Page 1

ZXP Series 7™

P1036102-007

Card Printer

Service Manual

Page 2

Corporate Headquarters

+1 800 423 0442

inquiry4@zebra.com

Asia-Pacific Headquarters

+65 6858 0722

contact.apac@zebra.com

EMEA Headquarters

zebra.com/locations

mseurope@zebra.com

Latin America Headquarters

+1 847 955 2283

la.contactme@zebra.com

http://www.zebra.com/locations

©2016 ZIH Corp. and/or its affiliates. All rights reserved. Zebra and the stylized Zebra head are trademarks of ZIH Corp., registered in many jurisdictions

worldwide. All other trademarks are the property of their respective owners.

Page 3

Contents

Introduction .....................................................................................................................1

Description ............................................................................................................................................. 1

Theory of Operation .......................................................................................................3

Introduction ............................................................................................................................................3

Card Movement During Printing .............................................................................................................4

Printing Technologies and Ribbons ........................................................................................................ 6

Dye Sublimation Printing .................................................................................................................8

Thermal Transfer Printing ................................................................................................................ 8

System-Level Electronics .......................................................................................................................9

Main PCBA (CPU) .........................................................................................................................10

High-Capacity Output Hopper .............................................................................................................. 13

Hopper Cassette ............................................................................................................................13

Stacker ..........................................................................................................................................13

Troubleshooting ........................................................................................................... 15

Introduction ..........................................................................................................................................15

OCP Error Messages ........................................................................................................................... 16

OCP Test Cards ................................................................................................................................... 25

Ethernet ...............................................................................................................................................26

Replacement Procedures for the Printer ...................................................................27

Introduction ..........................................................................................................................................27

Required Tools ..................................................................................................................................... 28

Removal Sequence ..............................................................................................................................29

Printer ............................................................................................................................................ 30

Feeder Module ..............................................................................................................................30

Flipper Module ............................................................................................................................... 31

Options Module .............................................................................................................................31

Procedures ...........................................................................................................................................32

Reject Bin ......................................................................................................................................32

Feeder Cartridge ...........................................................................................................................34

Ribbon Drawer ...............................................................................................................................40

Card Guides ..................................................................................................................................42

Shroud for Options ........................................................................................................................44

Back Cover .................................................................................................................................... 45

Rear Feeder Cover ........................................................................................................................ 46

Options Cover ................................................................................................................................47

P1036102-007 ZXP Series 7 Card Printer Service Manual i

Page 4

OCP PCBA .................................................................................................................................... 49

Right Cover ....................................................................................................................................51

Print Cover .....................................................................................................................................58

Door Button and Latch ...................................................................................................................60

Left Side Cover .............................................................................................................................. 63

Belt and Gear Panel ......................................................................................................................64

Bottom Cover .................................................................................................................................66

Feet ...............................................................................................................................................67

Reject Bin Bracket ......................................................................................................................... 68

Printer ............................................................................................................................................ 69

Main PCBA ....................................................................................................................................73

Ethernet PCBA ..............................................................................................................................76

Print Engine ................................................................................................................................... 77

Feeder/Flipper/Options Assembly ...............................................................................................137

Feeder/Flipper Assembly ............................................................................................................. 142

Ground Plate ...............................................................................................................................145

Power Switch ............................................................................................................................... 147

Feeder Module ............................................................................................................................149

Flipper Module ............................................................................................................................. 157

Options Module ...........................................................................................................................180

Torque Tools Calibration Instructions ........................................................................................... 187

Replacement Procedures for Factory Installed Options .......................................191

Introduction ........................................................................................................................................191

Required Tools ................................................................................................................................... 192

Procedures .........................................................................................................................................193

Barcode Scanner Assembly ........................................................................................................ 193

SmartCard Control PCBA ............................................................................................................199

MIFARE/Contact Encoder Module ...............................................................................................200

MIFARE Contact Encoder PCBA ................................................................................................. 203

Contact Station Module ...............................................................................................................205

Contact Station Module PCBA .....................................................................................................208

Pressure Roller Assembly ........................................................................................................... 209

Replacement Procedures for the Laminator ........................................................... 217

Introduction ........................................................................................................................................217

Required Tools ................................................................................................................................... 218

Removal Sequence ............................................................................................................................219

Procedures .........................................................................................................................................221

Back Cover .................................................................................................................................. 221

Side Cover ................................................................................................................................... 222

Lock Replacement for Left Cover ................................................................................................ 223

Lower Door .................................................................................................................................. 225

Door Assembly (Door and Hinges) ..............................................................................................227

Latch Assembly ...........................................................................................................................230

Laminator / Printer Separation .....................................................................................................232

Bottom Panel ............................................................................................................................... 236

Feet .............................................................................................................................................237

Mounting Plate .............................................................................................................................238

Molded Ribbon Spindle ...............................................................................................................240

Square Corner Spindle ................................................................................................................ 241

Laminator Heater Assembly ........................................................................................................ 242

Halogen Bulbs .............................................................................................................................243

24V Heater Fans .........................................................................................................................246

Motor and Plate Assembly ...........................................................................................................248

Laminator Controller PCBA .........................................................................................................251

Media Authentication PCBA .........................................................................................................253

ii ZXP Series 7 Card Printer Service Manual P1036102-007

Page 5

Top Laminator Control Motor ....................................................................................................... 254

Bottom Laminator Control Motor .................................................................................................255

Staging Motor ..............................................................................................................................256

Media Authentication Antenna PCBA ..........................................................................................257

Front Frame ................................................................................................................................. 259

Static Brush .................................................................................................................................261

Cassette Latch Assembly (Top & Bottom) ...................................................................................262

Thermopiles (Top & Bottom) ........................................................................................................ 270

Top Thermopile Cable ................................................................................................................. 274

Bottom Thermopile Cable ............................................................................................................ 275

Flexible Ribbed Rollers (Left & Right) .........................................................................................276

Card Staging Nip Rollers (Left & Right) ....................................................................................... 277

Platen Overrun Roller (Top & Bottom) ......................................................................................... 278

Exit Rollers ..................................................................................................................................279

Cutters (Upper & Lower) ..............................................................................................................280

Laminate Ribbon Rollers (Top & Bottom) .................................................................................... 284

Card Entry Sensor Cable Assembly ............................................................................................285

Card Laminator Sensor Cable Assembly .....................................................................................286

Card Exit Sensor Cable Assembly ...............................................................................................287

Door Sensor Cable Assembly .....................................................................................................288

Replacement Procedures for the High-Capacity Output Hopper ..........................289

Introduction ........................................................................................................................................289

Required Tools ................................................................................................................................... 290

Procedures .........................................................................................................................................291

Output Hopper Cassette .............................................................................................................. 291

High-Capacity Output Hopper .....................................................................................................292

Left Side Panel ............................................................................................................................304

Platen Roller ................................................................................................................................ 3 11

Pressure Roller ............................................................................................................................ 313

Sensors .......................................................................................................................................316

Drive Assembly ............................................................................................................................ 329

Elevator .......................................................................................................................................339

Elevator Bushing .........................................................................................................................346

Base Housing ..............................................................................................................................347

Base Cover and Latch Assembly .................................................................................................354

PCBA ...........................................................................................................................................355

Cleaning ......................................................................................................................361

Introduction ........................................................................................................................................361

Cleaning the Printer ...........................................................................................................................362

When to Clean ............................................................................................................................. 362

Initiate the Cleaning Process ....................................................................................................... 362

Clean the Card Path .................................................................................................................... 363

Clean the Feeder Path ................................................................................................................364

Polish the Printhead ....................................................................................................................365

Cleaning the Laminator ...................................................................................................................... 366

When to Clean ............................................................................................................................. 366

Initiate the cleaning process ........................................................................................................ 366

Clean the Laminator Card Path ................................................................................................... 367

Clean the Laminator Media Rollers ............................................................................................. 368

Clean the Laminator Oven (Heater Rollers) ................................................................................ 370

Cleaning the High-Capacity Output Hopper .......................................................................................373

Dual Cleaning Cartridge .....................................................................................................................374

Manual Feed Cleaning Cassette ........................................................................................................374

Cleaning Supplies .............................................................................................................................. 374

P1036102-007 ZXP Series 7 Card Printer Service Manual iii

Page 6

Field Upgrades............................................................................................................375

Introduction ........................................................................................................................................375

Placing Labels ....................................................................................................................................376

Field Upgrade Labels ......................................................................................................................... 377

iv ZXP Series 7 Card Printer Service Manual P1036102-007

Page 7

Description

This manual provides detailed information on the service of, and replacement

procedures for the Zebra ZXP Series 7 Card Printer, the optional laminator, and the

optional high-capacity output hopper.

1

Introduction

References to “the printer” in this document apply to either the single- or the doublesided printer. Similarly, references to “the laminator” apply to either the single- or the

double-sided Laminator.

P1036102-007 ZXP Series 7 Card Printer Service Manual 1

Page 8

2 ZXP Series 7 Card Printer Service Manual P1036102-007

Page 9

Introduction

This section includes five major topics:

• Card Movement During Printing

2

Theory of Operation

• Printing Technologies and Ribbons

• System-Level Electronics

• Main PCBA (CPU)

• High-Capacity Output Hopper

3

Page 10

Theory of Operation

Card Movement During Printing

Card Movement During Printing

Step 1. The card is fed from the Feeder Cartridge into the Printer.

Step 2. As the card is moved into the Printer, it is cleaned via the Cleaning Cartridge;

this cleans dust and dirt particles from both sides of the card.

Step 3. If the Printer includes an optional Smart Card Encoder (either contact-style

or contactless), the card is moved to the Encoder; and the smart card is

encoded. As the card is encoded, it is checked to verify that it was encoded

properly. If encoding fails, the card is moved to the Reject Bin. This is done

to avoid wasting time and ribbon panels on a defective card. If the encoding

is successful, the card is moved into the pre-print position, just before the

Printhead.

Step 4. If the Printer includes an optional Magnetic Stripe Encoder, the card is

moved to the Encoder; and the magnetic stripe is encoded. The card is then

backed up and run through the Magnetic Stripe Encoder again; on this pass

the card is read to verify that the magnetic stripe was properly encoded.

If encoding fails, the card is moved to the Reject Bin. As with failed smart

card encoding, this is done to avoid wasting time and ribbon panels on a

defective card. If the encoding is successful, the card is moved into the preprint position, just before the Printhead.

Step 5. The card is printed.

Dye-Sublimation Printing

When the Print Cover is opened and closed, the ribbon is synchronized,

thereby bringing the leading edge of the Yellow ribbon panel (e.g., a YMCKO

ribbon) under the Printhead.

The leading edge of the card is moved under the Printhead (over the Platen

Roller), and the Printhead is lowered. Lowering the Printhead reduces the

space between the Printhead, the ribbon, and the card, which produces

sharper images.

As the card and ribbon move along, each element of the Printhead receives

a pulse of variable width; a wider pulse results in a hotter element which

melts a larger amount of yellow dye onto that particular spot on the card.

After this Yellow (Y) pass is completed, the Printhead is raised, the card is

moved back, and printing continues with the Magenta (M) ribbon panel,

then the Cyan (C) panel, then the Black (K) panel, and finally the Overlay (O)

panel.

Thermal-Transfer Printing

If using a monochrome ribbon, the card makes a single pass under the

Printhead. The Printhead elements are energized to either on or o. The

on level actually transfers the spot of resin under the Printhead element to

the card. This results in the sharpest possible images; for bar codes you

want the sharpest edges and highest contrast between dark and un-printed

areas.

4 ZXP Series 7 Card Printer Service Manual P1036102-007

Page 11

Theory of Operation

Card Movement During Printing

Step 6. For double-sided printing, the card is now moved back to the Card Flipper

where the card is turned over (rotated 180 degrees). The card is moved into

the Print Engine; and the card is printed (same as Step 5).

Step 7. If the Printer has a Laminator:

a. The card is moved through the Printer into the Laminator.

b. As the card passes through the Laminator, laminating film is applied to

the card, the top side or both sides depending on the Laminator.

c. The card (with the laminating film) then passes between a pair of heated

rollers, which seal the laminating film to the card.

d. The card is moved from the Laminator to the Card Exit, where it falls into

the Output Hopper attached to the left side of the Laminator.

Step 8. If the Printer does not have a Laminator; the card moves through the Printer,

where it falls into the Output Hopper attached to the left side of the Printer.

P1036102-007 ZXP Series 7 Card Printer Service Manual 5

Page 12

Theory of Operation

Printing Technologies and Ribbons

Printing Technologies and Ribbons

There are two types of printing technology used in the printer: Dye Sublimation and

Thermal Transfer. The technology to use is determined by the type of dye or ink on

the ribbon.

Monochrome Ribbons have a single color ink on the length of the ribbon. The printer

is programmed to use Thermal Transfer printing for monochrome ribbons.

Multi-Panel Ribbons have a repeating sequence of panels of dierent dye. RFID

Multi-Panel Ribbons have an RFID tag on the supply spool; the RFID code identifies

the ribbon type and panel count. (Note that the lack of an RFID tag will be interpreted

by the printer as being a Monochrome Ribbon.) Printing with a Multi-Panel Ribbon

requires multiple passes of the card under the Printhead, once per panel.

For double-sided printing, a typical situation would be to print a full-color graphic (such

as a person’s picture) along with black text and/or bar-coding on the front, and black

text and/or bar-coding on the rear. In this case, a YMCKOK Multi-Panel Ribbon would

be used.

