Page 1

Cappa

Cooker hood

Hotte de cuisine

Dunstabzugshaube

Dampkap

ZHC 930 X

MANUALE DI INSTALLAZIONE, USO E MANUTENZIONE

INSTALLATION, USE AND MAINTENANCE HANDBOOK

MANUEL D’INSTRUCTIONS POUR L’INSTALLATION, L’EMPLOI ET L’ENTRETIEN

HANDBUCH FÜR INSTALLATION, BEDIENUNG UND WARTUNG

INSTRUCTIES VOOR MONTAGE, GEBRUIK EN ONDERHOUD

Page 2

Dear Customer,

If you follow the recommendations

contained in this Instruction Manual, your

appliance will give you constant high

performance and will remain efficient for

many years to come.

CONTENTS

RECOMMENDATIONS AND SUGGESTIONS 14

CHARACTERISTICS 15

INSTALLATION 17

USE 20

MAINTENANCE 21

GB

13

Page 3

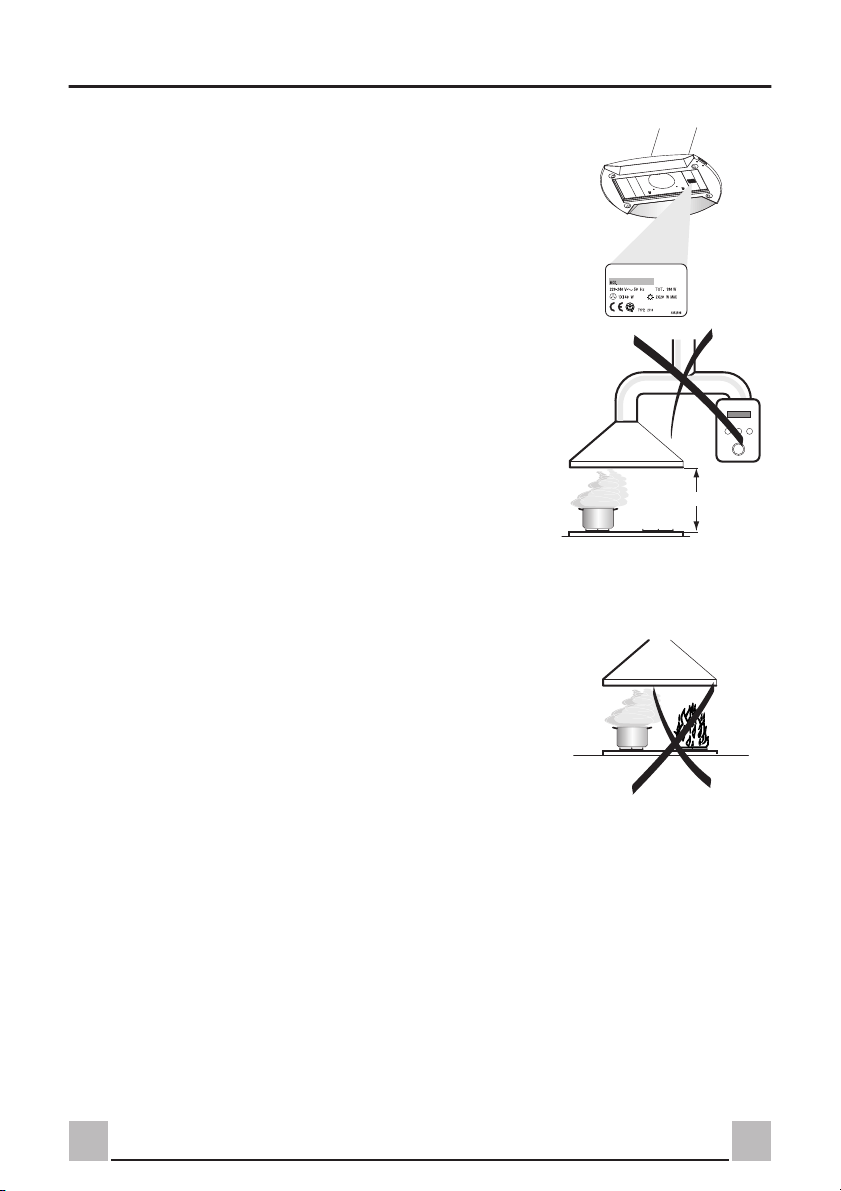

RECOMMENDATIONS AND SUGGESTIONS

650 mm min.

INSTALLATION

• The manufacturer will not be held liable for any damages resulting

from incorrect or improper installation.

• The minimum safety distance between the cooker top and the

extractor hood is 650 mm.

• Check that the mains voltage corresponds to that indicated on the

rating plate fixed to the inside of the hood.

• For Class I appliances, check that the domestic power supply

guarantees adequate earthing.

