Page 1

VC70N0 Vehicle Computer

Product Reference Guide

Page 2

Page 3

VC70N0 Vehicle Computer

Product Reference Guide

72-164686-05

Revision A

December 2020

Page 4

ii VC70N Vehicle Computer Product Reference Guide

No part of this publication may be reproduced or used in any form, or by any electrical or mechanical means,

without permission in writing. This includes electronic or mechanical means, such as photocopying, recording,

or information storage and retrieval systems. The material in this manual is subject to change without notice.

The software is provided strictly on an “as is” basis. All software, including firmware, furnished to the user is on

a licensed basis. We grant to the user a non-transferable and non-exclusive license to use each software or

firmware program delivered hereunder (licensed program). Except as noted below, such license may not be

assigned, sublicensed, or otherwise transferred by the user without prior written consent. No right to copy a

licensed program in whole or in part is granted, except as permitted under copyright law. The user shall not

modify, merge, or incorporate any form or portion of a licensed program with other program material, create a

derivative work from a licensed program, or use a licensed program in a network without written permission.

The user agrees to maintain copyright notice on the licensed programs delivered hereunder, and to include the

same on any authorized copies it makes, in whole or in part. The user agrees not to decompile, disassemble,

decode, or reverse engineer any licensed program delivered to the user or any portion thereof.

We reserve the right to make changes to any software or product to improve reliability, function, or design. We

do not assume any product liability arising out of, or in connection with, the application or use of any product,

circuit, or application described herein.

No license is granted, either expressly or by implication, estoppel, or otherwise under any of our intellectual

property rights. An implied license only exists for equipment, circuits, and subsystems contained in our

products.

Warranty

Subject to the terms of Zebra hardware warranty statement, the VC70 Vehicle Computer products are

warranted against defects in workmanship and materials for a period of one year from the date of shipment.

For the complete Zebra hardware product warranty statement, go to:

Revision History

Changes to the original manual are listed below:

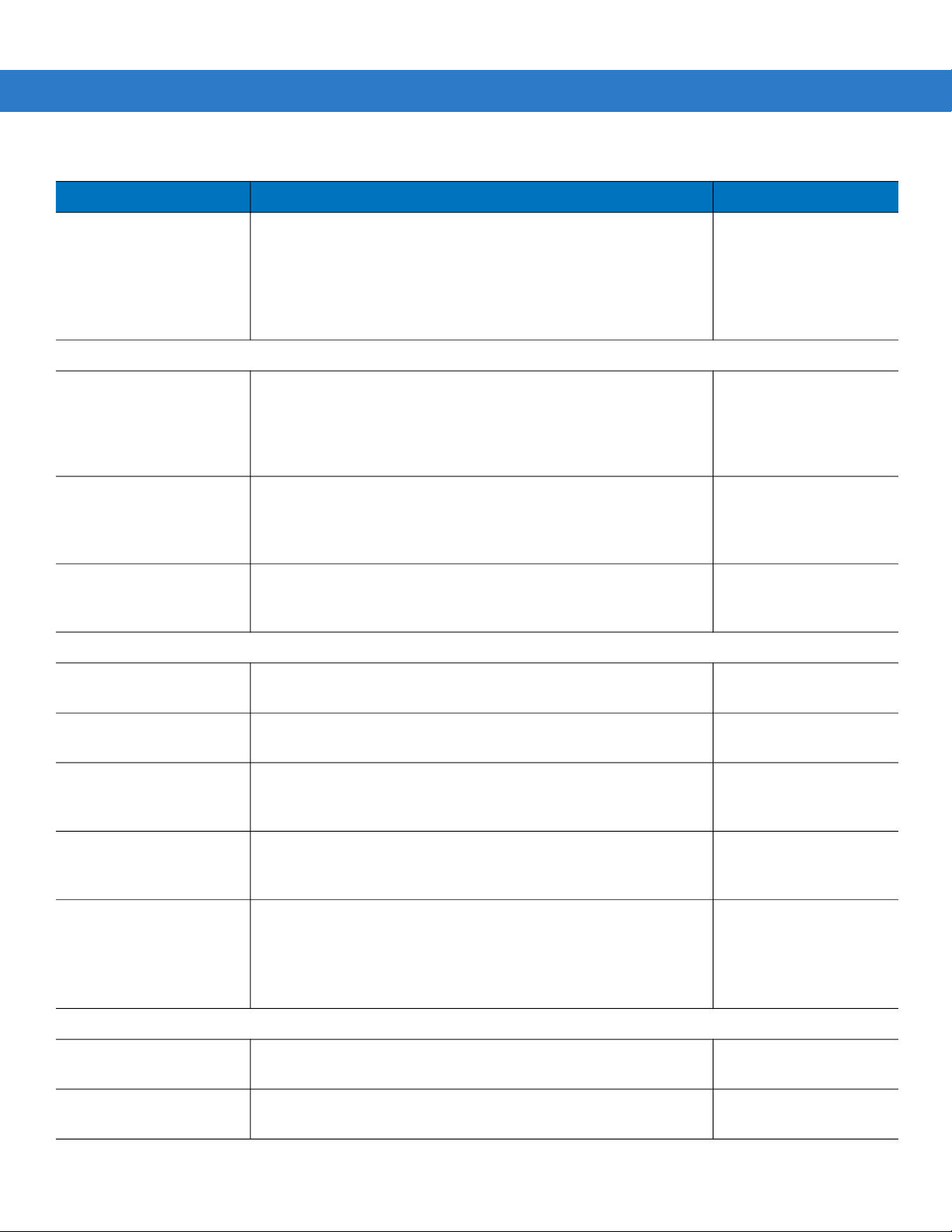

Change Date Description

-05 Rev A 12/2020 Replaced master/slave references with central/peripheral (for Bluetooth) and

-04 Rev A 1/2019 Correct DC power cable part number.

-03 Rev A 7/2018 Update memory size.

-02 Rev C 8/2016 Correct COM port on page 5-15, step 15. (Change from COM 9 to COM1).

-02 Rev B 1/2016 Add Caution not to use tool when connecting cables to COM and USB ports.

-02 Rev A 2/7/2015 Zebra Re-branding. Update accessory table.

-01 Rev C 09/01/2014 Revision C

www.zebra.com/warranty

controller/follower (for non-Bluetooth)

-01 Rev B 09/19/13 Revision B Release

-01 Rev A 11/30/12 Initial release.

Page 5

iii

Page 6

iv VC70N Vehicle Computer Product Reference Guide

Page 7

Table of Contents

Warranty ............................................................................................................................................... ii

Revision History.................................................................................................................................... ii

About This Guide

Introduction ........................................................................................................................................... xi

Documentation Set ......................................................................................................................... xi

Configurations....................................................................................................................................... xii

Software Versions........................................................................................................................... xii

Chapter Descriptions ............................................................................................................................ xiii

Notational Conventions......................................................................................................................... xiv

Related Documents and Software ........................................................................................................ xiv

Service Information............................................................................................................................... xiv

Returning the Vehicle Computer for Service................................................................................... xv

Chapter 1: Getting Started

Introduction .......................................................................................................................................... 1-1

Unpacking the VC70 ............................................................................................................................ 1-1

Features ............................................................................................................................................... 1-1

Accessories ......................................................................................................................................... 1-4

Chapter 2: Installation

Introduction .......................................................................................................................................... 2-1

Electrical Power Wiring ........................................................................................................................ 2-2

Forklifts and Trucks with 12V, 24V, 36V and 48V Batteries .................................................... 2-3

Ignition Sensing ............................................................................................................................. 2-5

VC70 Power States ............................................................................................................................. 2-6

Installing the VC70 on a Cart, a Wall, or a Desktop ............................................................................ 2-7

Mounting the Bracket on a Desktop ............................................................................................... 2-7

Connecting the Vehicle Computer to AC Power ............................................................................ 2-8

Installing the DC Power Supply (PSU) on the VC70 ........................................................................... 2-9

Installing a Micro SD Card ................................................................................................................... 2-10

RAM Mount Installation ........................................................................................................................ 2-11

Page 8

vi VC5090 Vehicle Computer Product Reference Guide

U-Mount Installation ............................................................................................................................. 2-13

Installing the VC70 on a Forklift ........................................................................................................... 2-14

Positioning the Vehicle Computer .................................................................................................. 2-14

U-Mount Installation Template ................................................................................................. 2-16

Mounting onto an Over-Head Cross-Beam Example ............................................................... 2-17

Mounting onto an Over-Head Cage Example .......................................................................... 2-17

Mounting on a Dashboard or Horizontal Surface Example ...................................................... 2-19

Installing the Optional QWERTY/AZERTY Keyboard .......................................................................... 2-20

Installing the Optional VC5090 Keyboard on the VC70 ....................................................................... 2-22

Installing a Numeric Keyboard ............................................................................................................. 2-23

Keyboard Protection Grill Installation ................................................................................................... 2-25

Installing the Scanner Mount ............................................................................................................... 2-26

Installing a Stubby Antenna ................................................................................................................. 2-27

Installing the External Roof-mounted Antenna .................................................................................... 2-28

Connecting Accessories ...................................................................................................................... 2-29

Connecting an External Speaker to the Vehicle Computer ................................................................. 2-29

Installing an External Microphone Mount ............................................................................................. 2-29

Chapter 3: Operating the VC70

Introduction .......................................................................................................................................... 3-1

Control Panel Applications ................................................................................................................... 3-1

Quick Access Panel ............................................................................................................................. 3-4

Power Button ................................................................................................................................. 3-4

Charging LED ................................................................................................................................ 3-4

COMM LED .................................................................................................................................... 3-5

Brightness and Speaker Buttons ................................................................................................... 3-6

Function LED ................................................................................................................................. 3-6

Programmable (“P”) Keys .............................................................................................................. 3-6

Using the Keyboard ............................................................................................................................. 3-6

Soft Input Panel (SIP) Keyboards .................................................................................................. 3-6

Keyboard Functionality .................................................................................................................. 3-10

Adjusting the Brightness ...................................................................................................................... 3-12

Controlling Screen Brightness ....................................................................................................... 3-12

Controlling the External Keyboards Backlight ................................................................................ 3-13

Adjusting the Volume ........................................................................................................................... 3-13

Taskbar ................................................................................................................................................ 3-14

Start Button .................................................................................................................................... 3-15

Programs Menu ............................................................................................................................. 3-15

Desktop Button .............................................................................................................................. 3-16

Task Manager and Properties ........................................................................................................ 3-16

Task Manager .......................................................................................................................... 3-16

Properties ................................................................................................................................. 3-17

Using Voice Communication ................................................................................................................ 3-18

Resetting the Vehicle Computer .......................................................................................................... 3-19

Performing a Warm Boot ............................................................................................................... 3-19

Performing a Cold Boot .................................................................................................................. 3-19

Boot Persistence ............................................................................................................................ 3-20

Power Status ....................................................................................................................................... 3-22

Power On ....................................................................................................................................... 3-22

Page 9

Table of Contents vii

Low Power Mode ........................................................................................................................... 3-22

Methods of Suspension ........................................................................................................... 3-22

Critical Suspension ........................................................................................................................ 3-22

Waking the Vehicle Computer ....................................................................................................... 3-23

Reduced Power Consumption ....................................................................................................... 3-23

Controlling the Display ......................................................................................................................... 3-25

Using the Display ........................................................................................................................... 3-25

Using the Keyboard ....................................................................................................................... 3-26

Screen Lock ................................................................................................................................... 3-28

Checking Backup Battery Status ......................................................................................................... 3-29

Disconnecting the Backup Battery ................................................................................................. 3-29

Checking the Status of the Backup Battery ................................................................................... 3-29

Sensors Configuration ......................................................................................................................... 3-30

Desiccant Warning ......................................................................................................................... 3-30

TouchPanel Heater ........................................................................................................................ 3-32

Real Time Log ..................................................................................................................................... 3-32

Shock Events Log ................................................................................................................................ 3-33

Chapter 4: DataWedge Scanner Connection

Introduction .......................................................................................................................................... 4-1

