Page 1

P1028026-002 Rev. A

April, 2011

Zebra

QLn

Series

Mobile Printers

Page 2

Table of Contents

Proprietary Statements ............................................................................................4

Document Conventions ...........................................................................................6

Introduction to the QLn™ Series Printers ...........................................................7

Unpacking and Inspection ............................................................... 7

Reporting Damage ........................................................................... 7

QLn Series Technology .............................................................................................8

Smart Battery .................................................................................................8

Printing Technology ......................................................................................9

Direct Thermal ...............................................................................................9

QLn Series Overview .............................................................................................10

Getting Ready to Print ........................................................................................... 12

Battery ............................................................................................. 12

Installing the Battery ...................................................................................12

Battery Safety ..............................................................................................13

Charger Safety .............................................................................................13

Smart Charger-2 (SC2) Single Battery Charger ............................ 14

Model UCLI72-4 Quad Charger ...................................................................16

Ethernet and Charging Cradles .....................................................19

Printer Operation with Cradle .....................................................................21

AC Power Adapter (included in kit p/n P1031365-024) ..............................23

Loading the Media in the QLn Series Printers ..........................24

Loading Media in Peel-off Mode .................................................................26

Operator Controls .......................................................................... 27

Standard Control Panel ...............................................................................27

LCD Control Panel .......................................................................................29

Status Bar Icons ..........................................................................................30

31

Main Menu Screen ......................................................................................32

Programmable LCD Settings ......................................................................33

Verify the Printer Is Working .........................................................34

Printing a Configuration Label ....................................................................34

Connecting the Printer ...................................................................34

Cable Communication .................................................................................35

RS-232C Communications ..........................................................................35

USB Communications ................................................................................35

Providing Strain Relief for Communications Cable ...................................36

Wireless Communications with Bluetooth™ ..............................................38

Bluetooth Networking Overview ................................................................38

WLAN Overview .............................................................................39

Setting Up the Software ................................................................39

Using the Accessories.............................................................................................40

Swivel Belt Clip ............................................................................................40

Soft Case......................................................................................................40

Adjustable Shoulder Strap ..........................................................................41

Hand Strap ...................................................................................................42

Preventive Maintenance ....................................................................................... 43

Extending Battery Life ...................................................................43

General Cleaning Instructions .......................................................43

QLn Series Cleaning .................................................................................44

Troubleshooting ......................................................................................................46

2

QLn Series User Guide

Page 3

Front Control Panel ........................................................................46

LCD Control Panel Indicators ........................................................ 47

Troubleshooting Tests ...................................................................50

Printing a Configuration Label ....................................................................50

Communications Diagnostics .....................................................................50

Contacting Technical Support .....................................................................51

Specications ............................................................................................................ 55

Printing Specifications ...............................................................................55

Memory and Communications Specifications for QLn Series ..................55

Label Specifications ....................................................................................56

CPCL Font and Bar Code Specifications and Commands .........................57

ZPL Font and Bar Code Specifications and Commands ............................58

Communications Ports ................................................................................59

Physical, Environmental and Electrical Specifications ..............................60

QLn Series Accessories .............................................................................63

Appendix A ................................................................................................................64

Interface Cables ...........................................................................................64

RS232 Cables ...............................................................................................64

USB Cable ....................................................................................................65

More Interface Cables .................................................................................65

Appendix B................................................................................................................. 66

Media Supplies ............................................................................................66

Appendix C ................................................................................................................66

Maintenance Supplies .................................................................................66

Appendix D ................................................................................................................ 67

Product Support ..........................................................................................67

Appendix E ................................................................................................................. 69

Battery Disposal ..........................................................................................69

Product Disposal .........................................................................................69

Appendix F ................................................................................................................. 70

Using zebra.com..........................................................................................70

Appendix G ................................................................................................................72

Alert Messages ............................................................................................72

Index ............................................................................................................................. 73

Patent Numbers ....................................................................................................... 74

3

QLn Series User Guide

Page 4

Proprietary Statements

This manual contains proprietary information of Zebra Technologies Corporation. It is

intended solely for the information and use of parties operating and maintaining the equipment described herein. Such proprietary information may not be used, reproduced, or disclosed to any other par ties for any other purpose without the expressed written permission

of Zebra Technologies Corporation.

Product Improvements

Since continuous product improvement is a policy of Zebra Technologies Corporation, all

specifications and signs are subject to change without notice.

Agency Approvals and Regulatory Information

• Design certified by TUV • FCC par t 15 Class B

• Canadian STD RSS-210 • EN55024:2003 European Immunity Standard

• EN60950: 2006 Safet y Standard • NOM/ETL (Mexico)

• C-Tick (Australia) • EN55022:2006 Class B European

Electromagnetic Radiation St andard

Liability Disclaimer

Inasmuch as every effor t has been made to supply accurate information in this manual,

Zebra Technologies Corporation is not liable for any erroneous information or omissions.

Zebra Technologies Corporation reserves the right to correc t any such error s and disclaims

liability resulting therefrom.

No Liability for Consequential Damage

In no event shall Zebra Technologies Corporation or anyone else involved in the creation,

production, or delivery of the accompanying product (including hardware and sof tware)

be liable for any damages whatsoever (including, without limitation, damages for loss of

business profits, business interruption, loss of business information, or other pecuniary

loss) arising out of the use of or the results of use of or inability to use such product, even

if Zebra Technologies Corporation has been advised of the possibility of such damages.

Because some states do not allow the exclusion of liability for consequential or incidental

damages, the above limitation may not apply to you.

Copyrights

The copyrights in this manual and the label print engine described therein are owned by

Zebra Technologies Corporation. Unauthorized reproduction of this manual or the soft ware

in the label print engine may result in imprisonment of up to one year and fines of up to

$10,000 (17 U.S.C.506). Copyright violators may be subject to civil liability.

This product may contain ZPL®, ZPL II®, and ZebraLinktm programs; Element Energy Equalizer® Circuit; E3®; and AGFA fonts. Soft ware © ZIH Corp. All rights reserved worldwide.

ZebraLink and all product names and number s are trademarks, and Zebra, the Zebra logo,

ZPL, ZPL II, Element Energy Equalizer Circuit, and E3 Circuit are registered trademarks of

ZIH Corp. All rights reser ved worldwide.

Monot ype®, Intellifont® and UFST® are trademarks of Monotype Imaging, Inc. registered in

the United States Patent and Trademark Of fice and may be registered in certain jurisdictions.

AndyTM , CG PalacioTM, CG Century SchoolbookTM, CG TriumvirateTM, CG TimesTM, Monot ype

KaiTM, Monot ype MinchoTM and Monotype SungTM are trademarks of Monotype Imaging,

Inc. and may be registered in some jurisdictions.

HY Gothic HangulTM is a trademark of Hanyang Systems, Inc.

AngsanaTM is a trademark of Unity Progress Company (UPC) Limited.

Andale®, Arial®, Book Antiqua®, Corsiva®, Gill Sans®, Sorts® and Times New Roman® are

trademarks of The Monotype Corporation registered in the United States Patent and Trademark Office and may be registered in certain jurisdictions.

Century Gothic™, Bookman Old StyleTM and Century SchoolbookTM are trademarks of The

Monot ype Corporation and may be regis tered in certain jurisdictions.

HGPGothicB is a trademark of the Ricoh company, Ltd. and may be registered in some jurisdictions.

UniversTM is a trademark of Heidelberger Druckmaschinen AG, which may be registered in

certain jurisdictions, exclusively licensed through Linotype Library GmbH, a wholly owned

4

QLn Series User Guide

Page 5

subsidiary of Heidelberger Druckmaschinen AG.

Futura® is a trademark of Bauer Types SA registered in the United States Patent and Trademark Office and may be registered in some jurisdictions.

TrueType® is a trademark of Apple Computer, Inc. registered in the United St ates Patent and

Trademark Office and may be registered in certain jurisdictions.

All other product names are the propert y of their respective owners.

© 1996 –2009, QNX Software Systems GmbH & Co. KG. All rights reserved. Published under license by QNX Sof tware Systems Co.

All other brand names, product names, or trademarks belong to their respective holders.

©

2011 ZIH Corp.

5

QLn Series User Guide

Page 6

Document Conventions

The following conventions are used throughout this docu-

ment to convey certain information:

Cautions, Important, and Note

Caution • Warns you of the potential for electrostatic discharge.

Caution • Warns you of a potential electric shock situation.

Caution • Warns you of a situation where excessive heat could cause

a burn

Caution • Advises you that failure to take or avoid a specic action

could result in physical harm to you.

Caution • Advises you that failure to take or avoid a specic action

could result in physical harm to the hardware.

Important • Advises you of information that is essential to complete a

task.

Note • Indicates neutral or positive information that emphasizes or

supplements important points of the main text.

6

QLn Series User Guide

Page 7

Introduction to the QLn™ Series Printers

Thank you for choosing our Zebra® QLn™ Series Mobile

Printers. You will find these rugged printers will become a productive and efficient addition to your workplace thanks to their

innovative design. Zebra Technologies is the leader in industrial printers with world-class support for all of your bar code

printers, software, and supplies.

This user’s guide gives you the information you will need

to operate the QLn320 and QLn220 printers. These printers

use CPCL and ZPL programming languages. To create and

print labels using the CPCL and ZPL languages, refer to the

Mobile Printing Systems CPCL Programming Manual and ZPL

Programming Guide (available at

www.zebra.com/manuals

)

QLn Series Software Utilities:

• Zebra Net Bridge™ : printer configuration, fleet management

• Zebra Setup Utility: single printer configuration, quick setup

• Zebra Designer Pro: label design

• Zebra Designer Drivers: Windows® driver

• OPOS Driver: Windows driver

• Multiplatform SDK

(These utilities can be found at www.zebra.com and on the

product CD that comes with the printer.)

Unpacking and Inspection

Inspect the printer for possible shipping damage:

• Check all exterior surfaces for damage.

• Open the media cover (refer to “Loading the Media” in

the Getting Ready to Print section) and inspect the media

compartment for damage.

In case shipping is required, save the carton and all packing mate-

rial.

Reporting Damage

If you discover shipping damage:

• Immediately notify and file a damage report with the shipping company. Zebra Technologies Corporation is not responsible for any damage incurred during shipment of

the printer and will not cover the repair of this damage

under its warranty policy.

• Keep the carton and all packing material for inspection.

• Notify your authorized Zebra re-seller.

7

QLn Series User Guide

Page 8

QLn Series Technology

The QLn320 and QLn220 use several technologies made

popular in other Zebra Mobile Printer product lines.

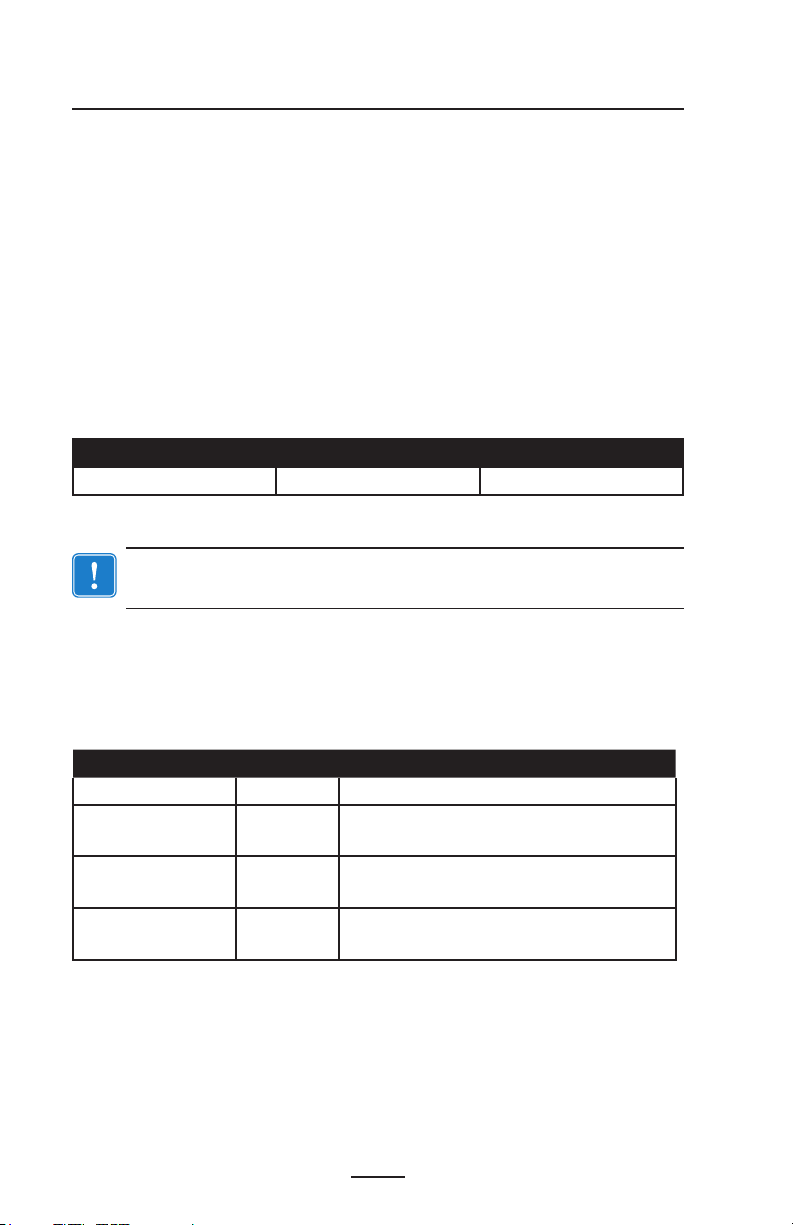

Smart Battery

The QLn Series battery pack is a high capacity, smart

Lithium Ion battery that contains electronics which allow the

printer to monitor its operating parameters. Among these are

the number of charge cycles it has undergone and its date of

manufacture. Using these parameters, the printer’s software

can monitor the battery’s condition and alert the user when to

recharge or remove the battery from service.

