Page 1

User’s Guide

P300 and P400

User’s Manual No. 980224-001 Rev. C

1999 Eltron International Inc.

Page 2

Page 3

FOREWORD

This manual contains installation and operation information for the Privilege Series card printers

manufactured by Eltron International Incorporated, Simi Valley, California.

RETURN MATERIALS AUTHORIZATION

Before returninganyequipmentto Eltron for in-warranty or out-of-warranty repair, contact Repair

Administration for a Return Materials Authorization (RMA) number. Repack the equipment in the

original packing material and mark the RMA number clearly on the outside. Ship the equipment,

freight prepaid, to the address listed below:

Eltron Repair Administration

1001 Flynn Road

Camarillo, CA. 93021-8706. USA

Phone: +1 (805) 579-1800

FAX: +1 (805) 579-1808

Label Printers: Card Printers:

Eltron International, Northern Europe Eltron International, Southern Europe

Unit 2, Rose Kiln Lane Zone Indutrielle, Rue d'Amsterdam

Reading, Berkshire, RG2 OHP England 44370 Varades, France

Phone: +44 (0) 118 975 2024 Phone: +33 (0) 240 097 070

FAX: +44 (0) 118 975 2005 FAX: +33 (0) 240 834 745

COPYRIGHT NOTICE

This document contains information proprietary to Eltron International Incorporated. This docu

ment and the information containedwithinis copyrighted by Eltron International Incorporated and

may not be duplicated in full or in part by any person without written approval from Eltron. While

every effort has been made to keep the information contained within current and accurate as of the

date of publication, no guarantee is given or implied that the document is error-free or that it is ac

curate with regard to anyspecification. Eltron reserves the right tomake changes,for the purpose of

product improvement, at any time.

TRADEMARKS

Privilege, Privilege P300 and Privilege P400 are service marks. Privilege Card is a trademark of

Privilege Card, S. A., a subsidiary of Eltron International Incorporated and Eltron is a trademark of

Eltron International Incorporated. Windows and MS-DOS are registered trademarks of Microsoft

Corp. All other marks are trademarks or registered trademarks of their respective holders.

980224-001 Rev.C iii

-

-

Page 4

WARRANTY INFORMATION

We Need To Hear From You!

To Establish Your Warranty Period And Provide Access To Technical Support,

Send Us Your Product Registration Card Today!

Eltron warrants the mechanism, control electronics and power supply, under normal use and serv

ice, to be free fromdefects in material and workmanship for a period oftwelve (12) months from the

date of purchase by the end user. Eltron warrants the print head, under normal use and service, to

be free from defects in material and workmanship for a period of twelve (12) months or 100,000

passes (whichever occurs first) from the date of purchase by the end user. Proof of purchase or

product registration is required. If proof of purchase or product registration cannot be established,

shipment date to the originalbuyer (dealeror distributor) will be usedto establish the warranty peri

od.

Failure to exercise caution to protect the equipment from electrostatic discharge damage, adverse

temperature and humidity conditions or physical abuse may void the warranty. Failure to use only

Eltron approved media may void the warranty. Eltron will, at it’s option, repair or replace the

equipment or any parts which are determined to be defective within this warranty period, and

which are returned to Eltron F.O.B. factory of origin.

The warranty set forth above is exclusive and no other warranty, whether written or oral, is expressed or implied. Eltron specifically disclaims the implied warranties of merchantability and fitness for a particular purpose.

FCC NOTICE:

This equipment has been tested and found to comply with the limits of a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates,uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference toradio communications. How

ever, there is no guarantee that interference will not occur in a particular installation. Operation of

this equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.

-

-

-

INDUSTRY CANADA NOTICE:

This device complies with Industry Canada ICS-003 class A requirements.

Cet equipement est conforme a l’ICS-003 classe A de la norm Industrielle Canadian

iv 980224-001 Rev.C

Page 5

Icon Descriptions

Indicates a mechanical hazard, such as one associ

ated with moving parts, capable of resulting in

equipment damage or personal injury.

Indicates an electrical hazard, such as an exposed

voltage point, capable of causing electrical shock

and personal injury if touched.

Indicates information of particular interest that re

quires consideration in the associated context.

Indicates a part that can operate at an elevated temperature capable of causing pain or a burn if

touched.

Indicates an area where an electrostatic discharge

(ESD) can cause component damage.Use a grounding wrist band.

Indicates that fiber deposits from fibrous cleaning

materials (e.g., cotton swabs) can reduce print quality.

-

-

Indicates that exposure to dust and other airborne

particles can contaminate the printer and reduce

print quality.

Indicates that except for ribbon loading and mainte

nance, the cover must remain closed.

Indicates that users should not (and need not) twist

the Take Up spindle to remove ribbon slack. Slack

take up occurs automatically when the panel button

is pressed.

980224-001 Rev.C v

-

Page 6

ELTRON INTERNATIONAL, INC.

declares that the

déclare que le

bescheinigt, daß das Gerät

declara que el

dichiara che

P300 Card Printer

P400 Card Printer

is in conformance with the requirements of the European Council Directives listed below:

est conforme aux spécifications des directives de l'Union Européenne ci-dessous:

der nachstehend angeführten Direktiven des Europäischen Rats:

cumple

con los requisitos de las Directivas del Consejo Europeo, según la lista siguiente:

è conforme alle specifiche delle sequenti direttive dell’Unione Europea:

89/336/EEC EMC Directive

92/31/EE EMC Directive

73/23/EEC Low Voltage Directive

On the approximation of the lawsof Member States relating to Electromagnetic Compatibility and Product Safety.

Basées sur la législation des Etats membres relative à la compatibilité électromagnétique et à la sécurité des produits.

ber die Annäherung der Gesetze der Mitgliedsstaaten in bezug auf elektromagnetische Verträglichkeit und

Ü

Basado en

la aproximación de las leyes de los Países Miembros respecto a la Compatibilidad electromagnética

Basate sulla legislazione degli stati membri relativa alla compatibilitá elettromagnetica e alla securezza dei prodotti.

This declaration is based upon compliance of the product to the following standards:

Cette déclaration repose sur la conformité du produit aux normes suivantes:

Diese Erklärung basiert darauf, daß das Produkt den folgenden Normen entspricht:

Esta declaración se basa en el cumplimiento del producto con las siguientes normas:

Questa dichiarazione si basa sulla conformitá del prodotto alle norme sequenti:

Produktsicherheit entspricht.

y las Medidas de seguridad relativas al producto.

EN 55022-B, CISPR 22RF Emissions Control

EN 500082-1 IEC 801Immunity to Electromagnetic Dicturbances

EN 60950 IEC 950 Product Safety

Hugh Gagnier, President

ELTRON INTERNATIONAL, Inc.

41 Moreland Road

Simi Valley, CA 93065-1692 U.S.A.

vi 980224-001 Rev.C

Page 7

Table of Contents

Getting Started . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Unpacking Your Privilege Card Printer. . . . . . . . . . . . . 4

Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Removing the Printer Case. . . . . . . . . . . . . . . . . . . 13

Memory Board Installation. . . . . . . . . . . . . . . . . . . 15

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Controls & Indicators . . . . . . . . . . . . . . . . . . . . . 17

Ribbon Preparation . . . . . . . . . . . . . . . . . . . . . . 19

Ribbon Loading . . . . . . . . . . . . . . . . . . . . . . . . 20

Handling the Media . . . . . . . . . . . . . . . . . . . . . . 23

Card Gate Adjustment . . . . . . . . . . . . . . . . . . . . . 24

Printer Access andUsage . . . . . . . . . . . . . . . . . . . . 28

Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Physical Printing Process. . . . . . . . . . . . . . . . . . . . 31

Cleaning The Printer. . . . . . . . . . . . . . . . . . . . . . 33

Cleaning Stationary Card Path Items . . . . . . . . . . . . . 36

Cleaning the Card-Feed Roller. . . . . . . . . . . . . . . . . 37

Cleaning the Upper and Lower Cleaning Rollers. . . . . . . . 38

Print Head Cleaning . . . . . . . . . . . . . . . . . . . . . . 39

Cleaning the Transport and Platen Rollers . . . . . . . . . . . 41

Magnetic Card Stripe Encoder . . . . . . . . . . . . . . . . 45

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Media Loading Orientation . . . . . . . . . . . . . . . . . . 46

Ensuring Data Reliability . . . . . . . . . . . . . . . . . . . 46

Command Conventions . . . . . . . . . . . . . . . . . . . . 46

Setting Coercivity . . . . . . . . . . . . . . . . . . . . . . . 47

Encoding . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

When to Clean the Encoder . . . . . . . . . . . . . . . . . . 49

Cleaning the Encoder . . . . . . . . . . . . . . . . . . . . . 49

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Smart Card Contact Station . . . . . . . . . . . . . . . . . 51

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Media Loading Orientation . . . . . . . . . . . . . . . . . . 52

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Smart Card Chip Interface . . . . . . . . . . . . . . . . . . . 53

Media Jams . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Appendix A Trouble Shooting . . . . . . . . . . . . . . . . 55

980224-001 Rev.C vii

Page 8

Other Support Resources . . . . . . . . . . . . . . . . . . . 58

Parallel Interface Cable Wiring . . . . . . . . . . . . . . . . . 59

Serial Interface Cable Wiring. . . . . . . . . . . . . . . . . . 60

Supported Card Media and Ribbon . . . . . . . . . . . . . . 61

Printer Features and Options . . . . . . . . . . . . . . . 63

Appendix B Supplies and Accessories . . . . . . . . . . . . 67

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Ribbons . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Appendix C Windows Card Printer Driver . . . . . . . . . . 71

Using The Windows Driver . . . . . . . . . . . . . . . . . . 74

Printer Setup. . . . . . . . . . . . . . . . . . . . . . . . . . 75

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Printer Control . . . . . . . . . . . . . . . . . . . . . . . . . 81

Memory Options . . . . . . . . . . . . . . . . . . . . . . . . 82

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

viii 980224-001 Rev.C

Page 9

1

Getting Started

Eltron

Privilege Card

Printers

This section contains information on the installation of Eltron PrivilegeSeries of card printers.

Introduction The Eltron Privilege Series of card printers are

a low cost, high quality printer family specifi

cally designed for printing and encoding of

credit card style plastic cards. The Privilege Se

ries card printers are ideal for personalized

identification, access control, visitor, member

ship, promotion and luggage card, badges and

tags.

-

-

-

980224-001 Rev. C 1

Page 10

Getting Started

Features

300 dots-per-inch print resolution for crisp,

•

clear printing.

Color models use high resolution dye

•

sublimation technology for photo quality

imaging.

Monochrome models use thermal transfer

•

technology.

Over 8 resident bar-code formats and 2

•

printer-resident fonts.

• A 3-Track Magnetic Encoder option that

writes and then read-verifies data. Either

high- or low-coercivity magnetic stripes may

be recorded.

• Magnetic encoder models support printing

and encoding of cardsin a single print cycle.

• Windows™ design and print user software

for both monochrome and color printer

models.

• Windows™ printer control driver that supports True Type fonts is included for color

printer models and monochrome models

with parallel interfaces.

• Compact size in a stylish enclosure.

•

Prints on plain or preprinted plastic materi

-

als of various thickness.

•

A Smart Card Programmer contact station

for programming ISO 7816 contact cards.

•

P400 models allow duplex (dual-sided)

printing in a single print cycle.

2

980224-001 Rev. C

Page 11

Getting Started

P500 and P600 printers are designed to oper

ate in industrial settings. Residential users may

experience TV and/or radio interference. If this

occurs, users must take the corrective steps.

