Page 1

Unpack Your Printer

Printer

Power Cord

UPS

2348 Thermal Printer

Quick Start

+

®

Parallel Cable

Quick Start

USB Cable

Note: Ethernet option printers do not include any interface cables.

UPS

2348 Thermal Printer

Quick Start

+

Page 2

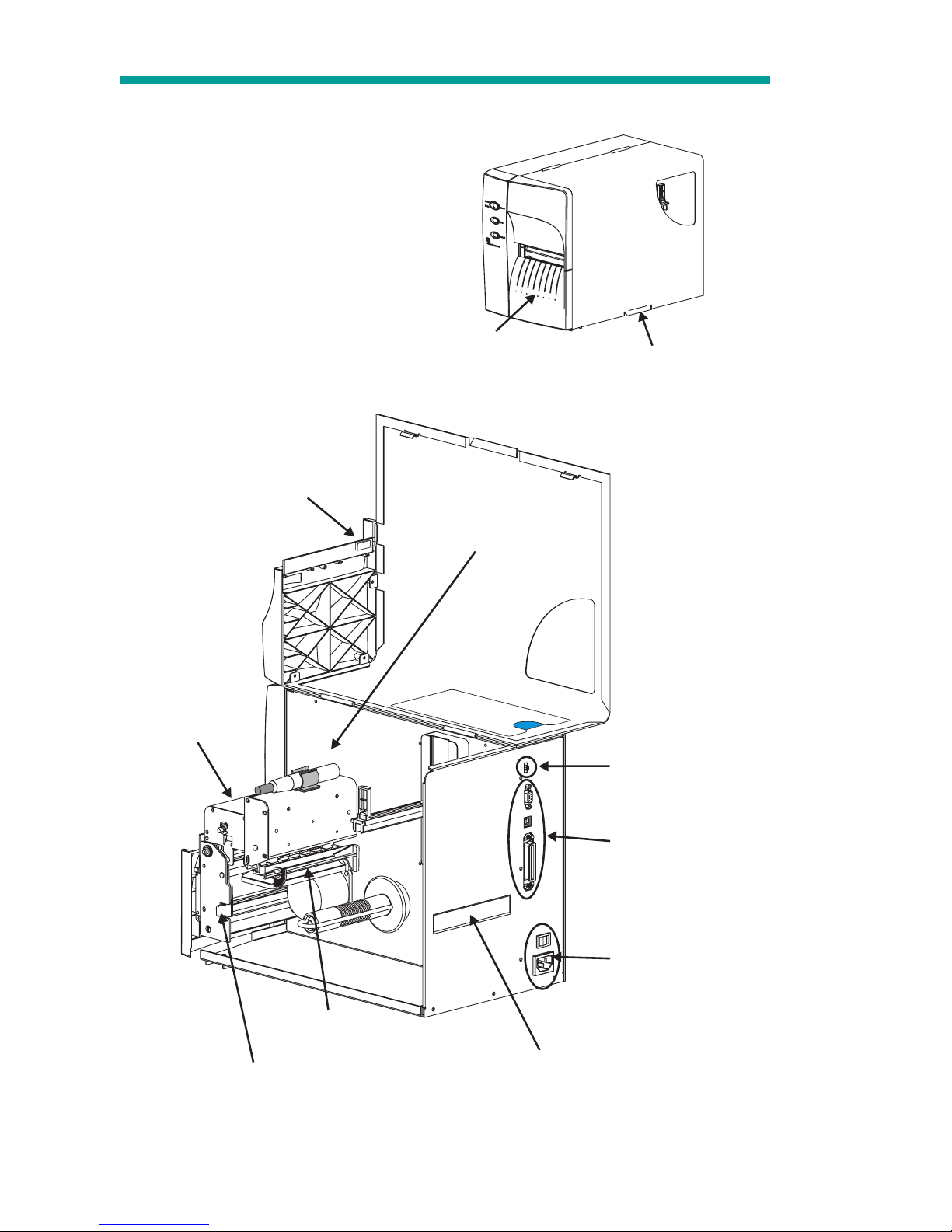

Getting To Know Your Printer

Page 2 980385-003 Rev.A

Auxiliary Media Access

Media Access

Door

(Lift to Open)

Peeler Bezel

Cleaning Pen

Label Taken Sensor

(Built into door)