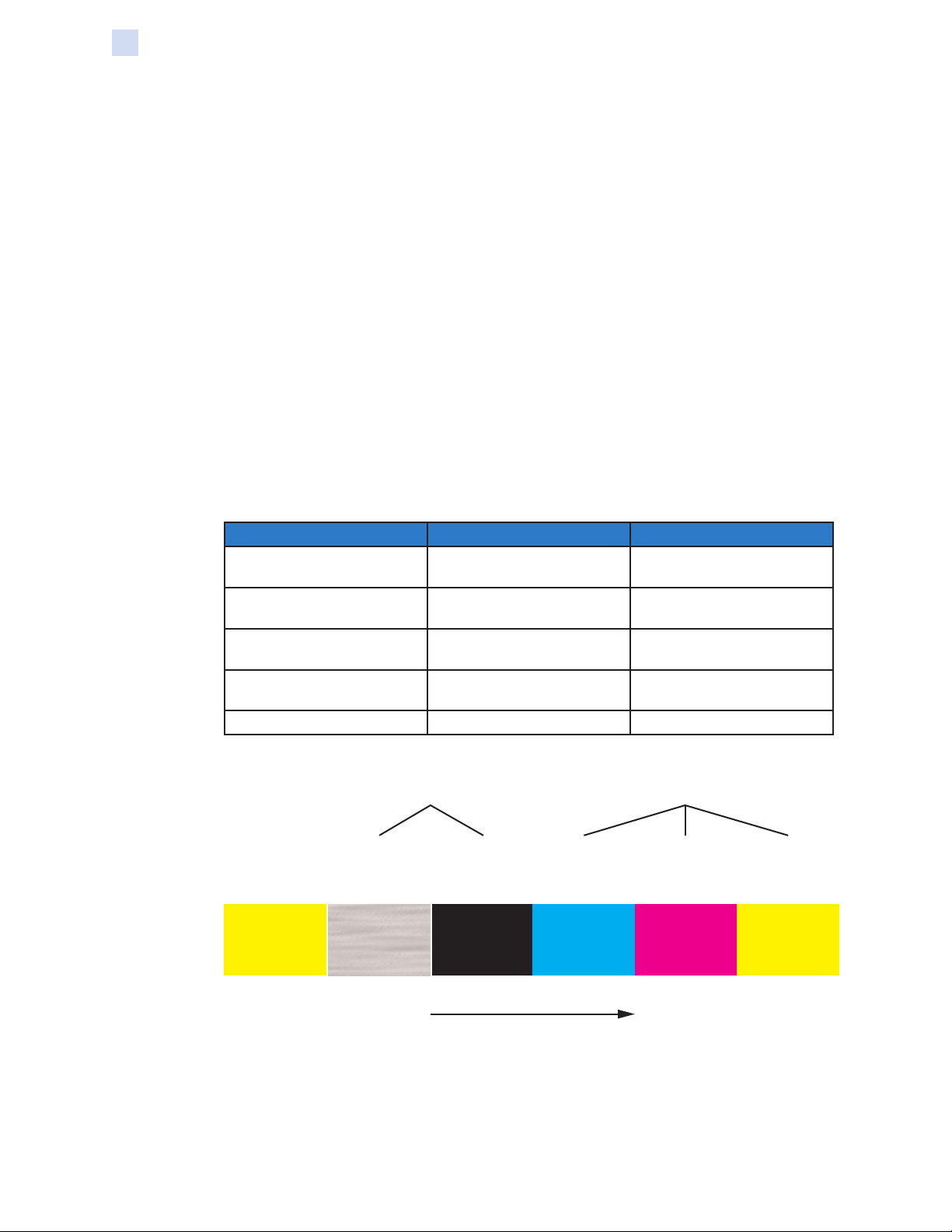

A YMCKO ribbon has successive panels as follows:

Color Technology Function / Usage

Yellow (“Y”) Dye Sublimation

Magenta (“M”) Dye Sublimation

Cyan (“C”) Dye Sublimation

Black Resin (“K”) Thermal Transfer

Overlay (O) - -

Thermal Transfer

Printing Process

(YMCKO)

Pattern

Repeats)

Overlay

(O)

Black

(K)

Resin

Cyan

(C)

Dye

Full-Color Printing and Dye

Sublimation Black Printing

Full-Color Printing and Dye

Sublimation Black Printing

Full-Color Printing and Dye

Sublimation Black Printing

K Resin Black Printing (for the

front of the card)

Dye Sublimation

Printing Process

Magenta

(M)

Dye

Yellow

(Y)

Dye

Ribbon movement from supply spool

Other ribbons are available for the printer; see the Supplies List on the Driver and

Documentation CD that came with the printer, or visit the Zebra Card Printer Solutions

website at zebra.com/supplies.

6 ZXP Series 7 Card Printer Service Manual P1036102-007

Page 13

Theory of Operation

Printing Technologies and Ribbons

The ribbon synchronizes to it’s “starting” position whenever the Print Cover is opened

and then closed. For a YMCKO ribbon, the starting position is with the leading edge of

a Yellow Panel at the printhead location.

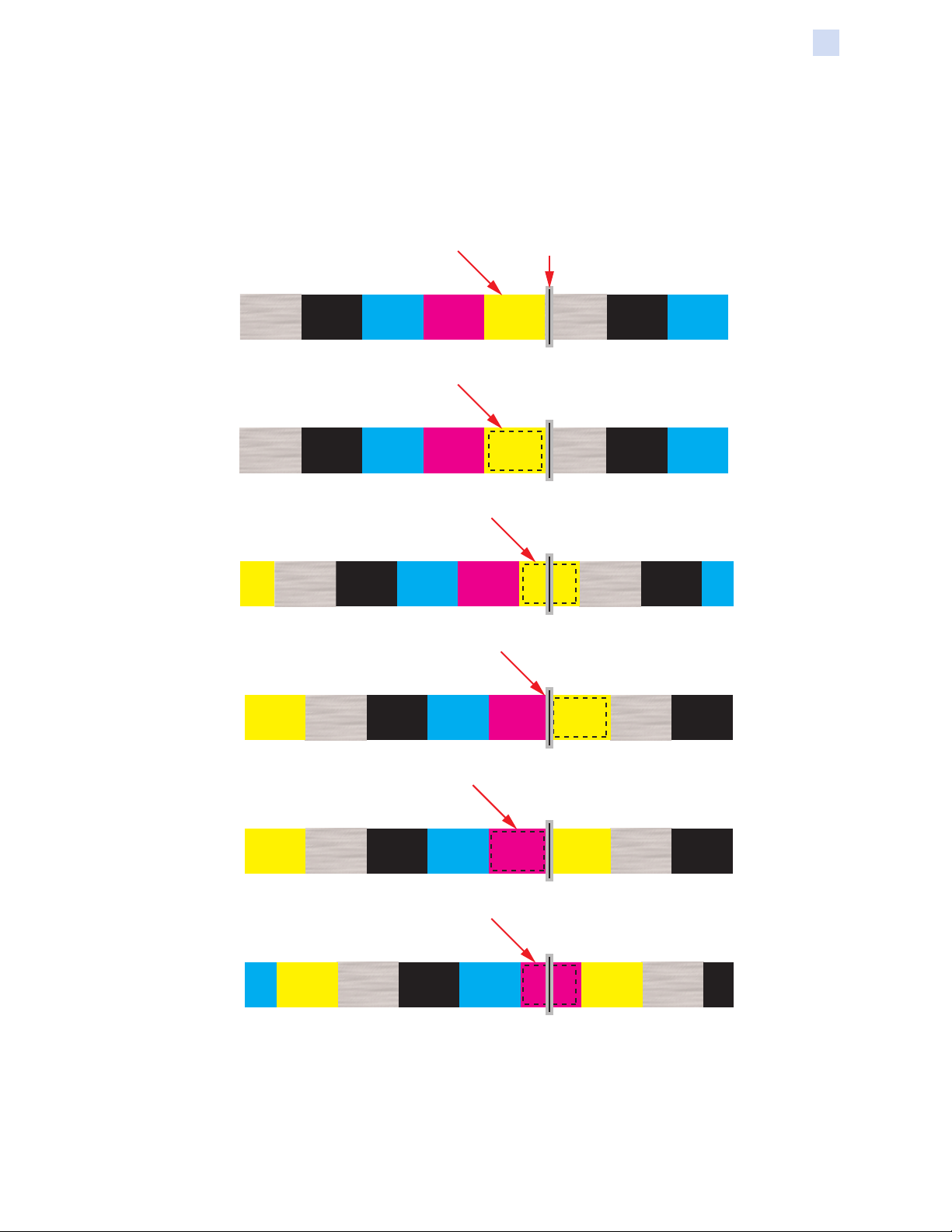

The figure below shows how the YMCKO ribbon and card move relative to each other

during printing.

Printhead in fixed position1. Ribbon move yellowpanel into

position at printhead.

2. Card is fed to printing position

under the printhead.

3. Card and ribbon move together as

yellow panel is printed.

4. Card and ribbon stop at the end

of the yellow panel.

5. Ribbon remains stationary as card

is moved back to printing position.

6. Card and ribbon move together as

magenta panel is printed.

In addition, the driver software allows the user to specify which ribbon panels are

printed on either side of the card.

P1036102-007 ZXP Series 7 Card Printer Service Manual 7

Page 14

Theory of Operation

Printing Technologies and Ribbons

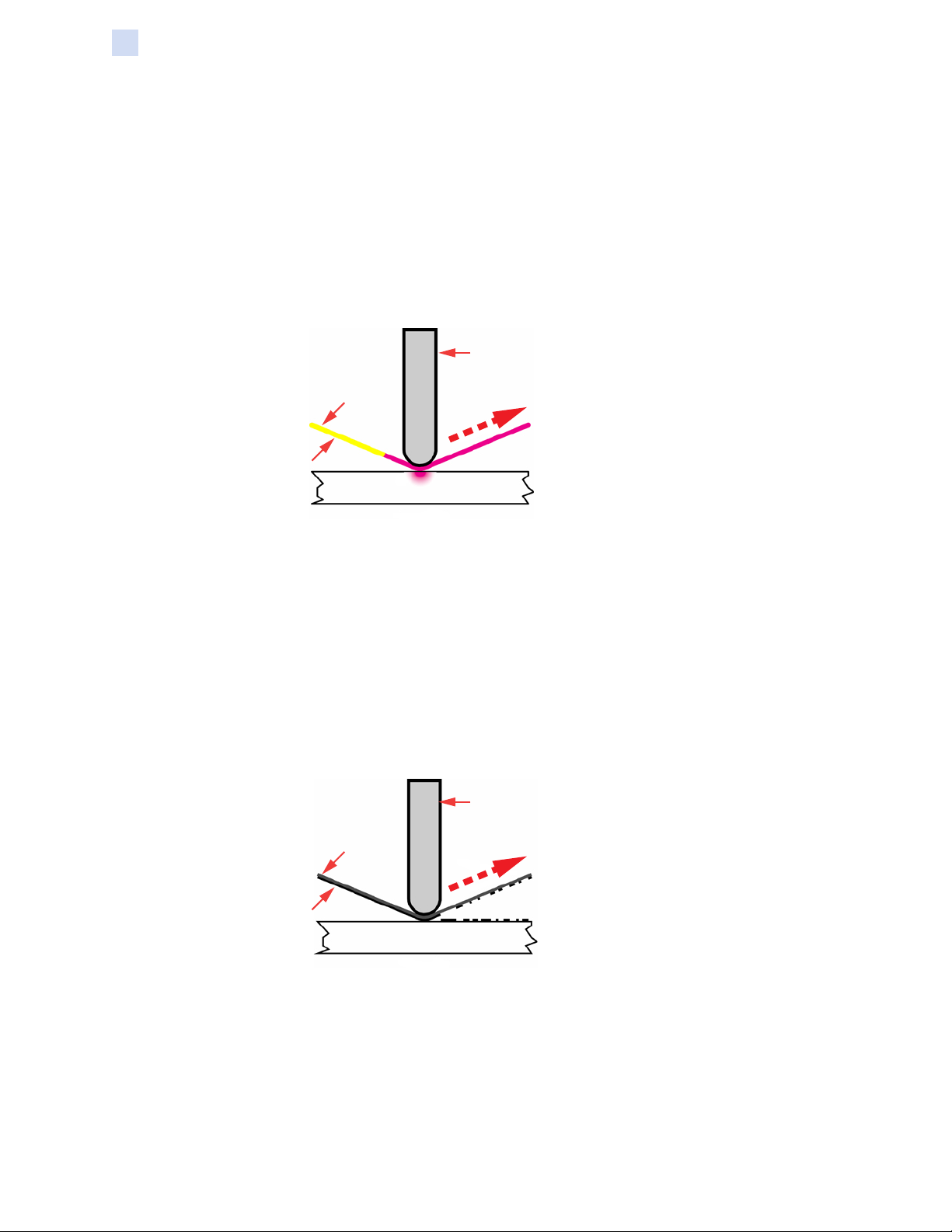

Dye Sublimation Printing

In Dye Sublimation Printing, each printhead heating element is applied voltage at one

of a number of pulse widths.

A wider pulse results in the element getting hotter, which converts more of the dye (at

that pixel location) to a gas and diuses it into the surface of the card (a wider pulse

gives more intense color at that pixel).

This is repeated for each of the dye panels (i.e., Yellow, Magenta, and Cyan), to result

in full-color images.

Ribbon Carrier

Layer

Ribbon Ink

Layer

Card

Printhead

Gaseous dye is

absorbed by the card

Thermal Transfer Printing

In Thermal Transfer Printing, voltage is either applied or not applied to each printhead

printing element. If voltage is applied, the ink at that location is transferred to the

surface of the card.

Each pixel is either printed (i.e., the ink is transferred to the card) or not; there are no

intermediate levels.

Thermal Transfer printing with a black (K) resin panel is used for printing bar codes,

since contrast between the light and dark areas is the highest and the edges are the

sharpest.

