Page 1

Zebra® P630

i /

P640

i

Card Printer

User’s Manual

980541-003 Rev. A

Page 2

P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 3

This manual contains installation and operation information for the Zebra P630i and P640i

card printers manufactured by Zebra Technologies Corporation.

Copyright Notice

© 2006, ZIH Corp.

This document contains information proprietary to Zebra Technologies Corporation. This

document and the information contained within is Copyrighted by Zebra Technologies

Corporation and may not be duplicated in full or in part by any person without written

approval from Zebra Technologies Corporation. While every effort has been made to keep the

information contained within current and a ccurate as of the date of publication, no guarantee is

given that the document is error-free or that it is accurate with regard to any specification.

Zebra T echnologies Corporation reserve s the right to make changes, for the purpose of product

improvement, at any time.

Foreword

Trademarks

Zebra is a registered trademark of Zebra Technologies Corporation. Windows and MS.DOS

are registered trademarks of Microsoft Corp. All other trademarks or registered trademarks are

marks of their respective holders.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual i

Page 4

Foreword

Return Materials Authorization

Product Disposal

Product Disposal Information • Do not dispose of this product in unsorted municipal waste.

This product is recyclable, and should be recycled according to your local st andards. For more

information, please see our web site at:

http://www.zebra.com/environment

Return Materials Authorization

Before returning any equipment to Zebra Technologies Corporation for in-warranty or out-ofwarranty repair, contact Repair Administration for a Return Materials Authorization (RMA)

number. Repack the equipment in the original packing material and mark the RMA number

clearly on the outside. Ship the equipment, freight prepaid, to the address listed below:

• For USA, Latin America, and Asia / Pacific:

Zebra Technologies Corporation

Zebra Card Printer Solutions

1001 Flynn Road

Camarillo, CA. 93012-8706.USA

Phone: +1 (805) 578-5001

FAX: +1 (805) 579-1808

• For Europe and Middle East:

Zebra Technologies Corporation

Zebra Card Printer Solutions

Pittman Way, Fulwood

Preston, PR2 9ZD

Lancashire, U.K.

Phone: +44 - 1 - 772 - 797555

FAX: +44 - 1 - 772 - 693000

ii P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 5

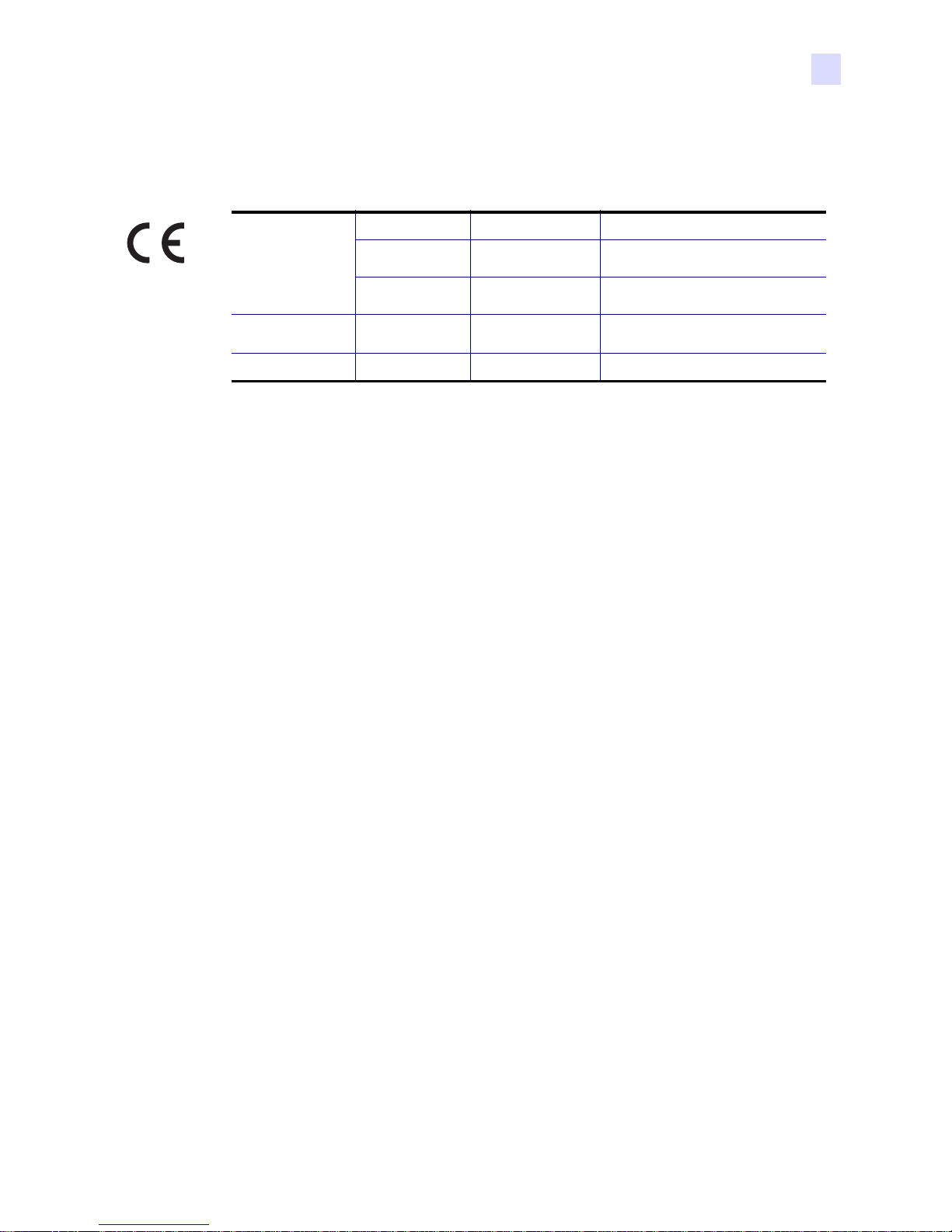

Declarations of Conformity

Foreword

Declarations of Conformity

89/336/EEC

modified by

92/31/EEC and

93/68/EEC

73/23/EEC modified

by 93/68/EEC

1999/5/CE

EMC Directive

EMC Directive

EMC Directive EN55024 (2001)

Low voltage

Directive

R&TTE Directive

EN 55022 (1998) RF Emissions control

EN 301489-3 V1.4.1 RF Emissions and Immunity for radio

equipment

Immunity to Electro-Magnetic

Disturbances

EN 60950-1 (2001) Product safety

EN300330-2 V1.1.1 Radio Frequency Interferences

For a formal certificate, please contact the Compliance Office at Zebra’s Camarillo facility.

EUROPE:

Norway Only: This product is also designed for IT power system with phase to phase

voltage 230V. Earth grounding is via the polarized, 3-wire power cord.

FI: “Laite on liitettävä suojamaadoitus koskettimilla varustettuun pistorasiaan”

SE: “Apparaten skall anslutas till jordat uttag”

NO: “Apparatet må tilkoples jordet stikkontakt”

FCC - DECLARATION OF CONFORMITY

Models P630i and P640i have been tested and found to comply with the limits for a Class

A device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment ge nerates, uses, and can radiate radio freq uency

energy and, if not installed and operated in accordance with the P630i / P640i User’s

Manual (this document), may cause harmful interference to radio communicat ion s .

Operation of this equipment in a residential area is likely to ca use harmful in terference, in

which case the user will be required to correct the interference at his own expense.

INDUSTRY CANADA NOTICE

This device complies with Industry Canada ICES-003 class A requirements.

Cet equipement est conforme a l’ICES-003 classe A de la norm Industrielle Canadian.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual iii

Page 6

Foreword

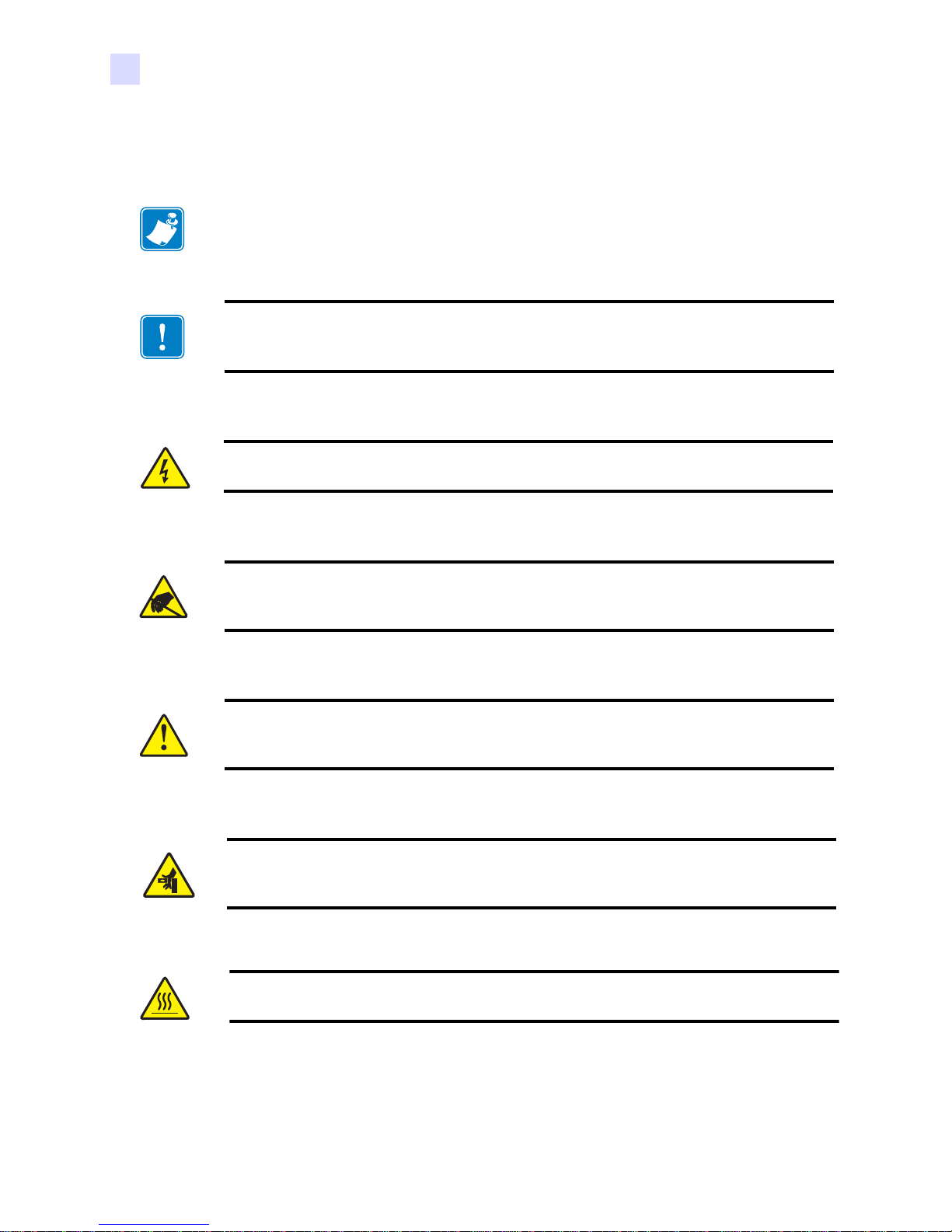

Icons

Icons

Throughout this manual, different icons highlight important information, as follows:

Note • Indicates information that emphasizes or supplements important points of the main

text.

Important • Advises you of information that is essential to complete a task, or points out the

importance of specific information in the text.

Electric Shock Caution • Warns you of a potential electric shock situation.

Electrostatic Discharge Caution • Warns you of a situation where electrostatic

discharge could cause damage to electronic components.

Caution • Advises you that failure to take or avoid a specific action could result in

physical harm to you, or could result in physical damage to the hardware.

Pinch Hazard • Keep fingers away from printer cover hinges and back of cleaning

cassette.

Hot Surface • Danger of skin burns near laminator components.

iv P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 7

P630i and P640i Printer Models

The Zebra Product Number tells a story. Model numbers include identifiers that specify

options using the following conventions:

Part Number Description

Base Printer

P 6 3 0 i - _ _ _ _ _ - _ _ _

P 6 3 0 is- _ _ _ _ _ - _ _ _

P 6 4 0 i - _ _ _ _ _ - _ _ _

P 6 4 0 is- _ _ _ _ _ - _ _ _

_ _ _ _ _ - 0 _ _ _ _ - _ _ _

_ _ _ _ _ - B _ _ _ _ - _ _ _

_ _ _ _ _ - D _ _ _ _ - _ _ _

_ _ _ _ _ - E _ _ _ _ - _ _ _

_ _ _ _ _ - H _ _ _ _ - _ _ _

_ _ _ _ _ - _ 0 _ _ _ - _ _ _

_ _ _ _ _ - _ M _ _ _ - _ _ _

_ _ _ _ _ - _ _ 0 _ _ - _ _ _

_ _ _ _ _ - _ _ 3 _ _ - _ _ _

_ _ _ _ _ - _ _ _ 0_ - _ _ _

_ _ _ _ _ - _ _ _ _ A - _ _ _

_ _ _ _ _ - _ _ _ _ C - _ _ _

_ _ _ _ _ - _ _ _ _ U - _ _ _

_ _ _ _ _ - _ _ _ _ _ - I _ _

_ _ _ _ _ - _ _ _ _ _ - U _ _

_ _ _ _ _ - _ _ _ _ _ - _ D _

P630i Dual-Sided Color Card Printer w/Single Linerless

Laminator

P630iS Dual-Sided Color Card Printer w/Single Linerless

Laminator with Advanced ID/Key Security Feature

Base Printer

P640i Dual-Sided Color Card Printer w/Dual Linerless

Laminator

P640iS Dual-Sided Color Card Printer w/Dual Linerless

Laminator with Advanced ID/Key Security Feature

Smart Card Options

None

Contact Encoder

Contact encoder & MIFARE contactless

Contact Station

MIFARE contactless

Magnetic Encoder

None

Yes (select defaults below)

Magnetic Encoder Defaults

None

Stripe Up, HiCo

Memory Expansion

None

Interface

USB Standard Configuration)

USB & Built-InEthernet 10/100T

USB and Parallel (Minimum Printer Order Applies)

