YOKOGAWA SmartDac + GX10, SmartDac + GX20, SmartDac + GP10, SmartDac + GP20, SmartDac + GM10 User Manual

Page 1

User ’s

Manual

Model GX10/GX20/GP10/GP20/GM10

EtherNet/IP Communication (/E1)

User’s Manual

IM 04L51B01-18EN

5th Edition

Page 2

Page 3

Introduction

Thank you for purchasing the SMARTDAC+ Series GX10/GX20/GP10/GP20/GM10

(hereafter referred to as the recorder, GX, GP, or GM).

This manual explains the EtherNet/IP communication function (/E1 option) of the GX, GP,

and GM.

In this manual, the GX20, GP20, and GM10 standard type and large memory type are

distinguished using the following notations.

• Standard type: GX20-1/GP20-1/GM10-1

• Large memory type: GX20-2/GP20-2/GM10-2

To ensure correct use, please read this manual thoroughly before beginning operation.

Please use this manual in conjunction with the User’s Manual (GX/GP: IM 04L51B01-01EN,

GM: IM 04L55B01-01EN)

The following manuals are provided for the GX/GP/GM.

● PaperManuals

Model Manual Title Manual No. Description

GX/GP Model GX10/GX20/GP10/GP20

Paperless Recorder

First Step Guide

GM Data Acquisition System GM

First Step Guide

GX/GPGMPrecaution on the use of SMARTDAC+ IM 04L51B01-91EN Provides precautions common to the SMARTDAC+

Regarding the Downloading and

Installing for the Software, Manuals and

Labels/ About the Usage of Open Source

Software

● DownloadableElectronicManuals

You can download the latest manuals from the following website.

www.smartdacplus.com/manual/en/

Model Manual Title Manual No. Description

GX/GP Model GX10/GX20/GP10/GP20

Paperless Recorder

First Step Guide

Model GX10/GX20/GP10/GP20

Paperless Recorder

User’s Manual

Model GX10/GX20/GP10/GP20

Advanced Security Function (/AS)

User’s Manual

GM GM Data Acquisition System

First Step Guide

GM Data Acquisition System

User’s Manual

GM Data Acquisition System

Advanced Security Function (/AS)

User’s Manual

GX/GPGMModel GX10/GX20/GP10/GP20/GM10

Communication Commands

User’s Manual

SMARTDAC+ STANDARD

Universal Viewer

User’s Manual

SMARTDAC+ STANDARD

Hardware Configurator

User’s Manual

Model GX10/GX20/GP10/GP20/GM10

Multi-batch Function (/BT)

User’s Manual

Model GX10/GX20/GP10/GP20/GM10

Log Scale (/LG)

User’s Manual

Model GX10/GX20/GP10/GP20/GM10

EtherNet/IP Communication (/E1)

User’s Manual

Model GX10/GX20/GP10/GP20/GM10

WT Communication (/E2)

User’s Manual

Model GX10/GX20/GP10/GP20/GM10

OPC-UA Server (/E3)

User’s Manual

Model GX10/GX20/GP10/GP20/GM10

SLMP Communication (/E4)

User’s Manual

Model GX10/GX20/GP10/GP20/GM10

Loop Control Function, Program Control

Function (/PG) User’s Manual

GX/GP DXA170 DAQStudio

User’s Manual

5th Edition: June 2019 (YK)

All Rights Reserved, Copyright © 2014, Yokogawa Electric Corporation

IM 04L51B01-02EN Explains the basic operations of the GX/GP.

IM 04L55B01-02EN Explains the basic operations of the GM.

IM 04L61B01-11EN Explains where software applications and electronic

IM 04L51B01-02EN This is the electronic version of the paper manual.

IM 04L51B01-01EN Describes how to use the GX/GP. The communication

IM 04L51B01-05EN Describes how to use the advanced security function (/

IM 04L55B01-02EN This is the electronic version of the paper manual.

IM 04L55B01-01EN Describes how to use the GM. The communication

IM 04L55B01-05EN Describes how to use the advanced security function (/

IM 04L51B01-17EN Describes how to use command control communication

IM 04L61B01-01EN Describes how to use Universal Viewer, which is a

IM 04L61B01-02EN Describes how to use the PC software for creating setting

IM 04L51B01-03EN Describes how to use the multi-batch function (/BT

IM 04L51B01-06EN Describes how to use the log scale (/LG option).

IM 04L51B01-18EN Describes how to use the communication functions

IM 04L51B01-19EN Describes how to use WT communication (/E2 option).

IM 04L51B01-20EN Describes how to use the OPC-UA server function (/E3

IM 04L51B01-21EN Describes how to use SLMP communication function (/

IM 04L51B01-31EN Describes how to use the PID control function and

IM 04L41B01-62EN Describes how to create custom displays (/CG option).

series.

manuals common to the SMARTDAC+ series can

be downloaded from and how to install the software

applications.

control commands and some of the options are excluded.

AS option).

control commands and some of the options are excluded.

AS option).

functions.

software that displays GX/GP/GM measurement data

files.

parameters for various GX/GP/GM functions.

option).

through the EtherNet/IP (/E1 option).

option).

E4 option).

program control (/PG option) function.

IM 04L51B01-18EN

i

Page 4

Notes

QR Code

Trademarks

• The contents of this manual are subject to change without prior notice as a result of

continuing improvements to the instrument’s performance and functions.

• Every effort has been made in the preparation of this manual to ensure the accuracy of its

contents. However, should you have any questions or find any errors, please contact your

nearest YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without the

permission of YOKOGAWA is strictly prohibited.

The product has a QR Code pasted for efficient plant maintenance work and asset

information management.

It enables confirming the specifications of purchased products and user’s manuals.

