Page 1

INSTRUCTION BOOKLET

COOKER HOOD

ZHC 951

Page 2

Thank you for buying a Zanussi product.

2

2

2

2

2

2

To enable you to use your appliance effectively and safely, please read this instruction

book carefully before using the appliance and retain for future reference. If you require

guidance in the use of the appliance or require further information on Zanussi Products,

please contact our Customer Care Department, at the address below or visit our website

at www.zanussi.co.uk

Customer Care Department

Zanussi

55 - 77 High Street

Slough

Berkshire

SL1 1DZ Tel: 08705 727 727*

*calls to this number may be recorded for traing purposes.

To register ownership, please ensure you complete and return the guarantee card

supplied with the appliance.

For the User

Important Safety Information

Y our Appliance

Operating Instructions

Cooker Hood Controls

To Operate

Recirculation

Extraction

Maintenance and Cleaning

External Cleaning

Metal Grease Filters

Charcoal Filters

To Remove/Replace the Charcoal

Filters

Changing the Light Bulb

Something Not Working

For the Installer

Technical Information

Electrical Connection

Electrical Requirements

Electrical Connection

Installing the Cooker Hood

Installation Requirements

Unpacking

Clearance Heights

Fitting the Wall Brackets

Fitting the Canopy Hood

Venting

Recirculation

Fitting the Chimney Stack

To register ownership, please ensure you

complete and return the guarantee card

supplied with the appliance.

Service and Spare Parts

Guarantee Conditions

Guide to use the instruction book

The following Symbols will be found in the text to guide you through the instruction book

Safety instructions Step by step instructions

1 2

Page 3

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2

2

2

2

2

2

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

IMPORT ANT SAFETY INFORMATION

These warnings are provided in the interests of safety. Ensure that you understand them all

before installing or using this appliance. Your safety is of paramount importance. If you are

unsure about any of the meanings of these warnings contact the Customer Care Department.

• Installation

• Any installation work must be undertaken

by a qualified electrician or a competent

person.

• This hood must be installed in accordance

with the installation instructions and all

measurements must be adhered to.

• If the cooker hood is installed for use above

a gas appliance then the provision for

ventilation must be in accordance with the

Gas Safety Codes of Practice BS.6172,

BS.5440 and BS.6891 (Natural Gas) and

BS.5482 (LP Gas) 1994, the Gas Safety

(Installation & Use) Regulations, the

Building Regulations issued by the

Department of the Environment, the

Building Standards (Scotland)

(Consolidated) Regulations issued by the

Scottish Development Department.

• The fan motor of this cooker hood

incorporates a cut-out device which will

operate if the cooker hood is installed

below the minimum height recommended

under the section ‘Clearance Height’, or if

the motor becomes overheated. If the cutout device is activated, switch off the fan

motor and allow the cooker hood to cool.

The cut-out device will reset itself when the

fan motor has cooled significantly.

• It is dangerous to alter the specifications or

modify this product in any way.

• When installed between adjoining wall

cabinets the wall cabinets must not

overhang the hob.

• If the room where the cooker hood is to be

used contains a fuel burning appliance

such as a central heating boiler then its flue

must be of the room sealed or balanced

flue type.

• If other types of flue or appliances are fitted

ensure that there is an adequate supply of

air to the room.

• The ducting system for this appliance must

not be connected to any existing ventilation

system which is being used for any other

purpose.

• Do not install above a cooker with a high-level

grill.

• Child Safety

• This appliance is designed to be operated by

adults. Children should not be allowed to

tamper with the appliance.

• During Use

• This product is for domestic use only.

• Never leave frying pans unattended during

use as overheated fats and oils might catch

fire.

• Never do flambé cooking under this cooker

hood.

• Do not leave naked flames under the cooker

hood.

• Maintenance and Service

• This appliance can be a hazard if the grease

filters and charcoal filters are not cleaned and

replaced as recommended.