Scanner Connection Method ............................................................................................................... 4-2

Scanner/SSI Firmware Compatibility ................................................................................................... 4-2

Scanner/SSI Firmware Compatibility ................................................................................................... 4-3

Installing a Scanner ............................................................................................................................. 4-3

Connect LS3408-ER Corded Scanner to a Serial Port of the VC70 (SSI) ............................... 4-4

Connect DS3508-ER Corded Scanner to a Serial Port of the VC70 (SSI) .............................. 4-8

Connect LS3408-ER Corded Scanner to a Serial Port of the VC70 (Serial) ........................... 4-11

Connect DS3508-ER Corded Scanner to a Serial Port of the VC70 (Serial) ........................... 4-14

Connect a Bluetooth Scanner DS3578 Directly to the VC70 (SPP Profile) ............................. 4-19

Connect a Bluetooth Scanner LS3578 Directly to the VC70 (SPP Profile) .............................. 4-25

Connect a Bluetooth Scanner RS507 Directly to the VC70 (Scan Profile) .............................. 4-29

Connect a Bluetooth Scanner RS507 Directly to the VC70 (SPP Profile) ............................... 4-31

Chapter 5: TelnetCE Configuration

Introduction .......................................................................................................................................... 5-1

Scanner Connection Method ............................................................................................................... 5-2

Scanner/SSI Firmware Compatibility ................................................................................................... 5-3

Wavelink TelnetCE .............................................................................................................................. 5-3

Connect LS3408-ER Corded Scanner to a Serial Port of the VC70 (SSI) ............................... 5-4

To connect a scanner: ) ........................................................................................................... 5-4

Connect DS3508-ER Corded Scanner to a Serial Port of the VC70 (SSI) .............................. 5-8

Connect LS3408-ER Corded Scanner to a Serial Port of the VC70 (Serial) ........................... 5-11

Connect DS3508-ER Corded Scanner to a Serial Port of the VC70 (Serial) ........................... 5-20

Connect LS3408-ER Scanner to USB Port of the VC70 (HID) ................................................ 5-28

Connect LS3408-ER Corded Scanner to USB Port of the VC70 (Scan Handlers) .................. 5-29

Connect DS3508-ER Scanner to USB Port of the VC70 (HID) ............................................... 5-36

Connect DS3508-ER Serial Scanner to USB Port of the VC70 (Scan Handlers) .................... 5-38

Connect a Bluetooth Scanner RS507 Directly to the VC70 (Scan Profile) .............................. 5-44

Page 10

viii VC5090 Vehicle Computer Product Reference Guide

Connect a Bluetooth Scanner RS507 Directly to the VC70 (SPP Profile) ............................... 5-46

Connect a Bluetooth Scanner DS3578 Directly to the VC70 (SPP Profile) ............................. 5-54

Connect a Bluetooth Scanner LS3578 Directly to the VC70 (SPP Profile) .............................. 5-63

Chapter 6: Wireless LAN Applications

Introduction .......................................................................................................................................... 6-1

Signal Strength Icon ............................................................................................................................ 6-2

Turning the WLAN Radio On and Off .................................................................................................. 6-3

With Fusion .................................................................................................................................... 6-3

Find WLANs Application ...................................................................................................................... 6-3

Chapter 7: Using Bluetooth

Introduction .......................................................................................................................................... 7-1

Adaptive Frequency Hopping .............................................................................................................. 7-1

Security ................................................................................................................................................ 7-2

Turning the Bluetooth Radio Mode On and Off ................................................................................... 7-2

Disabling Bluetooth ........................................................................................................................ 7-2

Enabling Bluetooth ......................................................................................................................... 7-3

Bluetooth Power States ................................................................................................................. 7-4

Cold Boot ................................................................................................................................. 7-4

Warm Boot ............................................................................................................................... 7-4

Low Power ............................................................................................................................... 7-4

Pairing Cordless Scanners .................................................................................................................. 7-4

Discovering Bluetooth Device(s) .......................................................................................................... 7-4

File Transfer Services .................................................................................................................... 7-7

Create New File or Folder ........................................................................................................ 7-8

Delete File ................................................................................................................................ 7-8

Get File .................................................................................................................................... 7-9

Put File ..................................................................................................................................... 7-9

Connect to Internet Using Access Point ........................................................................................ 7-9

OBEX Object Push Services .......................................................................................................... 7-9

Send a Picture ......................................................................................................................... 7-10

Headset Services ........................................................................................................................... 7-11

Serial Port Services ....................................................................................................................... 7-11

Personal Area Network Services ................................................................................................... 7-12

Bluetooth Settings ................................................................................................................................ 7-12

Device Info Tab .............................................................................................................................. 7-12

Services Tab .................................................................................................................................. 7-13

File Transfer Service ................................................................................................................ 7-14

Personal Area Networking Service .......................................................................................... 7-14

Serial Port Service ................................................................................................................... 7-15

Headset Service ....................................................................................................................... 7-16

Security Tab ................................................................................................................................... 7-16

Discovery Tab ................................................................................................................................ 7-16

Virtual COM Port Tab ..................................................................................................................... 7-17

Miscellaneous Tab ......................................................................................................................... 7-18

Page 11

Table of Contents ix

Chapter 8: Sync with Host Computer

Introduction .......................................................................................................................................... 8-1

Installing the Synchronization Software ............................................................................................... 8-2

Vehicle Computer Setup ...................................................................................................................... 8-2

Setting Up an ActiveSync Connection on the Host Computer (Windows XP) ..................................... 8-3

Setting up a Partnership ................................................................................................................ 8-4

Setting Up an Windows Mobile Device Center Connection on the Host Computer (Windows 7) ........ 8-6

Setting up a Partnership ................................................................................................................ 8-7

Chapter 9: Application Development and Deployment

Introduction .......................................................................................................................................... 9-1

Software Installation on Development PC (Application Development) ................................................ 9-1

Platform SDK ................................................................................................................................. 9-1

Zebra Developer Kit ....................................................................................................................... 9-2

Installing Other Development Software ......................................................................................... 9-2

Software Installation on Vehicle Computer .......................................................................................... 9-2

ActiveSync ..................................................................................................................................... 9-2

Micro SD Card ............................................................................................................................... 9-4

Flash Storage ...................................................................................................................................... 9-4

FFS Partitions ................................................................................................................................ 9-4

Working with FFS Partitions ........................................................................................................... 9-5

RegMerge.dll ............................................................................................................................ 9-5

CopyFiles ................................................................................................................................. 9-5

Non-FFS Partitions ........................................................................................................................ 9-6

Chapter 10: Staging and Provisioning

Introduction .......................................................................................................................................... 10-1

MSP 3 Agent .................................................................................................................................. 10-1

AppCenter ...................................................................................................................................... 10-2

Chapter 11: Software Configuration

Introduction .......................................................................................................................................... 11-1

VC70 Operating System - Image Upgrade .......................................................................................... 11-1

Updating the Image ........................................................................................................................ 11-1

Monitor Mode ........................................................................................................................... 11-1

To Update the Image ............................................................................................................... 11-1

OSupgrade Mode ........................................................................................................................... 11-2

Switch Between Microsoft and StoneStreet One (SS1) Bluetooth Stack ............................................ 11-3

Often Used Registry Settings .............................................................................................................. 11-3

Power Suspend .............................................................................................................................. 11-3

COM1 Power Output to Scanner ................................................................................................... 11-4

COM2 Power Output to Scanner ................................................................................................... 11-4

External Antenna ........................................................................................................................... 11-4

Ignition Timeout ............................................................................................................................. 11-5

Registry Values for P1/P2/P3/P4 Keys .......................................................................................... 11-5

Disabling the Fusion RX Sensitivity Degradation ........................................................................... 11-6

VC70N0 WinCE 7.0 Registry Settings for Control Panel Applets .................................................. 11-6

Page 12

x VC5090 Vehicle Computer Product Reference Guide

Screen locking feature ............................................................................................................. 11-6

Speaker control ........................................................................................................................ 11-8

Setting COM5 as Default Serial Port ............................................................................................. 11-9

Disable SIP from Auto-Launching ........................................................................................................ 11-9

Force Warm Boot or Cold Boot After Resuming From Critical Suspension ......................................... 11-9

Chapter 12: Maintenance

Introduction .......................................................................................................................................... 12-1

Maintaining the Vehicle Computer ....................................................................................................... 12-1

Returning the Vehicle Computer for Service .................................................................................. 12-2

Replacing the Desiccant Bag ......................................................................................................... 12-2

Replacing the Backup Battery ........................................................................................................ 12-3

Troubleshooting ................................................................................................................................... 12-4

Appendix A: Specifications

Technical Specifications ...................................................................................................................... A-1

Vehicle Computer .......................................................................................................................... A-1

Vehicle Computer Connectors ............................................................................................................. A-3

Glossary

Page 13

About This Guide

Introduction

The VC70 Product Reference Guide provides information about the VC70 vehicle computer using Microsoft®

Windows® CE 7.0 operating system and its accessories.

NOTE

Screens and windows pictured in this guide are samples and can differ from actual screens.

Documentation Set

The documentation set for the VC70 is divided into guides that provide information for specific user needs.

•

VC70 Quick Reference Guide - describes how to install and use the VC70 vehicle computer.

•

VC70 Product Reference Guide - provides an in-depth description on how to use and setup the VC70

vehicle computer and its accessories.

•

Microsoft Application Guide - describes how to use Microsoft developed applications that reside on the

VC70 vehicle computer.

•

Zebra Application Guide - describes how to use Zebra developed applications available for the VC70

vehicle computer.

•

EMDK Help File - provides API information for writing applications.

