FL370-I000CC

RF Forklift Base

FL370-I000CC

RF Forklift Base

© 2001 SYMBOL TECHNOLOGIES, INC. All rights reserved.

Symbol reserves the right to make changes to any product to improve reliability,

function, or design.

Symbol does not assume any product liability arising out of, or in connection with, the

application or use of any product, circuit, or application described herein.

No license is granted, either expressly or by implication, estoppel, or otherwise under

any patent right or patent, covering or relating to any combination, system,

apparatus, machine, material, method, or process in which Symbol products might

be used. An implied license on ly exist s for eq ui p men t, circui ts , and subsystems

contained in Symbol products.

Symbol and the Symbol logo are registered trademarks of Symbol T echnologies, Inc.

Other product names mentioned in this manual may be trademarks or registered

trademarks of their respective companies and are hereby acknowledged.

Symbol Technologies, Inc.

One Symbol Plaza

Holtsville, N.Y. 11742-1300

http://www.symbol.com

Patents

This product is covered by one or more of the following U.S. and foreign Patents:

U.S. Patent No. 4,460,120; 4,496,831; 4,593,186; 4,603,262; 4,607,156; 4,652,750;

4,673,805; 4,736,095; 4,758,717; 4,816,660; 4,845,350; 4,896,026; 4,897,532; 4,923,281;

4,933,538; 4,992,717; 5,015,833; 5,017,765; 5,021,641; 5,029,183; 5,047,617; 5,103,461;

5,113,445; 5,130,520; 5,140,144; 5,142,550; 5,149,950; 5,157,687; 5,168,148; 5,168,149;

5,180,904; 5,216,232; 5,229,591; 5,230,088; 5,235,167; 5,243,655; 5,247,162; 5,250,791;

5,250,792; 5,260,553; 5,262,627; 5,262,628; 5,266,787; 5,278,398; 5,280,162; 5,280,163;

5,280,164; 5,280,498; 5,304,786; 5,304,788; 5,306,900; 5,321,246; 5,324,924; 5,337,361;

5,367,151; 5,373,148; 5,378,882; 5,396,053; 5,396,055; 5,399,846; 5,408,081; 5,410,139;

5,410,140; 5,412,198; 5,418,812; 5,420,411; 5,436,440; 5,444,231; 5,449,891; 5,449,893;

5,468,949; 5,471,042; 5,478,998; 5,479,000; 5,479,002; 5,479,441; 5,504,322; 5,519,577;

5,528,621; 5,532,469; 5,543,610; 5,545,889; 5,552,592; 5,557,093; 5,578,810; 5,581,070;

5,589,679; 5,589,680; 5,608,202; 5,612,531; 5,619,028; 5,627,359; 5,637,852; 5,664,229;

5,668,803; 5,675,139; 5,693,929; 5,698,835; 5,705,800; 5,714,746; 5,723,851; 5,734,152;

5,734,153; 5,742,043; 5,745,794; 5,754,587; 5,762,516; 5,763,863; 5,767,500; 5,789,728;

5,789,731; 5,808,287; 5,811,785; 5,811,787; 5,815,811; 5,821,519; 5,821,520; 5,823,812;

5,828,050; 5,850,078; 5,861,615; 5,874,720; 5,875,415; 5,900,617; 5,902,989; 5,907,146;

5,912,450; 5,914,478; 5,917,173; 5,920,059; 5,923,025; 5,929,420; 5,945,658; 5,945,659;

5,946,194; 5,959,285; 6,002,918; 6,021,947; 6,036,098; 6,047,892; 6,050,491; 6,053,413;

6,056,200; 6,065,678; 6,067,297; 6,068,190; 6,082,621; 6,084,528; 6,088,482; 6,092,725;

6,101,483; 6,102,293; 6,104,620; 6,114,712; 6,115,678; 6,119,944; 6,123,265; 6,131,814;

6,138,180; 6,142,379; 6,172,478; 6,176,428; 6,178,426; 6,186,400; 6,188,681; D305,885;

D341,584; D344,501; D359,483; D362,453; D363,700; D363,918; D370,478; D383,124;

D391,250; D405,077; D406,581; D414,171; D414,172; D418,500; D419,548; D423,468;

D424,035; D430,158; D430,159; D431,562; D436,104.

