Page 1

FORM 160.81-EG1 (502)

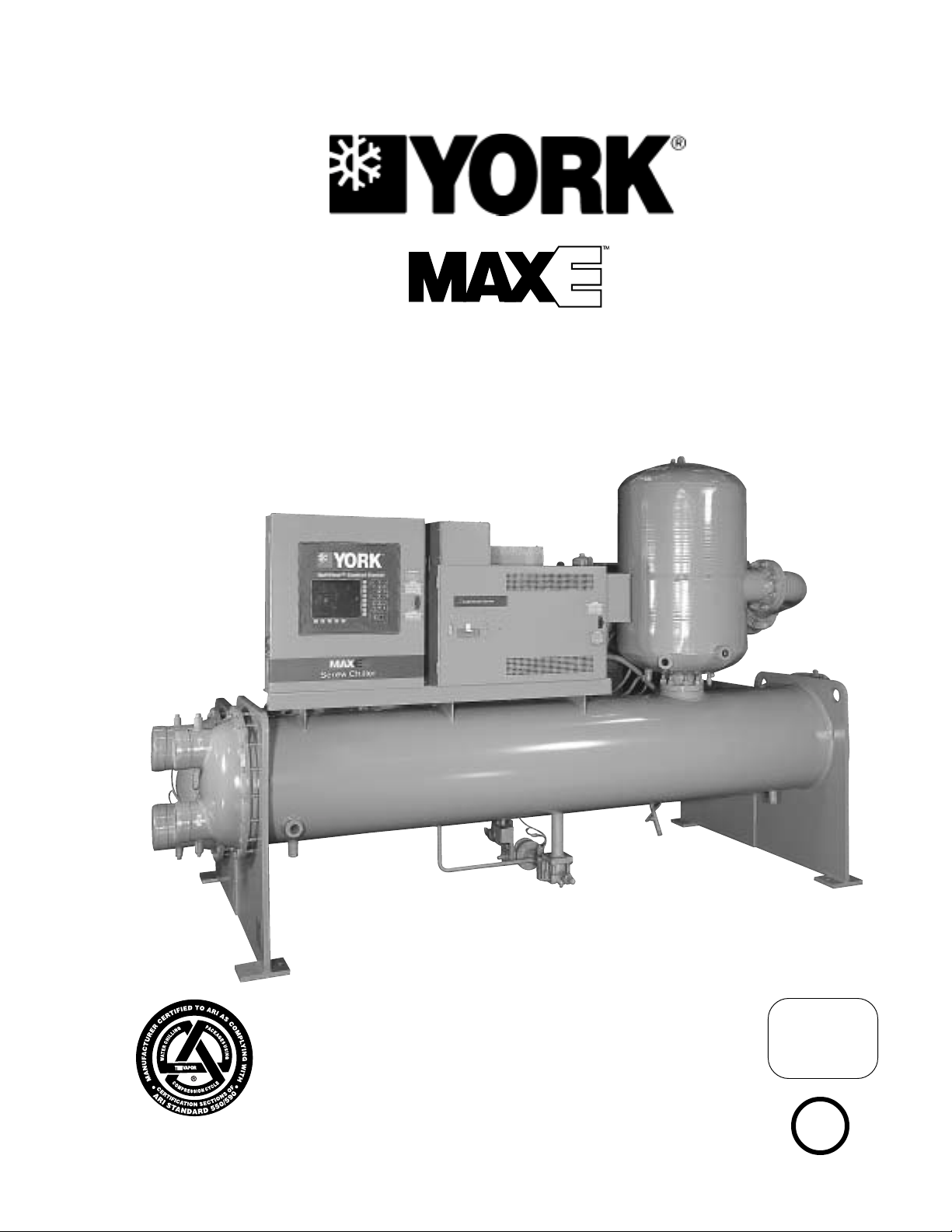

Model YR

Twin-Screw Compressor Liquid Chillers

Design Level A

Rated in Accordance

with the latest edition of ARI

ST ANDARD 550/590

200 through 430 tons (60 Hz)

700 through 1500 kW (50 Hz)

170 through 365 tons (50 Hz)

600 through 1280 kW (50 Hz)

Utilizing HFC-134a

00562VIP

ASHRAE

90.1

COMPLIANT

m

Metric Conversions

Page 2

Table of Contents

PAGE

INTRODUCTION.......................................................... 3

FORM 160.81-EG1

LIST OF TABLES

RATINGS ..................................................................... 4

OPTIVIEW CONTROL CENTER ................................. 5

MECHANICAL SPECIFICATIONS............................... 13

ACCESSORIES & MODIFICATIONS .......................... 17

SI METRIC CONVERSION.......................................... 18

APPLICATION DATA.................................................... 19

DIMENSIONS – STD. .................................................. 26

Evaporator, Condenser & Water Boxes ................... 26

Evaporators, Compact Water Boxes (ft.-in.)............ 28

Evaporators, Compact Water Boxes (mm).............. 29

Condensers, Compact Water Boxes (ft.-in.) ............ 30

Condensers, Compact Water Boxes (mm) .............. 31

Floor Layout, Neoprene Isolators (In.) ..................... 32

Floor Layout, Neoprene Isolators (mm) ................... 33

Floor Layout, Spring Isolators (In. and mm) ............ 34

WEIGHTS – Std. and Metric........................................ 35

GUIDE SPECIFICATIONS ........................................... 36

TABLE

NO.

1 Water Flow Rate Limits................ 19

2 Motor Voltage Variations .............. 22

3 60 Hz Electrical Data.................... 23

4 Motor Starters............................... 24

5 50 Hz Electrical Data.................... 24

6 Available Compressor/Shell/

Motor Combinations ..................... 24

PAGE

Model

Evaporator Code

Condenser Code

The model number denotes the following characteristics of the unit:

Compressor Code

NOMENCLATURE

YR TD TD T0 – 46 A S

Special Features

Design Level

Motor Code

Power Supply:

– for 60 Hz

5 for 50 Hz

2

YORK INTERNATIONAL

Page 3

Introduction

FORM 160.81-EG1

The YORK MAXE YR Chiller offers a complete combination of features for total owner satisfaction.

MATCHED COMPONENTS MAXIMIZE EFFICIENCY

Actual chiller efficiency cannot be determined by analyzing the theoretical efficiency of any one chiller component. It requires a specific combination of heat exchanger, compressor , and motor performance to achieve

the lowest system IPL V/NPL V . YORK M

AXE chiller tech-

nology matches chiller system components to provide

maximum chiller efficiency under actual – not just theoretical – operating conditions.

REAL-WORLD ENERGY PERFORMANCE

YORK pioneered the term “Real-World Energy” to illustrate the energy-saving potential of focusing on chiller

performance during off-design conditions. Off-design

is not only part-load, but full-load operation as well, with

reduced entering condenser water temperatures

(ECWT s). This is where chillers operate 99% of the time,

and where operating costs add up.

The YR M

AXE chillers are the only chillers designed to

operate on a continuous basis with cold ECWT and full

condenser flow at all load points, taking full advantage

of Real-World conditions. This type of operation benefits

the cooling tower as well; reducing cycling of the fan

motor and ensuring good coverage of the cooling fill.

YORK M

AXE chillers offer the most efficient Real-World

operation of any chiller, meaning lower operating costs

and an excellent return on your chiller investment.

HIGH-EFFICIENCY OIL SEPARATOR

HIGH-EFFICIENCY HEA T EXCHANGERS

M

AXE chiller heat exchangers offer the latest technology

in heat transfer surface design to give you maximum

efficiency and compact design. Waterside and

refrigerant-side design enhancements minimize both energy consumption and tube fouling. The “skip-fin” design

at all intermediate tube supports provides maximum tube

wall thickness at the support area to extend tube life.

FACTORY PACKAGING

REDUCES FIELD LABOR COSTS

YORK M

AXE screw chillers are designed to keep instal-

lation costs low. Where installation access is not a

problem, the unit can be shipped completely packaged,

requiring minimal piping and wiring to complete the

installation.

For those units utilizing a factory installed Solid-State

Starter, the three power leads provide all power to the

chiller and its auxiliaries.

T AKE ADVANTAGE OF COLDER COOLING TOWER

WATER TEMPERATURES

YORK M

AXE screw chillers are designed to take full ad-

vantage of colder cooling tower water temperatures,

which are naturally available during most operating

hours. Considerable energy savings are available by

letting tower water temperature drop, rather than artificially holding it above 75°F (23.9°C), especially at low

load, as some chillers require.

U.L. ACCEPTANCE – YOUR ASSURANCE

OF RELIABILITY

M

AXE YR Screw Chillers utilize high-efficiency oil sepa-

ration, limiting oil carry-over to less than 500 ppm. Oil

is vital in screw compressors for lubrication, rotor sealing and cooling. However, oil in the evaporator can lead

to reduced heat transfer and reduced system performance. The high-efficiency oil separator keeps the oil

in the lube circuit and maximizes heat transfer efficiency .