• Connect the extractor to the exhaust flue through a pipe of minimum

diameter 120 mm. The route of the flue must be as short as possible.

• Do not connect the extractor hood to exhaust ducts carrying

combustion fumes (boilers, fireplaces, etc.).

• If the extractor is used in conjunction with non-electrical appliances

(e.g. gas burning appliances), a sufficient degree of aeration must be

guaranteed in the room in order to prevent the backflow of exhaust

gas. The kitchen must have an opening communicating directly with

the open air in order to guarantee the entry of clean air.

USE

• The extractor hood has been designed exclusively for domestic use

to eliminate kitchen smells.

• Never use the hood for purposes other than for which it has ben

designed.

• Never leave high naked flames under the hood when it is in

operation.

• Adjust the flame intensity to direct it onto the bottom of the pan only,

making sure that it does not engulf the sides.

• Deep fat fryers must be continuously monitored during use:

overheated oil can burst into flames.

• The hood should not be used by children or persons not instructed in

its correct use.

MAINTENANCE

• Switch off or unplug the appliance from the mains supply before

carrying out any maintenance work.

• Clean and/or replace the Filters after the specified time period.

• Clean the hood using a damp cloth and a neutral liquid detergent.

GB

14

Page 4

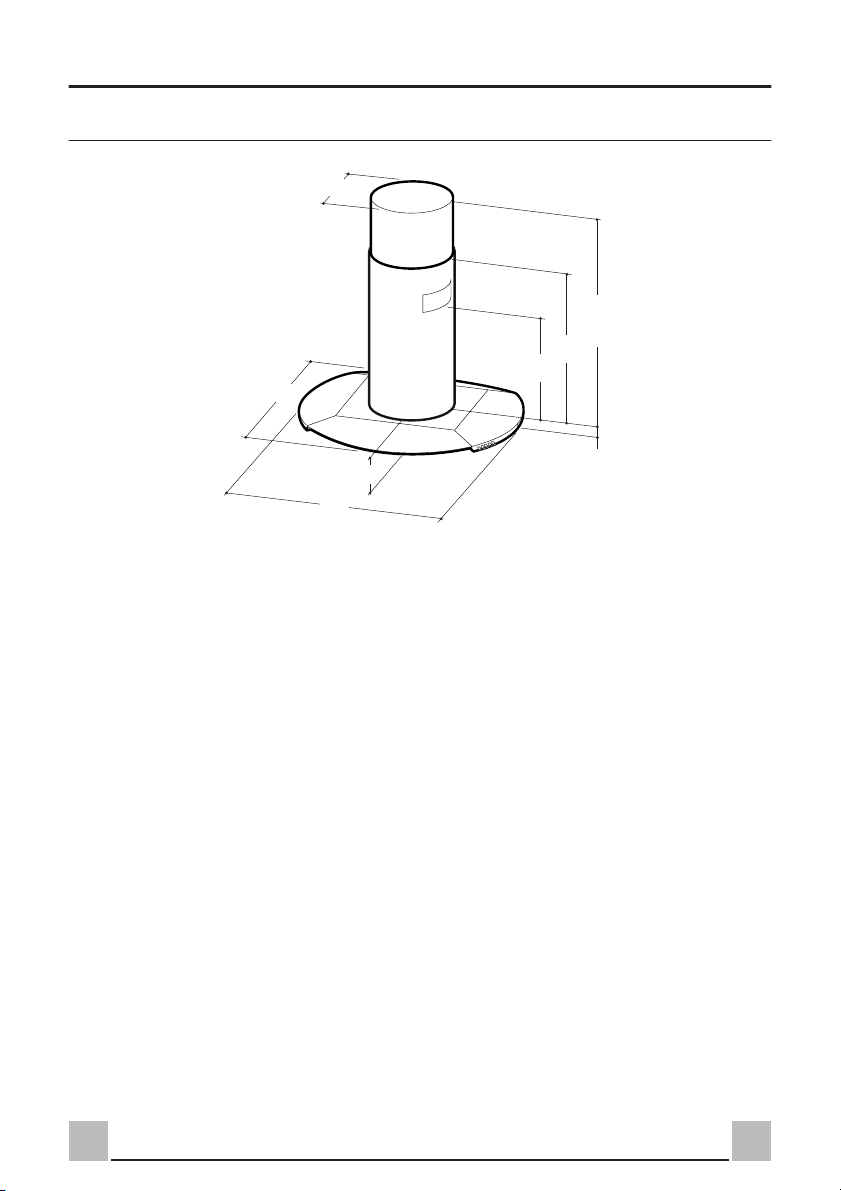

CHARACTERISTICS

732

ø 280

Dimensions

500

890

890 min

1170 max

898

72

55

15

GB

Page 5

21

22

zz

Components

Ref. Q.ty Product Components

1 1 Hood Body, complete with: Controls, Light,

2 1 Telescopic Chimney comprising:

2.1 1 Upper Section

23

14.1

11

12g

12h

14

25

9

2.1

2

2.2

12e

2.2 1 Lower Section

7.1 1 Telescopic frame complete with extractor,

7.1a 1 Upper frame

7.1b 1 Lower frame

15

8 1 Air Outlet Grill

9 1 Reducer Flange ø 150-120 mm

14 1 Hood Body Air Outlet Extension Piece

14.1 1 Air Outlet Connection Extension

15 1 Air Outlet Connection

24 1 Junction box

25 2 Pipe clamps

Ref. Q.ty Installation Components

11 4 Wall Plugs ø 10

12b 3 Screws 2,9 x 4,5

12c 4 Screws 2,9 x 6,5

12e 4 Screws 2,9 x 9,5

12f 4 Screws M6 x 10

12g 4 Screws M6 x 80

12h 4 Screws 5,2 x 70

8

21 1 Drilling template

22 4 6.4 mm int. dia washers

24

23 4 M6 nuts

Blower, Filters

consisting of:

consisting of two Half Shells

GB

Q.ty Documentation

1 Instruction Manual

1

12c

12f

16

Page 6

INSTALLATION

Drilling the Ceiling/shelf and fixing the frame

DRILLING THE CEILING/SHELF

• Use a plumb line to mark the centre of the hob on the ceiling/support shelf.

• Place the drilling template 21 provided on the ceiling/support shelf, making sure that the template is

in the correct position by lining up the axes of the template with those of the hob.

• Mark the centres of the holes in the template.

• Drill the holes at the points marked:

• For concrete ceilings, drill for plugs appropriate to the screw size.

• For hollow brick ceilings with wall thickness of 20 mm: drill ø 10 mm.

• For wooden beam ceilings, drill according to the wood screws used.

• For wooden shelf, drill ø 7 mm.

• For the power supply cable feed, drill ø 10 mm.

• For the air outlet (Ducted Version), drill according to the diameter of the external air exhaust

duct connection.

FIXING THE FRAME

Before fixing, separate the two sections of the frame

by unscrewing the 6 side screws to obtain the Upper

frame and Lower frame.

17

GB

Page 7

Upper frame

• Align the power supply cable feed hole

• Fix the upper frame to the ceiling or shelf using:

• For concrete ceilings, use the appropriate plugs for the screw size (not provided).

• For hollow brick ceilings of wall thickness of approximately 20 mm: use 4 plugs 11 and 4

screws 12h, provided.

• For wooden beam ceilings, use 4 wood screws (not provided).

• For wooden shelf, use 4 screws 12g with washers 22 and nuts 23, provided.

Lower frame

• Fix the lower frame using the 8 previously removed screws, adjusting the length according to the

installation height (hood body lower fixing surface must be at least 720 mm from the hob).

• For the recirculation version, turn the frame in the direction chosen for the recirculated air outlet.

• The frame mountings must be secure to withstand the weight of the hood and any stresses caused by

the occasional side thrust applied to the device. On completion, check that the base is stable, even if

the frame is subjected to bending.

• In all cases where the ceiling is not strong enough at the suspension point, the installer must provide

strengthening using suitable plates and backing pieces anchored to the structurally sound parts.

Connections

DUCTED VERSION AIR EXHAUST SYSTEM

When installing the ducted version, connect the hood to the chimney using either a flexible or rigid

pipe ø 150 or 120 mm, the choice of which is left to the installer..

• To install a ø 120 mm air exhaust connection,

insert the reducer flange 9 on the hood body

outlet.

• Fix the pipe using the pipe clamps 25 provided.

• Remove any activated charcoal filters.

9

RECIRCULATION VERSION AIR OUTLET

• Insert reducer flange 9 on the extractor outlet.

• Push fit the extension piece 14 onto the flange.

• Push fit connector 15 onto the extension piece.

• Insert extension piece/connector 14.1 laterally on

connector 15, ensuring that the outlet is in line with

the chimney intake.

GB

ø 120ø 150

15

14.1

14

9

18

Page 8

Flue assembly - Mounting the hood body

• Position the upper chimney section and fix the

upper part to the frame using the 2 screws 12c

provided.

• Similarly, position the lower chimney section

without fixing it, ensuring that the outlet from

connector 15 is in line with the chimney intake.

• The air outlet directional grill 8 must be fitted

after the installation of the chimney.

Before fixing the hood body to the frame:

• remove the grease filters from the hood body;

• remove the activated carbon odour filters, if

fitted.

• from below, use the 4 screws 12f provided to fix

the hood body to the frame.