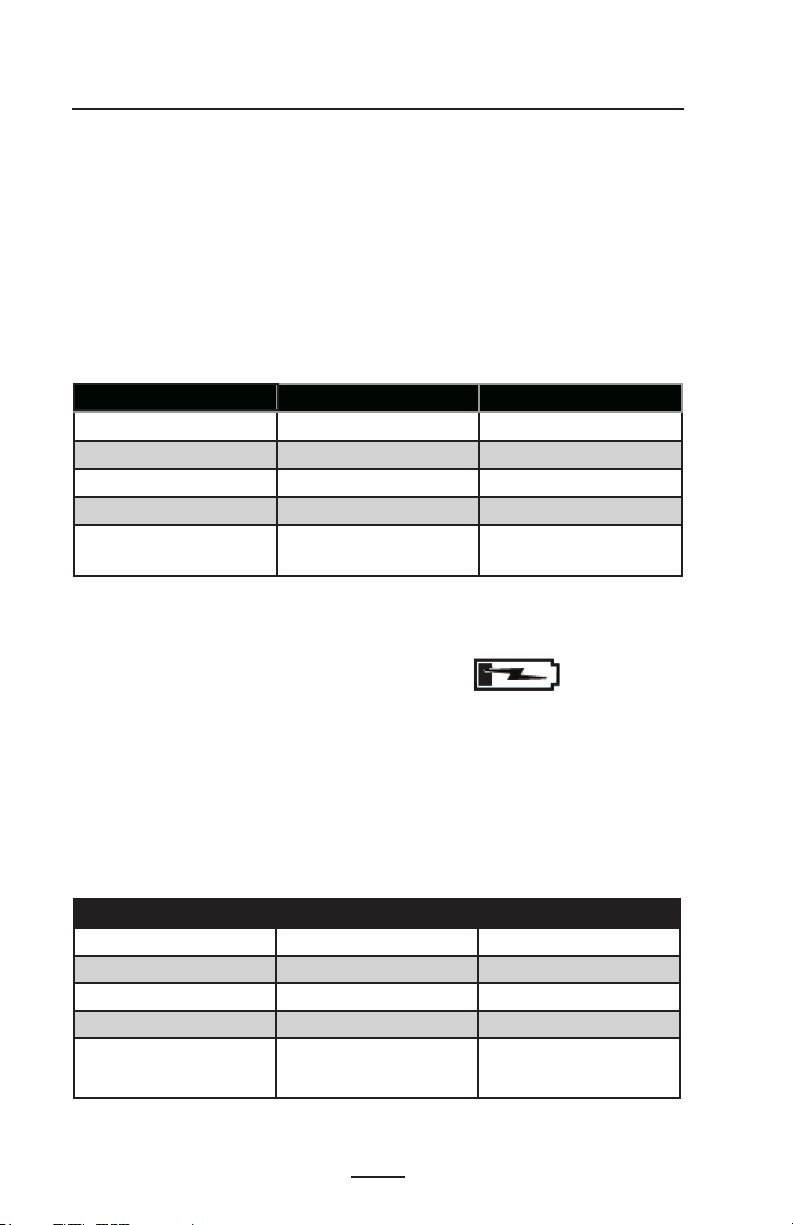

Operating Temperature Charging Temperature Storage Temperature

-200C to +500C 00C to +400C -250C to +650C

The QLn Series printers will only function properly with genuine

Zebra smart battery packs.

The smart battery’s health has three states: GOOD, REPLACE, and

POOR. The battery health factor determines whether or not the printer can operate and what is communicated to the user via the display.

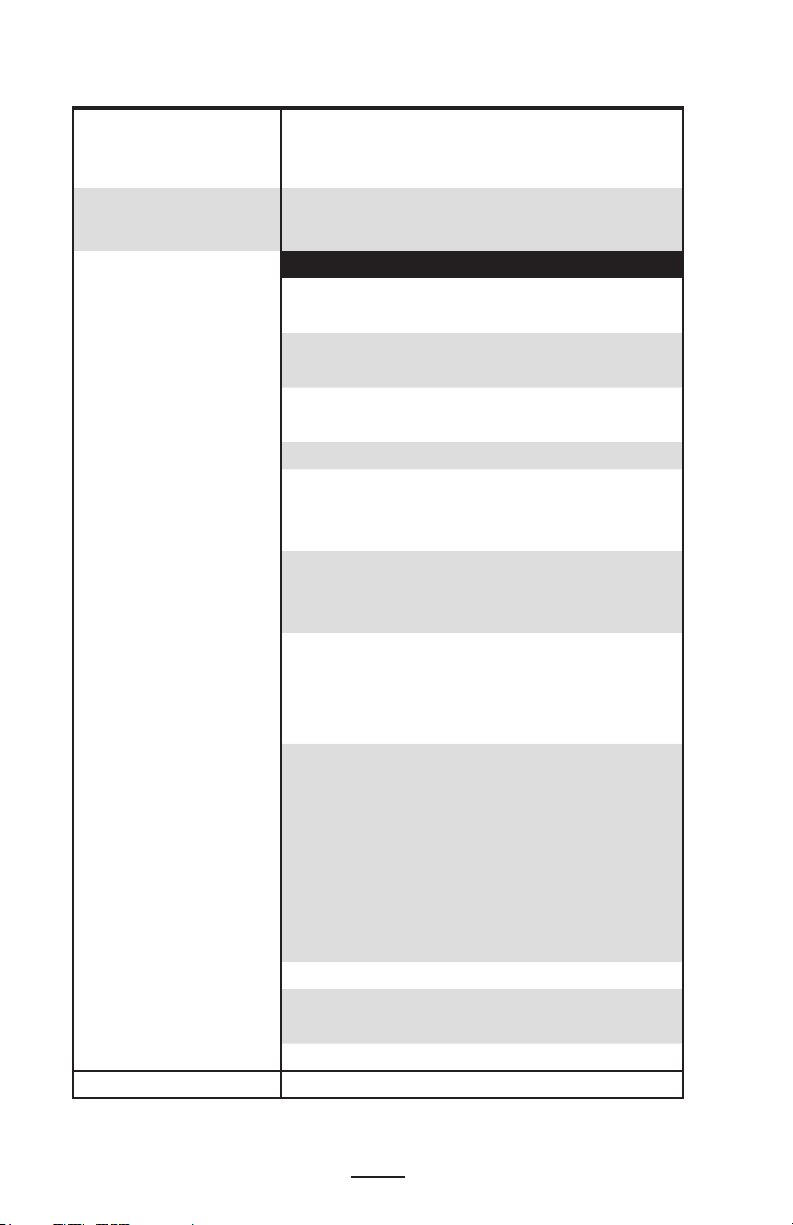

# of Charge Cycles Health Power-up Message

<300 GOOD None

<550 but >300

>550 but <600

>600

REPLACE

REPLACE

POOR

“Bat tery Diminished

Consider Replacing” *

“Warning-Battery

is Past its Useful Life” **

“Replace Battery

Shutting Down” ***

* Warning accompanied by three beeps in rapid succession.

** Warning accompanied by a series of three double beeps in rapid

succession.

*** Warning will ash on and o and be accompanied by beeping at

a rate of once per second. After 30 seconds the printer will shut down.

8

QLn Series User Guide

Page 9

Printing Technology

The QLn320 and QLn220 use the Direct Thermal method to

print human readible text, graphics and barcodes. It incorporates a sophisticated print engine for optimal printing under all

operational conditions.

Direct Thermal

Direct thermal printing uses heat to cause a chemical reaction on

specially treated media. This reaction creates a dark mark wherever

a heated element on the printhead comes in contact with the media.

Since the printing elements are arranged very densely at 203 d.p.i.

(dots per inch) horizontal and 200 d.p.i. vertical, highly legible characters and graphic elements may be created a row at a time as the

media is advanced past the printhead. This technology has the advantage of simplicity, as there is no requirement for consumable supplies such as ink or toner. However, since the media is sensitive to

heat, it will gradually loose legibility over long periods of time, especially if exposed to environments with relatively high temperatures.

