Page 1

TECHNICAL GUIDE

UP TO 98% AFUE MODULATING ECM

RESIDENTIAL GAS FURNACES

MULTI-POSITION

MODELS: YP9C*C

NATURAL GAS

60 - 120 MBH INPUT

Due to continuous product improvement,

specifications are subject to change without notice.

Visit us on the web at www.york.com for the most

up-to-date technical information.

Additional rating information can be found at

www.ahridirectory.org

WARRANTY SUMMARY

A 20-year limited warranty on heat exchangers in residential

applications.

A 10-year warranty on the heat exchanger in commercial

applications.

Standard 5-year limited Parts warranty.

Extended lifetime heat exchanger and 10-year limited

parts warranty when product is registered online within

90 days of purchase for replacement or closing for new

home construction.

See Limited Warranty certificate in Users Informat i on Manual for details.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

538513-YTG-D-0615

DESCRIPTION

These compact units employ induced combustion, reliable hot

surface ignition and high heat transfer aluminized tubular heat

exchangers. The units are factory shipped for installation in

upflow or horizontal applications and may be converted for

downflow applications.

These furnaces are designed for residential installation in a

basement, closet, alcove, attic, recreation room or garage and

are also ideal for commercial applications. All units are factory

assembled, wired and tested to assure safe dependable and

economical installation and operation.

These units are Category IV, National Fuel Gas Code and may

be vented either through side wall or roof applications using

approved plastic combustion air and vent piping. Approved

plastic combustion air and vent piping include Polyflue (a polypropylene venting systems).

FEATURES

• Modulating heating operation includes:

- Modulating gas valve, inducer and circulating blower

- Modulating operation from 100% to 35% input in 100

increments with nearly constant temperature rise.

• Easily applied in upflow, horizontal left or right, or downflow

installation with minimal conversion necessary.

• Compact, easy to install, ideal height 33" tall cabinet.

• ECM variable speed drive for cooling SEER enhancement,

improved comfort with optional airflow delay profiles, and

continuous fan options for IAQ performance.

• Easy access to controls to connect power/control wiring.

• Built-in, high level self diagnostics with fault code display.

• Low unit amp requirement for easy replacement

application.

• All models are convertable to use propane (LP) gas.

• Electronic Hot Surface Ignition saves fuel cost with

increased dependability and reliability.

• 100% shut off main gas valve for extra safety.

• 24V, 40 VA control transformer and blower relay supplied

for add-on cooling.

• Airflow leakage less than 1% of nominal airflow for

ductblaster conditions.

• Solid removable bottom panel allows easy conversion.

• Hi-tech tubular aluminized steel primary heat exchanger

with stainless steel tube/aluminum fin secondary heat

exchanger for outstanding efficiency.

• No knockouts to deal with, making installation easier.

• Movable duct connector flanges for application flexibility.

• Quiet inducer operation, burner, and blower operation.

• Inducer rotates for easy conversion of venting options.

• Fully supported blower assembly for easy access and

removal of blower.

• External air filters used for maximum flexibility in meeting

customers IAQ needs.

• Insulated blower compartment for thermal and acoustic

performance.

• 1/4 turn knobs provided for easy independent door

removal.

• Internal condensate trap design (patent pending) provides

condensate management options and is self priming to

prevent nuisance problems.

• These models may be connected as part of a

communicating control system using a 4-wire connection

bus.

• The York YP9C modulating ECM furnace is part of a

“Hybrid Comfort System” when paired with a York Heat

Pump.

