Page 1

ZD200 Series

Direct Thermal Printers

User’s Guide

212089-001 Rev. A

Page 2

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corporation, registered in many

jurisdictions worldwide. All other trademarks are the property of their respective owners. ©2019 Zebra

Technologies Corporation and/or its affiliates. All rights reserved.Information in this document is subject to

change without notice. The software described in this document is furnished under a license agreement or

nondisclosure agreement. The software may be used or copied only in accordance with the terms of those

agreements.

For further information regarding legal and proprietary statements, please go to:

COPYRIGHTS:www.zebra.com/copyright

WARRANTY:www.zebra.com/warranty

END USER LICENSE AGREEMENT: www.zebra.com/eula

SOFTWARE:www.zebra.com/linkoslegal

Terms of Use

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries

(“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced,

or disclosed to any other parties for any other purpose without the express, written permission of Zebra

Technologies.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are

subject to change without notice.

Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are

correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever

(including, without limitation, consequential damages including loss of business profits, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to

use such product, even if Zebra Technologies has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

Publication Date

May 2019

2

Page 3

About

This guide is for integrators and operators of the Zebra ZD200 Series desktop printers. Use this guide to

install, change configuration, operate, and physically support the product.

Other online resources are available to support this printer include:

• “How To” videos

• Product specifications

• Accessories, supplies, parts, and software links

• Various setup and configuration guides

• Programmer’s manuals

• Software to connect and use your product

• Firmware

• Fonts

• Utilities

• Knowledge base and support contacts

• Warranty and repair links

Use this link to get to your Online product support resources:

• ZD200 Series Direct Thermal Printer — www.zebra.com/zd200d-info

Zebra OneCare Printer Service and Support

For maximum productivity, we can help your business ensure its Zebra printers are Online and ready for

business. See the descriptions of the Zebra OneCare service and support options available for your

printers Online at this link: www.zebra.com/zebraonecare

3

Page 4

Document Conventions

The following graphic icons are used throughout the documentation set. These icons and their associated

meanings are described below.

Caution • If the precaution is not heeded, the user could receive minor or moderate injury.

Eye Injury Caution • If the precaution is not taken, the user’s eyes could be damaged. EXAMPLE: Wear protective

eyewear when installing or removing E-rings, C-clips, snap rings, springs, and mounting buttons. These are under

tension and could fly off.

Electrical Shock Caution • If the precaution is not taken, the user could receive an electrical shock. EXAMPLE: Turn

off (O) the printer and disconnect it from the power source before performing the following procedure.

Hot Surface Caution • If the precaution is not taken, the user could be burned. EXAMPLE: The printhead may be hot

and could cause sever burns. Allow the printhead to cool.

About

Product Damage Caution • If the precaution is not taken, the product could be damaged. EXAMPLE: Unplugging the

computer without properly shutting it down may corrupt the data on your hard drive.

ESD Caution • If the precaution is not taken, the product electronics could be damaged by an electrostatic discharge.

EXAMPLE: Observe proper electrostatic safety precautions when handling static-sensitive components such as circuit

boards and printheads.

Important • The text here indicates information that is important for the user to know. EXAMPLE: Run the setup.exe

file for the product BEFORE connecting the product to your printer.

Note • The text here indicates information that is supplemental for the user to know and that is not required to complete

a task. EXAMPLE: Refer to zebra.com for complete information on product warranties.

4

Page 5

Contents

Terms of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Proprietary Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Product Improvements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Liability Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Limitation of Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Publication Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

• About . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Zebra OneCare Printer Service and Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

• Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

• Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4-inch Desktop Thermal Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Common Desktop Printer Features:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4-inch Desktop Printer Options: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Zebra Label Printing Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Modes of Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

What’s in the Box? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Unpack and Inspect the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

• Printer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

External Printer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Inside the ZD200 Series Direct Thermal Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Label Dispenser Option (factory installed only) . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Cutter Option (factory installed only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

• Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

User Interface Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

FEED Button Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

FEED Button Modes - Power ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

FEED Button Modes - Power OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5

Page 6

Contents

• Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Printer Setup Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Select a Location for the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Attaching Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Getting Ready to Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Preparing and Handling Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Media Storage Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Loading Roll Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Setting Media Sensing by Media type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Instructions for media loading: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Run a SmartCal Media Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

SmartCal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Test Printing with the Configuration Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Detecting a Media Out Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Connecting your Printer to a Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Interface Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Wi-Fi and Bluetooth Classic Wireless Connectivity Option . . . . . . . . . . . . . . . . . . . . .37

• Setup for Windows® OS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Windows to Printer Communication Setup (Overview). . . . . . . . . . . . . . . . . . . . . . . . .38

®

install Windows

Setting Up the Wi-Fi Print Server Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Configure Using the ZebraNet Bridge’s Connectivity Wizard . . . . . . . . . . . . . . . . . . . .40

Using a Configuration Script. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Bluetooth Option Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Connecting to a Windows Vista

Connecting the Printer to a Windows 8 OS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Connecting the Printer to a Windows 10 OS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

After Your Printer is Connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Printer Drivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

®

SP2 or Windows 7® Master Device. . . . . . . . . .50

• Print Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Thermal Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Replacing Supplies while Using the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Sending Files to the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Determining Your Printer’s Configuration Settings. . . . . . . . . . . . . . . . . . . . . . . . .60

Select a Print Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Adjusting the Print Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Adjusting the Print Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Replacing Supplies while Using the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Printing on Fan-Fold Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Printing with Externally Mounted Roll Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Externally Mounted Roll Media Considerations:. . . . . . . . . . . . . . . . . . . . . . . . . . .64

Using the Label Dispenser Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

6

Page 7

Contents

Printer Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Identifying Fonts in Your Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Localizing the Printer with Code Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Asian fonts and Other Large Font Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Media Roll Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

• Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Cleaning Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Recommended Cleaning Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Cleaning the Printhead. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Media Path Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Sensor Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Platen Cleaning and Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Updating Printer Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Other Printer Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

• Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Resolving Alerts and Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Alert: Media Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Alert: PRINTHEAD OVER TEMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Alert: PRINTHEAD SHUTDOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Alert: PRINTHEAD UNDER TEMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Resolving Print Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Issue: No Print on the Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Issue: Labels Are Distorted in Size or Print Area Start Position Varies . . . . . . . . .90

Communication Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Issue: Label Job Sent, Data Transfers, But No Print . . . . . . . . . . . . . . . . . . . . . . .91

Miscellaneous Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Issue: Settings are Lost or Ignored . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Issue: Non-continuous labels act as Continuous labels. . . . . . . . . . . . . . . . . . . . .93

Issue: Printer Locks-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Printer Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Printer Network (and Bluetooth) Configuration Report. . . . . . . . . . . . . . . . . . . . . .95

Manual Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Communications Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

• Interface Connector Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Universal Serial Bus (USB) Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

7

Page 8

Contents

• Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

• Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Types of Thermal Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Determining Thermal Media Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

General Media and Print Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

• ZPL Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Managing the ZPL Printer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Configuration Setting to Command Cross-reference . . . . . . . . . . . . . . . . . . . . . . . . .113

Printer Memory Management and Related Status Reports . . . . . . . . . . . . . . . . . . . .116

ZPL Programming for Memory Management . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

8

Page 9

Introduction

This section introduces the Zebra® ZD200 Series 4-inch desktop direct thermal label printers. The

overview includes the printer’s features and options, and what ships with your new printer.

This document covers the following ZD-series desktop printer models: ZD220 and ZD230

• ZD200 Series Direct Thermal Printer — www.zebra.com/zd200d-info

4-inch Desktop Thermal Printers

The Zebra® 4-inch Desktop printers are compact label printers with essential features and options.

The ZD200 direct thermal printers can support:

• ZD220 model has a print speed of 101.6 mm/sec (4 ips - inches per second).

• ZD230 model has a maximum print speed of 152.4 mm/s (6 ips - inches per second) and

101.6 mm/sec (4 ips - inches per second) default speed.

• ZD200 models have a 203 dpi (dots per inch print density).

• ZPL ™ and EPL Zebra printer programming languages.

Common Desktop Printer Features:

• OpenAccess ™ design for simplified media loading.

• Color-coded “touch points” for operator controls and media guides.

• Simple single control button and single multi colored status indicator.

• Zebra’s printer operating system — an open platform with software tools needed to integrate,

manage, and maintain the printer.

• Media roll support:

• Outer Diameter (O.D.): Up to 127 mm (5 inch) and

• Inner Diameter (I.D.) roll cores:12.7 mm (0.5 inch), 25.4 mm (1 inch), and an optional

1.5 inch (38.1 mm) media core adapter set.

• Half width Movable Media Sensor provides compatibility with a wide range of media types:

• Compatible with full or partial width black mark media - center to left side of media.

• Compatible with notched or slotted media - center to left side of media.

• Center position transmissivity sensor for use with label gap/web media.

• On–the–fly OpenType and TrueType font scaling and import, Unicode, resident scalable font (Swiss

721 Latin 1 font), and a selection of resident bitmap fonts.

9

Page 10

• Backwards compatibility focused technology eases printer replacement:

• Drop in replacement of legacy Zebra desktop printers. The printer accepts both EPL and ZPL

programming languages.

• Universal Serial Bus (USB) 2.0 interface

• Factory installed network models support printer configuration via a setup utility running on mobile

devices.

• XML-Enabled printing—allows XML communications for barcode label printing, eliminating license

fees and print server hardware and lowering customization and programming costs.

• Zebra ™ Global Printing Solution – supports Microsoft Windows keyboard encoding (and ANSI),

Unicode UTF-8 and UTF 16 (Unicode Transformation Formats), XML, ASCII (7 and 8 bit used by

legacy programs and systems), basic single and double byte font encoding, JIS and Shift-JIS

(Japanese International Standards), Hexadecimal encoding, and custom character mapping (DAT

table creation, font linking, and character remapping).

• Printers have the Simplified Chinese SimSun font pre-installed (China only).

• A minimum of 50 MB of internal (E:\) printer memory for storing forms, fonts, and graphics.

4-inch Desktop Printer Options:

Introduction

• Factory Installed Wired and Wireless options:

• Wi-Fi (802.11ac – includes a/b/g/n), Bluetooth Classic 4.X (3.X compatible).

• Factory installed Internal Ethernet Print Server (LAN, RJ-45 connector) — supports 10Base-T,

100Base-TX and fast Ethernet 10/100 auto-switching networks for wired connectivity.

• Media Core Adapter kit include adapters for media rolls with Outer Diameters (O.D.) up to 127 mm

(5 inches):

• 38.1 mm (1.5 inch) I.D. media cores.

• Asian Language support with printer configuration options for the large Simplified and Traditional

Chinese, Japanese, or Korean character sets.

10

Page 11

Zebra Label Printing Solution

The printer is just one of three (3) parts of a printing solution. To print; you need a printer (ZD200 Series),

compatible media (direct thermal media), and software (driver, applications or programming) to tell the

printer what to do and print. The printer can print without being connected to other devices or systems.

The media may be labels, tags, tickets, receipt paper, fan-fold stacks, tamper proof labels, etc.

Zebra assists you with label design and print with the free label and form design software: ZebraDesigner

for Windows PC operating systems.

The Zebra web site or your reseller will be able to help you identify media for your desired use case.

Modes of Printing

You can operate this printer in many different modes and media configurations:

• Direct thermal printing (which uses heat sensitive media to print).

• Standard Tear-Off mode allows you to tear off each label/receipt or batch print a strip of labels and

tear them off after it is printed.

• Label Dispense Mode: If an factory optional dispenser is installed, the backing material can be

peeled away from the label as it is printed. After this label is removed, the next one is printed.

• Media Cutting: If a factory optional media cutter is installed, the printer can cut the label liner

between labels, receipt paper or tag stock.

• Stand-alone: The printer can print without being directly connected to a computer. An auto running

label format/form (programming based).

• Shared network printing: Printers configured with factory installed Ethernet (LAN) and Wi-Fi

interface options include an internal print server.

Introduction

11

Page 12

What’s in the Box?

After unpacking, make sure you have all parts shown below. Follow the procedures for inspecting the

printer to familiarize yourself with printer parts so you can follow the instructions in this book.

Introduction

Power Supply

What is Not Included in the Box

Print Media

(Labels, Paper, etc.)

USB CablePrinter

Power Cord varies by locale or region

Printer Documentation

12

Page 13

Unpack and Inspect the Printer

When you receive the printer, immediately unpack it and inspect for shipping damage.

• Save all packing materials.

• Check all exterior surfaces for damage.

• Open the printer and inspect the media compartment for damage to components.

If you discover shipping damage upon inspection:

• Immediately notify the shipping company and file a damage report. Zebra Technologies Corporation

is not responsible for any damage to the printer incurred during shipment, and will not cover the

repair of this damage under its warranty policy.

• Keep all packaging material for shipping company inspection.

• Notify your authorized Zebra

See the Zebra Web site for ‘How To’ videos on packing and unpacking your printer. Use this link to get to

your Online printer support resources:

Introduction

®

reseller.