• Under no circumstances should you attempt

to repair the appliance yourself. Repairs

carried out by inexperienced persons may

cause injury or more serious malfunction.

Refer to your local Zanussi Service Force

Centre. Always insist on genuine spare

parts.

Page 4

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2

2

2

2

2

2

2

2

2

2

2

2

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

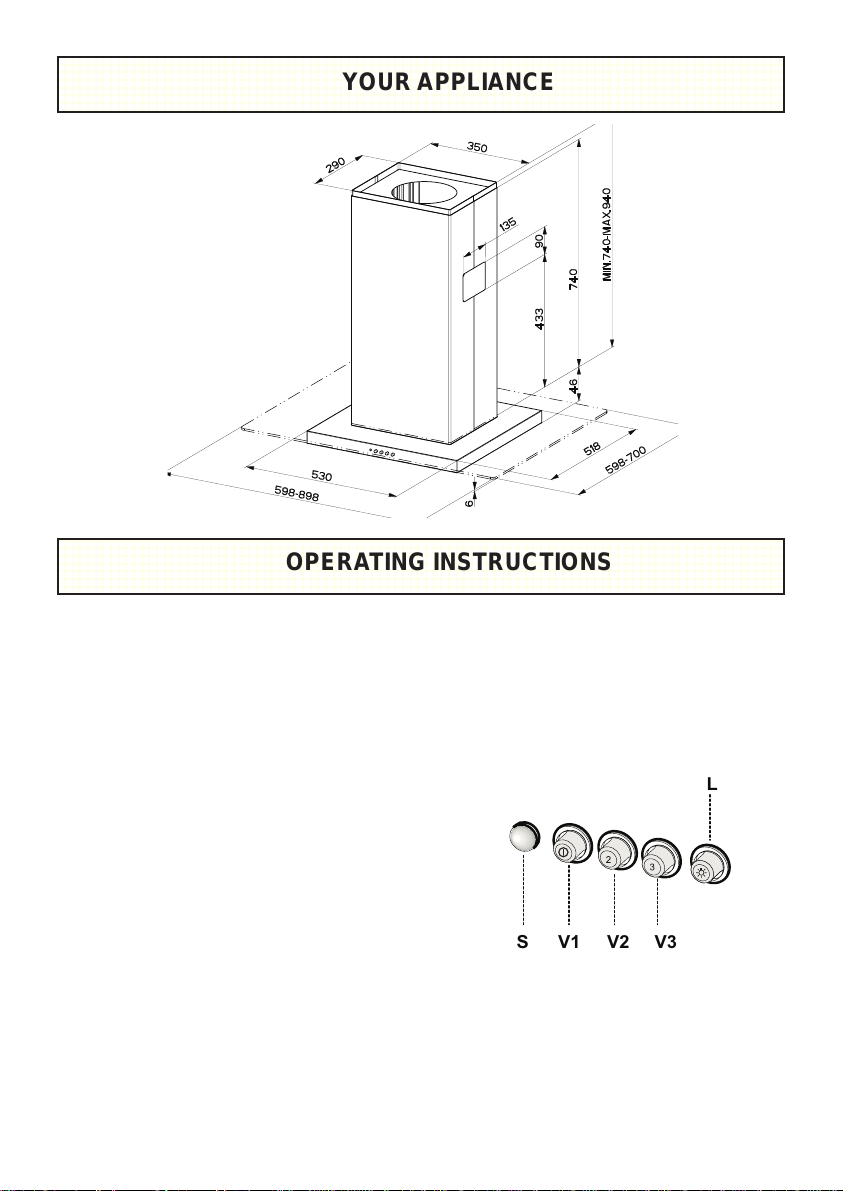

YOUR APPLIANCE

OPERA TING INSTRUCTIONS

This cooker hood is designed to extract

unpleasant odours from the kitchen, it

will not extract steam.

