Page 1

OPERATING MANUAL

4010-3W

IDS WA

ba76194e03 07/2018

MultiLab 4010-3W

DIGITAL METER FOR (WIRELESS) IDS SENSORS

Page 2

MultiLab 4010-3W

For the most recent version of the manual, please visit

www.ysi.com

.

Contact YSI

1725 Brannum Lane

Yellow Springs, OH 45387 USA

Tel: +1 937-767-7241

800-765-4974

Email: info@ysi.com

Internet: www.ysi.com

Copyright © 2018 Xylem Inc.

2 ba76194e03 07/2018

Page 3

MultiLab 4010-3W Contents

Contents

1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 MultiLab 4010-3W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.1 IDS sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.2 Wireless operation of IDS sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.3 IDS adapter for analog sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.4 Automatic sensor recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1.1 Safety information in the operating manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1.2 Safety signs on the meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1.3 Further documents providing safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Safe operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.1 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.2 Requirements for safe operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.3 Unauthorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.1 Connecting the power pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 General operating principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1.1 Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1.3 Status information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1.4 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1.5 Channel display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.6 Sensor info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.7 Display of several sensors in the measuring mode . . . . . . . . . . . . . . . . . . . . . . . 18

4.2 Switching on the meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 Switching off the meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4 Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4.1 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4.2 Measured value display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4.3 Menus and dialogs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.4.4 Navigation example 1:Setting the language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4.5 Example 2 on navigation: Setting the date and time. . . . . . . . . . . . . . . . . . . . . . . . . 23

ba76194e03 07/2018 3

Page 4

Contents MultiLab 4010-3W

5 pH value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1.1 Measuring the pH value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1.2 Measuring the temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2 pH calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2.1 Why calibrate?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2.2 When do you have to calibrate? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2.3 Calibration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2.4 Carrying out automatic calibration (AutoCal) . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2.5 Carrying out a manual calibration (ConCal). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2.6 Calibration points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.2.7 Calibration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2.8 Continuous measurement control (CMC function) . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2.9 QSC function (sensor quality control) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6 ORP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.1 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.1.1 Measuring the ORP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.1.2 Measuring the relative ORP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.1.3 Measuring the temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.2 ORP calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7 Ion concentration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.1 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.1.1 Measuring the ion concentration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.1.2 Measuring the temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.2 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.2.1 Why calibrate?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.2.2 When to calibrate?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.2.3 Calibration (ISE Cal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.2.4 Calibration standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.2.5 Calibration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.3 Selecting the measuring method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.3.1 Standard addition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.3.2 Standard subtraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.3.3 Sample addition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.3.4 Sample subtraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.3.5 Standard addition with blank value correction (Blank value addition) . . . . . . . . . . 66

8 Dissolved oxygen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.1 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.1.1 Measuring D.O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.1.2 Measuring the temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.2 FDO Check (checking the FDO 4410) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.2.1 Why should you check the sensor?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.2.2 When should you check the sensor?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.2.3 Perform a FDO Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.2.4 Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

8.3 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8.3.1 Why calibrate?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8.3.2 When to calibrate?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4 ba76194e03 07/2018

Page 5

MultiLab 4010-3W Contents

8.3.3 Calibration procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8.3.4 Calibration in water vapor-saturated air. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8.3.5 Calibrating with Comparison meas. (e.g. Winkler titration) . . . . . . . . . . . . . . . . . . . . 74

8.3.6 Zero Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8.3.7 Calibration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.4 Measuring with methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.4.1 General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.4.2 Selecting and starting the measuring method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.4.3 Editing the setting for the measuring method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.4.4 OUR (Oxygen Uptake Rate) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.4.5 SOUR (Specific Oxygen Uptake Rate) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.4.6 Measurement data storage for OUR/SOUR measurements . . . . . . . . . . . . . . . . . . . 87

9 Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

9.1 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

9.1.1 Measuring the conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

9.1.2 Measuring the temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.2 Temperature compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.3 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.3.1 Why calibrate?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.3.2 When to calibrate?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.3.3 Calibration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.3.4 Determining the cell constant (calibration in the check- and calibration standard) . . 93

9.3.5 Setting the cell constant

(calibration with freely selectable check- and calibration standard). . . . . . . . . . . . 94

9.3.6 Calibration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

10 Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10.1 pH measurement settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10.1.1 Settings for pH measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10.1.2 Buffer sets for calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

10.1.3 Calibration interval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.2 ORP measurement settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.3 ISE measurement settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.4 D.O. measurement settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

10.4.1 Settings for D.O. measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

10.4.2 Enter Sensor cap coefficients (ProOBOD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

10.4.3 DO % Saturation local . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

10.5 Cond measurement settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

10.5.1 Settings for IDS conductivity sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

10.6 Sensor-independent settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

10.6.1 System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

10.6.2 Data storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

10.6.3 Automatic Stability control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

10.7 Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

10.7.1 Resetting the measurement settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

10.7.2 Resetting the system settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

11 Data storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

11.1 Manual storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

11.2 Automatic data storage at intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

11.3 Measurement data storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

ba76194e03 07/2018 5

Page 6

Contents MultiLab 4010-3W

11.3.1 Managing the measurement data storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

11.3.2 Erasing the measurement data storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

11.3.3 Measurement dataset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

11.3.4 Storage locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

12 Transmitting data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

12.1 Saving data to a USB memory device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

12.2 Transmitting data to a USB printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

12.3 Transmitting data to a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

12.4 MultiLab Importer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

12.5 BOD Analyst Pro. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

13 Maintenance, cleaning, disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

13.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

13.1.1 General maintenance activities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

13.1.2 Exchanging the battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

13.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

13.3 Packing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

13.4 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

14 What to do if.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

14.1 pH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

14.2 ISE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

14.3 Dissolved oxygen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

14.4 Conductivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

14.5 General topics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

15 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

15.1 Measuring ranges, resolution, accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

15.2 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

16 Firmware update. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

16.1 Firmware update for the meter MultiLab 4010-3W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

16.2 Firmware-Update for IDS Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

17 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

18 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

19 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

19.1 Oxygen solubility table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

19.2 Calibration values for different barometric pressures and heights . . . . . . . . . . . . . . . . . . 149

19.3 Calculate the TDS Multiplier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

20 Contact Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

20.1 Ordering & Technical Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

20.2 Service Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

6 ba76194e03 07/2018

Page 7

MultiLab 4010-3W Overview

1

2

3

4010-3W

1 Overview

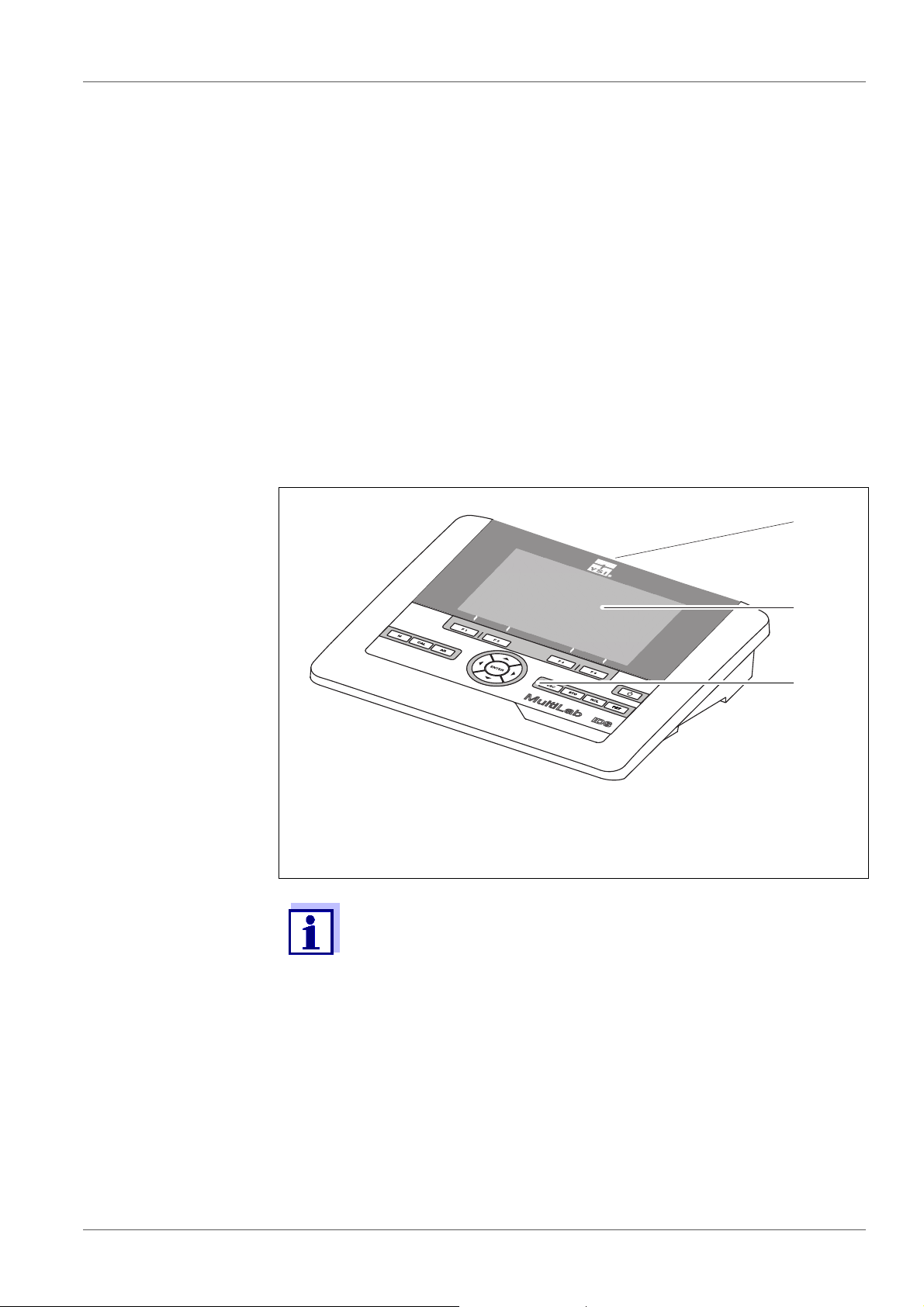

1.1 MultiLab 4010-3W

The MultiLab 4010-3W meter enables you to perform measurements (pH, U,

ISE, conductivity, and dissolved oxygen) quickly and reliably.

The MultiLab 4010-3W provides the maximum degree of operating comfort,

reliability and measuring certainty for all applications.

The MultiLab 4010-3W supports you in your work with the following functions:

proven calibration procedures

automatic stability control (AR)

automatic sensor recognition

CMC (continuous measurement control)

QSC (sensor quality control).

1 Keypad (antibacterial)

2 Display

3 Connectors

Due to its antibacterial properties, the keypad of the

MultiLab 4010-3W is especially suitable for applications in an environment where hygiene is important (see

DATA, page 135).

1.2 Sensors

SECTION 15.2 GENERAL

1.2.1 IDS sensors

IDS sensors

support the automatic sensor recognition

show only the settings relevant to the specific sensor in the setting menu

process signals in the sensor digitally so that precise and interference-free

ba76194e03 07/2018 7

Page 8

Overview MultiLab 4010-3W

measurements are enabled even with long cables

facilitate to assign a sensor to a measured parameter with differently colored

couplings

have quick-lock couplings with which to fix the sensors to the meter.

Sensor data from

IDS sensors

IDS sensors transmit the following sensor data to the meter:

SENSOR ID

– Sensor name

– Sensor serial number

Calibration data

Measurement settings

The calibration data are updated in the IDS sensor after e ach calibration procedure. A message is displayed while the data are being updated in the sensor.

In the measured value display, you can display the sensor name

and serial number of the selected sensor with the [

i

] softkey. You

can then display further sensor data stored in the sensor with the

[More] softkey (see section 4.1.6 S

ENSOR INFO, page 17).

1.2.2 Wireless operation of IDS sensors

With the aid of the adapters in the IDS WA Kit, IDS sensors with plug head

connectors (variant W) can be wirelessly connected to your MultiLab 4010-3W.