Ribbon Carrier

Layer

Ribbon Ink

Layer

Card

Printhead

Ink is transferred to the

surface of the card

8 ZXP Series 7 Card Printer Service Manual P1036102-007

Page 15

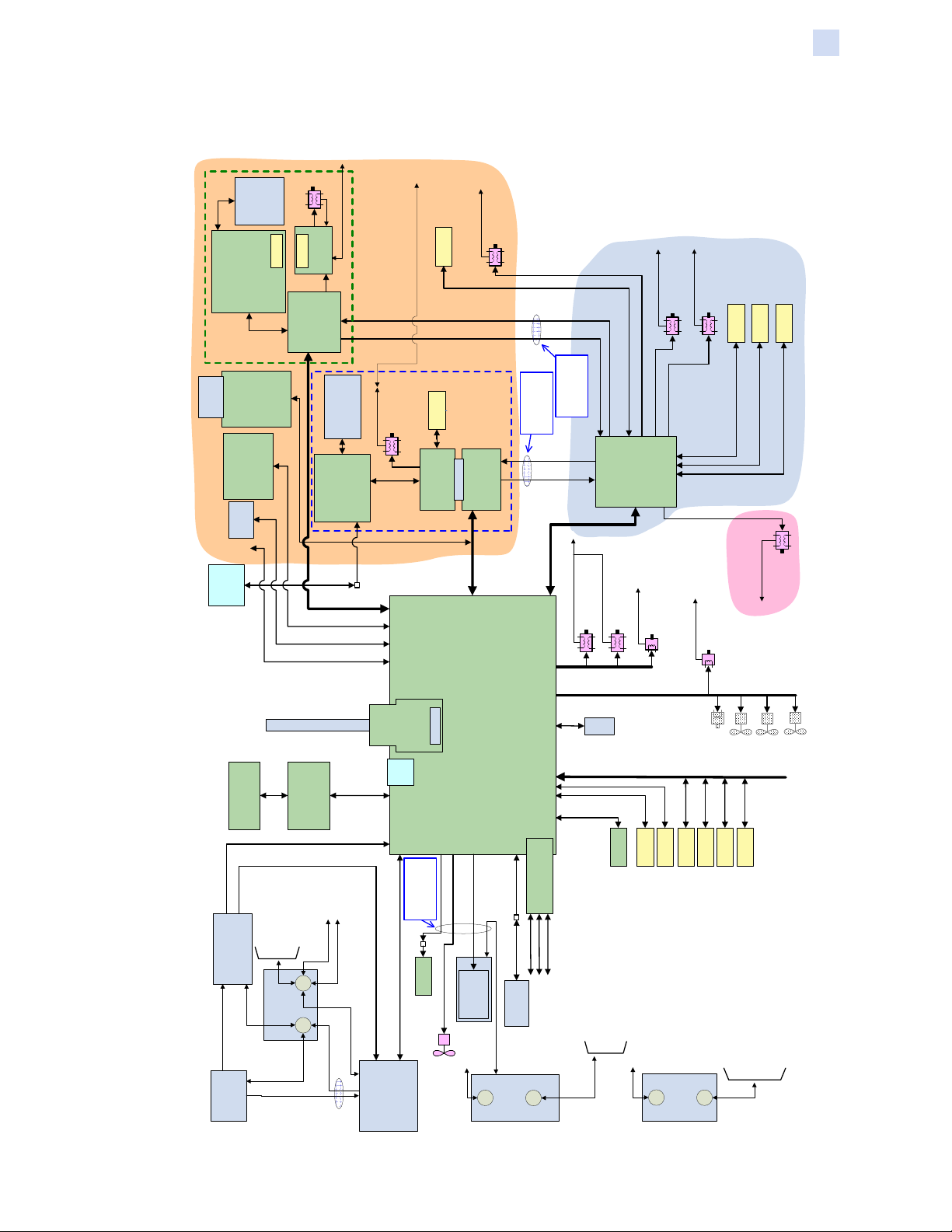

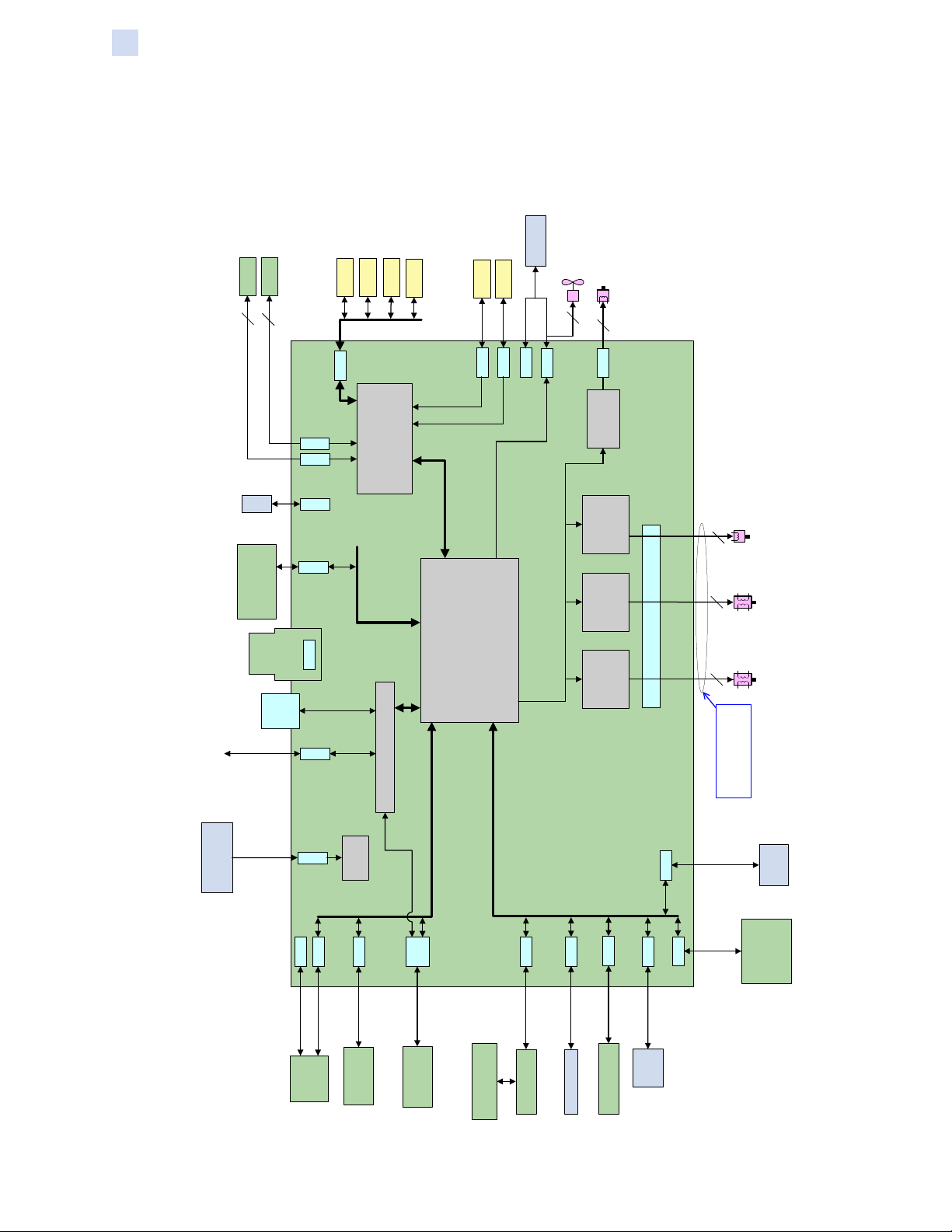

System-Level Electronics

)

MAG_ISO(P1029189

Mag Head

MTR_OPMG

(P1039207)

LED

Detector

(PCBA_MAG_

SEN_OPMG

P1038451-01)

Mag Module PCBA

(PCBA_MAG_MOD_IF

(P1031857)

Mag PCBA

CA_MAG_MOD_IF

Options Module

(P1027378-02)

PCBA_FELICA_CAR

or

or

UHF Mod

Felica Mod

OPTIONS MODULE

DB9 for

External

(P1027378-01)

PCBA_UHF_CAR

SmartCard

for User Auth)

Authentication

(Contact SmartCard

Reader

Barcode

(BARCD)

USB

Host

Ports

Station

Contact

MAG

MOD_DET,

P1038478-01)

CA_MTR_OPMG-MOD_GND (P1033288)

P1038415-01)

(PCBA_OPMAG,

(P1029200)

(if required)

MTR_OPCM

(P1033220)

(PCBA_CPLR_SC)

SmartCard Coupler

CA_MTR_OPCM_GND

PCBA

(SC_MOD,

P1006651-01)

806882-001) or

Ext Contact Stn i/f

SmartCard Module

(PCBA_EXTCNT_IF,

CA_SC_MOD

CA_SC_MOD

(P1029151) or

CA_EXT

(P1043050)

(P1042978)

CA_EXT_DB9

CA_OPMAG (P1026484)

CA_USRAUTH

CA_BARCD

CA_UCONN

Theory of Operation

System-Level Electronics

SEN_OPCD

(300238G-002)

Gap

Sensor

CA_MTR_OPCM-MOD_GND (P1033283)

OPMAG_PD_N

Gap

Sensor

SEN_OPCM

SmartCard

Module PCBA

P1028126-01)

(PCBA_SC_MOD,

_EXT

(P1042729)

(P1044093)

MTR_OPCD

CA_MTR_OPCD_GND

(P1042321)

MTR_FLCD

CA_MTR_FLCD_GND

SEN_FLCD

MTR_FLRO

(P1026465-002)

CA_MTR_FLRO_GND

Gap

SEN_FDOP

(P1030185)

SEN_FLRO

(300364-006)

(300364-007)

Gap

Gap

Sensor

Sensor

Sensor

SMARTCARD

(P1026478)

CA_FLOPMAG

are combined into

These connections

(P1026476)

(P1029126)

Connectors

P1028104-01)

(PCBA_OPSC,

Options Module

SmartCard PCBA

CA_OPSC_RF

CA_OPSC

(P1027859)

CA_FLOPSC

are combined into

These connections

CA_FLIP_PWR (P1026479)

CA_FLIP_CTL (P1026480)

MTR_OPMG_CTL

MTR_OPCM_CTL

OPSC_PD_N

(PCBA_FLIP,

P1021234-01)

Flipper Board PCBA

FLIPPER

FEEDER

CA_MTR_FEED_GND

(P1041216)

MTR_FEED

CA_MTRS_ENG_GND

MTR_MAIN (P1009157-001)

MTR_CAM (P1009302)

MTR_RIBS (P1020449)

CA_MTR_RIBS_GND

CA_MTR_MCB (P1014939)

MTR_RIBT (P1020406)

CA_MTR_RIBT_GND

(Individual motor cables)

WiFi Antenna (ANT, P1005199)

(300844-001)

CA_CPLR_MA

(PCBA_MAB,

P1008230-02)

(PCBA_CPLR_MA,

Media Auth Coupler

(P1029730)

CA_MTRS_ENG_GND

P1008702)

(PWR_SUP,

200W Power Supply

(P1014040)

CA_SUP_GND

CA_ACPWR (P1013793)

EMI Filter

P1035695)

(PWR_SW,

AC Switch &

404870-003P)

Media Auth PCBA

DC output CN2 is term block)

DC output CN2 is conn)

(P1029884)

(P1022300)

CA_MTR_RIBT_GND

CA_BRUSH_EXIT

CA_ENGINE_GND

CA_OPTIONS_GND

P1010902)

(GND_MCB,

Ground Plate

PE

(P1013891)

CA_SW_GND

CA_LAM_DC (P1030139)

(P1041281)

CA_LAM_GND

(Osprey P/N: P1004275)

CA_LAM_AC (P1029986)

or

Board

Ethernet

(P1025470)

CA_MAB

(Osprey P/N: 300827-001:

CA_DCPWR (P1030122:

(Osprey P/N: P1004276)

CA_LAM_CTL (P1030001)

Laminator

FSI Conn

P1006890-02

P1006890-03)

(PCBA_ENET,

Port

USB

Periph

CA_PH

are combined into

These connections

Tri-Color

SEN_RIBA

(Osprey P/N: P1004277)

(LAM)

(PCBA_MCB,

P1047494-01)

Main Controller Board PCBA

P1043417-01)

(PCBA_DIAG_IF,

(P1037316)

Emitter

Print Head

(404790-003P)

(P1044307)

FAN_PH (blower)

CA_ENGINE_GND (P1032223)

(P1032163)

IP/EP Diagnostic Board

CA_OCP_RECEPT

JTAG

(P1032161)

CA_IP_DEBUG

CA_EP_DEBUG

CA_OCP_PLUG

(PH,

P1040725)

(OCP,

OCP Assy

P1027292)

PH_GND

P1030086)

(GND_ENG,

Ground Plate

Thermistor

(P1051848)

CA_THERM

Gap

(P1037399)

CA_SEN_RIBB

CA_BRUSH_CLSOUTS (P1029745-001)

Gap

Sensor

Sensor

Detector

Tri-Color

SEN_EXIT

SEN_RIBB

SEN_TENC

(300364-003)

(405030-003B)

CA_BRUSH_FEED_RGHT (P1029727)

CA_MTR_RIBS_GND (P1029883-001)

CA_BRUSH_FEED_LEFT (P1029728)

CA_MTR_FEED_GND (P1029744-001)

CA_OPTIONS_GND

(300364-010)

(P1032220)

MTR_SP

CA_SEN_MCB (P1014941)

Gap

Sensor

SEN_SENC

(300364-002)

P1029901)

Ground Plate

(GND_FLOP,

FAN_PWR

Gap

Gap

Gap

Sensor

Sensor

SEN_CAM

SEN_CSYN

SEN_DOOP

(300364-009)

(300364-008)

CA_FLIP_SHFT_GND (P1029747-001)

CA_MTR_FLCD_GND (P1032300)

CA_MTR_OPCD_GND (P1032300)

FAN_SP2

FAN_SP1

Sensor

(300238G-004)

CA_MTR_FLRO_GND (P1032281)

CA_BRUSH_ATM (P1029833)

CA_BRUSH_FLIP (P1032340)

CA_MTR_OPMG-MOD_GND (P1033288)

CA_MTR_OPCM-MOD_GND (P1033283)

P1036102-007 ZXP Series 7 Card Printer Service Manual 9

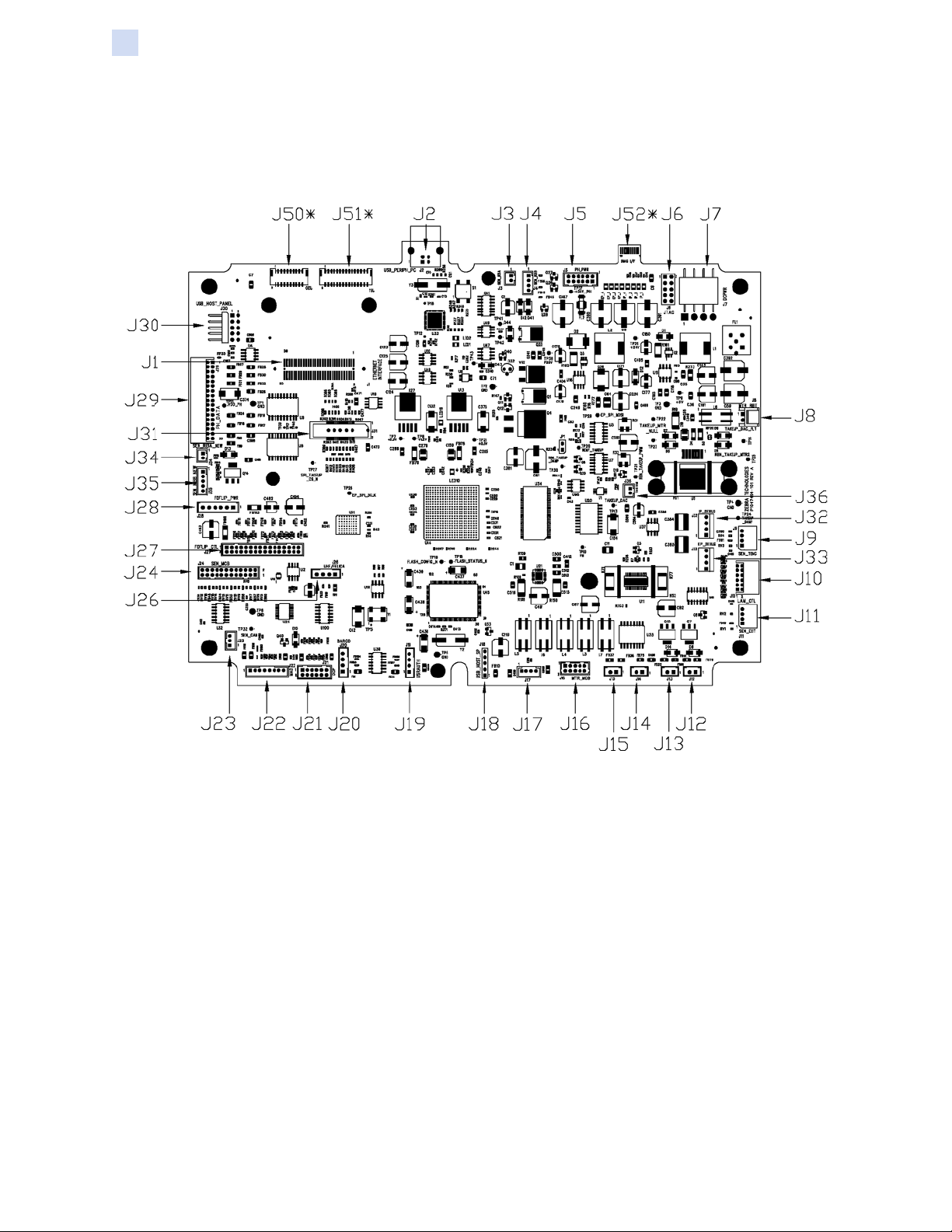

Page 16

Theory of Operation

System-Level Electronics

Main PCBA (CPU)

