Page 1

Zebra® CPM 2030

Ticket Printer

Technical Manual

P1003646-001

Page 2

© 2008 ZIH Corp. The copyrights in this manual and the software and/or firmware in the printer described

therein are owned by ZIH Corp. Unauthorized reproduction of this manual or the software and/or firmware in the

printer may result in imprisonment of up to one year and fines of up to $10,000 (17 U.S.C.506). Copyright violators

may be subject to civil liability.

This product may contain ZPL

®

, ZPL II®, and ZebraLink™ programs; Element Energy Equalizer® Circuit; E3®; and

Monotype Imaging fonts. Software © ZIH Corp. All rights reserved worldwide.

ZebraLink and all product names and numbers are trademarks, and Zebra, the Zebra logo, ZPL, ZPL II, Element

Energy Equalizer Circuit, and E

3

Circuit are registered trademarks of ZIH Corp. All rights reserved worldwide.

All other brand names, product names, or trademarks belong to their respective holders. For additional trademark

information, please see “Trademarks” on the product CD.

Proprietary Statement This manual contains proprietary information of Zebra Technologies Corporation and its

subsidiaries (“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced, or disclosed

to any other parties for any other purpose without the express, written permission of Zebra Technologies Corporation.

Product Improvements Continuous improvement of products is a policy of Zebra Technologies Corporation.

All specifications and designs are subject to change without notice.

Liability Disclaimer Zebra Technologies Corporation takes steps to ensure that its published Engineering

specifications and manuals are correct; however, errors do occur. Zebra Technologies Corporation reserves the right

to correct any such errors and disclaims liability resulting therefrom.

Limitation of Liability In no event shall Zebra Technologies Corporation or anyone else involved in the creation,

production, or delivery of the accompanying product (including hard ware and software) be liab le for any damages

whatsoever (including, without limitation, consequential damages including loss of busin ess profi ts, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to use such

product, even if Zebra Technologies Corporation has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation

or exclusion may not apply to you.

P1003646-001 CMP 2030 Technical Manual 12/18/08

Page 3

CONTENTS

1 Introduction...................................................................................................................5

2 Operation.......................................................................................................................9

3 Performance................................................................................................................11

4 Print data .....................................................................................................................12

1.1 Versions and configurations............................................................................5

1.2 Printer design ..................................................................................................6

1.3 Installation considerations...............................................................................7

2.1 Operator controls.............................................................................................9

2.2 General reset...................................................................................................9

2.3 Paper loading ................................................................................................10

4.1 General..........................................................................................................12

4.2 Graphics printing ...........................................................................................12

4.3 Bar code printing ...........................................................................................12

4.4 Text printing...................................................................................................13

5 Ticket separation ........................................................................................................15

5.1 Gapped tickets ..............................................................................................15

5.2 Non-gapped tickets .......................................................................................15

6 Control board ..............................................................................................................16

7 Command set ..............................................................................................................17

7.1 Syntax............................................................................................................17

7.2 Summary of commands ................................................................................18

7.3 Print-parameter commands...........................................................................18

8 Command Reference..................................................................................................19

8.1 System related commands............................................................................19

8.2 Print related commands ................................................................................23

9 Error codes..................................................................................................................30

10 Power requirements ...................................................................................................31

10.1 CPM 2030 Desktop .......................................................................................31

10.2 CPM 2030 OEM printer .................................................................................31

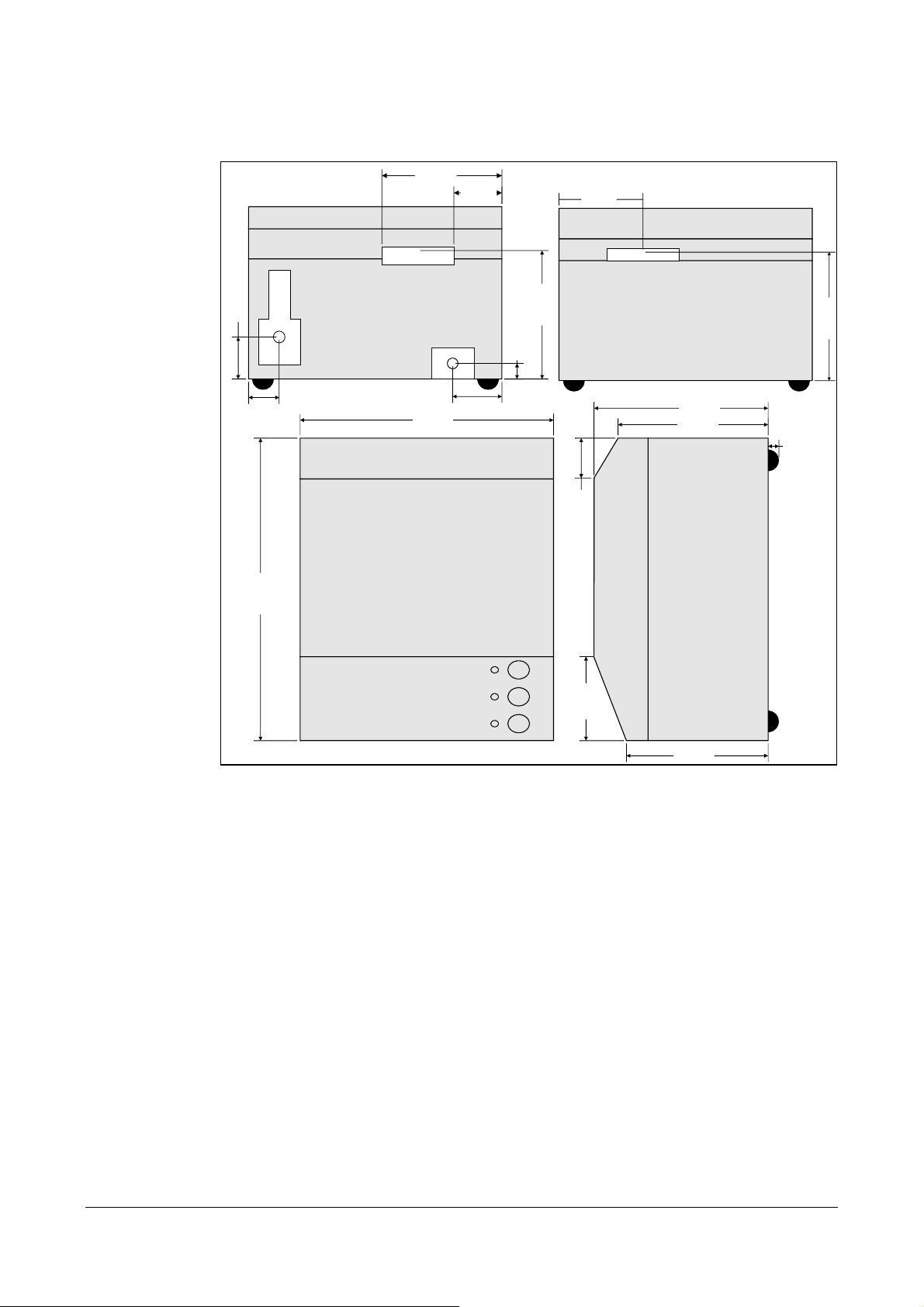

11 Dimensions and weight .............................................................................................32

11.1 CPM 2030 OEM printer .................................................................................32

11.2 CPM 2030 Desktop .......................................................................................35

11.3 Weight ...........................................................................................................36

P1003646-001 CPM 2030 Technical Manual 3

Page 4

12 Environmental conditions .........................................................................................36

13 MTBF............................................................................................................................37

14 Ticket stock .................................................................................................................38

14.1 Ticket base material ......................................................................................38

14.2 Coating and preprint......................................................................................38

14.3 TOF detection (if used) .................................................................................39

14.4 Ticket dimensions and perforation ................................................................40

15 Ordering information..................................................................................................41

16 Fault finding ................................................................................................................42

17 Maintenance ................................................................................................................44

17.1 Lubrication.....................................................................................................44

17.2 Functional description and disassembly .......................................................44

18 Drawings......................................................................................................................46

18.1 Control board interconnections .....................................................................46

18.2 Control board, logic diagram SWC-2210 (Part No 02448-901) sheet 1 .......47

18.3 Control board, logic diagram SWC-2210 sheet 2 .........................................49

18.4 Control board, logic diagram SWC-2210 sheet 3 .........................................51

18.5 Control board, logic diagram SWC-2210 sheet 4 .........................................53

19 Replacement parts .....................................................................................................55

19.1 Final assembly ..............................................................................................56

19.2 Cutter module 10803-060 .............................................................................58

19.3 Cutter Motor Assy. 10622-003 ......................................................................59

20 Index.............................................................................................................................60

REVISION HISTORY

Edition C, major changes

New ordering numbers in Order Information

Edition D, major changes

Discontinued models of CPM has been removed from the manual. CPM 2030 OEM

has been added.

New commands for speed and burn time etc, described (updated to cover firmware

2.35)

4 CPM 2030 Technical Manual P1003646-001

Page 5

1 INTRODUCTION

The CPM is a ticket printer with versatile ticket handling. It prints text, graphics and bar

codes. Finally, it cuts the ticket. The printer can be ordered for 50, 54, 60 or 63 mm wide

tickets. The ticket length is variable between 25 mm and 156 mm. Separate sensors facilitate the use of the standard ticket lengths 86 and 110 mm. Fanfold or roll ticket stock

can be handled.

1.1 Versions and configurations

The CPM comes in two basic versions (see Figure 1):

1. CPM 2030 OEM mechanism with control board for kiosk applications.

2. CPM 2030 Desktop printer with built-in power supply, and control board.

Both versions can be modified according to customer requests.

CPM 2030 OEM

CPM 2030 Desktop

Figure 1. Front view of the different CPM-versions.

SW97145A

P1003646-001 CPM 2030 Technical Manual 5

Page 6

Figure 2. Rear view, CPM 2030 Desktop

1.2 Printer design

Figure 3. Printer interior.

The CPM prints with direct thermal printing, requiring no consumables other than the paper itself. It uses a highly advanced long life print head with built in history control

1

History control means that the activity of each heating dot is logged. Based on this log, the heating time of consecutive dots

are adjusted to compensate for heat accumulated in the heating dot.

6 CPM 2030 Technical Manual P1003646-001

1

.

Page 7

To avoid paper jam, the CPM has a straight paper path where tickets pass virtually without bending. The straight paper path also enables the use of ticket thickness of up to

0.4 mm. A total of four optical sensors supervise the paper transport through the printer.

1.3 Installation considerations

The CPM 2030 OEM printer mechanism is designed to be installed in some kind of enclosure such as a self service kiosk.

Preventing ESD and ground currents from affecting the printer operation requires proper

connection of the printer chassis to protective ground through a mounting platform or

through a separate ground conductor.

Trouble free printer operation also requires that the printer’s optical sensors are shielded

from ambient light.

The printer additional space for paper stock. Consider mounting the printer on a movable

platform so that the printer can be maintained outside the printer enclosure.

1.3.1 Connections

The printer mechanism is connected to the control board through eight connectors according to Figure 4.

Ticket transport

stepper motor

J24

J1

Printhead

Cutter motor

SW1

8

DIP switches

ON OFF

1

Indicator and ticket feed button

Lithium

battery

EPROM

U10

CPM CONTROL BOARD, COMPONENT SIDE

Figure 4. Control board connections

J12 J6J7 J8 J9 J21

Paper-end

sensor

J5

1

6

J4

110 mm cut

sensor

86 mm cut

sensor

Black mark

sensor

Power

supply

unit

Ground

RS232

SW97 148

P1003646-001 CPM 2030 Technical Manual 7

Page 8

1.3.2 Power supply

The printer mechanism requires +5 Vdc 0.3 A,

and +24 Vdc 2 A continuous, 10 A peak.

Pin Voltage

1 +5 V

With a Swecoin power supply unit (see ordering

information on page 41, and dimensional drawing on page 34), just connect the cable from the

power supply to control board connector J5.

If you use another type of power supply unit,

connect the voltages according to the following

table. At the CPM end of the cable, use a Molex

22-01-2065 crimp terminal housing, and six Mo-

2 Ground (for 5 V)

3 +24 V

4 +24 V

5 Ground (for 24 V)

6 Ground (for 24 V)

lex 08-50-0032 crimp terminals.

NOTE! – Both the 5 V and 24 V ground, as well as the chassis of the printer, must be

connected to ground potential (safety ground).

1.3.3 Communications cable

Pin Function

2 RXD (Receive data)

3 TXD (Transmit data)

Pin 6

Pin 1

SW97101D

Figure 5. RS232 serial interface connector pin assignment

4 DTR (Data terminal ready)

5 Ground

7 RTS (Request to send)

8 CTS (Clear to send)

A serial communications cable is available from Swecoin. See ordering information on

page 41. The cable is 1.5 m long with 9-pole D-sub connectors at both ends.

9-pole to 25-pole D-sub adapters are commercially available.

8 CPM 2030 Technical Manual P1003646-001

Page 9

2 OPERATION

2.1 Operator controls

Yellow Indicator

Fixed: Out of paper.

Blinking: Print command

received, but out of paper.

Red indicator

Error, turn OFF

and ON the printer

to clear.

Center pushbutton

1. Eject ticket stock

Green indicator

Power ON & printer ready.

Fixed:

Blinking:

Flickering:

T e mporarily OFF:

Insert ticket.

Receiving data.

Commands are executed.

Figure 6. Indicators and pushbuttons

Front pushbutton

1.Cuts and ejects a ticket .

2. Press and hold at power ON to enter

self test mode. Press again to print

one ticket. The printout shows current

firmware version. Turn printer OFF

and ON to exit self test mode.

SW97108CPM

2.2 General reset

A general reset of the CPM, restoring all parameters to their default value, is effectuated

if when a self test is done, that is when the front button is kept depressed at power ON.

After the self-test, the power has to be turned OFF and ON once more. The CPM is then

reset.

1

1

Do not hold the front button depressed! Doing so will result in erroneously cut tickets often resulting in paper jam.

P1003646-001 CPM 2030 Technical Manual 9

Page 10

2.3 Paper loading

The yellow indicator indicates paper out.

Press the center button to eject remaining tickets if you want to replace paper stock before paper is out.

2.3.1 Paper stock positioning

The ticket stock should be oriented with the thermal coating upwards. The pile of fanfold

tickets should be placed at a distance of at least one ticket length behind the printer.

> One ticket length

90°

SW97116

Figure 7. Positioning the ticket stock

2.3.2 Loading through rear document entries

Insert the ticket stock into the document entry until it stops. Press the front button and the

printer will cut and eject one ticket.

10 CPM 2030 Technical Manual P1003646-001

Page 11

3 PERFORMANCE

Typical throughput 43 tickets/minute (1.4 s/ticket) when printing already

downloaded information on 86 mm tickets, and cutting the tickets.

NOTE! – Data transfer time is not included in the above throughput. At 9600 bps, typically add 0.3 s fixed time + 1 s / Kbytes of transferred data.

Cut time 0.2 s

Bar codes For east and west

oriented bar codes,

print speed is reduced to approx.

50 mm/s. Firmware

up to version 905200 slows down all

printing of tickets

with bar codes to

50 mm/s.

X

Y

FAST

Feed

direction

If dots are missing

the bar code will

still be readable

SLOWER

but more

reliable

SW97103A

P1003646-001 CPM 2030 Technical Manual 11

Page 12

4 PRINT DATA

4.1 General

Printing method Direct, parallel, thermal print

Ticket width 50, 54, 60 or 63 mm

Print width 384 pixels = 51.06 mm, centered on

ticket width

Print margins Top: 12 mm (can be reduced by

reversing the motor, see command

Y

!H)

Bottom: 0 mm

LEFT

Ticket length Fixed 86, or 110 mm. Software se-

lectable 25–156 mm, or controlled

by black-mark or punched hole

4.2 Graphics printing

Pixels / line 384

Resolution, X-axis 7.52 pixels/mm (191 dpi)

Resolution, Y-axis 5.7 pixels/mm (145 dpi), or 7.52 pix-

els/mm, software selectable.

Max graphics size Full width (51 mm) and full length (183 mm)

Figure 8. Margins are de-

fined with the ticket in por-

FEED DIRECTION

X

TOP

NORTH

oriented

text

BOTTOM

SW97 103A

RIGHT

No. of graphical

elements Limited only by the size of the ticket memory.

4.3 Bar code printing

Bar code standards EAN-13 (UPC-A): 13 digits printed as bar code. Check digit

(digit 13) must be calculated in host computer and sent to the

printer. Automatic wide/narrow bar ratio setting.

Code 39: Variable No. of characters in upper case alphanu-

meric coding. Leading and trailing asterisk added automatically.

Independently selectable bar width (narrow or wide).

Interleaved 2-of-5. Digits, even no of digits must be encoded.

Code 128 and EAN 128.

Basic height 16 pixels (2.8 mm for north and south orientated bar codes,

2.1 mm for east and west orientated bar codes)

Scaling From 1 to 16 x basic height

Orientation North, South, East and West oriented bar codes (see also

”Performance” on page 11).

No. of bar codes Up to 15 bar codes/ticket

12 CPM 2030 Technical Manual P1003646-001

Page 13

4.4 Text printing

Fonts Three mono spaced and one proportionally spaced font. Cus-

tom designed fonts can be ordered.

Character size, W x H Font 1 and 3 = 8 x 16 pixels. Font 2 = 16 x 30 pixels.

Font 4, width = 4 to 8 pixels depending on character, height =

16 pixels.

Scaling Font 1 and 4: From 1 to 16 x nominal size. Scaling in X and Y

direction are independent of each other.

Fonts 2 and 3: Width from 1 to 3 x nominal size, height from 1

to 16 x nominal size

Text orientation Fonts 1 and 4 can be printed in any of the four orientations

North, South, East and West. Fonts 2 and 3 can only be printed

in North orientation.

Text field contents Fixed, or variable text

No. of text fields Up to 16 text fields and 16 variable fields / ticket

P1003646-001 CPM 2030 Technical Manual 13

Page 14

Basic character set The table below shows the basic characters stored in PROM on

the printer control board. The set contains characters from

decimal position 32 (space) through 255.

Table 1 Character set used from firmware versions 220

NOTE! – Decimal 34 / HEX 23 (”) cannot be used in messages as it is used as string

identifier in the programming language of the printer.

14 CPM 2030 Technical Manual P1003646-001

Page 15

5 TICKET SEPARATION

5.1 Gapped tickets

For specification of gapped tickets, see page 40.

Cutter Guillotine-type, DC-motor operated, with cam shaft, micro-

switch controlled

Cutter position Between print head and ticket exit

Cutter life expectancy 1 000 000 cuts or more

5.2 Non-gapped tickets

For specification of non-gapped ticket, see page 40.

Burst separator Strikes the ticket stock across the tabs so that the tickets

burst apart. DC-motor operated, with cam shaft, microswitch controlled

Separator position Between print head and ticket exit

Separator life expectancy 1 000 000 separations or more

P1003646-001 CPM 2030 Technical Manual 15

Page 16

6 CONTROL BOARD

Controller 8-bit microcontroller type 80C320

Firmware memory 512 Kbytes EPROM

Page memory 128 Kbytes nonvolatile (battery backed up) RAM

Backup battery CR2025 (3V Lithium). Expected life is 7 years.

Interface Serial: RS232C (V.24)

Data format 8 data bits, 1 stop bit, no parity

Transmission speed 1200, 9600, 19200, or 115200 bps, switch selectable

Handshaking Hardware (RTS/CTS) or software (XON/XOFF)

Connection

CPM (9 pole D-sub) PC (25 pole D-sub) PC (9 pole D-sub)

RXD 2 2 TXD 3

TXD 3 3 RXD 2

DTR 4 6 DSR 6

GND 5 7 GND 5

DSR 6 20 DTR 4 (not used)

RTS 7 5 CTS 8

CTS 8 4 RTS 7 (not used)

NOTE! – The leads marked "Not used" make it possible to

turn the cable either way around.

Set up DIP-switches are used to set up the CPM printer (default

settings in parenthesis):

Switch 1 ON OFF ON OFF

Bits/s 1200 (9600) 19200 115200

2 OFF OFF ON ON

1

3 Not used

4 Auto clear ON = Clear all fixed and variable data during printing (OFF)

5 Handshaking ON = XON/XOFF, OFF = RTS/CTS (OFF)

6 ACK/NAK + error code ON = enabled, OFF = Silent (ON)

7 OFF ON OFF ON

Mode Default Res. Res. Test

8 OFF OFF ON ON

Default = Default setting

Res. and Test = Reserved setting, not to be used!

See also Figure 4 on page 7.

1

115200 bps from firmware version 2.35, 57600 bps in firmware 2.20.

16 CPM 2030 Technical Manual P1003646-001

Page 17

7 COMMAND SET

The command set is designed in accordance with industry standards and is enhanced

with functions unique to this product. The command language uses only printable ASCII

characters for easy adaptation to any host system.

7.1 Syntax

A command string always starts with an exclamation mark (ASCII 33 or HEX 21) serv-

ing as a command identifier.

The characters immediately following the ! (21H) is the actual command to the printer.

The command consists of 1–3 characters, followed, when applicable, by sub command, formatting commands, and data separated by space characters as shown in

Figure 9.

Carriage Return and Line Feed end each command.

Command identifier

Command (1 to 3 characters)

Sub command

Formatting commands

separated by spaces

1

1

1

Data enclosed in

quotation marks

2

New line = CR LF

Space character

(ASCII 32 or HEX 20)

1

Only used with some commands

2

Graphical data starts directly without any quotation mark

or HEX 0D 0A)

and ends after the specified number of bytes

Figure 9. Command syntax

(ASCII 13 10

SW97119

P1003646-001 CPM 2030 Technical Manual 17

Page 18

7.2 Summary of commands

7.2.1 System commands

CAN General reset, equivalent to power OFF/ON (takes 20 s to execute)

ENQ Status request immediate 19

!C Clear all 19

!C A Clear all and enable extended acknowledgement

!F A Feed- acceleration and speed

1

22

!H Top of form detection and ticket length 19

!H C Feed reverse 20

!P Print document 20

!P S Print slow

!P M Print medium

!P F Print fast

2

2

2

!Q Writes a transaction string to RAM 20

!S Status request 20

!U Firmware version query

!V Reads the transaction string written by !Q

!W Reads thermal print progress indicator

1

21

1

1

!X Set resolution 21

!Y Read ticket counter 1 21

!Z Burn time1 22

1

19

21

21

7.3 Print-parameter commands

!F T Print text 24

!F G Print graphics 26

!F C Print bar code 28

1

Introduced in firmware xxxxx-235

2

Obsolete commands, please use !F A instead

18 CPM 2030 Technical Manual P1003646-001

Page 19

8 COMMAND REFERENCE

8.1 System related commands

ENQ Status request, immediate

The CPM responds by sending one byte to the host computer, indicating the status of the

various CPM sensors according to the following table.

The ENQ command is effected immediately after receipt, whereas the !S command gives

the same response but is effected in sequence when received.

Bit Sensor Value ”1” Value ”0”

0 (LSB) Black mark sensor White paper

black mark or no paper 1

1 86 mm sensor Paper present No paper at sensor

2 110 mm paper Paper present

No paper at sensor 1

3 Paper end sensor Paper present No paper

4 Not used - 5 Cutter Cutter home Cutter not home

6 Print head OK Error

7(MSB) Not used - -

!C Clear all

All definitions are cleared. Stored layout is erased. Subsequent !C’s are ignored.

The !C command is also used to initialize the printer after a power ON. If existing print

layout shall be saved, !P shall be used for printer initialization.

If no fixed data is used on the tickets, Autoclear can be used to clear the memory between tickets instead of using !C. Autoclear executes faster than !C. When autoclear is

enabled any !C commands in the received data will be ignored, apart from when initiating

the printer. Setting DIP-switch 4 to ON enables Autoclear.

!CA, adding an A to the !C command enables extended acknowledgement.

!H Top of form detection and ticket length

!H n1 n2 n3 n1 = Select sensor, 0=No sensor, 1=Black mark, 2=86 mm and 3=110 mm

n2 = Sets No. of 0.93 mm steps after TOF detection, or sets ticket length if

no sensor is used.

n3 = Reverse.

0 = Reverse feed disabled.

1 = 7 mm reverse feed after cut (to minimize top margin on next ticket).

3 = Variable reverse. A number after 3 sets reverse in 0.93 mm steps.

Example for 86 mm gapped ticket according to ticket specification on page 40:

!H 2 2 1

1

Not implemented in firmware versions up to 905-200. Here bits 1 and 3 are always 1.

2

Introduced in firmware 2.43, where variable reverse replaces the fixed reverse.

P1003646-001 CPM 2030 Technical Manual 19

2

Page 20

!H C1 Feed reverse

!H C n1

Feeds the paper in the reverse direction

n1 = No. of pixel lines to feed

!P Print

This command triggers both the printing, cutting and ejecting of a ticket.

The Print command can also be used to initialize the CPM after power OFF (as an alternative to !C) in order to save any ticket layout stored in the printer. If !P is received and

the printer is out of paper, it will give error code NAK P and discard the received data.

SET PRINT SPEED3

Adding letters S, M, or F adjust the print speed:

!PS Print slow

!PM Print medium

!PF Print fast.

Print quality is very much dependent on speed. The normal print speed is used unless

you select Fast or Slow with this command.

2

!Q Write transaction string

!Q writes a string with up to 15 ASCII characters to a buffer memory in the printer.

Example:

!Q asdfgh <CR><LF>

After the ticket has been correctly printed, the string is copied to a buffer in the battery

backed up RAM. This buffer can be read by the !V-command.

The transaction string is committed at the precise point where a useable ticket has been

produced. The only way to reset a transaction string is to successfully print another useable ticket that was initiated with !Q. Loss of power or a reset or any other instruction

leaves the string intact.

!S Status request

The printer responds by sending two bytes to the host computer. Byte 1 indicates the

status of the various sensors according to the table under the ENQ command above.

Byte 2 reports the temperature of the thermal print head and is only used internally in the

printer.

See also: ENQ

1

Introduced in firmware version 2.48

2

Introduced in firmware version 2.35

3

Introduced in firmware version 2.35

20 CPM 2030 Technical Manual P1003646-001

Page 21

!SD Status request, DIP-switch settings

The CPM responds with one byte containing 1 bit for each switch. 1 = on, 0 = off.

Bit 7 6 5 4 3 2 1 0

Dip switch No: 8 7 6 5 4 3 2 1

!U Firmware version query1

The CPM responds by sending the following string:

00905_320 CPM Ticket Printer

Where 00905 is the firmware number for the standard CPM , and 320 is the firmware revision, in this case 3.20.

!V Read transaction string1

Reads the string stored by !Q from the memory in the printer.

!W Read thermal print progress indicator2

Reads a value indicating the number of bytes actually printed on the ticket (both blank

and non blank). The number consists of 4 hexadecimal digits and should normally be

equal to 5BE0. A lower number together with the absence of the 03H indicates that the

last ticket was not fully printed and a decision may be taken whether the system should

reissue the ticket or alert the supervisor.

This is a safety feature to minimize the risk of valid tickets being duplicated without attention from the system, by turning off the power at a certain point.

!X Set resolution

Sets the resolution of the print. This only affects the resolution in the transport direction of

the ticket. 0=normal resolution, (5.7dots/mm). 1=high resolution (8.5 dots/mm).

!Y Read ticket counter3

Reads out the internal ticket counter from the control board. This counter starts from 0

when the printer is new and is incremented by one fore each completed !P sequence.

The result is sent as 12 decimal digits + CR + LF

1

Introduced in firmware version 2.35

2

Introduced in firmware version 2.35

3

Introduced in firmware version 3.60

P1003646-001 CPM 2030 Technical Manual 21

Page 22

!Z Burn time1

The burn time controls the print density. It is used to set the heating so that

it is adequate for the thermal paper

used as ticket material. Set it to the

lowest burn time that gives acceptable

print quality.

Example:

!Z 20 <CR><LF>

sets burn time 640 μs

The burn time setting is stored in the

non-volatile memory.

Printing a self test ticket returns the

setting to default value.

CAUTION! – A longer burn time put more load on the printhead, so do not

use a longer burn time than required for a clearly legible print.

Settings over 27 are not recommended.

Setting Burn time Print density

16 512 μs

17 544 μs

18 576 μs

19 608 μs

20 640 μs

21 672 μs

22 704 μs

23 736 μs

24 768 μs

25 800 μs

26 832 μs

Test

Test

Test

Test

Test

Test

Test

Test

Test

Test

Test

Lightest print

27 864 μs Test Default

28 896 μs

29 928 μs

30 960 μs

31 992 μs

Test

Test

Test

Test

Darkest print

!F A Feed- acceleration and speed2

CPM has two feed motors, one for encoding and one for printing. This command sets the

start-frequency and the top speed of each motor.

NOTE1! – This command should not be used! Suitable speed is selected by Swecoin

and set as default parameters in the firmware. The speed setting has to reflect

the motors fitted in the printer and the mechanical buildup of the printer. A single unit may be tunable to a higher speed but it is not certain that the settings

work on the next printer.

NOTE2! – Printing a self test ticket will set the values to factory default.

Syntax for defining and downloading graphics data is as follows:

!F A N <start freq> <top speed> <motor> 1 1 1_”remark”

!F Command to load print-parameter information.

A Indicates acceleration and speed mode.

N Print orientation. This is ignored in acceleration and speed mode. Ori-

entation is always North (N). The printer requires the N to be inserted.

<start freq> Start frequency. Set the base frequency from where the acceleration

starts. A value of 30 indicates a start frequency of 300 Hz.

1

Introduced in firmware version 3.84

2

This command was introduced in firmware version 4.49d

22 CPM 2030 Technical Manual P1003646-001

Page 23

Top speed Top speed is the frequency at which the acceleration stops. A value of

190 sets top speed to 1900 Hz.

motor Must be set to 2.

1 Not used. Must be set to 1.

1 Not used. Must be set to 1.

1 Not used for graphics printing. Must be set to 1.

space One space has to follow the "1" before the graphics data.

Remark Here you can enter a remark describing the setting you just did. It will

not be printed.

Example:

!C<CR><LF>

!F A N 30 190 2 1 1 1 "Print speed (half-step)"<CR><LF>

!P<CR><LF>

8.2 Print related commands

INTRODUCTION

!F is the general command for formatting the ticket print.

!F<type> <data>

The parameters are used as follows:

!F Indicates that this is the start of a print field definition

<type> Specifies the type of the field

T = Text

G = Graphics

C = Bar code

<data> Depends on the type of field specified. See the following pages.

P1003646-001 CPM 2030 Technical Manual 23

Page 24

8.2.1 Text printing

!F T Format text for printing

!F T <orientation> <xpos> <ypos> 1 <height> <width> <font> <"text">

The parameters are used as follows:

!F Indicates that this is the start of a print field definition

T Indicates text mode

<orientation> Specifies the way in which the text is to be oriented. This can be either

N(orth), E(ast), S(outh) or W(est). This terminology is described in detail in the examples given in this document. Specific fonts may be limited to one orientation only, see <font> below.

<xpos> <ypos> Specifies starting position for the

text on the ticket. That is, the distance in pixels from the upper left

corner of the printable area to the

upper left-hand pixel of the bounding box of the first character to be

printed. Note that the resolution is

7.52 pixels/mm on the X-axis and

5.7 pixels/mm on the Y-axis.

<fixed pitch> No. of pixels from the start of one

character to the start of the next.

Range 6 to 16. A value below 6

sets the default pitch.

1

NOTE! – Only used for font 1.

Must be set to 1 for all other fonts.

Figure 10. Bounding box of a character.

<height> <width> Specifies the height and width

expansion of characters to be

printed. The height range is 1–16

Note that the space to the following

character is included in the bounding box,

and that the pixels are not square.

times the default value. The width

range is 1–16 for fonts 1 and 4, and 1–3 for fonts 2 and 3.

<font> Selects the font (text appearance). Fonts 1, 2, 3, and 4 apply. Font 2

and 3 can only be North oriented. Fonts 1 and 4 can be set to any orientation. Font 4 is a proportional character font. Font appearance may

differ from the font samples if you have custom firmware in your

printer.

<"text"> Text to be printed, or definition of a variable text field. Both plain text

and variable definitions have to be enclosed in quotes (" ").

Variable data to be printed as plain text is represented by "%V" in the

format data string. The information that should replace the variable

are sent before the !P print command at printout time.

1

Introduced in firmware version 3.2

24 CPM 2030 Technical Manual P1003646-001

Page 25

Example of a command for fixed text: !F T N 150 150 1 1 1 1 "Text"

Example of a command for variable text: !F T N 150 150 1 1 1 1 "%V"

TEXT ATTRIBUTES

CPM does not handle word processor-like text attributes. In version 4.07 of the firmware,

reversed text has been added, and you can make bold text according to the procedure

described below. Bold and reversed cannot be combined.

Printing Bold text

Bold text is created by repeating the text you want bold, but with new coordinates:

!C

!C

!F T E 370 087 10 02 01 1 "This text is normal"

!F T E 309 087 10 02 01 1 "This text is bold"

!F T E 309 088 10 02 01 1 "This text is bold"

!P

You can increase the "boldness" by changing the coordinates more than one pixel, or by

repeating the text more times with a shift also in the vertical direction.

Reversed text

1

Reversed text. If an R character is appended to the font selection digit (no space between), the text is reversed.

!C

!C

!F T E 100 110 1 02 02 1R "Reversed text"

!F T E 200 110 1 02 02 1 "Normal text"

!P

NOTE 1! – Only reverse single words. Reversing a complete line may reset the

printer due to the high current consumption when printing all black.

NOTE 2! – Reverse work with fonts 1, 2, and 4.

1

Introduced in firmware version 4.07

P1003646-001 CPM 2030 Technical Manual 25

Page 26

8.2.2 Graphics printing

!F G Format graphics for printing

CPM can print bit map graphics. Graphic images are stored in the fixed memory area and

will therefore be repeated on every ticket until the next !C command is received.

Remember, when creating graphics for the printer, that the pixels are not square but have

a height/width ratio of 1.32:1 in normal, and 1:1.13 in high resolution mode.

Syntax for defining and downloading graphics data is as follows:

!F G <orientation> <xpos> <ypos> 1 <height> <width> 1_<Graphic_data>

!F Command to load print-parameter information.

G Indicates graphics mode.

<orientation> Print orientation. This is ignored in graphics mode. Orientation is al-

ways North (N). The printer requires the N to be inserted.

xpos Horisontal starting position in pixels for the upper left-hand corner of

the graphics block. Position will automatically be rounded off to be divisible by 8 as a graphic block has to start at the first bit in a byte.

ypos Vertical starting position in pixels for the upper left corner of the graph-

ics block.

1 Not used for graphics printing. Must be set to 1.

height Height in pixel lines of the graphic block. The length of the ticket de-

termines maximum height. For an 86 mm ticket the maximum height is

approximately 500 pixel-lines.

width Width in bytes of the graphic block. Maximum width is 48 bytes.

1 Not used for graphics printing. Must be set to 1.

space One space has to follow the "1" before the graphics data.

Graphic_data This is a block of bit mapped graphics data. The block is stored in the

printer starting at <xpos>, <ypos>. The numbers of bytes specified by

<width> are stored in one pixel line. The <ypos> is then incremented

and the next line is stored. This is repeated <height> number of times.

It is up to the user to send the correct number of bytes to the printer,

that is, <height> × <width>, as the printer will scan the input character

stream for the correct number of bytes.

26 CPM 2030 Technical Manual P1003646-001

Page 27

1.

Create

pixel

graphics

2.

Add empty

vertical lines

to get full bytes

3.

Convert pixels

to bits

Black pixel=1

4.

Covert bits

to bytes

White pixel=0

1122335566778

4

4

1286432 842

16

000 00001

0011000

1

0 11 11001

111 1110

1

0 11 1100

1

0011000

1

000 00001

1

10 H

38 H

7C H

FE H

7C H

38 H

10 H

1 byte

SW97 123

Figure 11. Converting graphics to CPM format. Note that the appearance on your screen depends on the editor you use to write your program.

!F G N 140 140 1 17 1 10H 38H 7CH FEH 7CH 38H 10H

A file for downloading and printing the above graphics will look like this, in Windows Notepad:

!C

!C

!F G N 140 140 1 7 1 1 •8|þ|8• !C

!C

!L1

!P

A utility program called Swecoin CPM editor can help you convert Windows bitmap images (BMP-files) to CPM graphics format. You can download the CPM editor free of

charge from the Swecoin Internet web site at http://www.swecoin.se

.

P1003646-001 CPM 2030 Technical Manual 27

Page 28

8.2.3 Printing bar codes

!F C Format bar code printing

Bar code printing can be used as a machine readable ticket data carrier

NOTE! – To produce sharp code bars, the CPM printer automatically reduces the print

speed by approx. 50% when printing tickets with east and west oriented bar

codes. The speed reduction is only valid for bar widths 1 and 2. Wider bar

codes are printed at full speed.

Bar code data is treated as fixed data. You can however replace a bar code by overlaying

the previous data with new bar code data on the same X- and Y-coordinates. This way you

avoid deleting the complete ticket with a reset (!C) when you want to update the bar code.

The syntax for defining and downloading of bar code data is as follows:

!F C <orientation> <xpos> <ypos> <bar 1> <height> <bar 2> <type>_ <”bar code data”>

!F Command to load print parameter information

C Indicates bar code mode

<orientation> Indicates print orientation. Can be north (N), east (E), south (S), or west

(W).

xpos Starting position (pixel) for the upper, left-hand corner of the first code bar

in the string. Automatically rounded off to be divisible by 8, (first bit in a

byte).

ypos Starting position (pixel) for the upper, left-hand corner of the first code bar

Bar 1 Width in pixels of both black and white bars, range 1–16.

For EAN13 and EAN/Code 128 the value must be set to 1.

For Code 39 and Code 2-of-5 this sets the wide bars.

height Code bar height in pixels

Value 1 = 16 pixels = 2. 7 mm

2 = 32 pixels = 5.3 mm

3 = 48 pixels = etc.

4 = 64 pixels =

5 = 80 pixels =

…

16 = 256 pixels = 42.7 mm

Bar 2 Width in pixels of both black and white bars, range 1–16.

For EAN13 and EAN/Code 128 the wide/narrow ration is fixed and this sets

the width of the entire code.

For Code 39 and Code 2-of-5 this sets the narrow bars.

type Selects type of bar code. The following types are available:

Value 1 = EAN13 (partly implemented, no check sum)

Value 2 = Code 2-of-5 interleaved

Value 8 = EAN 128

1

Code 128 and EAN 128 is only implemented in firmware 905-235, and it replaces font 2.

28 CPM 2030 Technical Manual P1003646-001

1

Page 29

Value 9 = Code 1281

Value 11 = Code 39

space A space (blank) has to be inserted between the type parameter and the

data string.

bar code data This is a block of data to be converted by the CPM and printed in bar code

form in accordance with the parameters identified. For available characters

and data string formats, please refer to the specific type of bar code.

The following command string produces the ticket illustrated to the left below:

!C

!L1

!F C N 12 102 1 4 3 1 "1234567890128"

!P

X

If dots are missing

the bar code will

still be readable

Y

FAST

Feed

direction

Figure 12. EAN13 bar code. Use east or west oriented bar codes wherever possible, to guarantee readability.

Code 39 example

!F C N 100 230 6 2 2 11 "12345"

Code 128 example1

!F C N 100 320 1 5 2 9 "abc123"

SLOWER

but more

reliable

SW97103A

Code 2-of-5 example

!F C N 100 410 5 2 2 2 "123456"

NOTE! – Code 2-of-5 must have an even number of digits.

P1003646-001 CPM 2030 Technical Manual 29

Page 30

9 ERROR CODES

CPM reports error conditions in the form of error codes. If no error condition exists, the

CPM sends an ”ACK” (06H) to the host after each received print command !P. An error

condition is reported as a NAK (15H) followed by a one-character error code. The error

codes have been defined, starting with ASCII character "1" (31H) according to the following table:

"1" No tickets in the input path.

"2" Paper jam.

"3" Reserved.

"4" Cutter error. No full cut performed. Cutter blade returned to home position by

reversing the cutter motor.

"5" Cutter error. Cutter blade not returned to home position.

"6" Cutter error. Cutter blade not moving. If this error code is received immedi-

ately after power ON, it indicates that something is wrong with the +24V supply.

"7" Paper jam when executing the !P command.

NOTE! – For CPM to send ACK, or NAK + error codes, the DIP-switch 6 on the CPM

control board must be set to ON. Position OFF places the unit in a silent mode preventing

these codes from being transmitted to the host computer.

30 CPM 2030 Technical Manual P1003646-001

Page 31

10 POWER REQUIREMENTS

10.1 CPM 2030 Desktop

Supply voltage 115 Vac or 230 Vac, switch selectable

Supply current Up to 4A at 115 Vac, and 2A at 230 Vac

Fuse 5x20 mm 3.15A / 250V slow blow. Replacement fuse inside

power cable receptacle

Power consumption 50–190 W depending on print density

Frequency 50–60 Hz

10.2 CPM 2030 OEM printer

24 Vdc ±5% Text printing: Average 2A, peak 10A

All black printing: 10A

5 Vdc ±5% 300 mA

Power connector 6-pin Molex KK type connector, 2.54 mm division. Positioned at

the rear bottom of the control board.

P1003646-001 CPM 2030 Technical Manual 31

Page 32

11 DIMENSIONS AND WEIGHT

11.1 CPM 2030 OEM printer

Figure 13 . CPM 2030 OEM dimensions

32 CPM 2030 Technical Manual P1003646-001

Page 33

11.1.1 Printer mechanism

191 mm

124 mm

124 mm

67 mm

114 mm

∅

4.2mm

11 mm

23 mm

81 mm

12 mm

Figure 14 . Print mechanism from CPM 2030

49 mm

SW97141

11.1.2 Control board for printer mechanism

20

230

6

5

37.5

5

E-Prom

13

5

4

15

11.5

31

Battery

1,5V

6.5

9

100

130

4

38

20

SW97140

Figure 15. Control board dimensions. All measurements are in mm.

P1003646-001 CPM 2030 Technical Manual 33

Page 34

11.1.3 Power supply for CPM 2030 OEM printer mechanism

500

Type label

235.5 mm

110 mm

Figure 16. Power supply 01035-002 dimensions. All measurements are in mm.

2.5

54

159 mm

20

14.5

27

25

M3 (3x)

SW97128

34 CPM 2030 Technical Manual P1003646-001

Page 35

11.2 CPM 2030 Desktop

100 mm

40 mm

70 mm

35 mm

25,5 mm

252 mm

REAR VIEW

41 mm

211 mm

TOP VIEW

107 mm

13 mm

33 mm

70 mm

FRONT VIEW

145 mm

125 mm

118 mm

107 mm

7 mm

RIGHT VIEW

SW97138

Figure 17. Dimension drawing for CPM 2030 Desktop printer. All measurements are in mm

P1003646-001 CPM 2030 Technical Manual 35

Page 36

80 mm

365 mm

Figure 18. Approximate space required around the CPM 2030 printer

RIGHT VIEW

90 mm

125 mm

FANFOLD TICKET

STOCK

~270 —350 mm

11.3 Weight

CPM 2030 OEM: 2.7 kg

CPM 2030: 6.1 kg

12 ENVIRONMENTAL CONDITIONS

~350 mm

SW97142

Temperature Operation +5 °C to +40 °C

Storage –10 °C to +50 °C (without tickets)

Transportation –10 °C to +50 °C (without tickets)

Relative humidity Operation 35–75%, non-condensing

Storage 10–90%, non-condensing (without tickets)

Transportation 10–90%, non-condensing (without tickets)

Shock and vibration

Vibration tolerance during operation:

From 5 to 18 Hz with a displacement of 0.3 mm.

From 19 to 100 Hz at a constant acceleration of 0.2 g,

peaked, swept sine wave.

Shock during shipping:

Printers which are factory packaged for shipment can

tolerate a drop of 800 mm without sustaining any

damage.

36 CPM 2030 Technical Manual P1003646-001

Page 37

13 MTBF

Complete unit Approximately 1.4 years for the typical user profile given below.

MTBF for CPM

components Print head 1 000 000 tickets typically (54 x 86 mm)

Control board 40 000 hours typically

Cutter 1 000 000 cuts typically

NOTE! – Type of ticket stock affects the life of the CPM to a high degree. For maximum

MTBF, avoid abrasive inks and coatings, and inks with whiteners. Also clean the printer

from paper dust and residue regularly.

User profile: Operational 12 month/year. Average 30 000 tickets /month. Average printing density 20 % black. Cleaning of printer every 2 months.

P1003646-001 CPM 2030 Technical Manual 37

Page 38

14 TICKET STOCK

14.1 Ticket base material

Material Paper, 100 % chemical pulp, no ground wood permitted

Laminate (Triplex)

Plastic (PVC)

Stiffness 18–36 g/cm (in grain direction)

Thickness Paper and laminate: 0.18–0.40 mm, 170–210 g/m²

Plastic (PVC): 0.18–0.25 mm

Curl Deviation from flatness < 3 mm across the length, or diagonal

of the ticket, and <1 mm across the width of the ticket.

14.2 Coating and preprint

Thermal coating Shall meet or exceed the ANSI 3.11 specification

Smoothness: Max. 75 Sheffield units

Properties: Same as fax grade 3

Top coating The thermo-sensitive surface of the ticket stock can be pro-

vided with a protective UV or moisture proofing top coating .

Preprint Tickets can be preprinted on one, or both sides.

Ink for thermo-sensitive side: Laser printer approved ink with out whiteners

Ink for rear side: Offset ink

CAUTION! – Never use abrasive inks as they reduce the life of the thermal print head.

Thermal print to preprint alignment

Tolerances in the printer, and in the ticket stock itself, can

cause misalignment between the preprint of the ticket stock and

the thermal print.

The ticket guides in the printer are 0.5 mm wider than the nomi-

nal ticket width. Narrower tolerances would cause paper jam

when the relative humidity changes the ticket width. A ticket

width tolerance of ± 0.2 mm gives a maximum total misalignment of 0.7 mm (0.5 +0.2).

TIP! – Avoid designing tickets that require excessively close alignment between preprint

and thermal print.

38 CPM 2030 Technical Manual P1003646-001

Page 39

14.3 TOF detection (if used)

General Black marks or holes can be used to position the paper before

cutting. There shall be one mark or hole for each ticket to be

printed. The size and position is given below.

Print side for

black marks Opposite side to thermal coating

Density of black marks Standard wet offset mode is recommended for printing of the

mark. The full mark area must be printed. Screen printing is not

allowed. Measurement of print density shall be performed relative to the white paper background.

Using a MacBeth densitometer, the print density shall be grater

than 1.3. Anti-gloss filter is not allowed. Using a Gretag densitometer, the print density shall be greater than 1.5. The reflection from the black mark shall be less than 10%. The reflection

from the paper shall exceed 80%. Preprinting in the zone passing over the black mark sensor is not recommended. If required, OCR blind type of ink shall be used (outside 700-1100

nm range).

Holes Punching shall be done from the thermo-coating side. Distorted

print can be expected within a zone of approximately 2 mm

around the edges of the hole. The function shall be tested.

Black marks or punched holes

Side mounted sensor

One

form

length

≤

8 mm

≥

17 mm

(Paper viewed from non thermal-coating side)

Cut line

24.6 mm

34.6 mm

5±1 mm

Cut line

Min 25 mm

Paper

feed

direction

Preprinting not

recommended

within this zone

Center mounted sensor

≥

9 mm

5±1 mm

SW97 149

Figure 19. Position and size of black mark.

P1003646-001 CPM 2030 Technical Manual 39

Page 40

14.4 Ticket dimensions and perforation

Stock format Fanfold or roll, gapped or non-gapped consecutive form tickets.

Ticket width (W) 50 +0/–0.4 mm, 54 ± 0.2 mm, 60 +0/–0.4 mm or 63 +0/–0.4 mm

Ticket length 25 to 156 mm, with synchronized cut triggered by black mark

sensor, or with unsynchronized cut (without using sensors).

85.6 and 110.0 mm with cut triggered by optical edge sensors.

Corner radius, gapped tickets

3.15 ± 0.3 mm. Used for optical detection of top-of form.

Gapped tickets Two tabs according to Figure 20.

Non gapped tickets Equal distance between tabs according to Figure 21.

Figure 20. Gapped tickets (for printers with cutter)

Figure 21. Non gapped tickets (for printers with burst separator)

40 CPM 2030 Technical Manual P1003646-001

Page 41

15 ORDERING INFORMATION

The following printer versions where released when this manual was printed If you need

another configuration, or any other modifications, contact Swecoin, or a Swecoin representative.

Order-

ing No.

100842

100843

100820

N/A

01030-000

01030-001

01030-002

01030-003

01030-004

01030-005

01030-006

01030-800

Version

CPM 2030 Desktop Evaluation kit

CPM 2030 OEM printer mechanism with

control board

CPM 2030 Desktop printer with external

ticket magazine. Built-in power supply unit,

and control board.

Ticket width

Ticket length

50

54

60

63

54 86

54 110

50 86

50 110

63

60

60

54

Variable

Variable

Ticket loading options

Fanfold

Roll

Ticket separation

Cutter

Burst separator

No separation

Ordering No. Accessory description

01493-000

01035-002 Power supply for OEM printer mechanism, 150 VA (preferred model)

10828-050 Power supply for OEM printer mechanism, 50 VA (obsolete, only replacement part)

10825-000 Serial RS232 cable, 1.5 m

01024-001 Ticket tray assy (Output tray from CPM 2030 Desktop)

Side mounted black mark sensor (TOF), instead of the standard center

mounted sensor.

P1003646-001 CPM 2030 Technical Manual 41

Page 42

16 FAULT FINDING

The CPM informs the host of some error symptoms with status reports and error codes.

Error codes are only sent if DIP-switch 6 is ON. See DIP-switches on page 16, and “Error Codes” on page 30.

The lamps in the lid indicate errors requiring assistance of the operator.

Below follow some hints on other error symptoms and how to act upon them:

SYMPTOM

Fade print

ACTION

Clean the printhead using a cleaning card

Check that the paper is sensitive enough (especially if you just received a new batch

of tickets)

SYMPTOM

White lines in the ticket transport direction

ACTION

A pixel in the printhead is damaged, replace the printhead

SYMPTOM

No cutting, bad cutting, uneven cut edges, etc.

ACTION

Remove any obstructing paper particles in the cutting mechanism.

Check that the cutting motor and home position sensor connectors are fully seated on

the control board.

SYMPTOM

Cut in wrong position

ACTION

Check sensor levels

Clean sensors

Verify that preprint does not dis-

turb sensor by loading a white

ticket and measure levels.

42 CPM 2030 Technical Manual P1003646-001

Page 43

SYMPTOM

Only one self-test ticket can be done. When you press the print button again, only blank

tickets are produced.

ACTION

Check the setting of DIP-Switch 4, "Auto clear". If it is ON, this is the correct behavior.

If DIP-Switch 4 is OFF, test the printer with another power supply unit.

If the power supply fails to deliver enough current, the printer is reset when the black

line at the end of the self-test ticket is printed.

P1003646-001 CPM 2030 Technical Manual 43

Page 44

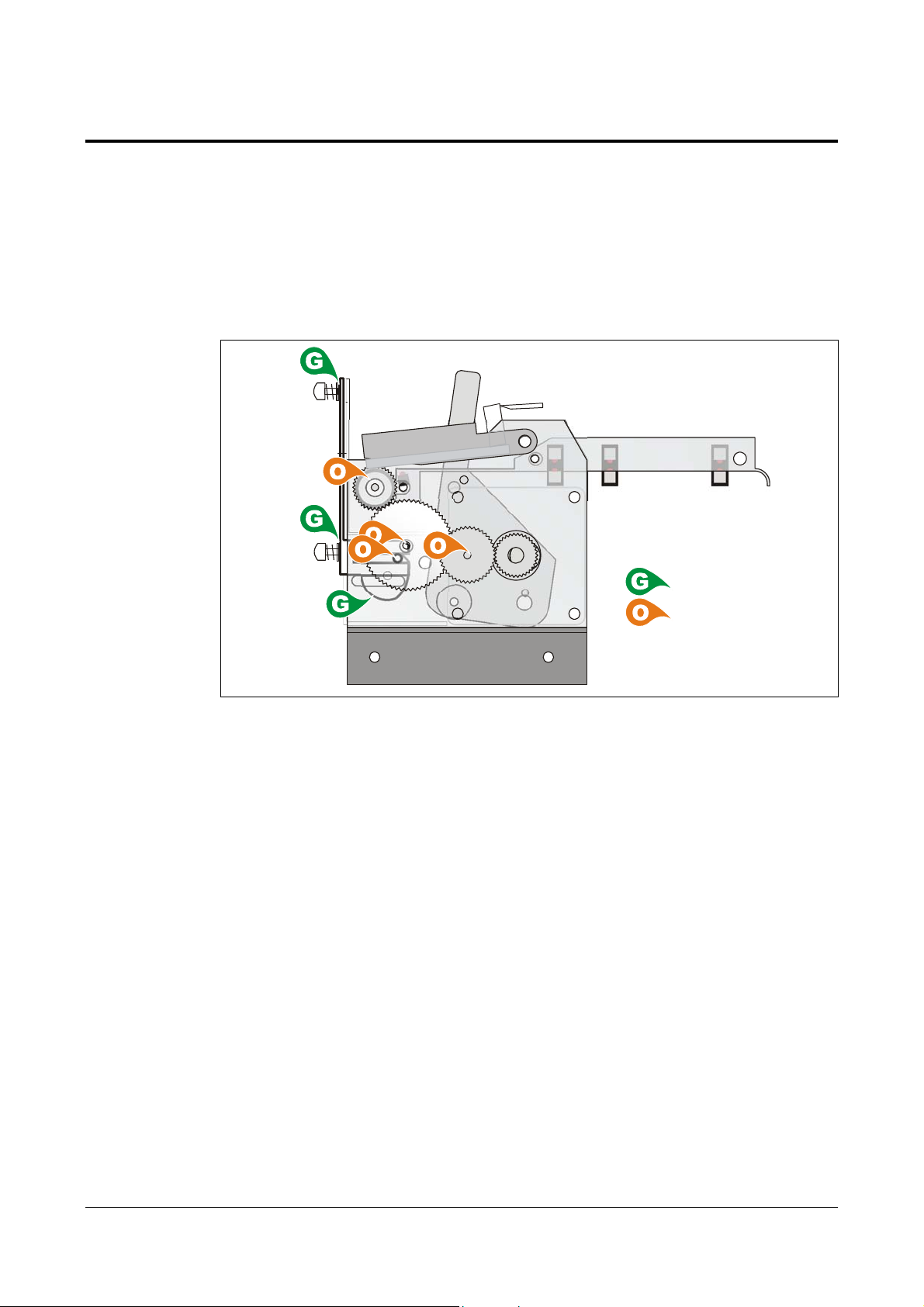

17 MAINTENANCE

17.1 Lubrication

When serviced, it is a good rule to clean and lubricate the printer. All bearings for the

platen and the cog wheels should be lubricated with oil, for example Dexron III automatic

gearbox oil. The outer surface of the cam wheel should be lubricated with a very thin

layer of lithium grease. The cutter pressure plate and the washers that rub against the

moving blade should also be lubricated with lithium grease.

= Grease

= Oil

Lubrication

17.2 Functional description and disassembly

17.2.1 Print Module

(See Figure 23)

The print module consist of a thermal printhead (24) with one line of 348 heating resistors

giving the print on the thermal paper. The paper is transported past the printhead by a

platen (11) driven by a stepper motor (21) via some gears (2, 15, and 20).

PRINTHEAD REMOVAL

1. Disconnect the printhead cable from the printhead.

2. Remove the two circlips (31) from the shaft (9) connecting the pressure plate (44)

with the chassis.

3. Pull the printhead release arm (43) forwards to relieve the printhead and then pull

out the shaft completely.

4. Remove the screw (34) and hub (13) holding the printhead to the pressure plate.

REPLACEMENT

5. Mount the printhead module in the reverse order.

6. Check that the printhead engagement arm connects to the spring-loaded rod extending outside the left side of the chassis.

44 CPM 2030 Technical Manual P1003646-001

Page 45

17.2.2 Cutting module

Moving blade

(a) DC Motor

(c) Micro switch

Fixed blade

(b) Cam wheel

The knife in the cutting module moves by means of a DC-motor (a) with a combined carrier and cam wheel (b). The motor runs in one direction only during normal cutting operations (see arrow). A micro-switch sensor (c) detects when the knife reaches its home position. If the mechanism cannot reach its home position, possibly due to a paper jam or

similar, the motor will run in the opposite direction until the mechanism reaches its home

position.

REMOVAL

(See Figure 23)

1. Remove the printer unit from the cabinet.

2. Remove the four spacers (18) and remove the control board (25)

3. Remove the bottom plate (12) from the printer chassis (2 screws)

4. Remove the two screws (33) holding the cutter module (49) to the chassis

5. Disconnect the cable from the control board connector J21.

REPLACEMENT

Mount the cutter module in the reverse order.

WARNING!

DANGER OF INJURY. Depending on the position of the carrier wheel on the cutter mod-

ule, the cutting mechanism may start moving when the mains power supply is switched

ON. KEEP HANDS AWAY WHEN SWITCHING ON THE POWER.

NOTE 1! – If the cutter blades has been removed or replaced, remember to lock the

screws with Locktite in the threads when assembling the cutter.

NOTE 2! – If the micro switch has been loosened, the screws should be locked with

Locktite in the thread and lacquer at the head of the screw.

P1003646-001 CPM 2030 Technical Manual 45

Page 46

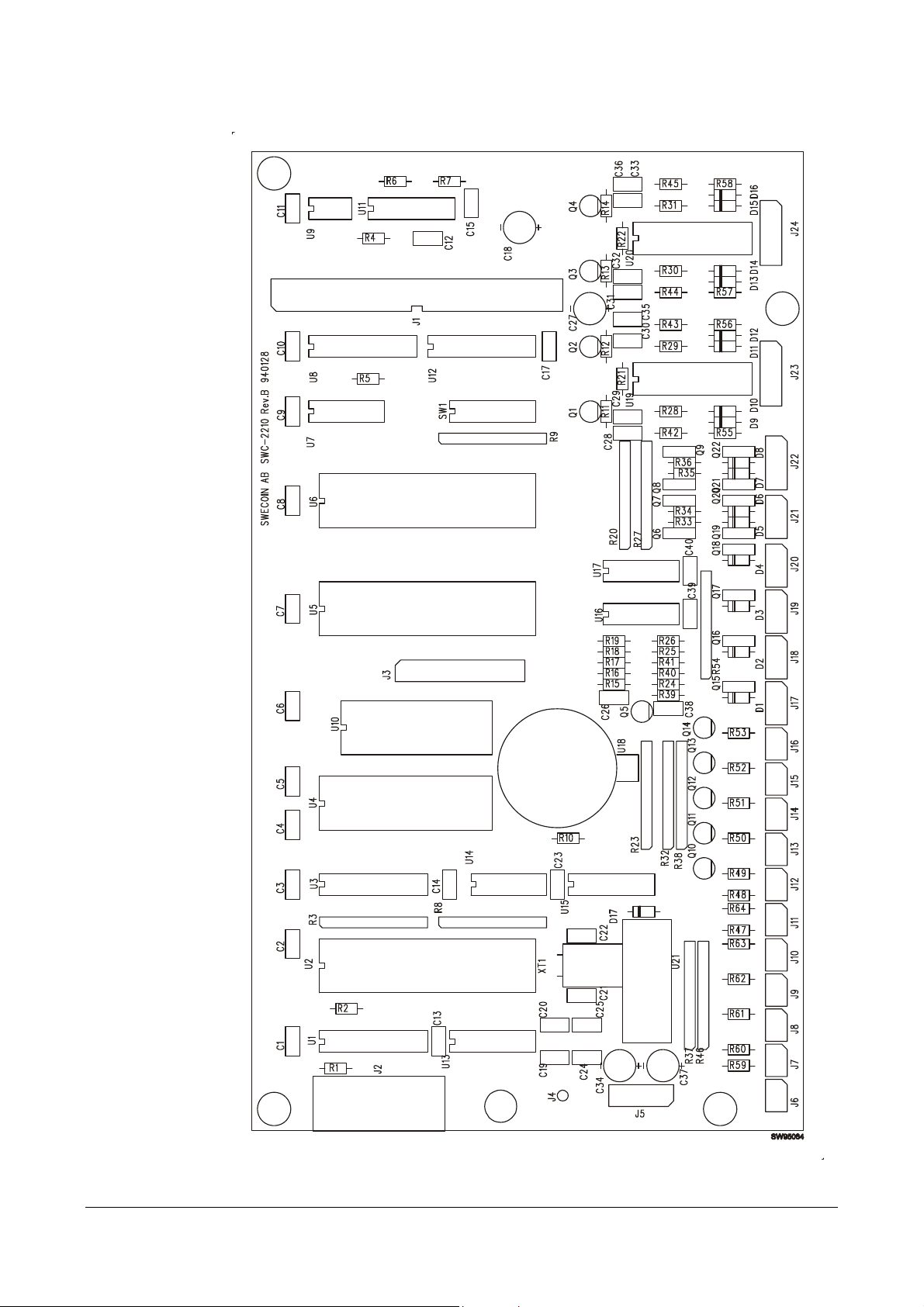

18 DRAWINGS

Control board interconnections Page 46

Control board, logic diagram SWC-2210 sheets 1—4 47

18.1 Control board interconnections

Ticket transport

stepper motor

J24

J1

Printhead

Cutter motor

SW1

8

DIP switches

ON OFF

1

Indicator and ticket feed button

J12 J6J7 J8 J9 J21

Lithium

battery

EPROM

U10

CPM CONTROL BOARD, COMPONENT SIDE

Figure 22. Control board interconnections.

Paper-end

sensor

J5

1

6

J4

110 mm cut

sensor

86 mm cut

sensor

Black mark

sensor

Power

supply

unit

Ground

RS232

SW97 148

NOTE 1! – Directly after replacing the battery, the board MUST be powered ON for a short

while. If not, the battery will be discharged within a couple of hours. Powering on the board

makes the SRAM enter low-power mode, and it retains that mode as long as it has battery

voltage.

46 CPM 2030 Technical Manual P1003646-001

Page 47

18.2 Control board, logic diagram SWC-2210 (Part No 02448-901) sheet 1

P1003646-001 CPM 2030 Technical Manual 47

Page 48

48 CPM 2030 Technical Manual P1003646-001

Page 49

18.3 Control board, logic diagram SWC-2210 sheet 2

P1003646-001 CPM 2030 Technical Manual 49

Page 50

50 CPM 2030 Technical Manual P1003646-001

Page 51

18.4 Control board, logic diagram SWC-2210 sheet 3

P1003646-001 CPM 2030 Technical Manual 51

Page 52

52 CPM 2030 Technical Manual P1003646-001

Page 53

18.5 Control board, logic diagram SWC-2210 sheet 4

P1003646-001 CPM 2030 Technical Manual 53

Page 54

54 CPM 2030 Technical Manual P1003646-001

Page 55

19 REPLACEMENT PARTS

Figure 23. Replacement parts, CPM2030

P1003646-001 CPM 2030 Technical Manual 55

Page 56

19.1 Final assembly

Pos. Part No. Designation Quantity

1 00358-000 Cable Clamp 1 Pcs.

2 00375-000 Cog Wheel 1 Pcs.

3 00515-000 Hub 1 Pcs.

4 00634-000 Printer chassis 1 Pcs.

5 00637-054 Rod 2 Pcs.

6 00705-000 Distance washer 1 Pcs.

7 00839-054 Ticket Guide Plate, 54 mm 1 Pcs.

8 00840-054 Shaft 1 Pcs.

9 02204-001 Shaft, upper 1 Pcs.

10 02207-000 Bearing 2 Pcs.

11 02242-002 Platen Assy 1 Pcs.

12 02245-000 Bottom Plate 1 Pcs.

13 02254-000 Spacer, Cylindrical 1 Pcs.

14 02257-000 Hub 1 Pcs.

15 02259-000 Cog Wheel, Platen 1 Pcs.

16 02273-000 Tension Spring 0.75x8x25 2 Pcs.

17 02279-000 Washer BRB 4,3x8x0,5 1 Pcs.

18 02283-000 Spacer Bolt, M4x18,5 4 Pcs.

19 02288-001 Bolt 1 Pcs.

20 02291-000 Cog Wheel, Rear, Ø39 mm 1 Pcs.

21 02302-205 Stepper Motor Assy 1 Pcs.

22 02311-000 Spacer 4 Pcs.

23 02336-000 Spacer DRM 3260x3 3 Pcs.

24 02431-000 Thermal Print Head Assy 1 Pcs.

25 02448-901 Control Board Assy, TTPM2, CPM 1 Pcs.

- 100979 Battery 3 V Lithium, type CR2025 1 Pcs.

26 09018-217 Screw SK6SS M3x3 1 Pcs.

27 09022-307 Nut M6M M2 2 Pcs.

28 09022-309 Nut M6M M2,5 2 Pcs.

29 09022-310 Nut M6M M3 4 Pcs.

30 09022-312 Nut M6M M4 4 Pcs.

31 09045-108 Circlip RS 4 11 Pcs.

32 09100-189 Screw MRX-H M2,5x4 2 Pcs.

33 09100-218 Screw MRX-H M3x4 2 Pcs.

34 09100-222 Screw MRX-H M3x8 8 Pcs.

35 09100-229 Screw MRX-H M3x18 1 Pcs.

36 09100-284 Screw, MRX-H 4x5 fzb 2 Pcs.

37 09100-301 Screw MRX-H M4x35 4 Pcs.

38 09101-170 Screw MFX-H M2x12 2 Pcs.

39 09101-222 Screw MFX-H M3x8 1 Pcs.

40 09101-229 Screw MFX-H M3x18 3 Pcs.

56 CPM 2030 Technical Manual P1003646-001

Page 57

Pos. Part No. Designation Quantity

41 102035 Light Shield 1 Pcs.

42 102887 Spacer DB 5X10X1 1 Pcs.

43 102888 Free Arm assy 1 Pcs.

44 102890 Pressure Plate Assy 1 Pcs.

45 103109 Guide plate 1 Pcs.

46 10620-200 Opto Sensor Assy 390 ohm 1 Pcs.

47 10632-190 Fork Opto Sensor Assy, 190mm 3 Pcs.

48 10634-000 Print Head Cable Assy 1 Pcs.

49 10803-060 Cutter Module Assy 1 Pcs.

P1003646-001 CPM 2030 Technical Manual 57

Page 58

19.2 Cutter module 10803-060

= Grease

= Oil

Pos Part No. Designation Quantity

1 00549-060 Cutter Support 1 Pcs.

2 00550-060 Print Mech. Support 1 Pcs.

3 00551-060 Cutter Blade, Moving 1 Pcs.

4 00555-000 Hub 5mm 2 Pcs.

5 00555-001 Hub 6.5mm 2 Pcs.

6 00556-000 Pressure Plate 1 Pcs.

7 00557-000 Compression Spring 0.4x5x11.2 4 Pcs.

8 00559-000 Distance washer, 4x8x0.5 4 Pcs.

9 00636-000 Guide 1 Pcs.

10 09023-118 Washer BRB 2.7x6x0.5 4 Pcs.

11 09100-188 Screw MRX-H M2.5x3 2 Pcs.

12 09100-193 Screw MRX-H M2.5x8 3 Pcs.

13 09101-195 Screw MFX-H M2,5x10 1 Pcs.

14 10622-003 Cutter Motor Assy 1 Pcs.

58 CPM 2030 Technical Manual P1003646-001

Page 59

19.3 Cutter Motor Assy. 10622-003

Part No. Designation Quantity

102056 DC Motor RHV 158.12.30 1 Pcs.

10622-002 Cable Assy, Cutter Motor 1 Pcs.

09100-220 Screw MRX-H M3x6 3 Pcs.

00372-000 Micro Switch, Gold Plated XCG3-81 1 Pcs.

00552-060 Motor bracket 1 Pcs.

00130-000 Spacer DRM 2240x12 2 Pcs.

09000-174 Screw MCS-H M2x20 2 Pcs.

01094-000 Cam Wheel Assy 1 Pcs.

101057 Lock washer 3 Pcs.

P1003646-001 CPM 2030 Technical Manual 59

Page 60

20 INDEX

A

Accessories .................. 41

ACK/NAK...................... 30

Ambient light................... 7

B

Bar code ....................... 12

Bar-code....................... 28

Battery .......................... 16

BMP-files ...................... 27

Bold text .......................25

Bounding box................ 24

Burst separator............. 15

Buttons ...........................9

Bar-code................... 28

Graphics printing18, 22, 26

Print field type, size,

position, orientation23

Text printing ............. 24

Front view....................... 5

Fuse ............................. 31

G

Gapped tickets ............. 40

Graphics....................... 12

Converting to TTPM2

format ................... 27

Data ......................... 26

H

C

Carriage Return............ 17

Character set................ 14

Clear all ........................ 19

Coating and preprint ..... 38

Code 39............ 12, 28, 29

Command Reference ...19

Command set ............... 17

Command syntax.......... 17

Commands

Print related .. 18, 19, 23

Summary .................. 18

System related.... 18, 19

Communications cable ... 8

Converting graphics...... 27

Corner radius................Se

Cut time........................ 11

Cutter............................ 15

Cutter error ................... 30

D

Data bits .......................16

Data transfer time.........Se

Default

Restore values ........... 9

Dimension drawing ....... 35

DIP switches................. 16

Document

Rear entry................. 10

Stock ........................38

E

EAN13 .......................... 28

EAN-13......................... 12

Earth.......... 7, See Ground

Environmental

conditions .................36

Error codes................... 30

ESD................................ 7

F

Feed reverse ............... 20

Firmware version query 21

Font ........................13, 24

Format

60 CPM 2030 Technical Manual P1003646-001

Handshaking ................ 16

Humidity ....................... 36

I

Indicators........................ 9

Installation ...................... 7

Interface ....................... 16

Inversed textSee Reversed text

L

Laminate ...................... 38

Light ............................... 7

Line Feed ..................... 17

M

Moisture proofing

coating...................... 38

MTBF ........................... 37

N

No paper ...................... 30

Non gapped tickets ...... 40

O

Orientation.................... 24

P

Paper ........................... 38

Loading .................... 10

Out indication ........... 10

Paper jam..................... 30

Parity............................ 16

Plastic .......................... 38

Power

Connector................. 31

Consumption ............ 31

Power supply............ 8, 34

Current ..................... 31

Voltage..................... 31

Preprint......................... 38

Print........................ 20, 22

Commands............... 23

Format parameter

commands...... 18, 19

Method ..................... 12

Speed .......................28

Width.........................12

Print data ......................12

Printer

Design.....................6, 7

Printer mechanism ........35

Printing

Bar-codes .................28

Graphics .............22, 26

Text...........................24

Progress indicator ...18, 21

Protective ground............7

Pushbuttons....................9

R

Read transaction string .21

Rear view........................6

Reset ..............................9

Resolution.....................12

Reverse Feed...............20

Reversed text................25

S

Separator ......................15

Serial interface

connector ....................8

Set up ...........................16

Shock............................36

Space required..............36

Status request.........20, 21

Immediate ...........19, 21

Stock format..................40

Stop bit..........................16

Summary of commands 18

Syntax...........................17

System commands .18, 19

T

Temperature .................36

Text.........................13, 24

Ticket base material......38

Ticket size.....................12

Top coating ...................38

Transaction string

Read .........................21

Write .........................20

Transmission speed......16

TTPM editor ..................27

U

UV coating ....................38

V

Variable.........................24

W

Weight...........................36

Windows bitmap............27

Write transaction string .20

Page 61

Page 62

Zebra Technologies International, LLC

333 Corporate Woods Parkway

Vernon Hills, Illinois 60061.3109 U.S.A

T: +1 847 79 3 260 0

Toll-free +1 800 423 0422

F: +1 847 913 8766

Zebra Technologies Europe Limited

Dukes Meadow

Millboard Road

Bourne End

Buckinghamshire, SL8 5XF, UK

T: +44 (0)1 62 8 55 60 00

F: +44 (0)1628 556001

Zebra Technologies Asia Pacific, LLC

120 Robinson Road

#06-01 Parakou Building

Singapore 068913

T: +65 685 8 07 22

F: +65 6885 0838

http://www.zebra.com

© 2008 ZIH Corp.

P1003646-001

Loading...

Loading...