ZD200 Series Direct Thermal Printer — www.zebra.com/zd200d-info

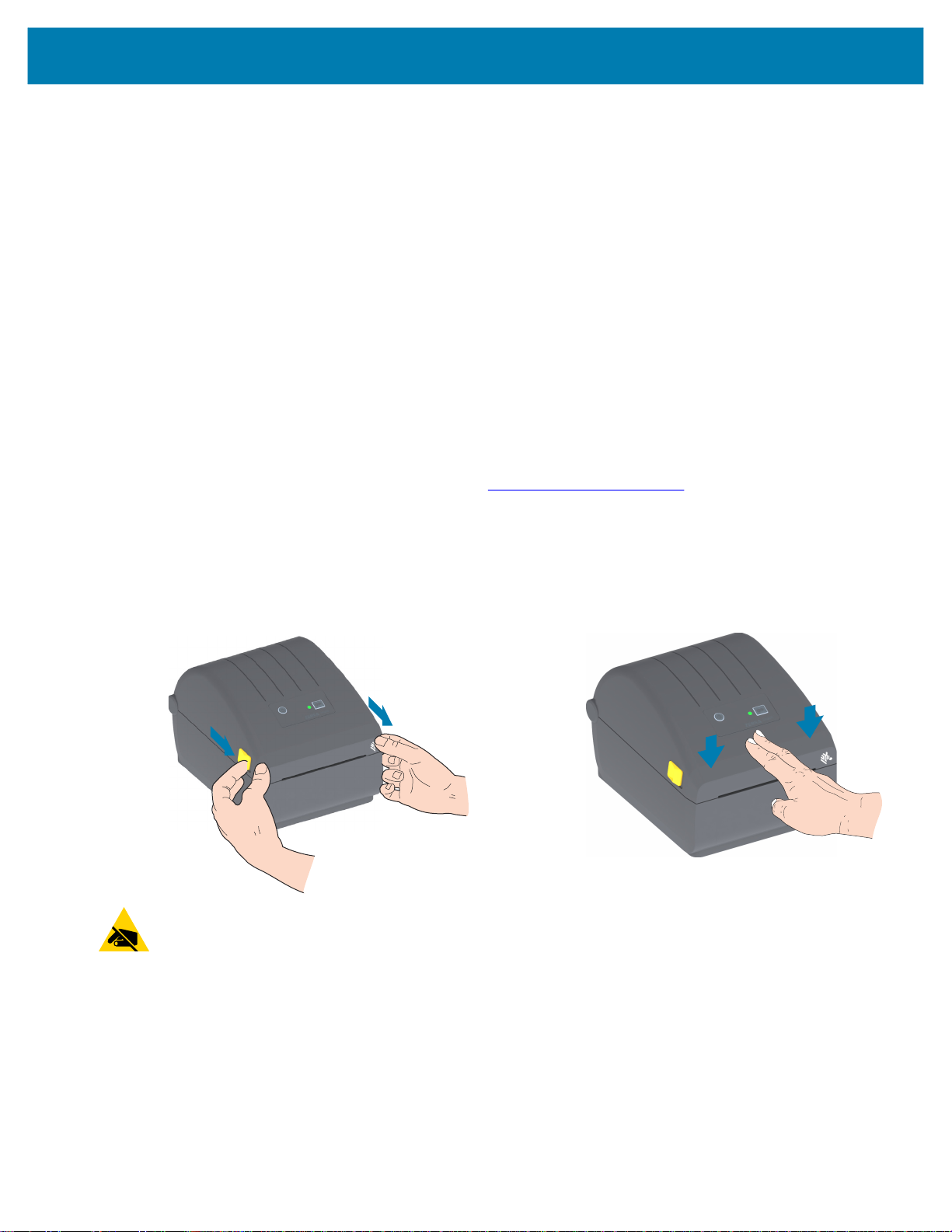

Opening and Closing the Printer

Open: To access the media compartment, pull the release latches towards you and lift the cover. Check

the media compartment for loose or damaged components.

Close: Lower the top cover. Press down in the middle of the cover in front until the cover snaps closed.

ESD Caution • The discharge of electrostatic energy that accumulates on the surface of the human body or other

surfaces can damage or destroy the printhead and other electronic components used in this device. You must observe

static-safe procedures when working with the printhead or the electronic components under the top cover.

Opening Closing

13

Page 14

Printer Features

This section will help you identify features of these Zebra® 4-inch ZD200 Series Direct Thermal label

printers. ‘How to’ videos on the Zebra Web site include a Printer Features video; as well as; other printer

setup and task specific videos. Links to these printers are:

• ZD200 Series Direct Thermal Printer — www.zebra.com/zd200d-info

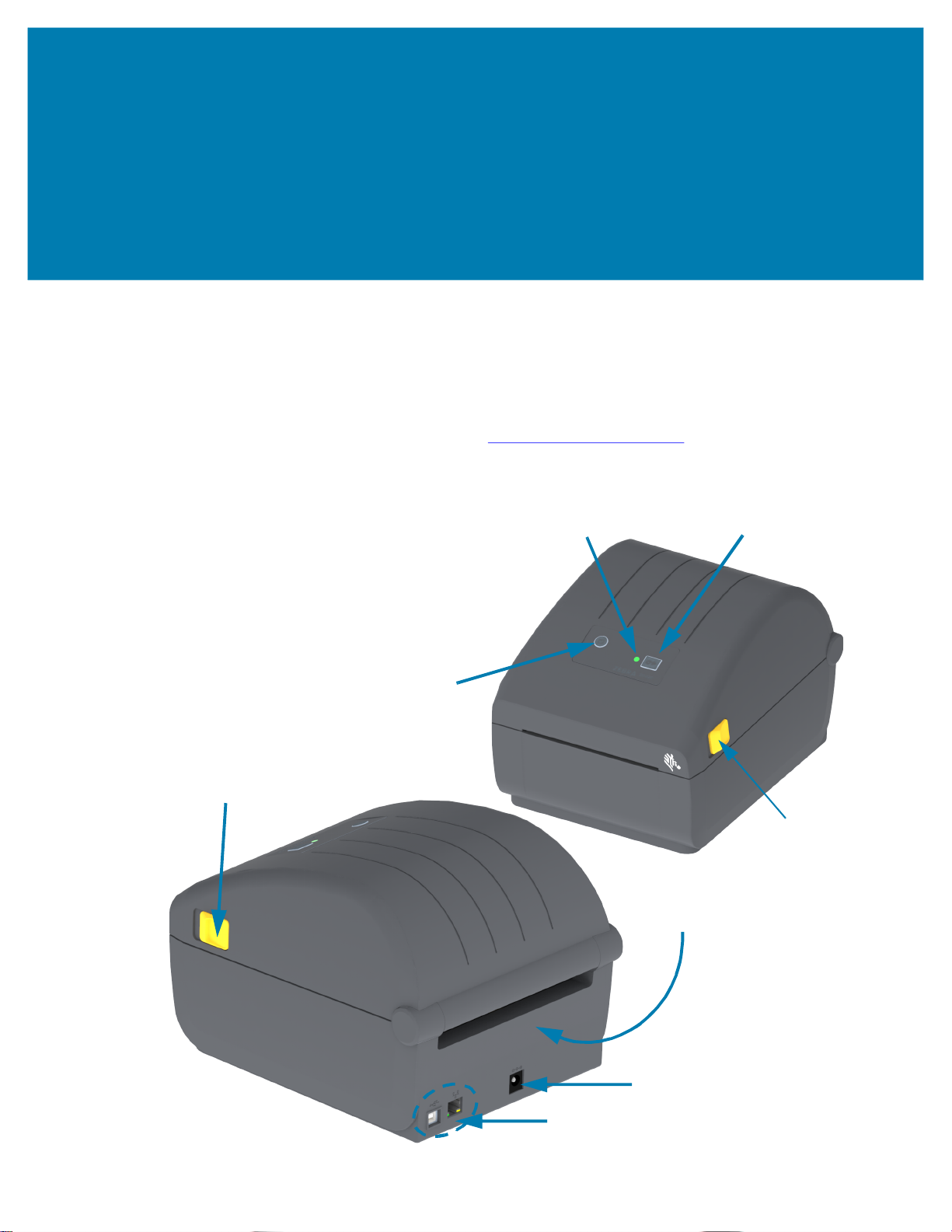

External Printer Features

Release Latch

Power

Button

STATUS Indicator

FEED Button

Release Latch

14

Fan-Fold Media

Entry Slot

DC Power Receptacle

Interface Access

Page 15

Printer Features

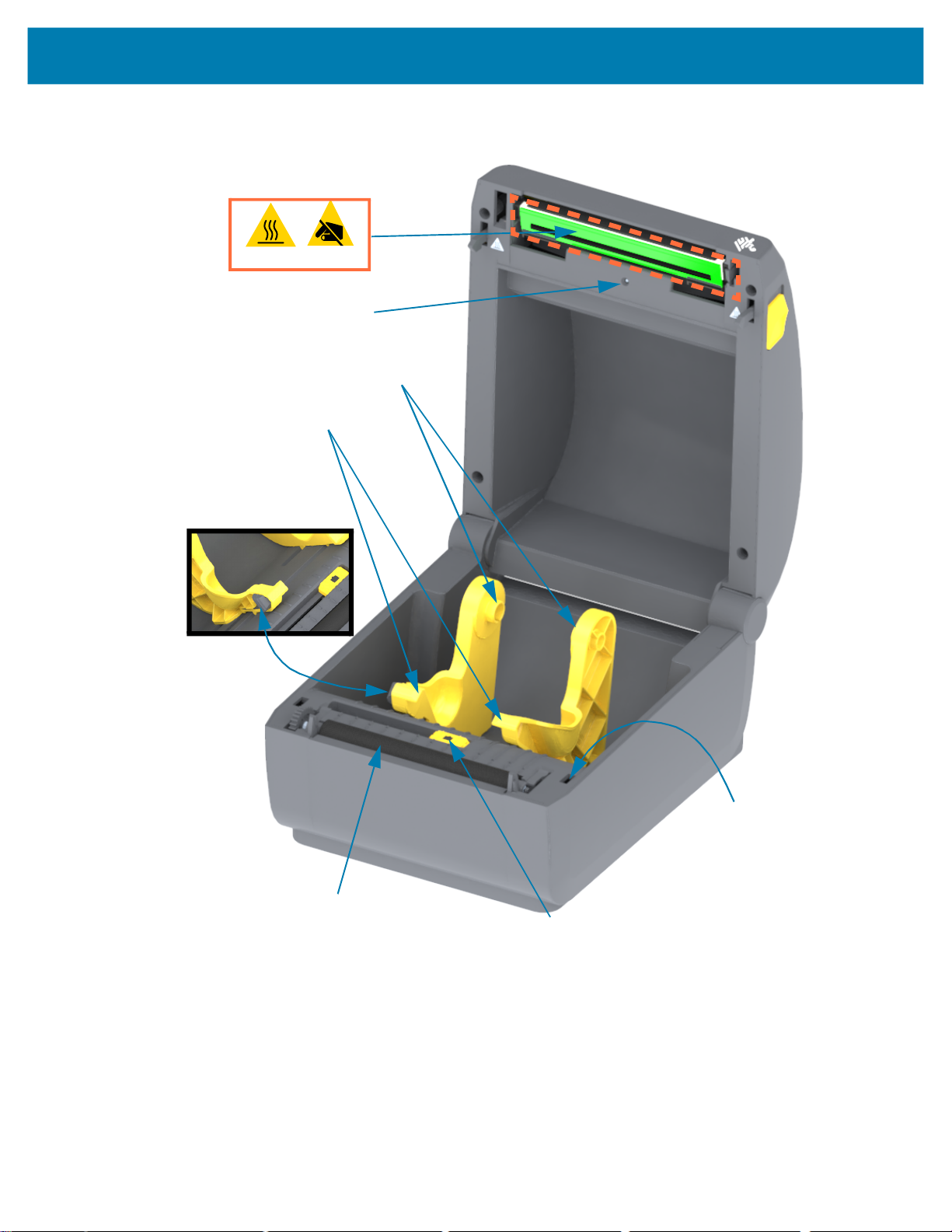

Inside the ZD200 Series Direct Thermal Printers

Printhead

Upper Web

(Gap) Sensor

Roll Holders

Media Guides

Media Guide Stop

Platen (Drive) Roller

Head-Up Sensor

(inside)

Movable Sensor

(Black Mark and Lower Web/Gap)

15

Page 16

Printer Features

Label Dispenser Option (factory installed only)

Label Taken

Sensor

Door Latch

Cutter Option (factory installed only)

