Page 1

DS8108

MN-002926-01

Digital Scanner

Product Reference Guide

Page 2

Page 3

DS8108 DIGITAL SCANNER

PRODUCT REFERENCE GUIDE

MN-002926-01

Revision A

March 2017

Page 4

ii DS8108 Digital Scanner Product Reference Guide

No part of this publication may be reproduced or used in any form, or by any electrical or mechanical means,

without permission in writing from Zebra. This includes electronic or mechanical means, such as photo copying,

recording, or information storage and retrieval systems. The material in this manual is subject to change

without notice.

The software is provided strictly on an “as is” basis. All software, including firmware, furnished to the user is on

a licensed basis. Zebra grants to the user a non-transferable and non-exclusive license to use each software

or firmware program delivered hereunder (licensed program) . Except as n oted below, such license may not be

assigned, sublicensed, or otherwise tran sfe rr e d by th e user without prior written consent of Zebra. No right to

copy a licensed program in whole or in part is granted, except as permitted under copyright law. The user shall

not modify , merge, or incorporate any for m or portion of a licensed program with other pro gram material, create

a derivative work from a licensed program , or us e a li censed program in a network without written permission

from Zebra. The user agrees to maintain Zebra’s copyright notice on the licensed programs delivered

hereunder , and to include the same on any au thorized copies it m akes, in whole or in part. The user agrees not

to decompile, disassemble, decode, or reverse engineer any licensed program delivered to the user or any

portion thereof.

Zebra reserves the right to make changes to any product to improve reliability, function, or design.

Zebra does not assume any product liability arising out of, or in connection with, the application or use of any

product, circuit, or application described herein. No license is granted, either expressly or by implication,

estoppel, or otherwise under any patent right or patent, covering or relating to any combination, system,

apparatus, machine, material, method, or process in which Zebra products might be used. An implied license

exists only for equipment, circuits, and subsystems contained in Zebra products.

Warranty

For the complete hardware product warranty statement, go to: http://www.zebra.com/warranty.

Page 5

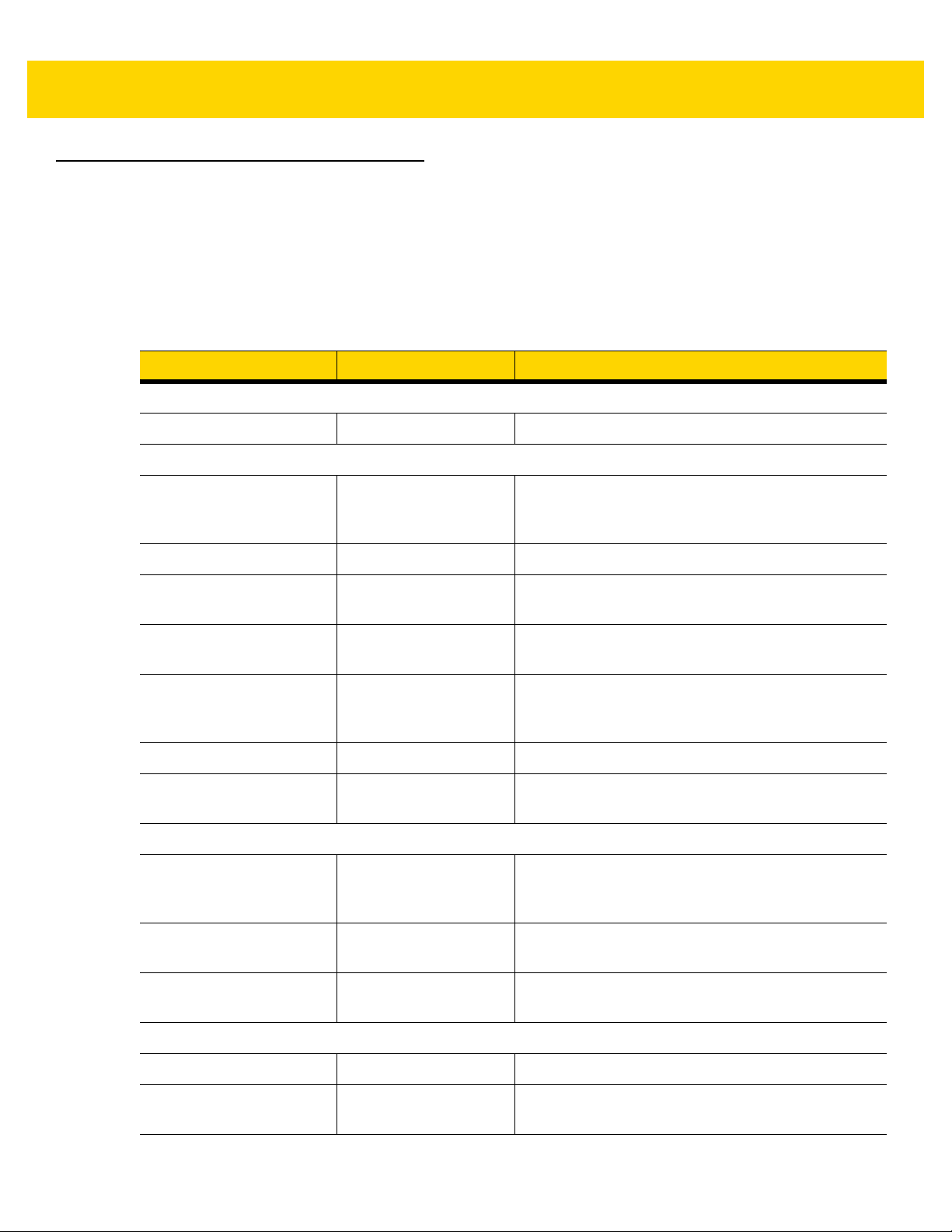

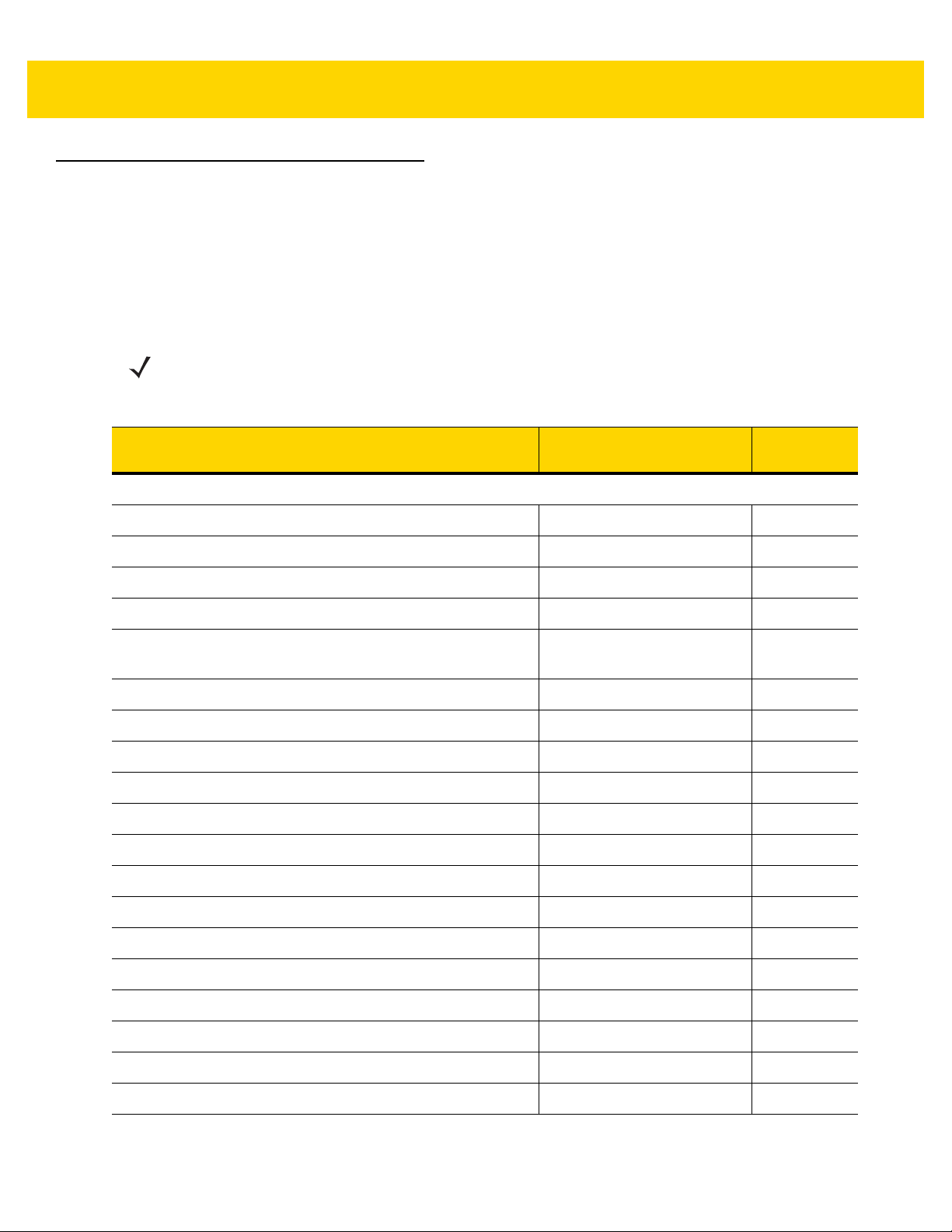

Revision History

Changes to the original guide are listed below:

Change Date Description

-01 Rev A 03/2017 Initial Release

iii

Page 6

iv DS8108 Digital Scanner Product Reference Guide

Page 7

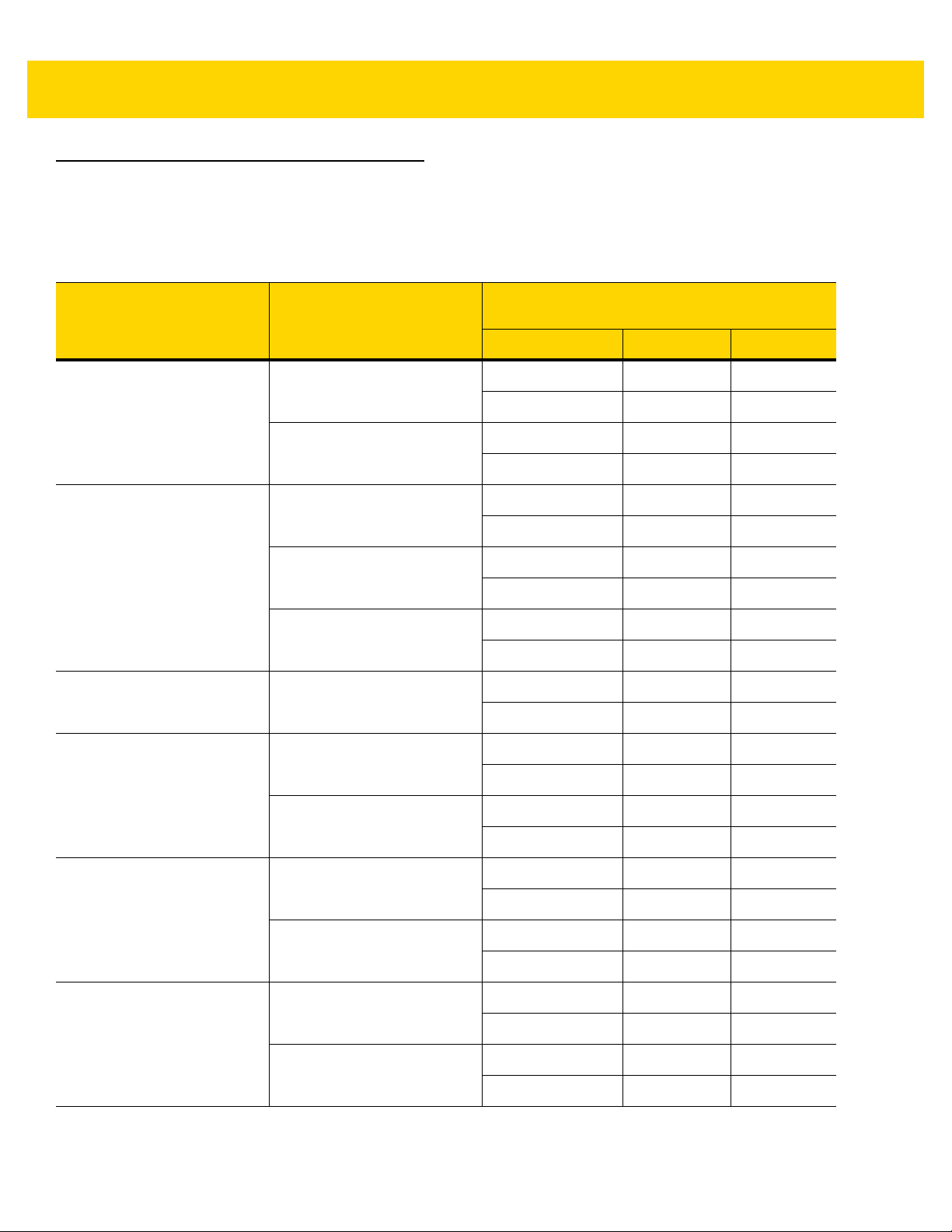

TABLE OF CONTENTS

Warranty ............................................................................................................................................ ii

Revision History................................................................................................................................. iii

About This Guide

Introduction...................................................................................................................................... xix

Configurations.................................................................................................................................. xix

Related Product Line Configurations/Accessories........................................................................... xx

Cables........................................................................................................................................ xx

Chapter Descriptions ....................................................................................................................... xx

Notational Conventions.................................................................................................................... xxi

Related Documents and Software.................................................................................................. xxii

Service Information........................................................................................................................ xxiii

Chapter 1: Getting Started

Introduction .................................................................................................................................... 1-1

Interfaces ....................................................................................................................................... 1-2

Unpacking ...................................................................................................................................... 1-2

Setting Up the Digital Scanner ....................................................................................................... 1-3

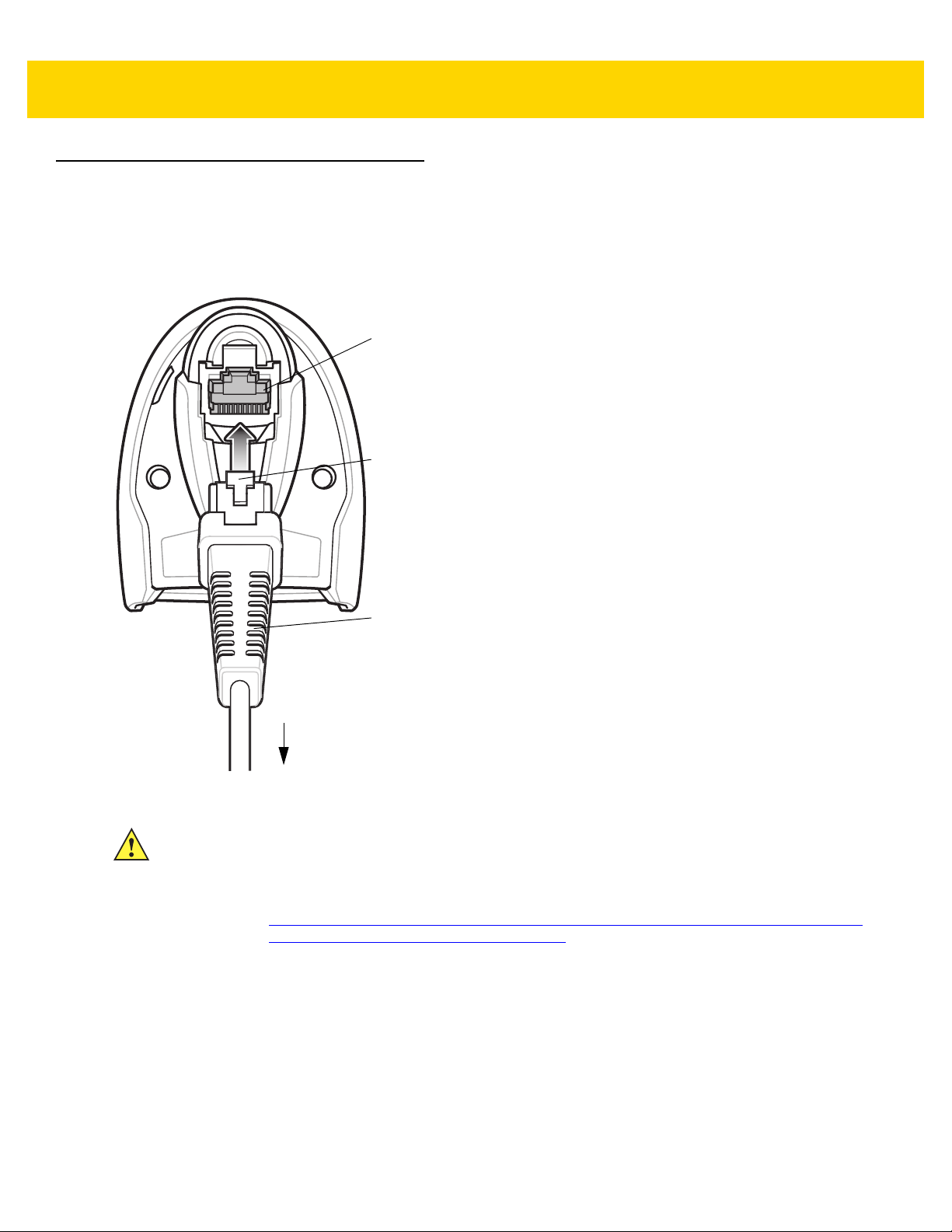

Installing the Interface Cable .................................................................................................... 1-3