9

QLn Series User Guide

Page 10

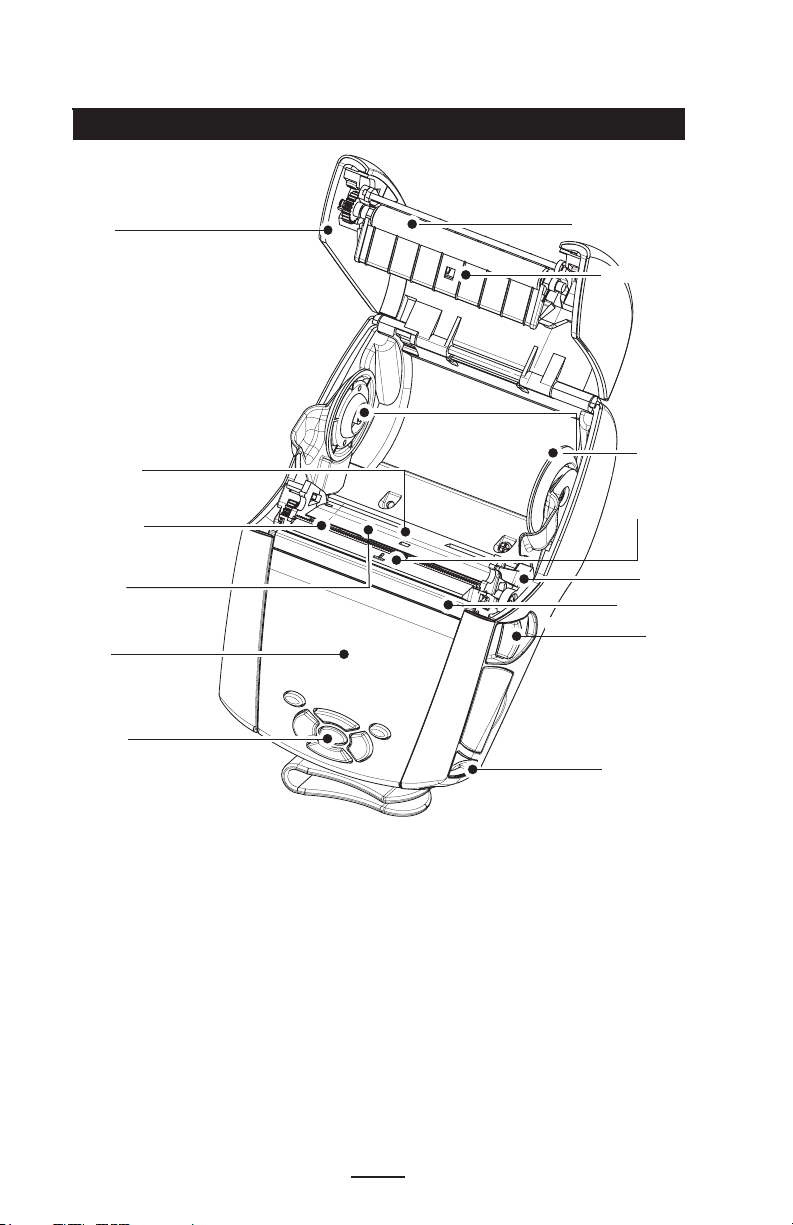

QLn Series Overview

Figure 1: QLn320 Shown

13

11

1

2

14

4

12

9

3

5

6

7

8

10

1 Platen Roller

2. Bar Sensor

3. Media Support Disks

4. Tear Bar

5. Label Presence Sensor

6. Peeler Lever

7. Peeler Bail

8. Latch Release Lever

9. Key Pad

10. Strap Post

11. Status Screen

12. Printhead

13. Media Cover

14. Gap Sensor

10

QLn Series User Guide

Page 11

15. Belt Clip

16. Bat tery

17. USB/ RS-232 Comm Ports

18. MAC Address Label

19. Docking Contacts

20. DC Input

17

15

16

18

19

20

11

QLn Series User Guide

Page 12

Getting Ready to Print

Battery

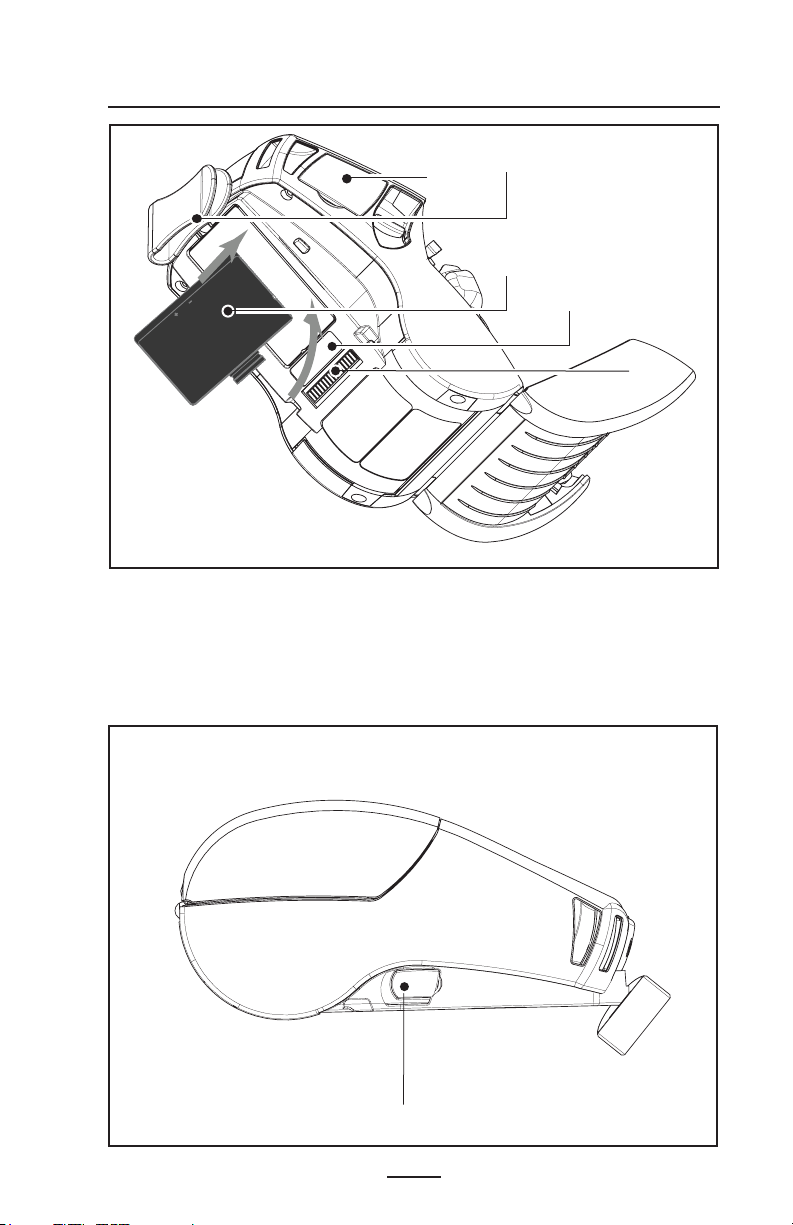

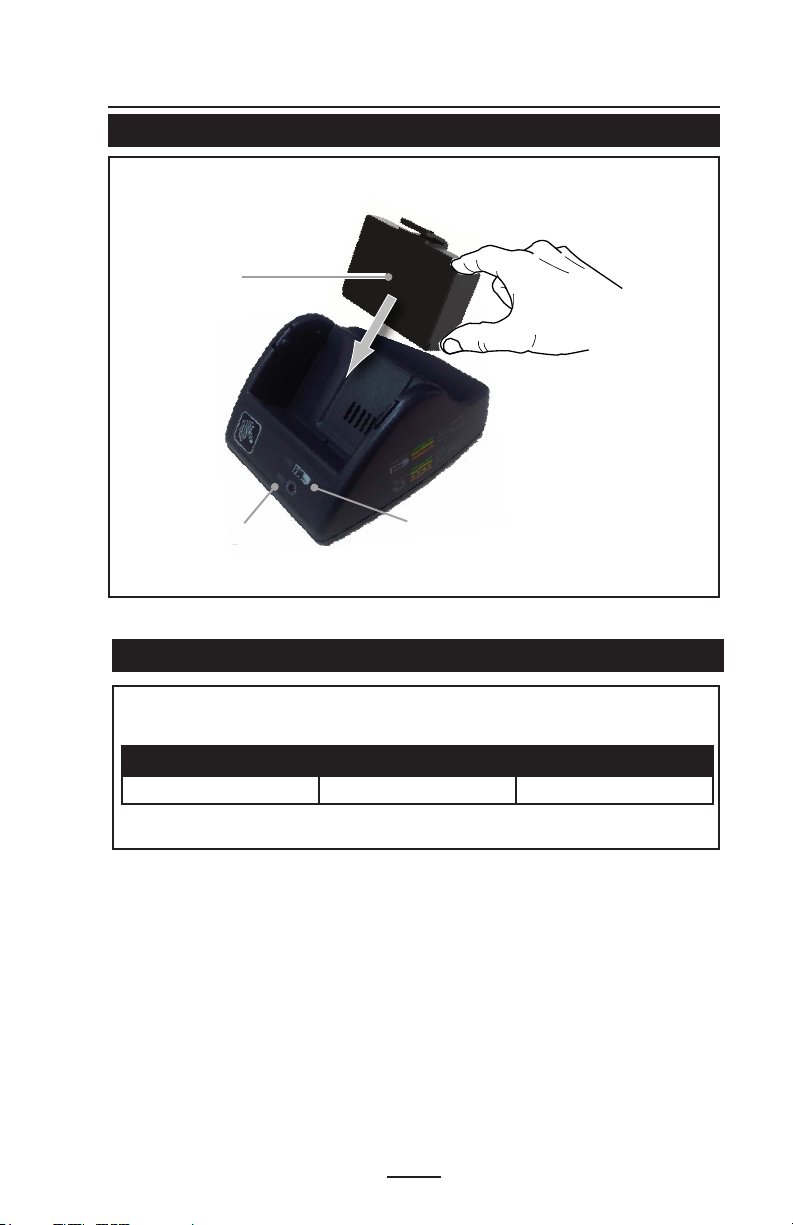

Installing the Battery

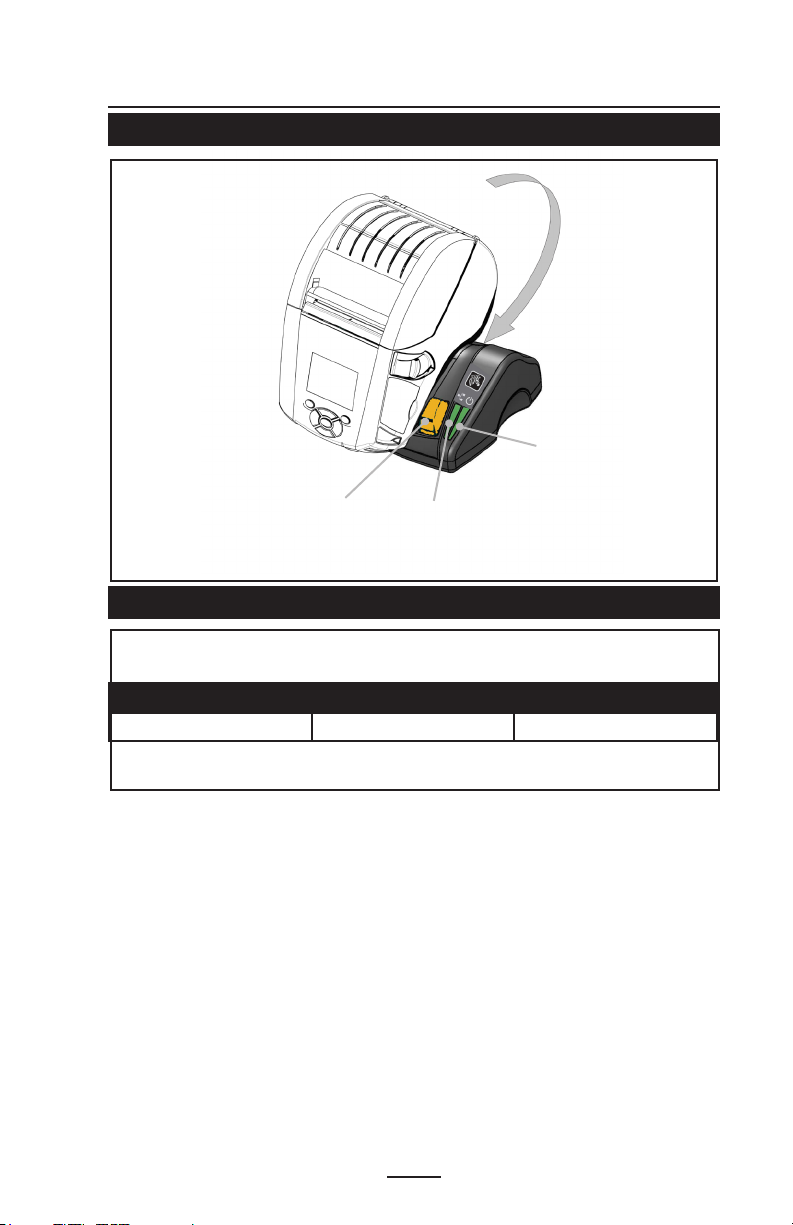

Important • Batteries are shipped partially charged. Remove

protective shrink-wrap and labels from new battery packs prior to use.

1. Locate the battery compartment on the bottom of the printer.

2. Insert the battery into the printer as shown in Figure 2. (It is not

possible to insert the pack in an incorrect orientation.)

3. Rock the battery into the compartment as shown until it locks in

place.

When the battery is first installed, the control panel indicators may briefly turn on and then go off which indicates the

battery is not fully charged (see “Charging the Battery” below

and “Operator Controls”).

You must charge the batteries fully before using them for

the first time. To ensure maximum battery capacity, new batteries should go through two or three complete charge/discharge cycles when first put into service.

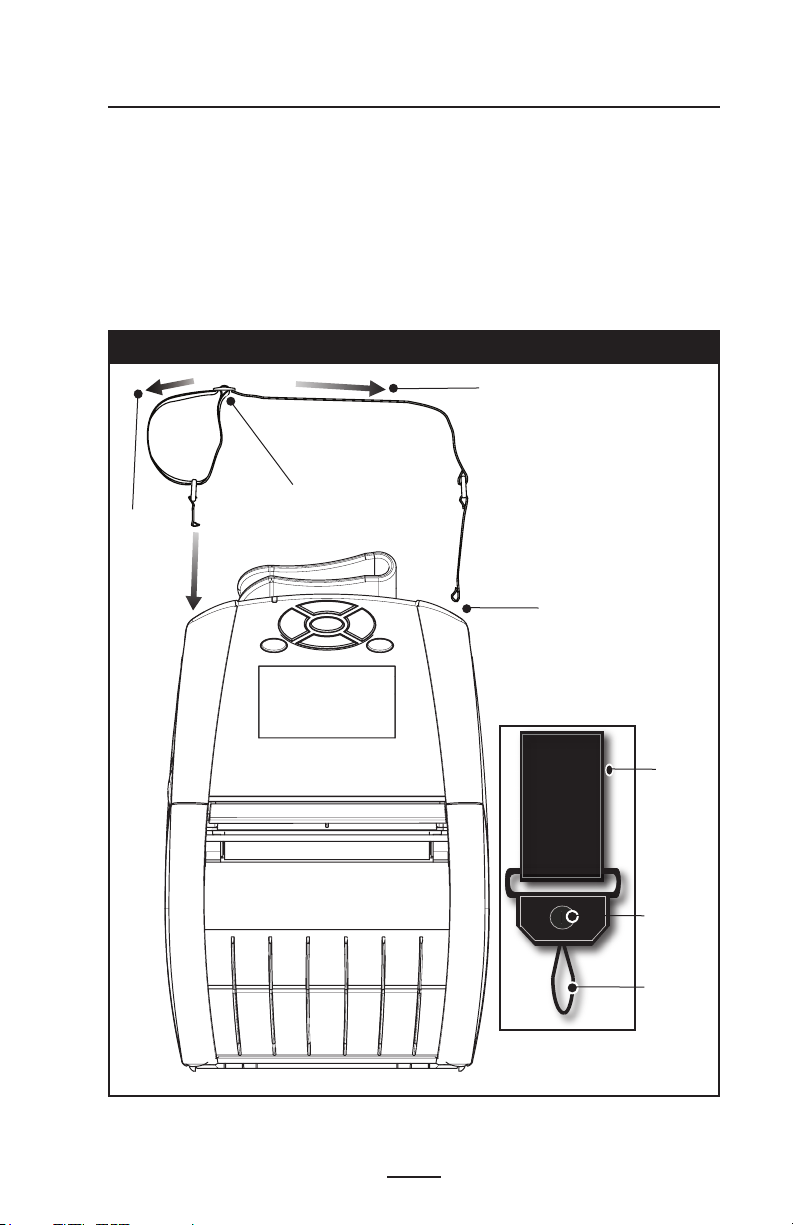

Figure 2: Installing the Battery

Belt Clip

Battery

12

QLn Series User Guide

Page 13

Battery Safety

Caution • Avoid accidental short circuiting of any battery. Allowing

battery terminals to contact conductive material will create a short

circuit which could cause burns and other injuries or could start a re.

Important • Always refer to the Important Safety Information data

sheet shipped with each printer and the Technical Bulletin shipped

with each battery pack. These documents detail procedures to

ensure maximum reliability and safety while using this printer.

Important • Always dispose of used batteries properly. Refer to

Appendix E for more battery recycling information.

Caution • Use of any charger not approved specically by Zebra for

use with its batteries could cause damage to the battery pack or the

printer and will void the warranty.

Caution • Do not incinerate, disassemble, short circuit, or expose to

temperatures higher than 60oC (140oF).

Charger Safety

Do not place any charger in locations where liquids or metallic

objects may be dropped into the charging bays.

13

QLn Series User Guide

Page 14

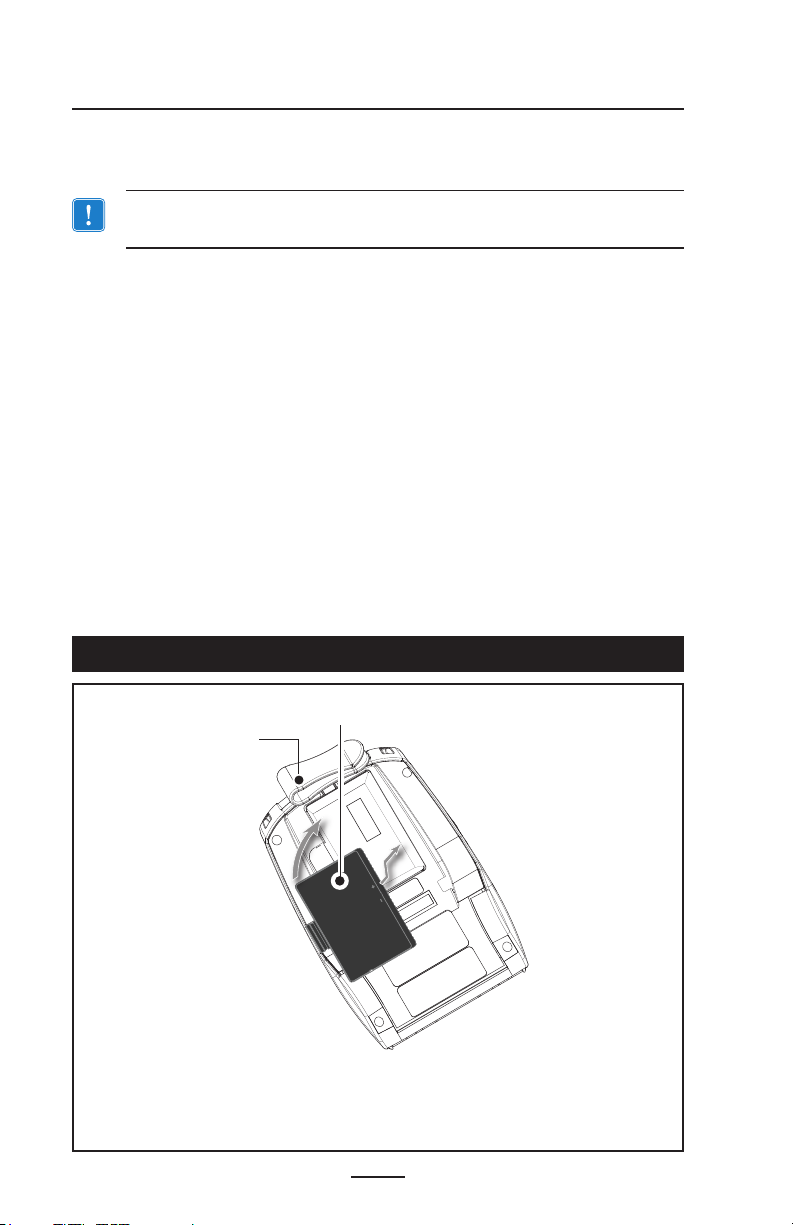

Smart Charger-2 (SC2) Single Battery Charger

The Smart Charger-2 (SC2) is a charging system for use with

the 2-cell lithium-ion smart batteries used in the QLn Series

printers. The goal of the SC2 is to fully charge a QLn battery in

an average time of three (3) hours.

