual labels

are separated by a gap, black mark, notch, or

hole, which enables you to see where one label

ends and the next one begins. When using media

that has holes or notches, position the media

sensor directly over a hole or notch. Figure 15

and Figure 16 show different types of

non-continuous media.

Figure 15 • Non-Continuous Web Media

Figure 16 • Non-Continuous

BlackMarkMedia

Continuous

Roll Media

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide 27

The media is wound on a core and is without

gaps, holes, notches, or black marks. This

allows the image to be printed anywhere on the

label.

Page 34

Getting Started

Types of Media

Table 3 • Types of Media (Continued)

Media Type How It Looks Description

Fanfold Media The media is folded in a zigzag pattern.

RFID “Smart” Media

(for use with

RFID-capable print

engines only)

Each label has a radio frequency identification

(RFID) chip and antenna inlay embedded

between the label and the liner. The media is

made from the same materials and adhesives as

non-RFID labels. The outline of the transponder

(which varies by manufacturer) can be seen

through the label. All “smart” labels have

memory that can be read, and many have

memory that can be encoded.

28 R110PAX4 User Guide 58981L-002 Rev . 1 2/11/05

Page 35

Ribbon

Ribbon is a thin film that is coated on one side with wax or wax resin, which is transferred to

the media during the thermal transfer process. The media determines whether you need to use

ribbon and how wide the ribbon must be.

When ribbon is used, it must be as wide as or wider than the media being used. If the ribbon is

narrower than the media, areas of the printhead are unprotected and subject to premature wear.

When to Use Ribbon

Thermal transfer media requires ribbon for printing while direct thermal media does not.

To determine if ribbon must be used with a particular media, perform a media scratch test.

To perform a label scratch test, complete these steps:

1. Scratch the print surface of the media with your fingernail.

2. Did a black mark appear on the media?

If a black mark... Then the media is...

Getting Started

Ribbon

Does not appear on the media Thermal transfer. A ribbon is required.

Appears on the media Direct thermal. No ribbon is required, though

Coated Side of Ribbon

Ribbon can be wound with the coated side on the inside or outside (Figure 17). This print

engine can only use ribbon that is coated on the outside. If you are unsure which side of a

particular roll of ribbon is coated, perform an adhesive test or a ribbon scratch test to

determine which side is coated.

Figure 17 • Ribbon Coated on Outside or Inside

ribbon may be used to help protect the printhead

from abrasion with the media.

Outside Inside

58981L-002 Rev. 1 2/11/05 R110PAX4 User Guide 29

Page 36

Getting Started

Ribbon

Adhesive Test

If you have labels available, perform the adhesive test to determine which side of a ribbon is

coated. This method works well for ribbon that is already installed.

To perform an adhesive test, complete these steps:

1. Peel a label from its liner.

2. Press a corner of the sticky side of the label to the outer surface of the roll of ribbon.

3. Peel the label off of the ribbon.

4. Observe the results. Did flakes or particles of ink from the ribbon adhere to the label?

If ink from the ribbon... Then...

Adhered to the label The ribbon is coated on the outer surface.

Did not adhere to

the label

The ribbon is coated on the inner surface. To verify this,

repeat the test on the inner surface of the roll of ribbon.

Ribbon Scratch Test

If you do not have labels available , perform the ribbon scratch test. T his method works best for

ribbon that is not installed.

To perform a ribbon scratch test, complete these steps:

1. Unroll a short length of ribbon.

2. Place the unrolled section of ribbon on a piece of paper with the outer surface of the

ribbon in contact with the paper.

3. Scratch the inner surface of the unrolled ribbon with your fingernail.

4. Lift the ribbon from the paper.

5. Observe the results. Did the ribbon leave a mark on the paper?

If the ribbon... Then...

Left a mark on the paper The ribbon is coated on the outer surface.

Did not leave a mark on

the paper

The ribbon is coated on the inner surface. To verify this,

repeat the test on the other surface of the roll of ribbon.

30 R110PAX4 User Guide 58981L-002 Rev . 1 2/11/05

Loading...

Loading...