PCBA Layout

* J50, J51, and J52 are on the bottom side of the Main PCBA

10 ZXP Series 7 Card Printer Service Manual P1036102-007

Page 17

Theory of Operation

System-Level Electronics

PCBA Connections

Connector PCBA ID Functional Description

J1 ETHERNET INTERFACE Ethernet Daughterboard

J2 USB_PERIPH_PC USB peripheral interface from host PC

J3 SEN_RIBA Ribbon tri-color sensor (detector)

J4 SEN_RIBB Ribbon tri-color sensor (emitter)

J5 PH_PWR Power to printhead

J6 JTAG RESERVED

J7 DCPWR DC power input to board

J8 MTR_RIBT Ribbon take-up motor

J9 SEN_TENC Ribbon take-up encoder wheel sensor

J10 LAM_CTL Control signals to Laminator or Hopper

J11 SEN_EXIT Exit sensor

J12 -- RESERVED

J13 -- RESERVED

J14 -- RESERVED

J15 -- RESERVED

J16 MTR_MCB Stepper motors driven by MCB

J17 -- RESERVED

J18 USB_HOST_SP RESERVED

J19 USRAUTH User Authentication

J20 BARCD Barcode Reader

J21 OCP Operator Control Panel

J22 MAB Media Authentication Board

J23 SEN_CAM RESERVED

J24 SEN_MCB Various sensors

J25 N/A N/A

J26 UHF/FELICA RESERVED

J27 FDFLIP_CTL Control signals to Flipper Board

J28 FDFLIP_PWR Power to Flipper Board

J29 PH_DATA Printhead Data

J30 USB_HOST_PANEL USB Dual Host cable

J31 -- RESERVED

J32 IP_DEBUG RESERVED

J33 EP_DEBUG RESERVED

J34 SEN_RIBA_NEW Ribbon tri-color sensor (emitter)

J35 SEN_RIBB_NEW Ribbon tri-color sensor (detector)

J36 THERM RESERVED

J50* OPSC SmartCard option board

J51* OPMAG Mag option board

J52* DIAG I/F Diagnostic test

* J50, J51, and 52 are on the bottom side of the Main PCBA

P1036102-007 ZXP Series 7 Card Printer Service Manual 11

Page 18

Theory of Operation

MTR_

System-Level Electronics

PCBA Block Diagram

Most of the circuitry in the printer is on the Main PCBA. Since the Main PCBA is not a

serviceable unit, there is no component level circuit analysis.

SEN_RIBB

SEN_RIBA

Emitter

Detector

Tri-Color

Tri-Color

2

5

Thermistor

CA_THERM

P1043417-01)

(PCBA_DIAG_IF,

IP/EP Diagnostic Board

Board

Ethernet

Daughter

(PCBA_ENET)

J2

Main PCBA

CA_UCONN

SEN_SENC

Gap

J24

J35

J34

J36

J52

J1

J30

SEN_CSYN

SEN_CAM

Gap

Sensor

USB_PERIPH_PC

SEN_DOOP

Gap

Gap

Sensor

Sensor

Sensor

CA_SEN_MCB

Sensor Interface

A2D for analog inputs)

(tri-color sensor circuit,

74HC14's for digital sensor inputs,

Debug Interfaces

USB Interfaces

USB Logic

USB_HOST_PANEL

Remote Board Interfaces

SEN_TENC

Gap

Sensor

J9

MCB Sensor Interfaces

Print Head Interface

CPU Subsystem

(FPGA, DDR, Flash,

clock buffering, I2C mux, etc.)

External Module Interfaces

(PH)

Print Head

SEN_EXIT

FAN_PH

Gap

Sensor

CA_PH

(PH_DATA)

(PH_PWR)

J5

J11

J29

MTR_RIBT

2

2

J8

BEMF Circuit

A3966

A4983

J16

MCB Motor Driver Interfaces

A3979

2

4

4

connects to J16 here.

a C/A (CA_MTR_MCB) that

These motors each plug into

MTR_RIBS

MTR_CAM

MAIN

J7

(PWR_SUP)

200W Power Supply

CA_DCPWR

J28

CA_FDFLIP_PWR

Flipper

Module

Power

DC-DC

Conversion

J21

J10

J51

J27

CA_OPMAG

CA_FDFLIP_CTL

PCBA

Mag PCBA

(PCBA_FLIP)

(PCBA_OPMAG)

CA_OPSC

SmartCard PCBA

J50

(PCBA_OPSC)

Media Auth

J22

CA_OCP

CA_LAM_CTL

CA_MAB

CA_CPLR_MAB

(PCBA_MAB)

Coupler PCBA

Media Auth PCBA

(PCBA_CPLR_MAB)

(PCBA_OCP)

Laminator (LAM)

OCP Support PCBA

J26

J19

J20

CA_BARCD

Reader

Barcode

(BARCD)

CA_UHF-FELICA

UHF/Felica

CA_USRAUTH

SmartCard

for User Auth)

Authentication

(PCBA_USRAUTH)

(Contact SmartCard

12 ZXP Series 7 Card Printer Service Manual P1036102-007

Page 19

High-Capacity Output Hopper

Hopper Cassette

Stacker

Theory of Operation

High-Capacity Output Hopper

Hopper Cassette

• Easily removable from, and replaceable back onto, stacker base (full, partial, or

empty of cards).

• Equipped with a locking mechanism for capturing and holding stacked cards.

• Open front slot to allow for manual removal of cards (from 1 to 250 cards) without

removing stacker from base.

• With the hopper cassette removed, cards can be removed from top, not from

bottom as locking mechanism is not reversible.

Stacker

The high-capacity output hopper receives and automatically stacks cards in the order

they were printed—top face up—with the first card printed at the top of the stack, and

the last card printed at the bottom of the stack.

The high capacity output hopper runs independently of the printer and responds only

to the card present sensor at the entrance to the hopper. With the cassette in place,

the hopper will stack cards continuously based on print job (including overfilling over

the top of the cassette). With the cassette removed, the elevator will not actuate,

but the printer will continue to print and printed cards will accumulate on the stacker

base—up to 9 cards (30 mil) will accumulate before being pushed o the stacker base.

P1036102-007 ZXP Series 7 Card Printer Service Manual 13

Page 20

14 Hopper Cassette

Page 21

Introduction

The table on the next page oers causes and solutions to symptoms related to

improper operation. Check the table on the following pages when experiencing any

loss of operation or print quality.

3

Troubleshooting

For additional information on troubleshooting and advanced operations, you can

access an extensive Knowledge Base at km.zebra.com.

P1036102-007 ZXP Series 7 Card Printer Service Manual 15

Page 22

Troubleshooting

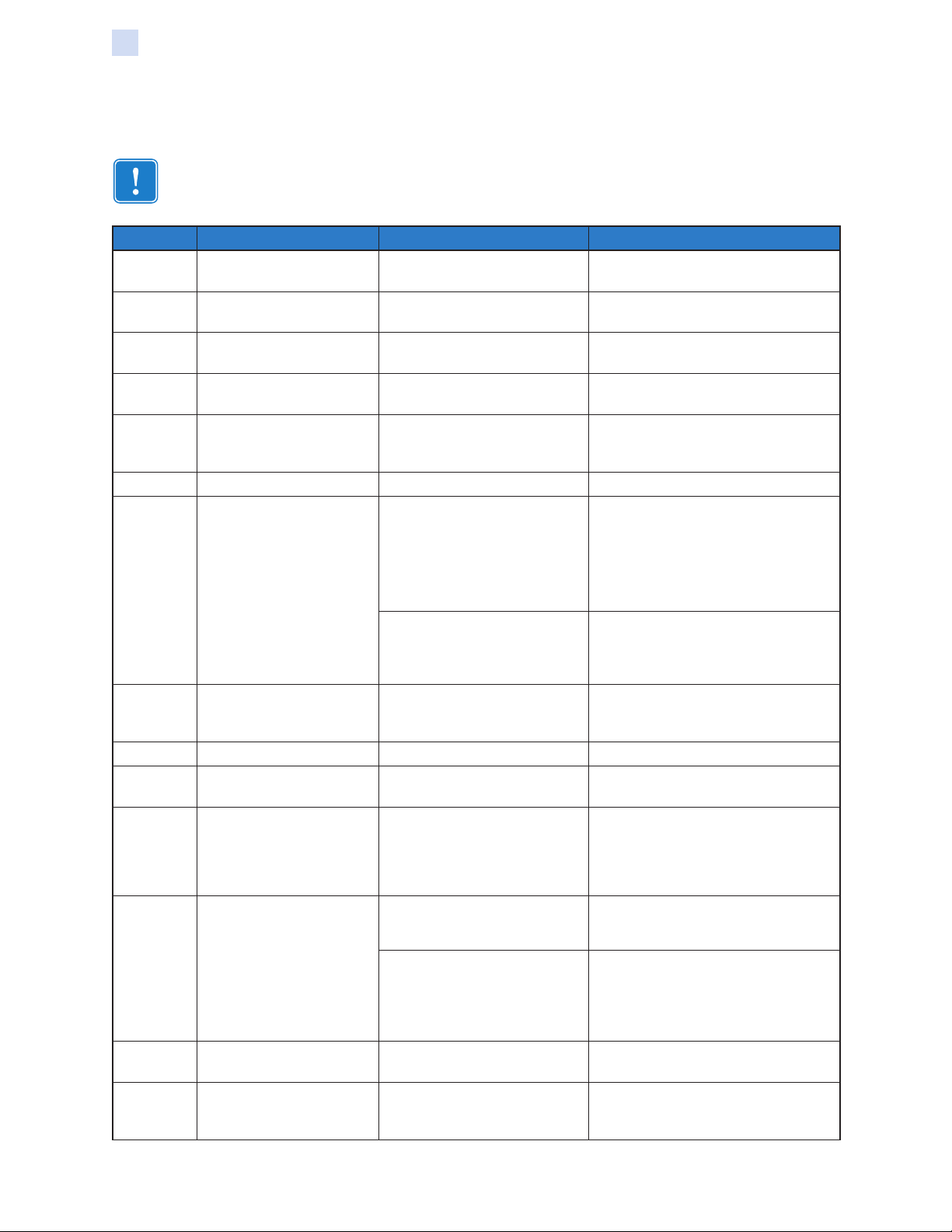

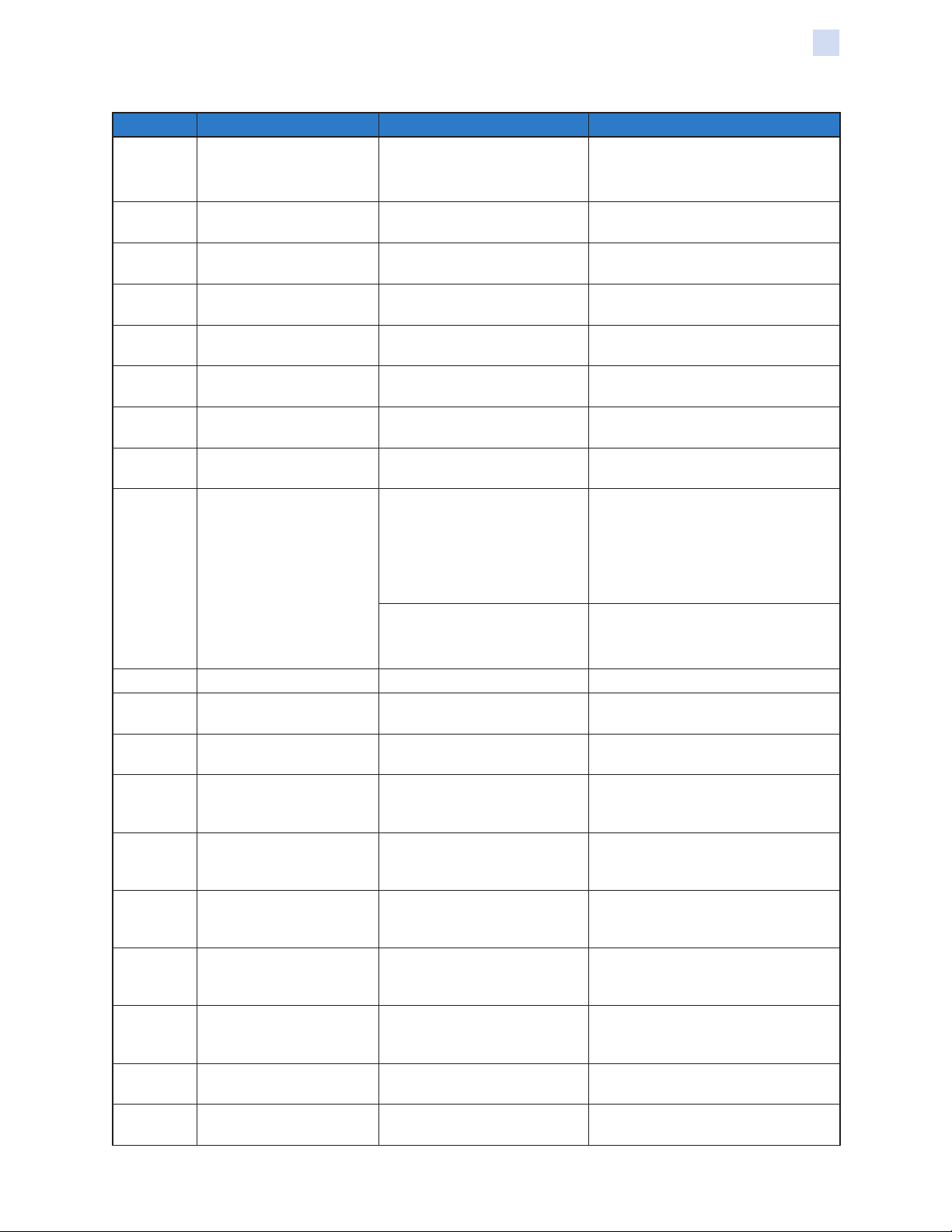

OCP Error Messages

OCP Error Messages

Important • If the Possible Solution does not solve your problem, contact Zebra

Technical Support.

