Page 1

96

Instruction for the use - Installation advice

COOKERS

Z 9060

Z 9060

WOS

WOS

Z 9060

Z 9060

XOS

XOS

Page 2

2

Dear Customer,

We thank you very much for choosing our products.

The instructions and advice included in this booklet are given

to safeguard your safety and to use this appliance correctly.

Be so kind as to keep this booklet.

It will be useful to clear any doubt concerning its operation.

This appliance must be only assigned to the use for which it

has been realized, that is for cooking food.

Any other use has to be considered incorrect and therefore

dangerous.

The manufacturer declines any liability for damages

caused by wrong, incorrect or irrational use of the appliance.

Read the instructions carefully before installing and using the appliance.

CAUTION: this apparatus must only be installed in a permanently ventilated room in

compliance with the applicable regulations.

IMPORTANT INSTRUCTIONS AND ADVICE FOR THE USE OF ELECTRICAL

APPLIANCES

The use of any electrical appliance requires the compliance with some basic rules,

namely:

– do not touch the appliance with wet or damp hands (or feet)

– do not use the appliance whilst in bare feet

– do not allow the appliance to be operated by children or unqualified persons without

supervision.

The manufacturer cannot be deemed responsible for damages caused by wrong or

incorrect use.

Page 3

3

FIRST USE THE OVEN

It is advised to follow these instructions:

– Clean the interior of the oven with cloth

soaked in water and detergent

(neutral) then dry carefully.

– Furnish the interior of the oven by

placing the wire racks as described at

chapter “Cleaning and maintenance”.

– Insert shelves and tray.

– Switch on the empty oven on max to

eliminate grease from the heating

elements.

IMPORTANT PRECAUTIONS

AND RECOMMENDATIONS

After having unpacked the appliance,

check to ensure that it is not damaged

and that the oven door closes correctly.

In case of doubt, do not use it and

consult your supplier or a professionally

qualified technician.

Packing elements (i.e. plastic bags,

polystyrene foam, nails, packing straps,

etc.) should not be left around within

easy reach of children, as these may

cause serious injuries.

● Do not attempt to modify the technical

characteristics of the appliance as

this may cause danger to users.

● Do not carry out cleaning or

maintenance operations on the

appliance without having previously

disconnected it from the electric

power supply.

● If you should decide not to use this

appliance any longer (or decide to

substitute an older model), before

disposing of it, it is recommended that

it be made inoperative in an

appropriate manner in accordance to

health and environmental protection

regulations, ensuring in particular that

all potentially hazardous parts be

made harmless, especially in relation

to children who could play with

unused appliances.

● After use, ensure that the knobs are

in off position.

● Do not allow children or other

unqualified people to use the

appliance without your supervision.

● During and after use of the cooker,

certain parts will become very hot. Do

not touch hot parts.

● Keep children away from the cooker

when it is in use.

● Some appliances are supplied with a

protective film on steel and aluminium

parts. This film must be removed

before using the appliance.

● Fire risk! Do not store flammable

material in the oven and in the

dishwarmer compartment.

● Make sure that electrical cables

connecting other appliances in the

proximity of the cooker cannot come

into contact with the hob or become

entrapped in the oven door.

● Do not line the oven walls with

aluminium foil. Do not place baking

trays or the drip tray on the base of

the oven chamber.

● The manufacturer declines all liability

for injury to persons or damage to

property caused by incorrect or

improper use of the appliance.

● The various components of the

appliance are recyclable. Dispose of

them in accordance with the

regulations in force in your country. If

the appliance is to be scrapped,

remove the power cord.

