Page 1

036-21217-001-B-1203

SINGLE PACKAGE AIR

CONDITIONING

WATER COOLED

®

MODELS: CU060 - 300 5-25 TONS

VERTICAL

MODELS: CH060 - 5-10 TONS

HORIZONTAL

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

TABLE OF CONTENTS

036-21217-001-B-1203

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

APPLICATION FLEXIBILITY . . . . . . . . . . . . . . . . . . . . . . . 3

CABINET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

REFRIGERATION CIRCUITS . . . . . . . . . . . . . . . . . . . . . . . 3

INDOOR FANS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ELECTRICAL/CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . 3

FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SUPPLY AIR/RETURN AIR CONFIGURATION . . . . . . . . 21

LIST OF FIGURES

Fig.# Pg.#

1 DIMENSIONAL DATA - CH 5 TON HORIZONTAL

MODEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 DIMENSIONAL DATA - CH 8 & 10 TON HORIZONTAL

MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 PHYSICAL CONFIGURATION DATA - CH 8 & 10 TON

WATER SIDE ECONOMIZER . . . . . . . . . . . . . . . . . . 16

4 DIMENSIONAL DATA - CU 5, 8, AND 10 TON

VERTICAL MODELS . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 DIMENSIONAL DATA - CU 15 TON VERTICAL

MODEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6 DIMENSIONAL DATA - CU 20 TON VERTICAL

MODEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7 DIMENSIONAL DATA - CU 25 TON VERTICAL

MODEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8 SUPPLY AIR/RETURN AIR CONFIGURATION . . . . . 21

9 HOT WATER & STEAM HEATING COILS

DIMENSIONAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . 22

10 HOT WATER & STEAM HEATING COILS

PERFORMANCE DATA . . . . . . . . . . . . . . . . . . . . . . . 23

11 TYPICAL WATER-SIDE ECONOMIZER PHYSICAL

CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

12 WATER-SIDE ECONOMIZER PIPING SCHEMATIC . 25

13 WATER-SIDE ECONOMIZER CONTROL - 15-20 TON

VERTICAL (208-230 V/3PH/60HZ) . . . . . . . . . . . . . . . 26

LIST OF TABLES

Tbl.# Pg.#

1 GENERAL DATA - CH060-120 5-10 TON HORIZONTAL

MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 GENERAL DATA CU 5-20 TON VERTICAL

MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 GENERAL DATA CU 300 25 TON VERTICAL

MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 SUPPLY AIR BLOWER PERFORMANCE CH060-120,

5 TO 10 TON HORIZONTAL MODELS . . . . . . . . . . . . 7

5 EVAPORATOR FAN PERFORMANCE - CU 5-25 TON

VERTICAL MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 EVAPORATOR BLOWER PERFORMANCE - DATA

CU300 - 25 TON MODEL . . . . . . . . . . . . . . . . . . . . . . . 8

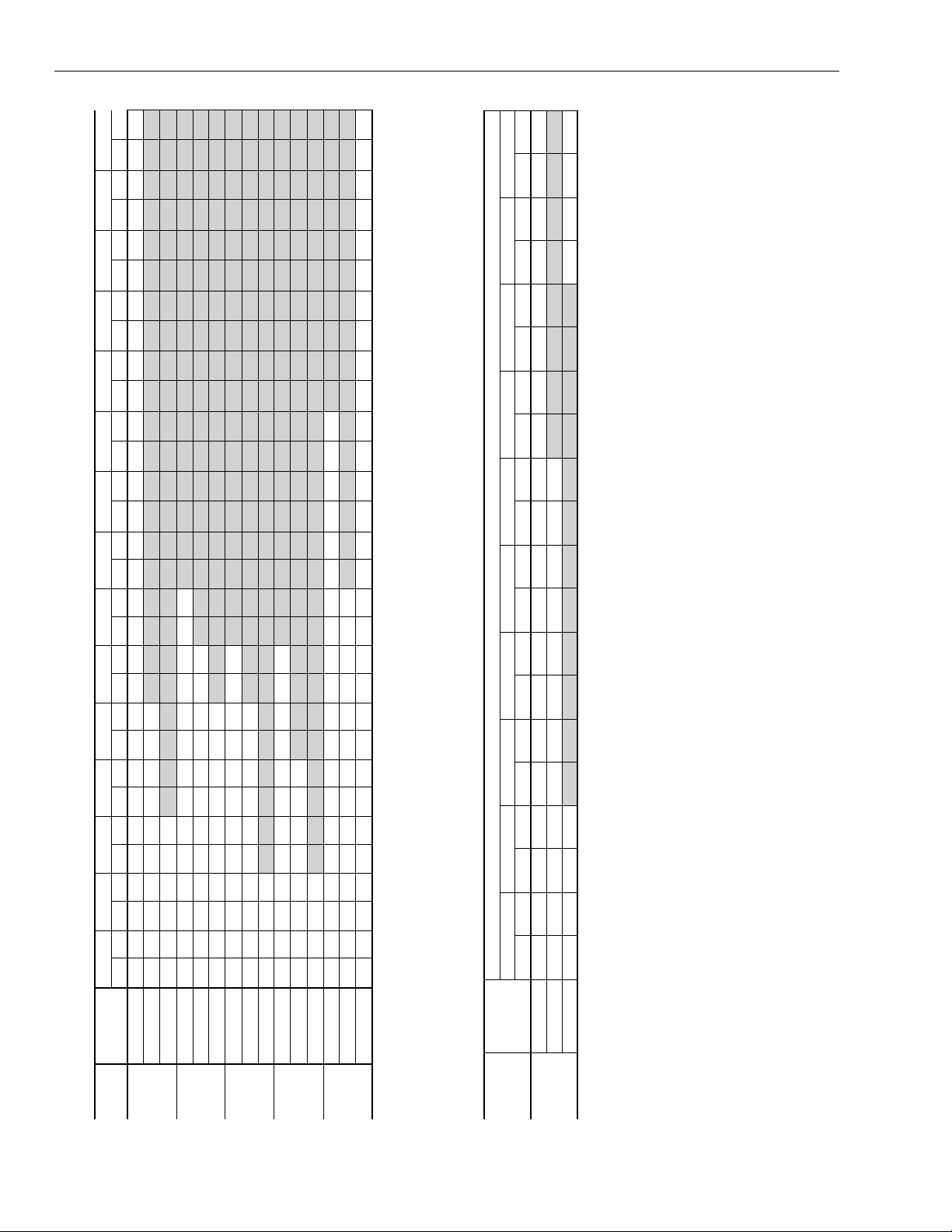

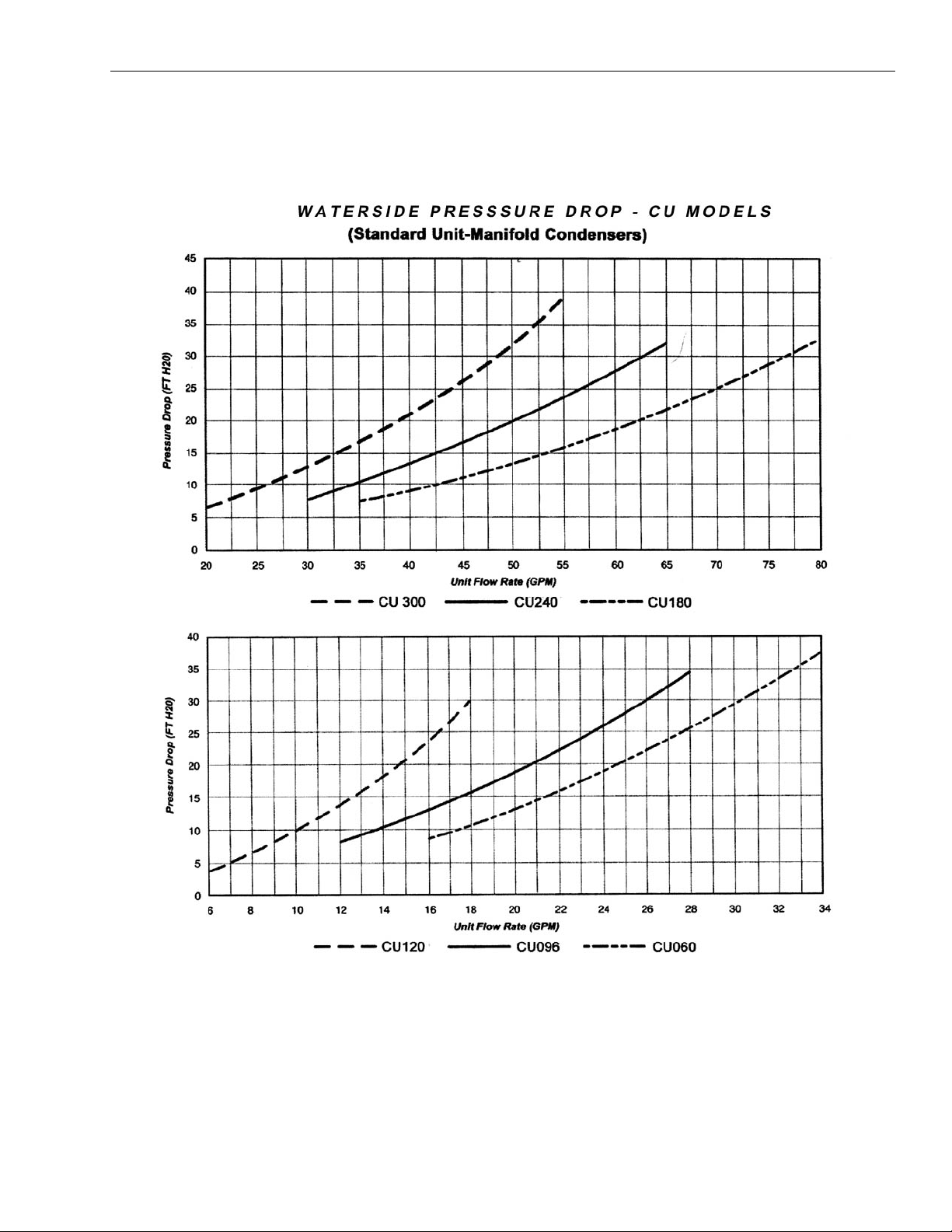

7 WATERSIDE PRESSURE DROP - CU MODELS . . . . 9

8 WATER PRESSURE DROP DATA - CH MODELS . . 10

9 COOLING PERFORMANCE DATA - CH 5-10 TON

HORIZONTAL MODELS . . . . . . . . . . . . . . . . . . . . . . 11

10 COOLING PERFORMANCE DATA - CU 5-20 TON

VERTICAL MODELS . . . . . . . . . . . . . . . . . . . . . . . . . 12

11 COOLING PERFORMANCE DATA - CU 300 25 TON

VERTICAL MODELS . . . . . . . . . . . . . . . . . . . . . . . . . 13

12 WATER-SIDE ECONOMIZER COOLING

PERFORMANCE DATA - CH 5-10 TON MODELS . . 13

13 WATER-SIDE ECONOMIZER COOLING PERFORM-

ANCE DATA - CU 300 25 TON MODEL . . . . . . . . . . 13

14 STANDARD MOTORS CH 5-10 TON MODELS . . . . 14

15 STANDARD MOTORS CU 5-20 TON MODELS . . . . 14

16 STANDARD EVAPORATOR MOTORS - CU300 - 25

TON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

17 DIMENSIONAL DATA - CU 5, 8, AND 10 TON

VERTICAL MODELS . . . . . . . . . . . . . . . . . . . . . . . . . 17

2 Unitary Products Group

Page 3

036-21217-001-B-1203

DESCRIPTION

These units are completely assembled, piped, wired, charged

and tested at the factory and are shipped ready for immediate

installation. Only the power supply wiring, the thermostat wir

ing, the condenser water piping, the condensate drain piping

and the ductwork are required to complete the installation.

Units include a one-year limited warranty on all replacement

parts and a five-year limited warranty on each compressor.

APPLICATION FLEXIBILITY

These ìcooling onlyî units can be applied with:

1. Cooling towers.

2. Well or surface water providing the temperature and the GPM of the water meet the application limitations of the unit.

3. Brackish or salt water and a secondary heat exchanger.

They can be installed:

1. Within the conditioned space as ìfree standingî units

without any ductwork. Supply air plenum and return air

grille accessories are available for these freestanding

applications.

2. In an equipment room with both supply and return air ductwork

charge are provided with the unit, for field installation. Duct

flange on CU240 evaporator return is incorporated into the fil

ter frame.

REFRIGERATION CIRCUITS

-

All models utilize "Scroll" type hermetic compressors. Compressors are mounted on rubber isolators to minimize vibration transmission. Internal overload protection is provided.

External high pressure and low pressure cutout switches are

included in each compressor control circuit. The 5 ton units

have a single refrigeration circuit. The 8 -20 ton units feature

two independent refrigeration circuits. Each refrigeration cir

cuit includes an adjustable thermal expansion valve (with

external equalizer), liquid line filter drier, sight glass/moisture

indicator, and service gauge ports.

The evaporator coils are constructed of internally enhanced

copper tubes mechanically bonded to rippled aluminum plate

fins. The evaporator coil is employed in a draw-through con

figuration, and features inter-laced circuiting. Large evaporator coil face area minimizes potential water blow-off.

The high-efficiency tube-in-tube condensers feature a convoluted inner tube design for optimum performance. Standard

models feature a copper inner tube surrounded by a steel

outer tube, and carry a 400 psig working pressure rating.

INDOOR FANS

-

-

-

GENERAL

Horizontal (CH) units are designed for suspended mounting.

HWC models are shipped with ëstraight-throughí evaporator

fan discharge as standard. Airflow orientation is field convert

ible to side discharge. Vertical (CU) units are designed for

free-standing floor mounting. All units are completely factory

wired and pre-piped. Water supply, water outlet, and conden

sate drain connections are via female pipe thread fittings.

All models 5 -25 tons ship as factory-charged unitized packages. The 5 -15 ton units may be field split between the evaporator /compressor section and the upper blower section;

installation is possible through standard height doorways and

elevators. All packages are designed for free-standing floor

mounting. All models are shipped with vertical evaporator fan

discharge as standard. Units are completely factory wired

and piped. Dual circuit models feature internally manifolded

condensers.

CABINET

All cabinets are completely constructed of 18 Ga. corrosion

resistant "Galvalume" coated steel. The entire unit interior

(both evaporator and condensing section) is insulated with

1/2" thick, 2 lbs. density insulation. Service panels are

equipped with lifting handles for ease of removal and han

dling. Duct flanges for return air intake and evaporator dis-

-

Forward curved, double inlet and double width centrifugal

blowers are used for evaporator air movement. Large diame

ter wheels are employed to provide required airflow perfor-

-

mance at minimum rpm and noise levels. Blower wheels are

fabricated of galvanized steel. Blowers employ solid steel

shafts, supported in permanently lubricated ball bearings. All

blowers are belt driven. Variable-pitch motor sheaves allow

for field adjustment of blower rpm.

ELECTRICAL/CONTROLS

All units are completely factory wired with all necessary controls. Manual reset protection is provided on evaporator

blower motors. A manual reset circuit is also provided on

each compressor control circuit in the event of high/low pres

sure cutout. A 24 volt control circuit, with oversize transformer, is provided for field connection. Units are designed to

operate with conventional thermostat control interface.

FILTERS

All models are shipped with 2 inch thick medium-efficiency

throwaway filters factory installed. Filters are accessible from

either front or right side on 5-15 ton models. The CU240 filter

rack is external to the cabinet (shipped loose).

-

-

Unitary Products Group 3

Page 4

036-21217-001-B-1203

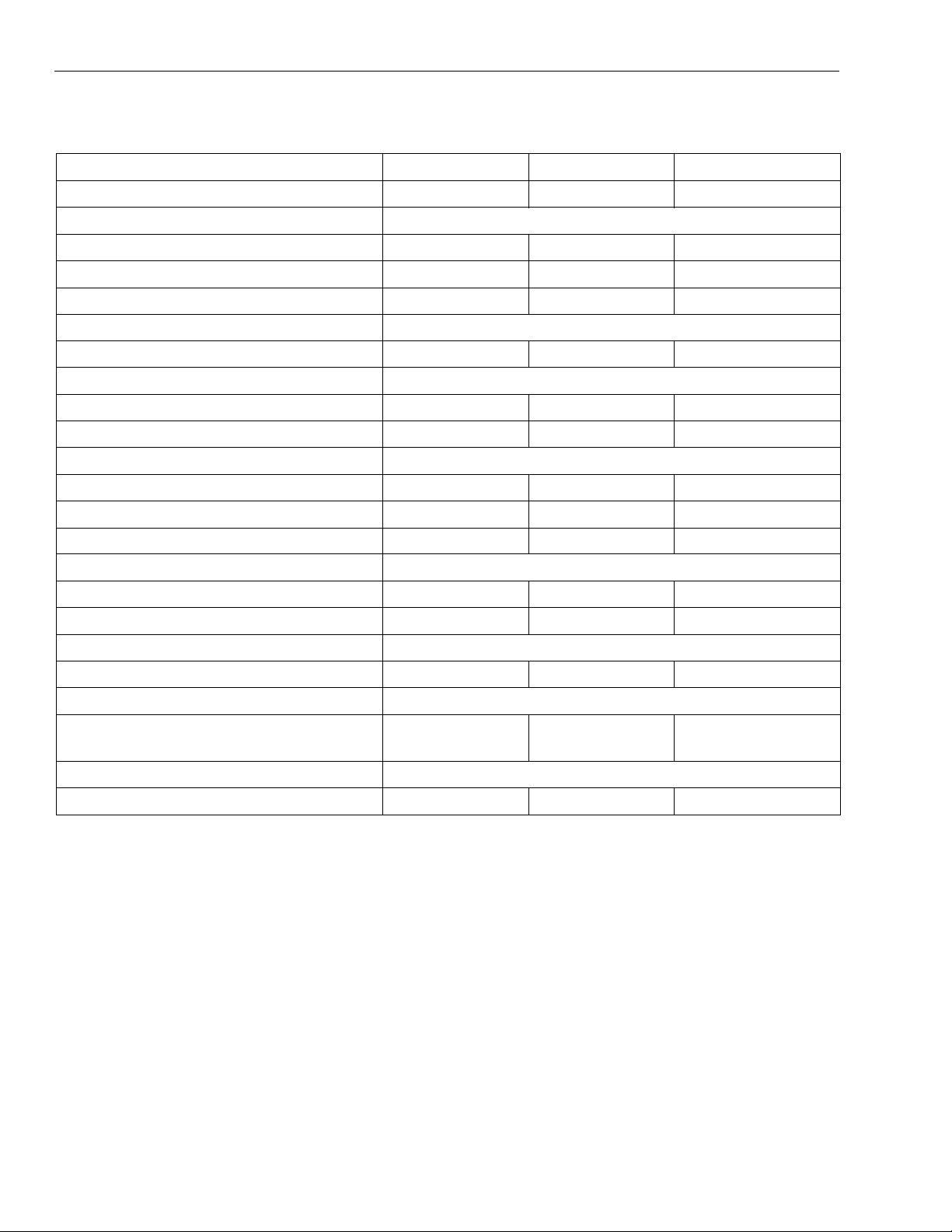

TABLE 1: GENERAL DATA - CH060-120 5-10 TON HORIZONTAL MODELS

Model CH060 CH096 CH120

Nominal Cooling(Ton) 5 8 10

Cooling Performance

Gross Cooling Capacity(Btuh) 64100 101800 126000

Design CFM 2000 3200 4000

EER 13.3 13.4 12.0

Compressor-Type Scroll

Number Used 1 2 2

Evaporator Coil-Type Copper Tubes, Aluminum Fins

Face Area(sq ft) 5.28 9.17 9.17

Rows/FPI 3/13 3/13 3/13

Condenser-Type Coaxial

Number Used/Tons Capacity 1/5 2/4 2/5

Nominal Water flow rate (gpm) 15 24 30

Condenser Water Connections 1" FPT 1-1/4" FPT 1-1/4" FPT

Evaporator Fan-Type Centrifugal, Forward Curved

Number Used 1 2 2

Diameter x Width (in) 10x10 10x8 10x8

Drive Adjustable Belt

Motor HP (Standard/Oversize) 1/NA 1.5/2 2/3

Filters

Number Used-Size(in) 2-20x20x2 2-20x25x2

1-20x20x2

2-20x25x2

1-20x20x2

Condensate Drain Connection 3/4FPT

Weight 460 710 760

NOTE: Cooling performance is rated at 80∞F dry bulb 67∞F wet bulb entering air temperature, CFM listed, 85∞F entering

95∞F leaving water temperature, and water flow rate listed. Gross capacity does not include the effect of evapora

tor fan motor heat.

-

4 Unitary Products Group

Page 5

036-21217-001-B-1203

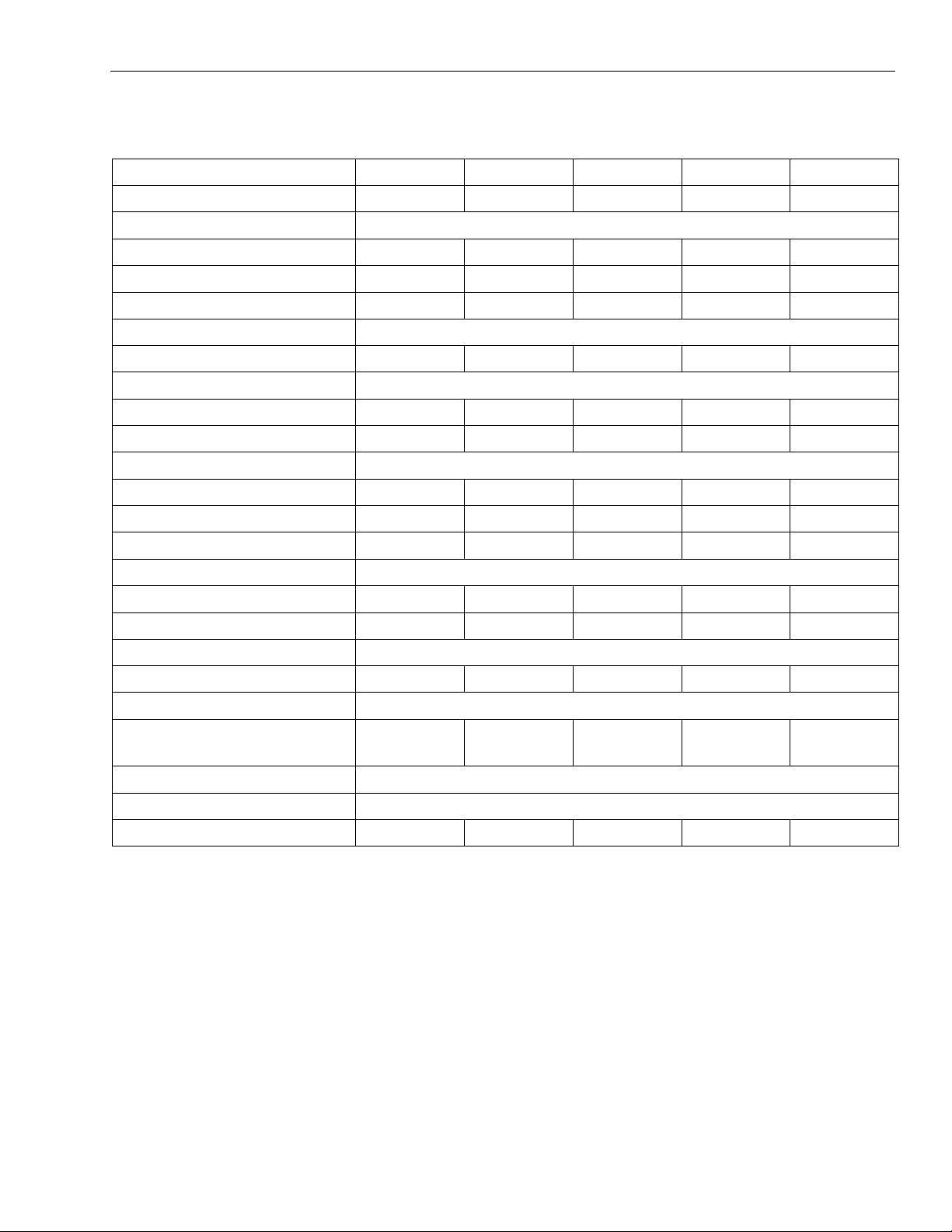

TABLE 2: GENERAL DATA CU 5-20 TON VERTICAL MODELS

Model CU060A CU096A CU120A CU180A CU240A

Nominal Cooling(Ton) 5 8 10 15 20

Cooling Performance

Gross Cooling Capacity(Btuh) 63300 100600 127800 188600 246800

Design CFM 2000 3200 4000 6000 8000

EER 12.5 13.2 12.5 12.0 11 .5

Compressor-Type Scroll

Number Used 1 2 2 2 2

Evaporator Coil-Type Copper Tubes, Aluminum Fins

Face Area(sq ft) 5.00 9.37 10.50 15.11 19.00

Rows/FPI 3/12 3/12 3/13 3/12 3/14

Condenser-Type Coaxial

Number Used/Tons Capacity 1/5 2/4 2/5 2/7.5 2/10

Nominal Water flow rate (gpm) 15 24 30 45 60

Unit Water Connection Size 1" FPT 1-1/4" FPT 1-1/4" FPT 1-1/2" FPT 2" FPT

Evaporator Fan-Type Centrifugal, Forward Curved

Number Used 1 1 1 2 2

Diameter x Width (in) 12x9 15x12 15x12 15x9 15x11

Drive Adjustable Belt

Motor HP (Standard/Oversize) 1/1.5 1.5/2 2/3 3/5 5/7.5

Filters

Number Used-Size(in) 2-20x16 4-14x25x2 6-14x20x2 2-16x20x2

6-20x25x2

4-16x25x2

Condensate Drain Connection 3/4FPT

Weight

Shipping 625 815 975 1350 1525

NOTE: Cooling performance is rated at 80∞F dry bulb 67∞F wet bulb entering air temperature, CFM listed, 85∞F entering

95∞F leaving water temperature, and water flow rate listed. Gross capacity does not include the effect of evapora

tor fan motor heat.

-

Unitary Products Group 5

Page 6

TABLE 3: GENERAL DATA CU 300 25 TON VERTICAL MODELS

Model CU300

Nominal Cooling(Ton) 25

Cooling Performance

Gross Cooling Capacity(Btuh) 322000

Design CFM 10000

EER 11.5

Compressor-Type Scroll

Number Used 3

Evaporator Coil-Type Copper Tubes, Aluminum Fins

Face Area(sq ft) 19.79

Rows/FPI 4/12

Condenser-Type Coaxial

Number Used/Tons Capacity 3/7.5

036-21217-001-B-1203

Nominal Water flow rate (gpm) 78

Unit Water Connection Size 2 in FPT

Evaporator Fan-Type Centrifugal, Forward Curved

Number Used 2

Diameter x Width (in) 15x11

Drive Adjustable Belt

Motor HP (Standard/Oversize) 7.5/10

Filters

Number Used-Size(in) 8-20x20x2

Condensate Drain Connection 3/4FPT

Weight

Shipping 1825

NOTE: Cooling performance is rated at 80∞F dry bulb 67∞F wet bulb entering air temperature, CFM listed, 85∞F entering

95∞F leaving water temperature, and water flow rate listed. Gross capacity does not include the effect of evapora

tor fan motor heat.

-

6 Unitary Products Group

Page 7

036-21217-001-B-1203

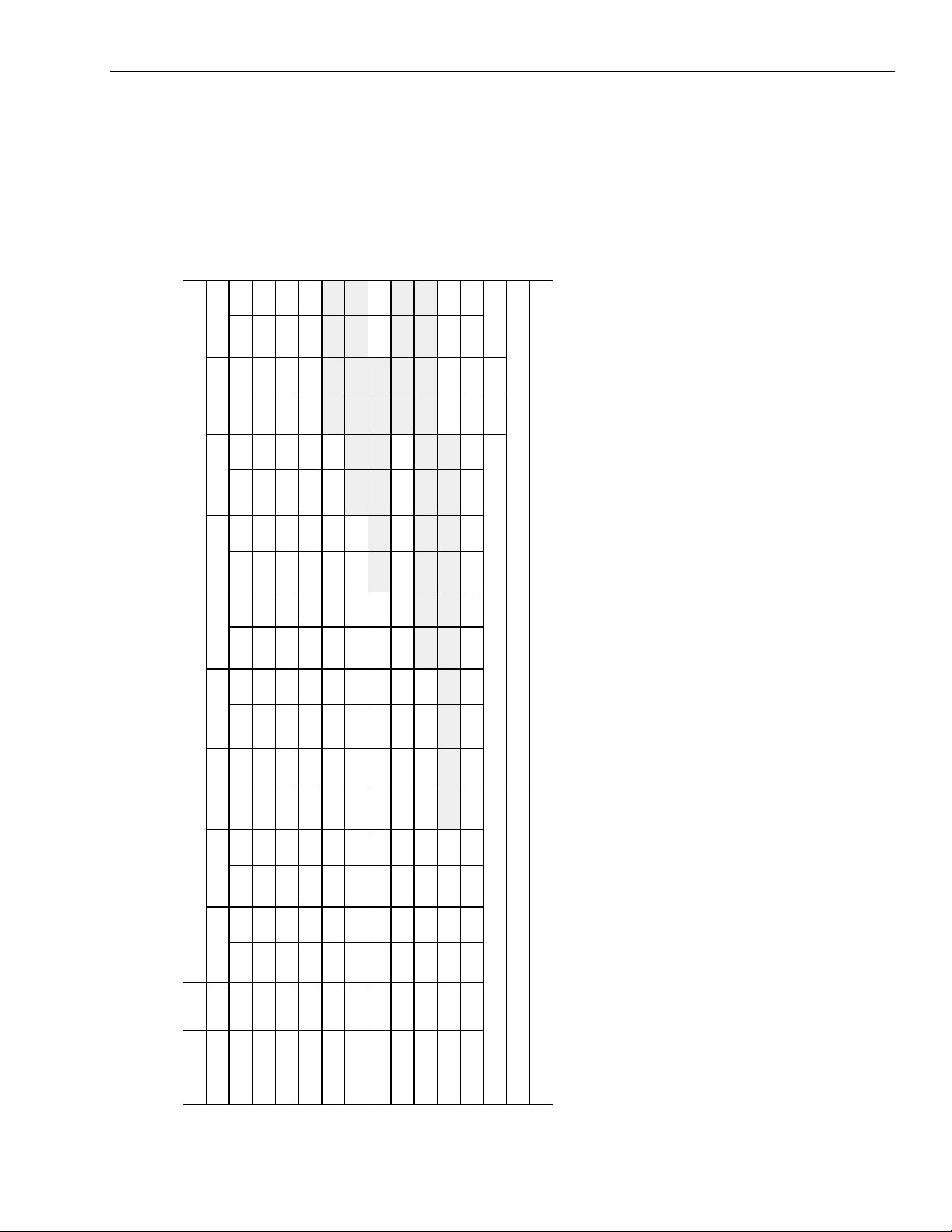

EXTERNAL STATIC PRESSURE - Inches W.C.

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8

1800 846 0.41 936 0.48 1024 0.56 1107 0.64 1195 0.74 1259 0.82 1325 0.90 1400 0.99 - -

2200 994 0.70 1069 0.79 1142 0.88 1214 0.98 - - - - - -----

3000 810 0.65 900 0.78 986 0.91 1066 1.04 1143 1.17 1221 1.32 1294 1.48 1363 1.63 1433 1.79

3400 892 0.91 974 1.05 1051 1.19 1125 1.33 1196 1.48 1266 1.64 1320 1.81 1390 1.90 - -

3600 927 1.05 1006 1.20 1081 1.34 1152 1.50 1220 1.65 1287 1.81 1353 1.98 1405 2.07 1472 2.17

SUPPLY

# CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

MODEL

CH060 2000 917 0.54 999 0.62 1079 0.71 1157 0.79 1233 0.89 1305 0.98 - -----

CH096 3200 851 0.78 938 0.91 1018 1.04 1095 1.18 1170 1.32 1236 1.42 1305 1.56 1380 1.74 1447 1.90

4400 1100 1.83 1166 2.00 1230 2.18 1292 2.37 1351 2.55 1410 2.74 1466 2.92 ----

CH120 4000 1012 1.40 1085 1.56 1153 1.73 1220 1.89 1283 2.06 1345 2.23 1405 2.41 1464 2.59 1522 2.78

NOTE:

1. At higher evaporator airflows, and wet bulb conditions condensate carry-over may occur. Adjust airflow downward as necessary.

2. Values include pressure drop from wet coil and clean filters.

3. Shaded areas indicate oversize motors

TABLE 4: SUPPLY AIR BLOWER PERFORMANCE CH060-120, 5 TO 10 TON HORIZONTAL MODELS

Unitary Products Group 7

Page 8

036-21217-001-B-1203

EXTERNAL STATIC PRESSURE - Inches - W.C.

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0

791 0.46 872 0.53 948 0.60 1019 0.68 1090 0.76 1159 0.85 1193 0.89 1259 0.98 1321 1.07 1380 1.16 1437 1.25 1492 1.35 1544- 1.44- - - - -

860 0.60 935 0.69 1006 0.77 1077 0.85 1136 0.94 1199 1.03 1263 1.12 1324 1.22 1383 1.32 1440 1.42 1494 1.52 - - - - - -

931 0.79 1001 0.88 1067 0.97 1129 1.06 1189 1.15 1247 1.25 1305 1.35 1363 1.45 1419 1.55 - - - - - - - - - -

568 0.70 628 0.81 688 0.92 746 1.05 801 1.19 855 1.35 906 1.50 954 1.65 1001 1.81 1046 1.97 - - - - - - - -

594 0.82 651 0.94 707 1.06 762 1.19 816 1.33 867 1.49 917 1.65 964 1.81 1010 1.98 - - - - - - - - - -

625 0.97 679 1.10 731 1.22 784 1.35 835 1.50 884 1.66 933 1.83 979 2.00 - - - - - - - - - - - -

620 1.04 666 1.16 716 1.29 765 1.43 815 1.56 864 1.71 912 1.88 958 2.00 1003 2.03 1046 2.41 1088 2.60 1129 2.78 1169 2.97 - - - -

681 1.40 721 1.53 765 1.68 811 1.83 856 1.97 900 2.13 945 2.29 988 2.46 1030 2.65 1071 2.84 111 2 3.05 - - - - - - - -

726 1.77 760 1.91 797 2.05 837 2.21 878 2.38 919 2.54 960 2.70 1001 2.87 1040 3.05 - - - - - - - - - -

645 1.52 709 1.79 770 2.06 829 2.35 885 2.65 939 2.96 991 3.28 1042 3.61 1092 3.96 1140 4.32 11 90 4.71 - - - - - - - -

700 2.00 759 2.30 815 2.60 870 2.91 922 3.23 973 3.56 1022 3.90 1070 4.25 1116 4.62 1162 4.99 - - - - - - - - - -

761 2.63 815 2.94 867 3.26 917 3.60 966 3.94 1014 4.29 1060 4.66 1104 5.02 - - - - - - - - - - - - - -

659 2.10 714 2.37 767 2.65 817 2.94 866 3.23 912 3.52 957 3.82 998 4.13 1037 4.44 1076 4.76 111 5 5.11 1154 5.47 1193 5.73 1230 6.10 1265 6.46

719 2.81 770 3.11 818 3.42 865 3.73 910 4.05 954 4.37 997 4.70 1038 5.03 1078 5.36 111 5 5.71 11 51 6.08 1186 6.46 1220 6.84 1254 7.23 - -

7200

8000

782 3.67 828 4.00 873 4.34 916 4.68 959 5.02 1000 5.37 1040 5.73 1079 6.09 111 7 6.45 1154 6.81 119 0 7.18 - - - - - - - -

8800

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

1800

2000

2200

3000

3200

3400

3600

4000

4400

5400

6000

6600

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

CFM

9000 800 3.93 846 4.27 890 4.61 932 4.96 974 5.32 1014 5.67 1053 6.03 1092 6.40 1129 6.77 1166 7.14

11000 958 6.95 996 7.37 1033 7.79 1069 8.21 11 04 8.63 1139 9.05 11 73 9.48 1206 9.92 - - - -

SUPPLY

10000 878 5.29 920 5.67 960 6.05 999 6.43 1037 6.82 1074 7.21 1111 7.61 1147 8.01 1182 8.41 1216 8.82

#

CU060

MODEL # SUPPLY CFM

TABLE 5: EVAPORATOR FAN PERFORMANCE - CU 5-25 TON VERTICAL MODELS

CU096

CU120

CU180

CU240

NOTE:

At higher evaporator airflows and wet bulb conditions, condensate carry-over may occur. Adjust airflow downward as necessary

Values include pressure drop from wet coil and clean filters.

Shaded areas indicate oversize motors.

MODEL

TABLE 6: EVAPORATOR BLOWER PERFORMANCE - DATA CU300 - 25 TON MODEL

CU300

NOTE:

At higher evaporator airflows and wet bulb conditions, condensate carry-over may occur. Adjust airflow downward as necessary

Values include pressure drop from wet coil and clean filters.

Shaded areas indicate oversize motors.

8 Unitary Products Group

Page 9

036-21217-001-B-1203

TABLE 7: WATERSIDE PRESSURE DROP - CU MODELS

Unitary Products Group 9

Page 10

TABLE 8: WATER PRESSURE DROP DATA - CH MODELS

036-21217-001-B-1203

10 Unitary Products Group

Page 11

036-21217-001-B-1203

TABLE 9: COOLING PERFORMANCE DATA - CH 5-10 TON HORIZONTAL MODELS

CH060

5 TON

2000 CFM

EWB EDB TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW

62∞F

67∞F

72∞F

EWB EDB TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW

62∞F

67∞F

72∞F

EWB EDB TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW

62∞F

67∞F

72∞F

75∞F 63.2 48.3 2.88 59.7 54.5 3.66 55.1 44.0 4.67 64.0 48.7 2.72 60.5 46 .2 3.47 56.1 44.6 4.42

80∞F 63.2 59.5 2.88 59.7 57.6 3.66 55.1 55.1 4.67 64.0 60.0 2.72 60.5 58 .3 3.47 56.1 55.8 4.42

85∞F 66.6 66.6 2.92 62.8 62.8 3.71 58.0 58.0 4.70 67.4 67.4 2.74 63.9 63 .9 3.49 59.2 59.2 4.43

75∞F 67.4 38.6 2.93 63.0 36.8 3.72 58.1 34.8 4.70 68.6 39.1 2.75 64.1 37 .4 3.50 59.3 35.3 4.44

80∞F 67.4 49.0 2.93 63.0 47.3 3.72 58.1 45.3 4.70 68.6 49.6 2.75 64.1 47 .8 3.50 59.3 45.8 4.44

85∞F 67.4 60.3 2.93 63.0 58.6 3.72 58.1 56.7 4.70 68.6 60.8 2.75 64.1 59 .1 3.50 59.3 57.2 4.44

75∞F 72.4 27.8 3.00 67.7 26.4 3.79 62.4 24.5 4.78 74.0 28.3 2.80 69.1 27 .0 3.55 63.8 25.1 4.49

80∞F 72.4 38.8 3.00 67.7 36.8 3.79 62.4 35.0 4.78 74.0 39.3 2.80 69.1 37 .5 3.55 63.8 35.6 4.49

85∞F 72.4 49.2 3.00 67.7 47.3 3.79 62.4 45.5 4.78 74.0 49.7 2.80 69.1 47 .9 3.55 63.8 46.1 4.49

CH096

8 TON

3200 CFM

75∞F 100.9 77.6 4.43 94.3 74.9 5.66 88.4 70.0 7.24 101.1 78.4 4.21 95.7 74.6 5.38 89.8 71.0 6.86

80∞F 100.9 95.4 4.43 94.3 92.7 5.66 88.4 88.4 7.24 101.1 96.2 4.21 95.7 93.3 5.38 89.8 89.8 6.86

85∞F 105.6 105.6 4.47 100.0 100.0 5.72 92.4 92.4 7.26 106.8 106.8 4.23 101.3 10 1.3 5.40 94.2 94.2 6.90

75∞F 106.8 62.3 4.48 100.1 59.4 5.73 92.6 56.4 7.27 108.3 62.9 4.24 101.8 59.9 5.41 94.4 56.9 6.91

80∞F 106.8 79.0 4.48 100.1 76.1 5.73 92.6 73.2 7.27 108.3 79.5 4.24 101.8 76.7 5.41 94.4 73.7 6.91

85∞F 106.8 96.8 4.48 100.1 93.9 5.73 92.6 91.0 7.27 108.3 97.3 4.24 101.8 94.5 5.41 94.4 91.6 6.91

75∞F 115.1 45.6 4.55 108.0 42.8 5.76 99.8 39.8 7.35 11 6. 8 46.2 4.25 110.0 43.4 5.42 101.8 40.6 6.94

80∞F 115.1 62.2 4.55 108.0 59.5 5.76 99.8 56.6 7.35 11 6. 8 62.8 4.25 110.0 60.1 5.42 101.8 57.4 6.94

85∞F 115.1 78.9 4.55 108.0 76.3 5.76 99.8 73.4 7.35 11 6. 8 79.4 4.25 110.0 76.8 5.42 101.8 74.2 6.94

CH120

10 TO N

4000 CFM

75∞F 123.6 95.2 5.73 11 6.8 91.1 7.30 96.0 86.2 9.32 125.2 96.0 5.42 118.5 92. 0 6.91 110.6 88.4 8.83

80∞F 123.6 116.7 5.73 11 6.8 11 3.9 7.30 109 .7 109.7 9.35 125.2 11 7.5 5.42 118.5 114 .8 6.91 110.6 110.6 8.83

85∞F 131.1 131.1 5.82 123.4 123.4 7.35 11 4. 5 114.5 9.40 132.8 132.8 5.48 125.8 12 5.8 6.96 116.5 116.5 8.86

75∞F 132.2 76.2 5.84 123.6 75.2 7.39 114 .7 69.0 9.40 134.1 77.2 5.49 126.0 73. 8 6.97 116.9 70.0 8.87

80∞F 132.2 96.3 5.84 123.6 95.4 7.39 114 .7 89.4 9.40 134.1 97.3 5.49 126.0 94. 0 6.97 116.9 90.4 8.87

85∞F 132.2 118.0 5.84 123.6 117 .0 7.39 114 .7 111 .0 9.40 134.1 11 9.0 5.49 126.0 115 .7 6.97 116.9 112.1 8.87

75∞F 142.4 56.2 5.96 133.2 52.8 7.53 123.3 49.0 9.55 144.9 57.2 5.57 135.8 53.8 7.06 126.0 50.3 8.95

80∞F 142.4 76.1 5.96 133.2 72.8 7.53 123.3 69.2 9.55 144.9 77.1 5.57 135.8 73.8 7.06 126.0 70.4 8.95

85∞F 142.4 96.3 5.96 133.2 93.1 7.53 123.3 89.6 9.55 144.9 97.2 5.57 135.8 94.1 7.06 126.0 90.7 8.95

65∞F 85∞F

65∞F 85∞F

65∞F 85∞F

9 GPM

EWT

105∞F 65∞F 85∞F

15 GPM

EWT

105∞F 65∞F 85∞F

18 GPM

EWT

105∞F 65∞F 85∞F

15 GPM

EWT

105∞F

24 GPM

EWT

105∞F

30 GPM

EWT

105∞F

Unitary Products Group 11

Page 12

036-21217-001-B-1203

TABLE 10: COOLING PERFORMANCE DATA - CU 5-20 TON VERTICAL MODELS

CU060

5 TON

2000 CFM

EWB EDB TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW

62∞F

67∞F

72∞F

EWB EDB TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW

62∞F

67∞F

72∞F

EWB EDB TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW

62∞F

67∞F

72∞F

EWB EDB TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW

62∞F

67∞F

72∞F

EWB EDB TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW

62∞F

67∞F

72∞F

75∞F 62.1 48.9 2.87 58.3 47.2 3.65 54.4 45.4 4.67 63.1 49.4 2.71 59.2 47 .5 3.45 62.1 48.9 2.87

80∞F 62.1 58.2 2.87 58.3 57.0 3.65 54.4 54.1 4.67 63.1 58.7 2.71 59.2 56 .7 3.45 62.1 58.2 2.87

85∞F 65.4 65.4 2.91 61.5 61.5 3.71 57.8 57.8 4.74 66.3 66.3 2.74 62.5 62 .5 3.53 65.4 65.4 2.91

75∞F 66.4 38.1 2.93 62.0 36.9 3.71 57.2 34.9 4.70 67.6 39.3 2.75 63.3 37 .5 3.49 66.4 38.1 2.93

80∞F 66.4 48.0 2.93 62.0 46.2 3.71 57.2 44.3 4.70 67.6 48.5 2.75 63.3 46 .7 3.49 66.4 48.0 2.93

85∞F 66.4 57.8 2.93 62.0 55.7 3.71 57.2 53.7 4.70 67.6 58.4 2.75 63.3 56 .3 3.49 66.4 57.8 2.93

75∞F 71.4 28.7 2.99 66.6 27.4 3.77 61.4 25.5 4.77 72.7 29.1 2.79 68.0 28 .0 3.53 71.4 28.7 2.99

80∞F 71.4 38.1 2.99 66.6 36.2 3.77 61.4 34.3 4.77 72.7 38.6 2.79 68.0 36 .8 3.53 71.4 38.1 2.99

85∞F 71.4 47.3 2.99 66.6 45.6 3.77 61.4 43.7 4.77 72.7 47.8 2.79 68.0 46 .1 3.53 71.4 47.3 2.99

CU096

8 TON

3200 CFM

75∞F 99.0 78.9 4.44 93.9 76.4 5.65 87.2 73.4 7.22 100.3 79.3 4.21 94.9 76 .8 5.38 99.0 78.9 4.44

80∞F 99.0 93.9 4.44 93.9 91.5 5.65 87.2 87.2 7.22 100.3 94.7 4.21 94.9 92 .0 5.38 99.0 93.9 4.44

85∞F 104.2 104.2 4.50 98.8 98.8 5.71 92.4 92.4 7.32 105.4 105.4 4.25 100.0 100 .0 5.44 104.2 104.2 4.50

75∞F 105.9 62.3 4.47 99.1 59.4 5.69 91.4 56.2 7.26 107.3 62.9 4.24 100.6 60.1 5.41 105.9 62.3 4.47

80∞F 105.9 77.5 4.47 99.1 74.6 5.69 91.4 71.5 7.26 107.3 78.0 4.24 100.6 75.2 5.41 105.9 77.5 4.47

85∞F 105.9 93.2 4.47 99.1 90.2 5.69 91.4 86.8 7.26 107.3 93.8 4.24 100.6 91.0 5.41 105.9 93.2 4.47

75∞F 113.6 45.7 4.54 106.5 43.9 5.76 98.3 40.9 7.33 11 5. 3 46.4 4.28 108.2 44.7 5.43 113.6 45.7 4.54

80∞F 113.6 61.2 4.54 106.5 58.4 5.76 98.3 55.3 7.33 11 5. 3 61.8 4.28 108.2 59.1 5.43 113.6 61.2 4.54

85∞F 113.6 76.3 4.54 106.5 73.6 5.76 98.3 70.6 7.33 11 5. 3 76.9 4.28 108.2 74.3 5.43 113.6 76.3 4.54

CU120

10 TO N

4000 CFM

75∞F 125.4 99.6 5.76 11 8.8 96.6 7.32 109.7 92.5 9.35 127.3 100.6 5.43 120.4 97.3 6.93 125.4 99.6 5.76

80∞F 125.4 118.6 5.76 11 8.8 11 5.4 7.32 109.7 109.7 9.35 127.3 119.6 5.43 120.4 116 .7 6.93 125.4 11 8.6 5.76

85∞F 132.4 132.4 5.86 125.2 125.2 7.52 117.0 117.0 9.48 134.2 134.2 5.47 127.1 12 7.1 7.07 132.4 132.4 5.86

75∞F 134.2 78.9 5.86 125.7 75.3 7.43 115.8 71.2 9.41 136.5 79.9 5.50 127.8 76.1 6.98 134.2 78.9 5.86

80∞F 134.2 98.0 5.86 125.7 94.4 7.43 115.8 90.5 9.41 136.5 98.9 5.50 127.8 95.4 6.98 134.2 98.0 5.86

85∞F 134.2 117.7 5.86 125.7 114 .0 7.43 115.8 109.7 9.41 136.5 118.8 5.50 127.8 114 .8 6.98 134.2 11 7. 7 5.86

75∞F 144.4 58.1 5.98 134.4 55.7 7.55 124.4 52.0 9.55 147.0 58.8 5.53 137.5 55.6 7.08 144.4 58.1 5.98

80∞F 144.4 77.6 5.98 134.4 73.8 7.55 124.4 69.9 9.55 147.0 78.5 5.53 137.5 75.0 7.08 144.4 77.6 5.98

85∞F 144.4 96.6 5.98 134.4 93.0 7.55 124.4 89.3 9.55 147.0 97.9 5.53 137.5 94.1 7.08 144.4 96.6 5.98

CU180

15 TO N

6000 CFM

75∞F 185.2 146.0 9.14 175.0 141.3 11 .2 5 163.0 136.1 14.03 187.5 147.0 8.65 177.4 142.3 10.64 185.2 146.0 9.14

80∞F 185.2 173.9 9.14 175.0 169.7 11 .2 5 163.0 162.4 14.03 187.5 175.3 8.65 177.4 170.2 10.64 185.2 173.9 9.14

85∞F 194.6 194.6 9.41 184.8 184.8 11 .5 4 172.8 172.8 14.28 197.8 197.8 8.90 187.8 187.8 10.94 194.6 194.6 9.41

75∞F 197.2 115.5 9.37 185.0 110 .4 11. 44 171.2 104.5 14.24 200.6 116.8 8.87 188.6 111 .8 10.80 197.2 115 .5 9.37

80∞F 197.2 143.0 9.37 185.0 138.1 11 .4 4 171.2 132.6 14.24 200.6 144.3 8.87 188.6 139.7 10.80 197.2 143.0 9.37

85∞F 197.2 172.2 9.37 185.0 166.8 11 .4 4 171.2 161.0 14.24 200.6 173.9 8.87 188.6 168.5 10.80 197.2 172.2 9.37

75∞F 211.5 86.3 9.66 198.2 81.1 11 .75 183.5 75.4 14.56 215.4 88.1 9.11 202.4 82 .8 11. 03 211.5 86.3 9.66

80∞F 211.5 109.5 9.66 198.2 104.4 11 .7 5 183.5 98.8 14.56 215.4 111 .1 9. 11 202.4 105. 9 11 .03 211.5 109.5 9.66

85∞F 211.5 134.1 9.66 198.2 129.1 11 .7 5 183.5 123.6 14.56 215.4 135.6 9.11 202.4 130. 6 11 .03 211.5 134.1 9.66

CU240

20 TO N

8000 CFM

75∞F 236.4 174.8 12.57 223.8 169.5 15.22 207.2 162.4 18.63 239.5 176.1 12.07 226.6 170.7 14.56 236.4 174.8 12.57

80∞F 236.4 207.6 12.57 223.8 202.3 15.22 207.2 195.1 18.63 239.5 208.9 12.07 226.6 203.4 14.56 236.4 207.6 12.57

85∞F 240.6 240.6 12.70 229.8 229.8 15.27 217.8 217.8 18.86 242.6 242.6 12.85 231.8 231.8 14.66 240.6 240.6 12.70

75∞F 256.6 139.3 12.97 243.0 134.1 15.53 226.0 128.0 19.00 259.5 140.5 12.41 246.8 135.7 14.84 256.6 139.3 12.97

80∞F 256.6 171.9 12.97 243.0 166.8 15.53 226.0 160.8 19.00 259.5 173.1 12.41 246.8 168.5 14.87 256.6 171.9 12.97

85∞F 256.6 204.6 12.97 243.0 199.5 15.53 226.0 193.7 19.00 259.5 205.8 12.45 246.8 201.2 14.87 256.6 204.6 12.97

75∞F 277.9 103.3 13.45 263.3 98 .5 16.04 245.3 92.5 19.46 281.7 105.0 12.83 268.0 100. 1 15.25 277.9 103.3 13.45

80∞F 277.9 135.8 13.45 263.3 131.2 16.04 245.3 125.5 19.46 281.7 138.2 12.83 268.0 133.0 15.25 277.9 135.8 13.45

85∞F 277.9 168.2 13.45 263.3 163.9 16.04 245.3 158.4 19.46 281.7 171.4 12.83 268.0 165.8 15.25 277.9 168.2 13.45

65∞F 85∞F

65∞F 85∞F

65∞F 85∞F

65∞F 85∞F

65∞F 85∞F

9 GPM

EWT

15 GPM

EWT

18 GPM

EWT

27 GPM

EWT

36 GPM

EWT

105∞F 65∞F 85∞F

105∞F 65∞F 85∞F

105∞F 65∞F 85∞F

105∞F 65∞F 85∞F

105∞F 65∞F 85∞F

15 GPM

EWT

105∞F

24 GPM

EWT

105∞F

30 GPM

EWT

105∞F

45 GPM

EWT

105∞F

60 GPM

EWT

105∞F

12 Unitary Products Group

Page 13

036-21217-001-B-1203

TABLE 11: COOLING PERFORMANCE DATA - CU 300 25 TON VERTICAL MODELS

GPM

CU300 45 75

25 TON EWT EWT

10000 CFM

EWB EDB TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW TC SC kW

75∞F 308.9 227.9 22.17 289.6 217.8 25.74 266.8 206.5 30.41 314.6 234.0 21.29 295.4 220.9 24.67 273.2 213.3 29.09

62∞F80∞F 308.9 267.2 22.17 289.6 257.1 25.74 266.8 246.2 30.41 314.6 275.2 21.29 295.4 260.2 24.67 273.2 255.1 29.09

85∞F 308.9 308.9 22.17 289.6 257.1 25.74 266.8 266.8 30.41 314.6 314.6 21.29 295.4 295.4 24.67 273.2 273.2 29.09

75∞F 335.8 180.6 22.74 314.8 171.2 26.32 290.4 161.4 31.09 342.0 183.3 21.73 321.6 175.9 25.14 298.2 166.7 29.57

67∞F80∞F 335.8 220.9 22.74 314.8 211.2 26.32 290.4 201.2 31.09 342.0 223.3 21.73 321.6 218.0 25.14 298.2 208.4 29.57

85∞F 335.8 260.9 22.74 314.8 251.2 26.32 290.4 241.3 31.09 342.0 263.6 21.73 321.6 259.8 25.14 298.2 250.5 29.57

75∞F 363.7 133.1 23.33 340.6 125.3 26.96 316.5 118.3 31.78 372.5 135.9 22.22 350.4 128.5 25.67 325.7 121.1 30.05

72∞F80∞F 363.7 174.2 23.33 340.6 166.2 26.96 316.5 159.5 31.78 372.5 178.0 22.22 350.4 170.3 25.67 325.7 162.5 30.05

85∞F 363.7 215.6 23.33 340.6 207.0 26.96 316.5 200.9 31.78 372.5 219.7 22.22 350.4 211.9 25.67 325.7 204.2 30.05

65∞F85∞F 105∞F65∞F85∞F 105∞F

TABLE 12: WATER-SIDE ECONOMIZER COOLING PERFORMANCE DATA - CH 5-10 TON MODELS

UNIT

Air @ 80OF EDB, 67OF EWB

CFM PD [in WG] Flow [GPM] PD [PSI]

9 1.4

CH060 2000 0.16

15 3.8

15 1.4

CH096 3200 0.14

24 3.4

18 1.9

CH120 4000 0.21

NOTE:

1. All economizer coils are 3R, 10 FPI, aluminum fins with copper tubes and headers.

2. For total system wa terside pressure drop, add condenser pressure drop and waterside economizer coil pressure drop.

30

Water Capacity [MBH]

EWT [OF]

Total Sensible

45 50.8 39.9

55 31.4 31.4

45 64.5 45.0

55 35.0 35.0

45 87.4 66.5

55 52.7 52.7

45 107.1 73.8

55 60.5 57.0

45 104.6 80.3

55 63.0 63.0

5.2

45 127.3 88.6

55 68.9 68.9

TABLE 13: WATER-SIDE ECONOMIZER COOLING PERFORMANCE DATA - CU 300 25 TON MODEL

o

F EDB, 6 7oF EW B

UNIT

Air @ 80

CFM PD [in W G] Flow [GPM]

45

CU300

10000 0.39

75 8.4

NOTE: All economizer coils are 3R, 10FPI, alum inum fins with copper tubes and headers.

For total system water-side pressure drop, add condenser pressure drop and water-side economizer coil

pressure drop.

Unitary Products Group 13

Water

PD [PSI] EWT [

3.0

45 265.2 200.0

55 155.0 155.0

45 317.0 219.1

55 181.5 170.6

Capacity [MBH]

o

F] Total Sensible

Page 14

036-21217-001-B-1203

#

8

8

8

8

0

0

0

8

L

V

YRLALRA

TABLE 14: STANDARD MOTORS CH 5-10 TON MODELS

MODEL VOLTAGE COMPRESSOR EVAPORATOR MIN. CCT. MAX FUSE /

QT Y RL A LRA HP FLA RPM AM PACITY CCT. BKR. A M P

CU060 208-230/3/60 1 @ 19.3 123.0 1.00 3.1 1800 27.23 45

460/3/60 1 @ 7.5 49.5 1.00 1.6 1800 10.9

575/3/60 1 @ 6.4 40.0 1.00 1.3 1800 9.30 15

15

CU096 208-230/3/60 2 @ 13.9 88.0 1.50 4.4 1800 35.6

460/3/60 2 @ 7.1 44.0 1.50 2.2 1800 18.1

575/3/60 2 @ 5.4 34.0 1.50 1.8 1800 13.95 15

CU120 208-230/3/60 2 @ 19.3 123.0 2.00 6.0 1800 49.43 60

460/3/60 2 @ 7.5 49.5 2.00 3.0 1800 19.8

575/3/60 2 @ 6.4 40.0 2.00 2.4 1800 16.8

CU180 208-230/3/60 2 @ 25.0 164.0 3.00 8.4 1800 64.65 80

460/3/60 2 @ 12.0 100.0 3.00 4.2 1800 31.2

575/3/60 2 @ 9.7 90.0 3.00 3.4 1800 25.23 30

CU240 208-230/3/60 2 @ 33.6 225.0 5.00 13.2 1800 88.8

460/3/60 2 @ 17.3 114.0 5.00 6.6 1800 45.53 60

575/3/60 2 @ 13.5 80.0 5.00 5.3 1800 35.6

NOTE: Single Phase CH060 located in 1-5 ton data.

TABLE 15: STANDARD MOTORS CU 5-20 TON MODELS

MODEL

#

CU060 208-230/3/60 1 @ 19.3 123.0 1.00 3.1 1800 27.23 45

VOLTAGE COMPRESSOR EVAPORATOR MIN. CCT. MAX FUSE /

QTY RLA LRA HP FLA RPM AMPACITY CCT. BKR. AMP

460/3/60 1 @ 7.5 49.5 1.00 1.6 1800 10.98 15

575/3/60 1 @ 6.4 40.0 1.00 1.3 1800 9.30 15

45

25

25

20

40

110

45

CU096

208-230/3/60 2 @ 13.9 88.0 1.50 4.4 1800 35.68 45

460/3/60 2 @ 7.1 44.0 1.50 2.2 1800 18.18 25

575/3/60 2 @ 5.4 34.0 1.50 1.8 1800 13.95 15

CU120

208-230/3/60 2 @ 19.3 123.0 2.00 6.0 1800 49.43 60

460/3/60 2 @ 7.5 49.5 2.00 3.0 1800 19.88 25

575/3/60 2 @ 6.4 40.0 2.00 2.4 1800 16.80 20

CU180 208-230/3/60 2 @ 25.0 164.0 3.00 8.4 1800 64.65 80

460/3/60 2 @ 12.0 100.0 3.00 4.2 1800 31.20 40

575/3/60 2 @ 9.7 90.0 3.00 3.4 1800 25.23 30

CU240A

208-230/3/60 2 @ 33.6 225.0 5.00 13.2 1800 88.80 110

460/3/60 2 @ 17.3 114.0 5.00 6.6 1800 45.53 60

575/3/60 2 @ 13.5 80.0 5.00 5.3 1800 35.68 45

NOTE: Single Phase unit found in smaller cabinet data 1-5 ton.

TABLE 16: STANDARD EVAPORATOR MOTORS - CU300 - 25 TON

MODE

#QT

CU300 208-230/3/60 3 @ 32.1 195.0 7.50 21.8 1800 126.13 150

14 Unitary Products Group

OLTAGE CO MPRESSOR EVAPORATOR MIN. CCT. MAX FUSE /

460/3/60 3 @ 16.4 95.0 7.50 10.0 1800 63.30 70

575/3/60 3 @ 12.0 80.0 7.50 8.4 1800 47.40 50

HP FLA RPMAMPACITYCCT. BKR. AMP

Page 15

036-21217-001-B-1203

FIGURE 1 - DIMENSIONAL DATA - CH 5 TON HORIZONTAL MODEL

FIGURE 2 - DIMENSIONAL DATA - CH 8 & 10 TON HORIZONTAL MODELS

Unitary Products Group 15

Page 16

036-21217-001-B-1203

Economizer

Coil

Water Out

Filter

Frame

Electrical

Connections

10

12

Water

2-3/4

Side View

6-1/2

Condensate

FIGURE 3 - PHYSICAL CONFIGURATION DATA - CH 8 & 10 TON WATER SIDE ECONOMIZER

16 Unitary Products Group

Page 17

036-21217-001-B-1203

H

I

2.63"

K

J

SUPPLY

AIR

D

FAN MO TO R

ACCESS

FILTER ACCESS

OPTIONAL R/A

GRILLE

B

E

FILTER

CONDENSATE

WATER OUT

WATER IN

F

DRAIN

COMPRESSOR/CONDENSER

ACCESS

G

C

0.63"

24.00"

ELECTRICAL

FIGURE 4 - DIMENSIONAL DATA - CU 5, 8, AND 10 TON VERTICAL MODELS

TABLE 17: DIMENSIONAL DATA - CU 5, 8, AND 10 TON VERTICAL MODELS

A B C D

CU060 26.00 72.00 42.00 23.00 20.00 4.00 34.00 12.25 14.88 13.50

CU096 29.00 82.00 64.00 27.00 25.00 4.00 56.00 14.75 24.63 15.88

CU120 29.00 82.00 64.00 27.00 25.00 4.00 56.00 14.75 24.63 15.88

RETURN AIR SUPPLY AIR

E F G H J K

COIL

DRAIN

PAN

CONDENSATE

DRAIN

PAN EL

A

Unitary Products Group 17

Page 18

16.50"

12.25"

20.50"

OPTIONAL R/A

GRILLE

12.25"

15.88

2.63"

85.00"

26.00"

30.00"

RETURN

AIR

FAN MOTOR

ACCESS

FILTER ACCESS

COIL

FILTER

SUPPLY

AIR

036-21217-001-B-1203

DRAIN PAN

WATER OUT

WATER IN

4.00"

CONDENSATE

DRAIN

COMPRESSOR/CONDENSER

ACCESS

68.00"

76.00"

24.00"

0.63"

FIGURE 5 - DIMENSIONAL DATA - CU 15 TON VERTICAL MODEL

ELECTRICAL

PANEL

30.00"

CONDENSATE

DRAIN

18 Unitary Products Group

Page 19

036-21217-001-B-1203

FIGURE 6 - DIMENSIONAL DATA - CU 20 TON VERTICAL MODEL

Unitary Products Group 19

Page 20

036-21217-001-B-1203

FIGURE 7 - DIMENSIONAL DATA - CU 25 TON VERTICAL MODEL

20 Unitary Products Group

Page 21

036-21217-001-B-1203

SUPPLY AIR/RETURN AIR

CONFIGURATION

All models are field convertible for multiple supply return configurations. The 5 through 15 ton models feature a removable

upper fan module that can be rotated 180∞ for top rear dis

-

charge applications. In addition, the blower outlet panel may

be interchanged with the front panel of the fan module. Inter

changing these two panels allows horizontal fan discharge to

either front or rear of the unit.

The blower outlet panel may also be interchanged on the 20

and 25 ton units to provide horizontal discharge.

-

FIGURE 8 - SUPPLY AIR/RETURN AIR CONFIGURATION

Unitary Products Group 21

Page 22

Hot Water and Steam Heating Coil Dimensions (Inches)

Unit Model A B C Inlet (MPT Outlet (MPT)

CU060 37.50 5.50 23 1 1/2 1 1/2

CU096 59.50 5.50 28 1 1/2 1 1/2

CU120 59.50 5.50 28 1 1/2 1 1/2

CU180 71.50 5.50 33 2 2

CU240 76.50 5.50 40.13 2 2

CU300 79.50 5.50 40.13 2 2

036-21217-001-B-1203

Plenum Dimensions (Inches)

A B C Side Grill Front Grill

5 Ton 42 26 20 16x12 (2x) 32x12

8/10 Ton 64 29 24 20x16 (2x) 38x16

15 Ton 64 29 24 20x18 (2x) 28x18 (2x)

20 Ton 83 32.5 28 24x20 (2x) 32x20 (2x)

25 Ton 88 34 28 24x20 (2x) 32x20 (2x)

Plenum Dimensions (Inches)

A B C Side Grill Front Grill

FIGURE 9 - HOT WATER & STEAM HEATING COILS DIMENSIONAL DATA

22 Unitary Products Group

Page 23

036-21217-001-B-1203

CU060 - 180

Steam Coil Performance @ 2 PSIG

Unit Model CFM

1800 140 126.6 113.1 99.7

CU060

CU096

CU120

CU180

CU240

CU300

ï Steam Heating Coils are tube-in-tube ësteam distributingí type to eliminate risk of con-

densate freezing.

ï Coils are constructed of 5/8 inch diameter outer copper tubes, with 3/8 inch diameter

inner tubes. The outer tube is mechanically bonded to rippled aluminum plate fins. Coil

casing is fabricated of heavy gauge galvanized sheet. Copper headers are complete

with MPT connections.

ï All coils are 1 row, 8 fins per inch.

2000 147.1 133 118.8 104.7

2200 153.6 138.9 124.1 109.3

3000 258.3 233.4 208.6 183.8

3200 266.6 241 215.3 189.7

3400 274.5 248.1 221.8 195.4

3600 282.1 255 227.9 200.8

4000 296.3 267.9 239.4 210.9

4400 309.5 279.8 250.1 220.3

5400 425.8 384.9 344 303.1

6000 447.4 404.4 361.4 318.4

6600 467.3 422.4 377.5 332.6

7200 569.6 514.9 460.2 405.5

8000 598.5 541 483.5 426

8800 625.3 565.2 505.1 445.1

9000 645.8 583.7 521.7 459.6

10000 677.1 612.1 54 7 481.9

11000 706.1 638.2 570.4 502.6

Entering Air Dry Bulb Temperature

10 30 50 70

CU240 - 300

Hot Water Coil Performance

Unit Model GPM CFM

1800 62.4 80.8 99.3 117.8

CU060 10

CU096 15

CU120 15

CU180 20

CU240 35

CU300 50

* Temperature difference between entering water and entering air temperature.

ï Hot Water Heating Coils are constructed of 1/2 inch diameter copper tubes, mechanically bonded to

rippled aluminum plate fins. Coil casing is fabricated of heavy gauge galvanized sheet. Copper tube

headers are complete with MPT connections.

ï All coils are 2 row, 8 fins per inch.

2000 66.2 85.9 105.5 125.3

2200 69.9 90.6 111.4 132.3

3000 111.6 144.3 177.1 209.9

3200 116 150.1 184.1 218.3

3400 120.2 155.5 190.9 226.3

3600 124.3 160.8 197.3 234

4000 131.9 170.7 209.6 248.6

4400 138.9 179.9 220.9 262

5400 183.5 237.3 291.2 345.2

6000 194.6 251.7 308.9 366.2

6600 204.8 265 325.3 385.7

7200 257.6 332.7 407.9 483.2

8000 274.2 354.2 434.3 514.6

8800 289.6 374.3 459 543.9

9000 313.2 404.3 495.5 586.8

10000 333.6 430.7 527.9 625.3

11000 352.5 455.3 558. 2 661.2

Temperature Difference*

70 90 110 130

FIGURE 10 - HOT WATER & STEAM HEATING COILS PERFORMANCE DATA

Unitary Products Group 23

Page 24

036-21217-001-B-1203

FIGURE 11 - TYPICAL WATER-SIDE ECONOMIZER PHYSICAL CONFIGURATION

24 Unitary Products Group

Page 25

036-21217-001-B-1203

FIGURE 12 - WATER-SIDE ECONOMIZER PIPING SCHEMATIC

Unitary Products Group 25

Page 26

036-21217-001-B-1203

FIGURE 13 - WATER-SIDE ECONOMIZER CONTROL - 15-20 TON VERTICAL (208-230 V/3PH/60HZ)

26 Unitary Products Group

Page 27

036-21217-001-B-1203

Unitary Products Group 27

Page 28

Subject to change without notice. Printed in U.S.A. 036-21217-001-B-1203

Copyright

© by Unitary Products Group 2004. All rights reserved. Supersedes: 036-21217-001-A-0503

Unitary 5005 Norman

Products York OK

Group Drive 73069

Loading...

Loading...