Installation shaft for

IDS adapter

Two adapters, one at the IDS meter (IDS WA-M) and one at the sensor (IDS

WA-S), replace the sensor cable with an energy-saving Bluetooth LE radio

connection.

Further information on the wireless operation of IDS sensors:

Web resources

Operating manual of the IDS WA Kit.

1.2.3 IDS adapter for analog sensors

With the aid of an IDS adapter, you can also operate analog sensors

on the MultiLab 4010-3W. The combination of the IDS adapter and analog

sensor behaves like an IDS sensor.

The YSI 4011 adapter can be used to connect a YSI 5010 BOD probe (any variation) to a IDS sensor port on the MultiLab 4010-3W instrument.

The MultiLab 4010-3W has a recess into which the IDS adapter (4010-2/3 pH

Adapter DIN or 4010-2/3 pH Adapter BNC) available as an accessory can be

permanently mounted.

In the MultiLab 4010-3W, the IDS adapter replaces a digital input (channel 2)

with a socket for an analog pH sensor (DIN or BNC plug) and a temperature

sensor.

8 ba76194e03 07/2018

Page 9

MultiLab 4010-3W Overview

Information on available IDS adapters is given on the Internet.

Detailed information on the IDS adapter is given in the operating

manual

of the adapter.

1.2.4 Automatic sensor recognition

The automatic sensor recognition for IDS sensors allows

to operate an IDS sensor with different meters without recalibrating

to operate different IDS sensors at one meter without recalibration

to assign measurement data to an IDS sensor

– Measurement datasets are always stored and output with the sensor

name and sensor serial number.

to assign calibration data to an IDS sensor

– Calibration data and calibration history are always stored and output with

the sensor name and sensor serial number.

to activate the correct cell constant for conductivity sensors automatically

to hide menus automatically that do not concern this sensor

To be able to use the automatic sensor recognition, a meter that supports the

automatic sensor recognition (e.g. MultiLab 4010-3W) and a digital IDS sensor

are required.

In digital IDS sensors, sensor data are stored that clearly identify the sensor.

The sensor data are automatically taken over by the meter.

ba76194e03 07/2018 9

Page 10

Safety MultiLab 4010-3W

2 S afety

2.1 Safety information

2.1.1 Safety information in the operating manual

This operating manual provides important information on the safe operation of

the meter. Read this operating manual thoroughly and make yourself familiar

with the meter before putting it into operation or working with it. The operating

manual must be kept in the vicinity of the meter so you can always find the information you need.

Important safety instructions are highlighted in this operating manual. They are

indicated by the warning symbol (triangle) in the left column. The signal word

(e.g. "CAUTION") indicates the level of danger:

WARNING

indicates a possibly dangerous situation that can lead to serious (irreversible) injury or death if the safety instruction is not

followed.

CAUTION

indicates a possibly dangerous situation that can lead to slight

(reversible) injury if the safety instruction is not followed.

NOTE

indicates a possibly dangerous situation where goods might be damaged

if the actions mentioned are not taken.

2.1.2 Safety signs on the meter

Note all labels, information signs and safety symbols on the meter. A warning

symbol (triangle) without text refers to safety information in this operating

manual.

2.1.3 Further documents providing safety information

The following documents provide additional information, which you should

observe for your safety when working with the measuring system:

• Operating manuals of sensors and other accessories

• Safety datasheets of calib ration or maintenance accessories (such as buffer

solutions, electrolyte solutions, etc.)

2.2 Safe operation

2.2.1 Authorized use

The authorized use of the meter consists exclusively of the measurement of the

pH, ORP, conductivity and dissolved oxygen in a laboratory environment.

10 ba76194e03 07/2018

Page 11

MultiLab 4010-3W Safety

Only the operation and running of

the meter according to the instructions and technical specifications given

in this operating manual is authorized (see section 15 T

ECHNICAL DATA, page

135).

Any other use is considered unauthorized.

2.2.2 Requirements for safe operation

Note the following points for safe operation:

• The meter may only be operated accord ing to the authorized use specified

above.

• The meter may only be supplied with power by the energy sources

mentioned in this operating manual.

• The meter may only be operated under the environmental conditions

mentioned in this operating manual.

• The meter may not be opened.

2.2.3 Unauthorized use

The meter must not be put into operation if:

• it is visibly damaged (e.g. after being transported)

• it was stored under adverse conditions for a lengthy period of time (storing

conditions, see section 15 T

ECHNICAL DATA, page 135).

ba76194e03 07/2018 11

Page 12

Commissioning MultiLab 4010-3W

3 C ommissioning

3.1 Scope of delivery

MultiLab 4010-3W

USB cable (A plug on mini B plug)

Power pack

Stand with stand base

Short instructions

Comprehensive operating manual

CD-ROM

3.2 Power supply

The MultiLab 4010-3W is supplied with power in the following ways:

Mains operation with the supplied power pack

In the case of power failure:

The system clock is operated via a buffer battery (see section 13.1.2

XCHANGING THE BATTERY, page 126).

E

3.3 Initial commissioning

Perform the following activities:

Connect the power pack

(see section 3.3.1 C

Switch on the meter (see section 4.2 S

Set the date and time (see section 4.4.5 E

THE DATE AND TIME, page 23)

Mount the stand

(see operating manual of the stand)

ONNECTING THE POWER PACK, page 13)

WITCHING ON THE METER, page 19)

XAMPLE 2 ON NAVIGATION: SETTING

12 ba76194e03 07/2018

Page 13

MultiLab 4010-3W Commissioning

3.3.1 Connecting the power pack

CAUTION

The line voltage at the operating site must lie within the input

voltage range of the original power pack (see section 15.2

G

ENERAL DATA, page 135).

CAUTION

Use original power packs only (see section 15.2 GENERAL DATA,

page 135).

1. Connect the plug of the power pack to the socket for the power pack on

the MultiLab 4010-3W.

2. Connect the original power pack to an easily accessible power outlet.

The meter performs a self-test.

ba76194e03 07/2018 13

Page 14

Operation MultiLab 4010-3W

4Operation

4.1 General operating principles

4.1.1 Keypad

In this operating manual, keys are indicated by brackets <..> .

The key symbol (e.g. <ENTER>) generally indicates a short keystroke (press

and release) in this operating manual. A long keystroke (press and keep

depressed for approx. 2 sec) is indicated by the underscore behind the key

symbol (e.g. <ENTER_>).

<F1>

<F4>

<On/Off>

<On/Off_>

<M> Selects the measured parameter

<CAL>

<CAL_>

<AR> Freezes the measured value (HOLD function)

<ESC> Switches back to the higher menu level /

<STO>

<STO_>

<RCL>

<RCL_>

<><>

Softkeys providing situation dependent functions, e.g.:

<F1>/[

Switches the meter on or off ( )

