Page 1

DS7708 2D VERTICAL

SLOT SCANNER

PRODUCT REFERENCE GUIDE

Page 2

Page 3

DS7708 2D VERTICAL SLOT SCANNER

PRODUCT REFERENCE GUIDE

MN001062A09EN

Revision A

April 2020

Page 4

ii DS7708 VERTICAL 2D SLOT SCANNER PRODUCT REFERENCE GUIDE

No part of this publication may be reproduced or used in any form, or by any electrical or mechanical means,

without permission in writing from Zebra. This includes electronic or mechanical means, such as photo copying,

recording, or information storage and retrieval systems. The material in this manual is subject to change

without notice.

The software is provided strictly on an “as is” basis. All software, including firmware, furnished to the user is on

a licensed basis. Zebra grants to the user a non-transferable and non-exclusive license to use each software

or firmware program delivered hereunder (licensed program) . Except as n oted below, such license may n ot be

assigned, sub-licensed, or otherwise transferred by the user without prior written consent of Zebra. No right to

copy a licensed program in whole or in part is granted, except as permitted under copyright law. The user shall

not modify , merge, or incorporate any for m or portion of a licensed program with other pro gram material, create

a derivative work from a licensed program , or us e a li censed program in a network without written permission

from Zebra. The user agrees to maintain Zebra’s copyright notice on the licensed programs delivered

hereunder , and to include the same on any au thorized copies it m akes, in whole or in part. The user agrees not

to decompile, disassemble, decode, or reverse engineer any licensed program delivered to the user or any

portion thereof.

Zebra reserves the right to make changes to any software or product to improve reliability, function, or design.

Zebra does not assume any product liability arising out of, or in connection with, the application or use of any

product, circuit, or application described herein.

No license is granted, either expressly or by implication, estoppel, or otherwise under any Zebra Technolo gies

Corporation, intellectual property rights. An implied license only exists for equipment, circuits, and su bsystems

contained in Zebra products.

Warranty

For the complete Zebra hardware product warranty statement, go to:

zebra.com/warranty.

Page 5

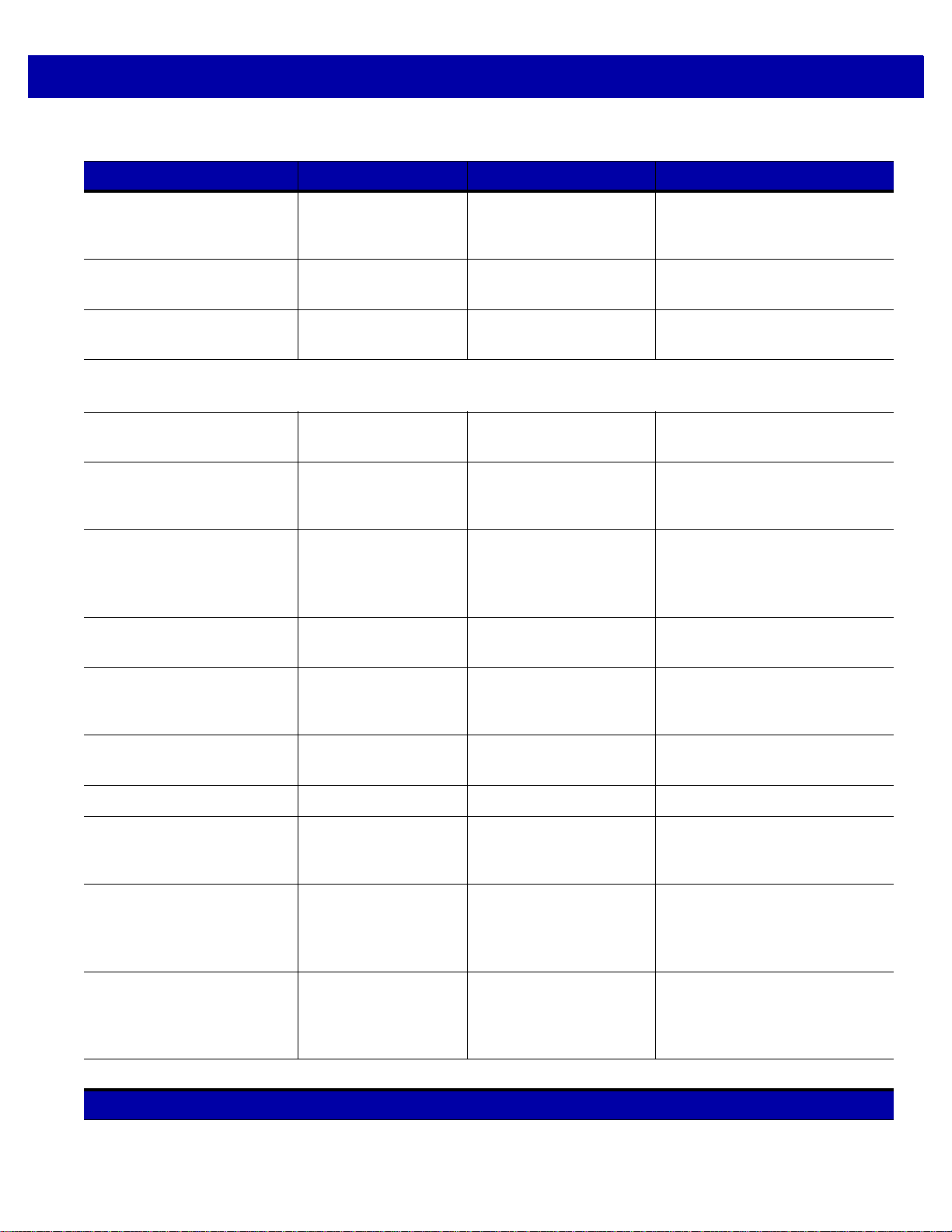

Revision History

Changes to the original guide are listed below:

Change Date Description

-01 Rev A 3/2015 Initial Release

-02 Rev A 4/2015 Updated note on page 11-2 regarding Using a Zebra Scanner as an Auxiliary

-03 Rev A 7/2015 Updated PIN #2 usage.

-04 Rev A 12/2015 Updated:

-05 Rev A 7/2018 - Added Note to PDF Prioritization parameter to update length ranges

iii

Scanner.

- Beeper Tone default from Medium to High.

- Table 13-2 on page 13-42 to reflect the correct behavior in the new image kit.

- Added Product ID (PID) Type parameter

- Renamed USB Device Type OPOS, and added Note

- Added Direct I/O Beep parameter

- Updated Beep Directive and Bar Code Configuration Directive for the IBM host

- Added IBM-485 Specification Version parameter

- Updated SSI Baud Rate option values

- Added Codabar Security Level parameter

- Added MSI Reduced Quiet Zone parameter

- Added Note for Inverse 1D parameter

- Added Mailmark parameter

- Added GS1 Databar Security Level parameter

- Renamed GS1 DataBar Limited Security Level parameter to GS1 DataBar

Limited Margin Check and updated description

- Added Composite Inverse parameter

- Added Grid Matrix, Grid Matrix Inverse, and Grid Matrix Mirrored parameters

- Removed QR Inverse parameter

- Removed OCR statements regarding slow decoding

Added OCR-B Passport option

- Added OCR Redundancy parameter

- Changed OCR Template default

- Updated 123Scan chapter

- Updated Code Identifiers and Modifier Characters tables

-06 Rev 06/2019 - Code 39 as a section heading in Chapter 12.

- Updated copyright statement.

-07EN Rev 02/2020 - Added Weblink QR code

- Updated default of Parameter #144 T imeout Between Decodes, Different

Symbols to 1 second.

-08EN Rev 08/2020 - Updated Electronic Article Surveillance (EAS)

- Updated Mobile Phone parameter

- Updated Scanner SDK, Other Software Tools, and Videos

- Added DotCode, DotCode Inverse, DotCode Mirrored, and DotCode Prioritize

parameters.

-09EN Rev 04/2021 Updated Mobile Phone parameter.

Page 6

iv DS7708 VERTICAL 2D SLOT SCANNER PRODUCT REFERENCE GUIDE

Page 7

TABLE OF CONTENTS

Warranty ......................................................................................................................................... ii

Revision History.............................................................................................................................. iii

About This Guide

Introduction..................................................................................................................................... v

Scanner Configurations .................................................................................................................. v

Accessories..................................................................................................................................... vi

Chapter Descriptions ...................................................................................................................... viii

Notational Conventions................................................................................................................... ix

Related Publications....................................................................................................................... x

Service Information......................................................................................................................... x

Chapter 1: GETTING STARTED

Introduction .............................................................................................................................. 1-1

Unpacking the Scanner ............................................................................................................ 1-1

Protective Cover ................................................................................................................ 1-1

Features ................................................................................................................................... 1-2

Setting Up the Scanner ............................................................................................................ 1-4

Power Options ................................................................................................................... 1-4

Ports ................................................................................................................................... 1-4