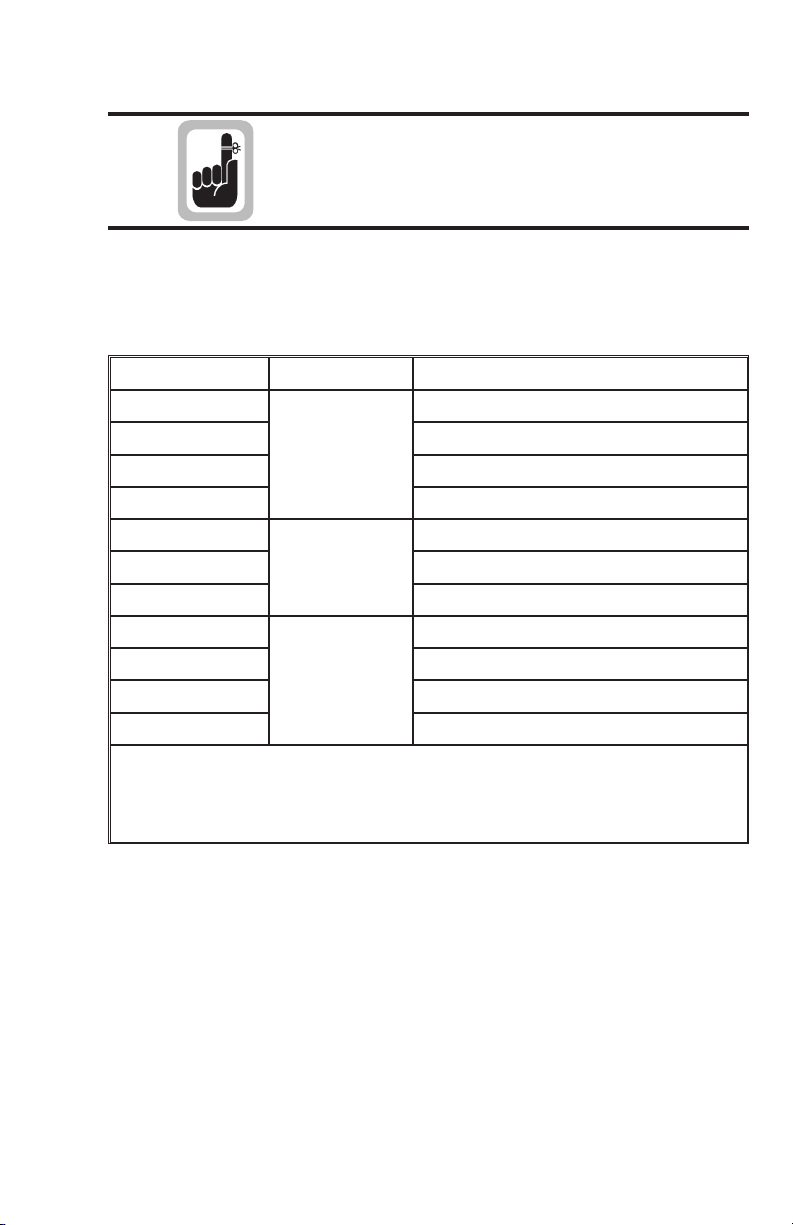

Models All printers have parallel printer ports. Printers

may be ordered in any of the following stan

dard configurations:

Model Description Option

P300CF

P300CML Low Coercivity Magnetic Encoder

P300CMH High Coercivity Magnetic Encoder

Color Dye

Sublimation

P300CE Smart Card Contact Station

P300FML Plus

P300FMH Plus High Coercivity Magnetic Encoder

P300F Plus Parallel Port

Monochrome

Thermal

Transfer

P400CF

Color Dye

P400CML Low Coercivity Magnetic Encoder

P400CMH High Coercivity Magnetic Encoder

Sublimation

with

Duplexer

P400CE Smart Card Contact Station

Note: Printers operated from 120-volt power initially default to High

Coercivity; printers operated from 240-volt power default to Low Co

ercivity. Users can change the default through use or the &C command. See Section 4.

None - Basic Printer Only

Low Coercivity Magnetic Encoder

None - Basic Duplex Printer Only

-

-

-

Options The following options are available:

•

Extended Memory Board- Allows storage of

entire bit map for card.

•

Serial interface suitable for Macintosh™-,

Unix-, and IBM

•

Top-of-Card Magnetic Encoding

980224-001 Rev. C 3

®

-compatible hosts.

Page 12

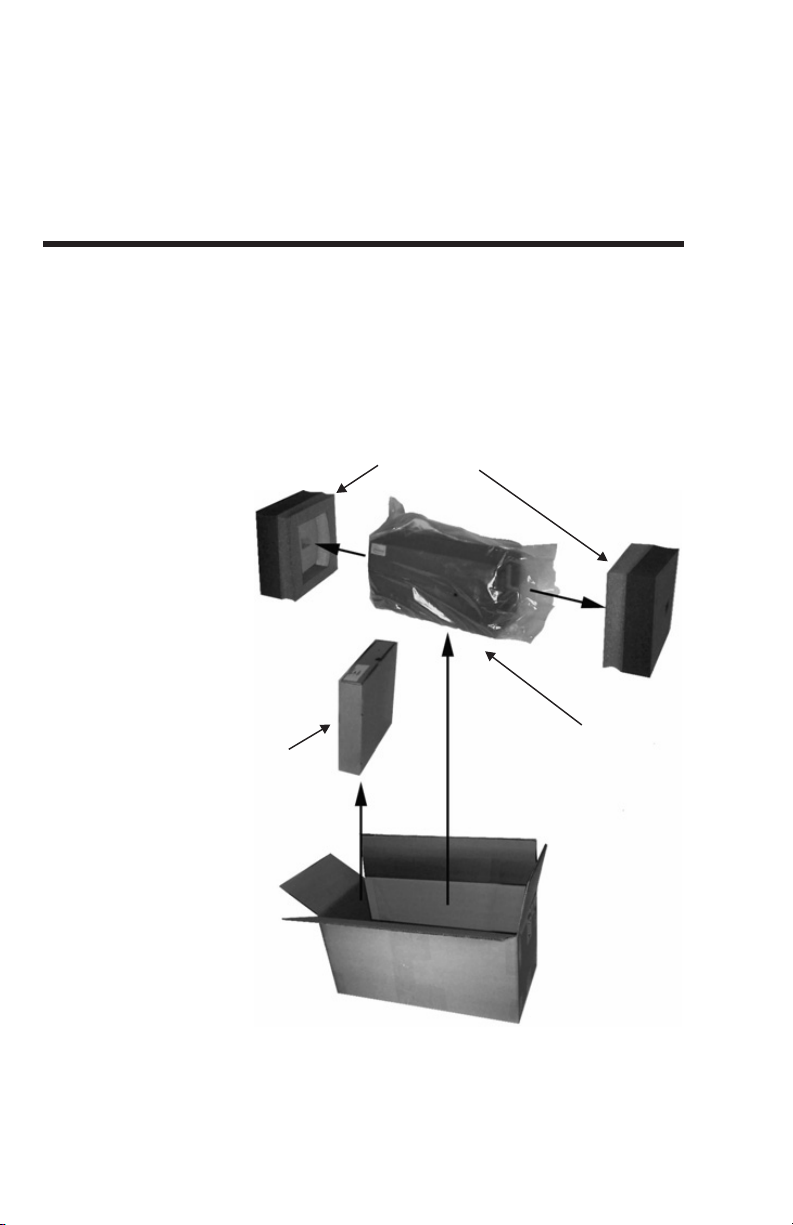

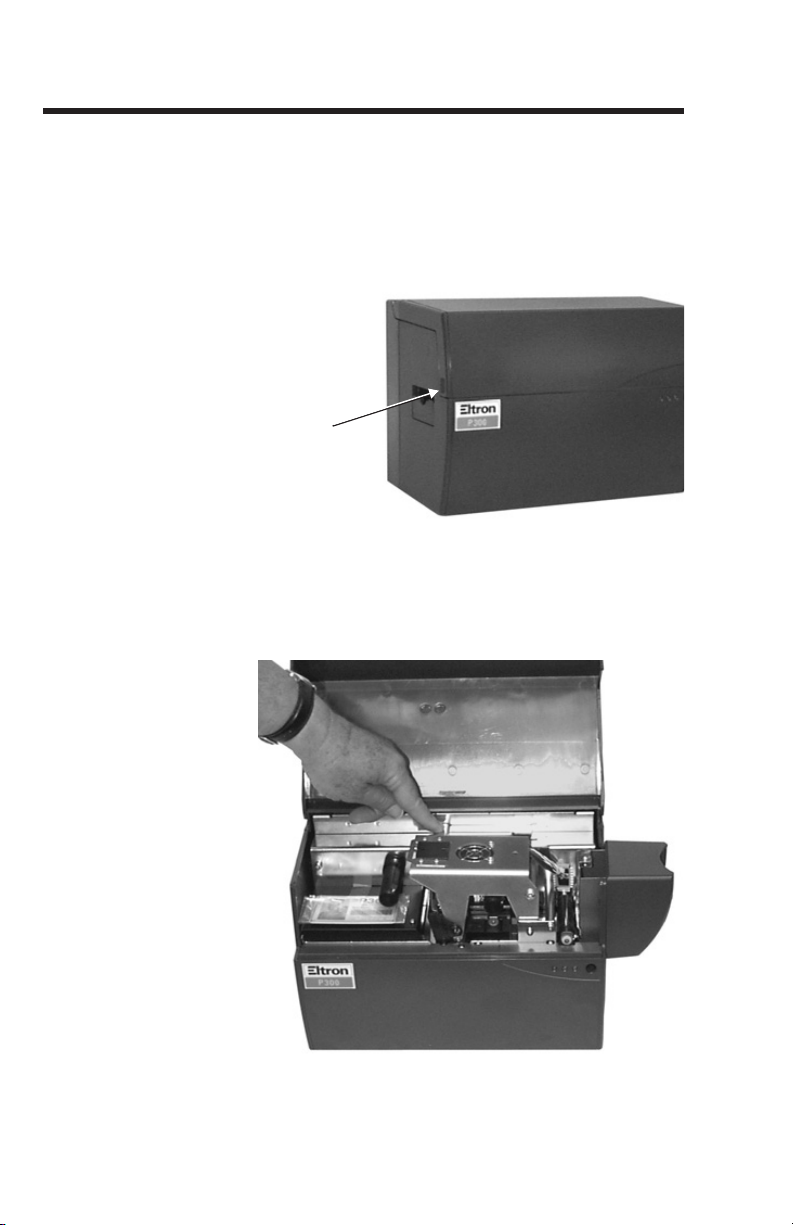

Getting Started

Foam End

Cushons

Printer in

Shipping Bag

Loose Equipment Box:

Printer Cable

Manuals

Card Weight

Software

Accessory Eltron offers a TWAIN-compatible video cap

Unpacking Your

Privilege Card

Printer

Unpacking Your

Privilege Card

Printer

ture system consisting of a video capture card

and video camera. This comprises an ideal

setup for including photos on cards.

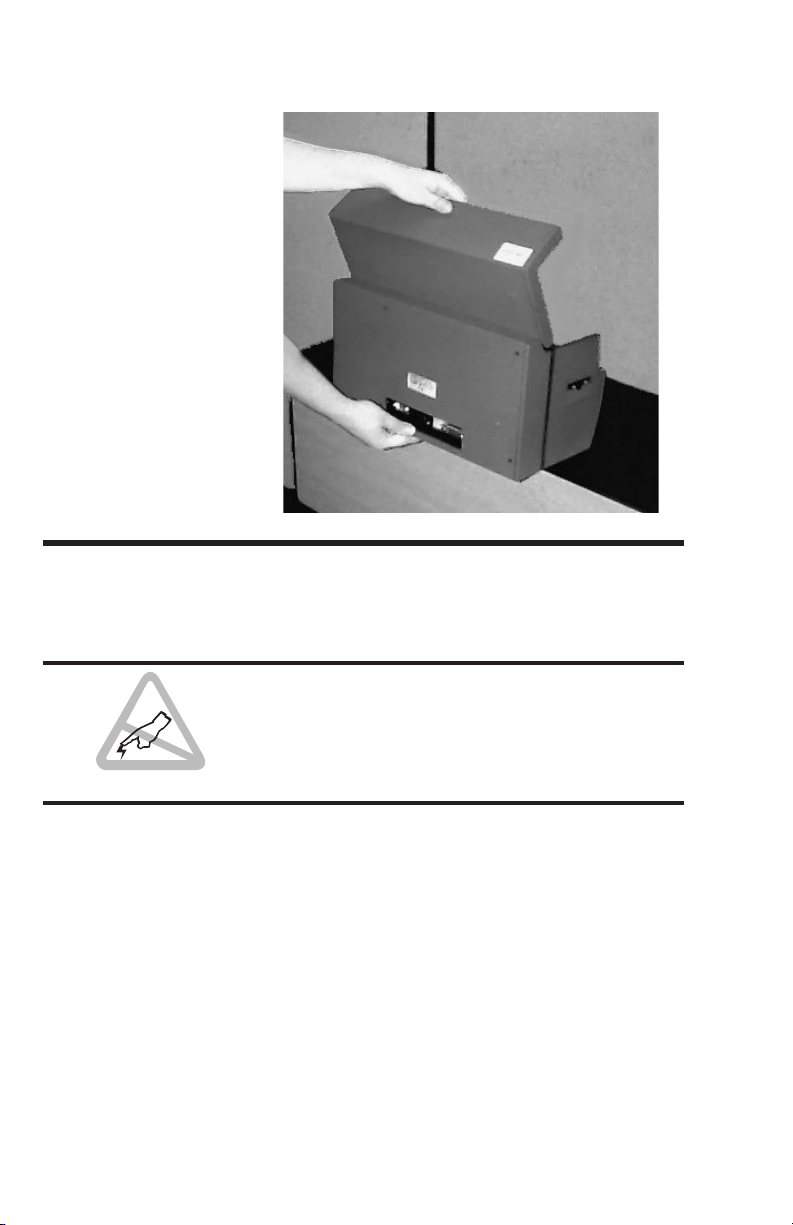

Printers ship in cartons and protective bags.

