PROMAN-CPCL Rev. P • April. 2005

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its

subsidiaries (“Zebra Technologies”). It is intended solely for the information and use of

parties operating and maintaining the equipment described herein. Such propriety

information may not be used, reproduced, or disclosed to any other parties for any other

purpose without the expressed written permission of Zebra Technologies.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications

and designs are subject to change without notice.

FCC Compliance Statement

Digital apparatus has been tested and found to comply with the limits for a Class B Digital

Device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the product manuals,

may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

The user is cautioned that any changes or modifications not expressly approved by Zebra

Technologies could void the user’s authority to operate the equipment. This unit was

tested with shielded cables on the peripheral devices. Shielded cables must be used with

the unit to insure compliance.

WARNING: EXPOSURE TO RADIO FREQUENCY RADIATION ON SOME MODELS. TO

CONFORM TO FCC RF EXPOSURE REQUIREMENTS THIS DEVICE SHALL BE USED

IN ACCORDANCE WITH THE OPERATING CONDITIONS AND INSTRUCTIONS

LISTED IN THE UNIT’S USER’S MANUAL.

Canadian DOC Compliance Statement

Digital apparatus does not exceed the Class A limits for radio noise emissions from digital

apparatus as set out in the radio interference regulations of the Canadian Department of

Communications.

Liability Disclaimer

Zebra Technologies takes steps to assure that its published Engineering specifications

and manuals are correct; however, errors do occur. Zebra Technologies reserves the right

to correct any such errors and disclaims liability resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production

or delivery of the accompanying product (including hardware and software) be liable for

any damages whatsoever (including, without limitation, consequential damages including

loss of business profits, business interruption or loss of business information) arising out

of the use of or the results of use of or inability to use such product, even if Zebra

Technologies has been advised of the possibility of such damages. Some jurisdictions do

not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

Copyrights

The copyrights in this manual and the label printer described therein are owned by Zebra

Technologies. All rights are reserved. Unauthorized reproduction of this manual or the

software in the label printer may result in imprisonment of up to one year and fines of up

to $10,000 (17 U.S.C.506). Copyright violators may be subject to civil liability.

© 2005 ZIH Corp. All trademarks and registered trademarks are property of their

respective owners. All rights reserved.

Mobile Printer CPCLProgramming Manual iii

TABLE OF CONTENTS

PROGRAMMING INTRODUCTION ......................... P1-1

PROGRAMMING LANGUAGE EMULATION .............................P1-1

PROGRAMMING LANGUAGE RECOMMENDATIONS ............P1-2

GETTING PRINTER INFORMATION .........................................P1-3

GETTING PRINTER INFORMATION EXAMPLE ...................... P1-4

COMMUNICATIONS DIAGNOSTICS MODE.............................P1-7

LABEL COORDINATE SYSTEM ................................................P1-8

LABEL VISTA™ ..........................................................................P1-9

PRINTER COMMANDS............................................ P2-1

PRINTER COMMANDS.............................................................P2-2

PRINT COMMAND .....................................................................P2-3

FORM COMMAND......................................................................P2-4

JOURNAL COMMAND ...............................................................P2-5

UNITS COMMANDS...................................................................P2-6

USING COMMENTS................................................................... P2-8

TEXT ......................................................................... P3-1

RESIDENT FONT SAMPLES .....................................................P3-1

TEXT COMMANDS.....................................................................P3-4

USING FONT GROUPS ............................................................. P3-6

TEXT CONCATENATION COMMANDS.....................................P3-8

MULTILINE (ML) COMMANDS................................................. P3-10

COUNT COMMAND .................................................................P3-12

SETMAG COMMAND ...............................................................P3-14

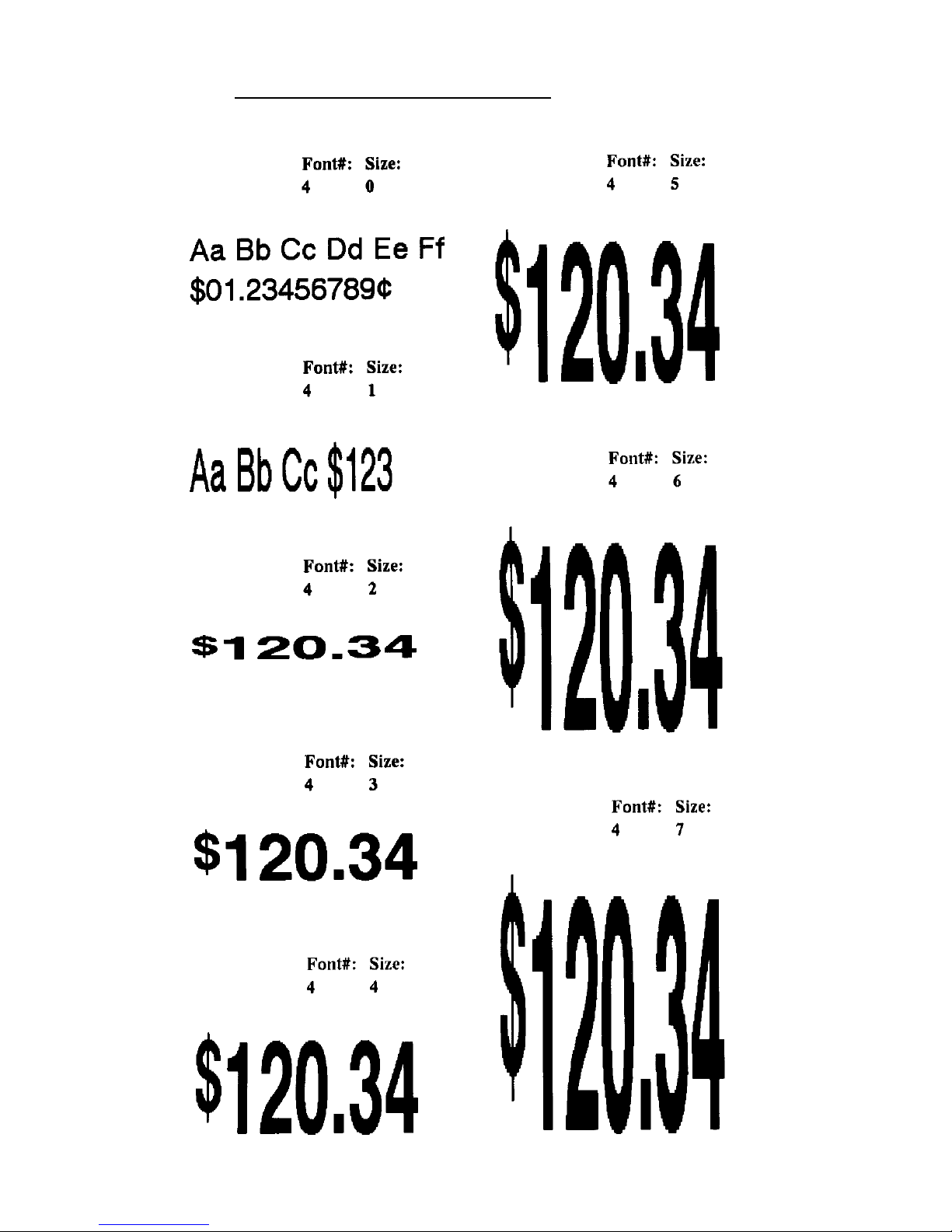

SCALABLE TEXT .................................................... P4-1

SCALE-TEXT COMMANDS .......................................................P4-2

SCALE-TO-FIT COMMANDS ..................................................... P4-4

SCALABLE CONCATENATION COMMANDS ...........................P4-6

ROTATE COMMANDS................................................................P4-8

LINEAR BAR CODES .............................................. P5-1

INTRODUCTION.........................................................................P5-1

UPC AND EAN/JAN BAR CODES .............................................P5-3

CODE 39 OR CODE 3 OF 9 BAR CODES ................................P5-6

CODE 93 OR CODE 9 OF 3 BAR CODES ................................P5-8

INTERLEAVED 2 OF 5 BAR CODES ......................................... P5-8

CODE 128 AND THE UCC-128 SHIPPING STANDARD...........P5-9

CODABAR................................................................................. P5-11

MSI PLESSEY BAR CODES .................................................... P5-12

POSTNET AND FACING IDENTIFICATION MARKS .............. P5-13

BAR CODE COMMANDS.........................................................P5-15

BARCODE COMMAND ............................................................P5-16

BARCODE-TEXT COMMAND..................................................P5-18

iv Mobile Printer CPCLProgramming Manual

TABLE OF CONTENTS (continued)

COUNT COMMAND .................................................................P5-20

TWO-DIMENSIONAL BAR CODES........................ P6-1

INTRODUCTION.........................................................................P6-1

PDF417 .......................................................................................P6-2

MAXICODE .................................................................................P6-2

TWO-DIMENSIONAL BAR CODE COMMANDS .......................P6-3

PDF417 (PORTABLE DATA FILE)............................................. P6-4

GRAPHICS ............................................................... P7-1

BOX COMMAND.........................................................................P7-1

LINE COMMANDS...................................................................... P7-2

INVERSE-LINE COMMANDS.....................................................P7-4

PATTERN COMMAND................................................................P7-6

GRAPHICS COMMANDS...........................................................P7-8

PCX COMMANDS ....................................................................P7-10

ADVANCED COMMANDS ....................................... P8-1

CONTRAST COMMAND ............................................................P8-1

TONE COMMAND .....................................................................P8-2

JUSTIFICATION COMMANDS ..................................................P8-3

PAGE-WIDTH COMMAND .......................................................P8-4

PACE COMMAND......................................................................P8-6

NO-PACE COMMAND ................................................................P8-9

WAIT COMMAND .....................................................................P8-10

REWIND COMMAND................................................................ P8-11

TENSION COMMANDS............................................................P8-12

SPEED COMMAND .................................................................. P8-13

SETSP COMMAND .................................................................P8-14

ON-OUT-OF-PAPER COMMAND.............................................P8-15

ON-FEED COMMAND..............................................................P8-16

PREFEED COMMAND ............................................................P8-18

POSTFEED COMMAND..........................................................P8-19

PRESENT-AT COMMAND.......................................................P8-20

COUNTRY / CODE PAGE COMMAND ................................... P8-22

USING FORMAT FILES............................................................P8-24

BEEP COMMAND.....................................................................P8-27

CUT COMMAND......................................................................P8-28

PARTIAL-CUT COMMAND...................................................... P8-29

CUT-AT COMMAND .................................................................P8-30

MCR COMMANDS....................................................................P8-31

LINE PRINT MODE .................................................. P9-1

INTRODUCTION.........................................................................P9-1

SPECIAL COMMANDS USING THE UTILITY FUNCTION ...... P9-2

UNITS COMMANDS...................................................................P9-3

SETLP COMMAND.....................................................................P9-4

Mobile Printer CPCLProgramming Manual v

SETLF COMMAND ..................................................................... P9-5

MOVING WITH X AND Y COORDINATES................................. P9-6

LMARGIN COMMAND................................................................ P9-7

SETBOLD COMMAND ............................................................... P9-8

SETSP COMMAND ....................................................................P9-9

PAGE-WIDTH COMMAND & PAGE-HEIGHT COMMAND ...... P9-10

SPECIAL ASCII CHARACTERS...............................................P9-10

SETFF COMMAND................................................................... P9-11

SET-TOF COMMAND ...............................................................P9-12

TEARING OR CUTTING THE PAPER .....................................P9-14

BAR CODES, GRAPHICS AND LINES ....................................P9-15

SETLP-TIMEOUT COMMAND .................................................P9-16

DESIGNING A RECEIPT ..........................................................P9-16

ADVANCED UTILITIES .......................................... P10-1

VERSION UTILITY....................................................................P10-2

CHECKSUM UTILITY ...............................................................P10-3

DEL UTILITY ............................................................................. P10-4

DIR UTILITY..............................................................................P10-5

DEFINE-FILE (DF) UTILITY .....................................................P10-6

TYPE UTILITY ..........................................................................P10-8

BAUD UTILITY.......................................................................... P10-9

COUNTRY / CODE-PAGE UTILITY OR ................................P10-10

CHAR-SET/CODE PAGE UTILITY .........................................P10-10

ANNOUNCE UTILITY .............................................................P10-12

TIMEOUT UTILITY..................................................................P10-14

TIMEOUT UTILITY EXAMPLE ...............................................P10-14

BEEP COMMAND...................................................................P10-15

BEEP COMMAND EXAMPLE ................................................P10-15

ON-LOW-BATTERY COMMAND............................................P10-16

LT COMMAND ........................................................................P10-17

LT COMMAND EXAMPLES....................................................P10-17

SET-TIME UTILITY .................................................................P10-18

GET-TIME UTILITY.................................................................P10-19

SET-DATE UTILITY ................................................................P10-20

GET-DATE UTILITY ................................................................P10-21

PRINTING A TIME STAMP .....................................................P10-22

PRINTING A DA TE STAMP ....................................................P10-23

PAPER-JAM UTILITY ............................................................. P10-24

MAGNETIC CARD READER (MCR) COMMAND.................. P10-25

MCR-QUERY COMMAND......................................................P10-31

MCR-CAN COMMAND ...........................................................P10-33

S-CARD COMMAND .............................................................. P10-34

S-CARD COMMAND EXAMPLES..........................................P10-37

DENSO BHT COMMANDS .................................. P10-38

SETTING THE DATA FORMAT ..............................................P10-38

vi Mobile Printer CPCLProgramming Manual

TABLE OF CONTENTS (continued)