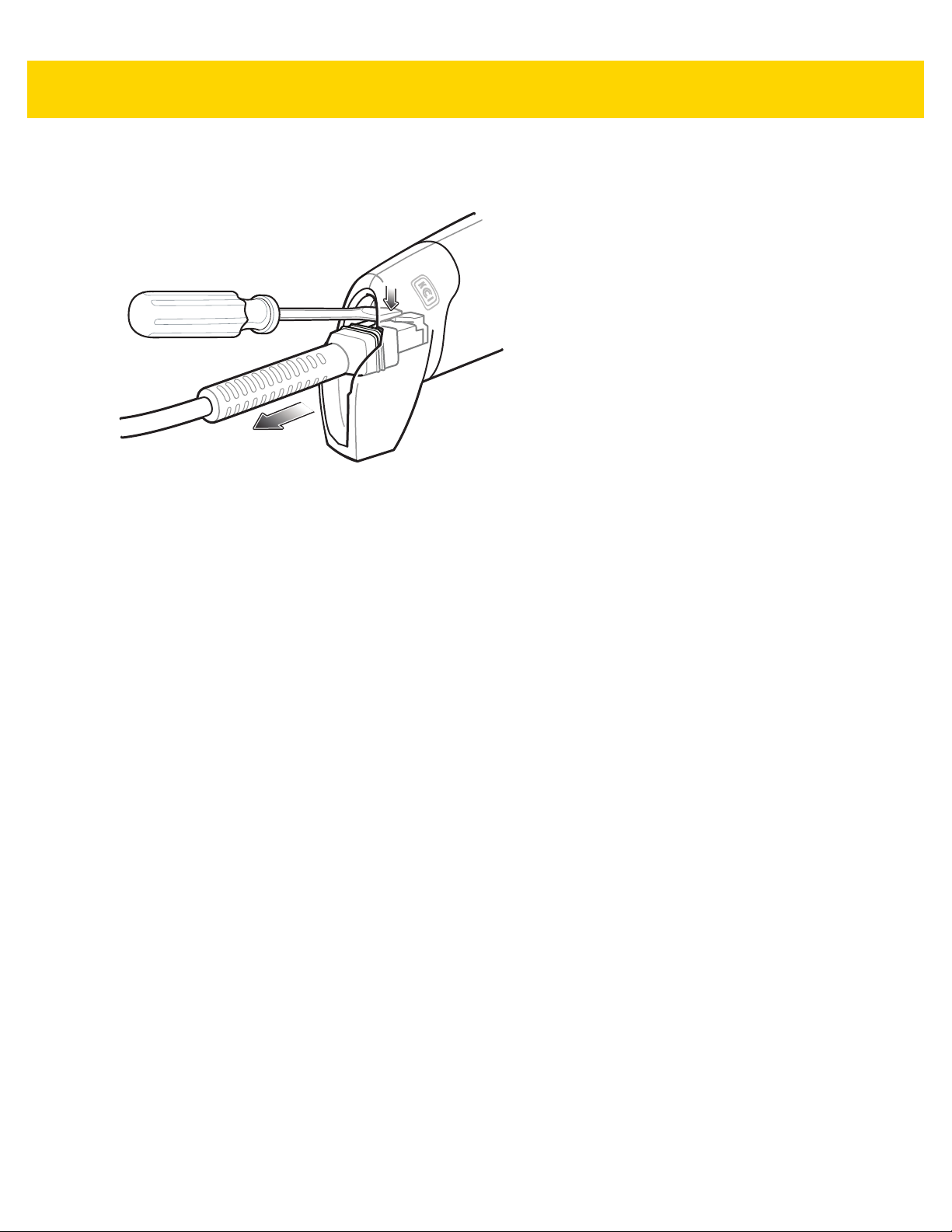

Removing the Interface Cable .................................................................................................. 1-4

Connecting Power (if required) ................................................................................................ 1-4

Configuring the Digital Scanner ............................................................................................... 1-4

Chapter 2: Data Capture

Introduction .................................................................................................................................... 2-1

Beeper and LED Indicators ............................................................................................................ 2-2

Scanning ........................................................................................................................................ 2-4

Scanning in Presentation (Hands-free) Mode .......................................................................... 2-4

Scanning in Hand-held Mode ................................................................................................... 2-7

Aiming ...................................................................................................................................... 2-7

Decode Ranges ............................................................................................................................. 2-9

Page 8

vi DS8108 Digital Scanner Product Reference Guide

DS8108-SR/DL Configurations ................................................................................................ 2-9

DS8108-HC Configurations .................................................................................................... 2-10

Assembling the Document Capture Stand ................................................................................... 2-11

Assembly ................................................................................................................................ 2-12

Chapter 3: Maintenance, Troubleshooting, & Technical Specifications

Introduction .................................................................................................................................... 3-1

Maintenance .................................................................................................................................. 3-1

Known Harmful Ingredients ...................................................................................................... 3-1

Approved Cleaners for Standard DS8108 Digital Scanners .................................................... 3-2

Approved Disinfectant Cleaners for Healthcare Configurations

of the DS8108 Digital Scanners ......................................................................................... 3-2

Cleaning the Digital Scanner .................................................................................................... 3-3

Troubleshooting ............................................................................................................................. 3-4

Dump Scanner Parameters ...................................................................................................... 3-6

Send Versions .......................................................................................................................... 3-7

Technical Specifications ................................................................................................................ 3-8

Digital Scanner Signal Descriptions ............................................................................................. 3-11

Chapter 4: USB Interface

Introduction .................................................................................................................................... 4-1

Setting Parameters ........................................................................................................................ 4-1

Scanning Sequence Examples ................................................................................................ 4-1

Errors While Scanning ............................................................................................................. 4-2

Connecting a USB Interface .......................................................................................................... 4-2

USB Parameter Defaults ................................................................................................................ 4-4

USB Host Parameters .................................................................................................................... 4-5

USB Device Type ..................................................................................................................... 4-5

Symbol Native API (SNAPI) Status Handshaking .................................................................... 4-7

USB Keystroke Delay ............................................................................................................... 4-7

USB Caps Lock Override ......................................................................................................... 4-8

Bar Codes with Unknown Characters ...................................................................................... 4-8

USB Convert Unknown to Code 39 .......................................................................................... 4-9

USB Fast HID ........................................................................................................................... 4-9

USB Polling Interval ............................................................................................................... 4-10

Keypad Emulation .................................................................................................................. 4-12

Quick Keypad Emulation ........................................................................................................ 4-12

Keypad Emulation with Leading Zero .................................................................................... 4-13

USB Keyboard FN1 Substitution ............................................................................................ 4-13

Function Key Mapping ........................................................................................................... 4-14

Simulated Caps Lock ............................................................................................................. 4-14

Convert Case ......................................................................................................................... 4-15

USB Static CDC ..................................................................................................................... 4-15

TGCS (IBM) USB Beep Directive ........................................................................................... 4-16

TGCS (IBM) USB Bar Code Configuration Directive ............................................................. 4-16

TGCS (IBM) USB Specification Version ................................................................................ 4-17

ASCII Character Sets ................................................................................................................... 4-17

Page 9

Table of Contents vii

Chapter 5: SSI Interface

Introduction .................................................................................................................................... 5-1

Communication .............................................................................................................................. 5-1

SSI Commands ........................................................................................................................ 5-2

SSI Transactions ............................................................................................................................ 5-3

General Data Transactions ...................................................................................................... 5-3

Decoded Data Transmission .................................................................................................... 5-4

Communication Summary .............................................................................................................. 5-5

RTS/CTS Lines ........................................................................................................................ 5-5

ACK/NAK Option ...................................................................................................................... 5-5

Number of Data Bits ................................................................................................................. 5-5

Serial Response Timeout ......................................................................................................... 5-6

Retries ...................................................................................................................................... 5-6

Baud Rate, Stop Bits, Parity, Response Timeout, ACK/NAK Handshaking ............................. 5-6

Errors ....................................................................................................................................... 5-6

