Page 1

Zebra® P4T/RP4T

Vehicle Cradle

Installation

Guide

UMAN-P4TVC-001 rev. C

December, 2008

Page 2

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation. It is intended solely for the

information and use of parties operating and maintaining the equipment described herein. Such proprietary

information may not be used, reproduced, or disclosed to any other parties for any other purpose without

the expressed written permission of Zebra Technologies Corporation. The Vehicle cradle can be used with

the P4T and the RP4T. P4T is used throughout the manual for simplicity.

Product Improvements

Since continuous product improvement is a policy of Zebra Technologies Corporation, all specifi cations

and signs are subject to change without notice.

FCC Compliance Statement

Class B digital device. Tested to comply with FCC standards for home or offi ce use.

WARNING: Exposure to Radio Frequency radiation with certain versions of the printer used with this product.

To conform to FCC RF exposure requirements this device shall be used in accordance with the operating

conditions and instructions listed in the printer’s User Guide. There are several radio options available

with the printer used in conjunction with this product. Additional regulatory information is contained in the

printer’s Users Guide in sections devoted to each radio option.

NOTE: This unit was tested with shielded cables on the peripheral devices. Shielded cables must be used

with the unit to insure compliance.

Changes or modifi cations to this unit not expressly approved by Zebra Technologies Corporation could

void the user’s authority to operate this equipment.

Canadian Compliance Statement

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme á la norme NMB-003 du Canada.

“IC:” before the equipment certifi cation number signifi es that the Industry Canada technical specifi cations

were met. It does not guarantee that the certifi ed product will operate to the user’s satisfaction.

Agency Approvals and Regulatory Information

• Design certifi ed by CSA

• FCC part 15 Class B

• Canadian STD ICES-003 Class B

• EN55022:1998 Class B European Electromagnetic Radiation Standard

• EN55022:1998 European Immunity Standard

• EN60950: 2000 Safety Standard

• NOM/NYCE (Mexico)

• C-Tick (Australia)

Liability Disclaimer

Inasmuch as every effort has been made to supply accurate information in this manual, Zebra Technologies Corporation is not liable for any erroneous information or omissions. Zebra Technologies Corporation

reserves the right to correct any such errors and disclaims liability resulting therefrom.

No Liability for Consequential Damage

In no event shall Zebra Technologies Corporation or anyone else involved in the creation, production, or

delivery of the accompanying product (including hardware and software) be liable for any damages whatsoever (including, without limitation, damages for loss of business profi ts, business interruption, loss of

business information, or other pecuniary loss) arising out of the use of or the results of use of or inability

to use such product, even if Zebra Technologies Corporation has been advised of the possibility of such

damages. Because some states do not allow the exclusion of liability for consequential or incidental damages, the above limitation may not apply to you.

Copyrights

The copyrights in this manual and the label print engine described therein are owned by Zebra Technologies Corporation. Unauthorized reproduction of this manual or the software in the label print engine may

result in imprisonment of up to one year and fi nes of up to $10,000 (17 U.S.C.506). Copyright violators may

be subject to civil liability.

This product may contain ZPL

and AGFA fonts. Software © ZIH Corp. All rights reserved worldwide.

ZebraLink and all product names and numbers are trademarks, and Zebra, the Zebra logo, ZPL, ZPL II,

Element Energy Equalizer Circuit, and E3 Circuit are registered trademarks of ZIH Corp. All rights reserved

worldwide.

CG Triumvirate is a trademark of AGFA Monotype Corporation. All rights reserved worldwide. CG Trium-

tm

font © AGFA Monotype Corporation. Intellifont® portion © AGFA Monotype Corporation. All rights

virate

reserved worldwide. UFST is a registered trademark of AGFA Monotype Corporation. All rights reserved

worldwide.

All other brand names, product names, or trademarks belong to their respective holders.

©

2008 ZIH Corp

®

, ZPL II®, and ZebraLinktm programs; Element Energy Equalizer® Circuit; E3®;

Page 3

Contents

Vehicle Installation Safety ................................. 4

Introduction ....................................................... 5

Required for Installation .........................................................................7

Refe renc e ................................................................................................. 7

Contents of the Package ......................................................................... 7

Installation ......................................................... 7

Introduction to Installation ..................................................................... 7

Vehicle Cradle Preparation ..................................................................... 9

Input Power Cable Completion ............................................................ 11

Using the Printer in the Vehicle Cradle ................................................ 12

Printer Preparation .............................................................................. 12

Printer Installation ............................................................................... 13

Removing the Printer .......................................................................... 14

Loading Media ....................................................................................... 15

Using the Printer’s Internal Media Supply ........................................ 15

Using an External Media Supply ........................................................ 15

Printer Access ....................................................................................... 15

Vehicle Cradle Indicators ...................................................................... 15

Connections to a Terminal .................................................................... 16

Communications with a Terminal ......................................................16

Power Connections to a Terminal ...................................................... 16

Installing the Mounting Arm ............................ 17

Description ............................................................................................ 17

Installation ............................................................................................. 17

Mounting Hardware ............................................................................ 17

Vehicle Cradle Preparation ................................................................. 17

Input Power Completion ..................................................................... 19

Technical Support ............................................ 20

3

P4T Vehicle Cradle Installation Guide

Page 4

Special Notices

The following notices emphasize certain information in the guide. Each serves a

special purpose and is displayed in the format shown:

NOTE: Note is used to emphasize any signifi cant information.