Keep all packing material in case the need to

move or reship the printer becomes necessary.

Avoid touching the electrical connectors topre

vent electrostatic discharge damage while set

ting up the printer.

Foam End

Cushons

-

-

-

Printer in

Shipping Bag

Loose Equipment Box:

Printer Cable

Manuals

Card Weight

Software

4

980224-001 Rev. C

Page 13

Getting Started

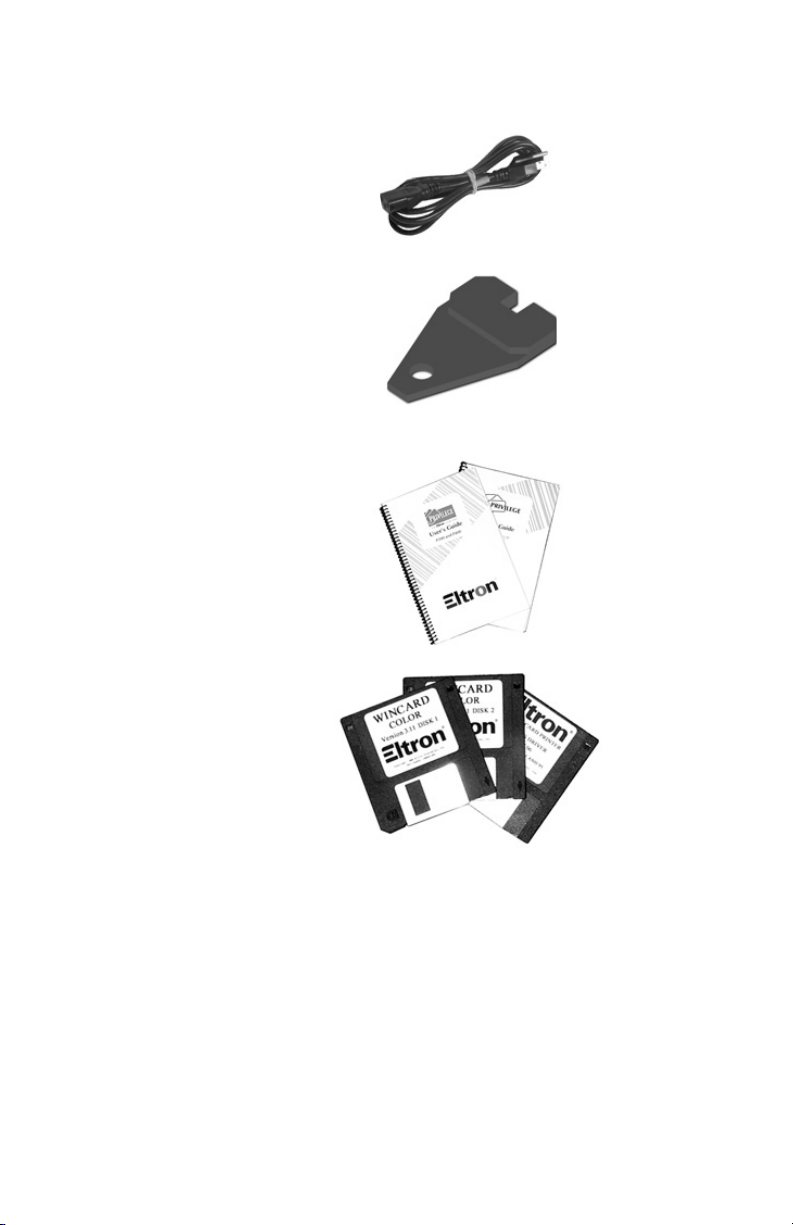

Check List Your Privilege Card Printer kit contains the

Printer (Check for

proper Configura-

tion):

The discharge of electrostatic energy that accu

mulates on the surface of the human body or

other surfaces can damage or destroy the

print head or other electronic components

used in this device.

When unpacking the Privilege card printer

(and card media), be aware that a clean and

nearly dust free environment is required for

proper operation and storage. The print quality

can be effected by dust, body oils and acids

(i.e., finger prints) and exposure to other foreign materials during unpacking or handling of

the printer and media.

items listed below:

-

P300

P400

Interface Cable

980224-001 Rev. C 5

Page 14

Getting Started

Power Cord

Card Feeder Weight

Manuals:

Printer User’s Guide

WindCard™ Software

•

Windows Drivers

6

Software:

WindCard

If any items are missing, contact your dealer for

replacement parts.

Card media, ribbon, and supplies are available

from your Eltron distributor or call ELTRON at

(800) 344-4003 for the distributor nearest

you. Refer to Appendix B for complete supplies

ordering information.

980224-001 Rev. C

Page 15

Getting Started

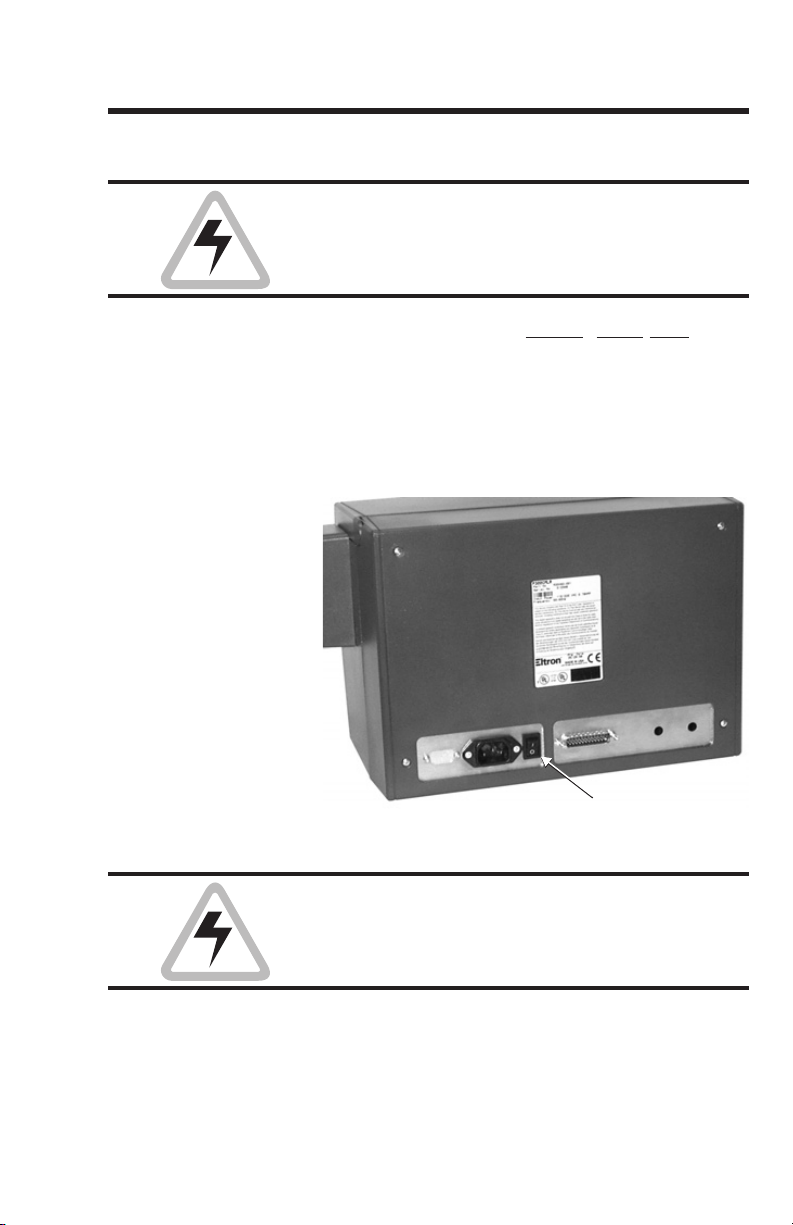

AC Power Switch:

1 = ON

O = OFF

Installation The following sections will guide you through

the installation of the Privilege card printer,

AC power supplied to Privilege card printers

must be current limited to 16-amps or less us

ing an associated circuit breaker or other such

electrical device.

-

Step 1

Attach Power

Figure 1-1

Printer

Rear Panel

Place the printer in a clean, dust free loca

tion that allows easy access to all sides of the

printer. The printer should never be operated

while resting on its side or upside down.

Set the AC power switch to OFF (0).

AC Power Switch:

1 = ON

O = OFF

Never operate the printer in a location where

the operator, computer or printer can get wet.

Personal injury could result.

-

980224-001 Rev. C 7

Page 16

Getting Started

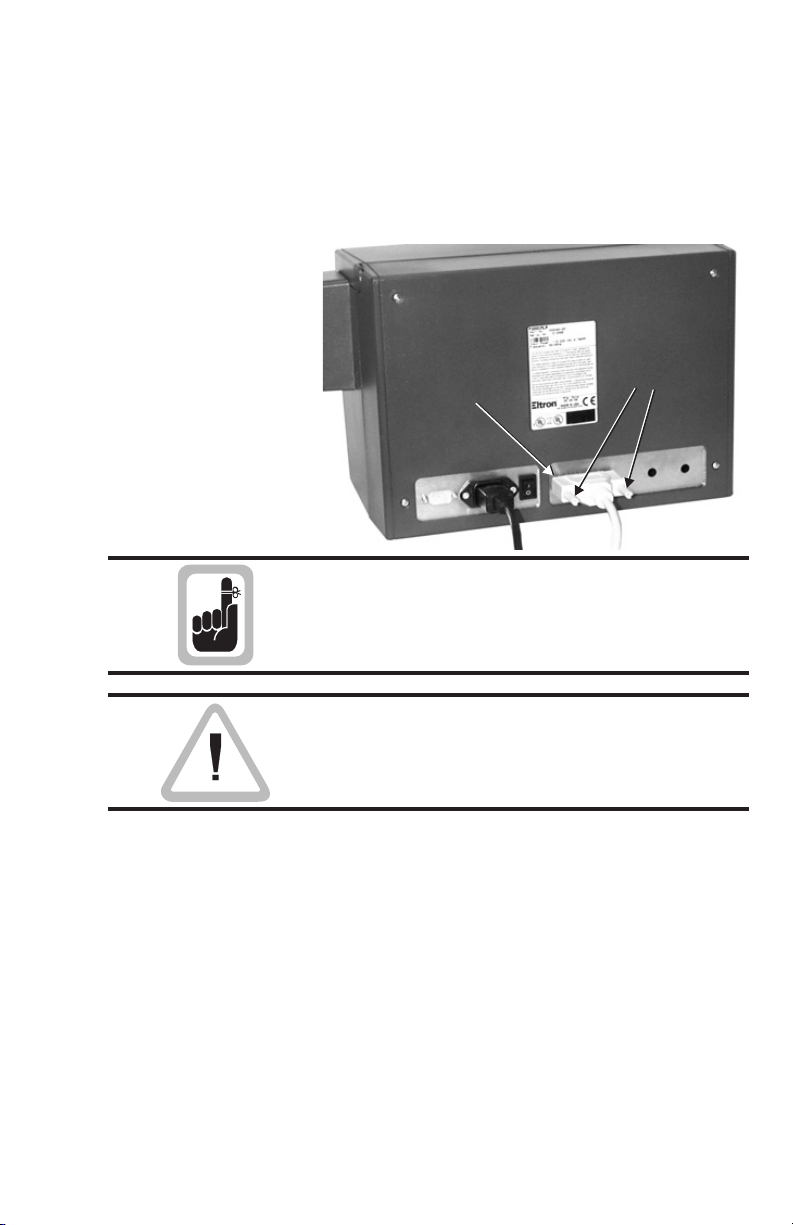

Figure 1-3

Power

Connection

Figure 1-2

AC Outlet

Connection

Attach the AC power cord to the AC power re

ceptacle in the rear of the printer.