YORK INTERNATIONAL

YORK M

AXE screw chillers are approved for listing by

Underwriter’s Laboratories for the United States and

Canada. Recognition of safety and reliability is your assurance of trouble-free performance in day-to-day building operation.

3

Page 4

Ratings

FORM 160.81-EG1

Rated in accordance with the latest

issue of ARI Standard 550/590.

ARI CERTIFICATION PROGRAM

The performance of YORK M

to the Air Conditioning and Refrigeration Institute (ARI)

complying with the certification sections of the latest

issue of ARI Standard 550/590. Under this Certification

Program, chillers are regularly tested in strict compliance with this Standard. This provides an independent,

third-party verification of chiller performance.

YORK YR screw chillers are designed to comply with

ASHRAE Standard 90.1-1999 and 90.1-2001. The superior part-load performance of the YORK YR chillers

far exceeds the IPLV/NPLV requirements of ASHRAE

90.1, providing superior Real World Energy savings

for efficiency conscious owners.

COMPUTERIZED PERFORMANCE RATINGS

Each chiller is custom-matched to meet the individual

building load and energy requirements. A large number of standard heat exchangers and pass arrangements are available to provide the best possible match.

It is not practical to provide tabulated performance for

each combination, as the energy requirements at both

AXE chillers is certified

full- and part-load vary significantly with each heat exchanger and pass arrangement. Computerized ratings

are available through each YORK sales office. These

ratings can be tailored to specific job requirements,

and are part of the ARI Certification Program.

OFF-DESIGN PERFORMANCE

Since the vast majority of its operating hours are spent

at off-design conditions, a chiller should be chosen not

only to meet the full-load design, but also for its ability

to perform efficiently at lower loads and lower tower

water temperatures. It is not uncommon for chillers with

the same full-load kW/TON to have an operating cost

difference of over 10% due to part-load operation.

Part-load information can be easily and accurately generated by computer. And because it is so important to

an owner’s operating budget, this information is now

standard within the ARI Certification Program in the

form of an Integrated Part-Load V alue (IPL V), and NonStandard Part-Load Value (NPLV).

The IPL V / NPLV formulas from ARI Standard 550/590

closely track chiller operations, and provide a more accurate indication of chiller performance than the previous IPL V / APLV formula. A more detailed analysis must

take into account actual building load profiles, and local weather data. Part-load performance data should

be obtained for each job using its own design criteria.

4

YORK INTERNATIONAL

Page 5

OptiView Control Center

FORM 160.81-EG1

OPTIVIEW CONTROL CENTER

The YORK OptiView Control Center , furnished as standard on each chiller, provides the ultimate in ef ficiency,

monitoring, data recording, chiller protection and operating ease. The control center is a factory-mounted,

wired and tested state-of-the-art microprocessor based

control system for R-134a screw chillers. The panel is

configured with a 10.4 inch diagonal color Liquid Crystal Display (LCD) surrounded by “soft” keys, which are

redefined with one keystroke based on the screen display at that time. This revolutionary development makes

chiller operation quicker and easier than ever before.

Instead of requiring keystroke after keystroke to hunt

for information on a small monochrome LCD screen, a

single button reveals a wide array of information on a

large, full-color illustration of the appropriate component, which makes information easier to interpret. This

is all mounted in the middle of a keypad interface and

installed in a locked enclosure.

The LCD display allows graphic animated display of

the chiller, chiller sub-systems and system parameters;

this allows the presentation of several operating parameters at once. In addition, the operator may view a

graphical representation of the historical operation of

the chiller as well as the present operation. A Status

Bar is displayed at all times on all screens. It contains

the System - Status Line and Details Line, the Control

Source, Access Level, Date and Time.

00550VIP

During the Start Sequence and System Lockout Delay ,

the system status will include a countdown timer indicating the time remaining. The control panel is compatible with the YORK Solid State Starter (optional),

Electro-mechanical (E-M) starter, or any customer supplied E-M starter that complies with the YORK R-1131

standard. The locations of various chiller parameters

are clearly marked and instructions for specific operations are provided. The panel verbiage is available in

other languages as an option, with English always available. Data can be displayed in either English or Metric

units, plus keypad entry setpoints of 0.1 increments.

Security access is provided to prevent unauthorized

change of setpoints. This is accomplished with three different levels of access and passwords for each level.

There are screens, displayed values, programmable

setpoints and manual controls only available with service level access to the chiller. They are only displayed

when logged in at the service access level. The Advanced

Diagnostics and troubleshooting information for the chiller

and the panel is also included at this access level.

The panel is fused through a 1-1/2 KVA transformer in

the compressor motor starter to provide individual overcurrent protected power for all controls. Numbered terminal strips for wiring such as Remote Start/Stop, Flow

Switch, Chilled Water Pump and Local or Remote Cycling Device are provided. The Panel also provides field

interlocks that indicate the chiller status. These con-

YORK INTERNATIONAL

5

Page 6

OptiView Control Center (continued)

FORM 160.81-EG1

tacts include a Remote Mode Ready To Start, a Cycling Shutdown, a Safety Shutdown and a chiller Run

Contact. Pressure transducers sense system pressures

and thermistors sense system temperatures. The output of each transducer is a DC voltage that is analogous to the pressure input. The output of each thermistor is a DC voltage that is analogous to the temperature it is sensing.

Setpoints can be changed from a remote location via

0-10VDC, 4-20mA, contact closures or through serial

communications. The adjustable remote reset range [up

to 20°F (11.1°C)] provides flexible, efficient use of remote signal depending on reset needs. Serial data interface to the YORK ISN Building Automation System (BAS)

is through the General Protocol Interface Card (GPIC),

which can be mounted inside the Control Center.

This printed circuit board requests the required data from

the Micro Board and makes it available for the YORK

ISN network. This optional board is available through

the YORK BAS group. The operating program is stored

in non-volatile memory (EPROM) to eliminate chiller

failure due to AC power failure/battery discharge. Programmed setpoints are retained in lithium batterybacked RTC memory for 11 years minimum.

Smart Freeze Point Protection can operate the chiller

as low as 36°F (2.22°C) leaving chilled water temperature, without nuisance trips on Low Water Temperature.

The sophisticated program and sensor monitors the

chiller water temperature to prevent freeze-up. Each

programmable point has a pop-up screen with the allowable ranges, so the chiller cannot be programmed

to operate outside of its design limits.

Thermal ice storage systems are based on the concept

of using off-peak, lower cost electricity to build ice for

handling the cooling load during peak hours. The most

efficient way to build ice is to maximize chiller load and

minimize run time. Standard chiller control systems are

not designed for this operating mode. In a typical application, chillers will load and unload to maintain a leaving

chilled liquid setpoint. When the YORK YR chiller operates in the thermal storage control mode, the unit will

remain at 100% load until the setpoint shutdown temperature is reached. To add greater operating flexibility

and eliminate unnecessary chiller cycling, two different

Low Water (Liquid) T emperature Restart Thresholds can

be programmed, one for the ice mode and one for the

standard cooling mode. This control enhancement is standard on all YR chillers. The chiller can also be left in the

standard control mode for temperatures ranging between

20 and 70°F (-6.7 and 21.1°C), for applications involving

a process or comfort cooling duty that requires leaving

chilled liquid temperature setpoint control.

When power is applied to the chiller, the HOME screen is

displayed. This screen displays a visual representation of

the chiller and a collection of data detailing important operations and parameters. When the chiller is running, the

flow of chilled liquid is animated by the alternating shades

of color moving in and out of the pipe nozzles. The primary values that need to be monitored and controlled are

shown on this screen. They are as follows:

Display Only:

• Chilled Liquid Temperature – Leaving

• Chilled Liquid Temperature – Return

• Condenser Liquid Temperature – Return

• Condenser Liquid Temperature – Leaving

• Motor Run (LED)

• % Full-load Amps

• Operating Hours

With the “soft” keys the operator is only one touch away

from the 8 main screens that allow access to the major

information and components of the chiller. The 8 screens

are the SYSTEM, EV APORAT OR, CONDENSER, COM-

PRESSOR, OIL SUMP, MOTOR, SETPOINTS, and the

HISTORY. Also on the Home Screen is the ability to Log

IN, Log OUT and Print. Log In and Log Out is the means

by which different security levels are accessed.

The SYSTEM screen gives a general overview of com-

mon chiller parameters for both shells. This is an end

view of the chiller with a 3-D cutaway of both the shells.