Label Liner

Exit Area

Label Peel Bar

Dispenser Door

Peel Roll

Media Exit Slot

Cutter Module

16

Page 17

Controls and Indicators

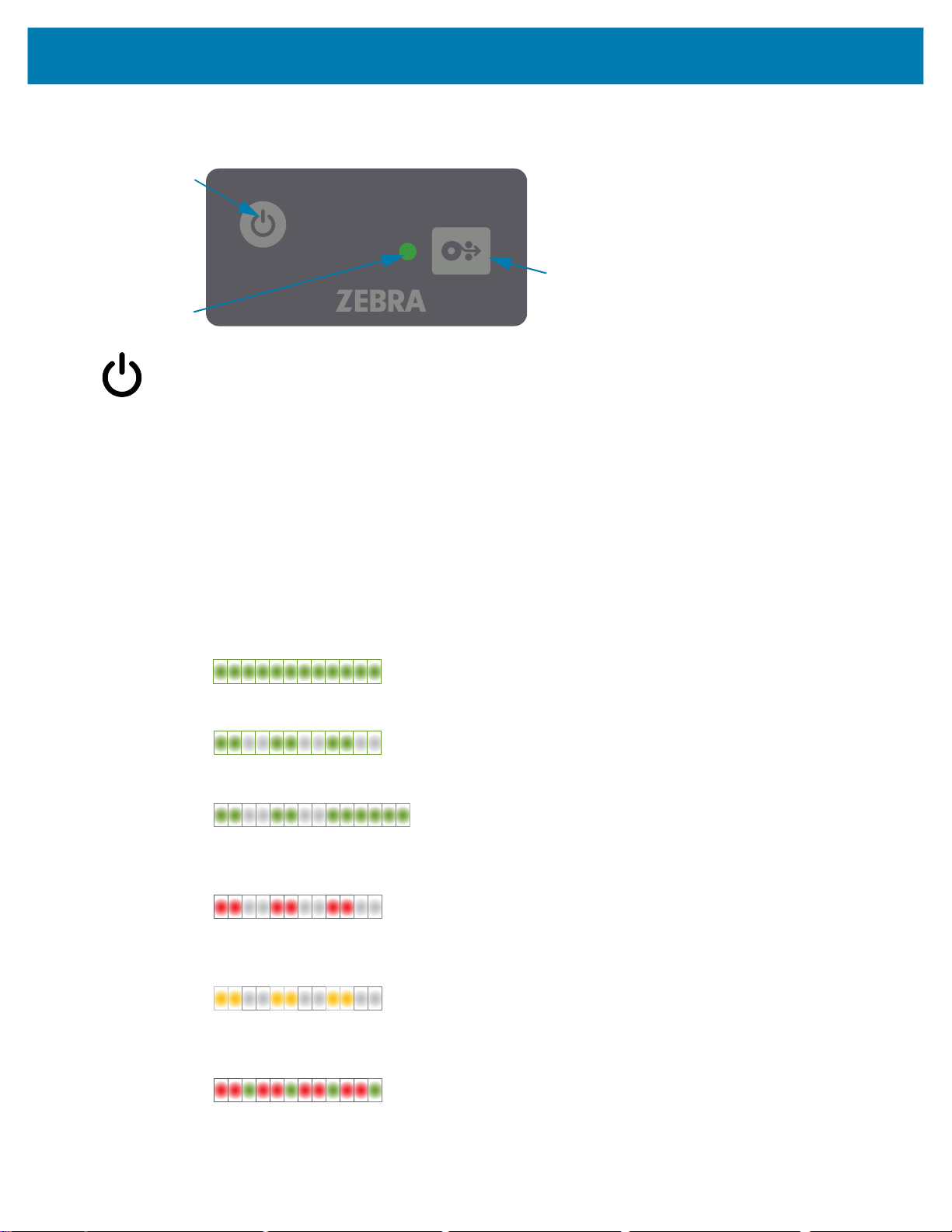

User Interface

The user controls are found on the front on top of the printer. This interface provides basic control and

status needed by an operator.

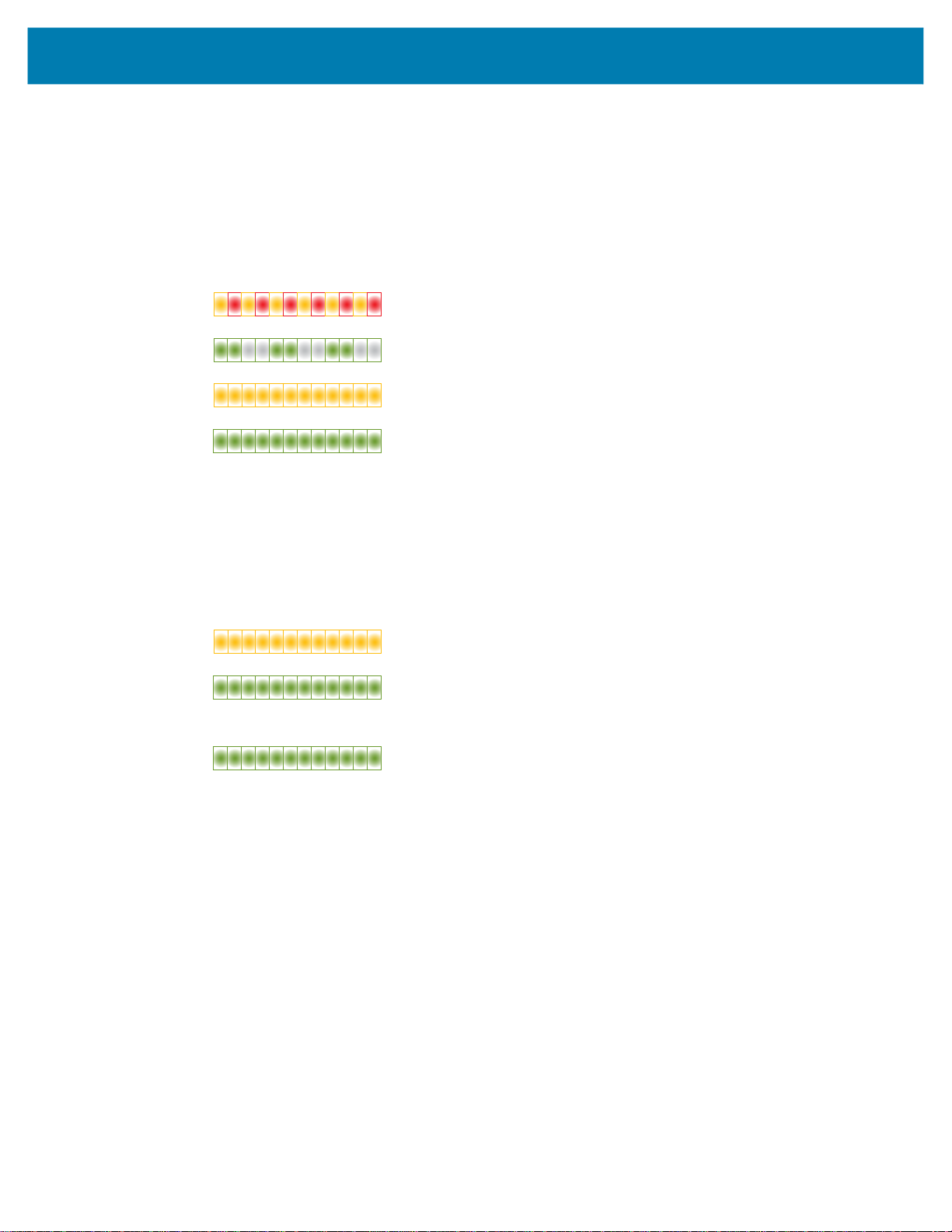

The interface consists of a Power button, a multi-function FEED button, and a single tri-color STATUS

Indicator. The buttons are modal and change behaviors depending upon what the print is doing. Using the

two (2) buttons and the STATUS Indicator light, an operator can perform a variety of functions, such as:

• Calibration of media (labels, paper, tags, etc.)

• Print a Configuration Report

• Reset the Printer Settings to Default Configuration

• Enter a ‘Forced’ firmware download mode.

• Enter and exit Diagnostic (Dump) Mode used to debug programming and printer communications.

Printer operating status is reported by a single indicator light. The STATUS Indicator light provides a range

of printer status.

• This interface supports operator tasks of replacing printing supplies (labels, receipt paper, etc.).

• Status indicator lights typically use color to show the operator the functional status of the printer.

The STATUS Indicator light may be Off (not lit), it can Flash (blink), or be ON.

• Red is ‘needs attention’.

• Green is for ‘ready’ or ‘functioning’.

• Amber (orange/yellow) is for busy or active process (boot-up, over-temperature cooling cycle,

etc.).

• The STATUS Indicator can be blinking (off and on) and alternate between colors in a variety of

patterns that denote various printer activities, and operational status.

17

Page 18

User Interface Controls

ZD220

6HF 6HF 6HF 6HF

6HF 6HF 6HF 6HF

6HF 6HF 6HF 6HF

6HF 6HF 6HF 6HF

6HF 6HF 6HF 6HF

1

2

1. Power Button — Turns power ON and OFF in the printer.

•

Power ON — Press the Power button once for less than two (2) seconds and the printer turns on.

The STATUS Indicator light will turn on Amber while the printer does self diagnostics, configuration

checks, and integrate optional components which will take several seconds to complete.

The Status Indicator will turn solid GREEN (or Flashing Green) indicating the printer is ready for

normal print operations.

•

Power OFF / Shutdown — Press and Hold the button for 4-9 seconds. The printer will turn

OFF.

Controls and Indicators

3

2. STATUS Indicator — The STATUS Indicator for provides the operator basic printer health and

operational status. This indicator is also serves as a power indicator. These are STATUS Indicator light

behaviors for normal printer operation.

• Green — Printer Ready for print and data activity.

6HF 6HF 6HF 6HF

• Flashing Green — Normal Operation. Printer may be communicating or processing data.

• Double Flashing Green (2 short flashes of green followed by a long green) — Printer is Paused.

• Flashing Red — Media Alert. The printer is out of media (paper, labels, tags, etc.), media sensing

failure, printer is open, or a cut error.

• Flashing Amber — Over Temp. The printhead is over temperature and must cool to resume

printing.

• Flashing Red, Red, Green — Critical Over Temp (temperature) — The printhead or motor has

failed.

18

Page 19

3. FEED (Advance) Button — The FEED button is a multi-function button. With the printer ON,

6HF 6HF 6HF 6HF

6HF 6HF 6HF 6HF

6HF 6HF 6HF 6HF

pressing the FEED button longer than two (2) seconds initializes the Power On FEED Button modes

• Feed One Label — Pressing the FEED button [and releasing before two (2) seconds] when the

printer is not printing, causes the printer to advance media one (1) blank form/format length (label,

receipt, tag, ticket, etc.).

• Reprint Last Label (activated via a SGD command: ezpl.reprint_mode or ZPL ^JJ command

parameters D and E use the FEED button as the ‘applicator signal’) - The intended purpose of this

feature is to allow reprint of a failed media print. If the printer runs out of media (paper, labels, etc.),

then the printer can re-print the last label (print form/format). The print buffer that stores the print

image available for reprint is cleared when the printer gets turned off or is reset.

• Pressing the FEED button while printing will stop print activities and place the printer into a

‘Pause’ state. The printer will complete printing a label that is printing before it pauses.

• Pressing the FEED button while in Pause state will return the printer to normal operation of the

first three. If printing a multi label (form/format) job or another print job is waiting to print in the print

queue, then the printer will resume printing.

FEED Button Modes

The printer includes some advanced features that are accessed via the FEED button. The operator

observes the STATUS Indicator light pattern changes to select each Advanced mode.

Controls and Indicators

FEED Button Modes - Power ON

The Power ON advanced modes are designed to help with printer configuration and print setup. By

pressing and holding the FEED button when the printer is ON and Ready (green STATUS Indicator) for

two (2) seconds, the printer enters Advanced mode. These Advanced modes are:

• Printing a Configuration Report (One Single Flash)

The STATUS Indicator flashes once. If you release the FEED button here, a Configuration Report

prints and exits Advanced mode.

• Media Calibration (Two Flash) - Calibrates the printer for the installed media (labels, paper, tags,

etc.) using Smart Cal routine to set media (label) sensing parameters

Continue holding the FEED button, the STATUS Indicator will flash twice. If you release the FEED

button here, the printer begins measuring media and then setting the start of the media position and

exits Advanced mode.

• Reset Factory Defaults (Three Flash) - Resets the printer to the factory default settings.

Continue holding the FEED button, the STATUS Indicator will flash three times. If you release the

FEED button here, the printer Resets to Factory Defaults (the equivalent of the ZPL ^JUN command)

and exits Advanced mode.

• Return to normal operating mode. Release the FEED Button two (2) or more seconds after the

third flash sequence.