Caution: Indicates information that, if not followed, can result in damage to software, hardware, or data.

not avoided, can result in personal injury.

which, if not avoided, may be a shock hazard.

which, if not avoided will result in death or serious injury. Before you work on any

equipment, be aware of the hazards involved with electrical circuitry and be familiar with standard practices for preventing accidents

Caution: This symbol indicates a potentially hazardous situation which, if

Caution: This warning symbol indicates a potentially hazardous situation

Warning: This warning symbol indicates an imminently hazardous situation

Vehicle Installation Safety

Caution: Only trained and qualifi ed personnel should be allowed to install,

replace, or service this equipment.

Caution: DO NOT USE THE PRINTER WHILE DRIVING, as this may result in

property damage or personal injury. Zebra Technologies Corp. does not promote

the use of these products except when parked or stationary, and is not responsible

for any loss resulting from the use or misuse of our products. Most importantly,

we do not want to see harm come to our customers or anyone else.

Caution: Do not install the Vehicle Cradle where it will be exposed to precipitation or excessive condensation.

Caution: Do not install the Vehicle Cradle on or near an airbag cover plate or

within an airbag zone. Also, do not install the Vehicle Cradle in a location that will

affect vehicle safety or drivability.

Caution: The means of routing and securing the Power Input cable from the

Vehicle Cradle through to the vehicle power source is extremely important. Hazards associated with improper wiring can be severe. To avoid unintentional contact

between the wire and any sharp edges, provide the cable with proper bushings

and clamping where it passes through openings. If the wire is subjected to sharp

surfaces and excess engine vibration, the wiring harness insulation can wear away,

causing a short between the bare wire and the chassis. This can start a fi re.

Caution: The vehicle charging circuit must neither undercharge nor overcharge the vehicle battery. Either fault condition in the vehicle electrical system

can cause a no-charge condition in the printer battery.

Warning: It is very important to ensure you make the correct cable to power

source connections, because electrical energy from a vehicle’s power system can

harm equipment and people.

Caution: If you need to jump start your vehicle from another vehicle battery,

disconnect the power cable running to the Vehicle Cradle. Failure to do so can

result in damage to your mobile printer and/or the Vehicle Cradle itself.

4

P4T Vehicle Cradle Installation Guide

Page 5

Introduction

NOTE: Zebra Technologies Corporation is not liable for personal injury

or damage to any equipment caused by the improper installation of this

equipment to any power source.

This equipment should be installed in accordance with this installation guide

and under the supervision of properly trained and qualifi ed personnel.

The P4T Vehicle Cradle allows use of the Zebra® P4T Printer in a

vehicle. The Vehicle Cradle will provide intelligent battery charging

for a P4T Printer while still maintaining all of the Printer’s functionality. Power for the Printer and the Vehicle Cradle’s built in charger

is provided by the vehicle’s electrical system.

The Vehicle Cradle is offered with two input power connection

options:

A power cable which can be plugged into an automotive ve-•

hicle’s cigarette lighter socket.

An unterminated cable which must be wired into the vehi-•

cle’s power system (12 VDC Nom.)

An optional mounting arm provides the ability to locate the

Printer and Vehicle Cradle in a variety of positions and mounting locations to enhance its accessibility and ease of use.

The following instructions detail the installation and use of the

P4T Vehicle Cradle. Following these instructions closely will ensure

safe, reliable performance of the P4T Printer when installed in the

Cradle.

The Printer runs off its own battery, which is monitored and

charged by circuitry within the Printer.

The user should always refer to the P4T Users Guide for complete

information on using the Printer.

It is important that the vehicle’s electrical system function properly. The vehicle’s charging circuit must work properly and vehicle-generated electrical “noise” must be minimized and within

specifi cations.

The vehicle charging circuit must neither undercharge nor overcharge the vehicle battery. Defective ignition wiring, damaged insulation, or faulty vehicle electrical components can cause excess

electrical noise severe enough to defeat the electrical fi ltering that

is built into the Cradle and the Printer.