Page 4

4

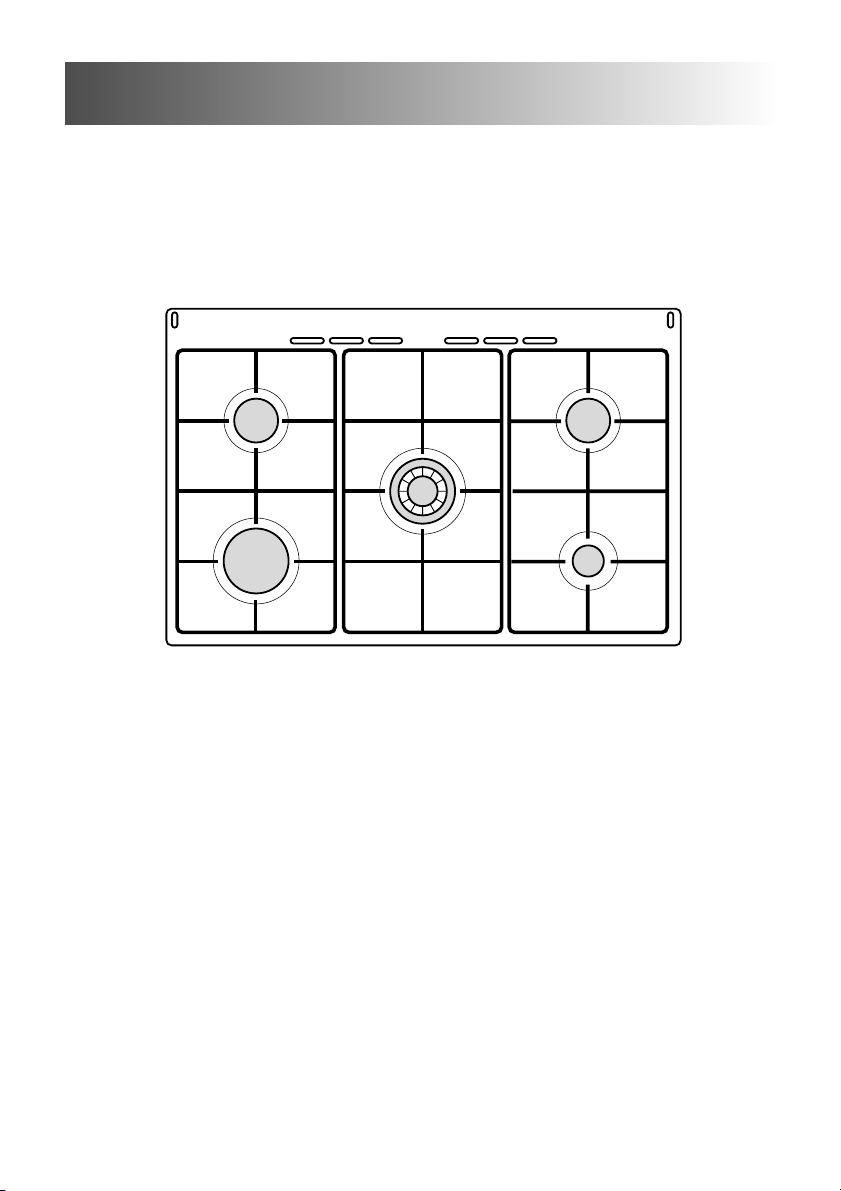

1 - COOKING HOB

1 - COOKING HOB

1. Auxiliary burner (A) - 1,00 kW

2. Semi-rapid burner (SR) - 1,90 kW

3. Rapid burner (R1) - 3,15 kW

4. Double- ring burner (PB) - 3,45 kW

Fig. 1.1

2

4

2

1

3

TECHNICAL FEATURES

– Gas cooker

Category II 2H3+

Class 1

– Glass lid

Page 5

5

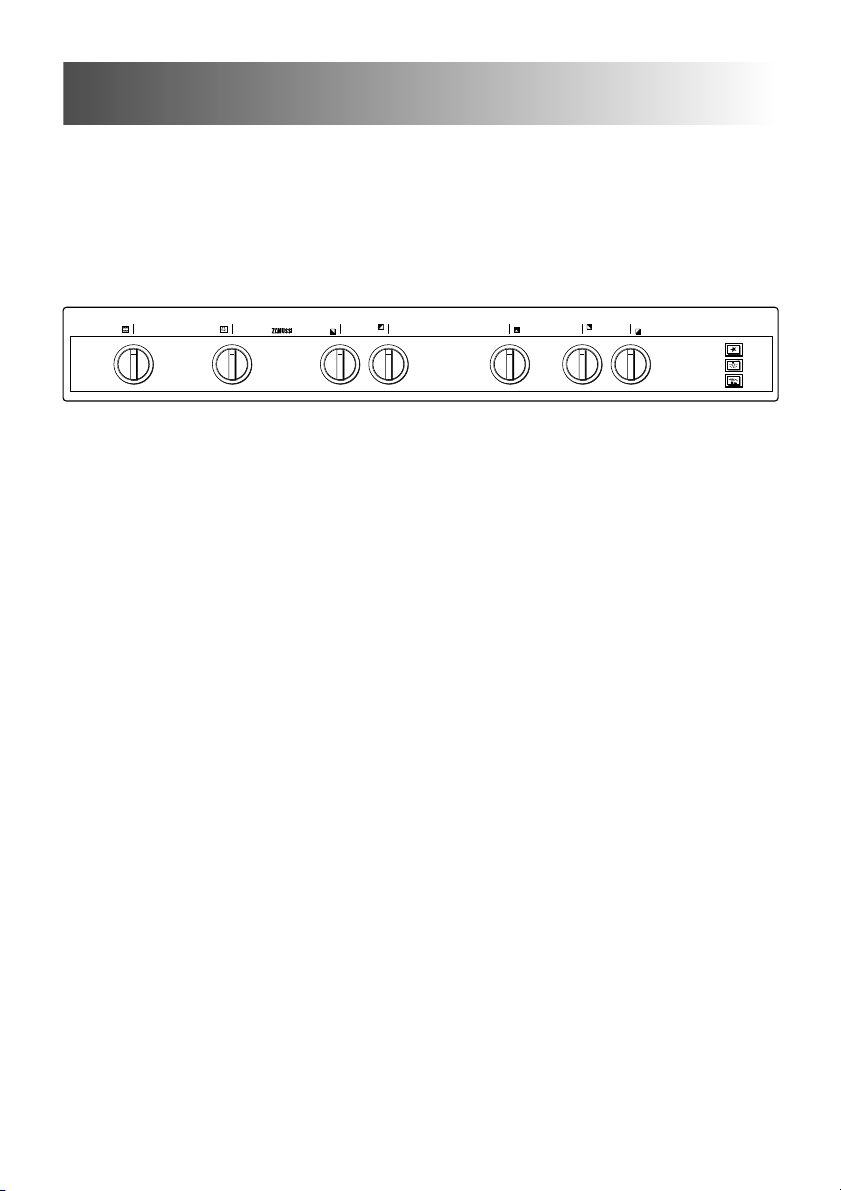

Pushbuttons:

8. Rotisserie switch

9. Oven light switch

10. Electric ignition pushbutton (cooktop burners only)

2 - CONTROL PANEL

1. Front right burner control knob

2. Rear right burner control knob

3. Central double-ring burner control knob

4. Rear left burner control knob

5. Front left burner control knob

6. 60’ timer knob

7. Gas oven/gas grill thermostat control knob

2 - CONTROL PANEL

1

10

9

8

23

45

6

7

Fig. 2.1

Z 9060 W

1

0

1

0

Page 6

6

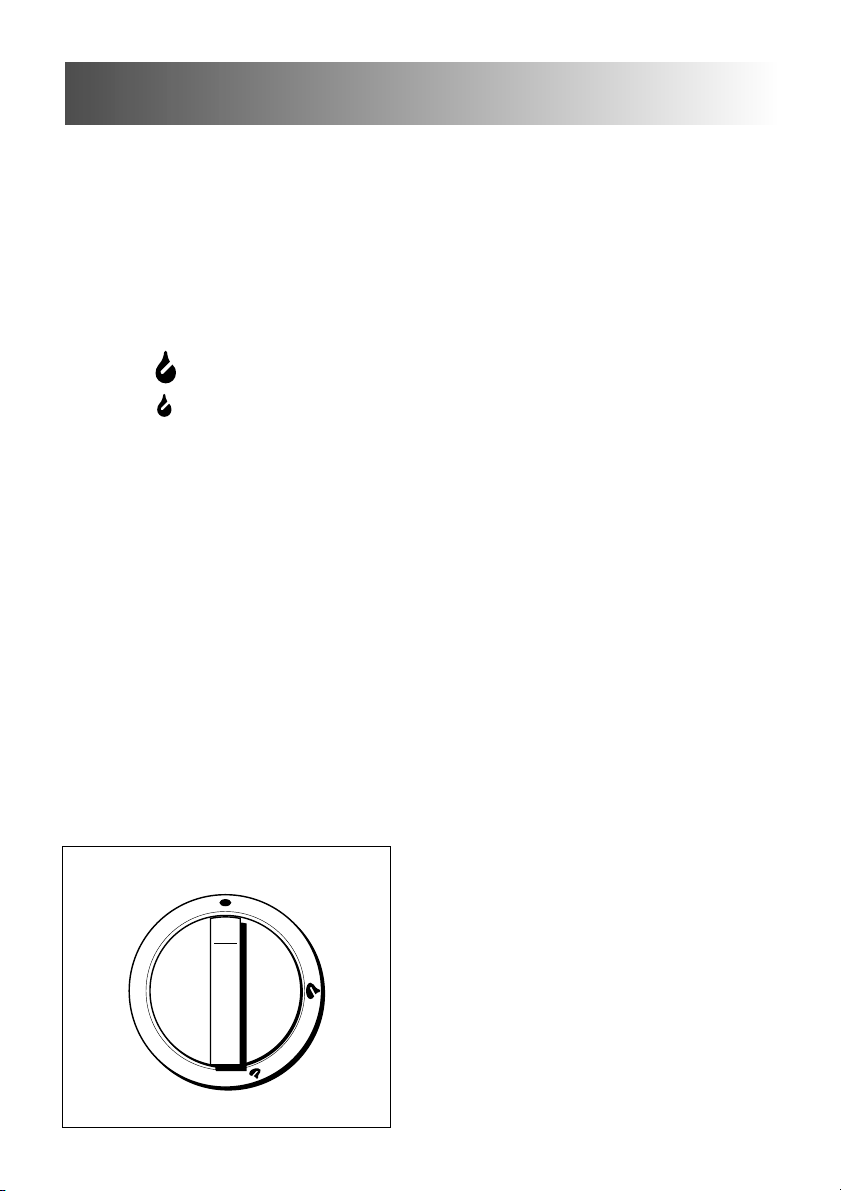

3 - USE OF COOKING HOB

Fig. 3.1

GAS BURNERS

Each burner is controlled by a gas tap

assuring the opening and the closing of

the gas supply.

Make the symbols printed on the knob to

match with the indicator on the control

panel to obtain:

– symbol

● : off

– symbol : full on (nominal rate)

– symbol : reduced rate

To light one of the gas burners, hold a

flame (i.e. a match) close to the top part

of the burner, push in and turn the relative knob in an anti-clockwise direction,

pointing the large flame symbol (i.e.

max. gas flow) towards the indicator on

the control panel.

To reduce the gas flow to minimum,

rotate the knob further anti-clockwise to

point the small flame symbol towards

the control panel indicator.

The maximum aperture position permits

rapid boiling of liquids, whereas the

minimum aperture position allows slower

warming of food or maintaining boiling

conditions of liquids.

Other intermediate operating adjustments can be achieved by positioning

the indicator between the maximum and

minimum aperture positions, and never

between the maximum aperture and

closed positions.

Page 7

7

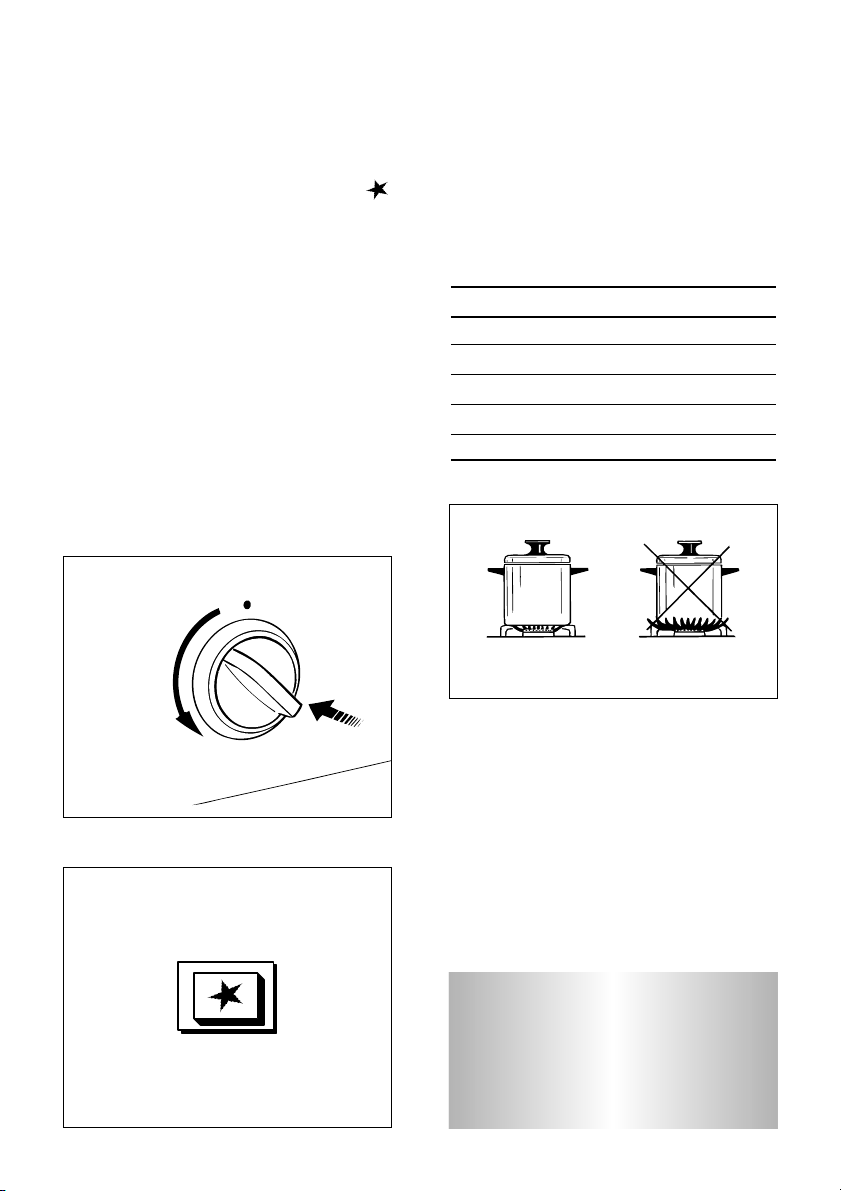

CHOICE OF THE BURNER

On the control panel, near every knob,

there is a diagram that indicates which

burner is controlled by that knob.