Charging Status Indicators

The SC2 uses a LED indicator to indicate the charge state in either

Green, Yellow, or Amber as detailed below.

DC Power Input Indicator Battery Status

Present Green

Present Green Fully charged

Present Yellow Charging

Present Amber Fault

Present Off Present and Battery

There will also be a battery charging graphic to indicate that

this LED is the charging status indicator .

Battery not present

Health = POOR

Battery Health Indicator

The SC2 features a tri-color (Yellow/Green/Amber) LED to indicate

the health of the battery pack. An evaluation of the battery health begins upon insertion of the battery in the charger and results in the appropriate LED being illuminated as shown below. The LED will remain

illuminated as long as input power is applied.

Battery Indicator

None or non-smart Off

Smart battery present Green

Smart battery present Yellow

Smart battery present Flashing yellow

Smart battery present Amber

Health Status

GOOD

CAPACITY DIMINISHED

PAST USEFUL LIFE

UNUSABLE- REPL ACE

(discard per Instructions in

Appendix E

14

QLn Series User Guide

Page 15

Figure 3: Single Charger (SC2)

Smart Battery

Health Status LED

Indicator

Charge Status LED

Indicator

Figure 4: SC2 Dimensions

Height Width Length

65,1 mm (2.56 in.) 101,5 mm (4 in.) 120,9 mm (4.75 in.)

15

QLn Series User Guide

Page 16

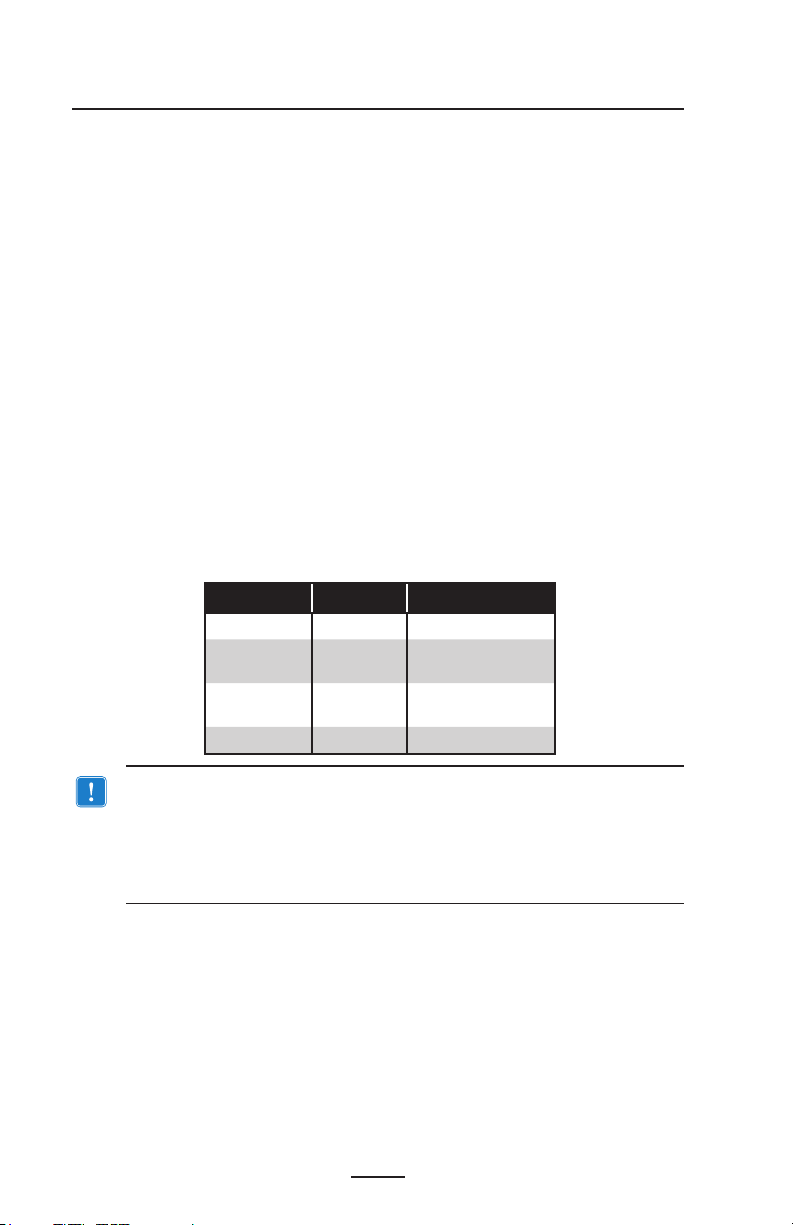

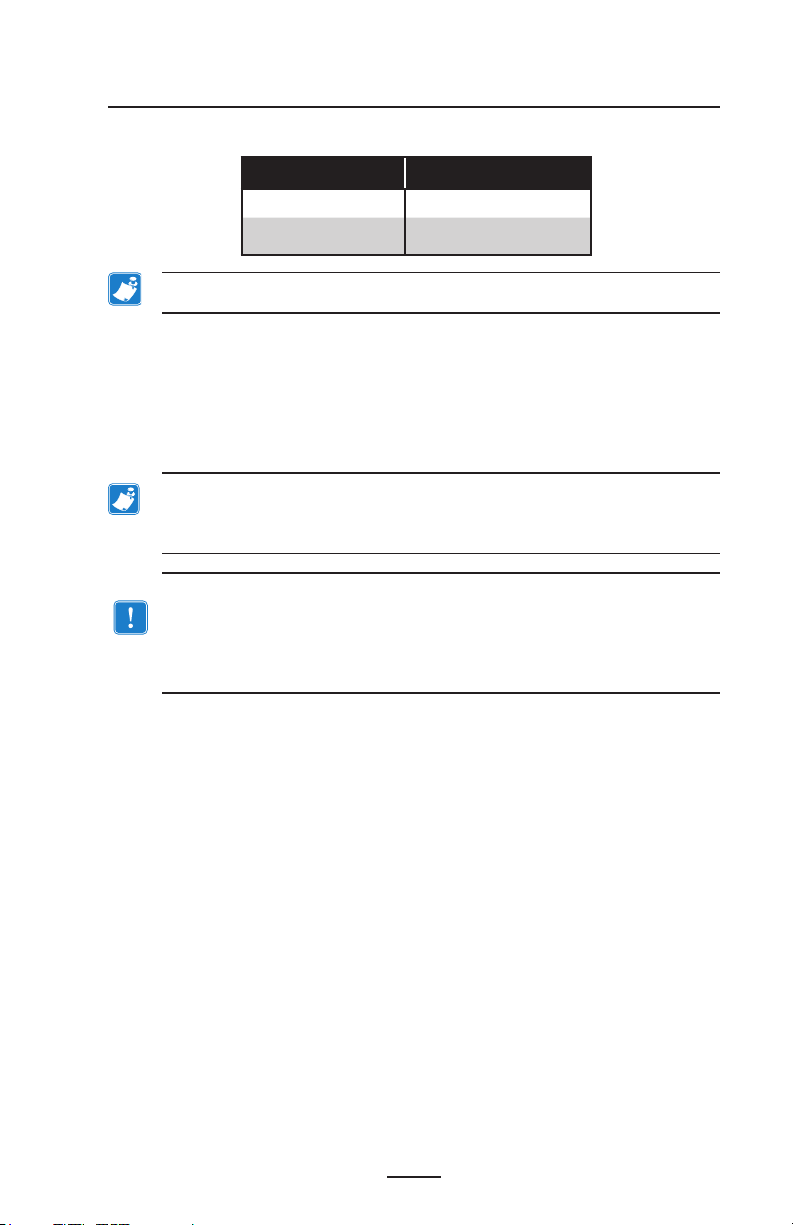

Model UCLI72-4 Quad Charger

The UCLI72-4 Quad Charger is designed to charge up to

four QLn battery packs simultaneously. Batteries must be removed from the printer to be charged in the Quad Charger.

1. Ensure that the charger has been installed properly per

the Quad Charger instruction manual. Ensure that the

power indicator on the front panel is on.

2. Remove any protective shrink-wrap and labels from all

battery packs prior to use. Plug a battery pack into any one

of the four charging bays as shown in Figure 5, noting the

orientation of the battery pack. Slide the battery pack into

the charging bay until it stops and then rock the battery

pack back until it snaps into place. The amber indicator directly under the battery being charged will turn on if the

battery is properly inserted.

The indicators under the battery will allow you to monitor

the charging process per the table below:

Amber Green Battery Status

On Off Charging

On Flashing

Off On

Flashing Off Fault

80% charged (O.K.

to use)

Completely

Charged

Important • A fault condition is caused by a problem with the battery.

The charger may indicate a fault because the battery is too hot or cold

to charge reliably. Try to charge the battery again when it returns to

the room’s ambient temperature. If the amber indicator starts ashing

on the second attempt, the battery should be discarded. Always

dispose of batteries in a proper manner as described in Appendix E.

16

QLn Series User Guide

Page 17

Quad Charger Cycle Times :

Battery Status QLn320

Battery 80% Charged 1.5 Hrs.

Battery Fully Charged 3 Hrs.

Note • These times are for completely discharged batteries.

Battery packs which are only partially discharged will take

less time to reach their charged state. Batteries which have

reached 80% of their charge capacity may be used, however,

it is recommended that you allow the batteries to reach a full

charge to maintain maximum battery life.

The UCLI72-4 Quad Charger has a safety feature which stops charging

a battery after six hours regardless of its charge state. If not fully

charged, it might be indicative of a battery that needs to be replaced.

Use care when installing the UCLI72-4 Quad Charger so that you

do not block the ventilating slots on the top and bottom covers.

Ensure that the charger is plugged into a power source which will not

accidently be turned o if you will be charging batteries overnight.

17

QLn Series User Guide

Page 18

Figure 5: Quad Charger

1. Slide Battery Pack into

Charger bay.