The following can be viewed from this screen:

Display Only:

• Discharge Temperature

• Chilled Liquid Temperature – Leaving

• Chilled Liquid Temperature – Return

• Chilled Liquid Temperature – Setpoint

• Evaporator Pressure

• Evaporator Saturation Temperature

• Condenser Liquid Temperature – Leaving

• Condenser Liquid Temperature – Return

• Condenser Pressure

• Condenser Saturation Temperature

• Oil Temperature

• Differential Oil Pressure

• % Full-load Amps

• Current Limit

• Slide Valve Position

6

YORK INTERNATIONAL

Page 7

FORM 160.81-EG1

The EVAPORATOR screen displays a cutaway view of

the chiller evaporator. All setpoints relating to the evaporator side of the chiller are maintained on this screen.

Animation of the evaporation process indicates whether

the chiller is presently in RUN condition (bubbling) and

liquid flow in the pipes is indicated by alternating shades

of color moving in and out of the pipes. Adjustable limits on the low water temperature setpoints allow the

chiller to cycle on and off for greater efficiency and less

chiller cycling. The chiller cycles off when the leaving

chilled water temperature is below setpoint and is adjustable from 1°F (0.55°C) below to a minimum of 36°F

(2.22°C). Restart is adjustable from setpoint up to a

max. of 80°F (26.6°C). The Panel will check for flow to

avoid freeze-up of the tubes. If flow is interrupted, shutdown will occur after a minimum of two seconds. The

following can also be performed through this screen:

Display Only:

• Chilled Liquid Flow Switch (Open/Closed)

• Chilled Liquid Pump (Run/Stop)

• Evaporator Pressure

• Evaporator Saturation Temperature

• Return Chilled Liquid Temperature

• Leaving Chilled Liquid Temperature

• Evaporator Refrigerant Temperature

• Small Temperature Difference

• Leaving Chilled Liquid Temperature Setpoints –

Setpoint

• Leaving Chilled Liquid Temperature Setpoints –

Remote Range

• Leaving Chilled Liquid Temperature Setpoints –

Shutdown

• Leaving Chilled Liquid Temperature Setpoints –

Shutdown Offset

• Leaving Chilled Liquid Temperature Setpoints –

Restart

• Leaving Chilled Liquid Temperature Setpoints –

Restart Offset

• Ice Storage Active (LED)

Programmable:

• Local Leaving Chilled Liquid Temperature – Range

• Local Leaving Chilled Liquid T emperature – Setpoint

• Leaving Chilled Liquid Temperature Cycling Offset –

Shutdown

• Leaving Chilled Liquid Temperature Cycling Offset –

Restart

The CONDENSER screen displays a cutaway view of

the chiller condenser. The liquid flow is animated to indicate flow through the condenser. All setpoints relating to the condenser side of the chiller are maintained

on this screen. With the proper access level this screen

also serves as a gateway to controlling the Refrigerant

Level. The following can also be viewed through this

screen:

Display Only:

• Leaving Condenser Liquid Temperature

• Return Condenser Liquid Temperature

• Condenser Pressure

• Condenser Saturation Temperature

• Small Temperature Difference

• High Pressure Switch (Open/Closed)

• Condenser Liquid Flow Switch

• Condenser Liquid Pump (Run/Stop)

Programmable:

• High Pressure Warning Threshold

• Freeze Warning (Enabled/Disabled)

• Freeze Time

The COMPRESSOR screen displays a cutaway view

of the chiller compressor, revealing the rotary screw,

and shows all conditions associated with the compressor. The slide valve positioning is animated and with

the proper Access level, it can be manually controlled.

Animation of the compressor rotors indicates whether

the chiller is presently in a RUN condition. This screen

also serves as a gateway to sub-screens for calibrating

the slide valve or configuring the optional Hot Gas Bypass. From this screen you can view the following:

Display Only:

• Differential Oil Pressure

• Oil Temperature

• Discharge Temperature

• Discharge Superheat

• Slide Valve Position

• Oil Return Solenoid (LED)

• Full-load Amps (E.M. Starter Only)

• Phase A, B, C Current (SSS Only)

Programmable:

• Slide Valve Load (Manual)

• Slide Valve Hold (Manual)

YORK INTERNATIONAL

7

Page 8

OptiView Control Center (continued)

FORM 160.81-EG1

• Slide Valve Unload (Manual)

• Slide Valve Auto

• Max. Load Temperature

• Minimum Load FLA

• Minimum Load Control Source

The HOT GAS BYPASS screen, accessed from the

COMPRESSOR screen, displays a pictorial of the bypass line and solenoid valve location on the chiller. The

Hot Gas ON and OFF Setpoints are programmed on

this screen and system parameters pertinent to Hot Gas

Bypass operation are displayed. An LED illuminates

when the Hot Gas solenoid is ON. If the chiller is

equipped with the Hot Gas Bypass option, operation

must be enabled on the OPERATIONS screen. From

this screen you can perform the following:

Display Only:

• Slide Valve Position

• Return Chilled Liquid Temperature

• Leaving Chilled Liquid Temperature

• Hot Gas Solenoid (LED)

Programmable:

• On Setpoint

• Off Setpoint

The SLIDE VALVE CALIBRATION screen displays a

cutaway view of the chiller compressor, revealing the

rotary screw and slide valve and provides the capability of calibrating the slide valve. From this screen, you

can perform the following:

Display Only:

• Slide Valve Loading (LED)

• Slide Valve Unloading (LED)

• Calibration Message

Programmable:

• Start Calibration

• Cancel Calibration

The OIL SEPARATOR screen displays a close-up view

of the chiller oil separator/sump.

Display Only:

• Discharge Temperature

• Discharge Superheat

• Oil Pressure

• Discharge Pressure

8

• Differential Oil Pressure

• Differential Filter Pressure

• Oil Return Solenoid (LED)

• Evaporator Pressure

• Condenser Pressure

• Condenser Saturation

1. The MOTOR “soft” key on the HOME screen, when

pressed, shows a picture of either a YORK ElectroMechanical Starter or a Solid State Starter, depending on chiller configuration. The Programmable

pulldown demand to automatically limit motor loading can be used to minimize building demand

charges. Pulldown time period control over four

hours, and verification of time remaining in pulldown

cycle from display readout. Separate digital setpoint

for current limiting between 30 and 100%.

The ELECTRO-MECHANICAL STARTER (E–M)

screen displays a picture of the starter and the following values. The ones below are common among both

offerings and the values will be displayed on both types

of starter screens. From this screen you can perform

the following:

Display Only:

• Motor Run (LED)

• Motor Current % Full-load Amps

• Current Limit Setpoints

• Pulldown Demand Time Left

Programmable:

• Local Motor Current Limit

• Pulldown Demand Limit

• Pulldown Demand Time

The SOLID STATE STARTER (SSS) screen displays a

picture of the starter and the following values, which are

displayed in addition to the common ones listed above.

From this screen, you can perform the following:

Display Only:

• Input Power kW

• kW Hours

• Starter Model

• Voltage – Phase A, B, C

• Current – Phase A, B, C

• Temperature – Phase A, B, C

YORK INTERNATIONAL

Page 9

FORM 160.81-EG1

Programmable:

• Full-load Amps

• Voltage Range

• Starting Current

• Open SCR

• Shorted SCR

• kWH Reset

The SETPOINTS screen provides a convenient location for programming the most common setpoints involved in the chiller control. The Setpoints are shown

on other individual screens, but to cut down on needless searching, they can all be found on this screen.

This screen also serves as a gateway to a sub-screen

for defining the setup of general system parameters.

From this screen you can perform the following:

Display Only:

• Leaving Chilled Liquid Temperature – Setpoint

• Leaving Chilled Liquid Temperature Cycling –

Shutdown

• Leaving Chilled Liquid Temperature Cycling –

Restart

• Current Limit Setpoint

Programmable:

• Local Leaving Chilled Liquid Temperature – Range

• Local Leaving Chilled Liquid T emperature – Setpoint

• Leaving Chilled Liquid Temperature Cycling Offset –

Shutdown

• Leaving Chilled Liquid Temperature Cycling Offset –

Restart

• Remote Analog Input Range

• Local Motor Current Limit

• Pulldown Demand Limit

• Pulldown Demand Time

• Print

The SETUP is the top level of the general configuration parameters. It allows programming of the time and

date, along with specifications as to how the time will

be displayed. In addition, the chiller configuration as

determined by the Micro Board program jumpers and

program switches is displayed. From this screen you

can perform the following:

Display Only:

• Chilled Liquid Pump Operation (Displays Standard

or Enhanced)

• Anti-Recycle (Displays Disabled or Enabled)

• Power Failure Restart (Displays Manual or Automatic)

• Liquid Type (Displays Water or Brine)

Programmable:

• Set Date

• Set Time

• Clock (Enabled/Disabled)

• 12/24 Hour

The following six subscreens can be accessed from

the SETUP screen:

The SCHEDULE screen contains more programmable

values than a normal display screen. Each programmable value is not linked to a specific button; instead,

the select key is used to enable the cursor arrows and

check key to program the Start/Stop times for any day

of the week up to 6 weeks in advance. The user has

the ability to define a standard set of Start/Stop times

that are utilized every week or specify exceptions to

create a special week.

