Page 1

DA402

Stripe Series Direct Thermal Printer

®

User s

'

Guide

Customer order # 52005L

Manufacturer part # 52005LB

Rev. 2

Page 2

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation. It is intended solely for the information and

use of parties operating and maintaining the equipment described herein. Such proprietary information may not be used,

reproduced, or disclosed to any other parties for any other purpose without the expressed written permission of Zebra

Technologies Corporation.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies Corporation. All specifications and signs are subject

to change without notice.

FCC Compliance Statement

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee

that the interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

n

Reorient or relocate the receiving antenna.

n

Increase the separation between the equipment and the receiver.

n

Connect the equipment into an outlet on a circuit different than that to which the receiver is connected.

n

Consult the dealer or an experienced Radio/TV technician for help.

NOTE: This unit was tested with shielded cables on the peripheral devices. Shielded cables must be used with the unit to

insure compliance.

“The user is cautioned that any changes or modifications not expressly approved by Zebra Technologies Corporation could

void the user’s authority to operate the equipment.”

Canadian DOC Compliance Statement

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus as set out in the radio

interference regulations of the Canadian Department of Communications.

Liability Disclaimer

Zebra Technologies Corporation takes steps to assure that its published Engineering specifications and Manuals are correct;

however, errors do occur. Zebra Technologies Corporation reserves the right to correct any such errors and disclaims liability

resulting therefrom.

No Liability for Consequential Damage

In no event shall Zebra Technologies Corporation or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever (including, without limitation,

damages for loss of business profits, business interruption, loss of business information, or other pecuniary loss) arising out of

the use of or the results of use of or inability to use such product, even if Zebra Technologies Corporation has been advised of

the possibility of such damages. Because some states do not allow the exclusion or limitation of liability for consequential or

incidental damages, the above limitation may not apply to you.

Copyrights

This copyrighted manual and the label printer described herein are owned by Zebra Technologies Corporation. All rights are

reserved. Unauthorized reproduction of this manual or the software in the label printer may result in imprisonment of up to

one year and fines of up to $10,000 (17 U.S.C.506). Copyright violators may be subject to civil liability.

All products and brand names are trademarks of their respective companies. All rights reserved.

© 1999 Zebra Technologies Corporation

Page 3

I have determined that the Zebra printers identified as the

Stripe Series

DA T

Zebra Technologies Corporation

333 Corporate Woods Parkway

Vernon Hills, Illinois 60061-3109 U.S.A.

have been shown to comply with the applicable technical standards of the FCC

®

402 and 402

manufactured by:

for Home, Office, Commercial, and Industrial use

if no unauthorized change is made in the equipment,

and if the equipment is properly maintained and operated.

Page 4

Page 5

Contents

Introduction

Hello! ..................................1

What’s in the Box ............................1

Unpacking and Inspection ........................2

Reporting Damage ..........................2

DC Power Supply ............................3

Printer Overview (illustration) .....................4

GettingReadytoPrint

LoadingtheMedia............................5

Tear-OffMode............................5

Peel-OffMode............................9

CutterMode.............................14

FanfoldMedia...........................17

AutoCalibration............................18

OperatorControls...........................19

PowerSwitch............................19

FeedButton.............................19

StatusLED.............................19

PrintingaTestLabel..........................20

HookingUpthePrinterandComputer.................20

Serial(RS-232)InterfaceRequirements..............20

ParallelInterfaceRequirements..................21

SerialandParallelCablingRequirements.............21

CommunicatingwiththePrinter....................22

ViatheSerialPort.........................22

ViatheParallelPort.........................22

UsingZPLII..............................23

AdjustingthePrintWidth.......................23

AdjustingthePrintDarkness......................23

AdjustingthePrintSpeed.......................23

i

Page 6

Troubleshooting

WhattheStatusLEDisTellingYou..................25

PrintQualityProblems.........................26

ManualCalibration...........................28

TroubleshootingTests.........................29

PrintingaConfigurationLabel...................29

Recalibration............................29

ResettingtheFactoryDefaultValues................30

CommunicationsDiagnostics....................30

FeedButtonModes...........................31

Maintenance

Cleaning................................33

Lubrication...............................33

PartsList................................35

ReplacingthePrinthead........................36

RemovingthePrinthead......................36

InstallingthePrinthead.......................38

Specifications

Printing.................................41

Label/Tag................................42

Font/BarCode.............................43

Physical/Environmental/Electrical...................43

AgencyApprovals...........................44

Options.................................44

Serial(RS-232)ConnectorTechnicalInformation..........45

InterconnectingtoDTEDevices..................45

InterconnectingtoDCEDevices..................45

ParallelInterfaceTechnicalInformation................48

Index

ii

Page 7

Introduction

Hello!

Thank you for choosing the ZebraDA402Printer. This rugged little

printer is certain to become a productive and efficient addition to your

workplace!

n

This user’s guide provides the information you will need to operate and

maintain the printer.

n

To create and print label formats, take a look at the ZPL II Programming

Guide. If one was not ordered with your printer, simply call your

distributororvisitourwebsiteatwww.zebra.com.

NOTE: Many printer settings may also be controlled by your

printer’s driver or label preparation software. Refer to the driver

or software documentation for more information.

What’s in the Box

Printer

Power

Supply

Quick

Product

Support Services

Brochure

Reference

Guide

User’s

Guide

CD-Rom

Registration

Card

Sample

Roll of Media

Test

Label

1

Page 8

Unpacking and Inspection

Inspect the printer for possible shipping damage:

n

Check all exterior surfaces for damage.

n

Raisethetopcover(referto“LoadingtheMedia”onpage5)andinspect

the media compartment for damage.

In case shipping is required, save the carton and all packing material.

Reporting Damage

If you discover shipping damage:

n

Immediately notify and file a damage report with the shipping company.

Zebra Technologies Corporation is not responsible for any damage

incurred during shipment of the printer and will not cover the repair of

this damage under its warranty policy.

n

Keep the carton and all packing material for inspection.

n

Notify your authorized reseller.

