Page 1

Card Printer

Programmer’s

Manual

CP PARD RINTER RODUCTS

User’s Manual No. 980081-001 Rev. F

©1999 Zebra Technologies Corporation.

Page 2

Page 3

FOREWORD

This manual contains installation and operation information for the Eltron Series card printers

manufactured by Zebra Technologies Corporation, Camarillo, California.

RETURN MATERIALS AUTHORIZATION

Before returning any equipment to Zebra Technologies Corporation for in-warranty or

out-of-warranty repair, contact Repair Administration for a Return Materials Authorization (RMA)

number. Repack the equipment in the original packing material and mark the RMA number

clearly on the outside. Ship the equipment, freight prepaid, to the address listed below:

For U.S.A and Latin America:

Zebra Technologies Corporation

Eltron Card Printer Products

1001 Flynn Road

Camarillo, CA. 93021-8706. U.S.A.

Phone: +1 (805) 579-1800

FAX: +1 (805) 579-1808

Toll Free in US: (800) 452 4056

For Europe, Asia, and Pacific:

Zebra Technologies Corporation

Eltron Card Printer Products

Zone Indutrielle, Rue d'Amsterdam

44370 Varades, France

Phone: +33 (0) 240 097 070

FAX: +33 (0) 240 834 745

COPYRIGHT NOTICE

This document contains information proprietary to Zebra Technologies Corporation. This docu

ment and the information contained within is copyrighted by Zebra Technologies Corporation

and may not be duplicated in full or in part by any person without written approval from Zebra.

While every effort has been madeto keep the information contained within currentand accurate

as of the date of publication, no guarantee is given or implied that the document is error-free or

that it isaccuratewithregardtoany specification. Zebra reserves theright tomake changes,for the

purpose of product improvement, at any time.

TRADEMARKS

Eltron is a trademark ofEltron International Incorporated. Windows and MS-DOS are registered

trademarks ofMicrosoft Corp.All other marks are trademarksor registered trademarks of their re

spective holders.

980081-001 Rev. F iii

-

-

Page 4

WARRANTY INFORMATION

WE NEED TO HEAR FROM YOU!

To Establish Your Warranty Period And Provide Access To Technical Support, Send Us your

Product Registration Card Today!

Zebra warrants the mechanism, control electronics and power supply, under normal use and ser

vice, tobe freefrom defects in materialand workmanshipfor a period of twelve(12) monthsfrom

the date ofpurchase bythe end user. Zebrawarrants theprint head, undernormal useand service,

to be free from defects in material and workmanship for a period of twelve (12) months or 100k

passes (whichever occurs first) from the date of purchase by the end user. Proof of purchase or

product registration isrequired. Ifproof ofpurchase orproduct registration cannot be established,

shipment date to the original buyer (dealer or distributor) willbe usedto establishthe warrantype

riod.

Failure to exercisecaution toprotect theequipment from electrostatic discharge damage, adverse

temperature and humidityconditions orphysical abusemay void thewarranty. Failureto useonly

Eltron approved media may void the warranty. Zebra will, at its option, repair or replace the

equipment or any parts which are determined to be defective within this warranty period, and

which are returned to Zebra F.O.B. factory of origin.

The warranty set forth above is exclusive and no other warranty, whether written or oral, is expressed or implied. Zebra specifically disclaims the implied warranties of merchantability and fitness for a particular purpose.

-

-

iv 980081-001 Rev. F

Page 5

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . 1-1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Related Publications:. . . . . . . . . . . . . . . . . . . . . . 1-8

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Basic Command Syntax . . . . . . . . . . . . . . . . . . . . 1-10

Command Editor . . . . . . . . . . . . . . . . . . . . . . . 1-11

Memory Arrangements. . . . . . . . . . . . . . . . . . . . . 1-12

Bit-Map Compression Algorithm . . . . . . . . . . . . . . . . 1-13

Data-to Card Mapping . . . . . . . . . . . . . . . . . . . . . 1-16

Control Commands . . . . . . . . . . . . . . . . . . . . . . 1-21

Card Handling Process . . . . . . . . . . . . . . . . . . . . 1-22

Batch Processing. . . . . . . . . . . . . . . . . . . . . . . . 1-23

Sample Card. . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Port Signals . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Error Line Coding . . . . . . . . . . . . . . . . . . . . . . . 1-24

COMMAND REFERENCE . . . . . . . . . . . . . . . . . . 2-1

Command List . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

. Command - Clear Error Status . . . . . . . . . . . . . . . . 2-5

R Command - Reset . . . . . . . . . . . . . . . . . . . . . . 2-6

MC Command - Clear Media Path . . . . . . . . . . . . . . 2-7

V Command - Check Printer Type/Version . . . . . . . . . 2-8

!V Command - Return Operational Parameter . . . . . . . . . 2-9

+O Command - Print Offset X-axis . . . . . . . . . . . . . . 2-10

+OY Command - Print Offset Y-axis . . . . . . . . . . . . . 2-11

+OLP Command - Offset Overlaminate Patch . . . . . . . . 2-12

+EC Command - End of Print . . . . . . . . . . . . . . . . 2-13

+LAYER Command - Choose Number of Card Layers . . . . 2-14

!R Command - Print Head Resistance . . . . . . . . . . . . . 2-15

M/m Commands - Multiple Command . . . . . . . . . . . . 2-16

MI Command - Input Card To Print . . . . . . . . . . . . . . 2-17

MIB Command - Reverse Card To Card Feeder . . . . . . . 2-18

ME Command - Exit Card To Output Tray . . . . . . . . . . 2-19

MB Command - Return Card To Card Feeder . . . . . . . . 2-20

MO Command - Exit Card To Output Tray . . . . . . . . . . 2-21

!FF Command - Set Ribbon Sequence . . . . . . . . . . . . 2-22

+RIB Command - Set Ribbon Type . . . . . . . . . . . . . 2-23

!M Command - Move Print Head Up . . . . . . . . . . . . . 2-25

!D Command - Move Print Head Down . . . . . . . . . . . . 2-26

!SA Command - Self Adjust . . . . . . . . . . . . . . . . . . 2-27

CLNCARD Command - Establish Cleaning Card Sequence . . 2-28

CLEAN Command - Start Cleaning Card Sequence . . . . . . 2-29

+BS Command - Set Black Speed . . . . . . . . . . . . . . 2-30

IM Command - Print Color Test Card . . . . . . . . . . . . . 2-31

980081-001 Rev. F v

Page 6

IMB Command - Print Black Test Card . . . . . . . . . . . . . 2-32

A Command - Print Test Card . . . . . . . . . . . . . . . . . . 2-33

F/vF Command - Clear Monochrome Image Buffers . . . . . . . 2-34

G/vG Command - Initialize Monochrome Graphic (B/W) . . . . 2-35

O/vO Commands - Load Single Line Bit-map (Mono.) . . . . . 2-36

Z/vZ Commands - Load Bit-map (Monochrome) . . . . . . . . 2-38

P/vP Commands - Write Dot (Monochrome) . . . . . . . . . . 2-40

L/vL Command - Write Line (Monochrome) . . . . . . . . . . . 2-41

C/vC Command - Write Box (Monochrome) . . . . . . . . . . 2-42

D/vD Commands - Write Diagonal (Monochrome) . . . . . . . 2-43

T/vT Commands - ASCII Text (Monochrome) . . . . . . . . . . 2-44

B/vB Command - Write Bar Code . . . . . . . . . . . . . . . . 2-46

I Command - Print Monochrome Graphics . . . . . . . . . . . 2-48

J Command - Print Multiple Monochrome Cards . . . . . . . . 2-49

+C Command - Adjusts Monochrome Intensity . . . . . . . . . 2-50

IV Command - Print Clear Veneer . . . . . . . . . . . . . . . . 2-51

+CV Command - Adjust Clear Veneer Intensity . . . . . . . . 2-52

$F Command - Clear Color Image Buffers . . . . . . . . . . . . 2-53

$FP Command - Clear Specified Bit-Maps . . . . . . . . . . . . 2-54

PS Command - Download Color Image Buffer . . . . . . . . . 2-55

GS Command - Download Color Graphic . . . . . . . . . . . . 2-56

+$L Command - Adjust Color Intensity . . . . . . . . . . . . . 2-57

+$C Command - Adjust Color Contrast . . . . . . . . . . . . 2-58

IS Command - Print Color Graphic . . . . . . . . . . . . . . . 2-59

IH Command - Print Hologram . . . . . . . . . . . . . . . . . 2-60

+CH Command - Adjust Hologram Intensity . . . . . . . . . . 2-61

MF Command - Rotate Card To Duplex . . . . . . . . . . . . 2-62

&R Command - Reset Magnetic Encoder . . . . . . . . . . . . 2-63

&E Command - Write Single Track . . . . . . . . . . . . . . . 2-64

&B Command - Write Buffer Single Track . . . . . . . . . . . . 2-65

&E* Command - Write Track Buffers . . . . . . . . . . . . . . 2-66

&L Command - Read Single Track . . . . . . . . . . . . . . . 2-67

&W Command - Change Encoding Direction . . . . . . . . . . 2-68

&D Command - Change Track Density . . . . . . . . . . . . . 2-69

&CDER Command - Read Custom Track Data . . . . . . . . . 2-70

&CDEW Command - Write Custom Track Data . . . . . . . . . 2-72

&T Command - Mag. Encoder - Eject Card . . . . . . . . . . . 2-74

&C Command - Set Coercivity. . . . . . . . . . . . . . . . . . 2-75

MS Command - Move To Smart Card Programmer . . . . . . . 2-76

MRB Command - Move Card to Rejected Box . . . . . . . . . . 2-77

+OS Command - Smart Card Y-axis Offset . . . . . . . . . . . 2-78

SXY Command - Center Image Maps . . . . . . . . . . . . . . 2-79

+OCL Command - Offset Contactless . . . . . . . . . . . . . . 2-80

MCL Command - Move Contactless . . . . . . . . . . . . . . . 2-81

CRB Command - Set Counter for Rejected Box . . . . . . . . . 2-82

+RB Command - Set Rejected Box . . . . . . . . . . . . . . . 2-83

vi 980081-001 Rev. F

Page 7

+B Command - Serial Interface Rate . . . . . . . . . . . . . 2-84

E Command - Retransmit Last Response . . . . . . . . . . . 2-85

+X Command - Change Command Initiator . . . . . . . . . 2-86

!X Command - Check Command Initiator . . . . . . . . . . . 2-87

&P Command - Check Card Present - Encoder . . . . . . . . 2-88

%CLN Command - Check Due-for-Cleaning Parameters . . . 2-89

SF Command - Synchronize Film (Overlaminate) . . . . . . . 2-90

TF Command - Film Type . . . . . . . . . . . . . . . . . . 2-91

+TC Command - Set Temperature . . . . . . . . . . . . . . 2-92

+DLAMI Command - Set Lamination Configuration . . . . . 2-93

+VL Command - Set Lamination Speed . . . . . . . . . . . 2-98

+VC Command - Reduce Color Print Speed . . . . . . . . . 2-99

RCBC Command - Reset Card Count of Reject Hopper . . . . 2-100

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Resident Fonts . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Code 39 (Code 3 of 9). . . . . . . . . . . . . . . . . . . . . A-3