Power Switch

& Cord Module

I/O Connectors

Label Mode

Switch

Media Sensor

and Guide

printhead

Release Lever

Printhead

Assembly

& Bracket

Page 3

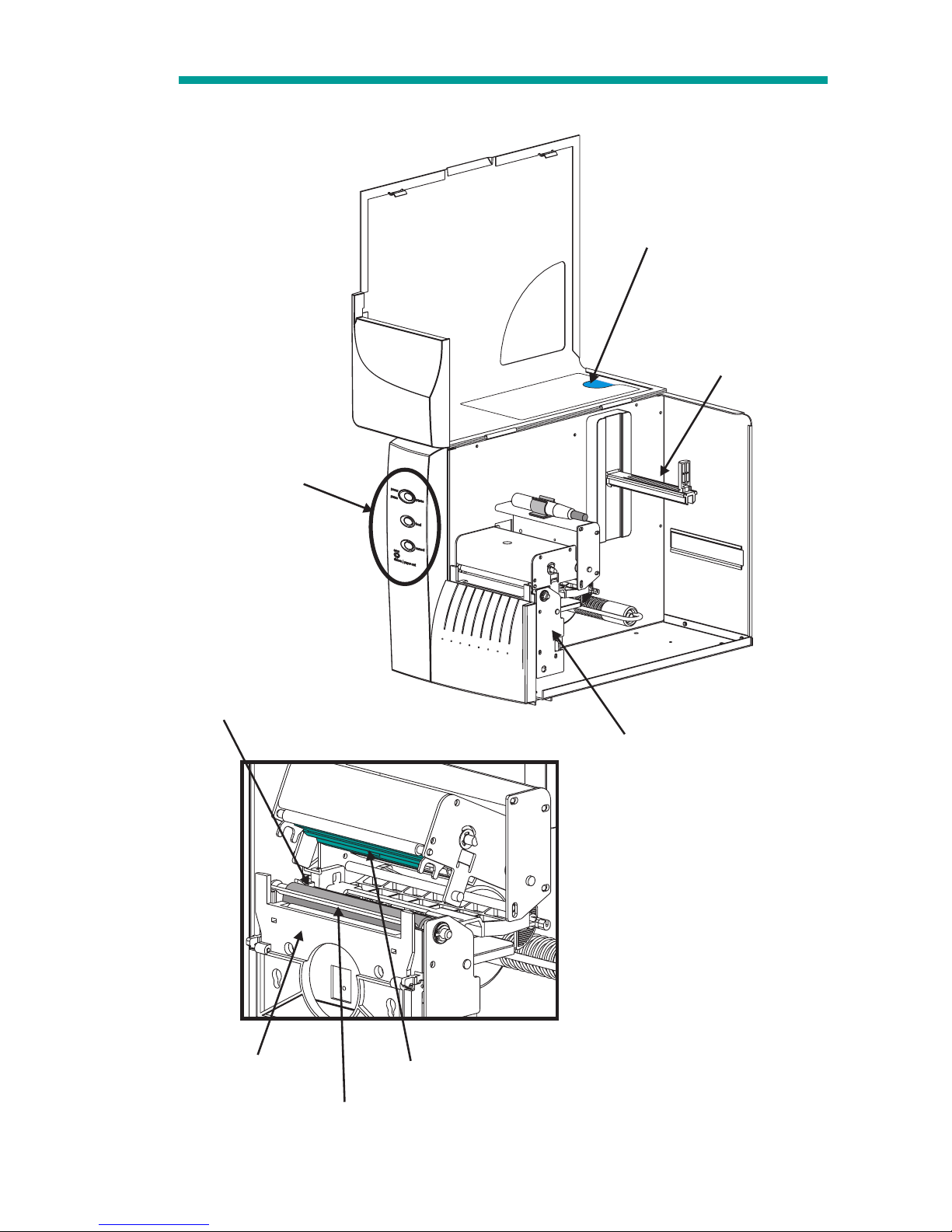

Getting To Know Your Printer

980385-003 Rev.A Page 3

printhead

Platen

Roller

Peel/Tear

Bar

Liner "Peeler"

Gate

Controls

Media Roll

Holder

Save-A-Printhead

Cleaning Film

(Storage Pocket)

Platen

(Media Drive)