Attach the AC power cord to a grounded electrical outlet of theproper voltage and plug type.

-

Attach Interface

8

Step 2

Cable

Parallel Interface

Printers with a parallel interface have a male

DB-25 connector. Attach and secure the sup

plied DB-25 (female) to DB-25 (male) parallel

printer cable from the computer’s parallel port

to the parallel interface connector atthe back of

the printer.

Serial Interface

Printers with a serial interface have a female

DB-25 connector. Attach and secure the serial

printer cable from the computer to the DB-25

980224-001 Rev. C

-

Page 17

Figure 1-4

Interface

Cable

Secure

Connector

Interface

Cable

Secure

Connector

Interface

Cable

Getting Started

RS-232 serial interface connector at theback of

the printer. The printer’s serial interface is com

patible with DB-9-to-DB-25 serial port adapt

ers.

Secure

Secure

Interface

Interface

Cable

Cable

Connector

Connector

Intermittent or unpredictable operation may

occur from unsecured connectors.

-

-

Only use the printer with the interface cable

supplied. An improper cable can prevent operation, produce radio interference, or cause

damage to the printer.

See Appendixes A and B for cable specifica

tions and ordering information.

980224-001 Rev. C 9

-

Page 18

Getting Started

Step

Applying Power

Removing the

Printer Case

When the power switch is moved to the ON (1)

position, the POWER and ERROR Indicators

should flash. The Power (green) Indicator will

remain on and the ERROR Indicators will turn

off. If the indicators fail to flash or if an ERROR

Indicator remains on, then refer to Appendix A

- Trouble Shooting.

Refer to Section 2 - Operation, for information

on loading cards and ribbons into the Privilege

card printer.

See Appendix C for information on loading the

Windows™ Printer Driver.

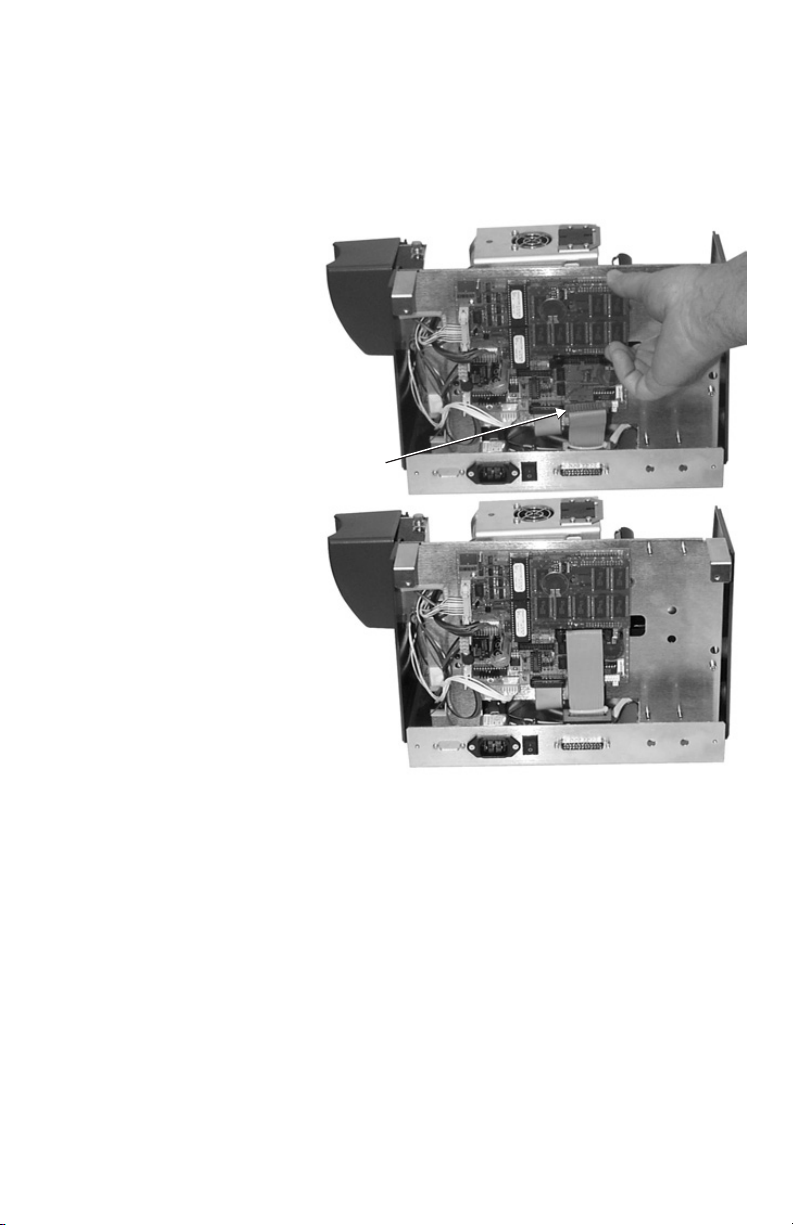

The Extended Memory Board plugs into the

main circuit board of the printer. Access to this

board requires removal of the printer case.

Avoid unnecessary risks! Removal of the

Rear Case of the printer exposes the Main Circuit Board, which contains a lithium battery.

These batteries operatefor long periods of time

and, a replacement may never become necessary. Anyone replacing this battery subjects his

or herself to the following risk:

WARNING:

• A Danger of Explosion exists if the

battery is incorrectly replaced.

• Replace only with the same or

equivalent type recommended by the

manufacturer.

• Dispose of used batteries according

to the manufacturer’s instructions.

10

980224-001 Rev. C

Page 19

Getting Started

Remove

Screws

Case removal exposes circuit points that, if

touched with power on, can present a hazard.

Therefore, never remove any case

component without first unplugging the

Power Cord.

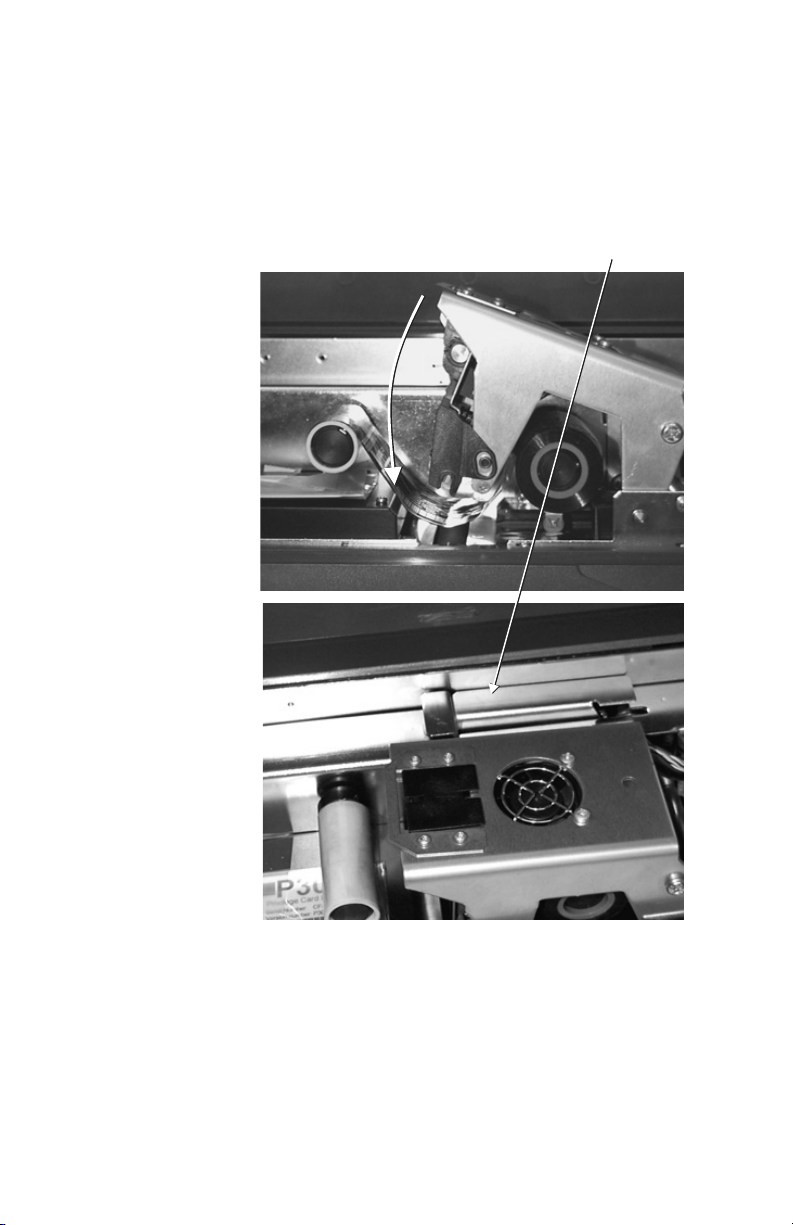

Case Removal

Step

Figure 1-5

Screws Holding

Case

Case Removal

Step

Using a medium sized Phillips screwdriver, re

move the screws that secure the case. P400

printers have five (5) screws, and the other

models have four (4).

Remove

Screws

Rest the printer on a table such that the rear

edge hangs over by about two and one-half

(2-1/2) inches.

Open the lid, and while holding the lid in one

hand and the bottom edge with the other,carefully slide the case off.

-

980224-001 Rev. C 11

Page 20

Getting Started

Case Removal

Figure 1-6

Memory Board

Installation

The addition of a Memory board allows the

host computer to download a complete image

all at once, instead of the panel-by-panel

downloads that occur without this addition.

Before touching any of the circuit components

on either the printer or the Expanded Memory

board, be sure todischarge any static charge by

touching an electrical ground point. If possible

wear a grounding wrist band.

12

980224-001 Rev. C

Page 21

Getting Started

Unplug

Cable First

Installing the

Memory Board

Step

Figure 1-7

Extended Memory

Installation

Unplug the connector centered below the

Memory board. Plugin the Memory Board into

the two connectors on the upper right side of

the main circuit board

Unplug

Cable First

Installing the

Memory Board

Replace the cable and printer case by reversing

the steps performed during their removal.

Step

980224-001 Rev. C 13

Page 22

Getting Started

14 980224-001 Rev. C

Page 23

2

Operation

This section contains information on the operation of the Privilege card printer.