Page 14

xii VC70 Vehicle Computer Product Reference Guide

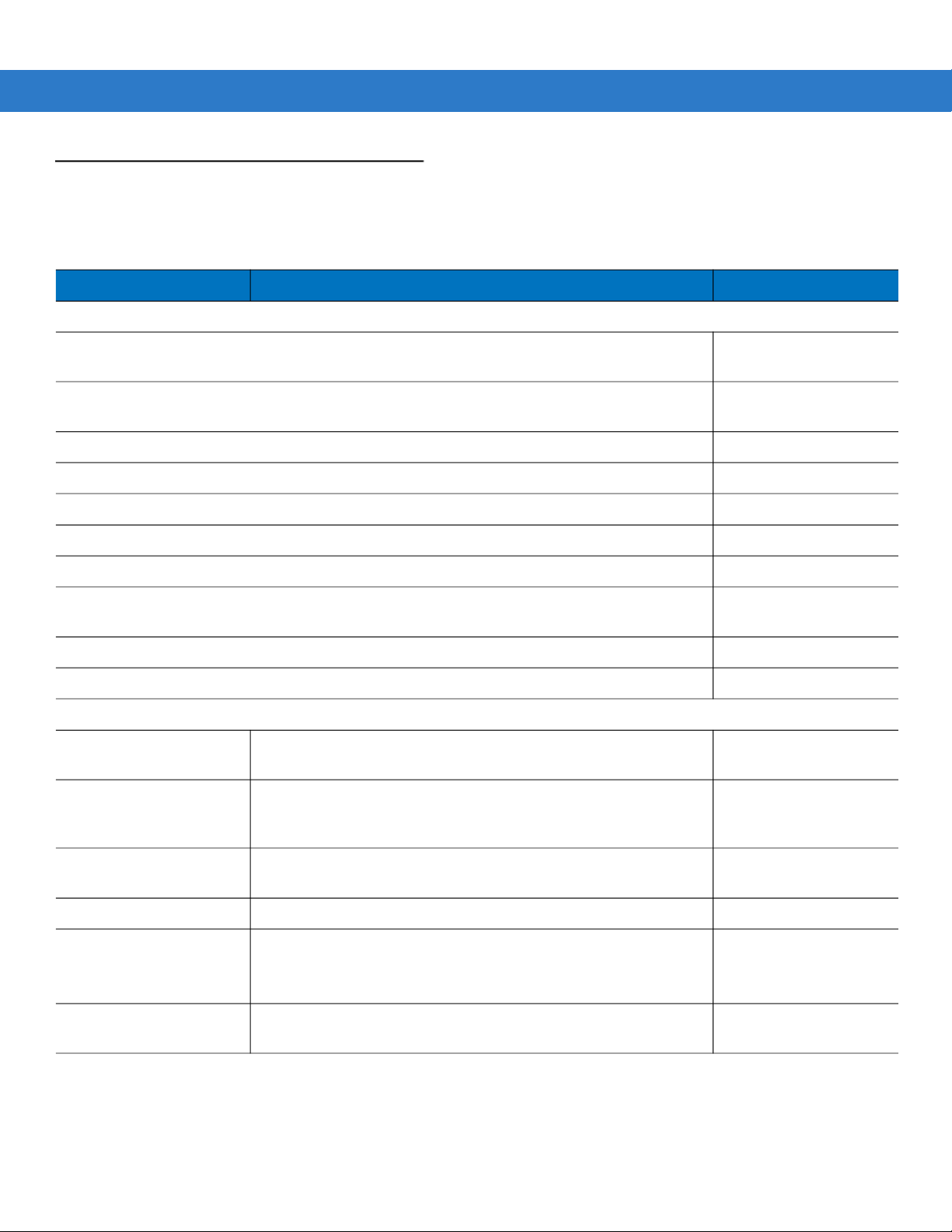

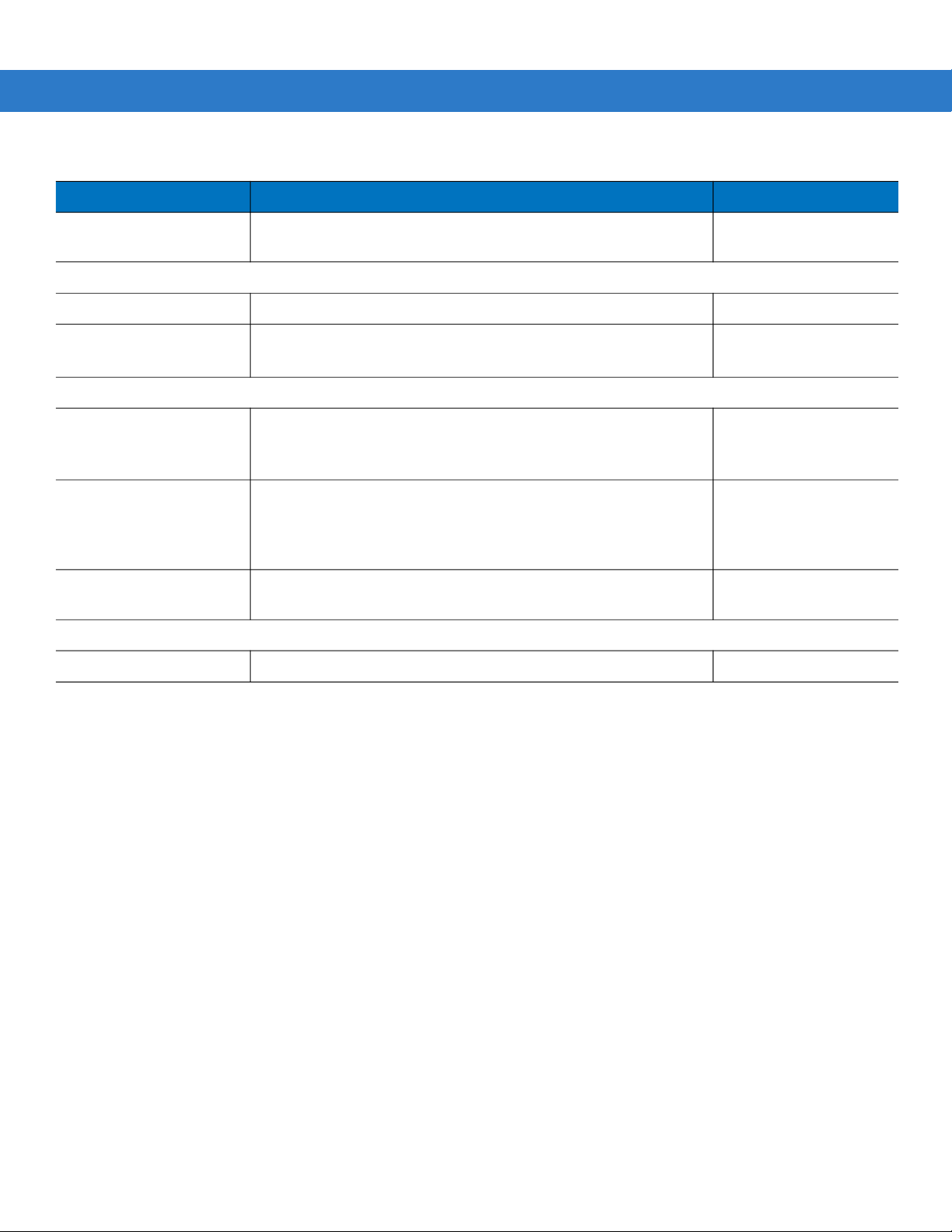

Configurations

This guide covers the following configurations:

Configuration Radios Display Memory

VC70 Full Screen WLAN:

802.11a/b/g/n

WPAN: Bluetooth

10.4” XGA

1024 x 768

Switchable to

SVGA

800x600

(4:3 format)

1 GB DDR2

volatile memory,

2 GB EMMC non

volatile memory

Data

Capture

Optional

Scanner

OS Keypad

Windows

CE 7.0

Professional

Optional USB

QWERTY or

AZERTY

keyboard

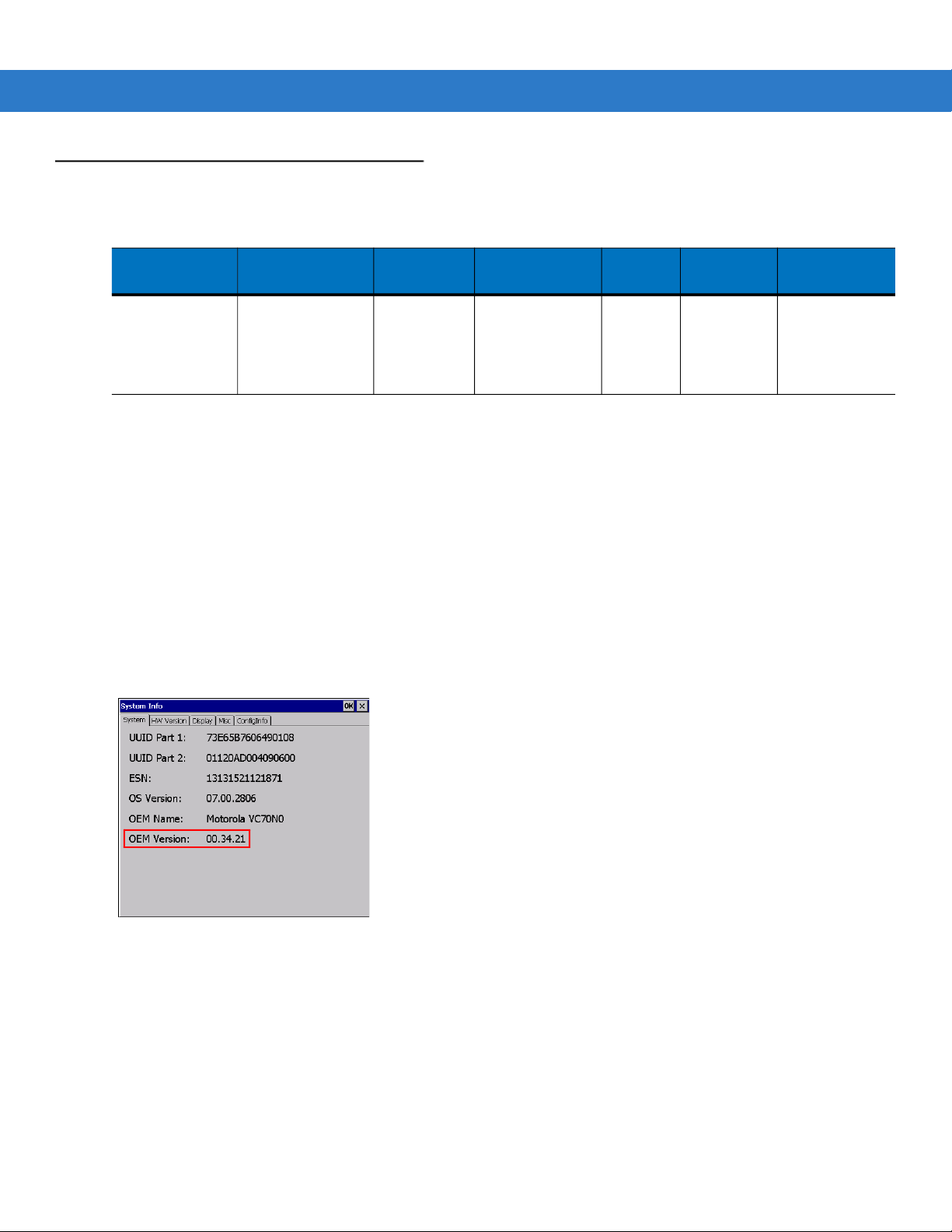

Software Versions

This guide covers various software configurations and references are made to operating system or software

versions for:

•

OEM version

•

Fusion version.

OEM Software

To determine the OEM software version:

Start > Settings > Control Panel > System Information icon > System tab.

Tap

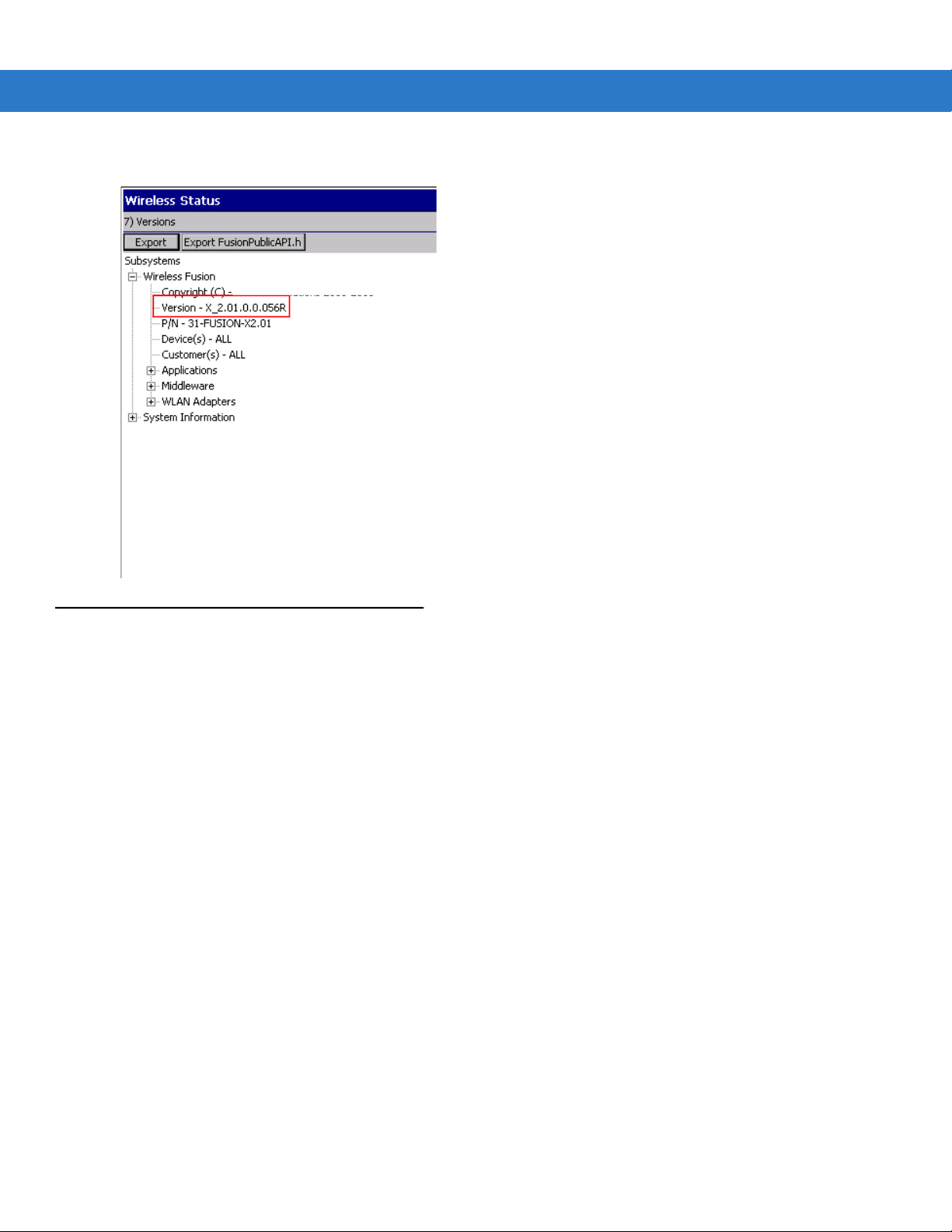

Fusion Software

To determine the Fusion software version:

Tap Fusion icon > Wireless Status > Versions.