Cooker Hood Controls

The cooker hood functions are controlled by

four push button switches located centrally in

the control fascia.

L Turns the worktop lighting On and Off

S Mains light - illumination indicates fan

motor is running

V1 Turns the fan motor On and Off at low

speed, suitable for one pan or when

simmering.

V2 Medium fan speed, suitable for use

when cooking with a number of pots

and pans.

V3 Maximum fan speed, suitable for

cooking foods with strong odours.

S

V1 V2 V3

L

3 4

Page 5

T o Operate

Select the required fan speed and light if required.

The appliance can be installed to recirculate or

extract contaminated air. The cooker hood is more

effective when used in the extraction mode.

Recirculation

The cooker hood is supplied specified for use in the

recirculation mode with the charcoal filter fitted.

In the recirculation mode the contaminated air is

passed through the charcoal filters to be purified

and recirculated into the kitchen through the

recirculation grilles in either side of the chimney

stack.

Extraction

In the extraction mode the contaminated air enters

the cooker hood passing through the grease filters

and is passed out through the ducting into the

atmosphere.

To obtain the best performance when cooking it is

advisable to switch the cooker hood on for a few

minutes before you start cooking and leave it

running for about 15 minutes after finishing.

When used in the extraction mode the

charcoal filters are not required.

Never do flambé cooking under this

cooker hood.

Never leave frying pans unattended during

use as overheated fats and oils can catch

fire.

Do not leave naked flames under the cooker

hood.

Ensure heating areas on your hob are

covered with pots and pans when using the

hob and cooker hood simultaneously.

Page 6

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2

2

2

2

2

2

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

MAINTENANCE AND CLEANING

Before carrying out any maintenance

or cleaning isolate the cooker hood

from the mains supply.

The cooker hood must be kept clean,

as a build up of grease or fat can be a

fire hazard.

External Cleaning

Wipe the cooker hood frequently with warm soapy

water using a mild detergent.

Never use scouring pads or abrasive

cleaners.

Never use excessive amounts of water

when cleaning particularly around the

control panel.

Metal Grease Filters

The grease filters absorb grease and dust during

cooking to help keep the cooker hood clean inside.

Cleaning

The filters must be washed once every

month, using a normal household

detergent; their compact dimension also

enables them to be washed in a

dishwasher. Allow to dry completely

before replacing.

Removing and replacing the filters

Remove the filters one at a time, press

against the metal actuator to release the

spring catch as illustrated. When

replacing, ensure that the handles face

outwards.

Charcoal Filter

In the recirculation mode the charcoal filter

absorbs smells and unwanted odours.

The charcoal filter cannot be cleaned or

regenerated, and must be replaced approximately

every 4 months, or more frequently if the hood is

subjected to heavy usage.

Replacing the charcoal filter

First remove the metal grease filters.

Remove the saturated activated charcoal

filter by releasing the fixing hooks as

illustrated.

5

Page 7

Position the new charcoal filter in the

position marked and while holding the

filter replace the fixing hooks as

illustrated.

This appliance can be a possible fire

hazard if the grease and charcoal

filters are not cleaned and replaced as

recommended.

Changing the Spot Lamps

Remove the two screws fixing the

lighting support.

Remove the spot lamp from the holder

by pulling the lamp downwards.

Replace the spot lamp by inserting the

two pins at the base of the lamp into

the holes in holder and pushing into

position.

Replace the lighting support, ensuring it

is located correctly and fix back into

position using the two screws.

If one of the spot lamps has failed to function

check that the lamp is fully seated into the lamp

holder. If lamp failure has occurred then it

should be replaced with a 12V 20W M262

halogen spot lamp.

Replacement filters and lamps can be

obtained from your local Service Force

Centre.

6

Page 8

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

3

3

3

3

3

3

2

2

2

2

2

2

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

1

1

1

1

1

1

1

1

1

1

1

1

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

SOMETHING NOT WORKING

If, having followed these instructions carefully, your cooker hood fails to work properly please carry

out the following checks.