Calls up the calibration procedure

Displays the calibration data

Switches the AutoRead measurement on or off

Cancels inputs

Saves a measured value manually

Opens the menu for the automatic save function

Displays the manually stored measured values

Displays the automatically stored measured values

Menu control, navigation

i

]: View information on a sensor

<>< >

<ENTER>

<ENTER_>

<PRT>

<PRT_>

14 ba76194e03 07/2018

Opens the menu for measurement settings / Confirms entries

Opens the menu for system settings

Outputs stored data to the interface

Outputs displayed data to the interface at intervals

Page 15

MultiLab 4010-3W Operation

4

3

2

5

7

8

9

6

1

HOLD AR

AutoCal TEC

01.09.2017 08:00

i

YSI

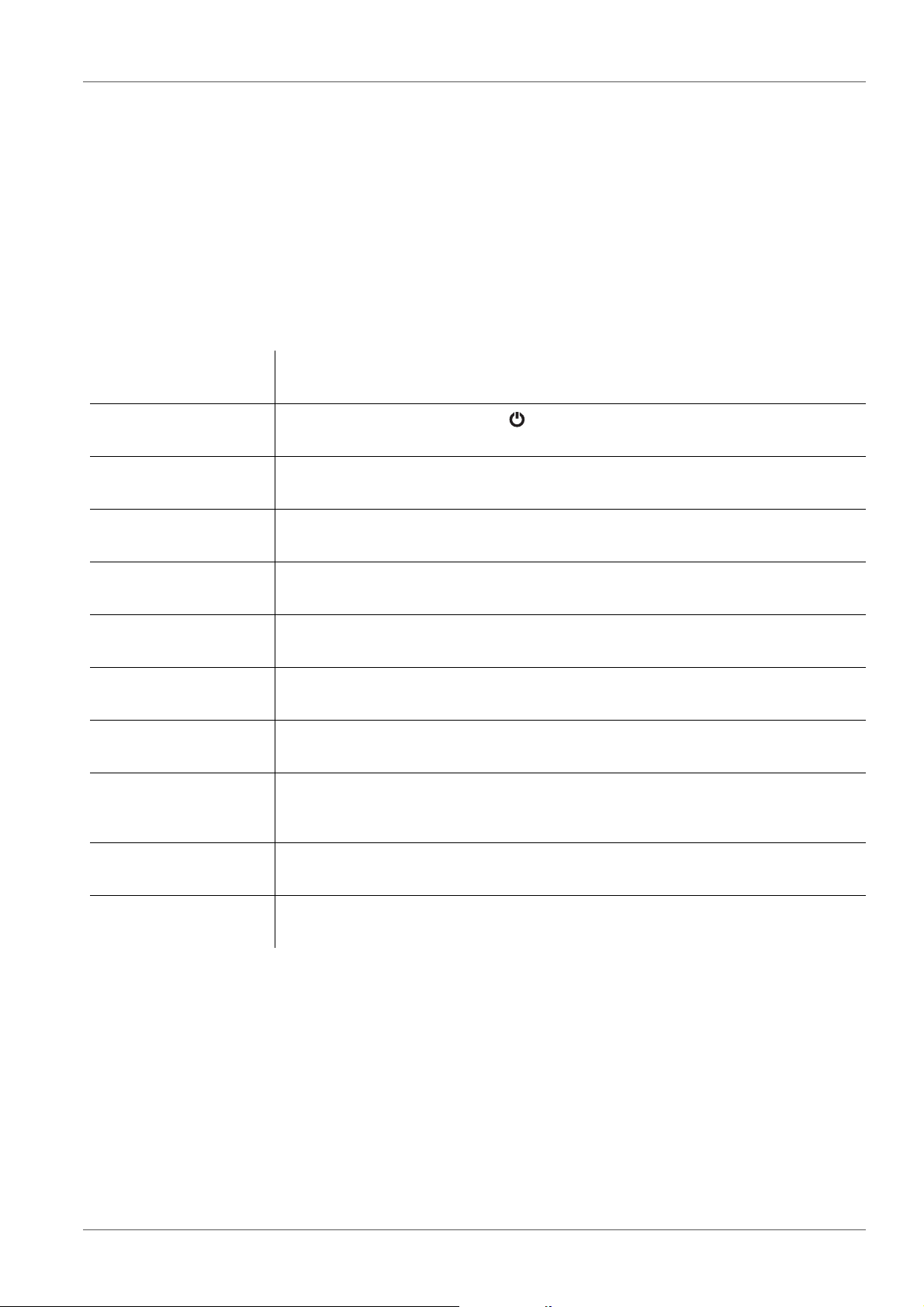

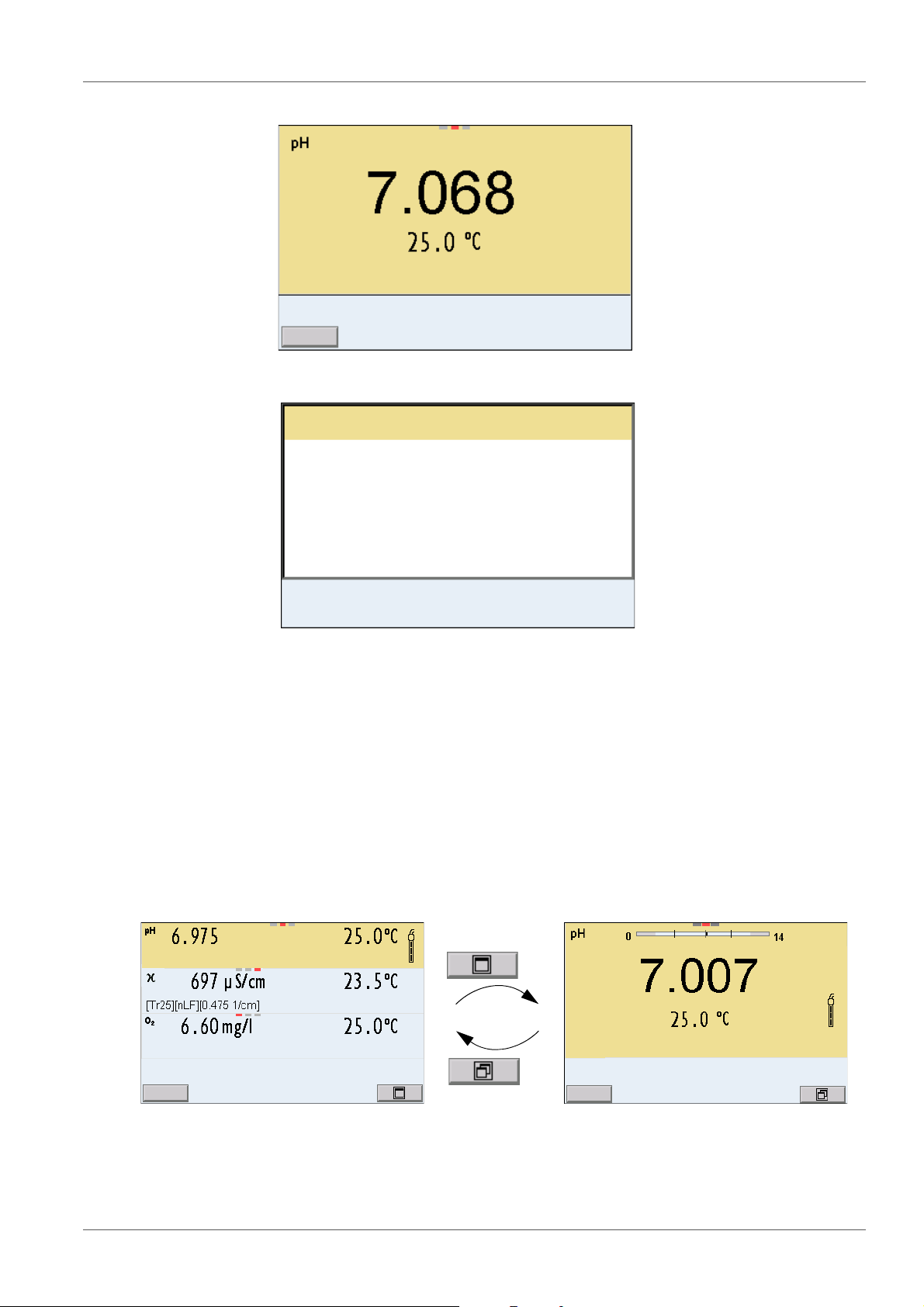

4.1.2 Display

Example

pH

1 Status information (meter)

2 Status information (sensor)

3 Measured value

4 Measured parameter

5 Continuous measurement control (CMC function)

6 Channel display: Plug position of the sensor

7 Sensor symbol (calibration evaluation, calibration interval)

8 Measured temperature (with unit)

9 Softkeys and date + time

4.1.3 Status information

AutoCal

e.g. YSI

ConCal Calibration with any buffers

Error An error occurred during calibration

AR Stability control (AutoRead) is active

HOLD Measured value is frozen (<AR> key)

Calibration with automatic buffer recognition, e.g. with the buffer set: YSI buffers

ZeroCal The zero point is calibrated.

Data are automatically output to the USB-B interface (USB Device, e.g. PC)

at intervals

A USB memory device is connected to the USB-A interface (USB Host, e.g.

USB flash drive)

Data are output to the USB-A interface (USB Host, e.g. USB printer). If there

is a connection via the USB-B interface at the same time (e.g. to a PC), the

data are output to the USB-B interface only.

Connection to a PC is active (USB-B interface)

ba76194e03 07/2018 15

Page 16

Operation MultiLab 4010-3W

746

3 51

bac

2

Data transmission from / to an IDS sensor is active

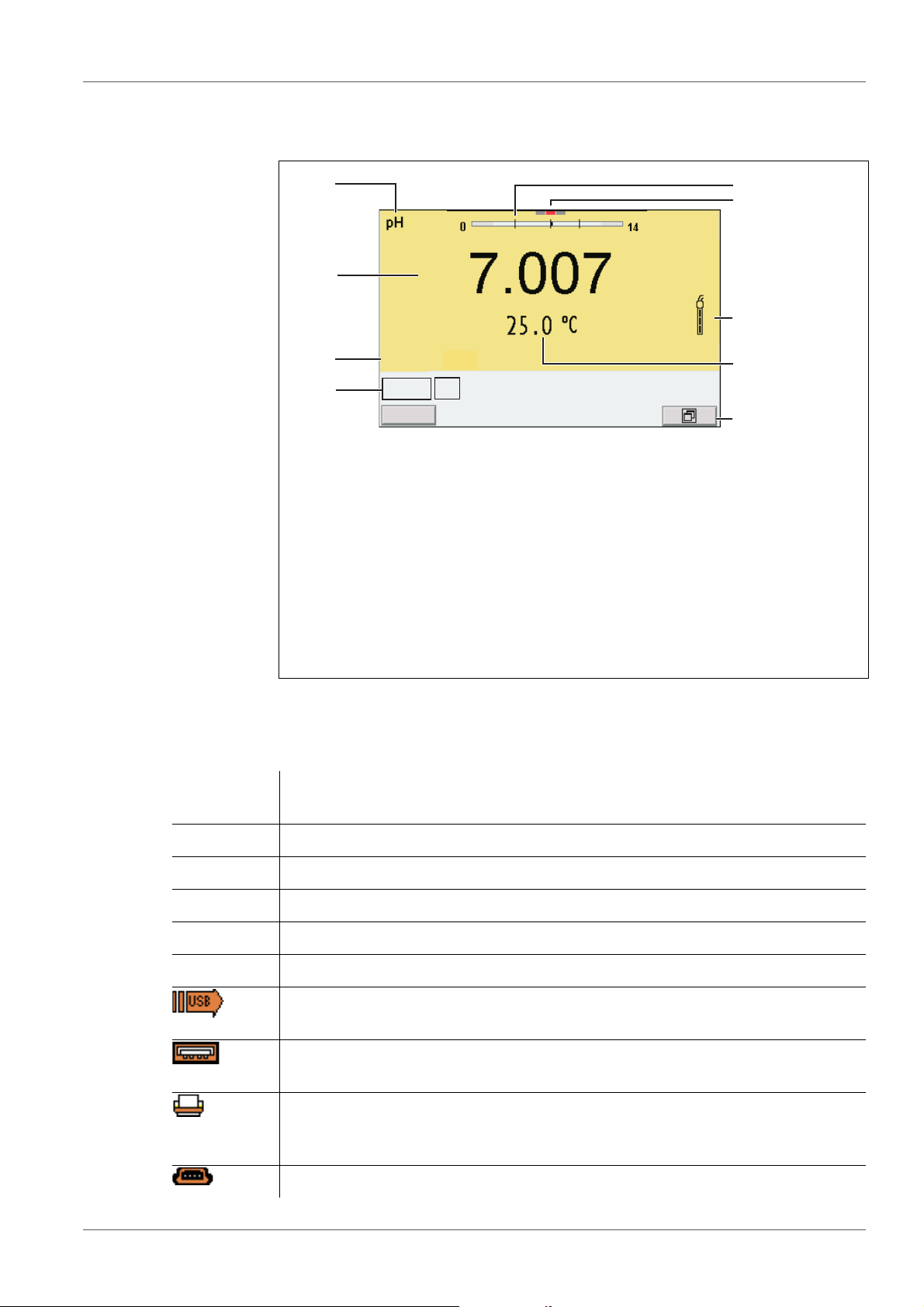

4.1.4 Connectors

1 IDS sensors: (pH, ORP, conductivity, D.O.)

a) Channel 1

b) Channel 2

c) Channel 3

2 USB-B (USB Device) interface

3 Stirrer (interface for BOD sensor)

4 USB-A (USB Host) interface

5 Power pack

6 Service interface

7 Cover plate

The cover plate closes the mounting slot for the IDS adapter (4010-2/

3 pH Adapter DIN or 4010-2/3 pH Adapter BNC) available as an

accessory

CAUTION

Only connect sensors to the meter that cannot return any voltages or currents that are not allowed (> SELV and > current circuit with current limiting).

YSI IDS sensors and IDS adapters meet these requirements.

16 ba76194e03 07/2018

Page 17

MultiLab 4010-3W Operation

1

01.09.2017 08:00

i

01.09.2017 08:00

i

4.1.5 Channel display

The MultiLab 4010-3W manages the connected sensors and displays which

sensor is plugged to which connection.

1 Channel display: Display of the plug position for the relevant param-

eter

The red bar indicates for each connected sensor to which plug posi-

tion (channel) of the meter it is connected.

4.1.6 Sensor info

You can display the current sensor data and sensor settings of a connected

sensor at any time. The sensor data are available in the measured value display with the /[

i

] softkey.

1. In the measured value display:

Display the sensor data (sensor name, serial number) with [

i

].