Programmable:

• Exception Start/Stop Times

• Schedule (Enable/Disable)

• Repeat Sunday Schedule

• Standard Week Start/Stop Times

• Reset All Exception Days

• Select

• Print

YORK INTERNATIONAL

9

Page 10

OptiView Control Center (continued)

FORM 160.81-EG1

The USER screen allows definition of the language for

the chiller to display and defines the unit of measure.

Programmable:

• System Language

• English/Metric Units

The COMMS screen allows the user to define communications parameters.

Programmable:

• Chiller ID

• COM 2 Baud Rate

• COM 2 Data Bit(s)

• COM 2 Parity Bit(s)

• COM 2 Stop Bit(s)

• Printer Baud Rate

• Printer Data Bit(s)

• Printer Parity Bit(s)

• Printer Stop Bit(s)

The PRINTER screen permits the user to define communications Parameters for the Printer.

Display Only

• Time Remaining Until Next Print

Programmable

• Log Start Time

• Output Interval

• Automatic Printer Logging (Enabled/Disabled)

• Print Type

• Print Report

• Print All Histories

The SALES ORDER screen allows definition of the order parameters. Note: This information is loaded at the

factory or by the installation service technician.

The OPERATIONS screen permits definition of param-

eters pertaining to operation of the chiller. What is defined is whether the control of the chiller will be Local,

Digital Remote, Analog Remote, Modem Remote or ISN

Remote.

Programmable

• Control Source

The HISTORY screen allows the user to browse through

the last ten faults; either safety or cycling shutdowns

with the conditions, while the chiller is running or

stopped. The faults are color coded for ease in determining the severity at a glance, recording the date, time

and description. (See Display Messages for Color Code

meanings.)

Display Only

• Last Normal Shutdown

• Last Fault While Running

• Last Ten Faults

Programmable:

• Print History

• Print All Histories

By pressing the VIEW DETAILS key you will move to

the HISTORY DETAILS screen. From these screens

you are able to see an on-screen printout of all the system parameters at the time of the selected shutdown.

Display Only:

• History Printout

Programmable:

• Page Up

• Page Down

• Print History

Display Only

• Model Number

• Panel Serial Number

• Chiller Serial Number

• YORK Order Number

• System Information

• Condenser and Evaporator Design Load Information

• Nameplate Information

10

Also under the HISTORY screen is the TRENDING

screen, accessible by the key marked the same. On

this screen, up to six operator-selected parameters, selected from a list of over 140, can be plotted in an X/Y

graph format. The graph can be customized to record

points once every second up to once every hour. There

are two types of charts that can be created: single

screen, or continuous screen. The single screen collects data for one screen width (450 data points across

the X-axis), then stops. The continuous screen keeps

YORK INTERNATIONAL

Page 11

FORM 160.81-EG1

collecting the data, but the oldest data drops off the

graph from left to right at the next data collection interval. For ease of identification, each plotted parameter,

title and associated Y-axis labeling is color coordinated.

Display Only:

• This screen allows the user to view the graphical

trending of the selected parameters and is a gateway to the graph setup screens.

Programmable:

• Start

• Stop

• y-axis

• x-axis

The TREND SETUP screen is used to configure the

trending screen. The parameters to be trended are selected from the Trend Common Slots screen, accessed

from the Slot Numbers button or the Master Slot Numbers List found in the Operating Manual. The interval at

which all the parameters are sampled is selected under

the Collection Interval button. The data point minimum

and maximum values may be adjusted closer to increase viewing resolution.

DISPLAY MESSAGES

The Control Center continuously monitors the operating system, displaying and recording the cause of any

shutdowns (Safety, Cycling or Normal). The condition

of the chiller is displayed at the System Status line that

contains a message describing the operating state of

the chiller; whether it is stopped, running, starting or

shutting down. A System Details Line displays Warning, Cycling, Safety, Start Inhibit and other messages

that provide further details of the Status Bar messages.

Messages are color-coded: Green – Normal Operations;

Yellow – Warnings; Orange – Cycling Shutdowns; and

Red – Safety Shutdowns to aid in identifying problems

quickly.

Status messages include:

• System Ready To Start

• Cycling Shutdown – Auto Restart

• Safety Shutdown – Manual Restart

• Start Sequence Initiated

• System Run (with countdown timers)

• Start Inhibit

• Slide Valve Closing Before Shutdown

• System Lockout Delay

Programmable:

• Chart Type (select continuous or one screen)

• Collection Interval

• Select

• Data Point Slot Number (1 - 6)

• Data Point Min. (1 - 6)

• Data Point Max (1 - 6)

The TREND COMMON SLOTS screen displays the

Master Slot Numbers List of the monitored parameters.

Display Only:

• Slot Numbers

Programmable:

• Page Up

• Page Down

• Print

Run Messages include:

• Leaving Chilled Liquid Control

• Motor Pulldown Limit

• Motor – High Current Limit

Start Inhibit Messages include:

• Anti-Recycle XX min/sec.

• Slide Valve – Position >30%

• Motor Current >15% FLA

• LCSSS – High-Temperature Phase X - Stopped

Warning Messages include:

• Real Time Clock Failure

• Setpoint Override

• Condenser – High Pressure Limit

• Evaporator – Low Pressure Limit

• Freeze Threat From Operating Chiller

• Freeze Threat, Condenser Flow Switch Open

• Low Discharge Superheat Limit

YORK INTERNATIONAL

11

Page 12

OptiView Control Center (continued)

FORM 160.81-EG1

• Low Discharge Superheat Detected

• Maximum Load – Load Limit

• Minimum Load – Load Limit

• Oil – Dirty Filter

• Oil – High Temperature

• Slide Valve Uncalibrated

Routine Shutdown Messages Include:

• Remote Stop

• Local Stop

• Place Compressor Switch In Run Position

Cycling Shutdown Messages Include:

• Multiunit Cycling – Contacts Open

• System Cycling – Contacts Open

• Control Panel – Power Failure

• Leaving Chilled Liquid – Low Temperature

• Leaving Chilled Liquid – Flow Switch Open

• Condenser – Flow Switch Open

• Motor Controller – Contacts Open

• Motor Controller – Loss of Current

• Power Fault

• Control Panel – Schedule

Solid State Starter Only (LCSSS)

• Initialization Failed

• Serial Communications

• Requesting Fault Data

• Stop Contacts Open

• Power Fault

• Low Phase (X) Temperature Sensor

• Run Signal

• Invalid Current Scale Selection

• Phase Locked Loop

• Low Supply Line Voltage

• High Supply Line Voltage

• Logic Board Processor

• Logic Board Power Supply

• Phase Loss

Safety Shutdown Messages include:

• Evaporator – Low Pressure

• Evaporator – Low Pressure – Smart Freeze

• Evaporator – Transducer or Leaving Liquid Probe

• Evaporator – Transducer or Temperature Sensor

• Condenser – High Pressure Contacts Open

• Condenser – High Pressure

• Condenser – Pressure Transducer Out of Range

• Auxiliary Safety – Contacts Closed

• Discharge – High Temperature

• Discharge – Low Temperature

• Oil – Low Differential Pressure

• Oil or Condenser Transducer Error

• Oil – Clogged Filter

• Oil – High Pressure

• Control Panel – Power Failure

• Watchdog – Software Reboot

Solid State Starter Only (LCSSS)

• Shutdown – Requesting Fault Data . . .

• High Instantaneous Current

• High Phase (X) Heatsink Temperature – Running

• 105% Motor Current Overload

• Motor or Starter – Current Imbalance

• Open SCR

• Phase Rotation

12

YORK INTERNATIONAL

Page 13

Mechanical Specifications

FORM 160.81-EG1

GENERAL

Each YORK M

factory-packaged including evaporator, condenser , compressor, motor, OptiView control center and all interconnecting unit piping and wiring. The chiller will be

painted prior to shipment and will be packaged to protect the unit during shipment.

Performance will be certified in accordance with ARI

Standard 550/590.

The initial charge of refrigerant and oil will be supplied

for each unit.

DRIVELINE

The compressor will be twin-screw, rotary-screw type.

The compressor housing will be of cast iron, precision

machined to provide minimal clearance for the rotors.