Power Cords

120V A.C. US & 230V A.C. European

U. K. and Australia

Windows Drivers and User Documentation / Training

Windows Driver CD (Win 2K and XP) & User

Documentation & Training CD

Foreword

P630i and P640i Printer Models

_ _ _ _ _ - _ _ _ _ _ - _ _ G

980541-003 Rev. A P630i, P640i Card Printer User’s Manual v

RoHS

Compliant

Page 8

Foreword

P630i and P640i Printer Models

vi P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 9

Contents

Foreword. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Copyright Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Trademarks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Return Materials Authorization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Declarations of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

P630i and P640i Printer Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

1 • Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Printer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Controls and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Control Panel Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Control Panel Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Rear of Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 • Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Remove the Printer from the Shipping Carton . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Remove Shipping Tape. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Attach the Output Hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Attach the Ribbon Take-Up Spool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Connecting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Ribbon Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing the Cleaning Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Loading Laminate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Loading the Laminate Cassette(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

980541-003 Rev. A P630i, P640i Card Printer User’s Manual vii

Page 10

Contents

Using Partial-Width Laminate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installing the Laminator Cassette(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Clearing the Laminate Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Loading Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connecting the Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3 • Printer Driver Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Installing the Printer Driver (USB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Installing the Printer Driver (Ethernet). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4 • Settings and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Sensors and Interlock Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Access Printer Sensor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Printer Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Sharing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Advanced . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Color Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Device Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Printing Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Card Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Image Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

YMC (Color) Printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

K (Black) Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Color Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Flip Station Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Laminator Station Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5 • Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Indicator Light Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Unusual Noises/Unreported Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Quality Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Laminate Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Examples of Printhead Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

System Related Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Invalid IP address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

DHCP is enabled but the printer is not connected to your network . . . . . . . . . . . . . . 77

viii P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 11

Contents

Valid host name has not been assigned to the printer . . . . . . . . . . . . . . . . . . . . . . . . 77

Color differences may be attributable to the Windows operating system installed . . . 77

6 • Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

P640i Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Appendix A • Magnetic Encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Magnetic Card Stripe Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

ISO Standard Encoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

AAMVA Standard Encoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Magnetic Encoder Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Media Loading Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Appendix B • Smart Card Contact Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Media Loading Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Laminating Smart Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Appendix C • Printer Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

ID/Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Replacing a Lost ID/Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Printer Parameters in the Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

ID/Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Update Backup Config . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Restoring the Backup Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Password Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Appendix D • Worldwide Sales & Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Sales and Support Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Corporate Headquarters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

980541-003 Rev. A P630i, P640i Card Printer User’s Manual ix

Page 12

Contents

x P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 13

1

Introduction

Thank you for choosing the Zebra P630i or P640i Card Printer. This manual guides you to

efficient start up and operation of your new Card Printer.

The Zebra P630i and P640i Card Printers provide high speed, full color dual-sided card

printing. A micro-positioning card transport system pr ovides enhanced color photos. A range

of interface, encoder/reader, and security options allow ordering the specific configuration

suitable for a particular application.

The difference between the P630i and the P640i is that the P630i has a single-sided

laminator (i.e., it lays down and seals a laminating film on the top surface of the

printed card), while the P640i has a dual-sided laminator (i.e., it lays down and seals

laminating film on both surfaces of the printed card).

References in this document that refer to either or both of the models will be in the form of

“the printer” or “the P630i/P640i Printer”; references that are specific to one or the other will

be in the form of “the P630i Printer” or “the P640i Printer.”

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 1

Page 14

Introduction

Printer Features

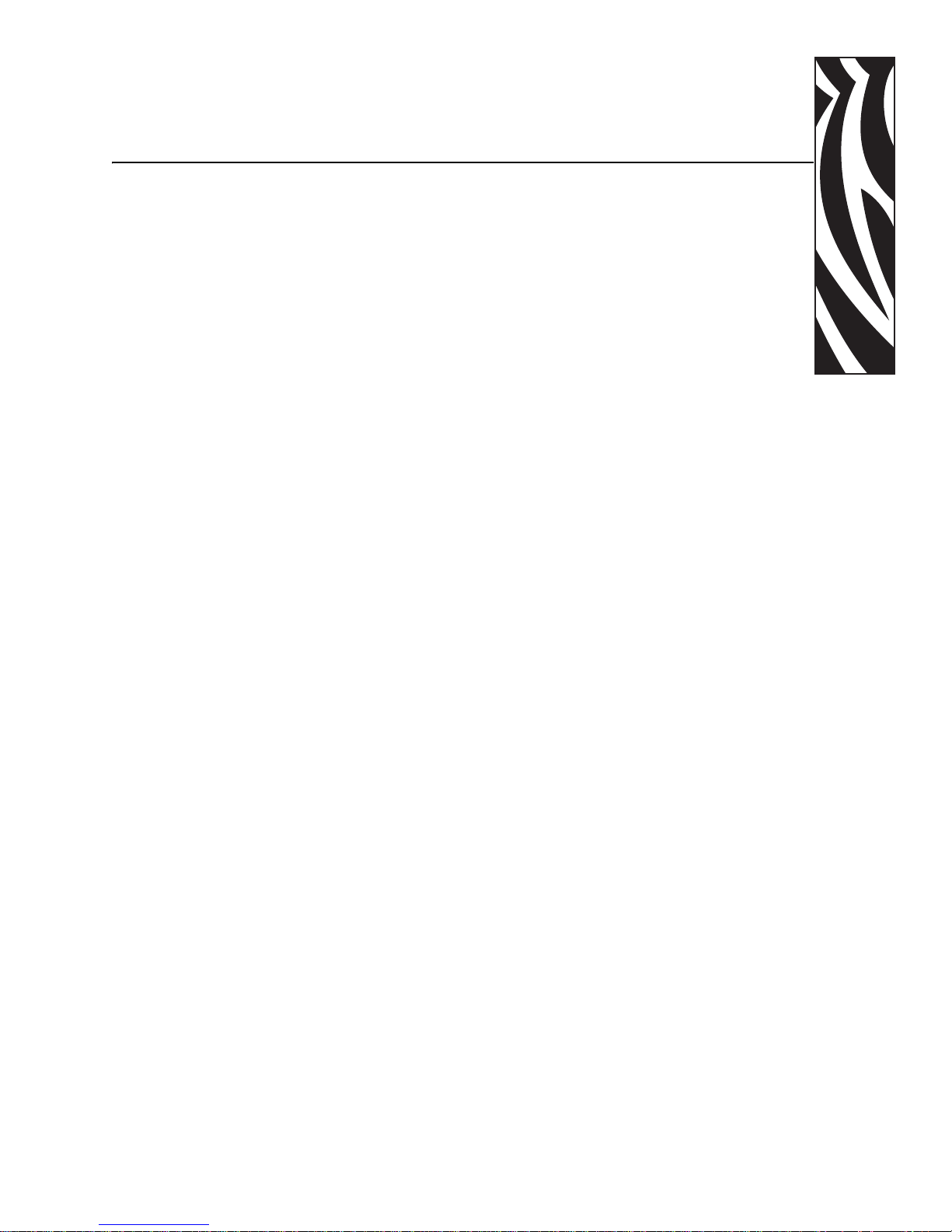

Printer Features

The following figure shows features of the P630i/P640i Printer.

Security

Key

(Optional)

Card

Feeder

Control

Panel

RibbonCleaning Cassette

Magnetic Encoder

(Optional)

Ribbon Take-Up Spool

Print

Head

Flip Station

Output

Hopper

Laminator Station (P640i)

Laminator Station (P630i)

Power Switch

2 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

AC Power Connector

Page 15

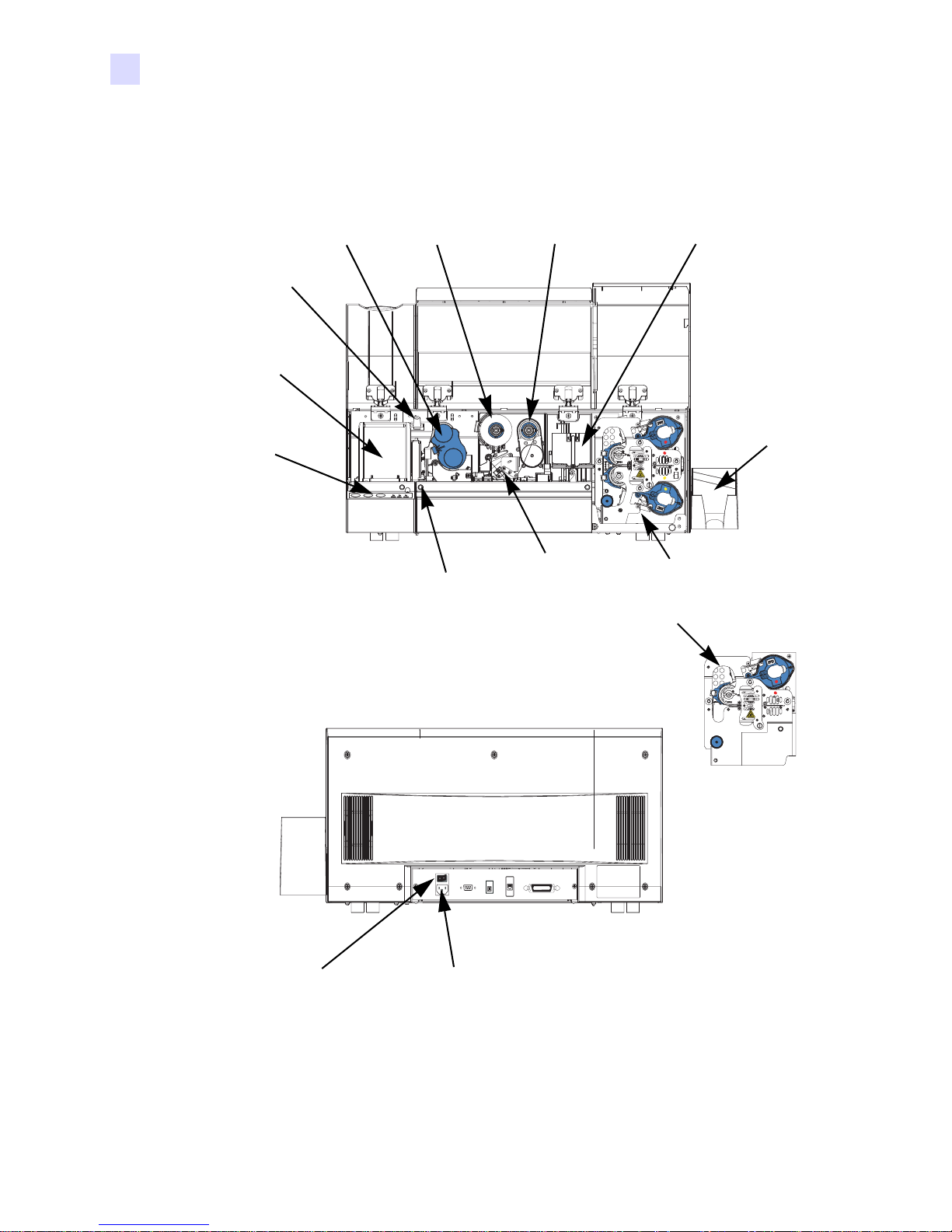

Controls and Indicators

Control Panel Buttons

A limited amount of control and status information is available at the Control Panel on the

front of the printer. Additional control functions and status information is available via the host

or networked computer(s).

Introduction

Controls and Indicators

Buttons

PRINT Button

Press the PRINT button to print the image stored in the printer’s me mory. When the printer is

powered up, the memory is loaded with a checkerboard test pattern.

PRINT

RIBBON

LAMINATE

READY

ALARM

EDIA

M

Indicators

In regular on-line use, the PRINT button reprints the last image downloade d from the

computer to the buffer memory . If you hold the PRINT button down and powe r up the pri nter,

the Ribbon Syncronization feature (which no rmally force s a ribbon synchroni zation wh enever

the door is closed or the printer is powered up) is disabled.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 3

Page 16

Introduction

Controls and Indicators

If you press and hold the PRINT button for more than two seconds, the printer will

continuously reprint the image in the buffer. Stop this action by pressing the button

momentarily while printing is in proces

Note that pressing the PRINT button will have no effect if any of the following applies:

• An error condition exists

• You have set up the print driver to print color on both sides of the card

• The optional hardware lockout key, ID/Key, is missing (but this does not disable the

checkerboard printout available after power-up).

RIBBON button

This button is used to synchronize the ribbon – in other words, to position it correctly under

the print head. If you hold the RIBBON button down and power up the printer, it toggles on/

off the Ribbon Syncronization feature when the door is closed.

In typical applications, the ribbon type is YMCK, and the back of the card is printed first. In

such cases, pressing the RIBBON button will advance the color ribbon to bring the leading

edge of the next black panel under the print head.

If back side printing is not enabl ed, the p rinter will synchronize on the n ext yello w panel when

the RIBBON button is pressed.

LAMINATE button

(For the P640i Printer, this applies to the Upper and Lower Laminator; the P630i Printer has

only the Upper Laminator.)

If either (or both) of the laminate transfer rollers is not loaded with a laminate patch, then

pressing the LAMINATE button will correct the condition , p r ov id ed the cassette is not out of

laminate, and if the cassette latch is closed (locked). If both transfer rollers are already loaded,

the LAMINATE button has no effect. If you hold the LAMINATE button down and power

up the printer, it toggles on/off the Ribbon Syncronization feature when the printer is powered

up.

A typical use of the LAMINATE button is in reloading a transfer roller after removing the

first hand-cut patch of laminate following installation of a fresh roll.