Standard 2 of 5 (Code 2/5) . . . . . . . . . . . . . . . . . . A-4

Interleaved 2 Of 5 (Code I 2/5) . . . . . . . . . . . . . . . . A-5

UPC-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

EAN-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

EAN-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Code 128 Subsets B & C . . . . . . . . . . . . . . . . . . . A-9

EAN International Regulation Agencies . . . . . . . . . . . . A-11

Appendix B . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Parallel Port Printer Data Handshake Signal Lines . . . . . . . B-1

Parallel Port Printer Error Response . . . . . . . . . . . . . . B-1

Serial Port Printer Data Handshake . . . . . . . . . . . . . . B-2

Serial Port Printer

Error Response . . . . . . . . . . . . . . . . . . . . . . . . B-2

Appendix C . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Magnetic Encoders. . . . . . . . . . . . . . . . . . . . . . . C-1

Encoder Operation . . . . . . . . . . . . . . . . . . . . . . C-2

Data Errors . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Encoder Default Configuration. . . . . . . . . . . . . . . . . C-3

Basic Commands . . . . . . . . . . . . . . . . . . . . . . . C-4

Advanced Encoder Commands . . . . . . . . . . . . . . . . C-4

Resetting The Encoder To ANSI/ISO Track Defaults . . . . . . C-5

Change Track Density . . . . . . . . . . . . . . . . . . . . . C-6

Changing Read Configuration . . . . . . . . . . . . . . . . . C-6

Changing Write Configurations . . . . . . . . . . . . . . . . C-6

Custom ISO Data . . . . . . . . . . . . . . . . . . . . . . . C-7

Unique Custom Data Formats . . . . . . . . . . . . . . . . . C-7

980081-001 Rev. F vii

Page 8

Appendix D . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Sample P600 Command Sequence . . . . . . . . . . . . . . D-2

Appendix E . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Sample Max3000 Command Sequences. . . . . . . . . . . . E-2

Sample Max3300 Command Sequences. . . . . . . . . . . . E-4

viii 980081-001 Rev. F

Page 9

INTRODUCTION

This manual describes programming commands

that control operations and specify data for the following card printer models:

· P3xx Monochrome (P300 and P310

·

P3xx Color (P300 and P310)

·

P4xx Duplex Color (P400 and P420)

·

P500 Duplex Color with Laminator

·

P600 Dual Print Station Duplex Color

·

Max SecureSeries CardSystems (Max3000 and

Max3300)

Features All of the covered models can print bar-codes in

several formats and have resident scalable font de

scriptions. Also, except for the Max Secure Series,

all models can include a Smart-Card Docking Sta

tion. P310 and P420s can have a Proximity Card

docking Station. All modelsare offeredwith orwith

out a Magnetic Stripe Encoder. A Serial host inter

face is an option on the P3xx and P4xx series,

where an associated RS-232C setup Command ex

ists. Max Secure Systems all have parallel host

ports.

-

-

-

-

-

980081-001 Rev. F 1-1

Page 10

The programming commands control the printing

process by color and by ribbon material, allowing

overprinting and separate control of various multi

ple-overlay finishes.

Print Engines:

P300 and P400—P300 print engine and

·

P300 print engine plus duplexer,respectively

P310 and P420—P310 print engine and

·

P310 print engine plus duplexer, respec

tively

P500 and P600—P300 print engine plus

·

Laminator and dual P300 print engines, re

spectively

Max Secure—P300 printengines on all mod

·

els.

Significant model/configuration differences

related to programming include the following:

P3xx Monochrome card printers have a limited

command set along with an image buffer sufficient

for a one-bit image mapping depth. Only imaging

using the thermal transfer methodology can occur.

For gray-scale images, host software must produce

multiple-dot pixel matrixes sized for the desired

gray-scale range (e.g., a four-by-four dot pixel matrix can produce 16 levels of gray plus white, [(4 x

2

/16 + white]).

4)

-

-

-

-

P3xx Color card printers employ dye sublimation

methodology for color imaging andthermal transfer

methodology for imaging from resin monochrome

ribbons or ribbon panels. A yellow, magenta, and

cyan imaging sequence occurs using five-bit-perdot data for imaging with three associated ribbon

panels.

The black panels on Eltron-supplied ribbons with

color panels have a resin coating that particularly

suits bar-code and other solid image printing (i.e.,

no gray scale). However, resinresponds poorly as a

dye sublimation printmedium. Therefore,the black

used for gray-scale imaging comes from formula

tions of yellow, magenta, and cyan (YMC), which

1-2 980081-001 Rev. F

-

Page 11

means dye-sublimation black also has a five-bitper-dot range (32 levels of gray). If the need for a

resin-panel-generated gray scale should ever be

come necessary, host software must generate

multiple-dot pixel matrixes as with the P3xx Mono

chrome.

Standard P3xx Color Card Printers have two

image buffers—one used for color and another

used for monochrome. The single color buffer re

quires print passes that follow each of the three

downloads associated with full-color dye

sublimation imaging. The single monochrome

buffer requires print passes following separate

downloads for resinblack and for overlay varnishin

situations that require different bit-maps. However,

because of its durability, card areas with resin im

ages may not require varnish for the associated ul

traviolet protection. Therefore, by using a reverse

imaging for varnish, thesame bit-mapused forresin

produces a varnish overlaythat omitsthe areas with

resin. Reverse imaging also means that a fullcoverage varnish can result after a clear command

sent for the monochrome buffer.

P310 (all models) and P300 Color Printers

with Extended Memory have the potential for

three color buffers and two monochrome buffers.

These buffers have the same uses as described for

the P3xx Color above. However, more buffers

means that a high probability exists that data for a

complete card image can download in a single host

access. With a complete image resident in the

printer, multiple card prints can occur at a much

faster rate.

-

-

-

-

-

P4xx's have all the same implementations as the

P3xx Color, including Extended Memory as a P400

option. BecauseP4xx's havea Card-Flipassembly,

these models respond to commands related to du

plex printing. P420 Card-Flip Stations can reject

cards into an associated hopper and includes re

lated commands. P420s also have an interface that

supports the programming of Proximity Cards (also

called Contactless Cards).

P500s have all the same implementations as a

P400, including Extended Memory, Smart Card

stations, and Magnetic Encoders as options. How

980081-001 Rev. F 1-3

-

-

-

Page 12

ever, P500s also have a Card Laminator station.

Laminators serve as heat-transfer devices for mate

rial or panels contained on Laminator Ribbons. A

variety of these kinds of ribbons exist:

Ribbons with die-cut panels can carry die-cut

·

panel sizes that substantially cover the card

Die cuts with cutouts for Smart cardcontacts,

·

and smaller die cuts that serve to avoid mag

netic stripes

Preprinted die cuts can contain security de

·

vices such as graphics, holograms, or opti

cally-encoded patches.

Laminators also servea thermal-transferfunction of

ribbon coated material instead ofthe die-cut panels.

However, only a total card application can occur.

Because the print station can have a dye sublimation ribbon witha varnishpanel, manychoices exist

for selection of protective coatings. Additional commands exist to implement Laminator use.

Whereas P3xx's and P4xx's have single CPU

boards, P500s employ two—one controls printing

and card feeds (Module 1 operations); the other

controls card flips and lamination (Module 2 operations). Because of a master-slave arrangement,

Module 1 also receives Laminator commands.

However, all commands destined for Module 2 require a #1 preface, for example:

-

-

-

-

#

1+TC165↵

P600s have two complete Print Station modules

(including associated CPU Boards) separated by a

Card-Flip assembly. Although controlled by a

common parallel host interface, both Print Stations

respond to the same command set (with some

additional positioning parameters and some

differing responses to positioning commands). To

simplify memory management, both Print Stations

have Extended Memory as a standard feature.

Overall, the same commands apply, but the Card

Feed command applies only to the print station

attached to the Card Feed assembly (Module 1).

Similarly, the Card Flip commands apply only to

the Print Station closestto theCard Output(Module

1-4 980081-001 Rev. F

Page 13

2). A communication protocol serves to direct

commands through the common parallel interface

lines to either Module.

While not being designed around a master-slave

arrangement, Module 2 commands can neverthe

less be sent to Module 1. As with P500s, Module 2

commands sent to Module1 requirea #

1 preface.

Either module can have a Smart-Card Station

and/or a Magnetic Stripe Encoder, with an

associated command set. However, Eltron

recommends Module 1 as the best place to locate

these options. Also, the faster path forcommands is

the direct route.

Max Secure Systems allhave Extended Memory

and can include the following:

Print Station Module (Max3000 or Max3300)

·

Laminator and Die Cutter Module

·

Magnetic Encoder Module

·

None of the media used in the other printer models

is intended for usein this model. Instead,the following are used:

Cards

The cards placed in the Input Hopper are

oversized White Chip Cards, either with or

without a Magnetic Stripe and with or without a printable surface.

-

An additional card material isused. This clear

material feeds from a roll, and the printer has

a Shear that delivers card-sized sections to

the card path.

Max Secure Systems use 0.022-inch thick

White Cards for two-layer laminates and

0.015-inch thick White Cards for three-layer

laminates.

980081-001 Rev. F 1-5

Page 14

Ribbons

Five imaging ribbons are offered: A YMC rib

bon for die sublimation only printing, a

YMCKr ribbon for those that need Kr (black

resin) imaging on one surface only, and a

YMCKr_Kr ribbon for those that need Kr im

ages to appear on two surfaces. Mono

chrome ribbons KsO and KrO can also be

used.

Also, destination controlof commandscan beused,

as follows:

-

-

-

#11command - directs an associated com

mand to the Print Station.

Printing occurs on Clear and White Chip Card media components. Color and black resin images can

print on the Clear Card,and Black Resinimages can

print on the White Card.

Max3000 Systems laminate the Clear and White

media into two-layer composites. These systems

cannot perform two jobssimultaneously. Forexample, the printer cannot receive downloaded data

with printing in process, and printing cannot occur

with downloading in process. Because of this, programming should employthe Moperator to concatenate printing for all panels within one command

string (e.g., M 1 IS 0[IS 1[IS 2[I[MO[MF[I[MO).

Max3300 Systems can add another Clear Card

that, while remaining unprinted, protects White

Card images, includingany securitydevices. There

fore, users can produce either two- or three-layer

composites using these systems. Unlike the

Max3000s, these systems can receive data down

loads while printing. Therefore,optimum speedcan

result by alternating downloads with print com

mands, so that one process can overlap the other.

Errors sensed during a series of downloadand print

commands results in the assertion of BUSY, during

which time, the bad card gets ejected, the ribbon

gets synchronized, and the printing sequence re

sumes using the data associated with the rejected

-

-

-

-

-

1-6 980081-001 Rev. F

Page 15

card. None of these operations require issuance of

additional commands.

The following describes a typical Max Secure

System operation:

A Clear Card feeds first. This card receives color im

aging associated with theYMC ribbonpanels, andif

desired, also from a Kr panel. After imaging, the

Clear Card goes to the output of the Print Station.

A White Card feeds next. Any image placed on this

card normally depends on the availability of an un

used Kr ribbon panel. A YMCKr ribbon used to

place a black resin image on the Clear Card would

not have a Kr panel left for imaging on the White

Card without first skipping over a whole set of color

panels. For Kr on both cards, a YMCKrKr ribbon

should be used.

After receiving any images, the White Card also

travels to the output of the Print Station and comes

to rest ontop ofthe Clear Card.As witha Max3000,

these cards go on to the Laminator. For three-layer

cards, a second Clear Card enters the card path.