19

Page 20

Controls and Indicators

6HF 6HF 6HF 6HF

6HF 6HF 6HF 6HF

6HF 6HF 6HF 6HF

6HF 6HF 6HF 6HF

6HF 6HF 6HF 6HF

6HF 6HF 6HF 6HF

6HF 6HF 6HF 6HF

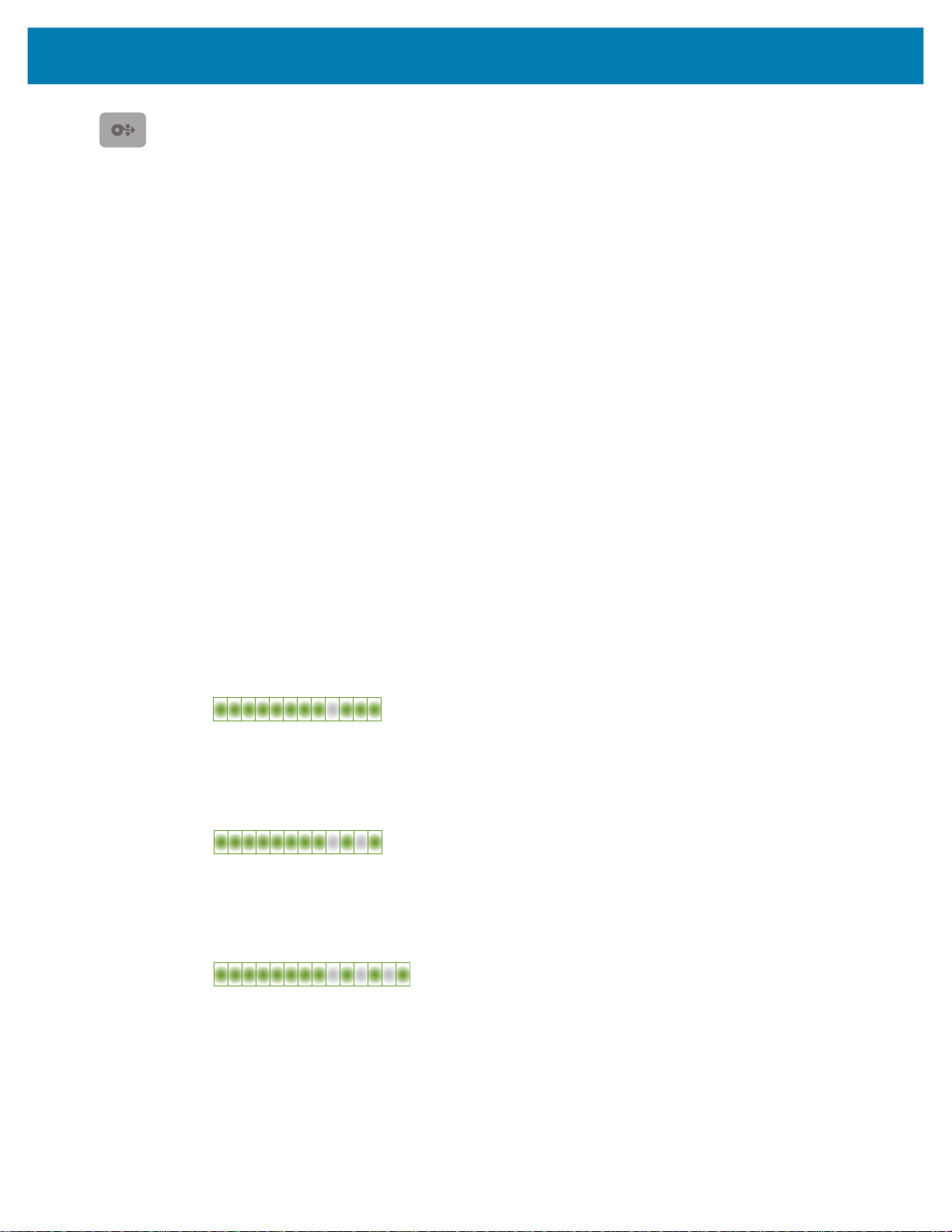

FEED Button Modes - Power OFF

The Power OFF advanced modes are used to update and troubleshoot the printer. By pressing and

holding the FEED button when the printer is turned ON, the printer enters Forced Firmware Download

mode.

Load a roll of media for printing.

• Forced Download Mode

Waiting

Data Transferring

Booting Up

Ready - Firmware Updated

The STATUS Indicator alternates Amber and Red. If you release the FEED button here, the printer

begins waiting for data to begin download (of the printer firmware file).

Your printer firmware may be configured to calibrate to the installed media and print a Configuration

Report.

• Begin Normal Printer Bootup

Continuing to hold the FEED Button for three (3) seconds the STATUS Indicator turns Amber,

releasing the FEED button here allows the printer to boot-up normally.

Booting Up

Ready

• Enter Data Diagnostics Mode

Continuing to hold the FEED Button for three (3) or more seconds the printer boot-up into Diagnostic

(Hex Data Dump). The FEED Button may be released at anytime after the three (3) seconds.

The printer prints:

***********************

* Entering Diag Mode *

***********************

• Return to normal operating mode. Release the FEED Button two (2) or more seconds after the

leaving the Data Diagnostic Mode or simply hold the FEED button down for five (5) or more seconds

after the STATUS indicator is green.

20

Page 21

Setup

This section assists you in setting up and operating your printer. The setup process can be broken down

into two (2) phases: hardware setup and host system (software/driver) setup. This section covers the

physical hardware setup needed to print your first label.

Printer Setup Overview

• Place the printer in a safe location with access to power and where you can connect interface cables

or wirelessly to the system.

• Attach the printer and power supply to a grounded AC power source.

• Select and prepare media for your printer.

• Load the media.

• Turn the printer ON. Calibrate the media with a SmartCal Media calibration.

• Print a ‘Configuration Report’ to verify basic printer operation.

• Turn the printer OFF.

• Choose a method to communicate via a wired or wireless connection to your printer. Available wired

local connections are:

• USB port

• Factory Installed Ethernet (LAN) Option

• Attach the printer cable to the network or host system (printer OFF).

• Begin second phase of printer setup: typically Setup for Windows

®

OS.

21

Page 22

Select a Location for the Printer

The printer and media need a clean safe area with moderate temperatures to have optimal print

operations.

Select a location for the printer that meets these conditions:

• Surface: The surface where the printer will be located must be solid, level, and of sufficient size and

strength to hold the printer with media.

• Space: The area where the printer will be located must include enough space for opening the

printer (media access and cleaning), and for printer access to connectivity and power cords. To

allow for proper ventilation and cooling, leave open space on all sides of the printer.

Important • Do not place any padding or cushioning material under or around the base of the printer because this

restricts air flow and could cause the printer to overheat.

• Power: Put the printer close to an easily accessible power outlet.

• Data Communication Interfaces: Please ensure that cabling and Wi-Fi or Bluetooth radios do not

exceed the maximum distance specified by the communication protocol standard or product data

sheet for this printer. Radio signal strength can be reduced by physical barriers (objects, walls, etc.).

• Data Cables: Cables should not be routed with or near power cords or conduits, fluorescent lighting,

transformers, microwave ovens, motors or other sources of electrical noise and interference. These

interference sources may cause problems with communications, host system operation, and printer

functionality.

• Operating Conditions: Your printer is designed to function in a wide range of environments.

• Operational Temperature: 40° to 105°F (5° to 41°C)

• Operational Humidity: 10 to 90% non-condensing

• Non-Operational Temperature: -40° to 140°F (-40° to 60°C)

• Non-Operational Humidity: 5 to 85% non-condensing

Setup

22

Page 23

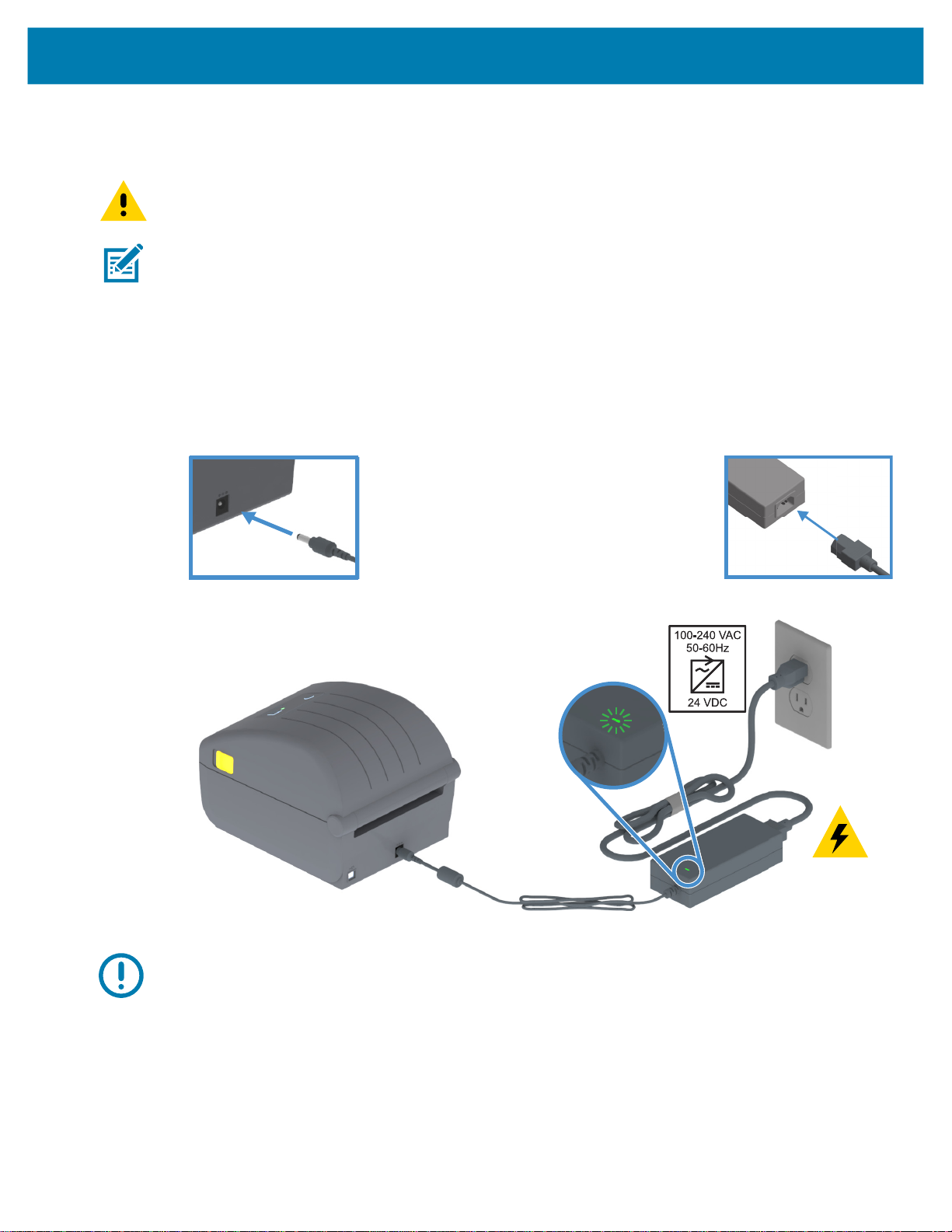

Attaching Power

o

p

q

n

Caution • Never operate the printer and power supply in an area where they can get wet. Serious personal injury could

result!

Note • Set up your printer so that you can handle the power cord easily if needed. Some processes for setup or

troubleshooting issues may ask you to remove power. Separate the power cord from the power supply receptacle or

AC electrical outlet to make certain the printer cannot carry electrical current.

1. Plug the power supply into the printer’s DC power receptacle.

2. Insert the AC power cord into the power supply.

3. Plug the other end of the AC power cord into an appropriate AC electrical outlet. Note that AC outlet

end of the power cord’s plug type can vary by region.

4. The active power light will turn on green if power is on at the AC outlet.

Setup

Important • Ensure the appropriate power cord with a three (3) prong plug and an

IEC 60320-C13 connector are used at all times. These power cords must bear the relevant

certification mark of the country in which the product is being used.

23

Page 24

Getting Ready to Print

The printer setup cannot be completed without media. The media may be labels, tags, tickets, receipt

paper, fan-fold stacks, tamper proof labels, etc. Ideally choose the same media used for normal operation.

This will help you identify any setup and real application issues while using this guide. The printer does not

come with media.

The Zebra Web site or your reseller may be able to help you select the right media for your intended

printing application. Find media at: www.zebra.com/supplies

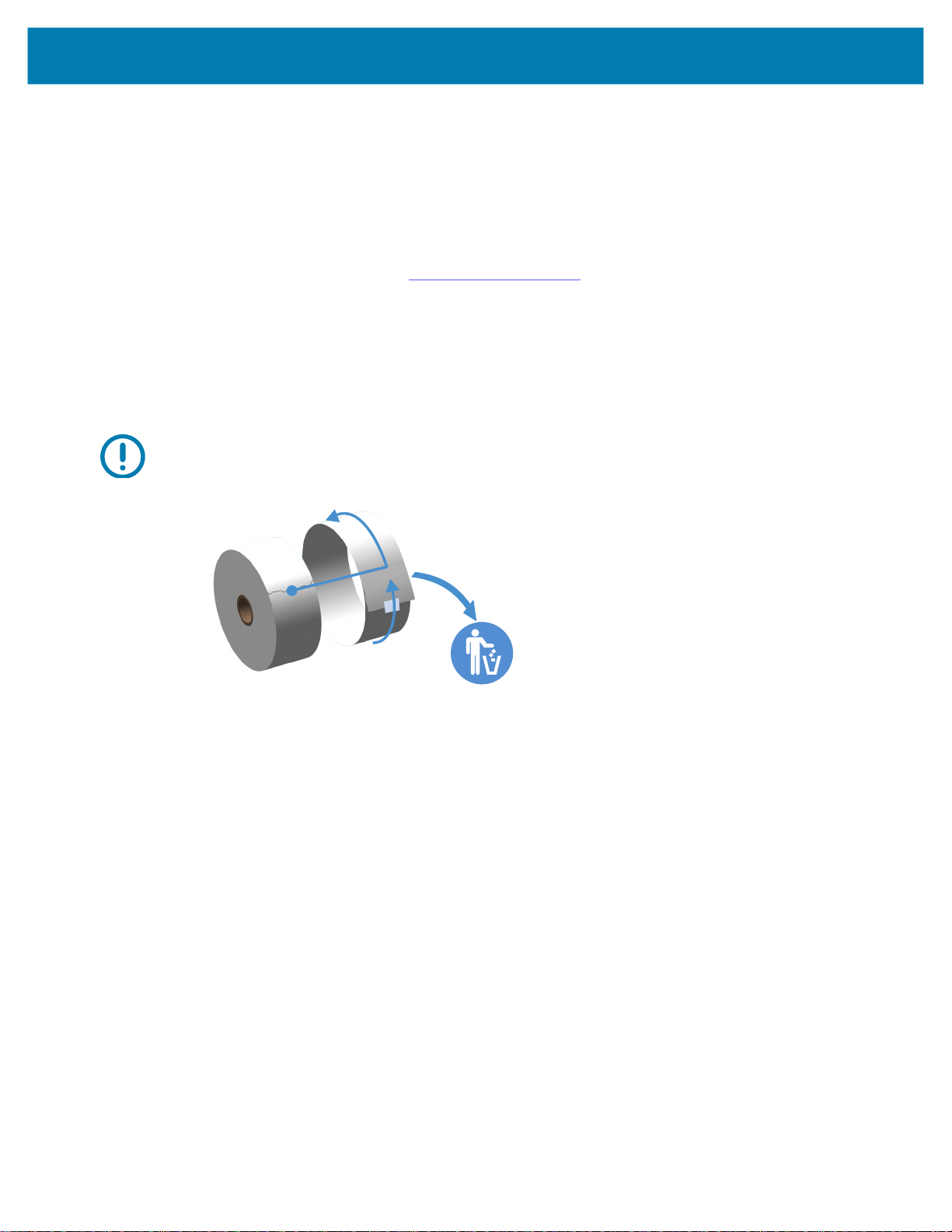

Preparing and Handling Media

Careful handing and storage of your media is important in order to maximize print quality. If the media

becomes contaminated or dirty, it can damage the printer and cause defects in the printed image (voids,

streaks, discoloration, compromise the adhesive, etc.).