SSI Communication Notes ....................................................................................................... 5-6

Using Time Delay to Low Power Mode with SSI ............................................................................ 5-7

Encapsulation of RSM Commands/Responses over SSI .............................................................. 5-8

Command Structure ................................................................................................................. 5-8

Response Structure ................................................................................................................. 5-8

Example Transaction ............................................................................................................... 5-9

Setting Parameters ...................................................................................................................... 5-10

Scanning Sequence Examples .............................................................................................. 5-10

Errors While Scanning ........................................................................................................... 5-10

Simple Serial Interface Parameter Defaults ................................................................................. 5-11

SSI Host Parameters ................................................................................................................... 5-12

Select SSI Host ...................................................................................................................... 5-12

Baud Rate .............................................................................................................................. 5-12

Parity ...................................................................................................................................... 5-14

Check Parity ........................................................................................................................... 5-15

Stop Bits ................................................................................................................................. 5-15

Software Handshaking ........................................................................................................... 5-16

Host RTS Line State .............................................................................................................. 5-17

Decode Data Packet Format .................................................................................................. 5-17

Host Serial Response Timeout .............................................................................................. 5-18

Host Character Timeout ......................................................................................................... 5-19

Multipacket Option ................................................................................................................. 5-20

Interpacket Delay ................................................................................................................... 5-21

Event Reporting ........................................................................................................................... 5-22

Decode Event ......................................................................................................................... 5-22

Boot Up Event ........................................................................................................................ 5-23

Parameter Event .................................................................................................................... 5-23

Chapter 6: RS-232 Interface

Introduction .................................................................................................................................... 6-1

Setting Parameters ........................................................................................................................ 6-1

Scanning Sequence Examples ................................................................................................ 6-2

Errors While Scanning ............................................................................................................. 6-2

Connecting an RS-232 Interface .................................................................................................... 6-2

Page 10

viii DS8108 Digital Scanner Product Reference Guide

RS-232 Parameter Defaults ........................................................................................................... 6-3

RS-232 Host Parameters ............................................................................................................... 6-4

RS-232 Host Types .................................................................................................................. 6-6

Baud Rate ................................................................................................................................ 6-8

Parity ........................................................................................................................................ 6-9

Stop Bits ................................................................................................................................. 6-10

Data Bits ................................................................................................................................. 6-10

Check Receive Errors ............................................................................................................ 6-11

Hardware Handshaking .......................................................................................................... 6-11

Software Handshaking ........................................................................................................... 6-13

Host Serial Response Timeout .............................................................................................. 6-15

RTS Line State ....................................................................................................................... 6-16

Beep on <BEL> ...................................................................................................................... 6-16

Intercharacter Delay ............................................................................................................... 6-17

Nixdorf Beep/LED Options ..................................................................................................... 6-18

Bar Codes with Unknown Characters .................................................................................... 6-18

ASCII Character Sets ................................................................................................................... 6-18

Chapter 7: IBM 468X / 469X Interface

Introduction .................................................................................................................................... 7-1

Setting Parameters ........................................................................................................................ 7-1

Scanning Sequence Examples ................................................................................................ 7-1

Errors While Scanning ............................................................................................................. 7-2

Connecting an IBM 468X/469X Host ............................................................................................. 7-2

IBM Parameter Defaults ................................................................................................................. 7-3

IBM Host Parameters ..................................................................................................................... 7-4

Port Address ............................................................................................................................ 7-4

Convert Unknown to Code 39 .................................................................................................. 7-5

RS-485 Beep Directive ............................................................................................................. 7-5

RS-485 Bar Code Configuration Directive ............................................................................... 7-6

IBM-485 Specification Version ................................................................................................. 7-6

Chapter 8: Keyboard Wedge Interface

Introduction .................................................................................................................................... 8-1

Setting Parameters ........................................................................................................................ 8-1

Scanning Sequence Examples ................................................................................................ 8-1

Errors While Scanning ............................................................................................................. 8-2

Connecting a Keyboard Wedge Interface ...................................................................................... 8-2

Keyboard Wedge Parameter Defaults ........................................................................................... 8-3

Keyboard Wedge Host Parameters ................................ ........... ........... .......... ............................... 8-4

Keyboard Wedge Host Types .................................................................................................. 8-4

Bar Codes with Unknown Characters ...................................................................................... 8-4

Keystroke Delay ....................................................................................................................... 8-5

Intra-keystroke Delay ............................................................................................................... 8-5

Alternate Numeric Keypad Emulation ...................................................................................... 8-6

Quick Keypad Emulation .......................................................................................................... 8-6

Simulated Caps Lock ............................................................................................................... 8-7

Caps Lock Override ................................................................................................................. 8-7

Page 11

Table of Contents ix

Convert Case ........................................................................................................................... 8-8

Function Key Mapping ............................................................................................................. 8-8

FN1 Substitution ....................................................................................................................... 8-9

Send Make and Break .............................................................................................................. 8-9

Keyboard Map .............................................................................................................................. 8-10

ASCII Character Sets ................................................................................................................... 8-10

Chapter 9: User Preferences & Miscellaneous Options

Introduction .................................................................................................................................... 9-1

Setting Parameters ........................................................................................................................ 9-1

Scanning Sequence Examples ................................................................................................ 9-2

Errors While Scanning ............................................................................................................. 9-2

User Preferences/Miscellaneous Options Parameter Defaults ...................................................... 9-2

User Preferences ........................................................................................................................... 9-5

Default Parameters .................................................................................................................. 9-5

Parameter Bar Code Scanning ................................................................................................ 9-6

Beep After Good Decode ......................................................................................................... 9-6

Beeper Volume ........................................................................................................................ 9-7

Beeper Tone ............................................................................................................................ 9-8

Beeper Duration ....................................................................................................................... 9-9

Suppress Power Up Beeps ...................................................................................................... 9-9

Direct Decode Indicator .......................................................................................................... 9-10

Decode Pager Motor .............................................................................................................. 9-11

Decode Pager Motor Duration ............................................................................................... 9-12

Night Mode (DS8108-HC Only) .............................................................................................. 9-13

Low Power Mode ................................................................................................................... 9-15

Hand-held Trigger Mode ........................................................................................................ 9-18

Hands-free Mode ................................................................................................................... 9-19

Hand-held Decode Aiming Pattern ......................................................................................... 9-20

Presentation (Hands-free) Decode Aiming Pattern ................................................................ 9-21

Picklist Mode .......................................................................................................................... 9-22

Continuous Bar Code Read ................................................................................................... 9-23

Unique Bar Code Reporting ................................................................................................... 9-23

Decode Session Timeout ....................................................................................................... 9-24

Hands-free Decode Session Timeout .................................................................................... 9-24

Timeout Between Decodes, Same Symbol ............................................................................ 9-25

Timeout Between Decodes, Different Symbols ...................................................................... 9-25

Triggered Timeout, Same Symbol ......................................................................................... 9-26

Mobile Phone/Display Mode .................................................................................................. 9-27

PDF Prioritization ................................................................................................................... 9-28

PDF Prioritization Timeout ..................................................................................................... 9-28

Presentation (Hands-free) Mode Field of View ...................................................................... 9-29

Decoding Illumination ............................................................................................................. 9-29

Illumination Brightness ........................................................................................................... 9-30

Motion Tolerance (Hand-held Trigger Modes Only) ............................................................... 9-31

Miscellaneous Scanner Parameters ............................................................................................ 9-31

Enter Key ............................................................................................................................... 9-31

Tab Key .................................................................................................................................. 9-31

Transmit Code ID Character .................................................................................................. 9-32

Page 12

x DS8108 Digital Scanner Product Reference Guide

Prefix/Suffix Values ................................................................................................................ 9-33

Scan Data Transmission Format ............................................................................................ 9-34

FN1 Substitution Values ......................................................................................................... 9-36

Transmit “No Read” Message ................................................................................................ 9-37

Unsolicited Heartbeat Interval ................................................................................................ 9-38

Chapter 10: Image Capture Preferences

Introduction .................................................................................................................................. 10-1

Setting Parameters ...................................................................................................................... 10-1

Scanning Sequence Examples .............................................................................................. 10-2

Errors While Scanning ........................................................................................................... 10-2

Image Capture Preferences Parameter Defaults ......................................................................... 10-2

Image Capture Preferences ......................................................................................................... 10-4

Operational Modes ................................................................................................................. 10-4

Image Capture Illumination .................................................................................................... 10-5

Image Capture Autoexposure ................................................................................................ 10-5

Fixed Exposure ...................................................................................................................... 10-6

Fixed Gain .............................................................................................................................. 10-6

Gain/Exposure Priority for Snapshot Mode ............................................................................ 10-7