Fast Charge

Full Charge

Fault

Ready

Amber

Indicator

Green

Indicator

2. Rock Battery Pack into place.

Fast Charge

Full Charge

Fault

Ready

Fast Charge

Full Charge

Fault

Ready

Fast Charge

Fault

Charger Bay

Power Indicator

Power Supply

Full Charge

Ready

Power

18

QLn Series User Guide

continued

Page 19

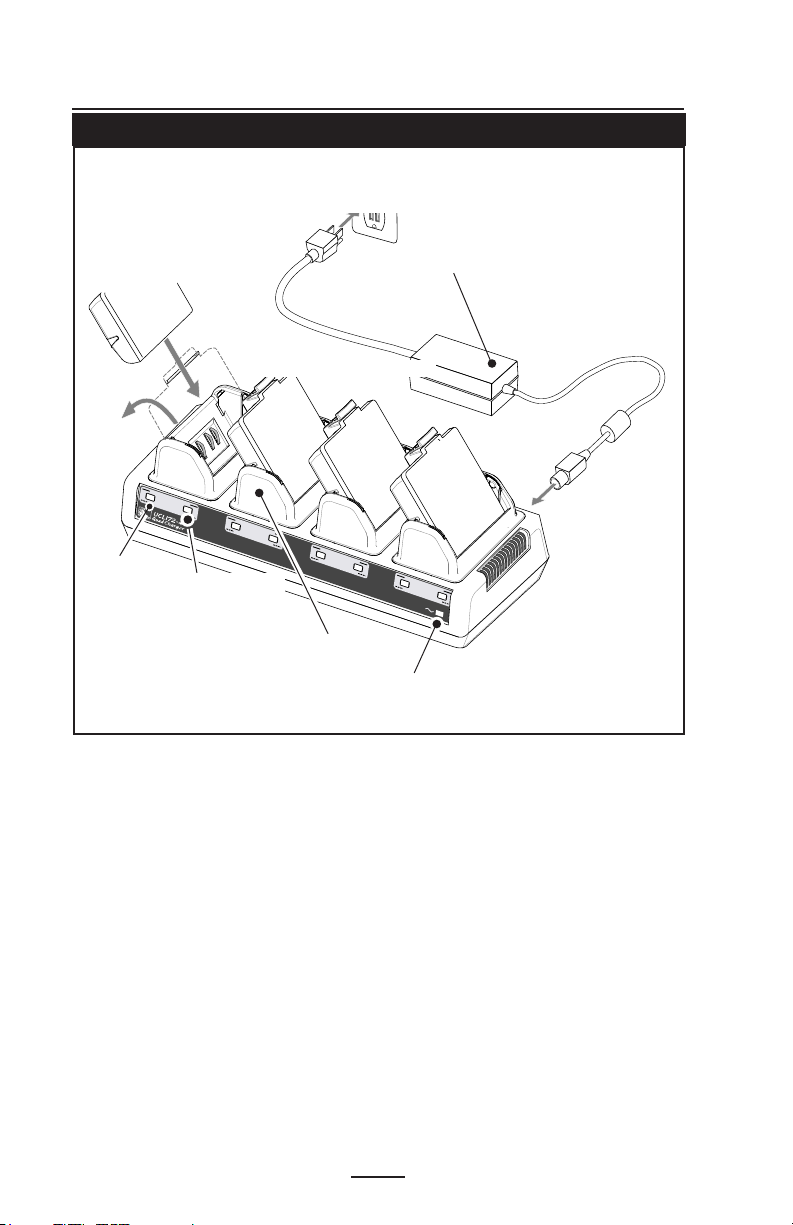

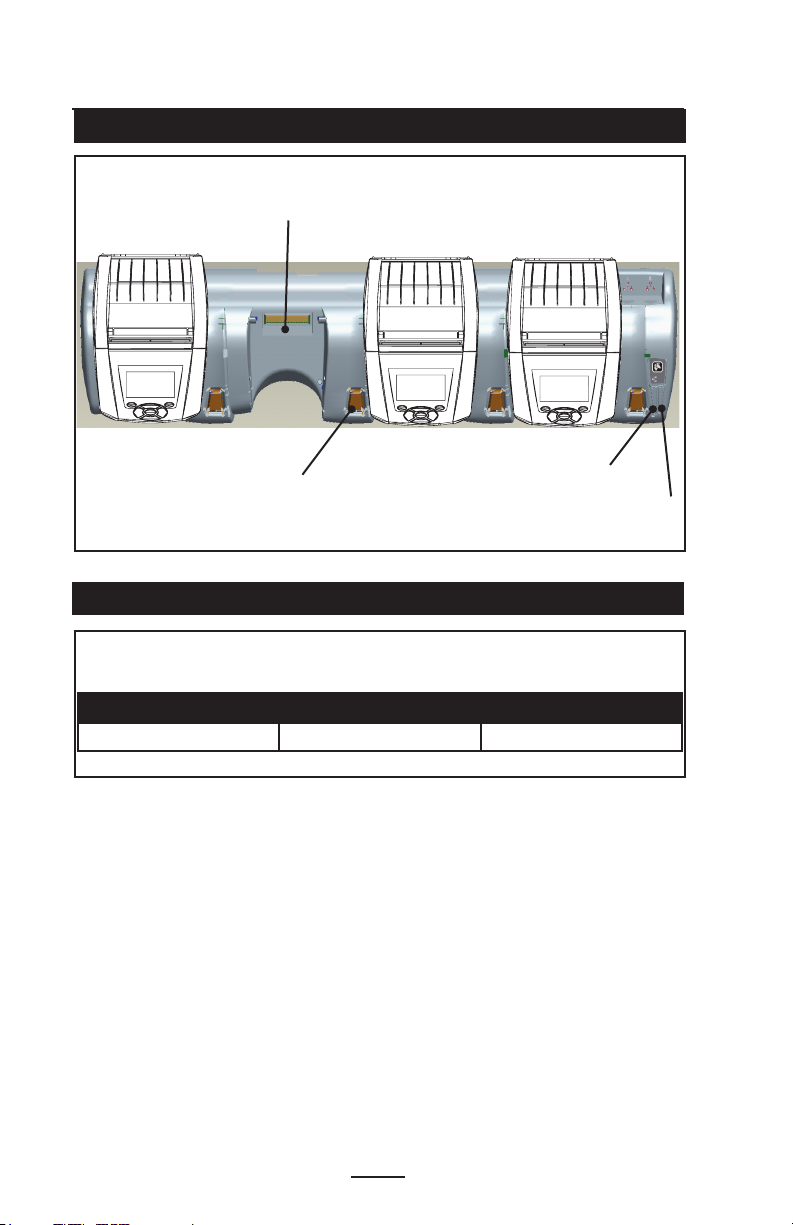

Ethernet and Charging Cradles

The cradle is an expansion base intended for use with the

QLn320 printer, as well as the QLn220 printer. There is a

four bay cradle (QLn-EC4) or a single bay option (QLn-EC) as

shown on pages 19 and 20.

It provides charging power to the docked printer as well as providing a standard 10/100Mb/S Ethernet port for communication to the

printer. The EC also supplies battery charging power to the docked

printer and acts as a supplementary power source for a functioning

QLn printer.

The EC features two green LED’s to indicate the status of the

cradle: Solid green to indicate when power is provided to

the input of the EC; and blinking green to indicate Ethernet activity .

The cradle allows the user to dock the printer easily and remove

it with the push of a button. The printer shall remain operable while

docked, i.e. display is viewable, charge LED status is viewable, and

printer controls and data entry are available. The printer will still print

while docked and the user shall be able to replace the media as well.

Note • Remove the “Docking Cradle Access” label on the bottom of

the printer before docking the printer in the cradle.

DOCKING CRADLE ACCESS

Note • Clean the docking contacts with the cleaning pen provided

with the printer to remove any residue from the label.

LED Status Indication

Solid Green Power On

Blinking Green Ethernet Activity

19

QLn Series User Guide

Page 20

Figure 6: Ethernet Cradle (Four Bay)

Docking Bay

Release Button

Ethernet Status

Indicator

Power Status Indicator

Figure 7: QLn-EC4 Dimensions

Height Width Length

66,7 mm (2.62 in.) 579,9 mm (22.83 in.) 150,57 mm (5.93 in.)

20

QLn Series User Guide

Page 21

Figure 8: Ethernet Cradler (Single Bay)

Power Status

Indicator

Release Button

Figure 9: QLn-EC Dimensions

Ethernet Status

Indicator

Height Width Length

66,7 mm (2.62 in.) 171,28 mm (6.74 in.) 150,57 mm (5.93 in.)

Printer Operation with Cradle

• All QLn Series printers will charge in the cradles

• Only QLn Series printers that have the Ethernet option installed will connect to an Ethernet network. Check the

PCC code on the back of the printer (see Appendix D

for location). Codes of the form QNX-XXXXX0XX-XX

do not support Ethernet, and codes of the form QNXXXXXXEXX-XX do support Ethernet (where “X” means

don’t care). You can also check the “Communications”

sub-menu on the LCD (see Main Menu Screen on page

17). After selecting this sub-menu, any communication

options not installed will be so indicated.

21

QLn Series User Guide

Page 22

• When power is applied to the cradle and the printer is

docked, the printer charge LED indicates the charge status of the printer (see Figure 14).

• Docking the printer in the cradle will automatically turn

the printer on to ensure it is available to be managed remotely.

• When the printer detects input power from the cradle, and

the presence of a live Ethernet link, it will automatically

reboot and connect to the Ethernet network.

• For printers with an 802.11 radio, this interface will be

turned off when the Ethernet link is active. It will turn

back on if the Ethernet link is no longer active.

• For printers with a Bluetooth radio, this interface will remain active while the printer is in the cradle.

• The serial and USB ports will remain active while the printer is in the cradle.

• When connected to Ethernet, if either the cradle DC power or the Ethernet link is removed for more than 10 seconds, the printer will reboot.

• The DC input barrel jack connector (see Figure 10) cannot

be used while the printer is in the cradle.

22

QLn Series User Guide

Page 23

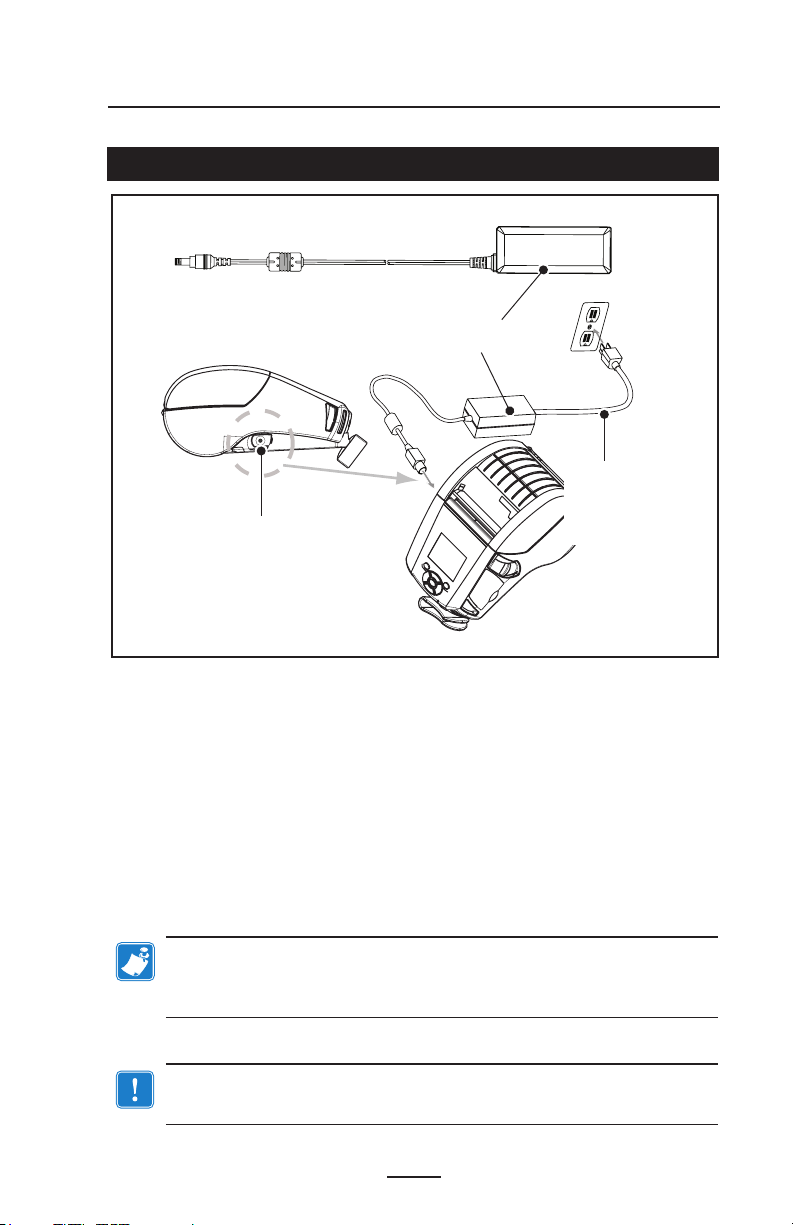

AC Power Adapter (included in kit p/n P1031365-024)

Figure 10: Charging the Battery Pack with the AC Power Adapter)

Qln Series

AC Adapter

AC Power Cord

(varies with

geographic

DC Input

location)

• Open the protective cover on the QLn Series printer to

expose the DC input charger jack.

• Connect the appropriate AC power cord for your location to the

adapter and then plug the power cord into an AC receptacle.

• Plug the barrel plug from the P1029871 AC adapter into the

charger jack on the printer.

• The printer will power up and begin charging. The printer can

be left on or turned off at this point. Charging will continue in either state.

Batteries are shipped uncharged. Remove protective shrink-wrap and

labels from new battery packs and allow them to charge completely

prior to initial use.

While it’s possible to charge the battery when using the printer,

charge times will increase under this condition.

23

QLn Series User Guide

Page 24

Loading the Media in the QLn Series Printers

You can operate QLn Series printers in one of two different

modes: Tear-Off or Peel-Off. Tear-Off mode allows you to tear

off each label (or a strip of labels) after it is printed. In Peel-Off

mode, the backing material is peeled away from the label as it

is printed. After you remove this label, the next one is printed.

1. Open the printer.

• Press down on the latch release lever on the side of the printer as shown at “1” in Figure 11 below. The Media Cover will

open automatically as shown at “2” below, exposing the Media

Compartment and the adjustable Media Supports.

Figure 11: Opening the QLn Series Printer

Media Cover

Media Compartment

Media Support

(opposite support

not visible)

Latch Release

Lever

24

QLn Series User Guide

Page 25

2. Load the media:

4

• Grasp the media supports where shown in Figure 12 and pull

them apart. Insert the roll of media between them, and let the

media supports close. Ensure that the media pulls off the core in

the direction shown below. The supports will adjust themselves

to the width of the media, and the media should be able to spin

freely on the supports.

Figure 12: Loading Media

Media Roll

Note direction media

pulls o the roll.

Grasp Media Supports where shown

and pull apart.

3. Close the Media Cover.

• If you plan to use the printer in the tear-off mode, close the media cover as shown below.

Pull Media out of

Printer.

25

QLn Series User Guide

Close Media

Cover.

continued

Page 26

Loading Media in Peel-o Mode

• If you plan to use the printer in the peel-off mode, peel a few labels off of the media and load the media as previously described.

• Push the peeler lever forward to release the peeler bail into the

“up” position as shown at “3” and “4” in Figure 13.

• Close the media cover to lock the peeler bail in place. The media

will feed between the peeler bail and platen.

Figure 13: Activating Peeler Bar

Peeler Bail

Pull up and ip down if

using media in the peelo mode.

4

Peeler Lever

Latch Release

Lever

• Turn on the printer or press the Feed button on the front of the

printer if the printer is already on.

The printer will advance the media to the next label, if printing

labels. If you are printing on journal media, the printer will advance a short strip of media.

To disengage the peeler bail, first open the media cover as previ-

ously described. The peeler bail will automatically return to the

Up position.

Press straight down on the peeler bail to lock it in place in its origi-

nal home position.