Symptom

The cooker hood will not start

Solution

• Check the hood is connected to the electricity

supply.

• Make sure the switch is in the ‘ON’ position.

• The fan speed is set high enough for the task.

• The grease filter is clean.

• The kitchen is adequately vented to allow the

entry of fresh air.

• If set up for recirculation, check that the

charcoal filter is still effective.

• If set up for extraction, check that the ducting

outlets are not blocked.

The cooker hood has switched off during

operation

• The safety cut-out device has been tripped.

• Turn off the hob and then wait for the device

to reset.

If after all these checks, the fault persists,

contact your local Service Force Centre, quoting

the model and serial number.

Please note that it will be necessary to provide

In-guarantee customers should ensure that

the above checks have been made as the

engineer will make a charge if the fault is not

a mechanical or electrical breakdown.

proof of purchase for any in-guarantee service

calls.

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

If you require an engineer or spare parts

contact your local Service Force Centre by

telephoning:

SERVICE AND SPARE P ARTS

For general assistance with your appliance or for

further information on Zanussi products please

contact our Customer Care Department at the

address below or visit our website at:

08705 929929

Your telephone call will be routed to your local

Service Force Centre.

For the address of your local Service Force

Centre and further information about Service

Force, please visit the website at

www.serviceforce.co.uk

www.zanussi.co.uk

Customer Care Department

Zanussi

55 - 77 High Street

Slough

Berkshire

SL1 1DZ

Telephone: 08705 727 727*

* calls to this number may be recorded for training

purposes.

7

Page 9

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

1

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890

1

1

1

1

1

1

1

1

1

1

1

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890

GUARANTEE CONDITIONS

We, Zanussi, undertake that if within twenty four months of the date of the purchase this

Electrolux built-in product or any part thereof is proved to be defective by reason only of faulty

workmanship or materials, the company will, at our option repair or replace the same FREE OF

ANY CHARGE for labour, materials or carriage on condition that:

• The appliance has been correctly installed and used only on the electrical supply stated on the

rating plate.

• The appliance has been used for normal domestic purposes only, and in accordance with the

manufacturer’s operating and maintenance instructions.

• The appliance has not been serviced, maintained, repaired, taken apart or tampered with by

any person not authorised by us.

• All service work under this guarantee must be undertaken by a Zanussi Service Force

Centre.

• Any appliance or defective part replaced shall become the property of this company.

Home visits are made between 8.30am and 5.30pm Monday to Friday. Visits may be available

outside these hours in which case a premium will be charged.

EXCLUSIONS

This Guarantee does not cover:

• Damage or calls resulting from transportation, improper use or neglect, the replacement of

any lamps or removable parts of glass or plastic.

• Costs incurred for calls to put right appliances improperly installed or calls to appliances

outside the United Kingdom.

• Appliances found to be in use within a commercial environment, plus those which are the

subject of rental agreements.

• Products of Zanussi manufacture which are not marked by Zanussi.

This guarantee is in addition to your statutory and legal rights.

ZANUSSI EUROPEAN GUARANTEE

If you should move to another country within Europe then your guarantee moves with you to your

new home subject to the following qualifications:

• The guarantee starts from the date you first purchased the product.

• The guarantee is for the same period and to the same extent for labour and parts as exists in

the new country of use for this brand or range of products.

• This guarantee relates to you and cannot be transferred to another user.

• Your new home is within the European Community (EC) or European Free Trade Area.

• The product is installed and used in accordance with our instructions and is only used

domestically, i.e. a normal household.

Before you move please contact your nearest Customer Care Centre, listed below,

to give them detailsof your new home. They will then ensure that the local Service

Organisation is aware of your move and able to look after you and your appliances.