This Clear Card first transitions in and out ofa Card

Flip Station before going on to the Laminator

Module. This card flip serves to place the side of the

Clear Card with the bonding agent in contact with

the White Card.

Note that Max3300s have a lever for users to select

between two- and three-layer composites. Users

must also load cards having the related thickness.

The +LAYER command also exists for use in speci

fying the number of layers.

-

-

-

Card alignment occurs at the first station in the

Laminator and Die Cutter assembly. From there,

the cards get laminated and then trimmed to the

standard card size. A heatsink between theLamina

tor and the Die Cutter reduces card temperatures

that became elevated during lamination. During

this transition, a speed setting for card cooling takes

effect.

Notably, only up-facing surfaces receive images.

After lamination, an inside surface has the image

placed on the Clear Card. Viewing from the back

980081-001 Rev. F 1-7

-

-

Page 16

side produces a mirrored picture of the Clear Card

image.

Max Secure Magnetic Encoder Modules,

when part of Max Secure Systems, receive card

composites after lamination and die cutting. En

coder commands for this printer duplicate those

used by the other printer models. For Max Secure

configurations without the Magnetic Encoder

Module, cards exit the system after a die cut. Since

the magnetic stripes on White Cards need direct

contact with read/write heads, stripeencoding must

only occur during production of two-layer cards.

Related Publications: Associated User’s and Quick Help Guides for

P-Series Printers, available in various languages

User’s and Quick Help Guides for Max Secure

Series

Associated Maintenance Manuals for P-Series

printers (Available in English Only)

Maintenance Manual for Max Secure (Available in

English Only)

-

1-8 980081-001 Rev. F

Page 17

Conventions In this manual, the following conventions apply:

Escape Key (Indicates command characters

follow)

Space Key (Delimiter used to separate com

mands from parameters and parameters

from other parameters)

p

1~pn

Required parameters that follow some com

mands, separated by space delimiters

{p

~ pn}

1

Optional Parameters

↵ Enter Key (Indicates the end of a Command

and Parameter string

→ Command string continues on next line (no

line feed at this text wrap)

data Specifies where to place data in an associ-

ated Command String

[ Linking delimiter when used with “M” and

“m” commands, which see;

Also, placed in front of [, , and ↵ to specify

data instead of control characters

# Placed after and followed by number to di-

rect command to other than module receiving command.

-

-

980081-001 Rev. F 1-9

Page 18

Basic Command

Syntax

Each command begins with a Command Initiator

(the “Escape” character). For some models, direct

ing characters follow the Escape character.

-

The Command Initiator serves to mark the charac

ter(s) immediately following as command

characters. Command characters varybetween one

and seven characters (or up toseven bytes of hexa

decimal data).

Some commands then haveone or more additional

parameters to supply the printer with information

necessary to complete the command. A “Space”

character delineates individual command control

parameters. The following Text command shows a

typical example.

Each command line requires a Carriage Return (↵)

character (13 dec. or 0D hex.). A single Line Feed

(LF) character (Dec. 10 or 0A Hex.) is ignored by

the printer when it immediately follows the command terminating Carriage Return. Most PC based

systems send a CR/LF when the Enter key is

pressed.

Command Name

WRITE TEXT

Tp1p2p3p4p5p6p7data↵

Parameters

ASCII Programming Code

Command

T 100 100 0 1 20 30 1 Text↵

Text

-

-

1B54203130302031303020302031203230203330203120546578740D

Hexadecimal Programming Code

Escape (Command Initiator)

Carriage Return (Command Terminator)

1-10 980081-001 Rev. F

Page 19

Command Editor Any ASCII based text editor can serve tocreate sim

ple command files. In the DOS environment, MSDOS EDIT offersa good choice.To execute the file,

use the Print command from the editor, or from

DOS, the COPY command, to send the file to the

printer. Examples using the COPY command are:

COPY file name.ext LPT1↵

or

COPY file name.ext COM1↵

-

For more information on theuse of the COPYcom

mand, refer to a DOS software manual.

Some text editingprograms cancause printer errors

by adding extra characters or by changing existing

characters when generating a near ASCII formatted

file.

Example: A commonASCII editor,BRIEF, changes

all NUL charactersto the SPACEor TAB characters

with a file save. The graphic data for print intensity

level “0" is the NUL character. This causes the resulting file to print with horizontal lines in all graphics with solid white, i.e., no print, areas. Other

editors may add a SUB character (Dec. 26 or 1A

Hex.), which causes the printer to error.

-

980081-001 Rev. F 1-11

Page 20

Memory

Arrangements

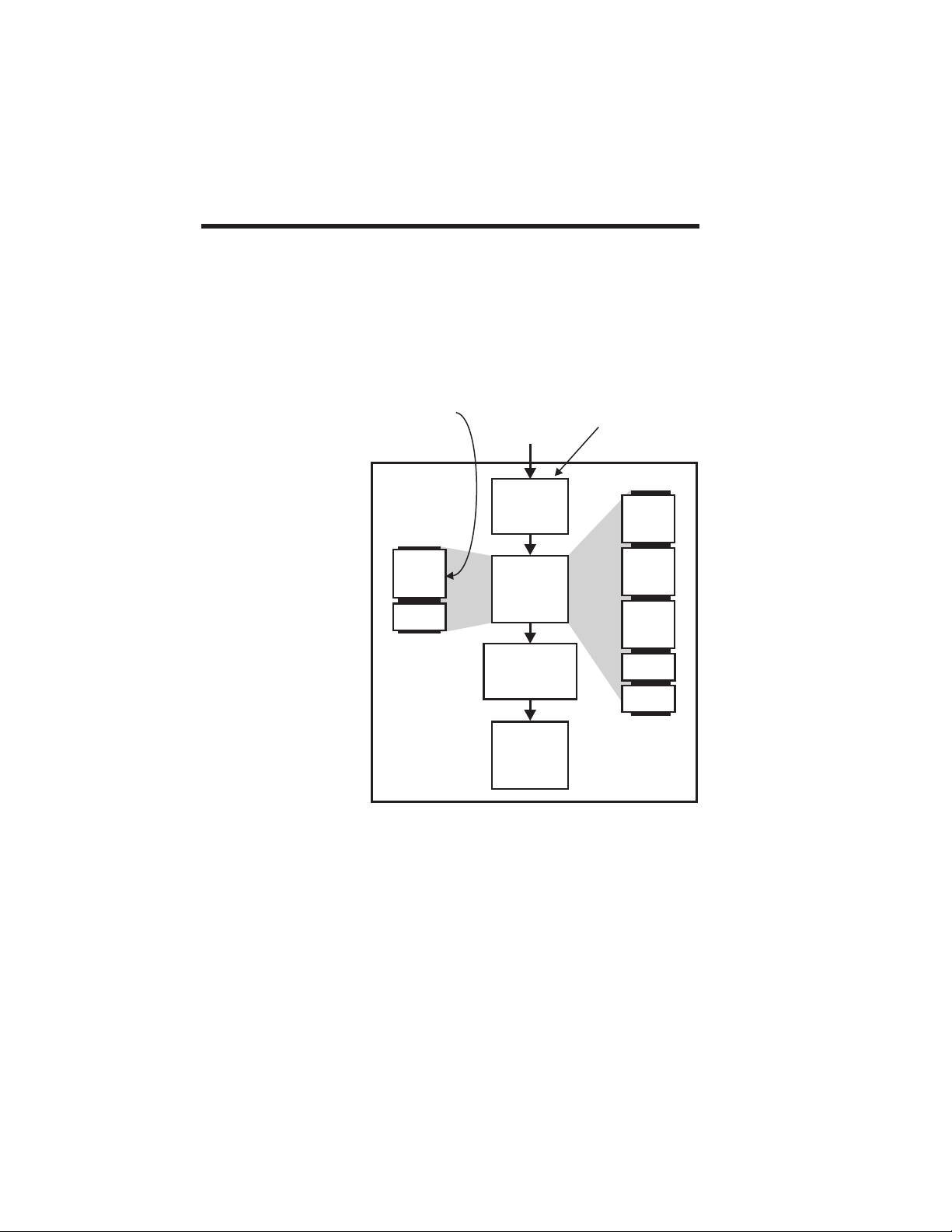

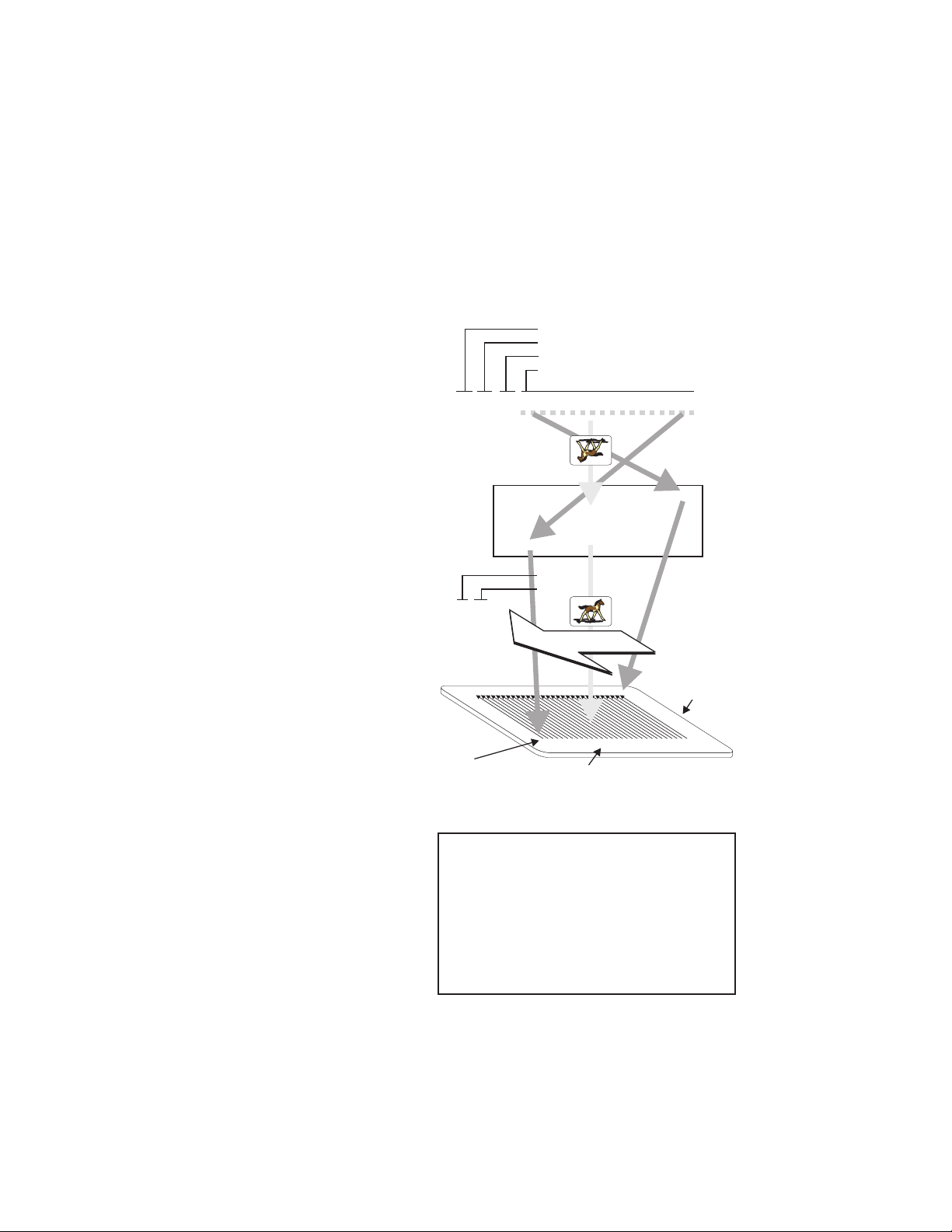

Figure 1-1 shows elements involved in image data

flow. Note that three Image Memory configurations

exist andthat Image Memory always contains com

pressed data. Ideally, hosts should send com

pressed data, which requires a compatible

compression algorithm. This can substantially re

duce the data transfer times of most image files.