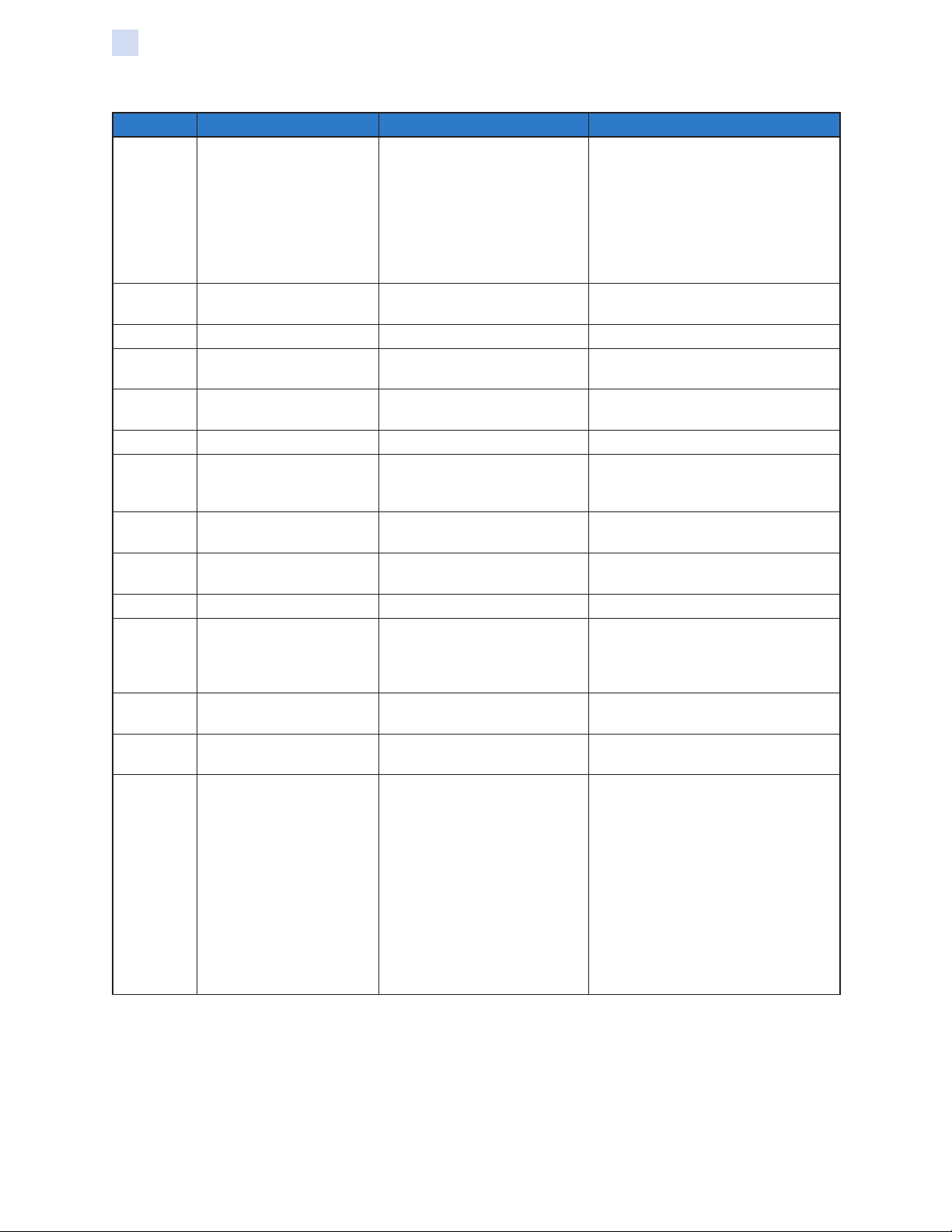

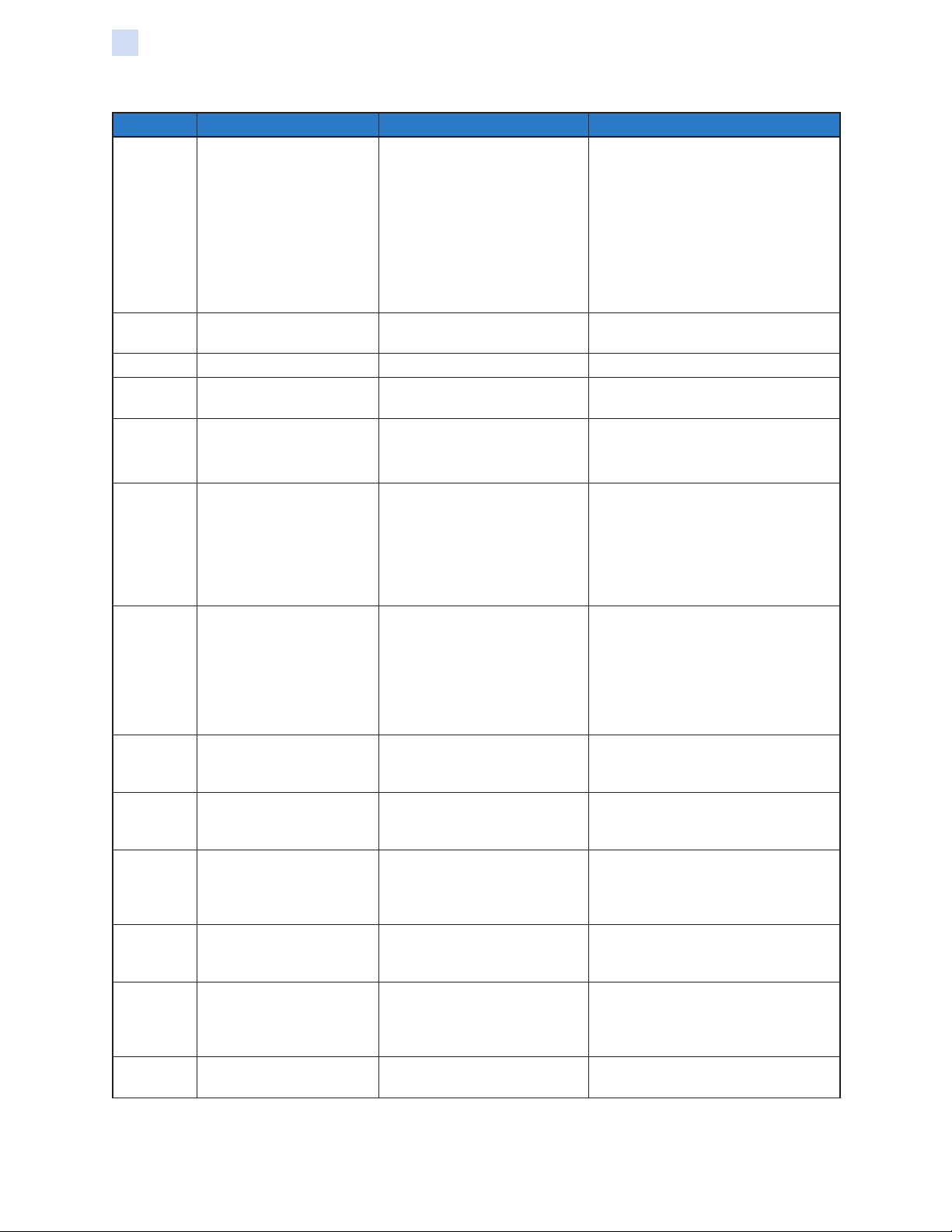

CODE MESSAGE POSSIBLE CAUSE POSSIBLE SOLUTION

5

6 DIAGNOSTIC ERROR

7

8

3001 PRINTER OFFLINE

4003 CARD JAM Card is jammed in the Printer. Clear the card path.

4014 CARD FEED ERROR

FIRMWARE UPGRADE

ERROR

FIRMWARE UPGRADE

ERROR

CRITICAL ERROR

SHUTTING DOWN

Firmware upgrade

incompatibility.

Error encountered in

Diagnostic Mode.

Firmware upgrade failed.

Major malfunction encountered. Contact Zebra Technical Support.

Status toggled (ofine/online)

via the OCP Advanced Settings

Menu.

Card is jammed in Feeder

Cartridge.

Verify the version, and retry installing

the rmware.

Power cycle the printer, and retry.

Verify the version, and retry installing

the rmware.

Change status to ONLINE via the

OCP Advanced Settings Menu.

1. Clear card jam in Feeder

Cartridge, and re-seat Feeder

Cartridge.

2. Ensure that cards are not stuck

together and that they are the

correct thickness (10 to 50 mil).

1. Load cards in the Feeder

Printer is out of cards.

Card was not fed into the

4015 CARD NOT INSERTED

5001 OUT OF RIBBON Print ribbon has run out. Load a new roll of print ribbon.

5002 INVALID RIBBON

5003 RIBBON JAM Print ribbon is jammed.

5004 RIBBON MOTION ERROR

5006 RIBBON BEMF ERROR

5007

RIBBON COLOR DETECT

ERROR

Manual Feed Slot within

30-second period.

Print ribbon does not match the

printer.

Print ribbon is stretched. Recalibrate ribbon torque.

Print ribbon is broken.

Problem with the Back EMF

(BEMF) of the ribbon motors.

Print ribbon is not installed

correctly.

Cartridge.

2. Re-seat the Feeder Cartridge.

Retry and feed a card into the Manual

Feed Slot, or cancel the operation.

Verify the part number of the print

ribbon is correct on OCP.

1. Check the print ribbon.

2. Reinstall the print ribbon.

3. Repair the break in the print ribbon

and reinstall.

Tape the broken ends of the ribbon

together, roll the ribbon around the

take-up spool, place the ribbon back

in the printer, and power cycle the

printer.

Contact Zebra Technical Support.

Reinstall the print ribbon. If reinstalling

the ribbon does not solve the problem,

contact Zebra Technical Support.