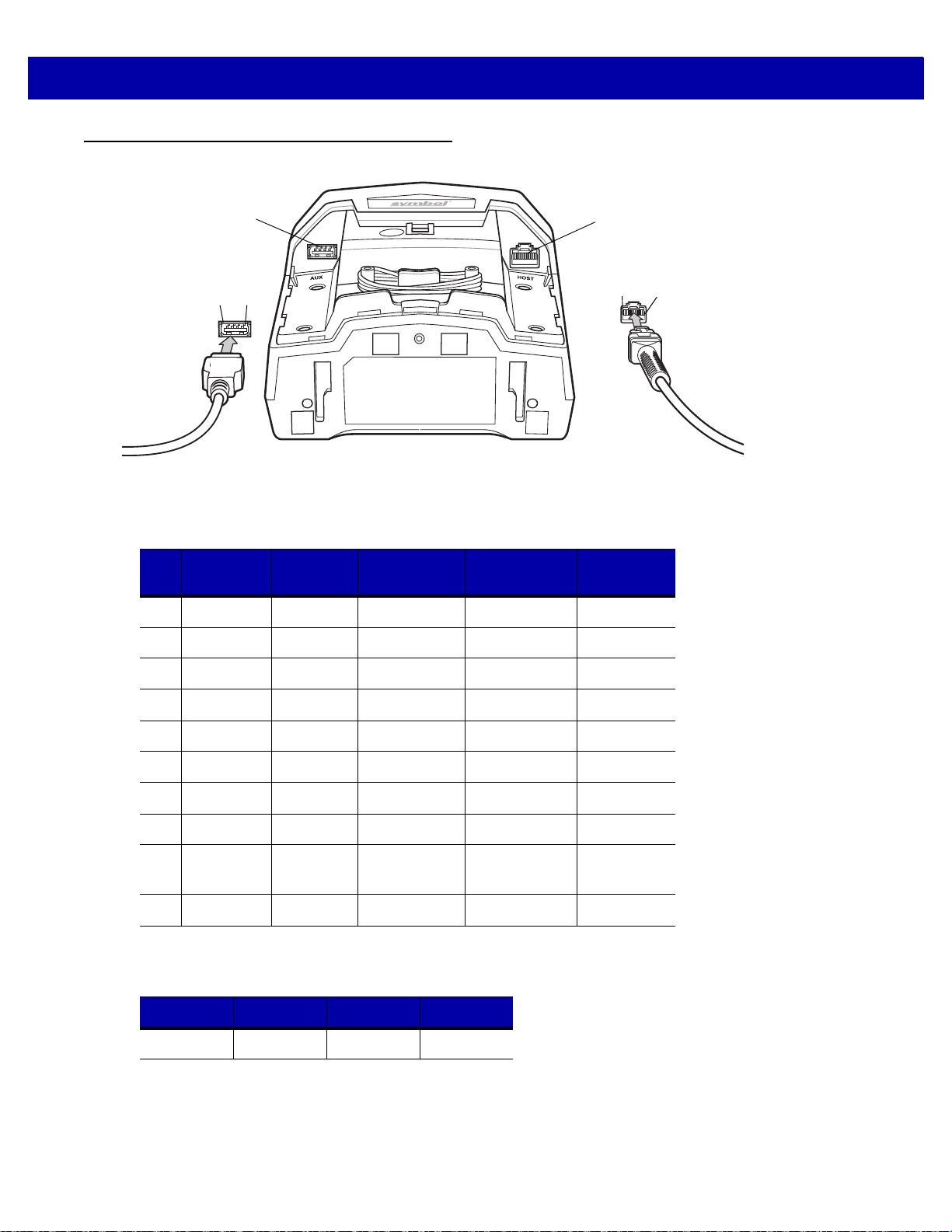

Connecting the Host and/or Auxiliary Scanner Cable ........................................................ 1-4

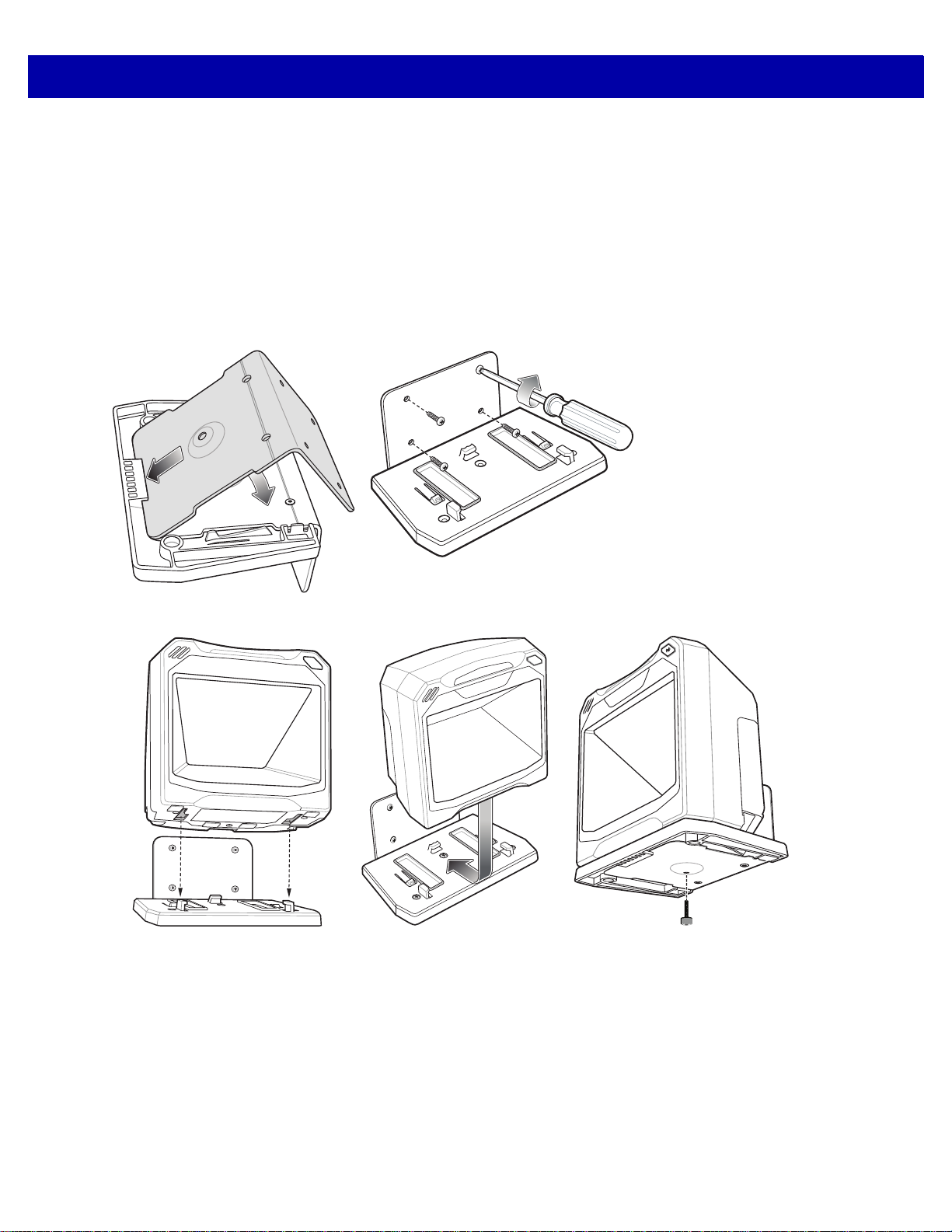

Removing and Replacing the Back Cover ......................................................................... 1-5

Removing the Back Cover ........................................................................................... 1-5

Installing the Cable(s) ........................................................................................................ 1-5

Removing the Back Cover with Cables Installed ......................................................... 1-6

Replacing the Back Cover ............................................................................................ 1-6

Configuring the Scanner .................................................................................................... 1-6

Synchronization of Settings ............................................................................................... 1-7

Host Requested Setting Changes ................................................................................ 1-7