ba76194e03 07/2018 17

Page 18

Operation MultiLab 4010-3W

01.09.2017 08:00

More

4110

B092500013

01.09.2017 08:00

Man. temperature: 25 °C

pH resolution 0.001

mV resolution 0.1

Buffer YSI

Calibration interval 7d

Unit for slope mV/pH

QSC: off

Software version 1.00

4110

B092500013

01.09.2017 08:00

i

760 mm Hg

01.09.2017 08:00

i

2. Display further sensor data (settings) with [More].

18 ba76194e03 07/2018

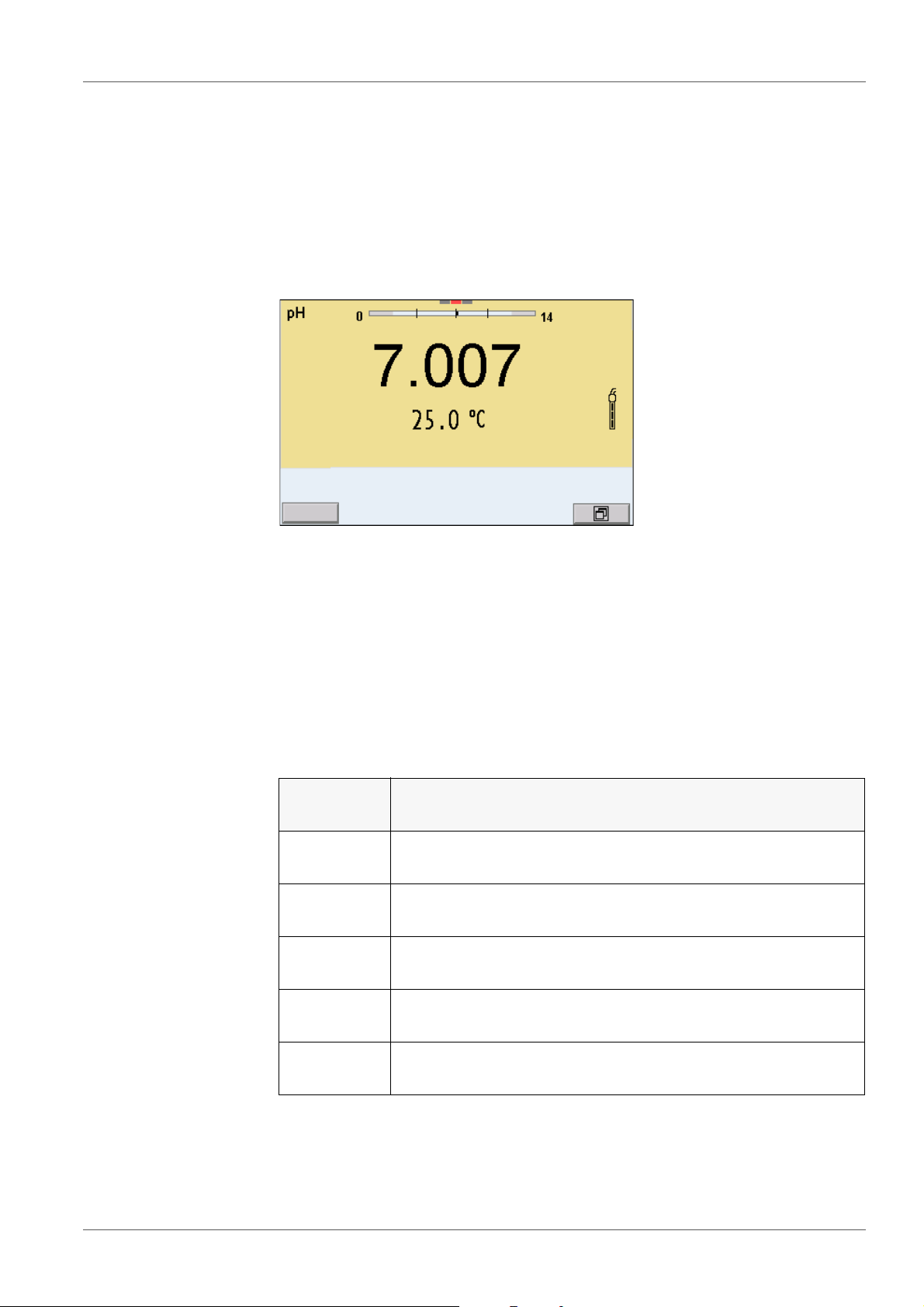

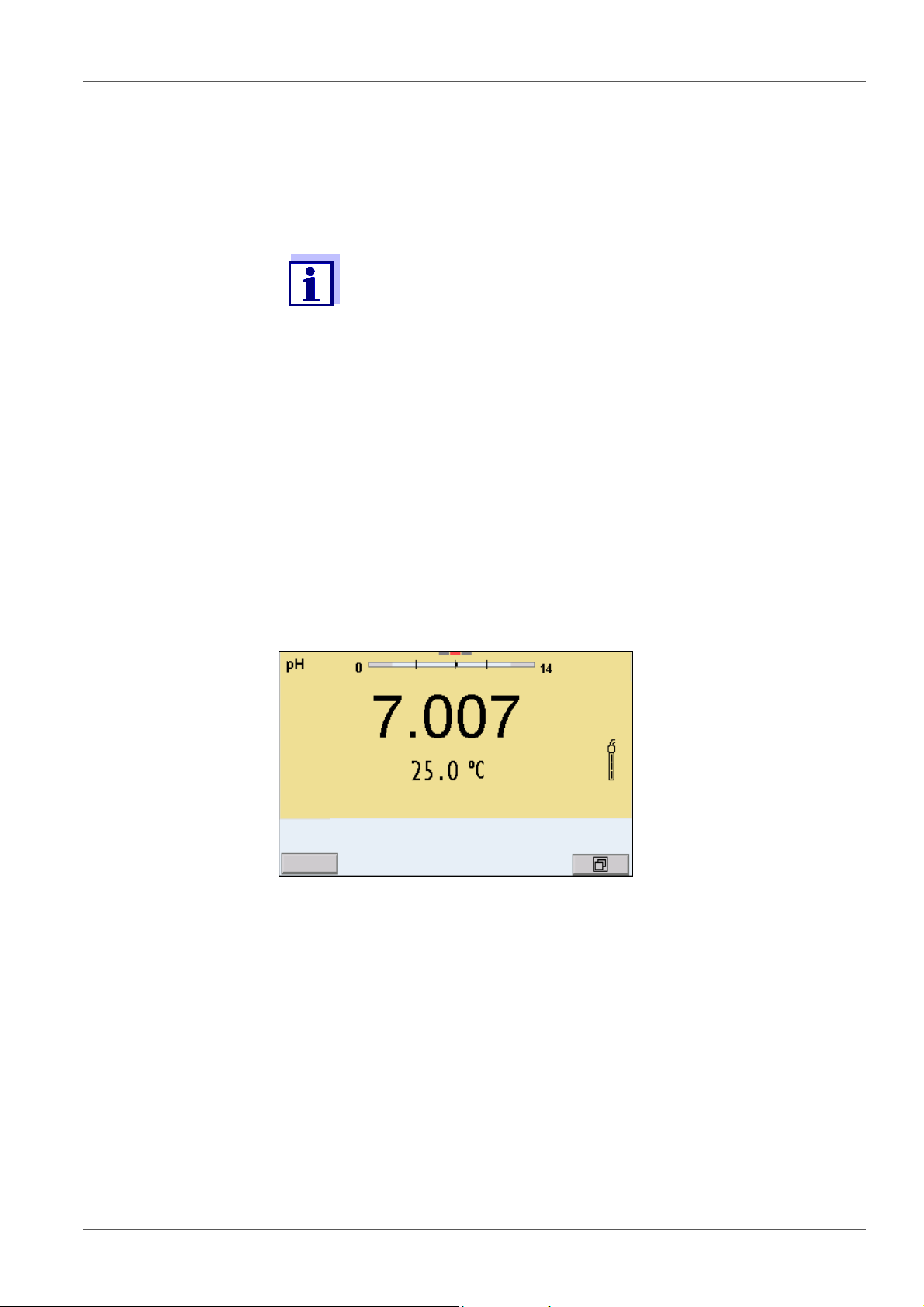

4.1.7 Display of several sensors in the measuring mode

The measured values of the connected sensors can be displayed in the following ways:

Clear display of all connected sensors

Detailed display of one sensor

(e.g. incl. CMC feature with pH sensors)

With the softkey you can very easily switch between the two display types. The

suitable softkey is displayed depending on the operating situation.

Page 19

MultiLab 4010-3W Operation

01.09.2017 08:00

i

4.2 Switching on the meter

1. Switch the meter on with <On/Off>.

The meter performs a self-test.

2. Connect the sensor.

The meter is ready to measure.

4.3 Switching off the meter

1. Switch the printer off with <On/Off>.

4.4 Navigation

4.4.1 Operating modes

Operating

mode

Measuring The measurement data of the connected sensor are shown

Calibration The course of a calibration with calibration information, func-

Data storage

Transmitting data

Explanation

in the measured value display

tions and settings is displayed

The meter stores measuring data automatically or manually

The meter transmits measuring data and calibration records

to a USB interface automatically or manually.

Setting The system menu or a sensor menu with submenus, set-

tings and functions is displayed

4.4.2 Measured value display

In the measured value display, you can

ba76194e03 07/2018 19

Page 20

Operation MultiLab 4010-3W

General

Interface

Clock function

Service information

Reset

System

01.09.2017 08:00

Language: Deutsch

Audio signal: on

Brightness: 12

Temperature unit: °C

Stability control

: on

General

01.09.2017 08:00

use <><> to select one of several connected sensors. The selected

sensor is displayed with a colored background.

The following actions / menus refer to the selected sensor

open the menu for calibration and measurement settings with <ENTER>

(short

keystroke)

open the system menu with the sensor-independent settings by pressing

<ENTER>Storage & config for a <ENTER_>long

keystroke, approx. 2 s).

change the display in the selected measuring screen (e. g. pH <-> mV) by

pressing <M>.

4.4.3 Menus and dialogs

The menus for settings and dialogs in procedures contain further sube lements.

The selection is done with the <

><

> keys. The current selection is dis-

played with a frame.

Submenus

The name of the submenu is displayed at the upper edge of the frame. Su bmenus are opened by confirming with <ENTER>. Example:

20 ba76194e03 07/2018

Settings

Settings are indicated by a colon. The current setting is displayed on the

right-hand side. The setting mode is opened with <ENTER>. Subsequently,

the setting can be changed with <

><

> and <ENTER>. Example:

Functions

Page 21

MultiLab 4010-3W Operation

pH

01.09.2017 08:00

Calibration record

Calibration data storage

Buffer: YSI

Single-point calibration: yes

Calibration interval: 7 d

Unit for slope: mV/pH

[

i

] 2.00 4.00 7.00 10.00

Calibration record

Calibration data storage

Buffer: YSI

Single-point calibration: yes

Calibration interval: 7 d

Unit for slope: mV/pH

[

i

] 2.00 4.00 7.00 10.00

pH

01.09.2017 08:00

01.09.2017 08:00

i

Functions are designated by the name of the function. They are immediately

carried out by confirming with <ENTER>. Example: Display the Calibration

record function.

Messages

i

Information is marked by the [

] symbol. It cannot be selected. Example:

4.4.4 Navigation example 1:Setting the language

1. Press the <On/Off> key.

ba76194e03 07/2018 21

The measured value display appears.

The instrument is in the measuring mode.

Page 22

Operation MultiLab 4010-3W

System

Data storage

Storage & config

01.09.2017 08:00

General

Interface

Clock function

Service information

Reset

System

01.09.2017 08:00

Language: Deutsch

Audio signal: on

Brightness: 12

Temperature unit: °C

Stability control

: on

General

01.09.2017 08:00

2. Open the Storage & config menu with <ENTER_>.

The instrument is in the setting mode.

3. Select the System submenu with <

><

>.

The current selection is displayed with a frame.

4. Open the System submenu with <ENTER>.

5. Select the General submenu with <

><

The current selection is displayed with a frame.

6. Open the General

submenu with <ENTER>.

>.

22 ba76194e03 07/2018

7. Open the setting mode for the Language with <ENTER>.

Page 23

MultiLab 4010-3W Operation

Language: Deutsch

Audio signal: o n

Brightness: 12

Temperature unit: °C

Stability control

: on

General

01.09.2017 08:00

8. Select the required language with <

><

>.

9. Confirm the setting with <ENTER>.

The meter switches to the measuring mode.

The selected language is active.

4.4.5 Example 2 on navigation: Setting the date and time

The meter has a clock with a date function. The date and time are indicated in

the status line of the measured value display.

When storing measured values and calibrating, the current date and time are

automatically stored as well.

The correct setting of the date and time and date format is important for the following functions and displays:

Current date and time

Calibration date

Identification of stored measured values.

Therefore, check the time at regular intervals.

Setting the date,

time and date format

The date format can be switched from the display of day, month, year

(dd.mm.yy) to the display of month, day, year (mm/dd/yy or mm.dd.yy).

1. In the measured value display:

ba76194e03 07/2018 23

2. Select and confirm the System / Clock function menu with <

The date and time are reset if the following conditions are met:

the supply voltage failed and

the buffer batteries for the system clock are empty.

Open the Storage & config menu with <ENTER_>.

The instrument is in the setting mode.

and <ENTER>.

The setting menu for the date and time opens up.

><

>

Page 24

Operation MultiLab 4010-3W

Date format: dd.mm.yy

Date: 01.09.2017

Time: 14:53:40

Clock function

01.09.2017 08:00

3. Select and confirm the Time menu with <><> and <ENTER>.

The hours are highlighted.

4. Change and confirm the setting with <

><

> and <ENTER>.

The minutes are highlighted.

5. Change and confirm the setting with <

><

> and <ENTER>.

The seconds are highlighted.

6. Change and confirm the setting with <

><

> and <ENTER>.

The time is set.

7. If necessary, set the Date and Date format. The setting is made similarly to that of the time.

8. To make further settings, switch to the next higher menu level with

<ESC>.

or

Switch to the measured value display with <M>.

The instrument is in the measuring mode.

24 ba76194e03 07/2018

Page 25

MultiLab 4010-3W pH value

01.09.2017 08:00

i

5 pH value

5.1 Measuring

5.1.1 Measuring the pH value

The sensor connection and the USB-B (USB Device) interface are

galvanically insulated. This facilitates interference-free measurements also in the following cases:

Measurement in grounded test samples

Measurement with several sensors connected to one

MultiLab 4010-3W in one test sample

1. Connect the IDS pH sensor to the meter.

The pH measuring window is displayed.

2. If necessary, select the measured parameter with <M>.

Stability control

(AutoRead)

& HOLD function

3. Adjust the temperature of the solutions and measure the current tem-

perature if the measurement is made without a temperature sensor.