4 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 17

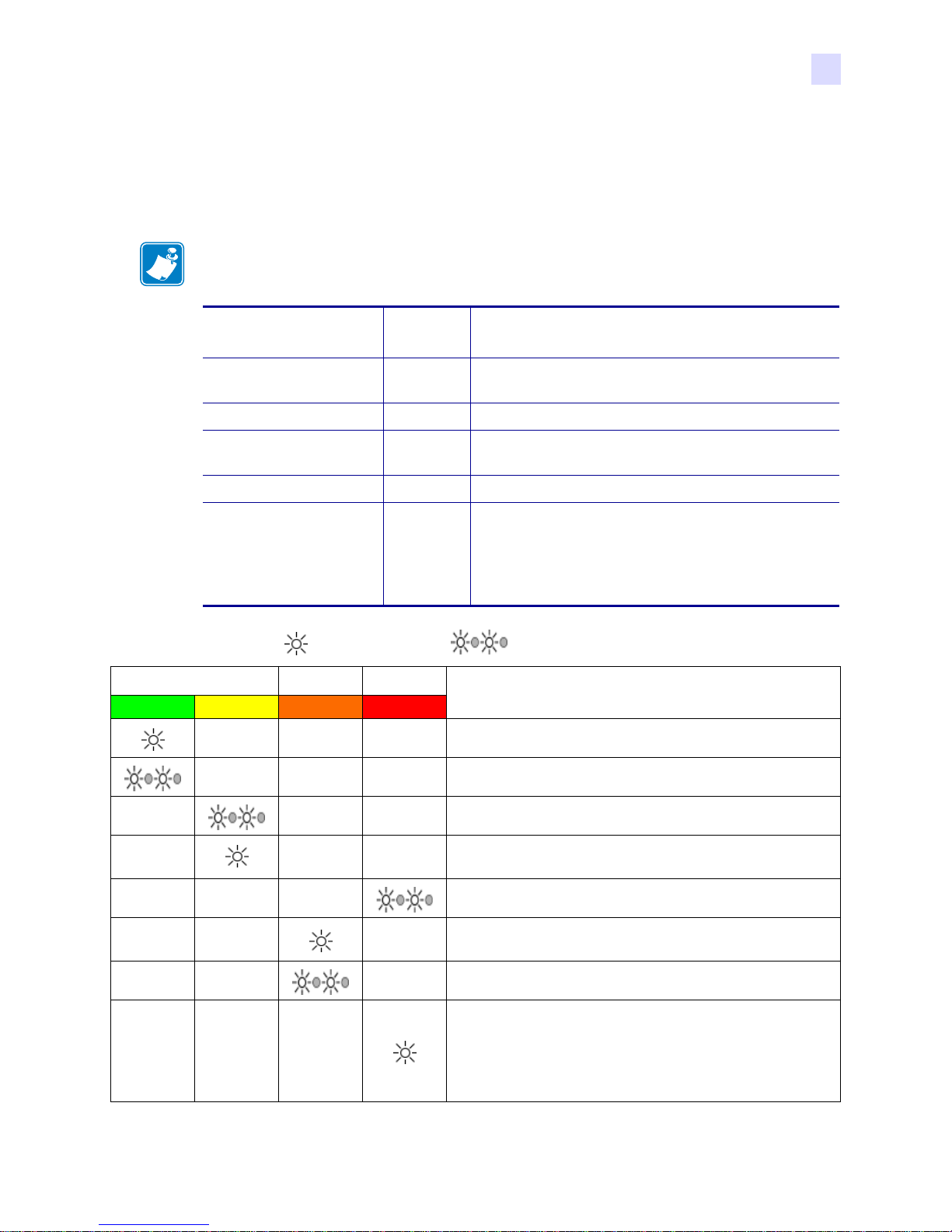

Control Panel Indicators

Depending on the condition they are reporting, the three indicator lights, READY, MEDIA,

and ALARM, can be in one of three states: Off, On (steady), or Flashing.

Note • The READY indicator is bi-colored. Its two color channels, green and yellow,

function independently.

READY Indicator Green: Steady = Ready to print

Introduction

Controls and Indicators

Flashing = Printer busy

Yellow:

MEDIA Indicator Off: Normal

On:

ALARM Indicator Off: Normal

On:

= LIGHT ON

READY MEDIA ALARM

GREEN YELLOW ORANGE RED

Steady = Laminator(s) in sleep mode

Flashing = Laminator(s) not at operating temperature

Steady = Any media outage

Flashing = Magnetic encoding failure

Steady = Error condition requiring intervention

Flashing = Printhead temperature error, or major

internal control problem requiring power cycling of

the printer (OFF, pause, then ON)

= LIGHT FLASHING

PRINTER STATUS

Ready to print

Printer busy

Laminator heating up, but not yet at operat in g t empe ra tu re

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 5

Laminator heaters in sleep mode (when not in use, the

o

heaters cool at 1

F per minute)

Printhead temperature error, or internal firmware problem.

No cards in hopper, color ribbon out, cleaning tape out,

laminator cassette(s) out.

Magnetic encoding write failure

Serious error conditions, including: Main cover open,

Laminator too hot, card transport stalled, card not seated

properly, magnetic encoding verification error, head lift

failure, ribbon jam, card jam (any location), card missing

(any location), no gap between laminator patches.

Page 18

Introduction

Controls and Indicators

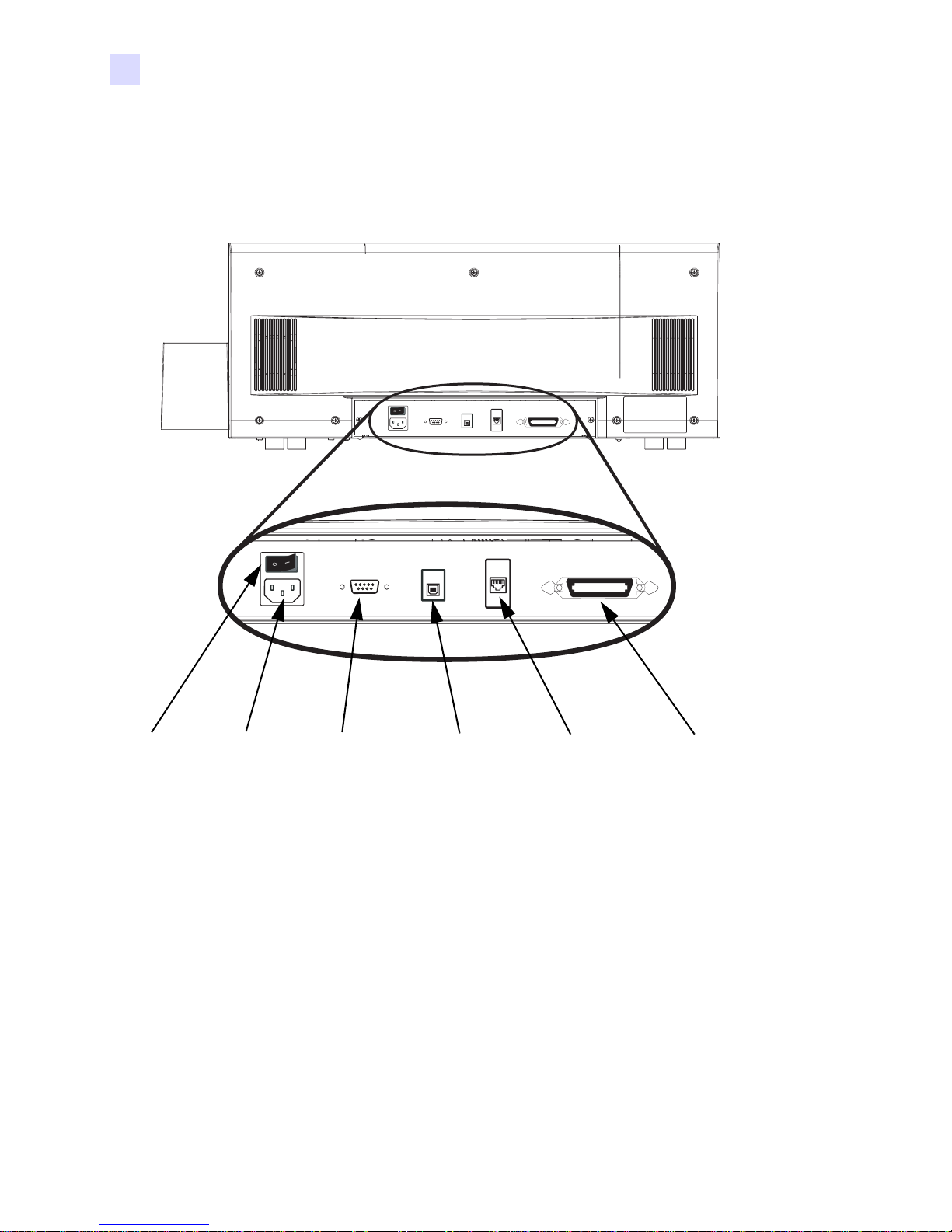

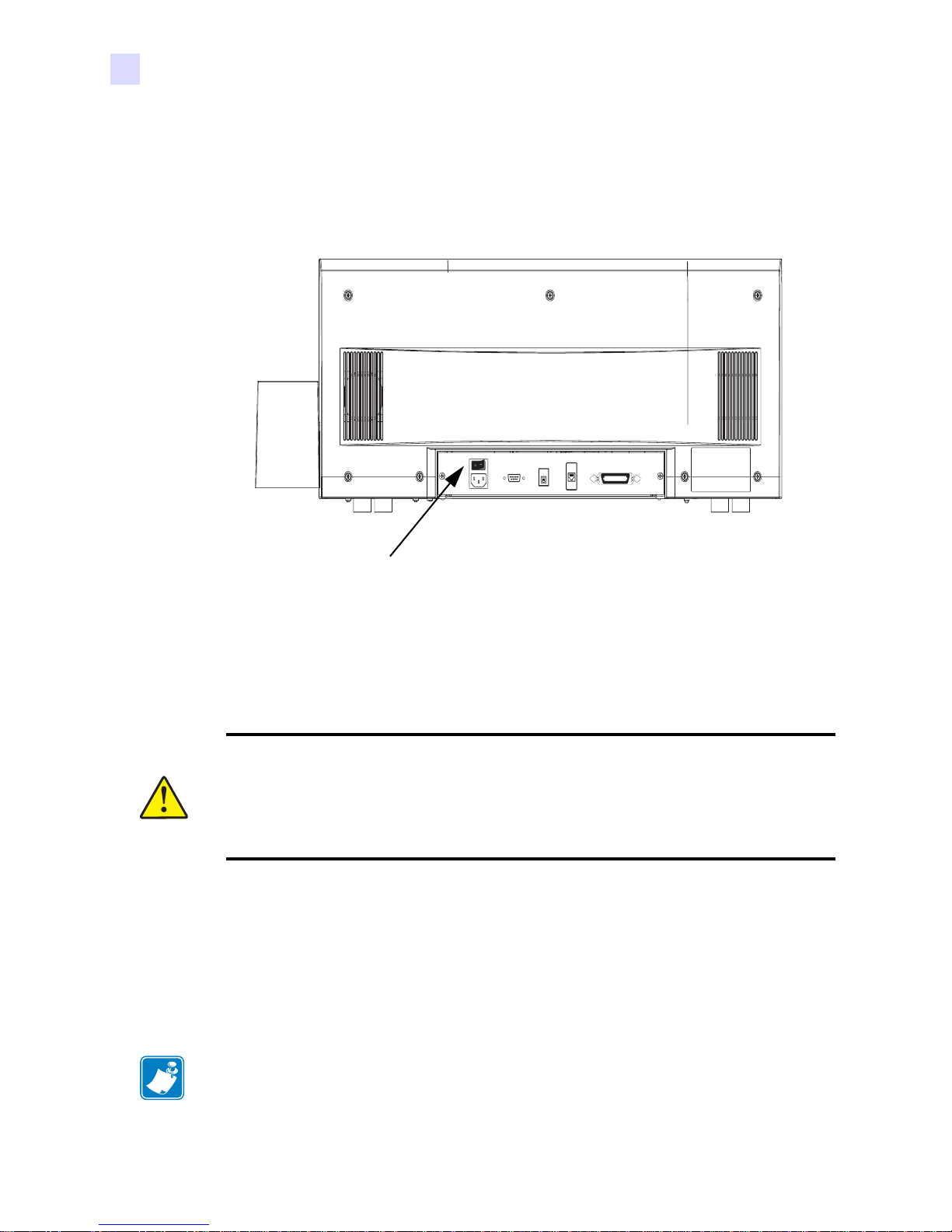

Rear of Printer

The Power Connector, Power Switch, and Int erface Connect or(s) are located on t he rear of the

printer, as shown below.

Power

Switch

6 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

AC Power

Connector

DB9 Serial Interface

Connector for Contact

Smart Card Contact

Station (Optional)

USB

Connector

Ethernet

Connector

(Optional)

Parallel

Connector

(Optional)

Page 19

Introduction

Installation includes setting up the printer, installing the printer driver in the computer(s) that

will be sending print jobs to the printer, connecting the interface, installing the Cleaning

Cartridge, loading the cards, ribbon, and laminate, and verifying that the printer can print a test

card.

2

Installation

Loading the Printer Driver software is described in Section 3.

Installation Procedure

Important • Execute the procedures that follow in the order given.

Remove the Printer from the Shipping Carton

Step 1. Open and remove the plastic handle/latches on either end of the shipping carton.

Step 2. Lift the upper part of the shipping carton off the lower part.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 7

Page 20

Installation

Installation Procedure

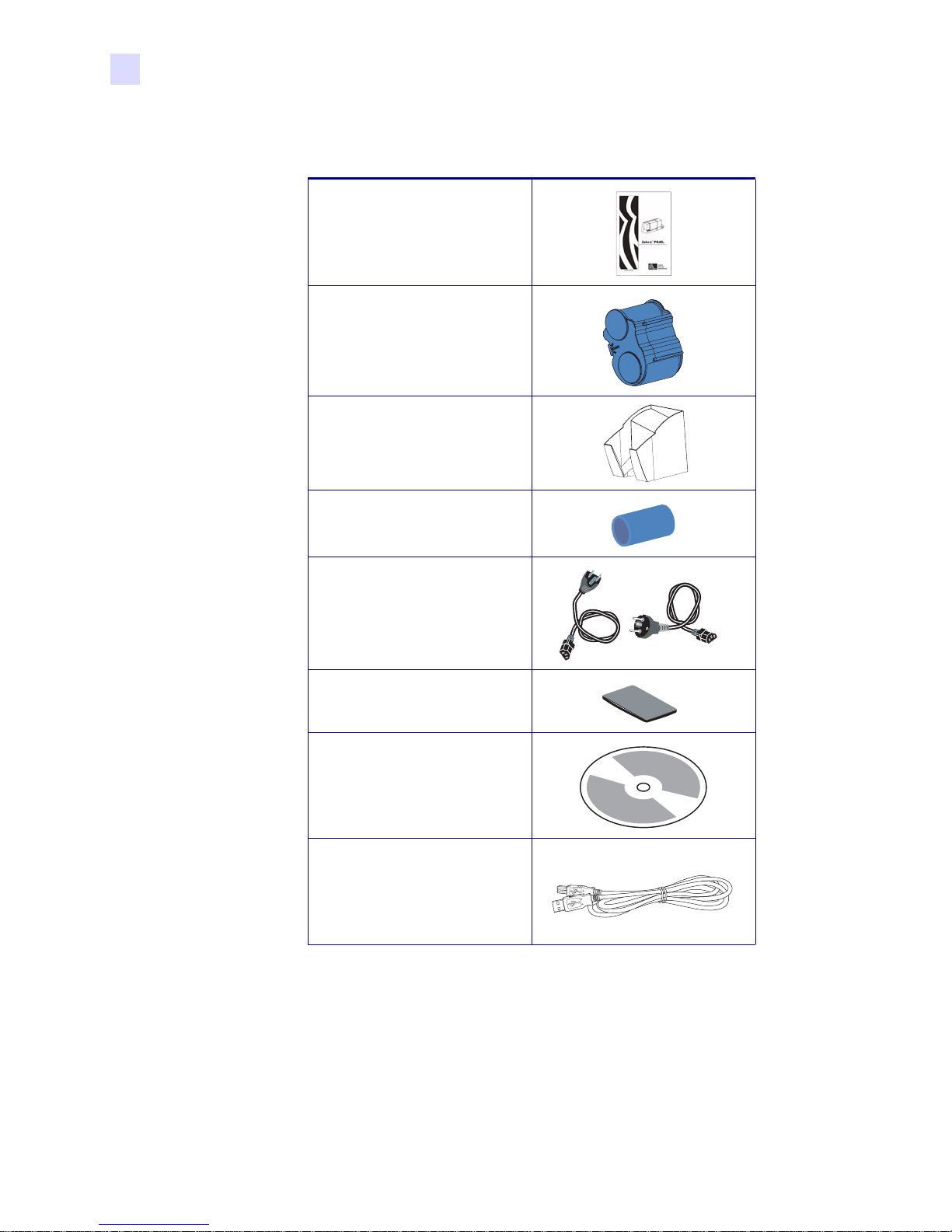

Step 3. Remove the items from the cutouts in the foam block atop the printer. Verify that the

following items are included:

Printed Quick-St art Guide

Cleaning Cartridge

Output Hopper

Ribbon Take-up Spool

Two Power Cords

Card Weight

Documentation & Driver CD

USB Interface Cable

8 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 21

Installation

Installation Procedure

Step 4. Remove the foam block from the top of the shipping carton.