5

P4T Vehicle Cradle Installation Guide

Page 6

Figure 1: Vehicle Cradle with P4T Printer Installed

Input Power Cable

Latch Release Button

Press to release Printer

from Cradle

6

P4T Vehicle Cradle Installation Guide

Power Indicator

Always Green when

power is on

Page 7

Required for Installation

An electrical drill, 1/4”(6 mm) drill bit•

Common hand tools.•

#10-32 or 10-24 Bolts with self-locking (ESN) nuts and appro-•

priate mounting hardware for securing the Vehicle Cradle

Note: Use of appropriate hardware used to secure the Vehicle Cradle to the

vehicle is the responsibility of the installer

Reference

P4T User’s Guide•

Contents of the Package

The P4T Vehicle Cradle Assembly•

One of two power input cables: either (1) an unterminated •

cable with an integrated fuse holder, or (2) a cable terminated

with a cigarette lighter adapter.

Hardware for routing and securing the input power cable.•

This Guide•

Installation

Introduction to Installation

The P4T Vehicle Cradle allows you to mount a P4T printer into virtually any vehicle with an electrical system voltage 12 VDC. The

installation kit provided with the Cradle includes an input power cable which, when connected to the vehicle’s electrical system, provides power to run the Printer and charge its battery.

The input power cable is wired to the vehicle’s battery power system indirectly through a power take-off point. One version of the

Vehicle Cradle supplies an input power cable that can be plugged

into an automotive vehicle’s cigarette lighter.

CAUTION: Under no circumstances should this equipment be attached di-

rectly to the vehicle’s battery without a proper fuse.

Since each situation or equipment type may pose unique requirements, mounting hardware selection and mechanical installation

shall be the responsibility of the installer. Zebra recommends using self-locking (ESN) nuts, bolts, and/or lock washers for installing

the mount. The Cradle is secured with #10-32 or #10-24 mounting

hardware (4 places).

Note: Hardware used to secure the Vehicle Cradle to the vehicle is not

supplied in the installation kit.

Your tasks are to:

Mechanically prepare and install the P4T Vehicle Cradle•

7

P4T Vehicle Cradle Installation Guide

Page 8

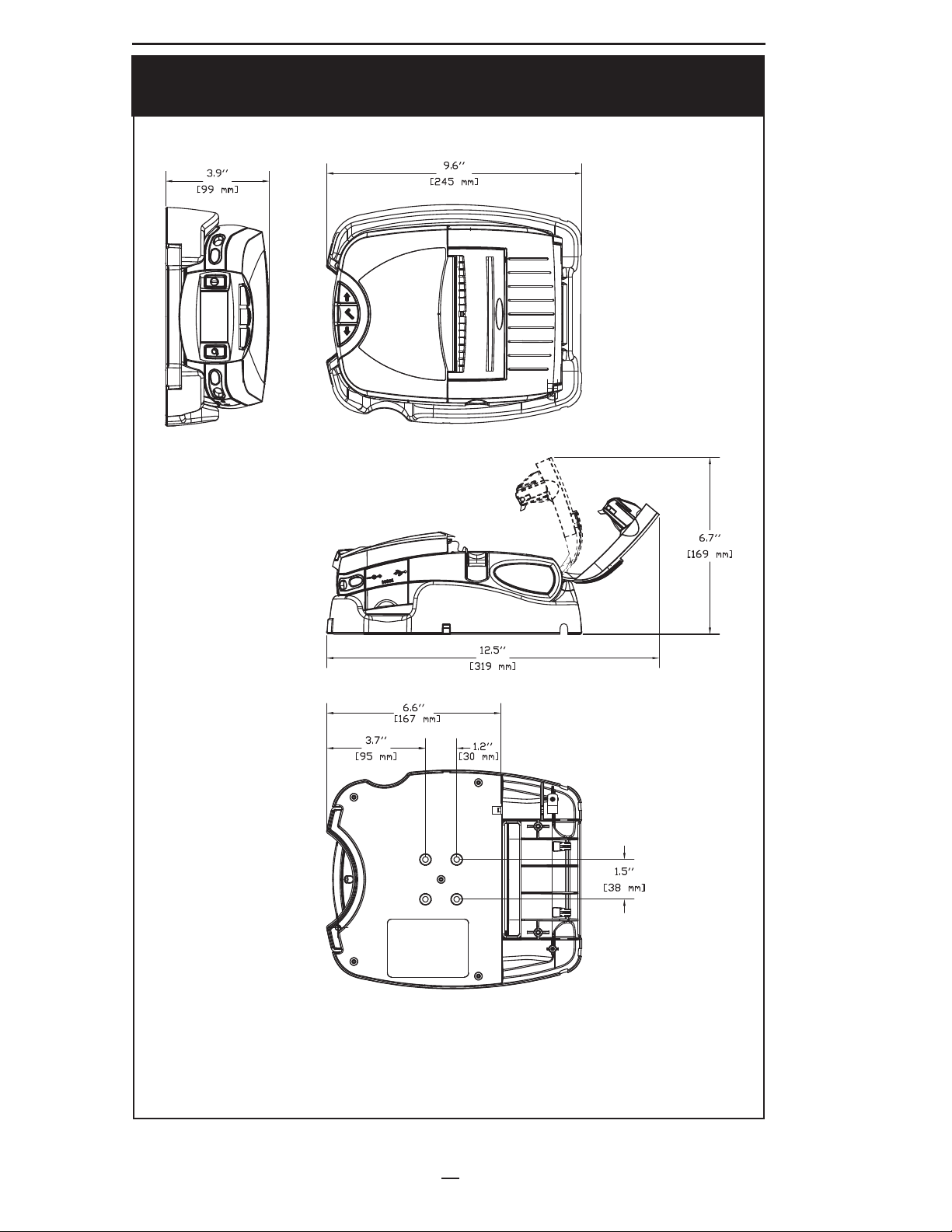

Figure 2: Vehicle Cradle Installation Dimensions

(P4T Printer Installed)

8

P4T Vehicle Cradle Installation Guide

Page 9

Connect the power input cable from the vehicle’s electrical •

system.

It is important to leave a free zone around the printer to allow

loading of paper and routine cleaning of the print head. Refer to

Figure 2.

If you are installing the optional mounting arm, remember the

arm provides a considerable range of movement for the Cradle and

Printer. This allows adjustment to the best position for the operator. Extra clearance should be provided for this movement if it is

desired in the installation. Refer to pages 17-19 for more information on installing the Cradle using the Mounting Arm.

Decide where you will mount the printer, and proceed with the

following instructions.

CAUTION: Mount the Printer and Vehicle Cradle where it will not hit the op-

erator in case of an accident.

Vehicle Cradle Preparation

Plan your installation with the above considerations in mind, and

locate the Printer and Vehicle Cradle so that the operator can easily load printing media, operate the printer’s controls and perform

routine maintenance such as cleaning the printhead. Follow these

steps:

Select a location in the vehicle that will avoid personal con-1.

tact in case of an accident.