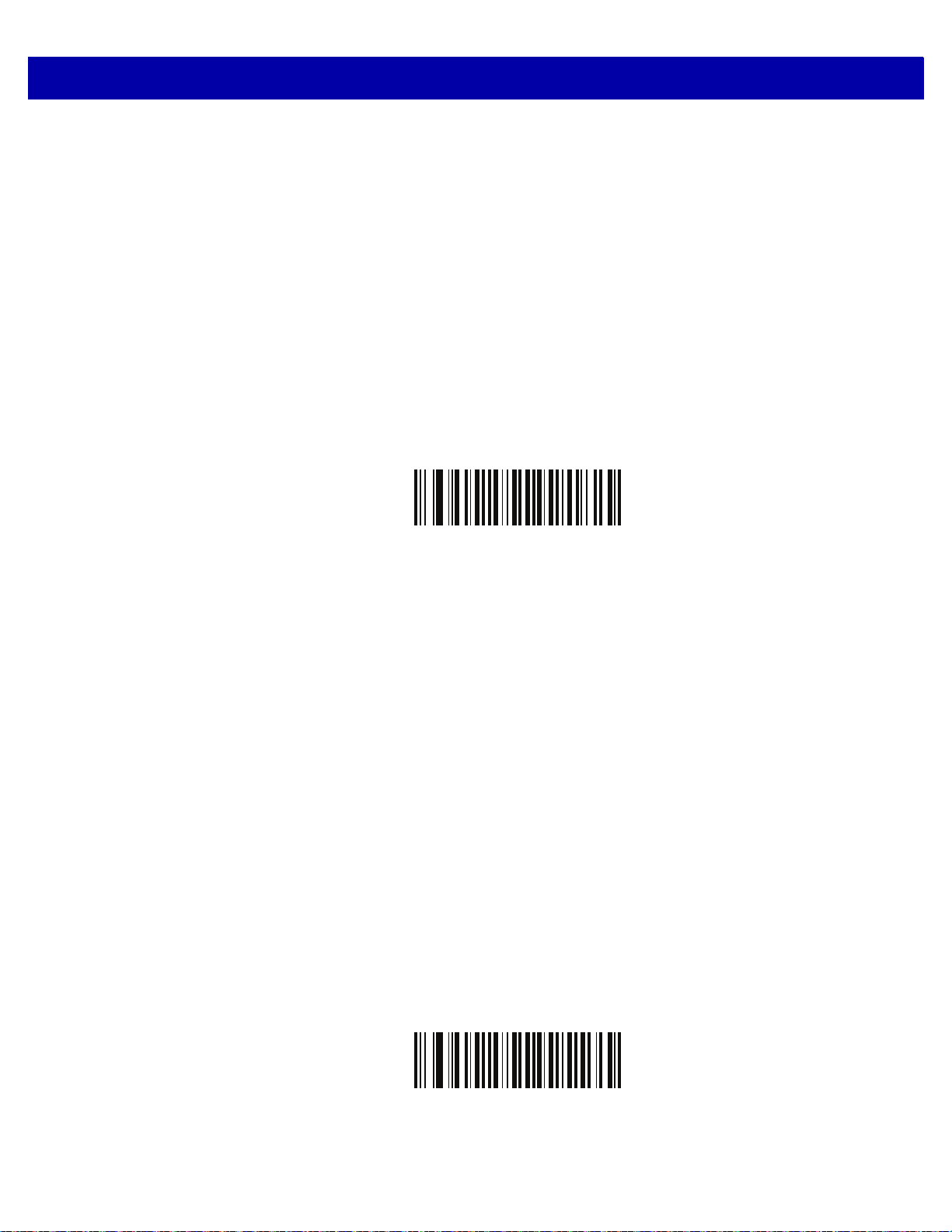

Bar Code Menu Symbols Scanned on the DS7708 ..................................................... 1-7

Bar Code Menu Symbols Scanned on the Hand-held Scanner ................................... 1-7

Mounting the Scanner (Optional Hardware Required) ............................................................. 1-8

Page 8

vi DS7708 2D Vertical Slot Scanner Product Reference Guide

Mounting the Scanner to the Table Top .............................................................................. 1-8

Mounting the Scanner to a Table Top with Double-sided Tape .................................... 1-8

Mounting the Scanner to a Table Top with Screws ...................................................... 1-8

Mounting the Scanner to a Wall .......................................................................................... 1-9

Removing the Scanner from the Mounting Bracket ............................................................ 1-10

Operating the Scanner .............................................................................................................. 1-11

Indicator Lights .................................................................................................................... 1-11

Adjusting Speaker Volume .................................................................................................. 1-11

Adjusting Speaker Tone ...................................................................................................... 1-11

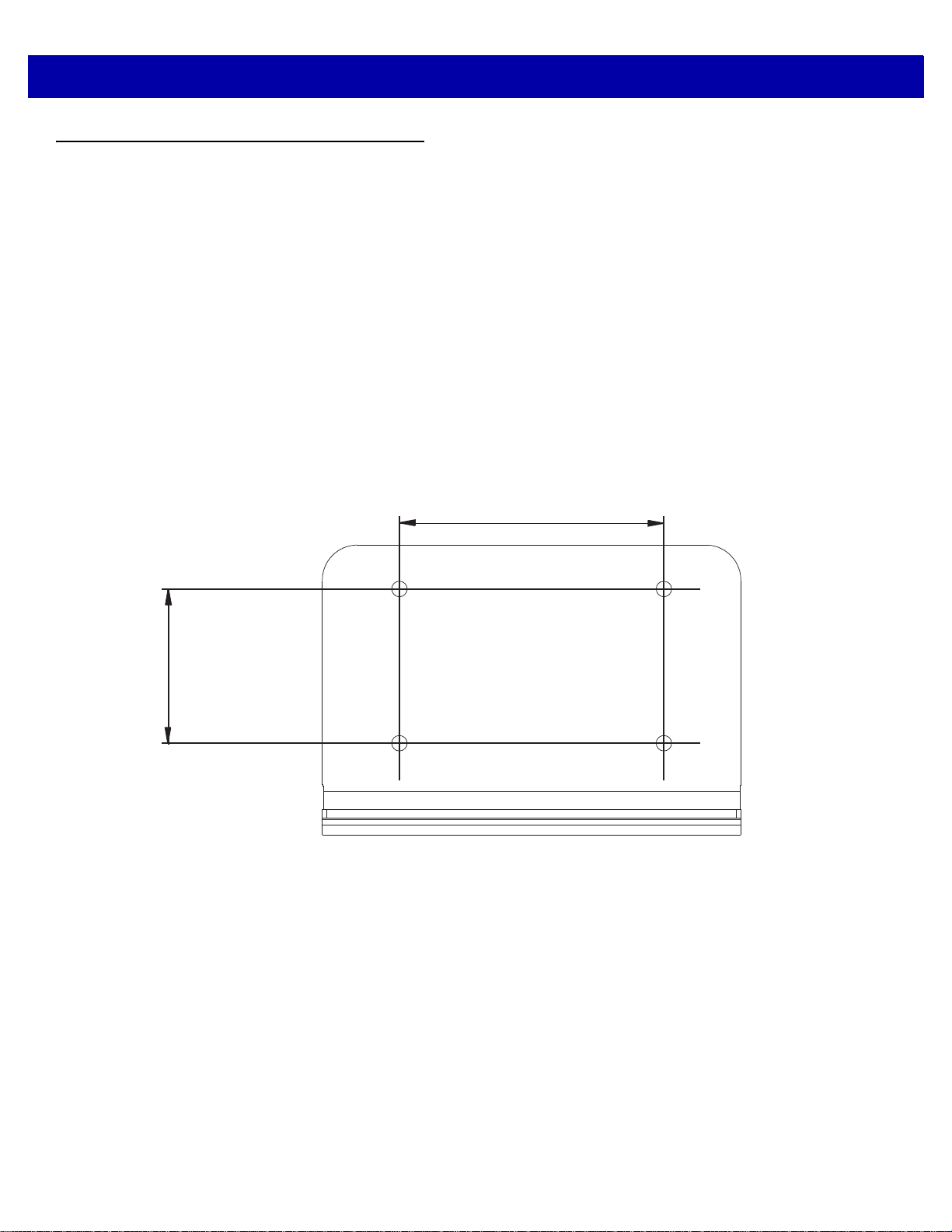

Wall Mount Template ................................................................................................................ 1-12

Table Mount Template .............................................................................................................. 1-13

Chapter 2: 123SCAN

Introduction ............................................................................................................................... 2-1

Communication with 123Scan .................................................................................................. 2-2

123Scan Requirements .............................................................. ........... ........... .......... .............. 2-2

123Scan Information ................................................................................................................. 2-3

Scanner SDK, Other Software Tools, and Videos .................................................................... 2-3

Chapter 3: DATA CAPTURE

Overview ................................................................................................................................... 3-1

Scanning Bar Codes on Products ............................................................................................. 3-2

Active Scan Area ................................................................................................................ 3-2

Decode Ranges ........................................................................................................................ 3-3

User Indicators .......................................................................................................................... 3-4

Beeper Volume/ Beeper Tone ............................................................................................ 3-4

LED and Beeper Indicators ................................................................................................. 3-4

Electronic Article Surveillance (EAS) ........................................................................................ 3-7

Installing .............................................................................................................................. 3-7

Checkpoint EAS Model Compatibility ........................................................................... 3-7

Considerations .............................................................................................................. 3-7

Checkpoint Contact Information .................................................................................... 3-7

Chapter 4: MAINTENANCE, TECHNICAL SPECIFICATIONS, MOUNTING TEMPLATES

Introduction ............................................................................................................................... 4-1

Maintenance ............................................................................................................................. 4-1

Troubleshooting ........................................................................................................................ 4-2

Technical Specifications ........................................................................................................... 4-4

Scanner Signal Descriptions ..................................................................................................... 4-7

Chapter 5: USER PREFERENCES & MISCELLANEOUS OPTIONS

Introduction ............................................................................................................................... 5-1

Scanning Sequence Examples ................................................................................................. 5-2

Errors While Scanning .............................................................................................................. 5-2

User Preferences/Miscellaneous Options Parameter Defaults ................................................. 5-2

User Preferences ...................................................................................................................... 5-4

Set Default Parameter ........................................................................................................ 5-4

Page 9

Table of Contents vii

Parameter Bar Code Scanning .......................................................................................... 5-6

Beep After Good Decode ................................................................................................... 5-7

Beeper Tone ...................................................................................................................... 5-8

Beeper Volume .................................................................................................................. 5-11

Beeper Duration ................................................................................................................. 5-13

Volume/Tone Button Control .............................................................................................. 5-15

Suppress Power-up Beeps ................................................................................................ 5-17

Timeout Between Decodes, Same Symbol ....................................................................... 5-18

Timeout Between Decodes, Different Symbols ................................................................. 5-18

Fuzzy 1D Processing ......................................................................................................... 5-19

Decode Mirror Images (Data Matrix Only) ......................................................................... 5-20

PDF Prioritization ............................................................................................................... 5-22

PDF Prioritization Timeout ................................................................................................. 5-23

Mobile Phone/Display Mode .............................................................................................. 5-24

Field of View ...................................................................................................................... 5-25

Product ID (PID) Type ........................................................................................................ 5-27

Miscellaneous Scanner Parameters ........................................................................................ 5-29

Transmit Code ID Character .............................................................................................. 5-29

Prefix/Suffix Values ............................................................................................................ 5-31

Scan Data Transmission Format ....................................................................................... 5-34

FN1 Substitution Values .................................................................................................... 5-38

Unsolicited Heartbeat Interval ............................................................................................ 5-39

Chapter 6: IMAGING PREFERENCES

Introduction .............................................................................................................................. 6-1

Scanning Sequence Examples ................................................................................................ 6-2

Errors While Scanning ............................................................................................................. 6-2