Step 5. Lift the printer from the shipping carton.

Caution • The printer weighs approximately 15.9 kg (35 lbs).

Step 6. Remove the protective plastic bag from the printer.

Important • Save all the packing material and the shipping carton in case the print er needs to

be moved or shipped. If the original material is lost or damaged, a replacement Shipping Kit

can be ordered from Zebra.

Step 7. Place the printer in a location that meets the following requirements:

• A reasonably dust- and dirt-free environment will give better print quality.

• Flat surface at least 699 mm (27.5 in) x 246 mm (9.7 in) that can support the weight of the

printer; additional space preferred. Vertical clearance at least 450 mm (17 in). There

should be easy access to all sides of the printer.

• Temperature within the range of 10° to 35°C (50° to 95°F).

• Relative Humidity 20 to 80%, non-condensing.

• AC power accessible.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 9

Page 22

Installation

Installation Procedure

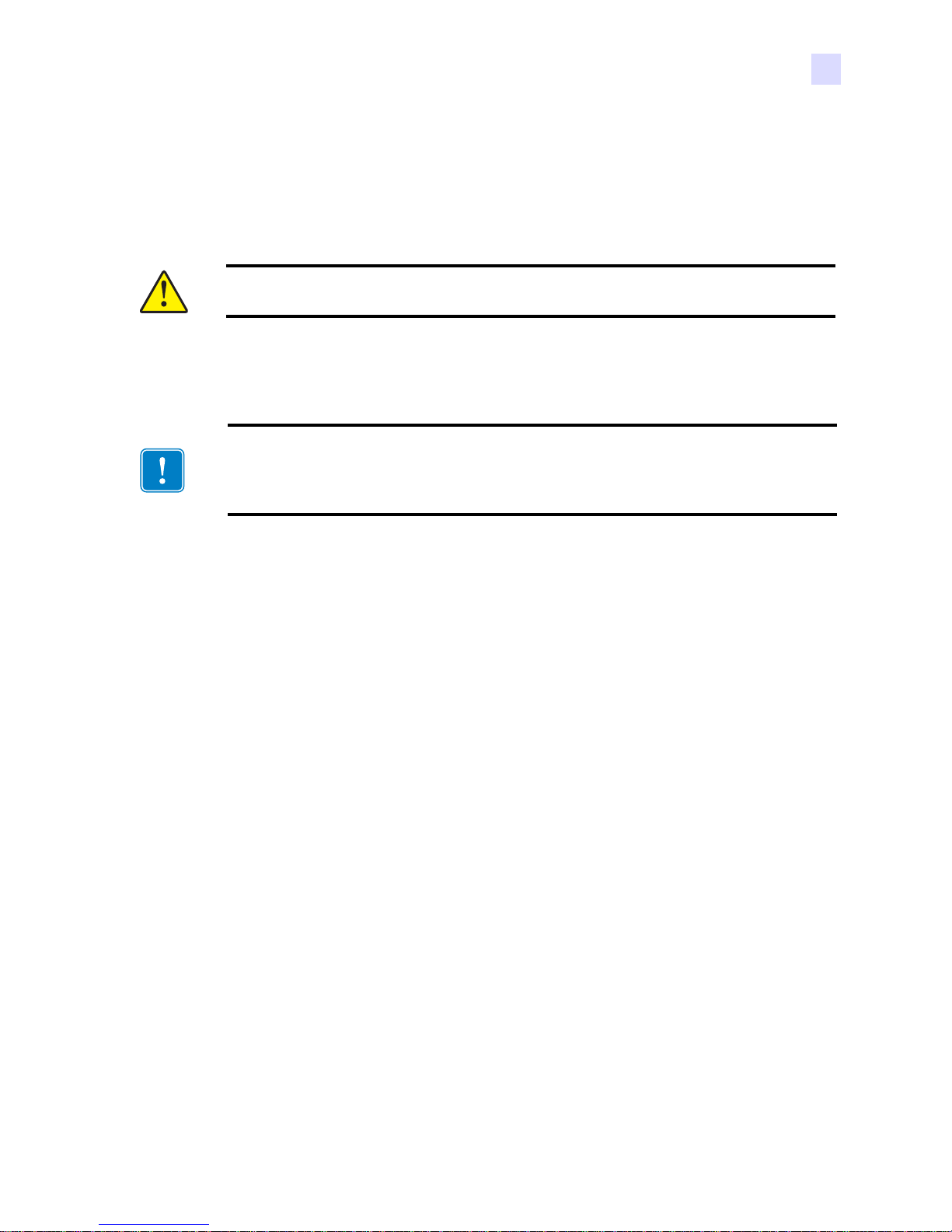

Remove Shipping Tape

Step 1. Open the printer Main Co ver. Locate and remove the blue tape that secures the flip

station in position.

10 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 23

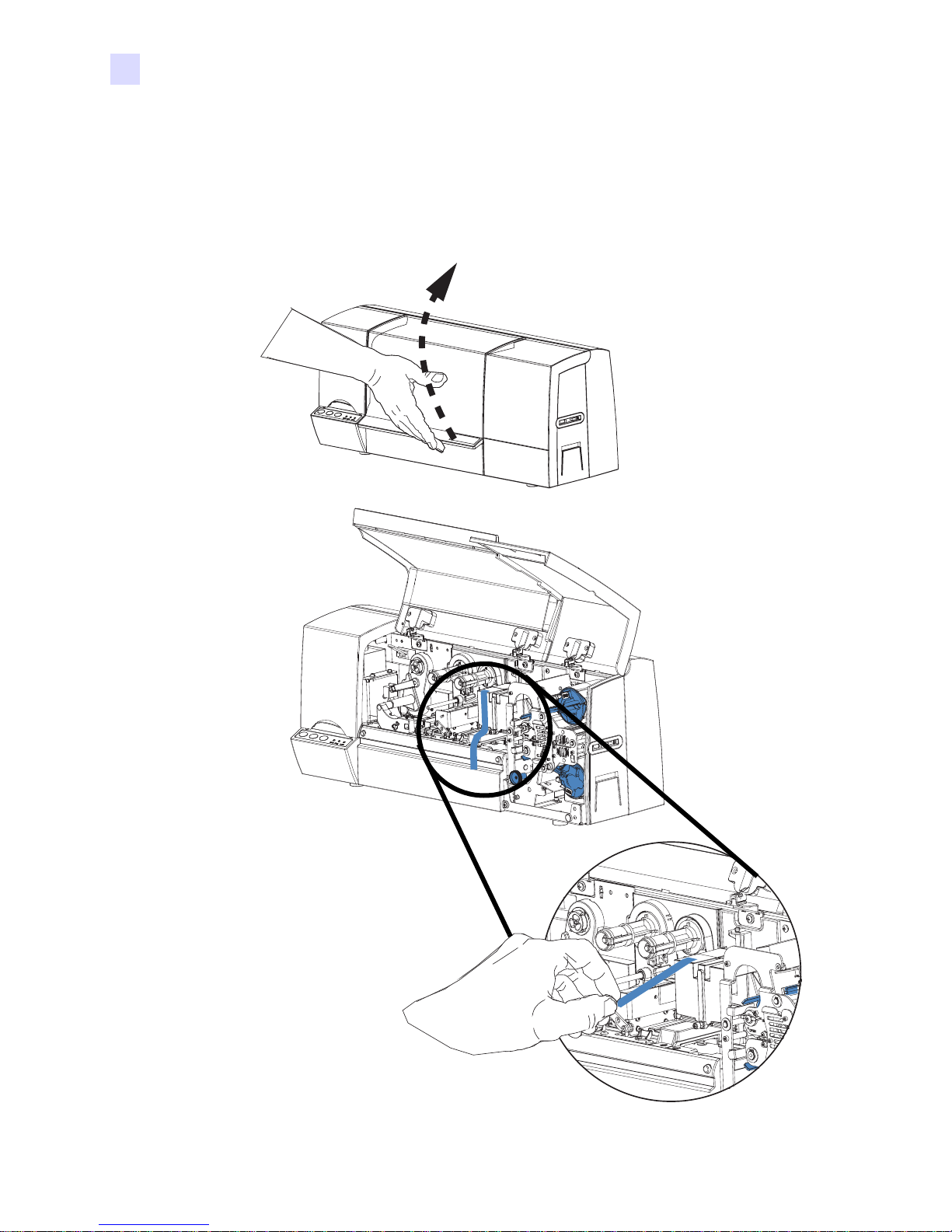

Attach the Output Hopper

Step 1. The Output Hopper is positioned on the right side of the printer to receive the printed

cards. Install the Output Hopper by in serting the tab on the si de of the Output Hopp er

into the slot on the right side of the printer.

Attach the Ribbon Take-Up Spool

Installation

Installation Procedure

Step 1. Attach the Ribbon T ake-Up Spool by sliding it onto the Ribbo n Take-Up Spindle and

pressing it straight back until in clicks into place.

Important • Make sure that the Ribbon Take-Up Spool is attached with its “toothed” end

toward the rear of the printer.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 11

Page 24

Installation

Installation Procedure

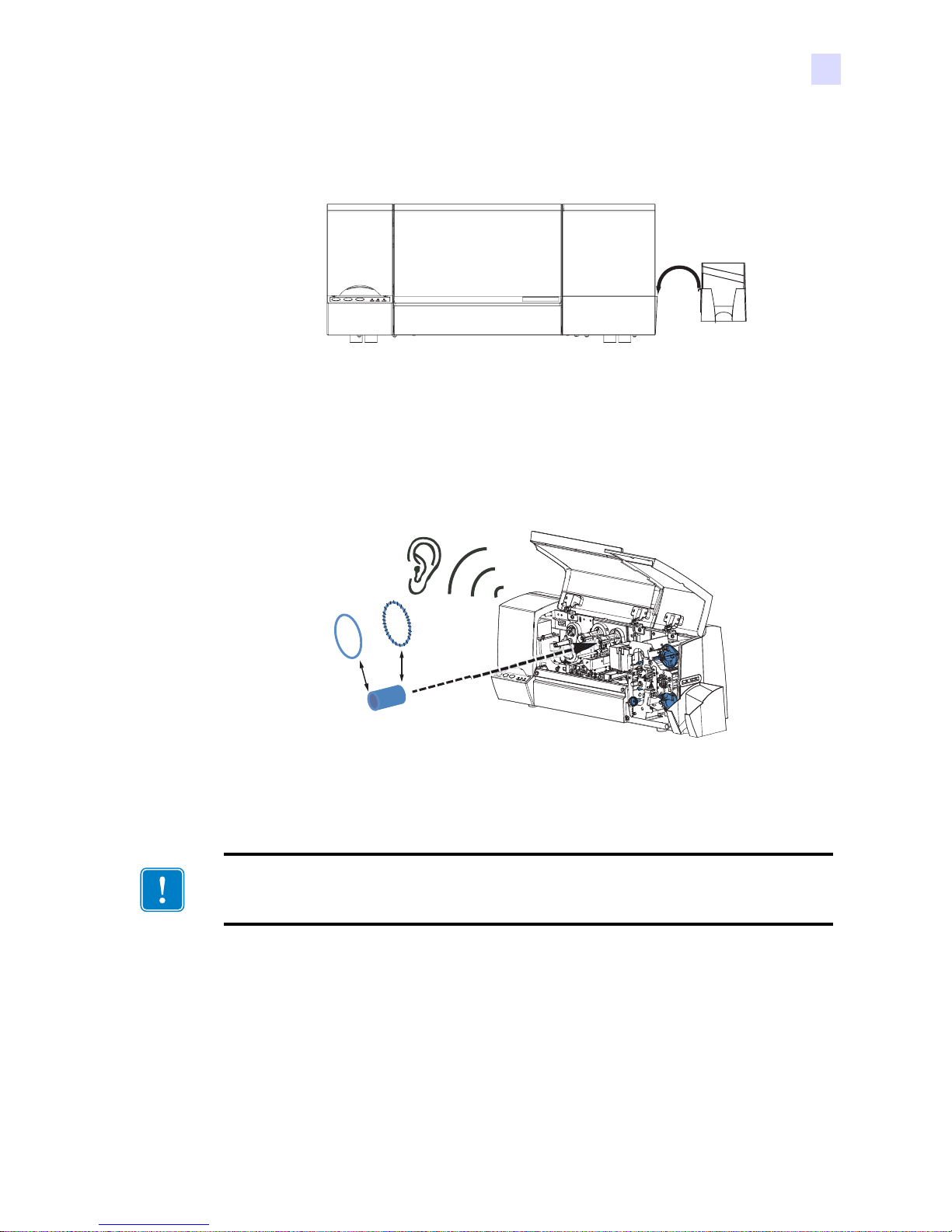

Connecting Power

The AC Power is connected and turned on so that in the next procedure, Ribbon Installation,

when the printer’s main cover is opened the Print Head will raise automatically.