Invention No. 55,358; 62,539; 69,060; 69,187 (Taiwan); No. 1,601,796; 1,907,875;

1,955,269 (Japan).

European Patent 367,299; 414,281; 367,300; 367,298; UK 2,072,832; France 81/03938;

Italy 1,138,713.

rev. 04/01

Quick Reference

Introduction

The FL-370-1000CC RF Forkl ift base is a commu nication cond uit

between the Phaser RF scanner and forklift moun ted term in al. It

is a sealed device designed to be mounted on a forklift. The RF

Forklift base receives data from the scanner via radio frequency

(RF) transmissions through its antenna, then transmits that d ata to

the forklift vehicle mounted terminal through an attache d cab le.

Quick Reference Guide

This

up and use of the RF Forklift base.

Unpacking the Radio Base

The shipping box includes the following:

• Fully sealed RF Forklift base

• Four screws (see page 3 for mounting)

• This Quick Reference Gui de (p/n 72-52373-xx)

• Radio Base mounting template (page 13)

Note: The Interface cable m ust be purchased separately.

Save the shipp ing container for s toring or shippi ng. Inspect all your

equipment for damage. If any th ing is damaged or missing, call

your authorized Customer Support Representative immediately.

provides basic instruct ion on the se t

1

FL370-I000CC

RF Forklift Base

About This Guide

This guide provides instructions for the foll ow ing:

• “Mounting the Radio Base” on page 3

• “Connecting to the Host” on page 3

• “Connector Pinout” on page 5

• “Pairing” on page 6

• “Spectrum 24 Environment” page 6

• “LED Indicator” on page 8

• “Cleaning the Base” on page 8

• “Troubleshooting” on page 8

• “Service Information” o n page 14

• “Warranty” on page 12

• “Mounting Template” on page 13 .