The suitable burner must be chosen

according to the diameter and the

capacity used.

As an indication, the burners and the

pots must be used in the following way:

It is important that the diameter of the

pot be suitable to the potentiality of the

burner so as not to compromise the high

output of the burners and therefore

energy waste.

A small pot on a large burner does not

give you a boiling point in a shorten

amount of time since the capacity of

heat absorption of a liquid mass

depends on the volume and the surface

of the pot.

Fig. 3.4

N.B. When the cooker top is not

being used, set the gas knobs

to their closed positions and

also close the cock valve on

the gas bottle or the main gas

supply line.

BURNERS POT DIAMETER

Auxiliary 12 - 16 cm

Semi-rapid 16 - 22 cm

Rapid 20 - 24 cm

Double-ring up to 30 cm

do not use pans with concave or convex bases

Fig. 3.2

ELECTRIC SPARK IGNITION

To light the burner you have to rotate

the knob corresponding to the specific

burner to the maximum flame position

(large flame symbol) and press the ignition button marked by the symbol

(fig. 3.3).

The sparks produced by the electrodes

situated next to the burner will light the

selected burner.

If conditions of the local gas supply

makes it difficult to light the gas burner

with the knob set to the high flame

position, rotate the knob to the lower

flame position and repeat the ignition.

If the burner flame should go out

accidentally wait for at last 1 minute

before re-light the burner.

Fig. 3.3

Page 8

8

GENERAL FEATURES

The oven is furnished completely clean;

it is advisable, however, upon first use,

to turn the oven on to the maximum temperature (position 10) to eliminate possible traces of grease from the oven burner. The same operation should be followed for grill burner.

The gas oven is provided with two burners:

a) Oven burner, mounted on the lower

part of the oven (wattage: 6,20 kW)

b) Grill burner, mounted on the upper

part of the oven (wattage: 4,65 kW).

OVEN BURNER

It carries out normal “oven cooking”.

The gas flow to the burner is regulated

by a thermostat which allow to maintain

the oven temperature constant.

The control of the temperature is assured by a thermostatic probe positioned

inside the oven.

The probe must be always kept in its

housing, in a clean condition, as an

incorrect position or encrustment may

cause an alteration in the control of the

temperature.

4 - GAS OVEN

The glass on the oven door reaches high temperatures during

operation.

Keep children away.

The cooker lid must be kept

open when the gas oven is in

use.

IGNITION OF THE OVEN BURNER

1

– Open the oven door to the full

extent.

WARNING: Risk of explosion!

The

oven door must be open during this

operation.

2

– Light the oven burner by applying a

flame to the hole ‘A’, as shown in fig.

4.2.

ATTENTION: Never turn the thermostat before approaching a flame to

the hole “A” of the floor of the oven.

3 – Press in the oven control knob (fig.

4.1) and turn counter-clockwise to

position 10. Keep the knob pressed.

Never continue this operation for

more than 15 seconds. If the burner has still not ignited, wait for

about 1 minute prior to repeating

the ignition.

4 – After lighting the burner, wait a few

seconds before releasing the knob

(until the safety valve stays open).

5 – Gently close the oven door and set

the oven control knob to the required

temperature.

If the flame extinguishes for any reason,

the safety valve will automatically shut

off the gas supply to the burner.

To re-light the burner, first turn the oven

control knob to position ●, wait for at

least 1 minute and then repeat the

lighting procedure.

Page 9

9

1

Fig. 4.3

Table 4.4

Fig. 4.2

A

For efficient oven preheating, we

recommend that grill trays and

racks are removed from the oven

and replaced after about 15 minutes.

THERMOSTAT GRADE TABLE

Thermostat Oven

indicator temperature

1 150 °C

2 165 °C

3 180 °C

4 195 °C

5 210 °C

6 225 °C

7 240 °C

8 255 °C

9 270 °C

10 285 °C

Fig. 4.1

THERMOSTAT

The numbers 1 to 10 printed on the

knob (fig. 4.3) indicate the increasing

oven temperature value (see table 4.4).

To regulate the temperature, set the

chosen number onto the control panel

indicator (or onto the knob indicator).

2

3

4

10

9

8

5

6

7

Page 10

10

OVEN COOKING

Before introducing the food, preheat the

oven to the desired temperature.

For a correct preheating operation, it is

advisable to remove the tray from the

oven and introduce it together with the

food, when the oven has reached the

desired temperature.

Check the cooking time and turn off the

oven 5 minutes before the theoretical

time to recuperate the stored heat.

COOKING EXAMPLES

Temperatures and times are approximate as they vary depending on the quality

and amount of food.

Remember to use ovenproof dishes and

to adjust the oven temperature during

cooking if necessary.

DISHES TEMPERATURE

Lasagne 190°

Baked pasta 190°

Pizza 220°

Creole rice 190°

Baked onions 190°

Spinach crêpes 185°

Potatoes baked in milk 185°

Stuffed tomatoes 180°

Cheese soufflé 170°

Roast veal 180°

Grilled veal chops 210°

Chicken breasts with tomato 180°

Grilled chicken - roast chicken 190°

Veal loaf 175°

Roast beef 170°

Fillet of sole 175°

Aromatic hake 170°

Beignets 160°

Ring cake 150°

Plum tart 170°

Jam tartlets 160°

Sponge cake 170°

Sweet dough 160°

Sweet puffs 170°

Plain sponge cake 170°

Page 11

11

Fig. 4.5

Fig. 4.6

IGNITION OF THE GRILL BURNER

1 – Open the oven door to the full

extent.