Important • During manufacturing, packaging, handling and storage, the outside length of media may become dirty or

contaminated. We recommend removing the outside layer of the media roll or stack. This will remove any

contaminants which might be transferred onto the printhead during normal operation.

Setup

Media Storage Tips

• Store media in a clean, dry, cool, dark area. Direct thermal media is chemically treated to be heat

sensitive. Direct sunlight or heat sources may ‘expose’ the media.

• Do not store media with chemicals or cleaning products.

• Leave media in its protective packaging until it is going to be put in the printer.

• Many media types and label adhesives have a ‘shelf life’ or expiration date. Always use the oldest,

viable (non-expired) media first.

24

Page 25

Loading Roll Media

The printers support the three basic types of media:

• Continuous (receipt, etc.) with no marks to define print length,

• Marked media (black lines, black marks, notches, or holes) to define print length

• Label media that uses the sensor to look through the media backing (liner) to see the beginning and

end of labels on the roll.

The printer utilizes two (2) sensing methods to accommodate a wide range of media

• Center area transmissive sensing for continuous media and gap/web label media.

• Half width movable (reflective) sensing for print format (length) using black marks, black lines,

notches or holes.

Setting Media Sensing by Media type

• For web/gap media, the printer senses the differences between the label and the liner to

determine the print format length.

•

For continuous roll media, the printer only senses the media’s characteristics. The print

format’s length is set by programming (driver or software) or the last stored form’s length.

•

For black mark media, the printer senses the beginning of the mark and the distance to the start

of the next black mark to measure the print format length.

•

For other common media and setting variations, see one of the following:

• Using the Label Dispenser Option after you have loaded media using this procedure.

• See Printing on Fan-Fold Media.

Setup

25

Page 26

Instructions for media loading:

This procedure works for Tear-Off (standard bezel), Label Dispense and Media Cutting printer options.

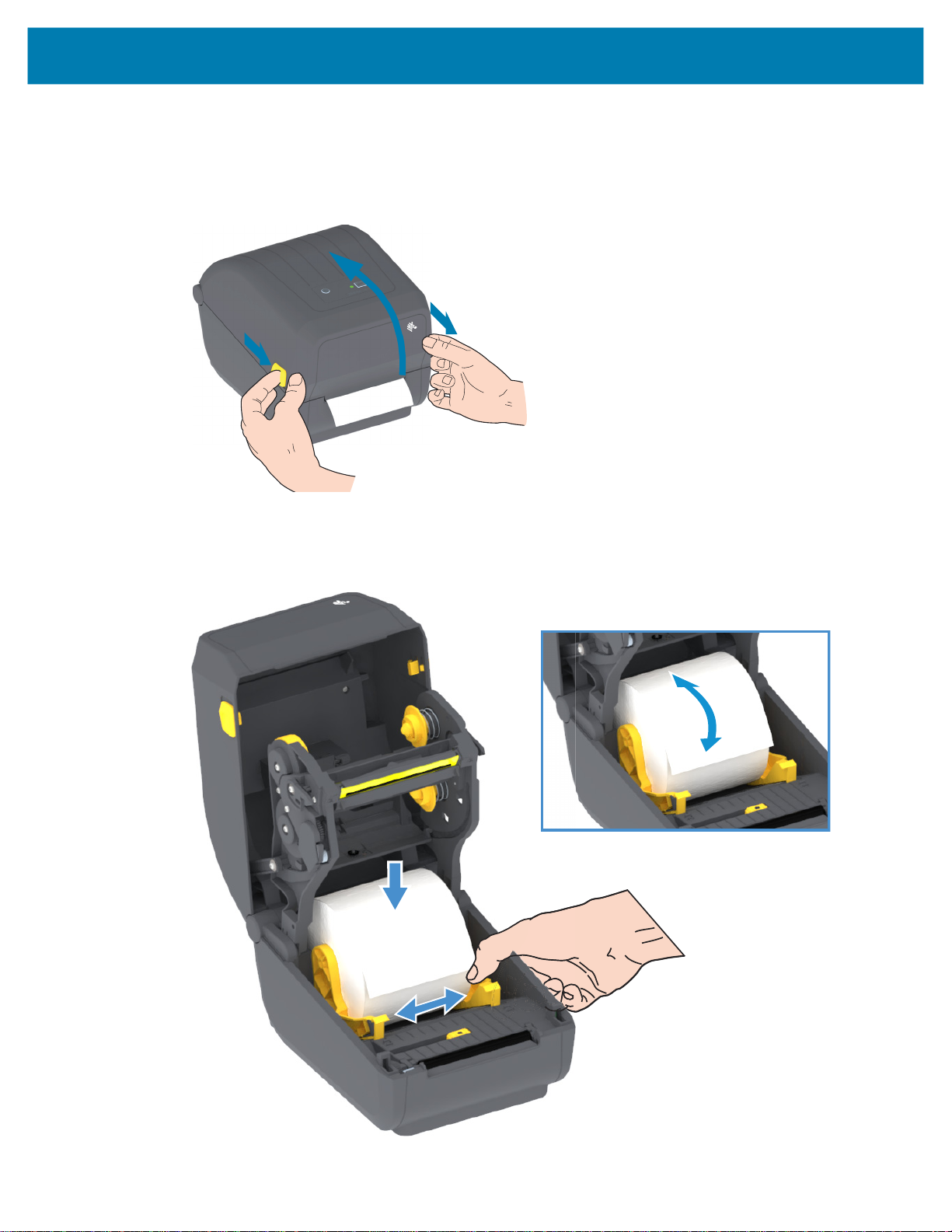

1. Open the printer. Pull the release latch levers toward the front of the printer.

Setup

2. Open the media roll holders. Orient the media roll so that its printing surface will face up as it passes

over the platen (drive) roller. Pull the media guides open with your free hand and place the media roll on

the roll holders and release the guides. Verify the roll turns freely. The roll must not sit in the bottom of

the media compartment.

26

Page 27

Setup

3. Pull the media so that it extends out of the front of the printer.

4. Push the media under both of the media guides.

27

Page 28

Setup

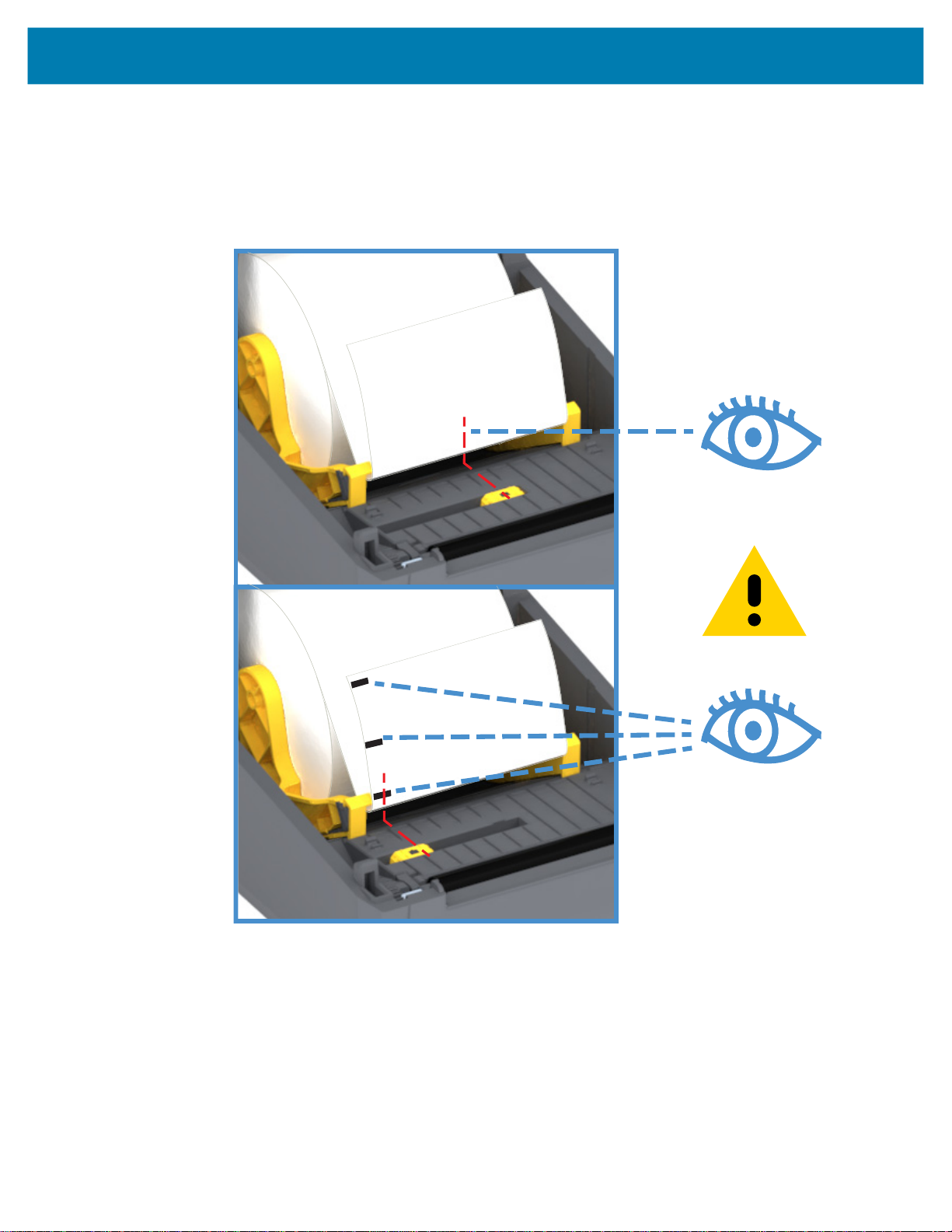

5. Flip the media up and align the movable media sensor for your media type.

• For continuous roll receipt type media or label media without black marks or notches, align

the media to the default center position.

• For black mark (black line, notches or holes) backed media, adjust the sensor position so

the sensor aligns to the center of the black mark. Avoid the center area of the media to only use

black mark sensing for operation with black marks.