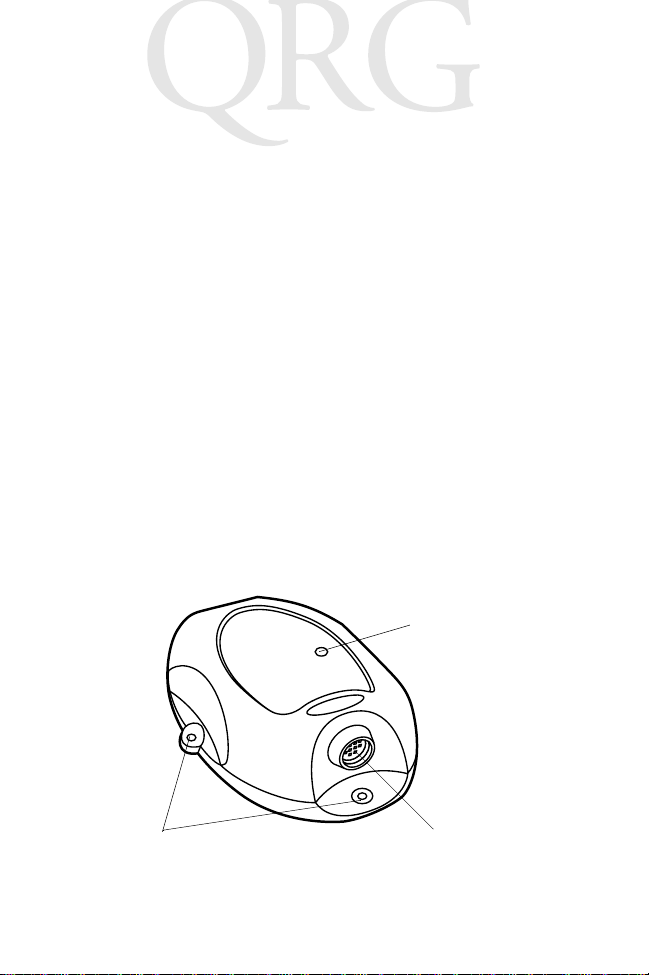

LED Light

Mounting Holes

Interface Cable

Connector

2

Quick Reference

r

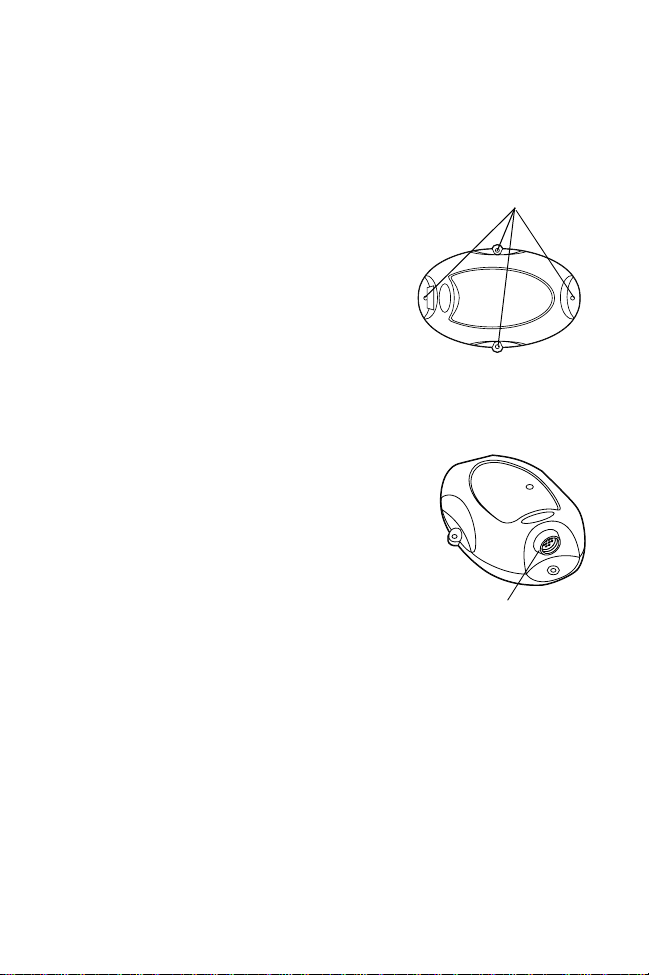

Mounting the Base

1. Mount the RF Forklift base on a flat

surface free of dirt and oi l and three

feet or more from an RF terminal’s

radio antenna.

2. Fasten the four screws provided

through the RF Forklift base and

into the mounting area. A mounting

template is provided for you on page

13.

3. Install the cable by aligning the alignment tab and firmly

pushing the cable into the connector.

Mounting Holes

Connecting to the Host

Note: The RF Forklift base power con-

sumption is 200mA maximum.

Interface Cable Connecto

3

FL370-I000CC

RF Forklift Base

Symbol Vehicle Mounted Terminals

To connect the radio base to a forklift vehicle mounted terminal:

1. Install the appr opriate interf ace cab le between the hos t computer and the RF Forklift base connector.

Note: Commonly used c ables which include RS232 and

scanner emulation cables are available.

2. Communication between the scanner and the RF Forklift

base is establishe d through the pa iring procedu re (see page

6).

3. The VRC terminal su pplies po wer to t he RF F orklift base using the appropriate interfa ce ca ble .

Other Vehicle Mounted Terminals

1. Install the appr opriate interf ace cab le between the hos t computer and the base’s connec tor.

2. The terminal or a separately sold Symbol external power

supply provides po w er to the RF Fork lift base using the ap propriate interface cable.

4

Quick Reference

Connector Pinout

12

1

4

3

5

11

10

9

Pin

Number

1 Command Mode 7 Transmit Data

2 5 Volt Supply 8 Data Terminal

3 Ground (When

4 Synapse Data 10 Request to Send

5 Synapse Clock 11 Ground (W hen

6 Receive Data

Function Pin Number Function

Using 5 Volt

Supply

(RXD)

2

6

7

8

(TXD)

Ready (DTR)

9 Clear to Send

(CTS)

(RTS)

Using 9 Volt

Supply

12 9-12 Volt Supply

5

FL370-I000CC

RF Forklift Base

Pairing

The scanner and RF Forklift base must be paired for

communication to occur.

Note: If a new host is connected to the RF Forklift base,

rescan the pairing bar code on the top of the unit

again.