Imaging Preferences Parameter Defaults ................................................................................ 6-2

Imaging Preferences ................................................................................................................ 6-4

Operational Modes ............................................................................................................. 6-4

Decode Mode ............................................................................................................... 6-4

Snapshot Mode ............................................................................................................ 6-4

Snapshot Mode Timeout .................................................................................................... 6-5

Image Size (Number of Pixels) .......................................................................................... 6-6

Image Brightness (Target White) ....................................................................................... 6-8

JPEG Image Options ......................................................................................................... 6-9

JPEG Target File Size ....................................................................................................... 6-10

JPEG Quality and Size Value ............................................................................................ 6-11

Image Enhancement .......................................................................................................... 6-12

Image File Format Selection .............................................................................................. 6-14

Image Rotation ................................................................................................................... 6-16

Bits Per Pixel (BPP) ........................................................................................................... 6-18

Bits Per Pixel (continued) ................................................................................................... 6-19

Signature Capture .............................................................................................................. 6-20

Output File Format ....................................................................................................... 6-20

Signature Capture File Format Selection ........................................................................... 6-21

Signature Capture Bits Per Pixel ....................................................................................... 6-23

Signature Capture Width .................................................................................................... 6-25

Signature Capture Height .................................................................................................. 6-26

Signature Capture JPEG Quality ....................................................................................... 6-27

Page 10

viii DS7708 2D Vertical Slot Scanner Product Reference Guide

Video View Finder ............................................................................................................... 6-28

Video View Finder Image Size ............................................................................................ 6-29

Chapter 7: USB INTERFACE

Introduction ............................................................................................................................... 7-1

Connecting a USB Interface ..................................................................................................... 7-2

USB Default Parameters .......................................................................................................... 7-4

USB Host Parameters .............................................................................................................. 7-5

USB Device Type ................................................................................................................ 7-5

Symbol Native API (SNAPI) Status Handshaking ............................................................... 7-9

USB Keystroke Delay ......................................................................................................... 7-10

USB CAPS Lock Override .................................................................................................. 7-12

USB Ignore Unknown Characters ....................................................................................... 7-13

USB Convert Unknown to Code 39 .................................................................................... 7-14

Emulate Keypad .................................................................................................................. 7-15

Keypad Emulation with Leading Zero ................................................................................. 7-16

USB Keyboard FN1 Substitution ......................................................................................... 7-17

Function Key Mapping ........................................................................................................ 7-18

Simulated Caps Lock .......................................................................................................... 7-19

Convert Case ...................................................................................................................... 7-20

USB Static CDC .................................................................................................................. 7-22

Direct I/O Beep ................................................................................................................... 7-23

USB Transmission Speed Parameters ............................................................................... 7-24

USB HID Polling Interval ............................................................................................... 7-24

Fast HID Keyboard ....................................................................................................... 7-29

Quick Keypad Emulation ............................................................................................... 7-30

IBM Specification Version ................................................................................................... 7-31

Optional USB Parameters ........................................................................................................ 7-32

Beep Directive ..................................................................................................................... 7-32

Bar Code Configuration Directive ....................................................................................... 7-33

ASCII Character Set for USB .................................................................................................... 7-34

Chapter 8: RS-232 INTERFACE

Introduction ............................................................................................................................... 8-1

RS-232 Host Parameters .......................................................................................................... 8-5

RS-232 Host Types ............................................................................................................. 8-7

Baud Rate ........................................................................................................................... 8-11

Parity ................................................................................................................................... 8-14

Check Receive Errors ......................................................................................................... 8-16

Hardware Handshaking ...................................................................................................... 8-17

None ............................................................................................................................. 8-18

Standard RTS/CTS ....................................................................................................... 8-18

RTS/CTS Option 1 ........................................................................................................ 8-19

RTS/CTS Option 2 ........................................................................................................ 8-19

RTS/CTS Option 3 ........................................................................................................ 8-20

Software Handshaking ........................................................................................................ 8-21

None ............................................................................................................................. 8-21

ACK/NAK ...................................................................................................................... 8-21

ENQ .............................................................................................................................. 8-22

Page 11

Table of Contents ix

ACK/NAK with ENQ ..................................................................................................... 8-22

XON/XOFF ................................................................................................................... 8-23

Host Serial Response Time-out ......................................................................................... 8-23

RTS Line State ................................................................................................................... 8-27

Stop Bit Select ................................................................................................................... 8-28

Data Bits ............................................................................................................................ 8-29

Beep on <BEL> .................................................................................................................. 8-30

Intercharacter Delay ........................................................................................................... 8-31

Nixdorf Beep/LED Options ................................................................................................. 8-34

Ignore Unknown Characters .............................................................................................. 8-36

ASCII Character Set for RS-232 .............................................................................................. 8-37

Chapter 9: IBM 468X/469X INTERFACE

Introduction .............................................................................................................................. 9-1

Connecting to an IBM 468X/469X Host ................................................................................... 9-2

IBM Default Parameters ........................................................................................................... 9-4

IBM 468X/469X Host Parameters ............................................................................................ 9-5

Port Address ...................................................................................................................... 9-5

Convert Unknown to Code 39 ............................................................................................ 9-7

RS-485 Beep Directive ...................................................................................................... 9-8

RS-485 Bar Code Configuration Directive ......................................................................... 9-9

IBM-485 Specification Version ........................................................................................... 9-10

Chapter 10: KEYBOARD WEDGE INTERFACE

Introduction .............................................................................................................................. 10-1

Connecting a Keyboard Wedge Interface ................................................................................ 10-2

Keyboard Wedge Default Parameters ..................................................................................... 10-4

Keyboard Wedge Host Types ............................................................................................ 10-5

Ignore Unknown Characters .............................................................................................. 10-6

Keystroke Delay ................................................................................................................. 10-7

Intra-Keystroke Delay ........................................................................................................ 10-9

Alternate Numeric Keypad Emulation ................................................................................ 10-10

Quick Keypad Emulation .................................................................................................... 10-11

Caps Lock On .................................................................................................................... 10-12

Caps Lock Override ........................................................................................................... 10-13

Convert Wedge Data ......................................................................................................... 10-14

Function Key Mapping ....................................................................................................... 10-16

FN1 Substitution ................................................................................................................ 10-17

Send Make Break .............................................................................................................. 10-18

ASCII Character Set for Keyboard Wedge .............................................................................. 10-19

Chapter 11: SSI INTERFACE

Introduction .............................................................................................................................. 11-1

Communications ...................................................................................................................... 11-1

SSI Transactions ...................................................................................................................... 11-2

General Data Transactions ................................................................................................ 11-2

ACK/NAK Handshaking ............................................................................................... 11-2

Transfer of Decode Data .................................................................................................... 11-4

Page 12

x DS7708 2D Vertical Slot Scanner Product Reference Guide

ACK/NAK Enabled and Packeted Data ........................................................................ 11-4

ACK/NAK Enabled and Unpacketed ASCII Data .......................................................... 11-4

ACK/NAK Disabled and Packeted DECODE_DATA .................................................... 11-4

ACK/NAK Disabled and Unpacketed ASCII Data ......................................................... 11-5

Communication Summary ........................................................................................................ 11-5

RTS/CTS Lines ................................................................................................................... 11-5

ACK/NAK Option ................................................................................................................. 11-5

Number of Data Bits ............................................................................................................ 11-5

Serial Response Time-out .................................................................................................. 11-5

Retries ................................................................................................................................. 11-5

Baud Rate, Stop Bits, Parity, Response Time-out, ACK/NAK Handshake ......................... 11-5

Errors .................................................................................................................................. 11-6

Things to Remember When Using SSI Communication ........................................................... 11-6

Encapsulation of RSM Commands/Responses Over SSI ........................................................ 11-7

Command Structure ............................................................................................................ 11-7

Response Structure ............................................................................................................ 11-7

Simple Serial Interface Default Parameters .............................................................................. 11-8

SSI Parameters ........................................................................................................................ 11-10

Select SSI Host ................................................................................................................... 11-10

Baud Rate ........................................................................................................................... 11-11

Parity ................................................................................................................................... 11-15

Check Parity ........................................................................................................................ 11-17

Stop Bits .............................................................................................................................. 11-18

Software Handshaking ........................................................................................................ 11-19

Host RTS Line State ........................................................................................................... 11-20

Decode Data Packet Format ............................................................................................... 11-21

Host Serial Response Timeout ........................................................................................... 11-22

Host Character Timeout ...................................................................................................... 11-24

Multipacket Option .............................................................................................................. 11-26

Interpacket Delay ................................................................................................................ 11-28

Event Reporting ........................................................................................................................ 11-31

Decode Event ..................................................................................................................... 11-31

Boot Up Event ..................................................................................................................... 11-32

Parameter Event ......................................................................................... .......... ........... ... 11-33

Chapter 12: AUXILIARY SCANNER

Connecting an Auxiliary Scanner .............................................................................................. 12-1

Programming the Auxiliary Scanner ......................................................................................... 12-1

Downloading Firmware ....................................................................................................... 12-1

12VDC Power Requirement ..................................................................................................... 12-2

Using Auxiliary Scanners .......................................................................................................... 12-2

Using a Zebra Scanner as an Auxiliary Scanner ................................................................ 12-2

Using a Zebra Scanner That Does Not Support RSM Commands as an Auxiliary Scanner 12-2

Using a Non-Zebra Scanner as an Auxiliary Scanner ........................................................ 12-2

Auxiliary RSM Communication Bar Codes ......................................................................... 12-3

Chapter 13: SYMBOLOGIES

Introduction ............................................................................................................................... 13-1

Scanning Sequence Examples ................................................................................................. 13-1

Page 13

Table of Contents xi

Errors While Scanning ............................................................................................................. 13-1

Symbology Parameter Defaults ............................................................................................... 13-2

Enable/Disable All Code Types ............................................................................................... 13-8

UPC/EAN ................................................................................................................................. 13-9

Enable/Disable UPC-A ....................................................................................................... 13-9

Enable/Disable UPC-E ....................................................................................................... 13-10

Enable/Disable UPC-E1 ..................................................................................................... 13-11

Enable/Disable EAN-8/JAN-8 ............................................................................................ 13-12

Enable/Disable EAN-13/JAN-13 ........................................................................................ 13-13

Enable/Disable Bookland EAN .......................................................................................... 13-14

Bookland ISBN Format ...................................................................................................... 13-15

Decode UPC/EAN/JAN Supplementals ............................................................................. 13-16

User-Programmable Supplementals .................................................................................. 13-24

UPC/EAN/JAN Supplemental Redundancy ....................................................................... 13-25

UPC/EAN/JAN Supplemental AIM ID Format .................................................................... 13-26

UPC Reduced Quiet Zone ................................................................................................. 13-28

Transmit UPC-A Check Digit ............................................................................................. 13-29

Transmit UPC-E Check Digit ............................................................................................. 13-30

Transmit UPC-E1 Check Digit ........................................................................................... 13-31

UPC-A Preamble ............................................................................................................... 13-32

UPC-E Preamble ............................................................................................................... 13-34

UPC-E1 Preamble ............................................................................................................. 13-36

Convert UPC-E to UPC-A .................................................................................................. 13-38

Convert UPC-E1 to UPC-A ................................................................................................ 13-39

EAN-8/JAN-8 Extend ......................................................................................................... 13-40

UCC Coupon Extended Code ............................................................................................ 13-41

Coupon Report ................................................................................................................... 13-42

ISSN EAN .......................................................................................................................... 13-44

Code 128 ................................................................................................................................. 13-45

Enable/Disable Code 128 .................................................................................................. 13-45

Set Lengths for Code 128 .................................................................................................. 13-46

Enable/Disable GS1-128 (formerly UCC/EAN-128) ........................................................... 13-49

Enable/Disable ISBT 128 ................................................................................................... 13-50

ISBT Concatenation ........................................................................................................... 13-51

Check ISBT Table .............................................................................................................. 13-53

ISBT Concatenation Redundancy ...................................................................................... 13-54

Code 128 Reduced Quiet Zone ......................................................................................... 13-55

Code 128 Security Level .................................................................................................... 13-56

Ignore Code 128 <FNC4> .................................................................................................. 13-58

Code 39 ................................................................................................................................... 13-59

Enable/Disable Code 39 .................................................................................................... 13-59

Enable/Disable Trioptic Code 39 ....................................................................................... 13-60

Convert Code 39 to Code 32 ............................................................................................. 13-61

Code 32 Prefix ................................................................................................................... 13-62

Set Lengths for Code 39 .................................................................................................... 13-63

Code 39 Check Digit Verification ....................................................................................... 13-66

Transmit Code 39 Check Digit ........................................................................................... 13-67

Code 39 Full ASCII Conversion ......................................................................................... 13-68

Code 39 Security Level ...................................................................................................... 13-69

Code 39 Reduced Quiet Zone ........................................................................................... 13-71

Code 93 ................................................................................................................................... 13-72

Page 14

xii DS7708 2D Vertical Slot Scanner Product Reference Guide

Enable/Disable Code 93 ..................................................................................................... 13-72

Set Lengths for Code 93 ..................................................................................................... 13-73

Code 11 .............................................................................................................................. 13-76

Set Lengths for Code 11 ..................................................................................................... 13-77

Code 11 Check Digit Verification ........................................................................................ 13-80

Transmit Code 11 Check Digits .......................................................................................... 13-82

Interleaved 2 of 5 (ITF) ............................................................................................................. 13-83

Enable/Disable Interleaved 2 of 5 ....................................................................................... 13-83

I 2 of 5 Check Digit Verification ........................................................................................... 13-87

Transmit I 2 of 5 Check Digit ............................................................................................... 13-89

Convert I 2 of 5 to EAN-13 .................................................................................................. 13-90

I 2 of 5 Security Level ......................................................................................................... 13-91

I 2 of 5 Reduced Quiet Zone ............................................................................................... 13-93

Discrete 2 of 5 (D 2 of F) ..................................................................................................... 13-94

Set Lengths for Discrete 2 of 5 ........................................................................................... 13-95

Codabar (NW - 7) ..................................................................................................................... 13-98

Enable/Disable Codabar ..................................................................................................... 13-98

Set Lengths for Codabar ..................................................................................................... 13-99

CLSI Editing ........................................................................................................................ 13-102

NOTIS Editing ..................................................................................................................... 13-103

Codabar Security Level ....................................................................................................... 13-104

Codabar Upper or Lower Case Start/Stop Characters Detection ....................................... 13-107

MSI ........................................................................................................................................... 13-108

Enable/Disable MSI ............................................................................................................ 13-108

Set Lengths for MSI ............................................................................................................ 13-109

MSI Check Digits ................................................................................................................ 13-112

Transmit MSI Check Digit(s) ............................................................................................... 13-113

MSI Check Digit Algorithm .................................................................................................. 13-114

MSI Reduced Quiet Zone ................................................................................................... 13-115

Chinese 2 of 5 ........................................................................................................................... 13-116

Enable/Disable Chinese 2 of 5 ............................................................................................ 13-116

Matrix 2 of 5 .............................................................................................................................. 13-117

Enable/Disable Matrix 2 of 5 ............................................................................................... 13-117

Set Lengths for Matrix 2 of 5 ............................................................................................... 13-118

Matrix 2 of 5 Check Digit ..................................................................................................... 13-120

Transmit Matrix 2 of 5 Check Digit ...................................................................................... 13-121

Korean 3 of 5 ............................................................................................................................ 13-122

Enable/Disable Korean 3 of 5 ............................................................................................. 13-122

Postal Codes ............................................................................................................................ 13-123

US Postnet .......................................................................................................................... 13-123

US Planet ............................................................................................................................ 13-124

Transmit US Postal Check Digit .......................................................................................... 13-125

UK Postal ............................................................................................................................ 13-126

Transmit UK Postal Check Digit .......................................................................................... 13-127

Japan Post .......................................................................................................................... 13-128

Australia Post ...................................................................................................................... 13-129

Australia Post Format ......................................................................................................... 13-130

Netherlands KIX Code ....................................................................................................... 13-132

USPS 4CB/One Code/Intelligent Mail ................................................................................. 13-133

UPU FICS Postal ................................................................................................................ 13-134

Mailmark ............................................................................................................................. 13-135

Page 15

Table of Contents xiii

Inverse 1D ................................................................................................................................ 13-136

GS1 DataBar ............................................................................................................................ 13-138

GS1 DataBar Limited ......................................................................................................... 13-139

GS1 DataBar Expanded .................................................................................................... 13-140

GS1 DataBar Security Level .............................................................................................. 13-141

GS1 DataBar Limited Margin Check .................................................................................. 13-143

Convert GS1 DataBar to UPC/EAN ................................................................................... 13-145

Composite ................................................................................................................................ 13-146

Composite CC-C ................................................................................................................ 13-146

Composite CC-A/B ............................................................................................................. 13-147

Composite TLC-39 ............................................................................................................. 13-148

Composite Inverse ............................................................................................................. 13-149

UPC Composite Mode ....................................................................................................... 13-150

Composite Beep Mode ...................................................................................................... 13-152

GS1-128 Emulation Mode for UCC/EAN Composite Codes .............................................. 13-154

2D Symbologies ....................................................................................................................... 13-155

Enable/Disable PDF417 ..................................................................................................... 13-155

Enable/Disable MicroPDF417 ............................................................................................ 13-156

Code 128 Emulation .......................................................................................................... 13-157

Data Matrix ......................................................................................................................... 13-158

Data Matrix Inverse ............................................................................................................ 13-159

GS1 Data Matrix ................................................................................................................ 13-161

Decode Mirror Images (Data Matrix Only) ......................................................................... 13-162

Maxicode ............................................................................................................................ 13-164

QR Code ............................................................................................................................ 13-165

Weblink QR ........................................................................................................................ 13-166

GS1 QR ............................................................................................................................. 13-167

MicroQR ............................................................................................................................. 13-168

Aztec .................................................................................................................................. 13-169

Aztec Inverse ..................................................................................................................... 13-170

Han Xin .............................................................................................................................. 13-172

Han Xin Inverse ................................................................................................................. 13-173

Grid Matrix ......................................................................................................................... 13-175

Grid Matrix Inverse ............................................................................................................. 13-176

Grid Matrix Mirrored ........................................................................................................... 13-178

DotCode ............................................................................................................................. 13-180

DotCode Inverse ................................................................................................................ 13-181

DotCode Mirrored .............................................................................................................. 13-183

DotCode Prioritize .............................................................................................................. 13-185

Redundancy Level ................................................................................................................... 13-186

Redundancy Level 1 .......................................................................................................... 13-186

Redundancy Level 2 .......................................................................................................... 13-186

Redundancy Level 3 .......................................................................................................... 13-186

Redundancy Level 4 .......................................................................................................... 13-187

Security Level .......................................................................................................................... 13-189

Intercharacter Gap Size ..................................................................................................... 13-191

1D Quiet Zone Level .......................................................................................................... 13-192

Macro PDF Features ................................................................................................................ 13-194

Flush Macro Buffer ............................................................................................................. 13-194

Abort Macro PDF Entry ...................................................................................................... 13-195

Page 16

xiv DS7708 2D Vertical Slot Scanner Product Reference Guide

Chapter 14: OCR PROGRAMMING

Introduction ............................................................................................................................... 14-1

OCR Parameter Defaults .......................................................................................................... 14-2

OCR Programming Parameters ................................................................................................ 14-3

Enable/Disable OCR-A ....................................................................................................... 14-3

OCR-A Variant .................................................................................................................... 14-4

Enable/Disable OCR-B ....................................................................................................... 14-7

OCR-B Variant .................................................................................................................... 14-8

Enable/Disable MICR E13B ................................................................................................ 14-15

Enable/Disable US Currency Serial Number ...................................................................... 14-16

OCR Orientation ................................................................................................................. 14-17

OCR Lines .......................................................................................................................... 14-20

OCR Minimum Characters .................................................................................................. 14-22

OCR Maximum Characters ................................................................................................. 14-22

OCR Subset ........................................................................................................................ 14-23

OCR Reduced Quiet Zone .................................................................................................. 14-24

OCR Template .................................................................................................................... 14-25

Required Digit (9) .......................................................................................................... 14-26

Required Alpha (A) ....................................................................................................... 14-26

Optional Alphanumeric (1) ............................................................................................ 14-27

Optional Alpha (2) ......................................................................................................... 14-27

Alpha or Digit (3) ........................................................................................................... 14-28

Any Including Space & Reject (4) ................................................................................. 14-28

Any except Space & Reject (5) ..................................................................................... 14-29

Optional Digit (7) ........................................................................................................... 14-29

Digit or Fill (8) ................................................................................................................ 14-30

Alpha or Fill (F) ............................................................................................................. 14-30

Optional Space ( ) ......................................................................................................... 14-31

Optional Small Special (.) ............................................................................................. 14-31

Other Template Operators ............................................................................................ 14-32

Repeat Previous (R) ..................................................................................................... 14-36

Multiple Templates ........................................................................................................ 14-37

Template Examples ...................................................................................................... 14-37

OCR Check Digit Modulus .................................................................................................. 14-37

OCR Check Digit Multiplier ................................................................................................. 14-39

OCR Check Digit Validation ................................................................................................ 14-40

None ............................................................................................................................. 14-40

Product Add Left to Right .............................................................................................. 14-40

Product Add Right to Left .............................................................................................. 14-41

Digit Add Left to Right ................................................................................................... 14-41

Digit Add Right to Left ................................................................................................... 14-42

Product Add Right to Left Simple Remainder ............................................................... 14-42

Digit Add Right To Left Simple Remainder ................................................................... 14-43

Health Industry - HIBCC43 ........................................................................................... 14-43

Inverse OCR ....................................................................................................................... 14-44

OCR Redundancy ............................................................................................................... 14-46

Chapter 15: ADVANCED DATA FORMATTING

Introduction ............................................................................................................................... 15-1

Page 17

Table of Contents xv

Appendix A: STANDARD DEFAULT PARAMETERS

Introduction .............................................................................................................................. B-1

Appendix B: COUNTRY CODES

USB and Keyboard Wedge Country Keyboard Types (Country Codes) .................................. B-2

Appendix C: COUNTRY CODE PAGES

Introduction .............................................................................................................................. C-1

Country Code Page Defaults ................................................................................................... C-2

Country Code Page Bar Codes ............................................................................................... C-6

Appendix D: CJK DECODE CONTROL

Introduction .............................................................................................................................. D-1

CJK Control Parameters .......................................................................................................... D-2

Unicode Output Control ..................................................................................................... D-2

CJK Output Method to Windows Host ............................................................................... D-3

Non-CJK UTF Bar Code Output ........................................................................................ D-8

Country Keyboard Type Missing Characters ............................................................... D-9

Unicode/CJK Decode Setup with Windows Host ..................................................................... D-10

Setting Up the Windows Registry Table for Unicode Universal Output ............................. D-10

Adding CJK IME on Windows ............................................................................................ D-10

Selecting the Simplified Chinese Input Method on the Host .............................................. D-11

Selecting the Traditional Chinese Input Method on the Host ............................................. D-12

Appendix E: PROGRAMMING REFERENCE

Symbol Code Identifiers ........................................................................................................... E-1

AIM Code Identifiers ................................................................................................................ E-3

Appendix F: SAMPLE BAR CODES

Code 39 ................................................................................................................................... F-1

UPC/EAN ................................................................................................................................. F-1

UPC-A, 100% ..................................................................................................................... F-1

EAN-13, 100% ................................................................................................................... F-2

Code 128 ................................................................................................................................. F-2

Interleaved 2 of 5 ..................................................................................................................... F-2

GS1 DataBar Omnidirectional .................................................................................................. F-3

PDF417 .................................................................................................................................... F-3

Data Matrix ............................................................................................................................... F-3

Maxicode .................................................................................................................................. F-3

QR Code .................................................................................................................................. F-4

Han Xin .................................................................................................................................... F-4

US Postnet ............................................................................................................................... F-4

UK Postal ................................................................................................................................. F-4

Page 18

xvi DS7708 2D Vertical Slot Scanner Product Reference Guide

Appendix G: NUMERIC BAR CODES

Numeric Bar Codes .................................................................................................................. G-1

0 .......................................................................................................................................... G-1

1 .......................................................................................................................................... G-1

2 .......................................................................................................................................... G-2

3 .......................................................................................................................................... G-3

4 .......................................................................................................................................... G-4

5 .......................................................................................................................................... G-5

6 .......................................................................................................................................... G-6

7 .......................................................................................................................................... G-7

8 .......................................................................................................................................... G-8

9 .......................................................................................................................................... G-9

Cancel ....................................................................................................................................... G-10

Appendix H: SIGNATURE CAPTURE CODE

Introduction ............................................................................................................................... H-1

Code Structure .......................................................................................................................... H-1

Signature Capture Area ...................................................................................................... H-1

CapCode Pattern Structure ................................................................................................. H-2

Start / Stop Patterns ................................................................................................................. H-2

Dimensions ............................................................................................................................... H-3

Data Format .............................................................................................................................. H-3

Additional Capabilities .............................................................................................................. H-4

Signature Boxes ....................................................................................................................... H-4

Appendix I: NON-PARAMETER ATTRIBUTES

Introduction ............................................................................................................................... I-1

Attributes ................................................................................................................................... I-1

Model Number .................................................................................................................... I-1

Serial Number ..................................................................................................................... I-1

Date of Manufacture ........................................................................................................... I-1

Date of First Programming .................................................................................................. I-2

Configuration Filename ....................................................................................................... I-2

Beep/LED ............................................................................................................................ I-3

Parameter Defaults ............................................................................................................. I-4

Beep on Next Bootup .......................................................................................................... I-4

Reboot ................................................................................................................................ I-4

Host Trigger Session .......................................................................................................... I-4

Firmware Version ................................................................................................................ I-4

Imagekit Version ................................................................................................................. I-5

Index

Page 19

ABOUT THIS GUIDE

Introduction

The DS7708 2D Vertical Slot Scanner Product Reference Guide provides general instructions for setting up,

operating, maintaining, and troubleshooting the scanner.

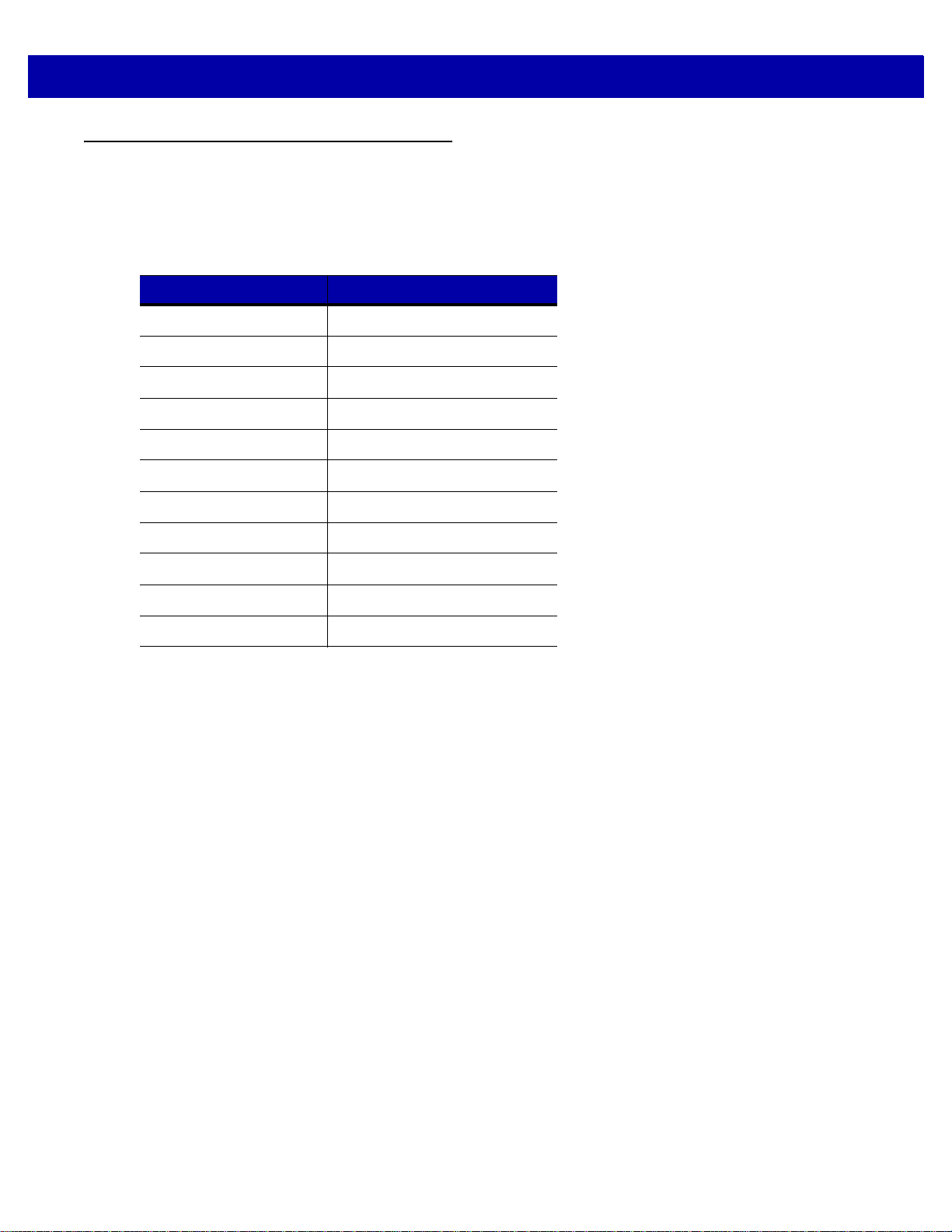

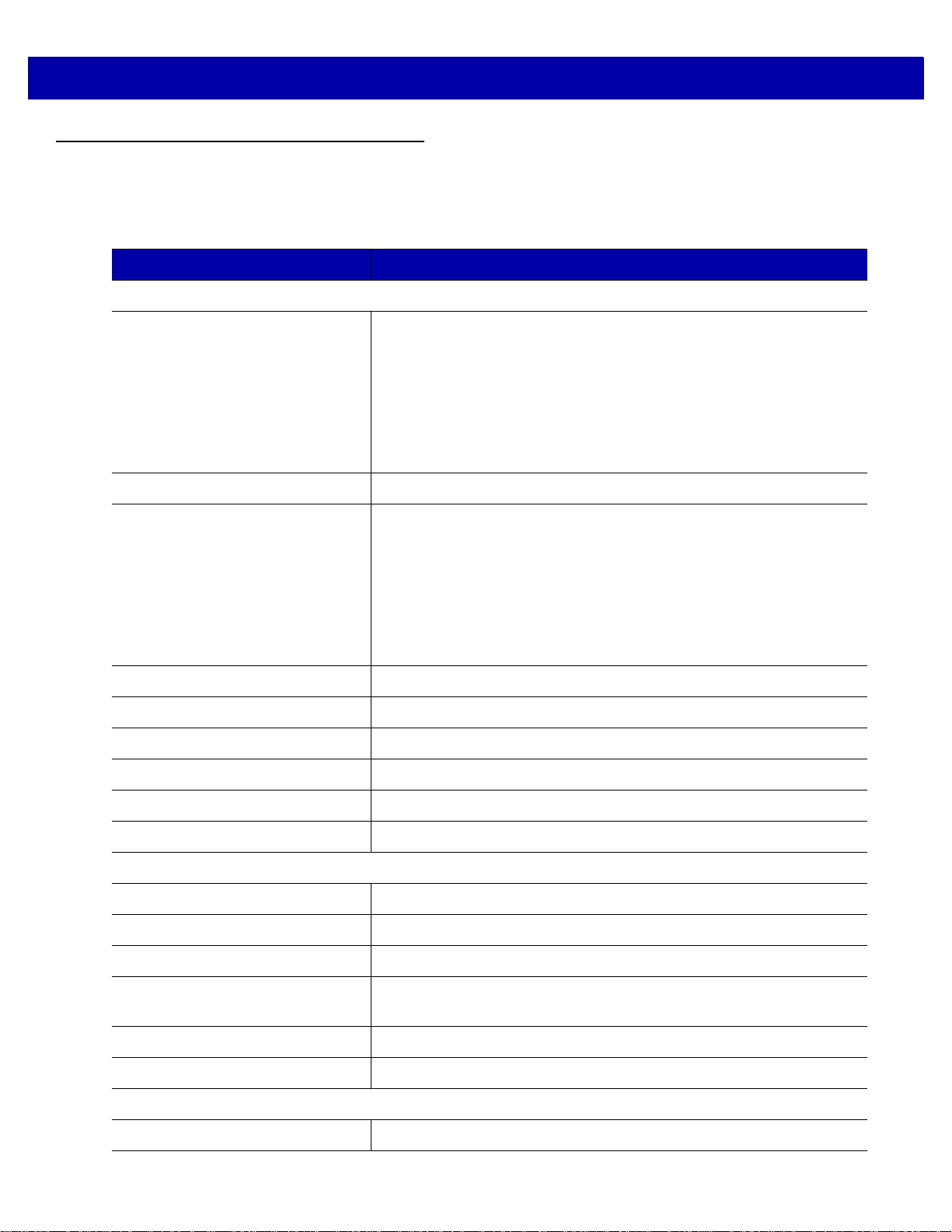

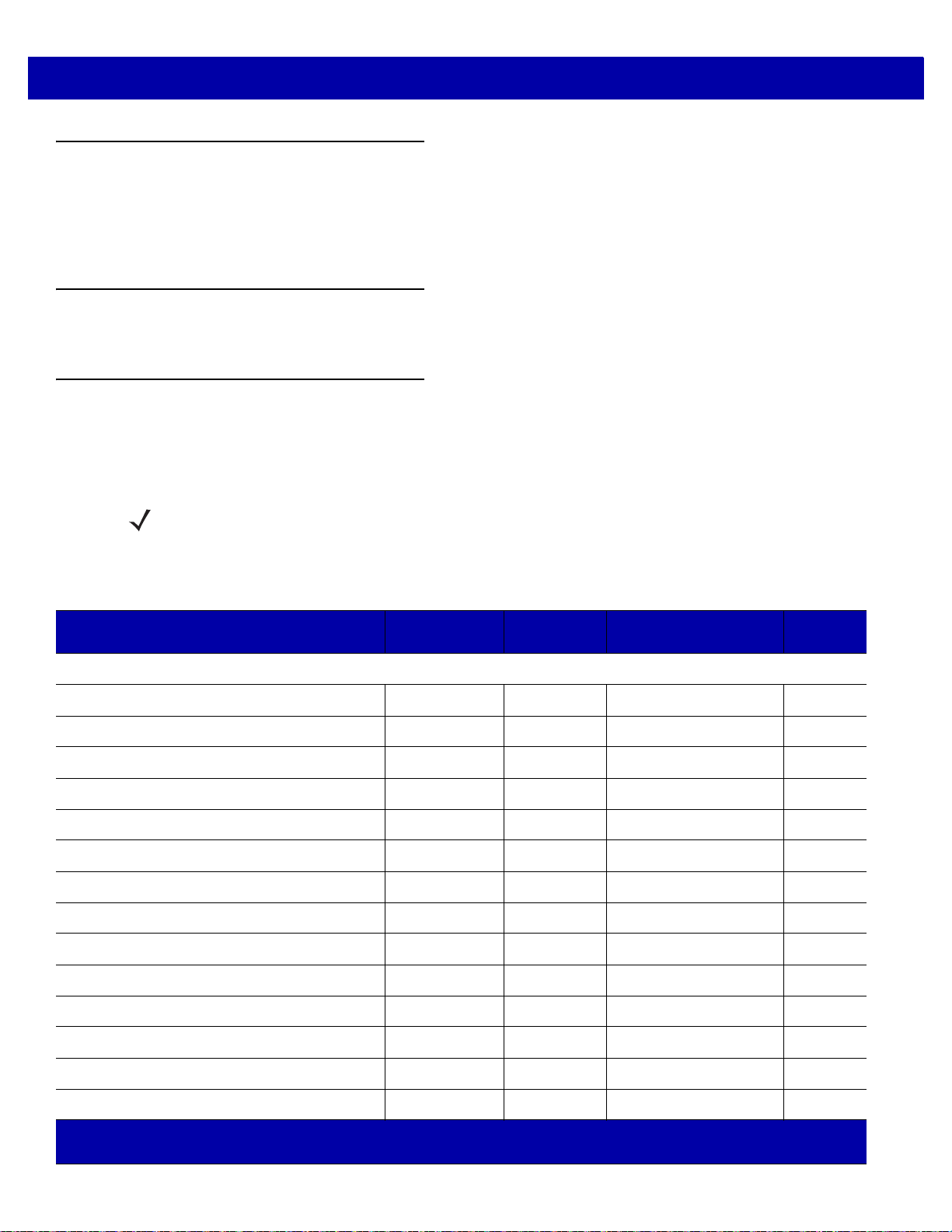

Scanner Configurations

Table a lists the configurations of the DS7708 2D Vertical Slot Scanner.