-

-

-

Figure 1-1

Memory

Arrangements

Color Card

Printers Only

CARD PRINTER

Normal

Memory

Color

Buffer

Mono.

Buffer

Host Computer

:

Image Data

Compression

Algorithm

Image

Buffers

Image Data

Decompression

Algorithm

Print Head

Registers

Bypassed

when Host

Compressed

Extended

Memory

Yellow

Buffer

Magenta

buffer

Cyan

Buffer

Black

Buffer

Var ni sh

Buffer

Monochrome printers have no color buffers. Color

printers without Expanded Memory have single

color and monochrome buffers, requiring a print

pass after each color download for yellow,

magenta, and cyan data, and as stated previously,

the same operation for monochrome when black

and varnish require different bit-maps. In contrast,

Extended Memory makes possible single

downloads containing commands that specify the

contents of all five buffers. All P310 and P420

1-12 980081-001 Rev. F

Page 21

Printers have the equivalent of an Extended Mem

ory. For Max Secure Systems, which have no var

nish requirements, the varnish buffer supplies the

bit map for the White Card image.

-

-

Bit-Map

Compression

Algorithm

Characteristically, a bit-map compression algo

rithm flags data segments as either repeating or

non-repeating, specifies the bytesrepeated, and the

number of repeats. For these card printers, com

pression applies to byte-wide bit-map segments,

which the host sends with the PS, GS, Z, and vZ

commands. The PS and GScommands include pa

rameters specifying a buffer (YMCK). Monochrome

commands Z and vZ send associated bit-map data

to the black (K) and Varnish buffers, respectively.

All of thesecommands include parameters that spe

cify whether or not the command applies to compressed data. For recognition by the card printer,

compressed data must conform to the following

rules:

Rule 1. When high, themost significantbit (theflag

bit) of a two-byte sequence indicates that the second byte repeats. The remaining seven bits of the

first byte specify the number of repeats, allowing a

field-specification of from zero to 127 repeats.

Rule 2. Whenlow, the most significant bit of a data

sequence indicates that the remaining seven bits of

the byte specify the number of the following bytes

that represent non-repeatingimage data. However,

only from zero to 31 repeats can occur.

Rule 3. The first byte in the data field of any com

mand specifying a compressed bit-map must have

the compression flaghigh, even if a onemust be en

tered as the number of bytes repeated.

-

-

-

-

-

-

Rule 4. No other algorithm can be used to com

press image data for this card printer.

Figure 1-2 includes examples of data strings

employing compression.

980081-001 Rev. F 1-13

-

Page 22

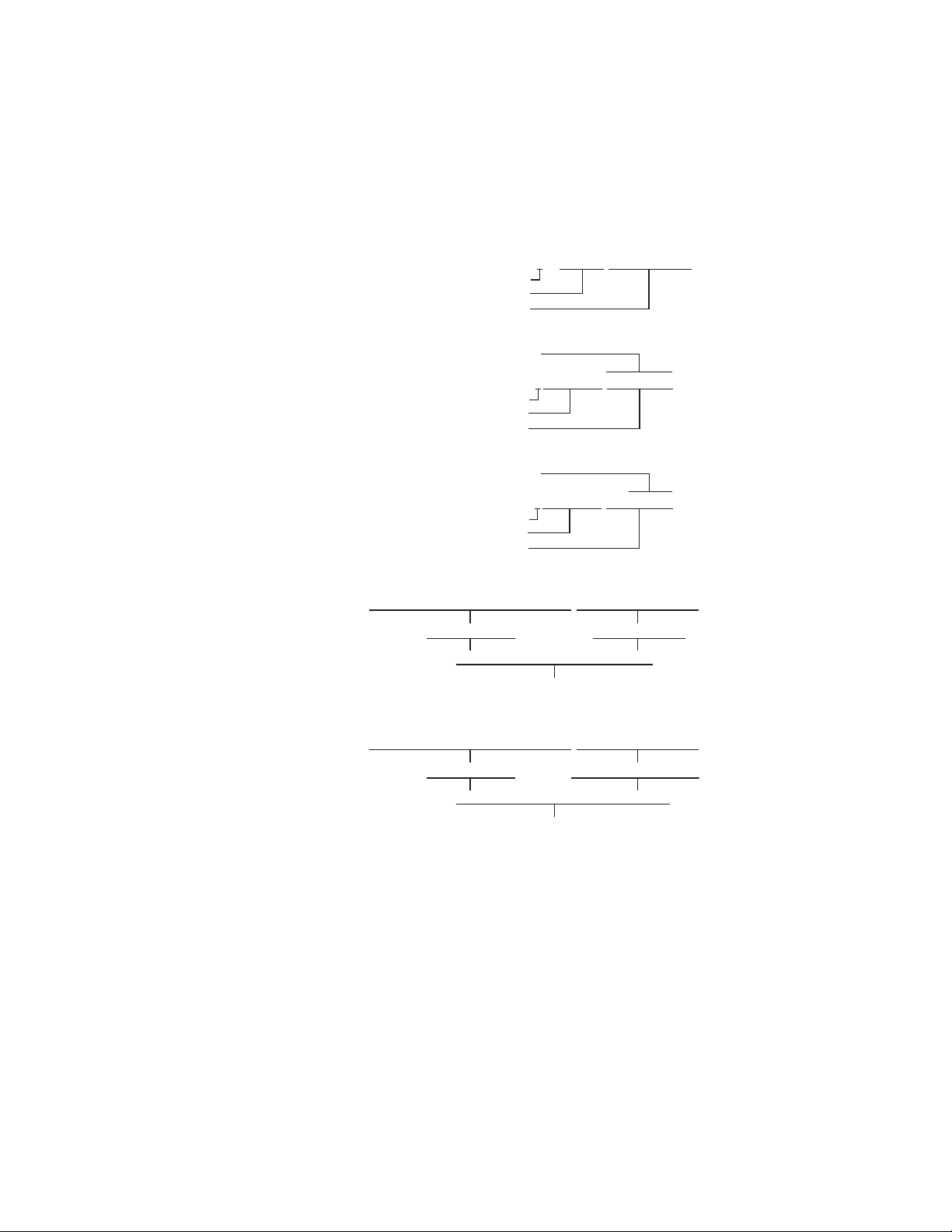

Figure 1-2

Bit-Map

Compression

0XXX XXXX

Data Compression Flag Off

No. of Non-Compressed Bytes

Non-Compressed Data

Mono. Panel 8-Dot Data Field

1XXX XXXX XXXX XXXX

Data Compression Flag Set

No. of Repeats (1~127)

Data Byte Repeated

Dye Sub. Panel 1-Dot Data Field

1XXX XXXX XXXX XXXX

Data Compression Flag Set

No. of Repeats (1~127)

Data Byte Repeated

Compression Example 1

0001 1111 0001 1111 0001 1111 0001 1111 0001 1111 0000 0011 0000 0011 0000 0011

1F Hex (5 repeats) 03 Hex (3 repeats)

85 1F 83 03

Compressed Data

1000 0101 0001 1111 1000 0011 0000 0011

---Bytes (0~31)---

Compression Example 2

0001 1111 0001 1111 0001 1111 0001 1111 0001 1111 0000 0100 0000 1011 0000 0011

1FHex(5repeats) 040B03Hex(0repeats)

85 1F 03 04 0B 03

1000 0101 0001 1111 0000 0011 0000 0100 0000 1011 0000 0011

Compressed Data

1-14 980081-001 Rev. F

Page 23

.