Page 15

© 2014 Symbol Technologies, Inc.

About This Guide xiii

Chapter Descriptions

Topics covered in this guide are as follows:

•

Chapter 1, Getting Started, provides information on getting the vehicle computer up and running for the first

time.

•

Chapter 2, Installation, provides instructions for installing the vehicle computer in a forklift, on a wall or on a

desktop. Provides instructions for installing accessories.

•

Chapter 3, Operating the VC70, explains how to use the vehicle computer. This includes instructions for

powering on and resetting the vehicle computer, entering and capturing data.

•

Chapter 4, DataWedge Scanner Connection, describes how to install the scanners and accessories for the

VC70 vehicle computer.

•

Chapter 5, TelnetCE Configuration, provides instructions required for connecting serial scanners in a

Wavelink TelnetCE session via the VC70 vehicle computer

•

Chapter 6, Wireless LAN Applications, provides instructions for using and configuring the mobile computer

on a wireless network.

•

Chapter 7, Using Bluetooth, explains how to use Bluetooth functionality on the vehicle computer.

•

Chapter 8, Sync with Host Computer, provides instructions for installing and configuring ActiveSync.

•

Chapter 9, Application Development and Deployment, provides instructions for installing the EMDK for C on

the host computer and downloading software files to the vehicle computer.

•

Chapter 10, Staging and Provisioning, provides instructions for staging and provisioning the vehicle

computer.

•

Chapter 11, Software Configuration, includes special configuration instruction for third party software used

with the vehicle computer.

Page 16

xiv VC70 Vehicle Computer Product Reference Guide

•

Chapter 12, Maintenance, includes instructions on cleaning and storing the vehicle computer, and provides

troubleshooting solutions for potential problems during vehicle computer operation.

•

Appendix A, Specifications, includes a table listing the technical specifications for the vehicle computer.

Notational Conventions

The following conventions are used in this document:

•

“Vehicle computer” refers to the VC70 series of vehicle computers.

•

Italics are used to highlight the following:

• Chapters and sections in this and related documents.

•

Bold text is used to highlight the following:

• Key names on a keyboard

• Button names on a screen

• Dialog box, window and screen names

• Drop-down list and text box names

• Check box and radio button names

• Icons on a screen.

•

Bullets (•) indicate:

• Action items

• Lists of alternatives

• Lists of required steps that are not necessarily sequential.

•

Sequential lists (e.g., those that describe step-by-step procedures) appear as numbered lists.

Related Documents and Software

The following documents provide more information about the VC70 vehicle computers.

•

VC70 Quick Reference Guide, p/n 72-76346-xx

For the latest version of this guide and all guides, go to: http://www.zebra.com/support.

Service Information

If you have a problem with your equipment, contact Zebra support for your region. Contact information is available

at: http://www.zebra.com/support.

When contacting support, please have the following information available:

•

Serial number of the unit

•

Model number or product name

•

Software type and version number.

Zebra responds to calls by email, telephone or fax within the time limits set forth in support agreements.

Page 17

About This Guide xv

If your problem cannot be solved by Zebra support, you may need to return your equipment for servicing and will

be given specific directions. Zebra is not responsible for any damages incurred during shipment if the approved

shipping container is not used. Shipping the units improperly can possibly void the warranty.

If you purchased your Zebra business product from a Zebra business partner, contact that business partner for

support.

Returning the Vehicle Computer for Service

NOTE

In the event, the vehicle computer needs to be shipped to Zebra for repair or maintenance, it is essential that

the user perform the following steps to electrically disconnect the internal backup battery:

1. Disconnect the power cable from the VC70. The VC70 will continue to work on backup battery power.

2. Perform cold boot (Performing a Cold Boot on page 3-19). The backup battery will stop powering the VC70.

Page 18

xvi VC70 Vehicle Computer Product Reference Guide

Page 19

Chapter 1 Getting Started

Introduction

The VC70 is Zebra ultra-rugged forklift mounted computer. It is designed to maximize productivity in harsh

environments. Its rugged construction and high-performance wireless networking enables real-time data access

and collection in a wide range of environments — from the loading dock and freezer to the warehouse.

The VC70’s compact design improves visibility and reduces safety concerns while retaining large screen size

(10.4”). Its 802.11 a/b/g/n WLAN provides real-time information that improves decision making, reduces errors, and

enhances productivity. Its rugged design with integrated shock-mount and MIL-STD 810 military rating for shock

and vibration ensures dependable operation in challenging environments. Its IP66 sealing, display, defroster and

wide temperature range ensures operation in and out of -30

With its high-resolution and high-brightness display, the VC70 provides the user access to more information in low

ambient light warehouse and outdoors.

The VC70 accessories allow backward compatibility with the VC5090 for easy and gradual migration.

o

C freezer storage warehouse.

Unpacking the VC70

When you remove the vehicle computer from its box, save the box and shipping material in case you need to ship

or store the vehicle computer. Check the contents of the box against the invoice for completeness and contact your

local Zebra service representative if there is a problem.

The VC70 shipping box contains:

•

vehicle computer

•

VC70 Quick Reference Guide

Features

The VC70 has the following features:

•

Integrated 802.11a/b/g/n wireless LAN radio

Page 20

1 - 2 VC70 Vehicle Computer Product Reference Guide

•

Windows® CE 7.0 Professional Operating System

•

TI OMAP4430 processor at 1GHz in turbo mode CPU

•

1 GB DDR2 volatile memory, 2 GB EMMC non volatile memory

•

10.4” XGA 1024 x 768, Switchable to SVGA 800x600, (4:3 format) color display

•

Wireless and wired printing

•

Integrated antennas

•

Integrated speaker.