For more details, please refer to the following URL.

https://www.yokogawa.com/qr-code

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

• SMARTDAC+ is a registered trademarks of Yokogawa Electric Corporation.

• Microsoft and Windows are registered trademarks or trademarks of Microsoft Corporation

in the United States and/or other countries.

• Adobe and Acrobat are registered trademarks or trademarks of Adobe Systems

Incorporated.

• Company and product names that appear in this manual are registered trademarks or

trademarks of their respective holders.

• The company and product names used in this manual are not accompanied by the

registered trademark or trademark symbols (® and ™).

UsingOpenSourceSoftware

This product uses open source software.

For details on using open source software, see Regarding the Downloading and Installing

for the Software, Manuals and Labels (IM 04L61B01-11EN).

Revisions

May 2014 1st Edition June 2019 5th Edition

December 2014 2nd Edition

December 2015 3rd Edition

June 2017 4th Edition

ii

IM 04L51B01-18EN

Page 5

Conventions Used in This Manual

Unit

K Denotes 1024. Example: 768K (file size)

k Denotes 1000.

Markings

WARNING Calls attention to actions or conditions that could cause serious or fatal

CAUTION Calls attention to actions or conditions that could cause light injury

Note Calls attention to information that is important for the proper operation

ReferenceItem

Improper handling or use can lead to injury to the user or damage to

the instrument. This symbol appears on the instrument to indicate that

the user must refer to the user’s manual for special instructions. The

same symbol appears in the corresponding place in the user’s manual

to identify those instructions. In the manual, the symbol is used in

conjunction with the word “WARNING” or “CAUTION.”

injury to the user, and precautions that can be taken to prevent such

occurrences.

to the user or cause damage to the instrument or user’s data, and

precautions that can be taken to prevent such occurrences.

of the instrument.

Reference to related operation or explanation is indicated after this

mark.

Example: section 4.1

ConventionsUsedintheProceduralExplanations

Bold characters Denotes key or character strings that appear on the screen.

Example: Volt

A

a# 1

Indicates the character types that can be used.

A

uppercase alphabet,

numbers

1

a

lowercase alphabet,

Procedure Carry out the procedure according to the step numbers. All procedures

are written with inexperienced users in mind; depending on the

Explanation

operation, not all steps need to be taken.

Explanation gives information such as limitations related the procedure.

Path Indicates the setup screen and explains the settings.

Description

#

symbol,

IM 04L51B01-18EN

iii

Page 6

AssumptionofExplanation

The explanation in this manual assumes that the recorder is connected via communications

with Rockwell Automation’s Programmable Logic Controller (PLC) of the Allen-Bradley

brand.The basic items for this configuration are explained. For the operation procedures of

Rockwell Automation products, see the user’s manuals of these products.

This manual is intended for those who have used an Allen-Bradley PLC and EtherNet/IP.

RecorderVersionDescribedinThisManual

The contents of this manual correspond to the GX/GP with release number 4 (see the

STYLE S number) and style number 2 (see the STYLE H number) and the GM10 with

release number 4 (see the STYLE S number) and style number 1 (see the STYLE H

number).

Edition Product Explanation

1 GX/GP: Version 2.01 and later —

2 GX/GP: Version 2.01 and later Describes the GM.

GM: Version 2.02 and later

3 GX/GP: Version 3.01 and later The number of math channels has been increased

GM: Version 3.01 and later

4 GX/GP: Version 4.01 and later Describes the PID control module.

GM: Version 4.01 and later

5 GX/GP: Version 4.06 and later Describes of the QR code has been added.

GM: Version 4.06 and later Improvements to explanations.

(GX20-2,GP20-2: 200 channels)

iv

IM 04L51B01-18EN

Page 7

Contents

Introduction of Features ....................................................................................................................... 1

Connection to a Network ..................................................................................................................... 3

Preparation for PLC ............................................................................................................................. 4

Explicit Message .................................................................................................................................. 5

I/O Messages ..................................................................................................................................... 18

Communication Considerations ......................................................................................................... 22

Specifications ..................................................................................................................................... 23

Example of an Explicit Message Using RSLogix 5000 ...................................................................... 24

Example of I/O Message Using RSLogix 5000 .................................................................................. 26

Introduction ................................................................................................................................................ i

Conventions Used in This Manual ............................................................................................................iii

Assumption of Explanation ...................................................................................................................... iv

Recorder Version Described in This Manual ........................................................................................... iv

EtherNet/IP ............................................................................................................................................... 1

What the Recorder Can Do ...................................................................................................................... 2

Settings of the Recorder ........................................................................................................................... 2

Access to the Recorder ............................................................................................................................ 2

Cable Connection ..................................................................................................................................... 3

Settings of the Recorder ........................................................................................................................... 3

EDS File 4

System Configuration ............................................................................................................................... 4

System Configuration on PLC .................................................................................................................. 5

Data on the Recorder ............................................................................................................................. 16

System Configuration on PLC ................................................................................................................ 18

Data on the Recorder ............................................................................................................................. 21

About Communication Interval ............................................................................................................... 22

Access to Non-existent Data .................................................................................................................. 22

Special data ............................................................................................................................................ 22

Writing Data to the Recorder .................................................................................................................. 22