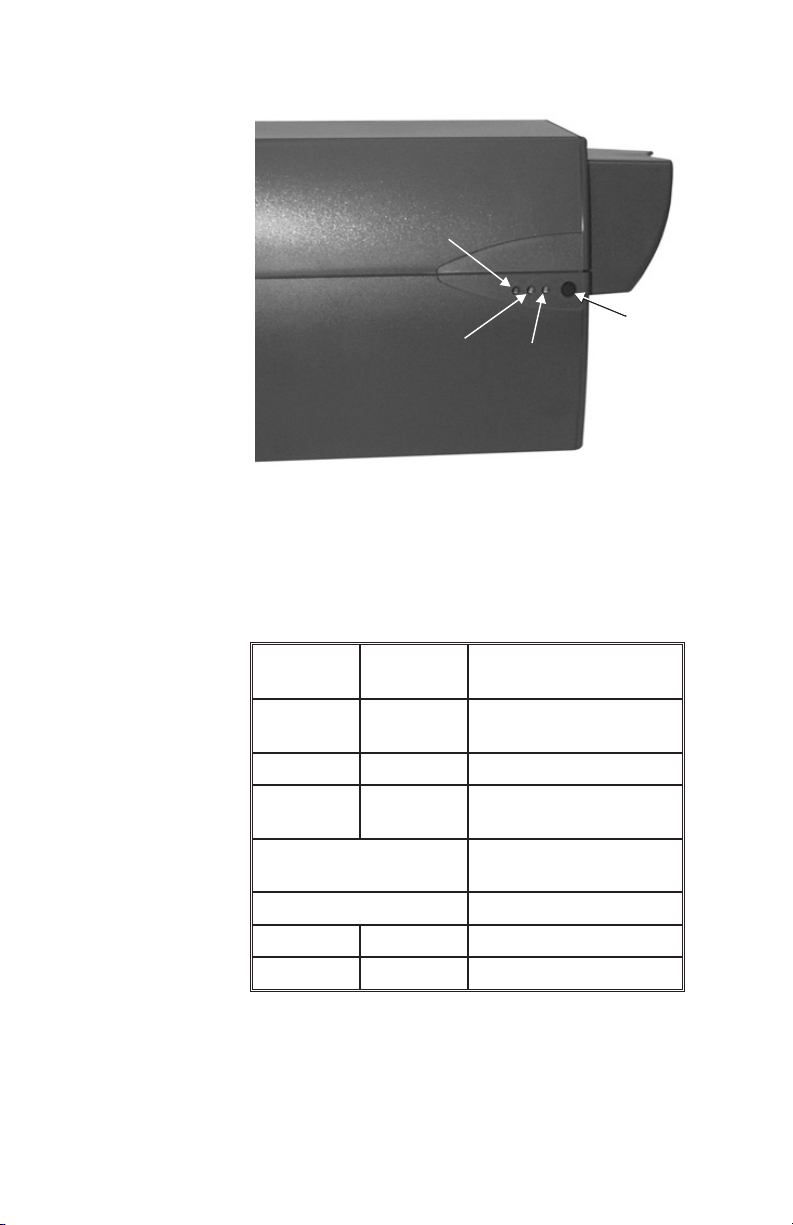

Controls &

Indicators

The POWER

SWITCH

The POWER

Indicator

980224-001 Rev. C 15

All the Privilege card printer controls and indicators, except for the power switch, are located

on the front of the printer. There are three (3)

indicator lights and one control button on the

front panel.

The POWER SWITCH is located on back

panel of the printer. Placing the switch in the

ON (1) position applies power to the printer.

Placing the switch in the OFF (0) position turns

off the printer. See Figures 1-1 and 1-2 in Sec

tion 1.

The POWER SWITCH also works in con

junction with the Panel Button. See the

Panel Button on the following pages.

The POWER indicator light is green when

power is ON. See Figure 2-1.

-

-

Page 24

Operation

Panel

Button

Power

Indicator

Printer Control

and Indicators

Figure 2-1

Power

Indicator

Status B

Status C

Panel

Button

The STATUS

Indicators

The STATUS indicator lights are amber. The

STATUS indicators report data or command

activity, command errors, or hardware faults,

as follows:

Status B

Indicator

ON OFF

Status C

Indicator

Activity or Error

Description

Data in transfer or executing command

Flash OFF Command Code Error

Flash ON

Flashing Together

Encoder Command

Code Error

Print Head too Hot

(Automatic Wait)

Alternate Flashing Cover Open (P400)

OFF ON End of ribbon

ON ON Mechanical Error

See Appendix A for troubleshooting tips.

16

980224-001 Rev. C

Page 25

Operation

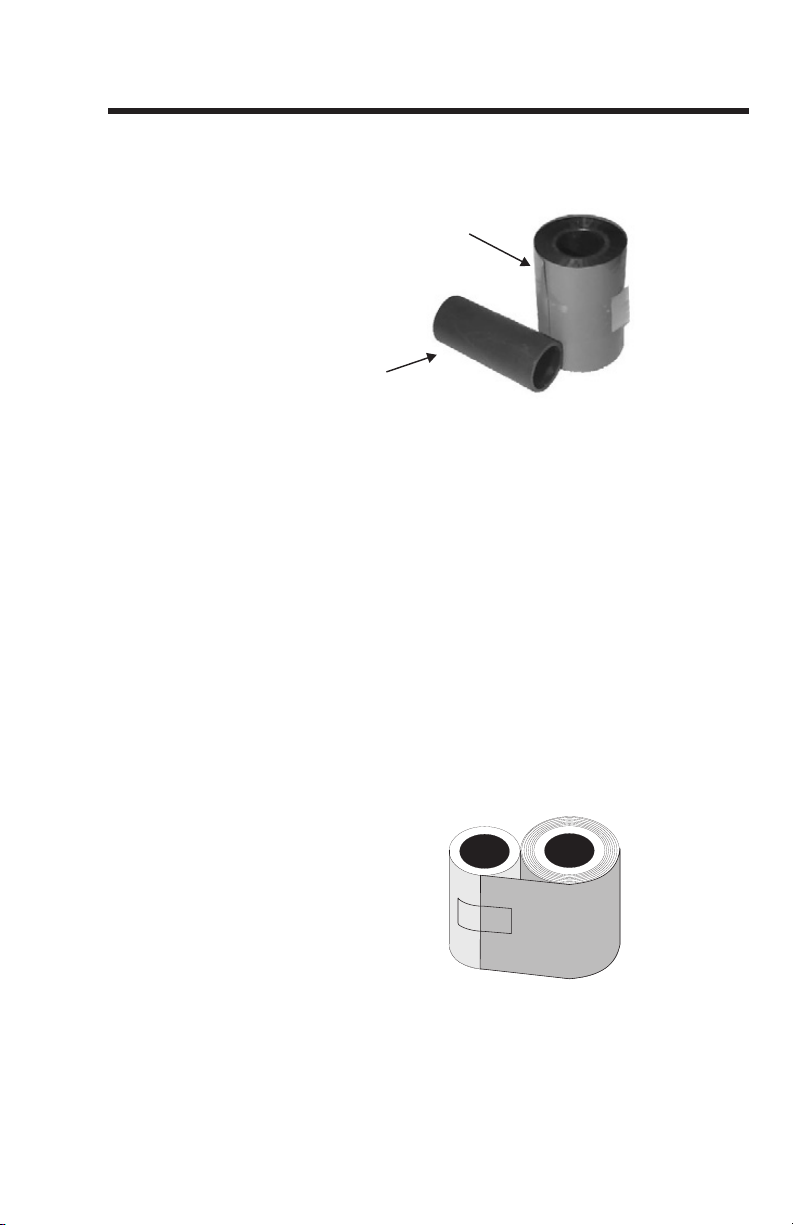

Empty

Core

Ribbon

Preparation

Figure 2-2

Ribbon and

Empty Core

Ribbon

Preparation

Step 1

Ribbon

Preparation

Step 2

Ribbon

Preparation

Step 3

To prepare the ribbon, the taped end must be

fastened to an empty core. Eltron recommends

the following:

Ribbon

Empty

Core

Place both the ribbon and an empty core on

end, next to one another, and touching.

Remove the tape end that fastens the ribbon

end to the roll such that the end with tape attached can be unwound.

Unwind enough ribbon to reach the empty

core and tape the end down. If both the ribbon

roll and the empty core are kept touching during this step, ribbon will be centered on the

core and ribbon take-up will occur without

wrinkling.

Figure 2-3

Ribbon

Preparation

Ribbon

Preparation

Wind one or two turns of ribbon onto the rib

bon core.

Step 4

980224-001 Rev. C 17

-

Page 26

Operation

Lift at

Recess

Ribbon Loading Ribbon loading involves the placement of the

prepared ribbon onto the Supply and Take-up

spindles, as follows:

Ribbon Loading

Step 1

Figure 2-4

Raising the Cover

Ribbon Loading

Step 2

Figure 2-5

Raising the

Print Head

Lift the printer’s access cover open. Hold by

the recessed areas on the sides of the cover.

Lift at

Recess

Press down on the Print Head Release Latch to

open the Print Head Carriage. The Print Head

Carriage will pop open.

18

980224-001 Rev. C

Page 27

Operation

Ta k e U p

Spindle

Supply

Spindle

Supply

Spindle

Ta k e U p

Spindle

Ribbon Path

(CAUTION: Print Head damage can occur if not as shown.)

Ribbon Path

(CAUTION: Print Head damage can occur if not as shown.)

Ribbon Loading

Step 3

Figure 2-6

Ribbon Path

DO NOT TOUCH the Print Head or the elec

tronic components on thePrint Head Carriage.

The discharge of electrostatic energy that accu

mulates on the surface of the human body or

other surfaces can damage or destroy the print

head or electronic components used in this de

vice.

Unroll enough ribbon to span the distance be

tween the Supply and Take Up spindles. Then,

at the same time, slide the Supply and Take Up

Cores onto their respective spindles. Make sure

to push both fully onto the spindles. Also make

sure that the ribbon comes off of the top of the

Supply Spindle and feeds onto the top of the

Take Up Spindle.

Supply

Ta k e U p

Ta k e U p

Spindle

Spindle

Supply

Spindle

Spindle

-

-

-

-

Ribbon Path

Ribbon Path

(CAUTION: Print Head damage can occur if not as shown.)

(CAUTION: Print Head damage can occur if not as shown.)

Take extra care when installing the printer

ribbon. The Print Head may be damaged or

will require an extensive cleaning if the wrong

side of the ribbon is used when printing.

980224-001 Rev. C 19

Page 28

Operation

Press Here to

Latch Down

Print Head

Ribbon Loading

Step 4

Figure 2-7

Latching Down

Print Head

Push the Print Head Carriage down and press

the Print Head Latch Lock down. The latch will

make an audible click when it locks.

Press Here to

Latch Down

Print Head

20

980224-001 Rev. C

Page 29

Operation

Ribbon Loading

Step 5

Handling

the Media

Initialize ribbon after changing or replacing rib

bons and following a mechanical error. To ini

tialize the ribbon for card printing:

Color Printer, Color Ribbon - Press and

hold the Panel Button until the ribbon ad

vances. The ribbon should stop with the print

head between a clear and a yellow panel.

Color Printer, Black Plus Overlay Rib

bon - Press and hold the Panel Button until the

ribbon advances. The ribbon should stop with

an overlay panel centered at the print head.

Color Printer, Monochrome Ribbon -No

initialization required.

Monochrome Printer - Use Monochrome

ribbons only. No initialization required.

The printer and media (cards) require a clean

and nearly dust free environment for proper

operation and storage. The print quality can be

effected by dust, body oils and acids (e.g., finger prints) and other foreign materials encountered during unpacking or handling of the

printer and media.

-

-

-

-

New cards in the media packaging usually

have a high electrostatic charge. This charge

can cause the cards to stick together making

card loading difficult. Some of this adhesive

force can be reduced by shuffling the stack of

cards. Do not over bend the card media or

touch the print surfaces of card.

980224-001 Rev. C 21

Page 30

Operation

Card-Feed

Extender

Card-Feed

Extender

DO NOT set unprinted cards on dust or lint

carrying surfaces, i.e., table tops, cloth, com

puters, etc..

DO NOT place media with the magnetic stripe

near or on magnetic sources, such as: moni

tors, non-electronic phones, paper clip hold

ers, speakers, etc.

-

-

-

Card Gate

Adjustment

Figure 2-8

Extending

Feeder Slide

Two Card Gate Adjustment procedures exist: a

Static procedure and a Dynamic procedure.

Both procedures setup the printer to allow just

one card to feed at a time. If two cards feed, a

card jam results. Repeat one of these procedures whenever switching to a different card

thickness. For both procedures, begin by pulling out the Card-Feed Tray Extender. This produces the proper angle for card feeds.

Card-Feed

Card-Feed

Extender

Extender

22

Prevent Media Jams!

Adjusting the Card Feeder is critical for proper

mechanical operation of the printer.

980224-001 Rev. C

Page 31

Operation

Card-Gate

Adjust Knob

Gate

Opening

Static Card Gate

Adjustment /

Media Loading

Step 1

Figure 2-9

Card Gate

Adjustment

Gate

Opening

Place a single card into the Card Feeder. Adjust

the Card Gate to allow the single card through

the gate. Turn the screw counterclockwise to

lower the gate andclockwise to raise the gate.

Slide the card out of the Card Gate and place

the Card Weight on top of the card. Verify that

the card still passes through the gate.

Card-Gate

Adjust Knob

Weight

Card

980224-001 Rev. C 23

Page 32

Operation

Static Card Gate

Adjustment /

Media Loading

Step 2

Figure 2-10

Card Gate

Adjustment

Place two or more cards (with the Card

Weight) into the Feeder.Push the bottom cards

in the stack into the feeder gate. Verify that the

second card in the stack cannot slide through

the gate.

