Page 1

Introduction

Battery Install &

Charging

Introduction

Thank you for choosing the Zebra QLn™ Series Mobile Printers. These rugged printers will

become a productive and efficient addition to

your workplace thanks to their innovative design. Because

it is made by Zebra Technologies you can be assured of

world-class support for all of your bar code printers, software, and supplies.

This document provides an easy reference for operating

and maintaining the QLn Series Mobile Printer.

Complete and current documentation for this printer

is provided by the QLn Series User Guide available on the

Internet at: www.zebra.com/manuals.

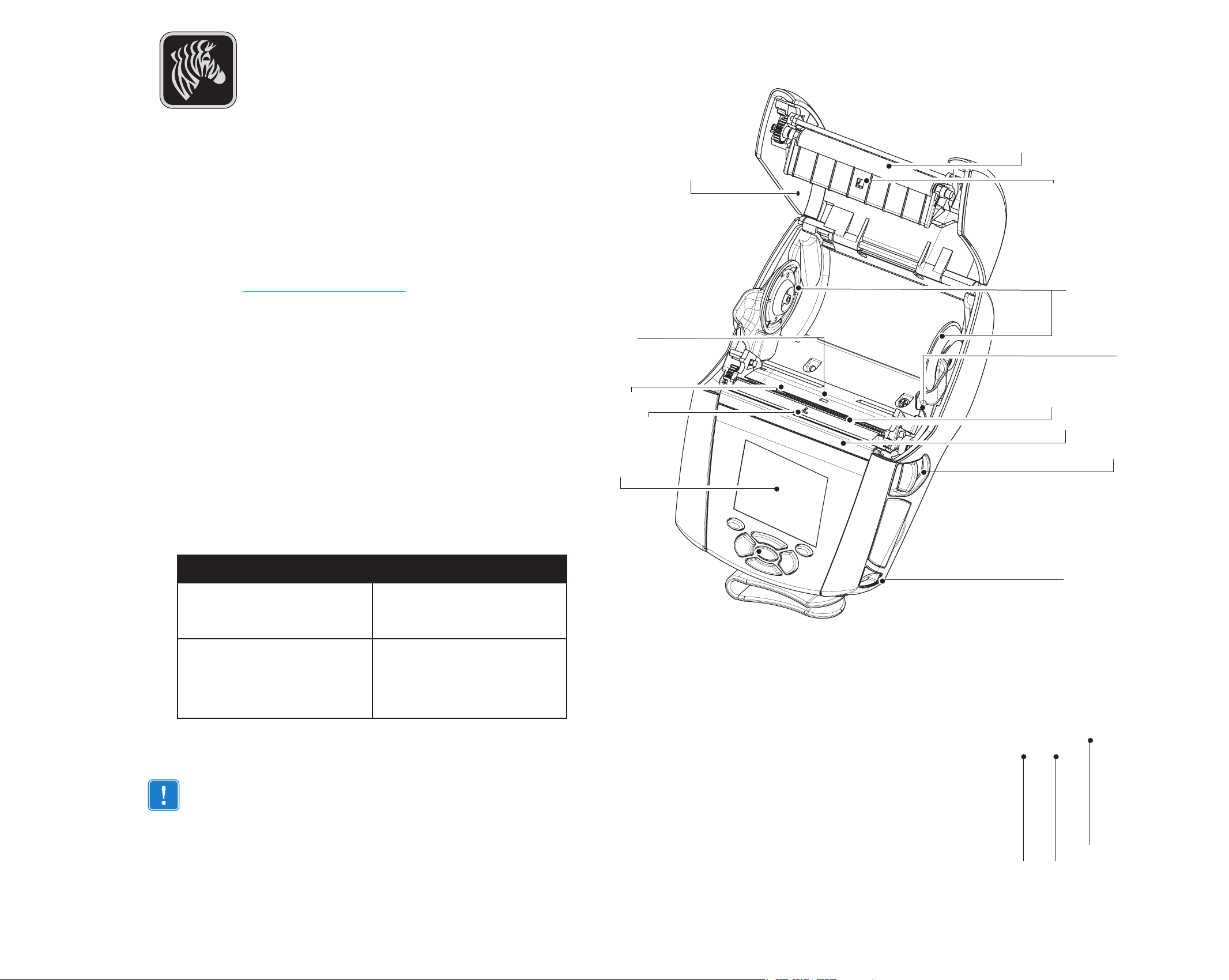

QLn Series Overview (QLn320 Shown)

1

13

2

3

14

6

Media Loading

Connect Printer/

Printer Controls

Cleaning and

Troubleshooting

Accessories and

Contact Info

QLn320

QLn320 QLn220

Media width:

1.0 in. to 3.125 in.