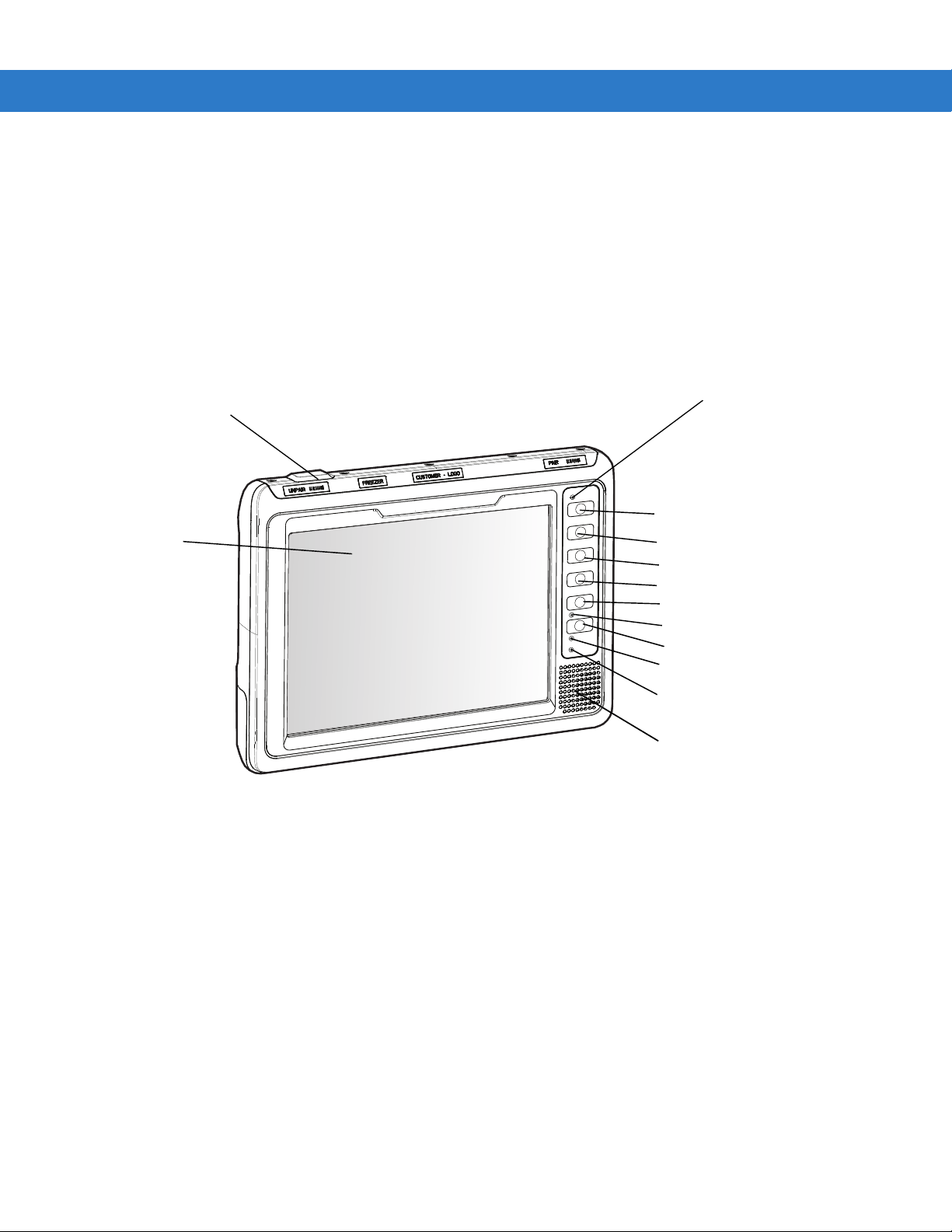

Antenna Port for

Optional External

Antenna

Display

Figure 1-1 VC70 Front View

Ambient Light Sensor

+, P1 Key

-, P2 Key

Keyboard, P3 Key

Speaker, P4 Key

Brightness Key

Function LED

Power Button

Charging LED

COMM LED

Internal Speaker

Page 21

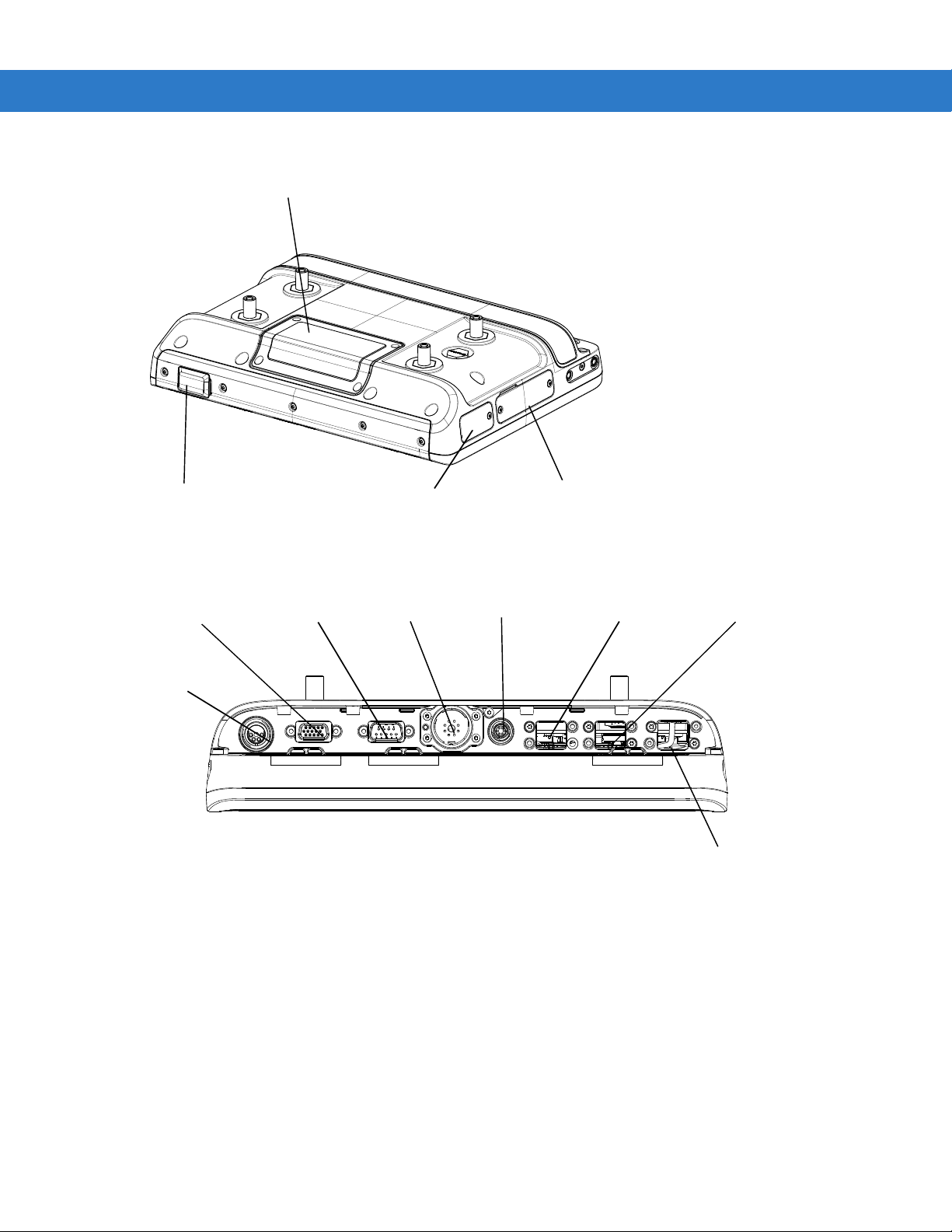

Backup Battery Door

Getting Started 1 - 3

Antenna Port for

Optional External

Antenna

Figure 1-2 VC70 Back View

COM2 + CAN-bus

Power

COM1 Port

Figure 1-3 VC70 Bottom View

Main Power

Switch

Microphone

External Speaker

Bottom Connectors

Service Door

USB 1

USB 2

Ethernet

Page 22

1 - 4 VC70 Vehicle Computer Product Reference Guide

Accessories

Table 1-2 lists the accessories available from Zebral for the VC70:

Table 1-1

Keyboards

Keyboard: QWERTY, 64-key Backlit, IP66, secured USB-A, VC70. Requires

KT-KYBDTRAY-VC70-R mounting tray

Keyboard: AZERTY, 64-key Backlit, IP66, secured USB-A, VC70. Requires

KT-KYBDTRAY-VC70-R mounting tray

Keyboard Protection Grill, QWERTY/AZERTY, VC70 KT-KYBDGRL1-VC70-R

QWERTY/AZERTY Keyboard mounting tray. Includes tilting arms, knobs and screws KT-KYBDTRAY-VC70-R

Keyboard: 21 Keys, BACKLIT, IP66 SEALED, USB, FUNC/NUM KYBD-NU-VC70-03R

Keyboard Protection Grill, Functional/Numeric, VC70 KT-KYBDGRL2-VC70-R

Function/Numeric keypad side mount bracket KT-KYBDMNT-VC70-R

VC5090 keyboard mounting and cable adapters for VC70. Used when reusing existing VC5090

keyboard

Ke yboard: 64 Keys, BACKLIT, IP66 SEALED, HT, QWERTY VC5090KYBD-02R

Ke yboard: 64 Keys, BACKLIT, IP66 SEALED, HT, AZERTY VC5090KYBD-03R

Accessories

Accessory Description Part Number

KYBD-QW-VC70-03R

KYBD-AZ-VC70-03R

KT-VC50KYBD-ADPT-R

Power supplies and power cables

External DC power supply VC70, 9-60VDC Requires 25-159551-01 fused DC power cable to

vehicle battery

AC Power supply Provides power to the VC70 from a 100-240V AC grid. Requires

25-159550-01 adapter cable. Order country specific three wire

grounded AC line cord separately.

External DC power supply

cable to vehicle battery

Cable External power supply cable to VC70 extender. 6.5 feet, VC70 25-159549-01

External power supply

cable, to existing VC5090

power cable

Power supply cable for AC

power supply

9-60V DC, 10 feet includes fuse, VC70. Required for the

PWRS-9-60VDC-R

Includes fuses, 2 feet, VC70.

(VC5090 Cable: 25-71919-03R or 25-71919-04R)

AC power supply adapter cable, 6.5 feet, VC70 25-159550-01

PWRS-9-60VDC-01R

PWRS-14000-241R

25-159551-01

25-159553-01

Page 23

Getting Started 1 - 5

Table 1-1

US AC line cord US AC line cord, grounded, three wire for power supplies

Scanner Cables

USB Cable for

DS3508-ER, LS3408-ER

scanners

RS232 Cable with TTL

Converter

DB15 to DB9 adapter DB15 to DB9 adapter, 6". Use with CBA-R49-C09ZAR for VC70

Accessories (Continued)

Accessory Description Part Number

PWRS-14000-148R, PWRS-14000-241R, PWRS-0102246H51R,

and PWRS-14000-148C. 7.5 feet long.

Associated Countries: United States Works with: MC1000, MC17,

MC55, MC65, MC70, MC75, MC75A, MC9000, MC9100, MC9500,

VC6000, WT4000, and ET1

Coiled, 12 feet, sealed USB secured connector, VC70. Required

when the DS3508-ER or LS3408-ER are connected via one of the

USB ports for HID interface. Can also be used to connect a

charge-only cradle when using the cordless DS3578-ER or

LS3578-ER.

DB9 Female Connector, 9 feet (2.8m) Coiled, Power Pin 9 with

RS232 to TTL converter. To be used with DS3508-ER or

LS3408-ER scanner. Can also be used to connect a charge-only

cradle when using the cordless DS3578-ER or LS3578-ER.

COM2 serial port scanner. Can also be used to connect other

equipment with RS232 interface when CAN bus is not needed.

23844-00-00R

25-159548-01

CBA-R49-C09ZAR

25-159547-01

Mounting

U mount for VC70 with

mounting hardware

Accessory side mount

bracket

Mounting holder

LS34x8ER/LS35x8ER

scanner

RAM bridge with

RAM-D-2461U RAM

MOUNT

RAM-D-2461U RAM

MOUNT

Audio

External speaker Zebra HSN4040A 13 Watt water-resistant loudspeaker. Requires

Used when replacing VC5090 mounted with its own U mount KT-U-MOUNT-VC70-R

Used with HMN1089B microphone or KT-SCANMNT-VC70-R

scanner mounting holder

Requires KT-ACCMNT-VC70-R Accessory side mount bracket KT-SCANMNT-VC70-R

D (2.25”) size ball with screws. Including screws to mount the

PWRS-9-60VDC-01R External DC Power Supply. Used when

replacing equipment already mounted with RAM mounts

D (2.25”) size ball with screws. Used when the

PWRS-9-60VDC-01R External DC Power Supply has to be

mounted away or when AC power supply is used.

Used when replacing equipment already mounted with RAM

mounts

25-159552-01

KT-ACCMNT-VC70-R

RAM-D-2461U-MOTO7

RAM-D-2461U-MOTO7B

HSN4040A

Push-To-Talk Hand

Microphone

GCAI connector, water resistant HMN1089B

Page 24

1 - 6 VC70 Vehicle Computer Product Reference Guide

Table 1-1

Miscellaneous

De siccant bags Set of 5 desiccant bags KT-DSCNT-VC70-05R

Screen protector Set of 5 screen protectors KT-SPRTCT-VC70-05R

Antenna

Antenna 2.4GHZ MIN, 5.9GHZ MAX.

Antenna adapter Adapter for WTS2450-RPSMA Antenna.

Roof mounted mobile

antenna

Accessories (Continued)

Accessory Description Part Number

Speaker cable adapter for HSN4040A, VC70. Required to connect

the HSN4040A external speaker

Connector-mount, multi-band, Omni. Requires the use of an

antenna adapter.

Reverse polarity SMA male reverse thread to reverse polarity SMA

female.

2.4GHZ MIN, 5.9GHZ MAX, 0DBI 8508851K46

25-159552-01

AN2030

RPSMA-RTRPSMA-05R

(Pack of five adapters)

RPSMA-RTRPSMA-10R

(Pack of 10 adapters)

Battery

VC70 battery Spare battery kit BTRY-VC70IAB00

Page 25

Chapter 2 Installation

Introduction

This chapter describes how to install the vehicle computer in a vehicle or on a desktop and connecting the vehicle

computer to a power source. There are different installation options depending on the type of vehicle. This chapter

also describes how to install the various accessories for the vehicle computer. Read all of the following instructions

before you begin.

WARNING

CAUTION

NOTE

!

The vehicle computer and bracket must be firmly secured to a surface that can support the

vehicle computer’s weight.

A competent engineer must perform the installation in a vehicle. Improper installation can damage your

vehicle and/or the VC70.

Do not install the vehicle computer in a location that will affect vehicle safety, drivability, or visibility.

All bolts and screws used for installing the VC70 are metric type with T7 to T30 TORX head.

Page 26

2 - 2 VC70 Vehicle Computer Product Reference Guide

Electrical Power Wiring

IMPORTANT

•

Establish a neat route for the cable, staying clear of moving parts or hot surfaces.

•

Fix the cable to existing cable runs inside the vehicle using cable ties, but make sure they are away from any

moving or hot surfaces.

•

When the cabling must go through a panel, use a suitable gland.

•

When fixing the conduit or cable on the outside of a vehicle, use P-Clips. Either drill and tap the hole or use a

nut and bolt to secure the clip.

•

Ensure the cable does not have tight bends. The minimum recommended radius is 63.5 mm (2.5 in.).

•

Ensure cables do not swing or chafe on the structure. This often requires using cable ties approximately

every foot, and ensuring the cables do not flex often, especially where they connect to the VC70. However, if

you must re-position the VC70 occasionally, ensure there is enough slack in the cable to accommodate

movement without putting tension on the cable.

•

DO NOT wind a cable in and out of the mesh on a cage.

•

On electric vehicles, take the power from as close to the battery as possible, but not directly from the battery

terminals, and not before any main fuse.

•

On gasoline, diesel or propane vehicles, take the power from as close to the battery terminals as possible,

and avoid using existing wiring.

•

Ensure that all fuses are as close as possible to the power source.

When replacing the forklift battery, avoid draining the internal backup battery of the VC70 by pressing

the power button on the front panel for putting the VC70 in unattended mode.