Table a. DS7708 2D Vertical Slot Scanner Configurations

Part Number Description

DS7708-SR00004ZCWW Vertical Presentation Area Imager, Standard Range, Corded, Midnight Black,

Checkpoint EAS

Page 20

vi DS7708 2D Vertical Slot Scanner Product Reference Guide

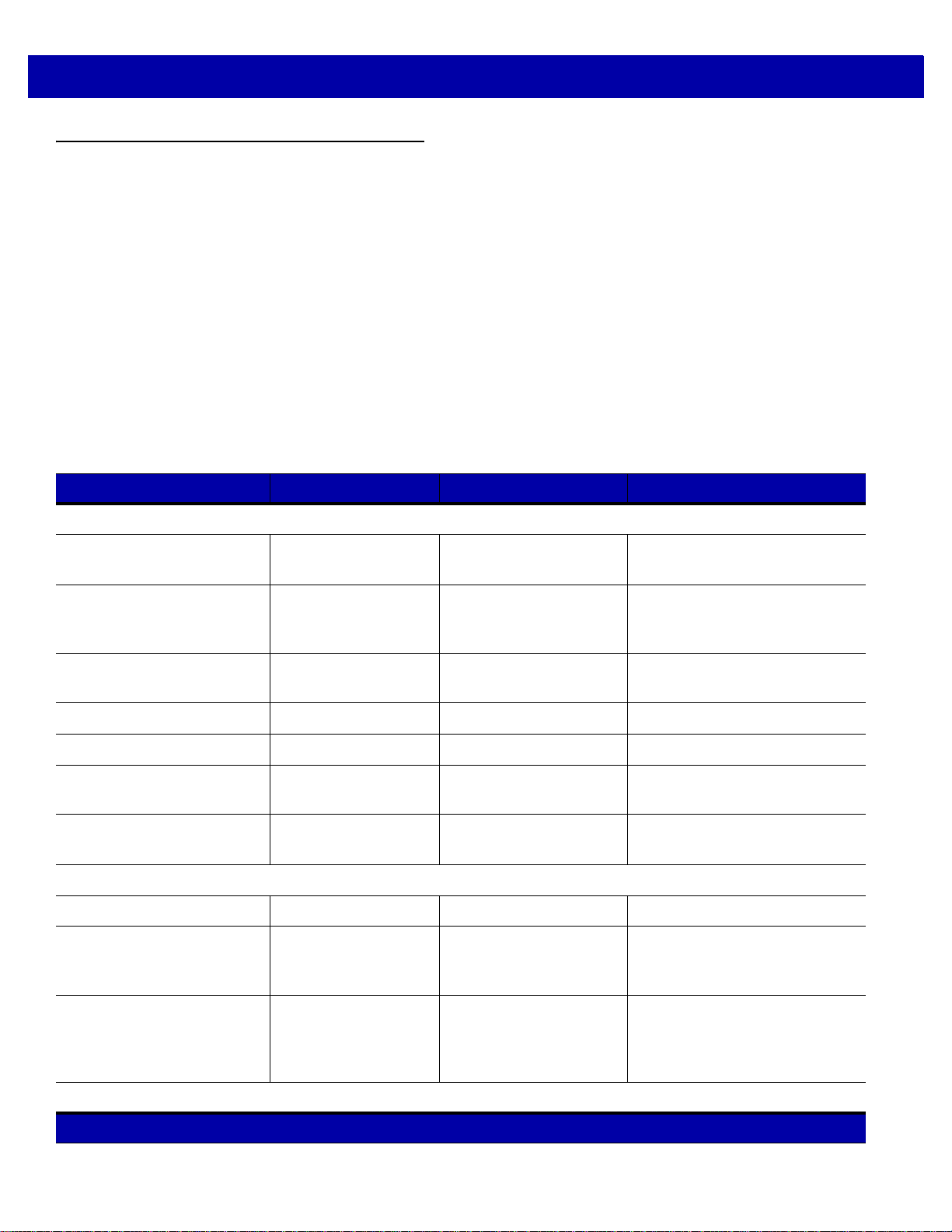

Accessories

Table b lists the accessories available for the DS7708 2D Vertical Slot Scanner.

Table b. Mounting Accessories

Part Number Description

11-TM0077-04 Table Mount Bracket - DS7708 (Midnight Black). Allows the scanner to be

fixed to the table top with a double sided tape or screws.

11-WM0077-04

Table c. Power Supplies

Part Number Description

PWRS-14000-253R Power Supply, 100 - 220VAC, Output 5V - US/CA/MX/JP/TW

PWRS-14000-255R Power Supply, 100 - 220VAC, Output 5V - Brazil Kor ea

PWRS-14000-256R Power Supply, 100 - 220VAC, Output 5V - EU/UK

PWRS-14000-257R Power Supply, 100 - 220VAC, Output 5V - CH

PWRS-14000-258R Power Supply, 100 - 220VAC, Output 5V - HK/AU

PWRS-14000-148R Power Supply, 100 - 220VAC, Output 12V - Worldwide

PWRS-14000-148C Power Supply, 100 - 240VAC, Output 12V - Worldwide

Table d. USB Cables

Wall Mount Bracket Kit - DS7708 (Midnight Black). Allows the scanner

to be fixed to the wall using screws.

Note: This power supply is required for Keyboard Wedge only.

Part Number Description

CBA-U21-S07ZAR USB Cable (Shielded Series A Connector, 7ft. Straight)

CBA-U23-S07ZAR USB Cable (Shielded Power Plus Connector, 7ft. Straight)

CBA-U28-C15ZAR USB Cable (Shielded Power Plus Connector, 15ft. Coiled)

CBA-U29-C15ZAR USB Cable (Shielded Series A Connector, 15ft. Coiled)

CBA-U30-S15ZAR USB Cable (Shielded Series A Connector, 15ft. Straight)

CBA-U32-C09ZAR USB Cable (Shielded Series A Connector, 9ft. Coiled)

CBA-U34-C09ZAR USB Cable (Shielded Power Plus Connector, 9ft. Coiled)

CBA-U35-S15ZAR USB Cable (Shielded Power Plus Connector, 15ft. Straight)

CBA-U42-S07PAR USB Cable (Shielded Series A Connector, 7ft. Straight), 12V

For the DS7708 with an auxiliary scanner the PWRS-14000-148R

power is required.

Page 21

About This Guide vii

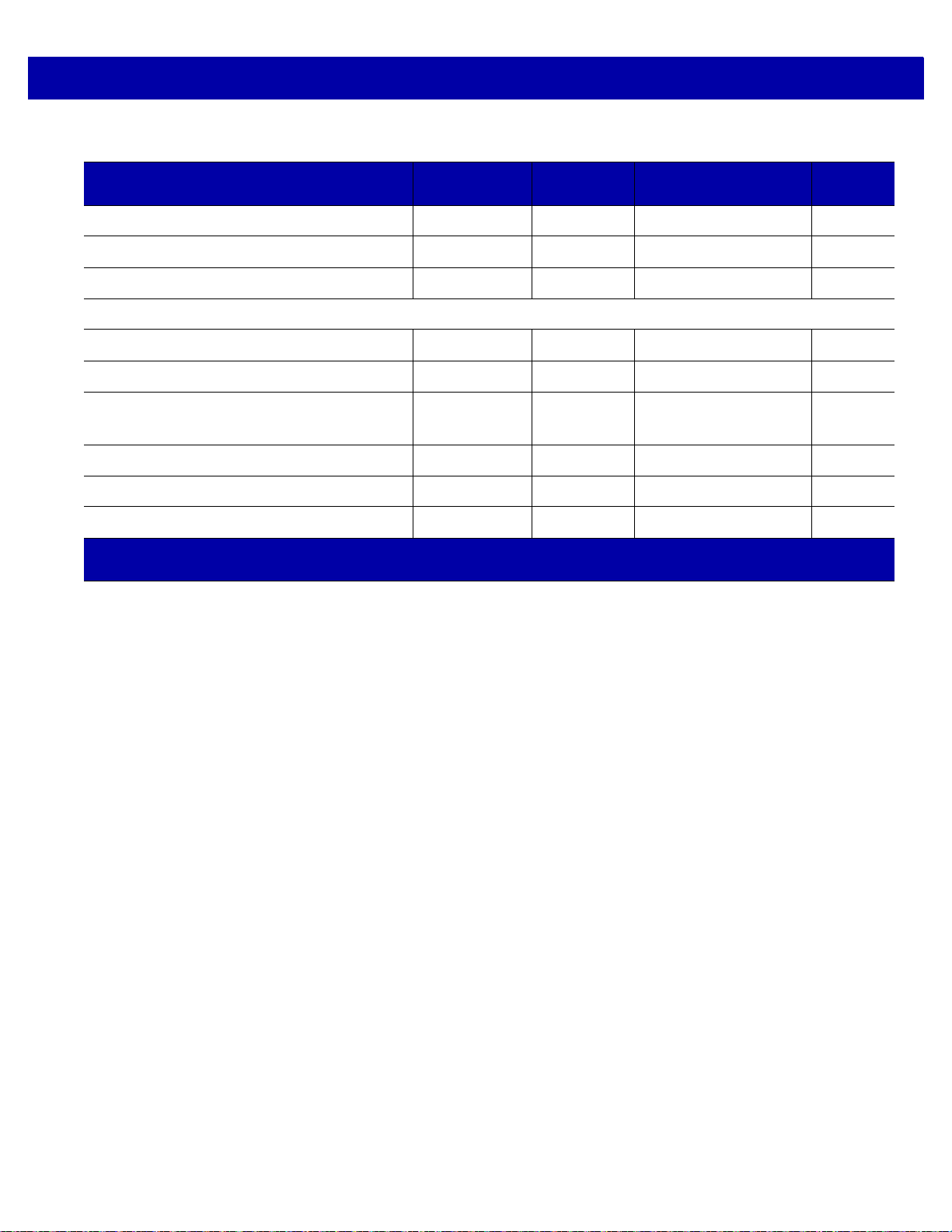

Table d. USB Cables (Continued)

Part Number Description

CBA-U44-S15PAR USB Cable (Shielded Series A Connector, 15ft. Straight), 12V

For the DS7708 with an auxiliary scanner the PWRS-14000-148R

power supply is required.

CBA-U43-S07ZAR USB Cable (Shielded Power Plus Connector, 7ft. Straight), 12V