(25,4 mm to 79,4 mm)

Printer Dimensions

H: 6.85 in. (173,659 mm)*

W: 4.65 in.(117,856 mm)

D: 3.15 in (76,9 mm)

* with belt clip

Media width:

.63 in. to 2.18 in.

(16 mm to 55,37 mm)

Printer Dimension

H: 6.73 in. (170,9 mm)*

W: 3.60 in. (91,4 mm)

D: 2.75 in. (69,9 mm)

* with belt clip

QLn220

Always refer to the Important Safety Information data

sheet shipped with each printer and the Technical Bulletin

shipped with each battery pack. These documents detail

procedures to ensure maximum reliability and safety while

using this printer.

12

5

11

1. Platen Roller

2. Bar Sensor

3. Media Support Disks

4. Tear Bar

5. Label Present Sensor

6. Peeler Lever

7. Peeler Bail

8. Latch Release Lever

9. Keypad

10. Strap Post

11. LCD Screen

12. Printhead

13. Media Cover

14. Gap Sensor

15. Power Button

16. Feed Button

17. LED Charge Indicator

4

7

8

10

17

1615

P1031679-002 Rev. A

© ZIH Corp 2011

1

Page 2

Introduction

Battery Install &

Charging

Printer Controls

Power Button

Press to turn unit on. There will be a 10

second boot up time.

Press again to turn unit o

LED Charge Indicator

Solid Yellow: Charging

Solid Green: Fully charged

O: No DC Power Applied

O: With DC Power Applied: Charge Fault

Feed Button

Press to advance a blank label or a software determined length of journal media.

Media Loading

Connect Printer/

Printer Controls

Cleaning and

Troubleshooting

Printer Status Bar

Indicates the status of several

printer functions.**

Main Menu Screen

Displays graphical options in-

cluding Communication, Display,

Media, Battery, and Help.

Status Screen

Default screen the

printer will display

when the user is not

navigating the main

menu screen.

Navigation Bar

Displays user-selectable

options.

Soft Keys

Press to select a

function on the

Navigation Bar.

Accessories and

Contact Info

Four Way Navigation

Buttons

Scroll through menu

choices on Status Screen

Press “OK” to enter.

** Not every icon will be displayed on the Status Bar at one

time, only those applicable to the

printer’s conguration.

8

Page 3

Cleaning the Printers

Caution • To avoid possible personal injury or damage to the printer never insert sharp or

pointed objects into the printer mechanism.

Introduction

Battery Install &

Charging

Media Loading

Printhead

Elements

Label Present

Sensor

Peeler Bar

Platen Surface

Avoid using alcohol on

linerless platen surface

Bar Sensor

Gap Sensor

Tear Bar

Scraper

Bearing Points

Linerless Platens only

Media Support Disks

Linerless units only

Linerless View

Connect Printer/

Printer Controls

Cleaning and

Troubleshooting

Accessories and

Contact Info

Area Cleaning Method Interval

Printhead Use the supplied cleaning pen to clean the print

elements from end to end (the print elements are

located in the thin gray line on the printhead).

Platen Surface

Linerless Platen

Surface

Peeler bar

Scraper (Linerless

units only)

Tear bar Clean thoroughly with the cleaning pen.

Exterior Wipe with water-dampened cloth

Interior

Interior of units

with Linerless

Platens

Rotate the platen roller and clean it thoroughly

with the cleaning pen.

Units with linerless platens: Rotate platen & clean

bearing points only. Avoid use of alcohol on the

surface of linerless platens!

Clean thoroughly with the cleaning pen. As needed

Clean thoroughly with the cleaning pen.

Brush/air blow. Ensure the Bar Sensor, Gap

Sensor and Label Present Sensor windows are

free of dust.

Clean inside surfaces of Media Supports & Media

Support Disks with the supplied cleaning pen or 70%

isopropyl alcohol on a cotton swab.