IM 04L51B01-18EN

v

Page 8

Blank

Page 9

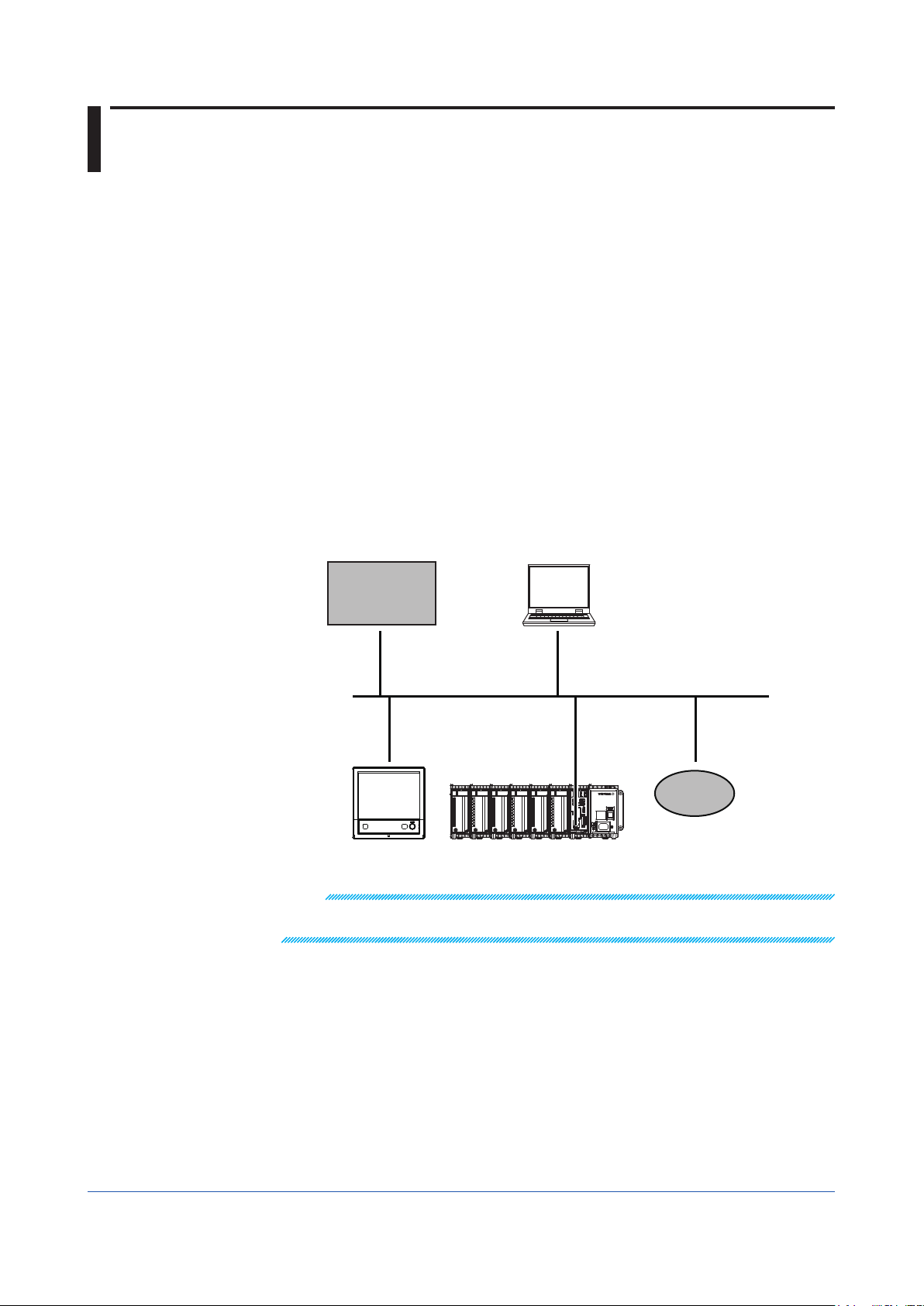

IntroductionofFeatures

EtherNet/IP

GX/GP

GM

EtherNet/IP

EtherNet/IP is a protocol that extends Common Industrial Protocol (CIP) to Ethernet.

The use of Ethernet enables high-speed and periodic exchange of massive control and

monitoring data between control devices placed at dispersed locations.

Devices that support EtherNet/IP are available from many vendors. Among them, Rockwell

Automation’s Programmable Logic Controller (PLC) and Remote I/O of the Allen-Bradley

brand are widely used. Yokogawa’s GX, GP, and GM, equipped with the EtherNet/IP server

function, supports communications with these PLCs.

ConfigurationComponents

• Scanner (Client)

A device that launches a request on EtherNet/IP. This is either a PLC or PC. For

the recorder, PLCs such as Allen-Bradley PLC-2, PLC-5, SLC 500, MicroLogix,

CompactLogix, and ControlLogix represent a Scanner (Client).

• Adapter (Server)

A remote I/O device that the Scanner (Client) can access to read or write data. The

recorder is an Adapter (Server).

• Configuration tool

A tool used to configure the system. This is either a PC on which configuration software

has been installed or the software itself. Rockwell Automation RSLogix500 and

RSLogix5000 and the communication driver software RSLinx are configuration tools.

Scanner

(Client)

Ethernet

Configuration tool

Adapter

(Server)

Remote I/O

Note

For details of EtherNet/IP, see the information supplied by the Open DeviceNet Vender Association

(ODVA).

IM 04L51B01-18EN

1

Page 10

Introduction of Features

What the Recorder Can Do

The recorder provides the following functions:

• Participate in an EtherNet/IP network as an Adapter (Server).

• Communicate with new and old Allen-Bradley PLCs such as MicroLogix, CompactLogix,

ControlLogix, SLC 500, PLC-5, and PLC-2.

• Support both Explicit and I/O messages.

• PLCs can access internal data of the recorder.

Data Access

Input/Output channel data Read

Computation channel

Communication channel

The following shows examples of usage.

• Data on devices on a network can be recorded by a PLC to the recorder.

• Data measured by the recorder can be acquired by a PLC.