Snapshot Mode Timeout ........................................................................................................ 10-8

Snapshot Aiming Pattern ....................................................................................................... 10-9

Silence Operational Mode Changes ...................................................................................... 10-9

Image Cropping .................................................................................................................... 10-10

Crop to Pixel Addresses ....................................................................................................... 10-10

Image Size (Number of Pixels) ............................................................................................ 10-12

Image Brightness (Target White) ......................................................................................... 10-13

JPEG Image Options ........................................................................................................... 10-13

JPEG Quality Value ............................................................................................................. 10-14

JPEG Size Value .................................................................................................................. 10-14

Image Enhancement ............................................................................................................ 10-15

Image File Format Selector .................................................................................................. 10-16

Image Rotation ..................................................................................................................... 10-17

Bits Per Pixel ........................................................................................................................ 10-18

Signature Capture ................................................................................................................ 10-19

Signature Capture File Format Selector ............................................................................... 10-20

Signature Capture Bits Per Pixel .......................................................................................... 10-21

Signature Capture Width ...................................................................................................... 10-22

Signature Capture Height ..................................................................................................... 10-22

Signature Capture JPEG Quality ......................................................................................... 10-22

Video View Finder ................................................................................................................ 10-23

Video View Finder Image Size ............................................................................................. 10-23

Chapter 11: Symbologies

Introduction .................................................................................................................................. 11-1

Setting Parameters ...................................................................................................................... 11-1

Scanning Sequence Examples .............................................................................................. 11-2

Errors While Scanning ........................................................................................................... 11-2

Symbology Parameter Defaults ................................................................................................... 11-2

Page 13

Table of Contents xi

Enable/Disable All Code Types ................................................................................................... 11-8

UPC/EAN/JAN ............................................................................................................................. 11-9

UPC-A .................................................................................................................................... 11-9

UPC-E .................................................................................................................................... 11-9

UPC-E1 ................................................................................................................................ 11-10

EAN-8/JAN-8 ........................................................................................................................ 11-10

EAN-13/JAN-13 .................................................................................................................... 11-11

Bookland EAN ...................................................................................................................... 11-11

Bookland ISBN Format ........................................................................................................ 11-12

ISSN EAN ............................................................................................................................ 11-13

Decode UPC/EAN/JAN Supplementals ............................................................................... 11-14

User-Programmable Supplementals .................................................................................... 11-17

UPC/EAN/JAN Supplemental Redundancy ......................................................................... 11-17

UPC/EAN/JAN Supplemental AIM ID Format ...................................................................... 11-18

Transmit UPC-A Check Digit ................................................................................................ 11-19

Transmit UPC-E Check Digit ................................................................................................ 11-19

Transmit UPC-E1 Check Digit .............................................................................................. 11-20

UPC-A Preamble .................................................................................................................. 11-21

UPC-E Preamble .................................................................................................................. 11-22

UPC-E1 Preamble ................................................................................................................ 11-23

Convert UPC-E to UPC-A .................................................................................................... 11-24

Convert UPC-E1 to UPC-A .................................................................................................. 11-24

EAN/JAN Zero Extend ......................................................................................................... 11-25

UCC Coupon Extended Code .............................................................................................. 11-25

Coupon Report ..................................................................................................................... 11-26

UPC Reduced Quiet Zone ................................................................................................... 11-27

Code 128 ................................................................................................................................... 11-28

Set Lengths for Code 128 .................................................................................................... 11-28

GS1-128 (formerly UCC/EAN-128) ...................................................................................... 11-30

ISBT 128 .............................................................................................................................. 11-30

ISBT Concatenation ............................................................................................................. 11-31

Check ISBT Table ................................................................................................................ 11-32

ISBT Concatenation Redundancy ........................................................................................ 11-32

Code 128 <FNC4> ............................................................................................................... 11-33

Code 128 Security Level ...................................................................................................... 11-34

Code 128 Reduced Quiet Zone ........................................................................................... 11-36

Code 39 ..................................................................................................................................... 11-37

Trioptic Code 39 ................................................................................................................... 11-37

Convert Code 39 to Code 32 ............................................................................................... 11-38

Code 32 Prefix ..................................................................................................................... 11-38

Set Lengths for Code 39 ...................................................................................................... 11-39

Code 39 Check Digit Verification ......................................................................................... 11-40

Transmit Code 39 Check Digit ............................................................................................. 11-41

Code 39 Full ASCII Conversion ........................................................................................... 11-41

Code 39 Security Level ........................................................................................................ 11-42

Code 39 Reduced Quiet Zone ............................................................................................. 11-44

Code 93 ..................................................................................................................................... 11-45

Set Lengths for Code 93 ...................................................................................................... 11-45

Code 11 ..................................................................................................................................... 11-47

Set Lengths for Code 11 ...................................................................................................... 11-47

Page 14

xii DS8108 Digital Scanner Product Reference Guide

Code 11 Check Digit Verification ......................................................................................... 11-49

Transmit Code 11 Check Digits ........................................................................................... 11-50

Interleaved 2 of 5 (ITF) .............................................................................................................. 11-51

Set Lengths for Interleaved 2 of 5 ........................................................................................ 11-51

I 2 of 5 Check Digit Verification ............................................................................................ 11-53

Transmit I 2 of 5 Check Digit ................................................................................................ 11-54

Convert I 2 of 5 to EAN-13 ................................................................................................... 11-54

I 2 of 5 Security Level ........................................................................................................... 11-55

I 2 of 5 Reduced Quiet Zone ................................................................................................ 11-56

Discrete 2 of 5 (DTF) ................................................................................................................. 11-57

Set Lengths for Discrete 2 of 5 ............................................................................................. 11-57

Codabar (NW - 7) ....................................................................................................................... 11-59

Set Lengths for Codabar ...................................................................................................... 11-59

CLSI Editing ......................................................................................................................... 11-61

NOTIS Editing ...................................................................................................................... 11-61

Codabar Upper or Lower Case Start/Stop Characters ......................................................... 11-62

MSI ............................................................................................................................................. 11-63

Set Lengths for MSI ............................................................................................................. 11-63

MSI Check Digits .................................................................................................................. 11-65

Transmit MSI Check Digit(s) ................................................................................................ 11-65

MSI Check Digit Algorithm ................................................................................................... 11-66

MSI Reduced Quiet Zone ..................................................................................................... 11-66

Chinese 2 of 5 ............................................................................................................................ 11-67

Matrix 2 of 5 ............................................................................................................................... 11-68

Set Lengths for Matrix 2 of 5 ................................................................................................ 11-68

Matrix 2 of 5 Check Digit ...................................................................................................... 11-70

Transmit Matrix 2 of 5 Check Digit ....................................................................................... 11-70

Korean 3 of 5 ............................................................................................................................. 11-71

Inverse 1D .................................................................................................................................. 11-72

GS1 DataBar .............................................................................................................................. 11-73

GS1 DataBar Omnidirectional (formerly GS1 DataBar-14) .................................................. 11-73

GS1 DataBar Limited ........................................................................................................... 11-73

GS1 DataBar Expanded ....................................................................................................... 11-74

Convert GS1 DataBar to UPC/EAN/JAN ............................................................................. 11-74

GS1 DataBar Security Level ................................................................................................ 11-75

GS1 DataBar Limited Margin Check .................................................................................... 11-76

Symbology-Specific Security Features ...................................................................................... 11-77

Redundancy Level ............................................................................................................... 11-77

Security Level ....................................................................................................................... 11-79

1D Quiet Zone Level ............................................................................................................ 11-80

Intercharacter Gap Size ....................................................................................................... 11-81

Composite .................................................................................................................................. 11-82

Composite CC-C .................................................................................................................. 11-82

Composite CC-A/B ............................................................................................................... 11-82

Composite TLC-39 ............................................................................................................... 11-83

Composite Inverse ............................................................................................................... 11-83

UPC Composite Mode ......................................................................................................... 11-84

Composite Beep Mode ......................................................................................................... 11-85

GS1-128 Emulation Mode for UCC/EAN Composite Codes ................................................ 11-85

2D Symbologies ......................................................................................................................... 11-86

Page 15

Table of Contents xiii

PDF417 ................................................................................................................................ 11-86

MicroPDF417 ....................................................................................................................... 11-86

Code 128 Emulation ............................................................................................................. 11-87

Data Matrix ........................................................................................................................... 11-88

GS1 Data Matrix ................................................................................................................... 11-88

Data Matrix Inverse .............................................................................................. .......... ...... 11-89

Decode Data Matrix Mirror Images ...................................................................................... 11-90

Maxicode .............................................................................................................................. 11-91