To pair the scan ner with the RF For klift base:

1. Scan the pairing bar cod e on the top or bottom of t he

RF Forklift base.

2. The scanner may briefly display the “pairing search for

channel” message while the scanner searches for the

base. Once the base is detec ted, infor mati on is ex changed (addressing, RF channels, etc.) between the

scanner and the cradle.

It may take up to 30 seconds for the

Note:

scanner to search for th e base

during over-the-air pairing.

3. After the exchange is complete, the scanner and cradle are paired. Successful pairing is indicated by a

warble beep and the base’s LED will flash; failure, or

an unsuccessful link, i s indi cated by a Lo Hi beep.

The pairing of a scanner to a cradle is one-to-one. Only one

scanner can be paired to a cradle at any point in time. If you

pair a second scanner to an in us e cradl e, the cradl e’s

connection to the first scanner will be broken and the

connection re-established with the second scanner.

6

Quick Reference

To pair a scanner to a different cradle, scan its pairing bar

code located on the top of the cradle.

Coexistence in Spectrum24 Env ironme nts

If you operate your scanner or cradle in close proximity to a

Spectrum24 device, maintain a buffer of 3 feet or greater

between the transmitter s . A Sp ec tru m24 de vi ce includes

but is not limited to a terminal with a Spectrum24 radio, PC

with a Spectrum24 card, or a Spectrum24 Access Point. If

a scanner or cradle is les s than 3 ft. from a 2.4 G Hz

Spectrum24 transmitter (antenna), especially an Ac c es s

Point, your communication performance may degrade

significantly.

Select a Channel Outside the Spectrum24 band

In the unlikely event that S24 radio traffic does cause

interference between the scanner and radio base, you can

change the base’s radio channel to one that minimizes or

eliminates interf er ence.

Phaser cordless scanners have three channels that are not

within the Spectrum24 band, 81, 82, and 83*. As a rule of

thumb, the Cordless systems closest to Spectrum24

devices should use these channels.

In applications with low scanning / data transmission duty

cycles, you may assign the same channel to more than one

Phaser.

After channels 81, 82 and 83, the next best channels to use

are 60 through 80; the higher the channel the better.

* Not available in some co untr i es.

7

FL370-I000CC

RF Forklift Base

Increase the number of RF Retries

If the scanner transmis sion is not re ceived b y the RF Forkl ift base

or the base acknow ledgment response is not received by the

scanner, the scanner retransmits the lost or corrupted data. The

scanner attempts 4 RF Retries (de f aul t) but can be prog ram me d

to attempt up to 8.

Depending on your particular RF environment, additional retries

may cause your scanner transaction ti me to increase in the

presence of heavy Spectrum24 traffic.

Radio Base LED Indicator.

LED Status Description

Off No scan signal received by base.

On Radio Base receiving scan signal.

Cleaning

The RF Forklift base meets IP 65 speci fications and is sealed

against dust and water . The R F Forklift base can be w ashed down

along with the forklift using a low pressure water source.

Troubleshooting

If the RF Forklift base does not work after you’ve followed these

operating instructions:

• Check the system power.

• Check for loose cable connections.

8

Quick Reference

Regulatory Information

Radio Frequency Interference Requirements

This device has been tested and found to comply with the limits for a Class A digital device pursuant

to Part 15 of the Federal Comm unicat ions Co mmission s Rules and Regulation. These limits are

designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Ope ration of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

However, there is no guarantee that interference will not occur in a particular installation. If the

equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Re-orient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

This device complies with FCC Part 15. Operation is subject to the following two conditions: (1) t his

device may not cause harmful interference and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Radio Frequency Interference Requirements - Canada

This Class A digital apparatus meets the requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique d e la Classe A respecte t outes les exi gences du Reglement su r le Mate riél

Brouilleur du Canada.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

European Economic Area

The European variant is intended for use throughout the European Economic Area, however

authorization for use is restricted to as follows:

European Economic Area-Frequency Range 2.400 - 2.4835 GHz.

France - Frequency Range 2.4465 - 2.454 GHz.

Belgium (outside) - Frequency Range 2.460 - 2.4835.