2

Page 9

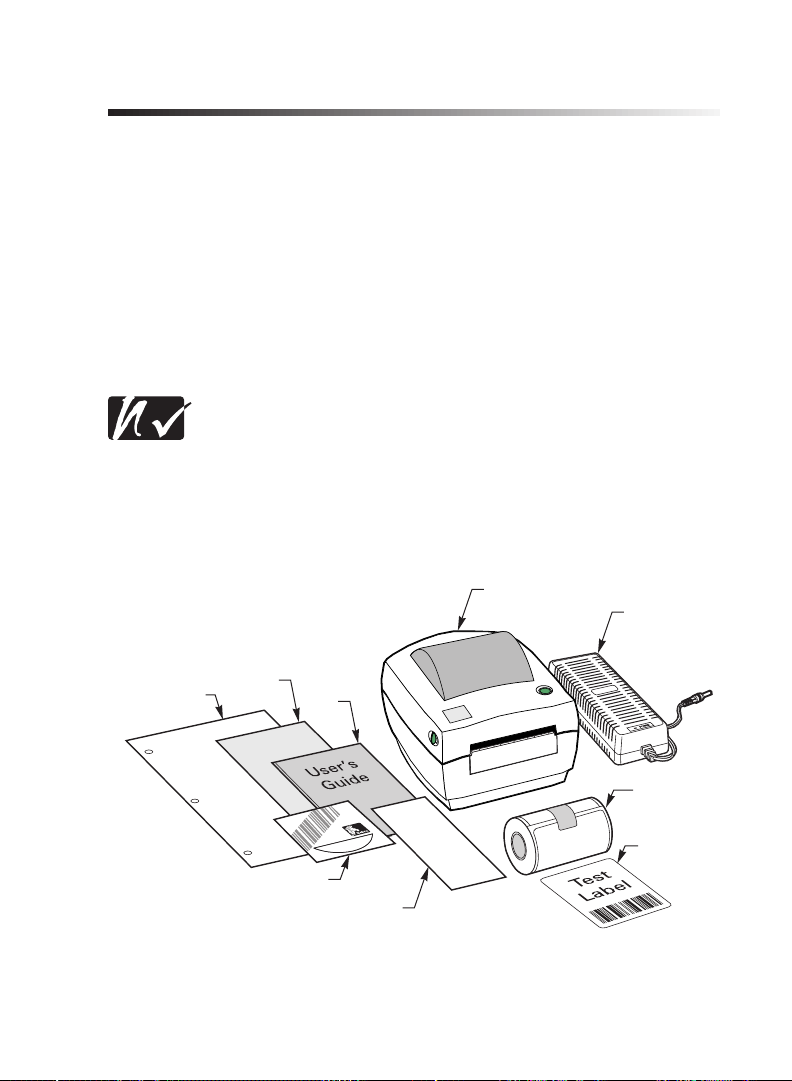

WARNING: NEVER OPERATE THE PRINTER AND POWER

SUPPLY IN AN AREA WHERE THEY CAN GET WET.

SERIOUS PERSONAL INJURY COULD RESULT!

DC Power Supply

Refer to Figure 1.

1. The DC power supply has a barrel connector on one end that must be

inserted into the power supply receptacle on the back of the printer.

2. Insert the separate AC power cord into the power supply.

3. Plug the other end of the cord into an appropriate AC electrical outlet.

Plug

Varies by

Country

Power

Switch

Power

Supply

Receptacle

Barrel

Connector

Figure 1

AC

Power

Cord

Power

Supply

3

Page 10

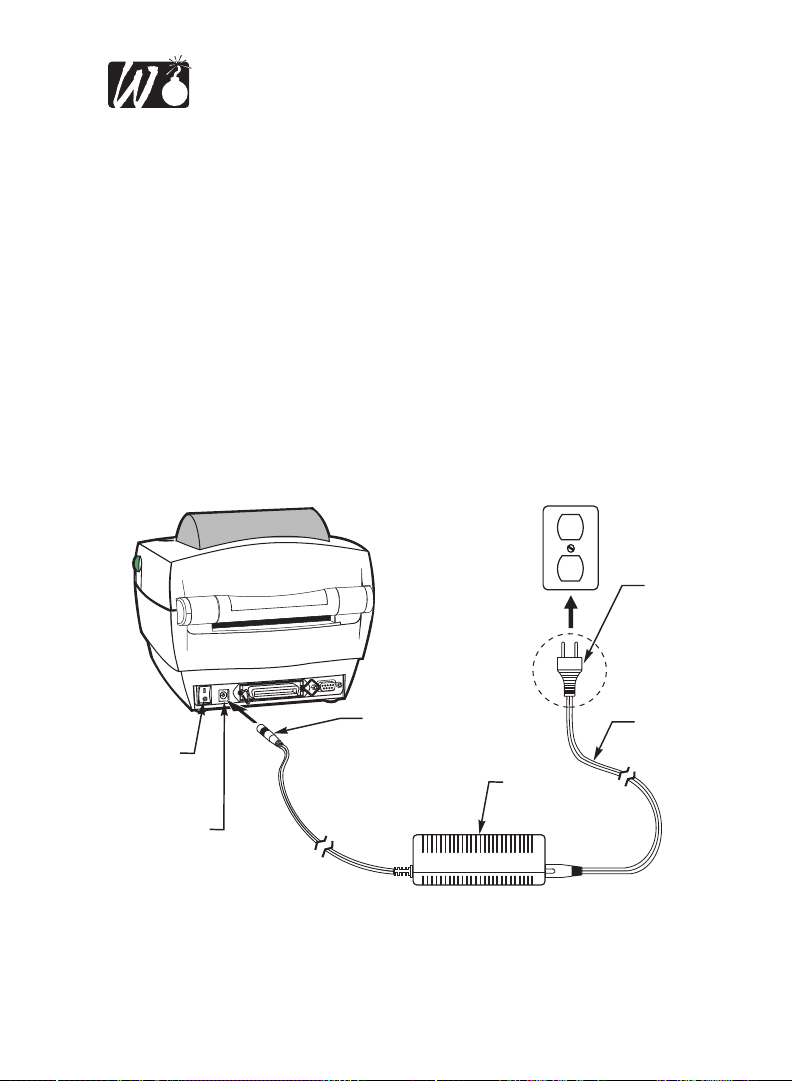

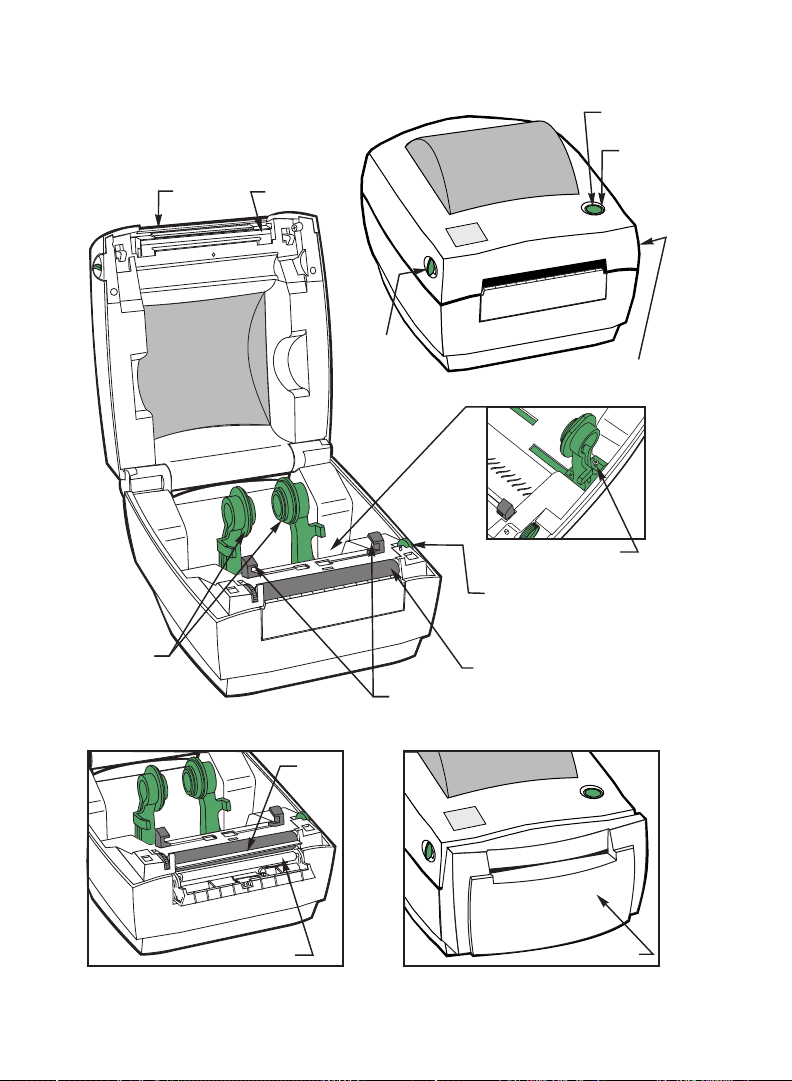

Printer Overview

Tear Bar

Printhead

Release

Lever

Feed

Button

Status

LED

Release

Lever

Lock-down Screw

Media Guide Adjuster

4

Media

Hangers

Peel-Off Option

Platen Roller

Media Guides

Cutter Option

Peel

Bar

Peel Roller Cutter Unit

Figure 2

Page 11

Getting Ready to Print

Loading the Media

You can operate this printer in three different modes: tear-off, peel-off, or

with a cutter.

n

Tear-off mode allows you to tear off each label (or a strip of labels) after

it is printed.

n

In peel-off mode, the backing material is peeled away from the label as it

is printed. After this label is removed, the next one is printed.

n

In cutter mode, the printer automatically cuts the label after it is printed.