SettingsoftheRecorder

The recorder is ready to use after the following settings have been made.

• IP address and other settings required to connect to Ethernet

• Enabling of EtherNet/IP server function

Access to the Recorder

The recorder is a passive device on an Ethernet network. The recorder cannot launch a

request. A PLC launches a request to the recorder.

A request is called a “message”. There are two message types: Explicit message and I/O

messages (Implicit message). An Explicit message, included in control logic, is used to

access the recorder, only when required, and transmit data. An I/O message is used to

transmit pre-specified recorder data at intervals.

1 Option (/MT)

2 Option (/MC)

1

data Read

2

data Read/write

The Recorder can also communicate with PLCs compatible with Programmable Controller

Communication Command (PCCC) using conversion of PCCC to EtherNet/IP at the

gateway. PCCC refers to serial communications that are also called DF1 communications.

The recorder supports EtherNet/IP in which PCCC requests are encapsulated. It can

communicate also with PLCs that support encapsulated PCCC.

2

IM 04L51B01-18EN

Page 11

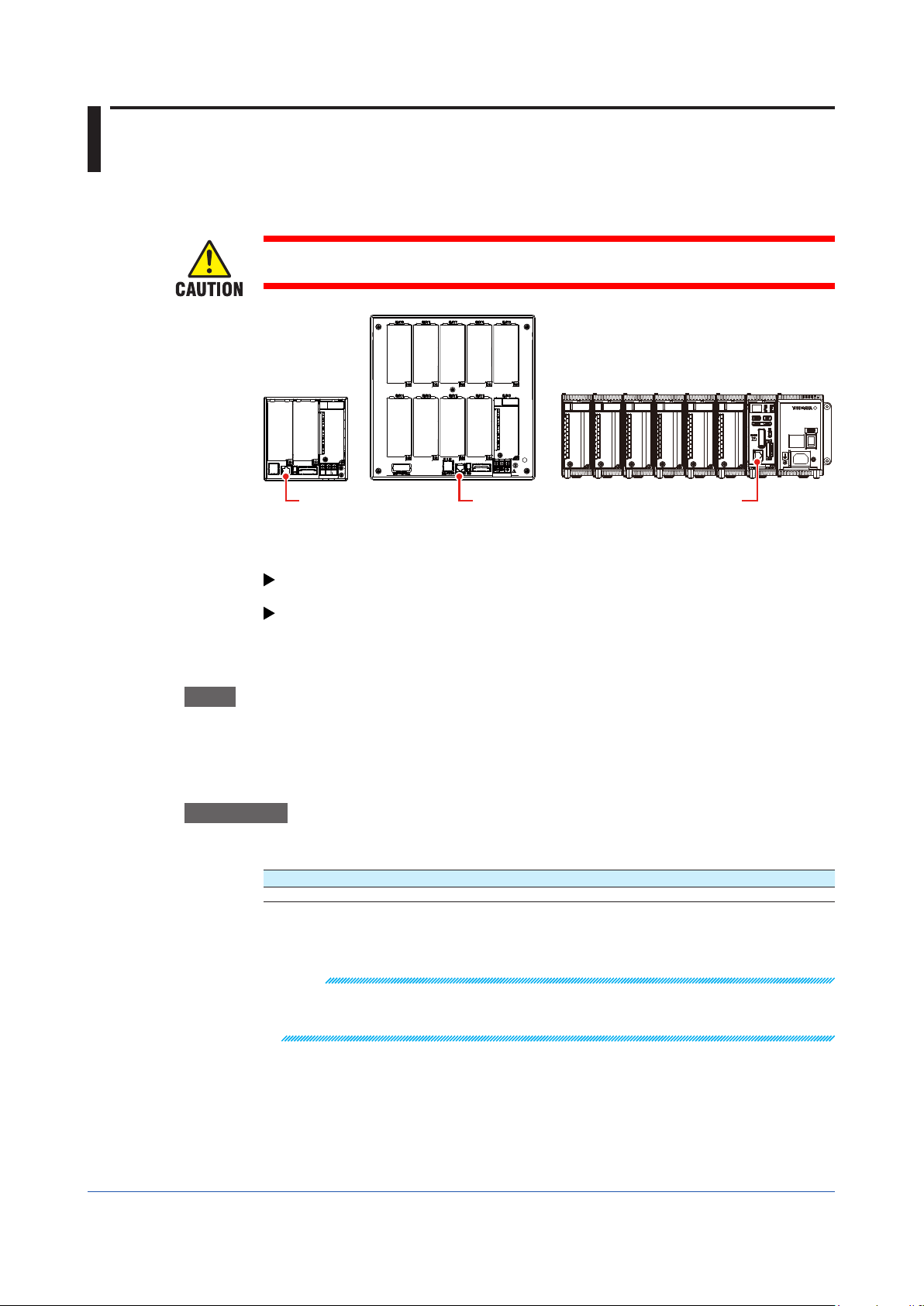

ConnectiontoaNetwork

Ethernet portEthernet port

Ethernet port

CableConnection

Connect the Ethernet cable to the Ethernet port provided on the back of the recorder.

Be sure to connect an Ethernet cable with an FCC-compliant plug. Not doing so may cause

a malfunction.

SettingsoftheRecorder

IPAddress,HostInformation,andDNSSetting,etc.

GX/GP: See section 1.17, “Configuring the Ethernet Communication Function” in the

User’s manual (IM 04L51B01-01EN) .

GM: See section 2.18, “Configuring the Ethernet Communication Function,” in the User’s

Manual (IM 04L55B01-01EN).

