Page 1

ZXP Series 9™

Card Printer

User Guide

P1086707-003

Page 2

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corporation, registered in many

jurisdictions worldwide. All other trademarks are the property of their respective owners.

© 2019 Zebra Technologies Corporation and/or its aliates. All rights reserved.

Information in this document is subject to change without notice. The software described in this document is

furnished under a license agreement or nondisclosure agreement. The software may be used or copied only

in accordance with the terms of those agreements.

For further information regarding legal and proprietary statements, please go to:

COPYRIGHTS: http://www.zebra.com/copyright

END USER LICENSE AGREEMENT: http://www.zebra.com/eula

SOFTWARE: http://www.zebra.com/linkoslegal

WARRANTY: http://www.zebra.com/warranty

Terms of Use

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries (Zebra

Technologies). It is intended solely for the information and use of parties operating and maintaining the

equipment described herein. Such proprietary information may not be used, reproduced, or disclosed to any

other parties for any other purpose without the express, written permission of Zebra Technologies.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specications and designs are

subject to change without notice.

Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specications and manuals are

correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever (including,

without limitation, consequential damages including loss of business prots, business interruption, or loss of

business information) arising out of the use of, the results of use of, or inability to use such product, even if

Zebra Technologies has been advised of the possibility of such damages. Some jurisdictions do not allow

the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may

not apply to you.

Publication Date

January 6, 2020

Page 3

Contents

Before Printing ................................................................................................................................ v

Card Type .................................................................................................................................................................vi

Single- or Double-Sided ........................................................................................................................................... vii

Ribbon Combination ............................................................................................................................................... viii

Print a Test Card .......................................................................................................................................................ix

Introduction ..................................................................................................................................... 1

Description ................................................................................................................................................................ 1

Printer and Laminator Components .......................................................................................................................... 2

Icons ......................................................................................................................................................................... 3

Zebra Supplies .......................................................................................................................................................... 4

Installation ....................................................................................................................................... 5

General Information .................................................................................................................................................. 5

Unpacking the Printer ............................................................................................................................................... 6

Unpacking the Printer with a Laminator .................................................................................................................... 7

Unpacking (continued) .............................................................................................................................................. 8

Loading Cards ......................................................................................................................................................... 11

Installing the Card Hoppers .................................................................................................................................... 12

Input Hopper ..................................................................................................................................................... 12

Output Hopper .................................................................................................................................................. 13

Installing the Cleaning Cartridge ............................................................................................................................. 14

Installing the Cleaning Roller .................................................................................................................................. 15

Loading the Transfer Film ....................................................................................................................................... 16

Loading Print Ribbon .............................................................................................................................................. 17

Loading Laminate ................................................................................................................................................... 18

Installing the Laminate Cassette ...................................................................................................................... 21

Replacing the Laminate .................................................................................................................................... 23

Using Partial-Width Laminate ........................................................................................................................... 26

Laminating Contact Smart Cards ..................................................................................................................... 28

Plugging in the Printer ............................................................................................................................................. 30

Connecting a USB Cable ........................................................................................................................................ 31

Connecting an Ethernet Cable ................................................................................................................................ 32

Turning on the Printer ............................................................................................................................................. 33

Installing the Software ............................................................................................................................................. 34

Supported Operating Systems ......................................................................................................................... 34

Supported Sharing Combinations ..................................................................................................................... 35

Packing for Shipment .............................................................................................................................................. 36

Printer ............................................................................................................................................................... 36

Printer with Laminator ....................................................................................................................................... 38

i

Page 4

Contents

Operation ....................................................................................................................................... 41

Introduction ............................................................................................................................................................. 41

Printing Preferences ............................................................................................................................................... 42

Card Type Selection ............................................................................................................................................... 43

Print Ribbon Selection ............................................................................................................................................ 44

Printing a Test Card ................................................................................................................................................ 46

Manual Card Feed .................................................................................................................................................. 49

Operator Control Panel (OCP) ................................................................................................................................ 51

Printer Menu Information .................................................................................................................................. 52

Messages ................................................................................................................................................................ 60

Operational ....................................................................................................................................................... 60

Warning Messages ........................................................................................................................................... 61

Error Messages ................................................................................................................................................ 61

Maintenance .................................................................................................................................. 63

Cleaning the Printer ................................................................................................................................................ 64

When to Clean .................................................................................................................................................. 64

Rollers .............................................................................................................................................................. 64

Platen ............................................................................................................................................................... 66

Replacing the Cleaning Rollers ........................................................................................................................ 66

Cleaning the Laminator ........................................................................................................................................... 67

When to Clean .................................................................................................................................................. 67

Laminator .......................................................................................................................................................... 67

Cleaning the Printhead ........................................................................................................................................... 72

Magnetic Encoder Cleaning .................................................................................................................................... 73

Troubleshooting ........................................................................................................................... 75

OCP Error Messages .............................................................................................................................................. 75

Clearing a Card Jam ............................................................................................................................................... 83

Printer ............................................................................................................................................................... 83

Laminator .......................................................................................................................................................... 84

OCP Test Cards ...................................................................................................................................................... 86

Adjustments ............................................................................................................................................................ 87

Overview ........................................................................................................................................................... 87

Laminator Adjustments ..................................................................................................................................... 89

Identifying Job Quality Issues ................................................................................................................................. 90

Print Quality Issues ........................................................................................................................................... 90

Transfer Quality Issues ..................................................................................................................................... 91

Ethernet Indicators—Detail ..................................................................................................................................... 98

Network Operations ..................................................................................................................... 99

Printer Connections .............................................................................................................................................. 100

Printer Sharing ................................................................................................................................................ 100

External Print Server ...................................................................................................................................... 100

Internal Print Server ........................................................................................................................................ 100

Adding a Network Printer (Windows 7) ................................................................................................................. 101

Wi-Fi Connectivity ................................................................................................................................................. 102

Description ...................................................................................................................................................... 103

Security ........................................................................................................................................................... 103

Setup via Browser Console ............................................................................................................................ 104

Setup via OCP ................................................................................................................................................ 107

Printer Pooling ...................................................................................................................................................... 108

Setting Up Printer Pooling (Windows 7) ......................................................................................................... 108

Using the Printer Pool ..................................................................................................................................... 109

Printer Sharing ...................................................................................................................................................... 109

ii

Page 5

Contents

Setting Custom Card Specications ........................................................................................ 111

Introduction ........................................................................................................................................................... 111

Process ................................................................................................................................................................. 112

Magnetic Card Encoder ............................................................................................................. 115

Introduction ........................................................................................................................................................... 115

Ribbon Selection ................................................................................................................................................... 116

Driver Setting ........................................................................................................................................................ 116

Media Loading Orientation .................................................................................................................................... 118

Magnetic Encoding Type ...................................................................................................................................... 119

ISO (Default) ................................................................................................................................................... 119

AAMVA ........................................................................................................................................................... 120

CUSTOM ........................................................................................................................................................ 120

BINARY .......................................................................................................................................................... 120

Laminating Mag Cards .......................................................................................................................................... 121

Using Partial-Width Laminate ............................................................................................................................... 121

Smart Card Encoder ................................................................................................................... 123

Introduction ........................................................................................................................................................... 123

Ribbon Selection ................................................................................................................................................... 124

Contact Smart Cards ...................................................................................................................................... 124

Printing on Contactless Smart Cards ............................................................................................................. 124

Driver Setting ........................................................................................................................................................ 125

Media Loading Orientation .................................................................................................................................... 126

Contact Smart Cards ...................................................................................................................................... 126

Contactless Smart Cards ................................................................................................................................ 126

Contact Station Smart Card Interface ................................................................................................................... 127

Laminating Contact Smart Cards .......................................................................................................................... 127

iii

Page 6

Contents

iv

Page 7

Before Printing

Before your rst print, there are several settings that need to be checked:

y Check that the proper card type is selected

y Check that either single- or double sided-printing is selected

y Check that the correct ribbon combination is selected

y Print a test card

v

Page 8

Before Printing

Card Type

From the Printing Preferences Control Panel, select the Card type in use drop-down menu and select the

appropriate card type.