QR Code .............................................................................................................................. 11-92

GS1 QR ............................................................................................................................... 11-92

MicroQR ............................................................................................................................... 11-93

Aztec .................................................................................................................................... 11-93

Aztec Inverse ....................................................................................................................... 11-94

Han Xin ................................................................................................................................ 11-95

Han Xin Inverse .................................................................................................................... 11-96

Macro PDF Features .................................................................................................................. 11-97

Flush Macro Buffer ............................................................................................................... 11-97

Abort Macro PDF Entry ........................................................................................................ 11-97

Postal Codes .............................................................................................................................. 11-98

US Postnet ........................................................................................................................... 11-98

US Planet ............................................................................................................................. 11-98

Transmit US Postal Check Digit ........................................................................................... 11-99

UK Postal ............................................................................................................................. 11-99

Transmit UK Postal Check Digit ......................................................................................... 11-100

Japan Postal ...................................................................................................................... 11-100

Australia Post ..................................................................................................................... 11-101

Australia Post Format ......................................................................................................... 11-102

Netherlands KIX Code ...................................................................................................... 11-103

USPS 4CB/One Code/Intelligent Mail ................................................................................ 11-103

UPU FICS Postal ............................................................................................................... 11-104

Mailmark ............................................................................................................................. 11-104

Chapter 12: OCR Programming

Introduction .................................................................................................................................. 12-1

Setting Parameters ...................................................................................................................... 12-1

Scanning Sequence Examples .............................................................................................. 12-2

Errors While Scanning ........................................................................................................... 12-2

OCR Parameter Defaults ............................................................................................................. 12-2

OCR Programming Parameters ................................................................................................... 12-3

OCR-A .................................................................................................................................... 12-3

OCR-A Variant ....................................................................................................................... 12-4

OCR-B .................................................................................................................................... 12-5

OCR-B Variant ....................................................................................................................... 12-6

MICR E13B .......................................................................................................................... 12-10

US Currency Serial Number ................................................................................................. 12-11

OCR Orientation ................................................................................................................... 12-11

OCR Lines ............................................................................................................................ 12-13

OCR Minimum Characters ................................................................................................... 12-13

OCR Maximum Characters .................................................................................................. 12-14

Page 16

xiv DS8108 Digital Scanner Product Reference Guide

OCR Subset ......................................................................................................................... 12-14

OCR Quiet Zone .................................................................................................................. 12-15

OCR Template ..................................................................................................................... 12-15

OCR Check Digit Modulus ................................................................................................... 12-25

OCR Check Digit Multiplier .................................................................................................. 12-26

OCR Check Digit Validation ................................................................................................. 12-27

Inverse OCR ........................................................................................................................ 12-32

Chapter 13: Intelligent Document Capture

Introduction .................................................................................................................................. 13-1

The IDC Process .......................................................................................................................... 13-1

Bar Code Acceptance Test .................................................................................................... 13-2

Capture Region Determination ............................................................................................... 13-2

Image Post Processing .......................................................................................................... 13-3

Data Transmission ................................................................................................................. 13-3

PC Application and Programming Support .................................................................................. 13-3

Setting Parameters ...................................................................................................................... 13-4

Scanning Sequence Examples .............................................................................................. 13-4

Errors While Scanning ........................................................................................................... 13-4

Image Document Capture Parameter Defaults ...................................................................... 13-5

IDC Operating Mode .............................................................................................................. 13-7

IDC Symbology ...................................................................................................................... 13-8

IDC X Coordinate ................................................................................................................... 13-9

IDC Y Coordinate ................................................................................................................... 13-9

IDC Width ............................................................................................................................. 13-10

IDC Height ............................................................................................................................ 13-10

IDC Aspect ........................................................................................................................... 13-11

IDC File Format Selector ...................................................................................................... 13-11

IDC Bits Per Pixel ................................................................................................................. 13-12

IDC JPEG Quality ................................................................................................................ 13-12

IDC Find Box Outline ........................................................................................................... 13-13

IDC Minimum Text Length ................................................................................................... 13-13

IDC Maximum Text Length .................................................................................................. 13-14

IDC Captured Image Brighten .............................................................................................. 13-14

IDC Captured Image Sharpen .............................................................................................. 13-15

IDC Border Type .................................................................................................................. 13-16

IDC Delay Time .................................................................................................................... 13-17

IDC Zoom Limit .................................................................................................................... 13-17

IDC Maximum Rotation ........................................................................................................ 13-18

Quick Start ................................................................................................................................. 13-19

Sample IDC Setup .................................................................................... ........... .......... ...... 13-19

IDC Demonstrations ............................................................................................................. 13-20

Other Suggestions ............................................................................................................... 13-21

Quick Start Form .................................................................................................................. 13-21

Page 17

Table of Contents xv

Chapter 14: DigiMarc Bar code

Introduction .................................................................................................................................. 14-1

DigiMarc Symbology Selection .................................................................................................... 14-1

Picklist .................................................................................................................................... 14-1

DigiMarc Bar Codes ..................................................................................................................... 14-2

Chapter 15: Driver’s License Set Up (DS8108-DL)

Introduction .................................................................................................................................. 15-1

Driver’s License Parsing .............................................................................................................. 15-2

Parsing Driver’s License Data Fields (Embedded Driver's License Parsing) ............................... 15-3

Embedded Driver's License Parsing Criteria - Code Type ..................................................... 15-3

Driver’s License Parse Field Bar Codes ................................................................................ 15-4

AAMVA Parse Field Bar Codes ............................................................................................. 15-7

Parser Version ID Bar Code ................................................................................................. 15-17

User Preferences ....................................................................................................................... 15-17

Set Default Parameter .......................................................................................................... 15-17

Output Gender as M or F ..................................................................................................... 15-17

Date Format ......................................................................................................................... 15-18

Send Keystroke (Control Characters and Keyboard Characters) ........................................ 15-20

Parsing Rule Example ............................................................................................................... 15-39

Embedded Driver's License Parsing ADF Example ............................................................. 15-43

Chapter 16: 123Scan and Software Tools

Introduction .................................................................................................................................. 16-1

123Scan ....................................................................................................................................... 16-1

Communication with 123Scan ................................................................................................ 16-2

123Scan Requirements .......................................................................................................... 16-2

123Scan Information .............................................................................................................. 16-3

Scanner SDK, Other Software Tools, and Videos ................................................................. 16-3

Scanner Control App .................................................................................................................... 16-4

Advanced Data Formatting (ADF) ................................................................................................ 16-4

Multicode Data Formatting (MDF) ................................................................................................ 16-5

Programming Options ............................................................................................................ 16-5

MDF Terms and Definitions ................................................................................................... 16-5

Preferred Symbol ......................................................................................................................... 16-6

Programming Options ............................................................................................................ 16-6