EtherNet/IPServerSettings

Path

GX/GP: MENU key > Browse tab > Setting > Setting menu Communication (Ethernet)

Web browser: Config. tab > Communication (Ethernet) settings > Serverlist

Hardware configurator: Communication (Ethernet) settings > Serverlist

Description

EtherNet/IP

SetupItem SelectableRangeorOptions DefaultValue

On/Off Off, On Off

On/Off

Specify On to enable the EtherNet/IP server.

settings > Serversettings > Serverlist

Note

On a GX/GP, you can check the EtherNet/IP server settings on the Network Information screen.

You can open the Network Information Screen by pressing the MENU key, tap the Browse tab >

Networkinformation.

IM 04L51B01-18EN

3

Page 12

PreparationforPLC

EtherNet/IP

GX/GP GM

Configuration tool

GM

EDSFile

Installation

To have the recorder participate in a network, first install the recorder device profile

(Electronic Data Sheet; EDS file) in the configuration tool. A PLC communicates with the

recorder based on the information in the EDS file.

Conduct installation using the “EDS Hardware Installation Tool” of RSLinx. For information

on using the configuration tool, see the user’s manual of the configuration tool.

Scanner

(Client)

PLC

Read/Write message

Ethernet

SystemConfiguration

EDS file for GX/GP

Adapter

(Server)

EDS file for GM

HowtoObtaintheEDSFile

Obtain the EDS file from the Yokogawa Web site:

URL: www.smartdacplus.com/software/en/

Use the configuration tool to make the communication settings.

Use RSLinx, RSLogix500, or RSLogix5000 to make an Explicit message or I/O message,

download it to the PLC, and execute it.

For information on using the configuration tool and a PLC, see the user’s manuals of these

products.

4

IM 04L51B01-18EN

Page 13

ExplicitMessage

An Explicit message is a point-to-point, request/response-type communication.

SystemConfigurationonPLC

Use the configuration tool to code an Explicit message as an MSG instruction in the

control logic. In the MSG instruction, set all the information including a target device,

target register, and read/write. Download the created control logic to a PLC and execute

it.

On the recorder the data count to be accessed per MSG instruction should be 100 or less.

InCaseofPLC-2,PLC-5,andSLC

• Commands

When creating an MSG instruction, specify a command. The recorder supports the

following commands:

TargetPLC Command name

PLC-2 PLC2 Unprotected Read/Write

PLC-5 PLC5 Word Range Read/Write

SLC SLC Typed Read/Write

• Specificationofdatatobeaccessed

Specify which of the data in the recorder should be accessed. The PLC-2, PLC-5, and

SLC manage data to be accessed in units of “files.”

PLC5 Typed Read/Write

Command:PLC2UnprotectedRead/Write

Datatobeaccessed Filenumber

Type Number

Input/Output channel

(GX/GP main unit)

(GM main unit)

0001 1000

• • • • • •

0050 1049

0101 1050

• • • • • •

0150 1099

0201 1100

• • • • • •

0250 1149

0301 1150

• • • • • •

0350 1199

0401 1200

• • • • • •

0450 1249

0501 1250

• • • • • •

0550 1299

0601 1300

• • • • • •

0650 1349

0701 1350

• • • • • •

0750 1399

0801 1400

• • • • • •

0850 1449

0901 1450

• • • • • •

0950 1499

Datatype:INT16

Continued on next page

IM 04L51B01-18EN

5

Page 14

Explicit Message

Datatobeaccessed Filenumber

Type Number

Input/Output channel

(GX/GP expandable I/O 1)

(GM sub unit 1)

(GX/GP expandable I/O 2)

(GM sub unit 2)

(GX/GP expandable I/O 3)

(GM sub unit 3)

1001 1500

• • • • • •

1050 1549

1101 1550

• • • • • •

1150 1599

1201 1600

• • • • • •

1250 1649

1301 1650

• • • • • •

1350 1699

1401 1700

• • • • • •

1450 1749

1501 1750

• • • • • •

1550 1799

2001 2000

• • • • • •

2050 2049

2101 2050

• • • • • •

2150 2099

2201 2100

• • • • • •

2250 2149

2301 2150

• • • • • •

2350 2199

2401 2200

• • • • • •

2450 2249

2501 2250

• • • • • •

2550 2299

3001 2500

• • • • • •

3050 2549

3101 2550

• • • • • •

3150 2599

3201 2600

• • • • • •

3250 2649

3301 2650

• • • • • •

3350 2699

3401 2700

• • • • • •

3450 2749

3501 2750

• • • • • •

3550 2799

Datatype:INT16

Continued on next page

6

IM 04L51B01-18EN

Page 15

Explicit Message

Datatobeaccessed Filenumber

Type Number

Input/Output channel

(GX/GP expandable I/O 4)

(GM sub unit 4)

(GX/GP expandable I/O 5)

(GM sub unit 5)

(GX/GP expandable I/O 6)

(GM sub unit 6)

4001 3000

• • • • • •

4050 3049

4101 3050

• • • • • •

4150 3099

4201 3100

• • • • • •

4250 3149

4301 3150

• • • • • •

4350 3199

4401 3200

• • • • • •

4450 3249

4501 3250

• • • • • •

4550 3299

5001 3500

• • • • • •

5050 3549

5101 3550

• • • • • •

5150 3599

5201 3600

• • • • • •

5250 3649

5301 3650

• • • • • •

5350 3699

5401 3700

• • • • • •

5450 3749

5501 3750

• • • • • •

5550 3799

6001 4000

• • • • • •

6050 4049

6101 4050

• • • • • •

6150 4099

6201 4100

• • • • • •

6250 4149

6301 4150

• • • • • •

6350 4199

6401 4200

• • • • • •

6450 4249

6501 4250

• • • • • •

6550 4299

Datatype:INT16

Continued on next page

IM 04L51B01-18EN

7

Page 16

Explicit Message

Datatobeaccessed Filenumber

Type Number

Input/Output channel

(Continuous channel data

area)*

Computation channel A001 5000

Communication channel

(Read/Write)

“• • •” stands for data in numerical order.