IR OR CABLE INTERFACE SELECTION ..............................P10-40

BHT-BAUD COMMAND..........................................................P10-40

SETTING THE MODE FOR IR DATA TRANSMISSION ........P10-40

CONFIGURING THE BHT FOR IR TRANSMISSION............P10-41

BHT-IR FILE TRANSMISSION ............................................... P10-42

CONFIGURING THE BHT FOR CABLE TRANSMISSION....P10-43

LOADING A .DAT FILE INTO THE BHT .................................P10-44

INTERRUPTED TRANSMISSIONS .......................................P10-45

EXAMPLE .DAT FILE..............................................................P10-46

SRF-ACCESS AND END-SRF-ACCESS COMMANDS ........P10-47

BHT-BAUD COMMAND..........................................................P10-48

BHT MODE COMMANDS.......................................................P10-49

BHT PROTOCOL COMMAND................................................P10-53

PRINTER ESCAPE COMMANDS ...........................P11-1

SET AND READ CODE COMMAND ........................................ P11-1

PRINTER ESCAPE COMMANDS FORMAT ............................ P11-2

STATUS/INFORMATION .......................................................... P11-3

USER LABEL COUNT .............................................................. P11-5

POWER OFF COMMAND ........................................................ P11-5

WIRELESS NETWORK PRINTERS....................... P12-1

INTRODUCTION.......................................................................P12-1

NETWORK PRINTER SAFETY CONSIDERATIONS .............. P12-1

LAN COMMAND .......................................................................P12-1

SETTING THE IP ADDRESS FOR NETWORK PRINTERS....P12-7

LAN COMMAND RESPONSE .................................................. P12-8

NETWORK PRINTER TROUBLESHOOTING ......................... P12-9

WIRELESS LAN REPORT EXAMPLE ...................................P12-10

PROGRAMMING FOR THE DISPLAY OPTION .... P13-1

INTRODUCTION:...................................................................... P13-1

EXAMPLE 1: .............................................................................P13-1

EXAMPLE 2: .............................................................................P13-5

CONFIGURATION/CONTROL COMMANDS......... P14-1

INTRODUCTION.......................................................................P14-1

COMMAND FORMAT ...............................................................P14-1

COMMANDS / PARAMETERS................................................. P14-3

BLUETOOTH® PARAMETERS................................................P14-5

COMM PORT PARAMETERS................................................ P14-11

DEVICE PARAMETERS.........................................................P14-13

DISPLAY PARAMETERS .......................................................P14-15

FILE PARAMETERS...............................................................P14-17

PRINTER MECHANISM PARAMETERS ...............................P14-19

INPUT PARAMETER ..............................................................P14-22

Mobile Printer CPCLProgramming Manual vii

MEDIA PARAMETERS ...........................................................P14-24

MEMORY PARAMETERS ......................................................P14-27

ODOMETER PARAMETERS .................................................P14-28

POWER PARAMETERS.........................................................P14-32

TEST FUNCTION PARAMETERS ......................................... P14-36

NETWORKING PARAMETERS .............................................P14-37

USB PARAMETERS...............................................................P14-59

WLAN PARAMETERS............................................................P14-63

WLAN.XXX FHSS COMPATIBILITY.......................................P14-63

ZEBRA PRINTER MIRROR PROCESS .................................P14-86

PRINTER CONFIGURATION AND SETUP............ P15-1

USING LABEL VISTA FOR PRINTER CONFIGURATION.......P15-1

USING LABEL VISTA FOR WIRELESS CONFIGURATION....P15-3

POWER MANAGEMENT..........................................................P15-4

BATCH FILES ...........................................................................P15-7

RUN.BAT COMMAND/FILE ...................................................... P15-8

RE-RUN COMMAND ................................................................P15-9

GAP-SENSE & BAR-SENSE COMMANDS ...........................P15-10

INDEX ......................................................................... A-1

APPENDIX A-FREQUENTLY ASKED QUESTIONS . A-14

APPENDIX B- INTERFACE CABLES...................... A-19

APPENDIX C- CHARACTER TABLES.................... A-24

APPENDIX D - FONT INFORMATION ..................... A-28

APPENDIX E- BAR CODE QUICK REFERENCE ... A-32

APPENDIX F - PRODUCT SUPPORT ..................... A-34

viii Mobile Printer CPCLProgramming Manual

Programming Section

Mobile Printer CPCLProgramming Manual P1-1

This manual details the various commands in the CPCL

language which allow the programmer to utilize the built

in text, graphics, bar code printing and communications

capabilities of Zebra mobile printers. The following notation conventions are used throughout this manual::

{ }

Required item

[ ]

Optional item

( )

Abbreviated command

< >

Literal item

A space character is used to delimit each field in a command line.

Many commands are accompanied by examples of the

command in use. After the word 'Input' in each example,

the file name of that example will appear in parentheses.

This manual can also be found on the Accessories CD

(Part Number 46984 ) available from Zebra.

PROGRAMMING LANGUAGE EMULATION

Zebra Mobile Printers can emulate the EPL2™ and ZPL

®

programming languages used by other types of Zebra

printers. Printers using emulation must be configured

with more memory and have a special emulation program

loaded. For more information on the appropriate uses of

these languages, refer to the following language comparison chart:

PROGRAMMING INTRODUCTION

continued on next page

P1-2 Mobile Printer CPCLProgramming Manual

PROGRAMMING LANGUAGE RECOMMENDATIONS

Language Native in Reccommended Use

CPCL Cameo®, Encore® • In new installations of

QL, RW and older mobiles, where CPCL is easily

Comtec® models integrated into the host

application

• When older Comtec models

are being upgraded- so that the

customer can use existing

application without code

modifications

ZPL PA/PT Series mobile • When an installation already

(emulation printers, Zebra High uses ZPL as a standard language

available on Performance/ Industrial & needs to maintain a consistant

QL series, /Commercial printers, language for all thermal printers.

std. on R-140 RFID printer, • When certain printer functions .

QL plus& LP/TLP 2844-Z and are not available in CPCL or

RW Series) PAX applicator printers EPL, such as: (ZBI, Datamatrix,

Code 11, Micro PDF)

• When replacing a PA/PT 40x, or

another Zebra printer using ZPL,

with a Zebra mobile printer

EPL Zebra Desktops, R402 • When an installation already

(emulation (RFID printer), TR 220, uses EPL- the most commonly

available on PS 21xx Series used Zebra language- as a

QL, Encore, standard language and needs to

or Cameo maintaina consistant language

series and for all thermal printers.

std. on RW • If you are replacing Eltron

& QL plus Transport or Xport mobile

series) printers, a Zebra mobile with an

EPL emulation will ease the

transition.

Note: QL Plus and RW Series printers have EPL and ZPL emulation

built into their operating system. See the “device.languages”

command under the “Device Parameters” topic in Section 14 for

more information on setting programming languages with these

products.

Mobile Printer CPCLProgramming Manual P1-3

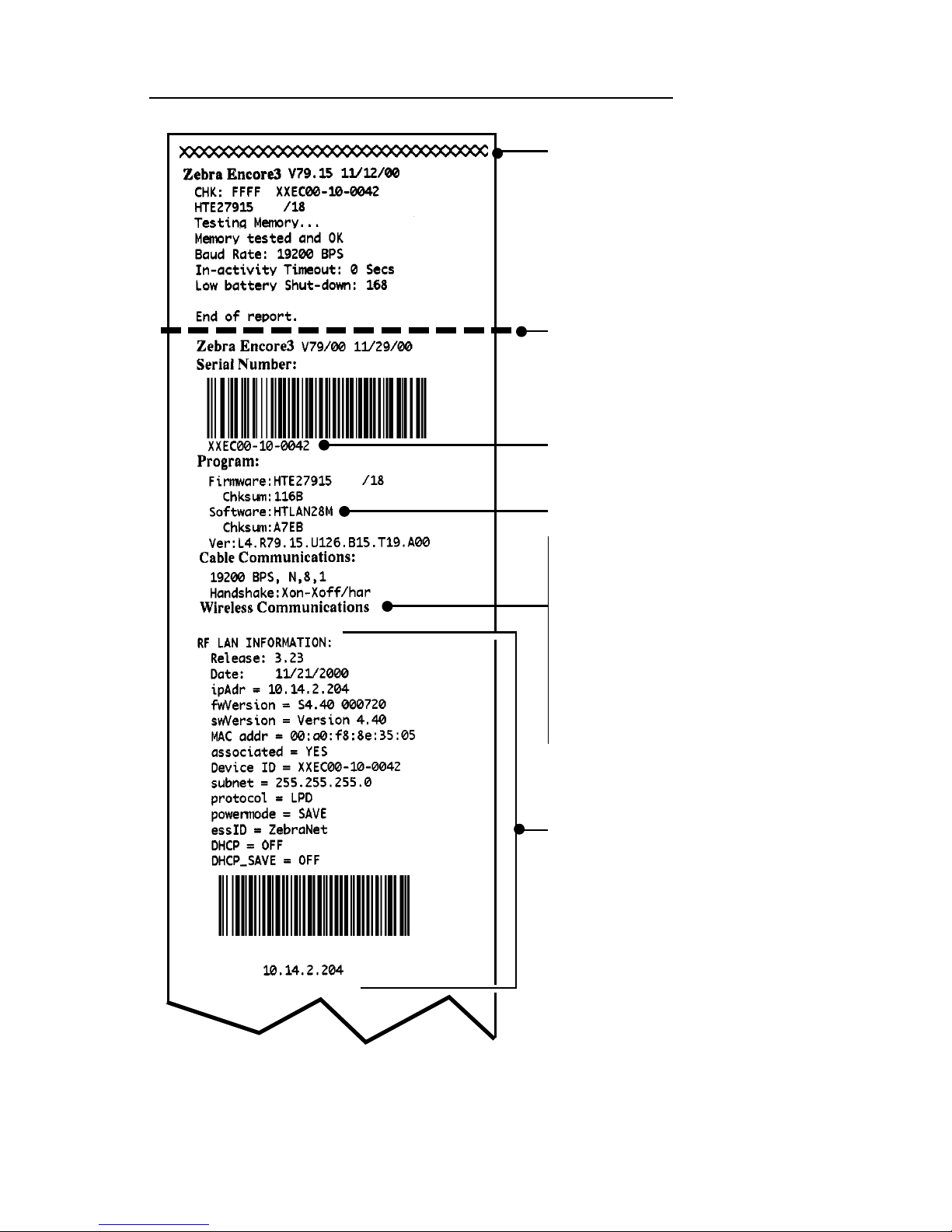

GETTING PRINTER INFORMATION

The printer can produce a report containing information

about the application resident in printer memory. A report

similar to the example printouts shown on the following

pages can be obtained from your printer by doing the following:

1. Turn the printer OFF.

2. While holding the FEED key down, turn the printer

ON.

3. When printing begins, release the FEED key.

The printer prints a line of interlocking “x” characters and

then produces two reports. The first report indicates the

printer model, ROM version, serial number, baud rate,

etc.

The second report contains application information. The

last digits in the application number indicate the software

version.(e.g. “Software: HTLK40d” indicates a software

version of 40.) If no second report appears, there is no

application loaded.

The Wireless Communications report will appear if a

Short Range Radio (SRRF), infrared (IrDA) or wireless

LAN (RF LAN) option has been installed in the printer. If

no wireless options are installed, the Wireless Communications Section will consist of a blank line.