24

Weight

980224-001 Rev. C

Page 33

Operation

Dynamic Card

Gate Adjustment /

Media Loading

Step 1

Figure 2-11

Checking the

Card-Gate

Opening

Correct

To adjust the card gate dynamically, begin by

completely closing the card gate, and placing

several cards of the desired thickness in the in

put tray, topped with the card weight. Turn the

screw counterclockwise to lower the gate and

clockwise to raise the gate.

-

Incorrect

980224-001 Rev. C 25

Page 34

Operation

Dynamic Card

Gate Adjustment /

Media Loading

Step 2

Issue a Card Feed Command (with no print

ing), and gradually raise the Card Gate until

just one card feeds. Each Card Feed command

produces about a five (5) second attempt.

When a card fails to feed within this time-out

period, another Card Feed command be

comes necessary. Make sure to double check

the setting, making sure only one card feeds at

a time. Otherwise media jams can occur.

Card Feed commands can be issued as fol

lows:

From the Windows Driver (See Appendix C),

type:

ME <CR>

From WindCard (See WindCard manual), Select Printer Tools. In the Printer Tools dialog

box Enter:

ME <CR>

After reaching the point where one card feeds,

add a quarter turn clockwise to assure that the

cards feed freely.

-

-

-

26

Printer

Access and

Usage

The Privilege card printer requires at least three

(3) inches of free space around all sides for ac

cess to printer controls, card input and card

output.

980224-001 Rev. C

-

Page 35

Operation

Tray Pulled Out

and Tipped Down

Do Not Operate Printer with Cover

Open.

Do Not Close Output Tray With Cards

Present.

To maintain a clean printing environment and

to prevent ESD damage, keep the cover of the

printer closed except during maintenance and

ribbon loading procedures. Some models have

an interlock that prevents print cycles with the

cover open.

With a fixed amount of space available, the

maximum number of cards the Output Tray

can hold varies as a function of card thickness.

The Output Tray can hold up to 20 of the 30mil (0.762 mm) cards, 45 of the 20-mil (0.508

mm) cards, and 90 of the 10-mil (0.254 mm)

cards. After the tray fills, cards begin spilling

onto the surface below the tray. Spilling onto

this surface also occurs with the printer operated with the Output Tray pushed in. For high

volume printing, operation with the tray

pushed in may be preferred.

Figure 2-12

Card Output

Tray

Tray Pulled Out

and Tipped Down

980224-001 Rev. C 27

Page 36

Operation

Printing When the ribbon and card media are loaded as

per the procedures previously described, and

the printer power is on, the Privilege card

printer is ready to print.

Printing requires the WindCard™software, (a

Windows™ software program),the Windows™

printer driver or direct printer command level

programming through the printer interface.

Printing a Test

Card

Figure 2-13

Color Printer

Test Card

Figure 2-14

Monochrome

Printer Test Card

The printer will print a Test Card if the

Panel Button is pressed and held in while

printer power is turned on. The Panel Button

can be released after the STATUS C indicator

turns off. Remember to synchronize the ribbon

for any color printing.

28

980224-001 Rev. C

Page 37

Operation

Adjustments The Privilege card printers have no user adjust

able features except for the card gate adjust

ment, see preceding pages.

Protect Your Factory Warranty!

Neglect in performing recommended cleaning

procedures can void your warranty, as can im

proper packaging and shipping.

Other than the recommended cleaning proce

dures described in this manual, only allow

Eltron factory authorized technicians to service

Privilege printers.

NEVER loosen, tighten, adjust, bend, etc. any

part or cable inside the printer.

The only user adjustable features of the Privilege card printers are made in software (or programming) and the card feeder gate

adjustment.

Physical Printing

Process

A sensor signals when the feeder roller feeds a

card into the drive system. Cleaning Rollers remove dust or lint, and drive rollers accurately

move the card under the print head. The print

head carriage physically moves down to the

surface of the card for printing. Printing occurs

with ribbon movement and card movement

synchronized. The card ejects at the end of a

print cycle.

-

-

-

-

Monochrome

Printing

The print operation is as described above. The

thermal transfer ribbon is advanced as the card

is advanced.

980224-001 Rev. C 29

Page 38

Operation

Color Dye

Sublimation

The color print process involves multiple

passes of the card under the print head. Each

pass of the card prints/bonds a different color

or material onto the card. The position of the

card is accurately controlled with the drive and

platen rollers under the card. For printers with

out Extended Memory, the typical print se

quence for CYMK with Overlay Ribbon

proceeds as follows:

Printer ribbon synchronizesto the yellow (Y)

•

ribbon panel prior to printing. If not, press

the RESET button to re-synchronize.

• Card from Input Tray feeds into printer.

• Data for Yellow (Y) panel downloads.

• Yellow Printing occurs.

• Card moves back, and ribbon advances to

next panel.

• Download, print, return card, and synchronize steps occur for ribbon panels Magenta

(M), Cyan (C), Black (Dye or Resin) and

Overlay. For duplex (two-sided) card printing (P400 Models), cards move back to the

card-flip before returning again to the print

head. Cards printed on both sides always

eject with the sideinitially printed facing up.

-

-

30

•

Card ejects.

980224-001 Rev. C

Page 39

Operation

Cleaning The

Printer

Quality card images require a clean, dust- and

lint-free printer. Any particles left on the

mechanisms in the card path can migrate onto

cards and interfere with both YMC dye

sublimination and resin thermal transfer.

These ribbon materials cannot penetrate any

particles left on the cards. The need for clean

ing varies, depending upon print environment

and usage.

Never use a shop air compressor to blow

away particles in the printer. Air compres-

sors can contain rust-inhibiting oil and may

have ineffective moisture traps. Oil and moisture adversely affect print quality, and when

sprayed, may spread contaminates throughout

the printer.

Also canned air requires a very careful usage.

Avoid directing an air stream in a way that

distributes particles from areas having a significant particle contamination.

Any vacuum used must have its outflow well filtered and directed away from the printer.

Never attempt to vacuum particles off of the

Print Head, as damage to delicate imaging elements can result.

-

980224-001 Rev. C 31

Page 40

Operation

Bend to Break

and Release Fluid

Eltron offers the following items for cleaning

the printer:

Disposable, Clean Non-fibrous (foam)

•

swabs with alcohol filled handle for head

cleaning and suitable for roller cleaning

An alcohol filled, felt pen suitable for roller

•

cleaning

Bend to Break

and Release Fluid

• A Cleaning Kit comprised of a spray can of

alcohol and a package of cleaningcards suitable for a general cleaning but required for

Magnetic Encoder head cleaning.

32

Cleaning products for the Privilege card printer

are available directly from your Eltron distribu

tor or call Eltron at (800) 344-4003 for the

distributor nearest you.

980224-001 Rev. C

-

Page 41

Operation

Alternate cleaning materials can include the

following:

Foam swabs (never use cotton or any other

•

fibrous material.)

99% pure or better Isopropyl Alcohol for

•

moistening swabs

Clean Running Water (Used for Upper

•

Cleaning Roller only).

Card Path

Elements

Figure 2-15

Media Path

Figure 2-15 shows the elements in the card

path that require a periodic cleaning. Procedures follow for the following items:

• Card Guides, Smart Card contacts, and Encoder Read-Write heads.

• Card Feed Roller

• Cleaning Rollers

• Print Head

• Transport and Platen Rollers

Card

Path

Card Feed

Card-Flip

Assembly

Roller

Cleaning

Rollers

Shroud

Ribbon

Take Up

Transport

Rollers

Print Head

Up/Down Cam

P300

Print Head

Magnetic

Encoder

(Option)

980224-001 Rev. C 33

Platen

Roller

Smart

Card

Station

(Option)

P400

Cleaning

Rollers

Card

Feed

Roller

Card-

Flip

Pulley

Page 42

Operation

When To Clean Cleaning frequency varies with different envi

ronments. Typically, a cleaning that follows

ribbon depletion will keep the card printer op

erating properly. If not, consider either another

printer location or a more frequent cleaning.

Cleaning

Stationary Card

Path Items

Using the

Cleaning Kit

Step 1

Using the

Cleaning Kit

Items in the card path that cannot be reached

directly require a cleaning using the alcoholmoistened cards of the Cleaning Kit. Encoder

Read-Write heads require thiskind of cleaning.

Remove the ribbon from both the Supply and

Take Up spindles. See Ribbon Loading in this

section.

Moisten a Cleaning Card by spraying with alcohol. Do Not soak.

Step 2

Using the

Cleaning Kit

Step 3

Place the moistened Cleaning Card in the Input Tray, topped with the card weight. If necessary, adjust the Card Gate for the card

thickness. (Since this procedure calls for only

one card, you can open the gate as much as

you like.)

-

-

34

Using the

Cleaning Kit

Step 4

Send the Cleaning Card through the printer

several times without enabling printing. De

pending on the setup,use one of the following:

Where:

= Space

↵ = Enter

Entry is either via WindCard™ (see manual) or

The Windows Driver (see Appendix C).

980224-001 Rev. C

-

Page 43

For P300:

M5!S[MM2200[MB

For P400:

M5!S[MM2200[!Z[MM20001

Also for single-pass card feed

ME↵

Operation

Cleaning the

Card-Feed Roller

Cleaning the

Feeder Roller

Step 1

Cleaning the

Feeder Roller

Step 2

Figure 2-16

Card-Feed Roller

Only the Card-Feed Roller resides outside the

printer case. A stack of clean cards and/or the

Card Weight should say in the Input Tray as a

defense from airborne particles. If left uncovered for any extended period, a preprint cleaning should occur.

Remove any cards from the printer’s feeder.

Clean the roller using a Swab or Cleaning Pen.

To gain access to initially unexposed areas, cycle the roller by applying the printer power

while holding the Panel Button on for three (3)

seconds (see Test Card sequence in Controls

and Indicators, Section 2.) Let the roller air dry

for two (2) or more minutes.

980224-001 Rev. C 35

Page 44

Operation

Upper

Cleaning

Roller

Spring

Clip

Cleaning the

Upper and Lower

Cleaning Rollers

Cleaning the

Cleaning Rollers

Step 1

Figure 2-17

Upper Cleaning

Roller

Upper

Cleaning

Roller

Spring

Clip

These rollers pick up cards fed from the Input

Tray. The upper roller has a coating that col

lects any loose particleson the surface of cards.

Remove any cards from the printer. Open the

printer cover. Remove the Upper Cleaning

Roller. Gently pull the Spring Tab out to free

the Upper Cleaning Roller pin. Then, remove

the Upper Cleaning Roller.

-

Cleaning the

Cleaning Rollers

Step 2

Cleaning the

Cleaning Rollers

Step 3

36

Clean the Upper Cleaning roller with running

water. Then allow the roller to air dry without

resting the rubberized part on a surface.

Use a swab or cleaning pen on the Lower

Cleaning Roller. Cycle the rollers by applying

the printer power while holding the Panel But

ton on for three (3) seconds to expose initially

unexposed areas. This is the Test Card se

quence described in Controls and Indicators,

Section 2.

980224-001 Rev. C

-

-

Page 45

Figure 2-18

Lower Cleaning

Roller

Operation

Cleaning the

Cleaning Rollers

Step 4

Print Head

Cleaning

Reinstall the Upper Cleaning Roller. First slide

the shaft pin into the hole in the chassis opposite the Spring Tab.

DO NOT

touch the roller surface that contacts

the media.

Snap the opposite shaft pin of theroller intothe

hole on the Spring Tab.

Without touching the body of the roller, make

sure the roller locks in place. To avoid contamination, always hold the roller by the metal

ends.

During printing, the ribbon isolates the Print

Head from the cards. Therefore, the ribbon has

the greatest influence on Print Head contami

nation. An improperly installed ribbon, with

the dye and resin deposits facing the Print

Head can cause permanent damage. No

amount of cleaning can remove dye or resin

fused onto the delicate Print Head elements.

-

980224-001 Rev. C 37

Page 46

Operation

Print Head

Cleaning

Step 1

Print Head

Cleaning

Step 2

Figure 2-19

Cleaning

Print Head

Turn the printer power OFF. Open the cover.

Open the print head Carriage and Remove the

Ribbon and Ribbon Core. See Ribbon Load

ing, in this Section.