Tear-Off Mode

1. Unlatch the top cover by pulling the two green release levers toward

you (refer to Figure 3). Then, lift the top cover to expose the media

compartment.

Release

Lever

Release

Lever

Figure 3

5

Page 12

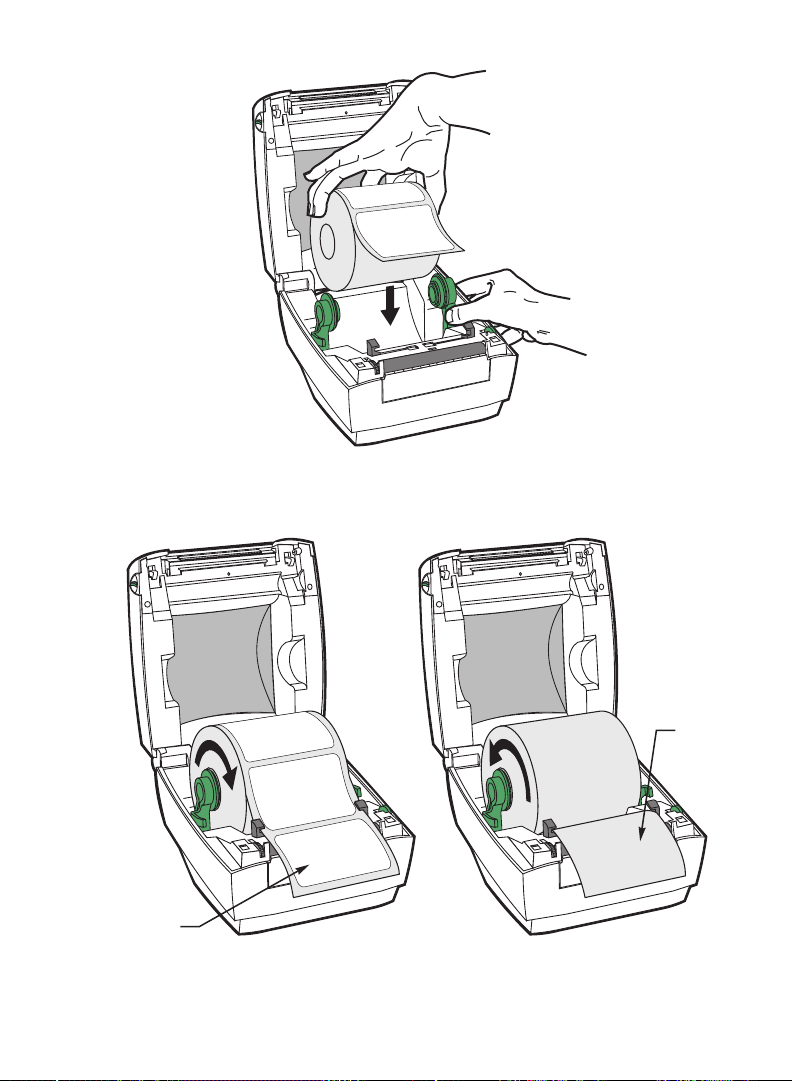

2. Separate and hold open the media hangers (refer to Figure 4).

3. Place the media roll onto the media hangers, ensuring that it is tightly

wound(refertoFigure5).

NOTE:RefertoFigure6.Ifyouareusinglabels,makesurethe

media unwinds from the top of the roll. Tags unwind from the

bottom of the roll.

Media

Hanger

Media

Hanger

Figure 4

6

Page 13

Labels

Figure 5

Tags

Figure 6

7

Page 14

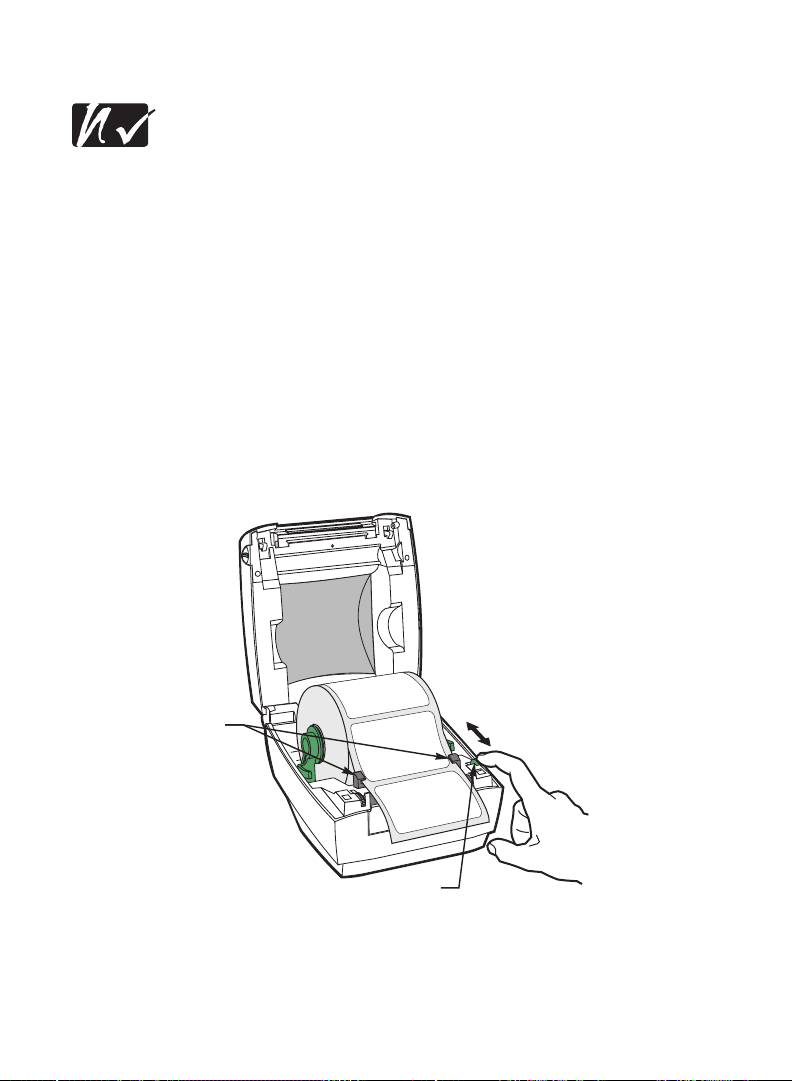

4. Refer to Figure 7. Thread the media through the media guides.

NOTE: If the media guides must be changed to accommodate the

width of the media, turn the green media guide adjuster (refer to

Figure 7). The media guides should just touch, but not restrict, the

edges of the media.

5. Close the top cover and turn on the printer or press the feed button if

theprinterisalreadyon(see“AutoCalibration”onpage18formore

information).

Media

Guides

Media Guide Adjuster

Figure 7

8

Wide Media

Narrow Media

Page 15

Peel-Off Mode (optional)

1. Unlatch the top cover by pulling the two green release levers toward

you (refer to Figure 8). Then, lift the top cover to expose the media

compartment.