The RF LAN Information section will only appear on Network Printers (units equipped with a WLAN card). Network printers are covered in detail in Section 12 of this

manual.

The Label section shown in the second report reports the

maximum size label that can be printed, based on a

printer resolution of 203 dots/inch (8 dots/mm).

In the example, the Label Height is 2224 dots, which

means for a label width of 576 dots (2.8 inches or 72

mm), you can print labels up to 10.9 inches (278 mm)

long. Reducing the label width results in a corresponding increase in the maximum label length.

P1-4 Mobile Printer CPCLProgramming Manual

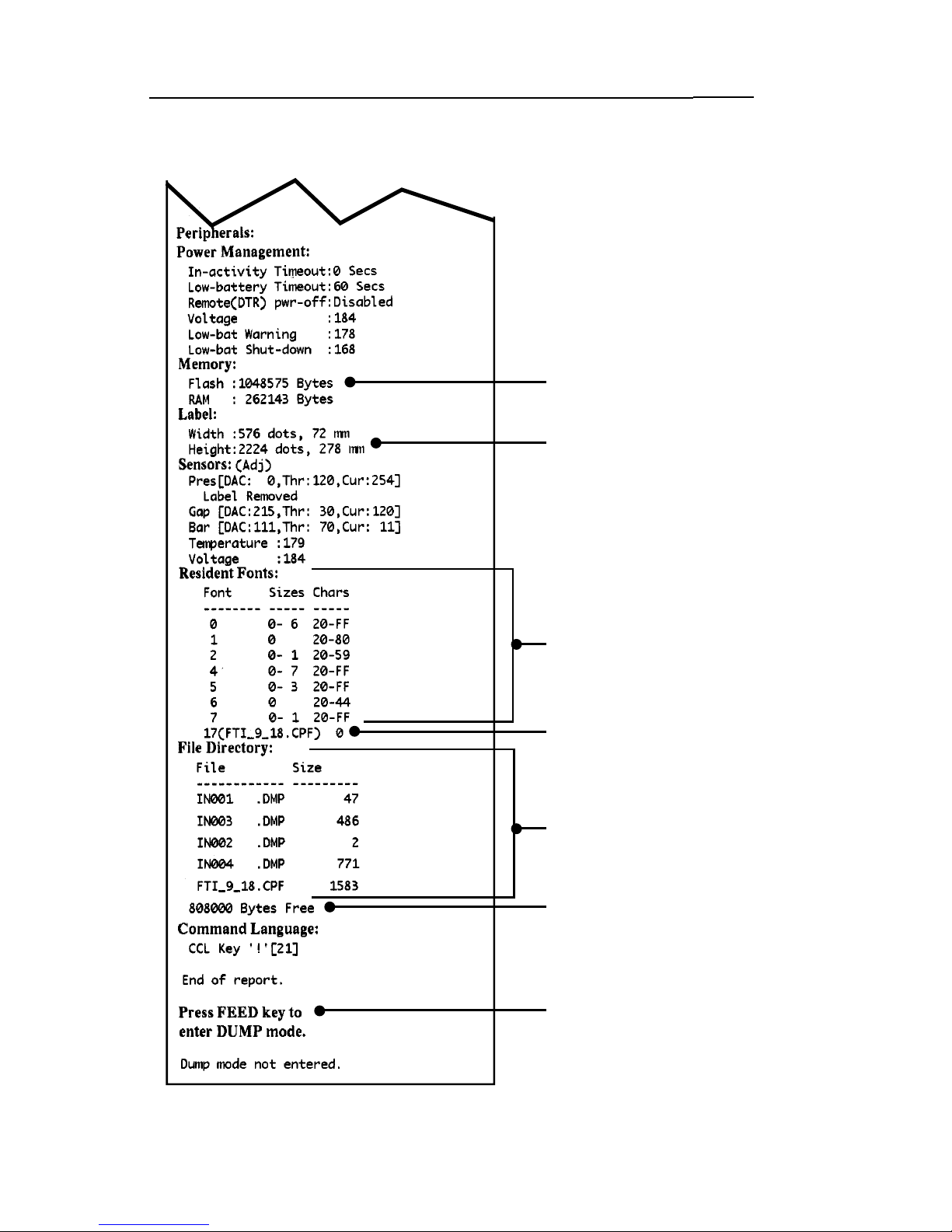

GETTING PRINTER INFORMATION EXAMPLE

Unit Serial Number

Application Number

End of First Report

Printhead Test

RF LAN Section

(Network Printers

only) Refer to

Section 12.

Report appears only

on units with wireless

options installed. (see

RF LAN section below

and next page)

Units with no wireless

options will print an

empty line and

resume the report.

Second report continues on P1-5

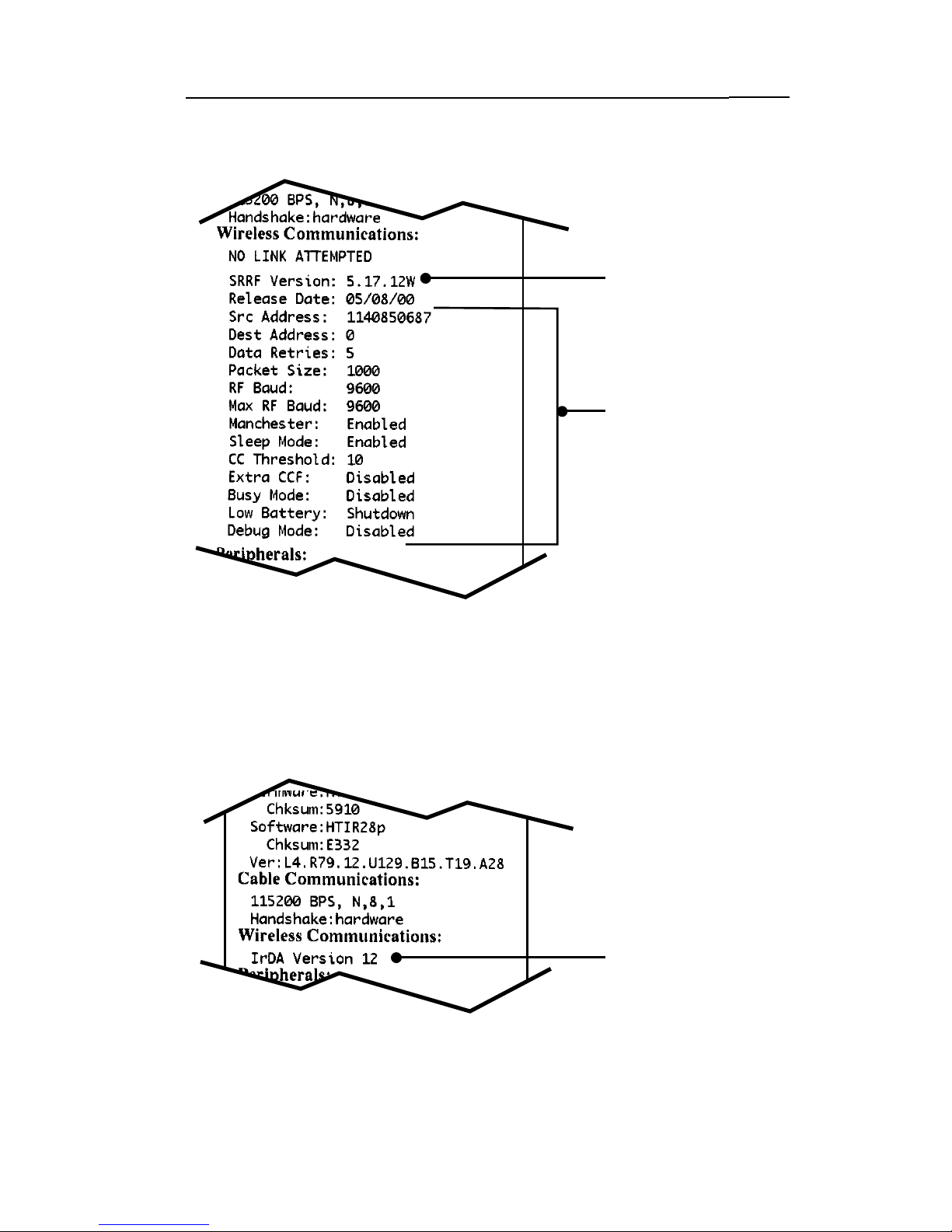

Mobile Printer CPCLProgramming Manual P1-5

GETTING PRINTER INFORMATION EXAMPLE, CONT.

Wireless Communications Section with IR Wireless Option Installed

Wireless Communications Section with Short Range Radio (SRRF)

Wireless Option Installed

SRRF Software version

IR Software version

SRRF settings

P1-6 Mobile Printer CPCLProgramming Manual

GETTING PRINTER INFORMATION EXAMPLE, CONT.

Continuation of Second Report

Flash Memory Size

Maximum Label Size

Refer to P1-7

Files Loaded in Printer

Memory (will include

Pre-scaled or

Scalable Fonts)

Amount of Memory

Available

Resident Fonts

Pre-scaled or

Scalable Fonts (if any)

loaded in Memory

Instructions on

entering

Communications

Diagnostics (Dump)

Mode. Refer to P1-6

Mobile Printer CPCLProgramming Manual P1-7

COMMUNICATIONS DIAGNOSTICS MODE

To aid the user in diagnosing communications problems,

the printer features a Communications Diagnostics Mode

(Dump Mode). In the dump mode, the printer will print

the ASCII hex codes of the data sent to it, and their text

representation (or the period '.', if not a printable character). As a test of the printer the “ALL CHRS.LBL” file on

the MPU disk may be sent.

To enter Communications Diagnostics Mode:

1.Turn the printer OFF.

2.Hold FEED key down.

3.Turn the printer ON.

4.Release FEED key when printer starts printing the

diagnostics.

5.At the end of 2nd diagnostics report, the printer will

print: "Press FEED key to enter DUMP mode".

6.Now press the FEED key. The printer will print:

"Entering DUMP mode".

Note: If the FEED key is not pressed within 3 seconds, the printer will print "DUMP mode not entered"

and will resume normal operation.

7.At this point, the printer is in DUMP mode and will

print the ASCII hex codes of the data sent to it, and

their text representation (or "." if not a printable

character).

Additionally, a file with a “.dmp” extension containing the ASCII information will be created and stored

in the printer’s memory. It can be viewed, “cloned”

or deleted using the Label Vista application. (Refer

to pg. P1-8 and the Label Vista documentation for

more information.)

To cancel Communications Diagnostics Mode:

1.Turn the printer OFF.

2.Wait 5 seconds.

3.Turn the printer ON.