Page 27

Installation 2 - 3

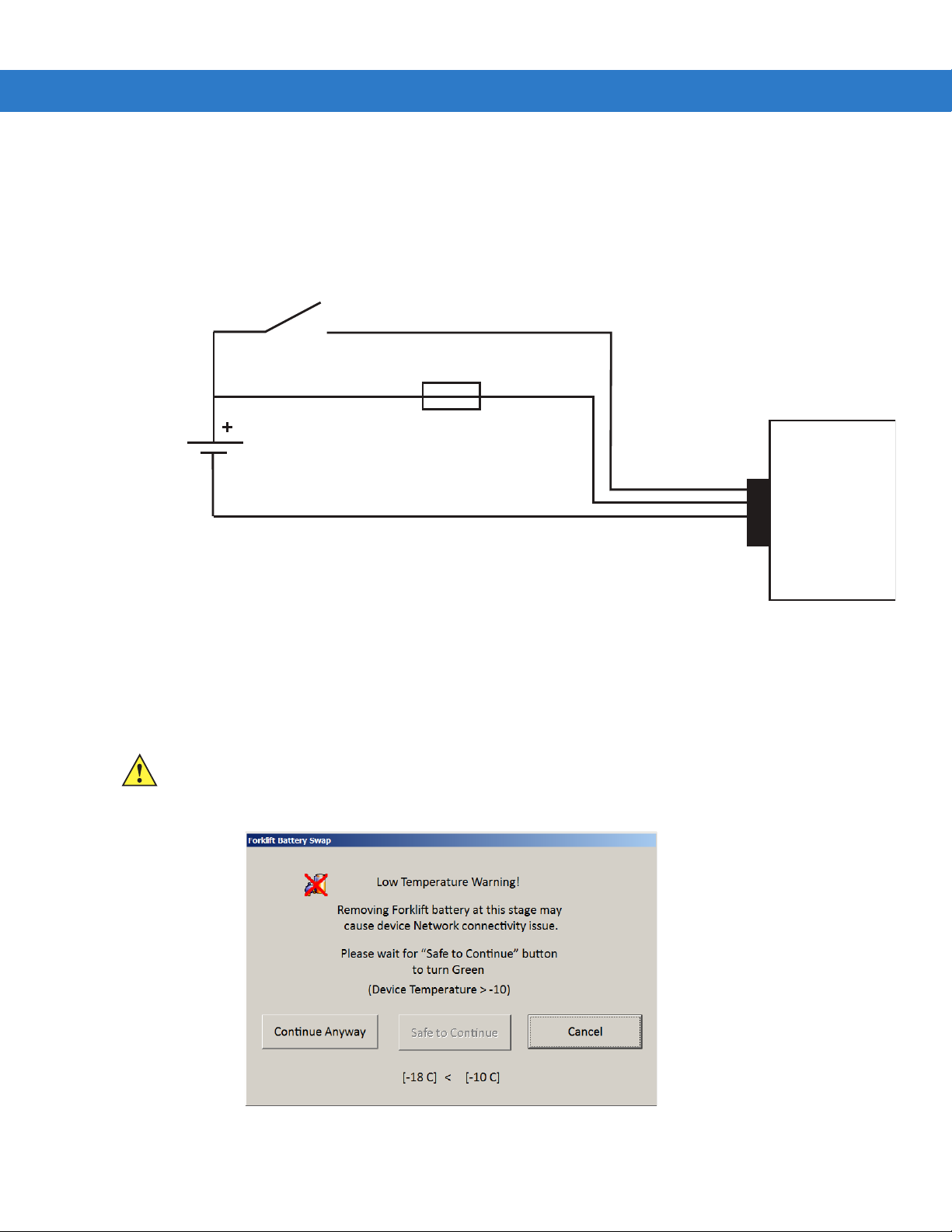

Forklifts and Trucks with 12V, 24V, 36V and 48V Batteries

•

All power wiring must use the supplied 25-159551-01 power cable.

•

One 3AB, 15A, 250V, FST BLO fuse.

•

Keep the path between the battery and the vehicle computer as short as possible and away from any part of

the ignition high tension system.

Yellow

Ignition Switch or Key Switch

15A Fuse

Red

Vehicle

Battery

Power Cable

25-159551-01

9-60V DC

Black

Important: If your vehicle is not equipped with an ignition or key switch, connect the yellow wire directly

to the positive terminal of the vehicle’s battery. Failure to comply, will disenable the VC70 operation.

Figure 2-1

Wiring Diagram

VC70

You can use your old VC5090 power cable. When employing this option, use VC5090 Bridge Cable, PN

25-159553-01. You must also replace the fuses on the red and black wires of the old cable with the new fuses

supplied with the bridge cable kit.

1. Disconnect the vehicle battery.

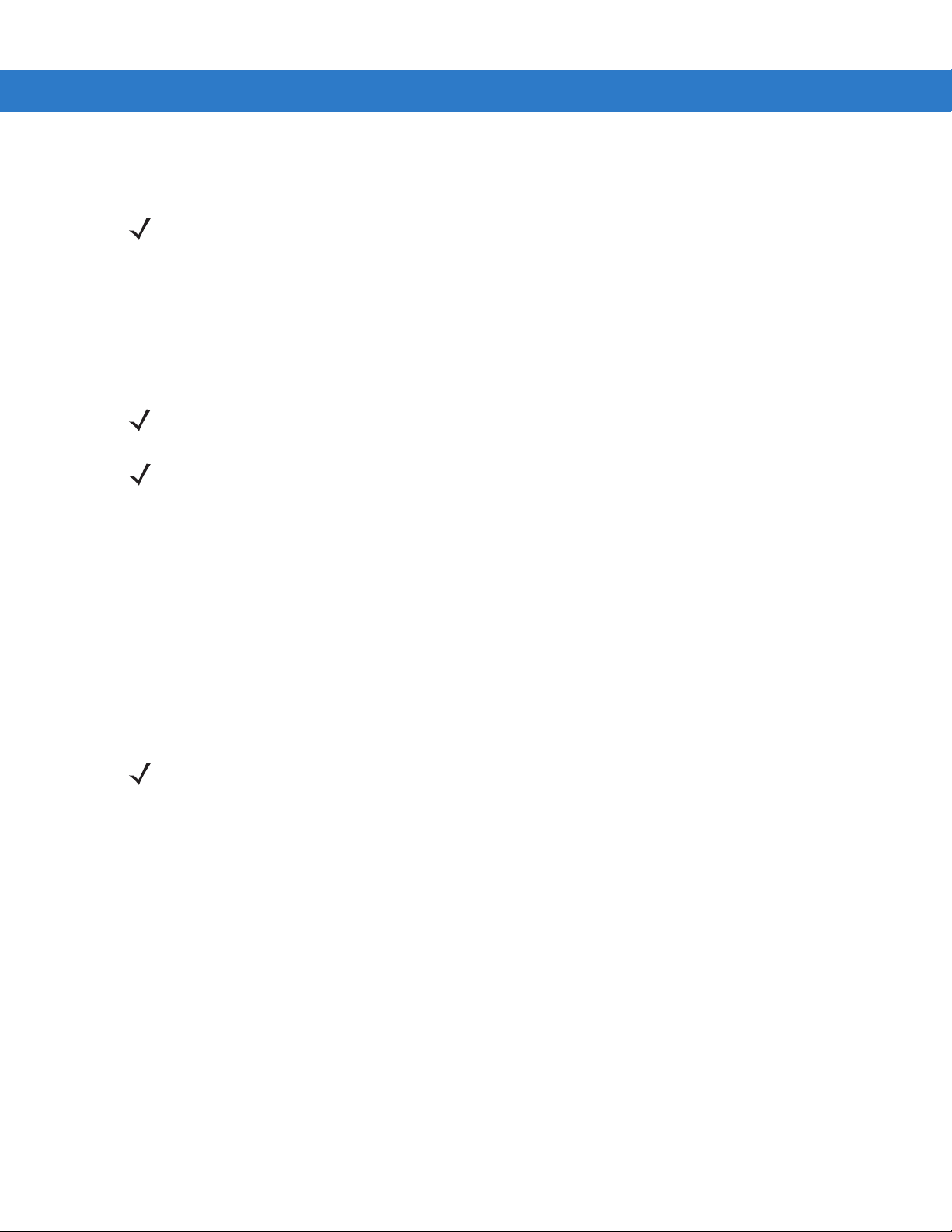

CAUTION

To prevent damage to the VC70, replacing the vehicle battery is forbidden when the ambient

temperature is under -10

shown on the VC70 screen and prevent the user from switching off the VC70. To replace the battery,

move to a place with temperature is above -10

°C

. Attempting to replace a battery under -10

°C

- the warning screen will disappear.

°C

will result in a warning

Figure 2-2

Forklift Battery Swap - Low Temperature Warning

Page 28

2 - 4 VC70 Vehicle Computer Product Reference Guide

2. Connect the red wire directly to the vehicle's battery positive terminal. Connect the black wire directly to the

vehicle's battery negative terminal.

The vehicle computer contains an Ignition Sense feature that detects when the ignition switch or key

NOTE

switch is turned off and shuts the vehicle computer down after a preprogrammed timeout. This feature

allows the operator to use the vehicle computer for a predetermined time period after the ignition switch or

key switch is turned off, then shuts the vehicle computer down automatically to prevent over-discharge of

the forklift battery. The timeout period is adjustable by the user (see Ignition Sensing on page 2-5 for

setting the timeout value). When the vehicle computer enters low power mode using the Ignition Sense

feature, current draw from the vehicle battery is reduced to less than 15mA and the vehicle computer

consumes current from it's internal battery. This feature provides the automatic shutoff functionality of an

external relay, without requiring an actual relay and has the added benefit of allowing the user to work for

a preset time period before shutting down.

NOTE

For power drain of the forklift battery under the various power conditions, refer to Power Status on page

3-22.

NOTE

See the vehicle Owner's Manual for specific wiring information.

3. Connect the yellow wire to the vehicle's ignition or key switch if such is used. If you do not plan on using the

Ignition Sense feature, connect the yellow wire directly to the vehicle’s battery positive terminal.

4. Ensure the wiring connections created are sufficiently insulated from each other.

5. Re-connect the vehicle battery.

6. Connect the power cable connector into the vehicle computer's Power port. Align the keyway on the power

connector with the notch on the vehicle computer’s power port.

7. If the power supply is mounted remotely from the VC70, use 25-159549-01 extender cable to connect

between the power supply and the VC70.

8. Secure the power cables on both sides of the power supply with cable ties as close as possible to the

connectors.

The VC70 display can be blanked when the vehicle is moving to eliminate driver distraction for safety

considerations (see Screen locking feature on page 11-6).

To recover from display lock:

1. Press and hold on touch screen (more than 1 second).

2. Remove your finger from the screen to resume operation.

Page 29

Installation 2 - 5

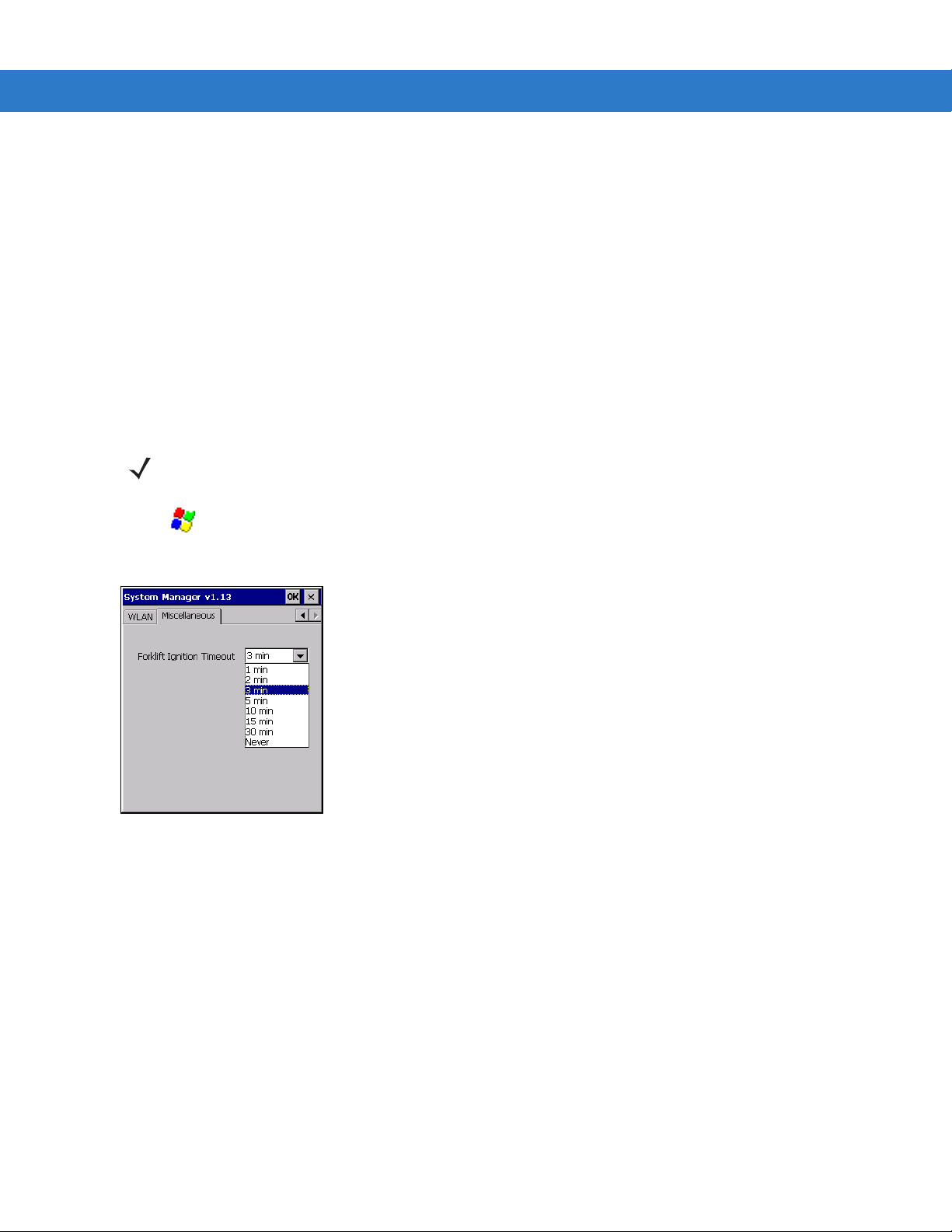

Ignition Sensing

The vehicle computer contains an Ignition Sense feature that detects when the ignition switch or key switch is