26

QLn Series User Guide

Page 27

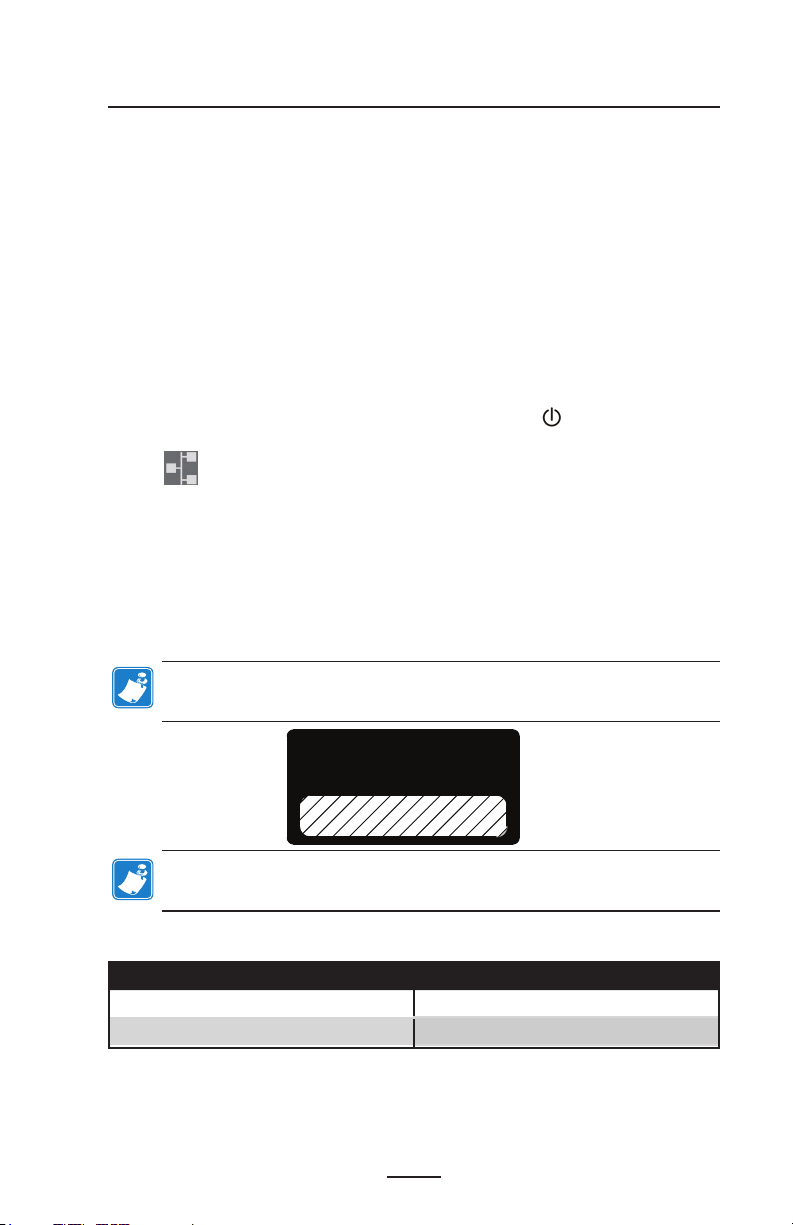

Operator Controls

The QLn Series printers come equipped with a keypad control panel and LCD graphical user interface. The standard control panel is illustrated in Figure 14 and 15 on pages 26 and 27.

The LCD interface allows easy display and selection of many

printer functions as detailed on following pages.

Standard Control Panel

The standard control panel has multiple control buttons and two

multipurpose indicators.

• The Power Button turns the printer on and off.

• The Media Feed Button advances a length of media which is de-

termined by the type of media being used. Label media will be

advanced to the next gap or bar sense marker. Journal (plain)

media will be advanced by a length determined by the printer’s

software.

• The LED Charge Indicator shows solid Yellow when charging, solid Green when fully charged, and is turned off

when there’s a fault condition and the printer is plugged

in.

• Four Way Navigation Buttons allow the user to scroll between

functions on the LCD user space. (The Navigation Buttons do

not apply to the Status Bar and Navigation Bar.)

• Enter Button allows the user to select the desired function high-

lighted on the LCD interface and is indicated by the word “OK”.

• Two software defined function keys allow the user to select a

function listed on the navigation bar.

27

QLn Series User Guide

continued

Page 28

Figure 14: Standard Control Panel for QLn Series

LED Charge Indicator

Solid Yellow: Charging

Solid Green: Fully charged

Off: No DC Power Applied

Off: With DC Power Applied: Charge Fault

Power Button

Press to turn unit

on. Press again to

turn unit o.

Feed Button

Press to advance the media

one blank label or a software

determined length of journal

media.

28

QLn Series User Guide

Page 29

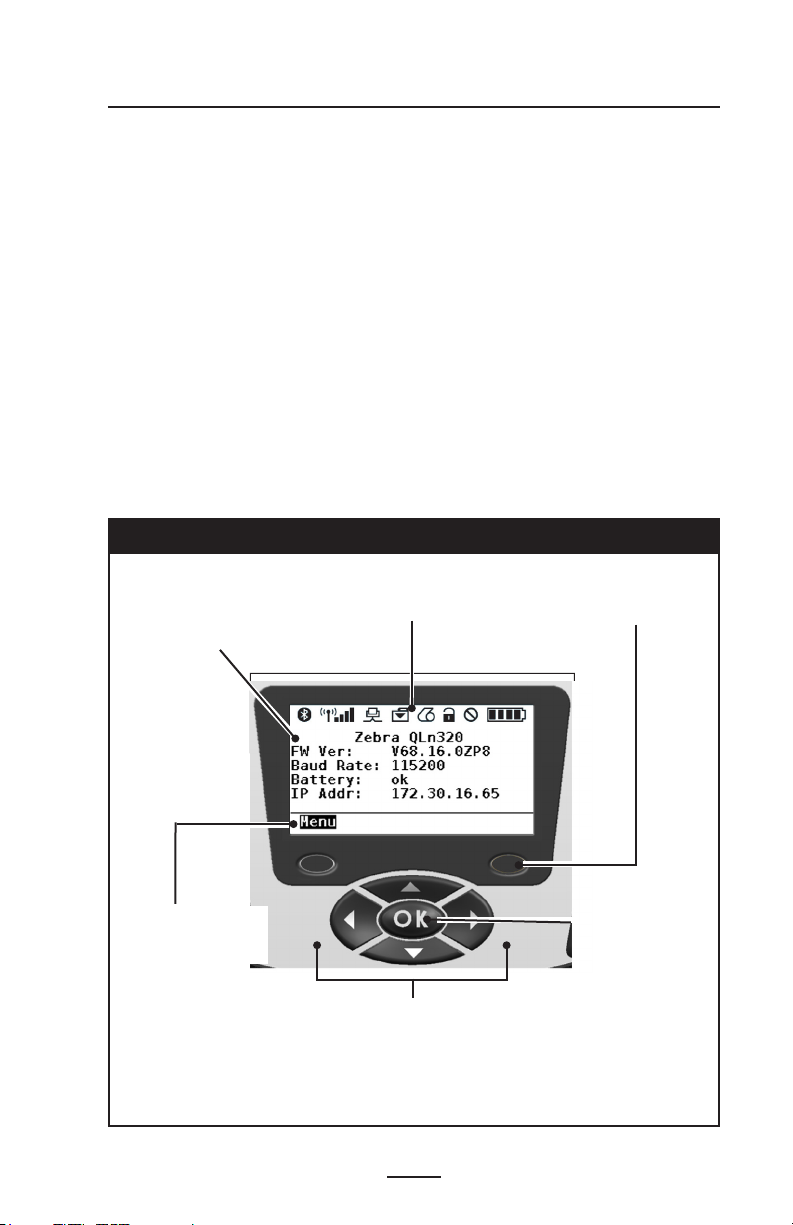

LCD Control Panel

The 240x128 pixel LCD control panel allows the user to view

the status of the QLn Series printer and have access to various

printer alerts and messages. It also has multi-directional keys

which allow navigation and selection of menu options affecting printer functions. These keys allow scrolling through the

various options and settings. The “OK” button allows selection

of the option or function displayed on the screen.

The top of the screen has a row of status icons, or a Status

Bar, which indicate the state of various printer functions. The

Status Bar is located above the Status Screen shown below along with a Navigation Bar. The Status Screen is the default display and is shown at power up. When navigating the

menus, the printer will automatically return to this screen

when the user is done navigating after an appropriate delay.

Figure 15: LCD Control Panel

Status Screen

Default screen the printer

will display when the user

is not navigating the menu

screen.

Printer Status Bar**

Indicates the status of

several printer functions.

Soft Keys

Press to select a function on the Navigation

Bar.

Navigation Bar

Displays user-selectable

options.

Four Way Navigation But tons

Scroll through menu choices on

Status Screen.

** Not every icon will be displayed on the Status

Bar, only those applicable to the printer’s conguration.

29

QLn Series User Guide

Select Button

Press to select a

menu choice on the

Status Screen.

continued

Page 30

Status Bar Icons

Indicates Bluetooth connection status. The icon will

blink to show that the printer is receiving label data via

Bluetooth, and is solid when link is established. This icon

appears only on printers with the Bluetooth wireless option installed.

Indicates that the printer is connected to a

radio network via 802.11 protocols. The antenna icon will

blink with no parentheses when looking for an access

point. One set of solid parentheses with blinking antenna

indicates WLAN is associated and attempting authentication. Two sets of solid parentheses and solid antenna indicate the printer is successfully connected to the WLAN.

The icon and two parentheses will blink to show the printer is receiving printer data via WLAN. The four (4)

bars indicate the strength of the WLAN connection to the access point. These icons appear only with the

802.11 radio installed.

The Ethernet icon will blink when the printer is receiv-

ing label data via the Ethernet connection. It will not be

displayed on the status bar when the Ethernet is inactive.

This icon appears only when the Ethernet option is installed and the printer is docked in Ethernet cradle.

The Data icon indicates data being sent to the printer,

i.e. the icon will blink when there is a label data transmission via the serial or USB ports.

The Media Out icon will blink when there is no media

in the printer and will not blink when there is media in the

printer.

The Head Latch icon indicates if the media cover is

closed or not properly latched. It will appear unlocked and

blinking if open and will not appear if the cover is closed.

30

QLn Series User Guide

Page 31

The Error icon will be displayed and blink if an error

condition exists. The icon will not be displayed if no printer error exists. Since there are separate icons for Media

Out and Head Latch Open, these two alerts do not apply

to the Error icon.

The Battery Charge Level icon indicates the reported state of charge from the battery pack. In a non-charging state, four (4) bars indicates the battery level is greater than 80%. Three (3) bars indicates if the battery level is

less than or equal to 80% but greater than 60%. Two (2)

bars indicates if the level is less than or equal to 60% but

greater than 40%. One (1) bar indicates if the battery level

is less than or equal to 40% but greater than 20%. And

zero (0) bars indicates if the level is less than or equal to

20%.

While the battery is charging, a lightning bolt will appear in the

battery icon to indicate that charging is taking place.

When the battery is charging and fully charged, four bars will be

displayed. When the battery is charging and the level is greater

than 80%, the battery icon will alternate between four bars and

three bars. When the battery is charging and the level is less than

or equal to 80% but greater than 60%, the icon will alternate between three bars and two bars. When the battery is charging and

the level is less than or equal to 60% but greater than 40%, the

icon will alternate between two bars and one bar. When the battery is charging and the level is less than or equal to 40% the icon

will alternate between one bar and zero bars.

31

QLn Series User Guide

Page 32

Main Menu Screen

The user can select options on the Main Menu screen by

pressing the soft key located beneath the Menu option on the

navigation bar (see Fig. 16). The Main Menu screen displays

graphical options including Communication, Display, Media,

Battery, and Help.

Figure 16: Main Menu Screen

Info (Help)

Icon

The user can scroll between icons using the four-way arrow

buttons. When an icon is highlighted, its text description will

be displayed in the middle of the navigation bar, and can be

selected by pressing the “OK” button. This will take the user to

the screen with status information specific to that option. The

Info (or Help) menu provides useful information on a variety of

topics. Please explore this menu to become more familiar with

your printer and how it operates.

The QLn Series printers will also display various alerts, such

as “Media Out”, “Media Cover Open”, or “Battery Low”. The

user can respond to questions by pressing one of the soft

keys to indicate that an action has been taken to address the

alert in question. Once the condition causing the alert has

been addressed (i.e. loading media), the alert message will be

cleared. (See Appendix G for a complete list of alerts for the

QLn Series printers.)

32

QLn Series User Guide

Page 33

Soft Keys

Programmable LCD Settings

In addition to the status icons, the LCD control panel can display other printer settings and functions as text. Applications

can be written to allow the user to view and /or modify these

settings using the scroll and select keys on the display. The

menu that comes with the printer provides access to the most

commonly used parameters. Refer to the CPCL Programming

Manual for a complete list of the parameters, and for details

on how to change the front panel display (p/n P1036975-001 at

www.zebra.com/manuals).

The LCD backlighting option allows viewing of the screen

in a dark environment, or provides better contrast in a very

bright environment. The QLn320 and QLn220 can be programmed to enter a low power mode (Backlight Off) during

periods of front panel inactivity. While in low power mode, the

screen is populated with menus and status icons, data which

may or may not be readable depending on ambient light conditions. The QLn Series printers provide a configurable time

delay from the time the backlight is turned on to when it turns

off. The time range for this delay is 5 to 1200 seconds with

a default time of 10 seconds. The backlight can be activated

within one second after any of the cursor, select, or soft keys

is pressed. (The feed button does not activate the backlight.)

The status bar icons, the user space content, and the navigation bar will remain on the screen with the backlight off.

Extensive use of the display backlight will decrease the time

the printer can run between charges. Refer to the section

“Extending Battery Life” for more information.

33

QLn Series User Guide

Page 34

Verify the Printer Is Working

Before you connect the printer to your computer or portable data

terminal, make sure that the printer is in proper working order. You

can do this by printing a configuration label using the “two key” method. If you can’t get this label to print, refer to “Troubleshooting”.

Printing a Conguration Label

1. Turn the printer off. Load the media compartment with

journal media (media with no black bars printed on the

back)

2. Press and hold the Feed Button.

3. Press and release the Power button and keep the Feed

button pressed. When printing starts, release the Feed

button.

The unit will print a line of interlocking “x” characters to

ensure all elements of the print head are working, print out the

version of software loaded in the printer and then print the report. Note that the report can also be printed from the Info

(Help) menu on the LCD.

The report indicates model, serial number, baud rate, and more

detailed information on the printer’s configuration and parameter settings. (See the Troubleshooting Section for sample printouts and a further discussion on how to use the configuration label as a diagnostic

tool.)

Connecting the Printer

The printer must establish communications with a host terminal which sends the data to be printed. Communications

occur in four basic ways:

• QLn Series printers can communicate by cable via either

RS-232C or USB 2.0 protocols. USB drivers are included

in the Zebra Designer Driver which can be downloaded

www.zebra.com/drivers

from

• By means of a Bluetooth™ short range radio frequency link.

(Optional)

• By means of a wireless LAN (Local Area Network) per 802.11 specifications. (Optional)

• By means of the Ethernet when docked on the Ethernet cradle.

(Optional)

QLn Series User Guide

.

34

Page 35

Cable Communication

Caution • The printer should be turned o before connecting or

disconnecting a communications cable.

The QLn320 and QLn220 printers can communicate by cable; the specific cable supplied with your printer will vary with

the host terminal and your model printer.