P1-8 Mobile Printer CPCLProgramming Manual

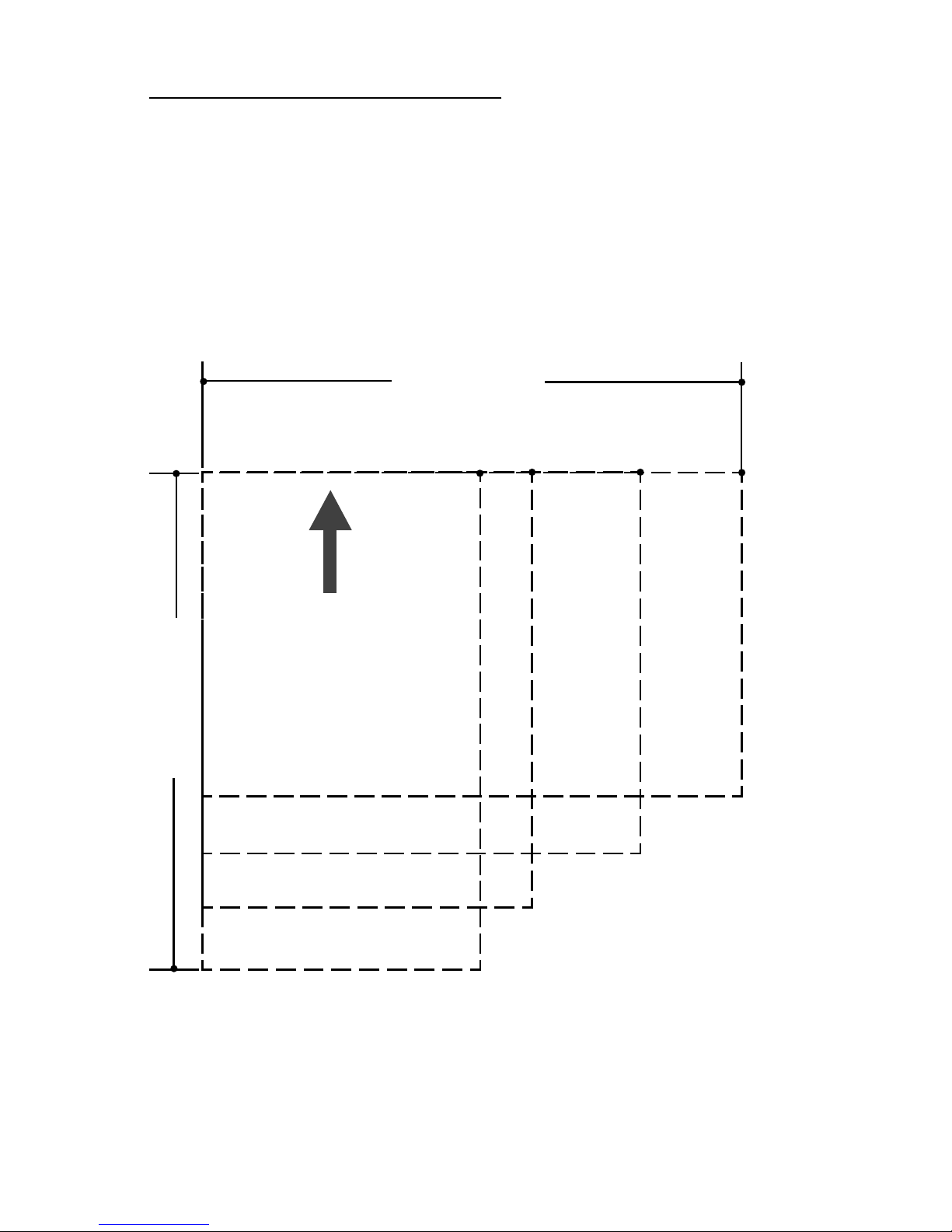

LABEL COORDINATE SYSTEM

The x and y coordinates are expressed here in terms of

dots. Coordinates in ( ) are for 200 dot per inch printers.

On 200 d.p.i. printers, 8 dots (either horizontally or vertically) equal 1 millimeter and 203 dots equate approximately to 1 inch.

Coordinates in [ ] are for 300 dot per inch printers. On

300 d.p.i. printers 12 dots equal 1 millimeter, and 305

dots equate approximately to 1 inch.

Notes:

1. Coordinates refer to the actual printing area of the printers.

2. ”y” =the available label height which can vary with the resident

application. (See Getting Printer Information, Page P1-3.)

4" Printer

2" Printer

3" Printer

(0,0)

Label Width

Label Height

2.25" Printer

(447, 0)

[670,0]

(383, 0)

[574,0]

(575, 0)

[862,0]

(831, 0)

[1246,0]

Print Direction

(383, y)

[574,y]

(447, y)

[670,y]

(575, y)

[862,y]

(831,y)

[1246,y]

Mobile Printer CPCLProgramming Manual P1-9

LABEL VISTA™

Label Vista is a stand-alone program running in

Windows

®

95/NT that allows users with little or no programming background to design labels which can be

printed on certain model Zebra portable printers. It combines an intuitive graphically based user environment

with powerful, but easily mastered, editing tools.

Label Vista allows the creation of printable, fixed-size

(pre-scaled) fonts derived from an included library of

TrueType™ fonts, which greatly enhances the versatility

of this program.

In addition, Label Vista allows the easy creation of format

files which can remain resident in the printer and be

merged with variable data files sent from the host. This

provides a very efficient method of printing labels that

have a mixture of data fields that change from label to label and elements that remain constant. Refer to Section

8 of this Manual for more information on format files.

Label Vista also provides a powerful set of diagnostics

tools. It is recommended that the Label Vista documentation package be consulted for a more detailed description of the printer diagnostics available in this program.

Label Vista utilizes a subset of the full Mobile Printing

Systems Programming Language described in this

manual. Files created in Label Vista are fully compatible

with any other label files created using the complete set

of Mobile Printer commands.

Label Vista requires an IBM compatible personal computer, running Windows 95 or later. A PC with the minimum configuration to run Windows 95 will have sufficient

memory to run Label Vista.

Note: Label Vista has proven to be compatible with Windows XP

in informal testing, however, compatibility problems with certain

unusual combinations of hardware and software may arise.

Mobile Printer CPCLProgramming Manual P2-1

PRINTER COMMANDS

A label file always begins with the “!” character followed by

an “x” offset parameter , “x” and “y” axis resolutions, a label

length and finally a quantity of labels to print. The line containing these parameters is referred to as the Command

Start Line.

A label file always begins with the Command Start Line

and ends with the “PRINT” command. The commands that

build specific labels are placed between these two commands.

A space character is used to delimit each field in a command line.

Note: Every line in the command session must be terminated with both

carriage-return

and line-feed characters. All Printer Commands must be in

uppercase characters ONLY.

P2-2 Mobile Printer CPCLProgramming Manual

<!> {offset} <200> <200> {height} {qty}

where:

<!>:

Use '!' to begin a control session.

{offset}:

The horizontal offset for the entire label.

This value causes all fields to be offset

horizontally by the specified number of

UNITS.

<200>:

Horizontal resolution (in dots-per-inch).

<200>:

Vertical resolution (in dots-per-inch).

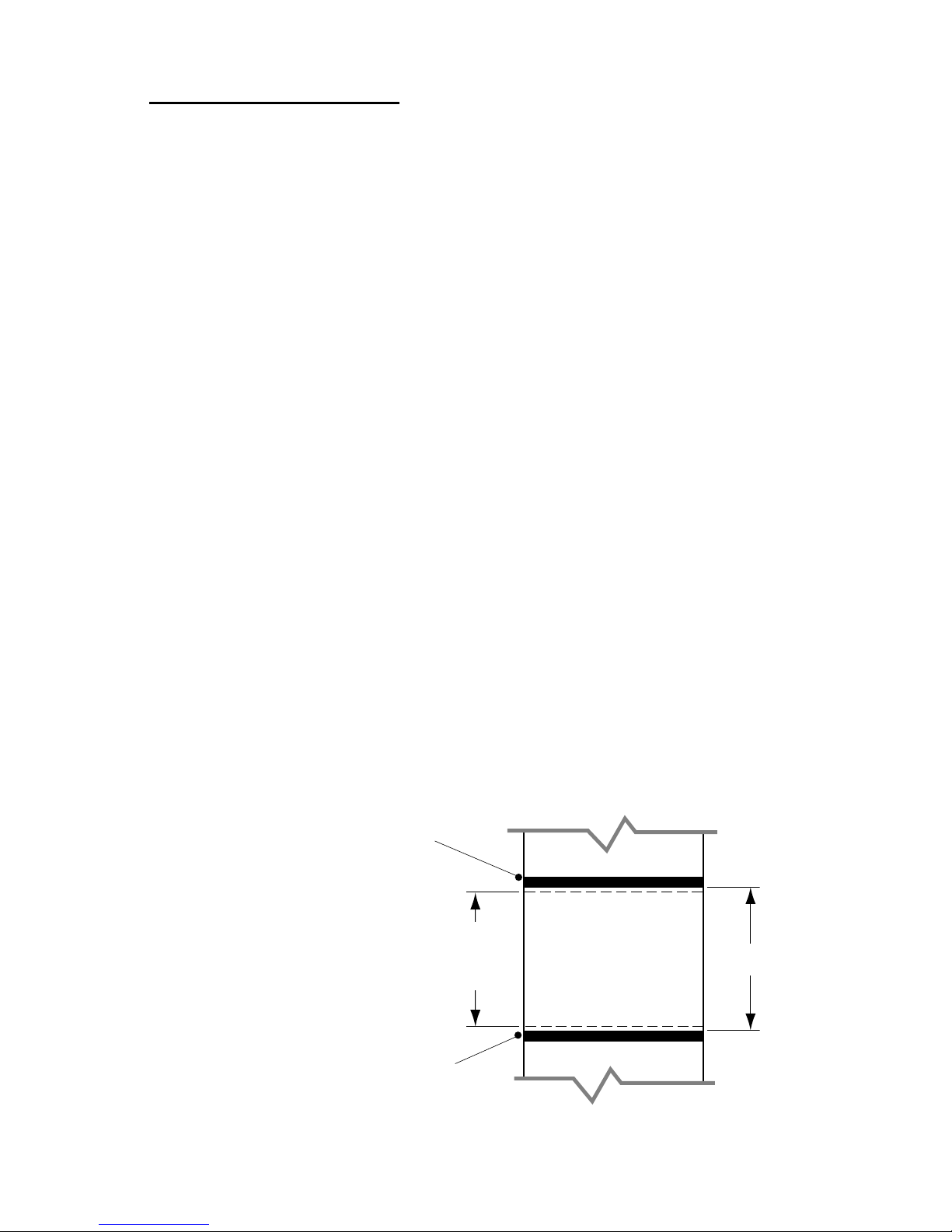

{height}:

The maximum height of the label.

The maximum label height is calculated by measuring from the bottom of the first black bar (or

label gap) to the top of the next black bar (or label

gap). Then 1/16” [1.5mm] is subtracted from this

distance to obtain the maximum height. (In dots:

subtract 12 dots on 203 d.p.i printers; 18 dots on

306 d.p.i. printers)

PRINTER Commands

Format:

{qty}:

Quantity of labels to be printed.

Maximum = 1024.

maximum ht. =

d - .062”

[1.5mm]

1

st

black bar or

gap

2

nd

black bar or

gap

“d”

Mobile Printer CPCLProgramming Manual P2-3

PRINT Command

The PRINT command terminates and prints the file. This

must always be the last command (except when in Line

Print Mode). Upon execution of the PRINT command,

the printer will exit from a control session. Be sure to

terminate this and all commands with both carriagereturn

and line-feed characters.

Format:

{command}

where:

{command}:

PRINT

PRINTER Command Example

Input (HELLO.LBL):

! 0 200 200 210 1

TEXT 4 0 30 40 Hello World

FORM

PRINT

Output:

P2-4 Mobile Printer CPCLProgramming Manual

FORM Command

The FORM command instructs the printer to feed to top

of form after printing.

Format:

{command}

where:

{command}:

FORM

In the following example, the printer will execute a form

feed after the label is printed. See the SETFF (set form

feed) command in the section on designing receipts and

lists for information on setting printer behavior when the

FORM command is executed.

Input: FORM.LBL

! 0 200 200 3 1

IN-CENTIMETERS

CENTER

TEXT 4 1 0 .5 Form Command

FORM

PRINT

Mobile Printer CPCLProgramming Manual P2-5

JOURNAL Command

By default, the printer will check for correct media alignment if it encounters the eye-sense mark (black horizontal bars on back of media) during a print cycle (LABEL

mode). If necessary, the JOURNAL command can be

used to disable this automatic correction feature. The

user's program is responsible for checking and assuring

presence of paper in JOURNAL mode. Please refer to

the status inquiry command for details on checking for

out-of-paper condition.

Format:

{command}

where:

{command}:

JOURNAL

P2-6 Mobile Printer CPCLProgramming Manual

UNITS Commands

The units commands are used to specify a measurement

system for all subsequent command fields in a control

session. Coordinates, widths, and heights for all control

commands can be entered with precision to four decimal

places. By placing a units command immediately after

the first line in a control session, the specified measurement system will also apply to the offset and height fields.

The printer measurement system will default to dots until

a units command is issued.

Format:

{command}

where:

{command}:

Choose from the following:

IN-INCHES Measurement in inches.

IN-CENTIMETERS Measurement in centimeters.

IN-MILLIMETERS Measurement in millimeters.

IN-DOTS Measurement in dots.