Default - Web (Gap) Sensing

Standard Operating Position

28

Off Center

Black Mark Sensing Only

Page 29

Setup

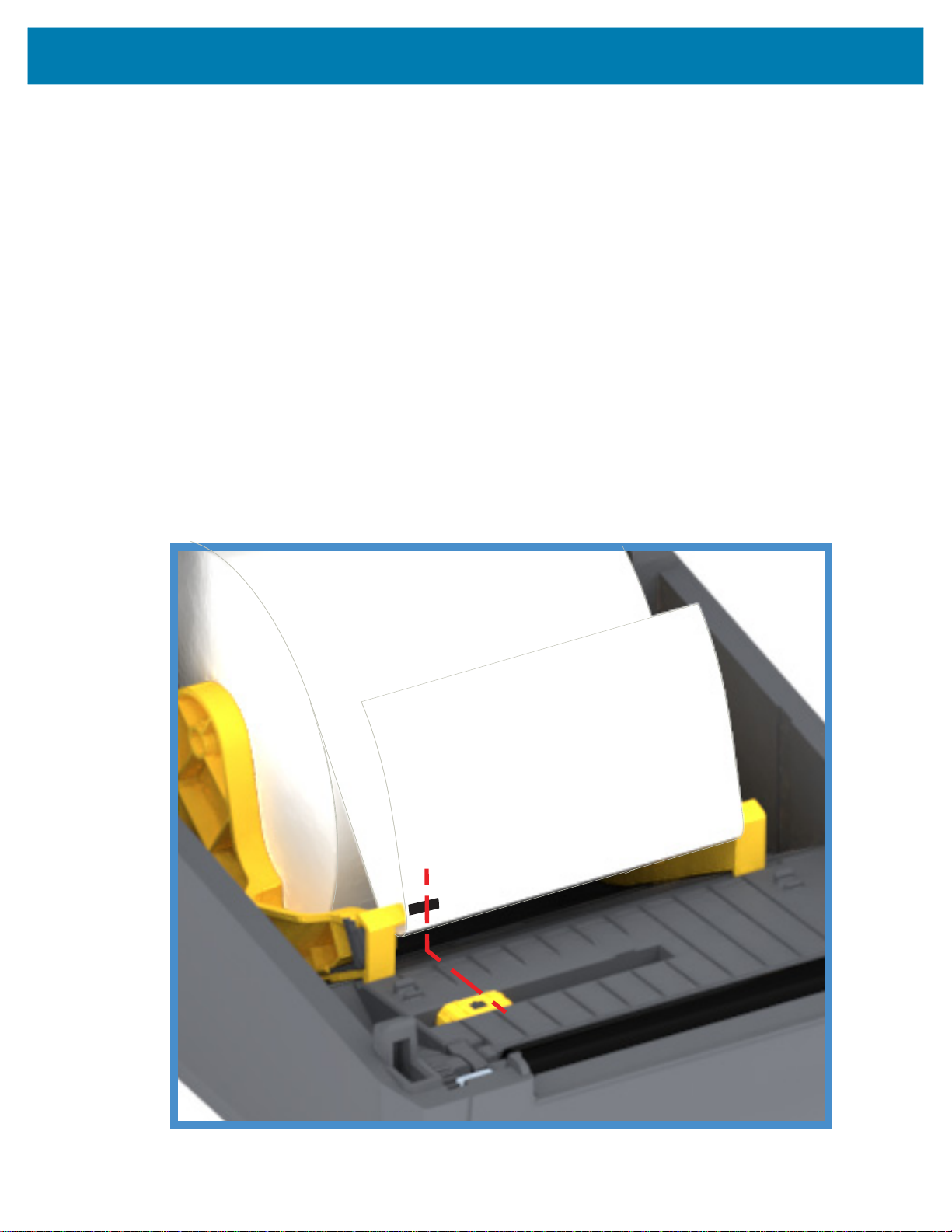

Using the Movable Sensor

The movable sensor is a dual function sensor. It provides transmissive (sees through media) and reflective

media sensing. The printer can use either sensing method, but not both at the same time.

The movable sensor has single sensor position for Web/Gap media, the Default position.

The movable sensor allows the printer to use media with black marks or notches (holes through the

media) on the back side of the media (or media liner). The sensor aligns to the middle of black marks or

notches not in the center of the media roll to avoid Web/Gap sensing array.

Adjusting the Movable Sensor for Black Marks or Notches

The black mark sensing looks for non-reflective surfaces such as black marks, black lines, notches or

holes on the back of the media which do not reflect the sensor’s near infrared light beam back to the

sensor’s detector. The sensor light and its black mark detector are next to each other under the sensor

cover.

Position the movable sensor’s alignment arrow to the middle of the black mark or notch in the underside of

the media. Sensor alignment should be set as far as possible from the edge of media but where 100% of

the sensor window is covered by the mark. When printing, the media can move from side to side ±1mm

(due to media variations and edge damage due to handling). Notches cut into the side of the media can

also become damaged.

29

Page 30

Loading Roll Media (continued)

1. Cutter Models - For printers with the optional cutter module installed, thread the media through cutter’s

media slot and pull it out the front of the printer.

Setup

2. Close the printer. Press down until the cover snaps closed.

You may need a calibrate your printer for the media. The printer’s sensors need to adjust to sense the

label, the liner, and the distance between labels to operate properly. When reloading the same media

(size, vendor, and batch), you can just press the FEED (Advance) button once to prepare the media for

printing.

30

Page 31

Run a SmartCal Media Calibration

The printer needs to set the media parameters prior to printing for optimal operation. The printer will

automatically determine media type (web/gap, black mark/notch, or continuous) and measure media

characteristics.

Important • After the initial calibration to a specific media is completed, it is not required to perform additional

calibrations each time the media is replaced. The printer automatically measures the media to adjust for small changes

in the media characteristics while printing.

Pressing the FEED (Advance) button once or twice after a new roll (from the same batch) of media has been installed,

will synchronize the labels. It is then ready to continue printing.

SmartCal Procedure

1. Make sure the media is loaded properly in the printer and the top cover of the printer is closed.

2. Press the POWER button to turn the printer on.

3. Once the printer is in the Ready state (STATUS Indicator is solid green), press and hold the FEED

button for two (2) seconds and the STATUS Indicator flashes the first time. Continue to hold the FEED

button until it has flashed 2 more times and immediately release the FEED button.

Setup

4. The printer will measure a few labels and adjust media sensing levels.

5. When the printer stops, the STATUS indicator will turn solid green.

31

Page 32

Setup

Test Printing with the Configuration Report

Before you connect the printer to a computer, make sure that the printer is in proper working order. You

can do this by printing a configuration report. The information on the Configuration Report’s printout may

be helpful with printer installation and troubleshooting of your printer.

1. Make sure the media is loaded properly in the printer and the top cover of the printer is closed.

2. Turn the printer ON.

3. Once the printer is in the ready state (STATUS indicator is solid green), press and hold the FEED

button for approximately two (2) seconds and the STATUS Indicator blinks off once and release.

4. The Printer and Network Configuration Reports (shown below) will be printed.

5. When the printer stops, the STATUS Indicator will turn solid green.

If you cannot get these reports to print, then see Troubleshooting.

32

Page 33

Detecting a Media Out Condition

When you run out of media, your printer will report a ‘Media Out’ condition with the STATUS Indicator

flashing red. This is part of the normal media usage cycle.

“Media Alert’

Flashing Red

Setup

Recovering from a Media Out condition

1. Open the printer.

2. Observe that the media is at the end or nearly at the end of the roll with a label missing from the liner.

3. Remove the remaining media and roll core.

4. Insert a new roll of media. See Loading Roll Media.

• If you are installing more of the same media, just load the new media and press the FEED

(Advance) button once to resume printing.

• If you are loading different media (size, vendor, or even batch is different), then reloading media

followed by a SmartCal is needed to ensure optimal operation.

• Note that changing media size (length or width) usually requires you to change the programmed

media dimensions or the active label format in the printer.

Important • Sometimes a label may be missing some where in the middle of your roll of labels (not at the end of

media). This will also cause a ‘Media Out” condition. To recover, just pull the media past the missing label until the next

label is over the platen roller. Close the printer. Press the FEED (Advance) button once. The printer will resynchronize

the label position and will be ready to resume printing.

33

Page 34

Setup

Connecting your Printer to a Computer

The printer supports a variety of interface options and configurations. These include:

• Universal Serial Bus (USB 2.0) interface - Standard.

• Ethernet (LAN) - Factory Installed Option.

• Internal Wi-Fi (802.11ac) and Bluetooth Classic 4.1 (3.0 Compatible) - Factory Installed Option.

• WiFi models include Bluetooth Low Energy (low speed connection) for printer configuration using

software running on an Android or iOS device.

Pre-install Windows® Printer Drivers

Install the Zebra Setup Utilities (ZSU) before applying power to the printer connected to the PC. The

utility installs the Zebra Windows drivers first. The ZSU installation wizard will then prompt you turn on the

printer. Follow the instructions to complete your printer installation.

The Zebra Setup Utility is designed to assist you with installing your printer. The cabling and unique

parameters for each of these physical printer communication interfaces is discussed in the following pages

to assist you with making configuration setup choices prior to and immediately following applying power.

The Zebra Setup Utilities configuration wizards will instruct you to turn the printer’s power on at the

appropriate time to complete the installation of your printer.

For more details on configuring network (Ethernet or Wi-Fi) and Bluetooth communication, see the

following guides:

• Wired and Wireless Print Server User Guide

• Bluetooth Wireless Guide

Interface Cable Requirements

Data cables must be of fully shielded construction and fitted with metal or metalized connector shells.

Shielded cables and connectors are required to prevent radiation and reception of electrical noise.

To minimize electrical noise pickup in the cable:

• Keep data cables as short as possible (1.83 m [6 foot] recommended).

• Do not tightly bundle the data cables with power cords.

• Do not tie the data cables to power wire conduits.

Important • This printer complies with FCC “Rules and Regulations,” Part 15, for Class B Equipment, using fully

shielded data cables. Use of un-shielded cables may increase radiated emissions above the Class B limits.

34

Page 35

USB Interface

USB

Universal Serial Bus (version 2.0 compliant) provides a fast interface that is compatible with your existing

PC hardware. USB’s “plug and play” design makes installation easy. Multiple printers can share a single

USB port/hub.

When using a USB cable, verify that the cable or cable packaging bears the “Certified USB ™ ” mark (see

below) to guarantee USB 2.0 compliance.

.

Setup

35

Page 36

Ethernet (LAN, RJ-45)

The printer requires UTP RJ45 Ethernet cable rated CAT-5 or better.

The printer has a built-in network print server. For more information on configuring your printer to run on a

compatible Ethernet based network, see the Wired and Wireless Print Server users guide. The printer

must be configured to run on your network. The print server on board your printer can be accessed through

the printer’s print server Web pages.

Setup

Ethernet Cable

(RJ45 Connector)

Ethernet Status/Activity Indicators

The Ethernet connector on the printer has two (2) status/activity indicators that are partially visible to

provide interface status at the connector.

LED Status Description

Both OFF No Ethernet link detected

Green 100 Mbps link detected

Green with the Amber flashing 100 Mbps link and Ethernet activity detected

Amber 10 Mbps link detected

Amber with the Green flashing 10 Mbps link and Ethernet activity detected

36

Page 37

Setup

Assigning an IP Address for Network Access

All devices on an Ethernet network (LAN and WLAN) require a network IP (Internet Protocol) address. The

printer’s IP address is needed to access the printer for printing and printer configuration. The five different

ways to assign an IP address are:

• DHCP (Dynamic Host Connection Protocol) - Default setting

• Zebra Setup Utilities (includes the ZebraDesigner Windows printer driver)

• Telnet

• Mobile Apps

• ZebraNet Bridge

DHCP for

Managed Networks

Print Server - Default User ID and Password

Personal Networks

The printer by default is set to operate on an Ethernet LAN or Wi-Fi network with DHCP. This setting is

intended primarily for personal networks. The network automatically provides a new network IP address

each time the printer is turned on. The Windows printer driver uses a Static IP address to connect to the

printer. The IP address set in the printer driver will need to be changed to access the printer if its assigned

IP address has changed after the printer’s initial installation.

Using the printer in a structured network (LAN or Wi-Fi) requires a network administrator to assign the

printer a Static IP address and other settings needed to operate on the network properly.

There are some features that require the default User ID and/or default password to access the printer’s

print server or if you have the Wi-Fi option in the printer. The Factory Default Values are shown below:

• User ID:

• Password:

admin

1234

Wi-Fi and Bluetooth Classic Wireless Connectivity Option

This guide covers basic configuration of your Internal Wi-Fi Print Server and Bluetooth Classic 4.X wireless

connectivity option.This manual only covers installing the Wi-Fi as part of the Wi-Fi and Bluetooth Classic

wireless connectivity option in the Setting Up the Wi-Fi Print Server Option. See the Zebra Web site for

Wired and Wireless Print Server User Guide for more information on the printer’s Ethernet operation.

This manual only covers installing the Bluetooth as part of the Wi-Fi and Bluetooth Classic wireless

connectivity option in the Bluetooth Option Configuration. See the Zebra Web site for Bluetooth Wireless

Guide for more information on the printer’s Bluetooth operation.

37

Page 38

Setup for Windows

The section helps you setup communications between your printer and the Windows operating system

environment.

Windows to Printer Communication Setup (Overview)

For supported Windows Operating systems (most common) with a Local (wired) connection:

1. Download the Zebra Setup Utilities from the Zebra web site.

• ZD200 Series Direct Thermal Printer — www.zebra.com/zd200d-info

2. Run’ the Zebra Setup Utilities from your Download directory.

3. Click on ‘Install New Printer’ and run the install wizard.

4. Select ‘Install Printer’.and select your printer’s model number from the list of ZDesigner printers.

5. Select the USB port and connect to the PC. Use the USB interfaces to assist Wizard guided

installation of networked or Bluetooth Classic (4.0).

6. Turn the printer ON and configure printer communications for your interface type.

7. Use the Windows driver to print a ‘Test Print’ to verify operation with Windows.

®

OS

38

Page 39

Setup for Windows® OS

install Windows® Printer Drivers

Install the Zebra Setup Utilities (ZSU) before applying power to the printer connected to the PC

(running a Zebra driver supported Windows operating system). The utility installs the Zebra Windows

drivers first. The ZSU installation wizard will then prompt you to apply the printer power. Continue to follow

the instructions to complete your printer installation.