The print head should only be cleaned with a

solution of 99% pure Isopropyl Alcohol and a

clean non-fibrous (foam) swab.

Avoid touching the Print Head elements. The

release of Static charges can damage the Print

Head elements and Internal circuits.

Gently rub the alcohol-moistened swab across

the print head from the front to the back of the

printer. Do Not Soak the Print Head.

-

38

Allow the printhead to dry for 2 minutes before

reloading the ribbon and core.

Initiate a Test Card sequence. See Printing a

Test Card is this section.

980224-001 Rev. C

Page 47

Operation

Shroud

Fasteners

Cleaning the

Transport and

Platen Rollers

Cleaning Platen

and Transport

Rollers

Step 1

Cleaning Platen

and Transport

Rollers

Step 2

Figure 2-20

Encoder Shroud

Shroud

Fasteners

Along with the Cleaning Rollers, these rollers

move the cards between the Input and Out

put Trays. Except for the Platen, these rollers

operate in pairs—a lower drive roller and an

upper pinch roller to hold the cards against

the drive roller.

Open the Cover, unlatch and raise the Print

Head, and remove any ribbon. Note that all

are described in previous parts of this section.

Remove the Shroud that covers the area that

has the Magnetic Stripe Encoder in printers so

equipped. Note that two self-tapping screws

hold the Shroud in place.

-

In the following steps, cycle the rollers to

reach initially unexposed areas by applying

the printer power while holding the Panel

Button pressed for three (3) seconds. This is

the Test Card sequence described in Controls

and Indicators in this section.

980224-001 Rev. C 39

Page 48

Operation

Encoder

Rollers

Encoder

Rollers

In the following steps, avoid touching the Print

Head. A static discharge can damage delicate

Print Head elements aswell as internal circuits.

Cleaning Platen

and Transport

Rollers

Step

Figure 2-21

Encoder Transport

Rollers

Cleaning Platen

and Transport

Rollers

Step

Using an alcohol-moistened Swab or a Felt

Pen, clean the two sets of rollers exposed with

removal of the Shroud

Encoder

Encoder

Rollers

Rollers

Using an alcohol-moistened Swab, clean the

Platen Roller.

40

980224-001 Rev. C

Page 49

Figure 2-22

Print

Station

Rollers

Platen Roller

Operation

Cleaning Platen

and Transport

Rollers

Step

Figure 2-23

Print Station Rollers

Print

Station

Rollers

Using an alcohol-moistened Swab, clean the

roller pair under the Print Head Cage

980224-001 Rev. C 41

Page 50

Operation

Card-Flip

Rollers

Cleaning Platen

and Transport

Rollers

Step

Figure 2-24

Card-Flip Rollers

Card-Flip

Rollers

Cleaning Platen

and Transport

Rollers

Step

Using an Alcohol-moistened Swab, clean the

Card-Flip Rollers (P400s only).

Replace Encoder Shroud (see Step 2), install,

Ribbon, place cards in the Input Tray, and print

some Test Cards. Inspect the cards for Print

Anomalies. If Anomalies appear, refer to Appendix A, Troubleshooting.

42

980224-001 Rev. C

Page 51

3

Magnetic Card Stripe Encoder

This section includes information on the additional operation and maintenance requirements of a Privilege Series card printer

equipped with the Magnetic Card Stripe Encoder option. Users can set these models to

record on either low- or high-coercivity magnetic card stripes. Printers that operate from

120-volt power default to a high coercivity setting; printers that operate from 240-volt power

default to low coercivity.

Introduction Privilege card printer models designated as ei-

ther ML or MH (e.g., P300FML and

P400CMH) have a magnetic stripe encoder

built into the printer. The general operation of

a printer with the encoder optionis nearly iden

tical to standard model printers.

-

Only use cards with flush magnetic stripes.

Never use pasted-on stripes.

980224-001 Rev. C 43

Page 52

Magnetic Card Stripe Encoder

Up-Facing Stripe

(Models with R Suffix)

Down-Facing Stripe

(Models without R Suffix)

Media Loading

Orientation

Figure 3-1

Magnetic Stripe

Position

Most Privilege printers with Magnetic Encoders

have their read/write heads positioned below

the path traveled by the cards. For these print

ers, load the media (cards) with the magnetic

stripe facing down and closest to the rear of the

printer. However, Eltron also supplies printers

with read/write head positioned above the

path traveled by the cards. For these printers,

load the cards with the magnetic stripe facing

up and closest to the rear of the printer.

Up-Facing Stripe

(Models with R Suffix)

Down-Facing Stripe

(Models without R Suffix)

-

Ensuring Data

Reliability

Conventions

44

Command

A read verify pass is always performed on all

encoded cards to guarantee data integrity.

Either Software (WindCard™) or command

programming controls the Write and Readverify data processes.

= Escape

= Space

↵ = Return

980224-001 Rev. C

Page 53

Magnetic Card Stripe Encoder

Setting Coercivity Using WindCard (see manual) or the Windows

Driver (see Appendix C), send the following

command:

&Cp1↵

where:

p1 = 0 for Low Coercivity

p1 = 1 for High Coercivity

Encoding Privilege Printers with Magnetic Encoders can

encode all three magnetic stripe tracks simultaneously. Encoders also support nonstandard

track densities and bits per track. After setting

read/write parameters, downloads to track

buffers occurs, as follows:

&Btrack#data↵

Initiation of simultaneous three-track magnetic

stripe encoding then occurs, as follows:

&E*↵

To order a manual describing all the commands, see Appendix B.

The following shows three examples that enter

data. initiate encoding, and set up read/write

parameters that can be sent from either the

Windows™ driver or directly using DOS (e.g.,

COPY file name LPT1) orvia aText Editor and

its Print facility (withPrivilege Driver selected):

980224-001 Rev. C 45

Page 54

Magnetic Card Stripe Encoder

Example 1. Download Data and Encode Card:

Direct Control Windows Driver

&B1JOHN DOE↵ ~C0&B 1 JOHN DOE

&B2555-46-5389↵ ~C0&B 2 555 46 5389

&B34789↵ ~C0&B 3 4789

&E*↵ ~C0&E*

Example 2. Set Read/Write Parameters, Enter Data, Encode

Stripe, and Eject:

Command Result

&D175↵ Sets track-1 density to 75 bpi

&D375↵ Sets track-3 density to 75 bpi

&CDEW1a3↵ Sets to encode track 1 with 3-bit

&CDER1q3↵ Sets to read 3-bit characters on

&B112345↵ Enters 12345 in track-1 buffer

&B254321↵ Enters 54321 in track-2 buffer

&B309876↵ Enters 09876 in track-3 buffer

&E*↵ Encodes three tracks using

ME↵ Ejects card from printer

characters

track 1

buffer data, and positions card

for printing

Example 3. Reset to ANSI/ISO:

Command Result

&CDEW1A↵ Resets track-1 encodes to

&CDER1Q↵ Resets track-1 reads for

&CDEW2B↵ Resets track-2 encodes to

&CDER2R↵ Resets track-2 reads for

&CDEW3C↵ Resets track-3 encodes to

&CDER3S↵ Resets track-3 reads for

ANSI/ISO std.

ANSI/ISO std.

ANSI/ISO std.

ANSI/ISO std.

ANSI/ISO std.

ANSI/ISO std.

46 980224-001 Rev. C

Page 55

Magnetic Card Stripe Encoder

When to Clean

the Encoder

Cleaning the

Encoder

The Read/Write Head and drive rollers of the

Encoder require a periodic cleaning to main

tain error-free encoding.

The encoder should be cleaned when:

A “General Cleaning” is performed on the

•

printer.

The printer’s Drive Rollers are cleaned.

•

• Write and Read verify process has failed on

more than one card. See Appendix A, Trou

ble Shooting.

Turn OFF printer power.

Remove all card media and both the Supply

and Take Up spools from the respective ribbon

spindles.

Use the Cleaning Kit procedure described in

Section 2.

-

-

Adjustments Privilege card printers with Magnetic Card

Stripe Encoders have no related user adjustments.

980224-001 Rev. C 47

Page 56

Magnetic Card Stripe Encoder

Protect Your Factory Warranty!

Neglect in performing recommended cleaning

procedures can void your warranty.

Other than the recommended cleaning proce

dures described in this manual, only allow El

tron factory authorized technicians to service

Privilege printers

NEVER loosen, tighten, adjust, bend, etc. any

part or cable inside of the printer.

The only user adjustable features of the Privilege card printers are made in software (or programming) and the card feeder gate

adjustment.

-

-

48

980224-001 Rev. C

Page 57

4

Smart Card Contact Station

This section contains information on the additional operations of Eltron Privilege Series card

printers with Smart Card contact stations.

Introduction Smart Cards can have a built-in microcom-

puter and a battery. Card Memory can store

fingerprints, voice recognition patterns,

medical records and other such data. Model

P300CE and P400CE printers have contact

stations for programming Smart Cards

(ISO7816). These printer models respond to

commands that position the cards at a contact

station, where the printer connects to the con

tacts on Smart Cards as follows:

Command Result

MS

OS value

All other printer operations remain the same as

those for other Privilege models.

Moves card to Contact

Station

introduces offset of

value dots from Sta

tion default (96)

-

-

980224-001 Rev. C 49

Page 58

Smart Card Contact Station

Up-Facing Chip

Contacts

Do not position printing over Smart Card con

tacts.

Media Loading

Orientation

Orient the media (cards) with the Smart Card

Chip on the top of the card and such that the

edge closest to the contacts feeds first.

Figure 4-1

Up-Facing Chip

Card Contact

Position

Contacts

Adjustments No adjustments exist for Privilege printers with

Smart Card programming stations other than

the Card Feeder Gate Adjustment described in

section 2.

-

50

980224-001 Rev. C

Page 59

Smart Card Contact Station

Smart Card

Contact

Interface

Host Computer

Interface

Smart Card

Contact

Interface

Host Computer

Interface

Protect Your Factory Warranty!

Neglect in performing recommended cleaning

procedures can void your warranty, as can im

proper packaging and shipping.

-

Smart Card

Chip Interface

Other than the recommended cleaning proce

dures described in this manual, only allow

Eltron factory authorized technicians to service

Privilege printers.

NEVER loosen, tighten, adjust, bend, etc. any

part or cable inside of the printer.

The only user adjustable features of the Privilege card printers are made in software (or programming) and the card feeder gate

adjustment (see Section 2).

When a command to the parallel printer interface sends a card to the Smart Card Programming station, the printer connects the Smart

Card Chip contacts to the female DB-9 connector on the rear of the printer. An attached

external Smart Card Programmer uses the

DB-9 as an interface to Smart Card chip connections.

-

Figure 4-2

Host Computer

Host Computer

Smart Card

Smart Card

Smart Card

Contacts Interface

980224-001 Rev. C 51

Contact

Contact

Interface

Interface

Interface

Interface

Page 60

Smart Card Contact Station

DB-9 Pins

Smart Card

Contact Points

1 C1 (Vcc)

2 C2 (Reset)

3

C3 (Clock)

4 C4 (RFU)

5 C5 (GND)

6 C6 (Vpp)

7 C7 (I/O)

8 C8 (RFU)

9

(GND when chip is at sta-

tion)

Media Jams Always remove the bottom card of a two-card

jam first. Never pull the top card out of the

printer. Instead, sequence the printer power

with only the top card remaining (the last card

to enter the print path). Remove all other cards

from the path and card feeder.

Damage may occur to the contactsat the Smart

Card chip programmer station if the top (last)

card is not ejected by the printer.

52

980224-001 Rev. C

Page 61

Common Printing

Problems Trouble

Shooting Guide

Problem Solution or Reason

Appendix A

Trouble Shooting

The following lists some common issues that

can confront users experiencing problems

when using Eltron Privilege Series card

printers.

POWER indicator does not

light when power switch is

turned to the ON (1) position.

With the POWER indicator

light ON, the printer appears to

be working, but nothing is

printed.

Printing is faded or poor

quality.

Parallel “Scratch Lines”, miss

ing print

-

1. Power Source

Printer to the outlet power. Verify power

outlet is on.

2. Fuse

3. Voltage Setting

1. Ribbon

2. Card Not Feeding

1. Clean the print head.

2. Adjust the contrast and intensity in software

1. Check ribbon

2. Clean Print Head

3. Call technical support

: Verify fuse is not blown. See Checking & Replacing the Fuse, this section.