Italy - Operation requires a user license.

CE Marking and European Union Compliance

Applicable Directives

• Electromagnetic Compatibility Directive 89/336/EEC

• Low Voltage Directive 73/23/EEC

Products intended for sale within the Europea n Union are marked with the CE Mark

which indicates compliance to applicable Directives and European Normes (EN), as

follows. Amendments to these Directives or ENs are included:

9

FL370-I000CC

RF Forklift Base

DECLARATION OF CONFORMITY

We, Symbol Technologies, Inc.

of One Symbol Plaza, Holtsville, NY 11742-1300, USA

declare under our sole responsibility that the product(s)

FL370 RF Forklift Base

to which this declaration relates, is in conformity with the following standards and/or other normative documents.

I-ETS 300 440 (December 1995)

ETS 300 683 (June 1997)

EN 60950: 1992 Incl Amdt 1-4, 11

We hereby declare that all essential radio test suites have been carried out and that the above named product(s) is in

conformity with all the essential requirements of Directive 1999/5/EC.

The conformity assessment procedure referred to in Article 10(5) and detailed in Annex IV of

Directive 1999/5/EC has been followed with the involvement of the following Notified Body(ies):

BABT, Claremont House, 34 Molesey Road, Walton-on-Thames, KT12 4RQ

Identification mark: 0168 The equipment will also carry the Class

The technical documentation relevant to the above equipment can be made available for

inspection on application to:

Symbol Technologies EMEA, Symbol Place, Winnersh Triangle, Berkshire, RG 41 5TP, UK

Dornu Narnor

(name)

Director, Regulatory and Technical Sales

(title)

(signature of authorised person) (date)

2 equipment identifier

3, May 2000

10

Quick Reference

Applicable Standards

• EN 300 440: 1999 - Electromagnetic and Radio Spectrum Matter (ERM) Sh ort Ran ge

De v ices: Technical Characteristics and Test Met hods for Radio Equipment to be Used in the

1 GHz to 40 GHz Frequency Range.

• ETS 300 683: 1997 - Radio Equipment and System (RES); Electromagnetic Compatibility

(EMC) Standard for Short Range Devices (SRD) Operating on Frequencies between 9kHz

and 25 GHz.

• EN 1000-4-2: 1995/EN 61000-4-2:1995 - Electromagnetic Compatibility (EMC); Part 4: Testing and Measurement Techniques; Section 4.2: Electrostatic Discharge Immunity Test.

• EN 61000-4-3: 1997 - Electromagnetic Compatibility (EMC); Part 4 Testing and Measurement Techniques; Section 3: Radiated, Radio Frequency, Electromagnetic Field Immunity

Test.

• IEC 1000-4-4: 1995/EN 61000-4-4: 1995 - Electromagnetic Compatibility (EMC); Part 4:

Testing and Measurement Techniques; Section 4: Testing Electrical Fast Transient, Burst

Immunity.

• IEC 1000-4-5: 1995/EN 61000-4-5: 1995 - Electromagnetic Compatibility (EMC); Part 4:

Testing and Measurement Techniques; Section 5 : Surge Immunity.

• IEC 1000-4-6: 1996/EN 61000-4-6: 1996 - Electromagnetic Compatibility (EMC); Part 4:

Testing and Measurement Techniques; Section 6: Immunity to Conducted Disturbances,

Induced by Radio Frequency Fields.

• IEC 1000-4-11: 1994/EN 61000-4-11: 1994 - Electromagnetic Compatibility (EMC); Part 4:

Testing and Measurement Techniques; Section 11: Voltage Dips, Short Interruptions and

Voltage Variations.

RF Devices

Symbol’s RF products are designed to be co mpli ant with the rule s and regu lations in the location s

into which they are sold and will be labeled as required. The majority of Symbol’s RF devices are

type approved and do not require the user to obtain license or authorization before using the

equipment. Any changes or modifications to Symbol Technologies equipment not expressly

approved by Symbol Technologies could void the user’s authority to operate the equipment.

Caution: RF Exposure Guidlines

To comply with FCC RF exposure requirements, antennas that are mounted externally at remote

locations or operating near users at stand-al one desktop or similar configurati ons must operate with

a minimum separation distance of 20 cm from all persons.