WARNING: Risk of explosion!

The

oven door must be open during

this operation.

2 – Light the grill by applying a flame to

pipe of the grill burner (fig. 4.6).

ATTENTION: Never turn the thermostat before approaching a

flame to pipe of the grill burner.

3 – Press in the oven control knob (fig.

4.5) and turn clockwise to the position marked by the symbol .

Keep the knob pressed.

Never continue this operation for

more than 15 seconds. If the

burner has still not ignited, wait

for about 1 minute prior to repeating the ignition.

4 – After lighting the burner, wait a few

seconds before releasing the knob

(until the safety valve stays open).

Do not close completely the oven

door. The grill must always be used

with the oven door slightly open

(Fig. 4.7).

The oven door must always be kept

half-open when the grill is in operation. See specific instructions in the sec-

tion ‘USE OF THE GRILL’.

If the flame extinguishes for any reason,

the safety valve will automatically shut

off the gas supply to the burner.

To re-light the burner, first turn the oven

control knob to position ●, wait for at

least 1 minute and then repeat the

lighting procedure.

Attention: the oven door becomes

very hot during operation.

Keep children away.

It is recommended that you do not

grill for longer than 30 minutes at any

one time.

Page 12

12

Fig. 4.7

A

USE OF THE GRILL

Very important: the grill must always

be used with the oven door ajar

(Fig. 4.7).

Mount shield “A” which serves to protect the control panel from the heat.

Turn on the grill, as explained in the preceding paragraphs and let the oven

preheat for about 5 minutes with the

door ajar.

Introduce the food to be cooked, positioning the rack as close to the grill as possible.

The dripping pan should be placed

under the rack to catch the cooking

juices and fats.

Attention: the oven door becomes very hot during operation.

Keep children away.

ROTISSERIE (Fig. 4.8)

This is used for spit roasting under the

grill and comprises:

– an electric motor fitted to the rear of

the oven

– a stainless steel skewer provided with

slide-out heatless handgrip and two

sets of adjustable forks

– a skewer support to be fitted in the

middle runner.

This spit roaster is operated by the

switch indicated by the symbol on

the control panel (fig. 4.9).

0

1

0

1

USE OF THE ROTISSERIE

Very important: the rotisserie must

always be used with the oven door

ajar and with shield “A” mounted

(Fig. 4.7).

– Insert the tray into the lowest rack

holders of the oven and insert the rod

support into the intermediate rack

holders.

– Put the meat to be cooked onto the

rod, being careful to secure it in the

center with the special forks.

– Insert the rod into the side gear

opening “P”

– Remove the grip “H” by turning it to

the left

– Insert completely the rotisserie

support; the shaft “S” must be inserted

in the spit motor collar “G”

It is recommended that you do not

grill for longer than 30 minutes at any

one time.

Page 13

13

OVEN LIGHT

The cooker is equipped with a light that

illuminates the oven to enable visually

controlling the food that is cooking.

This light is controlled by a switch on the

control panel (fig. 4.10).

Fig. 4.10

Fig. 4.9

Fig. 4.8

G

S

H

P

1

0

1

0

Page 14

14

GENERAL ADVICE

– When the appliance is not being used,

it is advisable to keep the gas tap

closed.

– Every now and then check to make

sure that the flexible tube that

connects the gas line or the gas

cylinder to the appliance is in perfect

condition and eventually substitute it if

it shows signs of wearing or damage.

– The periodical lubrication of the gas

taps must be done only by specialized

personnel.

– If a gas tap jams, do not try to force

it. Seek technical assistance.

– Important:

Before any operation of cleaning

and maintenance disconnect the

appliance from the electrical

network.

Fig. 5.1

5 - MINUTE COUNTER

MINUTE COUNTER (Fig. 5.1)

The minute counter is a timed acoustic

warning device which can be set for a

maximum of 60 minutes.

The knob (Fig. 5.1) must be rotated

clockwise as far as the 60 minute position and then set to the required time by

rotating it anticlockwise.

Do not use a steam cleaner

because the moisture can get into

the appliance thus make it unsafe.

50

10

40

20

30

Page 15

15

Fig. 6.1

S

D

R

GLASS LID

For cleaning purposes, the lid can be

easily removed upwards once taken to

the upright position.

Should the hinges slip off, replace them

in their housing being careful that:

– The right housing must receive the

hinge marked “D” while the left housing must receive the hinge marked “S”

(Fig. 6.1)

6 - CLEANING AND MAINTENANCE

REGULATING OF THE BALANCE

Lower the lid and check the correct balance. While opened at 45° it should

hang up.

The springs of the hinges can be adjusted if necessary by turning the screws

“R” clockwise (fig. 6.1).

Do not close the cooker lid when

the burners are still hot and

when the oven is on or still hot.

Do not rest hot pans or heavy

objects on the cooker lid.

Remove any spillages from the

surface of the cooker lid before

opening.

Page 16

16

CLEANING

All the enamelled parts must be cleaned

with a sponge and soapy water or other

non-abrasive products.

Dry preferably with a soft cloth.

Acidic substances like lemon juice,

tomato sauce, vinegar etc. can damage

the enamel if left too long.

STAINLESS STEEL, ALUMINIUM

PARTS AND SILK-SCREEN PRINTED

SURFACES

Clean using an appropriate product.

Always dry thoroughly.

IMPORTANT: these parts must be cleaned very carefully to avoid scratching

and abrasion. You are advised to use a

soft cloth and neutral soap.

CAUTION: Do not use abrasive substances or non-neutral detergents as

these will irreparably damage the protective surface.

REPLACING THE OVEN LIGHT BULB

Switch the cooker off at the mains.

Unscrew and replace the bulb with

another one resistant to high temperatures (300°C), voltage 230 V (50 Hz), 15

W, E14.

INSIDE OF OVEN

This must be cleaned every time it is

used.

Remove and refit the side runner frames

as described on the next chapter.

With the oven warm, wipe the inside

walls with a cloth soaked in very hot

soapy water or another suitable product.