(Some models may not have a fuse.)

See Verifying the Correct Voltage Setting,

this section. (Some models may have uni

versal power supplies.)

Verify that the ribbon is loaded, loaded cor

rectly and is unbroken.

a) Check for properly adjusted Card Gate

b) Clean Feeder Roller with alcohol

or with programming.

: Check AC cord from the

: Verify proper voltage is set.

-

:

:

-

980224-001 Rev. C 53

Page 62

Appendix A

Problem Solution or Reason

Printing stops and the

STATUS B indicator light

is ON.

Printing stops and the

STATUS B indicator light

is Blinking.

Printing stops and the

STATUS B indicator light

is ON and STATUS C indicator light is Blinking.

Printing stops and the

STATUS B and STATUS C in

dicator lights are ON.

Status B and Status C are

Blinking Alternately

Errors Using Windows Driver:

1. Printer Command Coding Error:

Clear command error by pressing the Panel

Button.

2. Ribbon Error:

Press Panel button; note card ejects, if pres

ent, and ribbon re synchronizes

3. Feeder Error (empty):

Press Panel Button; note that last command

repeats using another card.

4. Magnetic Stripe Write Error:

Press Panel Button; note that card ejects

and command repeats with another card

5. Other Errors:

Press Panel Button; note that any card

present ejects and error indications cease

6. Check the programming command syntax.

Ribbon or Card Out/Error:

1. Check for cards in tray.

2. Check for broken ribbon.

3. Replace ribbon or replenish cards.

Encoder Command Coding Error:

1. Verify command syntax

2. Call technical support

Mechanical Error:

1. Card Jam - Nonmagnetic Encoder

Open cover, remove upper cleaning roller,

empty feeder, pull jammed cards out. Re

place upper cleaning roller and run Test

Card

RESET. See Controls & Indicators Section

2.2.

-

2. Card Jam - Magnetic Encoder Models

See Section 3, Clearing Media Jams.

3. Card Not Feeding

printer. Release Print Head latch and run

Test Card

RESET, ( See Controls & Indicators Section

2.

Cover is open (P400 Printer).

completely through

:

-

-

:

54 980224-001 Rev. C

Page 63

Problem Solution or Reason

Print Head

Label

Printer cuts (melts) through the

transfer ribbon. The ribbon is ad

vancing at the same rate as the

card media.

Ribbon breaks during resynchronization of the color ribbon panel.

Voids on printed card, varies

from panel to panel.

Voids on printed card, same for

all card panels

Appendix A

1. Reinstall the ribbon.

2. Synchronize the ribbon panels by pressing

the Reset button until the ribbon starts ad

vancing.

3. Verify proper (or default) print settings in

software.

4. Verify the proper ribbon/panel combination

are selected in the software or program

ming sent to the printer.

5. Verify that the print heat (resistor) is set to

the correct level in the WindCard software,

Windows color printer driver or by pro

gramming commands sent to the printer.

Print a Test Card and note the resis

tance/heat setting. Verify the card values

match those that appear on the print head

label. (See following illustration.)

1. Open the Print Head and synchronize the

ribbon. The previous print process may

have been interrupted during the print process.

1. Clean the Cleaning Roller

2. Perform a General Maintenance

1. Card surfaces are not smooth/flat or have

burrs on card edges - Get new cards.

2. Using unapproved media.

-

-

-

Print Head

Label

980224-001 Rev. C 55

Page 64

Appendix A

Other Support

Resources

First attempt a repair using the forgoing table,

Then, if necessary, contact the dealer that sold

you the printer.

Eltron International also offers a variety of in

formation and user support services, as fol

lows:

Internet:

•

Web Address:http://www.eltron.com

ftp://ftp.eltron.com

e-mail:

Label Printers: techsup@eltron.com

Card Printers: privsup@eltron.com

Europe: eurosup@eltron.com

Singapore: asiasup@eltron.com

Latin America: latinsup@eltron.com

• BBS: +1 (805) 579-3445

The BBS supports data rates up to 28.8 BPS

with No Parity, 8 data bits, and 1 stop bit

(n,8,1). Communications software should

have an ANSI Terminal Mode (not MS Windows Terminal) such as Q-Modem.

-

-

56

• CompuServe e-mail: 102251,1164

• Customer Service: +1 (800) 344-4003

For the name of a dealer in your area.

•

Technical Support FAX:

U.S.A.: +1 (805) 579-1808

Asia: +65 73 38 206

Europe: +44 (0) 1185 985 762

French Branch: +33 (0) 1 55 20 93 93

Latin America: +1 (847) 584 2725

For your assistance and support with Eltron

printers and software.

980224-001 Rev. C

Page 65

Appendix A

Parallel Interface

Cable Wiring

STROBE

DATA 0

DATA 1

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA 7

ACK

BUSY

PAPER ERR.

READY

N/A

ERROR

N/A

N/A

N/A

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

The figure below displays the cable wiring re

quired to use the printer’s parallel interface.

DB-25

Pin #

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Female DB-25 to Male DB-25

DB-25

Pin #

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

PrinterHost

STROBE

DATA 0

DATA 1

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA 7

ACK

BUSY

PAPER ERR.

READY

N/A

ERROR

N/A

N/A

N/A

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

-

980224-001 Rev. C 57

Page 66

Appendix A

Serial Interface

Cable Wiring

N/C

RxD

TxD

DTR

GND

DSR

RTS

CTS

RI

Male DB-25 to Female DB-25

N/C

RxD

TxD

DTR

GND

DSR

RTS

CTS

RI

The figure below displays the cable wiring re

quired to use the printer’s serial interface.

DB-25

Pin #

8

2

3

20

7

6

4

5

22

DB-9

Pin #

1

2

3

4

5

6

7

8

9

DB-25

Pin #

8

2

3

20

7

6

4

5

22

DB-25

Pin #

8

2

3

20

7

6

4

5

22

PrinterHost

N/C

TxD

RxD

N/C

GND

N/C

N/C

N/C

N/C

PrinterHost

N/C

TxD

RxD

N/C

GND

N/C

N/C

N/C

N/C

-

58

Female DB-9 to Male DB-25

980224-001 Rev. C

Page 67

Appendix A

Supported Card

Media and Ribbon

Card Media

Ribbons Eltron Privilege card printers require Eltron ap-

The Privilege card printers support a wide vari

ety of card media and ribbon types. Card me

dia should match with ribbon type to avoid

ribbon burning, sticking, and to achieve proper

dye sublimination printing. For optimum per

formance and printer (Print Head) life

, always

use Eltron approved media.

CR-80 credit card style cards (ISO 7810)

made of PVC (recommended) or Polyester

ABS card materials. Some card manufacturing

processes use a thin, clear over-lamination.

Magnetic (Mag.) Stripe Card (ISO 7811)

Smart Card with ISO 7816 Chip, With AF-

NOR Chip, or a combination of the Magnetic

Stripe on one side and one of the Chip versions

on the other side.

proved ribbons. Use Eltron’s printer-matched

media for optimum performance. (See Appendix B.)

-

-

-

Thermal Transfer (Resin) - Both Color and

Monochrome printers can use resin Thermal

Transfer ribbons. Resin offers more durability

than dye sublimation and greater resistance to

scratches and UV-induced fading.

Dye Sublimination (Color Printers) Printing requires dye sublimation ribbons with

either black or Cyan (C), Magenta (M) and Yel

low (Y) panels. These ribbons have Overlay

(varnish) panels to add UV protection and du

rability. Color ribbons have black thermal

transfer resin panels for bar code and other

solid imaging.

980224-001 Rev. C 59

-

-

Page 68

Appendix A

Radius 0.125 in (3.18mm)

3.375 in ± 0.010 in

(85.72mm ± 0.25mm)

Card Dimensions

2.125 in

± 0.002 in

(53.98mm

± 0.05mm)

Thickness

0.009 in to 0.034 in

(0.23mm to 0.84mm)

Magnetic Stripe Dimensions

0.218 in (5.54mm) Max.

0.623 in

(15.82mm) Min.

0.000 in to 0.115 in

(0.00mm to 2.92mm)

0.000 in to 0.115 in

(0.00mm to 2.92mm)

Smart Card Chip

0.221 in (5.62mm) max. gap

0.01 in

(2.54mm)

Min. gap

0.395 in

(8.25mm)

C1

0.210 in

(3.54mm)

No-print Area

0.790 in

21.87mm

0.782 in (19.87mm) Min.

0.403 in (10.25mm) Max.

0.631 in

(7.54mm)

C1C4C5

0.218 in (5.54mm) Max.

0.623 in (15.82mm) Min.

C1 - VCC (Supply Voltage)

C2 - RST (Reset Signal)

C3 - CLK (Clock)

C4 - RFU

C5 - GND (Logic Ground)

C6 - VPP (Programming Voltage)

C8

C7 - I/O (Data Input/Output)

C8 - RFU

60 980224-001 Rev. C

Page 69

Appendix A

Printer Features

and Options

Privilege card printers are part of the Eltron

personal and industrial printer family. A Privi

lege card printer prints on standard credit card

size PVC cards. A color printer can printin both

dye sublimination (color) and thermal transfer

(monochrome) modes. This list only serves as

a reference. Consult the latest Data Sheet.

PRIVILEGE SERIES CARD PRINTERS

Print Resolution

• 300 dots per inch (11.8 dots per mm)

Printing Technology

• Monochrome - Thermal Transfer

• Color - Dye Sublimation

Print Time

• Monochrome - 3 sec. per card (typ.)

• Color - 45 sec. per card (typ.)

Print Speed

• 0.5 ips

Font Support

• Arial 100 Normal and Bold

• True Type fonts with the WindCard™ or

Windows™ compatible printer driver to access Windows™-resident fonts.

Bar Code Symbologies

• Code 39 (3 of 9)

•

Interleaved 2 of 5 (I-2/5)

•

Standard 2 of 5 (2/5)

•

EAN 8

•

EAN 13

•

UPC A

•

MONARCH

•

Code 128

- Subset B with or without Check Digit

- Subset C with or without Check Digit

-

980224-001 Rev. C 61

Page 70

Appendix A

Card Types - ISO Format

CR-80 - ISO 7810

•

Option; Magnetic Stripe - ISO 7811

•

Option: Smart Card - ISO 7816

•

PVC (recommended), PVC w/Polyester

•

core, ABS card materials

Magnetic Encoding - Option

3 tracks

•

3 Media Recording Densities:

•

Low Coercivity, 300 Oersteds

Medium Coercivity, 2750 Oersteds

High Coercivity, 4,000 Oersteds

• Supports recording formats: ITA, ABA and

Thrift.

Smart Card - Option

• Supports ISO 7816 Smart Card standards

Card Dimensions

• Width - 3.375 inches (85.7 mm) typ.

• Length - 2.125 inches (53.98 mm) typ.

• Monochrome Thickness:

0.010 to 0.040 inch (0.254 to 1.016 mm)

• Color Thickness:

0.020 to 0.030 inch (0.508 to 0.762 mm)

• Standard Thicknesses:

0.010 inch (0.254 mm)

0.020 inch (0.508 mm)

0.024 inch (0.610 mm)

0.030 inch (0.762 mm)

Card Feeder Capacity

•

Up to 90, 0.010-inch cards

•

Up to 45, 0.020-inch cards

•

Up to 30, 0.030-inch cards

Power Requirements

•

100 to 120 or230 to 240 VAC, 50-~60Hz

Operating Temperature-

•

Monochrome 40 to 104° F (4 to 86° C)

•

Color 60 to 86° F (16 to 68° C)

62

980224-001 Rev. C

Page 71

Dimensions-

P300:

Width 12.4 inches (315 mm)

•

Height 7.8 inches (198 mm)

Depth 8.7 inches ( 220 mm)

P400:

•

Width 16 inches (405 mm)

Height 7.9 inches (200 mm)

Depth 8.6 inches (218 mm)

Weight

P300:

18 lb (8.2 kg)

•

P400:

• 23 lb (10.4 kg)

Appendix A

980224-001 Rev. C 63

Page 72

Appendix A

64 980224-001 Rev. C

Page 73

Appendix B

Supplies and

Accessories

Contact your Eltron dealer when placing an or

der for any of the following:

Accessories Accessories available for the Privilege card

printer are listed below. Always refer to the ELTRON part number when placing an order.

Description Part Number