France Senlis +33 (0)3 44 62 22 22

Germany Nurnberg +49 (0)911 323 2600

Italy Pordenone +39 (0)1678 47053

Sweden Stockholm +46 (0)20 78 77 50

United Kingdom Slough +44 (0)1753 219897

8

Page 10

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2

2

2

2

2

2

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

1

1

1

1

1

1

1

1

1

1

1

1

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

INST ALLA TION INSTRUCTIONS

It is dangerous to alter the specifications or attempt to modify this product in any way.

T echnical information

DIMENSIONS HEIGHT OF CANOPY: (incl glass visor) 46mm

HEIGHT OF CHIMNEY: (UPPER SECTION) 215mm

(LOWER SECTION) 740mm

WIDTH OF CANOPY: (incl glass visor) 898mm

DEPTH OF CANOPY: (incl glass visor) 700mm

ELECTRICAL SUPPL Y VOLTAGE: (~50Hz) 230V

POWER CONSUMPTION: 230W

FA N MO TO R: 150W

LAMPS: (4x20W) 80W

SUITABLE FOR INSTALLATION ABOVE: ELECTRIC HOB: 7KW (MAX)

GAS HOB: 10KW (MAX)

SLOT-IN ELECTRIC COOKER: 12.4KW (MAX)

SLOT-IN GAS COOKER: 13.5KW (MAX)

Note: CE Marking certifies that this appliance complies with the

requirements laid down in EEC directive 89:336 (Electromagnetic

compatibility) and subsequent modifications and Low Votage directive

72/23/E.

DOUBLE INSULATED DO NOT EARTH

Electrical Requirements

Any permanent electrical installation must

comply with the latest I.E.E. Regulations and

local Electricity Board regulations. For your own

safety this should be undertaken by a qualified

electrician e.g. your local Electricity Board, or a

contractor who is on the roll of the National

Inspection Council for Electrical Installation

Contracting (NICEIC).

Electrical Connection

Before connecting to the mains supply ensure

that the mains voltage corresponds to the

voltage on the rating plate inside the cooker

This appliance is fitted with a 2 core mains

cable and must be permanently connected to

the electricity supply via a double-pole switch

having 3mm minimum contact gap on each

pole. A Switched Fuse Connection Unit to

BS.1363 Part 4, fitted with a 3 Amp fuse, is a

recommended mains supply connection

accessory to ensure compliance with the Safety

Requirements applicable to fixed wiring

instructions.

This appliance conforms to BS.800:1988 and

EEC Directive No. 78 308 regarding

suppression of radio and television interference.

9

Page 11

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

1

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890

1

1

1

1

1

1

1

1

1

1

1

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890

INSTALLING THE COOKER HOOD

Unpacking

The hood is supplied with the following

components for installation as illustrated.

Item Qty Description

1 1 Hood body, complete with:

Controls, lighting, blower and

filters

2 1 Telescopic chimney comprising:

2.1 1 Upper section

2.2 1 Lower section

7.1 1 Telescopic frame complete with

extractor, consisting of:

7.1a 1 Upper frame

7.1b 1 Lower frame

8a 1 Right-hand air outlet grille

8b 1 Left-hand air outlet grille

9a 1 Ø120-125mm Ducting collar

9b 1 Ø150-120mm Ducting spigot

14 1 Recirculation extension ducting

14.1 2 Recirculation extension ducting

15 1 Recirculation spigot

24 1 Junction box

25 2 Jubilee Clips

7.1

21

22

12c

7.1a

12g

7.1b

23

11

12h

14.1

15

14

9

25

Item Qty Installation Components

12c 6 Ø2.9 x9.5mm Chimney fixing

screws

2.1

2

12e 2 Ø2.9 x6.5mm Junction box

fixing screws

2.2

12f 4 M6x10mm Hood body fixing

12g 4 M6x80mm Lower frame fixing

screws

screws

12h 4 Ø5.2x70mm Upper frame fixing

8b

8a

12e

screws

21 1 Ceiling drilling template

Item Qty Documents

1 Instruction Manual

12c

12c

1

12f

10

24

Page 12

Please ensure that when the appliance is

installed it is easily accessible to an engineer

in the event of a breakdown.