8b

• For the recirculation version, locate the

directional grill 8 in its housing. Ensure that it is

inserted correctly in connector 15.

ELECTRICAL CONNECTION

• Connect the hood to the mains through a twopole switch having a contact gap of at least 3 mm.

• Connect the control connector Cmd.

• Place the connector in the junction box 24 and

close it using the 4 screws 12e provided.

• Fix the junction box to the hood body using the 2

screws 12c provided.

• For the recirculation version, fit the activated

carbon odour filter.

• Replace the grease filters.

12f

24

12e

Cmd

12c

19

GB

Page 9

USE

Control panel

LM V3S1 S2V2V1

L Light Switches the lighting system on and off.

S1 Led Motor running led. Flashes when the grease filters are saturated.

S2 Led Intensive speed led. Flashes when the activated carbon odour filters are exhausted.

M Motor Switches the extractor motor on and off at low speed. Used to provide a contin-

uos and silent air change in the presence of light cooking vapours.

V1 Speed Reduces the operating speed

V2 Speed Increases the operating speed

V3 Intensive

speed

Maximum speed, used for eliminating the highest cooking vapour emission.

Switches off automatically after 10 minutes operation. Can also be switched off

manually by pressing the button

GB

20

Page 10

MAINTENANCE

Grease filters

CLEANING METAL SELF-SUPPORTING GREASE FILTERS

Alarm signal reset

• Switch of the lights and extractor motor.

• Press button V3 for at least 3 seconds, until the

leds start to flash.

Cleaning the filters

• The filters are washable and must be cleaned when

led S1 flashes or at least every 2 months of

operation, or more frequently for particularly

heavy usage.

• Remove the filters one at a time by pushing them

towards the back of the group and pulling down

at the same time.

• Wash the filters, taking care not to bend them.

Allow them to dry before refitting.

• When refitting the filters, make sure that the

handle is visible on the outside.

21

GB

Page 11

Activated charcoal filter (Recirculation version)

REPLACING THE ACTIVATED CHARCOAL FILTER

• The filter is not washable and cannot be

regenerated. It must be replaced when led S2

flashes or at least every 4 months. The alarm

signal will only light up when the extractor motor

is switched on.

Alarm signal reset

• Switch off the lights and extractor motor.

• Press button V3 for at least 3 seconds, until the

leds start to flash.

Replacing the Filter

• Remove the metal grease filters

• Remove the saturated activated carbon filter by

releasing the fixing hooks

• Fit the new filter by hooking it into its seating

• Replace the metal grease filters.

Alarm signal activation

• On the recirulcation version extractor hood, the

filter saturation alarm is activated during

installation or at a later date.

• Switch off the lights and extractor motor.

• Press button V3 for at least 10 seconds, until the

leds start to flash:

• 2 flashes of the activated carbon odour filter

saturation alarm led = filter ACTIVATED

• 1 flash of the activated carbon odour filter

saturation alarm led = filter DEACTIVATED

Lighting

LIGHT REPLACEMENT

• 20 W halogen light.

• Remove the 2 screws fixing the ring nut.

• Extract the lamp from the lamp holder by pulling

gently.

• Replace with another of the same type, making

sure that the two pins are properly inserted in the

lamp holder socket holes.

• Replace the ring nut and fix it in place using the

two screws removed as above.

GB

22

Page 12

Page 13

Quest’apparecchio é conforme alla norma europea sulla bassa tensione C.E.E. 73/23 relativa

alla sicurezza elettrica e alle norme europee: C.E.E. 89/336 relativa alla compatibilità elettromagnetica e C.E.E. 93/68 relativa alla marcatura CE.

This appliance complies with European regulations on low voltages, EEC Directive 73/23 on

electrical safety, and with the following European regulations: EEC Directive 89/336 on

electromagnetic compatibility and EEC Directive 93/68 on EC marking.

Cet équipement est conforme à la norme européenne sur la basse tension C.E.E. 73/23 relative à la sécurité électrique et aux normes européennes: C.E.E. 89/336 relative à la compatibilité

électromagnétique et C.E.E. 93/68 relative au marquage CE.

Dieses Gerät entspricht den europäischen Niederspannungsrichtlinien 73/23/EWG zur

elektrischen Sicherheit, den europäischen Richtlinien 89/336/EWG zur elektromagnetischen

Verträglichkeit und den Richtlinien 93/68/EWG zur CE-Kennzeichnung

Dit apparaat voldoet aan de Europese Laagspanningsrichtlijn 72/23/EEG inzake de elektrische

veiligheid en aan de Europese normen 89/336/EEG inzake de elektromagnetische compatibiliteit

en 93/68/EEG inzake de CE-markering.

436000235 01 - 011214

Loading...

Loading...