RS-232C Communications

The 14-pin serial connector on your communications cable

plugs into the serial communications port on the side of the

printer. QLn Series printers also have a USB port.

USB Communications

The small 5-pin connector on the USB cable plugs into the

printer. The connectors are keyed to assure correct alignment; do not try to force the cable if it does not plug in.

Figure 17: Cable Communications

Communications

Port

Figure 18: Communications with a P.C.

Communications Cable to Terminal

Part numbers vary. Refer to Appendix A.

QLn Series User Guide

RS-232C or USB Communications

Cable to Computer

Refer to Appendix A for part numbers.

35

Page 36

The other end of the cable must be plugged into the host terminal as shown in Figure 18, or to a serial or USB port on a

computer (Figure 18). The QLn Series is configured with the

USB Open HCI interface driver allowing it to communicate

with Windows® based devices.

USB drivers are included in the Zebra Designer Driver which can be

downloaded from the Zebra Web site. Other terminals or communications devices may require the installation of special drivers to use the

USB connection. Consult the factory for further details.

Providing Strain Relief for Communications Cable

If you are connecting either a USB or RS-232 communications cable

to the printer permanently, access the communications port on the

side of the printer next to the latch release lever. Plug the connector

into the appropriate port and align the plastic locking cap with the cut

outs shown below. Rotate the locking cap clockwise to lock the cable

in place. (Turn counterclockwise to unlock the cable.) Once locked in

place, this provides strain relief for the cable and will prevent the cable

from disconnecting from the printer.

Note • Only one cable can be present in the USB/RS-232

communications port at a time for strain relief purposes.

Figure 19: Communications Port

Align locking

connector

with these

cut-outs.

USB Port

QLn Series User Guide

RS-232 Port

36

Page 37

Figure 20: Communications Port Strain Relief

Rotate locking cap in a

clockwise direction to lock

cable in place.

37

QLn Series User Guide

Page 38

Wireless Communications with Bluetooth™

Bluetooth is a worldwide standard for the exchange of data

between two devices via radio frequencies. Bluetooth radios

are relatively low powered to help prevent interference with

other devices running at similar radio frequencies. This limits

the range of a Bluetooth device to about 10 meters (32 feet).

Both the printer and the device it communicates with must follow the Bluetooth standard. Other than conditions specified

elsewhere in this manual, only one of the radio options can be

installed in the printer at one time and the antenna used for

these transmitters must not be co-located or must not operate

in conjunction with any other antenna.

Bluetooth Networking Overview

Each Bluetooth enabled QLn320 and QLn220 printer is identified by a unique Bluetooth Device Address (BDA). In order to

exchange data, two Bluetooth enabled devices must establish

a connection.

Bluetooth software is always running in the background,

ready to respond to connection requests. One device (known

as the master or the client) must request a connection with another. The second device (the slave or the server) then accepts

or rejects the connection. A Bluetooth enabled QLn Series

printer will normally act as a slave creating a miniature network with the terminal sometimes referred to as a “piconet”.

For the most part, communications using the Bluetooth protocol are initiated and processed without any operator intervention.

38

QLn Series User Guide

continued

Page 39

WLAN Overview

QLn320 and QLn220 printers can be equipped with a radio

using the industry standard 802.11 protocols. They will have

the FCC ID number on the serial number label on the back of

the unit.

• QLn Series Wireless Network Printers with the Zebra

802.11 WLAN radio module can be identified by the text

“Wireless Network Printer” on the serial number label on

the back of the printer.

• These printers allow communication as a node within a

wireless local area network (WLAN). Methods of establishing communications to the printer will vary with each

application.

General information on establishing WLAN communications can be found in the ”CPCL Programming Manual” which

is available on-line. More information and LAN configuration

utilities are included in Zebra’s Net Bridge™ program (version 2.8 and later). Net Bridge may be downloaded from the

Zebra Web site.

Setting Up the Software

QLn Series printers use Zebra’s CPCL and ZPL Programming

languages which were designed for mobile printing applications. CPCL and ZPL are fully described in the ”CPCL

Programming Manual” and the “ZPL Programming Guide”

available on-line at

You can also use Designer Pro, Zebra’s Windows® based label creation program which uses a graphical interface to create and edit labels in either language.

Refer to Appendix F for tips on downloading the Designer Pro application from Zebra’s Web site.

www.zebra.com/manuals

.

39

QLn Series User Guide

Page 40

Using the Accessories

Swivel Belt Clip

Refer to Figure 21. Most QLn320 and QLn220 printers have a

belt clip installed as a standard feature. To use: hook the clip

over your belt, and ensure that the clip is securely attached

to the belt. The belt clip will pivot to allow you to move freely

while wearing the printer.

In order to install or remove the Belt Clip you will need to remove

the battery pack.

Figure 21: Using the Belt Clip

Clip printer to

belt

Belt

Printer can

pivot freely

Soft Case

Both the QLn220 and QLn320 have soft case options that

also allow you to carry the printer from your belt. The QLn320

soft case can be ordered through accessory kit number

P1031365-029 while the QLn220 accessory kit is yet to be determined.

40

QLn Series User Guide

Page 41

Adjustable Shoulder Strap

Refer to Figure 22 if your printer is equipped with the shoulder strap option (p/n P1031365-026). Insert each end of the

shoulder strap into the cut-outs in each top corner of the printer and secure the looped end over the button on the end of

the strap to fasten.

Hold the buckle and pull the strap as shown below until you

achieve the desired length.

Figure 22: Using the Optional Shoulder Strap

Pull Strap here

to lengthen.

Hold Buckle.

Pull

Strap

here to

shorten.

Insert loop into

cut-outs on

printer.

41

QLn Series User Guide

End of

strap

Button

Loop

continued

Page 42

Hand Strap

The QLn Series hand strap accessory (p/n P1031365-027) attaches to the printer’s cut-outs as does the shoulder strap to

provide the user with a convenient and secure method of carrying the printer. To attach the hand strap to the printer:

• Insert the end of the strap through the cut out on the front of the

printer as shown.

• Loop the end of the strap back around the cut out and secure it

over the button.

• Repeat this process for the opposite end of the strap.

Figure 23: Detachable Hand Strap

Loop strap into

cut-outs on

printer.

The QLn320 and QLn220 printers also features two mounting holes on the base of the printer to accommodate future

mounting options.

42

QLn Series User Guide

Page 43

Preventive Maintenance

Extending Battery Life

• Never expose the battery to direct sunlight or temperatures over 104° F (40° C).

• Always use a Zebra charger designed specifically for Lithium-Ion

batteries. Use of any other kind of charger may damage the battery.

• Use the correct media for your printing requirements. An

authorized Zebra re-seller can help you determine the optimum media for your application.

• If you print the same text or graphic on every label, consider using a pre-printed label.

• Choose the correct print darkness, and print speed for

your media.

• Use software handshaking (XON/XOFF) whenever possible.

• Remove the battery if the printer won’t be used for a day or more

and you’re not performing a maintenance charge.

• Consider purchasing an extra battery.

• Remember that any rechargeable battery will lose its

ability to maintain a charge over time. It can only be recharged a finite number of times before it must be replaced. Always dispose of batteries properly. Refer to

Appendix E for more information on battery disposal.

General Cleaning Instructions

Caution • Avoid possible personal injury or damage to the printer: never

insert any pointed or sharp objects into the printer.

Always turn the printer o before performing any cleaning

procedures.

Use care when working near the tear bar. The edges are very sharp.

Caution • The printhead can be very hot after prolonged printing.

Allow it to cool o before attempting any cleaning procedures.

Only use the cleaning pen supplied with the printer or a cotton swab

saturated with alcohol for cleaning the printhead.

Caution • Use only cleaning agents specied in the following tables.

Zebra Technologies Corporation will not be responsible for damage

caused by any other cleaning materials used on this printer.

43

QLn Series User Guide

Page 44

QLn Series Cleaning

Area Method Interval

Printhead (Figure 24)

Platen Roller (Figure 24)

Platen Roller (Figure 25)

Peel bar (Figure 24)

Tear bar (Figure 24)

Use the supplied cleaning pen or 70%

Isopropyl alcohol on a cotton swab to

clean the print elements from end to

end (the print elements are located in

the thin gray line on the printhead).

Rotate the platen roller and clean it

thoroughly with the cleaning pen or

70% Isopropyl alcohol and a cotton

swab.

Units with linerless platens: Rotate

platen & clean bearing points only.

Avoid use of alcohol on the surface

of linerless platens

Clean thoroughly with the cleaning pen

or 70% Isopropyl alcohol and a cotton

swab.

After every five rolls of

media (or more often, if

needed),

Linerless media requires

more frequent cleaning

As needed

As needed

Exterior

Interior (Figure 24)

Interior (Figure 25)

Water-dampened cloth or 70%

Isopropyl alcohol wipe.

Brush/air blow. Ensure the Bar

Sensor, Gap Sensor and Label

Present Sensor windows are free

of dust.

Units with linerless platens: Clean inside

surfaces of edge guides & media rollers

with the supplied cleaning pen or 70%

Isopropyl alcohol on a cotton swab.

As needed

After every five rolls of

media (or more often, if

needed)

44

QLn Series User Guide

Page 45

Figure 24: Cleaning the QLn Series Printers

Platen surface

Peeler Bar

Bar Sensor

Printhead

Elements

Peeler

Bar

Label

Presence

Sensor

Figure 25: Cleaning the Linerless QLn Series Printers

Gap

Sensor

Tear Bar

Bearing Points

Linerless Platens only

Scraper

Platen surface

Avoid using alcohol

on linerless platen

surface.

Media Support

Disks, Inner

surfaces on

both sides.

Linerless units only.

45

QLn Series User Guide

Page 46

Troubleshooting

Figure 26 QLn Series Control Panel

Front Control Panel

LCD Control Panel

Green/Yellow

LED

Status icons

Front Control Panel

If the printer is not functioning properly, refer to the chart

below to find the state of the LED charge indicator on the

Front Control Panel. Then refer to the Troubleshooting topic referenced in the chart to resolve the problem. Please note

that the charge LED is only on when DC power is applied to

the printer. If no DC power is applied the LED is off, which

does not apply to the table below.

Green Yellow Indication

Solid

Off

Off

Off

Solid Charging n/a

Off

46

QLn Series User Guide

Fully charged

Fault

Ref. to

Topic

n/a

1

Page 47

LCD Control Panel Indicators

The top of the display shows several icons which indicate

the status of various printer functions. Check the indicator status, then refer to the Troubleshooting topic referenced in the

chart to resolve the problem.

Icon Status Indication

On Bluetooth Link estab-

Not Present Bluetooth Link inactive

Blinking

Antenna Blinking Looking for AP

Antenna Blinking/1 Parenthe-

sis Solid

Antenna and 2 Parentheses

Solid

Antenna and 2 Parentheses

Blinking

Not Present

4 Bars >80% Charged

3 Bars 60%-80% Charged

2 Bars 40%-60% Charged

1 Bar 20%-40% Charged

0 Bars Low Bat ter y

4 Blinking w/ Lightning Bolt Charging >80% Capacity

3 Blinking w/ Lightning Bolt

2 Blinking w/ Lightning Bolt

1 Blinking w/ Lightning Bolt

0 Bars w/ Lightning Bolt Charging <20% Capacity

lished

Connecting or Transmitting Labels

WLAN Associated & Attempting Authentication

WLAN Associated and

Authenticated

Receiving Data

No Radio Present

Charging 60 -80% Capacity

Charging 40 -60% Capacity

Charging 20-40% Capacity

Blinking Media cover open

Blinking Receiving data

Solid Ethernet Connected

Not Present No Ethernet Connection

47

QLn Series User Guide

continued

Page 48

Blinking

Steady No data being processed

Blinking Out of Media

Steady Media present

Blinking

Not Present No error exists

4 Bars

3 Bars

2 Bars

1 Bar

0 Bars No Signal Strength

Data processing in

progress

Error exists (excluding

Media Out and Head

Latch Open)

802.11 signal strength

> 75%

802.11 signal strength

</= 75%

802.11 signal strength </=

50% but >25%

802.11 signal strength

</= 25%

Troubleshooting Topics

1. No power

• Check that battery is installed properly.

• Recharge or replace battery as necessary.

Always dispose of batteries properly. Refer to Appendix E for more

information on proper battery disposal.

2. Media does not feed:

• Be sure print head is closed and latched.

• Check spindle holding media for any binding.

• Ensure most recently printed label is removed (only in peel mode).

• Also ensure label sensor is not blocked.

3. Poor or faded print:

• Clean print head.

• Check quality of media.

4. Partial or missing print:

• Check media alignment

• Clean print head.

• Ensure printhead is properly closed and latched.

5. Garbled print:

• Check baud rate.

48

QLn Series User Guide

Page 49

6. No print:

• Check baud rate.

• Replace battery.

• Check cable to terminal.

• Establish RF Link (Wireless units only) and/or restore LAN

associativity (Printers with WLAN radios only).

• Invalid label format or command structure. Place printer in

Communications Diagnostic (Hex Dump) Mode to diagnose

problem.

7. Reduced battery charge life

• Check battery date code — if battery is older than 1 year old, short

charge life may be due to normal aging.

• Check battery health.

• Replace battery.

8. ashing:

• Flashing indicator is normal while data is being received.

9. or ashing:

• Check that media is loaded and that the media cover is closed and

securely latched.

10. Skips labels:

• Check media for top of form sense mark or label gap.

• Check that the maximum print field has not been exceeded

on label.

• Ensure bar or gap sensor is not blocked or malfunctioning

11. Communication error:

• Check baud rate.

• Replace cable to terminal.

12. Label jam:

• Open head release latch and media cover.

• Remove and reinstall media.

13. Blank LCD screen

• Make sure printer is turned on.

• No application loaded or application corrupted: reload

program.

49

QLn Series User Guide

Page 50

Troubleshooting Tests

Printing a Conguration Label

To print out a listing of the printer’s current configuration fol-

low these steps:

1. Turn the printer off. Load the media compartment with

journal media (media with no black bars printed on the

back).

2. Press and hold the Feed Button.

3. Press and release the Power button and keep the Feed

button pressed. When printing starts, release the Feed

button.