All installations must comply with the local

authorities requirements for the discharge of

exhaust air.

Incorrect installation may affect the safety of

this cooker hood.

Installation Requirements

Before installation check that the wall to

which the cooker hood is to be fitted for

electric cables, water pipes and gas.

This cooker hood is designed to be fixed to any

vertical surface over a cooking area, and can be

used in the extraction (ducted to the outside) or

recirculation mode.

The installation work must be undertaken by a

qualified and competent person.

The manufacturer disclaims any responsibility for

damage due to incorrect installation of the cooker

hood or if the hood is not installed in compliance with

relevant regulations controlling this type of installation.

Clearance Heights

The cooker hood is designed to be fitted over a

cooking appliance at the clearance heights stated,

providing the maximum output of the appliance

beneath does not exceed the maximums quoted in the

Technical Specifications.

If the output of the appliance below the cooker hood

exceeds the maximum outputs quoted, please refer to

the cooker manufacturer’s installation instructions.

A minimum clearance height of 650mm (25½ins) is

required when installed above a built-in electric hob,

or 700mm (27½ins) when installed above a built-in

gas hob.

A minimum clearance height of 685mm (27ins) is

required when installing above a slot-in electric

cooker, or 787mm (30½ins) when installed above a

slot-in cooker.

When installed between adjoining wall cabinets, the

wall cabinets must not overhang the hob and the

distance between the underside of the cabinet and

the worktop must be 450mmm (17¾ins), a gap of

50mm (2ins) must be maintained either side of the

hob.

This cooker hood must not be installed

above a cooking appliance with a high

level grill.

The hood can be installed above these heights but for

optimum performance it should be installed at the

distances quoted for the appropriate heat source.

11

Page 13

Drilling the Ceiling/Support

Shelf

Using a plumb line mark the centre point

of the hob on the ceiling or support

shelf.

Position the drilling template item 21 on

the ceiling or support shelf ensuring the

template is aligned correctly with the

angles of the hob.

Mark the hole centres.

Pilot drill the fixing holes at the points

marked for the approprate size rawl

plugs and screws (not supplied).

It will also be necessary to drill a

Ø10mm hole for the mains cable and the

ducting if the hood is to be installed

ducted to the outside.

Fixing the Frame

IMPORTANT: Before fixing, separate

the Upper Chimney section 2.1 and the

Lower Chimney section 2.2 from the

frame by removing the screws 12c.

Then separate the two sections of the

frame by unscrewing the 8 screws

located on each side of the frame.

Upper Frame

Feed the mains cable through the frame

and the hole in the ceiling or support

shelf.

Fix the Upper Frame 7.1a to the ceiling

(screws not supplied).

Lower Frame

Fix the lower frame using the 8

screws removed earlier and adjust the

length according to the installation

height (the minimum distance before

fitting the hood body 1 must be 710mm).

When the hood is to be installed in the

recirculation mode, position the frame in

the direction you want the recirculated

air to pass into the kitchen.

The frame mountings must be secure

enough to withstand the weight of the

cooker hood and any knocks the hood

may get through normal ware and tear.

12

Page 14

On completion check that the base is stable

14

15

14.1

even if the frame is subject to movement.

The installer must provide ample

support where the ceiling or support

shelf is not strong enough by

installing cross beams over the joists

or above the shelf to ensure the

frame is quite rigid at its mounting

point.

Extraction

The cooker hood is more effective when used in the

extraction mode (ducted to the outside).

Venting kits may be purchased through your

retailer or DIY store, and must be ducted to an

outside vent of Ø125mm (5”) or Ø150mm (6”).

For the best performance use the shortest possible

duct run and the minimum number of bends.