The Zebra Setup Utility is designed to assist you setting up printer communication on a PC running

the Windows operating system. The cabling and unique parameters for each of these physical printer

communication interfaces is discussed in the following pages to assist you with making configuration setup

choices prior to and immediately following applying power. The Zebra Setup Utilities configuration wizards

will instruct you to turn the printer’s power on at the appropriate time to complete the installation of your

printer.

For more details on installing Ethernet (network) and Bluetooth interfaces:

• Wired and Wireless Print Servers User Guide

• Bluetooth Wireless Guide

Setting Up the Wi-Fi Print Server Option

This section covers basic configuration of your internal Wi-Fi Print Server option. For more detailed

information, refer to the Wired and Wireless Print Servers User Guide.

Note • The wireless radio option, which includes Wi-Fi, Bluetooth classic and Bluetooth low energy, is only available as

a factory installed configuration.

You may configure your printer for wireless operation in the following ways. This basic guide covers only

the first option, the Connectivity Wizard.

• Through the Connectivity Wizard, which writes a ZPL script for you. On the last screen of the

utility, you may choose to send the command directly to your printer, or you may choose to save the

ZPL script to a file. The saved ZPL file has several purposes:

• The file can be sent to the printer through any available connection (serial, parallel, USB, or

wired print server).

• The file can be resent to the printer after the network settings have been restored to factory

defaults.

• The file can be sent to multiple printers that will use the same network settings.

• Through ZPL script that you write yourself. Use the ^WX command to set the basic parameters for

security type. You can send the command through any available connection (serial, parallel, USB,

or wired print server). Refer to the ZPL Programming Guide for more information on this option.

• Through Set/Get/Do (SGD) commands that you send to the printer. Begin with wlan.security to set

the wireless security type. Depending on which security type that you select, other SGD commands

will be necessary to specify other parameters. You can send the commands through any available

connection (serial, parallel, USB, or wired print server). Refer to the ZPL Programming Guide for

more information on this option.

39

Page 40

Setup for Windows® OS

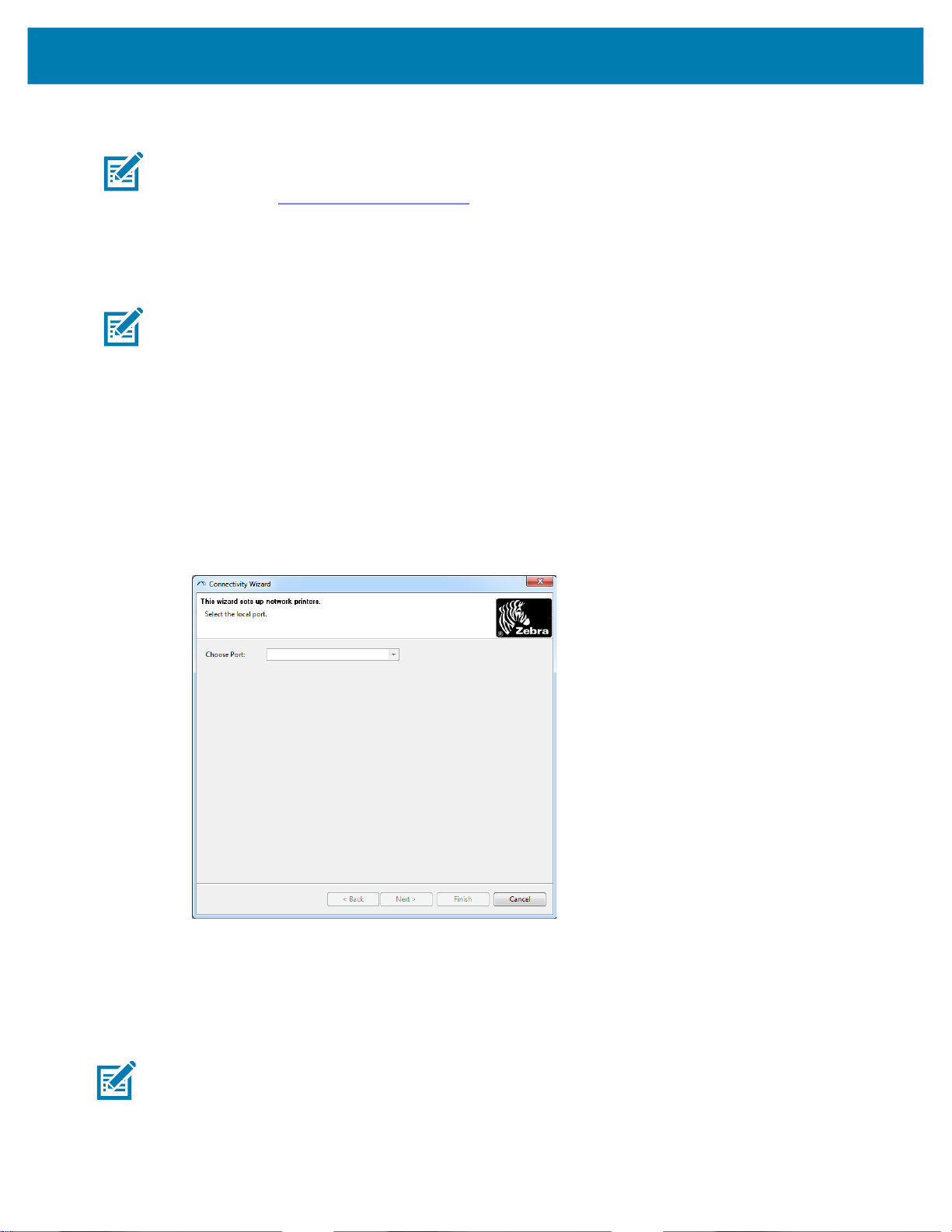

Configure Using the ZebraNet Bridge’s Connectivity Wizard

Note • The preferred tool for connecting and configuring your printers to cloud, WLAN, and LAN; is now Link-OS

Profile Manager. You can get Profile Manager and ZebraNet Bridge Enterprise (local and LAN configurations) utility is

available through http://www.zebra.com/software

configure the printer correctly for use.

The Connectivity Wizard, which is part of this software, allows you to configure your printer easily for

wireless operation by writing the appropriate ZPL script for you. Use this utility when you are first installing

the wireless print server or after you set the network options back to factory defaults.

Note • You can only set up one print server at a time with the Connectivity Wizard. To configure multiple print servers

(wired and wireless), run the program once for each print server.

To use the Connectivity Wizard, complete these steps:

1. If it is not already installed, install ZebraNet Bridge Enterprise on your computer.

You can get the program from the Zebra Web site at http://www.zebra.com/software.

2. Launch the ZebraNet Bridge Enterprise program.

If you are prompted for a serial number, you may click Cancel. You will still be able to use the

Connectivity Wizard.

. ZebraNet Bridge Enterprise version 1.2.5 or later is required to

3. From the Menu bar, select Tools > Connectivity Wizard. The Connectivity Wizard opens.

4. From the Choose Port list, select the port to which your printer is connected.

• If you will save the file without sending it to the printer, you may select any available port.

• If you select File, you will be asked to browse to the location of the file you want to save.

• If you select a serial port, the serial configuration information appears below the ‘Choose Port’ list. If

necessary, change the serial communication settings to match your printer’s settings.

Note • If a port is in use by another device, it will not be included in the drop-down list.

40

Page 41

Setup for Windows® OS

5. Click Next.

The wizard prompts for the print server device to configure.

6. Select Wireless and then click Next.

The wizard prompts you for the type of printer you are using.

41

Page 42

Setup for Windows® OS

7. Select the type of printer you are using and then click Next.

The wizard prompts for the wireless IP information.

8. Enable the DHCP (dynamic) or Static IP option.

•

DHCP

1. Select DHCP and click Next.

2. Continue with step 9.

•

Static (IP)

3. Select Static.

4. The IP settings fields are activated.

5. Enter the IP Address, Default Gateway, and Subnet Mask for the wireless print server. Contact

your network administrator for the correct values.

6. Continue with step 9.

42

Page 43

Setup for Windows® OS

9. Click Next.

The Wireless Settings window opens.

43

Page 44

Setup for Windows® OS

10.Enter the ESSID.

Note • The ESSID and pass phrase, if used, must be set at your access point before completing

these steps.

11.From the drop-down, select your Security Mode.

•

None (no security protocol selected)

•

EAP-TLS, EAP-TTLS, EAP-FAST, or WPA-EAP-TLS

In the EAP section of the window, if necessary, enter the Optional Private Key.

Click Next and continue with step 12.

•

PEAP, LEAP, WPA-EAP-TTLS, WPA-PEAP, or WPA-LEAP

In the General Security section of the window, enter the Security Username and Password.

Click Next and continue with step 12.

•

WPA-PSK

In the WPA section of the window:

1. Select the PSK Type.

2. Enter the PSK Name.

Click Next and continue with step 12

•

WPA-EAP-FAST

3. In the General Security section of the window, enter the Security Username and Password.

4. In the EAP section of the window, if necessary, enter the Optional Private Key.

Click Next and continue with step 12.

•

KERBEROS

In the Kerberos Settings section of the window, enter the following values:

• Kerberos User

• Kerberos Password

• Kerberos Realm

• Kerberos KDC

Note • KERBEROS is not supported on Internal Wireless Plus print servers or radio cards.

Click Next and continue with step 12.

44

Page 45

Setup for Windows® OS

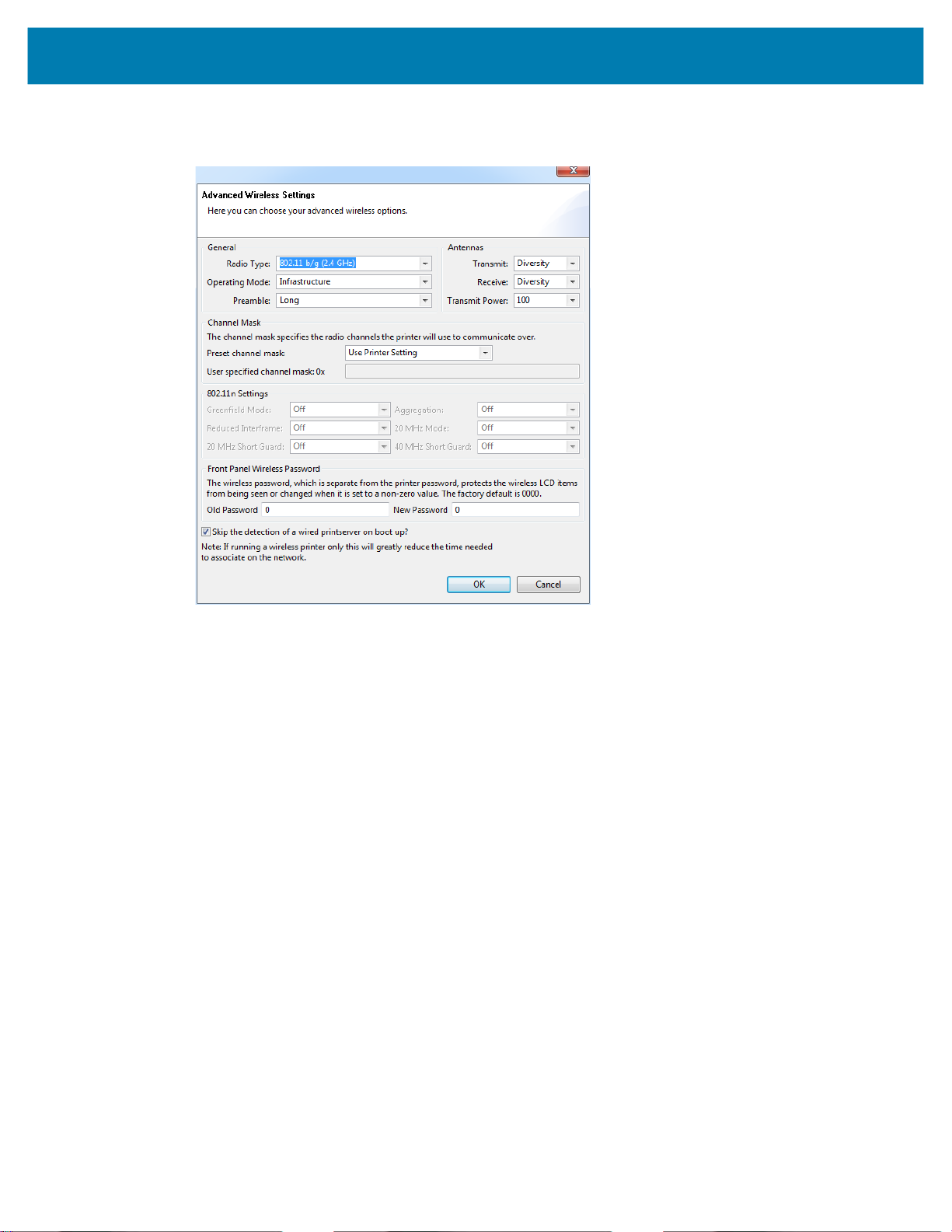

12.Click Advanced Options in the Wireless Settings window. step 12

The Advanced Wireless Settings window opens.

13.Review the settings in the Advanced Wireless Settings window. Change the settings as necessary, and

then click OK. The Wireless Settings window returns.