1

Non-Compressed

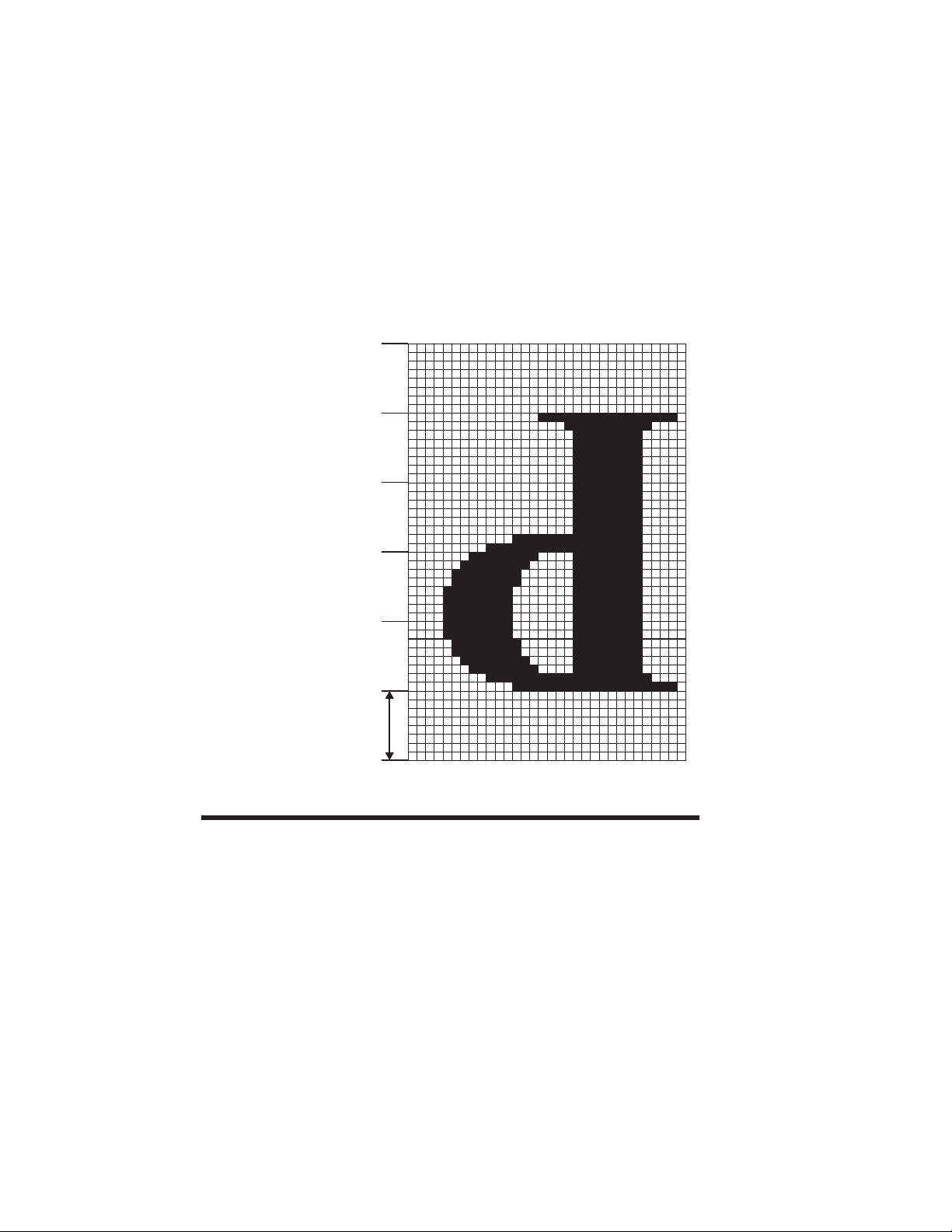

Figure 1-3

Bit-Map

Figure 1-3 shows how a bit-map relates to associ

ated non-compressed data. Figure 1-4 shows the

same bit-map in association withcompressed data

B 5A

1

00 00 00 00 00 00

00 00 00 00 00 00

00 00 00 00 00 00

00 00 00 00 00 00

00 03 F0 00 00 00

00 0F FC 00 00 00

00 1F FE 00 00 00

00 3F FF 00 00 00

00 3F FF 00 00 00

00 7F FF 80 00 00

00 7F FF 80 00 00

00 7F FF 80 00 00

00 FC 0F C0 00 00

00 F0 03 C0 00 00

00 E0 01 C0 00 00

00 C0 00 C0 01 00

00 C0 00 C0 01 00

00 C0 00 C0 01 00

00 C0 00 C0 03 00

00 FF FF FF FF 00

00 FF FF FF FF 00

00 FF FF FF FF 00

00 FF FF FF FF 00

00 FF FF FF FF 00

00 FF FF FF FF 00

00 FF FF FF FF 00

00 FF FF FF FF 00

00 C0 00 00 03 00

00 80 00 00 01 00

00 80 00 00 01 00

00 80 00 00 01 00

00 00 00 00 00 00

-

0D

Byte

x axis

980081-001 Rev. F 1-15

Page 24

1

Figure 1-4.

Compressed

Bit-Map

1B 5A

99 00 02

03 F0 84 00 02

0F FC 84 00 02

1F FE 84 00 02

3F FF 84 00 02

3F FF 84 00 3C

7F FF 80 00 00

00 7F FF 80 00 00

00 7F FF 80 00 00

00 FC 0F C0 00 00

00 F0 03 C0 00 00

00 E0 01 C0 00 00

00 C0 00 C0 01 00

00 C0 00 C0 01 00

00 C0 00 C0 01 00

00 C0 00 C0 03 00

00 84 FF 02 00

00 84 FF 02 00

00 84 FF 02 00

00 84 FF 02 00

00 84 FF 02 00

00 84 FF 02 00

00 84 FF 02 00

00 84 FF 18 00

00 C0 00 00 03 00

00 80 00 00 01 00

00 80 00 00 01 00

00 80 00 00 01 87

00

0D

Byte

Data-to Card

Mapping

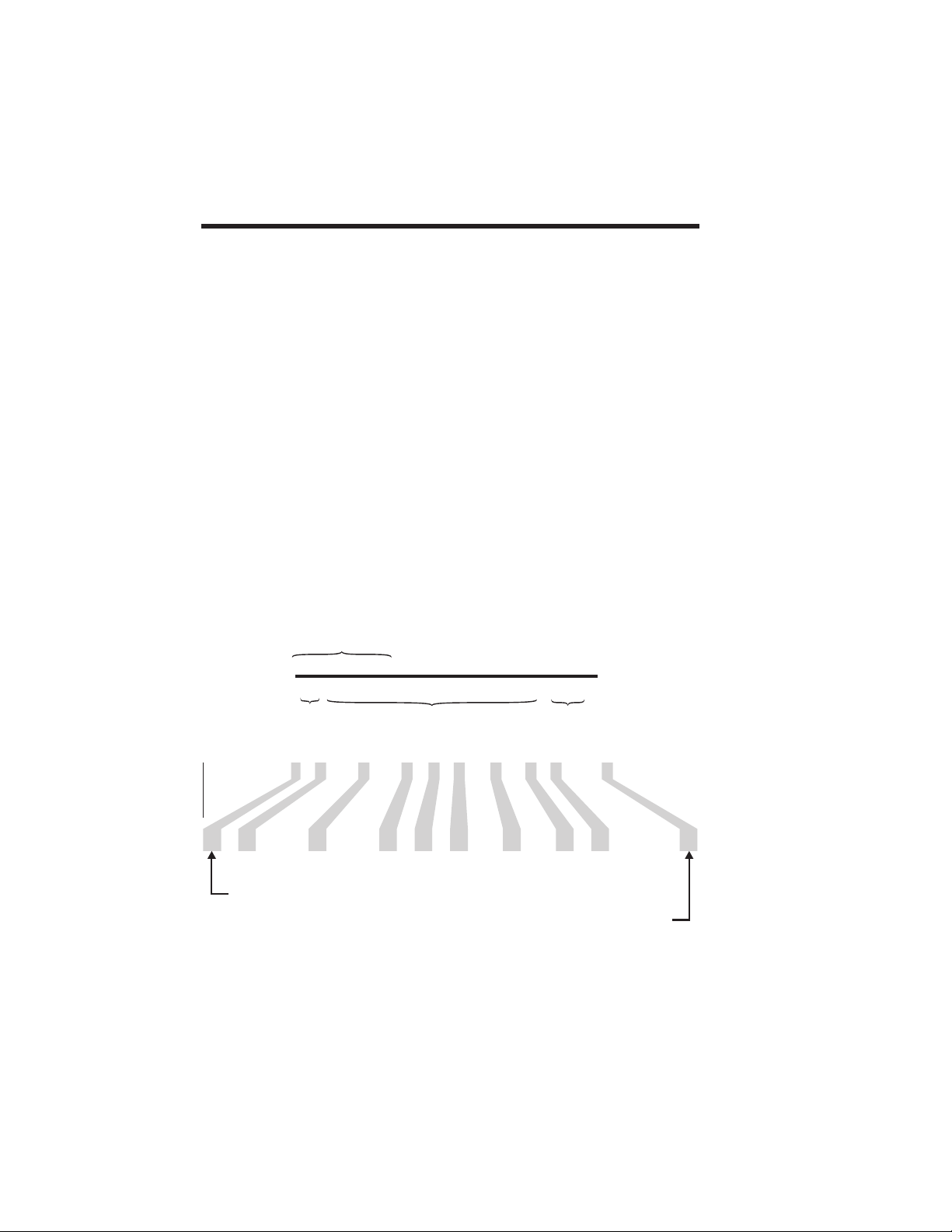

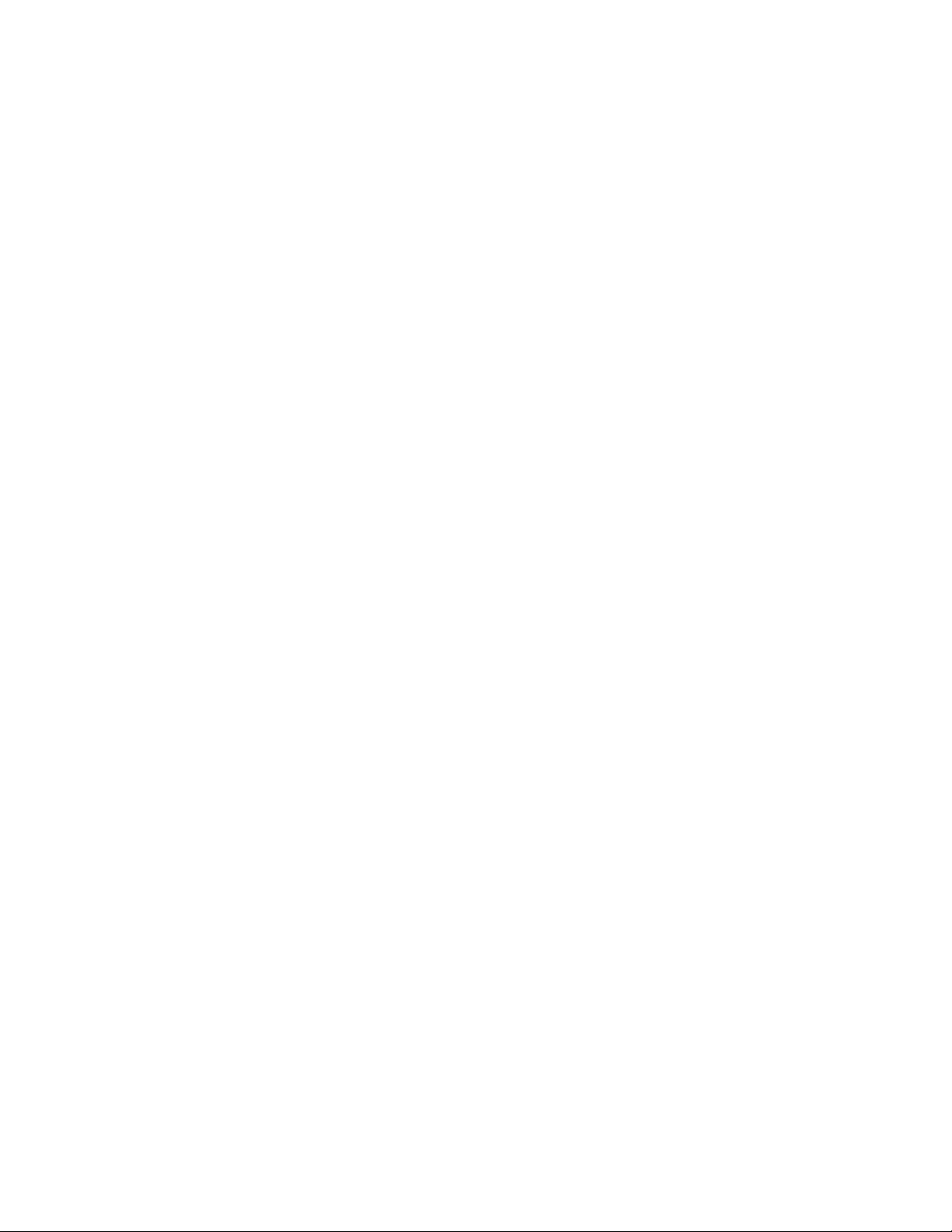

Figure 1-5 shows a card consistent with the orienta

tion of a cardtraveling rightto leftin the card pathof

a printer. From this perspective,the data field of the

PS, GS, Z, and vZ commands first becomes a

memory-resident image in a designated image

buffer. TheImage Buffer,as shown, fills from top to

bottom and from right to left. Because the Image

Buffer has a last-in-first-out arrangement, card im

ages build from bottom totop and fromleft to right.

1-16 980081-001 Rev. F

-

-

Page 25

This suits the front-to-back loading of Print Head

Registers and the right-to-left card movement dur

ing print cycles. As noted in the figure, an object

mirrored in both axis in the data sent to the buffer

would print normally on the card.

-

Figure 1-5

Data Sent verses

Card Mapping

Download Buffer Data Command

Buffer Select (CMYK) Parameter

Compressed vs. Uncompressed Parameter

Data Downloaded (300dpi/11,8dpmm)

PS p1 p2 data.............................data

Last In

First Out

Image Buffer

Print Buffer Command

Buffer Select (CMYK) Parameter

IS p1

Print Direction

Card Size

3.375 x 2.125 in

85,7 x 53,9 mm

PartialImage

Origin

652 Lines Bytes by 1048 Lines (Max Secure Systems)

* Objects drawn with these commands have an upper-left origin.