Note • The conguration report can also be printed from the Info

(Help) menu on the LCD.

Refer to Figures 27a, b, and c for sample configuration print-

outs.

Communications Diagnostics

If there is a problem transferring data between the computer

and the printer, try putting the printer in the Communications

Diagnostics Mode (also referred to as the “DUMP” mode). The

printer will print the ASCII characters and their text representation (or the period ‘.’, if not a printable character) for any data

received from the host computer.

To enter Communications Diagnostics Mode:

1. Print a configuration label as described above.

2. At the end of the diagnostics report, the printer will print: “Press

FEED key to enter DUMP mode”.

3. Press the FEED key. The printer will print: “Entering

DUMP mode”.

Note • If the FEED key is not pressed within 3 seconds, the printer will

print “DUMP mode not entered” and will resume normal operation.

4. At this point, the printer is in DUMP mode and will print

the ASCII hex codes of any data sent to it, and their text

representation (or “.” if not a printable character).

Additionally, a file with a “.dmp” extension containing the

50

QLn Series User Guide

Page 51

ASCII information will be created and stored in the printer’s

memory. It can be viewed, “cloned” or deleted using the Net

Bridge application. (Refer the Net Bridge documentation for

more information.)

To terminate the Communications Diagnostics Mode and re-

turn the printer to normal operations:

1. Turn the printer OFF.

2. Wait 5 seconds.

3. Turn the printer ON.

Contacting Technical Support

If the printer fails to print the configuration label, or you encounter problems not covered in the Troubleshooting Guide,

contact Zebra Technical Support. Technical Support addresses and phone numbers for your area can be found in

Appendix D of this manual. You will need to supply the following information:

• Model number and type (e.g. QLn320)

• Unit serial number (Found on the large label on the back of the

printer, also found in the configuration label printout.

• Product Configuration Code (PCC) (15 digit number found on the

label on the back of the unit)

51

QLn Series User Guide

Page 52

Figure 27a: QLn Series Conguration Label Example (QLn320 Shown)

Identifies

Printer as a

QLn320 series

Unit Serial

Number

Report appears

only on units

with wireless

options installed.

Units with no

wireless options

will print an

empty line and

resume.

Application

Number

This unit has a

802.11b/g radio

option installed.

This section

details the

radio’s network

settings.

Note • Wireless conguration settings may not print correctly when us-

ing the Power and Feed key method of printing as the radio takes time to initialize before these settings are valid. To get the correct setting, turn the printer on,

wait 60 seconds, and then print the report from the Info (Help) menu.

52

QLn Series User Guide

Page 53

Figure 27b: Conguration Label Example (continued)

Peripherals

installed: In

this example

the 802.11

option is

installed.

Flash

and RAM

Memory

Installed

Maximum

Label Size

Resident

Human

Readable

fonts

installed.

53

QLn Series User Guide

continued

Page 54

Figure 27c: Conguration Label Example (continued)

Files Loaded

in Printer

Memory

(will include

Pre-scaled

or Scalable

Fonts).

54

QLn Series User Guide

Page 55

Specifications

Note • Printer specications are subject to change without notice.

Printing Specications

Parameter QLn320 QLn220

Print Width Up to 2.91 in. (74 mm) Up to 1.89 in. (48 mm)

4 in./second (101,6 mm/second)

Print Speed

Printhead Burn

Line to Tear

Edge Distance

Print Head Life,

calculated

Print Density 203 dots/in. Same

2 in./second (50,8 mm/second) with

without peeler

peeler

0.20 in. (5,08 mm) 0.17 in. (4,31 mm)

1 million inches of paper fed Same

Memory and Communications Specications for QLn Series

Flash Memory 256 MB Flash

RAM Memory 128 MB RAM

RS-232 serial port (14 Pin serial connector)

Configurable Baud rate (from 9600 to 115.2 Kbps),

Standard

Communications

parity and data bits.

Software (X-ON/X-OFF) or hardware (DTR/

STR) communication handshake protocols.

USB 2.0 Full Speed Inter face (12 Mbps)

Optional Wireless

Communications

Bluetooth v2.1 compatible 2.4 GHz SRRF link

Optional wireless LAN capabilities comply

with802.11b/g protocols

Time and date under application control. Refer to

Real Time Clock (RTC)

CPCL and ZPL Programming Manuals, available at

www.zebra.com/manuals for RTC commands.

Ethernet

10 or 100 mps Ethernet auto detect when docked in

cradle.

1

1

Same

Same

1. Memory configuration on your printer may be ascertained by printing a configuration

label as detailed on pages 48.

55

QLn Series User Guide

Page 56

Label Specications

Parameter QLn320 QLn220

Media Width

1.0 in. to 3.125 in. (38,1 to

78,4 mm)

.63 in to 2.18 in. (16 mm to

55,37 mm)

Max/Min Label

Length

Black Bar

Sensor to

Printhead Burn

Line Distance.

Label Thickness

Tag Thickness

Max. Label Roll

dia.

Label Inner

Core**

Black Mark

Location

Black Mark

Dimensions

0.5 in. minimum to 32 in.

maximum

0.56 in. (14,22 mm) 0.53 in. (13,46 mm)

0.0023 in to 0.0065 in

(0.058 mm to 0.165 mm)

0.0055 in. (0.152 mm)

maximum

2.6 in. (66,8 mm) O.D. 2.2 in. max (55,8 nn) O.D.

0.75 in. (19 mm) or 1.38 in

(35,05 mm) minimum dia. for

linered

1.38 in. (35,05 mm) minimum

dia. for linerless media

The reflective media black

marks should be centered on

the media roll.

Minimum mark width: 0.5

in. (12,7 mm) perpendicular

to inside edge of media,

centered within the width of

the roll.

Mark length: 0.12 in. to 0.43

in. (3-11 mm) parallel to

inside edge of media

0.0023 in. to 0.0055 in.

(0.058mm to 0.140 mm)

Same

Same

Same

Same

Same

Same

Use Zebra brand direct thermal media that is outside wound. Media

may be reective (black mark) sensing, or transmissive (gap) sensing,

die-cut, continuous, or linerless.

For die-cut labels, use only full auto dies.

** QLn Series printers support coreless media which is 0.75 in. (19 mm) in

inner diameter.

56

QLn Series User Guide

Page 57

CPCL Font and Bar Code Specications and Commands

25 bit-mapped fonts; 1 scalable font (CG Trimvirate Bold

Standard Fonts

Available Optional Fonts

Linear Bar Codes Available

2-D Bar Codes Available

Rotation Angles 0°, 90°, 180°, and 270°

Condensed*) *Contains UFST from Agfa Monotype Corporation

Downloadable optional bit-mapped & scalable fonts via Net

Bridge software.

Optional International character sets: Chinese 16 x 16

(trad), 16 x 16 (simplified),24 x 24 (simplified); Japanese

16 x 16, 24 x 24

Barcode (CPCL Command)

Aztec (AZTEC)

Codabar (CODABAR, CODABAR 16)

UCC/EAN 128 (UCCEAN128)

Code 39 (39, 39C, F39, F39C)

Code 93 (93)

Code 128 (128)

EAN 8, 13, 2 and 5 digit extensions (EAN8, EAN82, EAN85, EAN13,

EAN132, and EAN135)

EAN-8 Composite (EAN8)

EAN-13 Composite (EAN13)

Plessey (PLESSEY)

lnterleaved 2 of 5 (I2OF5)

MSI (MSI, MSI10, MSI1110)

FIM/POSTNET (FIM)

TLC39 (TLC39)

UCC Composite A/ B/C (128(Auto))

UPCA, 2 and 5 digit extensions (UPCA2 and UPCA5)

UPCA Composite (UPCA)

UPCE, 2 and 5 digit extensions (UPCE2 and UPCE5)

UPCE Composite (UPCE)

MaxiCode (MAXICODE)

PDF 417 (PDF-417)

Datamatrix (using ZPL emulation) (DATAMATRIX)

QR Code (QR)

RSS-14 (RSS-Subtype 1)

RSS-14 Truncated (RSS-Subtype 2)

RSS-14 Stacked (RSS -Subtype 3)

RSS:

RSS-14 Stacked Omnidirectional (RSS-Subtype 4)

RSS Limited (RSS-Subtype 5)

RSS Expanded (RSS-Subt ype 6)

57

QLn Series User Guide

Page 58

ZPL Font and Bar Code Specications and Commands

15 bit-mapped fonts; 1 scalable font (CG Trimvirate Bold

Standard Fonts

Available Optional Fonts

Linear Bar Codes Available

2-D Bar Codes Available

Rotation Angles 0°, 90°, 180°, and 270°

*Contains UFST from Agfa Monotype Corporation

Condensed*)

Downloadable optional bit-mapped & scalable fonts via

Net Bridge software.

Zebra offers font kits covering multiple languages including

Simplified and Traditional Chinese, Japanese, Korean,

Hebrew/Arabic, and others.

Barcode (ZPL Command)

Aztec (^B0)

Codabar (^BK)

Codablock (^BB)

Code 11 (^B1)

Code 39 (^B3)

Code 49 (B4)

Code 93 (^BA)

Code 128 (^BC)

DataMatrix (^BX)

EAN-8 (^B8)

EAN-13 (^BE)

GS1 DataBar Omnidirectional (^BR)

Industrial 2 of 5 (^BI)

lnterleaved 2 of 5 (^B2)

ISBT-128 (^BC)

LOGMARS (^BL)

Micro-PDF417 (^BF)

MSI (^BM)

PDF-417 (^B7)

Planet Code (^B5)

Plessey (^BP)

Postnet (^BZ)

Standard 2 of 5 (^BJ)

TLC39 (^BT)

UPC/EAN extensions (^BS)

UPC-A (^BU)

UPC-E (^B9)

Maxi Code (^BD)

QR Code (^BQ)

58

QLn Series User Guide

Page 59

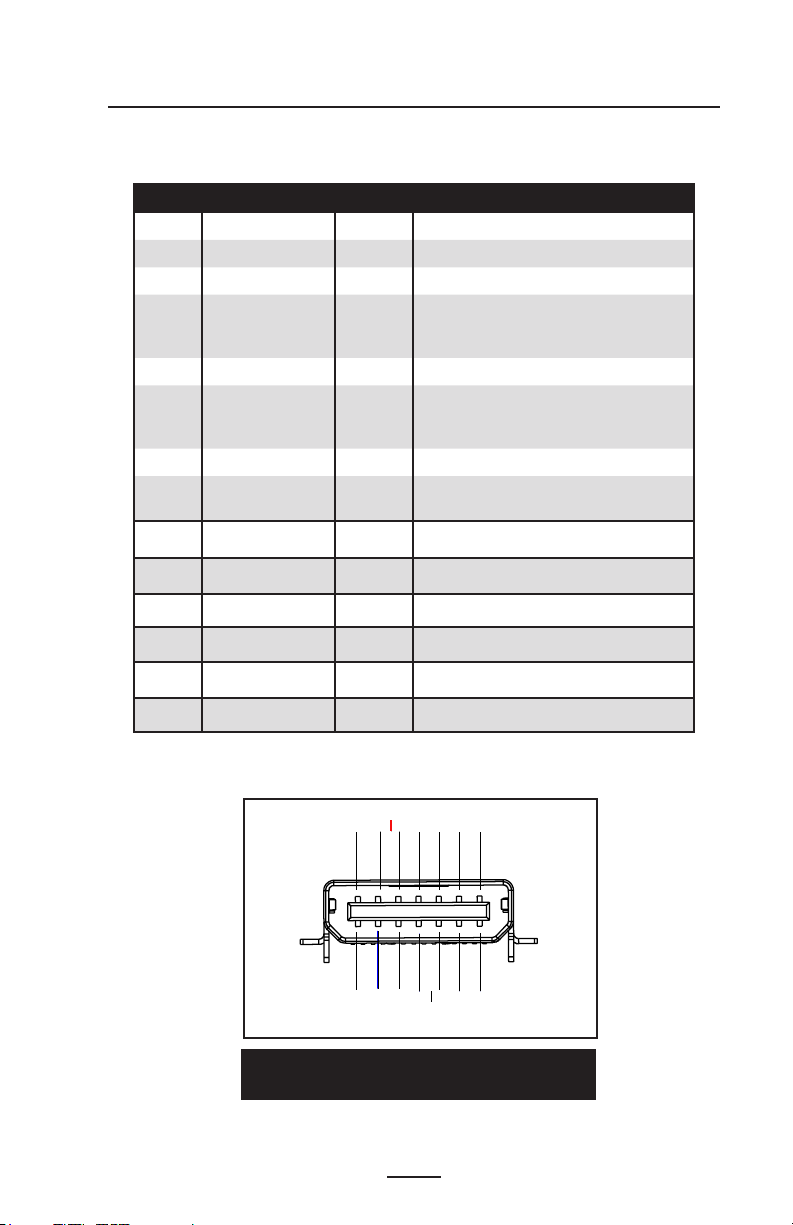

Communications Ports

RS-232C

Pin# Signal Name Type Description

1

2 TXD output Transmit Data

3

4

5 GND Ground

6

7

8

9 N/A Do Not Use

10 N/A Do Not Use

11 N/A Do Not Use

12 N/A Do Not Use

13 N/A Do Not Use

14 N/A Do Not Use

CTS

RXD

DSR input Data Set Ready: low to high transition

DTR output Data Terminal Ready: set high when

N/A Do Not Use

RTS

input

input

output

Clear To Send from host

Receive Data

turns printer on, high to low transition

turns printer off (if enabled)

printer is on.

Switched 5V (300mA max)

Request To Send set high when printer is

ready to accept a command or data

10

12

8

4

6

2

1

5

3

7

14

9

11

13

Figure 28: RS-232C Communications Port

59

QLn Series User Guide

Page 60

USB

Pin

Pin # Signal Name Type Description

1 VBUS - USB Bus Power

2 USB - bi-directional I/O signals

3 USB + bi- directional I/O signals

4 USB_ID - Identifies A/B connector

5 Return Ground

5

1

Figure 29: USB Communications Port

Physical, Environmental and Electrical Specications

Parameter

Weight w/

battery,excluding

media & wireless

options.

Temperature