45

Page 46

Setup for Windows® OS

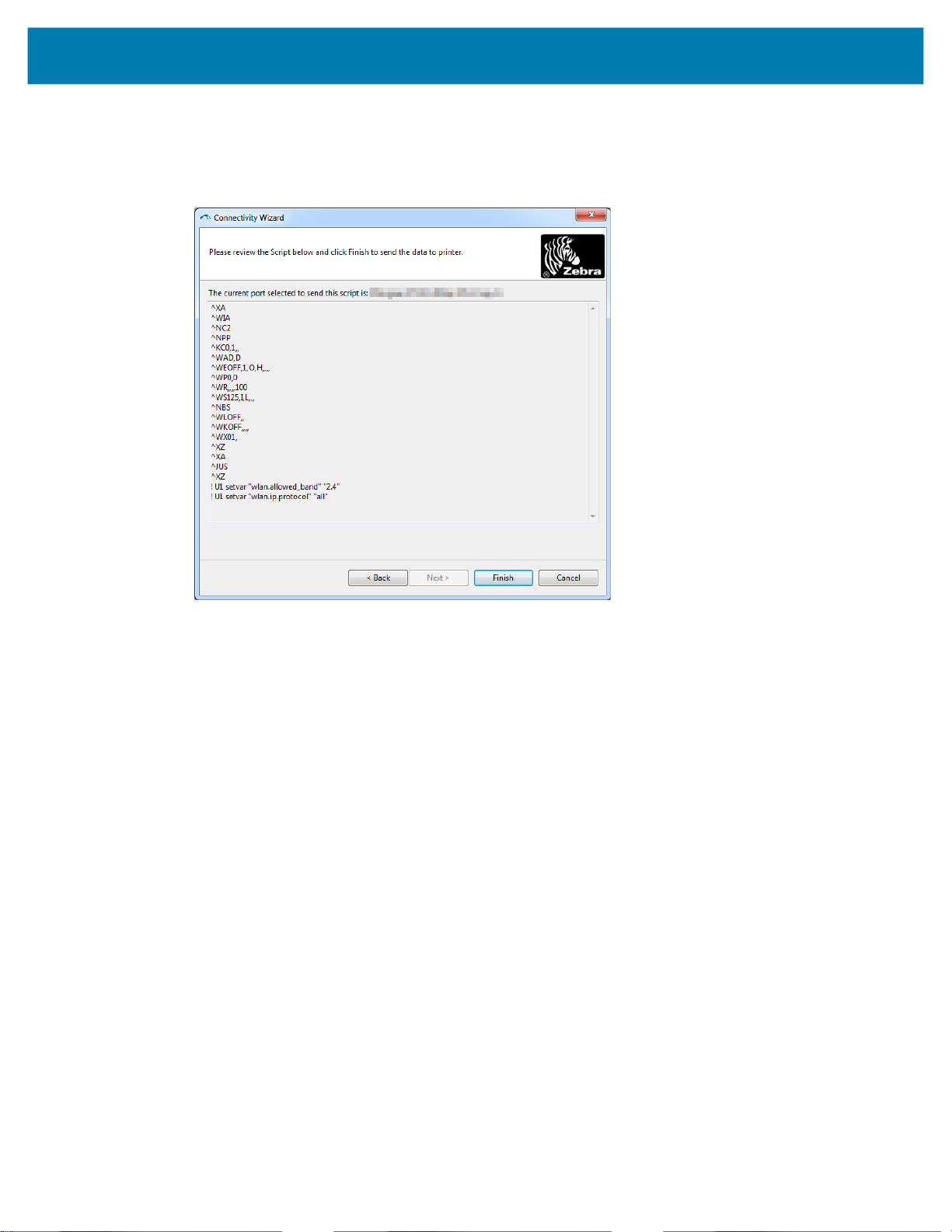

14.Click Next.

Based on your selections in the Wireless Setup Wizard, the program writes the appropriate ZPL

commands and displays them for your review. If you selected Tabletop/Desktop then the a dialog box

similar to this displays.

15.Determine if you will send the script immediately, or save it for use at a later time.

Using a Configuration Script

Complete setup by sending the ZPL script to the printer through the port selected at the beginning of this

procedure.

1. Verify that the printer is connected to the computer through the wired cable connection to the USB port.

2. If you have not already done so, turn ON the printer.

3. On the Review and Send ZPL for Wireless window, click Finish.

4. The printer sends the ZPL script to the printer through the interface port. The Wireless Setup Wizard

screen closes.

5. Turn the printer OFF and then back ON.

46

Page 47

Saving a Configuration Script

Save the ZPL script to a file for use later or for use with other printers.

Note • You can send the ZPL script file to multiple printers that use the same configuration, or you can send the file to

a printer that had the network settings restored to the factory defaults. This saves you from having to go through the

Wireless Setup Wizard more than once.

1. On the ‘Review and Send ZPL for Wireless’ window, highlight the script, right-click, and select Copy.

2. Open a text editor, such as Notepad, and paste the script into the application.

3. Save the script.

4. In the Connectivity Wizard, click Cancel to exit without sending the script at this time.

5. If you have not already done so, turn ON the printer.

6. Send the ZPL file to the printer through the connection of your choice.

7. Observe the wireless status on the printer’s indicator lights, and confirm that you have set up your

printer for wireless connectivity.

Setup for Windows® OS

47

Page 48

Setup for Windows® OS

Bluetooth Option Configuration

The Zebra Setup Utilities provides a quick and easy way to configure a Bluetooth wireless connection with

your printer.

1. Double-click the Zebra Setup Utilities icon on your desktop.

2. Connect a USB cable from your printer to your computer.

3. On the first ZSU screen, highlight the printer displayed in the window and click on the Configure Printer

Connectivity where shown.

4. Select ‘Bluetooth’ on the Connectivity Type screen and click on the Next button.

5. On the Bluetooth Settings screen, check “Enabled” to enable Bluetooth functionality.

6. In the Friendly Name text field, set the Bluetooth name of the device. This name appears during device

discovery and the master device will label the printer with this name.

7. Set Discoverable to “On” or “Off” to set whether the device will appear when master devices are looking

for new devices to pair with.

8. Set Authentication to “On.” (Note: This setting does not exist in Link-OS, but you need to turn on if you

want to enter a PIN in ZSU. Actual authentication setting on the printer is set in the Security Mode on

the Advanced Settings menu.)

48

Page 49

Setup for Windows® OS

9. The values set in the Authentication PIN field will vary depending on the Bluetooth (BT) version of the

master device. If the master uses BT v2.0 or older

prompted to enter this same value on the master device to verify pairing. Security Mode 2 or 3 in

Advanced Settings should also be selected for PIN paring.

, enter a numeric value in this field. You will be

10.If the master device uses BT v2.1 or newer

Simple Paring (SSP) which does not require the use of a PIN.

11.Clicking on the Advanced Settings button will display the Advanced Bluetooth Settings window. For

more information on Advanced Settings, refer to the Wired and Wireless Print Server Guide.

12.Click Next to continue configuring your printer.

13.The SGD commands to properly configure your printer will be displayed. Click Next to continue to the

Send Data screen.

14.On the Send Data screen, click on the Printer that you want to send the commands to or click on the

File button to save the commands to a file for reuse later.

15.To send the commands to the printer, click on the Finish button. The printer will update and then reboot.

You may disconnect the USB interface from your printer now.

16.To complete the Bluetooth pairing process, enable Bluetooth device discovery on your master device

and follow the directions provided with the master device.

, this setting has no effect. BT v2.1 and newer uses Secure

49

Page 50

Setup for Windows® OS

Connecting to a Windows Vista® SP2 or Windows 7® Master Device

The Windows Vista (SP2 or higher) and Windows 7 Bluetooth install differs from the XP install.

• Windows Vista: Open the ‘Add Printer’ wizard by clicking the ‘Start’ button, clicking ‘Control Panel’,

clicking ‘Hardware and Sound’, clicking ‘Printers’, and then clicking ‘Add a printer’.

• Windows 7: Open Devices and Printers by clicking the ‘Start’ button, and then, on the ‘Start’ menu,

clicking ‘Devices and Printers’

• Some non-Microsoft Bluetooth dongles and built-in Bluetooth devices in the host PC’s have

marginal driver support for Secure Simple Paring (SSP) printing and may not complete the ‘Add

printer’ wizard normally. You may need to go to the ‘Bluetooth Devices’ in the ‘Control Panel’ or from

the system tray on the Windows ‘Start’ bar and activate SPP for the ‘device’, your Bluetooth printer

you are installing. Install the printer to a local printer (USB for your printer) and then change the

‘Port’ after the install has completed to the SPP (virtual serial port) COM port.

1. Access the ‘Devices and Printers’ from the Windows Start menu.

2. Check for Bluetooth devices in the ‘Devices and Printers’ window. Note the generic Windows Bluetooth

icon below.

50

Page 51

Setup for Windows® OS

3. Hover over the Bluetooth icon with the mouse pointer and the icon will highlight. Right-Click on the

high-lighted Bluetooth icon. Select ‘Bluetooth Settings’ from the pop-up menu. Verify that both of the

Connections check boxes are checked. Verify that the ‘Turn off the Bluetooth adapter’ is not checked.

Click the ‘Apply’ button. Click the ‘OK’ button to close the window.

4. Click on the ‘Add a device’ in the top bar of the “Devices and Printers’ window. The “Add a device’

windows will populate with Bluetooth devices near you.

5. Turn the Bluetooth 4.0 (3.0 compatible) enabled Zebra printer on. After a few moments the “Add a

device’ windows will add your new printer. Click on the printer icon. Right-Click and select ‘Add device’.

51

Page 52

Setup for Windows® OS

6. The printer will print a pairing code. Verify that the pairing numbers match with those on your display

screen. If the numbers match, then press the ‘Next button’ in the ‘Add a device’ window.

7. When the pairing process successfully completes, the following message will be displayed.

Note • The COM port number displayed in the task bar pop-up. It will only remain for a few seconds.

52

Page 53

Setup for Windows® OS

Connecting the Printer to a Windows 8 OS

Before adding (also called pairing) a Bluetooth enabled device, make sure it is turned on and discoverable.

As stated in the previous section under Connecting to a Windows Vista

®

SP2 or Windows 7® Master

Device, your Windows device may need a Bluetooth adapter to connect to Bluetooth device. Check with

your device manufacturer’s User Manual for further information.

1. Swipe in from the right edge of the screen or move your mouse towards the right edge of the screen,

select Settings, and then select Change PC Settings.

.

2. Select PC and devices, and then select Bluetooth. Once Windows displays the Bluetooth-enabled

devices, select the device and click Pair.

Note • Windows will display the pairing code for only 10 seconds, so complete this step quickly!

3. Follow the instructions on your screen to finish pairing your device.

53

Page 54

Setup for Windows® OS

Connecting the Printer to a Windows 10 OS

Before adding (also called pairing) a Bluetooth enabled device, make sure it is turned on and discoverable.

As stated in the previous section under “Installing the Printer on a Windows 7 PC,” your Windows device

may need a Bluetooth adapter to connect to Bluetooth device. Check with your device manufacturer’s User

Manual for further information.

1. Open the Windows Start Menu by clicking on the Windows Start ( )button and select Settings.

.

2. Click on the Devices category in the Settings window.

54

Page 55

Setup for Windows® OS

3. Click on Bluetooth. If your PC doesn’t have Bluetooth installed, the Bluetooth category will not be

displayed in the list of device categories. The printer is identified by the serial number.

Printer Serial Number

4. Click on the printer and then click on the ‘pairing’ button for the printer.

55

Page 56

Setup for Windows® OS

5. The printer will print a passcode. Compare that with the passcode showing on screen. Click ‘Yes’ if they

match.

6. The printer status changes to connected when pairing has completed.

56

Page 57

Setup for Windows® OS

After Your Printer is Connected

Now that you have basic communication to your printer, you may want to test printer communications and

then install other printer related applications, drivers or utilities.

Testing Communications by Printing

Verifying the print system’s operation is a relatively simple process. For Windows operating systems, use

the Zebra Setup Utility or the Windows ‘Printers and Faxes’ Control Panel to access and print a test label.

For non-Windows operation systems, copy a basic ASCII text file with a single command (

configuration status report.

Test Printing with Zebra Setup Utility:

1. Open the Zebra Setup Utility.

2. Click on the newly installed printer’s icon to select the printer and activate the printer configuration

buttons below it in the window.

3. Click the ‘Open Printer Tools’ button.

4. In the ‘Print’ tab window, click on the ‘Print configuration label’ line and click on the ‘Send’ button. The

printer should print a configuration report.

~WC) to print a

Test Printing with Windows ‘Printer and Faxes’ menu:

1. Click on the Windows ‘Start’ menu button, to access the ‘Printers and Faxes’ menu or ‘Control Panel’ to

access the ‘Printers and Faxes’ menu. Open the menu.

2. Select the newly installed printer’s icon to select the printer and right-click the mouse to access the

printer ‘Properties’ menu.

3. From the printer’s ‘General’ tab window, click on the ‘Print Test Page’ button. The printer should print a

Windows test print page.

Test Print with an Ethernet printer connected to a network