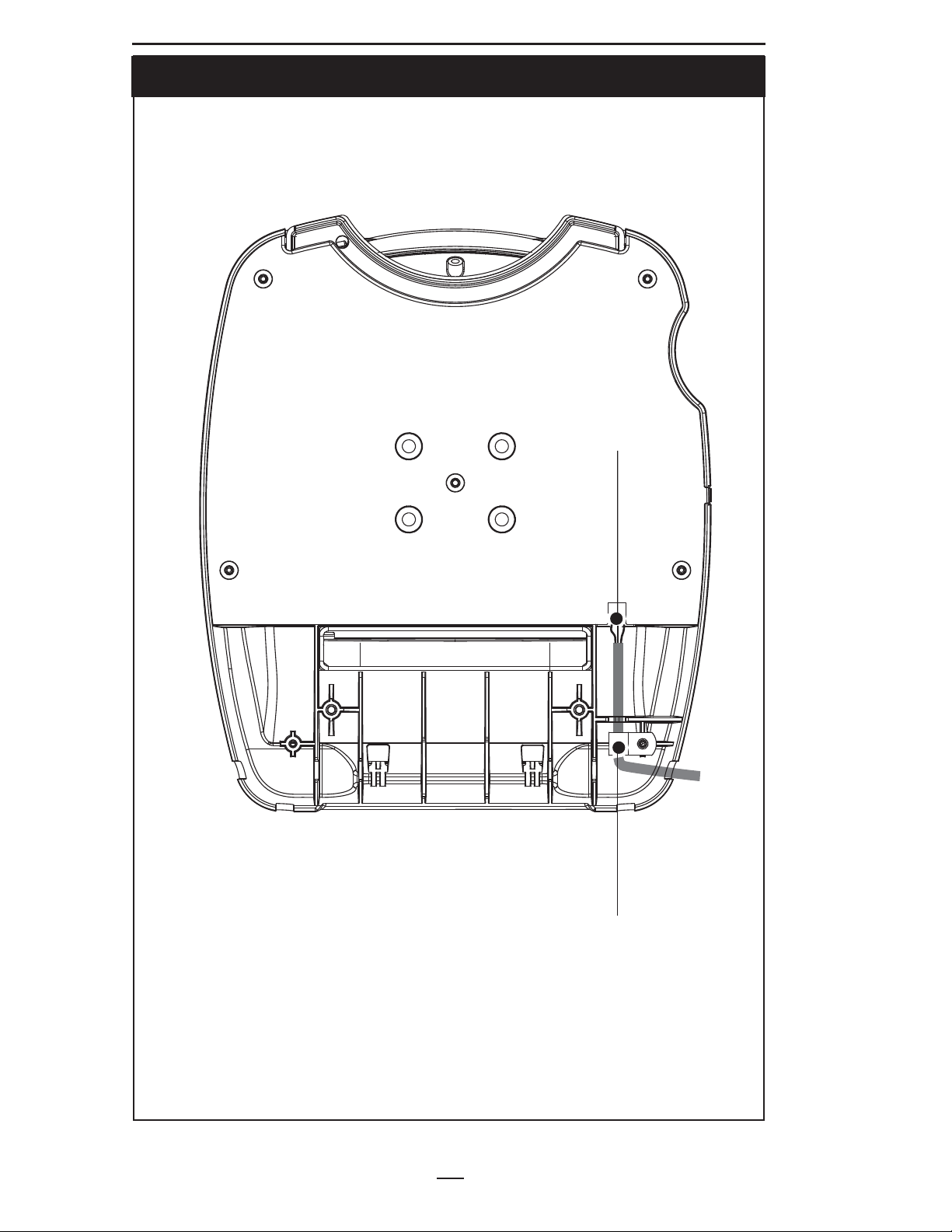

Turn the Cradle upside down, and plug the input power cable 2.

into the bottom of the Cradle.

Route the input power cable out of the Cradle. Note that there 3.

are retaining features in the Cradle to keep the cable in place.

Refer to Figure 3.

Once the Cable has been located, secure it to the Cradle with 4.

the cable clamp supplied with the installation kit. Use the

self-tapping screw and fl at washer supplied in the kit to attach the clamp to the Cradle.

Make sure that the input power cable routing does not invite 5.

damage to the cable. To avoid unintentional contact between

the wire and any sharp edges, provide the cable with proper

bushings and clamping where it passes through openings.

Route the input power cable to the vehicle’s power take-off 6.

point you will be using.

9

P4T Vehicle Cradle Installation Guide

Page 10

Figure 3: Input Power Cable Routing

Plug Input

Power Cable

into Cradle

Cable Clamp

Secure with supplied

hardware

10

P4T Vehicle Cradle Installation Guide

Page 11

Input Power Cable Completion

There are two power cable options that can be used with the

Vehicle Cradle. One terminates in a (fused) cigarette lighter adapter. The other terminates in bare wire and is intended for direct wiring into the vehicle electrical system. This second option has an

in-line fuse holder near the end of the cable that connects to the

vehicle electrical system.

If you are using a Vehicle Cradle with the cigarette lighter plug, all

you need to do is plug the power cable into the vehicle’s cigarette

lighter socket. The cable must be secured along its entire length

and must not be allowed to hang loose, as described in the section

“Secure the Power Cable”, below

If you are using the cable that terminates in bare wire, the directions are as follows:

You must not cut the cable shorter as this will cut off the in-•

line fuse holder. If there is extra length bundle the cable securely to eliminate the excess.

CAUTION: There must be a fuse between the vehicle’s power source and the

input power cable connection! If you are not using the cable supplied with

the Vehicle Cradle, selecting the size and rating of this fuse is the installer’s

responsibility.

The installer must fi nd the nearest practical connection point •

to the vehicle’s main battery voltage. Consult the vehicle

manufacturer or a dealer to determine the best power connection location. Note that the vehicle wiring leading to the

connection point must be at least 18 AWG. Note also that

many vehicles use SAE wiring gage, which is different from

AWG.

Prepare the Cable Ends:

NOTE: Actual cable termination used must be compatible with the power

source. The following is a guideline.

Strip 1/4” (6 mm) of insulation from the BLACK wire.1.

Securely crimp the supplied 3/8” terminal ring onto the 2.

BLACK wire.

Strip 1/4” (6 mm) of insulation from the RED wire.3.

Securely crimp the supplied 3/8” terminal ring onto the RED 4.

wire.

Connect Cable to the Power Source

Ensure that cable terminals are well connected to the cable.1.

Connect black cable ground (-) terminal to vehicle ground lo-2.

cation.

Connect red cable power (+) terminal to vehicle power 3.

source.

11

P4T Vehicle Cradle Installation Guide

Page 12

Secure the Power Cable

Make sure that the cable routing does not interfere with other

equipment or vehicle controls. Insure that the cable routing protects the cable from damage during vehicle use.

Using the Printer in the Vehicle Cradle

Printer Preparation

Prepare the printer for installation into the Vehicle Cradle by doing the following:

It is strongly recommended as a safety precaution that the adjustable shoul-

der strap be removed prior to docking the Printer. This precaution will ensure the strap will not interfere with proper operation of the vehicle.

Always install the Battery prior to mounting the printer in the •

Cradle.