Roller Bracket

Page 4

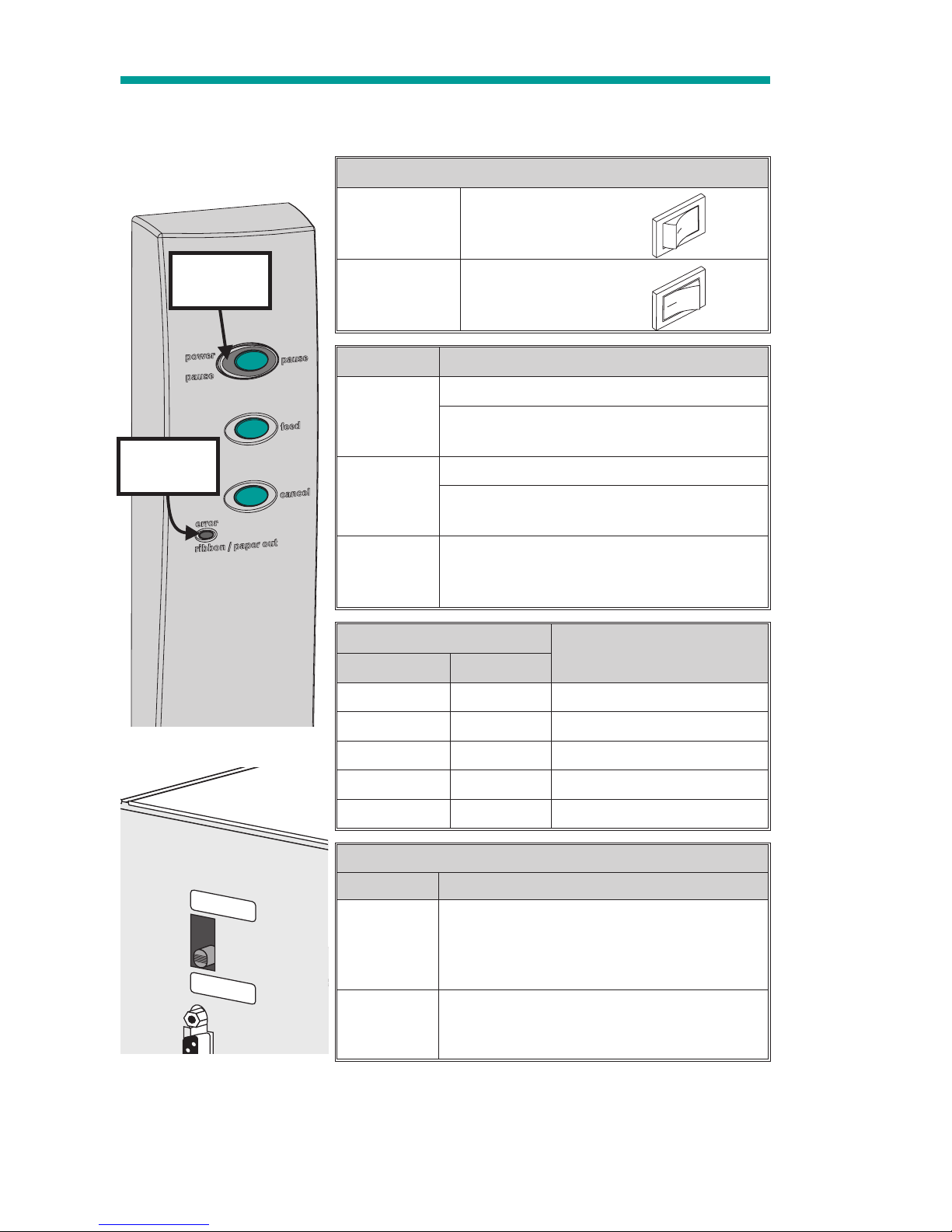

Controls and Indicators

Power Switch

OFF

0 = Off

ON

1 = On

Button Function

PAUSE

Press Once - Halt batch printing.

Press Second Time - Resume batch

printing operation.

FEED

Press Once - Feed one label or “form”.

Press & Hold - Will feed labels until the

FEED button is released.

CANCEL

Press Once - resets and terminates any

print operation in progress and clears the

command input buffer.

Indicator LEDs

Condition Report

POWER ERROR

On Solid OFF

Power On

Flashing OFF

Pause

OFF Flashing

Printhead Open

OFF On Solid

Labels Out

OFF

On Solid

Hardware Error

Label Mode Switch

Mode Description

Peel

Print one label and pause. Remove label.

Prints next label. Repeats until print opera

tion is completed. Use label liner rewinder

to peel the liner from the label.

Batch

Standard operation - Prints one or more

labels until the print form operation is

complete.