4. If necessary, calibrate or check the IDS pH sensor.

5. Immerse the IDS pH sensor in the test sample.

The stability control function (AutoRead) continually checks the stability of the

measurement signal. The stability has a considerable impact on the reproducibility of measured values.

The measured parameter flashes on the display

as soon as the measured value is outside the stability range

when the automatic Stability control is switched off.

You can start the Stability control manually at any time, irrespective of the setting for automatic Stability control (see section 10.6.3 A

CONTROL, page 110) in the System menu.

UTOMATIC STABILITY

To start the Stability control function manually, the HOLD function must be

enabled.

ba76194e03 07/2018 25

Page 26

pH value MultiLab 4010-3W

Hold function

Stability control

1. Freeze the measured value with <AR>.

The [HOLD] status indicator is displayed.

The HOLD function is active.

You can terminate the HOLD function and the Stability control function with <AR> or <M> at any time.

2. Using <ENTER>, activate the Stability control function manually.

The [AR] status indicator appears while the measured value is assessed

as not stable. A progress bar is displayed and the display of the measured parameter flashes.

As soon as a measured value meets the stability criteria, it is frozen. The

[HOLD][AR] status indicator is displayed, the progress bar disappears,

the display of the measured parameter stops flashing, and there is a

beep.

The current measurement data is output to the interface. Measurement

data meeting the stability control criterion is marked by AR.

Criteria for a stable

measured value

You can prematurely terminate the Stability control function manually with <ENTER> at any time. If the Stability control function is

prematurely terminated, the current measurement data are output

to the USB-B (USB Device, e.g. PC) or USB-A (USB Host, e.g.

USB memory device or USB printer) interface without AutoRead

info.

You can switch off the beep (see section 10.6 S

DENT SETTINGS, page 109).

ENSOR-INDEPEN-

3. Using <ENTER>, start a further measurement with stability control.

or

Release the frozen measured value again with <AR> or <M>.

The [AR] status display disappears. The display switches back to the

previous indication.

The Stability control function checks whether the measured values are stable

within the monitored time interval.

Measured

Time interval Stability in the time interval

parameter

pH value 15 seconds

Temperature 15 seconds

∆ : better than 0.01 pH

∆ : better than 0.5 °C

The minimum duration until a measured value is assessed as stable is the

monitored time interval. The actual duration is mostly longer.

26 ba76194e03 07/2018

Page 27

MultiLab 4010-3W pH value

5.1.2 Measuring the temperature

For reproducible pH measurements, it is essential to measure the temperature

of the test sample.

IDS sensors measure the temperature with a temperature sensor integrated in

the IDS sensor.

When operating a sensor without integrated temperature sensor, e.g. via a n

IDS-pH adapter, there are the following ways to measure the temperature of

the test sample:

Measurement of the temperature with the integrated temperature sensor

of an IDS sensor.

If the measured value is taken over from an IDS sensor, the status indi-

↑

cator [TP

adapter. The status indicator [TP

dow of the IDS-pH sensor providing the temperature value.

Manual determination and input of the temperature.

] is displayed in the measurement window of the IDS-pH

↓

] is displayed in the measurement win-

The display of the temperature indicates the active temperature measuring

mode:

Temperature

sensor

yes 0.1 °C Automatic with temperature

- 1 °C Manual

If you wish to measure (or calibrate) without temperature sensor, proceed as

follows:

1. Measure the current temperature of the test sample.

2. Set the temperature value with <

or

In the <ENTER>//Man. temperature menu, set the temperature value

><

with <

Resolution of the

temp. display

>.

><

Temp. measurement

sensor

>.

5.2 pH calibration

5.2.1 Why calibrate?

pH electrodes age. This changes the zero point (asymmetry) and slope of the

pH electrode. As a result, an inexact measured value is displayed. Calibration

determines and stores the current values of the zero point and slope of the

electrode.

Thus, you should calibrate at regular intervals.

ba76194e03 07/2018 27

Page 28

pH value MultiLab 4010-3W

5.2.2 When do you have to calibrate?

Routinely within the framework of the company quality assurance

When the calibration interval has expired

5.2.3 Calibration procedure

The MultiLab 4010-3W provides 2 calibration procedures:

Automatic calibration (AutoCal)

The buffer solutions used are automatically identified during the calibration

procedure. The relevant nominal values are used automatically.

Prerequisite: The buffer set used has been set in the meter (see section

10.1.2 B

UFFER SETS FOR CALIBRATION, page 99).

Manual calibration (ConCal)

Any buffer solutions can be used. The nominal values of the buffer solutions

are manually entered by the user during the calibration procedure.

For most applications, automatic calibration (AutoCal) is the safest

and most convenient way of executing a calibration.

5.2.4 Carrying out automatic calibration (AutoCal)

Make sure that, in the menu for measurement and calibration settings (in the

menu pH/<ENTER>/Calibration / Buffer), the correct buffer set is selected (see

section 10.1.1 S

ETTINGS FOR PH MEASUREMENTS, page 97).

Use one to five buffer solutions of the selected buffer set in any order.

Below, calibration with YSI buffers (YSI) is described. When other buffer sets

are used, other nominal buffer values are displayed. Apart from that, the procedure is identical.

If single-point calibration was set in the menu, the calibration procedure is automatically finished with the measurement of buffer solution 1 and the calibration record is displayed.

1. Connect the pH sensor to the meter.

The pH measuring window is displayed.

2. Keep the buffer solutions ready.

When measuring without temperature sensor:

Temper the buffer solutions or measure the current temperature.

3. Start the calibration with <CAL>.

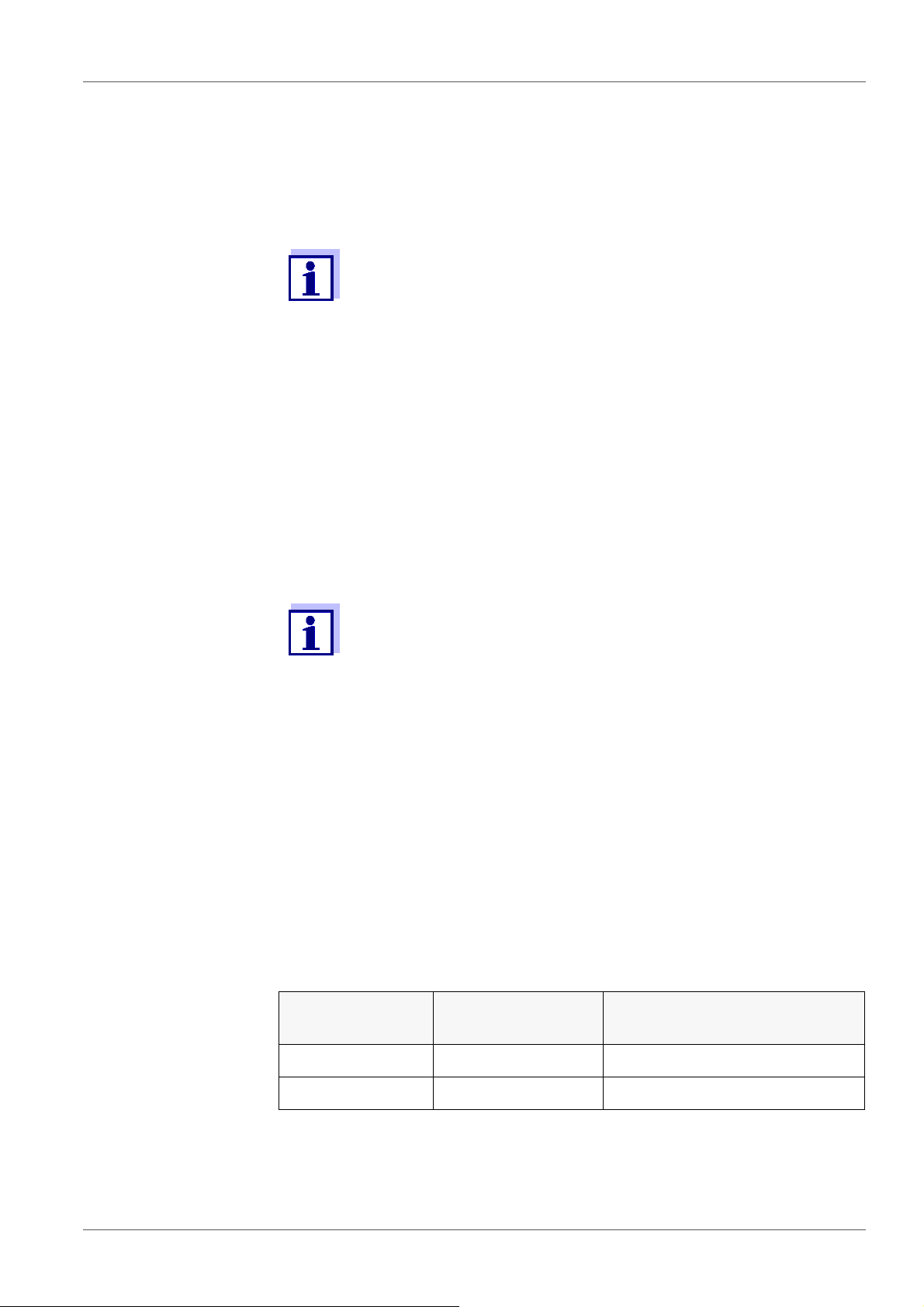

The calibration display for the first buffer appears (voltage display).

28 ba76194e03 07/2018

Page 29

MultiLab 4010-3W pH value

01.09.2017 08:00

YSI

01.09.2017 08:00

YSI

10.000

4. Thoroughly rinse the sensor with deionized water.

5. Immerse the sensor in the first buffer solution.

6. For measurements without temperature sensor

(e.g. when using an IDS adapter

Enter the temperature of the buffer with <

):

><

>.

7. Start the measurement with <ENTER>.

The measured value is checked for stability (stability control).

The [AR] status indicator is displayed. The measured parameter

flashes.

8. Wait for the end of the measurement with stability control (beep,

[HOLD][AR] status indicator) or take over the calibrated value with

<ENTER>.

The calibration display for the next buffer appears (voltage display).

9. If necessary, finish the calibration procedure as a single-point calibration

with <M>.

The calibration record is displayed.

For singl e-point calibration, the instrument uses the Nernst slope

(-59.2 mV/pH at 25 °C) and determines the zero point of the IDSpH sensor.

Continuing with two-

point calibration

ba76194e03 07/2018 29

10. Thoroughly rinse the sensor with deionized water.

Page 30

pH value MultiLab 4010-3W

01.09.2017 08:00

YSI

11. Immerse the pH sensor in buffer solution 2.

12. When measuring without temperature sensor:

Enter the temperature of the buffer with <

><

>.

13. Start the measurement with <ENTER>.

The measured value is checked for stability (stability control).

The [AR] status indicator is displayed. The measured parameter

flashes.

Continuing with

three- to five-point

calibration

14. Wait for the end of the measurement with stability control (beep,

[HOLD][AR] status indicator), or take over the calibrated value with

<ENTER>.

The calibration display for the next buffer appears (voltage display).

15. If necessary, finish the calibration procedure as a two-point calibration

with <M>.

The calibration record is displayed.

16. Thoroughly rinse the sensor with deionized water.

17. Immerse the sensor in the next buffer solution.

18. When measuring without temperature sensor:

Enter the temperature of the buffer with <

><

>.

19. Start the measurement with <ENTER>.

The measured value is checked for stability (stability control).

The [AR] status indicator is displayed. The measured parameter

flashes.

30 ba76194e03 07/2018

Page 31

MultiLab 4010-3W pH value

01.09.2017 08:00

YSI

4.000

20. Wait for the end of the measurement with stability control (beep,

[HOLD][AR] status indicator), or take over the calibrated value with

<ENTER>.

The calibration display for the next buffer appears (voltage display).

21. If necessary, use <M> to finish the calibration.

The calibration record is displayed.

or

Switch to calibration with the next buffer with <ENTER>.

Calibration is automatically completed after the last buffer of a buffer set has been measured. Then the calibration record is displayed.

The calibration line is determined by linear regression.

5.2.5 Carrying out a manual calibration (ConCal)

Make sure that, in the menu for measurement and calibration settings (in the

menu pH/<ENTER>/Calibration / Buffer) the buffer set ConCal is selected (see

section 10.1.1 S

ETTINGS FOR PH MEASUREMENTS, page 97).