turned off and shuts the vehicle computer down after a preprogrammed timeout. This feature allows the operator to

use the vehicle computer for a predetermined time period after the ignition switch or key switch is turned off, then

shuts the vehicle computer down automatically to prevent over-discharge of the forklift battery. The timeout period

is adjustable by the user. When the vehicle computer enters low power mode using the Ignition Sense feature,

current draw from the vehicle battery is reduced to less than 15mA and the vehicle computer consumes current

from it's internal battery. This feature provides the automatic shutoff functionality of an external relay, without

requiring an actual relay and has the added benefit of allowing the user to work for a preset time period before

shutting down.

The power cable must be connected to the ignition switch or key switch. See Forklifts and Trucks with 12V, 24V,

36V and 48V Batteries on page 2-3 for information on connecting the power cable to enable the Ignition Sense

feature.

NOTE

These settings are not persistent across a cold boot.

1. Tap > Settings > Control Panel > VC70 System Manager icon. The System Manager window displays.

2. Select the Miscellaneous tab.

Figure 2-3

3. In the Forklift Ignition Timeout drop-down list, select the amount of time before the vehicle computer shuts

Miscellaneous Tab Window

down after the ignition switch or key switch is turned off.

4. Tap OK.

Page 30

2 - 6 VC70 Vehicle Computer Product Reference Guide

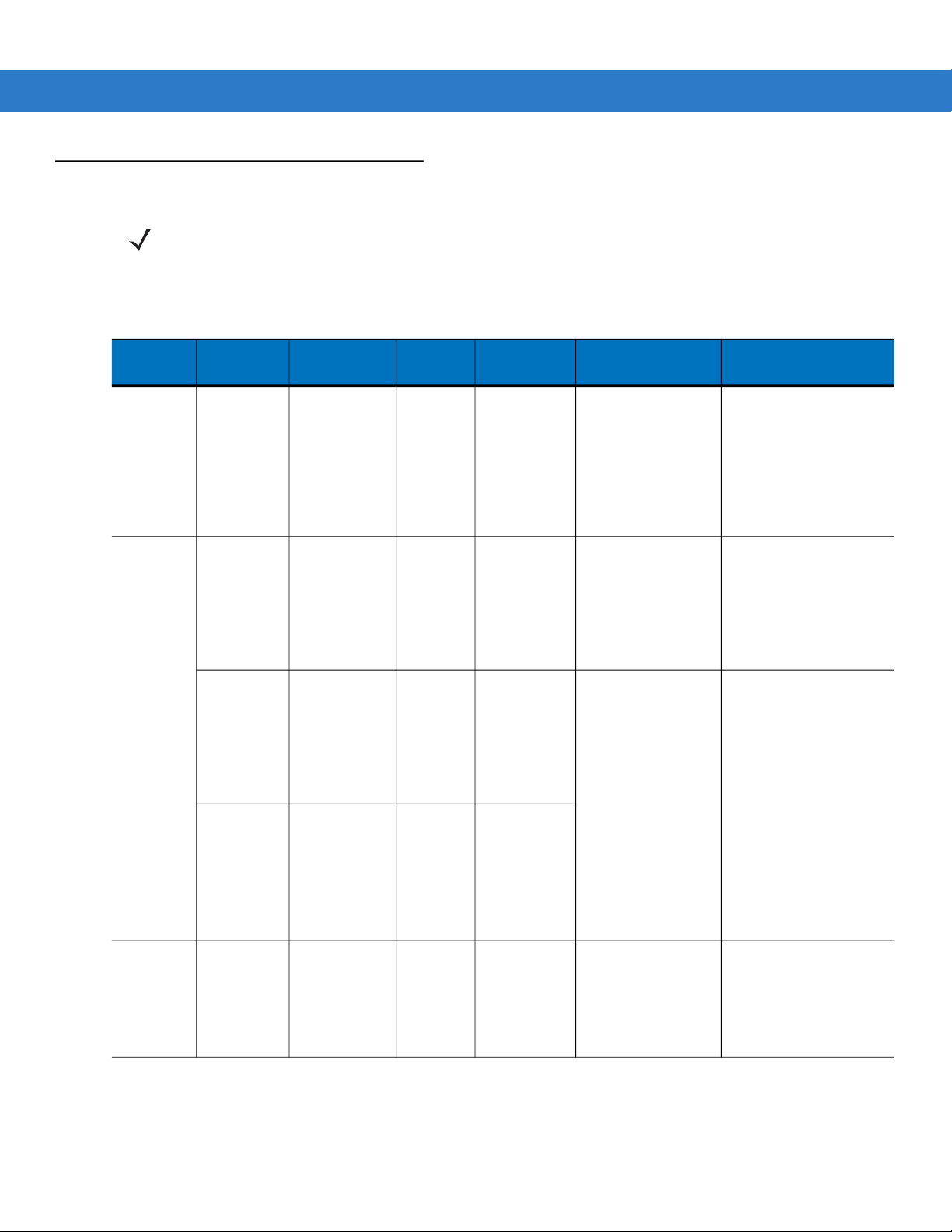

VC70 Power States

NOTE

Refer to Power Status on page 3-22 for description of the various power states.

Table 2-1 describes the power drain of the forklift battery under various power conditions.

Table 2-1

Power

State

Power On Connected On On Not Pressed

Low

Power

VC70 Power States

Forklift

battery

Connected On On

Connected

Not

Connected

Ignition

Off after

inactivity

timer expires

(programma

ble, 3

minutes

default)

Don't Care On Pressed

Power

Switch

On Not Pressed

Power Key

Pressed

(from Power

On State)

Power State

Description

System on with full

functionality.

System on with

display, touch

screen and audio

off. (see Waking

the Vehicle

Computer on page

3-23)

Reduced power

consumption mod,

external power

turned off - 15mA

current drain from

forklift battery.

System powered

from internal

battery. When the

capacity of the

internal battery is

reduced to 50%,

the device goes to

Critical Suspend

state.

Power drain from

forklift battery

Typical when internal

battery is not charging

- 15W.

Typical during internal

battery charging 22W.

Maximum during

operation - 100W.

No internal battery

charging - 7.5W.

Internal battery

charging - 15W

External power supply

idle current - 0.2W

Critical

Suspend

Don't Care Don't Care Off Don't Care

System off. Unit in

backup mode up to

72 hours.

Unit kept alive by

internal backup

battery.

External power supply

idle current - 0.2W

Page 31

Installing the VC70 on a Cart, a Wall, or a Desktop

To mount the vehicle computer on a cart, a wall, or a desktop:

•

Install the U-mount to the desktop.

•

Connect the vehicle computer to the AC power supply.

NOTE

For AC power supply and cables, refer to Accessories on page 1-4.

Mounting the Bracket on a Desktop

Installation 2 - 7

CAUTION

NOTE

Lock Washers

Flat Washers

If mounting to a thin surface such as drywall or plywood, a reinforcing plate is required.

The VC70 ships with four No. 8 Allen head screws (M10x50mm) for securing the mounting bracket. If the

supplied cap screws are not long enough, use M10 - X stainless steel Allen head screws where X represents

the length in millimeters of the required screws.

Allen Head Screws

U-mount

Flat Washers

Mounting Surface

Lock Washers

Nuts

Figure 2-4

Mounting on a Desktop

Page 32

2 - 8 VC70 Vehicle Computer Product Reference Guide

Connecting the Vehicle Computer to AC Power

NOTE

Use only a Zebra-approved power supply, output rated 12 VDC and minimum 9A (part number

50-14000--241R). The power supply is certified to EN60950 with SELV outputs.

To provide power from an AC source:

1. Insert the AC line cord into the AC connector on the universal power supply.

AC Line Cord

Power Port

Figure 2-5

2. Plug the other end of the AC power cable into a wall outlet.

3. Insert the DC power cable into the DC connector on the universal power supply.

4. Plug the other end of the cable into the vehicle computer’s Power port.

Connecting AC power

NOTE

For power supply and cables, refer to Accessories on page 1-4.

Universal Power Supply

(PWRS-14000-24

1R)

DC Power Cable

(25-159550-01)

Page 33

Installing the DC Power Supply (PSU) on the VC70

NOTE

Follow this procedure when using the U-mount. The PSU fastening screws are supplied with the U-mount kit.

5. Attach the PSU to the back of the vehicle computer.

6. Screw the four M5x14mm screws into the PSU mounting holes and tighten. Torque the screws 20 ± 10%

kgf-cm (17 ± 10% lbs-in).

Installation 2 - 9

Figure 2-6

NOTE

Vehicle Computer

PSU

Fastening Screws

Installing the PSU

Whenever the PSU needs to be mounted remotely, refer to Installing the PSU on page 2-9 to prepare the

mounting solution. You need to also use an extender cable PN 25-159549-01 to connect the PSU to the

vehicle computer. For power supply and cables, refer to Accessories on page 1-4.

Page 34

2 - 10 VC70 Vehicle Computer Product Reference Guide

Measurements are given in

millimeters.

Figure 2-7

PSU Installation Template

Installing a Micro SD Card

A micro SD (Secure Digital) card provides secondary non-volatile storage. The card holder is located on the right

side of the VC70 under the Service door.

To install the micro SD card:

1. Remove the two T8 TORX screws securing the Service door.

Service Door

Micro SD Card

Memory Card

Slot

Figure 2-8

2. Push the memory card, with the contacts up, into the card slot until it locks.

3. Replace the Service door and secure using two T8 TORX screws.

Install Memory Card

CAUTION

Ensure to torque the screws to seal the device properly. Otherwise, sealing can be compromised.

Torque the Torx head screws to 4.0 + 10% kgf-cm (3.5 ± 10% lbs-in).

Page 35

RAM Mount Installation

Installation 2 - 11

CAUTION

NOTE

If mounting to a thin surface such as drywall or plywood, a reinforcing plate is required.

For RAM Mounts, refer to Accessories on page 1-4.

The RAM Double Socket Arm Mount allows the VC70 to be easily adjusted to most comfortable location. A single

Adjustment Knob enables simultaneous adjustment of both upper and lower ball joints. The mount affixes to the

forklift cage or other strong surface by the supplied hardware kit and bolts provided by the customer (Search for

VC70 on http://www.rammount.com

).

