Page 1

®

OPTION PACKAGES

INSTALLATION INSTRUCTION

MODELS DHE, DHG 036, 048 & 060, 180 & 240

GENERAL

Below are descriptions of option packages available on the

Sunline Plus (3 and 7.5 through 20 ton) and Sunline Ultra (3,4

and 5ton)units. There are 4 optionpackages,the: BASE OPTION PACKAGE, PROTECTION PACKAGE, INSTALLATION

PACKAGE, and CABINET PACKAGE. The BASE OPTION

PACKAGE can be ordered alone, but is always included with

any of the other option packages.

FACTORY OPTIONS

The following factory options can be ordered in conjunction

with any of the OPTION PACKAGES:

A. No Economizer.

Supersedes: 530.24-N1Y (199)

FOR SUNLINE™

MODELS DEE, DEG 036

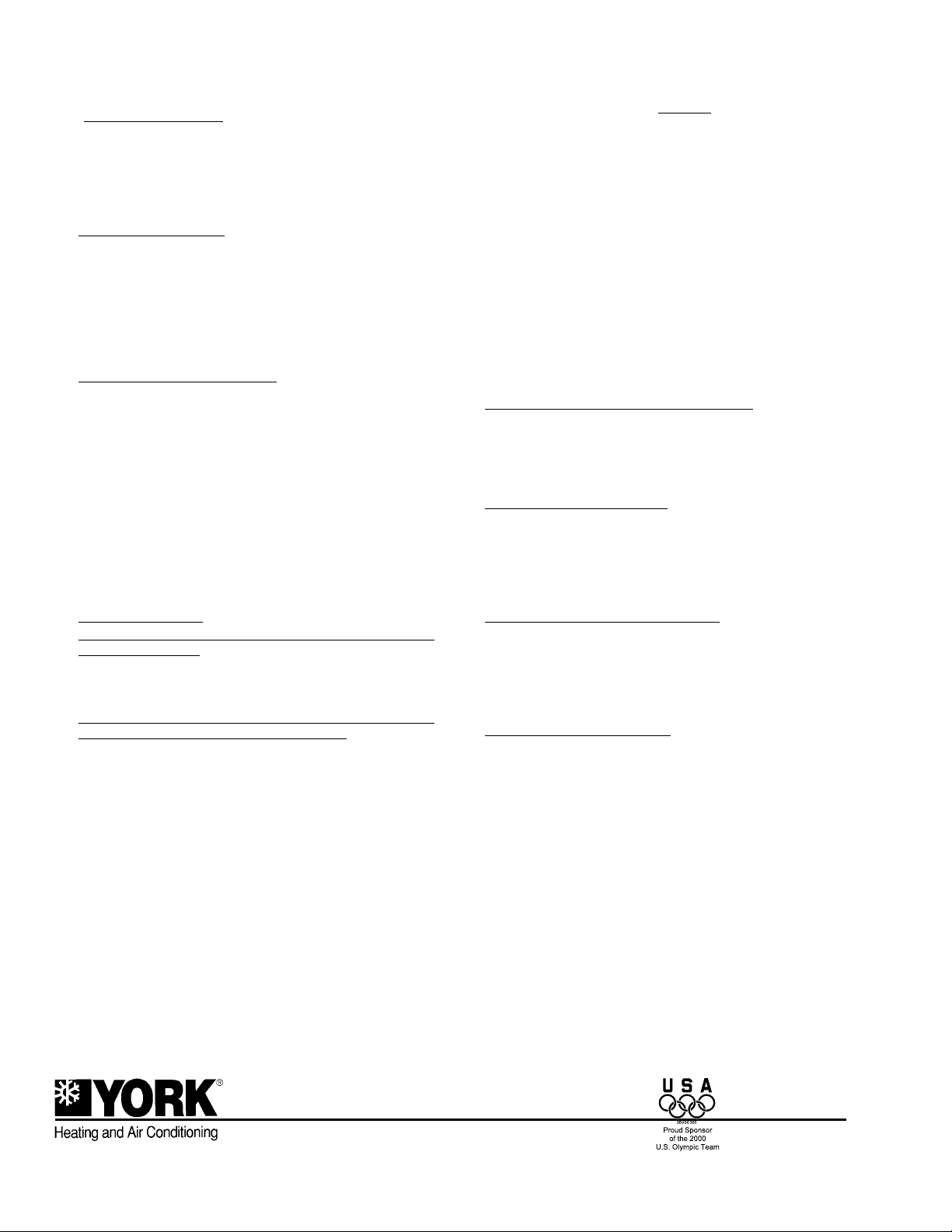

D. Smokedetectorterminal block provisions

wiring means for powering a 24VAC duct smoke detector

anda single set of normally closed contacts, which open to

shut down the unit upon detection of smoke. Although the

air conditioning unit is shut down when the smoke detector

alarms, the 24V power supply to the smoke detector is not

interrupted.Actualmounting means for thesmokedetector

are not provided due to the wide variation in regulations

and codes.

CAUTION: Normal maintenance activity will require discon-

035-16134-000 Rev. A(0501)

providefield-

necting power to the unit. When the YORK suppliedterminal stripis usedto provide24V powerto

a smoke detector; the smoke detector will not be

powered when the power supply is interrupted to

theunit. Ifthe smoke detectoris linked toseparate

monitoring system that would detect this power

shutdown and report it as an alarm condition, do

not use the unit terminal strip to power the smoke

detector.

B. Dry Bulb Economizer.

C.DryBulbEconomizerwithPowerExhaust(15&20tonunitsonly).

NOTE:Notall combinations of base unitsand option packages

are available. See the Price Pages for specific model

and option combinations.

All option packages are available with the dry bulb

economizer option only.

Individual items within each package can not be

broken-out and ordered separately.

BASE OPTION PACKAGE

A. High-speed drive (15 & 20 ton units) includes a belt and

blower pulley upgrade, an alternate hp motor (7 - 12 tons)

or the belt drive option (3 - 5 tons).

B. Self-primingcondensatecover

C. A sloped drain pan

to prevent standing water in the drain

pan.

NOTE:The internal drain connection is not offered with the

sloped drain pan design on the 15 & 20 ton units.

assistsinprimingadrytrap.

SMOKE DETECTOR TERMINAL BLOCK DIAGRAM

NORM ALY

C LO SED

CONTACTS

24 VA C

UNIT W IRING

JUM PER

Rem ove

ju m p e r a n d

w ire to th e

norm ally

clo sed

contacts of

th e s m o k e

detector

Wired to

24 VAC

pow er

te rm in a ls

of sm oke

d e te c to r

24 VA C

POW ER SUPPLY

5VA (Max.)

UNIT W IRING

TER M INAL

BLOCKS

(located in

Econom izer

section)

Field S upplied W iring

Page 2

PROTECTION PACKAGE

A. A check filter switch operates on differential pressure

and indicates when the airflow pressure drop has in

creased past a user defined setpoint (field adjustable from

0.05- 5 inches of water;factory setat 0.25 inches). Factory

wire leads are provided in the control box for wiring to a re

mote 24V indicator, see the unit wiring label.

mounted switch for disconnecting power during routine

maintenance or service, but does not

-

-

or short circuit protection for the unit's power supply.

NOTE:This breaker is not intended to replace any additional

provide over-current

circuit protection required by any local or national code.

B. A phase loss monitor

protects against phase loss, low

voltageandphasereversal. The switchautomaticallyshuts

offpower to the units control circuit if one of the above con

ditionsis detected andwill automatically resetupon correc

tion of the problem. The sensitivity is field adjustable and

hasavisualLEDindicationofitsoperationalstatus.Factory

wire leads are provided in the control box for wiring to a re

mote 24V indicator, see the unit wiring label.

C. Acondensate overflow switch

shuts down and locks out

theunit prior tooverflow of the evaporator condensatepan.

To resetthelockout, power must beresetat the unitandthe

faultconditionmust be cleared beforeproperoperation can

berestored.It requires periodiccleaningand maintenance.

Factorywire leadsare provided in the control box for wiring

to a remote 24V indicator, see the unit wiring label.

To modify the condensate overflow switch system to act as

a auto-reset safety only requires removing one wire. Re

move the wire that leads from the overflow switch to the

lockout relay. See unit wiring diagram for wire number and

details

INSTALLATION PACKAGE

A. Disconnect Switch

For units with gas heat or factory installed electric heat this

package includes a: HACR Molded Case Circuit Breaker

that doubles as a disconnect switch while also providing

unit mounted over-current and short circuit protection.

For units shipped as cooling only or utilizing field mounted

electric heat kits this package includes a: Non-Fused

Molded Case Disconnect Switch. This switch is sized for

the largest electric heat kit available from York for each

model size and voltage. This switch provides a unit

WARNING:The breaker shipped with dual voltage (208/230V)

-

-

15tonand20 ton modelsutilizing36or 72kW elec

tric heat is sized only for 240V service. These

models: DHE180E03625, DHE180E07225,

DHE240E02625 and DHE2400E07225, require a

-

208V rated breaker when powered by 208V serv

ice. A kit is available to provide a breaker properly

sized for 208V applications that mounts in the

same location as the factory mounted breaker.

B. Non-powered 120V G.F.C.I. duplex outlet

is rated at 20

Amps for U.S. locations and 15 Amps for Canadian loca

tions (Requires separate 120V power be supplied to the

unit).

CABINET PACKAGE

A. Tool-less, hinged filter door allows for easy access and

-

maintenance.

NOTE:Knobs are shipped separately within the unit toprevent

shippingdamage.These must befieldinstalledfor toolless operation.

B. Tool-less blower and control panels

(not hinged) allows

for easy access and maintenance.

NOTE:Knobs are shipped separately within the unit toprevent

shippingdamage.These must befieldinstalledfor toolless operation.

C. Condenser coil grill guards

to protect the coil surface

from damage.

-

-

-

Unitary Products Group

5005 York Drive, Norman, Oklahoma 73069

Subject to change without notice. Printed in U.S.A

Copyright by York International Corporation 2001. All Rights Reserved.

Supersedes: 530.24-N1Y (199)

035-16134-000 Rev. A(0501)

Loading...

Loading...