Use one to five buffer solutions in any order.

The pH values of the buffer solutions have to differ by at least one pH unit.

If single-point calibration was set in the menu, the calibration procedure is automatically finished with the measurement of buffer solution 1 and the calibration record is displayed.

1. Connect the pH sensor to the meter.

The pH measuring window is displayed.

2. Keep the buffer solutions ready.

When measuring without temperature sensor:

Temper the buffer solutions or measure the current temperature.

3. Start the calibration with <CAL>.

The calibration display for the first buffer appears (voltage display).

ba76194e03 07/2018 31

Page 32

pH value MultiLab 4010-3W

01.09.2017 08:00

ConCal

01.09.2017 08:00

ConCal

01.09.2017 08:00

ConCal

4. Thoroughly rinse the sensor with deionized water.

5. Immerse the pH sensor in buffer solution 1.

6. For measurements without temperature sensor

(e.g. when using an IDS adapter

Enter the temperature of the buffer with <

):

><

>.

7. Start the measurement with <ENTER>.

The measured value is checked for stability (stability control).

The [AR] status indicator is displayed. The measured parameter flashes.

8. Wait for the end of the measurement with stability control (beep,

[HOLD][AR] status indicator), or take over the calibrated value with

<ENTER>.

The pH value of the buffer solution is displayed.

32 ba76194e03 07/2018

Page 33

MultiLab 4010-3W pH value

01.09.2017 08:00

ConCal

9. Set the nominal buffer value for the measured temperature with

<

><

>.

10. Accept the calibration value with <ENTER>.

The calibration display for the next buffer appears (voltage display).

11. If necessary, finish the calibration procedure a s a single-point calibration

with <M>.

The calibration record is displayed.

For singl e-point calibration, the instrument uses the Nernst slope

(-59.2 mV/pH at 25 °C) and determines the zero point of the IDSpH sensor.

Continuing with two-

point calibration

12. Thoroughly rinse the sensor with deionized water.

13. Immerse the pH sensor in buffer solution 2.

14. When measuring without temperature sensor:

Enter the temperature of the buffer with <

><

>.

15. Start the measurement with <ENTER>.

The measured value is checked for stability (stability control).

The [AR] status indicator is displayed. The measured parameter

flashes.

16. Wait for the end of the measurement with stability control (beep,

[HOLD][AR] status indicator), or take over the calibrated value with

<ENTER>.

The pH value of the buffer solution is displayed.

17. Set the nominal buffer value for the measured temperature with

><

<

>.

18. Accept the calibration value with <ENTER>.

The calibration display for the next buffer appears (voltage display).

19. If necessary, finish the calibration procedure as a two-point calibration

with <M>.

The calibration record is displayed.

ba76194e03 07/2018 33

Page 34

pH value MultiLab 4010-3W

01.09.2017 08:00

ConCal

Continuing with

three- to five-point

calibration

20. Thoroughly rinse the sensor with deionized water.

21. Immerse the sensor in the next buffer solution.

22. When measuring without temperature sensor:

Enter the temperature of the buffer with <

><

>.

23. Start the measurement with <ENTER>.

The measured value is checked for stability (stability control).

The [AR] status indicator is displayed. The measured parameter

flashes.

24. Wait for the end of the measurement with stability control (beep,

[HOLD][AR] status indicator), or take over the calibrated value with

<ENTER>.

The pH value of the buffer solution is displayed.

25. Set the nominal buffer value for the measured temperature with

<><>.

26. Accept the calibration value with <ENTER>.

The calibration display for the next buffer appears (voltage display).

27. If necessary, use <M> to finish the calibration.

The calibration record is displayed.

or

Continue calibrating using the next buffer with <ENTER>.

After the fifth buffer has been measured the calibration is automatically finished. Then the calibration record is displayed.

The calibration line is determined by linear regression.

5.2.6 Calibration points

Calibration can be performed using one to five buffer solutions in any order

(single-point to five-point calibration). The meter determines the following

values and calculates the calibration line as follows:

34 ba76194e03 07/2018

Page 35

MultiLab 4010-3W pH value

Calibration Determined val-

Displayed calibration data

ues

1-point Asymmetry Zero point = Asymmetry

Slope = Nernst slope

(-59.2 mV/pH at 25 °C)

2-point Asymmetry

Slope

3-point to 5point

Asymmetry

Slope

Zero point = Asymmetry

Slope = Slope

Zero point = Asymmetry

Slope = Slope

The calibration line is calculated by

linear regression.

You can display the slope in the units, mV/pH or % (see section

10.1.1 S

ETTINGS FOR PH MEASUREMENTS, page 97).

5.2.7 Calibration data

The calibration record is automatically transmitted to the interface

after calibrating.

The calibration record of the last calibration is available in the menu Calibration

/ Calibration record. To open it in the measured value display, press the

<CAL_> key.

The calibration records of the last 10 calibrations are available in the menu Cali-

bration / / Calibration data storage. To open the Calibration menu in the

measured value display, press the <ENTER> key.

ba76194e03 07/2018 35

Page 36

pH value MultiLab 4010-3W

Menu item Setting/

function

Calibration /

- Displays the calibration records.

Calibration data storage / Display

Calibration /

- Outputs the stored calibration data to

Calibration data storage / Output to USB

flash drive or printer

Explanation

Further options:

Scroll through the calibration

records with <

><

>.

Using <PRT>, output the dis-

played calibration record to the

interface USB-B (USB Device,

e.g. PC) or USB-A (USB Host,

e.g. USB printer).

Using <PRT_>, output all calibra-

tion records to the interface USBB (USB Device, e.g. PC) or USBA (USB Host, e.g. USB printer).

Quit the display with <ESC>.

Switch directly to the measured

value display with <M>.

the USB-A interface (USB Host, e.g.

USB memory device/USB printer)

(see section 12 T

RANSMITTING DATA,

page 120).

Calibration

evaluation

Calibration /

Calibration data storage / Output to

RS232/USB

- Outputs the stored calibration data to

the USB-B interface (USB Device,

e.g. PC) (see section 12 T

TING DATA, page 120).

RANSMIT-

After calibrating, the meter automatically evaluates the calibration. The zero

point and slope are evaluated separately. The worse evaluation of both is taken

into account. The evaluation appears on the display and in the calibration

record.

Display Calibration

record

+++

++

Zero point

Slope [mV/pH]

[mV]

-15 ... +15 -60.5 ... -58.0

-20 ... <-15

>-58.0 ... -57.0

or

>+15 ... +20

+

-25 ... <-20

or

>+20 ... +25

-61.0 ... <-60.5

or

>-57.0 ... -56.0

-

36 ba76194e03 07/2018

-30 ... <-25

or

->+25 ... +30

-62.0 ... <-61.0

or

>-56.0 ... -50.0

Page 37

MultiLab 4010-3W pH value

CALIBRATIONpH

01.09.2017 07:43:33

4110

Ser. no. B092500013

YSI

Buffer 1 4.00

Buffer 2 7.00

Buffer 3 10.00

Voltage 1 184.0 mV

Voltage 2 3.0 mV

Voltage 3 -177.0 mV

Temperature 1 24.0 °C

Temperature 2 24.0 °C

Temperature 3 24.0 °C

Slope -60.2 mV/pH

Asymmetry 4.0 mV

Sensor +++

etc...

Calibration record

Display Calibration

record

Clean the IDS sensor according

to the sensor operating manual

Error Error

Error elimination (see section 14

HAT TO DO IF..., page 128)

W

For pH IDS sensors you can optionally enable a more finely graded

calibration evaluation (QSC) (see section 5.2.9 QSC

SENSOR QUALITY CONTROL), page 39).

(

Zero point

[mV]

<-30

or

>+30

Slope [mV/pH]

<-62.0

or

> -50,0

FUNCTION

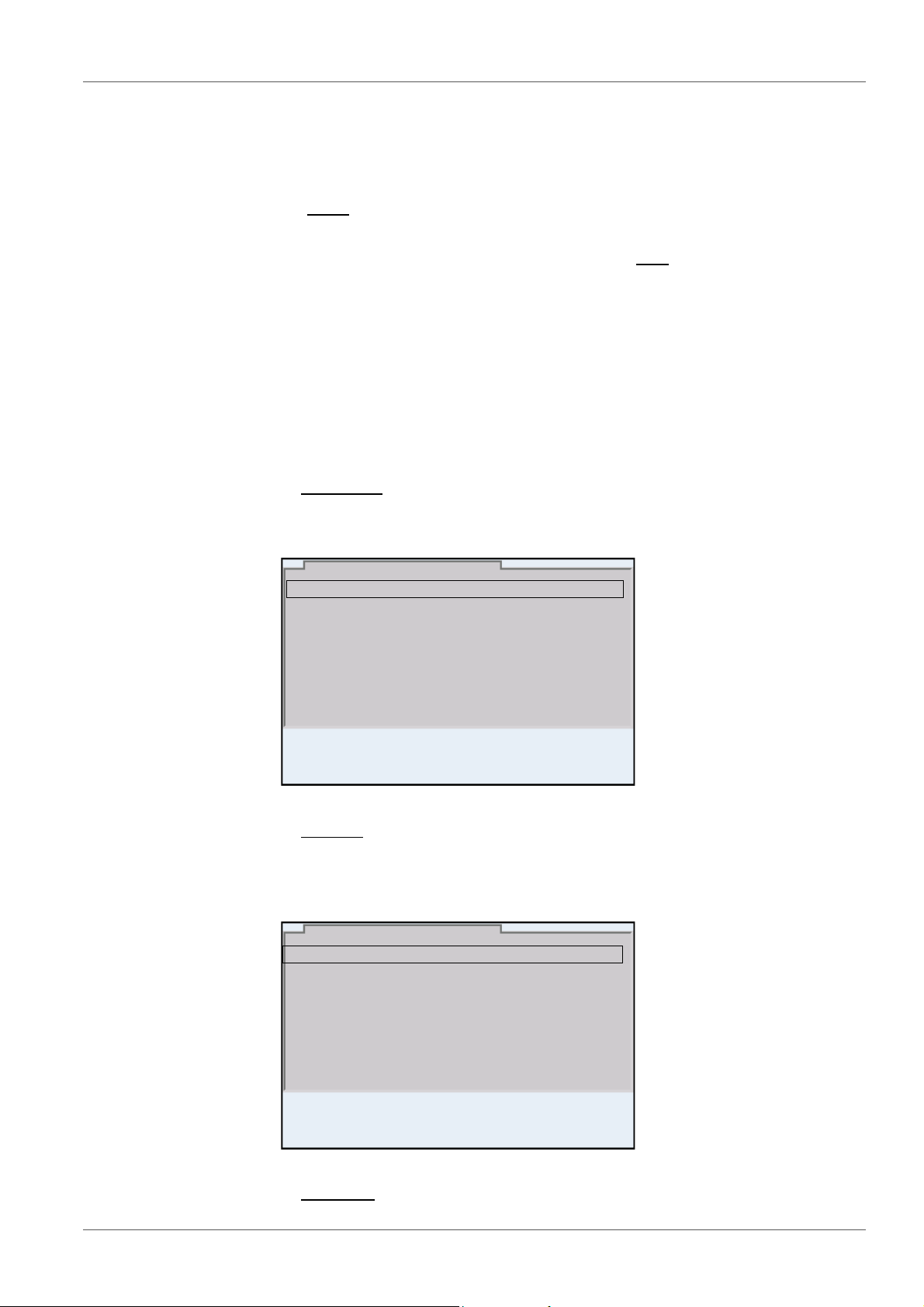

5.2.8 Continuous measurement control (CMC function)

The Continuous Measurement Control (CMC function) facilitates to evaluate

the current measured value instantly and definitely.

After each successful calibration the scale of the pH measuring range is

displayed in the measured value display. Here you can very clearly see

whether or not the current measured value is in the calibrated part of the

ba76194e03 07/2018 37

measuring range.