The bottom of the oven, side runner frames, tray and rack can be removed and

washed in the sink.

BURNERS

They can be removed and washed with

soapy water only.

They will remain always perfect if cleaned

with products used for silverware.

After cleaning or wash, check that burnercaps and burner-heads are dry before placing them in the respective housings.

Special attention has to be paid in

order not to exchange the housing of

the two small burners shown in fig. 6.2.

It is absolutely necessary to check the

perfect housing of the burner-ring as an

incorrect housing may cause serious

inconvenience.

Check also that the electrodes for ignition be always clean in order to ensure a

regular spark shooting.

Burner-cap ring

partially drilled

Burner-cap ring

fully drilled

Fig.

6.2

Page 17

17

STORAGE COMPARTMENT

The storage compartment is accessible

through the pivoting panel (fig. 6.4).

Fig. 6.4

Fig. 6.3

OVEN DOOR

The internal glass panel can be easily

removed for cleaning by unscrewing the

4 retaining screws (Fig. 6.3)

Do not store flammable material in

the oven or in the storage

compartment.

Page 18

18

The oven door can easily be removed as

follows:

– Open the door to the full extent (fig.

6.5A).

– Attach the retaining rings to the hooks

on the left and right hinges (fig. 6.5B).

– Hold the door as shown in fig. 6.5.

– Gently close the door and withdraw the

lower hinge pins from their location

(fig. 6.5C).

– Withdraw the upper hinge pins from

their location (fig. 6.5D).

– Rest the door on a soft surface.

– To replace the door, repeat the above

steps in reverse order.

Fig. 6.5

Fig. 6.5D

Fig. 6.5C

Fig. 6.5B

Fig. 6.5A

REMOVING THE OVEN DOOR

Page 19

19

ASSEMBLY AND DISMANTLING OF

THE SIDE RUNNER FRAMES

– Fit the side runner frames into the

holes on the side walls inside the

oven (Fig. 6.6).

– Slide the tray and rack into the run-

ners as shown in Fig. 6.7.

– To dismantle, operate in reverse

order.

OVEN FLOOR

The oven floor “F” (fig. 6.8) can be easily

removed to facilitate cleaning.

Remember to replace the floor correctly

afterwards.

Be careful not to confuse the tray “L”

with the oven floor “F”.

Fig. 6.6

Fig. 6.8

L

F

Fig. 6.7

Page 20

20

IMPORTANT

– Cooker installation, regulation and conversion to other gas types must only be carried

out by QUALIFIED TECHNICIANS and in compliance with the local safety stan-

dards. Failure to observe this rule will invalidate the warranty.

– The electrical mains outlet, if located behind the cooker, must not be higher than 18 cm

above the floor level.

– The surfaces of adjacent furniture and walls must be capable of withstanding tempera-

tures in excess of 75˚C.

– Some appliances are supplied with a protective film on steel and aluminium parts.

This film must be removed before using the cooker.

Advice for

the

installer

Page 21

21

Fig. 7.1

500 mm

300 mm

20 mm

20 mm

800 mm

500 mm

INSTALLATION

The cooker afford class ‘1’ protection against overheating surrounding surfaces.

A space of at least 2 cm must be left between the cooker and any adjacent furniture,

which must not exceed the height of the cooktop (fig. 7.1).

The surfaces of adjacent furniture must be capable of withstanding temperatures

up to 75˚C.

7 - INSTALLATION

Page 22

22

Fig. 7.4

Fig. 7.2

FITTING THE ADJUSTABLE FEET

The adjustable feet must be fitted to

the base of the cooker before use.

Rest the rear of the cooker on a

piece of the polystyrene packaging

exposing the base for the fitting of

the feet.

Fit the 4 legs by screwing them tight

into the support base as shown in

picture 7.3.

WARNING

When raising cooker to upright position always ensure two people carry

out this manoeuvre to prevent damage to the adjustable feet (fig. 7.4).

Fig. 7.3

Page 23

23

Fig. 7.5

Fig. 7.6

Fig. 7.7

WARNING

Be carefull: DO NOT LIFT

the cooker by

the door handle when raising to the

upright position (fig. 7.5).

LEVELLING THE COOKER

The cooker may be levelled by screwing

the lower ends of the feet IN or OUT (fig.

7.7)

WARNING

When moving cooker to its final position

DO

NOT DRAG (fig. 7.6).

Lift feet clear of floor (fig. 7.4).

Page 24

24

CHOOSING SUITABLE

SURROUNDINGS

In the room chosen to accommodate the

gas appliance, there must be an adequate natural draft to allow combustion of

the gas.

The natural draft must be produced

directly by one or more vents made in

the external walls and providing a total

opening of at least 100 cm

2

.

If the appliance does not have a noflame safety device this opening must

have an area of at least 200 cm

2

.

The vents must be positioned close to

the floor, preferably on the opposite side

to the combustion discharge outlet and

must be designed in such a way that

they cannot be obstructed either from the

inside or the outside.

When it is not possible to provide the

necessary vents, the draft may be supplied from an adjacent room, ventilated in

the required manner, provided it is not a

bedroom or an area at risk.

In this event, the door of the kitchen must

be opened to allow the draft to enter the

room.

DISCHARGING PRODUCTS OF

COMBUSTION

Extractor hoods connected directly to the

outside must be provided, to allow the

products of combustion of the gas appliance to be discharged (fig. 7.8).

If this is not possible, an electric fan may

be used, attached to the external wall or

the window; the fan should have a

capacity to circulate air at an hourly rate

of 3-5 times the total volume of the

kitchen (fig. 7.9).

The fan can only be installed if the room

has suitable vents to allow air to enter,

as described under the heading

“Choosing suitable surroundings”.

Fig. 7.8

Fig. 7.9

Air vent

Air vent

Extractor hood

for products of

combustion

Electric fan to

extract products

of combustion

H min 650 mm

Page 25

25

Plug

Fig 8.1

The walls adjacent to the cooker

must be of material resistant to

heat.

INSTALLATION

The connection must be executed by a

qualified technician according to the

relevant standards.