Where flexible ducting is fitted it should not be turned

through very tight bends as this may impair the

performance of the hood.

It is recommended a maximum length of 3 metres

with one bend, to be installed, to be reduced metre

for each 90o bend.

If a distance is greater than 3 metres the efficiency

of the hood could be impaired.

The ducting used must be manufactured

from fire retardent material conforming to the

relevant British Standard or DIN 4102-B1.

When the cooker hood is ducted to the outside the

charcoal filter must be removed.

Ducting Connection

Connect the ducting chosen to:

the Ø150mm ducting spigot on top of the

motor housing, or the Ø150-120mm ducting

spigot 9 and secure using the jubilee clips

25.

A Ø120-125mm collar 10 is provided

to fit over the Ø120mm ducting spigot

when 125mm ducting is fitted.

If the room where the cooker hood is to

be used contains a fuel burning

appliance such as a central heating

boiler, then its flue must be of the room

sealed or balanced flue type.

If other types of flue or appliances are fitted

ensure that there is an adequate supply of

air to the room.

The cooker ducting (extraction mode) must

never be connected to central heating flues,

radiators or water heaters etc.

ø 150

25

13

ø120

25

9

Page 15

Recirculation

14

15

14.1

The cooker hood is supplied specified for use in the

recirculation mode, with the charcoal filter fitted.

In the recirculation mode contaminated air is passed

through the charcoal filter to be purified and

recirculated into the kitchen through the grille outlets

on either side of the chimney.

Recirculation Connection

Assemble the two halves of the round

recirculation extension duct 14.

Push fit the assembled extesion duct 14

on to Ø150mm ducting spigot on top of

the motor housing.

Push fit the recirculation spigot 15 onto

the other end of the extension duct 14.

Insert the extension ducts item 14.1 into

either side of the recirculation spigot 14

ensuring the connections are vertically

and horizontally aligned with the outlets

in the chimney .

Chimney Stack

The chimney consists of two sections. The lower

chimney measures 740mm (with the recirculation

grilles on either side) and the upper chimney

measures 215mm. The overall installed

measurement is min. 740-940mm max.

Fitting the Chimney

Position the upper chimney section 2.1 and

fix the chimney to the upper frame using two

Ø2.9x9.5mm screws 12c.

Slide the lower chimney section 2.2 up over

the upper chimney and fix the chimny to the

lower frame using two Ø2.9x9.5mm screws

12c.

When installed in the recirculation mode the

ducting outlet extension pieces 14.1 should

align with the rectangular holes in each side

of the chimney.

Position the recirculation grilles 8a and 8b so

the slats face in a forwards and upwards

direction.

Fitting the Hood Body 1

Before fixing the hood body to the frame:

Remove the grease filters from the hood

body.

Remove the activated charcoal filter.

Using the four M6x10 12f fix the hood body

1 to the frame 7.1b.

12c

8b

12c

12f

14

8a

Page 16

Electrical Connection

Push fit the Cmd connecter on the cable

from the motor housing to the one from the

control box.

Place the Cmd connector in the junction box

24 and clamp it together using two

Ø2.9x6.5mm screws 12e.

Fix the junction box 24 to the hood body 1

using the two Ø2.9x9.5mm screws 12c.

Working T est

When the electrical connection has been made, test

the three speed fan and worktop illumination.

24

12e

Cmd

12c

15

Page 17

© Electrolux plc 2002

436001739 01 - 030415

Page 18

documentation manual, user maintenance, brochure, user reference, pdf manual

This file has been downloaded from:

User Manual and User Guide for many equipments like mobile phones, photo cameras, monther board, monitors, software, tv, dvd, and othes..

Manual users, user manuals, user guide manual, owners manual, instruction manual, manual owner, manual owner's, manual guide,

manual operation, operating manual, user's manual, operating instructions, manual operators, manual operator, manual product,

Loading...

Loading...