16 ZXP Series 7 Card Printer Service Manual P1036102-007

Page 23

Troubleshooting

OCP Error Messages

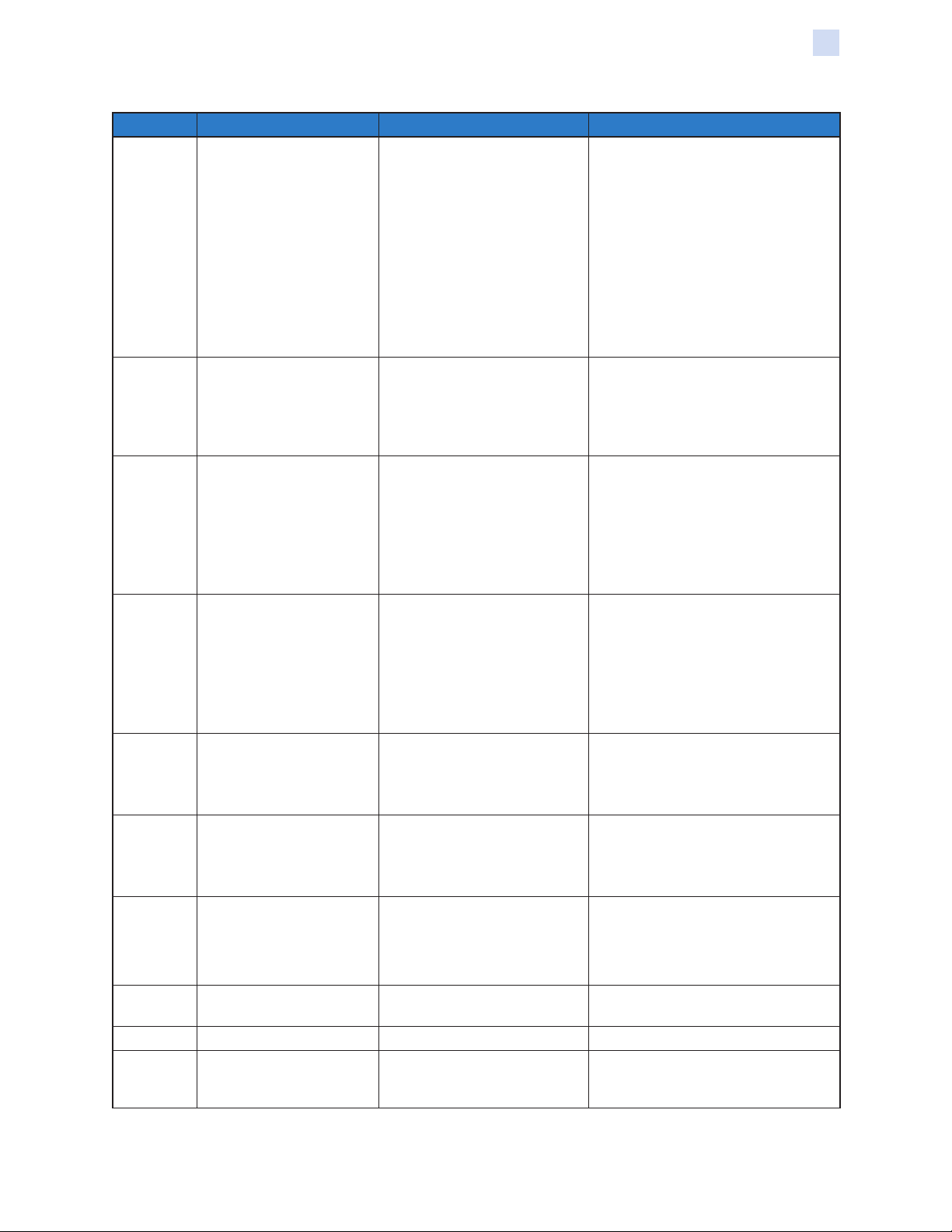

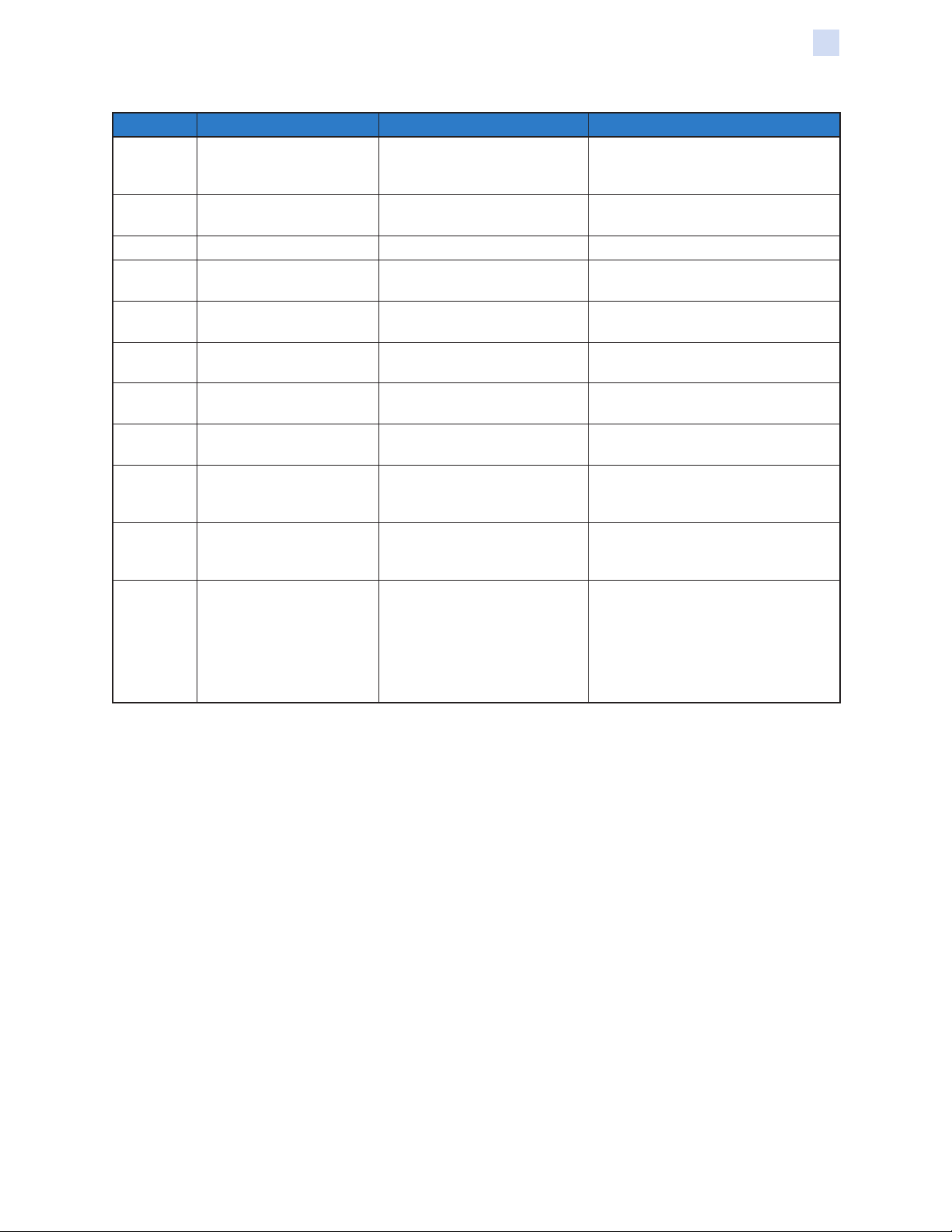

CODE MESSAGE POSSIBLE CAUSE POSSIBLE SOLUTION

1. Verify the part number of the print

ribbon is correct on OCP.

2. Power cycle the printer, and retry.

Power cycle the printer, and retry.

Power cycle the printer, and retry.

Power cycle the printer, and retry.

Power cycle the printer, and retry.

Power cycle the printer, and retry.

Power cycle the printer, and retry.

Power cycle the printer, and retry.

1. Clear card jam in Feeder

Cartridge, and re-seat Feeder

Cartridge.

2. Ensure that cards are not stuck

together and that they are the

correct thickness (10 to 50 mil).

1. Load cards in the Feeder

Cartridge.

2. Re-seat the Feeder Cartridge.

Check printhead cable connection,

reconnect if loose or disconnected.

Remove the card from the exit area.

Move the printer to a cooler

environment, or cool the area of

operation.

Move the printer to a warmer

environment, or warm the area of

operation.

This warning will be cleared when the

printer cover is closed.

Power cycle the printer, and retry.

Power cycle the printer, and retry.

Power cycle the printer, and retry.

5008 INVALID RIBBON

6001 6008

6009 FLASH ERASE ERROR

6010

6011

6012

6013 INVALID FW S-RECORD

6015 6025

7001 CARD FEED ERROR

7002 CARD CLEAN ERROR

7003

7004 CARD EJECT ERROR

7005 PRINTHEAD TOO HOT

7006 PRINTHEAD TOO COLD

7008 PRINT COVER OPEN

7010

7013

7014

7015 MAG MOTION ERROR

GENERAL MEMORY

ERROR

FLASH ERASE VERIFY

ERROR

FLASH PROGRAM

ERROR

FLASH PROGRAM

VERIFY ERROR

GENERAL MEMORY

ERROR

PRINTHEAD CABLE

ERROR

PRINTHEAD MOTION

ERROR

MOTOR VOLTAGE

ERROR

SCRIPT PROCESSING

ERROR

Print ribbon does not match the

printer.

There is a problem when

accessing general memory.

There is a problem when

accessing ash memory.

There is a problem when

accessing ash memory.

There is a problem when

accessing ash memory.

There is a problem when

accessing ash memory.

There is a problem when

accessing ash memory.

There is a problem when

accessing general memory.

Card is jammed in Feeder

Cartridge.

The printer is out of cards.

Printhead cable loose or

disconnected.

Card from previous job is stuck

in the exit area.

Environmental issue -- the

ambient temperature is too hot.

Environmental issue -- the

ambient temperature is too

cold.

This warning will be displayed if

the cover protecting the Printer

Module is opened.

Printhead did not move

to proper position during

initialization.

Incorrect voltage detected at

one or several motors in the

unit.

Internal logic error. Power cycle the printer, and retry.

This is a magnetic encoding

retrace error.

P1036102-007 ZXP Series 7 Card Printer Service Manual 17

Page 24

Troubleshooting

OCP Error Messages

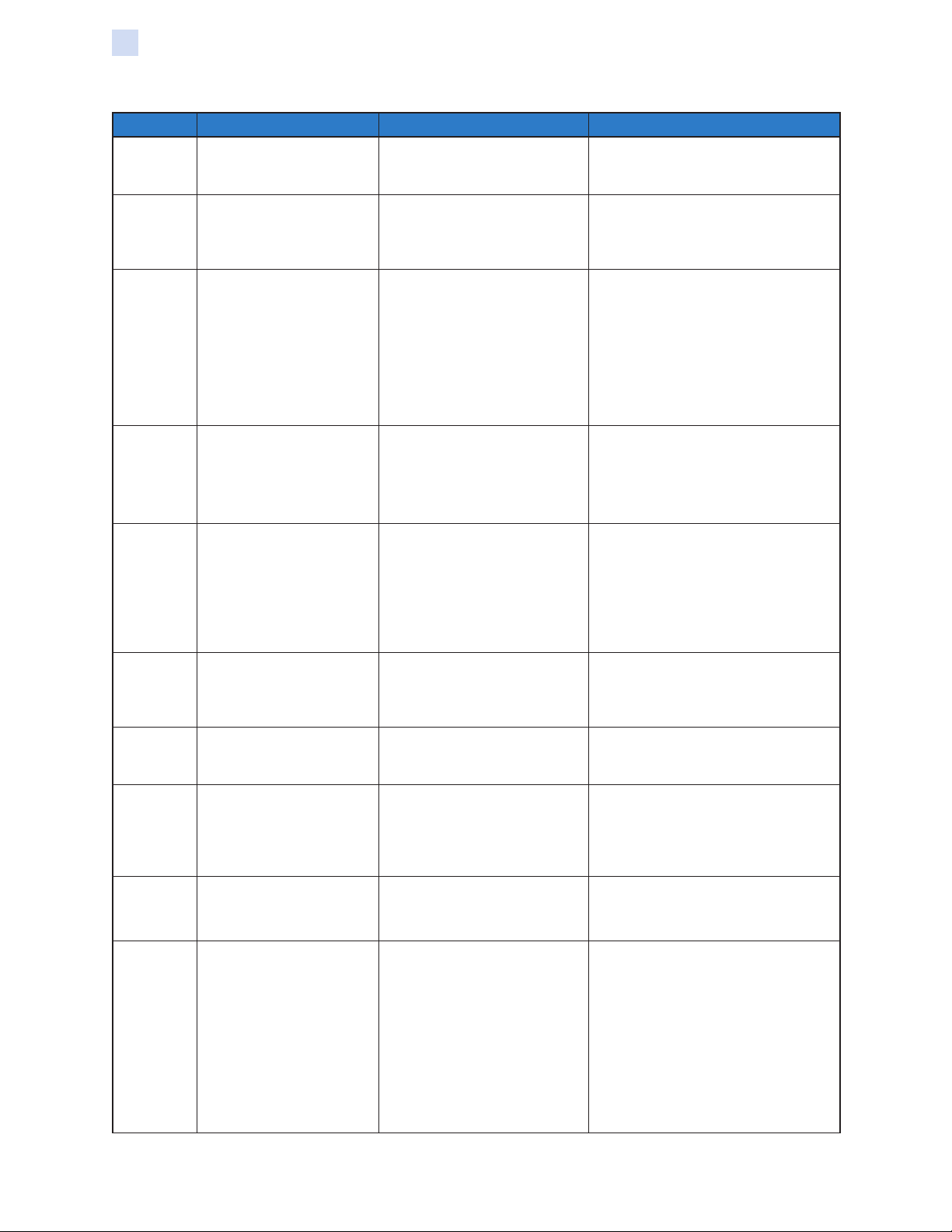

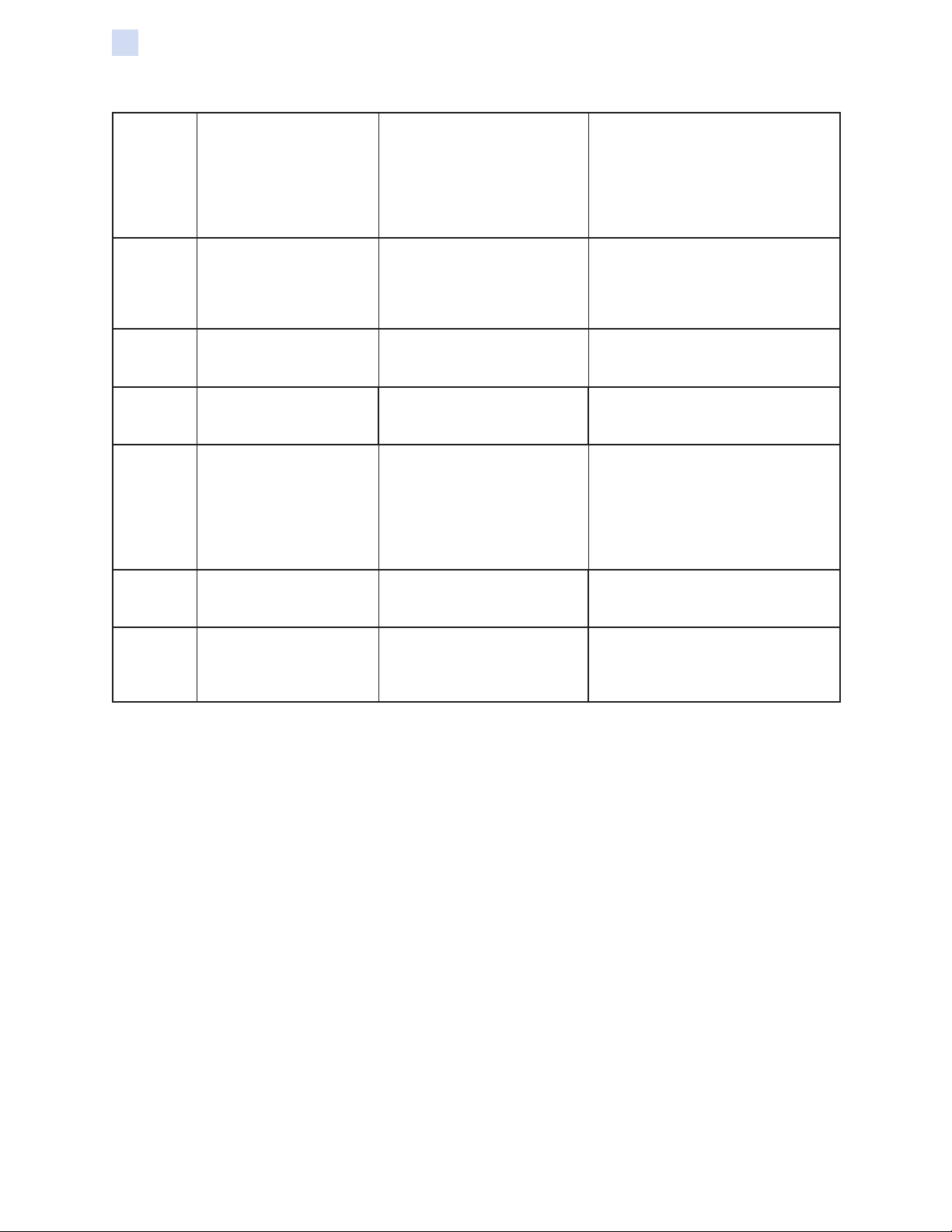

CODE MESSAGE POSSIBLE CAUSE POSSIBLE SOLUTION

1. Ensure that you are using the

correct card type.

7018 SMARTCARD ERROR

7019

7020 SCRIPT SEND ERROR Internal logic error. Power cycle the printer, and retry.

7023

7024 OPTIONS CARD JAM

7026 FLIPPER CARD JAM Card is jammed in the Flipper. Clear the card path.

7028 OPTIONS COVER OPEN

7029

7032 SINGLE CARD FEED JAM

7033 FLIPPER BOARD ERROR The Flipper has failed. Contact Zebra Technical Support.

7034

7035 OPTIONS CARD JAM

7036 7039

9001 MAG READ ERROR

SCRIPT CONTENT

ERROR

SMART CARD CAM INIT

ERROR

FLIPPER ROTATION

ERROR

REJECT BIN FULL

REMOVE CARDS

PRINT CARD JAM

• Encoding error.

• Faulty card.

Internal logic error. Power cycle the printer, and retry.

Mechanical positioning issue. Power cycle the printer, and retry.

Card is jammed in the Options

Module, Feeder Cartridge.

This warning will be displayed

if the cover protecting the

Options Module is opened.

The Flipper has failed. Contact Zebra Technical Support.

Card is jammed in the Options

Module, Single Card Feed Slot.

The Reject Bin is full.

Card is jammed in the Options

Module, Magnetic Encoder.

Card is jammed in Printer

Module.

• Encoding error.

• Defective magnetic stripe.

2. Check that the cards are loaded in

the correct orientation.

3. Ensure that the data conforms to

ISO Specications.

4. Retry writing and reading.

Clear the card path.