The menu contains six dierent card types that are supported by the printer, if there is not a card type that suits

your needs, select either Custom 1 or Custom 2 and enter the specications for the custom card type—see Setting

Custom Card Specications on page 111.

See Card Type Selection on page 43 for more detailed information.

vi

Page 9

Before Printing

Single- or Double-Sided

The ZXP Series 9 comes in either a single- or double sided conguration. If you have a

single-sided printer, you can skip this step. If you have a double-sided printer, and want to be able to print on both

sides of the card, select Yes from the Print on both sides drop-down menu.

vii

Page 10

Before Printing

Ribbon Combination

The ZXP Series 9 supports many dierent ribbon types for many dierent printing

requirements, and each ribbon type may support multiple ribbon combinations. For example, a YMCK ribbon may

support printing color on the front and black on the back (YMC Front / K Back), or color on the back and front

(YMCK Front / YMCK Back). Depending on your printing requirements, select the appropriate ribbon combination

from the Ribbon combination drop-down menu.

See Print Ribbon Selection on page 44 for more detailed information.

viii

Page 11

Before Printing

Print a Test Card

Once all your preferences have been set, click Test Print.

See Printing a Test Card on page 46 for more detailed information.

ix

Page 12

Before Printing

x

Page 13

Introduction

Description

This manual contains installation, operation, maintenance, troubleshooting, and networking information for the

ZXP Series 9; and describes single- and double-sided printers, and double-sided printers with either a single- or

double-sided laminator; and is intended to be used by an operator, as well as an experienced IT person.

The ZXP Series 9 uses reverse transfer printing technology to create photo-quality and over-the-edge images on

plastic identication cards. The ZXP Series 9 provides fast throughput and a range of encoding options for a variety

of markets and applications.

The single-sided laminator applies a laminating lm on the top surface of the printed card for added security; the

double-sided laminator applies laminating lm on both the top and bottom surfaces of the card.

References in this document to “the laminator” apply to either a single- or double-sided laminator.

1

Page 14

Introduction

Printer and Laminator Components

Transfer Film Take-

Transfer Film Take-Up

Transfer Film Take-Up

Transfer Station

Transfer Station Card Slot

Transfer Station Card Slot

Manual Advance

Manual Advance Wheel

Transfer Film Supply

Transfer Film Supply

Transfer Film Supply

Print Ribbon Take-

Print Ribbon Take-Up

Print Ribbon Take-Up

Up

Card Slot

Wheel

Up

Printhead

Printhead

Printhead

Print Ribbon Supply

Print Ribbon Supply

Print Ribbon Supply

Input Hopper

Input Hopper

Input Hopper

Card Cleaning

Card Cleaning Roller

Card Cleaning Roller

Roller

Card Cleaning

Card Cleaning Cartridge

Card Cleaning Cartridge

Cartridge

Operator Control

Operator Control Panel

Operator Control Panel

Panel

Manual Card Feed

Manual Card Feed

Manual Card Feed

Output Hopper

Output Hopper

Output Hopper

Upper Laminate

Upper Laminate Cassette

Cassette Release

Cassette Release

Cassette

Upper Laminate

Upper Laminate

Cassette Release

Lower Laminate

Lower Laminate

Cassette Release

Lower Laminate

Lower Laminate Cassette

Manual Advance

Manual Advance Tool

Cassette

Tool

Output Hopper

Output Hopper

2

Page 15

Power Switch

Power Switch

Introduction

Power Connector

Power

Connection

DB9 Connection (optional)

DB9 Connection

USB Connection Ethernet Connection

Connection

USB

Ethernet Connection

Icons

Throughout this manual, dierent icons highlight important information, as follows:

Note • Indicates information that emphasizes or supplements important points of the main text.

Important • Advises you of information that is essential to complete a task, or points out the importance of

specic information in the text.

Electrostatic Discharge • Warns you of the potential for electrostatic discharge.

Electric Shock • Warns you of a potential electric shock situation.

Hot Surface • Warns you of a situation where excessive heat could cause a burn.

Wi-Fi Antenna

Wi-Fi Antenna (optional)

(optional)

Caution • Advises you that failure to take or avoid a specic action could result in physical harm to you, or

could result in physical damage to the hardware.

3

Page 16

Introduction

Zebra Supplies

Genuine Zebra supplies meet stringent quality standards and are recommended for optimal printing quality and

proper printer performance. The ZXP Series 9 is designed to work only with Zebra True Colours® i Series™

Ribbons, Zebra True Colours i Series Transfer Film, and Zebra True Secure™ i Series Laminates. Go to the

ZXP Series 9 Card Printer support page at www.zebra.com/zxp9-info for ordering information.

4

Page 17

Installation

General Information

This section provides information on the installation and setup of the ZXP Series 9—procedures should be

performed in the order presented.

5

Page 18

Installation

Unpacking the Printer

Important • Save all the packing material and the shipping carton in case the printer needs to be moved or

shipped. If the original packing material is lost or damaged, a replacement shipping kit can be ordered from

Zebra.

Make sure the following items are included with your printer:

Setup Guide (to be used as a reference poster)

Product Registration Card

Printer Test Cards

Input Hopper with stack of 100 cards

Output Hopper

Cleaning Cartridge

Cleaning Roller

USB Cable

Power Cable

If any items are missing, please contact your Zebra representative.

Place the printer in a location that meets the following requirements:

y A reasonably dust- and dirt-free environment.

y Flat surface at least 27 x 28 inches (686 x 711 mm) that can support the weight of the printer; additional

space preferred. Allow a 4-inch minimum clearance on all sides.

y Vertical clearance at least 32 inches (813 mm).

y Temperature within the range of 59–95°F (15–35°C).

y Relative humidity 20–80% inclusive, non-condensing.

y AC power accessible.

6

Page 19

Installation

Unpacking the Printer with a Laminator

Important • Save all the packing material and the shipping carton in case the printer needs to be moved or

shipped. If the original packing material is lost or damaged, a replacement shipping kit can be ordered from

Zebra.

Make sure the following items are included with the printer:

Setup Guide (to be used as a reference poster)

Product Registration Card

Printer Test Cards

Upper Laminate Cassette (for single- and double sided printers)

Lower Laminate Cassette (for double-sided printers)

Input Hopper with stack of 100 cards

Output Hopper

Cleaning Cartridge

Cleaning Roller

USB Cable

Power Cable

If any items are missing, please contact your Zebra representative.

Place the printer in a location that meets the following requirements:

y A reasonably dust- and dirt-free environment.

y Flat surface at least 38 x 28 inches (965 x 711 mm) deep that can support the weight of the printer;

additional space preferred. Allow a 4-inch minimum clearance on all sides.

y Vertical clearance at least 32 inches (813 mm).

y Temperature within the range of 59–95°F (15–35°C).

y Relative Humidity 20–80% inclusive, non-condensing.

y AC power accessible.

7

Page 20

Installation

Unpacking (continued)

The ZXP Series 9 ships with packing material and tape to protect the printer from damage during shipment—it is

important to remove all packing material and tap prior to using the printer.

Remove the tape and packing material from the front and rear of the printer as shown.

8

Page 21

Installation

Then, open the printer by pressing the yellow release button and remove the packing material.

If the printer came with the optional laminator installed, remove the packing tape from the laminator.

9

Page 22

Installation

Then, open the laminator cover by pulling forward on the tab on the left side of the laminator cover and remove the

packing tape.

10

Page 23

Installation

Loading Cards

Caution • DO NOT bend cards or touch print surfaces as this can reduce print quality. The surface of the

cards must remain clean and dust free. Always store cards in an enclosed container. Ideally, use cards as

soon as possible.

Step 1. Remove the wrapping from the card deck.

Step 2. Holding the card deck by the sides (do not touch the print surfaces), hold it vertically against a at

surface such as a desktop. If the deck is too thick for your hand to hold it comfortably, use about half

a deck at a time.

Step 3. Push the stack back and forth to an angle of about 45° from vertical, so as to separate all of the

cards.

Note • Static charges and edge burrs from the card die-cutting process can render individual cards stuck

together with signicant adhesion force. These cards must be physically separated from each other before

inserting into the feeder; if not separated, feeding or printing problems may occur.

Step 4. Restore the card stack to its original squared-o condition.

Step 5. Open the input hopper door—cards can be loaded into the hopper while it is attached to the printer.

Step 6. Place the cards in the input hopper in the orientation shown: smart card contacts (if present) up and

toward the body of the printer; mag stripe (if present) down and to the rear). Ensure that the cards

are seated at on the bottom of the hopper.

Step 7. Close the input hopper door.

11

Page 24

Installation

Installing the Card Hoppers

Input Hopper

The input hopper is positioned on the right side of the printer and holds the cards to be printed.

Step 1. Install the input hopper by sliding it into the receptacle so that the guide posts on the hopper (circled

below) align with the guide slots (arrows below).

Step 2. Ensure that the input hopper locks securely in place.

12

Page 25

Installation

Output Hopper

The output hopper is positioned on the left side of the printer (or the left side of the laminator if the printer includes a

laminator) and receives the printed cards.

Step 1. Install the output hopper by placing the hopper onto the printer or laminator, and then sliding

downward into the corresponding slots on the printer or laminator.

13

Page 26

Installation

Installing the Cleaning Cartridge

The card cleaning cartridge (X-Cleaning Roller) cleans the cards entering the printer through the input hopper. The

cleaning cartridge consists of a cartridge frame and an adhesive roller.

Step 1. While holding the cleaning cartridge by the frame, peel the protective wrapper from the adhesive

roller. Do not touch the adhesive surface of the roller.

Step 2. Install the cleaning cartridge into the area shown in the gure below by sliding the cartridge guide

pins into the guide slots on the printer.

Step 3. Press down on the cartridge until it is fully seated.

Note • To ensure print quality, the card cleaning cartridge requires periodic replacement. New card

cleaning rollers are included with each print ribbon or may be purchased separately. Before replacing the

card cleaning cartridge or its adhesive roller, clean the printer—see Cleaning the Printer on page 64. To

replace the X-Roller, refer to Maintenance on page 63.

14

Page 27

Installation

Installing the Cleaning Roller

The cleaning roller (Y-Cleaning Roller) cleans the cards entering the printer from either the input hopper or the

manual feed slot.

Step 4. Peel the protective wrapper from the cleaning roller.

Step 5. Install the cleaning cartridge into the area shown in the gure below by placing it into the notches

on the printer. Use the protective wrapper to push the cleaning roller into place until it locks into

position.

Note • To ensure print quality, the card cleaning cartridge requires periodic replacement. New card

cleaning rollers are included with each print ribbon or may be purchased separately. Before replacing the

card cleaning cartridge or its adhesive roller, clean the printer—see Cleaning the Printer on page 64. To

replace the Y-Roller, refer to Replacing the Cleaning Rollers on page 66.

15

Page 28

Installation

Loading the Transfer Film

The ZXP Series 9 is designed to work only with Zebra True Colours® i Series™ Transfer Film for near photographic

print resolution and over-the-edge printing.

Step 1. Locate the transfer lm supply spindles and the transfer lm take-up spindles. Note that the anges

and spindles are color coded (white-to-white, green-to-green).

Step 2. Unroll about 1 foot (30 cm) from the full roll of transfer lm on the supply spool and wind it (about 2

wraps) onto the empty take-up spool.

Step 3. Load transfer lm supply spool onto the supply spindles—green ange side to the left.

Step 4. Load the empty take-up spool onto the take-up spindles—white ange side to the right.

Step 5. Make sure the spring-loaded spindles on the right seat into the spools.

Step 6. Make sure the transfer lm comes o the bottom of the supply spool and feeds to the bottom of the

take-up spool.

Step 7. Route the transfer lm under the retaining tab.

16

Page 29

Installation

Loading Print Ribbon

The ZXP Series 9 is designed to work with Zebra True Colours® i Series™ Ribbons. Each new ribbon comes

with a replacement set of cleaning rollers. It is recommended that they be replaced for each new ribbon or

every 5,000 cards. Refer to Cleaning the Printer on page 64 for recommended cleaning intervals, and

Maintenance on page 63 for replacement instructions.

Step 1. Locate the print ribbon supply spindles and the print ribbon take-up spindles. Note that the anges

and spindles are color coded (blue-to-blue, purple-to-purple).

Step 2. Load the print ribbon supply spool onto the supply spindles—purple ange side to the left.

Step 3. Load the empty take-up spool onto the take-up spindle, blue ange side to the right—make sure the

spring-loaded spindles on the left seat into the spools.

Step 4. Make sure the print ribbon comes o the bottom of the supply spool and feeds to the bottom of the

take-up spool.

17

Page 30

Installation

Loading Laminate

Note • The laminate roll is specic to either the top (blue) or the bottom (yellow) laminate cassette.

Note • The lower laminate cassette (yellow) is used on a double-sided laminator only.

Important • The geared ange on the laminate spool is removable, but do not remove it. If it does come

o, snap it back onto the end of the spool.

Step 1. Remove a new roll of laminate from its packaging and place it in the upper laminate cassette—note

the orientation of the laminate spool with respect to the laminate cassette.

Step 2. Pull out an inch or two of laminate past the lip of the cassette.

Step 3. Close the cassette—press the two halves of the cassette together until it clicks.

Step 4. Cut the laminate square (as close to perpendicular as possible) with scissors. Hold the scissors in

one hand. Hold the cassette with the other hand. Press the laminate rmly against the white roller

thereby keeping the laminate from moving while cutting.

18

Page 31

Installation

Step 5. Remove a second new roll of laminate from its packaging and place it in the lower laminate

cassette—note the orientation of the laminate spool with respect to the laminate cassette.

Step 6. Pull out an inch or two of laminate past the lip of the cassette.

Step 7. Close the cassette—press the two halves of the cassette together until it clicks.

Step 8. Cut the laminate square (as close to perpendicular as possible) with scissors. Hold the scissors in

one hand. Hold the cassette with the other hand. Press the laminate rmly against the white roller

thereby keeping the laminate from moving while cutting.

19

Page 32

Installation

Step 9. Rotate the core to adjust the laminate overhang. Stop when the end of the laminate is just beyond

the lip of the cassette, as shown below.

Important • Check for laminate overhang any time the locking lever is pressed or the cassette is removed.

0 - 0.5 mm

0 - 1/32"

0 - 0.5 mm

0 - 1/32"

20

Page 33

Installation

Installing the Laminate Cassette

Step 1. Grasp the door at the side tab front and pull forward and lift the door to its upright position.

Step 2. Slide the cassette onto the spindle.

21

Page 34

Installation

Step 3. Rotate each cassette (in the direction indicated in the gure below).

Step 4. Continue to turn the cassette. The locking lever will move to the left as the cassette rotates over the

locking mechanism, and will then click into the locked (green) position.

22

Page 35

Installation

Replacing the Laminate

Step 1. Grasp the door at the side tab front and pull forward and lift the door to its upright position.

Step 2. Unlock the laminate cassette by rotate the locking lever in the direction indicated.

23

Page 36

Installation

Step 3. Rotate each cassette in the direction indicated below until it stops.

Step 4. Remove each cassette by pulling straight out from its spindle.

24

Page 37

Installation

Step 5. Open each cassette by separating its two halves at the hinge—grasp the two halves rmly then pull

apart. DO NOT use tools.

Step 6. If there is an empty laminate core in the cassette, remove it.

Step 7. Proceed to Loading Laminate on page 18.

25

Page 38

Installation

Using Partial-Width Laminate

Note • Since partial-width laminates are only used for the back (i.e., lower) surface of the card, this section

only applies to the double-sided laminator.

Laminates come in three widths:

y Full-Width laminate is 2-inch (51 mm) wide. The full-width laminate is used on the front (i.e., upper) or back

(i.e., lower) surface of the card.

y “Partial-Width” laminate is available as 1.33-inch (33 mm) wide (used for cards with a magnetic stripe).

2-inches

(51mm)

1.3-inches

(33mm)

FRONT OF CARD

Full Width

BACK OF CARD

Magnetic Stripe

Step 1. Remove the lower laminate cassette.

Step 2. Open the cassette, and remove the laminate if present.

26

Page 39

Installation

Step 3. Load the partial-width laminate into the cassette. Note that the collar on the laminate spool is on the

end opposite the geared ange and keeps the laminate positioned correctly.

Collar

Step 4. Trim the partial-width laminate.

Step 5. Rotate the core to adjust the laminate overhang—stop when the end of the laminate is even with the

edge of the cassette.

Step 6. Install the cassette.

27

Page 40

Installation

Laminating Contact Smart Cards

The laminate for the top surface of a contact smart card has a repeating pattern of an index hole and a rectangular

cutout to expose the card’s electrical contacts.

Electrical Contacts

Electrical Contacts Cutout

Index Hole

Step 1. Remove the upper laminate cassette.

Step 2. Open the cassette, and remove the laminate if present.

Step 3. Load the smart card laminate into the cassette.

Step 4. Cut the laminate, splitting the index hole as shown.

28

Page 41

Installation

Step 5. Rotate the core to adjust the laminate overhang. Stop when the end of the laminate (not the edge of

the index hole) is even with the edge of the lips of the cassette.

Step 6. Install the cassette—see Installing the Laminate Cassette on page 21.

29

Page 42

Installation

Plugging in the Printer

Step 1. Insert the female end of the power cord into the printer (as shown in the gure below).

Step 2. Insert the male end of the power cord into the power source as shown (power receptacle

conguration may vary).

30

Page 43

Installation

Connecting a USB Cable

Step 1. Insert the device side of the USB cable into the USB receptacle on the printer (as shown in the gure

below).

Step 2. Insert the host side of the USB cable into an appropriate host port.

31

Page 44

Installation

Connecting an Ethernet Cable

Step 1. Insert one end of the Ethernet cable into the Ethernet receptacle on the printer (as shown in the

gure below).

Step 2. Insert the opposite end of the Ethernet cable into an appropriate Host port.

32

Page 45

Installation

Turning on the Printer

The power switch is located at the rear of the printer next to the power receptacle (as shown in the gure below).

Press the upper portion of the power switch to the ON ( | ) position.

Press the lower portion of the power switch to the OFF ( O ) position.

33

Page 46

Installation

Installing the Software

The CD that comes with the printer contains the latest driver software at the time of shipping.

It is recommended that the latest driver software be downloaded from the ZXP Series 9 support page at

www.zebra.com/zxp9-info.

When installing the software, follow the on-screen instructions to install and congure your printer for the desired

network.

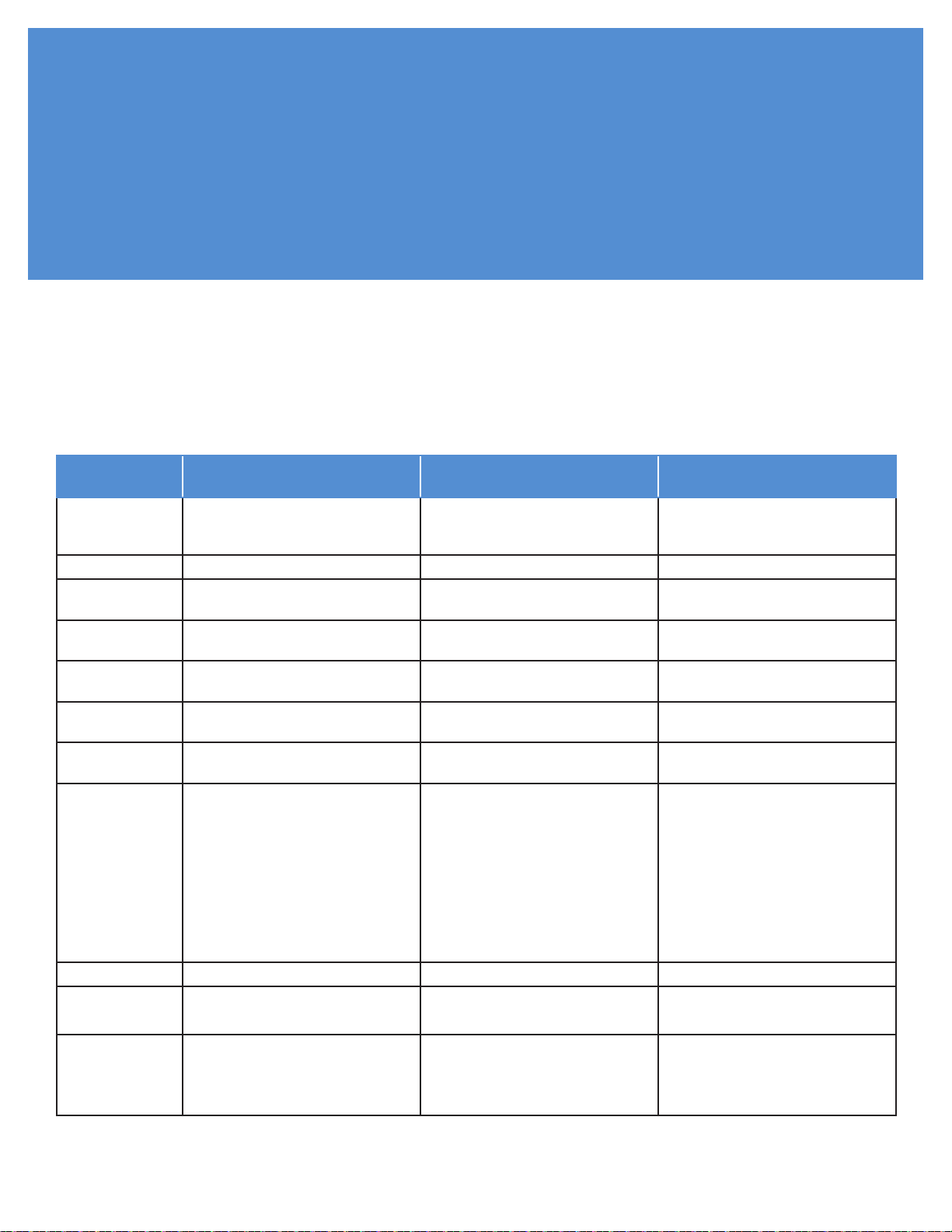

Supported Operating Systems

Supported Windows Drivers

Microsoft OS 1

Server 2016 Yes Yes Yes Yes Yes

Server 2012 Yes Yes Yes Yes Yes

Server 2008 (64-bit) Yes Yes Yes Yes Yes

Server 2008 (32-bit) Yes Yes Yes Yes Yes

Windows 10 (64-bit) Yes Yes Yes Yes Yes

Windows 10 (32-bit)

Windows 8 (32-bit)

Windows 8 (64-bit) Yes Yes Yes Yes Yes

Windows 7 (64-bit) Yes Yes Yes Yes Yes

Windows 7 (32-bit) Yes Yes Yes Yes Yes

1. Driver installed on individual Client PC

2. Printer Pooling Sharing not supported.

3. Windows 10 Home and Pro only (No support for Windows 10 Mobile)

4. No support for Win 8 Metro GUI print driver environment.

3

4

One to One One to Many Many to One Many to Many

1 Printer -

1 Host

Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes

One Host -

Many Printers

Multiple Hosts

(Drivers) One

Printer

Multiple Hosts

(Drivers) -

Many Printers

Printer

Pooling

2

34

Page 47

Installation

Supported Sharing Combinations

Windows OS (Driver Clients)

Windows OS Server

(Driver Host)

Server 2016 Yes Yes Yes Yes Yes Yes

Server 2012 Yes Yes Yes Yes Yes Yes

Server 2008 (64-bit) Yes Yes Yes Yes Yes Yes

Server 2008 (32-bit) Yes Yes Yes Yes Yes Yes

Windows 10 (64-bit) Yes Yes Yes Yes Yes Yes

Windows 10 (32-bit) Yes No Yes No Yes No

Windows 8 (64-bit) Yes Yes Yes Yes Yes Yes

Windows 8 (32-bit) Yes No Yes No Yes No

Windows 7 (64-bit) Yes Yes No No Yes Yes

Windows 7 (32-bit) Yes No No No Yes No

Win 10

(32 bit)

Win 10

(64 bit)

Win 8

(32 bit)

Win 8

(64 bit)

Win 7

(32 bit)

Win 7

(64 bit)

35

Page 48

Installation

Packing for Shipment

If the printer is to be shipped, it is important to use the original packing and shipping material to prevent damage to

the printer.

If the original material is lost, a replacement shipping kit can be ordered from Zebra. Go to the ZXP Series 9

support page at www.zebra.com/zxp9-info for more details.

Printer

Note • The specics of the shipment and the printer condition may inuence which of the following steps are

followed; common sense should prevail.

Step 1. Ensure the printer power is set to the o ( ) position.

Step 2. Disconnect the power cable from the power source, then from the rear of the printer.

Step 3. Disconnect the USB cable from the host computer, then from the rear of the printer; or disconnect

the Ethernet cable from the network source, then from the rear of the printer.

Step 4. Remove any cards from the input and output hoppers—place the hoppers into the foam insert.

Step 5. Open the printer door.

Step 6. Remove the print ribbon and transfer lm (if you wish to save the print ribbon and lm for future use,

you may want to put them in a plastic bag for storage).

Step 7. Remove the card cleaning cartridge and card cleaning roller—place them in the foam insert.

Step 8. Close the printer door.

Output Hopper

Input Hopper

Cleaning Cartridge

Cleaning Roller

Step 9. Place the printer in its protective bag.

Step 10. Place the lower foam insert with the accessories into the shipping carton.

Caution • The printer weighs approximately 27.5 lbs (12.5 kg). Two people may be necessary to lift the

printer.

36

Page 49

Installation

Step 11. Carefully place the printer into the recess in the lower foam insert (shown out of box for clarity).

Step 12. Place the upper foam insert onto the printer, and gently press it down so it makes a snug t on the

printer—the top of the upper foam insert should be even with the upper edge of the shipping carton.

Step 13. Roll up the power cord and USB cable and place them in the recess of the upper foam insert.

Step 14. Close the shipping carton and tape it securely.

37

Page 50

Installation

Printer with Laminator

Step 1. Ensure the printer power is set to the o ( ) position.

Step 2. Disconnect the power cable from the power source, then from the rear of the printer.

Step 3. Disconnect the USB cable from the host computer, then from the rear of the printer; or disconnect

the Ethernet cable from the network source, then from the rear of the printer.

Step 4. Remove any cards from the Input and output hoppers—place the hoppers into the lower foam insert.

Step 5. Open the printer door.

Step 6. Remove the print ribbon and transfer lm (if you wish to save the print ribbon and lm for future use,

you may want to put them in a plastic bag for storage).

Step 7. Remove the card cleaning cartridge and card cleaning roller—place them in the foam insert.

Step 8. Close the printer door.

Output Hopper

Input Hopper

Cleaning Roller

Cleaning Cartridge

Step 9. Open the laminator door.

Step 10. Place the lower foam insert with the accessories into the shipping carton.

Step 11. Remove the laminate cassette(s)—any unused laminate can remain in the cassette(s)—and place

the cassette(s) into the upper foam insert from the underside.

Laminate Cassette(s)

38

Page 51

Installation

Step 12. Close the laminator door.

Step 13. Place the unit in its protective bag.

Caution • The printer weighs approximately 44 lbs (20 kg). Use two people to lower it into the shipping

carton.

Step 14. With two people, carefully lift and place the unit into the recess in the lower foam insert.

Step 15. Place the two corner blocks on top of the right front and left front corners of the lower foam insert.

39

Page 52

Installation

Step 16. Place the upper foam insert onto the unit, and gently press it down so it makes a snug t on the

unit—the top of the upper foam insert should be even with the upper edge of the carton.

Step 17. Roll up the power cord and USB cable and place them in the recess of the upper foam insert.

Step 18. Close the shipping carton.

Step 19. Tape the shipping carton securely.

40

Page 53

Operation

Introduction

Printing with the ZXP Series 9 is similar to printing with any other printer in a Windows environment:

y The printer is connected to either a host computer (via USB), or to a network (via Ethernet).

y The printer is selected by either the operating system or the appropriate software application.

y Printer properties are set via the printer driver (although the factory default values will be appropriate for

many applications).

41

Page 54

Operation

Printing Preferences

The Printing Preferences Control panel can be used to determine preferences such as which ribbon panels will be

used to print images on the card, what card type will be used, where the card comes from (i.e., the input hopper or

the manual feed slot) and its destination. It is also used to make adjustments to colors and black panel quality.

The following tabs are included in the Printing Preferences Control Panel:

y Card Setup Tab

y Encoding Tab

y Black Panel (K) Optimization Tab

y Color (YMC) Optimization Tab

y About Tab

The Restore Defaults button sets the printing preferences back to factory settings.

The OK button applies the settings and closes the Printing Preferences Control Panel.

The Cancel button closes the Printing Preferences Control Panel without applying the changes made.

The Apply button makes (or applies) the changes. The Printing Preferences Control panel remains open.

The Help button shows this help content.

To open the Printing Preferences Control Panel:

y Windows 7: Select Start > Devices and Printers, right click the ZXP Series 9 Card Printer, and select

Printing preferences from the pop-up menu.

y Windows 8: Right-click the screen’s bottom-left corner (or press Windows+I) and choose Control Panel from

the pop-up menu, right click the ZXP Series 9 Card Printer, and select Printing preferences from the popup menu.

y Windows 10: Select the Start menu and then select Settings > Devices, right click the ZXP Series 9

Card Printer, and select Printing preferences from the pop-up menu.

42

Page 55

Operation

Card Type Selection

The Printing Preferences Control Panel enables you to specify the card type in use. Based on your selection, the

printer makes adjustments for optimum print quality.

Step 1. Open the Printing Preferences Control Panel—see Network Operations on page 99.

Step 2. From the Card Setup tab, click the Card type in use drop-down menu and select the appropriate

card type (circled below). Supported card types are:

y PVC, Standard

y PVC, Mag Stripe

y PVC, Contactless SC

y PVC, Contact SC

y Composite, Standard

y Composite, Mag Stripe

If your card type is not listed in the drop-down menu, select Custom and ll out the Card

Specications pop-up screen—see Network Operations on page 99 for details.

For help setting the custom card specications, see Setting Custom Card Specications on

page 111.

Step 3. Click Apply and then click OK.

43

Page 56

Operation

Print Ribbon Selection

A variety of ribbons are available for use with the ZXP Series 9 Card Printer.

For example, the YMC ribbon prints yellow (Y), magenta (M), and cyan (C) on the front and the back (if the printer is

double-sided). The YMCK ribbon prints yellow, magenta, and cyan on the front of the card, and black on the back of

the card (if the printer is double-sided).

The YMCKI ribbon is for use with mag stripe cards, and will print yellow, magenta, and cyan on the front of the card,

and black on the lower half of the back—avoiding printing over the mag stripe.

The YMCUvK ribbon adds a layer of ultra-violet (Uv) to print invisible images (text or graphics) that will glow in the

visible spectrum when exposed to a Uv light.

The printer will recognize the type of print ribbon installed and display it in the Ribbon type eld of the Printing

Preferences Control Panel Card Setup tab, and (as shown in the following gure) will make available the ribbon

combinations from the Ribbon combinations drop-down menu. Additionally, selecting Yes or No (double- or singlesided, respectively) from the Print on both sides drop-down list will aect the available ribbon combinations.

The table below shows the supported print ribbons and their respective combinations for single- and double-sided

printing.

YMCK

YMCKK

YMCKI

YMCKKI

Ribbon Print on both sides Ribbon Combinations

No YMCK

Yes

No YMCK Front

Yes

No YMCKI Front

Yes

No YMCKI Front

Yes

No YMCUvK Front

YMC Front / K Back

YMCK Front / YMCK Back

YMCK Front / K Back

YMCK Front / YMCK Back

YMC Front / KI Back

YMCI Front / K Back

YMCKI Front / YMCKI Back

YMCK Front / KI Back

YMCKI Front / K Back

YMCKI Front / YMCKI Back

YMCUvK

YMC

K (Monochrome)

YMCUv Front / K Back

Yes

No YMC Front

Yes YMC Front / YMC Back

No K Front

Yes K Front / K Back

44

YMC Front / UvK Back

YMCUvK Front / YMCUvK Back

Page 57

Operation

Step 1. Open the Printing Preferences Control Panel—see Network Operations on page 99.

Step 2. From the Card Setup tab, click the Ribbon combination drop-down menu and make the appropriate

selection (circled below).

In the example above, the available ribbon combinations for the installed YMCK ribbon are YMC on the front of

the card, and K on the back of the card; or YMCK on both the front and back of the card. The available Ribbon

combinations is also dependent on if printing is set to single- or double sided.

45

Page 58

Operation

Printing a Test Card

The Printing Preferences Control Panel has the option for printing a test card. This is a simple device to ensure the

printer is working properly, and to check the quality of the print. The test card is printed according to the settings in

the Card Setup tab.

Step 1. Open the Printing Preferences Control Panel—see Network Operations on page 99.

Step 2. From the Card Setup tab, adjust the Card Options, Printing Options, etc., to suit your preferences.

Step 3. Click Test Print (circled below).

46

Page 59

Operation

An enhanced test print feature is also available from the ZXP Toolbox. This feature oers a wider range of test cards

to showcase the quality of print from the ZXP Series 9 The test card is printed according to the settings in the Card

Setup tab.

To print a test card from the ZXP Toolbox:

Step 1. Open the Printer Properties control panel:

y Windows 7: Select Start > Devices and Printers, right click the ZXP Series 9 Card Printer, and

select Printer Properties from the pop-up menu.

y Windows 8: Right-click the screen’s bottom-left corner (or press Windows+I) and choose Control

Panel from the pop-up menu, right click the ZXP Series 9 Card Printer, and select Printer

Properties from the pop-up menu.

y Windows 10: Select the Start menu and then select Settings > Devices, right click the

ZXP Series 9 Card Printer, and select Printer Properties from the pop-up menu.

Step 2. Select the Device Information tab and click the ZXP Toolbox button.

47

Page 60

Operation

Step 3. Select the Tools & Utilities page (the Test Cards menu is displayed by default).

Step 4. Select an image from the Test Card Library and click either Set as Front or Set as Back to set the

front and back of the test card; or you can add your own images to the library and use them for the

test card.

Step 5. When the front and the back images are set, click Print Test Cards.

48

Page 61

Operation

Manual Card Feed

A manual feed slot is available for feeding single cards. Note that this option works with cards in the input hopper.

Step 1. Open the Printing Preferences Control Panel—see Network Operations on page 99.

Step 2. From the Card Setup tab, click the Card source drop-down menu and select Manual Feed (circled

below).

Step 3. Click Apply.

Step 4. Send the print job to the printer. When ready, the printer OCP will prompt you to insert the card.

49

Page 62

Operation

Step 5. Insert a single card into the slot in the correct orientation. Do not feed more than one card at a time.

Caution • DO NOT bend cards, and refrain from touching print surfaces as much as possible as this can

reduce print quality. The surface of the cards must remain clean and dust free. Always store cards in an

enclosed container. Ideally, use cards as soon as possible.

Step 6. The printer will feed in the card and start printing.

Step 7. Once the printing job is complete, the card is ejected from the printer into the output hopper.

50

Page 63

Operation

Operator Control Panel (OCP)

The printer is equipped with an OCP display and three OCP buttons which give access to the printer menus.

READY

MENU INFO PRINT

y Press the MENU button to access the Main Menu.

y Press the INFO button to access and view the printer information pages.

y Press the PRINT button to print the last card stored in memory.

51

Page 64

Printer Menu Information

PREV NEXT EXIT

Displays Settings: Top and Bottom temperature; and Current

Displays RX Bytes, Discards, TX Bytes, Discards, Errors; TX

Info Menu

INFO Button

(Operating Mode Display)

Operation

PRINTER INFO

NETWORK INFO Displays DHCP, IP, Mask, GW, and MAC.

RIBBON INFO Displays Type, # Images, and % Remaining.

FILM INFO Displays Type, # Images, and % Remaining.

PRINTHEAD USAGE Displays Card Count and Printhead Lines.

REJECT BIN Displays Card Count.

CONFIGURATION INFO

TEMPERATURE INFO

LAMINATOR INFO *

Displays MCB FW Ver, HCB FW Ver, MAB FW Ver, and Mfr

Serial Number.

Displays RAM, Single or Dual Sided, and Options Installed:

Mag, Encoder, Laminator.

Temperature: Top and Bottom.

Displays LCB, MAB, LSN, Top installed (yes/no), Bottom

installed (yes/no).

TOP LAMINATE INFO * Displays P/N, Type, # Images, and % Remaining.

BTM LAMINATE INFO * Displays Type, # Images, and % Remaining.

LAM TEMPERATURE INFO *

LAMINATOR ODOMETER *

CAL LUT INFO Displays Look-Up Table info for LUT1 and LUT2.

WIRELESS INFO **

WIRELESS STATISTICS **

Info Menu

Displays Settings: Top and Bottom temperature; and

Current: Top and Bottom temperature.

Displays Unit on (# days), Top on (# days), Bottom on (#

days), # Laminated, # Processed.

Displays Settings: SSID, Channel Noise Floor, WEP, DHCP,

IP, Mask, GW, and MAC. Only applies to Printers with the

Wireless option installed.

Success, TX Retry, RX Success,

RX Duplicate, and RTS Success. Only applies to Printers

with the Wireless option installed.

* Applies to printer with attached laminator.

** Applies to printer with optional wireless upgrade.

52

Page 65

Main Menu

Operation

MENU Button

(Operating Mode Display)

RETURN

PRINT TEST CARDS Print Test Cards see page 54

NETWORK SETTINGS Network Settings Menu see page 54

ADVANCED SETTINGS

ENCODER SETTINGS

WIRELESS SETTINGS Wireless Settings Menu see page 54

Main Menu

UP DOWN SELECT

Advanced Settings Menu see page 54

Encoder Settings Menu see page 54

53

Page 66

Print Test Cards Menu

Operation

Main Menu

RETURN

> COUNT

> SIDES Selects single-sided or double-sided printing.

> CARD TYPE

GRADIENT BOXES Prints a test card with varying gradient boxes.

DENSITY SETUP

MONOCHROME ONLY

Print Test Cards Menu

UP DOWN

SELECT /

PRINT

Selects the number of cards to be printed (1, 5, 10, 25, 50,

75, 100)

Selects the type of cards being printed on (varying types of

PVC, Composite, etc.).

Prints a test card with varying color densities.

Prints a test card with monochrome bitmap elements. Only

works when monochrome ribbon is installed.

54

Page 67

Network Settings Menu

UP DOWN SELECT

Operation

Main Menu

RETURN WITHOUT SAVE

SAVE SETTINGS

DHCP MODE

SET IP ADDRESS

SET SUBNET MASK Change the subnet mask.

SET DEFAULT GATEWAY Change the gateway.

Network Settings Menu

Enable or disable DHCP mode.

Change the IP address of the printer.

55

Page 68

Advanced Settings Menu

UP DOWN SELECT

Operation

Main Menu

RETURN

SELECT LANGUAGE

FLUSH PRINT QUEUE

PRINTER ONLINE

CLEAN PRINTER

SET SLEEP TIMER

SET SCREEN CONTRAST

CLEAR REJECT BIN

HOST USB SETTINGS

SET WARMUP DELAY

Select the language of the OCP.

Deletes all pending print jobs stored in the printer.

Toggles printer online/oine.

Runs the cleaning routine—see Network Operations on

page 99

Sets the idle duration before entering sleep mode.

Sets the contrast level of the OCP.

Resets the reject bin count to zero.

Host USB settings.

Sets the idle duration before beginning warm-up.

Advanced Settings Menu

56

Page 69

Encoder Settings Menu

Operation

Main Menu

RETURN

USB ENCODING

ETHERNET ENCODING

Encoder Settings Menu

UP DOWN SELECT

Select if printer is connected via USB.

Select if printer is connected via Ethernet.

57

Page 70

Clean Printer Menu

Operation

Main Menu

RETURN

CLEAN SIDE CARD PATH

CLEAN FRONT CARD PATH

CLEAN HEATER ROLLERS

CLEAN LAM CARD PATH *

CLEAN MED LAM ROLLERS * Use the Cleaning Swab and follow the OCP instructions.

CLEAN LAM OVEN *

Clean Printer Menu

UP DOWN SELECT

Use the X Roller Cleaning Card and follow the OCP

instructions.

Use the Y Roller Cleaning Card and follow the OCP

instructions.

Use the Hot Roller Cleaning Card and follow the OCP

instructions.

Use the Laminator Cleaning Card and follow the OCP

instructions.

Use the Laminator Hot Roller Cleaning Card and follow

the OCP instructions.

* Applies to printer with attached laminator.

58

Page 71

Wireless Settings Menu

Operation

Main Menu

RETURN WITHOUT SAVE

SAVE SETTINGS

RADIO CONTROL

SETUP WIZARD

DHCP MODE

SET IP ADDRESS Change the IP address of the printer.

SET SUBNET MASK

SET DEFAULT GATEWAY

SET DEFAULTS

Advanced Settings Menu

UP DOWN SELECT

Enable or disable the radio.

Easily connect you printer to a wireless network.*

Enable or disable the DHCP.

Change the subnet mask.

Change the gateway.

Return to the default wireless settings.

* See Network Operations on page 99 for additional

information.

59

Page 72

Operation

Messages

Operational

Operational messages are displayed during normal operation.

Message Description

ALARM

CANCELING

CONFIG DATA

CONTACT OPERATION

CONTACTLESS OPERATION

COOLING

COOLING PRINT JOB WAITING Print job received, cooling rollers to temperature.

COOLING PRINTHEAD TEMPERATURE Cooling printhead to temperature.

COOLING WAITING TO LAMINATE Print job completed, laminator cooling to temperature.

DIAGNOSTIC Diagnostic testing in progress.

JOB DATA Data is being transferred from the computer to the printer.

LAMINATING Print job received, laminating in process.

MAG OPERATION

MANUALLY INSERT CARD FROM

FRONT

OFFLINE Status toggled (oine/online) via the OCP Advanced Settings Menu.

PRINTING Print job received, printing in process.

READY Ready and at temperature.

STANDBY Printer is in “sleep” mode; i.e., power save mode.

WAIT INITIALIZING Performing a self test on startup.

WARMING

WARMING PRINT JOB WAITING Print job received, warming rollers to temperature.

WARMING

WAITING TO LAMINATE

WARMING PRINTHEAD TEMPERATURE Warming printhead to temperature.

WARNING

An error message needs to be cleared before normal operations can

resume.

The Cancel button was pressed, and the current operation is being

terminated.

Conguration data is being transferred from the computer to the

printer.

Contact Smart Card is being encoded; i.e., the card is in position and

data is being transferred.

Contactless Smart Card is being encoded; i.e., the card is in position

and data is being transferred.

Ready to accept a print job, rollers cooling; e.g., when switching from

2-sided printing to 1-sided printing.

A Magnetic Stripe Card is being encoded; i.e., card is in position and

data is being transferred.

Waiting for manual card feed.

Ready to accept a print job, rollers heating; e.g., at startup or when

switching from 1-sided printing to 2-sided printing.

Ready to accept a print job, laminator warming; e.g., when switching

from 1-sided laminating to 2-sided laminating.

Indicates that additional OCP instructions need to be performed; e.g.,

PRINT RIBBON LOW, etc.

60

Page 73

Operation

Warning Messages

Warnings alert the operator to action that should be taken—the printer will generally continue operation.

Warning Message Description

BOTH LAMINATES LOW

BOTTOM LAMINATE LOW

CLEAN FEEDER Indicates that the Feeder needs cleaning.

CLEAN FRONT CARD PATH

CLEAN LAM CARD PATH

CLEAN LAM MED ROLLERS

CLEAN LAM OVEN

CLEAN SIDE CARD PATH

CLEAN TRANSFER PATH

PRINT RIBBON LOW

TOP LAMINATE LOW

TRANSFER FILM LOW

Indicates that the Top Laminate cassette and the Bottom Laminate

cassette are low.

Indicates that the Bottom Laminate cassette is low—see Network

Operations on page 99.

Indicates that the Front Card Path (Y-Drive Rollers) needs cleaning—

see Network Operations on page 99.

Indicates that the Laminator Card Path needs cleaning—see Network

Operations on page 99.

Indicates that the Laminator Media Feed Rollers need cleaning—see

Network Operations on page 99.

Indicates that the Laminator Transfer Path (Heated Rollers) needs

cleaning—see Network Operations on page 99.

Indicates that the Side Card Path (X-Drive Rollers) needs cleaning—

see Network Operations on page 99.

Indicates that the Transfer Path (Heated Rollers) needs cleaning—

see Network Operations on page 99.

Indicates that the Print Ribbon spool is low—see Network Operations

on page 99.

Indicates that the Top Laminate cassette is low—see Network

Operations on page 99.

Indicates that the Transfer Film spool is low—see Network

Operations on page 99.

Error Messages

Errors are displayed when a situation causes the printer to stop operating. Depending on the cause of the error

message, restarting the printer or clearing the displayed error may return the printer to operational status; or the

printer may require troubleshooting and repair.

See Network Operations on page 99 for a list of the error messages, possible causes, and possible solutions.

61

Page 74

Operation

62

Page 75

Maintenance

Caution • PROTECT YOUR FACTORY WARRANTY!

The recommended maintenance procedures must be performed to maintain the factory warranty. Other

than the recommended cleaning procedures described in this manual, allow only Zebra authorized

technicians to service the Printer.

NEVER loosen, tighten, adjust, or bend, etc., a part or cable inside the printer.

NEVER use a high-pressure air compressor to remove particles from the printer.

63

Page 76

Maintenance

Cleaning the Printer

The regular use of cleaning cards will clean and maintain important parts of your printer that cannot be reached,

including the printhead, transport rollers, and optional magnetic encoder station.

Printer usage (total number of cards printed and total number of cards laminated) can be found on the printer

Properties, Device Information tab, or via the OCP Info Menu—see Maintenance on page 63.

To order cleaning supplies, please visit www.zebra.com/zxp9-info.

When to Clean

y X-Cleaning Roller and Y-Cleaning Roller replacement should occur every 5,000 cards—see Maintenance on

page 63.

y Heated Roller cleaning should occur every 20,000 cards.

Rollers

Important • Do not reuse cleaning cards.

To initiate the cleaning process:

Step 1. On the operator control panel (OCP) select Menu.

Step 2. From the Main Menu select Advanced Settings.

Step 3. From the Advanced Settings menu select Clean Printer.

To clean the X-drive rollers:

Step 1. Select Clean Side Card Path to run the X-roller cleaning routine.

Step 2. Use the X-roller cleaning card.

Step 3. Follow the OCP instructions.

Step 4. When complete, the OCP will return to the Clean Printer Menu.

64

Page 77

Maintenance

To clean the Y-drive rollers:

Step 1. Select Clean Front Card Path to run the Y-roller cleaning routine.

Step 2. Use the Y-roller cleaning card.

Step 3. Follow the OCP instructions.

Step 4. When complete, the OCP will return to the Clean Printer Menu.

To clean the heated rollers:

Note • To avoid a long wait while the heated rollers cool to 140°F (60°C), perform cleaning before the

rollers heat up (i.e., when rst turned on and the rollers are still cold).

Step 1. Select Clean Transfer Path to run the heated roller cleaning routine.

Step 2. Use the hot roller cleaning card.

Step 3. Follow the OCP instructions.

Step 4. When complete, the OCP will return to the Clean Printer Menu.

65

Page 78

Maintenance

Platen

Platen cleaning is done manually, there is no OCP cleaning routine.

Step 1. Open the printer door.

Step 2. Remove the transfer lm.

Step 3. Manually run the hot roller cleaning card over the platen.

Step 4. Re-install the transfer lm.

Step 5. Close the printer door.

Replacing the Cleaning Rollers

The X-cleaning roller is part of the cleaning cartridge assembly—only the roller is replaceable.

To replace the X-cleaning roller:

Step 1. Open the printer and remove the cleaning cartridge from the printer.

Step 2. Grasp the used roller and pull it out from the cartridge.

Step 3. Insert the new cleaning roller into the cartridge—press rmly until it snaps into place.

Step 4. Remove the protective cover.

To replace the Y-cleaning roller:

Step 1. Open the printer.

Step 2. Grasp the used cleaning roller and pull down and out in a singular motion.

Step 3. Grasp the new roller by the edges and remove the protective cover.

Step 4. While still holding the roller at the edges, insert the new cleaning roller into position by pressing in

and up in a singular motion.

66

Page 79

Maintenance

Cleaning the Laminator

The regular use of cleaning cards will clean and maintain important parts of your laminator that cannot be reached.

Printer usage (total number of cards printed and total number of cards laminated) can be found on the printer

Properties, Device Information tab, or via the OCP Info Menu—see Maintenance on page 63.

When to Clean

y Cleaning should occur every 5,000 cards.

y Heated Roller cleaning should occur every 20,000 cards.

Laminator

Note • To avoid a long wait while the card transport rollers cool to 140°F (60°C), perform cleaning before

the rollers heat (i.e., when rst turned on and the rollers are still cold).

Important • Do not reuse cleaning cards.

To initiate the cleaning process:

Step 1. On the operator control panel (OCP) select Menu.

Step 2. From the Main Menu select Advanced Settings.

Step 3. From the Advanced Settings menu select Clean Printer.

To Clean the Card Path:

Step 1. Select Clean Lam Card Path to run the laminator cleaning routine.

Step 2. Use the laminator cleaning card in the laminator cleaning kit.

Step 3. Follow the OCP instructions.

Step 4. When complete, the OCP will return to the Clean Printer Menu.

67

Page 80

Maintenance

To Clean the Media Feed Rollers:

Step 1. Select Clean Lam Med Rollers to run the laminator media roller cleaning routine.

Step 2. Lift the laminator door to its upright position.

Step 3. Remove the laminate cassette(s)—see Maintenance on page 63.

Step 4. Leave the laminator door open

Step 5. Use the cleaning swab in the laminator cleaning kit. Bend the swab to release the cleaning uid.

Step 6. Press Next when ready, then press Top.

Step 7. Clean the top media roller (circled below) by moving swab tip side-to-side as it turns ve full

revolutions. Only use moderate force.

68

Page 81

Step 8. For the double-sided laminator only:

a. Locate the roller (circled below) for the lower cassette.

Maintenance

b. Use a second cleaning swab in the laminator cleaning kit. Bend the swab to release the cleaning

uid.

c. Press Bottom.

d. Clean the bottom media roller by moving swab tip side-to-side as it turns ve full revolutions.

Only use moderate force.

e. When the operation is complete, press Exit.

Step 9. Reinstall the laminate cassette(s).

Step 10. Close the laminator door.

69

Page 82

Maintenance

To Clean the Heater Assembly Rollers:

Step 1. Select Clean Lam Oven to run the laminator oven cleaning routine.

Step 2. Observe the OCP, and wait until the laminator temperature goes below 140°F (60°C).