Page 4 980385-003 Rev.A

PEEL

BATCH

O

O

Power

Indicator

Error

Indicator

Page 5

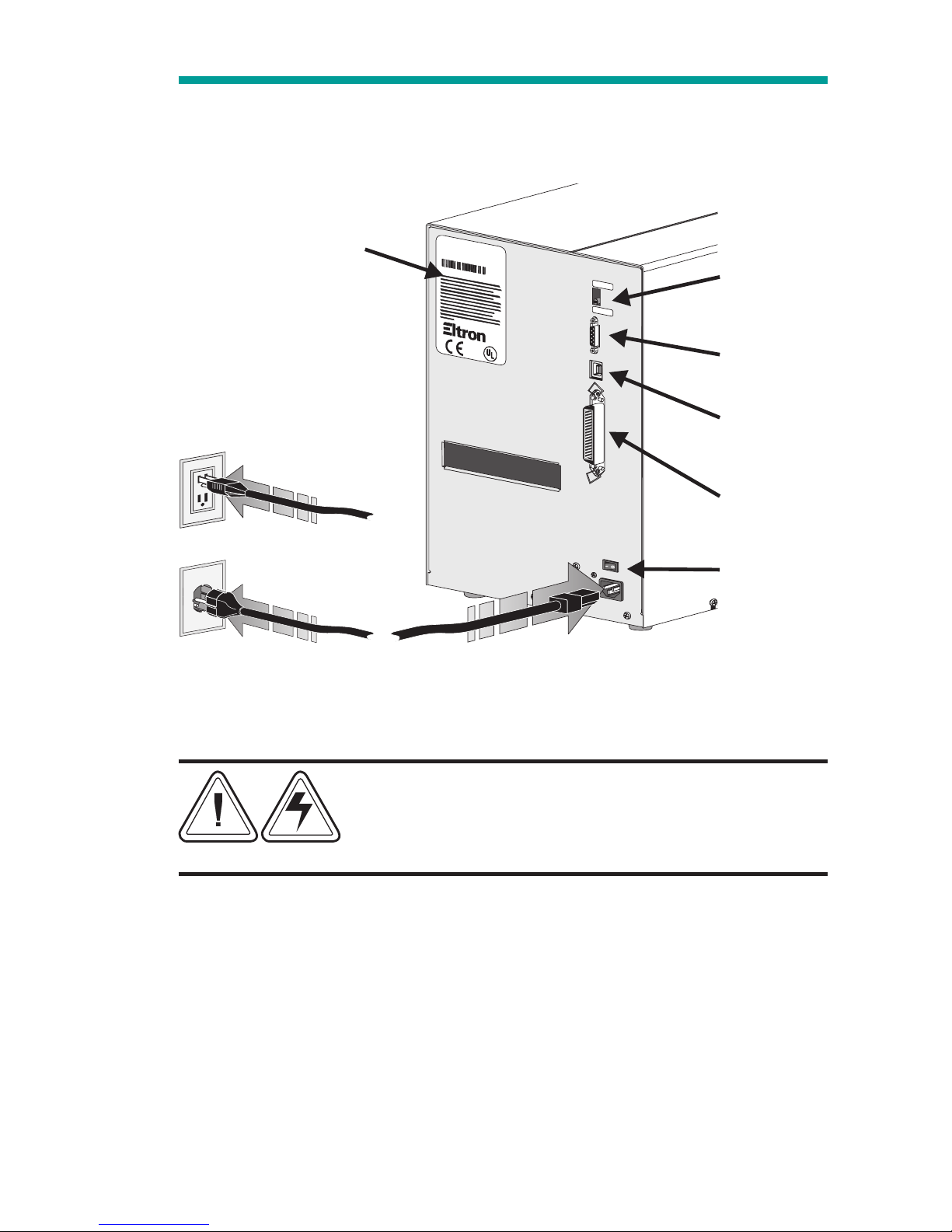

Installation

Connect the printer power and interface cable.

The printer’s serial port interface (RS-232) default setting is 9600 baud,

No parity, 8 Data bits and 1 stop bit.

Warning - Shock Hazard

See the back page, page 27, for important

information on handling, set-up and installation

of your printer.

If you use a USBcable, the New Hardwareand Printer Wizards help

you. Attachthe USB cable between the printer and the computer. Turn

on the printer. The computer detects a USB device, installs USB printer

support; then installs the printer driver.

If the computer prompts you to browse to file locations, find the

OEMSETUP.INF and USBPRINT.INF files under the UPS folder:

c:\UPS\Common\Foss\Drivers

980385-003 Rev.A Page 5

PEEL

BATCH

0 = Off

Batch

Mode

USB

Interface

Serial

Interface

Parallel

Interface

Check

Voltage

Part No.: 120XXX-XXX

Serial No.: XXXXXXXX

Input Power:115VAC 6.3A 50/60Hz

LP 2348 Plus

Page 6

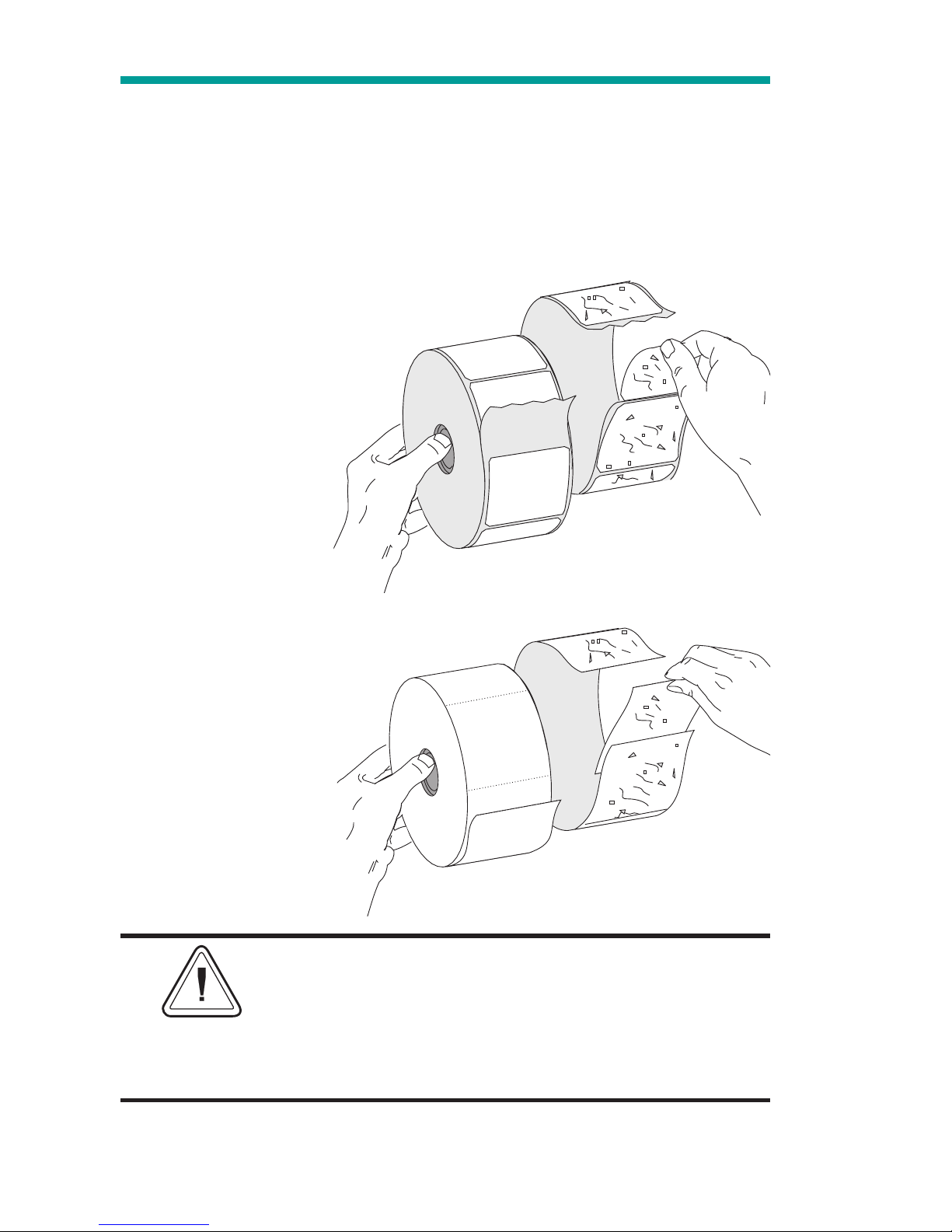

Before Loading Media

You must remove the outside length of media (that is, one, full revolution of

labels and any liner). Tape or adhesive holds the loose end andthe outside

length of media becomes contaminated when handled or stored.When

you remove this part of the media, you remove the oils, dust,and adhe

-

sives that contaminate it.

You must avoid dragging adhesive or dirty

media between the printhead and platen. Such

an occurrence damages the printhead and is

not covered under your warranty. Using clean

media prevents damage and reduces wear on

the printhead and platen.

Page 6 980385-003 Rev.A

Labels

Remove all labels

that are held by

adhesives or tape

Tag Stock

Detach both ends of

the bottom tag

Page 7

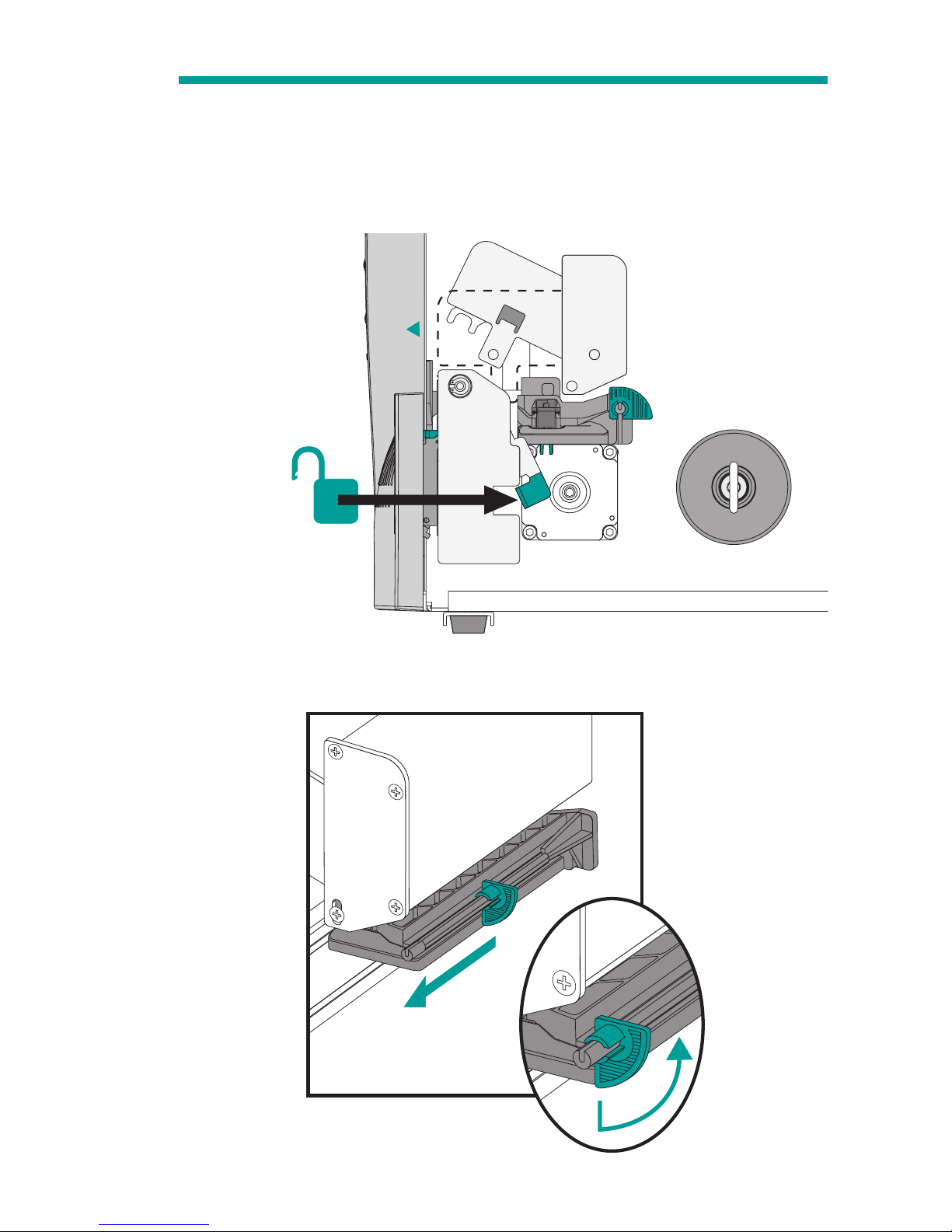

Loading Media

Use approved media for best results.

Step 1

Open printhead.

Step 2

Open media guide.

980385-003 Rev.A Page 7

B

A

Page 8

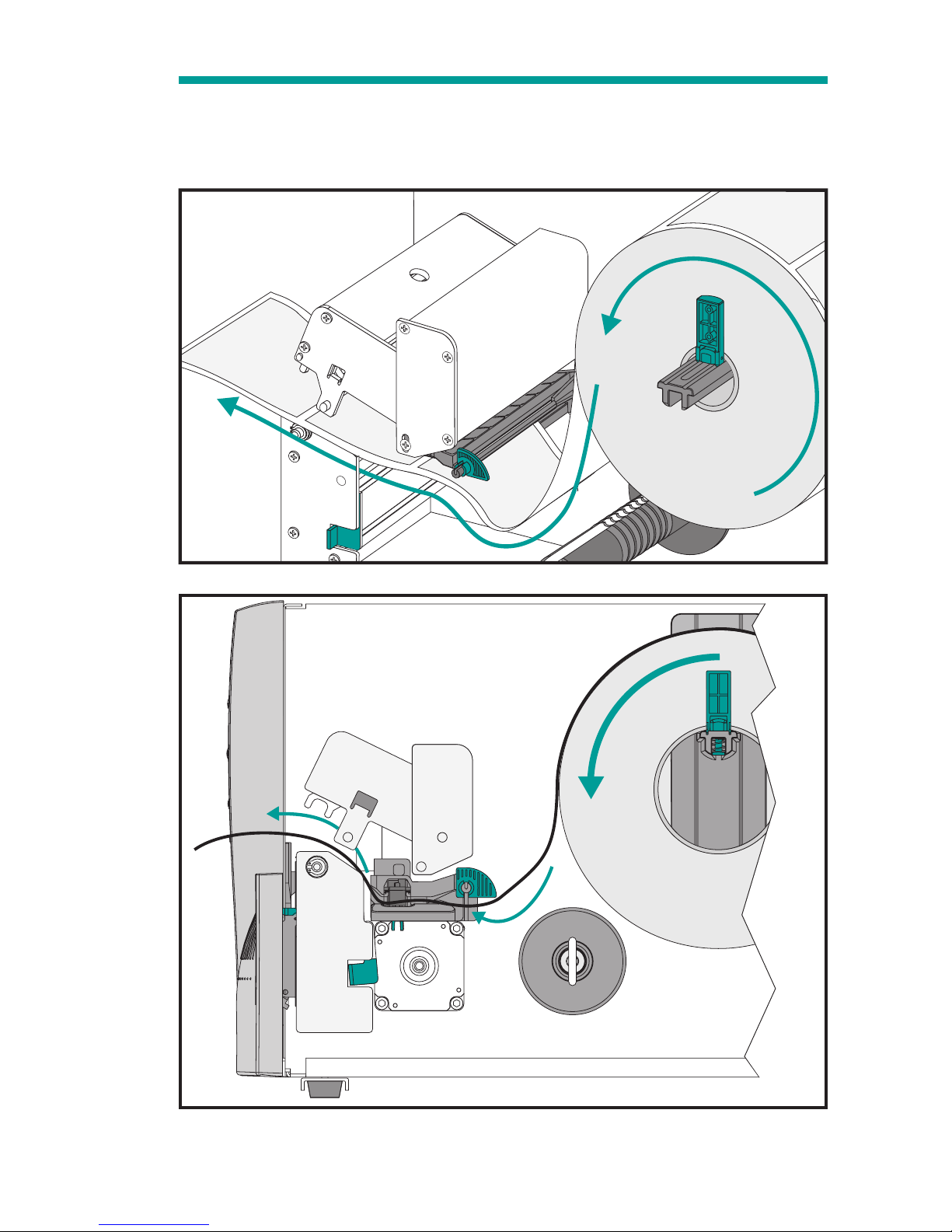

Step 3

Mount and thread the media.

Push the roll tight againsttheinsiderollbracketwiththegreenfliparm.

Page 8 980385-003 Rev.A

Page 9

Step 4

Thread the media through the media guide and printhead.

980385-003 Rev.A Page 9

Page 10

Step 5

Close media guide. Slide the guide against the media until the media

touches the inside stop.

Step 6

Close the printhead.

Page 10 980385-003 Rev.A

A

B

2"

(50mm)

4"

(100mm)

Page 11

AutoSense: Media Calibration

Run the printer's AutoSense routine to calibrate the printer for new

media.The printer will measure the label, liner and gap parameters and

print a configuration status label.

Step 1

Close the printer.

Step 2

With the label mode switch set to "Batch", turn on the printer.

980385-003 Rev.A Page 11

PEEL

BATCH

PEEL

BAT

C

H

I

nputPower: 115VAC 6.3A 50/60Hz

ate:

PartNumber:

SerialNo.:

InputPower:

2746-120XXX-001

Forhomeorofficeuse

02/01/0

1

12345678912

115-230VAC, 2-1Amps, 50/60 Hz

N2557

®

C

US

I.T.E.

8T34

MADEIN

U

SA

withforeign and domestic parts

Page 12

AutoSense: Media Calibration

Step 3

Press and hold the Cancel and Feed buttons for one (1) second and then

release only the Cancel button. Afterthree(3)more seconds, release the

Feed button.

Step 4

A "Dump" mode configuration status label will print. Press the FEED

button (do not hold down feed button) until “Out of DUMP” prints.

Page 12 980385-003 Rev.A

4 MO3257 3.18.01

Serial port : 96,N,8,1

Image buffer size:245K

Fmem:000,0K,019.9K avl

Gmem:000K,0241K avl

E

I8,0,001 rY

S8 D12 R032,000 ZT UN

q0784 Q1227,034

Option:D

11 12 13

now in DUMP

mem:000K,0241K avl

1 sec.

3 sec.

3

sec.

1 sec.

Page 13

Label Peel Mode

The printer can present a single peeled label and wind the backing.

Removing the presented label will prompt the printer to print the next

label.

Preparation

Feed approximately 16 inches of media and remove the exposed labels

from the liner.

980385-003 Rev.A Page 13

Page 14

Step 1

Open the peeler gate. Push the peeler bezel in the lower middle area

and the gate will snap open.

Page 14 980385-003 Rev.A

Page 15

Step 2

Thread the media through the peeler gate and attach the media to the

rewind tube with the clip.

980385-003 Rev.A Page 15

Page 16

Step 3

Wind the rewind tube counter-clockwise (to remove liner slack) and

close the peeler gate.

Step 4

Set the Label Mode switch on the rear panel to PEEL.

Page 16 980385-003 Rev.A

PEEL

BATCH

Page 17

Step 5

Press CANCEL to initialize the Peel Mode. Carefully close the printer

door.

Step 6 - Optional

Press the FEED button to remove slack and the firstlabelispresented.

980385-003 Rev.A Page 17

CANCEL

FEED

Page 18

Using UPS Internet Shipping to Install the Printer

1

1. Click on the Shipping tab after Log In.

2 Click on 'Create a Shipment'. Accept “Terms and

Conditions” to continue.

3 Click on 'Set Preferences'.

4 Scroll to Printing Preferences and click 'Install UPS

Thermal Printer'.

5 Follow the instructions to install the printer driver and

plug-in.

6 Now you are able to print via UPS Internet Shipping using

your UPS 2348 Thermal Label Printer.

If you have any questions, call the UPS Internet Shipping

Support Help Desk at 877-289-6418.

Page 18 980385-003 Rev.A

Page 19

980385-003 Rev.A Page 19

Page 20

Cleaning Your Printer

The printer’s media path allows for cleaningand clearing of media jams.

The user can clean the printhead, platenroller and areas adjacentto the

media path surfaces.

Warning -Shock Hazard

Always turn the printer off before cleaning.

The media path surfaces (except the printhead) can be cleaned with a

lint free, clean, damp cloth very lightly moistened with medical grade

alcohol. Alcohol may be used to help remove any adhesive or label

material buildup.

Warning - Static Discharge.

Never touch the printhead. Always clean the

printhead with a cleaning pen (to protect the

printhead from static discharge and fibers).

If a label has become jammed in the printer,

remove the label and any adhesive residue,

immediately. Adhesive may spread throughout

the printer’s media path if not completely

removed. Many adhesives are permanent and

have short “set” times.

Page 20 980385-003 Rev.A

Page 21

Cleaning the Print Head

As you use your printer, the printhead may become contaminated

resulting in poor print quality. Whenever new labels are loaded into the

printer, the printhead should be cleaned with a cleaning pen.

Step 1

Open the printer and the printhead carriage.

Step 2

Gently rub the cleaning pen across the amber area of the printhead.

Allow the printhead to dry for 1 minute before loading labels.

Do Not Clean the printhead with sharp

objects! Only used approved cleaning

materials.

980385-003 Rev.A Page 21

Thermal Printer

Cleaning Pen

Printhead

Page 22

Print Head Care

The main factors that contribute to reduced head life are:

Touching the printhead! Static electricity can discharge and

damage the printhead. The body's oils and acids also damage

the printhead.

Cleaning - For optimum performance, clean the printhead

regularly after every roll of direct thermal labels.

Abrasion - Over time, the movement of media/ribbon across

the printhead will wear through the protective ceramic coating,

exposing and eventually damaging the print elements (dots).

Use of proper media - Use only approved media.

Non-approved media may contain chemicalsthat can destroy or

dramatically reduce the printhead's life.

Temperature - printhead density (heat) setting. Set the density

to the lowest possible setting that prints a good image.