This warning will be cleared when the

options cover is closed.

Clear the card path.

Remove the cards from the bin, and

reset the reject bin card count to 0

via the OCP (Main Menu > Advanced

Settings > Clear Reject Bin).

Clear the card path.

Clear the card path.

1. Ensure that you are using the

correct card type.

2. Check that the cards are loaded

with the magnetic stripe in the

correct orientation.

3. Ensure that the cards are setup correctly in the printer driver

(coercivity setting).

4. Ensure that the data conforms to

ISO Specications.

5. Retry reading.

18 ZXP Series 7 Card Printer Service Manual P1036102-007

Page 25

Troubleshooting

OCP Error Messages

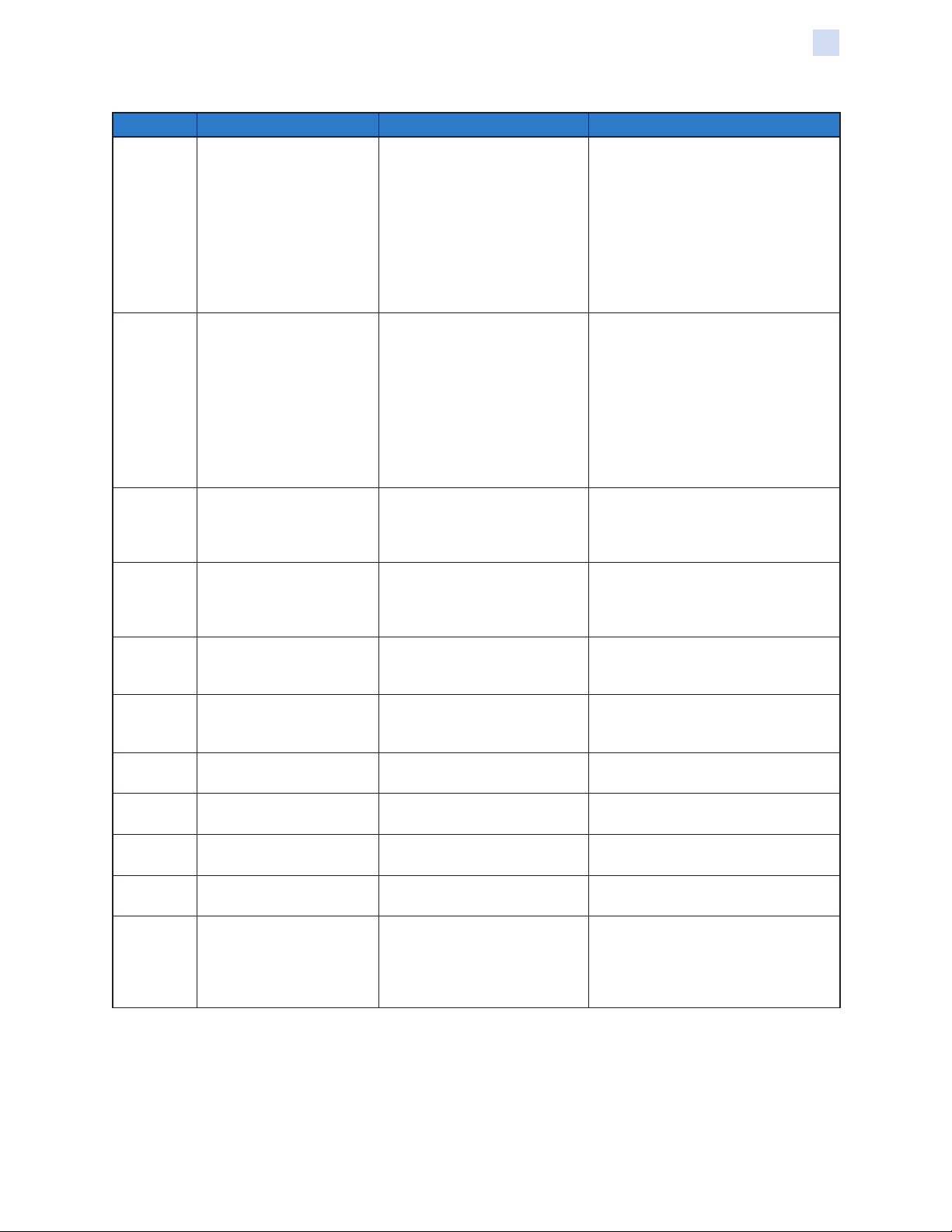

CODE MESSAGE POSSIBLE CAUSE POSSIBLE SOLUTION

1. Ensure that you are using the

correct card type.

2. Check that the cards are loaded

with the magnetic stripe in the

9002 MAG WRITE ERROR

9004 NO MAG STRIPE Magnetic stripe not detected.

10001 CONTACT READ ERROR

10002

11001

11002

15001 MISSING MAB

15002

17001 LAMINATOR MISSING

17002

CONTACT WRITE

ERROR

CONTACTLESS READ

ERROR

CONTACTLESS WRITE

ERROR

MAB FIRMWARE

MISSING

LAMINATOR FAILED

INITIALIZATION

• Encoding error.

• Defective magnetic stripe.

• Wrong card type is in use.

• Card orientation in the

Feeder Cartridge is wrong.

• Smart Card Options Module

is incorrectly installed.

• Wrong card type is in use.

• Card orientation in the

Feeder Cartridge is wrong.

• Wrong card type is in use.

• Smart Card Options Module

is incorrectly installed.

• Wrong card type is in use.

• Smart Card Options Module

is incorrectly installed.

An error occurred when

reading the RFID Tag by the

MAB (Media Authentication

Board).

MAB (Media Authentication

Board) Firmware is missing.

Laminator was detected by

the printer, but was unable to

communicate to it.

correct orientation.

3. Ensure that the cards are setup correctly in the printer driver

(coercivity setting).

4. Ensure that the data conforms to

ISO Specications.

5. Retry writing.

1. Ensure that you are using the

correct card type.

2. Check that the cards are loaded

with the magnetic stripe in the

correct orientation.

1. Ensure that you are using the

correct card type.

2. Check that the cards are loaded

with the chip in the correct

orientation.

3. Re-seat the Smart Card Options

Module.

1. Ensure that you are using the

correct card type.

2. Check that the cards are loaded

with the chip in the correct

orientation.

3. Re-seat the Smart Card Options

Module.

1. Ensure that you are using the

correct card type.

2. Re-seat the Smart Card Options

Module.

1. Ensure that you are using the

correct card type.

2. Re-seat the Smart Card Options

Module.

1. Check print ribbon orientation.

2. Verify part number of the print

ribbon.

3. Power cycle the printer, and retry.

Install the rmware.

Contact Zebra Technical Support.

P1036102-007 ZXP Series 7 Card Printer Service Manual 19

Page 26

Troubleshooting

OCP Error Messages

CODE MESSAGE POSSIBLE CAUSE POSSIBLE SOLUTION

17003

17004

17005

17006

17007

17008

17009

17010

17011

17012

LAMINATOR UNKNOWN

ERROR

MISSING LAMINATOR

MAB

TOP LAMINATE FEED

FAIL

BOTTOM LAMINATE

FEED FAIL

TOP LAMINATE

REGISTRATION ERROR

LAMINATOR CARD FEED

FAIL

LAMINATOR EARLY

CARD JAM

LAMINATOR MIDDLE

CARD JAM

LAMINATOR LATE CARD

JAM

LAMINATOR POLL

TIMEOUT

An unknown error has occurred

– this is an indication of a FW

problem and should not occur.

An error occurred when

trying to communicate to

the Laminator MAB (Media

Authentication Board).

• Top laminate cartridge is not

installed properly.

• Cartridge is not removed

when that side of the card is

not being laminated.

• A mis-cut piece of laminate

(rare) is obscuring the media

sensor.

• Bottom laminate cartridge is

not installed properly.

• Cartridge is not removed

when that side of the card is

not being laminated.

• Improperly prepared

registered laminate.

• Media misfeed.

• Patch length improperly set.

• Unexpected end of laminate

roll detected.

Printer has not fed the card

far enough into laminator

mechanism for infeed rollers to

grab it.

Card did not make it to the

staging rollers.

Card and laminate have

jammed inside heater

assembly, often due to mispositioned laminate patch

sticking to heated rollers.

Card did not unblock the exit

sensor in the specied time.

The laminator expects the

printer to periodically send

commands to it within a

specied time period. If it

fails to do so, it assumes that

something is wrong with the

communication link or that the

printer is down. This error may

occur if the printer-to-laminator

communications is having

intermittent problems.

1. Press RETRY on the OCP.

2. Contact Zebra Technical Support.

1. Power cycle the printer, and retry.

2. Contact Zebra Technical Support.

1. Remove, reposition, and re-install

the top laminate cartridge.

2. Remove the top laminate

cartridge.

3. Remove the mis-cut piece of

laminate.

1. Remove, reposition, and re-install

the bottom laminate cartridge.

2. Remove the bottom laminate

cartridge.

Remove and re-cut laminate in the

center of the index notch, re-install,

and retry.

Open the Laminator and printer doors

to check for jammed/stuck cards.

Remove the card and/or laminate

that is stuck in the laminator staging/

cutting area.

Remove the oven, and inspect for

stuck cards.

1. Check for card jam in the exit area.

2. Assure that the sliding exit door is

not partially blocking the exit path.

Power cycle the printer, and retry.

20 ZXP Series 7 Card Printer Service Manual P1036102-007

Page 27

Troubleshooting

OCP Error Messages

CODE MESSAGE POSSIBLE CAUSE POSSIBLE SOLUTION

Top heater did not turn on

after being instructed to

do so. When the heater

is enabled, the controller

17013

17014

17015

17016

17017

17118

17019

17020

17021

17022

17023 LAMINATOR FAN FAIL

LAMINATOR TOP

HEATER FAIL

LAMINATOR BOTTOM

HEATER FAIL

LAMINATOR TOP

TEMPERATURE HIGH

LAMINATOR BOTTOM

TEMPERATURE HIGH

LAMINATOR TOP

CUTTER STALL

LAMINATOR BOTTOM

CUTTER STALL

LAMINATOR TOP

CUTTER FAIL

LAMINATOR BOTTOM

CUTTER FAIL

LAMINATOR TOP TEMP

SENSOR FAIL

LAMINATOR BOTTOM

TEMP SENSOR FAIL

will wait a certain specied

amount of time for it to attain

the set target temperature. If

the heater fails to reach the

target in the specied time, the

TopHeaterFail fault will be set.

Bottom heater did not turn

on after being instructed

to do so. When the heater

is enabled, the controller

will wait a certain specied

amount of time for it to attain

the set target temperature. If

the heater fails to reach the

target in the specied time, the

BotHeaterFail fault will be set.

If the top roller temperature

ever exceeds a xed

temperature threshold, the over

temp error occurs.

If the bottom roller temperature

ever exceeds a xed

temperature threshold, the over

temp error occurs.

Top cutter blade is obstructed,

or top cutter mechanism is

damaged.

Bottom cutter blade is

obstructed, or bottom cutter

mechanism is damaged.

Top cutter has failed.

Bottom cutter has failed.

The top temperature

(thermopile) sensor has failed.

The bottom temperature

(thermopile) sensor has failed.

This should only happen if one

or both cooling fans fail or the

cooling vents near the heated

roller assembly are blocked or

the fan(s) have failed.

Replace the top halogen bulb.

Replace the bottom halogen bulb.

1. Power cycle the printer, and retry.

2. If this error persists, contact Tech

Support.

1. Power cycle the printer, and retry.

2. If this error persists, contact Tech

Support.

If this error persists, contact Tech

Support.

If this error persists, contact Tech

Support.

If this error persists, contact Tech

Support.

If this error persists, contact Tech

Support.

If this error persists, contact Tech

Support.

If this error persists, contact Tech

Support.

Check for blocked vents.

P1036102-007 ZXP Series 7 Card Printer Service Manual 21

Page 28

Troubleshooting

OCP Error Messages

CODE MESSAGE POSSIBLE CAUSE POSSIBLE SOLUTION

The parameters stored in

EEPROM have been reset

to their default values. This

will not normally happen, but

17024

17026

17027 TOP LAMINATE OUT The top laminate has run out. Load new roll of laminate.

17028 BOTTOM LAMINATE OUT

17029 INVALID TOP LAMINATE

17030

17031

17032 REMOVE TOP LAMINATE

17033

17034

17038

17040

17041

LAMINATOR EEPROM

DEFAULT

TOP AND BOTTOM

LAMINATES OUT

INVALID BOTTOM

LAMINATE

BOTTOM LAMINATE

REGISTRATION ERROR

REMOVE BOTTOM

LAMINATE

REMOVE TOP AND

BOTTOM LAMINATES

LAMINATOR COVER

OPEN

LAMINATOR

INITIALIZING

LAMINATOR FIRMWARE

MISSING

could be seen with certain

FW upgrades when new

parameters have been added

by Engineering. It could also

indicate a problem with the

Laminator’s EEPROM.

The top and bottom laminates

have run out.

The bottom laminate has run

out.

Laminate does not match the

printer.

Laminate does not match the

type allowed in the laminator

or top and/or bottom has been

swapped.

• Improperly prepared

registered laminate.

• Media misfeed.

• Patch length improperly set.

• Unexpected end of laminate

roll detected.

Top laminate is installed when

the driver lamination mode

“Bottom” is selected.

Bottom laminate is installed

when the driver lamination

mode “Top” is selected.

Top and bottom laminates

are installed when the driver

lamination mode “Pass

through” is selected.

This warning will be displayed

if the cover protecting the

laminator is opened.

This warning will be displayed

after the laminator door is

closed and laminate spools are

re-read/detected.

Laminator Controller Board

(LCB) Firmware is missing.

1. Press RETRY on the OCP when

this error occurs.

2. Power cycle the printer, and retry.

Load new rolls of laminate.

Load new roll of laminate.

1. Verify the part number of the

laminate is correct on OCP.

2. Power cycle the printer, and retry.

1. Verify that the top and bottom

laminate cassettes are installed in

the correct locations.

2. Verify the part number of the

laminate is correct on OCP.

3. Power cycle the printer, and retry.

Remove and recut laminate in the

center of the index notch, re-install,

and retry.

Remove the top laminate cassette.

Remove the bottom laminate

cassette.

Remove both laminate cassettes.

This warning will be cleared when the

laminator cover is closed.

No action needed

Install the rmware.