Page 2

538513-YTG-D-0615

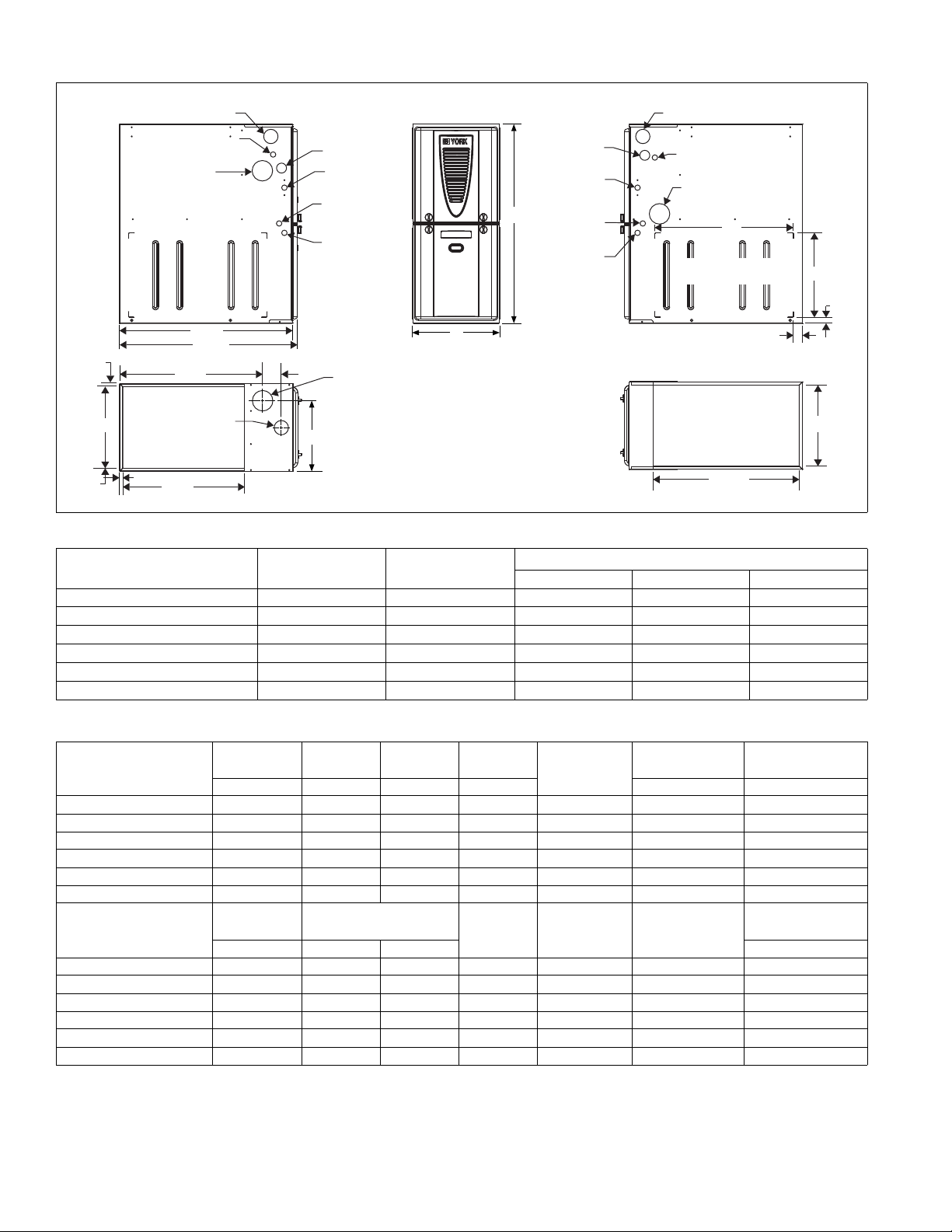

FRONT

LEFT SIDE

Combustion Air Inlet

Condensate Drain

(Downflow)

Thermostat

Wiring

28.5”

Gas Pipe

Entry

Electrical

Entry

Condensate

Drain

Thermostat

Wiring

RIGHT SIDE

Condensate Drain

(Downflow)

14”

1”

1.5”

23”

Combustion Air Inlet

Gas Pipe

Entry

Electrical

Entry

Condensate

Drain

Optional Return Air

Cutout (Either side)

30.25”

A

33”

C

SUPPLY END

.56”

.56”

20”

B

3”

23.8”

.56”

Combustion

Air Inlet

RETURN END

B

24.25”

2” Vent

Connection

Outlet

2” Vent

Connection

Outlet

2” Vent

Connection

Outlet

Cabinet and Duct Dimensions

Models Nominal CFM Cabinet Size

YP9C060B12MP12C 1200 B 17 1/2 16 3/8 13 1/4

YP9C080B12MP12C 1200 B 17 1/2 16 3/8 14 3/4

YP9C080C16MP12C 1600 C 21 19 7/8 16 1/2

YP9C100C16MP12C 1600 C 21 19 7/8 18 1/4

YP9C100C20MP12C 2000 C 21 19 7/8 18 1/4

YP9C120D20MP12C 2000 D 24 1/2 23 3/8 21 3/4

Cabinet Dimensions (Inches)