Mobile Printer CPCLProgramming Manual P2-7

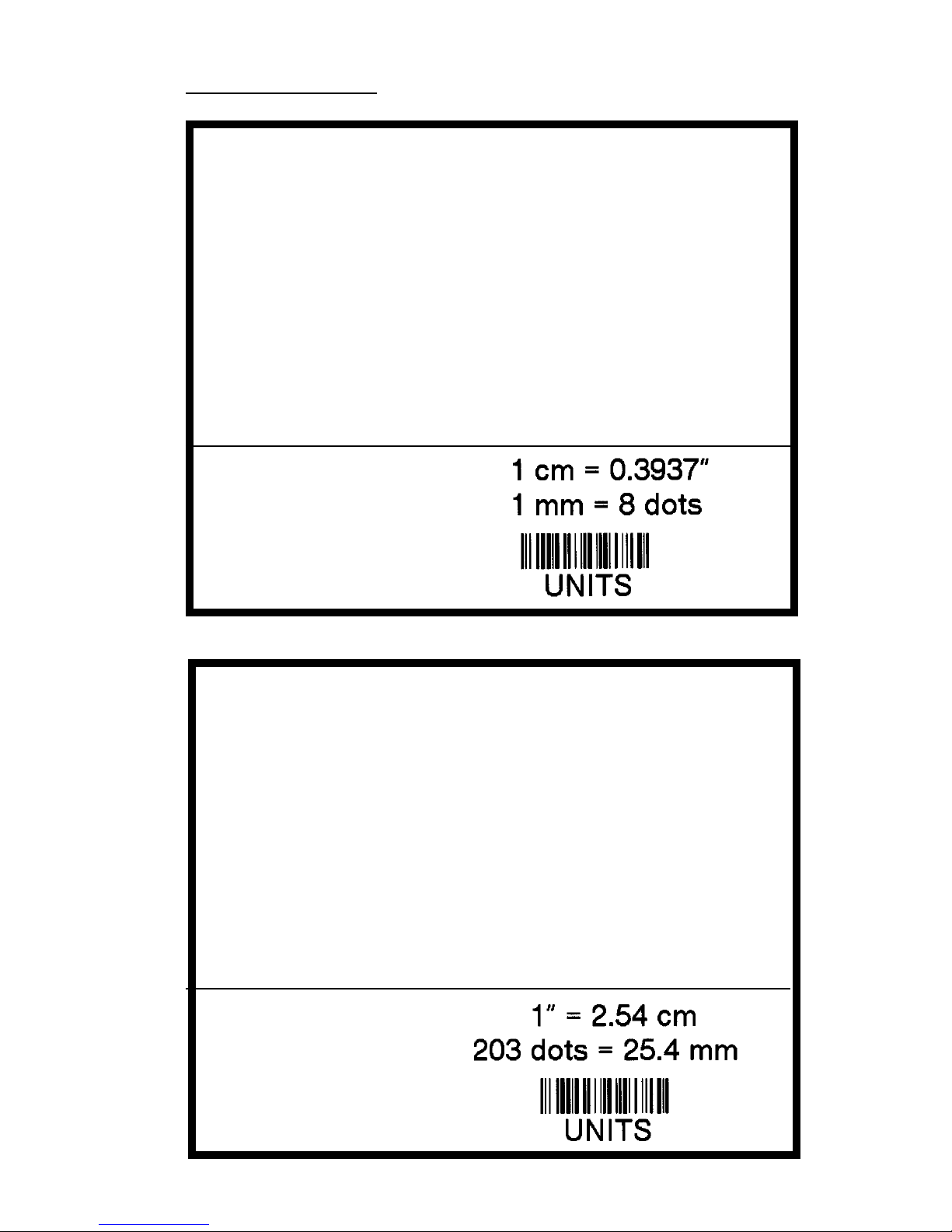

UNITS Examples

Input 1 (UNITS1.LBL):

! 0.3937 200 200 1 1

IN-INCHES

T 4 0 0 0 1 cm = 0.3937"

IN-DOTS

T 4 0 0 48 1 mm = 8 dots

B 128 1 1 48 16 112 UNITS

T 4 0 48 160 UNITS

FORM

PRINT

Output 1:

Output 2:

Input 2 (UNITS2.LBL):

! 0 200 200 2.54 1

IN-CENTIMETERS

T 4 0 1 0 1" = 2.54 cm

IN-MILLIMETERS

T 4 0 0 6 203 dots = 25.4 mm

B 128 0.125 1 6 12 14 UNITS

T 4 0 16 20 UNITS

FORM

PRINT

P2-8 Mobile Printer CPCLProgramming Manual

USING COMMENTS

Comments can be added between the first line of a

command session and the “PRINT” command.

A comment is placed in the file by starting a line with the

';' character in the first column. Any remaining text to the

end of the line will be ignored. Comments are illegal

between the CONCAT and ENDCONCAT commands.

Mobile Printer CPCLProgramming Manual P2-9

Input (COMMENT.LBL):

! 0 200 200 25 1

IN-MILLIMETERS

JOURNAL

; Center justify text

CENTER

; Print the words 'A COMMENT'

TEXT 5 1 0 5 A COMMENT

; Print the label and go to top of next fo

FORM

PRINT

Output:

COMMENTS Example

Mobile Printer CPCLProgramming Manual P3-1

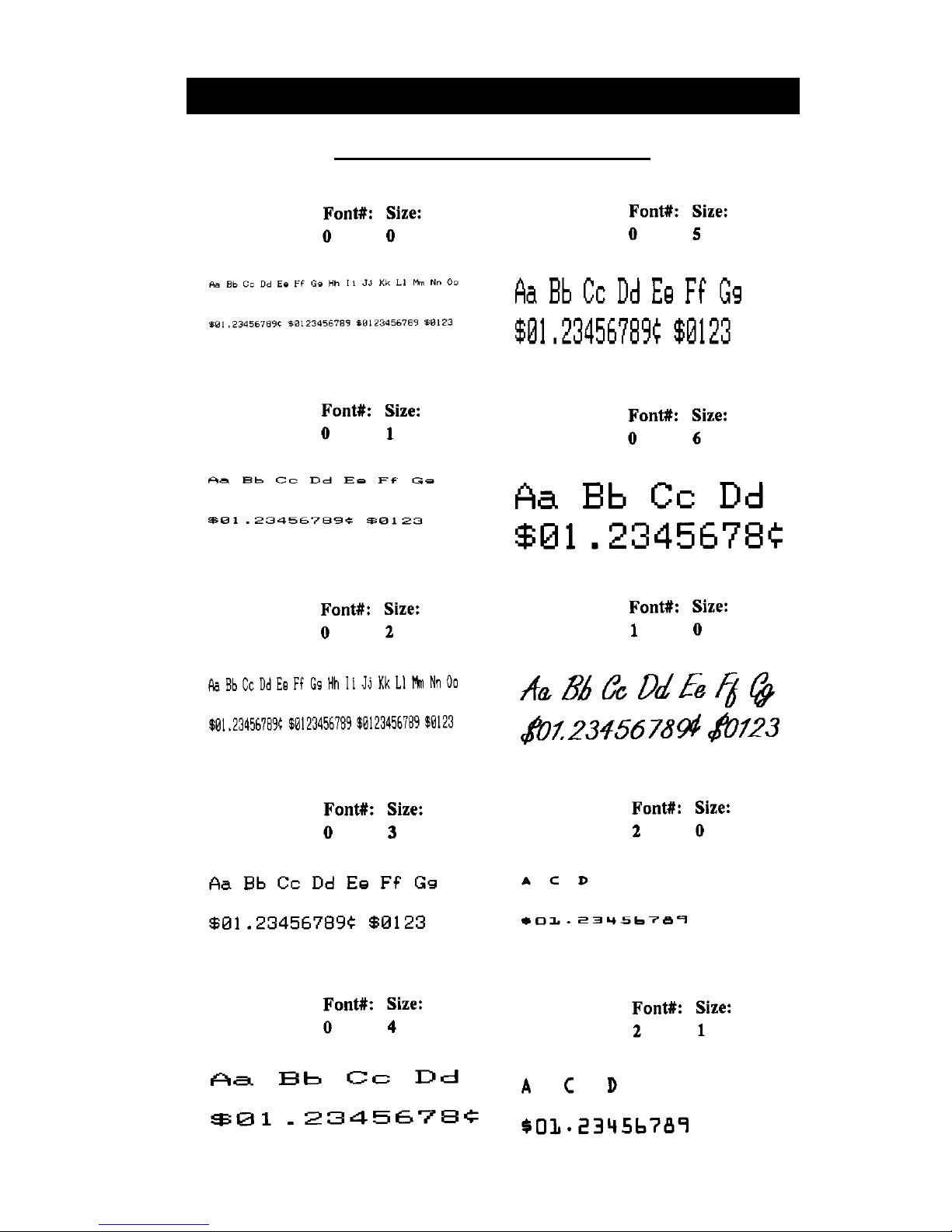

RESIDENT FONT SAMPLES

TEXT

P3-2 Mobile Printer CPCLProgramming Manual

RESIDENT FONT SAMPLES (continued)

Mobile Printer CPCLProgramming Manual P3-3

RESIDENT FONT SAMPLES (continued)

P3-4 Mobile Printer CPCLProgramming Manual

TEXT Commands

The TEXT command is used to place text on a label. This

command and its variants control the specific font number and size used, the location of the text on the label,

and the orientation of this text. Standard resident fonts

can be rotated to 90˚ increments as shown in the example.

Format:

{command} {font} {size} {x} {y} {data}

where:

{command}:

Choose from the following:

TEXT Prints text horizontally .

(or T)

VTEXT Prints text (vertically) rotated 90

(or VT) degrees counterclockwise.

TEXT90 (Same as VTEXT above.)

(or T90)

TEXT180 Prints text (upside down) rotated

(or T180) 180 degrees counterclockwise.

TEXT270 Prints text (vertically) rotated 270

(or T270) degrees counterclockwise.

{font}:

Name/number of the font.

{size}:

Size identifier for the font.

{x}:

Horizontal starting position.

{y}:

Vertical starting position.

{data}:

The text to be printed.

Mobile Printer CPCLProgramming Manual P3-5

TEXT Example

Input (TEXT.LBL):

! 0 200 200 210 1

TEXT 4 0 200 100 TEXT

TEXT90 4 0 200 100 T90

TEXT180 4 0 200 100 T180

TEXT270 4 0 200 100 T270

FORM

PRINT

Output:

P3-6 Mobile Printer CPCLProgramming Manual

USING FONT GROUPS

FONT -GROUP (FG) Command

The FG command gives a user the ability to group up to

10 pre-scaled font files into a single group. A user can

later specify the font group in a TEXT command. If a font

group is used in a text command, the printer will use the

largest

font specified in the font group that will produce

the required text data and still remain within the available

width of the label for the text. When specified in the

TEXT command, the {font} parameter is specified as FG,

and the {size} parameter is specified as the {fg}. Note

that a user can also specify an FG command within a

CONCA T/ENCONCA T command.

Format:

{command} {fg fn fs} [fn fs] ...

where:

{command}:

FG

{fg}:

Font group number . Up to 10 font

groups can be specified. Valid font

groups range from 0 to 9.

{fn}:

Name/number of the font.

{fs}:

Size identifier for the font.

NOTE: Up to 10 font number/font size pairs can be

assigned to a font group.

Mobile Printer CPCLProgramming Manual P3-7

Input (FG.LBL):

! 0 200 200 250 1

; Specify fonts 0-0, 7-0, 5-0, 4-0 as members

; of font group 3.

FG 3 0 0 7 0 5 0 4 0

VT FG 3 10 250 Ketchup

VT FG 3 70 250 Fancy Ketchup

VT FG 3 120 250 Extra Fancy Ketchup

VT FG 3 180 250 Large Size Extra Fancy Ketchup

FORM

PRINT

Output:

FG Example

In the example, the descriptions will be printed with the

largest font in the specified font group that is capable of

fitting the requested text in a 250 dot label field.

P3-8 Mobile Printer CPCLProgramming Manual

TEXT CONCATENATION COMMANDS

Text concatenation allows you to assign different character styles to strings, printing them with uniform spacing on

the same text line. This command can be used in combination with scalable fonts. See Scalable Concatenation

Commands

Format:

{command} {x} {y}

{font} {size} {offset} {data}

“““ “

{font} {size} {offset} {data}

<ENDCONCAT>

where:

{command}:

Choose from the following:

CONCAT Horizontal concatenation.

VCONCAT Vertical concatenation.

{x}:

Horizontal starting position.

{y}:

Vertical starting position.

{font}:

Name/number of the font.

{size}:

Size identifier for the font.

{offset}:

Unit-value to offset text from the

starting position. Used to align

individual text strings or create

superscript/subscript characters.

{data}:

Text to be printed.

<ENDCONCAT>:

Terminates concatenation.

Mobile Printer CPCLProgramming Manual P3-9

Input (CONCAT.LBL):

! 0 200 200 210 1

CONCAT 75 75

4 2 5 $

4 3 0 12

4 2 5 34

ENDCONCAT

FORM

PRINT

Output:

TEXT CONCATENATION Example

P3-10 Mobile Printer CPCLProgramming Manual

MULTILINE (ML) Commands

MULTILINE (ML) allows you to print multiple lines of text

using the same font and line-height.