MAXIMUM CARD IMAGING

624 Line Bytes by 1008 Lines (Standard Memory)

640 Line Bytes by 1024 Lines (Extended Memory)

ASSOCIATED COMMANDS

Monochrome

G

O

Z

P

L*

C*

D*

T

B

I

Overlay

IH

IV

vZ

vP

vL*

vC*

vD*

vT

vB

Color

PS

GS

IS

980081-001 Rev. F 1-17

Page 26

Color Data

Considerations

Color data always enters a color image buffer, ei

ther as yellow, magenta, cyan, or in the case of a

KsO ribbon, dye sublimationblack. Ifonly onecolor

image buffer exists, the command designates the

buffer differently according to the buffer specifica

tion parameter in the command. Note that the

specification for dye sublimation onlyapplies to im

ages produced using a dye sublimation black rib

bon. All data associated with these commands

represent five-bit-per-dot imaging.

Whether downloading data for a partial image (GS

command) or for a complete card image (PS com

mand) the data must match the associated card

area. For partial images(sometimes calledlogos be

cause of a typicalapplication) theGS command pa

rameters specify the area imaged. This assures

proper line breaks. Any either over- or under-flow

produces an error. Note that the previous figure

shows different full-card image areas for Standard,

Extended, and Max Secure memory. For proper

appearance, color images should not overprint

other card printing.

-

-

-

-

-

-

-

Max Secure

Monochrome Data

Considerations

P3xx~P600

Monochrome Data

Considerations

Max Secure printers have no need to print varnish.

However, the varnish buffer is used for monochrome data. Therefore, all data commands for

monochrome data require the“v” preface.A subsequent “I” command printsdata stored inthe varnish

buffer. Note that the IVcommand serves to indicate

the presence of a ribbon with varnish panels that

then get bypassed.

P-Series printers always download monochrome

data to a monochrome image buffer. Monochrome

data commands prefaced with a “v” designate the

varnish buffer. Commands without the “v” preface

designate the buffer used for resin printing. If only

one monochrome image buffer exists, the com

mand designates the buffer differently depending

on the associated data.

However, most color imaging does not need a

pre-established varnish buffer to apply the varnish

coating. If no varnish buffer is downloaded, the

printer defaults to theresin bufferfor theapplication

of varnish. This works for three reasons. First, color

1-18 980081-001 Rev. F

-

Page 27

ribbons have resin black followed by varnish pan

els, both limited to monochrome data. Second, the

primary use of varnish is to protect thedye sublima

tion imaging from ultraviolet radiation. Third, be

cause resin may need no varnish protection, an

inverted-resin bit-map can apply varnish.

-

-

-

The IV command has a parameter setting to pro

duce an inverted data print. In summary, leave the

resin buffer unchanged afterprinting resin.Then, is

sue an IV command for inverted data to print the

varnish. Note that full-coverage varnish,as required

for ultraviolet protection using dye-sublimation

black ribbons, requires only a buffer clear com

mand (F) followed by theinverted print command.

A watermark simulation can result by, in effect,

punching holes in the varnish image. A hologram

transfer from an associated ribbon occurs by

printing a varnish buffer that images the area of the

ribbon containing the hologram. Both of these images require data previously downloaded into the

Varnish buffer.

Monochrome graphic objects can download

into either the resin or varnish buffer. As with the

preceding, a “v” preface designates a buffer that

prints with the “IV” command, and commands

without the “v” preface designate a buffer that

prints with the “I” command. Commands exist for

downloads of the following graphic objects:

P/vP Write Dot

L/vL Write Line

C/vC Write Box

-

-

-

D/vD Write Diagonal Line

T/vT Write Text

B/vB Write Bar-Code

980081-001 Rev. F 1-19

Page 28

Rotational parameters (clockwise) exist for the fol

lowing:

D/vD 0, 90, or 180°

Center of Rotation lower-left

T/vT 90° Increments (0~270)

Center of Rotation lower-left or object center

B/vB 90° Increments (0~270)

Center of Rotation lower-left or object center

Monochrome bit-maps require entry of two

commands—first an initializing command (G) and

then the associated data command. The “G” com

mand specifies image placements associated with

the following commands:

O/vO Download Single Line

Z/vZ Download Multiple Lines

Figure 1-5 shows the relationshipbetween datasent

by “O” or “Z” commands and an area previously

established by a “G” command. The “G” command can also define data as single bits (i.e., image

dots).

With dots selected as the data mode in the “G”

command, data sent to the printer must, nevertheless, finish on an even byte boundary.When necessary, fill in zero bits to bytes that do not reach the

boundary specified in the “G” command.

-

-

Data is handled in bytes (0~255 decimal or hexa

decimal 00~FF) by the printer.

Bar Codes Bar codes vary in capacity, size, character sets, and

density. Several industries have adopted specific

coding and bar code formats. Verify that the se

lected bar code matches a code supported by the

scanning equipment.

All the bar codes supported by the card printers

have the data characters, 2 quiet zones, and a start

and stop character. The bar codes can include text

as part of the printed bar code. Some of the bar

codes include a printer-generated check digit (or

data check sum) character automatically or as an

option.

1-20 980081-001 Rev. F

-

-

Page 29

A command error condition occurs whenimage

data extends beyond the addressable range of the

image buffer. The bar code and text fields must re

main within the addressable area of the image

buffer. Each one of the bar codes, described in the

Command B and Appendix A, have a formula to

determine a bar code length.

Selecting a larger bar code width multiplier and a

higher ratio of the narrow to wide bars (and spaces

where applicable), improves the general readability

of a given bar code. Additionally, for a given bar

code, wider bars and spaces increase the depth of

field for improved performance with moving-beam

lasers and other non-contact scanning devices .

Control Commands The cardprinter canperform avariety ofprint, card,

ribbon, and headmovement andcontrol command

operations.

-

Print Controls

1. Intensity - Adjusts the amount of heat used to

transfer maximum intensity color or Monochrome

dot.

2. Contrast (Color Only) - Adjusts the minimum

amount of heatused to printdots at thelowest color

setting.

3. Image Positioning - Locates the printable im

age on the card.

4. Head - Raises the print head to move the card

and lowers it to print. Not normally required.

5. Print Test Cards

Card Movement

1. Print Ready position - Thecard movesto aposi

tion just prior to the card edge sensor.

2. Exit Card - The printer exits the card to the Ou

tput Hopper or tray. Printers with multiple stations,

exit the card to the next station.

980081-001 Rev. F 1-21

-

-

-

Page 30

3. Duplex - Flips the card over using the Card-Flip

Assembly, initiated by the ‘MF’ command.

4. Ready Smart Card - Positions a Smart Card

under the SmartCard Docking stationwith the con

tacts of a Smart Card chip engaged.

5. Encode Ready position - The card moves to a

position just prior to the magnetic encoding station

read/write head.

-

Ribbon

Card Handling

Process

1. Reset Ribbon - Setsthe ribbon panel to the first

panel (color - yellowpanel) orcycles thecontinuous

color Monochrome ribbon.

2. Select Panel - Resets, then selects a specific rib

bon panel.

The following outlines a recommended card handling sequence.

1. Smart Card Programming - Option

2. Magnetically Encode Card - Option

3. Print Card

For color printing:

Yellow

Magenta

Cyan

Black

Clear Varnish or Hologram Transfer

4. Duplex - Flip Card - Option

5. Print Card Backside - Option

For color printing:

Yellow

Magenta

Cyan

Black

Clear Veneer

Hologram Lamination

6. Eject Card

-

1-22 980081-001 Rev. F

Page 31

DO NOT print, veneer, or laminate over the mag

netic stripe or Smart Card contacts. This can impair

subsequent associated read and write operations

and must be controlled by the programming.

Batch Processing The “M” and “m” commands serve as command

linking operators. A string of linked commands may

execute one (1) time ormultiple times.The “[” char

acter acts as delimiter for linked commands in the

associated syntax.

-

-

Sample Card Figure 5-6shows aprinted card along withthe com-

Figure 1-6

Sample Monochrome

Card

For the complete “M” commandsyntax, and an ex

ample, see M/m in the Command Reference,

mands used.

Commands

¿

+RIB 4 Ribbon Type

¿

+C 3 Thermal Intensity

¿

F Clear Monochrome Buffer

B51260040241001TEST Write Bar Code

T51275400351Company Name, Incorporated Write Text

T200200010501FIRSTNAME WriteText

T200300010501LASTNAME WriteText

T200400010501ACCOUNT NUMBER Write Text

T65320710500Reversetext WriteText

L158097041 WriteLine¿

I Print Monochrome¿

¿

¿

¿

¿

¿

Descriptions

¿

-

980081-001 Rev. F 1-23

Page 32

Port Signals P3xx andP4xx printershave anoptional serialport.

Serial equipped printerscommunicate withthe host

over an RS-232C interface using ACK/NAK flow

control. Parallel ports are the standard. P500,

P600, and Max Secure card printers have no serial

option.

Card printers with Parallel Ports communicate with

the host using the following signal lines:

DATA (0~7) Eight bits of parallel data.

STROBE (Pin 1) A host signal that indicates stable data.

ACK/ (Pin 10) A printer signal that indicates data received. The

host drops the STROBE signal in response.

BUSY (Pin 11) A printer signal indicates an inability to accept

commands due to ongoing processing. P500 and

P600 card printers have two processors. A BUSY

response from one processor does not imply a

BUSY at the other processor.

READY (Pin 13) A printer signal that indicate its availability to

receive host commands.

PAPER ERROR (Pin 12)

Card printers report errors to the host by encoding the PAPER ERROR and ERROR lines (see Error Line Coding below).

ERROR/ (Pin 15) Card printers report errors to the host by encod-

ing the PAPER ERROR and ERROR lines (see Error Line Coding below).

INIT (Pin 14) Only used by P600 card printers, where a high (1)

directs commands to Module 1 (Master) and a

low (0) directs commands to Module 2 (Slave).

Error Line Coding

Paper Error Error/ Description

01

00

11

10

Note: To clear an Error, Send: .↵ (1B 2E 0D Hex)

No Error

Syntax Error

Ribbon End/Empty Feeder

Mechanical Error

1-24 980081-001 Rev. F

Page 33

COMMAND REFERENCE

This section contains descriptions of printer commands used to print,magnetically encode,position,

and control card movements. The following table

groups commands by function. Note printer applicability to avoid using commands that do not apply

to the targeted model(s).

980081-001 Rev. E 2-1

Page 34

Command List

DESCRIPTION

COMMAND

Setup Commands

Offset Start Print Position (X-axis)

+O

Offset Start Print Position (Y-axis)

+OY

Offset Overlaminate Patch

+OLP

Print Length (X-axis)

+EC

+LAYER

+OCL

Tests

Initialize Commands

Choose Number of Card Layers (Max3300)

Print Head Resistance

!R

Set Ribbon Color Sequence

!FF

Ribbon Type

+RIB

Set Black Speed

+BS

Adjust Thermal Transfer Intensity Level

+C

Adjust Overlay Application Intensity Level

+CV

Adjust Independent Color Intensity Level

+$L

Adjust Hologram Application Intensity

+CH

Adjust Independent Color Contrast Level

+$C

Offset (X-axis) Smart Card

+OS

Center Image Maps (P310)

SXY

Offset Contactless (Proximity Card)(P420)

Move Contactless (±1-Step)(P420)

MCL

Card Rejects for REJECTED BOX FULL Error (P420)

CRB

Hopper Selection for Rejected Cards (P420)

+RB

Print Test Card

A

Print Color Test Card

IM

Print Test Card

IMB

Clears Error Status Lines

.