Step 1. Verify that the printer’s Power Switch is set to OFF (O).

Step 2. Select the proper power cord for the local ac power source from the accessories that

are shipped with the printer.

Caution • If you do not have the proper power cord for your local power source, or if the

power cord appears frayed or damaged in any way, or if the power cord will not securely

plug into the printer’s power connection or the source outlet, STOP! Use of a damaged or

incorrect power cord could cause equipment damage, result in an electrical fire, or

possibly cause injury.

Step 3. Plug the power cord into the printer’s power connection and a grounded AC power

source connection.

Step 4. Turn the printer on by setting the Power Switch to ON (I).

Ribbon Installation

Power Switch

Note • In normal printer operation, when the ribbon is exhausted, a warning message appears

on the monitor and the MEDIA indicator on the printer lights.

12 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 25

Installation

Installation Procedure

Step 1. Open the printer Main Cover. The printhead will raise for easy ribbon loading.

Step 2. Remove the ribbon from its packaging. Remove the tape that holds the end of the

ribbon (save this tape; it will be used shortly).

Step 3. Install the Ribbon on the left (supply) spindle, with the free end of the ribbon coming

from the roll pointing down to your right. Note that the “flanged” end of the ribbon

spool is toward the rear of the printer, and make sure the internal grooves on the core

engage the teeth on the supply spindle.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 13

Page 26

Installation

Installation Procedure

Step 4. Route the Ribbon as shown in the figure below. The Ribbon Supply Spindle is free-

wheeling; pull ribbon off it as needed. If the tape removed from the new ribbon in

step 2 is undamaged, use it to attach the end of the ribbon to the Take-Up Spool;

otherwise use other adhesive-backed tape.

Important • When the end of the ribbon is attached to the Take-Up Spool, any slack in the

ribbon can be taken up by rotating the Ribbon Supply Spool; do not try to turn the Take-Up

Spool

14 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 27

1. Pass Ribbon

Over the

Round

Guide Bar

Installation

Installation Procedure

4. Attach

Ribbon to

Take-Up

Spool

With Tape

2. Ribbon Goes

Through the

Ribbon

Sensor

3. Ribbon

Goes

Under

the

Print

Head

Step 5. Close the printer main cover, then press the RIBBON button on the Control Panel.to

initialize the color ribbon. If the MEDIA light fails to go out, check the ribbon

sensor.

Important • Color ribbon wrinkling and “fold-over” can seriously affect print quality

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 15

Page 28

Installation

Installation Procedure

Step 6. Re-open the printer cover to inspect the ribbon path fo r wrinkles and folds. Correct if

necessary, then close the cover. If you do not then hear the ribbon motor advancing

the ribbon, press the RIBBON button.

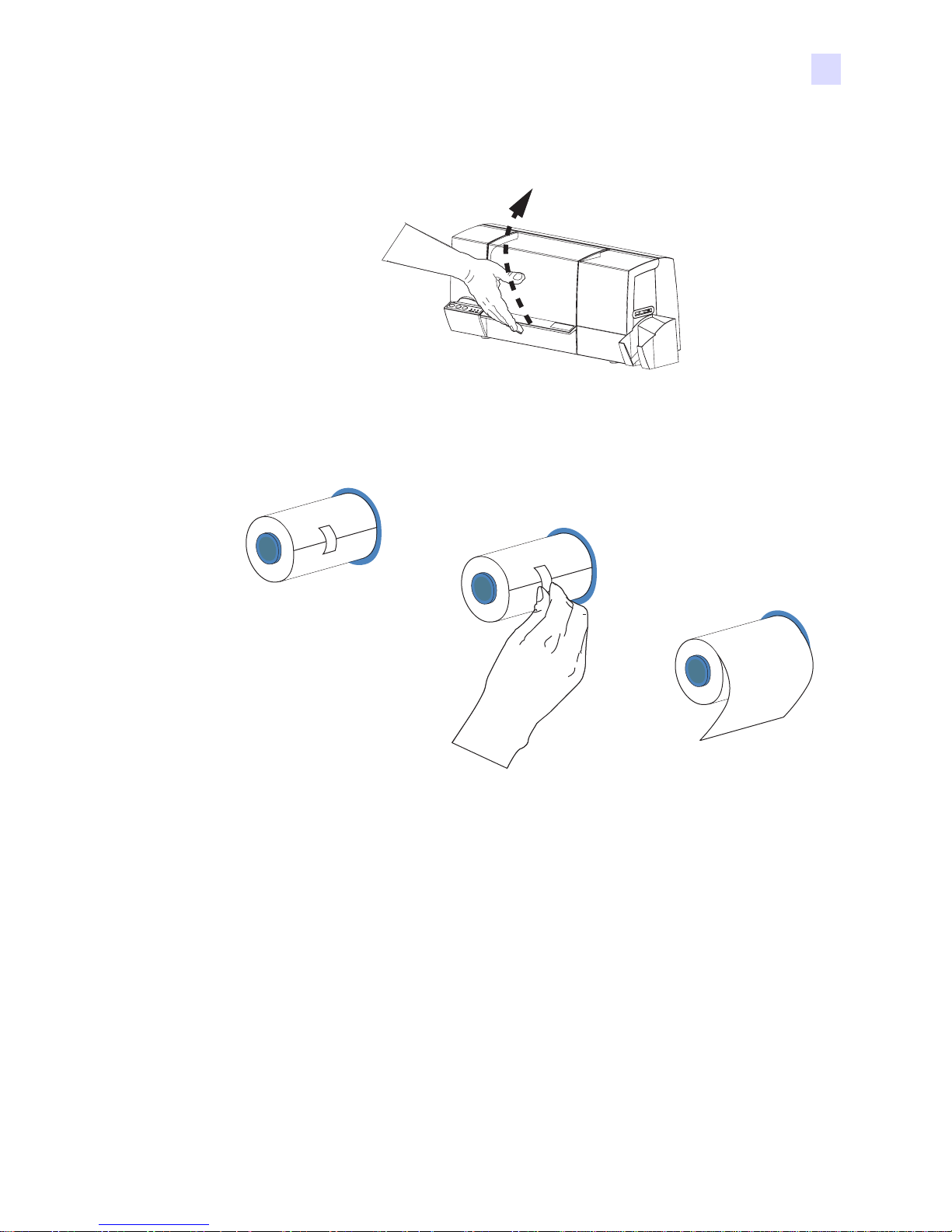

Installing the Cleaning Cassette

Before being printed, each surface of the card is cleaned by a soft tacky roller that is itself

cleaned periodically by adhesive tape in the Cleaning Cassette. Typically, the roller is cleaned

every 10 cards. The printer driver software allows the card count to be modified.

By cleaning the roller every 10 cards, the Cleaning Cassette contains sufficient tape

for 3,000 cards. This matches the other components of the standard Zebra media pack

(3,000 cards, 3,000 color ribbon images).

Step 1. Open the main cover of the printer.

Step 2. Remove the Cleaning Cassette from its packaging.

Step 3. Remove the protective foil from the Cleaning Cassette. Avoid touching the exposed

tacky surface.

Step 4. Install the Cleaning Cassette on the printer by locating the rectangular pin on the

cleaning mechanism in the receptacle on the cassette. Push the cassette gent ly home,

ensuring that the internal grooves on the upper spool engage the teeth on the takeup

drive; you will hear a click when it is fully engaged.

16 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 29

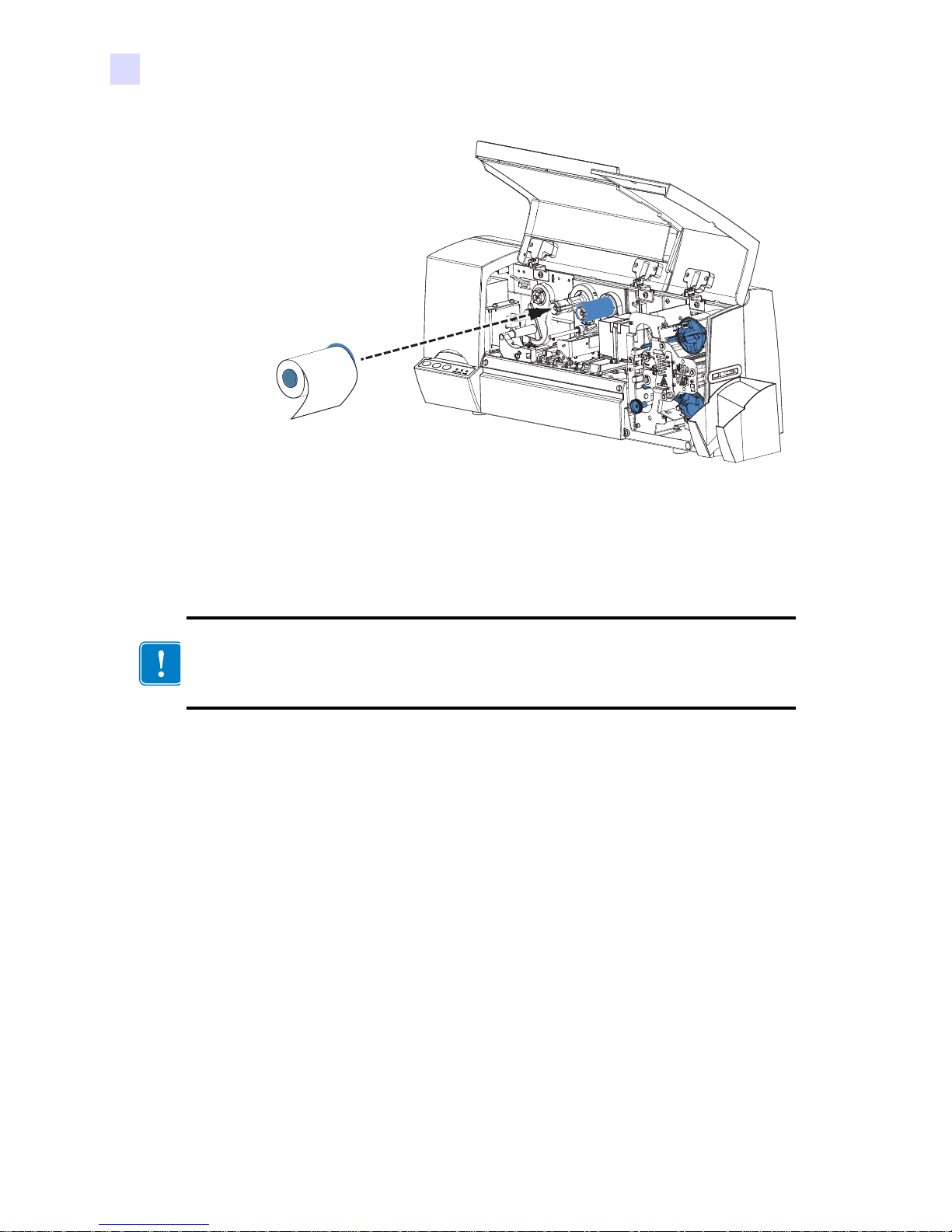

Loading Laminate

Installation

Installation Procedure

Note • In this description of loading laminate, references to the lower Laminate Cassette

apply only to the P640i Printer. The P640i Printer can apply laminate to both surfaces of the

card; the P630i Printer only to the upper surface.

The Laminate (laminating film) is loaded into cassettes to protect it from dirt or other

contaminants.

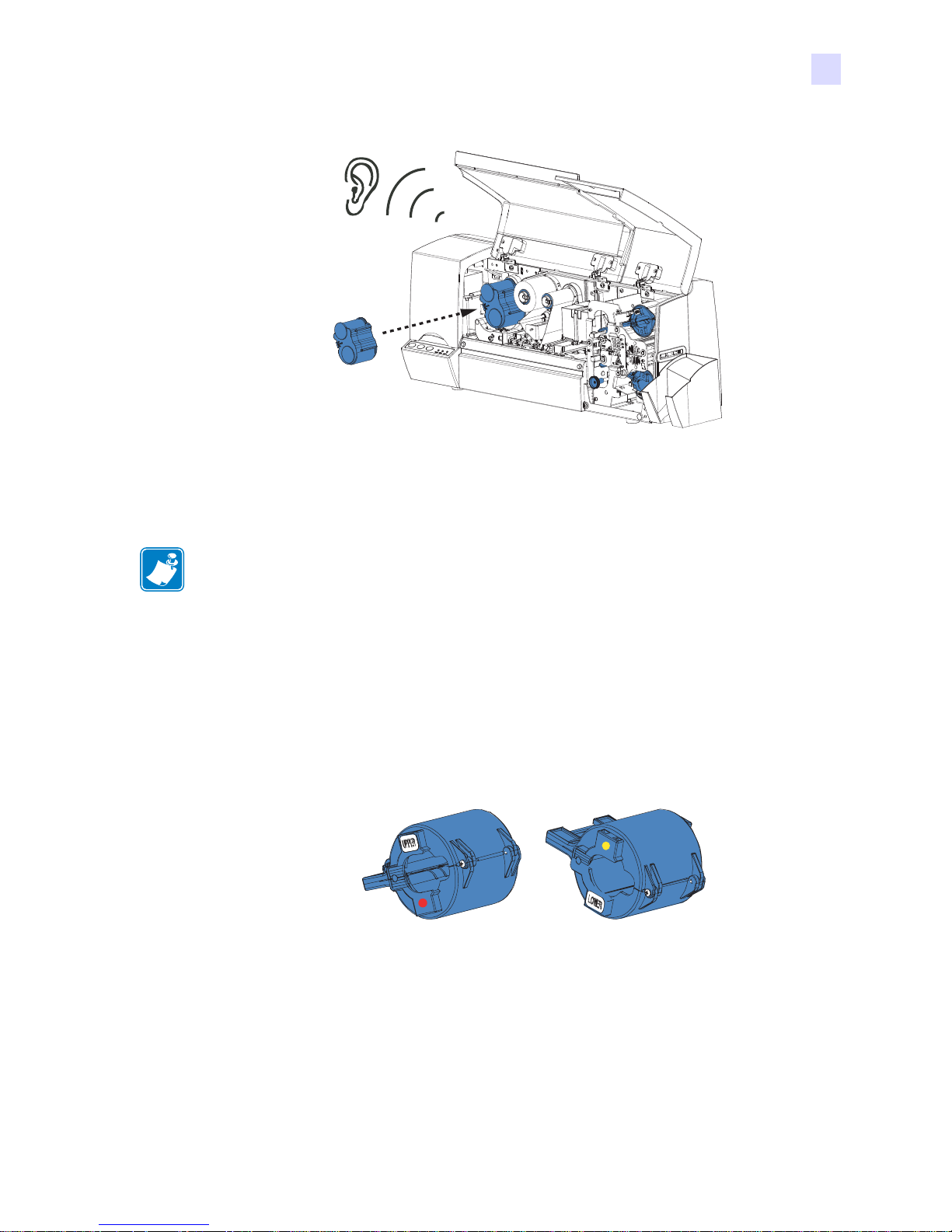

See the figure below. The “Upper Laminate Cassette”, used on both the P630i and P640i

Printers, has a label with the word “UPPER” and another “label” of a red dot. The “Lower

Laminate Cassette”, used only on the P640i Printer, has a label with the word “LOWER” and

another “label” of a yellow dot.