Remove the Docking Connector Cover from the bottom of the •

printer, and retain it for future use. (Refer to Figure 4)

Printer Installation

The P4T Printer can now be installed in the Vehicle Cradle:

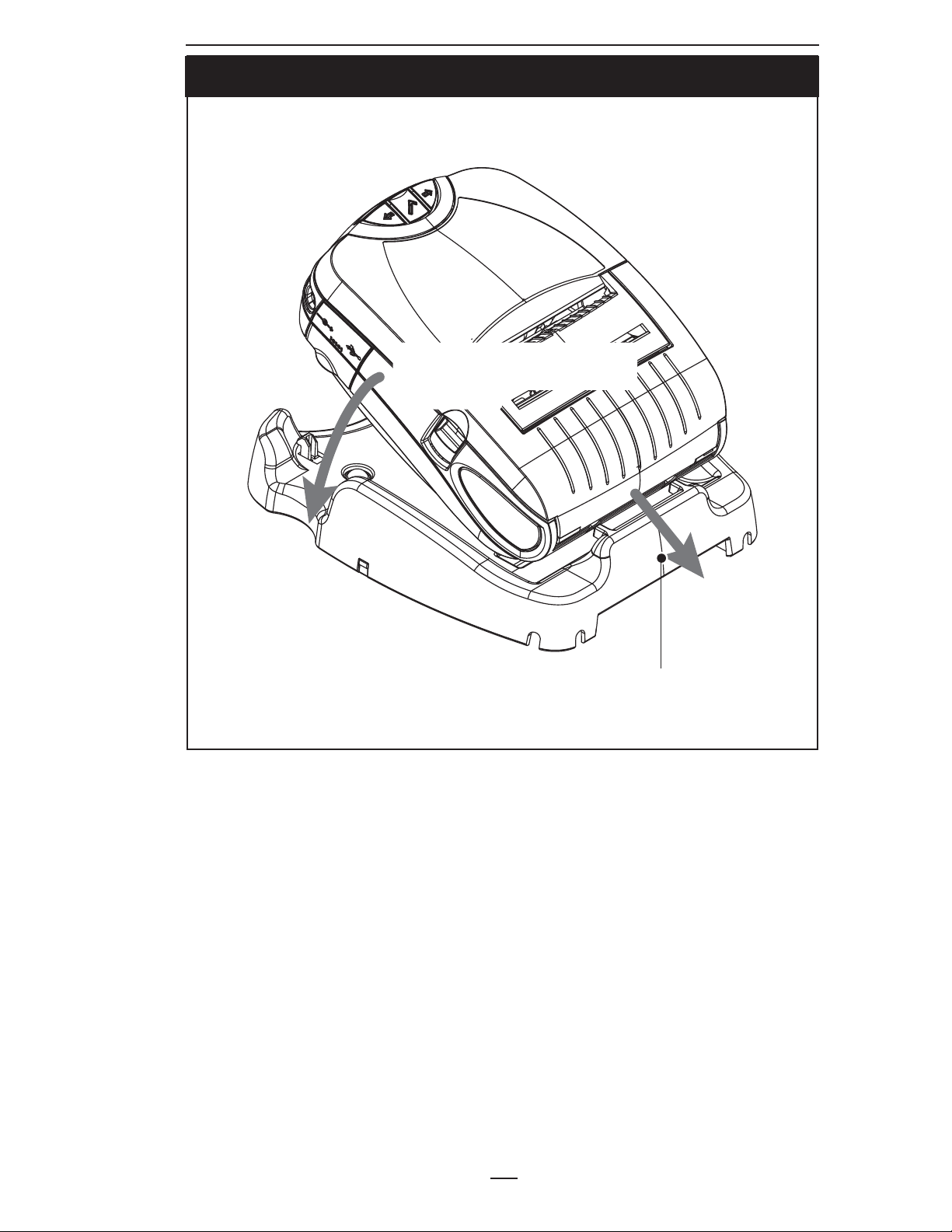

Figure 4: Printer Preparation

Remove and retain the

Docking Connector

Cover and attaching

Hardware

12

P4T Vehicle Cradle Installation Guide

Page 13

Figure 5: Installing the Printer In The Vehicle Cradle

Rock the Printer into the

Cradle to latch it in position.

Place the bottom of the printer over the two pegs in the •

Cradle.

Rotate the Printer into the Cradle and press fi rmly until it •

latches in place.

Turn the vehicle’s power source for the Cradle on, and verify •

that the charger indicator on printer LCD and power indicator

light on the Cradle’s side panel are lit.

Turn the printer on and print a confi guration label to verify •

that the printer is functioning properly. Refer to the P4T

User’s Guide for instructions on printing a confi guration label.