The appliance is predisposed and

adjusted to operate with the gas

indicated on the specifications plate

applied onto the appliance.

GASES

The gases used for the operation of

cooking appliances may be grouped by

their characteristics into two types:

– G20

– G30 / G31

If the appliance must be operated with a

gas different than that indicated on the

plate, it is necessary to execute the

following operations:

– Gas connection

– Replacement of the top injectors

– Regulating of the primary air of the

top burners

– Adjustment of the minimum of the

top burners

– Replacement of the injector of oven

burner

– Replacement of the injector of grill

burner

– Primary air of oven burner

– Primary air of grill burner

– Adjustment of the oven burner

minimum

8 - GAS SECTION

Page 26

26

These operations must be carefully fulfilled as follows.

GAS CONNECTION

– Connect the cooker to the gas mains

utilizing rigid or flexible pipes.

– The connection must be executed to

the rear of appliance (left or right) (fig.

8.1); the pipe do not cross the cooker.

– The unused end inlet pipe of the cook-

er (left or right) must be closed with the

plug interposing the gasket.

Natural gas G20

– Fit up the holder “C” interposing gasket

“D”.

– Connect the cooker to the gas net by a

suitable rubber tube (inside diameter

15 mm).

M

ake sure the tube is snugly fit at both

ends and use a standard tube clamp (not

supplied) to fasten it.

L.P.G. G30 / G31

– Fit up the holder “B” interposing gasket

“D”.

– Connect the cooker to the cylinder

pressure regulator by a suitable rubber

tube (inside diameter 6 mm).

M

ake sure the tube is snugly fit at both

ends and use a standard tube clamp (not

supplied) to fasten it.

The rubber tube:

- must be as short as possible, without contractions or kinks;

- must be easy to inspect along its

entire length to check its wear;

- must never be at any point in its

length in contact with the “hot” parts

of the cooker.

Gas connection for:

Cat: II 2H3+

The fitting (fig. 8.2) is made up of:

– 1 adapter “C” for G20

– 1 adapter “B” for G30/G31

– gasket “D”

D

B C

Fig. 8.2

Fig. 8.3

Page 27

27

B

D

B

A

E

E

Fig. 8.4a

C

C

B

B

B

B

Fig. 8.4b

IMPORTANT:

To replace the adapters it is necessary

to operate with 2 spanners (fig. 8.3).

After connecting to the mains, check

that the couplings are correctly sealed, using soapy solution, but never a

naked flame.

From time to time check to make sure

that the rubber tube is in perfect condition and substitute it at printed due

date or if it shows signs of wearing or

damage.

D

REPLACEMENT OF THE TOP

INJECTORS

To replace the injectors, raise the cooktop in the following manner:

– Pull the lid “A” upwards to remove

from the cooker.

– Remove the pan supports and burners

from the cooktop.

– Remove the 4 screws “B” and the cen-

tral screw “C” (fig. 8.4a - fig. 8.4b).

– Remove the two hinge brackets “D” by

pulling them upwards.

– Raise the cooktop in the direction

shown by the arrow “E”.

– Prop the cooktop up.

Page 28

28

AIR VENT NECESSARY FOR GAS COMBUSTION = (2 m

3

/h x kW)

BURNERS

Air vent necessary [m3]

Auxiliary (A) 2,00

Semirapid (SR)

3,80

Rapid 6,30

Double-ring 6,90

Oven 12,40

Grill 9,30

TABLE FOR THE CHOICE OF THE INJECTORS

Cat: II 2H3+

Auxiliary (A) 1,00 0,30 27 50 3

*

Semirapid (SR)

1,90 0,38 29 67 5,7

*

Rapid 3,15 0,60 39 86

Fully open

*

Double-ring 3,45 0,85 47 92

Fully open

*

Oven 6,20 1,30 58 120

8

*

Grill 4,65 – – 107

Fully open

*

Nominal

power

[kW]

Reduced

power

[kW]

Tube ring

opening [mm]

Ø injector

[1/100 mm]

By-pass

[1/100 mm]

G 30 / G 31

28-30/37 mbar

BURNERS

Auxiliary (A) 1,00 0,30 72 1

*

Semirapid (SR)

1,90 0,38 100 2

*

Rapid 3,15 0,60 130

5

*

Double-ring 3,45 0,85 135

5

*

Oven 6,20 1,30 180

1,5

*

Grill 4,65 – – 165

3

*

Nominal

power

[kW]

Reduced

power

[kW]

Tube ring

opening [mm]

Ø injector

[1/100 mm]

By-pass

[1/100 mm]

G 20

20 mbar

BURNERS

Adjusted

*

Reference value

Page 29

29

Fig. 8.5

M

J

A

ADJUSTMENT OF PRIMARY AIR OF

TOP BURNERS

By operating on the screw “M”, reset the

air adjuster “A” according to the instructions indicated on the table for the

choice of the injectors, where the distance between injector and air adjuster

is recommended (in mm).

Before lowering the cooktop, set the

burners on their sites and light them in

order to check whether the flames are

correct, as per the specifications given

in the next page. In case of uncorrect

flame, lift or lower the air adjuster.

Flame Flame Flame

faulty in correct with excess

primary air primary air

long, yellow clear short and sharp

and interior blue too blue interior

trembling cone cone tending to

detach

CAUSE

air regulating correct air regulating

tube, too distance of tube, too

closed the tube open

REPLACEMENT OF THE TOP

INJECTORS

(Fig. 8.5)

– Loose the screw “M” of each injector

and fully raise the adjusting air tube

“A”.

– By a polygonal 7 spanner, remove the

injector “J” from their housing and

replace it by the proper one according

to the kind of gas (see injectors table).

Fig. 8.6

ADJUSTMENT OF THE MINIMUN OF

THE TOP BURNERS

Considering that in the minimum position the flame must have a length of

about 4 mm and must remain lit even

with a brusque passage from the maximum position to that of minimum.

The flame adjustment is done in the following way:

– Turn on the burner

– Turn the tap to the MINIMUM position

– Take off the knob

– With a small flat screwdriver turn the

screw inside the tap rod to the correct

regulation (fig. 8.6).