Release

Lever

Release

Lever

Figure 8

9

Page 16

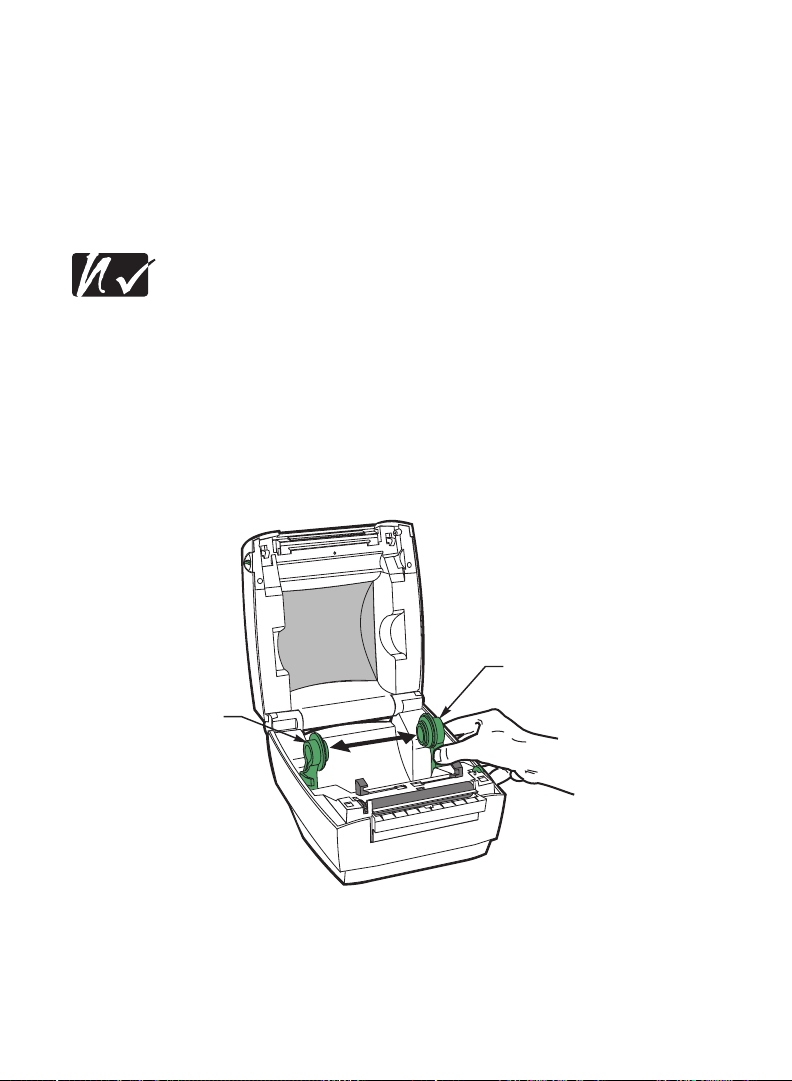

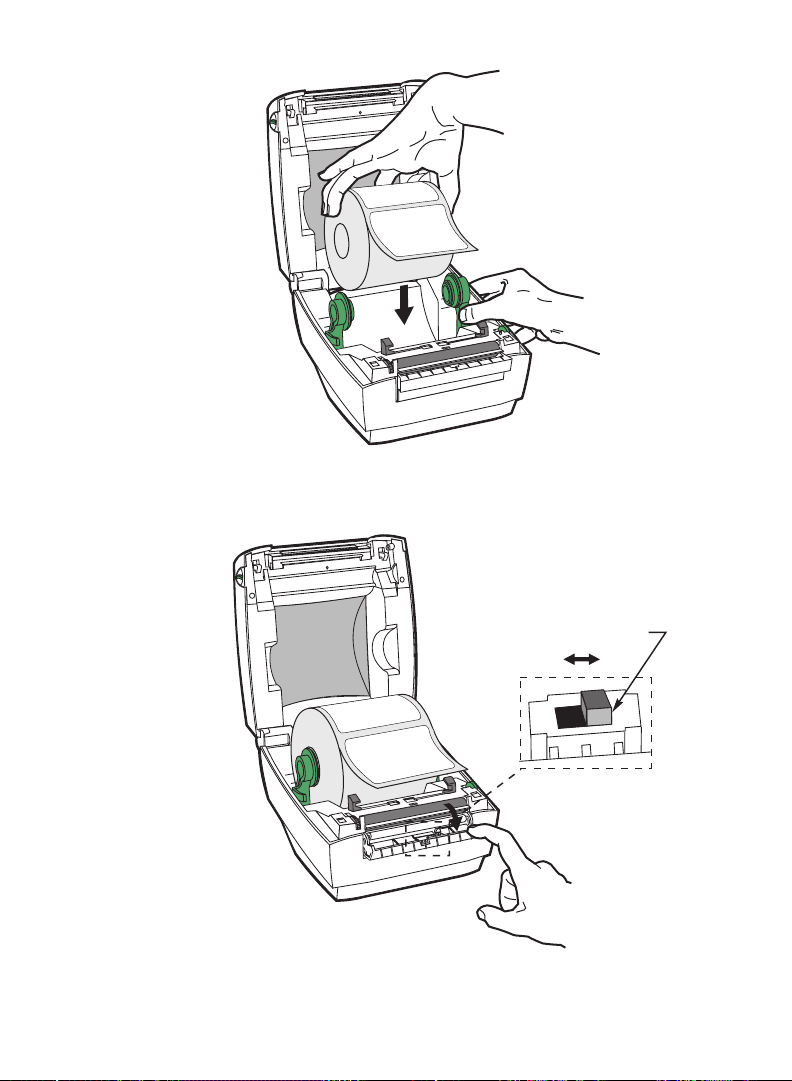

2. Separate and hold open the media hangers (refer to Figure 9).

3. Place the media roll onto the media hangers, making sure it is tightly

wound(refertoFigure10).

4. Open the peel-off unit by pulling down on its textured top surface (refer

toFigure11).

5. Activate the peel-off unit by moving the peel-off switch to the left

(refertoFigure11inset).

NOTE: When not operating the printer in peel-off mode, always

deactivate the peel-off unit by moving the peel-off switch to the

right.

6. Remove approximately 6” (152 mm) of labels from the label backing.

10

Media

Hanger

Media

Hanger

Figure 9

Page 17

Figure 10

Figure 11

Peel-off Switch

ON OFF

11

Page 18

7. Refer to Figure 12. Thread the label backing through the media guides

and over the peel bar.

NOTE: If the media guides must be changed to accommodate the

width of the media, turn the green media guide adjuster (refer to

Figure 12). The media guides should just touch, but not restrict,

the edges of the media.

12

Media

Guides

Peel Bar

Media Guide Adjuster

Wide Media

Narrow Media

Figure 12

Page 19

8. Thread the label backing between the black platen roller and white peel

roller until it comes out of the slot beneath the peel-off unit (refer to

Figure 13).

9. Close the peel-off unit by pushing in on its smooth side surface.

10. To remove any slack, rewind media onto the roll.

11. Close the top cover and turn on the printer or press the feed button if

theprinterisalreadyon(see“AutoCalibration”onpage18formore

information).

Slot

Platen

Roller

Peel Bar

Peel

Roller

Figure 13

13

Page 20

Cutter Mode (optional)

NOTE: The cutter is designed to cut through paper labels or the

backing between labels, not the adhesive backing of the label.

Adhesive build-up on the cutter blade may cause thecutter to jam.

1. Unlatch the top cover by pulling the two green release levers toward

you (refer to Figure 14). Then, lift the top cover to expose the media

compartment.

2.Separateandholdopenthemediahangers(refertoFigure15).

3. Place the media roll onto the media hangers, ensuring that it is tightly

wound(refertoFigure16).

Release

Lever

14

Release

Lever

Figure 14

Page 21

Media

Hanger

Media

Hanger

Figure 15

Figure 16

15

Page 22

4. Refer to Figure 17. Thread the media through the media guides.

NOTE: If the media guides must be changed to accommodate the

width of the media, turn the green media guide adjuster (refer to

Figure 17). The media guides should just touch, but not restrict,

the edges of the media.

5. Refer to Figure 17. Thread the media through the cutter unit.

6. Close the top cover and turn on the printer or press the feed button if

theprinterisalreadyon(see“AutoCalibration”onpage18formore

information).

16

Media

Guides

Wide Media

Narrow Media

Media Guide Adjuster

Figure 17

Page 23

Fanfold Media

Fanfold media loads from the outside of the printer. Refer to Figure 18.

1. Thread the media through the access slot in the back of the printer.

2. Separate and hold open the media hangers.

3. Lock the media hangers in position by tightening the screw located on

the right media hanger.

CAUTION: Do not overtighten the screw! Overtightening

could pierce the case and damage the printer’s electronics!

4. Thread the media through the media guides.

NOTE: If the media guides must be changed to accommodate the

width of the media, turn the green media guide adjuster. Media

guides should just touch, but not restrict, the edges of the media.

5. Close the top cover and turn on the printer or press the feed button if

theprinterisalreadyon(see“AutoCalibration”onpage18formore

information).

Media

Hangers

Access

Slot

Lock-down

Screw

Media

Guide

Adjuster

Media

Guides

Figure 18

17

Page 24

Auto Calibration

NOTE: If you are using pre-printed labels, pre-printed label

backing,orcontinuousmedia,see“ManualCalibration”on

page 28.

Anautocalibrationisperformedwhentheprinteristurnedon(ifmediais

loaded) or after a media error is cleared. When it is auto calibrating, the

printer sets the sensor levels for, and determines the length of, the label you

are using.

IfthestatusLEDflashesred,referto“ManualCalibration”onpage28.

18

Page 25

Operator Controls

Refer to Figure 19.

Power Switch

n

Press to turn on and turn off the printer.

CAUTION: The power should be turned off before connecting

or disconnecting the communications and power cables.

Feed Button

n

Forces the printer to feed one blank label.

n

Takes the printer out of a “pause” condition. (The printer is put into

“pause”byeitheraZPLIIcommandoranerrorcondition.)See“What

theStatusLEDisTellingYou”onpage25.

n

Usedforprintersetupandstatus(see“FeedButtonModes”onpage31).

Status LED

n

Functionsasaprinteroperationalindicator(see“WhattheStatusLEDis

TellingYou”onpage25).

Feed

Button

Status

LED

Figure 19

Power

Switch

19

Page 26

Printing a Test Label

Before you connect the printer to your computer, make sure that the printer

is in proper working order. You can do this by printing a configuration

label:

1. Make sure the media is properly loaded and the top cover of the printer

is closed. Then, turn the printer power on if you have not already done

so.

2. When the status LED is solid green, press and hold the feed button until

the status LED flashes once.

3. Release the feed button. A configuration label will print.

Ifyoucannotgetthislabeltoprint,refertoTroubleshooting.

Hooking Up the Printer and Computer

CAUTION: The power supply barrel connector must be

inserted into the power supply receptacle on the back of the

printer before connecting or disconnecting the

communicationscables.(Ifnecessary,refertoFigure1.)

This printer comes with both a nine-pin Electronics Industries Association

(EIA) RS-232 serial data interface and an IEEE 1284-compliant

bidirectional parallel data interface. In either case, you must supply the

required interface cable for your application.

CAUTION: This printer complies with FCC “Rules and

Regulations,” Part 15, for Class B Equipment, using fully

shielded six-foot data cables. Use of longer cables or

unshielded cables may increase radiated emissions above the

Class B limits.

Serial (RS-232) Interface Requirements

The required cable must have a nine-pin “D” type (DB-9P) male connector

on one end, which is plugged into the mating (DB-9S) serial port located on

the back of the printer (refer to Figure 20). The other end of this signal

interface cable connects to a serial port at the host computer. Depending on

the specific interface requirements, this will most likely be a null modem

cable.

Fortechnicalandpinoutinformation,refertopage45.

20

Page 27

ParallelInterfaceRequirements

Therequiredcable(IEEE1284-compliantisrecommended)musthavea

standard36-pinparallelconnectorononeend,whichispluggedintothe

parallelportlocatedonthebackoftheprinter(refertoFigure20).The

otherendoftheparallelinterfacecableconnectstotheprinterconnectorat

thehostcomputer.

Forpinoutinformation,refertopage48.

SerialandParallelCablingRequirements

Datacablesmustbeoffullyshieldedconstructionandfittedwithmetalor

metalizedconnectorshells.Shieldedcablesandconnectorsarerequiredto

preventradiationandreceptionofelectricalnoise.

Tominimizeelectricalnoisepickupinthecable:

n

Keepdatacablesasshortaspossible(6’[1.83m]recommended).

n

Donottightlybundlethedatacableswithpowercords.

n

Donottiethedatacablestopowerwireconduits.

Parallel

Port

Figure20

Serial

Port

Connectsto

SerialPorton

HostComputer

Connectsto

ParallelPorton

HostComputer

21

Page 28

Communicating with the Printer

Via the Serial Port

Serial communications between the printer and the host computer can be set

by either autobaud synchronization or the ^SC command.

Autobaud

Autobaud synchronization allows the printer to automatically match the

communication parameters of the host computer. To autobaud:

1. Press and hold the feed button until the green status LED flashes once,

twice, and then three times.

2. While the status LED flashes, send a ZPL II format to the printer.

3. When the printer and host are synchronized, the LED changes to solid

green. (No labels will print during autobaud synchronization.)

^SC Command

Use the Set Communications (^SC) command to change the

communications settings on the printer.

1. With the host computer set at the same communications settings as the

printer, send the ^SC command to change the printer to the desired

settings.

2. Change the host computer settings to match the new printer settings.

Refer to the ZPL II Programming Guide for more information about this

command.

Setting the Communications Parameters

To reset the communications parameters on the printer to the factory

defaults (9600 baud, 8 bit word length, no parity, 1 stop bit, and

XON/XOFF), do the following:

1. Press and hold the feed button until the green status LED flashes once,

twice, and then three times.

2. While the status LED rapidly flashes yellow and green, press the feed

button.

Via the Parallel Port

Typically, no setup is required once the cable is plugged in. If you should

encounter any problems, consult the user’s guide that came with your

computer.

22

Page 29

Using ZPL II

For detailed information about creating labels using ZPL II, refer to the

ZPLIIProgrammingGuideorvisitourwebsiteatwww.zebra.com.

Adjusting the Print Width

Print width must be calibrated when:

n

You are using the printer for the first time.

n

There is a change in the width of the media.

Printwidthmaybesetbywayofthefive-flashsequencein“FeedButton

Modes”(seepage31)orrefertothePrintWidth(^PW)command(consult

your ZPL II Programming Guide).

Adjusting the Print Darkness

The relative darkness setting is controlled by either the six-flash sequence in

“FeedButtonModes”(seepage31)ortheSetDarkness(~SD)ZPLII

command (follow the instructions in the ZPL II Programming Guide).

Adjusting the Print Speed

Printqualityisaffectedbyprintspeedandthemediayouareusing.Only

by experimenting will you find the optimal mix for your application.

If you find that the print speed needs to be adjusted, refer to the Print Rate

(^PR) command in the ZPL II Programming Guide.

23

Page 30

24

Page 31

Troubleshooting

What the Status LED is Telling You

Status LED

Condition and Color

Off Off 1

Solid Green On 2

Flashing Yellow Stopped 3

Flashing Green Normal Operation 4

Flashing Red Stopped 5

Double Flashing Green Paused 6

Solid Yellow Various 7

Alternately Flashing Green and Red Needs Service 8

Printer

Status

For a Resolution,

Refer to:

RESOLUTIONS:

1. The printer is not receiving power.

n

Have you turned on the printer power?

n

Check power connections from the wall outlet to the power supply,

and from the power supply to the printer.

2. The printer is on and in an idle state.

3. The printer has failed its power on self test (POST).

n

If this error occurs right after you turn on the printer, contact an

authorized reseller for assistance.

There is a shortage of memory.

n

If this error occurs after you have been printing, turn the printer

power off and on. Then, resume printing.

4. The printer is receiving data.

n

As soon as all of the data has been received, the status LED will

turn green; then, the printer will automatically resume operation.

25

Page 32

5. The media is out.

n

Loadarollofmedia,followingtheinstructionsin“Loadingthe

Media”onpage5.Then,pressthefeedbuttontoresumeprinting.

The printhead is open.

n

Close the top cover. Then, press the feed button to resume printing.

The cutter is jammed.

n

Turn off the printer and remove any jammed labels from the cutter

unit. Then, turn on the printer to resume printing.

6. The printer is paused.

n

Press the feed button to resume printing.

7. The printhead is under temperature.

n

Continue printing while the printhead reaches the correct operating

temperature.

The printhead is over temperature.

n

Printing will stop until the printhead cools to an acceptable printing

temperature. When it does, the printer will automatically resume

operation.

8. FLASH memory is not programmed.

n

Return the printer to an authorized reseller.

Print Quality Problems

No print on the label.

n

Make sure the correct media (direct thermal) is loaded. Try this:

Quickly rub your nail or a blunt object over the label surface. If it does

not produce dark marks, the wrong media (thermal transfer) is loaded.

n

Isthemedialoadedcorrectly?Followtheinstructionsin“Loadingthe

Media”onpage5.

The printed image does not look right.

n

Theprintheadisdirty.Cleantheprintheadaccordingtotheinstructions

on page 33.

n

The printhead is under temperature.

26

Page 33

n

Adjust the print darkness and/or print speed. Refer to the six-flash

sequencein“FeedButtonModes”onpage31,orthe^PRand~SD

commands in the ZPL II Programming Guide.

n

The media being used is incompatible with the printer. Be sure to use

the recommended media for your application, and always use

Zebra-approved labels and tags.

There are long tracks of missing print (blank vertical

lines) on several labels.

n

Theprintheadisdirty.Cleantheprintheadaccordingtotheinstructions

on page 33.

n

The printhead elements are damaged. Replace the printhead (see

“ReplacingthePrinthead”onpage36).

The printing does not start at the top of the label, or

misprinting of one to three labels.

n

The media may not be threaded under the media guides. Refer to

“LoadingtheMedia”onpage5.

n

Theprinterneedstobecalibrated.Referto“AutoCalibration”on

page 18.

n

The correct media sensor may not be activated. Manual calibration

selects the media sensing method for the labels being used (refer to the

^MN command in the ZPL II Programming Guide).

n

Verify that the Label Top (^LT) command is correctly set for your

application (consult the ZPL II Programming Guide).

A label format was sent to, but not recognized by, the

printer.

n

Is the printer in pause mode? If so, press the feed button.

n

IfthestatusLEDisonorflashing,referto“WhattheStatusLEDis

TellingYou”onpage25.

n

Make sure the data cable is correctly installed.

n

A communications problem has occurred. First, make sure that the

correct communications port on the computer is selected. Next, verify

that the same handshaking is in use by both the printer and the computer.

Then, ensure that the baud rates of the printer and the computer match.

Referto“CommunicatingwiththePrinter”onpage22.

27

Page 34

Manual Calibration

Manual calibration is recommended whenever you are using pre-printed

labels (or label backing) or if the printer will not correctly auto calibrate.

1. Turn on the printer power.

2. Remove approximately 4” (102 mm) of labels from a section of

backing material. Load the media so that only the backing material is

threaded through the printer and under the printhead.

3. Press and hold the feed button until the green status LED flashes once,

then twice. Release the feed button.

4. The printer will set the media sensor for the label backing being used.

After it is done making this adjustment, the roll will automatically feed

until a label is positioned at the printhead.

5. A profile of the media sensor settings (similar to the example in

Figure 21) will print. Upon completion, the printer will save the new

settings in memory and the printer is ready for normal operation.

6. Press the feed button. One entire blank label will feed. If this does not

happen,trydefaulting(refertothefour-flashsequencein“FeedButton

Modes”onpage31)andrecalibratingtheprinter.

NOTE: Performing a manual calibration disables the auto

calibration function. To return to auto calibration, default the

printer(seethefour-flashsequencein“FeedButtonModes”on

page 31).

28

Figure 21

Page 35

Troubleshooting Tests

Printing a Configuration Label

To print out a listing of the printer’s current configuration (an example is

showninFigure22),refertotheone-flashsequencein“FeedButton

Modes”onpage31.

Recalibration

Recalibrate the printer if it starts to display unusual symptoms, such as

skippinglabels.See“AutoCalibration”onpage18.

Figure 22

29

Page 36

Resetting the Factory Default Values

Sometimes, resetting the printer to the factory defaults solves some of the

problems.Followthefour-flashsequenceinstructionsin“FeedButton

Modes”onpage31.

Communications Diagnostics

If there is a problem transferring data between the computer and printer, try

putting the printer in the communications diagnostics mode. The printer

will print the ASCII characters and their respective hexadecimal values (a

sample is shown in Figure 23) for any data received from the host

computer.Tofindouthow,refertothepoweroffmodeprocedurein“Feed

ButtonModes”onpage31.

30

Figure 23

Page 37

Feed Button Modes

Power Off Mode (Communications Diagnostics Mode)

With the printer power off, press and hold the feed button while you turn on the

power.Theprinterprintsoutalistingofitscurrentconfiguration(seeFigure22).

After printing the label, the printer will automatically enter a diagnostic mode in

whichtheprinterprintsoutaliteralrepresentation(seeFigure23)ofalldata

subsequently received. To exit the diagnostic mode and resume printing, turn off

and then turn on the printer.

Power On Modes

With the printer power on and top cover closed, press and hold the feed button for

several seconds. The green status LED will flash a number of times in sequence.

The explanation at the right (Action) shows what happens when you release the key

after the specific number of flashes.

Flash

Sequence Action

* A configuration label prints.

*

**

*

**

***

*

**

***

****

*

**

***

****

*****

*

**

***

****

*****

******

If the feed button remains pressed after a 7-flash sequence, the printer will ignore

the button when it is released.

The media sensor calibrates and a media sensor profile prints (see

“ManualCalibration”onpage28).

To reset the communication parameters: Press and release the feed

button while the LED rapidly flashes yellow and green. The serial

communication parameters reset to 9600 baud, 8 bits per character,

no parity, 1 stop bit, and XON/XOFF.

For autobaud synchronization: Send a ZPL II format to the printer

while the LED rapidly flashes yellow and green. When the printer and

host are synchronized, the LED changes to solid green. NOTE: No

labels will print during autobaud synchronization.

Resets the factory defaults, auto calibrates, and saves settings into

memory.

The print width calibrates. While the status LED alternately flashes

green and yellow, a series of stacking rectangles print on the label.

When the rectangle prints to the outer edges of the label, press and

release the feed button. The label width and current communication

parameters will be saved into memory.

The print darkness calibrates. A series of nine samples print, starting

with the lightest and ending with the darkest image. When the desired

print darkness is achieved, press and release the feed button. The

print darkness will be saved into memory.

31

Page 38

32

Page 39

Maintenance

Cleaning

CAUTION: Use only the cleaning agents indicated. Zebra

Technologies Corporation will not be responsible for damage

caused by any other cleaning materials used on this printer.

Ifnecessary,refertoFigure2forpartlocations.