The rotors will be manufactured from forged steel and

use asymmetric profiles operating at a maximum speed

of 3570 RPM (60 Hz) or 2975 RPM (50 Hz). The compressor will incorporate a complete anti-friction bearing

design to reduce power and increase reliability; cylindrical roller bearings to handle radial loads; and 4 point

angular contact ball bearings to handle axial loads. The

compressor will have an internal oil reservoir to assure

a constant supply of oil to the bearings at all times. A

check valve will be incorporated in the compressor housing to prevent rotor backspin during shutdown.

Capacity control will be achieved by use of a slide valve

to provide fully modulating control from 100% to 20%

of full-load. The slide valve will be actuated by system

differential pressure, controlled by external solenoid

valves through the OptiView control center. The unit

will be capable of operating with off-design cooling tower

water during part-load operation in accordance with ARI

Standard 550/590.

The motor will be 2-pole, continuous-duty, cage-induction type, and will utilize suction gas cooling (semi-hermetic design). Motor full-load amperes at design conditions will not exceed chiller nameplate (FLA). Motor will

be designed for use with the type starter specified.

LUBRICATION SYSTEM

An adequate supply of oil will be available to the compressor at all times. During operation, oil will be delivered by positive system pressure differential.

An immersion oil heater will be provided, (temperature

actuated), to effectively remove refrigerant from the oil

during the chiller off-cycle. An external, replaceable cartridge, oil filter will be provided, along with manual isola-

AXE YR Screw Chiller will be completely

tion stop valves for ease of servicing. An oil eductor will

be provided to automatically remove oil which may have

migrated to the evaporator, and return it to the compressor. The oil separator will be of a vertical design with no

moving parts, and will provide high-efficiency oil separation before the refrigerant enters the heat exchangers.

The oil separator will be designed, tested, and stamped

in accordance with the ASME Boiler and Pressure Vessel Code, Section VIII Division 1. Liquid refrigerant injection will be provided to maintain satisfactory oil temperatures and allow operation of the chiller over the full

range of conditions.

EVAPORATOR

Evaporator will be of the shell-and-tube, flooded type

designed for 235 PSIG (1620 kPa) working pressure on

the refrigerant side, and will be tested in accordance with

ASME code. The shell will be fabricated from rolled carbon steel plate with fusion welded seams or carbon steel

pipe; have carbon steel tube sheets, drilled and reamed

to accommodate the tubes; and intermediate tube supports spaced no more than four feet apart. The refrigerant side will be designed, tested and stamped in accordance with the ASME Boiler and Pressure Vessel Code,

Section VIII Division 1. Tubes shall be high-efficiency,

internally and externally enhanced type having plain copper lands at all intermediate tube supports to provide

maximum tube wall thickness at the support area. Each

tube will be roller expanded into the tube sheets providing a leak-proof seal, and be individually replaceable.

Water velocity through the tubes will not exceed 12 fps.

A liquid level sight glass will be located on the side of the

shell to aid in determining proper refrigerant charge. The

evaporator will have a refrigerant relief device to meet

the requirements of the ASHRAE 15 Safety Code for

Mechanical Refrigeration.

Water boxes will be removable to permit tube cleaning

and replacement. Stubout water connections having

victaulic grooves will be provided. Vent and drain connections with plugs will be provided on each water box.

CONDENSER

Condenser will be of the shell-and-tube type, designed

for 235 psig (1620 kPa) working pressure on the refrigerant side, and be tested in accordance with ASME code.

The shell will be fabricated from rolled carbon steel plate

with fusion welded seams or carbon steel pipe; have

carbon steel tube sheets, drilled and reamed to accommodate the tubes; and intermediate tube supports

spaced no more than four feet apart. A refrigerant

subcooler will be provided for improved cycle efficiency .

The refrigerant side will be designed, tested and

stamped in accordance with the ASME Boiler and Pres-

YORK INTERNATIONAL

13

Page 14

Mechanical Specifications (continued)

FORM 160.81-EG1

sure Vessel Code, Section VIII, Division 1. Tubes shall

be high-efficiency, internally and externally enhanced

type having plain copper lands at all intermediate tube

supports to provide maximum tube wall thickness at

the support area. Each tube will be roller expanded into

the tube sheets providing a leak proof seal, and be individually replaceable. Water velocity through the tubes

will not exceed 12 fps. The condenser will have refrigerant relief devices to meet the requirements of the

ASHRAE 15 Safety Code for Mechanical Refrigeration.

Water boxes will be removable to permit tube cleaning

and replacement. Stubout water connections having

victaulic grooves will be provided. Vent and drain connections with plugs will be provided on each water box.

REFRIGERANT SYSTEM

A modulating variable orifice controlled by the OptiV iew

Control Center to accommodate varying head conditions will meter refrigerant flow to the evaporator.

The condenser shell will be capable of storing the entire system refrigerant charge during servicing. Service

valves will be provided to facilitate removal of refrigerant charge from the system.

The unit will be equipped with a suction strainer to prevent any foreign debris introduced to the system during

maintenance or service to be allowed into the motor

housing. Motors cooled by refrigerant must be protected

by means of filter or strainer to protect the motor and

prolong motor life.

OPTIVIEW CONTROL CENTER

General

The chiller will be controlled by a stand-alone microprocessor based control center. The chiller control panel

will provide control of chiller operation and monitoring

of chiller sensors, actuators, relays and switches.

Control Panel

The control panel will include a 10.4 inch diagonal color

liquid crystal display (LCD) surrounded by “soft “ keys

which are redefined based on the screen displayed at

that time. It will be mounted in the middle of a keypad

interface and installed in a locked enclosure. The screen

will detail all operations and parameters, using a graphical representation of the chiller and its major components. Panel verbiage is available in other languages

as an option with English always available. Data can be

displayed in either English or Metric units. Smart Freeze

Point Protection will run the chiller at 36 °F (2.2°C) leav-

ing chilled water temperature, and not have nuisance

trips on low water temperature. The sophisticated program and sensor will monitor the chiller water temperature to prevent freeze up. When needed, Hot Gas Bypass is available as an option. The panel displays countdown timer messages so the operator knows when functions are starting and stopping. Every programmable

point will have a pop-up screen with the allowable

ranges, so that the chiller can not be programmed to

operate outside of its design limits.

The control panel is provided with a thermal ice storage control mode to enhance system performance during ice building operation. In the thermal storage control mode, the chiller will stay at 100% load until the

setpoint shutdown temperature is reached. To add

greater operating flexibility and eliminate unnecessary

chiller cycling, two different Low Water (Liquid) Temperature Restart Thresholds are programmable, one for

the ice mode and one for the standard cooling mode.

The chiller has the capability to remain in the standard

control mode for temperatures between 20 to 70°F (-

6.6 to 21.1°C) for applications involving a process or

comfort cooling duty that requires leaving chilled liquid

temperature setpoint control.

The chiller control panel also provides:

1. System operating information including:

a. return and leaving chilled liquid temperature

b. return and leaving condenser liquid

temperature

c. evaporator and condenser saturation

temperature

d. oil pressure at compressor and oil filter

differential

e. percent motor current

f. evaporator and condenser saturation

temperature

g. compressor discharge temperature

h. oil temperature

i. percent slide valve position

j. operating hours

k. number of unit starts

2. Digital programming of setpoints through the universal keypad including:

a. leaving chilled liquid temperature

b. percent current limit

c. pull-down demand limiting

d. six-week schedule for starting and stopping the

chiller, pumps and tower

e. remote reset temperature range

14

YORK INTERNATIONAL

Page 15

FORM 160.81-EG1

3. Status messages indicating:

a. system ready to start

b. system running

c. system coastdown

d. system safety shutdown-manual restart

e. system cycling shutdown-auto restart

f. start sequence initiated

g. start inhibit

4. The text displayed within the system status and

system details field will be displayed as a color

coded message to indicate severity: red for safety

fault, orange for cycling faults, yellow for warnings,

and green for normal messages.

5. Safety shutdowns enunciated through the display

and the status bar, and consist of system status,

system details, day, time, cause of shutdown, and

type of restart required. Safety shutdowns with a

fixed speed drive will include:

a. evaporator – low pressure

b. evaporator – low pressure – smart freeze

c. evaporator – transducer or leaving liquid probe

d. evaporator – transducer or temperature sensor

e. condenser – high pressure contacts open

f. condenser – high pressure

g. condenser – pressure transducer out of range

h. auxiliary safety – contacts closed

i. discharge – high temperature

j. discharge – low temperature

k. oil – low differential pressure

l. oil or condenser transducer error

m. oil – clogged filter

n. oil – high pressure

o. control panel – power failure

p. watchdog – software reboot

5.1. Safety shutdowns with a Solid State Starter

(LCSSS) will include:

a. shutdown – requesting fault data…

b. high instantaneous current

c. high phase (X) heatsink temperature - running

d. 105% motor current overload

e. motor or starter – current imbalance

f. phase (X) shorted SCR

g. open SCR

h. phase rotation

6. Cycling shutdowns enunciated through the display

and the status bar, and consists of system status,

system details, day , time, cause of shutdown, and

type of restart required. Cycling shutdowns with a

fixed speed drive will include:

a. multiunit cycling – contacts open

b. system cycling - contacts open

c. control panel - power failure

d. leaving chilled liquid - low temperature

e. leaving chilled liquid - flow switch open

f. condenser – flow switch open

g. motor controller – contacts open

h. motor controller – loss of current

i. power fault

j. control panel - schedule

6.1. Cycling shutdowns with a Solid State Starter

(LCSSS) will include:

a. initialization failed

b. serial communications

c. requesting fault data

d. stop contacts open

e. power fault

f. low phase (X) temperature sensor

g. run signal

h. invalid current scale selection

i. phase locked loop

j. low supply line voltage

k. high supply line voltage

l. logic board processor

m. logic board power supply

n. phase loss

7. Security access to prevent unauthorized change

of setpoints, to allow local or remote control of the

chiller, and to allow manual operation of the slide

valve. Access is through ID and password recognition, which is defined by three different levels of

user competence: view, operator, and service.