Reset Printer

R

Clear Monochrome Image Buffers

F

Clear Color Bit-maps

$F

Clear Specified Bit Map (P310/P420)

$FP

P3xx Monochrome

P3xx/Color

P4xx Duplex Color

P500 Laminate

P600 Dual Print

Max Secure

PAGE

••••••2-10

••••••2-11

• 2-12

••••••2-13

• 2-14

••••••2-15

•••••2-22

•••••2-23

••••••2-30

••••••2-50

•••• 2-52

•••••2-57

•••• 2-61

•••••2-58

••••• 2-78

• 2-79

• 2-80

• 2-81

• 2-82

• 2-83

••••••2-33

•••••2-31

••••••2-32

••••••2-5

••••••2-6

••••••2-34

•••••2-53

• • • 2-54

2-2 980081-001 Rev. F

Page 35

DESCRIPTION

COMMAND

Reset Encoder

&R

Change Encoding Direction

&W

Change Encoder Track Write Density

&D

Custom Encoder Read Density

&CDER

Custom Encoder Write Density

&CDEW

Set Encoder Coercivity

&C

Serial Interface Rate (Serial I/O)

+B

Change Control Character (Serial I/O)

+X

Synchronize Film (P500 Overlaminate Only)

SF

Film Type (P500 Laminator)

TF

Set Temperature (P500 Laminator)

+TC

Set Lamination Configuration (P500)

+DLAMI

Set Lamination Speed

+VL

Reduce Color Print Speed (P310/P420/Max3300)

+VC

Reset Rejected Card Box to Zero (P420)

RCBC

Printer Query Commands

Check Printer Type/Version

V

Return Operational Parameter (Max3300)

!V

Retransmit Last Response (Serial I/O)

E

Check Command Initiator (Serial I/O)

!X

Check Card Presence - Encoder (Serial I/O)

&P

Check Due-for-Cleaning Set (P310/P420/Max3300)

%CLN

Image Data Download Commands

Initialize Monochrome Graphic

G

Load Single Line Graphic Dots Download

O/vO

Multiple Line of Graphic Dots Download

Z/vZ

Write Dot

P/vP

Write Line

L/vL

Write Box

C/vC

Write Diagonal Line

D/vD

Write Text

T/vT

P3xx Monochrome

P3xx/Color

P4xx Duplex Color

P500 Laminate

P600 Dual Print

Max Secure

PAGE

••••••2-63

••••••2-68

••••••2-69

••••••2-70

••••••2-72

••••••2-75

• • • • 2-84

• • • • 2-86

• 2-90

• 2-91

• • 2-92

• 2-93

• • 2-98

• • 2-99

•

2-10

0

••••••2-8

• 2-9

• • • • 2-85

• • • 2-87

• • • 2-88

• • • 2-89

••••••2-35

••••••2-36

••••••2-38

••••••2-40

••••••2-41

••••••2-42

••••••2-43

••••••2-44

980081-001 Rev. F 2-3

Page 36

DESCRIPTION

COMMAND

Write Bar Code

B/vB

Download Color Image Data

PS

Download Color Graphic

GS

Card Positioning Commands

Clear Media Path

MC

Input Card To Print Position

MI

Reverse Card to Print Position

MIB

Exit Card To Output (Hopper)

ME

Back Card Into Feeder

MB

Exit Loaded Card To Output

MO

Flip-over the card 180°

MF

Switch to White Card (Max3000)

MF

Eject Card with Magnetic Encoder Option

&T

Move Smart Card to Programming Station

MS

Move Card to Reject Box (P420)

MRB

Print Commands

Print Card Panel (YMC)

IS

Print Card Monochrome Panel

I

Print Varnish Overlay

IV

Print Hologram Overlay

IH

Print Multiple Cards “N” times

J

Magnetic Stripe Encoder Commands

Encode Single Data Track

&E

Buffer Track Data

&B

Encode All Data Tracks

&E*

Read Single Track Data

&L

Miscellaneous Commands

Multiple Command Strings

M/m

Move Print Head Up

!M

Move Print Head Down

!D

Self Adjust (P310/420/Max3300)

!SA

CLNCARD

Set Cleaning Card Sequence (P310/P420/Max3300)

Start Cleaning Card Sequence (P310/P420/Max3300)

CLEAN

P3xx Monochrome

P3xx/Color

P4xx Duplex Color

P500 Laminate

P600 Dual Print

Max Secure

PAGE

••••••2-39

•••••2-55

•••••2-56

••••• 2-7

••••• 2-17

••••• 2-18

••••••2-19

••••• 2-20

••••••2-21

• • • • 2-62

• 2-62

••••• 2-74

••••• 2-76

• 2-77

•••••2-59

••••••2-48

•••••2-51

•••• 2-60

••••• 2-49

••••••2-64

••••••2-65

••••••2-66

••••••2-67

••••••2-16

••••••2-25

••••••2-26

• • • 2-27

• • • 2-28

• • • 2-29

2-4 980081-001 Rev. E

Page 37

. Command - Clear Error Status

Description Clears the Paper Error (Paper Fault) and Error

(Fault) printer return signal status lines. Note that

this command does not execute when sent via the

Driver. Send the command directly to the printer

port.

P3xx M

P3xx C

P4xx

P500

P600

•

•

Max

•

•

•

Syntax

.↵

Parameters None

980081-001 Rev. F 2-5

Page 38

P3xx C

P4xx

P500

P600

• P3xx M

•

Max

•

•

•

•

R Command - Reset

Description Reinitializes printer—also the Max3000 Printer

module.

Syntax

Syntax (Max3000

Laminator)

Parameters None

To reset another Max3000 module, direct the com

mand to the Laminator/Die Cutter Station, or En

coder.

R↵

#11 R↵

-

-

2-6 980081-001 Rev. F

Page 39

MC Command - Clear Media Path

Description Sends any card in the Media Path of the printer to

the Output Tray.

Note: A Ribbon Errorcan leavea cardin theprinter.

If issued at Power-On,this command assures aclear

media path for subsequent operations.

Syntax MC↵

Parameters None

P3xx M

P3xx C

P4xx

P500

P600

•

•

Max

•

•

•

980081-001 Rev. F 2-7

Page 40

P3xx C

P4xx

P500

P600

• P3xx M

•

Max

•

•

•

•

V Command - Check Printer Type/Version

Description This command serves to check the model (and op

tions) of a printer. Serial port connected printers re

spond with a model numberand firmware version.

Parallel port connected printers respond with

NACK when the ‘V’ command parameter received

does not match the configuration. A matching

printer parameter code produces anACK response.

Note that parallel-connected color printers do not

report firmware and model. For this information,

use the “A” command.

Syntax V{p1}↵

p1 = Optional Configuration Parameter (for Parallel I/O)

P3xx, P400, P500, and P600 Printers

SN<7000 Monochrome printers only.

None

P3xxCF

10

Magnetic Encoder Installed

12

Smart-Card Docking Installed

13

P400CF

14

Extended Memory Option Installed

20

Magnetic Encoder with expanded encoder

30

command set. (Serial numbers > 5000)

Monochrome printer with Parallel or Serial Port

50

(Serial numbers >7000).

P500 Printer

70

P600 Printer

80

P310 Printer

100

-

-

Max Secure Printers

Encoder and Laminator

80

Laminator only

81

Encoder only

82

Printer

83

Max3300

85

2-8 980081-001 Rev. F

Page 41

P3xx M

!V Command - Return Operational Parameter

Description Returns value for a selected parameter.

Note that this command only applies to Max3300

Printer and Laminator Modules.

Syntax !V{p1}↵

p1 = Requested Parameter

Where for Printer Module:

None = Return Black Printing Parameters

0 = Return Black Printing Parameters

1 = Return X Offset

2 = Return Y Offset

3 = Return Print Head Resistance

4 = Return X offset for Clear Card Material

5 = (Not Used)

6 = Card Layers Set (0 for 2; 1 for 3)

7 = Return First Layer Cut Offset

8 = Return Third Layer Cut Offset

For Laminator Module:

0 = Bottom Roller Temp. (Layer Configuration

Dependant)

1 = Die Cutter Offset (!CM 08)

2 = Lamination Speed (Layer Configuration

Dependant)

3 = Good Lamination Counter

4 = Error Counter

5 = Movement Speed

6 = Idle Time in Standby Mode

7 = Standby Mode Temp.

8 = Layer Configuration (0 for 2; 1 for 3)

9 = Top Roller Temp. Setting (Layer Configuration

Dependant)

P3xx C

P4xx

P500

P600

Max

•

980081-001 Rev. F 2-9

Page 42

P3xx C

P4xx

P500

P600

• P3xx M

•

Max

•

•

•

•

+O Command - Print Offset X-axis

Description Alters the horizontal (X-axis) start print offset point,

in dots.

Syntax +O p1↵

Parameters p1 = Horizontal (X-axis) start print offset, in dots:

Where:

10 = Default (Std Memory)

10 = Default (Max3000)

8 = Default (Expanded Memory)

0~20 =Range (1~20 for Max Secure)

2-10 980081-001 Rev. F

Page 43

+OY Command - Print Offset Y-axis

Description Offsets the vertical (Y-axis) start print location in

dots.

Syntax +OY p1↵

Parameters p1 = Vertical (Y-axis) offset, in dots

Where:

15 = Default (Standard Memory)

6 = Default (Extended Memory)

6 = Default (Max)

P3xx C

P4xx

P500

P600

• P3xx M

•

Max

•

•

•

•

980081-001 Rev. F 2-11

Page 44

P3xx M

P3xx C

P4xx

P500

P600

Max

•

+OLP Command - Offset Overlaminate Patch

Description Specifies the relationship between card positions

and Ribbon Sync Markersused to placeLamination

Patches on cards.

Note that exceptfor the first patch, thefirmware can

use Ribbon Sync Marker sensing in concert with

Flag Sensor Increment sensing todetermine Ribbon

Advance Step requirements for patch applications.

However, a Ribbon Initialization leaves the firm

ware without an associated history for Ribbon Step

requirements. Because ofthis, thefirmware needs a

beginning step valuefor use onlyto position therib

bon after an Initialization.

Note: This command only applies to P500

Laminator Stations and ribbons with Sync.

Markers.

-

-

Syntax

+OLPp1p2p3¿

Parameters p1 = Card Offset Count from Ribbon Sync. Marker sense to the

point p2 takes effect. Only used to synchronize lamina-

tion patches that follow Initializations

p2 = Offset between where patch applications start

p3 = Count where patch applications end

Default Settings

+OLP11014090¿

2-12 980081-001 Rev. F

Page 45

+EC Command - End of Print

Description Specifies a point, beyond which, no card printing

occurs. Print stations with associated Extended

Memory installedhave storage for 1024 lines of im

aging, which exceeds the x-axis image area on the

cards.