11

FL370-I000CC

RF Forklift Base

Warranty

Symbol Technologies, Inc. (“Symbol”) manufactures its hardware products in accordance with

industry-standard practices. Symbol warrants that for a period of twelve (12) months from date of

shipment, products will be free from defects in materials and workmanship.

This warranty is provided to th e ori ginal owner only an d is not tr ansferable to any thir d party. It shall

not apply to any product (i) whi ch has been repair ed or altered un less done or appr oved by Symbol,

(ii) which has not been maintained in accordance with any operating or handling instructions

supplied by Symbol, (iii) which has been subjected to unusual physical or electrical stre ss, misuse,

abuse, power shortage, negligence or accident or (iv) which has been used other than in

accordance with the product operating and handling instructions. Preventive maintenance is the

responsibility of customer and is not covered under this warranty.

Wear items and accessories having a Symbol serial number, will carry a 90-day limited warranty.

Non-serialized items will carry a 30-day limited warranty.

Warranty Coverage and Procedure

During the warranty period, Symbol will repair or replace defective products returned to Symbol’s

manufacturing plant in the US. For warranty service in North America, call the Symbol Support

Center at 1-800-653-5350. International customers should contact the local Symbol office or

support center. If warranty service is required, Symbol will issue a Return Material Authorization

Number. Products mu st be shipped in the original or comparable packaging, shipping and

insurance charges prepaid. Symbol will ship the repaired or replacement product freight and

insurance prepaid in North America. Shipments from the US or other locations will be made F .O.B.

Symbol’s manufacturing plant.

Symbol will use new or refurbished parts at its discretion and will own all parts removed from

repaired products. Customer will pay for the replacement product in case it does not return the

replaced product to Symbol within 3 days of receipt of the replacement product. The process for

return and customer’s charges will be in accordance with S ymbol’ s Exchange P olicy in ef fect at th e

time of the exchange.

Customer accepts full responsibility for its software and data including the appropriate backup

thereof.

Repair or replacement of a product during warranty will not extend the original warranty term.

Symbol’s Customer Service organizat ion offers an array of service plans, such as on-site, depot, or

phone support, that can be implemented to meet customer’s special operati onal requirements and

are available at a substantial discount during warranty period.

General

Except for the warranties stated above, Symbol disclaims all warranties, express or implied, on

products furnished hereunder , incl uding without lim itation implied w arranties of mer chantability and

fitness for a particular purpose. The stated express warranties are in lieu of all obligations or

liabilities on part of Symbol for damages, including without limitation, special, indirect, or

consequential damages arising out of or in connection with the use or perfor mance of the product.

Seller’s liability for damages to buyer or other s resulting from the u se of any product, sha ll in no way

exceed the purchase price of said product, except in instances of injury to persons or property.

Some states (or jurisdiction s) do n ot allow the exclusion or l im itati on o f incidental or consequ ential

damages, so the proceeding exclusion or limitation may not apply to you.

12

Quick Reference

Mounting Dimensions

Not to actual size.

5.819”

3.756”

13

Service Information

Before you use the unit, it must be configured to operate in your facility’s network and

run your applications.

If you have a problem running your unit or using your equipment, contact your

facility’s T echnical or Systems Support. If there is a problem with the equipment, they

will contact the Symbol Support Center:

United States 1-800-653-5350 Ca na da 905-629-7226

United Kingdom 0800 328 2424 Asia/Pacific 337-6588

Australia 1-800-672-906 Austria 1-505-5794

Denmark 7020-1718 Finland 9 5407 580

France 01-40-96-52-21 Germany 6074-49020

Italy 2-484441 Mexico 5-520-1835

Netherlands 315-271700 Norway 66810600

South Africa 11-4405 668 Spain 913244000

Sweden 84452900

Latin America Sales Support 1-800-347-0178 In side U S

Europe/Mid-East Distributor Operations Contact local distributor or call

+1-561-483-1275 Outside US

+44 208 945 7360

72-52373-01

Revision B — August 2001

Symbol Technologies, Inc. One Symbol Plaza Holtsville, NY 11742-1300

Loading...

Loading...