ABC

Ratings & Physical / Electrical Data

Input

Models

Max/Min

MBH MBH % CFM °F °F

YP9C060B12MP12C 60/21 58/20 97.5 1200 7.0 40-70 20-50

YP9C080B12MP12C 80/28 77/27 97.5 1200 7.5 40-70 20-50

YP9C080C16MP12C 80/28 78/27 97.7 1600 10.0 40-70 20-50

YP9C100C16MP12C 100/35 97/34 97.7 1600 10.0 40-70 20-50

YP9C100C20MP12C 100/35 97/34 97.7 2000 12.0 45-75 25-55

YP9C120D20MP12C 120/42 116/40 98.0 2000 12.0 45-75 25-55

Models

YP9C060B12MP12C 170 1/2 4.8 11 x 8 15 14 113

YP9C080B12MP12C 175 1/2 4.8 11 x 8 15 14 119

Max. Outlet

Air Temp

°F HP Amps Lbs

YP9C080C16MP12C 175 3/4 7.5 11 x 10 15 14 134

YP9C100C16MP112C 175 3/4 7.5 11 x 10 15 14 140

YP9C100C20MP12C 180 1 14.5 11 x 11 20 12 143

YP9C120D20MP12C 180 1 14.5 11 x 11 20 12 152

Annual Fuel Utilization Efficiency (AFUE) numbers are determined in accordance with DOE Test procedures.

Wire size and over current protection must comply with the National Electrical Code (NFPA-70-latest edition) and all local codes.

The furnace shall be installed so that the electrical components are protected from water.

2 Johnson Controls Unitary Products

Max/Min

Output

Blower

AFUE

Nominal

Airflow

Blower

Wheel Size

Total

Unit

Amps

Max

Over-Current

Protect

Air Temp.

Rise Max Input

Min. wire Size

(awg) @ 75 ft

one way

Air Temp.

Rise Min Input

Approximate

Operating Weights

Page 3

538513-YTG-D-0615

FILTER PERFORMANCE

The airflow capacity data published in the “Blower Performance” table represents blower performance WITHOUT filters.

All applications of these furnaces require the use of field

installed air filters. All filter media and mounting hardware or

provisions must be field installed external to the furnace cabinet. DO NOT attempt to install any filters inside the furnace.

NOTE: Single side return above 1800 CFM is approved as long

as the filter velocity does not exceed filter manufacturer ’s recommendation and a transition is used to allow use of a 20 x 25

filter.

Recommended Filter Sizes

CFM

1200 B 16 x 25 16 x 25

1600 C 16 x 25 20 x 25

2000 C (2) 16 x 25 20 x 25

2000 D (2) 16 x 25 22 x 25

NOTES:

1. Air velocity through throwaway type filters may not exceed 300 feet per minute (91.4 m/min). All velocities over this require the use of high velocity filters.

2. Do not exceed 1800 CFM using a single side return and a 16x25 filter. For

CFM greater than 1800, you may use two side returns or one side and the

bottom or one return with a transition to allow use of a 20x25 filter.

Cabinet

Size

Side

(in)

Bottom

(in)

Unit Clearances to Combustibles

Application

Top 1" 0" 0"

Vent 0" 0" 0"

Rear 0" 0" 0"

Side 0" 0" 1"

1

Front

Floor Combustible

Closet Yes Yes Yes

Line Contact No No Yes

1.Line contact only permitted between lines formed by the intersection of the

rear panel and side panel (top in horizontal position) of the furnace jacket

and building joists, studs or framing.

2. For combustible floors only when used with special sub-base.

All furnaces approved for alcove and attic installation.

Upflow Downflow Horizontal

0" 0" 0"

2

Combustible

Combustible

ACCESSORIES

Propane (LP) Conversion Kit -

1NP0681 - All Models

This accessory conversion kit may be used to convert natural

gas (N) units for propane (LP) operation.

Do not use Conversion Kit S1-1NP0680 with these models, as

the control/gas valve combination have been updated, and that

kit S1-1NP0680 will not function correctly with these models.

Concentric Vent Termination -

S1-1CT0302 (2")

S1-1CT0303 (3")

For use through rooftop, sidewall. Allows combustion air to

enter and exhaust to exit through single common hole. Eli minates unslightly elbows for a cleaner installation.