Format:

{command} {height}

{text} {font} {size} {x} {y}

{data}

“

{data}

<ENDMULTILINE>

where:

{command}:

Choose from the following:

MULTILINE Prints multiple lines of text.

(or ML)

{height}:

Unit-height for each line of text.

{text}:

Text command (TEXT, VTEXT, etc.).

{font}:

Name/number of the font.

{size}:

Size identifier for the font.

{x}:

Horizontal starting position.

{y}:

Vertical starting position.

{data}:

Text to be printed.

<ENDMULTILINE>:

Terminates MUL TILINE.

(or ENDML)

Mobile Printer CPCLProgramming Manual P3-11

MULTILINE Example

Input (MULTIL.LBL):

! 0 200 200 210 1

ML 47

TEXT 4 0 10 20

1st line of text

2nd line of text

:

Nth line of text

ENDML

FORM

PRINT

Output:

P3-12 Mobile Printer CPCLProgramming Manual

COUNT Command

The COUNT command is used for printing multiple labels

where a numeric text field or numeric data encoded in a

bar code is to be incremented or decremented for each

label. The TEXT/BARCODE command string must contain this numeric data as the last characters of the string.

The numeric data portion can be up to 20 characters, and

can be preceded by the '-' sign. Incrementing or

decrementing the numeric data thru '0' is not allowed.

Leading zeros will be retained. Up to 3 COUNT commands can be used in a label file.

The numeric data incremented/decremented is contained

in the TEXT or BARCODE command that immediately

preceded the COUNT command.

Format:

{command} {numeric value}

where:

{command}:

COUNT

{numeric value}:

Any integer value up to 20 characters. The value can be preceded

by a '-' sign if decrementing of the

TEXT/BARCODE value is desired.

Leading zeros will be retained in

the output.

Mobile Printer CPCLProgramming Manual P3-13

COUNT Example

Input (COUNT.LBL):

! 0 200 200 210 3

; Print 3 labels

CENTER

TEXT 4 0 0 50 TESTING 001

COUNT 1

TEXT 7 0 0 100 Barcode Value is 123456789

COUNT -10

BARCODE 128 1 1 50 0 130 123456789

COUNT -10

FORM

PRINT

Output:

P3-14 Mobile Printer CPCLProgramming Manual

SETMAG Command

The SETMAG command magnifies a resident font to the

magnification factor specified.

Format:

{command} {w} {h}

where:

{command}:

SETMAG

{w}:

Width magnification of the font.

Valid magnifications are 1 thru 16.

{h}:

Height magnification of the font.

Valid magnifications are 1 thru 16.

NOTE: The SETMAG command stays in effect after

printing a label. This means that the next label

printed will use the most recently set SETMAG

values. To cancel any SETMAG values and

allow the printer to use its default font sizes, use

the SETMAG command with magnifications of

0,0.

Mobile Printer CPCLProgramming Manual P3-15

SETMAG Example

Input (SETMAG.LBL):

! 0 200 200 210 1

CENTER

SETMAG 1 1

TEXT 0 0 0 10 Font 0-0 at SETMAG 1 1

SETMAG 1 2

TEXT 0 0 0 40 Font 0-0 at SETMAG 1 2

SETMAG 2 1

TEXT 0 0 0 80 Font 0-0 at SETMAG 2 1

SETMAG 2 2

TEXT 0 0 0 110 Font 0-0 at SETMAG 2 2

SETMAG 2 4

TEXT 0 0 0 145 Font 0-0 at SETMAG 2 4

; Restore default font sizes

SETMAG 0 0

FORM

PRINT

Output:

Mobile Printer CPCLProgramming Manual P4-1

SCALABLE TEXT

Scalable text allows a user to print text at any point size.

Point size can be specified for both the X and Y directions

to produce characters that are "stretched" in either their

width or height. Point sizes specified and text produced

will print at 72 points equating to one inch (25.4mm).

The printer can contain scalable font files as part of the

application, or scalable font files can be downloaded to

the printer using one of the utilities on the supplied disk.

A scalable text file must be present in your printer’s

memory in order to use scalable text features.

P4-2 Mobile Printer CPCLProgramming Manual

SCALE-TEXT Commands

The SCALE-TEXT commands allow the user to specify

the point size of

both

the width and height of the font.

Format:

{command} {name} {width} {height} {x} {y} {data}

where:

{command}:

Choose from the following:

SCALE-TEXT: Prints scaled text horizontally.

(or ST)

VSCALE-TEXT: Prints scaled text vertically.

(or VST)

{name}:

Font name.

{width}:

Font width (point size).

{height}:

Font height (point size).

{x}:

Horizontal starting position.

{y}:

Vertical starting position.

{data}:

Text to be printed.

Mobile Printer CPCLProgramming Manual P4-3

SCALE-TEXT Example

Input (SCALE.LBL):

! 0 200 200 300 1

CENTER

; Print using x and y scales of 10 points

SCALE-TEXT PLL_LAT.CSF 10 10 0 10 10 POINT FONT

; Print using x scale of 20 points and y scale

; of 10 points

SCALE-TEXT PLL_LAT.CSF 20 10 0 80 WIDER FONT

; Print using x scale of 10 points and y scale

; of 20 points

SCALE-TEXT PLL_LAT.CSF 10 20 0 150 TALLER FONT

FORM

PRINT

Output:

P4-4 Mobile Printer CPCLProgramming Manual

SCALE-TO-FIT Commands

The SCALE-TO-FIT commands automatically calculate

the scale in order to fit text inside a window.

Format:

{command} {name} {width} {height} {x} {y} {data}

where:

{command}:

Choose from the following:

SCALE-TO-FIT: Prints scaled text horizontally.

(or STF)

VSCALE-TO-FIT: Prints scaled text vertically.

(or VSTF)

{name}:

Font name.

{width}:

Unit-width of the window.

{height}:

Unit-height of the window.

{x}:

Horizontal starting position.

{y}:

Vertical starting position.

{data}:

Text to be printed.

Mobile Printer CPCLProgramming Manual P4-5

SCALE-TO-FIT Example

Input (STF.LBL):

! 0 200 200 100 1

IN-MILLIMETERS

CENTER

; Fit a text string into an area 40mm wide by 10mm

; high

SCALE-TO-FIT PLL_LAT.CSF 40 10 0 10 SALE

; Fit a longer text string into the same 40mm wide

; by 10mm high area

SCALE-TO-FIT PLL_LAT.CSF 40 10 0 20 SALE PRICE

; Fit “SALE” text into a 40mm wide by 20mm high

; area

SCALE-TO-FIT PLL_LAT.CSF 40 20 0 30 SALE

FORM

PRINT

Output:

P4-6 Mobile Printer CPCLProgramming Manual

SCALABLE CONCATENATION Commands

Scalable concatenation allows you to assign different

character styles to strings, printing them with uniform

spacing on the same text line. Both scalable and bitmap

text can be combined between a CONCAT/ENCONCA T

command. See also Text Concatenation Commands

Format:

{command} {x} {y}

<ST> {name} {width} {height} {offset} {data}

“ “““““

<ST> {name} {width} {height} {offset} {data}

<ENDCONCAT>

where:

{command}:

Choose from the following:

CONCAT Horizontal concatenation.

VCONCAT Vertical concatenation.

{x}:

Horizontal starting position.

{y}:

Vertical starting position.

{name}:

Font name.

{width}:

Font width point size.

{height}:

Font height point size.

{offset}:

Unit-value to offset text from the

starting position. Used to align

individual text strings or create

superscript/subscript characters.

{data}:

Text to be printed.

<ENDCONCAT>:

Terminates concatenation.

Mobile Printer CPCLProgramming Manual P4-7

SCALABLE CONCATENATION Example

Input (STC.LBL):

! 0 200 200 210 1

CENTER

; Concatenate 3 scalable font strings and 1

; Resident font string

CONCAT 0 20

4 1 0 2/

ST PLL_LAT.CSF 20 20 15 $

ST PLL_LAT.CSF 40 40 0 22

ST PLL_LAT.CSF 20 20 0 99

ENDCONCAT

FORM

PRINT

Output:

P4-8 Mobile Printer CPCLProgramming Manual

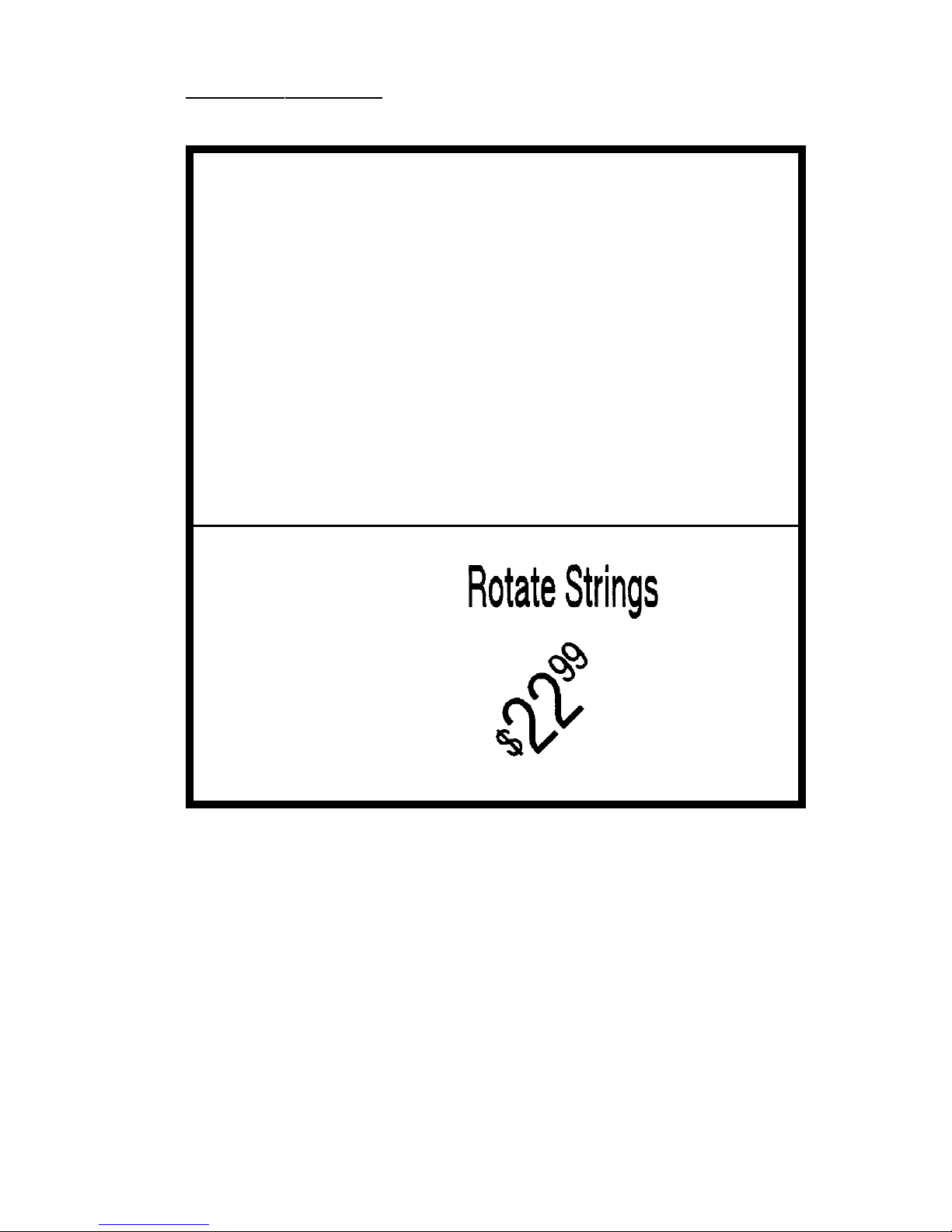

ROTATE Commands

ROTA TE commands are used to rotate all subsequent

scalable text fields at a specified angle. Rotation direction is counter-clockwise about the center point of the

text. This rotation remains in effect until another ROTA TE

command is issued. Default angle is zero degrees.

Format:

{command} {angle}

where:

{command}:

Choose from the following:

ROTATE Rotates scalable fonts.

(or R)

{angle}:

Degree of rotation (ccw).