The parameter for End of Print causes the print

head to raise atthe end-of-card point,not theend of

data. If left down beyond the end of card, the print

head can shear the ribbon as the print head

abruptly drops below the surface of the card. Note

that higher values of p1 result in shortened line

counts.

Syntax +ECp1↵

Parameters p1 = line count for end-of-print

Where:

8 = default (standard)

0 = default (Max3000)

0~24=range

P3xx C

P4xx

P500

P600

• P3xx M

•

Max

•

•

•

•

-

Example The followingexample sets theEnd ofPrint to8 (the

default value).

+EC8↵

980081-001 Rev. F 2-13

Page 46

P3xx M

P3xx C

P4xx

P500

P600

Max

•

+LAYER Command - Choose Number of Card

Layers

Description Specifies creation of two- or three-layer cards

Note that this command only applies to Max3300

Systems. When sent, both the Printer and

Laminator receive this command.

Syntax +LAYERp1↵

Parameters p1 = Number of Layers

Where:

0 = Two Layers

1 = Three Layers

2-14 980081-001 Rev. F

Page 47

!R Command - Print Head Resistance

P3xx C

P4xx

P500

P600

• P3xx M

•

Max

•

•

•

•

Description Enters manufacture’s average resistance that ap

pears on the print headlabel. Note thatreplacement

to a print head with 10-micron glass can produce

faint printing if not offset (typically from between

180 and 225 ohms). An offset that optimizes print

quality should be found.

Note: This setting interacts with the following com

mands:

+C Thermal Transfer Intensity

+$L Color Intensity

+$C Color Contrast

Syntax !Rp1↵

Parameters p1 = Resistance

Where:

p1 range = 1400~2350

Example In the following example, 1567 ohms is entered

based on the print head label.

!R1567↵

-

-

980081-001 Rev. F 2-15

Page 48

P3xx C

P4xx

P500

P600

• P3xx M

•

Max

•

•

•

•

M/m Commands - Multiple Command

Description Groups and repeats a string of commands “N”

times. “M” differs from “m” only regarding the re

sponse to errors. Errors encountered during com

mands linked by “m” commands abort any

remaining commands, while M-linked commands

resume after error removal.

Note that Max3000s perform best with this kind of

command linking for the print-related commands

(see Appendix E).

-

-

Syntax

M p1c1[c2[c3...[cn↵

Parameters p1 = Number of times to repeat following command string.

1~Cn =

C

Series of linked commands repeated p1 times. Note the

square bracket ([) delimiters.

Example This example shows an “M” command used to

group and repeat four commands.

M

3MI[ !D[ !M[MO↵

The “M” command groups a command string. A

card loads to the print ready position with the “MI”

command. “!D” lowers the print head; “!M” raises

the print head, and “MO” sends the card tothe out

put tray.

The “M” command specifiesthree repeatsof thisse

quence. If an error occurs (e.g., the input hopper

runs out of cards) a command sequence linked by

the “M” command terminates. In contrast, after er

ror correction and an associated pressing of the

Panel Button, a command sequence linked by the

“m” command resumes.

-

-

-

2-16 980081-001 Rev. F

Page 49

MI Command - Input Card To Print

Description Moves a card from the Card Input Hopper to the

Print Ready position.

For P600:

Moves card to the PrintReady position ofModule 1.

Syntax MI{p1}↵

Parameters p1 = none (Moves card to first Station)

p1 = 1 (Moves card to second station—P500 only)

P3xx C

P4xx

P500

P600

• P3xx M

•

Max

•

•

•

•

980081-001 Rev. F 2-17

Page 50

P3xx C

P4xx

P500

P600

• P3xx M

•

Max

•

•

•

•

MIB Command - Reverse Card To Card Feeder

Description For P300/P400:

Moves a card from beyondthe print positionback to

the Print Ready position.

For P500/P600:

Sent to Module 1, returns a card from beyond the

Print Ready position of Module 1 (not yet in Card

Flip of Module 2) to the Print Ready position of

Module 1.

Sent to Module2, returns a card toLaminate Ready

position from beyond Laminator of Module 2.

Syntax MIB↵

Parameters None

2-18 980081-001 Rev. F

Page 51

ME Command - Exit Card To Output Tray

Description For P300,P310 and P400,moves and exits a single

card from any position to the output tray.

For P500 and P600, moves and exits a single card

from any position except the Feeder to the Output

Tray.

Sent to Module 1,ejects a cardanywhere inthe card

Module.

Sent to Module2, ejects any card presentin Module

2. If no card is present, a Ribbon End or Card-Feed

error occurs.

Syntax ME{p1}↵

Parameters p1 = Number of cards to pass through printer.

P3xx M

P3xx C

P4xx

P500

P600

•

•

Max

•

•

•

980081-001 Rev. F 2-19

Page 52

P3xx C

P4xx

P500

P600

• P3xx M

•

Max

•

•

•

•

MB Command - Return Card To Card Feeder

Description Moves the card in the reverse direction and returns

the card to the card feed point (just inside the card

printer) from any position between the card feeder

and the output tray.

Sent to Module 2 of P500 and P600:

Returns a card in Module 2 to the Module 1 exit

point.

Syntax MB↵

Parameters None

2-20 980081-001 Rev. F

Page 53

MO Command - Exit Card To Output Tray

Description For P3xx and P400:

Moves and exits a single card from any position

except the Input Hopper to the output tray.

For P500:

Sent to Module 1, ejects a card from anywhere in

printer except the Input Hopperto the OutputTray.

Sent to Module 2, ejects a card in Module 2 to the

Output Tray. If no card is present, printer responds

ACK.

For P600:

Sent to Module 1,moves cardto Module2 fromany

position in Module 1, except the Input Hopper.

Sent to Module 2, moves card to Output Tray from

any position in Module 2. If no card is present,

printer responds ACK.

For Max:

Sent before an MF command, sends Clear Card to

the Card Assembly Station. Sent after an MF command, sends a White Card to the Card Assembly

Station, and if needed, sends the assembled cards

to the Laminator and Die Cutter module.

P3xx C

P4xx

P500

P600

• P3xx M

•

Max

•

•

•

•

Syntax MO↵

Parameters None

980081-001 Rev. F 2-21

Page 54

P3xx M

P3xx C

P4xx

P500

P600

•

Max

•

•

•

•

!FF Command - Set Ribbon Sequence

Description Resets and moves the ribbon to a selected panel.

The printer firstaligns onthe Cyan (andBlack) pan

els and then counts ribbon panel positions from the

Yellow “0" panel.

Syntax !FFp1↵

Parameters p1 = Panel detection number where:

p1 = 0 = Move ribbon to Sync Position, as follows:

Ribbon Sync Position

YMC Yellow Panel

YMCKr Yellow Panel

YMCKrO Yellow Panel

YMCKrOKr Yellow Panel

KsO Mid Overlay

KrO Mid Overlay

p1 =1 = Move to next transparent panel, unless already there

p1 =2 = Move to next non-transparent panel, unless already there

p1 = 3 = Move to beginning of Black (for YMCKrO ribbons only)

-

2-22 980081-001 Rev. F

Page 55

+RIB Command - Set Ribbon Type

Description Sets printer operation for either a Standard or one

of the nonstandard ribbons, as follows:

Standard Ribbons:

·

Kr (Monochrome—except P310 and Max3300)

YMCKrO

KsO

KrO

nonstandard Ribbons:

·

YMCKrOKr

YMC

YMCKr

YMCKrKr

YMCKr_Kr

Note: Parameter settings associated with this command establish the ribbon positioning that occurs

following a long press of the Panel Button. P310s

synchronize ribbons automatically after an unlatch

and latch of the Print Head, but require a P1 setting

of 4 toavoid attempted ribbon synchronization with

monochrome ribbons installed. Without this set-

ting, some ribbon wasteoccurs inan attemptedsynchronization.

P3xx M

P3xx C

P4xx

P500

P600

•

Max

•

•

•

•

Syntax +RIBp1↵

Parameters p

980081-001 Rev. F 2-23

= Ribbon Type

1

Where:

0 = Standard Ribbon

4 = Monochrome Ribbon (P310/P420/Max3300 only)

10 = 6-Panel Ribbon (YMCKrOKr)

11 = 3-Panel Ribbon (YMC)

13 = 4-Panel Ribbon (YMCKr)

21 = 5-Panel Ribbon w/spaced Kr (YMCKr_Kr)

Page 56

P3xx M

P3xx C

P4xx

P500

P600

•

Max

•

•

•

•

+RIB Command - Set Ribbon Type Continued)

Note: Card imaging using the YMCKOK ribbon re

quires the following command sequence:

IS 0 Image Yellow

IS 1 Image Magenta

IS 2 Image Cyan

I Image Black & Return (YMCKOK only)

IV 10 Image Varnish and Return

I 20 Image Black and Return

MO Eject Card

-

2-24 980081-001 Rev. F

Page 57

!M Command - Move Print Head Up

Description Moves the Print Head assembly up from the card

(and platen roller).

Syntax !M↵

Parameters None

P3xx C

P4xx

P500

P600

• P3xx M

•

Max

•

•

•

•

980081-001 Rev. F 2-25

Page 58

P3xx C

P4xx

P500

P600

• P3xx M

•

Max

•

•

•

•

!D Command - Move Print Head Down

Description Moves the Print Head assembly down to the card

(and platen roller).

Syntax !D↵

Parameters None

2-26 980081-001 Rev. F

Page 59

!SA Command - Self Adjust

Initiates a printer self-adjust sequence.

P3xx M

P3xx C

P4xx

P500

P600

•

Max

•

•

Note that this command requires the prior installa

tion of a 5-panel ribbon and works best with 10-mil

cards. Successful completion results in adjustment

of all sensors and voltages, confirmed by no errors

indicated.

Note that this command only applies to P310,

P420, and Max3300 printers.

Syntax !SA↵

Parameters None

-

980081-001 Rev. F 2-27

Page 60

P3xx M

P3xx C

P4xx

P500

P600

•

Max

•

•

CLNCARD Command - Establish Cleaning Card

Sequence

Allows settings for a time-to-clean alert and the cy

cling of cleaning card in card path.

Note that this command only applies to P310,

P420, and Max3300 printers.

Syntax CLNCARDp1p2↵

Parameters p1 = Ribbon Panel Count to Cleaning Notification (Default =

5000)

p2 = Number of Cleaning Card Passes Through Printer

(Default = 5)

-

2-28 980081-001 Rev. F

Page 61

P3xx M

P3xx C

P4xx

P500

P600

•

•

CLEAN Command - Start Cleaning Card Sequence

This command requires the prior removal of any

ribbon and a manual feed of a Cleaning Card. The

following occurs:

Raise Print Head

·

Feed a card to a position under Print Head

·

Lower Print Head

·

Move card back and forth the number of times

·

specified by CLNCARD Command.

Raise Print Head

·

Exit card

·

Note that this command only applies to P310,

P420, and Max3300 printers.

Syntax CLEAN↵

Parameters None

Max

•

980081-001 Rev. F 2-29

Page 62

P3xx C

P4xx

P500

P600

• P3xx M

•

Max

•

•

•

•

+BS Command - Set Black Speed

Description Optimizes Resin printing for either quality or print

speed.

Syntax +BSp1↵

Parameters p1 = Speed

Where:

0 = High Speed Printing

1 = High Quality Printing

2-30 980081-001 Rev. F

Page 63

IM Command - Print Color Test Card