After every ve rolls of media (or more often,

if needed) Linerless media requires more

frequent cleaning

After every ve rolls of media (or more

often, if needed)

As needed

After every ve rolls of media (or more

often, if needed)

9

Page 4

Troubleshooting

LCD Control Panel

The top of the display shows icons indicating the status of various printer functions. Check

the indicator status and refer to the referenced Troubleshooting table below.

Introduction

Battery Install &

Charging

Media Loading

Icon Status Indication

On

Not Present

Blinking

Antenna Blinking

Antenna Blinking 1 Parenthesis Solid

Antenna and 2 Parentheses Solid

Antenna and 2 Parentheses Blinking

Not Present

4 Bars >80% Charged

3 Bars 60%-80% Charged

2 Bars 40%-60% Charged

1 Bar 20%-40% Charged

0 Bars Low Battery

4 Bars Blinking w/ Lightning Bolt Charging at >80% Capacity

3 Bars Blinking w/ Lightning Bolt Charging at 60-80% Capacity

Associated/Attempting WLAN Authentication

Bluetooth Link established

Bluetooth Link inactive

Connecting and Transmitting Labels

Looking for AP

Associated and Authenticated

Receiving Data

No Radio Present

Connect Printer/

Printer Controls

Cleaning and

Troubleshooting

2 Bars Blinking w/ Lightning Bolt Charging at 40-60% Capacity

1 Bar Blinking w/ Lightning Bolt Charging at 20-40% Capacity

0 Bars w/ Lightning Bolt Charging at <20% Capacity

Blinking Media Cover Open

Blinking Retrieving printer data

Solid Connected & Not Receiving Label Data

Not Present No Ethernet Connection

Blinking Data processing in progress

Steady No data being processed

Blinking Out of Media

Steady Media present

Blinking

Not Present No error exists

4 Bars 802.11 signal strength > 75%

3 Bars 802.11 signal strength </= 75%

2 Bars 802.11 signal strength </= 50% but >25%

Error exists (excluding Media Out and Head Latch

Open)

Accessories and

Contact Info

1 Bar 802.11 signal strength </= 25%

0 Bars No signal strength

10

Page 5

Introduction

Battery Install &

Charging

Accessories

Adjustable Shoulder Strap

Pull

Strap

here to

shorten

Hand Strap

Pull Strap

here to

lengthen

Hold Buckle

Insert loop

into cut-outs

on printer.

Secure loop

over button to

fasten.

Media Loading

Connect Printer/

Printer Controls

Cleaning and

Troubleshooting

Belt Clip (standard on most printers)

To use: Hook the clip over your belt, and ensure that the clip is

securely attached to the belt. The belt clip will pivot in all directions to allow you to move freely while wearing the printer.

Soft Case

Both the QLn220 and 320 have soft case options that

also allow you to carry the printer from your belt.

Belt

Clip printer to

belt

Accessories and

Contact Info

Printer can pivot

freely

11

Page 6

Introduction

Battery Install &

Charging

Product Support

For product support, and the latest versions of all customer documentation, contact

Zebra Technologies at: www.zebra.com

Refer to Appendix D in the QLn320 User Guide for more detailed contact information

In the AmerIcAs contAct:

Zebra Technologies Corporation

475 Half Day Road, Suite 500

Lincolnshire, IL 60069

Phone: +1.847.634.6700 or +1.866.230.9494

Fax: +1.847.913.8766

Media Loading

Connect Printer/

Printer Controls

In europe, AfrIcA, the mIddle eAst, And IndIA contAct:

Zebra Technologies Europe Limited

Dukes Meadow, Millboard Road

Bourne End

Buckinghamshire, SL8 5XF, UK

Phone: +44.1628.556000

Fax: +44.1628.556001

In the AsIA pAcIfIc regIon contAct:

Zebra Technologies Asia Pacic Pte. Ltd.

120 Robinson Road

#06-01 Parakou Building

Singapore 068913

Phone: +65-6858 0722

Fax: +65-6885 0838

Go to www.zebra.com/contact for complete contact information.

Cleaning and

Troubleshooting

Accessories and

Contact Info

Zebra Technologies Corporation

475 Half Day Road, Suite 500

Lincolnshire, IL 60069

Phone: +1.847.634.6700 or +1.800.423.0442

Fax: +1.847.913.8766

12

Loading...

Loading...