Mobile Printer CPCLProgramming Manual P4-9

ROTATE Example

Input (ROTATE.LBL):

! 0 200 200 440 1

CENTER

TEXT 4 1 0 50 Rotate Strings

ROTATE 45

CONCAT 50 300

ST PLL_LAT.CSF 20 20 20 $

ST PLL_LAT.CSF 40 40 0 22

ST PLL_LAT.CSF 20 20 0 99

ENDCONCAT

FORM

PRINT

Output:

Mobile Printer CPCLProgramming Manual P5-1

INTRODUCTION

Bar codes allow easy implementation of automated

identification, cataloging and processing of almost any

object. They have been successfully used on items

ranging in size from boxcars to bumblebees.

This overview of bar code symbologies will help when

programming Zebra mobile printers and/or designing

labels with Label Vista software.

If you plan to create software using these bar codes,

we recommend ordering the uniform symbology specification from AIM or the UCC to determine the uses and

limitations pertaining to that type of bar code. The information in this document is in no way complete.

The following discussions contain basic information

and some suggested applications for each type of bar

code. The quick reference table in Appendix E lists

specific data for each bar code in one location. All the

information on ideal widths and ratios comes directly from

the uniform symbology specification. Please note that all

measurements contained in this document are in printer

dots. On 200 dot per inch (dpi) printers, one dot is equal

to 0.005” or 0.13 millimeters, on 300 dpi printers one dot

is equal to 0.003” or 0.07 millimeters.

LINEAR BAR CODES

P5-2 Mobile Printer CPCLProgramming Manual

RESIDENT LINEAR BAR CODE SAMPLES

UPC-A UPC-E

CODE 39 CODE 93

I 2 OF 5 CODE 128

UCC-128 CODABAR

PLESSY MS110 POSTNET

EAN-13 EAN-8

UPC/EAN Plus 2 UPC/EAN Plus 5

Extender Extender

Mobile Printer CPCLProgramming Manual P5-3

The first number in the UPC/EAN bar code is the number system character. The specification lists use of

characters 0 through 9 as follows.

0 Regular UPC codes (UPC-A and UPC-E)

1Reserved

2 Random weight items, like store packaged meat.

(UPC-A only)

3 National Drug Code and National Health Related

Items Code in current 10-digit code length (UPC-A

only)*

4 In-store marking of non food items without code

format restriction and with check digit protection

(UPC-A only)

5 Coupons (UPC-A only)

6 Regular UPC codes (UPC-A only)

7 Regular UPC codes (UPC-A only)

8Reserved

9Reserved

* Number system 3 has the following note in the specification. “…the symbol

is not affected by the various internal structures possible with the NDC or

HRI codes.” The users should determine what effect this statement may

have on their program. It will not change how bar codes are printed.

UPC AND EAN/JAN BAR CODES

UPC and EAN/JAN bar codes are typically used for

marking products with a unique code used to look up

prices and to track inventories of goods sold. They are

also used for store coupons, periodicals, and paperback

books. UPC and EAN/JAN bar codes are generally

rectangular, contain a fixed amount of data, and in most

cases are accompanied by human readable text printed

below them. For best results, this text should be an

OCR-A (resident font 2), a sans serif font (resident font 7)

or an OCR-B font.

P5-4 Mobile Printer CPCLProgramming Manual

The checksum is the last number in the bar code and

can be used to make certain that the bar code is decoded

properly. This digit is

automatically

calculated by the

printer. The UPC bar code specification has the full

instructions for calculating this checksum. The methodology is as follows:

For this example, the bar code will be 01234567890.

Step 1: Starting at the left, including the number system

character, add up all the numbers in the ODD positions. (0 + 2+ 4 + 6 + 8 + 0 = 20)

Step 2: Multiply this sum by 3. (20 x 3 = 60)

Step 3: Starting at the left again, add up all the numbers

in the EVEN positions. (1 + 3 + 5 + 7 + 9 = 25).

Step 4: Add the results from step 2 and step 3. (60 + 25

= 85)

Step 5: The checksum is the smallest number when

added to step 4 will equal a multiple of ten. In our

example: 85 + 5 = 90, which is a multiple of 10.

Therefore, the check digit should be 5. It is called a

modulo checksum because you take the modulo, or

remainder , of the sum. For the programmers, it is:

10 - (85 mod 10) = the checksum.

UPC-A and EAN13 bar codes can be created with and

without a checksum supplied. If the programmer supplies

a checksum digit, the printer will create the bar code with

that check digit,

even if it is incorrect

. Most laser scanning devices will not be able to decode the bar code if the

check digit is incorrect,

UPC-E bar codes, useful for small items like candy and

gum, are created through the method of “zero suppression.” For example, if you were to encode 01000000567,

the resulting bar code would be a compressed bar code

Mobile Printer CPCLProgramming Manual P5-5

that only contains the data, the compression scheme,

and the checksum without all the extra zeros. For our

example, the bar code would decode to 1056707. Please

refer to the UPC Symbol Specification Manual from the

Uniform Code Council for more information on zero

suppression.

UPC-E and EAN8 bar codes have a few restrictions.

First, the number system character must be set to 0.

Number systems 1 through 9 do not support UPC-E and

EAN8 bar codes and may not be decoded by a laser

scanning device. In case your application requires it, the

number system may be set to something other than 0.

Second, if the programmer supplies a checksum digit, the

printer will create the bar code with that check digit,

even

if it is incorrect

. If the check digit is incorrect, most laser

scanning devices will not be able to decode the bar code.

Therefore, the programmer may send six digits (no number system, no checksum), seven digits (number system,

no checksum), or eight digits (number system and

checksum) and create a bar code.

Plus 2 and plus 5 bar code extensions are only used

for periodicals and paperback books. Specifically, the bar

code specification states that the plus 2 extension should

only be used for a periodical issue number . The plus 2

and plus 5 extensions do not contain any checksum

according to the bar code specification.

To create an extended bar code, place a space between the data that should go into the UPC/EAN bar

code and the data that should go into the extension. You

can also use the PLUS2 and PLUS5 bar code types to

create the extension separately. Remember to leave

ample space (about 9 times the ratio) between the UPC/

EAN bar code and the extension.

P5-6 Mobile Printer CPCLProgramming Manual

CODE 39 OR CODE 3 OF 9 BAR CODES

The Code 39 bar code is used for many applications

including inventories, hospital applications, or any other

place where the code length may change between items

being scanned (e.g. a bar code stating there were 420

pieces in one box and 20004 pieces in another box would

have a different physical length). This bar code can use

the characters 0 through 9, A through Z, ‘-’ (dash), “.”

UPC/EAN SPECIFICATIONS

Ideal Ideal

Bar code Bar code Wide/Narrow Narrow Checksum

Symbology Type Input Length Characters Ratio Dot Width Calculation

UPC-A UPCA 11 or 12 digits 0-9 only 2:1 2 mod 10

UPC-A plus 2UPCA2 13 digits 0-9 only 2:1 2 mod 10

(UPC-A)

UPC-A plus 5UPCA5 16 digits 0-9 only 2:1 2 mod 10

(UPC-A)

UPC-E UPCE 6, 7 or 11 digits 0-9 only 2:1 2 mod 10

UPC-E plus 2UPCE2 8 or 13 digits 0-9 only 2:1 2 mod 10

(UPC-E)

UPC-E plus 5UPCE5 11 or 16 digits 0-9 only 2:1 2 mod 10

(UPC-E)

EAN/JAN-13 EAN13 12 or 13 digits 0-9 only 2:1 2 mod 10

EAN/JAN-13 mod 10

plus 2 EAN132 14 digits 0-9 only 2:1 2 (EAN13)

EAN/JAN-13 mod 10

plus 5 EAN135 17 digits 0-9 only 2:1 2 (EAN13)

EAN/JAN-8 EAN8 6, 7 or 8 digits 0-9 only 2:1 2 mod 10

EAN/JAN-8

plus 2 EAN82 9 digits 0-9 only 2:1 2 mod 10 (EAN8)

EAN/JAN-8

plus 5 EAN85 12 digits 0-9 only 2:1 2 mod 10 (EAN8)

(period), space, “$” (dollar sign), “/”(forward slash), “+”

(plus) and “%” (percent). There is also a special character called “S/S” used as a start/ stop character. The F39

and F39C types allow the use of carriage return, line

feed, and null characters.

The checksum for this bar code is located as the last

(or least significant) digit of the decoded bar code. To

assure data integrity in your application, use a bar code

with a checksum. The printer will

automatically

supply

Mobile Printer CPCLProgramming Manual P5-7

this digit if the user selects a 39C or a F39C bar code.

Check Character Numerical Value Table

Char Value Char Value Char Value Char Value

00 C12 O24 - 36

11 D13 P25 . 37

22 E14 Q26

SP ACE 38

33 F15 R27 $ 39

44 G16 S28 / 40

55 H17 T29 + 41

66 I18 U30 % 42

77 J19V31 $ (full) 43*

88 K20W32 % (full) 44*

99 L21X33 /(full) 45*

A10M22 Y 34 + (full) 46*

B11 N23 Z35

* Full represents F39 or F39C for Full ASCII

Refer to the full bar code symbology specification for

complete information on checksum calculation. For a

short example, take an example bar code with the data

“CODE 39” .

Step 1: Assign a value to each character per the Char-

acter Numerical Value Table above . C=12, O=24,

D=13, E=14, space = 38, 3=3, 9=9.

Step 2: Add the values 12+24+13+14+38+3+9=113.

Step 3: Divide this number by 43. The remainder or

modulo, 27, is the checksum.

Step 4: Referring to the table, 27 is the character R.

Therefore, the checksum in the bar code should be R.

The final code reads “CODE 39R” when it is decoded.

CODE 39 (3 OF 9) SPECIFICATIONS

Ideal Ideal

Bar code Bar code Wide/Narrow Narrow Checksum

Symbology Type Input Length Characters Ratio Dot Width Calculation

Code 39 39 Variable Refer text 2.5:1 2 none

39C Variable Refer text 2.5:1 2 mod 43

F39 V ariable Refer text 2.5:1 2 none

F39C Variable Refer text 2.5:1 2 mod 43

P5-8 Mobile Printer CPCLProgramming Manual

CODE 93 OR CODE 9 OF 3 BAR CODES

The Code 93 bar code is used for applications that

require heavy error checking capabilities. To accomplish

this, the Code 93 bar code contains two separate error

checking checksums that are automatically calculated

and placed into the bar code. This bar code is used for

inventories, hospital applications, or any other place

where the length may change between items being

scanned. (See Code 39 above.) This bar code type can

use the entire ASCII 128 character set. It is useful for

encoding data and phrases like “Code 93”.

The two checksums in this bar code are located as the

last and second to last characters in the decoded bar

code. Code 93 has a complex checksum calculation.

Please see the bar code symbology specification for

information on how to create and decode this checksum.

Please also note that the bar code symbology specification does not state any ideal values for the ratio and the

width of the narrow bar.

INTERLEAVED 2 OF 5 BAR CODES

The Interleaved 2 of 5 (or ITF) bar code is used for

applications that have a fixed data length for all items

scanned. A date, telephone number, or a SKU of fixed

length would be a good application for this bar code. The

symbology specification states that a ITF bar code may

be partially decoded without any recognizable difference.

Therefore, to prevent this problem, you must keep the

length of data to a constant and perform an error checking routine on the decoding program to determine if the

data is correct.

Only the digits 0-9 can be encoded, and there should

CODE 93 SPECIFICATIONS

Ideal Ideal

Bar code Bar code Wide/Narrow Narrow Checksum

Symbology Type Input Length Characters Ratio Dot Width Calculation

Code 93 93 Variable 128 ASCII 1.5:1 1 two mod 47

Mobile Printer CPCLProgramming Manual P5-9

be an even number of digits in the data. If there is an

odd number of digits, the printer will automatically insert a

zero (0) at the beginning of the bar code.

There are two bar code varieties with a checksum:

Interleaved 2 of 5 “with checksum” and German Post

Code. German Post Code has fixed length – either 12 or

14 characters (including checksum).

Here is an example how to calculate modulo 10

checksum:

Step 1: To calculate the checksum, first ensure that you

are starting with an odd number of digits in the data.

If not, add a zero (0) to the beginning of the data.

Step 2: Multiply every other digit by 3, and add up the

numbers. So, if your data was “43827” your calculation should be (4 x 3) + 3 + (8 x 3) + 2 + (7 x 3) = 62.

Step 3: Divide this number by 10, resulting in 6 with a

remainder of 2. Subtract the remainder from 10. In

our example, 10 - 2 = 8. The checksum is this final

number, 8. Append this to the end of your data. Note

that if the remainder was a zero, your checksum

should be zero.

