YSI 400427 Operating Manual

Required Equipment

• Ion meter or pH/mV meter.

• W ash bottle w ith distill ed or d ei onized wat er.

• Several clean beakers.

• 1 mL, 10 mL and 10 0 m L pip ettes.

Required Solutions

• Reference Fill Solution YSI #400429

• 1000 ppm Potassium Standard YSI #400432

• 100 ppm Potassium Standard YSI #4 00 431

• Ionic Strength Adjustor (ISA) YSI #400430

Overview

The YSI 400427 Potassium Ion Selective Electrode is a

combination electrode (includes both reference and sensing

half c ells in one body h ousing) for m easuring potassium ion

+

) activity in aqueous samples.

(K

• Technology: Replaceable Polymer/PVC Membrane

(Replacement Potassi um Sensor Modul e YS I #400428)

• Size and material:

Body (Epoxy)—12 mm OD x 155mm L

Cap (ABS) —16 m m OD x 5 7 m m L

Cable (Coax type) – 100cm

BNC Connector

• Reference: Double-junction, Ag/AgCl, ceramic pin junction,

refillable, sodium chloride electrolyte

• Features: Replaceable Sensor Modules

• Range: 0.04-39,000 mg/L

• Reproducibility: ±4%

• Slope: 54 t o 59 mv/decade @ 25°C typical

• pH range: 2-12

• Operating Temperature: 0 to 40°C

• Interferences:

• Applications/Notes: Very popular for agriculture,

food/b everage, environmental, in dus t rial

Cs

+

+

, NH

, Tl+, H+, Ag+,Tris+, Na+, Li+ others

4

Electrode Preparat io n

1. This electrode performs better when the reference

junction is kept wetted during transit and storage.

However the sensor module is best stored and

transp orted dry. T heref ore, the electr ode is shipped with

a Module Blank that must be removed prior to use.

Unscrew the cap of the storage solution bottle (Soaker

Bottle) and remove the electrode. Unscrew the Module

Blank and replac e it with a sensor modu le prior to use.

The M odul e Bl ank c an be r etain ed f or l ong t er m st or age.

Caution: Do not touch the PVC sensor membrane

with your fingers.

2. Filling the electrode with electrolyte - the reference

(outer) chamber must be filled with Reference Fill

Solution and remain open during testing:

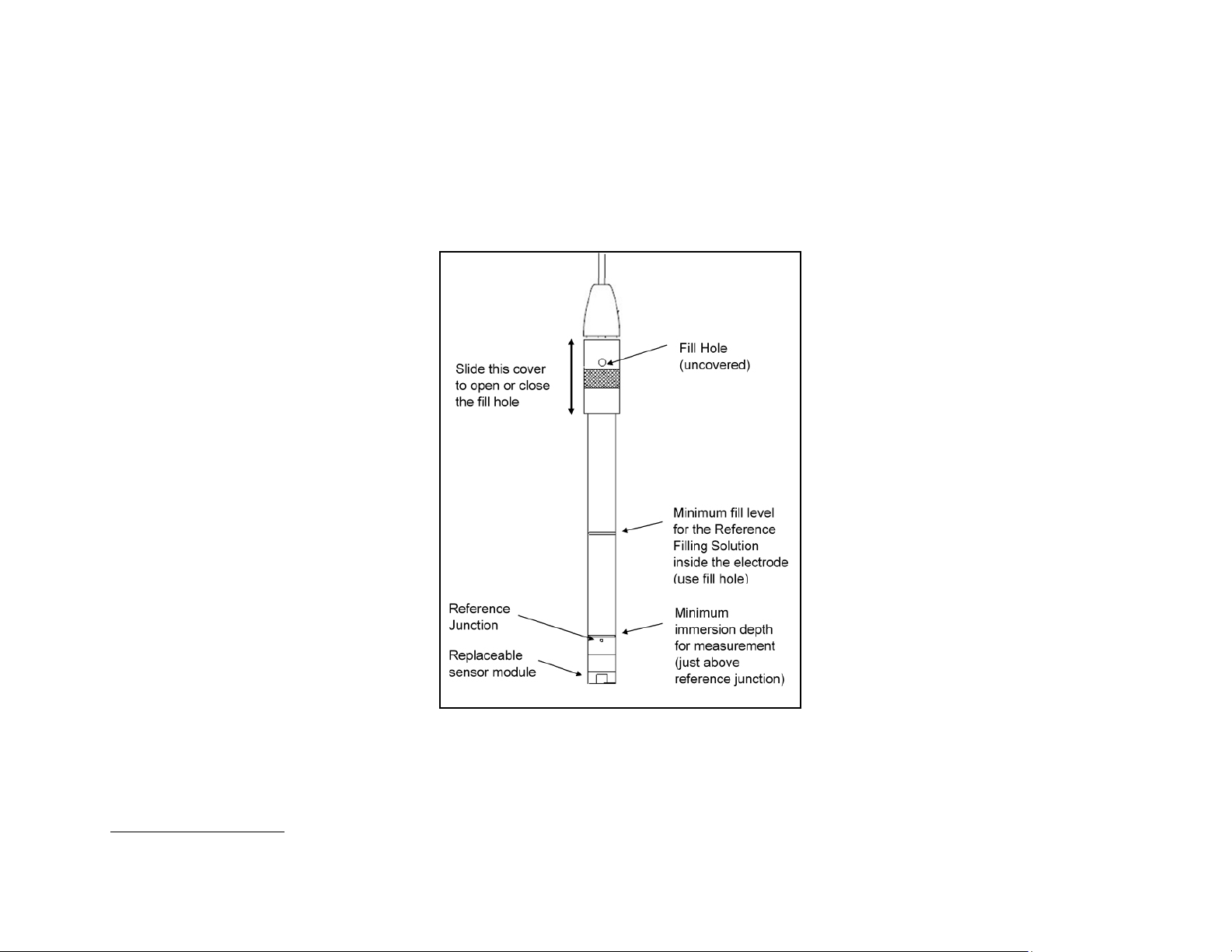

a) Slide the sleeve of the electrode FastFil cap down to

uncover the fill hole. (see fig. 1)

b) Shake the electrode downward like a thermometer to

remove an y air bubbles trapped inside .

c) The surface of the Reference Fill Solution in the

refer ence chamber mus t b e ab ov e the inner junc t i on.

This is approximately 3" from the electrode tip.

3. Rinse the electrode with Dl water, blot dry. Do not rub

dry.

4. Soak th e electr ode in Dl water f or 10 minu tes, then i n a

diluted Potassium Standard Solution for two hours prior to

calibration or use.

Electrode Diag ram (fig. 1)

Checking Electrode Operation (Slope)

1. Connect the el ectrode to t he met er. Place 1 00 mL D l w ate r

into a 1 50 mL b eaker. Add 2 mL Potassium ISA to the Dl

water and stir t h oroughly.

2. Set the function switch to the mV mode.

3. Rinse the el ect rod e with D l water , blot dr y and plac e in th e

solution prepared in step 2.

4. Pipet 1 mL of 1000 ppm Potassium Standard into the

beaker. Stir th oroughly, then r ec ord the potent i al (

when a stable reading is displayed.

5. Pipett e 10 mL of the s ame st and ard i nto th e sam e beak er .

Stir th oroughly. When a s table r ead i ng is display ed , record

the potential (E

6. The dif ferenc e between the first and the second potential

readings (E

normal range for the slope is 56±4 mV at 25°C.

) in mV.

2

) is defined as the electrode slope. The

2-E1

E

) in mV

1

Troubleshooting

If the electrode slope is not within the normal range, the

follow in g procedure m ay restor e the el ectrode.

1. Soak the electrode in a diluted standard solution for 2

hours before use.

2. Repeat "C hecking Elec trode Operati on" procedure ag ain.

Note: A ll st and ard s olutions s houl d be pr epar ed f resh . For

best performance use ISA in all solutions.

Periodically check the Reference Fill Solution level in the

refer ence chamber of the electrode. Th e s olut ion level m us t be

higher than the inner junction which is visible as a white

ceramic pin on the inner body.

If the electrod e s l op e i s s til l out s i d e the normal r an g e after this

procedure, you must replace the sensing module.

Reading a Sample with the Elect rod e

Various procedures may be used to determine the

concentration of a sample. The most common is the Direct

Calibration method, which is described below . Contact YSI’s

technical service department for details of other methods.

In Dir ect Cal ibrati on a s eries of stand ard s oluti ons of d iff ering

concent rations are us ed to c alibr ate the electr ode. Th en each

sample requires only a single meter reading, which is

compar ed with the c alibration r eadings to obt ain the sample

concentration. ISA is added to all solutions to ensure the

samples and the standards have the same ionic strength.

Set up:

1. Prepare the electrode as described in "Electrode

Prepar ati on" and " C h ec k in g E l ec trode Operation". Connect

the electrode to the meter.

2. Prepar e two st andard s olut ions th at diff er in c oncentr atio n

by a factor of ten and bracket the expected sample

concentration range. For example, if your expected sample

concent ration is 50 mg/L Potassium, you s hould us e a 10

mg/L low S t an dard Sol ution and a 100 mg/L hi gh Standar d

Solution.