8. Trending data with the ability to customize points

of once every second to once every hour. The panel

shall trend up to 6 different parameters from a list

of over 140, without the need of an external monitoring system.

9. The operating program stored in non-volatile

memory (EPROM) to eliminate reprogramming the

chiller due to AC power failure or battery discharge.

Programmed setpoints will be retained in lithium

battery-backed RTC memory for a minimum of 11

years with power removed from the system.

10. A fused connection through a transformer in the

compressor motor starter to provide individual

over-current protected power for all controls.

YORK INTERNATIONAL

15

Page 16

Mechanical Specifications (continued)

FORM 160.81-EG1

11. A numbered terminal strip for all required field interlock wiring.

12. An RS-232 port to output all system operating data,

shutdown / cycling message, and a record of the

last 10 cycling or safety shutdowns to a field-supplied printer. Data logs to a printer at a set programmable interval. This data can be

preprogrammed to print from 1 minute to 1 day.

13. The capability to interface with a building automation system to provide:

a. remote chiller start and stop

b. remote leaving chiller liquid temperature adjust

c. remote current limit setpoint adjust

d. remote ready to start contacts

e. safety shutdown contacts

f. cycling shutdown contacts

g. run contacts

STARTUP AND OPERATOR TRAINING

The services of a factory-trained, field service representative will be provided to supervise the initial startup

and conduct concurrent operator instruction.

CODES AND STANDARDS

• ASME Boiler and Pressure Vessel Code – Section

Vlll Division 1.

• ARI Standard 550/590

• c/U.L. – Underwriters Laboratory

• ASHRAE 15 – Safety Code for Mechanical Refrigeration

• ASHRAE Guideline 3 – Reducing Emission of Halogenated Refrigerants in Refrigeration and Air-Conditioning Equipment and Systems

• NEC – National Electrical Code

• OSHA – Occupational Safety and Health Act

ISOLATION MOUNTING

The unit is provided with four vibration isolation mounts

consisting of 1" (25.4 mm) thick neoprene isolation pads

for field mounting under the steel mounting pads located on the tube sheets.

REFRIGERANT CONTAINMENT

The standard unit has been designed as a complete

and compact factory packaged chiller. As such, it has

minimum joints from which refrigerant can leak. The

entire assembly has been thoroughly leak tested at

the factory prior to shipment. The YORK chiller includes service valves conveniently located to facilitate transfer of refrigerant to a remote refrigerant storage/recycling system. Optional condenser isolation

valves permit storage of the charge in the condenser.

PAINT

Exterior surfaces are protected with one coat of Caribbean blue, durable alkyd-modified, vinyl enamel, machinery paint.

SHIPMENT

The unit shall be completely assembled, with all main,

auxiliary, and control piping installed, controls wired,

leak tests completed, functional run tests completed,

and refrigerant charge in place. The oil charge, relief

device and other miscellaneous materials shall be

packed separately.

Protective covering is furnished on the Control Center

and unit-mounted controls. The entire unit is then shrinkwrapped with high-quality reinforced plastic to provide

maximum protection during transit. Water nozzles are

capped with fitted plastic enclosures.

16

YORK INTERNATIONAL

Page 17

Accessories and Modifications

FORM 160.81-EG1

SOLID STATE STARTER

The Solid State Starter is a reduced voltage starter that

controls and maintains a constant current flow to the

motor during startup. It is compact and mounted on the

chiller at the motor terminals. Power and control wiring

is factory supplied. Available for 200-600 volts, the

starter enclosure is NEMA-1 with a hinged access door

with lock and key. Electrical lugs for incoming power

wiring are provided.

Standard features include: digital readout at the OptiView Control Center of the following:

Display Only:

• 3-phase voltage A, B, C

• 3-phase current A, B, C

• Input power (kW)

• kW Hours

• Starter Model

• Motor Run (LED)

• Motor Current % Full-load Amps

• Current Limit Setpoints

• Pulldown Demand Time Left

Programmable:

• Local Motor Current Limit

• Pulldown Demand Limit

• Pulldown Demand Time

FACTORY INSULATION OF EVAPORATOR

Factory-applied thermal insulation of the flexible, closedcell plastic type, 3/4" (19mm) thick is attached with vapor-proof cement to the evaporator shell, flow chamber, evaporator tube sheets, suction connection, and

(as necessary) to the auxiliary tubing. Not included is

the insulation of water boxes and nozzles. This insulation will normally prevent condensation in environments

with relative humidities up to 75% and dry bulb temperatures ranging from 50° to 90°F (10° to 32°C). 1-1/

2" (38mm) thick insulation is also available for relative

humidities up to 90% and dry bulb temperatures ranging from 50° to 90°F (10° to 32°C).

WATER FLANGES

Four 150 Ib. ANSI raised-face flanges, for condenser

and evaporator water connections, are factory welded

to water nozzles. Companion flanges, bolts, nuts and

gaskets are not included.

SPRING ISOLATION MOUNTING

Spring Isolation mounting is available instead of standard isolation mounting pads when desired. Four leveladjusting/spring-type vibration isolator assemblies with

non-skid pads are provided with mounting brackets for

field installation. Isolators are designed for one-inch

(25.4 mm) deflection.

Other features include: low line voltage; 115-volt control transformer; three-leg sensing overloads; phase rotation and single-phase failure protection; high temperature safety protection; motor current imbalance and

undervoltage safeties; open and close SCR protection;

momentary power interruption protection. The LCSSS

is cooled by a closed-loop, fresh water circuit consisting of a water-to-water heat exchanger and 1/25 HP

circulating pump. All interconnecting water piping is

factory installed and rated for 150 PSIG working pressure. Optional unit-mounted circuit breaker includes

ground fault protection and provides 65,000 amp shortcircuit withstand rating in accordance with UL Standard

508. A non-fused disconnect switch is also available.

Both options are padlockable.

BAS REMOTE CONTROL

A communication interface permitting complete exchange of chiller data with any BAS system is available

with optional ISN translator. ISN translator also allows

BAS system to issue commands to the chiller to control

its operation. ISN translators come in two models, controlling up to four chillers and eight chillers respectively .

WATER FLOW SWITCHES

Paddle-type, vapor-proof water flow switches suitable

for 150 psig (1034 kPa) DWP for chilled and condenser

water circuits. Switch for 115V-1-50/60 Hz service. A

chilled water flow switch is required. Condenser water

flow switch is optional.

SEQUENCE CONTROL KIT

For two, three or four units with chilled water circuits

connected in series or parallel, the kit consists of return

water thermostat, lead-lag selector switch for sequence

starting, and time delay relay , with NEMA-1 enclosures,

designed for 115V-1-50/60 Hz.

STARTER – FIELD INSTALLED

A field installed, electro-mechanical compressor motor

starter is available, selected for proper size and type

for job requirements and in accordance with YORK Engineering Standard R-1131 for Starters.

YORK INTERNATIONAL

17

Page 18

FORM 160.81-EG1

Accessories and Modifications (continued)

MARINE WATER BOXES

required to rig into tight spaces. This is particularly convenient for existing buildings where equipment room

Marine water boxes allow service access for cleaning

access does not allow rigging a factory packaged chiller.

of the heat exchanger tubes without the need to break

the water piping. Bolted-on covers are arranged for con-

REFRIGERANT STORAGE/RECYCLING SYSTEM

venient access. Victaulic nozzle connections are standard; flanges are optional. Marine water boxes are available for condenser and/or evaporator.

A refrigerant storage/recycling system is a self-contained

package consisting of a refrigerant compressor with oil

separator, storage receiver , water-cooled condenser , fil-

KNOCK-DOWN SHIPMENT

ter drier and necessary valves and hoses to remove,

replace and distill refrigerant. All necessary controls and

The chiller can be shipped knocked-down into major

assemblies (evaporator, condenser, driveline, etc.) as

safety devices are a permanent part of the system. T ypi-

cally not required if unit isolation valves are provided.