CODE 128 AND THE UCC-128 SHIPPING STANDARD

Code 128 is used for applications that need to contain

a large amount of data such as shipping applications,

marking blood donations, and any other application that

can vary in length between bar codes being scanned.

The bar code also contains a checksum as the last char-

INTERLEAVED 2 OF 5 SPECIFICATIONS

Ideal Ideal

Bar code Bar code Wide/Narrow Narrow Checksum

Symbology Type Input Length Characters Ratio Dot Width Calculation

Interleaved

2 of 5 I2OF5 Varies 0-9 only 2.5:1 2 See text

Interleaved 2 of 5 I2OF5C

Varies 0-9 only 2.5:1 2 See text

with checksum

German Post I2OF5G 11, 12,

0-9 only 2.5:1 2

mod 10,

Code 13 or 14 weights 4,9

P5-10 Mobile Printer CPCLProgramming Manual

acter in the code which ensures that data remains intact.

Code 128 can use the entire ASCII 128 character set

as well as other subsets available in the universal symbology specification. The three start and stop characters

determine which character set to use. The checksum for

this bar code is located immediately before the stop

character. The bar code symbology specification contains all the information on calculating this checksum.

For a short example, we desire to encode “BAR128” in a

bar code. We will use “A” as our start and stop character

in this example.

Step 1: The symbology specification assigns a numeri-

cal value for each character . Find the values of all the

characters in the data.

Step 2: Add the value of the start character and all the

data characters multiplied by its position in the bar

code. For our example, the calculation would be 103

+ (34 x 1) + (32 x 2) + (50x 3) + (17x 4) + (18x 5) +

(24 x 6) = 672.

Step 3: Divide this number by 103. The remainder or

modulo, 54, is the checksum. The character that

assigned to 54 in the specification is “V”. Our final

code will look like “ABAR128V” where “A” is the start

character , “BAR128” is the data, and “V” is the

checksum.

The UCC-128 Shipping Standard is part of a document

called

Application Standard for Shipping Container Codes

available from the Uniform Code Council. This 90-page

guide contains the entire specification on marking any

shipment sent anywhere in the United States. Seventeen

pages are dedicated to the technical considerations of

using, placing, and printing these bar codes. We highly

recommend getting this information if your application

involves shipping.

Mobile Printer CPCLProgramming Manual P5-11

CODE 128/ UCC-128 SPECIFICATIONS

Ideal Ideal

Bar code Bar code Wide/Narrow Narrow Checksum

Symbology Type Input Length Characters Ratio Dot Width Calculation

Code 128 128 Variable Refer text 1.5:1 1 mod 103

/A/B/C/Auto

UCC-128Std. UCCEAN Refer text Refer text 3:1 3 mod 103

16

CODABAR

Codabar is ideal for applications that contain mostly

numeric symbols that may vary in length from bar code to

bar code. It can encode the digits from 0 to 9, the characters “-”(dash), “$”(dollar sign), “:” (colon), “/” (forward

slash), “.” (period), and “+” (plus) as well as start/stop

characters A through D.

One optional checksum is automatically appended as

the least significant digit in the bar code data directly

before the stop character. The bar code symbology

specification contains all the information on calculating

the checksum. As a short example, our data will be

“A37859B” where A and B are start/stop characters. The

characters 0 through 9 are assigned the numerical values

0 through 9 respectively. “-” is 10, “$” is 1 1, “:”is 12, “/” is

13, “.” is 14, “+” is 15, and start/stop characters A B C and

D are 16, 17, 18, and 19 respectively.

Step 1: Add the numerical value of all the characters.

16 + 3 + 7 + 8 + 5 + 9 + 17 = 65.

Step 2: Divide this number by 16 and use the remain-

der, or modulo. In our example, this is 1

Step 3: Subtract the modulo from 16. This is the small-

est number that can be added to the sum in step 1 to

make a multiple of 16. (65 + 15 =80. 80 /16= 5)

Therefore, the check sum for our example is 15.

Step 4: The character that corresponds to 15 is “+” and

is added in before the stop character. Our final bar

code looks like “A37859+B”.

P5-12 Mobile Printer CPCLProgramming Manual

MSI PLESSY SPECIFICATIONS

Ideal Ideal

Bar code Bar code Wide/Narrow Narrow Checksum

Symbology Type Input Length Characters Ratio Dot Width Calculation

MSI Plessey MSI 13 digits max 0-9 only 2:1 2 none

MSI10 13 digits max 0-9 only 2:1 2 mod 10

MSI1010 13 digits max 0-9 only 2:1 2 two mod 10

MSI1110 13 digits max 0-9 only 2:1 2 mod 11 mod 10

The bar code type NW7 is for reverse compatibility

only. We do not recommend using this command for new

systems. There is no difference between CODABAR and

NW7.

MSI PLESSEY BAR CODES

The MSI Plessey bar code is a fixed length code that

uses only numerical characters. It is primarily used for

grocery applications. Three different types of encoding

exist with different levels of data protection. Please see

the bar code symbology specification for more information on how to calculate these checksums.

The bar code type “PLESSEY” is used for reverse

compatibility only. We do not recommend using this

command for new systems. The PLESSEY type will force

a 2:1 ratio of the wide to narrow bar width.

CODABAR SPECIFICATIONS

Ideal Ideal

Bar code Bar code Wide/Narrow Narrow Checksum

Symbology Type Input Length Characters Ratio Dot Width Calculation

Codabar CODABAR Variable 0-9,A-D 2.5:1 2 none

symbol

CODABAR Variable 0-9,A-D, 2.5:1 2 mod 16

16 symbol

Mobile Printer CPCLProgramming Manual P5-13

POSTNET AND FACING IDENTIFICATION MARKS

The US Postnet bar code is used only to help automate

mail delivery. To comply with postal regulations, set the

height of the bar code to 30 dots, the wide/narrow bar

ratio at 3.5:1, and the width of the narrow bar to 3 dots on

a 200 dpi printer. The data sent to the bar code can be 5,

9, or 11 digits long. For example, to send mail to 30 Plan

Way, Warwick, RI 02886-1234, the data would be

5 digits- ZIP Code only: 02886

9 digits - ZIP + 4 Code: 028861234

11 digits - ZIP + 4 Code and last two digits in address:

02886123430

The Postnet bar code also contains an automatically

calculated checksum as the last character in the

decoded bar code. As a short example, our data will

be “02881123430”

Step 1: Add the numerical value of all the characters.

0+2+8+8+1+1+2+3+4+3+0 = 32.

Step 2: Divide this number by 10 and use the remain-

der , or modulo. In our example, this is 2

Step 3: Subtract the remainder (or modulo) from 10 to

get the check sum. The check sum for our example

would be 8 (10 - 32 mod 10 for programmers).

A Facing Identification Mark (FIM) is the bar in the

upper right corner of an envelope near the stamp. To

comply with postal regulations, set the height of the bar

code to 125 dots, the ratio to 1.5:1 dots, and the width of

the narrow bar to 6 dots. There are three different characters you can send as data: A, B, and C.

FIM A: Courtesy Reply Mail with Postnet Bar code

FIM B: Business Reply Mail, Penalty Mail, or Franked

P5-14 Mobile Printer CPCLProgramming Manual

Postnet POSTNET 5, 9, 11 digits 0-9 only 3.5:1 3 mod 10

Facing

Ident Mark FIM A, B, or C only A, B, or C 1.5:1 6 N/A

Ideal Ideal

Bar code Bar code Wide/Narrow Narrow Checksum

Symbology Type Input Length Characters Ratio Dot Width Calculation

Mail without Postnet Bar code

FIM C: Business Reply Mail, Penalty Mail, or Franked

Mail with Postnet Bar code.

For more information, please see Publication 25 from

the USPS Postal Business Center . If you are making a

label with an address, try using resident font 7 or font 4

for best results with the optical character recognition

software used by the post office.

POSTNET AND FIM SPECIFICATIONS

Mobile Printer CPCLProgramming Manual P5-15

BAR CODE COMMANDS

The following commands are used for the creation and

formatting of bar codes on labels. Insure that the bar

code symbology chosen agrees with its intended use,

and that it conforms to the guidelines in the previous

section.

A Quick Reference Guide for the linear bar code symbologies discussed in this manual can be found in Appendix “E”.

Note that the “COUNT” command is also discussed in

Section 3 of this manual.

P5-16 Mobile Printer CPCLProgramming Manual

BARCODE Command

The BARCODE command prints bar codes in both vertical and horizontal orientations at specified widths and

heights.

Standard Bar Codes

Format:

{command} {type} {width} {ratio} {height} {x} {y} {data}

where:

{command}:

Choose from the following:

BARCODE Prints bar code horizontally.

(or B)

VBARCODE Prints bar code vertically.

(or VB)

{type}:

Choose from the following table:

Symbology: use:

UPC-A UPCA, UPCA2, UPCA5

UPC-E UPCE, UPCE2, UPCE5

EAN/JAN-13 EAN13, EAN132, EAN135

EAN/JAN-8 EAN8, EAN82, EAN 85

Code 39 39, 39C, F39, F39C

Code 93/Ext. 93 93

Interleaved 2 of 5 I2OF5

Interleaved 2 of 5 I2OF5C

with checksum

German Post Code I2OF5G

Code 128 (Auto) 128

UCC EAN 128 UCCEAN128

Codabar CODABAR, CODABAR16

MSI/Plessy MSI, MSI10, MSI1010, MSI1110

Postnet POSTNET

FIM FIM

Mobile Printer CPCLProgramming Manual P5-17

{height}:

Unit-height of the bar code.

{x}:

Horizontal starting position.

{y}:

Vertical starting position.

{data}:

Bar code data.

Output:

Input (BARCODE.LBL):

! 0 200 200 210 1

BARCODE 128 1 1 50 150 10 HORIZ.

TEXT 7 0 210 60 HORIZ.

VBARCODE 128 1 1 50 10 200 VERT.

VTEXT 7 0 60 140 VERT.

FORM

PRINT

BAR CODE Example

{width}:

Unit-width of the narrow bar.

{ratio}:

Ratio of the wide bar to the narrow bar.

Refer to the table in Appendix “E” for appropriate settings.

0 = 1.5 : 1 20 = 2.0:1 26 = 2.6:1

1 = 2.0 : 1 21 = 2.1:1 27 = 2.7:1

2 = 2.5 : 1 22 = 2.2:1 28 = 2.8:1

3 = 3.0 : 1 23 = 2.3:1 29 = 2.9:1

4 = 3.5 : 1 24 = 2.4:1 30 = 3.0:1

25 = 2.5:1

Note: The ratios in the Appendix are suggested for best results, however

any ratio can be assigned.

P5-18 Mobile Printer CPCLProgramming Manual

BARCODE-TEXT Command

The BARCODE-TEXT command is used to label bar

codes with the same data used to create the bar code.

The command eliminates the need to annotate the bar

code using separate text commands. The text will be

centered below the bar code.

Use BARCODE-TEXT OFF (or BT OFF) to disable.

Format:

{command} {font number} {font size} {offset}

where:

{command}:

BARCODE-TEXT

(or BT)

{font number}:

The font number to use when

annotating the bar code.

{font size}:

The font size to use when annotating the bar code.

{offset}:

Unit distance to offset text away

from the bar code.

Mobile Printer CPCLProgramming Manual P5-19

BARCODE-TEXT Example

Input (BARTEXT.LBL):

! 0 200 200 400 1

JOURNAL

CENTER

; Annotate bar codes using font 7 size 0

; and offset 5 dots from the bar code.

BARCODE-TEXT 7 0 5

BARCODE 128 1 1 50 0 20 123456789

VBARCODE 128 1 1 50 40 400 112233445

BARCODE-TEXT OFF

FORM

PRINT

Output:

P5-20 Mobile Printer CPCLProgramming Manual

COUNT Command

The COUNT command is used for printing multiple labels

where a numeric text field or numeric data encoded in a

bar code is to be incremented or decremented for each

label. The TEXT/BARCODE command string must contain this numeric data as the last characters of the string.

The numeric data portion can be up to 20 characters, and

can be preceded by the '-' sign. Counts of 9 ➝ 0 will

wrap to 9. Counts of 00 ➝ 99 will wrap to 00. Leading

zeros will be retained. Up to 3 COUNT commands can

be used in a label file.

The numeric data incremented/decremented is contained

in the TEXT or BARCODE command that immediately

preceded the COUNT command.

Format:

{command} {numeric value}

where:

{command}:

COUNT

{numeric value}: