Page 1

530.26-TG3YI (1294)

®

SINGLE P ACKAGE

GAS / ELECTRIC UNITS AND

SINGLE P ACKAGE AIR CONDITIONERS

D3CE / D3CG 180 & 240

(WORLD 50 HZ)

DCG

Shown

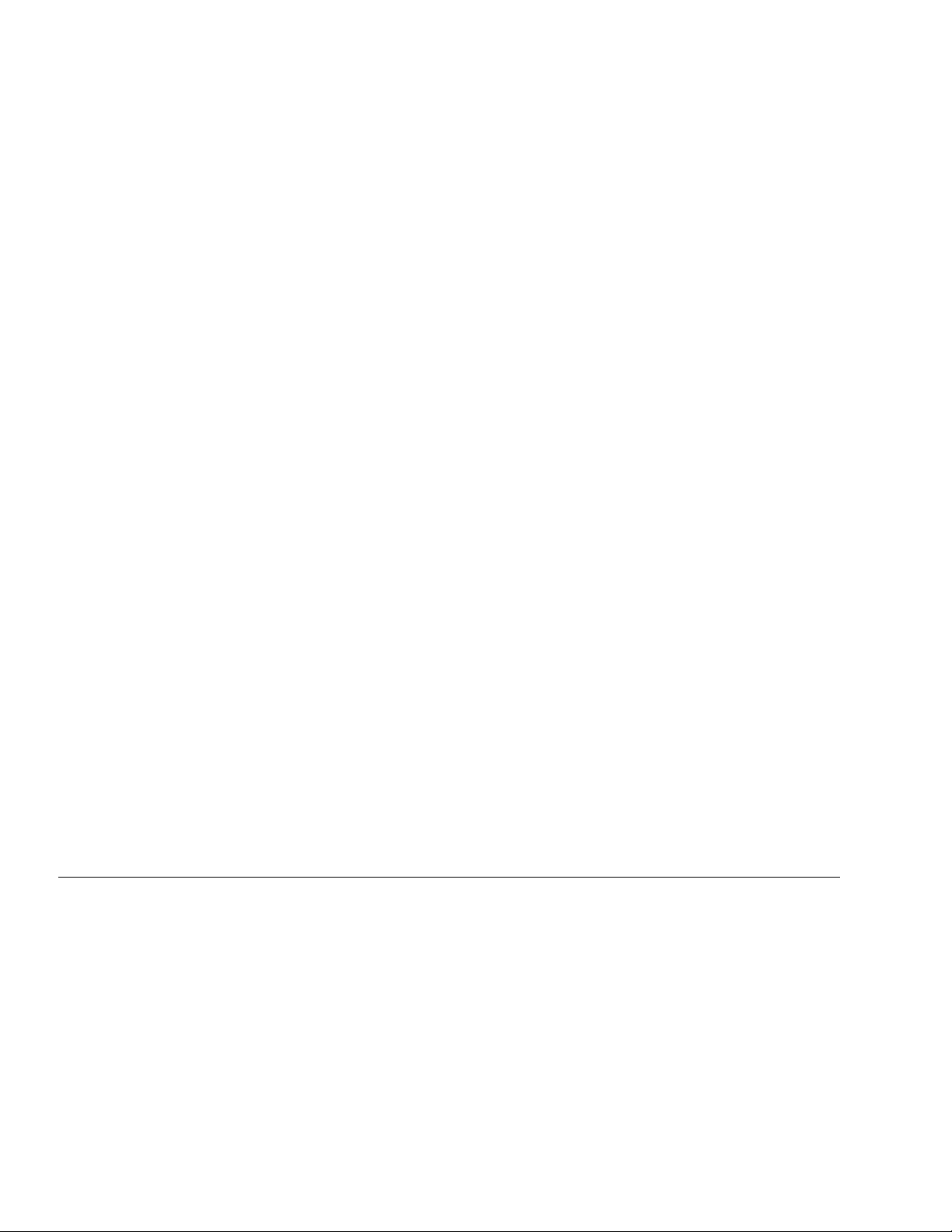

DESCRIPTION

Sunline 2000 units are highly efficient, convertible rooftops. All

models have dual refrigerant circuits for efficient part load

operation. Although the units are primarily designed for curb

mounting on a roof, they can also be slab-mounted at ground

level or set on steel beams above a finished roof.

These units are designed and manufactured under ISO 9002

Quality System Certification.

Cooling only, cooling with gas heat and cooling with

supplemental electric heat units are available with a wide

variety of field-installed accessories to make them suitable for

almost every applicatio n.

All units are self-contained and assembled on full perimeter

base rails. The base rails have holes in the four corners for

overhead rigging.

Every unit is completely piped, wired, charged and tested at

the factory to simplify the field installation and to provide years

of dependable operation. Powder paint cabinets provide an

exceptionally durable finish with the 750 hour salt spray

process per ASTM-B117 test standard.

All models are available with three different outdoor air damper

accessosries:

• Single enthalpy economizer

• Differential enthalpy economizer

• Motorized outdoor air intake damper

All models (including those with an economizer ) are suitable

for either downflow or sideflow duct connections. For downflow

duct, remove the sheet metal panels from the supply and return

air openings through the base of the unit. For sideflow duct,

replace the supply and return air panels on the rear of the unit

with a side duct flange accessory.

A fixed outdoor air intake assembly is shipped in the return air

compartment of all units. The assembly includes a rain hood

with a damper that can be set for 10, 15 or 25% outdoor air.

With bottom duct connections, the intake damper assembly

should be mounted over the opening in the return air panel.

SUNLINE 2000

With horizontal ductwork, it should be mounted on the return

air duct.

All supply air blowers are equipped with a belt drive that can

be adjusted to meet the exact requirements of the job.

All compressors include crankcase heat and internal pressure

relief. Every refrigerant circuit includes an expansion valve, a

liquid line filte r-drier, a d ischarg e line high pre ssure s witch a nd

a suction line with a freezestat and low pressure switch. The

unit control circuit includes a 75 V A transf ormer, a 24-volt circuit

breaker and a relay board wi th two compressor lockout c ircuits,

a terminal strip for thermostat wiring, plus an additional set of

pin connectors to simplify the interface of additional field

controls.

All gas heat models are built with two heating sections for two

equal stages of capacity control. Each section includes a

durable heat exchanger with aluminized steel tubes, a

redundant gas valve, spark ignition, power venting, an ignition

module for 100% shut-off and all of the safety controls required

to meet the latest ANSI standards.

The gas supply piping can be routed into the heating

compartment through a hole in the base pan of the unit or

through a knockout in the piping panel on the front of the unit.

All electric heat models are wired for a single pow er source and

include a bank of nickel chromium elements mounted at the

discharge of the supply air blower to provide a high velocity and

uniform distribution of air across the heating elements. Every

element is fully protected against excessive current and

temperature by fuses and two thermal limit switches.

The power supply wiring can be routed into the control box

through a threaded pipe connection in the base pan of the unit

or through a knockout in the wiring panel on the front of the unit.

Page 2

530.26-TG3YI

FIELD-INST ALLED ACCESSORIES

SINGLE INPUT ELECTRONIC ENTHALPY ECONOMIZERS

Includes a slide-in / plug-in damper assembly with fully

modulating spring-return motor actuator capable of introducing

up to 100% outdoor air with nominal 1% leakage type dampers.

The enthalpy system contains one sensor that monitors the

outdoor air and determines when the air is cool enough and dry

enough to provide “free” cooling.

The rain hood is painted to match the basic unit and must be

field-assembled before installing.

On units built prior to January 1995 an accessory field harness

must be installed.

Power exhaust is not available as a field installed option.

DUAL INPUT ELECTRONIC ENTHALPY ECONOMIZERS

Includes a slide-in / plug-in damper assembly with fully

modulating spring-return motor actuator capable of introducing

up to 100% outdoor air with nominal 1% leakage type dampers.

This enthalpy system contains one sensor that monitors the

outdoor air and one sensor that monitors the return air. The

logic module compares the two values and modulates the

dampers, providing the ma ximum ef ficie ncy of the econom izer

system.

The rain hood is painted to match the basic unit and must be

field-assembled before installing.

On units built prior to January 1995 an accessory field harness

must be installed.

Power exhaust is not available as a field installed option.

MOTORIZ ED O UTDO OR A IR INTAKE DAMPER - Includes a

slide-in / plug-in damp e r with a 2-position, spring-return mo t o r

actuator which opens to a pre-set position whenever the supply

air blower is operating and drives fully clo sed when the blower

shuts down.

On units built prior to January 1995 an accessory field harness

must be installled.

Power exhaust is not available as a field installed option.

BAROMETRIC RELIEF DAMPER - This damper accessory

can be used to relieve internal air pressure on units with an

economizer. This accessory includes a rain hood, a bird screen

and a fully assembled damper. With bottom duct connections,

the damper should be mounted over the opening in the return

air panel. With horizontal ductwork, the accessory should be

mounted on the return air duct.

ROOF CURBS - Roof curbs, 356mm (14 in.) high, provide a

water-tight seal between the unit and the finished roof. These

full perimeter curbs meet the requirements of the National

Roofing Contractors Association (NRCA) and are shipped

knocked-down for field assembly . They’re designed to fit inside

the base rails of the unit and include both a wood nailing strip

and duct hanger supports.

SIDE DUCT FLANGES - Twenty-five mi llimeter (1 in .) flanges

replace the supply and return air panels on the rear of the unit

to accommodate horizontal duct connections. These flanges

can also be used individually for bottom supply/horizontal

return or horizontal supply/bottom return.

HIGH SPEED DRIVE - A sma ller b lo wer p ulle y, a larger motor

pulley (including a replacement belt) increase the speed of the

supply air blower for applications with a higher airflow and/or

static pressure requirement.

ANTI-RECYCLE TIMERS - Two solid st ate t ime rs preve nt t he

compressors from short-cycling. Once a compressor is

de-energized, it remains de-energized for approximately five

minutes.

LOW AMBIENT CONTROLS TO 18°C (0°F) - An

autotransformer and a thermostat maintain stable system

operation by reducing the speed of the #1 condenser fan motor

at low oudoor temperatures. The kit also includes a 1-phase

motor to replace the unit’s standard 3-phase condenser fan

motor. Standard units can operate down to 4 °C (25 °F).

TABLE OF CONTENTS

Description ...........................................................................1

Field-Installed Accessories...................................................2

Ratings .................................................................................3

Cooling Capacities ...............................................................4

Blower Performance.............................................................8

Blower Motor and Drive Data.............................................12

Static Resistances..............................................................10

Field Wiring ........................................................................13

2 Unitary Products Group

Electrical Data - Cooling and Gas Heat .............................13

Electrical Data - Units with Electric Heat............................14

Physical Data .....................................................................14

Unit Dimensions.................................................................15

Roof Curb Dimensions.......................................................18

Typical Applications............................................................18

Page 3

MODEL DCG

(Gas Heating)

THROWA W AY

(OPTION / ACCESSORY)

530.26-TG3YI

®

SUNLINE 2000

(OPTION / ACCESS.) DCE UNITS

ALUMINIZED STEEL

D*CG UNITS

FEMALE

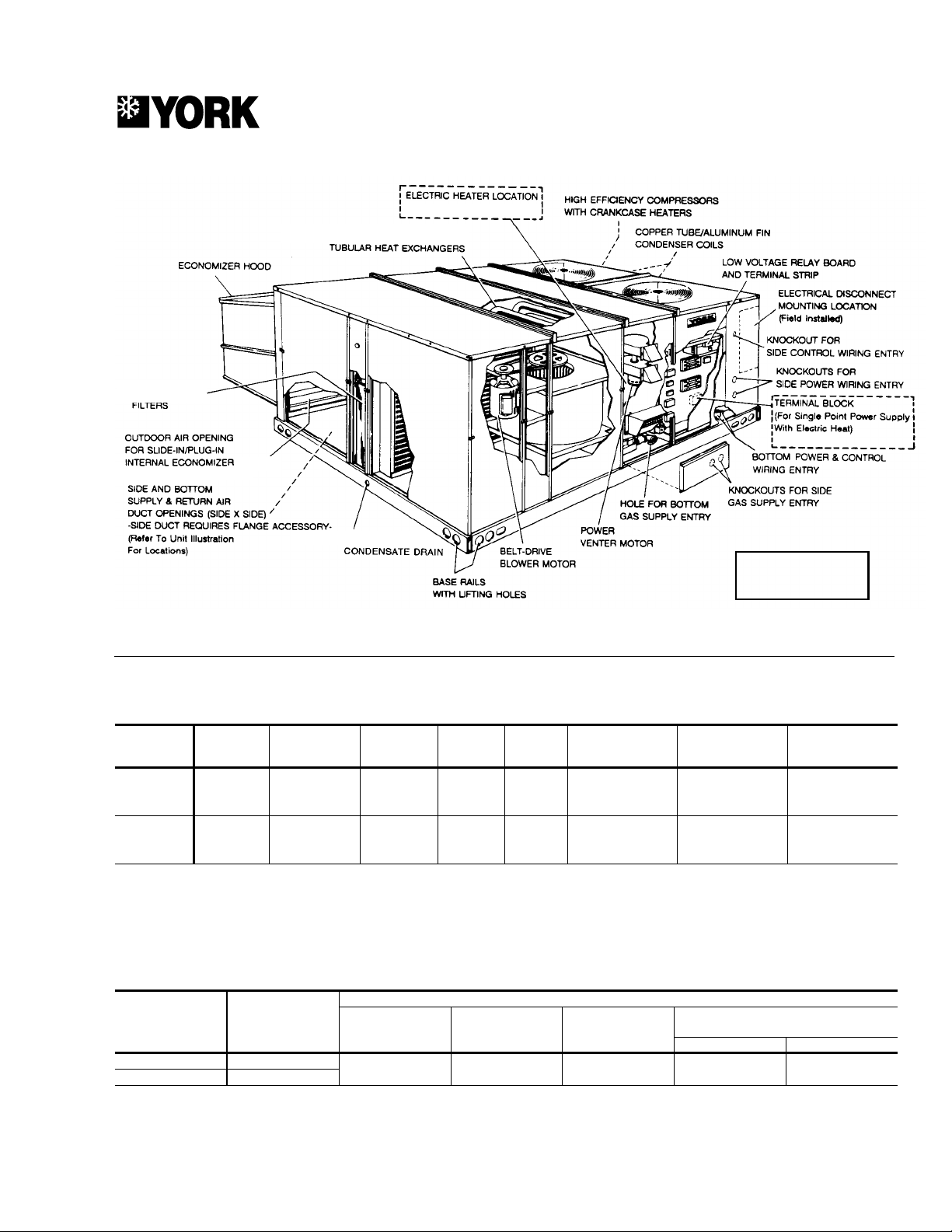

RATINGS

CAPACITY RA TINGS - Cooling / Electric Heating

Model

Rating

Point

1

Total Output,

Mbh / kW

Total Input,

kW

COP

2

EER

Sensible Output,

3

Mbh / kW

Latent Output,

Mbh / kW

T1 159 / 46.6 18.2 2.60 8.80 132 / 38.7 26.9 / 7.9

D3CE180

T2 142 / 41.7 20.0 2.10 7.15 141 / 41.2 1.6 / 0.5 18, 36, 54, 72

T3 152 / 44.6 16.4 2.75 9.40 119 / 34.9 33.2 / 9.7

T1 210 / 61.5 24.8 2.50 8.50 176 / 51.5 34.0 / 10.0

D3CE240

1

T1 = Moderate Climates, T2 = Hot Climates, T3 = Cool Climates.

2

COP = Coefficient of Performance - total output kW divided by the total input kW.

3

EER = Energy Efficiency Ratio - total ou t pu t Mb h divided by the total input kW.

4

Heaters available as factory-installed options or field-installed accessories - all with single point power supply.

T2 182 / 53.3 27.1 2.00 6.75 182 / 53.3 0.0 / 0.0 18, 36, 54, 72

T3 196 / 57.5 22.2 2.60 8.80 152 / 44.6 42.6 / 12.5

CAPACITY RATINGS - Gas Heating

Gas Heat Capacity

Model

D3CG180N320 180 / 52.7

D3CG240N320 240 / 70.3

NOTE: Gas Heaters are shipped available for natural gas, but can be converted to L.P. / propane gas with a field-installed conversion accessory. All gas units are two-stage heating.

First stage is 50% of total.

*Based on net input and 2nd. -H family, G20 (methane) net fuel value (9.97 kWh/m

Cooling Capacity,

Mbh / kW

Input (Net)

Mbh / kW

Output

Mbh / kW

Gas Rate*

3

cfh / m

/h

291 / 85.2 258 / 75.6 302 / 8.5 30 / 17 60 / 33

3

).

Temp. Rise (°F / °C)

At Full Input

Min. Max.

Electric Heat 4

Nominal Capacity,

kW

Unitary Products Group 3

Page 4

530.26-TG3YI

COOLING CAPACITIES (m3/s Air Flow) - 180 UNITS

Air On

Evaporator Coil

3

/s

m

WB °C

Total

Cap.

kW

Power

1

Input

kW

2

32 30 28 26 24 22

@27°C Air Temperature on Condenser C oil

23 66.4 14.7 51 44 37 30 23 -

2162.314.4595244373023

3.40

1958.214.0585852453831

1756.714.0575756494134

1555.213.9555555524537

23 61.5 14.5 46 40 34 27 21 -

2157.714.2534640342822

2.80

1953.913.9545347413528

1752.513.8525251443832

1551.113.7515151484235

23 57.1 14.3 37 32 28 23 19 -

2153.614.0433833292419

2.10

1950.113.6484439343025

1748.713.6494742373328

1547.413.5474745403631

@35°C Air Temperature on Condenser C oil

23 60.7 15.9 50 43 36 29 22 -

2157.215.5575043362922

3.40

1953.715.2545451433629

1752.315.1525252474032

1551.015.0515151474033

23 56.3 15.9 44 38 32 25 19 -

2153.115.6514438322620

2.80

1949.815.2505045393226

1748.615.1494948413529

1547.315.0474747443832

23 51.9 15.6 36 31 27 22 17 -

2148.915.3413732272318

2.10

1945.914.9464238332824

1744.714.8454540353126

1543.614.7444443383329

@46°C Air Temperature on Condenser C oil

23 49.6 18.2 46 39 32 25 18 -

2147.317.6474639322518

3.40

1945.017.1454545393225

1743.617.1444444403326

1542.117.1424242393124

23 49.4 17.8 41 35 29 23 17 -

2147.217.2474236292317

2.80

1944.916.6454542363024

1743.416.6434343373125

1542.016.6424242393327

23 46.5 17.5 33 29 24 19 15 -

2144.417.0393430252016

2.10

1942.316.4424035312621

1740.916.4414136322722

1

These capacities are gross ratings. For net capacity, deduct the heat of the supply air blower motor. Refer to the appropriate Blower Performance Table for the kW of the

supply air blower motor.

2

These ratings include the condenser fan motors (Total 2.3 kW) and the compressor motors but not the supply air blower motor.

1539.516.4404038332824

Sensible Capacity

Entering Dry Bulb Temp., °C

1

, kW

4 Unitary Products Group

Page 5

530.26-TG3YI

COOLING CAPACITIES (CFM Air Flow) - 180 UNITS

Air On

Evaporator Coil

CFM

WB °F

Total

Cap.

MBH

Power

1

Input

kW

2

90 86 82 79 75 72

@80°F Air Temperature on Condenser Coil1

73 227 14.7 175 151 126 102 78 70 213 14.4 200 176 152 127 103 79

7200

66 199 14.0 199 199 177 153 128 104

63 193 14.0 193 193 190 166 142 117

59 188 13.9 188 188 188 176 152 128

73 210 14.5 157 136 115 93 72 70 197 14.2 180 159 138 116 95 74

5930

66 184 13.9 184 182 160 139 1 18 97

63 179 13.8 179 179 172 151 130 109

59 174 13.7 174 174 174 163 142 121

73 195 14.3 127 11 1 95 79 63 70 183 14.0 146 130 114 98 82 66

4450

66 171 13.6 165 149 133 117 101 86

63 166 13.6 166 159 143 127 111 96

59 162 13.5 162 162 153 137 121 105

@95°F Air Temperature on Condenser Coil

73 207 15.9 170 146 122 98 74 70 195 15.5 195 171 147 123 99 75

7200

66 183 15.2 183 183 172 148 124 100

63 179 15.1 179 179 179 159 135 1 11

59 174 15.0 174 174 174 162 138 113

73 192 15.9 150 129 108 87 66 70 181 15.6 172 151 130 109 88 67

5930

66 170 15.2 170 170 153 132 1 10 89

63 166 15.1 166 166 162 141 120 99

59 161 15.0 161 161 161 151 130 109

73 177 15.6 123 107 91 75 59 70 167 15.3 142 126 110 94 78 62

4450

66 157 14.9 157 145 129 113 97 81

63 153 14.8 153 153 137 121 105 89

59 149 14.7 149 149 145 129 1 13 97

@115°F A ir Temperature on C ondenser Coi l

73 169 18.2 157 133 109 85 61 70 161 17.6 161 158 134 110 85 61

7200

66 154 17.1 154 154 154 135 1 10 86

63 149 17.1 149 149 149 137 1 12 88

59 144 17.1 144 144 144 132 107 83

73 169 17.8 141 120 99 78 57 70 161 17.2 161 142 121 100 79 58

5930

66 153 16.6 153 153 144 123 102 81

63 148 16.6 148 148 148 128 107 86

59 143 16.6 143 143 143 133 1 12 90

73 159 17.5 114 98 82 66 50 70 151 17.0 133 1 17 101 85 69 53

4450

66 144 16.4 144 136 120 104 88 72

63 139 16.4 139 139 124 108 92 76

1

These capacities are gross ratings. For net capacity, deduct the heat of the supply air blower motor. Refer to the appropriate Blower Performance Table for the kW of the

supply air blower motor.

2

These ratings include the condenser fan motors (Total 2.3 kW) and the compressor motors but not the supply air blower motor.

59 135 16.4 135 135 128 112 96 80

Sensible Capacity

Entering Dry B ulb Temp., °F

1

, MBH

Unitary Products Group 5

Page 6

530.26-TG3YI

COOLING CAPACITIES (m3/s Air Flow) - 240 UNITS

Air On

Evaporator Coil

3

/s

m

WB °C

Total

Cap.

kW

Power

1

Input

kW

2

32 30 28 26 24 22

@27°C Air Temperature on Condenser C oil

23 80.4 19.0 74 65 55 46 37 -

2177.618.8787061524333

4.40

1974.818.6757567574839

1772.418.4727271625344

1570.018.1707070655647

23 76.9 18.8 68 60 52 44 36 -

2174.318.6736557494133

3.80

1971.618.4727062544638

1769.318.2696967595143

1567.017.9676767635547

23 71.2 18.5 56 50 44 37 31 -

2168.718.3605448423630

2.80

1966.318.1655952464034

1764.117.9646256504438

1562.017.6626260544741

@35°C Air Temperature on Condenser C oil

23 74.9 21.0 71 61 52 43 34 -

2172.320.7726858494031

4.40

1969.820.4707065554637

1767.420.1676767584940

1565.019.9656565605142

23 71.3 20.7 65 57 49 41 33 -

2168.920.5696254463830

3.80

1966.420.2666660524436

1764.219.9646463554739

1561.919.7626262585042

23 65.4 20.4 52 46 40 34 28 -

2163.120.1575145393327

2.80

1960.919.8615650443831

1758.819.6595852464034

1556.719.3575754484236

@46°C Air Temperature on Condenser C oil

23 66.4 23.4 65 56 47 38 29 -

2163.322.9636253443526

4.40

1960.222.3606060514132

1759.022.3595959534334

1557.822.2585858534435

23 63.8 23.3 60 52 44 36 28 -

2160.822.7615850423426

3.80

1957.822.2585856484032

1756.722.1575757504234

1555.522.1565656524435

23 59.4 23.1 49 42 36 30 24 -

2156.622.5544741352923

2.80

1953.822.0545346403428

1752.821.9535348423630

1

These capacities are gross ratings. For net capacity, deduct the heat of the supply air blower motor. Refer to the appropriate Blower Performance Table for the kW of the

supply air blower motor.

2

These ratings include the condenser fan motors (Total 2.3 kW) and the compressor motors but not the supply air blower motor.

1551.721.9525249433731

Sensible Capacity

Entering Dry Bulb Temp., °C

1

, kW

6 Unitary Products Group

Page 7

530.26-TG3YI

COOLING CAPACITIES (CFM Air Flow) - 240 UNITS

Air On

Evaporator Coil

CFM

WB °F

Total

Cap.

MBH

Power

1

Input

kW

2

90 86 82 79 75 72

@80°F Air Temperature on Condenser Coil

73 274 19.0 252 221 189 158 127 70 265 18.8 265 240 208 177 146 114

9320

66 255 18.6 255 255 227 196 164 133

63 247 18.4 247 247 243 211 180 149

59 239 18.1 239 239 239 223 192 161

73 263 18.8 232 205 177 150 123 70 253 18.6 250 222 195 168 141 113

8050

66 244 18.4 244 240 213 186 158 131

63 236 18.2 236 236 228 200 173 146

59 229 17.9 229 229 229 215 188 160

73 243 18.5 191 170 149 128 107 70 234 18.3 206 185 164 143 122 101

5930

66 226 18.1 221 200 179 158 137 116

63 219 17.9 219 212 191 170 149 128

59 212 17.6 212 212 204 183 162 141

@95°F Air Temperature on Condenser Coil

73 256 21.0 241 209 178 147 115 70 247 20.7 247 230 199 168 136 105

9320

66 238 20.4 238 238 220 189 157 126

63 230 20.1 230 230 230 199 168 136

59 222 19.9 222 222 222 206 175 143

73 243 20.7 221 193 166 139 11 1 70 235 20.5 235 213 186 158 131 104

8050

66 227 20.2 227 227 206 178 151 124

63 219 19.9 219 219 215 188 161 133

59 211 19.7 211 211 211 197 170 143

73 223 20.4 179 158 137 116 95 70 215 20.1 195 174 153 133 112 91

5930

66 208 19.8 208 191 170 149 128 107

63 201 19.6 201 199 178 157 136 115

59 193 19.3 193 193 186 165 144 123

@115°F A ir Temperature on Condens er Coi l

73 226 23.4 223 191 160 129 97 70 216 22.9 216 213 182 151 119 88

9320

66 205 22.3 205 205 204 172 141 110

63 201 22.3 201 201 201 179 148 117

59 197 22.2 197 197 197 182 150 119

73 218 23.3 204 177 149 122 95 70 207 22.7 207 197 170 142 115 88

8050

66 197 22.2 197 197 190 163 136 108

63 193 22.1 193 193 193 169 142 115

59 189 22.1 189 189 189 176 148 121

73 203 23.1 166 145 124 103 82 70 193 22.5 183 162 141 120 99 78

5930

66 184 22.0 184 179 158 137 116 95

63 180 21.9 180 180 164 143 122 101

1

These capacities are gross ratings. For net capacity, deduct the heat of the supply air blower motor. Refer to the appropriate Blower Performance Table for the kW of the

supply air blower motor.

2

These ratings include the condenser fan motors (Total 2.3 kW) and the compressor motors but not the supply air blower motor.

59 176 21.9 176 176 169 148 127 106

Sensible Capacity

Entering Dry Bulb T emp., °F

1

, MBH

Unitary Products Group 7

Page 8

530.26-TG3YI

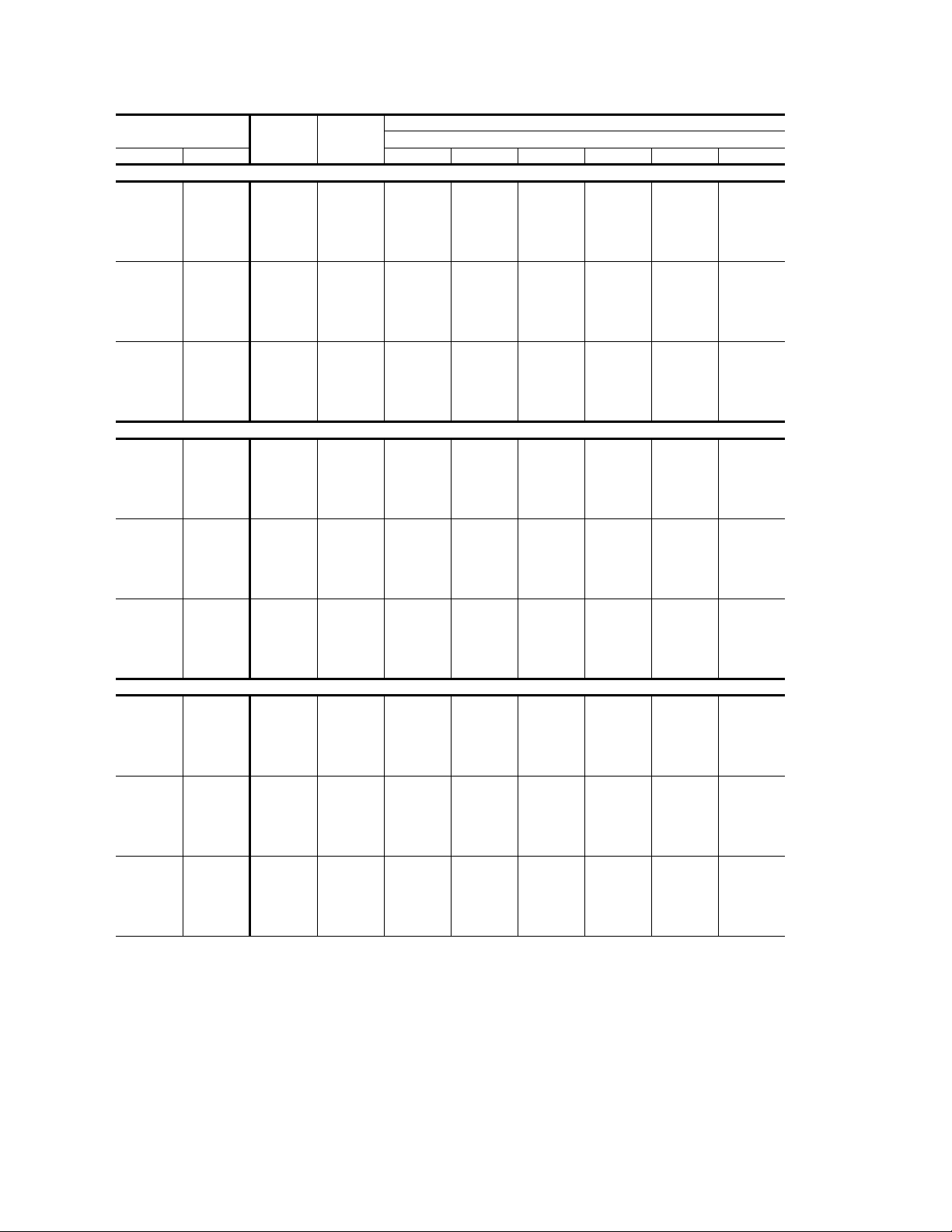

BLOWER PERFORMANCE (D*CE180 UN IT SUPPLY AIR) -

w/DOWNFLOW DUCT APPLICATIONS

STANDARD DRIVE (m /s)

BLOWER

SPEED,

RPM

845 6.0 173 1.8 2.2 138 2.2 2.6 83 2.6 3.1 18 3.0 3.5 - - 885 5.0 208 1.9 2.3 172 2.3 2.8 115 2.7 3.3 49 3.1 3.7 - - 925 4.0 245 2.0 2.4 208 2.4 2.9 149 2.9 3.4 82 3.3 3.9 - - -

960 3.0 281 2.1 2.6 242 2.6 3.1 182 3.0 3.6 114 3.4 4.1 30 3.8 4.6

1000 2.0 323 2.3 2.7 283 2.7 3.2 222 3.2 3.8 152 3.6 4.3 67 4.0 4.8

1040 1.0 369 2.4 2.9 327 2.9 3.4 264 3.3 4.0 193 3.8 4.5 107 4.2 5.1

MOTOR

PULLEY

(TURNS

OPEN)*

3

ESP

(Pa)

ESP

(Pa)

AIRFLOW

Output

(kW)

Input

(kW)

ESP

(Pa)

Output

(kW)

Input

(kW)

3

2.10 m

/s 2.45 m3/s 2.80 m3/s 3.10 m3/s 3.40 m3/s

Output

(kW)

Input

(kW)

ESP

(Pa)

Output

(kW)

Input

(kW)

ESP

(Pa)

Output

(kW)

Input

(kW)

HIGH SPEED DRIVE (m /s)

BLOWER

SPEED,

RPM

1030 6.0 357 2.4 2.8 316 2.8 3.4 253 3.3 3.9 183 3.7 4.5 97 4.2 5.0

1070 5.0 405 2.5 3.0 362 3.0 3.6 298 3.5 4.2 226 3.9 4.7 - - 1 115 4.0 461 2.7 3.2 416 3.2 3.8 351 3.7 4.4 278 4.2 5.0 - - 1155 3.05142.93.44683.44.04013.94.7-----1200 2.0 577 3.1 3.7 529 3.6 4.3 461 4.1 5.0 -----1240 1.0 636 3.3 3.9 587 3.8 4.5 ---------

MOTOR

PULLEY

(TURNS

OPEN)*

3

ESP

(Pa)

ESP

(Pa)

AIRFLOW

Output

(kW)

Input

(kW)

ESP

(Pa)

Output

(kW)

Input

(kW)

3

2.10 m

/s 2.45 m3/s 2.80 m3/s 3.10 m3/s 3.40 m3/s

Output

(kW)

Input

(kW)

ESP

(Pa)

Output

(kW)

Input

(kW)

ESP

(Pa)

Output

(kW)

STANDARD DRIVE (CFM)

ESP

(iwg)

AIRFLOW

Output

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

BLOWER

SPEED,

RPM

845 6.0 0.7 2.4 2.2 0.6 2.9 2.6 0.3 3.5 3.1 0.1 4.0 3.5 - - 885 5.0 0.8 2.6 2.3 0.7 3.1 2.8 0.5 3.7 3.3 0.2 4.2 3.7 - - 925 4.0 1.0 2.7 2.4 0.8 3.3 2.9 0.6 3.8 3.4 0.3 4.4 3.9 - - -

960 3.0 1.1 2.9 2.6 1.0 3.4 3.1 0.7 4.0 3.6 0.5 4.6 4.1 0.1 5.2 4.6

1000 2.0 1.3 3.0 2.7 1.1 3.6 3.2 0.9 4.2 3.8 0.6 4.8 4.3 0.3 5.4 4.8

1040 1.0 1.5 3.2 2.9 1.3 3.8 3.4 1.1 4.5 4.0 0.8 5.1 4.5 0.4 5.7 5.1

MOTOR

PULLEY

(TURNS

OPEN)*

4450 CFM 5190 CFM 5930 CFM 6565 CFM 7200 CFM

ESP

Output

(iwg)

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

Input

(kW)

Input

(kW)

HIGH SPEED DRIVE (CFM)

ESP

(iwg)

AIRFLOW

Output

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

BLOWER

SPEED,

RPM

1030 6.0 1.4 3.2 2.8 1.3 3.8 3.4 1.0 4.4 3.9 0.7 5.0 4.5 0.4 5.6 5.0

1070 5.0 1.6 3.4 3.0 1.5 4..0 3.6 1.2 4.7 4.2 0.9 5.3 4.7 - - 1 115 4.0 1.9 3.6 3.2 1.7 4.3 3.8 1.4 5.0 4.4 1.1 5.6 5.0 - - 1155 3.0 2.1 3.9 3.4 1.9 4.5 4.0 1.6 5.2 4.7 - - - - - 1200 2.0 2.3 4.1 3.7 2.1 4.8 4.3 1.8 5.5 5.0 - - - - - 1240 1.0 2.6 4.4 3.9 2.4 5.1 4.5 - - - - - - - - -

NOTES: 1. Blower performance values include fixed outdoor air, a dry indoor coil, the standard unit filters and no electric heat.

8 Unitary Products Group

MOTOR

PULLEY

(TURNS

OPEN)*

2. Refer to Page 12 for the resistance values for all other unit options or applications.

ESP = External Stat ic Pr essu re available for the supply and return air duct system. All internal unit resistances have been deducted from the total static pre ssure of the blower.

*Do NOT close pulley below minimum turns o pen.

4450 CFM 5190 CFM 5930 CFM 6565 CFM 7200 CFM

ESP

Output

(iwg)

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

Page 9

BLOWER PERFORMANCE (D*CE240 UNIT SUPPLY AIR) -

w/DOWNFLOW DUCT APPLICATIONS

530.26-TG3YI

STANDARD DRIVE (m /s)

BLOWER

SPEED,

RPM

765 6.01372.93.3932.93.3233.23.7-----795 5.01763.03.41323.13.5623.43.9-----820 4.0 209 3.1 3.6 165 3.2 3.7 95 3.6 4.1 40 4.0 4.5 - - 850 3.0 250 3.3 3.8 206 3.4 3.9 136 3.8 4.4 81 4.2 4.8 16 4.7 5.3

875 2.0 284 3.4 3.9 240 3.6 4.1 170 4.0 4.6 1 15 4.4 5.0 51 4.9 5.6

905 1.0 327 3.6 4.1 283 3.8 4.3 212 4.3 4.9 157 4.7 5.3 93 5.2 5.9

MOTOR

PULLEY

(TURNS

OPEN)*

HIGH SPEED DRIVE (m /s)

BLOWER

SPEED,

RPM

895 6.0 312 3.5 4.0 268 3.7 4.3 198 4.2 4.8 143 4.6 5.2 79 5.1 5.8

930 5.0 362 3.7 4.3 318 4.0 4.5 248 4.5 5.1 193 4.9 5.6 129 5.4 6.2

970 4.0 421 4.0 4.5 377 4.2 4.9 306 4.8 5.5 252 5.2 6.0 187 5.8 6.6

1005 3.0 473 4.2 4.8 429 4.5 5.1 359 5.1 5.8 304 5.6 6.4 240 6.1 7.0

1045 2.0 535 4.4 5.0 491 4.8 5.5 420 5.4 6.2 365 5.9 6.8 - - 1080 1.0 590 4.6 5.3 546 5.0 5.8 475 5.7 6.5 420 6.2 7.1 - - -

MOTOR

PULLEY

(TURNS

OPEN)*

3

ESP

(Pa)

3

ESP

(Pa)

ESP

(Pa)

ESP

(Pa)

AIRFLOW

Output

(kW)

AIRFLOW

Output

(kW)

Input

(kW)

Input

(kW)

ESP

(Pa)

ESP

(Pa)

Output

(kW)

Output

(kW)

Input

(kW)

Input

(kW)

3

2.80 m

/s 3.30 m3/s 3. 80 m3/s 4.10 m3/s 4.40 m3/s

Output

2.80 m

Output

Input

ESP

(kW)

(kW)

3

/s 3.30 m3/s 3. 80 m3/s 4.10 m3/s 4.40 m3/s

Input

(kW)

(kW)

(Pa)

ESP

(Pa)

Output

Output

(kW)

(kW)

Input

(kW)

Input

(kW)

ESP

(Pa)

ESP

(Pa)

Output

(kW)

Output

(kW)

Input

(kW)

Input

(kW)

STANDARD DRIVE (CFM)

ESP

(iwg)

AIRFLOW

Output

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

BLOWER

SPEED,

RPM

765 6.00.63.83.30.43.93.30.14.33.7-----795 5.00.74.03.40.54.13.50.24.63.9-----820 4.0 0.8 4.2 3.6 0.7 4.4 3.7 0.4 4.8 4.1 0.2 5.3 4.5 - - 850 3.0 1.0 4.4 3.8 0.8 4.6 3.9 0.5 5.1 4.4 0.3 5.6 4.8 0.1 6.2 5.3

875 2.0 1.1 4.6 3.9 1.0 4.8 4.1 0.7 5.4 4.6 0.5 5.9 5.0 0.2 6.6 5.6

905 1.0 1.3 4.8 4.1 1.1 5.1 4.3 0.9 5.7 4.9 0.6 6.3 5.3 0.4 6.9 5.9

MOTOR

PULLEY

(TURNS

OPEN)*

5930 CFM 6990 CFM 8050 CFM 8685 CFM 9320 CFM

ESP

Output

(iwg)

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

HIGH SPEED DRIVE (CFM)

ESP

(iwg)

AIRFLOW

Output

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

BLOWER

SPEED,

RPM

895 6.0 1.3 4.7 4.0 1.1 5.0 4.3 0.8 5.6 4.8 0.6 6.1 5.2 0.3 6.8 5.8

930 5.0 1.5 5.0 4.3 1.3 5.3 4.5 1.0 6.0 5.1 0.8 6.6 5.6 0.5 7.2 6.2

970 4.0 1.7 5.3 4.5 1.5 5.7 4.9 1.2 6.4 5.5 1.0 7.0 6.0 0.8 7.8 6.6

1005 3.0 1.9 5.6 4.8 1.7 6.0 5.1 1.4 6.8 5.8 1.2 7.4 6.4 1.0 8.2 7.0

1045 2.0 2.1 5.9 5.0 2.0 6.4 5.5 1.7 7.3 6.2 1.5 7.9 6.8 - - 1080 1.0 2.4 6.2 5.3 2.2 6.8 5.8 1.9 7.7 6.5 1.7 8.4 7.1 - - -

NOTES: 1. Blower performance values include fixed outdoor air, a dry indoor coil, the standard unit filters and no electric heat.

MOTOR

PULLEY

(TURNS

OPEN)*

2. Refer to Page 12 for the resistance values for all other unit options or applications.

ESP = External Stat ic Pr essu re available for the supply and return air duct system. All in ternal unit resistances have been deducted from the total static pressure of the blower.

*Do NOT close pulley below minimum turns open.

5930 CFM 6990 CFM 8050 CFM 8685 CFM 9320 CFM

ESP

Output

(iwg)

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

Input

(kW)

Input

(kW)

Unitary Products Group 9

Page 10

530.26-TG3YI

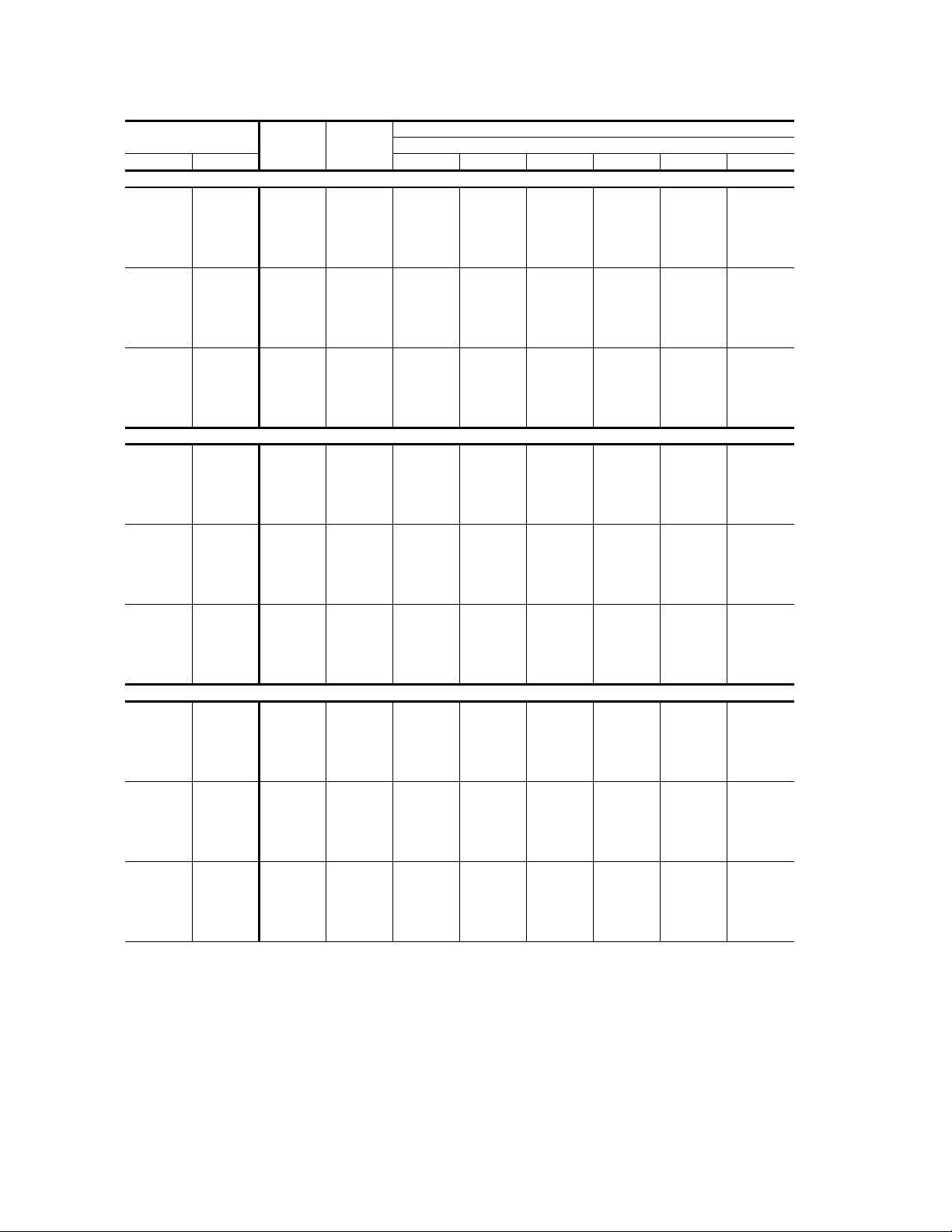

BLOWER PERFORMANCE (D*CG180 UNIT SUPPLY AIR) -

w/DOWNFLOW DUCT APPLICATIONS

STANDARD DRIVE (m /s)

BLOWER

SPEED,

RPM

845 6.0 206 1.8 2.2 146 2.0 2.5 80 2.4 2.8 18 2.7 3.2 - - 885 5.0 242 1.9 2.3 183 2.2 2.6 117 2.5 3.0 56 2.9 3.4 - - 925 4.0 278 2.0 2.4 220 2.3 2.7 155 2.7 3.2 94 3.1 3.7 28 3.5 4.2

960 3.0 311 2.1 2.5 253 2.4 2.9 189 2.8 3.4 128 3.2 3.9 63 3.7 4.5

1000 2.0 349 2.2 2.6 292 2.6 3.1 228 3.0 3.6 168 3.5 4.2 103 4.0 4.8

1040 1.0 387 2.3 2.8 331 2.7 3.3 268 3.2 3.9 209 3.7 4.4 144 4.3 5.1

MOTOR

PULLEY

(TURNS

OPEN)*

3

ESP

(Pa)

ESP

(Pa)

AIRFLOW

Output

(kW)

Input

(kW)

ESP

(Pa)

Output

(kW)

Input

(kW)

3

2.10 m

/s 2.45 m3/s 2.80 m3/s 3.10 m3/s 3.40 m3/s

Output

(kW)

Input

(kW)

ESP

(Pa)

Output

(kW)

Input

(kW)

ESP

(Pa)

Output

(kW)

Input

(kW)

HIGH SPEED DRIVE (m /s)

BLOWER

SPEED,

RPM

1030 6.0 378 2.3 2.7 321 2.7 3.2 258 3.2 3.8 199 3.6 4.4 134 4.2 5.0

1070 5.0 417 2.4 2.9 361 2.9 3.4 299 3.4 4.1 240 3.9 4.7 - - 1115 4.0 461 2.6 3.1 407 3.1 3.7 345 3.7 4.4 286 4.2 5.0 - - 1155 3.05022.83.34483.34.03873.94.7-----1200 2.0 548 3.0 3.6 495 3.6 4.3 435 4.2 5.0 -----1240 1.0 590 3.2 3.8 538 3.8 4.6 ---------

MOTOR

PULLEY

(TURNS

OPEN)*

3

ESP

(Pa)

ESP

(Pa)

AIRFLOW

Output

(kW)

Input

(kW)

ESP

(Pa)

Output

(kW)

Input

(kW)

3

2.10 m

/s 2.45 m3/s 2.80 m3/s 3.10 m3/s 3.40 m3/s

Output

(kW)

Input

(kW)

ESP

(Pa)

Output

(kW)

Input

(kW)

ESP

(Pa)

Output

(kW)

STANDARD DRIVE (CFM)

ESP

(iwg)

AIRFLOW

Output

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

BLOWER

SPEED,

RPM

845 6.0 0.8 2.5 2.2 0.6 2.7 2.5 0.3 3.2 2.8 0.1 3.6 3.2 - - 885 5.0 1.0 2.6 2.3 0.7 2.9 2.6 0.5 3.4 3.0 0.2 3.8 3.4 - - 925 4.0 1.1 2.7 2.4 0.9 3.1 2.7 0.6 3.6 3.2 0.4 4.1 3.7 0.1 4.7 4.2

960 3.0 1.2 2.8 2.5 1.0 3.2 2.9 0.8 3.8 3.4 0.5 4.3 3.9 0.3 5.0 4.5

1000 2.0 1.4 2.9 2.6 1.2 3.4 3.1 0.9 4.0 3.6 0.7 4.7 4.2 0.4 5.3 4.8

1040 1.0 1.6 3.1 2.8 1.3 3.7 3.3 1.1 4.3 3.9 0.8 5.0 4.4 0.6 5.7 5.1

MOTOR

PULLEY

(TURNS

OPEN)*

4450 CFM 5190 CFM 5930 CFM 6565 CFM 7200 CFM

ESP

Output

(iwg)

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

Input

(kW)

Input

(kW)

HIGH SPEED DRIVE (CFM)

ESP

(iwg)

AIRFLOW

Output

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

BLOWER

SPEED,

RPM

1030 6.0 1.5 3.1 2.7 1.3 3.6 3.2 1.0 4.3 3.8 0.8 4.9 4.4 0.5 5.6 5.0

1070 5.0 1.7 3.3 2.9 1.4 3.8 3.4 1.2 4.5 4.1 1.0 5.2 4.7 - - 1 115 4.0 1.9 3.5 3.1 1.6 4.1 3.7 1.4 4.9 4.4 1.2 5.6 5.0 - - 1155 3.0 2.0 3.7 3.3 1.8 4.4 4.0 1.6 5.2 4.7 - - - - - 1200 2.0 2.2 4.0 3.6 2.0 4.8 4.3 1.7 5.6 5.0 - - - - - 1240 1.0 2.4 4.3 3.8 2.2 5.1 4.6 - - - - - - - - -

NOTES: 1. Blower performance values include fixed outdoor air, a dry indoor coil, the standard unit filters and no electric heat.

10 Unitary Products Group

MOTOR

PULLEY

(TURNS

OPEN)*

2. Refer to Page 12 for the resistance values for all other unit options or applications.

ESP = External Stat ic Pr essu re available for the supply and return air duct system. All internal unit resistances have been deducted from the total static pre ssure of the blower.

*Do NOT close pulley below minimum turns o pen.

4450 CFM 5190 CFM 5930 CFM 6565 CFM 7200 CFM

ESP

Output

(iwg)

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

Page 11

BLOWER PERFORMANCE (D*CG240 UNIT SUPPLY AIR) -

w/DOWNFLOW DUCT APPLICATIONS

530.26-TG3YI

STANDARD DRIVE (m /s)

BLOWER

SPEED,

RPM

765 6.02022.12.4802.73.1- ------795 5.02382.32.61172.93.3--------820 4.02682.42.71503.03.4--------850 3.03052.52.91893.23.7503.94.5-----875 2.03362.73.02223.43.8854.14.7-----905 1.0 347 2.8 3.2 262 3.6 4.1 128 4.3 5.0 37 4.8 5.5 - - -

MOTOR

PULLEY

(TURNS

OPEN)*

HIGH SPEED DRIVE (m /s)

BLOWER

SPEED,

RPM

895 6.0 361 2.8 3.2 249 3.5 4.0 114 4.3 4.9 22 4.7 5.4 - - 925 5.0 400 2.9 3.4 290 3.7 4.2 157 4.5 5.1 66 5.0 5.7 - - 955 4.0 439 3.1 3.6 332 3.9 4.4 201 4.7 5.4 112 5.2 6.0 15 5.8 6.6

990 3.0 486 3.3 3.8 381 4.1 4.7 254 5.0 5.7 166 5.5 6.3 70 6.1 7.0

1020 2.0 527 3.5 4.0 425 4.3 5.0 299 5.2 6.0 213 5.8 6.7 119 6.4 7.3

1050 1.0 569 3.7 4.2 469 4.6 5.2 346 5.5 6.3 261 6.1 7.0 - - 1080 0.0 612 3.9 4.4 514 4.8 5.5 393 5.8 6.6 310 6.4 7.3 - - -

MOTOR

PULLEY

(TURNS

OPEN)*

3

ESP

(Pa)

3

ESP

(Pa)

ESP

(Pa)

ESP

(Pa)

AIRFLOW

Output

(kW)

AIRFLOW

Output

(kW)

Input

(kW)

Input

(kW)

ESP

(Pa)

ESP

(Pa)

Output

(kW)

Output

(kW)

Input

(kW)

Input

(kW)

3

2.80 m

/s 3.30 m3/s 3.80 m3/s 4.10 m3/s 4.40 m3/s

Output

2.80 m

Output

Input

ESP

(kW)

(kW)

3

/s 3.30 m3/s 3.80 m3/s 4.10 m3/s 4.40 m3/s

Input

(kW)

(kW)

(Pa)

ESP

(Pa)

Output

Output

(kW)

(kW)

Input

(kW)

Input

(kW)

ESP

(Pa)

ESP

(Pa)

Output

(kW)

Output

(kW)

Input

(kW)

Input

(kW)

STANDARD DRIVE (CFM)

ESP

(iwg)

AIRFLOW

Output

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

BLOWER

SPEED,

RPM

765 6.00.82.82.40.33.63.1--------795 5.01.03.02.60.53.83.3--------820 4.01.13.22.70.64.03.4--------850 3.01.23.42.90.84.33.70.25.34.5-----875 2.01.33.63.00.94.53.80.35.54.7-----905 1.0 1.5 3.8 3.2 1.1 4.8 4.1 0.5 5.8 5.0 0.1 6.5 5.5 - - -

MOTOR

PULLEY

(TURNS

OPEN)*

5930 CFM 6990 CFM 8050 CFM 8685 CFM 9320 CFM

ESP

Output

(iwg)

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

HIGH SPEED DRIVE (CFM)

ESP

(iwg)

AIRFLOW

Output

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

BLOWER

SPEED,

RPM

895 6.0 1.5 3.7 3.2 1.0 4.7 4.0 0.5 5.7 4.9 0.1 6.3 5.4 - - 925 5.0 1.6 3.9 3.4 1.2 4.9 4.2 0.6 6.0 5.1 0.3 6.7 5.7 - - 955 4.0 1.8 4.2 3.6 1.3 5.2 4.4 0.8 6.3 5.4 0.4 7.0 6.0 0.1 7.8 6.6

990 3.0 2.0 4.4 3.8 1.5 5.5 4.7 1.0 6.7 5.7 0.7 7.4 6.3 0.3 8.2 7.0

1020 2.0 2.1 4.7 4.0 1.7 5.8 5.0 1.2 7.0 6.0 0.9 7.8 6.7 0.5 8.6 7.3

1050 1.0 2.3 4.9 4.2 1.9 6.1 5.2 1.4 7.4 6.3 1.0 8.2 7.0 - - 1080 0.0 2.5 5.2 4.4 2.1 6.4 5.5 1.6 7.7 6.6 1.2 8.5 7.3

NOTES: 1. Blower performance values include fixed outdoor air, a dry indoor coil, the standard unit filters and no electric heat.

MOTOR

PULLEY

(TURNS

OPEN)*

2. Refer to Page 12 for the resistance values for all other unit options or applications.

ESP = External Stat ic Pr essu re available for the supply and return air duct system. All in ternal unit resistances have been deducted from the total static pressure of the blower.

*Do NOT close pulley below minimum turns open.

5930 CFM 6990 CFM 8050 CFM 8685 CFM 9320 CFM

ESP

Output

(iwg)

(bhp)

Input

(kW)

ESP

(iwg)

Output

(bhp)

Input

(kW)

Input

(kW)

Input

(kW)

Unitary Products Group 11

Page 12

530.26-TG3YI

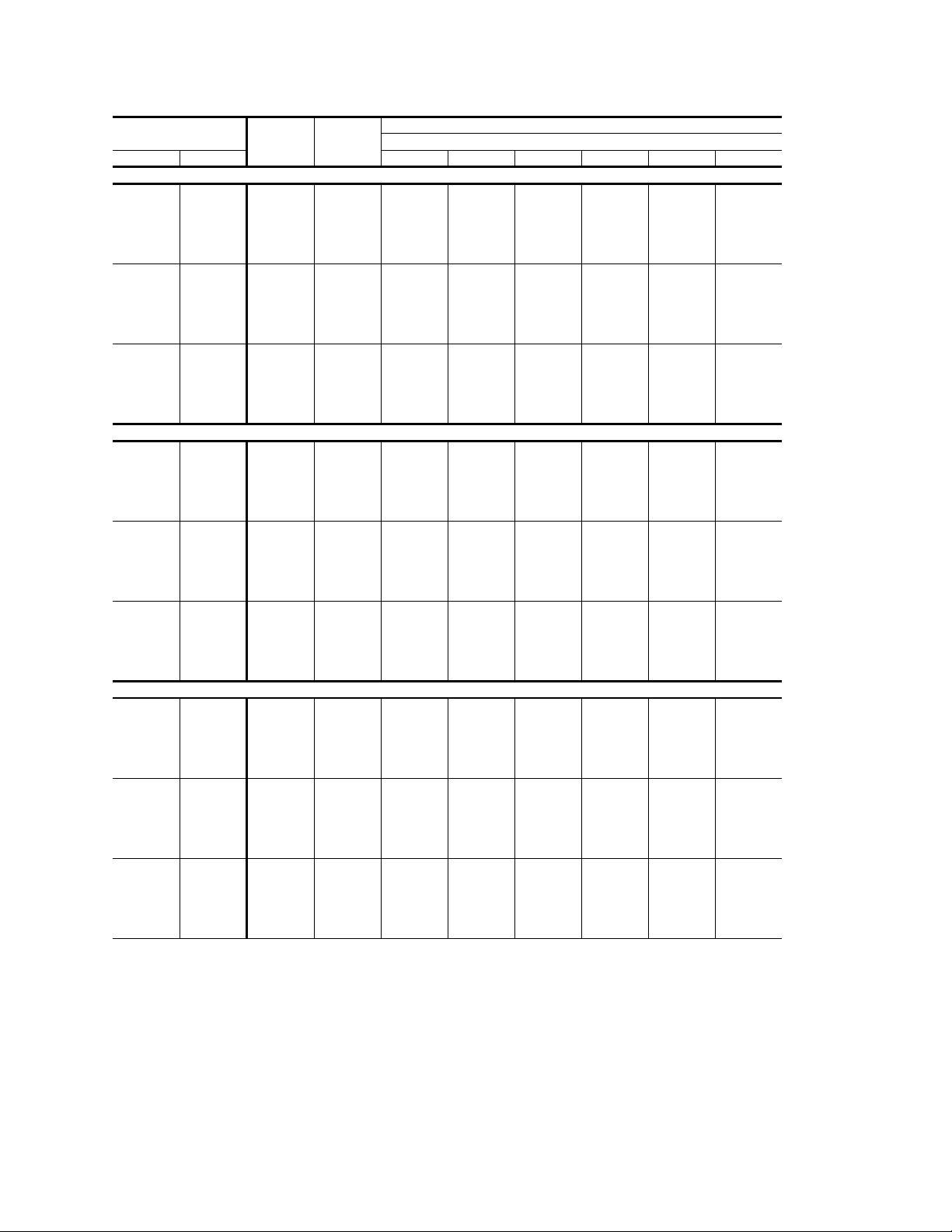

BLOWER MOTOR AND DRIVE DATA

1

kW/HP

MOTOR

FRAME

SIZE

EFF.

(%)

UNIT

SIZE

STD.

DRIVE

HIGH

BLOWER

RANGE

(RPM)

180 845-1040 3.0 / 4. 0 184T 84

240 765-905 5.6 / 7.5 213T 87

180 1030-1240 3.0 / 4.0 184T 84

SPEED

DRIVE

1

All motors are totally enclosed, fan cooled (TEFC), 1450 RPM with solid bases and a 1.15 service factor.

2

Do NOT close this pulley below the minimum number of turns open.

240 895-1080 5.6 / 7. 5 213T 87

ADJUSTABLE

MOTOR PULLEY

PITCH

DIA.

(mm/in.)

109-135

4.3-5.3

140-165

5.5-6.5

124-150

4.9-5.9

147-178

5.8-7.0

BORE

(mm/in.)

1

29 / 1

3

35 / 1

1

29 / 1

3

35 / 1

⁄

8

⁄

8

⁄

8

⁄

8

2

DESIG-

NATION

PITCH

DIA.

(mm / in.)

1VP56 188 / 7.4 25 / 1 BK80 1773 / 69.8 BX68 1

1VP68 264 / 10.4

1VP62 175 / 6.9 25 / 1 BK75 1773 / 69.8 BX68 1

1VP75 239 / 9.4

FIXED

BLOWER PULLEY

BORE

(mm/in.)

30 / 1

30 / 1

3

3

⁄

16

⁄

16

NATION

BELT (NOTCHED)

DESIG-

PITCH

LENGTH

(mm/in.)

DESIG-

NA TION

BK110 2103 / 82.8 BX81 1

BK100 2103 / 82.8 B X 8 1 1

STATIC RESISTANCES*

EXTERNAL STATIC [RESSURE DRP RESISTANCE, Pa/IWG

3

M

DESCRIPTION

MODEL 180 MODEL 240

2.1 / 4500 2.8 / 6000 3.4 / 7200 2.8 / 6000 3.8 / 8000 4.4 / 9400

WET COIL 24.8 / 0.1 24.8 / 0.1 24.8 / 0.1 24.8 / 0.1 24.8 / 0.1 24.8 / 0. 1

18 kW 24.8 / 0.1 24.8 / 0.1 24.8 / 0.1 24.8 / 0.1 24.8 / 0.1 24.8 / 0. 1

ELECTRIC HEAT

OPTIONS

36 kW 24.8 / 0.1 50.0 / 0.2 74.4 / 0.3 24.8 / 0.1 50.0 / 0.2 74.4 / 0. 3

54 kW 50.0 / 0.2 74.4 / 0.3 99.2 / 0.4 50.0 / 0.2 74.4 / 0.3 99.2 / 0. 4

72 kW 50.0 / 0.2 99.2 / 0.4 149.0 / 0.6 50.0 / 0.2 99.2 / 0.4 149.0 / 0.6

ECONOMIZER OPTION 24.8 / 0.1 24.8 / 0.1 24.8 / 0.1 24.8 / 0.1 24.8 / 0.1 24.8 / 0. 1

HORIZONTAL DUCT

CONNECTIONS

* Deduct these resistance values from the available unit ESP values listed in the respective blower performance table except for Horizontal Duct Connections. Add the Horizontal Duct

Connection values due to less airflow resistance.

50.0 / 0.2 74.4 / 0.3 124.0 / 0.5 50.0 / 0.2 74.4 / 0.3 124.0 / 0.5

/S / CFM

QTY

12 Unitary Products Group

Page 13

UNIT

SIZE

POWER

SUPPLY

COMPRESSOR

OUTDOOR

FAN

MOTOR,

(#1 & #2)

FLA, EACH

SUPPLY AIR

BLOWER

MOTOR, (FLA)

TOTAL UNIT

AMPACITY,

(AMPS)

MAX.

FUSE

SIZE

1

MIN.

WIRE SIZE2,

(mm2/AWG)RLA LRA

3 kW

4 HP

5.6 kW

7.5 HP

3 kW

4 HP

5.6 kW

7.5 HP

#1 #2 #1 #2

180 380/400/415-3+N-50 19.2 9.6 146 73 2.4 8.6 - 47.0 - 60 10 / 8

240 380/400/415-3+N-50 19.2 19.2 146 146 2.4 - 11.7 - 59.7 70 16 / 6

NOTES: 1. Slow blow type fuse.

2. Based on 105°C insulated copper conductors in conduit.

FIELD WIRING - Electric/Electric and Gas/Electric Units

530.26-TG3YI

L1

L2

L3

N

24 VOLT

TRANSFORMER

LINE VOLTAGE

TERMINAL

BLOCK 2TB

IN UNIT

CONTROL BOX

NEUTRAL

TERMINAL

GRD. LUG

ELECTRICAL DATA - Cooling Only Units and Units With Gas Heat

Refer to the

ELECTRICAL DATA

tables to size the

power wiring, the fuses and

the disconnect switch.

Unitary Products Group 13

Page 14

530.26-TG3YI

ELECTRICAL DATA

UNIT

SIZE

180

240

NOTES: 1. Slow blow type fuse.

2. Based on 105°C copper conductors.

POWER

SUPPLY

(VOLTS)

380-3+N-50

415-3+N-50

380-3+N-50

415-3+N-50

- Units With Supplemental Electric Heating

HEATER OPTION MINIMUM

MODEL

E018

E036

E054

E072

E018

E036

E054

E072

E018

E036

E054

E072

E018

E036

E054

E072

OUTPUT

kW

11.3

22.6

33.8

45.1

13.5

26.9

40.4

53.8

11.3

22.6

33.8

45.1

13.5

26.9

40.4

53.8

STAGES AMPS

1

2

2

2

1

2

2

2

1

2

2

2

1

2

2

2

17.1

34.3

51.4

68.6

18.7

37.4

56.2

74.9

17.1

34.3

51.4

68.6

18.7

37.4

56.2

74.9

CIRCUIT

AMPACITY

(AMPS)

47.0

53.6

75.0

96.5

47.0

57.5

80.9

104.0

59.7

59.7

78.9

100.0

59.7

61.4

84.8

108.0

MAXIMUM

FUSE SIZE

60

60

80

100

60

60

90

110

70

70

80

110

70

70

90

110

MINIMUM

WIRE SIZE

1

(mm2/AWG)

2

10 / 8

16 / 6

25 / 4

35 / 2

10 / 8

16 / 6

25 / 4

35 / 2

16 / 6

16 / 6

25 / 4

35 / 2

16 / 6

16 / 6

25 / 4

50 / 2

PHYSICAL DATA

COMPONENT DESCRIPTION

SUPPLY AIR

BLOWER

INDOOR

COIL

OUTDOOR

FANS

(Two Per Unit)

OUTDOOR

COIL

COMPRESSOR

(Qty. Per Unit)

AIR

FILTERS

CHARGE REFRIGERANT 22

This compressor will be energized first.

*

CENTRIFUGAL BLOWER

FAN MOTOR kW / HP 3.7 / 5 5.6 / 7.5

ROWS DEEP 3 3

FINS PER 25mm (1 in.) 13.5 13.5

FACE AREA m

PROPELLER DIA. mm / in. 762 / 30 (ea.)762 / 30 (ea.)

FAN MO TOR kW / HP 0.7 / 1 (ea.) 0.7 / 1 (ea.)

NOMINAL AIRFLOW

ROWS DEEP 2 2

FINS PER 25mm (1 in.) 13 20

FACE AREA m

TANDEM (10 TON NOMINAL CAPACITY) 1* 2

HERMETIC (5 TON NOMINAL C A PACITY) 1 -

QUANTITY PER UNIT

QUANTITY PER UNIT

QUANTITY PER UNIT

TOTAL FACE AREA m

UNIT SIZE (MBH)

180 240

DIA. x WD. (mm) 381 x 381 457 x 381

DIA. x WD. (in.) 15 x 15 18 x 15

2

2

/ Ft.

3

/ s 2.83 (ea.) 3.78 (ea.)

m

1.45 / 15.5 1.92 / 20. 5

CFM 6000 (ea.) 8000 (ea.)

2

2

/ Ft.

406 x 508 x 51 (mm)

16 x 20 x 2 (in.)

406 x 635 x 51 (mm)

16 x 25 x 2 (in.)

457 x 610 x 51 (mm)

18 x 24 x 2 (in.)

2

2

/ Ft.

3.35 / 36.0 4.02 / 43. 3

-4

-4

5-

1.40 / 15.0 1.87 / 20. 0

SYS. #1 ( kg. / lbs.) 7.94 / 17.5 8.16 / 18.0

SYS. #2 (kg. / lbs.) 3.86 / 8.5 8.16 / 18.0

WEIGHTS (kg. / lbs.)

D*CE UNITS

180 866 / 1910

BASIC

UNIT

240 957 / 2110

D*CG UNITS

180 975 / 2150

240 1066 / 2350

OPTIONS / ACCESSORIES

Economizer 73 / 160

Motorized Damper 68 / 150

18 kW 11 / 25

Electric

Heaters

36 kW 14 / 30

54 kW 16 / 35

72 kW 18 / 40

Roof Curb

180 79 / 175

240 84 / 185

Barometric Damper 20 / 45

Wood

Skid*

*

Allows handling of unit using 2300mm (90")

long forks.

180 91 / 200

240 100 / 220

14 Unitary Products Group

Page 15

HOLE

OPENING

DIAMETER*

(mm / in.)

USED FOR

A

28.6 / 1

1

⁄

8

KO

Control

Wiring

Front

19.1 /

3

⁄

4

NPS (Fem.) Bottom

B

92.1 / 3

5

⁄

8

KO

Power

Wiring

Front

76.2 / 3 NPS (Fem.) Bottom

*KO denotes Knockout facility.

UNIT DIMENSIONS - D*CE180 & 240 UNITS

3181 (125-1/4") (180)

3461 (136-1/4") (240)

616 (24-1/4") (180)

895 (35-1/4") (240)

1235 (48-5/8") (180)

1337 (52-5/8") (240)

530.26-TG3YI

All dimensions are in millimeter s and inches,

unless otherwise specif ied. They are s ubject

to change without notice. Certified

dimensions will be provided upon request.

CLEARANCES (mm / in.)

Front 914 / 36

Back

Left Side (Filter Acces s)

610 / 24 (Less Economizer)

1245 / 49 (With Economizer)

610 / 24 (Less Economizer)

1372 / 54 (With Economizer)

Right Side (Outdoor Coil) 914 / 36

Below Unit 20 / 0

1829 / 72 With 914 / 36

Above Unit*

NOTE: Unit and ductwork are approve d for zero clearance to combustible

materials when equipped with electric he at.

*Units must be installed oudoors. Overhanging structures or shrubs should not

obstruct outdoor air discharge outle t.

Maximum Horizontal Overhang

(For Outdoor Air Discharge)

Unitary Products Group 15

RETURN AIR

SUPPL Y AIR

OUTDOOR AIR

(Discharge)

OUTDOOR AIR

(Economizer)

UTILITIES ENTRY DATA

Page 16

RETURN AIR

OUTDOOR AIR

(Economizer)

SUPPLY AIR

OUTDOOR AIR

(Discharge)

530.26-TG3YI

UNIT DIMENSIONS - D*CG180 & 240 UNITS

3181 (125-1/4") (180)

3561 (136-1/4") (240)

1235 (48-5/8") (180)

1337 (52-5/8") (240)

616 (24-1/4") (180)

895 (35-1/4") (240)

CLEARANCES (mm / in. )

1

Front

Back

Left Side (Filter Access)

Right Side (Outdoor Coil) 914 / 36

Below Unit

Above Unit

1

Locate unit so that the vent air outl et ho ods are at least:

• 0.9 meter (3 ft) above any forced air inlet located within 3.0m (10 ft) horizontal

(excluding those integral to the unit).

• 1.2 meters (4 ft ) b el o w, 1.2m (4 ft.) horizonta l f rom , or 0. 3 1m(1 ft) above any door

or gravity air inlet into the building.

• 1.2 meters (4 ft) from electric meters, gas meters, regulators and relief equipment.

2

Units may be installed on combustible surfaces capable of continuous exposure to

temperatures of 92°C (19 7 ° F), a nd intermittent exposure to temperatures of 1 24°C (255 ° F) .

3

Units must be installed outdoors. Overhanging structures or shrubs should not

obstruct the outdoor air discharge outlet.

NOTE: A 25mm (1 in.) clearance must be provided between any combustible material and the

supply air ductwork for a distance of 0.9m (3 ft) from the unit.

The products of combustion must not be allowed to accumulate within a confined space

and recirculate.

2

3

914 / 36

610 / 24 (Less Economizer)

1245 / 49 (With Economizer)

610 / 24 (Less Economizer)

1372 / 54 (With Economizer)

0 / 0

1829 / 72 with 914 / 36 maximum

Horizontal Overhang

(For Outdoor Air Discharge)

All dimensions are in millimeters and inches,

unless otherwise specified. They are subject to

change without notice. Certified dimensions

will be provided upon request.

UTILITIES ENTRY DATA

HOLE

A

B

C 2-3/8 / 60 KO Gas Piping (Front)

D 1-11/16 / 43 Hole Gas Piping (Bottom)**

*KO denotes Knockout facility.

**Opening in the bottom of the unit can be located by the slice in the insulation.

OPENING

DIAMETER*

USED FOR

(in. / mm)

1-1/8 / 29 KO

3/4 NPS / 19 (Fem.) Bottom

3-5/8 / 92 KO

3 NPS / 76 (Fem.) Bott om

Control Wiring

Power Wiring

Front

Front

16 Unitary Products Group

Page 17

UNIT DIMENSIONS - D*CE / D*CG180 & 240 UNITS (Cont’d.)

727 (28-5/8") (180)

OUTDOOR COIL

END OF UNIT

1006 (39-5/8") (240)

530.26-TG3YI

DUCT COVERS - Uni ts are shipped with the bottom

duct openings covered. An accessory flange kit is

available for connecting side ducts.

For

downflow duct appli cations:

1. Remove the side panels from the s uppl y and return

air compartments to gain access to the bottom

supply and return air duct covers.

2. Remove and discard the bot tom duct covers.

3. Replace the side supply and return air compartment

panels.

For

sideflow duct applications;

1. Replace the side panels on the s upply and return air

compartments with the acc essory flange kit panels.

2. Connect ductwork to the duct flanges on the rear of

the unit.

ACCESSORY SIDE SUPPLY AND RETURN AIR DUCT OPENINGS

DETAIL “X”

397

5

15

⁄8“

610 (24") (180)

889 (35") (240)

DET AIL “Y”

UNIT WITH ECONOMIZER AND FIXED OUTDOOR AIR HOODS

2337

(92")

1 143

(45")

3181 (125-1/4") (180)

3461 (136-1/4") (240)

CENTER OF GRA VITY

Unitary Products Group 17

1524

(60")

Page 18

2927 (115-1/4") (180)

3207 (126-1/4") (240)

530.26-TG3YI

ROOF CURB DIMENSIONS - D*CE / D*CG180 & 240 UNITS

362 (14-1/4") (180)

641 (25-1/4") (240)

ROOF CURB BENEFITS

2927 (115-1/4") (180)

3207 (126-1/4") (240)

* Supply and Return Air (including duct suppport rails)

as shown, are typical for

For location of

(on back of unit), refer to Unit Dimension de tails.

sideflow duct applications

UNIT AND CURB APPLICATION

downflow duct applications.

TYPICAL APPLICA TIONS

18 Unitary Products Group

Page 19

TYPICAL APPLICATIONS - Cont’d.

ROOF-TOP INSTALLATION

(GAS/ELECTRIC UNIT SHOWN)

530.26-TG3YI

Unitary Products Group 19

Page 20

P.O. Box 1592, York, Pennsylvania USA 17405-1592

530.26TG3YI

Supersedes: Nothing

Subject to change without notice. P rinted in U.S.A

Copyright by York International Corporation 1994. All Rights Reserved.

Loading...

Loading...