Area Method Interval

After allowing the printhead to cool for approximately one

minute, use 70% isopropyl alcohol on a cotton swab to

clean the print elements from end to end (the print

elements are located in the thin gray line on the printhead).

NOTE: You do not have to turn off the printer to do this.

Printhead

Platen roller

Peel bar

Tear bar

Cutter

Exterior Water-dampened cloth

Interior Brush/air blow

If print quality has not improved after performing this

procedure, try cleaning the printhead with

Save-a-Printhead cleaning film. This specially coated

material removes contamination buildup without

damaging the printhead. Call your authorized reseller for

more information.

Manually rotate the platen roller. Clean it thoroughly with

70% isopropyl alcohol and a cotton swab or lint-free cloth.

Clean it thoroughly with 70% isopropyl alcohol and a

cotton swab.

Clean it thoroughly with 70% isopropyl alcohol and a

cotton swab.

Turn off the printer power. Use tweezers to remove the

media.

After

every five

rolls of

media

As

needed

As

needed

As

needed

As

needed

As

needed

Lubrication

CAUTION! No lubricating agents of any kind should be used

on this printer! Some commercially available lubricants, if

used, will damage the finish and the mechanical parts inside

the printer.

33

Page 40

1

2

3

4

5

6

9

34

7

8

Figure 24

Page 41

Parts List

RefertoFigure24.

Item

Number Description

Feed Switch Assembly (set of 3)

1

Printhead and Latch Assembly

2

Printhead Assembly

3

Media Sensor PCB Assembly (set of 3)

4

Platen Roller Kit, Standard (set of 3)

5

Platen Roller Kit, Linerless

Front Bezel, Standard (set of 10)

Front Bezel, Peel-Off (set of 5)

6

Peel-Off Sensor PCB Assembly (set of 3)

Base Housing (set of 3)

7

Rubber Foot Kit (set of 24)

8

Main Logic Board Kit, Maintenance

9

Stepper Motor, (set of two)

Power Supply Assembly (90-264 VAC, 47-63 Hz)

Power Cord, 110V (set of 5)

Power Cord, 230V European (set of 5)

Power Cord, 230V UK (set of 5)

Power Cord, 230V Australian (set of 5)

Not

shown:

Cutter

4M FLASH Memory Option Assembly

8M FLASH Memory Option Assembly

4M FLASH Memory w/Real Time Clock Option Assembly

8M FLASH Memory w/Real Time Clock Option Assembly

User’s Guide

Quick Reference Guide

Part

Number

105910-004

105910-003

105910-010

105910-011

105910-001

105910-002

105910-005

105910-012

105910-013

105910-006

105910-007

52050M

105910-009

105903-040

105950-014

105950-015

105950-030

105950-029

105910-028

52051

52052

52053

52054

52005L

52006L

35

Page 42

Replacing the Printhead

Removing the Printhead

1. Turn printer power off and unplug the printer.

2. Refer to Figure 25. Remove the four screws that secure the printhead

and latch assembly to the top cover.

3.RefertoFigure26.Slidethetensionbarallthewaytotherightinits

mounting bracket (1). Then, while gently pressing on the opposite

mounting bracket (2), lift and remove the tension bar (3).

4.RefertoFigure27.Removebothprintheadwireharnessconnectors

from their receptacles.

5.RefertoFigure27.Removethetwoscrewsandwashersthatsecure

the printhead to the printhead bracket. Then, lift the lip on the front of

the printhead bracket to remove the printhead.

Printhead and Latch Assembly

Top Cover

36

Screws (4)

Figure 25

Page 43

Tension Bar

Tension Bar

Mounting

Bracket

2

Screw

and

Washer

Connector

3

Tension Bar

Mounting

Bracket

1

Figure 26

Screw

and

Washer

Connector

Receptacle

(shown hidden)

Printhead

Bracket Lip

Receptacle

(shown hidden)

Printhead

Figure 27

37

Page 44

Installing the Printhead

1. Ensure that the printer is turned off and unplugged.

2. Refer to Figure 28. Route the two printhead wire harness connectors as

shown. Then, insert the connectors into their receptacles.

3. Insert the printhead into the printhead bracket.

4.RefertoFigure29.Reinstallthetwoscrewsandwashersthatsecure

the printhead to the printhead bracket.

NOTE: The green grounding cable, which attaches to the feed

switch assembly PC board, must also be secured by one of the

screws.

5.RefertoFigure30.Insertoneendofthetensionbarintoitsmounting

bracket (1). Then, gently push down on the opposite end of the tension

bar until it locks into place (2).

NOTE: Make sure the “V” of the tension bar fits into the notch in

the printhead bracket.

6. Insure that all cables are properly dressed between the printhead and

latch assembly and the top cover.

7. Reinstall the four screws that secure the printhead and latch assembly

to the top cover. Then, plug in the printer and turn on the power.

Connector

Receptacle

(shown hidden)

38

Connector

Receptacle

(shown hidden)

Printhead

Figure 28

Page 45

Screw

and

Washer

Green

Grounding

Cable

Screw

and

Washer

Printhead

Printhead

Bracket

Figure 29

Tension Bar

2

Printhead

Bracket

Notch

1

“V” of Tension Bar

Figure 30

39

Page 46

40

Page 47

Specifications

NOTE: Printer specifications are subject to change without

notice.

Printing Specifications

Print Density 203 dots/inch (8 dots/mm)

Print Speed 1.5” (38 mm), 2” (51 mm), and 2.5” (64 mm) per second

Print Width

Print Length .005” to 22” (.125 mm to 559 mm) with standard memory

Registration

Tolerance

FLASH Memory

(User Available)

DRAM Memory

(User Available)

1” to 4.09” (25.4 mm to 104 mm)

1” to 2.25” (25.4 mm to 57 mm) for tag stock

Horizontal: +/- 0.0591” (1.5 mm)

Vertical: +/- 0.0393” (1 mm)

1MB

1MB

41

Page 48

Label/Tag Specifications

Label/Tag Width

Label/Tag Length 0.5” to 22” (13 mm to 559 mm) with standard memory

Interlabel Gap

Label/Tag Thickness

Label

Roll

Size

Media

Requirements

Max. Outer

Diameter

Inner Core

1” to 4.25” (25.4 mm to 108 mm)

1” to 2.25” (25.4 mm to 57 mm) for tag stock

0.08” to 0.16” (2 mm to 4 mm)

0.118” (3 mm) recommended

.003” to .007” (.08 mm to .18 mm)

.003” to .0053” (.08 mm to .135 mm) for cutter option

5” (127 mm)

1” (25.4 mm) or 1.5” (38 mm)

Use Zebra-brand direct thermal media that is outside

ü

wound. Media may be reflective (black mark) sensing

or transmissive sensing, die-cut, notched, or

continuous.

ü For die-cut labels, use only full auto dies.

ü Notched media must have a 0.5” (13 mm) wide x

0.094” (2.4 mm) long cutout located in the center of the

roll. The reflective media black marks must be located

in the center of the roll.

Minimum Black Mark Dimensions:

ü

Mark width: 0.5” (13 mm) centered and perpendicular

to the edge of the media.

ü

Mark length: 0.094” (2.4 mm) parallel to the bottom

edge of the media.