The following information is displayed:

Page 38

pH value MultiLab 4010-3W

1

2

3

4

01.09.2017 08:00

i

1 Currently measured pH value (needle)

2 Marking lines for all nominal buffer values used with the last valid cali-

bration

3 Measuring range for which a valid calibration is available. Measured

values in this range are suitable for documentation.

4 Measuring range for which no valid calibration is available (dark

gray). Measured values in this range are not suitable for documentation. Calibrate the meter with buffers covering this measuring range.

If the current measured value is outside the calibrated range, this area

is displayed in a darker gray.

If a measured value is outside the measuring range pH 0 - 14, overflow arrows are displayed at the left or right edge of the measuring

range.

The limits of the calibrated range are determined by the buffers used for calibration:

Lower limit: Buffer with lowest pH value - 2 pH units

Upper limit: Buffer with highest pH value + 2 pH units

38 ba76194e03 07/2018

Page 39

MultiLab 4010-3W pH value

01.09.2017 08:00

i

1

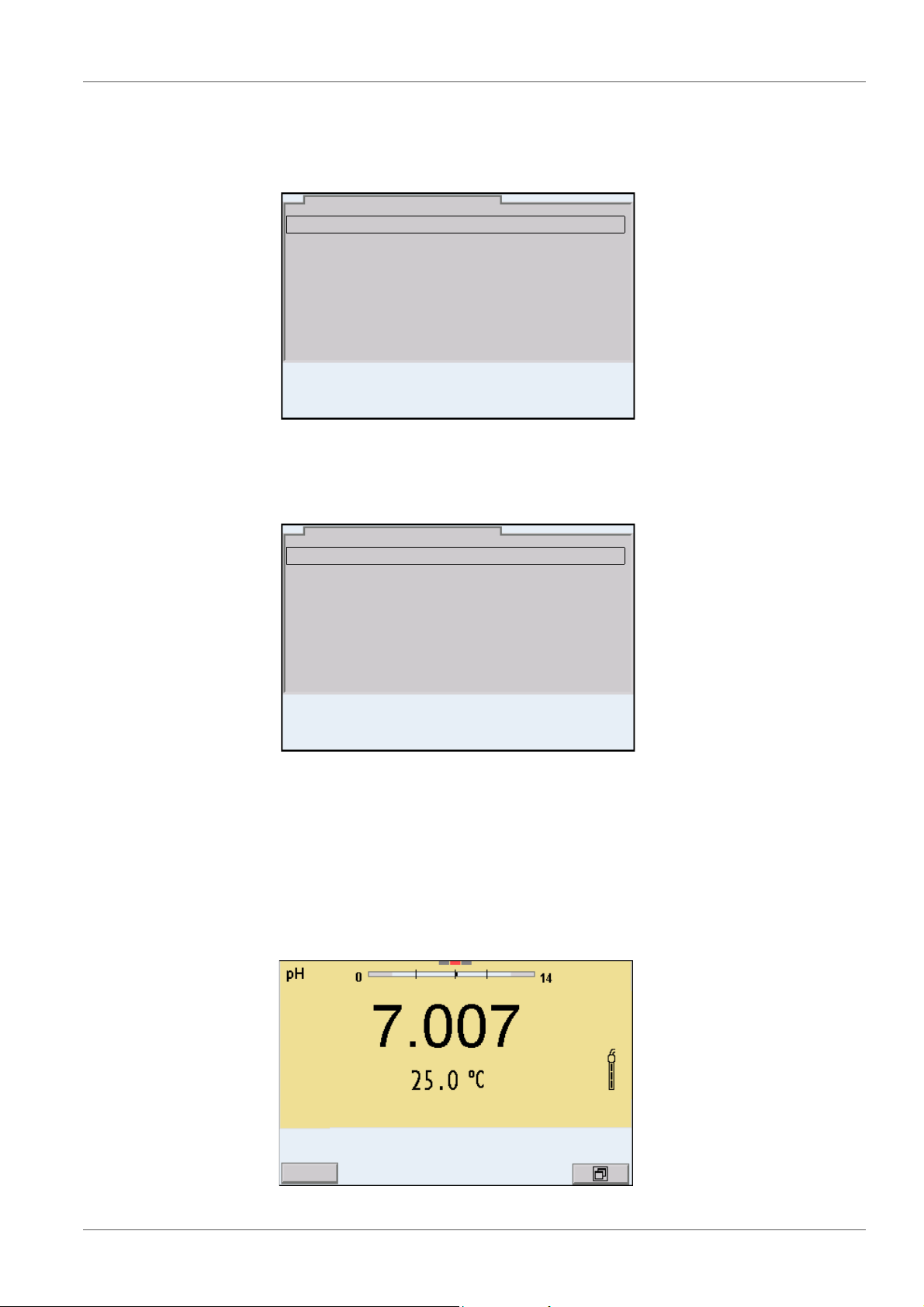

5.2.9 QSC function (sensor quality control)

General information

on the QSC function

The QSC function (Quality Sensor Control) is a new sensor evaluation for

digital IDS sensors. It evaluates the condition of an IDS pH sensor individually

and with a very fine grading.

The QSC scale shows the current sensor evaluation with an indicator on the

display.

1QSC scale

The double arrow on the QSC scale indicates the current sensor evaluation

Sensor evaluation

with / without

QSC function

In the USB output the sensor evaluation is given as a percentage (1-100).

The finely graded sensor evaluation of the QSC function promptly calls your

attention to changes of the sensor.

Thus you can do what is necessary to restore the optimum measuring quality

(e.g. clean, calibrate or replace the sensor). clean, calibrate or replace the

sensor).

With QSC function Without QSC function (sensor

symbol)

Very fine grading of the sensor evaluation (100 grades)

The reference value is individually

determined for each sensor during

Rough grading of the sensor evaluation (4 grades)

A theoretical reference value is used

for all sensors

the QSC initial calibration.

Low tolerances for zero point and

slope when using QSC buffer solutions

Additional QSC calibration required

Greater tolerances for zero point and

slope when using commercial buffer

sets

No additional calibration required

(with special QSC buffer set)

QSC calibration The QSC function is enabled by once carrying out an additional three-point cali-

bration with special QSC buffer solutions. It covers the measuring range of the

sensor from pH 2 to pH 11. The QSC initial calibration determines the actual

condition of the sensor and stores it as a reference in the sensor.

To meet the high requirements of a QSC initial calibration, the QSC initial cali-

ba76194e03 07/2018 39

Page 40

pH value MultiLab 4010-3W

01.09.2017 08:00

bration should optimally be carried out with the initial commissioning of the

sensor.

Carry out the normal calibrations for your special measuring range with your

usual standard solutions as previously done.

As soon as the QSC function was enabled for an IDS sensor, it is

not possible to return to the sensor evaluation with the sensor

symbol for this sensor.

Carrying out a QSC

initial calibration

Carry out the QSC initial calibration very carefully. It determines the

reference value for the sensor. This reference value cannot be

overwritten or reset.

As soon as the QSC function was enabled, it is not possible to

return to the sensor evaluation with the sensor symbol.

1. Prepare for calibration the meter, sensor and the buffer solutions of the

QSC-Kit.

2. Open the menu for measurement settings with <ENTER>.

3. In the QSC menu, select First calibration with <

><

>.

The calibration display appears. AutoCal QSC-Kit is displayed as the

buffer.

Exclusively use the QSC-Kit for the QSC calibration. If you use other buffers, you will have no valid QSC calibration.

4. Start the measurement with <ENTER>.

Calibration with the buffers of the QSC-Kit is done like a normal threepoint calibration (see section 5.2.4 C

TION (AUTOCAL), page 28).

ARRYING OUT AUTOMATIC CALIBRA-

5. As soon as the three-point calibration has been successfully carried out

you can decide whether to accept or discard the calibration as the QSC

initial calibration.

The QSC initial calibration is completed. The sensor is calibrated. If you want

to calibrate with special buffers for your measurements, you can subsequently

carry out a normal calibration with your buffers. The reference values deter-

40 ba76194e03 07/2018

Page 41

MultiLab 4010-3W pH value

01.09.2017 08:00

i

1

mined with the QSC calibration are also used for the evaluation of normal calibrations. In the measured value display, the QSC scale of the QSC function is

always displayed. A double arrow on the QSC scale indicates the current sensor evaluation.

1QSC scale

The double arrow on the QSC scale indicates the current sensor evaluation

Carrying out a QSC

control calibration

A QSC control calibration can, e.g. be useful if the sensor evaluation noticeably

changed (after some normal calibrations).

You can carry out QSC control calibrations at greater intervals than normal calibrations.

1. Prepare for calibration the meter, sensor and the buffer solutions of the

QSC-Kit.

2. Open the menu for measurement settings with <ENTER>.

3. In the QSC menu, select Control calibration with <

><

>.

The calibration display appears. AutoCal QSC-Kit is displayed as the

buffer.

Exclusively use the QSC-Kit for the QSC calibration. If you use other buffers, you will have no valid QSC control calibration.

4. Start the measurement with <ENTER>.

Calibration with the buffers of the QSC-Kit is done like a normal threepoint calibration (see section 5.2.4 C

TION (AUTOCAL), page 28).

ARRYING OUT AUTOMATIC CALIBRA-

As soon as the three-point calibration has been successfully carried out

you can decide whether to accept or discard the calibration as the QSC

control calibration.

ba76194e03 07/2018 41

Page 42

ORP MultiLab 4010-3W

01.09.2017 08:00

i

6ORP

6.1 Measuring

6.1.1 Measuring the ORP

The sensor connection and the USB-B (USB Device) interface are

galvanically insulated. This facilitates interference-free measurements also in the following cases:

Measurement in grounded test samples

Measurement with several sensors connected to one

MultiLab 4010-3W in one test sample

IDS ORP sensors are not calibrated. However, you can check IDS

ORP sensors using a test solution.

Stability control

(AutoRead)

& HOLD function

1. Connect the ORP sensor to the meter.

The ORP measuring window is displayed.

2. Adjust the temperature of the solutions and measure the current temperature if the measurement is made without a temperature sensor.

3. Check the meter with the ORP sensor.

4. Immerse the ORP sensor in the test sample.

The stability control function (AutoRead) continually checks the stability of the

measurement signal. The stability has a considerable impact on the reproducibility of measured values.

The measured parameter flashes on the display

as soon as the measured value is outside the stability range

when the automatic Stability control is switched off.

You can start the Stability control manually at any time, irrespective of the

setting for automatic Stability control (see section 10 .6.3 A

CONTROL, page 110) in the System menu.

42 ba76194e03 07/2018

UTOMATIC STABILITY

Page 43

MultiLab 4010-3W ORP

To start the Stability control function manually, the HOLD function must be

enabled.

Hold function

Stability control

1. Freeze the measured value with <AR>.

The [HOLD] status indicator is displayed.

The HOLD function is active.

You can terminate the Stability control function and the HOLD function with <AR> or <M> at any time.