Appendix A: Standard Parameter Defaults

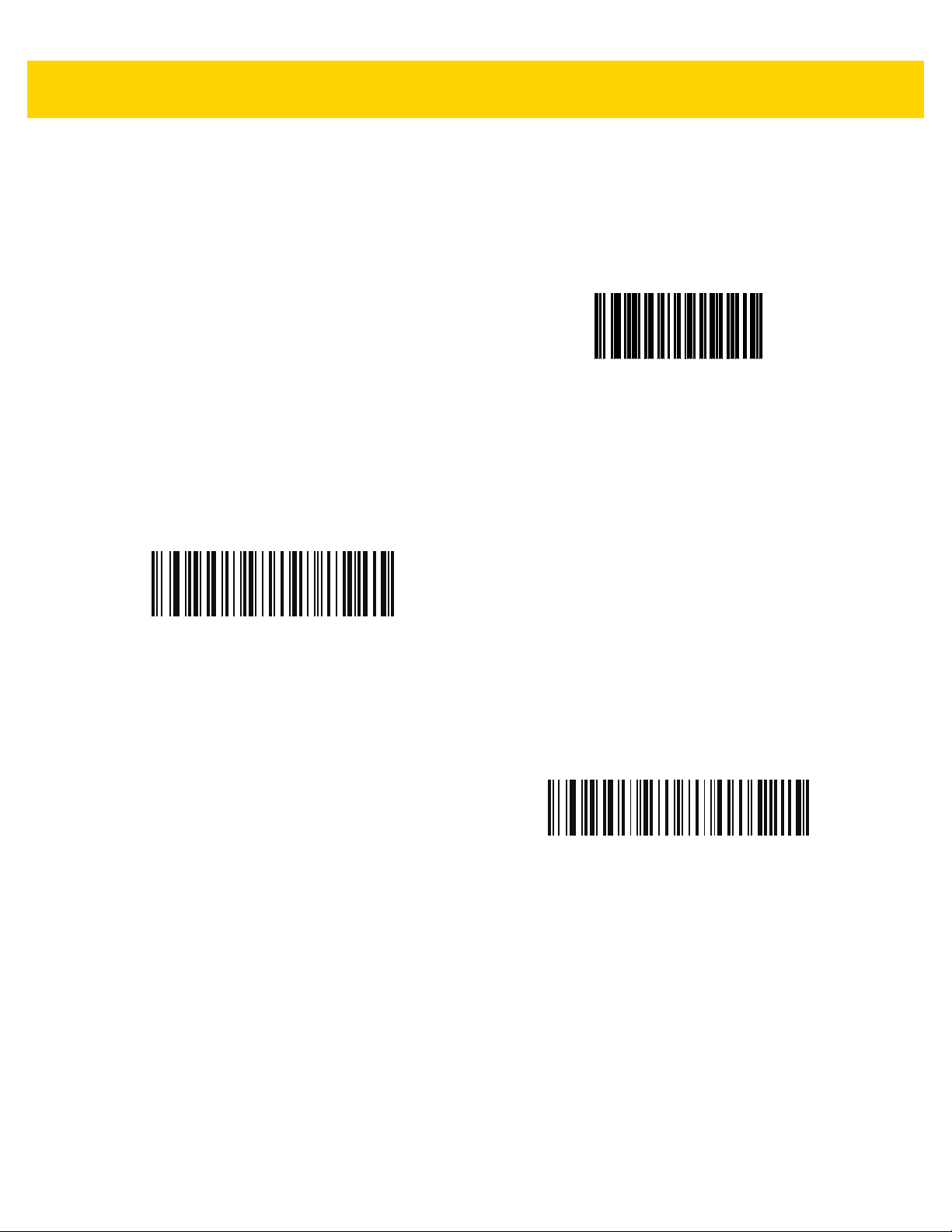

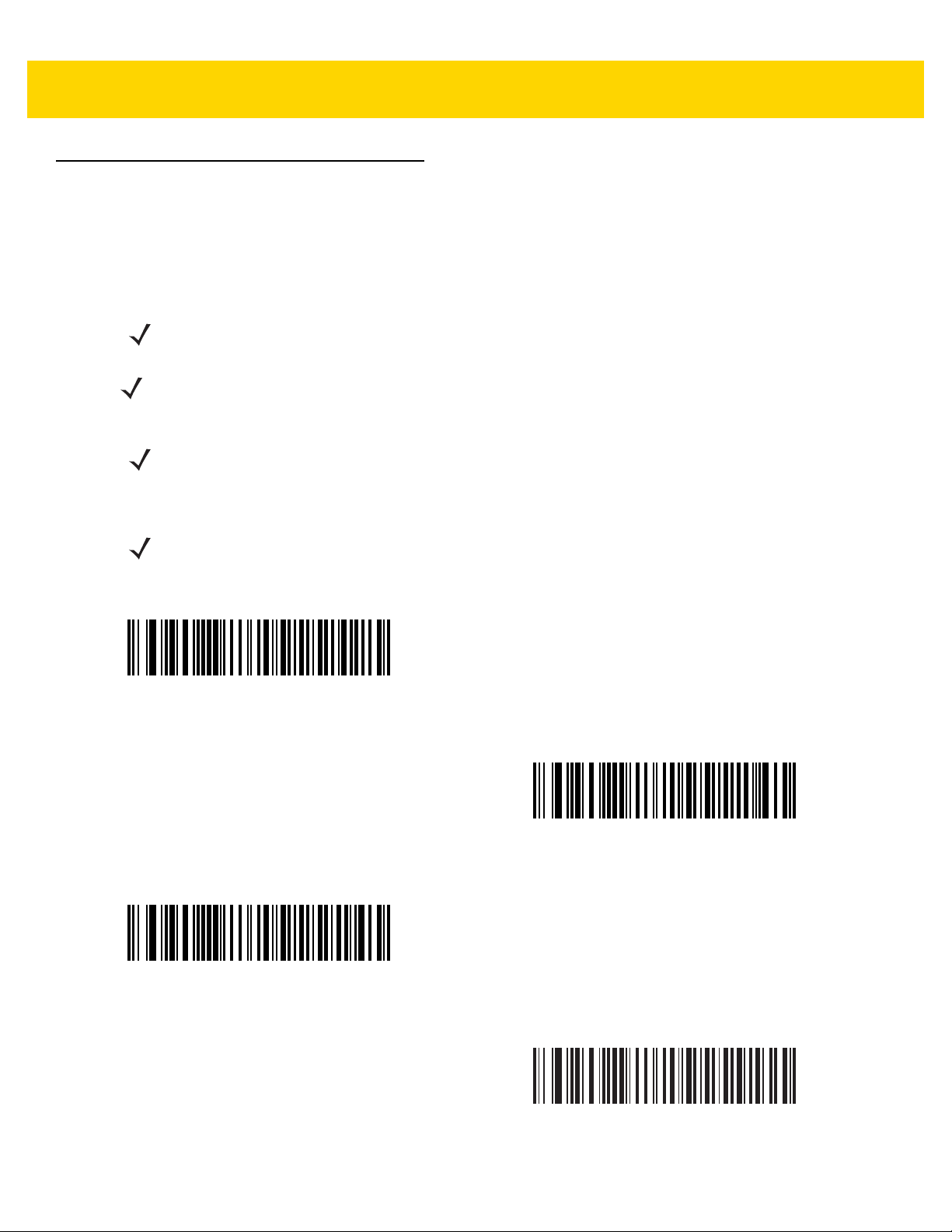

Appendix B: Numeric Bar Codes

Numeric Bar Codes ....................................................................................................................... B-1

Cancel ........................................................................................................................................... B-3

Page 18

xvi DS8108 Digital Scanner Product Reference Guide

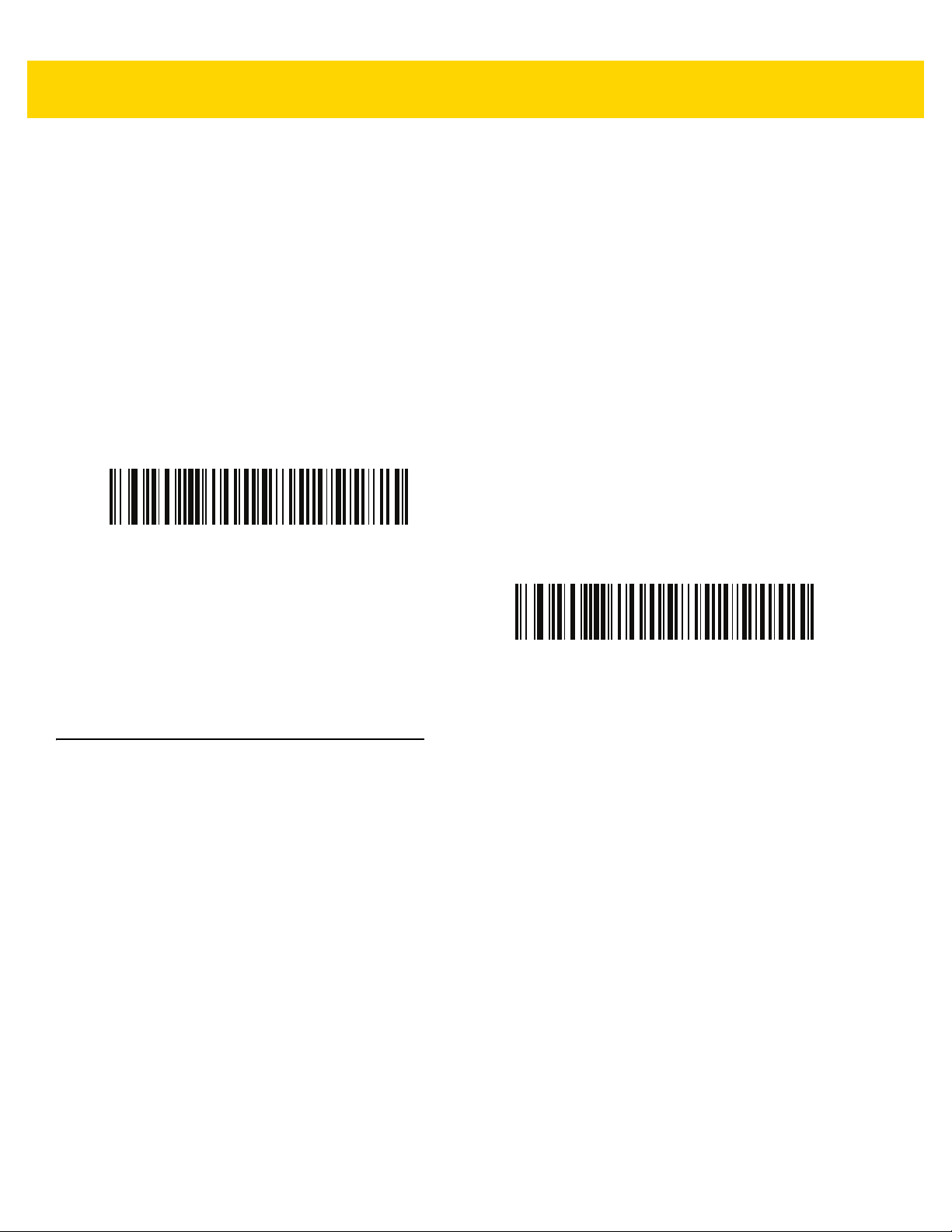

Appendix C: Alphanumeric Bar Codes

Cancel ........................................................................................................................................... C-1

Alphanumeric Bar Codes .............................................................................................................. C-2

Appendix D: ASCII Character Sets

Appendix E: Programming Reference

Symbol Code Identifiers ................................................................................................................ E-1

AIM Code Identifiers ..................................................................................................................... E-3

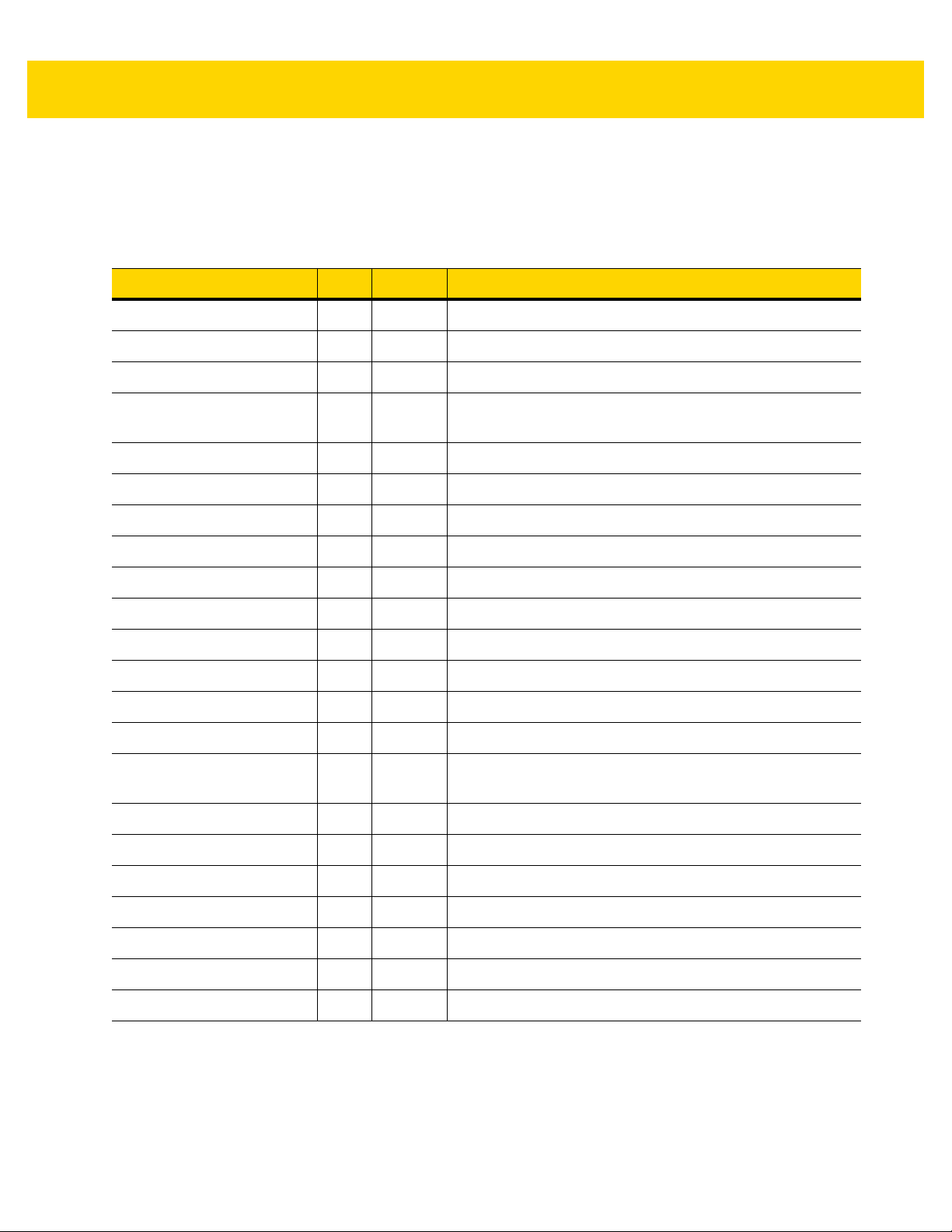

Appendix F: Communication Protocol Functionality

Functionality Supported via Communication (Cable) Interface ...................................................... F-1

Appendix G: Country Codes

Introduction ................................................................................................................................... G-1

USB and Keyboard Wedge Country Keyboard Types (Country Codes) ....................................... G-2

Appendix H: Country Code Pages

Introduction ................................................................................................................................... H-1

Country Code Page Defaults ........................................................................................................ H-1

Country Code Page Bar Codes .................................................................................................... H-5

Appendix I: CJK Decode Control

Introduction ..................................................................................................................................... I-1

CJK Control Parameters ................................................................................................................. I-2

Unicode Output Control ............................................................................................................. I-2

CJK Output Method to Windows Host ....................................................................................... I-3

Non-CJK UTF Bar Code Output ................................................................................................ I-5

Unicode/CJK Decode Setup with Windows Host ............................................................................ I-7

Setting Up the Windows Registry Table for Unicode Universal Output .................................... I-7

Adding CJK IME on Windows ................................................................................................... I-7

Selecting the Simplified Chinese Input Method on the Host ..................................................... I-8

Selecting the Traditional Chinese Input Method on the Host .................................................... I-9

Appendix J: Signature Capture Code

Introduction .................................................................................................................................... J-1

Code Structure ............................................................................................................................... J-1

Signature Capture Area .................................................................. .......... ........... .................... J-1

CapCode Pattern Structure ...................................................................................................... J-2

Start / Stop Patterns ....................................................................................................................... J-2

Dimensions .................................................................................................................................... J-3

Data Format ................................................................................................................................... J-3

Additional Capabilities .................................................................................................................... J-4

Signature Boxes ............................................................................................................................ J-4

Page 19

Table of Contents xvii

Appendix K: Non-Parameter Attributes (Attribute Data Dictionary)

Introduction ................................................................................................................................... K-1

Attributes ....................................................................................................................................... K-1

Model Number ......................................................................................................................... K-1

Serial Number ......................................................................................................................... K-1

Date of Manufacture ........................................................................................................... ..... K-2

Date of First Programming ...................................................................................................... K-2

Configuration Filename ........................................................................................................... K-2

Beeper/LED ............................................................................................................................. K-3

Parameter Defaults ................................................................................................................. K-4

Beep on Next Bootup .............................................................................................................. K-4

Reboot ..................................................................................................................................... K-4

Host Trigger Session ............................................................................................................... K-4

Firmware Version .................................................................................................................... K-5

Scankit Version ....................................................................................................................... K-5

Appendix L: Sample Bar Codes

UPC/EAN ...................................................................................................................................... L-1

UPC-A, 100% ........................................................................................................................... L-1

UPC-A with 2-digit Add-on ....................................................................................................... L-1

UPC-A with 5-digit Add-on ....................................................................................................... L-2

UPC-E ...................................................................................................................................... L-2

UPC-E with 2-digit Add-on ....................................................................................................... L-2

UPC-E with 5-digit Add-on ....................................................................................................... L-3

EAN-8 ....................................................................................................................................... L-3

EAN-13, 100% ......................................................................................................................... L-3

EAN-13 with 2-digit Add-on ...................................................................................................... L-4

EAN-13 with 5-digit Add-on ...................................................................................................... L-4

Code 128 ....................................................................................................................................... L-4

GS1-128 ................................................................................................................................... L-5

Code 39 ......................................................................................................................................... L-5

Code 93 ......................................................................................................................................... L-5

Code 11 with 2 Check Digits .......................................................................................................... L-6

Interleaved 2 of 5 ........................................................................................................................... L-6

MSI with 2 Check Digits ................................................................................................................. L-6