* The “continuous channel data area” is a special area that enables continuous reading by limiting

the number of channels of each module to 10.

For only the I/O channels on a GX/GP main unit or I/O channels on a GM main unit, this area

can be used to read data consecutively.

0001 4500

• • • • • •

0010 4509

0101 4510

• • • • • •

0110 4519

0201 4520

• • • • • •

0210 4529

0301 4530

• • • • • •

0310 4539

0401 4540

• • • • • •

0410 4549

0501 4550

• • • • • •

0510 4559

0601 4560

• • • • • •

0610 4569

0701 4570

• • • • • •

0710 4579

0801 4580

• • • • • •

0810 4589

0901 4590

• • • • • •

0910 4599

• • • • • •

A200 5199

C001 6000

• • • • • •

C500 6499

Datatype:INT16

8

IM 04L51B01-18EN

Page 17

Explicit Message

Commands:PLC5WordRangeRead/Write,PLC5TypedRead/Write,andSLCTyped

Read/Write

Datatobeaccessed Filenumber

Type Number Datatype

Input/Output channel

(GX/GP main unit)

(GM main unit)

(GX/GP expandable I/O 1)

(GM sub unit 1)

0001 N10:00 L10:00 F10:00

• • • • • • • • • • • •

0050 N10:49 L10:49 F10:49

0101 N10:50 L10:50 F10:50

• • • • • • • • • • • •

0150 N10:99 L10:99 F10:99

0201 N11:00 L11:00 F11:00

• • • • • • • • • • • •

0250 N11:49 L11:49 F11:49

0301 N11:50 L11:50 F11:50

• • • • • • • • • • • •

0350 N11:99 L11:99 F11:99

0401 N12:00 L12:00 F12:00

• • • • • • • • • • • •

0450 N12:49 L12:49 F12:49

0501 N12:50 L12:50 F12:50

• • • • • • • • • • • •

0550 N12:99 L12:99 F12:99

0601 N13:00 L13:00 F13:00

• • • • • • • • • • • •

0650 N13:49 L13:49 F13:49

0701 N13:50 L13:50 F13:50

• • • • • • • • • • • •

0750 N13:99 L13:99 F13:99

0801 N14:00 L14:00 F14:00

• • • • • • • • • • • •

0850 N14:49 L14:49 F14:49

0901 N14:50 L14:50 F14:50

• • • • • • • • • • • •

0950 N14:99 L14:99 F14:99

1001 N15:00 L15:00 F15:00

• • • • • • • • • • • •

1050 N15:49 L15:49 F15:49

1101 N15:50 L15:50 F15:50

• • • • • • • • • • • •

1150 N15:99 L15:99 F15:99

1201 N16:00 L16:00 F16:00

• • • • • • • • • • • •

1250 N16:49 L16:49 F16:49

1301 N16:50 L16:50 F16:50

• • • • • • • • • • • •

1350 N16:99 L16:99 F16:99

1401 N17:00 L17:00 F17:00

• • • • • • • • • • • •

1450 N17:49 L17:49 F17:49

1501 N17:50 L17:50 F17:50

• • • • • • • • • • • •

1550 N17:99 L17:99 F17:99

INT16

Datatype

INT32

Datatype

FLOAT

Continued on next page

IM 04L51B01-18EN

9

Page 18

Explicit Message

Datatobeaccessed Filenumber

Type Number Datatype

Input/Output channel

(GX/GP expandable I/O 2)

(GM sub unit 2)

(GX/GP expandable I/O 3)

(GM sub unit 3)

(GX/GP expandable I/O 4)

(GM sub unit 4)