SI Metric Conversion

The following factors can be used to convert from English to the most common Sl Metric values.

MEASUREMENT

MULTIPLY THIS

ENGLISH VALUE METRIC VALUE

BY

TO OBTAIN THIS

CAPACITY TONS REFRIGERANT EFFECT (ton) 3.516 KILOWATTS (kW)

POWER

FLOW RATE GALLONS / MINUTE (gpm) 0.0631 LITERS / SECOND (L/s)

LENGTH

WEIGHT POUNDS (lb) 0.4536 KILOGRAMS (kg)

VELOCITY FEET / SECOND (fps) 0.3048 METERS / SECOND (m/s)

PRESSURE DROP

Integrated Part Load Value (IPLV)

In the English I-P system, IPLV is calculated by the fol-

KILOWATTS (kW) NO CHANGE KILOWATTS (kW)

HORSEPOWER (hp) 0.7457 KILOWATTS (kW)

FEET (ft) 304.8 MILLIMETERS (mm)

INCHES (in) 25.4 MILLIMETERS (mm)

FEET OF WATER (ft) 2.989 KILOPASCALS (k Pa)

POUNDS / SQ. INCH (psi) 6.895 KILOPASCALS (k Pa)

In SI Metric, the formula is:

IPLV* = 0.01A + 0.42B + 0.45C + 0.12D

lowing formula. A full explanation is shown on page 4:

1

IPLV*=

Where: A = kW / ton at 100% Load @ 85°F ECFT

0.01

ABCD

B = kW / ton at 75% Load @ 75°F ECFT

C = kW / ton at 50% Load @ 65°F ECFT

D = kW / ton at 25% Load @ 65°F ECFT

0.42

+

0.45

+

0.12

+

Where: A = COP at 100% Load @ 29.4°C ECFT

B = COP at 75% Load @ 23.9°C ECFT

C = COP at 50% Load @ 18.3°C ECFT

D = COP at 25% Load @ 18.3°C ECFT

NOTE:

* The Non-Standard Part-Load V alue (NPL V) uses the IPL V formula

with the following exceptions: the ECFT for part-load points varies

linearly from the selected EFT to 65°F (18.3°C) from 100% to 50%

loads, and fixed at 65°F (18.3°C) for 50% to 0% loads.

18

YORK INTERNATIONAL

Page 19

Application Data

FORM 160.81-EG1

The following is a user’s guide in the application and

installation of MAXE Chillers, and will ensure the reliability and trouble-free life for which this equipment was

designed. While this guide is directed towards normal,

water-chilling applications, the YORK sales representatives can provide complete recommendations on other

types of applications.

Location

M

AXE Chillers are virtually vibration-free and generally

can be located at any level in a building where the construction will support the total system operating weight.

The unit site must be a floor, mounting pad or foundation which is level within 1/4" (6.4 mm) and capable of

supporting the operating weight of the chiller.

Sufficient clearance to permit normal service and maintenance work should be provided all around and above

the unit. Additional space should be provided at one

end of the unit to permit cleaning of evaporator and

condenser tubes as required. A doorway or other properly located opening may be used.

The chiller should be installed in an indoor location where

temperatures range from 40°F to 1 10°F (4.4°C to 43.3°C).

Water Circuits

Flow Rate – For normal water chilling duty, evaporator

flow rates are permitted at water velocity levels in the heat

exchangers tubes of between 3 ft./second and 12 ft./second (0.91 m/s and 3.66 m/s). Condenser flow rates are

permitted between 3.33 ft./sec. and 12 ft./sec. (1.01 m/s

and 3.66 m/s). V ariable flow applications are possible, and

initial chiller selections should be made accordingly to

permit proper range of flow while maintaining the mini-

mum velocity noted above. V ariable flow in the condenser

is not recommended, as it generally raises the energy consumption of the system by keeping the condenser pressure high in the chiller. Additionally, the rate of fouling in

the condenser will increase at lower water velocities associated with variable flow, raising system maintenance costs.

Cooling towers typically have narrow ranges of operation

with respect to flow rates, and will be more effective with

full design flow. Ref. Table 1 for flow limits.

Temperature Ranges – For normal water chilling duty,

leaving chilled water temperatures may be selected between 38°F (3.3°C) [36°F (2.2°C) with Smart Freeze enabled) and 70°F (21.1°C) for water temperature ranges

between 3°F and 30°F (1.7°C and 16.7°C).

Water Quality – The practical and economical application

of liquid chillers requires that the quality of the water supply

for the condenser and evaporator be analyzed by a water

treatment specialist. Water quality may affect the performance of any chiller through corrosion, deposition of heatresistant scale, or sedimentation or organic growth. These

will degrade chiller performance and increase operating and

maintenance costs. Normally , performance may be maintained by corrective water treatment and periodic cleaning

of tubes. If water conditions exist which cannot be corrected

by proper water treatment, it may be necessary to provide a

larger allowance for fouling, and/or to specify special materials of construction.

General Piping – All chilled water and condenser water

piping should be designed and installed in accordance

with accepted piping practice. Chilled water and condenser

water pumps should be located to discharge through the

chiller to assure positive pressure and flow through the

unit. Piping should include offsets to provide flexibility and

should be arranged to prevent drainage of water from the

TABLE 1 – WATER FLOW RATE LIMITS – GPM (L/s)

SHELL

CODE

TB, VB

TC, VC

TD, VD

WB, XB

WC, XC

WD, XD

YORK INTERNATIONAL

PASS

1 3 83 (24.2) 1525 (96.2) 613 (38.7) 2204 (139.1)

2 1 92 (12.1) 762 (48.1) 307 (19.4) 1102 (69.5)

3 1 28 (8.1) 508 (32.1) 205 (12.9) 734 (46.3)

1 4 68 (29.5) 1866 (118.0) 683 (43.1) 2455 (154.9)

2 2 34 (14.8) 932 (58.8) 342 (21.6) 1227 (77.4)

3 1 57 (9.9) 621 (39.2) 228 (14.4) 818 (51.6)

1 5 70 (36.0) 2277 (143.7) 771 (48.7) 2774 (175.0)

2 2 86 (18.0) 1 1 3 8 (71.8) 386 (24.4) 1386 (87.5)

3 ––– ––– ––– ––– ––– ––– ––– –––

1 6 93 (43.7) 2771 (174.9) 866 (54.6) 3462 (218.5)

2 3 46 (21.8) 1385 (87.4) 433 (27.3) 1731 (109.2)

3 2 31 (14.6) 924 (58.3) 289 (18.2) 1154 (72.8)

1 8 22 (51.9) 3287 (207.4) 1082 (68.3) 4328 (273.1)

2 411 (25.9) 1644 (103.7) 541 (34.1) 2164 (136.5)

3 2 74 (17.3) 1096 (69.2) 361 (22.8) 1443 (91.1)

1 9 86 (62.2) 3945 (248.9) 1350 (85.2) 5400 (340.1)

2 4 93 (31.1) 1972 (124.4) 675 (42.6) 2700 (170.0)

3 ––– ––– ––– ––– ––– ––– ––– –––

MINIMUM

EVAPORATOR CONDENSER

MAXIMUM

MINIMUM

MAXIMUM

19

Page 20

Application Data (continued)

FORM 160.81-EG1

evaporator and condenser when the pumps are shut off.

Piping should be adequately supported and braced independently of the chiller to avoid the imposition of strain on

chiller components. Hangers must allow for alignment of

the pipe. Isolators in the piping and in the hangers are

highly desirable in achieving sound and vibration control.

Convenience Considerations – T o facilitate the performance of routine maintenance work, some or all of the

following steps may be taken by the purchaser. Evaporator and condenser water boxes are equipped with plugged

vent and drain connections. If desired, vent and drain

valves may be installed with or without piping to an open

drain. Pressure gauges with stop cocks, and stop valves,

may be installed in the inlets and outlets of the condenser

and chilled water line as close as possible to the chiller.

An overhead monorail or beam may be used to facilitate

servicing.

Connections – The standard chiller is designed for 150

psig (1034 kPa) design working pressure in both the

chilled water and condenser water circuits. The connections (water nozzles) to these circuits are furnished

with grooves for Victaulic couplings. Piping should be

arranged for ease of disassembly at the unit for tube

cleaning. All water piping should be thoroughly cleaned

of all dirt and debris before final connections are made

to the chiller.