Print Speed - Fast print speeds have higherfrictionlevelsonthe

printhead's surface.

Regular printhead Conditioning-UsetheSave-A-Printhead

cleaning film to remove printhead contamination buildup

quickly and easily. (Part No.105950-047)

Page 22 980385-003 Rev.A

Page 23

Printhead Conditioning

Every third new roll of labels the printhead needs regular printhead

conditioning. Use the Save-A-Printhead cleaning film to keep particle

and contamination build-up from occurring.

Using the Save-A-Printhead cleaning film:

1. Turn the printer power off. Remove the media.

2. Clean the printhead with the cleaning pen.

3. Insert the cleaning film with the label near the printhead.

4. Close and latch the printhead. Grasp the cleaning film and

pull it out of the front of the printer.

5 Clean the printhead with the cleaning pen.

6. Record the date cleaned on the rear of the film's label.

7. Load media and resume printing.

980385-003 Rev.A Page 23

Save-A-Printhead

Cleaning Film

Follow Instructions

On The Label

Page 24

Cleaning the Platen Roller

The platen (drive) roller normally does not require cleaning. Paper and

liner dust can accumulate without effecting print operations. Contami

nates on the platen roller can damage the printhead or cause the media

to slip when printing. Adhesive, dirt, general dust, oils and other

contaminates should be cleaned immediately off the platen.

The platen can be cleaned with a fiber free swab (such as a Texpad

swab) or a lint free, clean, damp cloth (such as Kimwipes) very lightly

moistened with medical gradealcohol (95% pure or better).Do Not Use

the Cleaning Pen!

1. Open the printhead and remove the media.

2. Clean the platen surface with the alcohol moistened swab.

Hand rotate the platen while swabbing.

3. Repeat this process two to three times with a new swab to

remove residual contaminates. Adhesives and oils, for example, may be thinned by the initial cleaning but not completely removed.

Page 24 980385-003 Rev.A

Page 25

Printer Configuration Settings

The printer has flash (non-volatile) memory to store printer configura

tion settings. The settings are stored in flash memory and are set by

programing, printer drivers or the AutoSense routine. The settings are

shown on the Dump mode printout or can be reported back to the host

via the serial port or USB interfaces.

The data printed out above the stripe bar is used to identify the printer.

The first line has Print Width (4”), Model Code (MO3257) and Firm

ware Version (V4.XX.XX XXX). The next lines are Serial Number

(S/N: XXXXXXXX) and serial port setting.

The following are the basic settings stored in the printer:

Speed (S)

Density (D) or heat applied

Form (label) length and gap in dots (Q)

Form (label) width in dots (q)

Serial port - Set by command line programming with Ycommand

Margin (R)

Buffer Mode (r)

Options: D

Print Mode is Direct Thermal (OD)

980385-003 Rev.A Page 25

Sample

Dump Mode

Printout

Page 26

Page 26 980385-003 Rev.A

Page 27

Warning - Shock Hazard

Never operate the printer in a location where it can get wet.

Personal injury could result.

Caution - Printer Setup & Handling

1)When installing or modifying the printer setup or

configuration, ALWAYS TURN POWER OFF Before

:

A) Connecting any cables.

B) Performing any cleaning or maintenance operations.

C) Moving the printer.

2) Damage to the printer interface connector, accessories or

door may result from placing the printer on it’s front bezel or

backside during unpacking or handling.

Warning - Static Discharge

The discharge of electrostatic energy that accumulates on the

surface of the human body or other surfaces can damage or

destroy the printhead or electronic components used in this

device. DO NOT TOUCH the printhead or the electronic

components under the printhead carriage.

LP2348+ Thermal Printers

European Council Directive Compliance to Standards

89/336/EEC EMC Directive EN55022-B,1998 RF Emissions Control

EMC Directive EN50024,1998

Immunity to

Electromagnetic

Disturbances

EMC Directive EN61000-3-2: 1995 Harmonic Emissions

EMC Directive EN61000-3-3: 1995 Voltage Variation

CB Scheme

EN60950

IEC60950

Product Safety

FCC - Declaration Of Conformity:

Models: LP 2348+ conform to the following specification:

FCC Part 15, Subpart B, Section 15.107(a) and Section 15.109(a) Class B

digital device.

Supplemental Information:

This device complies with Part 15 of the FCC Rules. Operation is subject to the following Two

Conditions: (1) This device may not cause harmful interference , and (2) this device must accept

any interference received, including interference that may cause undesired operation.

Industry Canada Notice:

This device complies with Industry Canada ICS-003 class A requirements.

Cet équipement est conforme à l’ICS-003 classe A de la norme Industrielle Canadienne.

©2004 Zebra Technologies Corporation, all rights reserved.

UPS

®

, UPS OnLine®and UPS OnLine®WorldShip®are registered trademarks of United Parcel

Service of America, Inc. Windows® is a registered trademark of Microsoft Corporation.

LP2348 and LP2348+ are trademarks of Zebra Technologies Corporation

980385-003 Rev.A Page 27

Page 28

Page 28 980385-003 Rev.A

980385-003

&

Loading...

Loading...