2001 N20:00 L20:00 F20:00

• • • • • • • • • • • •

2050 N20:49 L20:49 F20:49

2101 N20:50 L20:50 F20:50

• • • • • • • • • • • •

2150 N20:99 L20:99 F20:99

2201 N21:00 L21:00 F21:00

• • • • • • • • • • • •

2250 N21:49 L21:49 F21:49

2301 N21:50 L21:50 F21:50

• • • • • • • • • • • •

2350 N21:99 L21:99 F21:99

2401 N22:00 L22:00 F22:00

• • • • • • • • • • • •

2450 N22:49 L22:49 F22:49

2501 N22:50 L22:50 F22:50

• • • • • • • • • • • •

2550 N22:99 L22:99 F22:99

3001 N25:00 L25:00 F25:00

• • • • • • • • • • • •

3050 N25:49 L25:49 F25:49

3101 N25:50 L25:50 F25:50

• • • • • • • • • • • •

3150 N25:99 L25:99 F25:99

3201 N26:00 L26:00 F26:00

• • • • • • • • • • • •

3250 N26:49 L26:49 F26:49

3301 N26:50 L26:50 F26:50

• • • • • • • • • • • •

3350 N26:99 L26:99 F26:99

3401 N27:00 L27:00 F27:00

• • • • • • • • • • • •

3450 N27:49 L27:49 F27:49

3501 N27:50 L27:50 F27:50

• • • • • • • • • • • •

3550 N27:99 L27:99 F27:99

4001 N30:00 L30:00 F30:00

• • • • • • • • • • • •

4050 N30:49 L30:49 F30:49

4101 N30:50 L30:50 F30:50

• • • • • • • • • • • •

4150 N30:99 L30:99 F30:99

4201 N31:00 L31:00 F31:00

• • • • • • • • • • • •

4250 N31:49 L31:49 F31:49

4301 N31:50 L31:50 F31:50

• • • • • • • • • • • •

4350 N31:99 L31:99 F31:99

4401 N32:00 L32:00 F32:00

• • • • • • • • • • • •

4450 N32:49 L32:49 F32:49

4501 N32:50 L32:50 F32:50

• • • • • • • • • • • •

4550 N32:99 L32:99 F32:99

INT16

Datatype

INT32

Datatype

FLOAT

Continued on next page

10

IM 04L51B01-18EN

Page 19

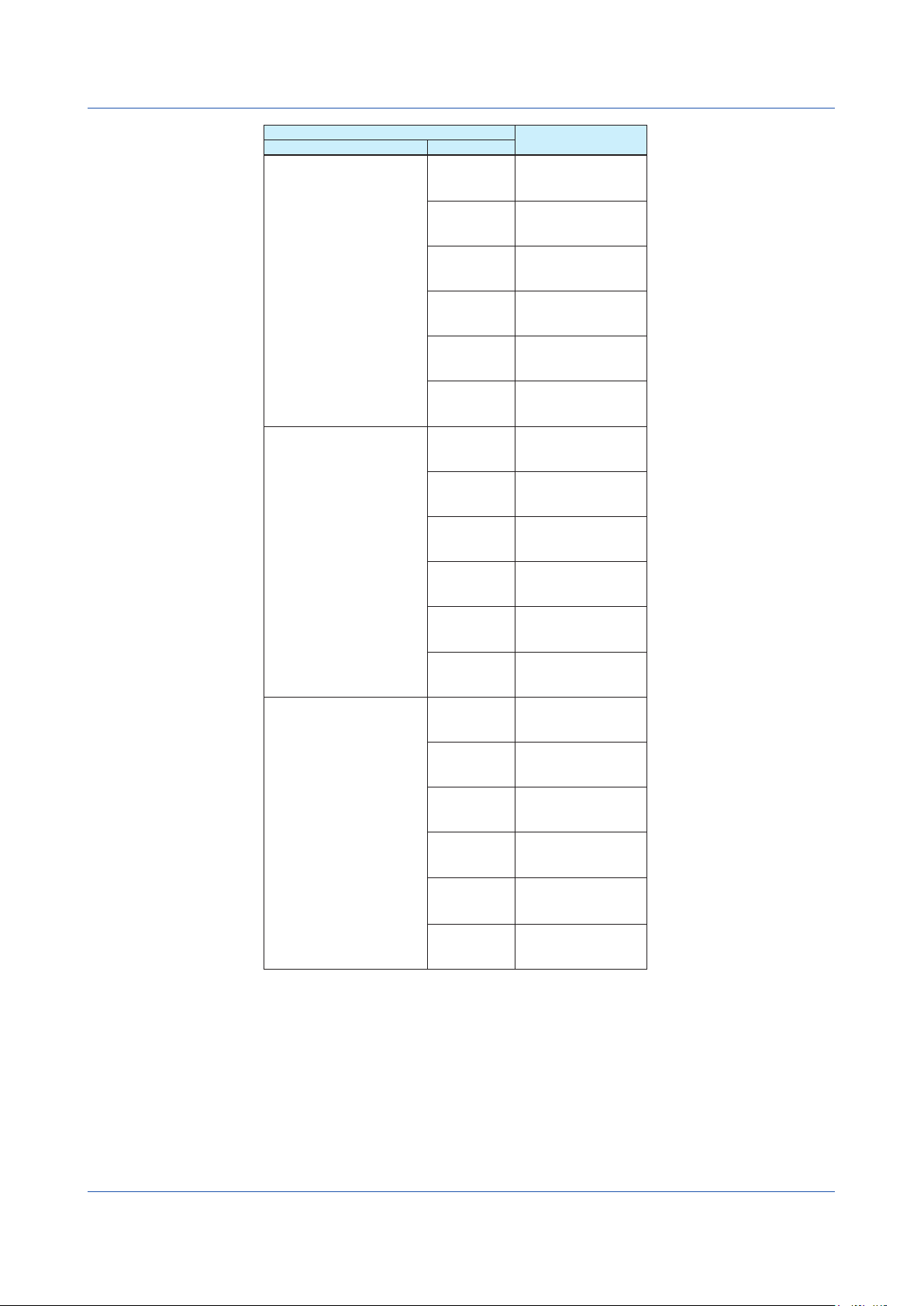

Datatobeaccessed Filenumber

Type Number Datatype

Input/Output channel

(GX/GP expandable I/O 5)

(GM sub unit 5)

(GX/GP expandable I/O 6)

(GM sub unit 6)

5001 N35:00 L35:00 F35:00

• • • • • • • • • • • •

5050 N35:49 L35:49 F35:49

5101 N35:50 L35:50 F35:50

• • • • • • • • • • • •

5150 N35:99 L35:99 F35:99

5201 N36:00 L36:00 F36:00

• • • • • • • • • • • •

5250 N36:49 L36:49 F36:49

5301 N36:50 L36:50 F36:50

• • • • • • • • • • • •

5350 N36:99 L36:99 F36:99

5401 N37:00 L37:00 F37:00

• • • • • • • • • • • •

5450 N37:49 L37:49 F37:49

5501 N37:50 L37:50 F37:50

• • • • • • • • • • • •

5550 N37:99 L37:99 F37:99

6001 N40:00 L40:00 F40:00

• • • • • • • • • • • •

6050 N40:49 L40:49 F40:49

6101 N40:50 L40:50 F40:50

• • • • • • • • • • • •

6150 N40:99 L40:99 F40:99

6201 N41:00 L41:00 F41:00

• • • • • • • • • • • •

6250 N41:49 L41:49 F41:49

6301 N41:50 L41:50 F41:50

• • • • • • • • • • • •

6350 N41:99 L41:99 F41:99

6401 N42:00 L42:00 F42:00

• • • • • • • • • • • •

6450 N42:49 L42:49 F42:49

6501 N42:50 L42:50 F42:50

• • • • • • • • • • • •

6550 N42:99 L42:99 F42:99

INT16

Datatype

INT32

Explicit Message

Datatype

FLOAT

Continued on next page

IM 04L51B01-18EN

11

Page 20

Explicit Message

Datatobeaccessed Filenumber

Type Number Datatype

Input/Output channel

(Continuous channel data

area)*

Computation channel A001 N50:00 L50:00 F50:00

Communication channel

(Read/Write)

Specify a data address, for example, as N10:0 (where N is INT16, the file number is 10, and the

element number is 0).