Removing the Printer

Remove the Printer by doing the following:

Turn the Printer off.•

If the Printer is directly connected to a communications ca-•

Place the Printer over

the retaining pins in

the Cradle.

13

P4T Vehicle Cradle Installation Guide

Page 14

Figure 6: Removing the Printer from the Vehicle Cradle

Press the

Latch Button

to release

the Printer.

Rotate the Printer out of the

Cradle.

Lift the printer free

of the retaining pins.

ble, unplug and remove the cable from the Printer.

Press the latch release button on the Vehicle Cradle and pivot •

the Printer out of the Cradle.

If you will be using the Printer out of the Vehicle Cradle for a •

prolonged period, replace the Docking Connector Cover on

the Printer.

Loading Media

Using the Printer’s Internal Media Supply

If you are using the Printer’s internal media compartment, follow

the loading procedures found in the P4T User’s Guide.

14

P4T Vehicle Cradle Installation Guide

Page 15

Using an External Media Supply

If the printer’s media supply is from an external supply, typically fanfold media, you must make provisions for a media bin to be

positioned to allow media to enter the printer through either the

bottom or the back of the Vehicle Cradle. If the Cradle is mounted

against a vertical surface there is a slot and guiding features in the

base to insure the media will feed properly into the printer.

If you are using an external media supply follow these steps to

load media:

Open the P4T’s media supply compartment.1.

Load the media from the external supply through the feed 2.

slots in the bottom of the Cradle and the Printer and past the

printhead. Note that if you are using 4 inch (10.16 cm) wide

external media, you can install the Fanfold Spacer (Zebra p/n

BA16625-1) between the printer’s media supports to keep

them from binding on the edges of the media.

Close and latch the media compartment.3.

NOTE: Your printer must be confi gured with the External Media option to use

an external media supply. If using an external media supply bin, ensure no

extra items are suspended from either the Printer or the Vehicle Cradle.

Printer Access

The media compartment and operator controls can be reached

while the printer is secured in the Vehicle Cradle.

If you need to remove the printer for servicing follow the removal

procedure detailed above in the Printer Installation and Removal

section.

Vehicle Cradle Indicators

The Vehicle Cradle has one LED indicator on the side panel as

shown in Figure 1. The power LED is green when power is supplied

to the Cradle.

Charging status will be displayed on the printer LCD.

A fault condition could be caused by the battery’s internal temperature exceeding its specifi ed limits (too hot or too cold) or could

be caused by an internal short in the battery. Allow the battery to

return to specifi ed charging temperature range and try to recharge.

If the fault condition persists, discontinue use of that battery.

NOTE: If the charge indicator on the Printer LCD does not indicate charging

when the printer is installed, it may be the result of one of two possible

conditions:

1) The printer is not seated properly in the cradle. Unlatch and redock the

printer into the cradle. Observe if LCD indicates charging.

2) If redocking the printer does not cause the LCD to indicate charging it is

because the printer has entered a 30 minute prequalifi cation process. At the

end of this process the printer will either (1) commence charging or (2) not

15

P4T Vehicle Cradle Installation Guide

Page 16

commence charging in which case there is a battery error.

Connections to a Terminal

Communications with a Terminal

If you are also installing a terminal in the vehicle, consult the terminal manufacturer’s literature for installation instructions. If the

terminal and Printer will communicate using either an RS232 or

USB cable, use shielded cables and keep their length as short as

possible. Ensure the routing of the cable does not invite damage to

the cable or interfere with the control or use of the vehicle.

Consult the factory for information on the various I/O data cables

offered by Zebra for use with a variety of widely used terminals.

NOTE: This unit was tested with shielded cables on the peripheral devices.

Shielded cables must be used with the unit to insure compliance.

If the terminal and the Printer will communicate via an RF link, it

is the installer’s responsibility to test the strength and reliability of

such a link prior to fi nal installation.

Power Connections to a Terminal

If you are also installing a terminal in the vehicle, you must run

two separate cables from the vehicle power source: one to the

printer and one to the terminal.

Warning: Do not attempt to power both devices from the same power cable.

The terminal power cable must be either supplied by the terminal

manufacturer or fabricated by the installer.

It is the installer’s responsibility to determine the suitability of

running a terminal from the vehicle’s battery.

NOTES: This Installation Guide does not cover the installation of any terminal

used in conjunction with the P4T Printer or Vehicle Cradle.

Zebra Technologies Corporation is not liable for personal injury or damage to

equipment caused by improper installation to any power source.

16

P4T Vehicle Cradle Installation Guide

Page 17

Installing the Mounting Arm

Description

An optional mounting arm (Zebra p/n P1010338) is offered for

use with the Vehicle Cradle which allows a more versatile method of positioning the P4T printer. It consists of an arm with a ball

and socket joint at either end, which in turn are terminated with a

mounting fl ange. One fl ange is secured to the Cradle by the four

mounting holes provided on the bottom plate, and the other is secured to the desired mounting surface. A clamp on the arm locks

the Cradle in the desired position.