Chilled Water – A flow switch must be installed in the

chilled water line of every unit. The switch must be located in the horizontal piping close to the unit, where the

straight horizontal runs on each side of the flow switch

are at least five pipe diameters in length. The switch

must be electrically connected to the chilled water interlock position in the unit control center. A water strainer of

maximum 1/8" (3.2 mm) perforated holes must be fieldinstalled in the chilled water inlet line as close as possible to the chiller. If located close enough to the chiller,

the chilled water pump may be protected by the same

strainer. The flow switch and strainer assure chilled water flow during unit operation. The loss or severe reduction of water flow could seriously impair the chiller performance or even result in tube freeze-up.

°F Min ECWT = LCHWT + 16 + [(% load/100) x

(10 - full-load condenser water ∆ T)]

°C Min ECWT = LCHWT + 8.9 + [(% load/100) x

(5.6 - full-load condenser water ∆ T)]

Where: ECWT = entering condenser water temperature

LCHWT = leaving chilled water temperature

MULTIPLE UNITS

Selection – Many applications require multiple units to

meet the total capacity requirements as well as to provide flexibility and some degree of protection against

equipment shutdown. There are several common unit

arrangements for this type of application. The M

chiller has been designed to be readily adapted to the

requirements of these various arrangements.

Parallel Arrangement (Refer to Fig. 1) – Chillers may

be applied in multiples with chilled and condenser water circuits connected in parallel between the units. Fig.

1 represents a parallel arrangement with two chillers.

Parallel chiller arrangements may consist of equally or

unequally sized units. When multiple units are in operation, they will load and unload at equal percentages

of design full-load for the chiller.

Depending on the number of units and operating characteristics of the units, loading and unloading schemes

should be designed to optimize the overall efficiency of

the chiller plant. It is recommended to use an evaporator

bypass piping arrangement to bypass fluid around evaporator of any unit which has cycled off at reduced load

conditions. It is also recommended to alternate the chiller

cycling order to equalize chiller starts and run hours.

AXE

Condenser Water – The chiller is engineered for maximum efficiency at both design and part-load operation

by taking advantage of the colder cooling tower water

temperatures which naturally occur during the winter

months. Appreciable power savings are realized from

these reduced heads.

The minimum entering condenser water temperature

for other full and part-load conditions is provided by the

following equation:

20

LD00507

FIG. 1 –

Series Arrangement (Refer to Fig. 2) – The chillers

may be applied in pairs with chilled water circuits con-

PARALLEL EVAPORATORS

PARALLEL CONDENSERS

YORK INTERNATIONAL

Page 21

FORM 160.81-EG1

nected in series and condenser water circuits connected

in parallel. All of the chilled water flows through both coolers with each unit handling approximately one-half of the

total load. When the load decreases to a customer selected load value, one of the units will be shut down by a

sequence control. Since all water is flowing through the

operating unit, that unit will cool the water to the desired temperature.

LD00508

FIG. 2 – SERIES EVAPORATORS

P ARALLEL CONDENSERS

BRINE APPLICA TIONS

The YR Screw Chiller , utilizing the Frick Refrigeration compressor, is a good match for the high head requirements

of low temperature brine applications. This is particularly

true of thermal ice storage systems, typically requiring 22°F

(–5.6°C) to 24°F (–4.4°C) leaving brine temperatures. This

performance is enhanced with the standard thermal storage control mode described on page 6.

Particular attention must be paid to the application of

two or more chillers with evaporators in parallel or series when the brine temperature is below 32°F (0°C).

The brine MUST NOT flow through the evaporator of

the idle chiller, because it can cause the condenser water to freeze. A bypass or other type of arrangement is

required that shuts off flow to the idle evaporator . When

units are applied in series with lead/lag capability, the

units should be identical.

REFRIGERANT RELIEF PIPING

Each chiller is equipped with pressure relief devices.

The purpose of the relief devices is to quickly relieve

excess pressure of the refrigerant charge to atmosphere,

as a safety precaution in the event of an emergency

such as a fire. They are set to relieve at an internal

pressure of 235 psig (1620 kPa) and are located on the

condenser, evaporator and oil separator; and are provided in accordance with ASHRAE 15 Safety Code and

ASME or applicable pressure vessel code. Under these

circumstances the relief devices may be relief valves,

overflow valves or type tested Safety Pressure switches

or a combination of these devices.

Sized to the requirements of applicable codes, a vent

line must run from the relief device to the outside of the

building. This refrigerant relief piping must include a

cleanable, vertical-leg dirt trap to catch vent-stack condensation. Vent piping must be arranged to avoid imposing a strain on the relief connections and should

include one flexible connection.

SOUND AND VIBRATION CONSIDERATIONS

A M

AXE chiller is not a source of objectionable sound

and vibration in normal air conditioning applications. Neoprene isolation mounts are furnished as standard with

each unit. Optional level-adjusting spring isolator assemblies designed for 1" static deflection are available.

M

AXE chiller sound pressure level ratings will be fur-

nished upon request.

Control of sound and vibration transmission must be taken

into account in the equipment room construction as well

as in the selection and installation of the equipment.

THERMAL INSULATION

No appreciable operating economy can be achieved

by thermally insulating the chiller. However , the chiller’s

cold surfaces should be insulated with a vapor barrier

insulation sufficient to prevent condensation. A chiller

can be factory insulated with 3/4" (19mm) or 1-1/2"

(38mm) thick insulation, as an option. This insulation

will normally prevent condensation in environments

with dry bulb temperatures of 50°F to 90°F (10°C to

32°C) and relative humidities up to 75% [3/4" (19mm)

thickness] or 90% [1-1/2" (38mm) thickness]. The insulation is painted and the surface is flexible and reasonably resistant to wear. It is intended for a chiller

installed indoors and, therefore, no protective covering of the insulation is usually required. If insulation is

applied to the water boxes at the job site, it must be

removable to permit access to the tubes for routine

maintenance.

VENTILATION

The ASHRAE Standard 15 Safety Code for Mechanical Refrigeration requires that all machinery rooms be

vented to the outdoors utilizing mechanical ventilation

by one or more power-driven fans. This standard, plus

National Fire Protection Association Standard 90A,

state, local and other related codes should be reviewed

for specific requirements.

YORK INTERNATIONAL

21

Page 22

Application Data (continued)

FORM 160.81-EG1

In addition, the ASHRAE Standard 15 requires a refrigerant vapor detector to be employed for all refrigerants. It is

to be located in area where refrigerant from a leak would

be likely to concentrate. An alarm is to be activated and

the mechanical ventilation started at a value no greater

than the TL V (Threshold Limit V alue) of the refrigerant.

ELECTRICAL CONSIDERATIONS

Motor Voltage – Low voltage motors (200 - 600 volts)

are furnished with six leads. Motor circuit conductor size

must be in accordance with the National Electrical Code

(NEC), or other applicable codes, for the motor fullload amperes (FLA). Flexible conduit should be used

for the last several feet to the chiller in order to provide

vibration isolation. Table 2 lists the allowable variation

in voltage supplied to the chiller motor. The unit nameplate is stamped with the specific motor voltage and frequency for the appropriate motor.

TABLE 2 – MOTOR VOLTAGE VARIATIONS

FREQ.

60 HZ

50 HZ

RA TED

VOLTAGE

200 200/208 180 220

230 220/240 208 254

380 380 342 415

460 440/460/480 414 508

575 575/600 520 635

380 380/400 342 423

415 415 374 440

NAMEPLATE

VOLTAGE

OPERATING VOL T AGE

MIN. MAX.

Starters – The chiller is available with a factory-mounted

and wired YORK Solid State Starter for 200 - 600 volt

applications. Other types of remote mounted starters

are available. These electro-mechanical starters must

be furnished in accordance with YORK Standard R-

1131. Specification. This will ensure that starter components, controls, circuits, and terminal markings will

be suitable for required overall system performance.

Controls – A 115 volt, single phase, 60 or 50 Hertz

(4.5 kV a) power supply must be furnished to the chiller

from a separate, fused disconnect or from a control

transformer included as an option with electro-mechanical starters. No field control wiring is required, when

the YORK SSS is supplied.

Copper Conductors – Only copper conductors should

be connected to compressor motors and starters. Alu-

minum conductors have proven to be unsatisfactory

when connected to copper lugs. Aluminum oxide and

the difference in thermal conductivity between copper

and aluminum cannot guarantee the required tight connection over a long period of time.

Power Factor Correction Capacitors – Capacitors can

be applied to a chiller for the purpose of power factor

correction. For remote-Mounted Electro-Mechanical

Starters, the capacitors should be located on the load

side of the starter. For YORK SSS, the capacitors must

be located on the line side of the starter. The capacitors

must be sized and installed to meet the National Electrical Code (NEC) and be verified by YORK.

Ampacity on Load Side of Starter – Electrical power

wire size to the chiller is based on the minimum unit

ampacity. For YORK SSS, this wiring is done at the

factory . For remote starters, the National Electrical Code