“Upper

Laminate

Cassette”

(P630i and

P640i)

Removing the Laminate Cassette(s)

“Lower

Laminate

Cassette”

(P640i only)

Step 1. The Laminate Cassette(s) (Upper only for the P630i Printer; Upper and Lower for the

P640i) are held in position by latch plates. The Upper Cassette is freed by turning its

Latch Plate counter-clockwise to a full vertical position; the Lower Cassette (only

present on the P640i Printer) is freed by turning its Latch Plate clockwise. Then pull

the cassette straight out from its holder.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 17

Page 30

Installation

Installation Procedure

Upper Laminate

Cassette Latch Plate

(P630i and P640i)

Heater

Cores

area

Lower Laminate

Cassette Latch Plate

(P640i only)

Hot Surface • If the printer has been in use, the Heater Cores area of the Laminator

may be hot.

Important • If either Latch Plate is opened, even unintentionally, the corresponding Cassette

must be removed and the Laminate reeled in.

18 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 31

Installation

Installation Procedure

Caution • If you feel resistance when removing the cassette, the laminate has likely run

out, leaving one end attached to the core and the other end under the cutter. Keep

tugging on the cassette, which will come free with a short tail of laminate.

Step 2. Temporarily remove the corresponding Transfer Guide to be sure there are no scraps

of laminate remaining. If there are any, remove them. Then slide the Transfer Guide

back in until it is held in place by the Retaining Clip.

1. Push the

Retaining

Clips (A) to

the Left

2. Slide the

Transfer

Guides (B)

Straight Out

(B)

(A)

(A)

(B)

Step 3. Open the Cassette, like a clam shell, by separating its two halves. Grasp the two

halves firmly with your fingers, then pull it apart. Do NOT use tools. (Upper

Cassette shown.)

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 19

Page 32

Installation

Installation Procedure

Step 4. If there is an empty laminate core in the Cassette, remove it.

Loading the Laminate Cassette(s)

uently

Important • If you are using partial-width laminate in the Lower Cassett e of a P640i Printer,

read the following section, Using Partial-Width Laminate, before proceeding with this

procedure. (Partial-width laminates are frequently used on the bottom surface of cards that

have a signature panel or a magnetic stripe.)

Important • The Upper and Lower La minate Cassettes (the low er one only used on th e P640i

Printer; the upper one used on both printers) are loaded diff erently, even though the Casset tes

appear virtually the same.

Note • Handle the laminate by the ends of the spools only to avoid contaminating the

laminate.

Step 1. Remove the new roll of laminate from its packaging.

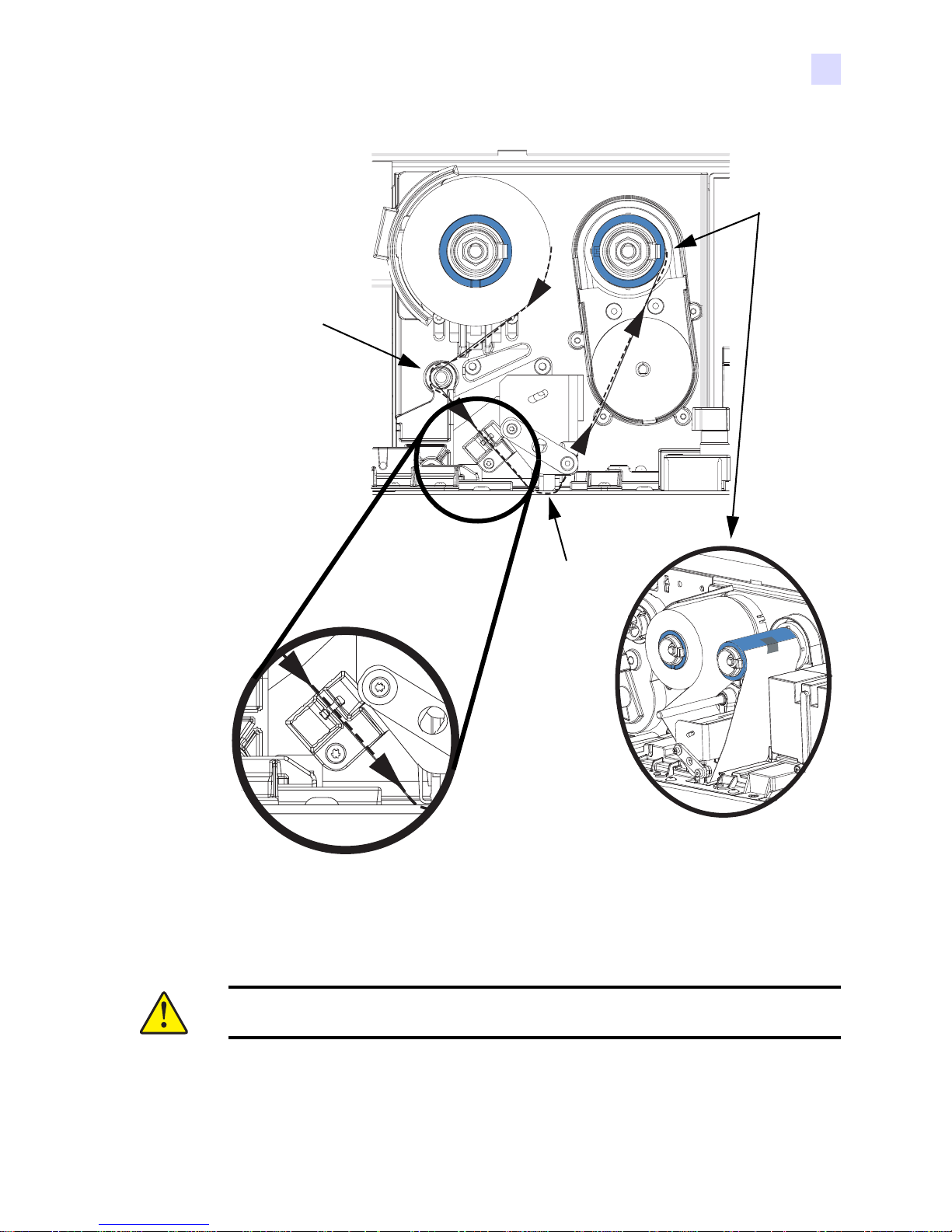

Step 2. Carefully following the guidelines in the following figure, place the laminate in the

Cassette.

20 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 33

.

Notched End of

Spool to Left

Laminate Unrolls

Under Spool

Laminate Unrolls

Over Spool

Installation

Installation Procedure

Upper Cassette

(Used on Both P630i and P640i)

White Roller Up

Notched End of

Spool to Right

White Roller Down

Lower Cassette

(Used on P640i Only)

Step 3. Pull out an inch or two of laminate past the lip of the cassette.

Step 4. Close the cassette by firmly pressing the “clamshell” together. You will hear a click

and feel a detent when the halves of the cassette seat together.

Step 5. Pull out a little more laminate between the lips of the cassette. If it suddenly stops,

resisting further pulling, a spring detent on the cassette has probably snagged a notch

on the end of the core. This means that the core was installed the wrong way. Open

the cassette and re-install the laminate.

Step 6. If the exposed end of the laminate is uneven or crinkled, cut it as square as you can

with scissors.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 21

Page 34

Installation

Installation Procedure

Step 7. Holding the cassette with the white roller up and pointing to your left, rotate the core

counter-clockwise to reel in the laminate. Stop when the end of the laminate is even

with the edge of the lips of the cassette.

Important • Check for overhang any time the cassette latch is opened or the cassette is

removed.

Using Partial-Width Laminate

Note • Since partial-width laminates are only used for the back (i.e., lower) surface of the

card, this section only applies to the P640i Printer.

Laminate come in three widths:

“Full-Width” laminate is 2 in (51 mm) wide. Full-width laminate is used on the front (i.e.,

upper) or back (i.e., lower) surface of the card.

“Partial-Width” laminate is available in two widths:

• 1.66 in (42mm) wide laminate is used for cards with a writable signature panel.

• 1.33 in (33 mm) wide laminate is used for cards with a magnetic stripe

If there is no signature panel or magnetic stripe on the back of the card, full-width laminate

would generally be used.

22 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 35

These are shown in the following figure.

Installation

Installation Procedure

2“

1.66“

BACK OF CARD

1.3”

Step 1. Remove the Laminate Edge Guide from its “storage location” on the Laminator

Frame (it snaps out).

Laminate

Edge

Guide

Step 2. For 1.3 in (33 mm) laminate for use with magnetic stripe cards, snap the Laminate

Edge Guide into the inner hole-and-slot in the lower cassette, as shown in the

following pictures. For 1.66 in (42 mm) laminate for use with signature-stripe cards,

use the outer hole-and-slot.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 23

Page 36

Installation

Installation Procedure

Inner Holeand-Slot

Outer Holeand-Slot

Laminate Edge

Guide in Inner

Hole-and-Slot

for 1.33 in (33

mm) Laminate

Used With

Magnetic Stripe

Cards

Installing the Laminator Cassette(s)

Step 1. Insert the cassette into its black molded pocket, then close the cassette latch

(clockwise for the UPPER, counterclockwise for the LOWER).

1.33 in

(33 mm)

Laminate

for

Magnetic

Stripe

Cards

24 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 37

Step 2. Close the main cover. If there was a laminate error before you replaced the cassette,

laminate will automatically feed from the just-loaded cassette, followed by a cutting

action to free a “patch” of laminate onto the transfer roller. If laminate does not feed

automatically, press the LAMINATE button on the printer control panel.

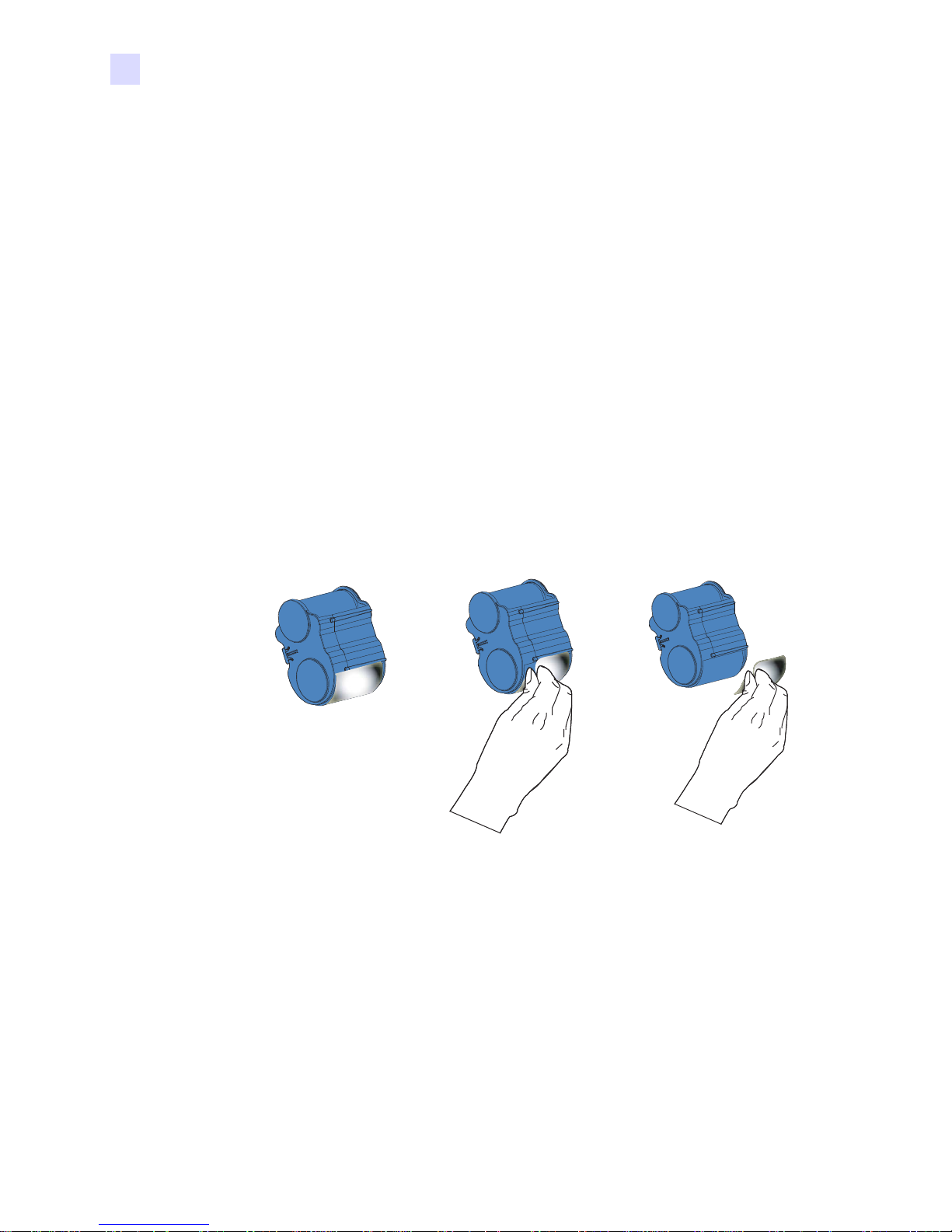

Clearing the Laminate Channels

If your scissor cuts were neat enough to pass for machine-made cuts, continue with printing

cards. If not, don’t waste a print cycle. Instead, remove the hand-cut patch(es) from the

Transfer Roller(s) as follows.