To install the RAM Mount:

1. If Installed, remove the two threded booshings from within the supporting bracket.

Supporting Bracket

Threded Booshings

Torx 8 screw Locations

Figure 2-9

2. Place the Bridge Mount onto the Supporting Bracket.

3. Use two M12x40mm hex head bolts into mounting holes and tighten. Torque the hex head screws to 350 ±

Removing the Threded Booshings from within the Supporting Bracket

10% kgf-cm (300 ± 10% lbs-in)

4. Use four bolts, nuts, lock washers and flat washers to install the Ball Base to the Bridge Mount. Torque the

bolts to 91.7 kgf-cm ± 10% (79.6 ± 10% lbs-in).

5. Use four bolts, nuts, lock washers and flat washers to install the Ball Base to the forklift surface. Torque the

bolts to 91.7 kgf-cm ± 10% (79.6 ± 10% lbs-in).

Page 36

2 - 12 VC70 Vehicle Computer Product Reference Guide

6. Install the Double Socket Arm Mount. Adjust the VC70 to the best view position and fasten the Adjustment

Knob.

Bushing

Lock Washers

M12x40mm Hex Hhead Bolt

Nut

Flat Washers

Lock Washers

M6 X 22 Bolt

Bridge Mount

Ball Plate

Nut

Lock Washer

Flat Washers

M6 X 22 Bolt

Adjustment Knob

Double Socket

Arm Mount

Ball Plate

Figure 2-10

RAM Double Socket Arm Mount

Page 37

U-Mount Installation

Installation 2 - 13

The U Mount (P/N:

KT-U-MOUNT-VC70-R)

for is used for replacing a mounted VC5090 with the VC70.

To install the U-mount:

1. Position the friction pads in the friction pad mounting area.

2. Position the U-mount over the mounting holes.

3. Place lock and flat washers onto cap screws.

4. Screw the M12x40mm hex head screws into mounting holes and tighten. Torque the hex head screws to 350 ±

10% kgf-cm (300 ± 10% lbs-in).

U -Mount

Lock Washer

Hex Head Screw

Supporting Bracket

Flat Washer

Friction Pad

Friction Pad Mounting Area

Figure 2-11

U-mount Installation

To remove the U-mount:

1. Release and remove the two hex head screws, lock washers, flat washers and friction pad.

2. Remove the U-Munt from the supporting bracket.

Remove the two Torx 8 screws that secure the two threded booshings.

Page 38

2 - 14 VC70 Vehicle Computer Product Reference Guide

Installing the VC70 on a Forklift

CAUTION

Follow the instructions below to properly install the VC70 on a forklift.

•

Determine the best location for mounting the vehicle computer taking into consideration the driver’s field of

view and ease of accessing the vehicle computer.

•

Install the appropriate mounting hardware.The VC70 ships with four No. 8 Allen head screws (M10x50mm)

for securing the mounting bracket. If the supplied cap screws are not long enough, use M10 - X stainless

steel Allen head screws where X represents the length in millimeters of the required screws.

•

Connect the vehicle computer to the vehicle’s wiring system.

A competent engineer must perform the installation in a vehicle. Improper installation can injure the

operator and damage your vehicle and/or the VC70.

Positioning the Vehicle Computer

•

Determine the best position for the vehicle computer and all the associated components. If a similar vehicle

computer was previously installed, check to see if the position it used is suitable for the VC70.

•

Test the installation for at least 30 minutes before installing on another vehicle. Record all details:

• Check that the position of the vehicle computer does not obstruct vehicle controls.

Figure 2-12

View Obstruction

• Check that the vehicle computer does not obstruct the driver's view.

• Check the position of the vehicle computer for user comfort over long periods.

• Check positioning to avoid extreme wrist angles that may cause injury.

Page 39

Installation 2 - 15

Figure 2-13

Figure 2-14

Avoid Extreme Wrist Angles

Optimum Wrist Positions

Page 40

2 - 16 VC70 Vehicle Computer Product Reference Guide

Mounting the Vehicle Computer

U-Mount Installation Template

Drill Holes: 10.1 mm ± 0.1 mm

0.43 ± 0.004 in.

160.00 ± 0.20 mm

6.299 ± 0.008 in.

25.40 ± 0.10 mm

1.00 ±0.004 in.

Figure 2-15

Mounting Template

Page 41

Important Fixing Information

Installation 2 - 17

CAUTION

•

Mounting surface must be flat and stiff and it must extend evenly for the entire length of the mounting bracket

Any modification to supplied mounting bracket could cause failure of the unit and/or mountings.

surface.

•

All four mounting holes must be used.

•

All nuts and bolts must be checked periodically and tightened if required.

•

When installing the vehicle computer, care must be taken to ensure that the mounting bracket footprint is fully

supported. Additional plates may be required to achieve this.

•

Do not mount the vehicle computer with the mounting bracket perpendicular to a wall.

Mounting onto an Over-Head Cross-Beam Example

The diagram below illustrates a typical installation where the vehicle computer is mounted onto a cross-beam.

Lock Washers

Nuts

Flat Washers

Flat Washers

Vehicle Cross-Beam

Allen Head Screws

Figure 2-16

Lock Washers

Mounting the VC70 onto an Over-Head Cross-Beam Example

U-mount

Mounting onto an Over-Head Cage Example

The diagrams below illustrates a typical installation where the vehicle computer is mounted on an overhead cage.

A customer supplied mounting plate must be used that can withstand the weight of the vehicle computer under

vibration and shock. The plate must be made of stainless steel or hardened steel with the following dimensions: 3.0

in. (76.0 mm) wide, 8.66 in. (220.0 mm) long and 0.2 in. (5.0 mm) thick. The plate must be secured with hardware

or to the underside of the cage by welding.

Page 42

2 - 18 VC70 Vehicle Computer Product Reference Guide

Lock Washers

Flat Washers

Flat Washers

Lock Washers

Allen Head Screws

Nuts

Customer Supplied

Mounting Plate

U-mount

Figure 2-17

Mounting on Flat Overhead Beams

Page 43

Installation 2 - 19

Nuts

Allen Head Screws

Figure 2-18

Lock Washers

Flat Washers

Flat Washers

Lock Washers

Mounting on Transverse Overhead Beams

Mounting on a Dashboard or Horizontal Surface Example

Customer Supplied

Mounting Plate

Welded to Beams

U-mount

The diagram below illustrates a typical installation where the vehicle computer is mounted on a dashboard or

horizontal flat surface.

NOTE

If mounting to a thin surface, a reinforcing plate maybe required.

Allen Head Screws

Lock Washers

Flat Washers

U-mount

Flat Washers

Lock Washers

Nuts

Mounting Surface

Figure 2-19

Mounting on a Vehicle Dashboard

Page 44

2 - 20 VC70 Vehicle Computer Product Reference Guide

Installing the Optional QWERTY/AZERTY Keyboard

The keyboard kit contains the following items:

•

Keyboard

•

Right and left mounting arms

•

Four torx head screws with flat and lock washers

•

Six screws with captive flat and lock washers (for keyboard fastening)

•

Two locking knobs, two flat washers and two lock washers.

1. Position the keyboard on the tray and fasten six M4x10mm screws.

6 Screws with

captive washers

Tray

Keyboard

Figure 2-20

2. Attach the left and right mounting arms to both sides of the VC70, using the M5x14mm Torx head screws with

flat and lock washers. Only tighten the cap screws three turns.

Attaching the Keyboard to the Tray

NOTE

For optional QWERTY/AZERTY keyboards, refer to Accessories on page 1-4.

Page 45

Left Mounting

Arm

Torx Head

Screws with Flat

and Lock

Washers

Flat Washer

Lock Washer

Locking

Knob

Installation 2 - 21

Figure 2-21

1. Insert the keyboard locking knobs through the washers and brackets and screw into the keyboard tray. Tighten

Attaching the Brackets to the VC70

fully to lock into place.

2. Torque the mounting arms torx head screws to 40 + 10% kgf-cm (35 + 10% lbs-in).

3. To adjust keyboard tray position, loosen the right and left locking knobs two full turns and rotate the keyboard

tray to the desired position. The keyboard tray snaps into possible positions as it is rotated.

Figure 2-22

Adjusting the Keyboard Tray Position

4. Tighten the keyboard tray locking knobs to secure the tray in position.

5. Plug the keyboard cable into one of the USB connectors and carefully screw the locking screws using a flat

head screw driver.

Page 46

2 - 22 VC70 Vehicle Computer Product Reference Guide

USB Connector

Figure 2-23

USB Connectors

Installing the Optional VC5090 Keyboard on the VC70

You can install the VC5090 keyboard on the VC70 using the keyboard adapter kit (PN KT-VC50KYBD-ADPT-R).

The kit contains the following items:

•

Two spacers with screws and washers

•

Adapter cable

NOTE

When using the VC5090 keyboards, the integrated keyboard heater is not supported.

For optional VC5090 keyboards, refer to Accessories on page 1-4.

1. Attach the keyboard spacers to both sides of the VC70 using 2 M5x14mm torx head screws with captive

washers for each spacer. Tork the screws to 20 + 5% kgf-cm (17 + 5% lbs-in).

Left Hand

Bracket

VC70 Spacer

Torx Head

Screws

VC70

Locking Knob with Flat and

Lock Washers

Figure 2-24

Cap

Screws

VC5090 Keyboard

Installing the VC5090 Keyboard on the VC70

Page 47

Installation 2 - 23

2. Attach the VC5090 keyboard brackets (part of the VC5090 keyboard assembly) to both sides of the VC70,

using the cap screws with captive washers. Only tighten the cap screws three turns.

3. Insert the keyboard locking knobs through the washers and brackets and screw into the keyboard. Tighten fully

to lock into place.

4. Torque the bracket cap screws to 230 kgf-cm (200 lbs-in).

5. Connect the VC5090 keyboard cable to the supplied adapter cable.

Connect the VC5090 Keyboard Cable here

Connect to a VC70 USB Connector

Figure 2-25

6. Connect the USB connector of the adapter cable into one of the VC70 USB connectors and carefully screw the

VC5090 Adapter Cable

locking screws using a flat head screw driver.

Installing a Numeric Keyboard

The Numeric keyboard is installed using the following items:

•

numeric keyboard mount with all required screws for attaching the keyboard to the mount and the mount to

the vehicle computer

1. Attach the numeric keyboard to the mount, using six M4x10mm torx head screws with captive washers.

2. Torque the numeric keyboard Torx head screws to 8 + 10% kgf-cm (7 + 10% lbs-in).

NOTE

The Numeric Keyboard can be installed on both sides of the Numeric Keyboard Mount.

For optional numeric keyboards, refer to Accessories on page 1-4.

Page 48

2 - 24 VC70 Vehicle Computer Product Reference Guide

Numeric Keyboard

Figure 2-26

3. Attach the numeric keyboard mount to the VC70, using four M5x14mm torx head screws with captive

Installing the Numeric Keyboard on the Mount

Numeric Keyboard Mount

6 Torx Head Screws with captive washers

washers.Tighten the screws.

4. Torque the numeric keyboard torx head screws to 20 + 10% kgf-cm (17 + 10% lbs-in).

Numeric Keyboard

Numeric Keyboard Connector

4 Torx Head Screws with

Captive Washers

Figure 2-27

5. Connect the numeric keyboard to a free USB connector. Fasten the screws using a flat head screw driver.

Installing the Mount on the VC70

Page 49

Keyboard Protection Grill Installation

To protect the VC70 keyboard, it is recommended to install a protection grill. Different grills should be used with the

QWERTY/AZERTY or Numeric keyboard.

Each grill kit includes the following items:

•

Two Securing Strings

•

Keyboard Protection Grill

To install the grill:

1. Place the cover onto to the VC70 keyboard.

2. Use the two Securing Strings to attach the Protection Grill to the keyboard.

Installation 2 - 25

Numeric Keyboard Protection Grill

Figure 2-28

Keyboard Covers

NOTE

For Keyboard Protection Grills, refer to Accessories on page 1-4.

QWERTY/AZERTY Keyboard Protection Grill

Securing

Strings

Page 50

2 - 26 VC70 Vehicle Computer Product Reference Guide

Installing the Scanner Mount