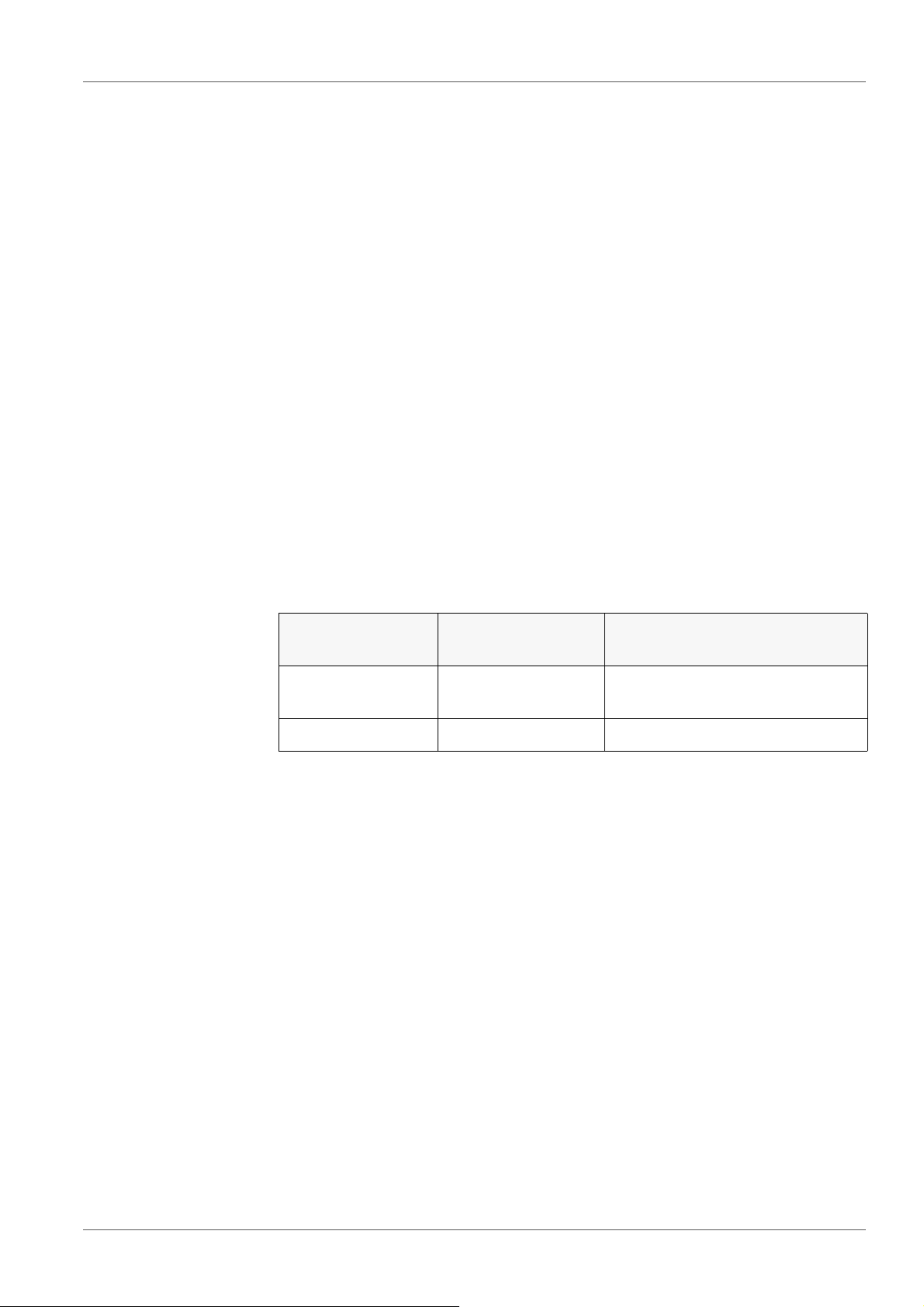

2. Using <ENTER>, activate the Stability control function manually.

The [AR] status indicator appears while the measured value is assessed

as not stable. A progress bar is displayed and the display of the measured parameter flashes.

As soon as a measured value meets the stability criteria, it is frozen. The

[HOLD][AR] status indicator is displayed, the progress bar disappears,

the display of the measured parameter stops flashing, and there is a

beep.

The current measurement data is output to the interface. Measurement

data meeting the stability control criterion is marked by AR.

Criteria for a stable

measured value

You can prematurely terminate the Stability control function manually with <ENTER> at any time. If the Stability control function is

prematurely terminated, the current measurement data are output

to the interfaces USB-B (USB Device, e.g. PC) and USB-A (USB

Host, e.g. USB memory device or USB printer) without AutoRead

info.

You can switch off the beep (see section 10.6 S

DENT SETTINGS, page 109).

ENSOR-INDEPEN-

3. Using <ENTER>, start a further measurement with stability control.

or

Release the frozen measured value again with <AR> or <M>.

The [AR] status display disappears. The display switches back to the

previous indication.

The Stability control function checks whether the measured values are stable

within the monitored time interval.

Measured parameter Time interval Stability in the time

interval

ORP 15 seconds

Temperature 15 seconds

∆ : better than 0.3 mV

∆ : better than 0.5 °C

The minimum duration until a measured value is assessed as stable is the

monitored time interval. The actual duration is mostly longer.

ba76194e03 07/2018 43

Page 44

ORP MultiLab 4010-3W

01.09.2017 08:00

i

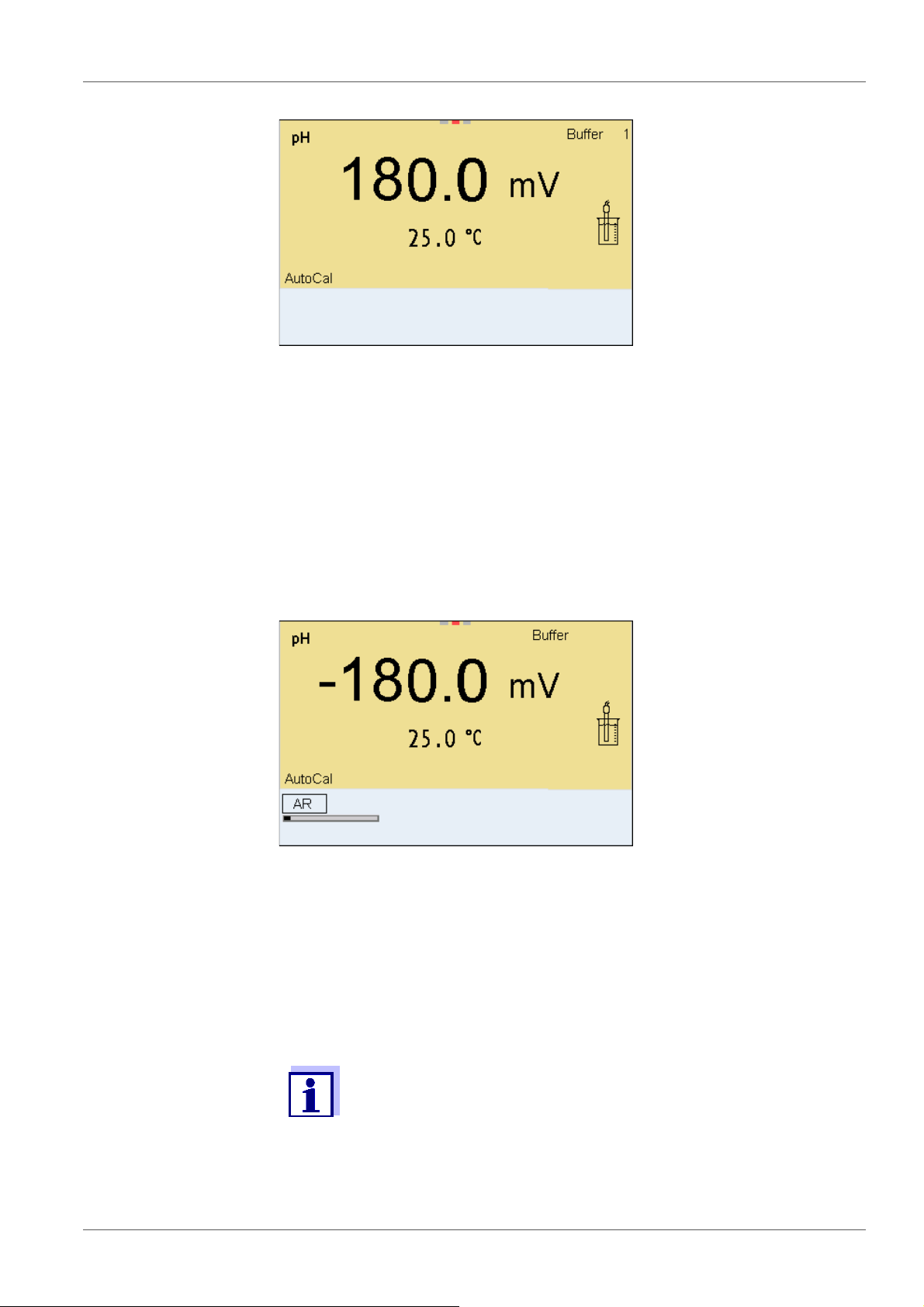

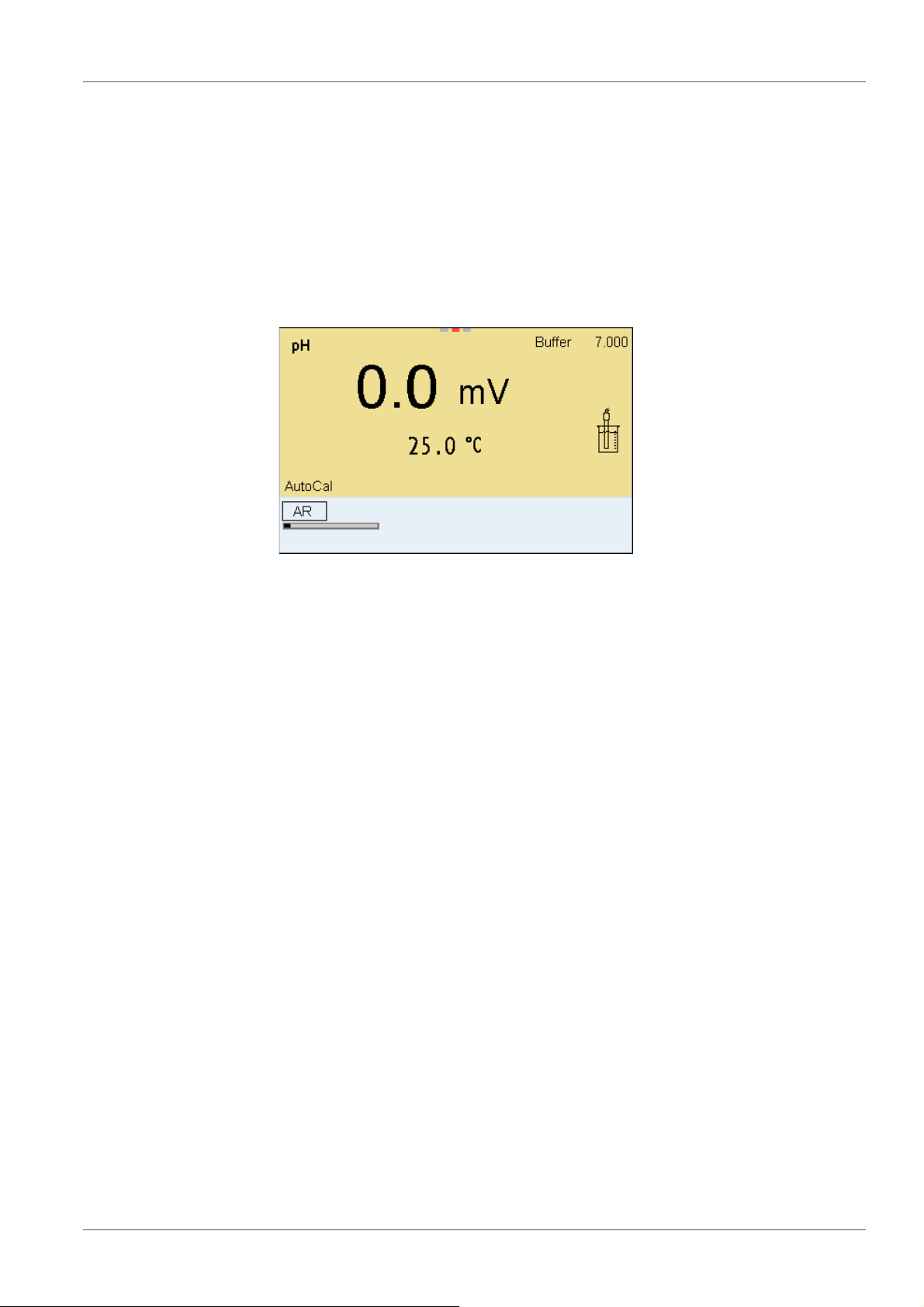

6.1.2 Measuring the relative ORP

To measure the difference of the ORPs of two solutions, you have to define the

ORP of one solution as the zero point first.

ORP electrodes can be used to determine the relative ORP.

1. Connect the ORP electrode to the meter.

2. Prepare the reference solution for the determination of the reference

point.

3. Select the ΔU (mV display with <M>.

4. Immerse the ORP electrode in the reference solution.

5. Display the potential of the current zero point with <CAL>.

6. Press <ENTER> to measure the reference solution.

The measured value is checked for stability (automatic stability control). The display of the measured parameter flashes.