Note • Clearing procedures for the upper and lower laminate channels are similar. The upper

channel is shown here.

Removal of the Transfer Guide gives access to the Transfer Roller

Installation

Installation Procedure

Retaining

Springs

Transfer

Guides

Transfer Toggle

(Shown in Normal

RUN Position; Set

to OPEN Only

When Specified)

OPEN

RUN

Step 1. Push the Retaining Spring to the left; pull the T ransfer Guide straig ht out toward yo u.

Step 2. Remove and discard the laminate patch on the Transfer Roller. Never re-use!

Step 3. Turn the Transfer Toggle to the OPEN position.

Step 4. Remove any laminate between the Transfer Rollers.

Step 5. Return the Transfer Toggle to the RUN position.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 25

Page 38

Installation

Installation Procedure

Step 6. Re-install the Transfer Guide with its top edge above the laminate cutter guide. Pull

Important • Improper replacement of the Transfer Guide can cause laminate skewing

and misfeeding. Be sure the Transfer Toggle is set to RUN. Take care to avoid damaging

the Transfer Roller ribs when replacing the Transfer Guide.

Loading Cards

The P630i and P640i Printers use standard ISO CR-80 PVC Composite cards. Do not use

cards with a paper or peel-off / adhesive backing.

• Size 54 x 86 mm (2.125 x 3.375 in) ± 10%

back the retaining spring while re-inserting the guide, then release the spring as you

push the guide into position. Press the LAMINATE button to load the Transfer

Roller(s).

• Thickness .75 mm (.03 in) ± 10%, frequently referred to as “30 mil cards”.

Important • Do not bend card s or touch the print surfaces a s this can reduce print quality. The

surface of the cards must remain clean and dust free. Always store cards in an enclosed

container. Ideally, use cards as soon as possible.

Step 1. Open the Card Feeder Cover.

26 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 39

Installation

Installation Procedure

Step 2. Remove all wrapping from the card deck.

Caution • Do not touch print surfaces of the cards; this can reduce print quality.

Step 3. Holding the card deck by the sides, hold it vertically against a flat surface such as a

desktop. If the deck is too thick for your hand to hold it comfortably, use about half a

deck at a time.

Step 4. Push the stack back and forth to an angle of about 45° from vertical, so as to separat e

all of the cards.

Important • Static charges and edge burrs from the card die-cutting process can render

individual cards stuck together with significant adhesion force. These cards must

be

physically separated from each other before inserting into the Card Feeder; if not separated,

feeding or printing problems may occur.

Step 5. Restore the card stack to its original squared-of f condition, and place the cards in the

input hopper. The input hopper can hold up to 150 cards.

Note • Cards with a Magnetic Stripe should be loaded with the stripe up and toward the front

of the printer, as shown in the figure below.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 27

Page 40

Installation

Installation Procedure

Step 6. Place the Card Weight on top of the card stack.

Step 7. Close the Card Feeder Cover.

28 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 41

Connecting the Interface

The P630i and P640i Printers have a USB interface as standard. As options (must be specified

at time of order), the printer can addi tionally have a 10/100T Ethernet port for connection to an

Ethernet Network, or a parallel (“Centronics”) port. Normally only one interface at a time will

be connected.

Installation

Installation Procedure

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 29

USB

Connector

Ethernet

Connector

(Optional)

Parallel

Connector

(Optional)

Page 42

Installation

Installation Procedure

30 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 43

Printer Driver Installation

Overview

3

Each computer that will use the P630i or P640i Printer must have the Printer Driver installed.

A common Printer Driver serves both P630i and P640i Printers.

To install the Printer Driver, insert the User Documentation, Drivers, and Training CD,

included with your printer, into the host computer and the InstallShield Wizard will walk you

through the required installation steps. The InstallShield Wizard will:

• Automatically install the User Interface when the driver CD is inserted.

• Start the installation process when the Install Printer Driver menu item is selected

from the Main Menu.

• Allow you to install either a local printer and driver or a networked printer and driver.

• Detect previous versions of the driver and clean up any unnecessary Windows registry

entries. You must select Uninstall Printers and Drivers in the Printer Setup window

to remove any previous driver versions.

• Install the new driver files

• Reboot your computer

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 31

Page 44

Printer Driver Installation

Installing the Printer Driver (USB)

Installing the Printer Driver (USB)

Note • To install the Ethernet driver, see the procedure starting on page 41.

Step 1. Connect the printer power and connect the USB port on the rear of the printer to the

computer’s USB port. Turn the Printer on and let it initialize until the READY LED

on the front panel is lit.

Step 2. The Windows “Found New Hardware” screen will appear at this time. Click

“Cancel”.

Step 3. Insert the User Documentation, Drivers, and Training CD into the CD drive of the

host computer. The Select Language window will open.

Step 4. From the Select Language window, choose the appropriate language for your

system. The Main Menu will open in the selected language (English shown below).

32 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 45

Printer Driver Installation

Installing the Printer Driver (USB)

Step 5. From the Main Menu, click Install Printer Driver. The Printer Setup window will

open.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 33

Page 46

Printer Driver Installation

Installing the Printer Driver (USB)

Step 6. If an older P630i or P640i Printer and Driver is installed on your computer, click on

Uninstall Printers and Drivers to remove it. Follow the screen prompts. At the end

of the uninstall process you will be asked to re-boot your computer. Before rebooting, exit from the Driver Installation program and remove the CD. Then re-boot

your computer and start over with Step 1. If the computer enters the Found New

Hardware Wizard at this time, cancel this wizard.

Click on Install a USB or Parallel Printer and Driver.

34 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 47

Printer Driver Installation

Installing the Printer Driver (USB)

Step 7. This will bring up the End User License Agreement. To proceed with the

installatiion, click Accept.

Step 8. This will bring up the Add Zebra Printer Port window. Select the USB Port, and

then click Next >>.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 35

Page 48

Printer Driver Installation

Installing the Printer Driver (USB)

Step 9. This brings up the Browse Printers window, shown below. If your P640i / P630i

Printer is listed, select (highlight) it and click OK.

If your printer is not listed, make sure the printer is powered on and check the USB

cable connections; then click Rescan. When it appears, select (highlight) it and click

OK.

Step 10. This brings up the Configure USB Port window. If your printer is not listed in the

Printer info area, click Browse.

Leave the two timeout values alone. Click OK.

Step 11. This will bring up the Printer Installation window. Note the value shown on the first

line (ATLUSB001 for the screen shown here), then click OK.

36 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 49

Printer Driver Installation

Installing the Printer Driver (USB)

Step 12. This opens the Add Printer Wizard welcome window. Click Next >.

Step 13. This brings up the Add Printer Wizard Local or Network Printer window. For a

typical USB installation, select Local Printer attached to this computer and check

the box to detect a Plug and Play printer.

Then click Next >.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 37

Page 50

Printer Driver Installation

Installing the Printer Driver (USB)

Step 14. This brings up the Found New Hardware Wizard welcome window. In general, select

Yes, this time only and then click Next >.

Step 15. The next window helps install the software driver. Select Install the software

automatically (Recommended) and then click Next >.

Step 16. The Wizard will search for the Printer. The screen that appears while searching

appears on the next page.

38 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 51

Printer Driver Installation

Installing the Printer Driver (USB)

Step 17. When the Wizard finds the Printer, it may display a window referring to

compatibility, as shown below. If so, click Continue Anyway.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 39

Page 52

Printer Driver Installation

Installing the Printer Driver (USB)

Wait while the Wizard installs the software.

Step 18. When software installation is complete, the following window will display. Click

Finish.

Step 19. This completes software driver installation. To use the P630i or P640i Printer, you

would select it just like you would any other printer connected to a Windows system.

40 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 53

Installing the Printer Driver (Ethernet)

Note • To install the USB driver, see the procedure starting on page 32.

Important • The Ethernet Network must be configured correctly, with the Printer and the host

computer on the same subnet mask. If you are not sure how to verify this or change the

configuration, consult someone knowledgeable on Ethernet Networks.

Step 1. Connect the printer power and connect the Ethernet Port on the rear of the printer to

an Ethernet Network Port. Turn the Printer on and let it initialize until the READY

LED on the front panel is lit.

Step 2. Insert the User Documentation, Drivers, and Training CD into the CD drive of the

host computer. The Select Language window will open.

Printer Driver Installation

Installing the Printer Driver (Ethernet)

Step 3. From the Select Language window, click on the appropriate language for your

system. The Main Menu will open in the selected language (English shown below).

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 41

Page 54

Printer Driver Installation

Installing the Printer Driver (Ethernet)

Step 4. From the Main Menu, click Install Printer Driver. The Printer Setup window will

open. Click Install an Ethernet Printer and Driver.

42 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 55

Printer Driver Installation

Installing the Printer Driver (Ethernet)

Step 5. This will bring up the End User License Agreement. To proceed with the installation,

click Accept.

Step 6. This brings up the Configure Ethernet Port screen. Click the Browse button.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 43

Page 56

Printer Driver Installation

Installing the Printer Driver (Ethernet)

Step 7. Any Zebra printers will be located. Select (highlight) the desired printer (for this

procedure it is a P640i, but the steps would be the same for a P630i) and click the

OK button.

Note • If the Printer is not found, check to make sure the Printer is powered on and the

Ethernet connector is engaged. Also, the Ethernet Network must be configured correctly, with

the Printer and the host computer on the same subnet mask. If you are not sure how to verify

this or change the configuration, consult someone knowledgeable on Ethernet Networks.

Step 8. The Configure Ethernet Port screen will reappear, but now the information for the

P640i printer selected in step 7 will be displayed.

Then click OK.

44 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 57

Printer Driver Installation

Installing the Printer Driver (Ethernet)

Step 9. This brings up the Add Printer Wizard. Click Next >.

Step 10. The next screen lets you specify the type of printer to set up. Select “Local printer

attached to the computer.”

“Automatically detect and install my Plug and Play printer” should be un-checked.

Then click Next >.

Click Next >.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 45

Page 58

Printer Driver Installation

Installing the Printer Driver (Ethernet)

Step 11. The Add Printer Wizard / Select a Printer Port screen will now appear.

Step 12. Click on “Use the following port”; scroll to “ENETxxx (Zebra Ethernet (internal))”

where “xxx” is the number of the port - any Zebra Ethernet port number can be used.

Check that the printer is turned on (and the READY LED is lit), then click Next >.

Then click Next >. This will bring up the “Add Printer Software Wizard”, as shown

on the next page.

46 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 59

Printer Driver Installation

Installing the Printer Driver (Ethernet)

Select the Manufacturer (Zebra Technologies) and the printer model number; then

click Next >.

Step 13. This brings up the “Name Your Printer” screen.

Verify that the printer name is correct. Specify if you want to use this printer as your

default printer (this can always be changed in the Windows Printers or Printers and

FAXes control panel).

Then click Next >.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 47

Page 60

Printer Driver Installation

Installing the Printer Driver (Ethernet)

Step 14. Specify whether or not you want to allow printer sharing, then click Next >.

Step 15. Specify if you wish to print a test page (note that card printers consider each card to

be a page); then click Next >.

48 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 61

Installing the Printer Driver (Ethernet)

Step 16. Click Finish. The following screen will appear.

Printer Driver Installation

Step 17. Click on Continue Anyway. You will see files being copied to the Windows folder.

When the file copying is complete, your printer is ready to use.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 49

Page 62

Printer Driver Installation

Installing the Printer Driver (Ethernet)

50 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 63

Settings and Adjustments

Introduction

This section describes settings and adjustments that can be made to the P630i and P640i

Printers.

4

Sensors and Interlock Switches

These are of several different types of sensors and interlock switches, but they have one thing

in common - they tell the printer’s control logic what’s happening and where, enabling it to

continue with the process or, if a malfunction occurs, to light the appropriate indicator light

and report a specific error condition on the host computer screen.

The sensors and iterlocks are shown in the following figure.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 51

Page 64

Settings and Adjustments

Sensors and Interlock Switches

Card

Presence

Sensor

Truck

Near

Hopper

Interlock

Truck

Home

Sensor

Cover

Interlock

Cleaning

Sensor

Ribbon

Motion

Sensor

Ribbon Sensor

(Not Accessible)

Flip

Sensor

Printhead Motion Sensor

(Not Accessible)

Infeed

Sensor

Outfeed

Sensor

(Lower Laminator

Present on P640i Only)

Access Printer Sensor Data

To access the Sensor Data screen, select Start > Printers (or Printers and Faxes). Right click

Zebra P630i or Zebra P640i, then select Properties > Device Settings > Control > Advanced Utilities

> Show Sensor data.

52 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 65

Settings and Adjustments

Sensors and Interlock Switches

Ribbon Panel Detect. The current reading of the color ribbon sensor.

Panel Threshold. The current value of the detection threshold for the color ribbon. Above

this value is termed “black,” below this value is termed “not black.”

Laminate Sensors. Reflective sensor that detect the presence of laminate on the transfer

rollers: below threshold = laminate present, above threshold = laminate absent.

Card presence Sensor. The reflective sensor to the right of the card hopper: High = no

card, Low = card present

Printhead Voltage. Should be about 24V.

AC Frequency. 50 or 60 Hz

Assumed AC Voltage. 110V assumed for 60 Hz.

Printhead Temperature. Temperature ceiling 70°C (above that temperature, printing is

stopped until the head cools).

Controller Board Temperature. Should be about 5° above ambient.

Heater Temperature. Temperatures at the top and bottom laminate heater cores.

Logic States. Summarizes all two-state interlocks and photo sensors - a very useful

diagnostic tool

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 53

Page 66

Settings and Adjustments

Printer Properties

Printer Properties

To access the various Printer Properties, select Start > Printers (or Printers and Faxes). Right click

Zebra P630i or Zebra P640i, then select Properties

General

Printing Preferences Brings up the

preferences screen. Reference Printing

Preferences below.

Print Test Page Prints the standard

Windows test page.

Sharing

This is sharing according to the Microsoft

Windows definition. In a network

environment, it allows other computers to

send jobs to the printer that’s connected to

your computer.

54 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 67

Ports

Settings and Adjustments

Printer Properties

Specifies the computer port to which the

P630i or P640i is connected. This will have

been established at the initial installation of

the printer, and will not normally require

attention.