NOTE: Do not use #8 screws.

Installation

CAUTION: Mount the Printer and Vehicle Cradle where it will not hit the op-

erator in case of an accident.

Warning: Do not connect the input power cable to the Vehicle Cradle until the

Cradle and Mounting Arm installation have been completed.

For ease of installation, the Arm can be disassembled by loosening the clamp enough to remove the two ball and socket fl anged

ends. These end fl anges can then be easily secured to the Vehicle

Cradle and the desired mounting surface. Then the arm can be

slipped over the two ends and the clamp tightened to secure the

Cradle in position.

When installing the mounting arm, remember that the arm provides a considerable range of movement for the Vehicle Cradle

and Printer. Extra clearance should be provided for this movement

if it is desired in the installation.

Mounting Hardware

Mounting hardware is supplied with the Mounting Arm Kit. The

#10-32 or #10-24 screws should be used to secure one end of the

arm to the bottom of the Vehicle Cradle. The #10-24 x 3/4” screws

and associated hardware may be used to secure the other end of

the arm to the desired mounting surface.

Vehicle Cradle Preparation

Refer to the section on Vehicle Cradle Preparation earlier in this

manual for more specifi c instructions and illustrations on securing the power cable to the Cradle. Locate the Printer and Cradle so

when installed with the Mounting Arm the operator can easily load

printing media, operate the printer’s controls and perform routine

maintenance such as cleaning the printhead. Follow these steps:

Select a location in the vehicle that will avoid personal con-1.

tact in case of an accident.

Turn the Cradle upside down, and plug the input power cable 2.

17

P4T Vehicle Cradle Installation Guide

Page 18

Figure 7: Optional Mounting Arm Dimensions

[187 mm]

2.43” [62 mm}

R .91” [23 mm}

1.19” [30 mm}

7.35”

1.50” [38 mm}

Figure 8: Securing the Vehicle Cradle to the Mounting Arm

Use #10 (1” long srews)

hardware supplied with

kit to secure to Cradle

Vehicle Cradle

Tightening Clamp

Use #10 (3/4” small srews)

hardware supplied with

kit to secure to mounting

surface

18

P4T Vehicle Cradle Installation Guide

Page 19

into the bottom of the Cradle.

• Route the input power cable out of the Cradle. Note that it

can be routed out either side of the Cradle and that there are

retaining features in the Cradle to keep the cable in place.

Refer to Figure 3.

• Be sure to leave enough slack in the power cable to allow

the Mounting Arm to pivot freely without putting strain on

the power connections.

• Make sure that the input power cable routing does not invite damage to the cable when the Vehicle Cradle is pivoted.

Once the cable routing has been determined, secure it to the 3.

Vehicle Cradle with the cable clamp(s) supplied with the installation kit. Use the self-tapping screws and fl at washers

supplied in the kit to attach the clamp to the Cradle.

Secure one of the mounting fl anges from the movable Arm to 4.

the bottom of the Vehicle Cradle with the (4) #10-32 or #1024 screws supplied with the Mounting Arm.

Secure the other mounting fl ange on the Movable Arm to 5.

the desired mounting surface. You can use the #10-24 x 3/4”

screws and associated hardware supplied in the Mounting

Arm Kit or use other hardware as the mounting conditions

dictate.

Input Power Completion

Route the input power cable per the earlier section in this Guide:

“Input Power Cable Completion.”

19

P4T Vehicle Cradle Installation Guide

Page 20

Technical Support

U.S. ONLY

Zebra maintains a help line for questions involving installation

and use of the P4T Vehicle Cradle.

Please have as much information as possible regarding your

particular application ready when you call to enable the technical support personnel to help you. The number in the U.S. is

(800)-423-0442 and is open Monday through Friday from 8:00 am

to 4:30 P.M. E.S.T.

ALL OTHERS

For Technical Support please contact your local Zebra sales representative listed below:.

Zebra Technologies Europe Limited

Dukes Meadow

Millboard Road

Bourne End

Buckinghamshire

SL8 5XF

United Kingdom

Phone: +44 (0)1628 556000

Fax: +44 (0)1628 556001

Zebra Technologies

Latin American Sales Offi ce

9800 NW 41Street

Suite 220

Doral, Florida 33178 USA

Phone: +1.305.558.8470

Fax: +1.305.558.8485

Zebra Technologies Asia Pacifi c, LLC

16 New Industrial Road

#05-03 Hudson TechnoCentre

Singapore 536204

Phone: +65-6858 0722

Fax: +65-6885 0838

Loading...

Loading...