42

Page 49

Font/Bar Code Specifications

CG Triumvirate Bold Condensed scalable smooth (0)

ü

Zebra fonts A-H, GS, P-V

Fonts Available

Bar Codes

Available (1D)

Bar Codes

Available (2D)

Rotation Angles 0°,90°, 180°, and 270°

ü

IBM Code Page 850 International Symbols

ü

Codabar (supports ratios

ü

of 2:1 to 3:1)

Code 11

ü

Code 128/USD 8 (supports

ü

serialization in all subsets

and UCC Case Codes)

Code 39 (supports ratios

ü

of 2:1 to 3:1)

Code 93

ü

EAN 8/JAN 8

ü

EAN 13/JAN 13

ü

EAN 14/UPC-A

ü

ü Codablock

ü Code 49

ü Data Matrix

ü MaxiCode

Industrial 2 of 5

ü

Standard 2 of 5

ü

Interleaved 2 of 5

ü

(supports ratios of 2:1 to

3:1, Modulus 10 Check

Digit)

LOGMARS

ü

MSI

ü

Plessey

ü

POSTNET

ü

UPC-E

ü

ü UPC/EAN Extensions

ü MicroPDF417

ü PDF 417

ü QRcode

Physical/Environmental/Electrical

Specifications

Physical Size (LxWxH) 8.5” x 7.6” x 6.6” 216 mm x 193 mm x 167 mm

Weight

Temperature

Range

Relative

Humidity

Electrical

Printer

Shipping

Operating

Storage

Operating

Storage

3 lbs. 1.4 kg.

9 lbs. 4.1 kg.

40° to 105° F5°to 41° C

-40° to 140° F -40° to 60°C

10% to 90% (non-condensing)

5% to 95% (non-condensing)

External 90-264 VAC, 47-63 Hz universal power

supply. Regional line cords are available.

43

Page 50

Agency Approvals

n

UL 544 Medical Equipment Standard Part 42.5

n

CSA 22.2 No. 950-95 Canadian Safety Standard

n

IEC 950/EN 60950 International Safety Standard

n

FCC Class B

n

UL 1950 Domestic Safety Standard, 3rd Ed.

n

Canadian DOC Class A

n

EN50082-1:1997 International Immunity Standard

n

EN55022 Class B European Electromagnetic Radiation Standard

n

EN61000-3-2, 3 Powerline Disturbance

n

AS/NZS 3548 Australia EMC

n

CE Compliant

n

EMC Taiwan

n

CB Scheme Documents

Options

n

Peel-off

n

Cutter

n

Linerless

n

4 MB FLASH memory

n

8 MB FLASH memory

n

Real time clock with 4 MB FLASH

n

Real time clock with 8 MB FLASH

n

Power rewinder, 110 VAC

n

Power rewinder, 230 VAC

For details, call your authorized reseller.

44

Page 51

Serial (RS-232) Connector Technical

Information

Pin No. Description

1

2

3

4

5

6

7

8

9

Not used

RXD (receive data) input to the printer

TXD (transmit data) output from the printer

DTR (data terminal ready) output from the printer -- controls when

the host may send data

Chassis ground

DSR (data set ready) input to the printer

RTS (request to send) output from the printer -- always in the

ACTIVE condition when the printer is turned on

Not used

+5 V @ 0.75 A fused

NOTES: The maximum current available through the serial

and/or parallel port is not to exceed a total of 0.75 Amps.

When XON/XOFF handshaking is selected, data flow is controlled

by the ASCII control codes DC1 (XON) and DC3 (XOFF). The

DTR control lead will have no effect.

Interconnecting to DTE Devices

The printer is configured as data terminal equipment (DTE). To connect the

printer to other DTE devices (such as the serial port of a personal

computer), use an RS-232 null modem (crossover) cable.

Figure31showstherequiredcableconnections.

Interconnecting to DCE Devices

When the printer is connected via its RS-232 interface to data

communication equipment (DCE) such as a modem, a STANDARD

RS-232(straight-through)interfacecablemustbeused.Figure32shows

the connections required for this cable.

45

Page 52

Connecting the Printer to a DTE Device

DB-25S

Connector

to DTE Device (PC)

TXD

2

RXD RXD

3

RTS

4

CTS

5

DSR

6

GND

7

DCD

8

DTR

20

22

DB-9S

Connector

to DTE Device (PC)

DCD

1

2

3

4

5

6

RTS

7

CTS

8

9

DB-9P

Connector

to Printer

DCD

1

2

TXD

3

DTR

4

GND

5

DSR

6

RTS

7

CTS

8

9

DB-9P

Connector

to Printer

DCD

1

RXDRXD

2

TXDTXD

3

DTRDTR

4

GNDGND

5

DSRDSR

6

RTS

7

CTS

8

9

46

Figure 31

Page 53

Connecting the Printer to a DCE Device

DB-25S

Connector

to DCE Device

RXD

2

TXD

3

CTS

4

RTS

5

DTR

6

GND

7

DCD

8

DSR

20

22

DB-9S

Connector

to DCE Device

DCD

1

TXD

2

RXD

3

DSR

4

5

DTR

6

CTS

7

RTS

8

9

DB-9P

Connector

to Printer

DCD

1

RXD

2

TXD

3

DTR

4

GND

5

DSR

6

RTS

7

CTS

8

9

DB-9P

Connector

to Printer

DCD

1

RXD

2

TXD

3

DTR

4

GNDGND

5

DSR

6

RTS

7

CTS

8

9

Figure 32

47

Page 54

Parallel Interface Technical Information

Pin No. Description

1

2-9

10

11

12

13

14

15

16 & 17

18

19-30

31

32

33 & 34

35

36

nStrobe/Host Clk

Data Bits 1-8

nACK/PtrClk

Busy/Per Busy

PError/ACK Data Req.

Select/Xflag

nAuto Fd/Host Busy

Not Used

Ground

+5 V @ 0.75 A Fused

Ground

nInit

nFault/nData Avail.

Not Used

+5V through 1.8 KΩ Resistor

nSelectin/1284 active

48

NOTE: The maximum current available through the serial and/or

parallel port is not to exceed a total of 0.75 Amps.

Page 55

Index

A

Adjustments

Printdarkness........23

Printspeed.........23

Printwidth.........23

Agencyapprovals........44

Autocalibration.........18

Autobaud............22

C

Calibration

Auto.............18

Manual...........28

Cleaning

Cutter............33

Exterior...........33

Interior...........33

Peelbar...........33

Platenroller.........33

Printhead..........33

Tearbar...........33

Communicationsparameters,

setting............22

Communicationsdiagnostics..30

Configurationlabel.......29

Cuttermode...........14

D

Damage,shipping........2

Darkness,adjusting.......23

DCEdevices,

interconnecting........45

Defaultingtheprinter......30

DTEdevices,

interconnecting........45

F

Factorydefaults,

resetting..........30,31

Fanfoldmedia..........17

Feedbutton...........19

Feedbuttonmodes.......31

I

Inspection............2

L

Loading the media

Cuttermode.........14

Fanfold...........17

Peel-offmode.........9

Tear-offmode........5

Lubrication...........33

49

Page 56

M

Maintenanceparts........35

Manualcalibration.......28

Medialoading

Cuttermode.........14

Fanfold...........17

Peel-offmode.........9

Tear-offmode........5

O

Operatorcontrols........19

Options.............44

P

Parallelconnectorpinouts...48

Partslist.............35

Peel-offmode..........9

Pinouts

Parallel...........48

Serial............45

Powerswitch..........19

Printdarkness,adjusting..23,31

Printspeed,adjusting......23

Printwidth,adjusting....23,31

Printhead,replacing.......36

S

Serialconnectorpinouts....45

Setcommunications(^SC)...22

Specifications

Font/barcode........43

Label/tag..........42

Physical/environmental/

electrical..........43

Printing...........41

StatusLED.........19,25

T

Tear-offmode..........5

Troubleshooting.........25

Troubleshootingtests......29

U

Unpacking............2

Z

ZPLII..............23

ZPLIIProgramming

Guide............1,23

R

Recalibratingtheprinter....29

Repairparts...........35

Replacingtheprinthead.....36

Reportingdamage,shipping...2

Resettingthefactory

defaults..........30,31

50

Loading...

Loading...