22 ZXP Series 7 Card Printer Service Manual P1036102-007

Page 29

Troubleshooting

OCP Error Messages

CODE MESSAGE POSSIBLE CAUSE POSSIBLE SOLUTION

17042

18001

19001 WIFI COMM ERROR Hardware failure. Replace the Wireless PCBA.

19002

19003 WIFI LINK LOST Network failure.

19004

19005

19006

20001 BARCODE ERROR INIT

20002 BARCODE ERROR READ

20003

LAMINATOR MAB

FIRMWARE MISSING

ETHERNET COMM

ERROR

WIFI ACCESS POINT

MISSING

WIFI INCOMPATIBLE

NETWORK

WIFI ASSOCIATION

FAILED

WIFI CONNECTION

FAILED

BARCODE ERROR NO

DATA

Laminator MAB (Media

Authentication Board)

Firmware is missing.

Ethernet connection failed. Check network connectivity.

Network failure.

Network failure.

Network failure.

Network failure.

The Barcode Scanner

Assembly may be incorrectly

installed or defective.

Communications problem

with the Barcode Scanner

Assembly.

Cannot read the barcode.

Install the rmware.

Attempt to reconnect to the Access

Point (AP).

Attempt to reconnect to the Access

Point (AP).

Attempt to reconnect to the Access

Point (AP).

Attempt to reconnect to the Access

Point (AP).

Attempt to reconnect to the Access

Point (AP).

Check the Barcode Scanner

Assembly.

Check the Barcode Scanner

Assembly.

1. Check for defective barcode on the

card being read.

2. Check the orientation of the cards

in the Feeder cartridge.

3. The barcode is printed in the

wrong location.

P1036102-007 ZXP Series 7 Card Printer Service Manual 23

Page 30

Troubleshooting

OCP Error Messages

21001 STACKER MISSING

21002

21003 STACKER INIT ERROR

21004 STACKER CARD JAM

21005

21006 STACKER COMM ERROR

21010 STACKER FW MISSING

STACKER

UNAUTHORIZED

STACKER ELEVATOR

JAM

Stacker is missing but is

congured to have it. Stacker

may have been removed or

communication has been lost

between stacker and main logic

board. Printer will still print,

however no cards will stack.

Stacker has been found but

has not been enabled. Printer

will not print until stacker is

enabled.

Something mechanically has

prevented the stacker from fully

initializing. Printer will not print.

Card has jammed at the

stacker entry sensor. Printer

will not print.

Elevator jam in which the

elevator has not detected

the home position. Could be

the possibility of a faulty cam

sensor for elevator, a card jam,

or too many card in the hopper.

Printer will not print.

Cannot communicate between

printer and hopper. Printer will

not print until error is xed.

Firmware corrupt or missing.

Printer will not print until

stacker rmware is installed

and power is cycled.

Replace the stacker. The printer

conguration will recognize the

stacker and operate normally.

Remove the stacker. The printer

must be congured at the factory

to recognize the stacker. Once the

stacker is removed, the printer will

operate normally.

Check the card path. Remove the

high-capacity output hopper from the

stacker and clear any obstruction.

Clear the card jam.

1. Replace cam sensor.

2. Check the stacker card path for

jammed or stuck cards.

3. Remove nished cards from the

hopper.

Cycle printer power. Check

connections between printer and

stacker.

Update printer and stacker rmware.

24 ZXP Series 7 Card Printer Service Manual P1036102-007

Page 31

OCP Test Cards

Image Title Description Use

Troubleshooting

OCP Test Cards

GRADIENT BOXES

DENSITY SETUP

MONOCHROME ONLY Barcode and text

3 sets of light-to-dark

grayscale ramps

Mid-gray and maximum

density elds on a at gray

surface

For factory use only.

Used to measure mid

and max densities. Also

used to check the left/right

offsets or the centering of

the image on the card.

Used to verify

monochrome print

capability.

Also used to check the left/right osets or the centering of the image on the card.

P1036102-007 ZXP Series 7 Card Printer Service Manual 25

Page 32

Troubleshooting

Ethernet

Ethernet

• Indicators -- Detail

• Link Speed Indicator (Orange)

O No link (disconnected)

1 Blink The LED blinks once (one blink, pause, one blink,

etc.) when a 10Base link has been established.

2 Blinks The LED blinks twice (two blinks, pause, two blinks,

etc.) when a 100Base link has been established.

• Link Activity Indicator (Green)

O No link (disconnected)

On Network link has been established

Blinking Network activity has been detected

• Issues

If both LEDs are o, the printer has not detected the presence of a network cable.

To solve the problem:

• Verify that the network cable is appropriate and has an RJ-45 connector.

• Remove the network cable from the printer. Plug the network cable back in

until you hear a positive click. Check the other end of the cable in the same

manner. If the printer still does not detect a cable, then continue.

• Connect the printer to a known good network. If the printer is still unable to

detect the network cable, contact Technical Support for assistance.

26 ZXP Series 7 Card Printer Service Manual P1036102-007

Page 33

Introduction

The following sections describe removing both major assemblies and—where

applicable—sub-assemblies and/or components that are considered replaceable.

4

Replacement Procedures

for the Printer

In general, only removal directions are presented. Unless otherwise noted,

replacement would be performed by reversing the removal steps. Replacement

instructions for some common or simple procedures are not presented.

For a complete listing of Spare Part Kits and Upgrade Kits available for the Zebra ZXP

Series 7 Card Printer, see the ZXP Series 7 Spare Parts Catalog at www.zebra.com/

parts.

Electric Shock • Before performing any of the procedures in this section, set the

printer power to OFF (O) and disconnect the power cord.

Electrostatic Discharge • All replacement procedures must be performed at a staticfree work station, an anti-static wrist strap must be worn and properly terminated, or

other appropriate protection must be used.

Caution • Before beginning any of the procedures that follow, read completely

through the procedure. If you do not have the specified tools or if any step(s) seem

beyond your skill or experience level, do not attempt the procedure. You may cause

additional damage to the printer.

Note • Some of the photographs in this section may show additional parts removed in

addition to removals for the process being described.

P1036102-007 ZXP Series 7 Card Printer Service Manual 27

Page 34

Replacement Procedures for the Printer

Required Tools

Required Tools

The following list specifies the tools required to perform the replacement procedures

described in this section. Naturally, not all tools are required for a particular procedure;

specific tools are called out in each step as appropriate.

• Flat-blade Screwdrivers: from 1/16 inch (1.5 mm) to 1/4 inch (6.5 mm)

• Phillips Screwdrivers: #0, #1, and #2

• TORX T8, T9, and T10 (standard, 12-inch shaft, and/or ball-end; magnetic tip

recommended)

• Fine-Point, Oset Fine-Point, and Needle-Nose Pliers

• Small Diagonal Cutters or other cutter for cutting cable ties

• 5.5 mm nut driver (this can also be used for securing push nuts)

• 3–10 mm E-Ring Clip Tool

• Small and Medium Spring Hooks

• Adjustable Wrench

• Multimeter

• Loctite® 242

The following list specifies the Zebra Special-Purpose Tools required to calibrate

specific parts/assemblies reinstalled in selected procedures. Note that the Zebra Part

Number is in parentheses following the description.

• Torque Tools for RTU Motor Calibration ZXP7 (P1037750-400)

This kit is comprised of a High Torque Tool and a Low Torque Tool. The recommended calibration cycle for these tools is 50 uses or every 6 months. Please

return your torque tools to the nearest Zebra Repair Center for calibration; or see

page 187 for torque tool calibration instructions.

• Print Head Cam Sync Fixture ZXP7 (P1037750-401).

• Flipper Deck Level (P1037750-402).

• Contact Station Upgrade Tool (P1037750-403).

• AC Power Filter Release Tool (P1037750-404).

• Mag Tensioning Spring Tool (included with all magnetic encoder upgrade kits).

• Gates Sonic Tension Meter 507C. Note that this item is not being sold by Zebra.

• Kit Service CD / ZXP7 (P1037750-090).

• ZMotif Service Partner Tool (SW0000194)

28 ZXP Series 7 Card Printer Service Manual P1036102-007

Page 35

Removal Sequence

The following figures show the recommended removal sequence. For each item,

follow the diagram upward to see what must be removed for access. For example: to

remove the control panel door open sensor, remove the back cover, the options cover,

and the right cover.

Replacement Procedures for the Printer

Removal Sequence

“Ribbon

Drawer” on

page 40

“Left Side

Cover” on

page 63

“Belt and

Gear Panel”

on page 64

“Reject Bin”

on page 32

“Back Cover”

on page 45

“Ethernet

PCBA” on

page 76

“Rear Feeder

Cover” on

page 46

“Print Cover”

on page 58

“Door Button

and Latch” on

page 60

“Bottom

Cover” on

page 66

“Main PCBA”

on page 73

“Ground

Plate” on

page 145

“Right Cover”

on page 51

“Lock Replacement

for Right Cover” on

“Control Panel Door

Open Sensor” on

“Options

Cover” on

page 47

page 53

page 57

“Card Guides”

on page 42

“OCP PCBA”

on page 49

“Printer” on page 69

P1036102-007 ZXP Series 7 Card Printer Service Manual 29

Page 36

Replacement Procedures for the Printer

Removal Sequence

Printer

“Printer” on page 30

Feeder Module

“Print Engine”

on page 77

Assembly” on page

“Feeder

Module” on

page 149

“Torque Tools Calibration

Instructions” on page

Options Assembly”

“Feeder/Flipper

142

187

“Feeder/Flipper/

on page 137

“Flipper

Module” on

page 157

“Options

Module” on

page 180

“Feeder

Module” on

page 149

“Feeder

Motor” on

page 155

“Drive Assembly

Feeder” on page

149

30 ZXP Series 7 Card Printer Service Manual P1036102-007

Page 37

Flipper Module

Replacement Procedures for the Printer

Removal Sequence

“ESD Brush”

on page 159

“Flipper

PCBA” on

page 161

“Flipper

Module” on

page 157

“Flipper

Position

Sensor” on

page 163

“Flipper

Assembly” on

page 157

“Flipper

Rotation

Gear” on

page 164

“85/35T Gear”

on page 166

“Flipper

Rotation

Motor” on

page 167

“Flexible

Roller” on

page 169

“Flipper Drive

Motor” on

page 168

Options Module

“Drive Platen

Roller” on

page 183

“Flipper Deck

Platen Roller”

on page 176

“Options

Module” on

page 180

“Card Sensor”

on page 180

“Card Present

On Flipper

Sensor” on

page 178

“Options

Motor” on

page 182

P1036102-007 ZXP Series 7 Card Printer Service Manual 31

Page 38

Replacement Procedures for the Printer

Procedures: Reject Bin

Procedures

Reject Bin

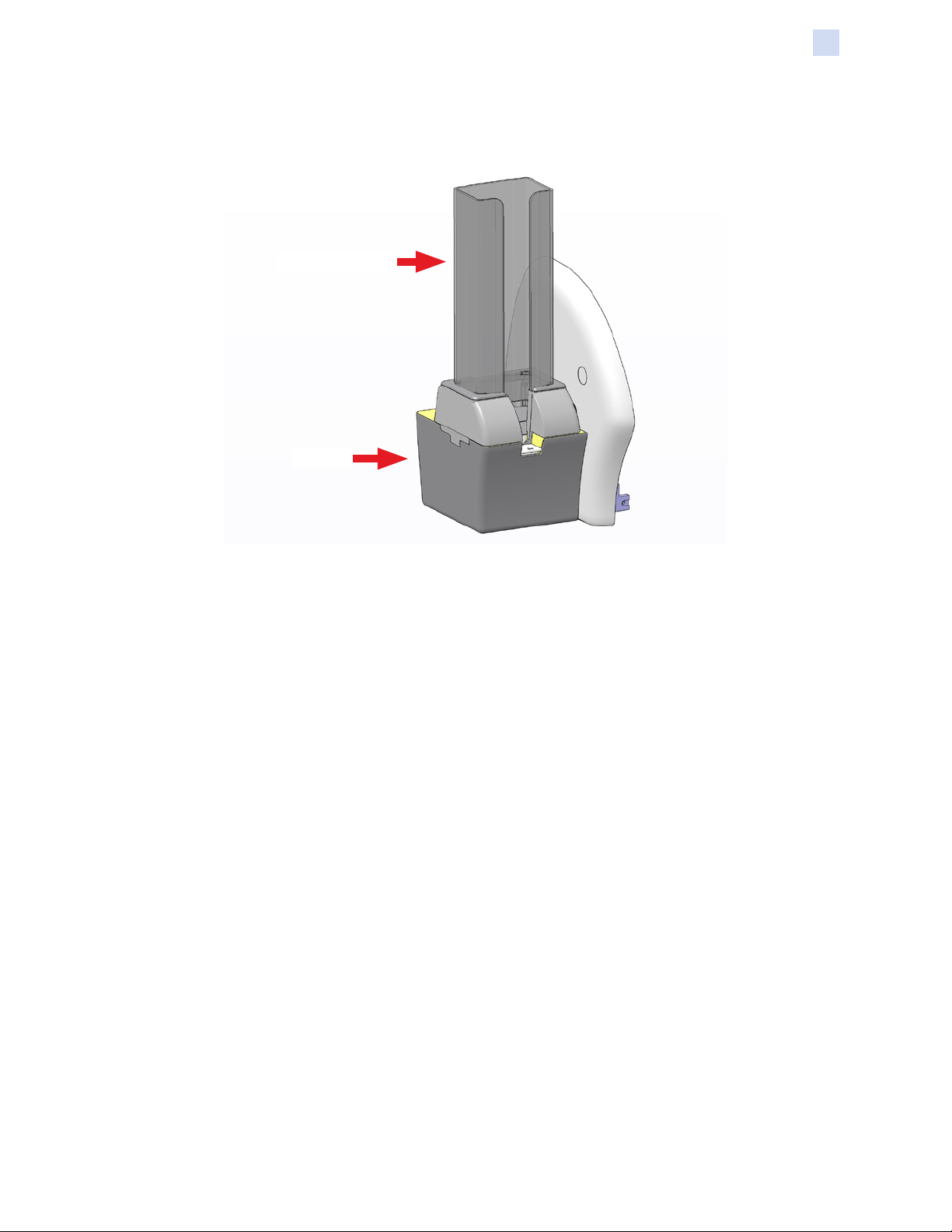

Step 1. Locate the Reject Bin (circled below).

Step 2. Slide the Reject Bin out of the Printer until it stops.

32 ZXP Series 7 Card Printer Service Manual P1036102-007

Page 39

Replacement Procedures for the Printer

Procedures: Reject Bin

Step 3. Using two fingers, simultaneously, depress the two locking tabs (arrows

below) that prevent the Reject Bin from being removed.

Step 4. Slide the Reject Bin out of the Printer, and set it aside.

P1036102-007 ZXP Series 7 Card Printer Service Manual 33

Page 40

Replacement Procedures for the Printer

Procedures: Feeder Cartridge

Feeder Cartridge

This is the replacement kit for the Standard Feeder Cartridge (i.e., the entire

assembly).

Feeder Cartridge Cover

Step 1. With a Flat-blade screwdriver, carefully press the pivot arm in (arrow below)