NOTE: Temperature compensation is not typical of ISE

measurements - for best per f or m ance, try to ens ure that

the standards are within 5 to 10°C of the sample.

Measurement:

If using a meter with direct concentration reading capability

(see the meter instruction manual for specific information):

1. Place 1 00 mL of the low stan dard into a 150 mL be aker.

Add 2 mL of ISA. Stir thoroughly.

2. Rinse electrode with Dl water, blot dry and place in the

beaker. Wait for a stable reading, and then adjust the

meter to display the value of the standard. Refer to th e

meter's instruction manual for the meter adjustment

procedure.

3. Measur e 100 mL of the high standard into a second 150

mL beaker. Add 2 mL of ISA an d stir.

4. Rinse electrode with Dl water, blot dry and place in the

second b eaker . Wait for a s tabl e readin g, an d then adjus t

the meter to display the value of the second standard.

5. Pipett e 100 mL of s ampl e into a 150 mL beak er. A dd 2 mL

of ISA. Stir tho roughly .

6. Rinse electrode with Dl water, blot dry and place in the

sampl e beaker. W ait f or a stabl e reading and th e sampl e

concent r at i on w il l be dis p l ay ed on the met er.

7. Determ ine the s ample conc entration us ing the c alibratio n

curve prepared in Step 6 above.

Electrode Storage

Short Term (over night or the weekend):

Rinse the el ectr ode thor oughl y with Dl wat er and pl ace the tip

in a diluted standard solution between measurements. Slide

the FastFil sleeve to close the fill hole.

Refill the reference before putting the electrode back into

service.

Long Term:

Refill the electr ode with R eferenc e Filling S olution an d close

the fill hole. Remove the sensing element and store in the

glass vial or replace the cap to protect the sensing element.

Follow procedures in "Electrode Preparation" and "Checking

Electrode Operation" before using the electrode again.

Electrode Cleaning

Cleaning should only be attempted if troubleshooting methods

fail. The PVC membrane is a delicate sensor and should not

be brush ed or oth erwise contacted. It can be rinsed vigorously

under warm water to remove debris. Soaking for 10-15

minutes in DI water might be useful in extracting other

contaminants.

Recondition the electrode by soaking in a low standard

soluti on im m ed iately aft er an y cl eaning method.

Warr anty Statement

The YSI TruLine Potassium ISE is warranted for nine (9)

months from date of purchase b y t he end user ag ains t def ec ts

in materi als and work mans hip. W ithin the w arr anty p eri od, YSI

will r epair or r eplac e, at its s ole dis cr eti on, f ree of ch ar ge, any

product that YSI determines to be covered by this warr anty.

To exerc ise this war ranty, c all your local YSI representative, or

contact YSI Cust omer Service in Yell ow Springs, Ohio at +1

937 767-7241, 800-897-4151, info@ysi.com or visit ysi.com

(Support tab). Send the product and proof of purchase,

transportation prepaid, to the Authorized Service Center

select ed by YSI . Repair or replacement will be made and t he

product returned, transportation prepaid. Repaired or replaced

products ar e warran ted f or the bal anc e of the ori ginal warr ant y

period, or at least 90 days from date of repair or replacement.

LIMITAT ION OF WARR A NTY

This W arr anty does not app l y to any YSI produc t d am ag e or

failure caused by:

1) failure to install, operate or use the product in

accord ance with YSI's wr i tt en ins tructi ons ;

2) abuse or misus e of the product ;

3) failure to main t ain the product in ac cordanc e wi th YSI 's

written ins tructions or standard industry procedure;

4) any improper repairs to the product;

5) use by you of defect i ve or im pr oper components or p arts

in servicing or repairing the product;

6) modificati on of th e product in any w a y not e xpressl y

authorized by YSI.

THIS WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING

ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. YSI's LIABILIT Y UNDER

THIS WARRANTY IS LIMITED TO REPAIR OR

REPLACEMENT O F THE PRODUCT, AND THIS SHALL BE

YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY

DEFECTIVE PRODUCT COVERED BY THIS WARRANTY.

IN NO EVENT SHALL YSI BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES

RESULTING FROM ANY DEFECTIVE PRODUCT COVERED

BY THIS WARRANTY.

1725 Brannum Lane

Yellow Springs, OH

Tel: +1 937-767-7241

DOCUMENT ID: 400427MAN FEB2016C

YSI

800-765-4974

info@ysi.com

ysi.com

Loading...

Loading...