An exception to this is if you wish to use

“printer pooling”, the ability to distribute

print jobs to multiple printers. To enable

printer pooling, check the “Enable Printer

Pooling” box, then check multiple ports.

Each port should have a single Zebra printer

installed on it, and all printers should be

configured identically (for example: all with

YMC front, K back). Now, when you print to

the “main printer” (that is, whichever printer

you right-clicked in Printers and Faxes to get

to this screen), this printer will get print jobs

until it has buffered as many jobs as it can

take. Remaining jobs will then “spill over” to

other printers until all printers in the pool are

busy.

Advanced

Determines the spooling (queuing) of print

jobs, and how spooled jobs are handled

relative to the most recent job. Printing

Defaults allows the system administrator to

establish default settings such as print

quality.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 55

Page 68

Settings and Adjustments

Printer Properties

Color Management

Color Management settings allow you to

associate color profiles on the printer based

on the type of media being used and printer

configuration. The Add button allows the

operator to add additional profiles to the

color profile list.

Automatic Allows Windows to select the

best color profile.

Manual Allows the operator to select the

desired profile from the list shown in the

Color Profile Window.

Security

This is the standard Windows security

screen, showing user access to various

printer control options. Both Print and

Manage Printers must be checked for full

functionality of the printer.

56 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 69

Device Settings

Settings and Adjustments

Printer Properties

The Device Settings screen allows you to

access various adjustment and calibration

screens.

Printer Adjustment The following procedures can be performed from the Printer

Adjustment screen:

1. Print Station Adjustment

2. Laminate Station Adjustment

3. Flip Station adjustment

4. Advanced Adjustments:

a. Magnetic Encoder Position

b. Smart Card Position

5. Card Hopper Pick Position

6. Cleaning Frequency

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 57

Page 70

Settings and Adjustments

Printer Properties

Color Calibration The following procedures can be performed from the Color Calibration

screen:

1.Yellow

a.Gain

b.Offset

c.Preheat

2.Magenta

a.Gain

b.Offset

c.Preheat

3.Cyan

a.Gain

b.Offset

c.Preheat

4.Black Panel Density

5.Black Panel Preheat

6.Contrast Adjustment

7.

8.

Status The Status screen displays the current state of the printer and provides standard

printer information and sensor data, which is updated every few seconds

58 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 71

Settings and Adjustments

Printing Preferences

Control The following procedures can be performed from the Control screen:

1. Advance the Ribbon

2. Advance the laminate

3. Run a cleaning cycle

4. Print a test card

5. Clear an Error

6. Reprint the last card and select number of

copies

7. Zero the buffer

8. Select advanced utilitles such as:

a. Flip Test 1

b. Flip Test 2

c. Flip/Pause

d. Move carriage

e. Calibration

f. Update the backup configuration

g. Upgrade the firmware

h. Send the features file

i. Control the Password

j. Control the ID/Code

k. Disable the control panel buttons

l. Set the printer status

Printing Preferences

The Preferences screens the operator may be asked to refer to and/or modify are Card Setup,

Image Adjustment, YMC (Color) Printing, and K (Black) Panel.To access the Printing

Preferences screens, select Start > Printers (or Printers and Faxes), then right click

Zebra P630i or Zebra P640i printer and select Printing Preferences or Properties.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 59

Page 72

Settings and Adjustments

Printing Preferences

Card Setup

From the Card Setup screen, the operator can adjust the following settings:

Image Size Sets the image area for

both front and back of the card (1 inch =

300 pixels).

Cards Specifies the type of card

loaded in the hopper - typically a PVC/

polyester/PVC composite card for

applications where durability is

important.

Ribbon This is the color ribbon

installed in the printer. Choice of two

for most applications: YMCK = 3 color

panels + 1 black panel, and YMCKK =

3 color panels + 2 black panels. For

secure applications a third type of

ribbon is available: YMCUvK (“Uv” is

a panel of ultraviolet responsive resin).

Front/Back Allows you to apply

color or black, or both, to either side of

the card. For example, with a 4-panel

YMCK ribbon the usual arrangement is

YMC (Color) on the front, K (Black) on

the back. If you check both YMC and K

on one side, this sets up a special

condition known as black extraction.

Laminate Allows you to choose

whether laminate will be applied to the

front side, to both sides (P640i Printer

only), or to neither side.

Orientation Allows you to set up the

front and back images, independently,

for landscape or portrait orientation. By

checking the Rotate box, you can also

flip either image upside down.

Note • The following combination is not available: Front landscape and Back portrait.

60 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 73

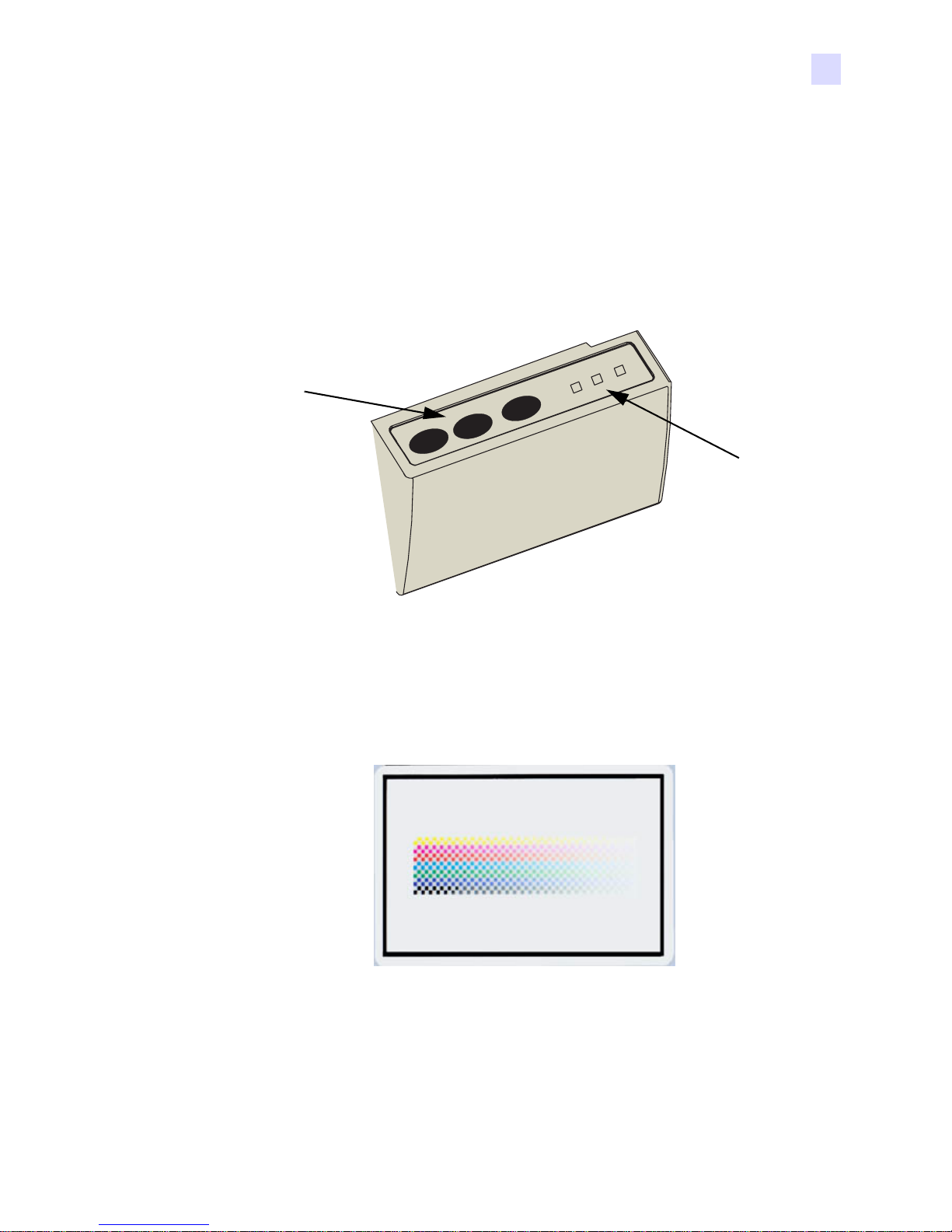

Image Adjustment

Settings and Adjustments

Printing Preferences

From the Image Adjustment screen,

the operator can adjust the brightness

and contrast of the images printed on the

cards. To access the Image Adjustment

screen, select Start >Settings >Printers

and Faxes. Right click on the Zebra

P630i or Zebra P640i printer listing.

Select Printing Preferences > Image

Adjustment.

Brightness and Contrast controls on the

Image Adjustment screen have same

effect on the printed image as do similar

controls on typical office color

printers.Reference the Contrast and

Brightness sample cards below for

examples of the different settings

available. Click the Reset Brightness/

Contrast to Defaults button to restore

default conditions.

Contrast 50

Brightness 25

Contrast 50

Brightness 50

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 61

Contrast 0

Brightness 50

Contrast 50

Brightness 75

Contrast 100

Contrast 100

Brightness 50

Brightness 50

Contrast 25

Brightness 50

Contrast 75

Brightness 50

Page 74

Settings and Adjustments

Printing Preferences

YMC (Color) Printing

The printer accepts 24-bit color images,

meaning that each of the colors (Y, M

and C) is represented by 8 bits per

pixel. In High Quality, the default

setting, all 24 bits are processed. In

Low Quality the printer driver transmits

a smaller amount of color information,

the effect being a slight degradation of

the printed image. The advantage of

low quality is increased transmission

speed, which can be helpful if the

connection is through a conventional

parallel port. With a USB connection,

there will be no noticeable difference.

K (Black) Panel

When the Card Setup screen is set for YMC and K on the same side of a card, a process called

Black Extraction is enabled. The K Panel screen displays available options for Black

Extraction.

62 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 75

Settings and Adjustments

Printing Preferences

Black Extraction

Black extraction has to do with the way the

printer driver handles the K (black) panel. It

applies only to surfaces of the card on which

both YMC (color) and K (black) are to be

printed.

Equal amounts of Y, M and C dyes, at

maximum intensity, deliver a near-black image,

but one that is not machine readable. A bar code

printed from YMC will be visible to the eye, but

will not be detectable by most bar code readers.

The remedy for this is to extract the black;

which means printing the same bar code, using

the K panel, on top of the YMC bar code. You

can also choose to print only in K, omitting

YMC from that region. The K panel is not a

dye. It is more of a paint containing carbon

black, which is highly visible to infrared-type

readers.

Printing Elements

Depending on the application used to create the card layout, elements of the design may be

identified in different ways to the printer driver. This printer driver recognizes, and rasterizes,

five types of elements: text, lines and pixels, area fills, monochrome bitmaps, and color bit

maps:

Text Text which is sent explicitly as such to the printer driver.

Lines and Pixels Lines and dots (pixels) sent as such to the printer driver.

Area Fills Color-filled geometric shapes.

Monochrome Bitmaps 1-bit bitmaps (every pixel either black or white).

Color Bitmaps Full color uncompressed pixel maps.

The above elements may not always be sent to the driver as expected. For example, a bar code

may be sent as text, a series of area fills, or a monochrome bitmap. Results will vary by

application used to create the card design. Another variable, again controlled by the card

layout application, is the precedence (stacking order) of the various element types in the event

that one or more of them overlap.

980541-003 Rev. A P630i, P640i Card Printer User’s Manual 63

Page 76

Settings and Adjustments

Color Calibration

Any of the above five elements may be selected for black extraction when the ribbon is set up

to apply YMC (color) and K (black) to the same surface of the card. In this condition, the

driver generates an extracted K image by looking for “true-black” features in the selected

element types, that is, instances where all three YMC values are at the maximum (full

intensity). Each such true-black instance generates a corresponding cluster of black pixels in

the extracted image, which will be printed with the K (black) panel either on top of the YMC

image, or replacing it entirely – your choice.

Color Calibration

Color rendering in the printer can be

described in terms of a curve, which

determines how much power is put

into the printhead for a given shade.

The Y, M and C color curves can be

separately modified by the Gain and

Offset parameters. Click Restore

Defaults if you are not satisfied with

adjustments made.

To access the Color Calibration

screen, select Start > Printers (or

Printers and Faxes). Right click on

the Zebra P630i or Zebra P640i

printer listing. Select Properties >

Device Settings > Color Calibration.

Offset Shifts the color curve up

(darker) and down (lighter).

Gain Adjusts steepness of the

curve. Lighter shades will remain

unchanged, but darker shades will

get darker or lighter as the number is

increased or decreased.

Note • Typically, the set of values should be the same for each color.

Preheat Adjusts how much the head is preheated before each print line (every three

hundredths of an inch). A larger value darkens (sharpens) the leading edges of colored areas. A

lower value may result in “feathering” - starting light, then darkening over the following few

pixels as the head heats up.

Black Panel Density This controls the amount of heat energy applied to any pixel required

to be black. A higher value gives darker printing, but can cause undesirable blooming

(indefinite edges).

64 P630i, P640i Card Printer User’s Manual 980541-003 Rev. A

Page 77

Black Panel Preheat Temperature offset applied across the entire head, specifically for K

panel printing. A higher value results in better resin transfer on the leading edge of graphics

and text than you would get with a cold start, but it may lead to undesirable blooming

(indefinite edges) overall.

Note • The printer must be power cycled for any Contrast Adjustments to take effect.

Contrast Adjust A subtle color printing control, allows the user to shape the printer’s

lightness curve. This means the ability to control how the printer resolves, or differentiates, the

lighter and darker shades. Between contrast settings of 0 and 100, the lightness curve

transitions from linear to sinusoidal. Linear (0%) tends to result in a low contrast, muddy

looking image. Sinusoidal (100%) gives mostly good results, but tends to sacrifice the lightest

and darkest shades. For most purposes, select 80% and leave it there.

Flip Station Routines

To access the Advanced Utilities screen, select Start > Printers (or Printers and Faxes). Right

click on the Zebra P640i or Zebra P640i printer listing. Select Properties > Device Settings >

Control > Advanced Utilites.

Settings and Adjustments

Flip Station Routines

Flip Test 1 Picks up a card, runs it to the flip station, flips it, raises it to the laminator infeed,

then ejects it through the laminator. The sequence repeats until the PRINT button is pressed

and released.

Flip Test 2 Picks up a card, runs it to the flip station, flips it, returns it to the platen, then

backs it out to the card sensor (by the mag head). The sequence repeats until the PRINT button

is pressed and released.