Normally for G30/G31 gas, tighten up

the regulation screw.

D

Page 30

30

OVEN BURNER AND GRILL BURNER

REPLACEMENT OF INJECTORS

a) oven burner

– Lift and remove the lower panel inside

the oven.

– Unscrew and remove the burner

securing screw A (fig. 8.7).

– Slacken screw B (fig. 8.7).

– Withdraw the burner in the manner

shown in figure 8.8, and rest it inside

the oven. Take care not to damage

the wire to the safety valve probe.

– Using a 10 mm box spanner, unscrew

the injector (indicated by the arrow in

fig. 8.8) and replace with a new injec-

tor selected in accordance with the

“

TABLE FOR THE CHOICE OF THE

INJECTORS

”; then replace the burner

repeating the above steps in reverse

order.

A

B

Fig. 8.7

Fig. 8.8

Page 31

31

b) grill burner

– Unscrew and remove the burner

securing screw ‘C’ (fig. 8.9).

– Slacken screw ‘D’ (fig. 8.9).

– Move the burner in the manner shown

in figure 8.10.

Take care not to damage the wire to

the safety valve probe.

– Using a 10 mm box spanner, unscrew

the injector (indicated by the arrow in

fig. 8.10) and replace with a new injec-

tor selected in accordance with the

“

TABLE FOR THE CHOICE OF THE

INJECTORS

”; then replace the burner

repeating the above steps in reverse

order.

Fig. 8.10

Fig. 8.9

C

D

Page 32

32

Fig. 8.11

Fig. 8.12

Ring opening

(see ‘Injector Table)

REGULATION OF AIR SUPPLY TO

OVEN AND GRILL BURNERS

Using a cross-head screwdriver, slacken

the screw securing the air flow regulation collar (fig. 8.11 and 8.12) and move

the collar forward or backward to

increase or reduce the air aperture in

accordance with gas type and the indications in the “

TABLE FOR THE

CHOICE OF THE INJECTORS

”.

Light the burner and check the flame.

Page 33

33

Fig. 8.13

G

ADJUSTMENT OF THE OVEN

BURNER MINIMUM

This needs to be done only for the oven

burner (the grill is a fixed capacity) by

acting on the thermostat in the following

way:

– turn on the burner by setting the ther-

mostat knob on position 10

– unscrew the by-pass screw (fig. 8.13)

about three times by a flat screwdriver

– let the oven heat up for about 10 min-

utes, then bring the thermostat to position 1 (minimum) to operate the thermostat by-pass

– slowly screw the by-pass screws “G”

(fig. 8.13) until you obtain a flame of 34 mm in height.

N.B. For G30/G31 the by-pass screw

must be fixed thoroughly.

LUBRICATION OF THE GAS TAPS

If the gas taps are not working correctly,

call the After-Sales Service.

Flame correct

Flame faulty in

primary air

Flame with excess

primary air

IMPORTANT

All interventioni regarding installation maintenance and conversion of the appliance must be

fulfilled with original factory

parts.

The manufacturer declines any

liability resulting from the noncompliance of this obligation.

Page 34

34

N.B. For connection to the mains, do

not use adapters, reducers or branching devices as they can cause

overheating and burning.

If the installation requires alterations to

the domestic electrical system or if the

socket and appliance plug are incompatible, call an expert.

He should also check that the socket

cable section is suitable for the power

absorbed by the appliance.

IMPORTANT: The cooker must be

installed in accordance with the

manufacturer’s instructions.

Incorrect installation, for which the

manufacturer accepts no responsibility, may cause damage to persons, animals and things.

GENERAL

– Connection to the mains must be car-

ried out by qualified personnel in

accordance with current regulations.

– The appliance must be connected to

the mains checking that the voltage

corresponds to the value given in the

rating plate and that the electrical

cable sections can withstand the load

specified on the plate.

– The cooker is supplied without a

power supply plug and therefore if

you are not connecting directly to the

mains, a standardized plug suitable

for the load must be fitted.

– The plug must be connected to an

earthed socket in compliance with

safety standards.

– The appliance can be connected

directly to the mains placing an omnipolar switch with minimum opening

between the contacts of 3 mm

between the appliance and the mains.

– The power supply cable must not

touch the hot parts and must be positioned so that it does not exceed 75°C

at any point.

– Once the appliance has been instal-

led, the switch or socket must always

be accessible.

The connection of the appliance

to earth is mandatory.

The manufacturer declines all

responsability for any inconvenience resulting from the inobservance of this condition.

9 - ELECTRICAL SECTION

Page 35

35

FEEDER CABLE SECTION TYPE

HO5RR-F

230 V 3 x 0,75 mm

2

Fig. 9.2

ELECTRICAL FEEDER CABLE

CONNECTION

To connect the supply cable:

- Remove the screws securing the

cover “A” on the rear of the cooker

(fig. 9.1).

- Feed the supply cable through the

cable clamp “D”. The supply cable

must be of a suitable size for the current requirements of the appliance;

see the section “Feeder cable section” (fig. 9.1).

- Connect the wires to the terminal

block “B” as shown in the diagram in

figure 9.2; or connect the phase wires

to the terminal block “B” and the earth

wire to the terminal PE (fig. 9.1) as

shown in figure 9.2.

- Take up any slack in the cable and

secure with the cable clamp “D”.

- Replace the cover “A”.

Fig. 9.1

D

B

PE

A

Switches igniter and electrodes can be

replaced after lifting the cooktop, following the instructions shown in the chapter

‘REPLACEMENT OF THE TOP INJECTORS”

REMPLACEMENT OF ELECTRICAL

COMPONENTS SITUATED UNDER

THE COOKTOP

Before effecting any intervention on

the electrical parts of the appliance,

the connection to the network must

be interrupted.

230 V

L

PEN

1

(L2)

Page 36

The manufacturer cannot be held responsible for possible inaccuracies due to printing or

transcription errors in the present booklet.

The manufacturer reserves the right to make all modifications to its products deemed

necessary for manufacture or commercial reasons at any moment and without prior notice, without jeopardising the essential functional and safety characteristics of the appliances.

Cod. 1101939

ß2

Loading...

Loading...