Sidewall Vent Termination Kit -

S1-1HT0901 (3")

S1-1HT0902 (2")

For use on sidewall, two-pipe installations only. Provide a more

attractive termination for locations where the terminal is visable

on the side of the home.

Condensate Neutralizer Kit -

1NK0301

Neutralizer cartridge has a 1/2" plastic tube fittings for installa-

tion in the drain line. Calcium carbonate refill media is also

available from the Source 1 Parts (p/n 026-30228-000).

Side Return Filter Racks -

1SR0200 - All Models

1SR0402 - All Models

1SF0101 - All Models

Bottom Return Filter Racks -

1BR0517 or 1BR0617 - For 17-1/2” cabinets

1BR0521 or 1BR0621 - For 21” cabinets

1BR0524 or 1BR0624 - For 24-1/2” cabinets

1BR05xx series are galvanized steel filter racks. 1BR06xx are

pre-painted steel filter racks to match the appearance of the furnace cabinet.

Combustible Floor Base Kit -

For installation of these furnaces in downflow applications

directly onto combustible flooring material, These kits are

required to prevent potential overheating situations. These kits

are also required in any applications where the furnace in

installed in a downflow configuration without an evaporator coil,

where the combustible floor base kit provides access for combustible airflow.

1CB0517 - For 17-1/2” cabinets

1CB0521 - For 21” cabinets

1CB0524 - For 24-1/2” cabinets

High Altitude - No high altitude kits are required.

Thermostats - Compatible thermostat controls are available

through accessory sourcing. For optimum performance and

installation, refer to the UPGNET “Low Voltage Wiring Diagram”

document to select and apply controls.

Johnson Controls Unitary Products 3

Page 4

Blower Performance CFM - Any Position

060B12*C 080B12*C Jumper Settings

Hi Cool Lo Cool Hi Cool Lo Cool COOL Jumper ADJ Jumper

1305 850 1290 840 H B

1100 715 1090 710 MH B

1065 690 1015 660 H A

1000 650 1000 650 MH A

960 625 960 625 H C

760 495 760 495 ML B

900 585 900 585 MH C

660 430 660 430 L B

690 450 680 445 ML A

600 400 600 400 L A

620 400 620 400 ML C

550 400 540 400 L C

080C16*C 100C16*C Jumper Settings

Hi Cool Lo Cool Hi Cool Lo Cool COOL Jumper ADJ Jumper

1670 1085 1655 1075 H B

1295 840 1275 820 MH B

1385 900 1345 875 H A

1175 765 1160 755 MH A

1245 810 1210 785 H C

995 645 1000 650 ML B

1055 685 1045 680 MH C

935 605 955 620 L B

905 590 910 590 ML A

850 550 870 565 L A

815 530 815 530 ML C

765 500 785 510 L C

100C20*C 120D20*C Jumper Settings

Hi Cool Lo Cool Hi Cool Lo Cool COOL Jumper ADJ Jumper

2215 1440 2180 1415 H B

1765 1145 1760 1140 MH B

1820 1180 1800 1170 H A

1605 1040 1595 1035 MH A

1635 1060 1620 1050 H C

1270 825 1255 815 ML B

1445 940 1435 935 MH C

1055 685 1050 680 L B

1155 750 1160 755 ML A

960 620 960 615 L A

1040 675 1035 670 ML C

860 560 840 545 L C

High / Low Speed Cooling CFM

High / Low Speed Cooling CFM

High / Low Speed Cooling CFM

All CFM’s are shown at 0.5” w.c. external static pressure.These units have variable speed motors that automatically adjust to provide constant CFM from 0.0”

to 0.6” w.c. static pressure. From 0.6” to 1.0” static pressure, CFM is reduced by 2% per 0.1” increase in static. Operation on duct systems with greater than

1.0” w.c. external static pressure is not recommended.

NOTE: At some settings, LOW COOL airflow may be lower that what is requir ed to oper ate an airflow swit ch on cert ain mode ls of elect ronic air cleaners. Con-

sult the instructions for the electronic air cleaner for further details.

Subject to change without notice. Published in U.S.A. 538513-YTG-D-0615

Copyright © 2015 by Johnson Controls, Inc. All rights reserved. Supersedes: 538513-YTG-C-0713

York International Corp.

5005 York Drive

Norman, OK 73069

Loading...

Loading...