Use only N file for command, “PLC5 Word Range Read/Write”

“• • •” stands for data in numerical order.

* The “continuous channel data area” is a special area that enables continuous reading by limiting

the number of channels of each module to 10.

For only the I/O channels on a GX/GP main unit or I/O channels on a GM main unit, this area

can be used to read data consecutively.

0001 N45:00 L45:00 F45:00

• • • • • • • • • • • •

0010 N45:09 L45:09 F45:09

0101 N45:10 L45:10 F45:10

• • • • • • • • • • • •

0110 N45:19 L45:19 F45:19

0201 N45:20 L45:20 F45:20

• • • • • • • • • • • •

0210 N45:29 L45:29 F45:29

0301 N45:30 L45:30 F45:30

• • • • • • • • • • • •

0310 N45:39 L45:39 F45:39

0401 N45:40 L45:40 F45:40

• • • • • • • • • • • •

0410 N45:49 L45:49 F45:49

0501 N45:50 L45:50 F45:50

• • • • • • • • • • • •

0510 N45:59 L45:59 F45:59

0601 N45:60 L45:60 F45:60

• • • • • • • • • • • •

0610 N45:69 L45:69 F45:69

0701 N45:70 L45:70 F45:70

• • • • • • • • • • • •

0710 N45:79 L45:79 F45:79

0801 N45:80 L45:80 F45:80

• • • • • • • • • • • •

0810 N45:89 L45:89 F45:89

0901 N45:90 L45:90 F45:90

• • • • • • • • • • • •

0910 N45:99 L45:99 F45:99

• • • • • • • • • • • •

A200 N51:99 L51:99 F51:99

C001 N60:00 L60:00 F60:00

• • • • • • • • • • • •

C500 N64:99 L64:99 F64:99

INT16

Datatype

INT32

Datatype

FLOAT

12

IM 04L51B01-18EN

Page 21

Explicit Message

InCaseofCompactLogix,etc.

• Command:CIPDataTableRead/Write

The recorder supports the following commands:

TargetPLC Command name

CompactLogix, etc. CIP Data Table Read/Write

• Specifyingdatatobeaccessed

Specify which of the data in the recorder should be accessed. For Logix, data can be

accessed by a “tag name”.

Datatobeaccessed Tag name

Type Number Datatype

Input/Output channel

(GX/GP main unit)

(GM main unit)

(GX/GP expandable I/O 1)

(GM sub unit 1)

0001 int[1000] dint[1000] real[1000]

INT16

• • • • • • • • • • • •

0050 int[1049] dint[1049] real[1049]

0101 int[1050] dint[1050] real[1050]

• • • • • • • • • • • •

0150 int[1099] dint[1099] real[1099]

0201 int[1100] dint[1100] real[1100]

• • • • • • • • • • • •

0250 int[1149] dint[1149] real[1149]

0301 int[1150] dint[1150] real[1150]

• • • • • • • • • • • •

0350 int[1199] dint[1199] real[1199]

0401 int[1200] dint[1200] real[1200]

• • • • • • • • • • • •

0450 int[1249] dint[1249] real[1249]

0501 int[1250] dint[1250] real[1250]

• • • • • • • • • • • •

0550 int[1299] dint[1299] real[1299]

0601 int[1300] dint[1300] real[1300]

• • • • • • • • • • • •

0650 int[1349] dint[1349] real[1349]

0701 int[1350] dint[1350] real[1350]

• • • • • • • • • • • •

0750 int[1399] dint[1399] real[1399]

0801 int[1400] dint[1400] real[1400]

• • • • • • • • • • • •

0850 int[1449] dint[1449] real[1449]

0901 int[1450] dint[1450] real[1450]

• • • • • • • • • • • •

0950 int[1499] dint[1499] real[1499]

1001 int[1500] dint[1500] real[1500]

• • • • • • • • • • • •

1050 int[1549] dint[1549] real[1549]

1101 int[1550] dint[1550] real[1550]

• • • • • • • • • • • •

1150 int[1599] dint[1599] real[1599]

1201 int[1600] dint[1600] real[1600]

• • • • • • • • • • • •

1250 int[1649] dint[1649] real[1649]

1301 int[1650] dint[1650] real[1650]

• • • • • • • • • • • •

1350 int[1699] dint[1699] real[1699]

1401 int[1700] dint[1700] real[1700]

• • • • • • • • • • • •

1450 int[1749] dint[1749] real[1749]

1501 int[1750] dint[1750] real[1750]

• • • • • • • • • • • •

1550 int[1799] dint[1799] real[1799]

Datatype

INT32

Datatype

FLOAT

Continued on next page

IM 04L51B01-18EN

13

Page 22

Explicit Message

Datatobeaccessed Tag name

Type Number Datatype

Input/Output channel

(GX/GP expandable I/O 2)

(GM sub unit 2)

(GX/GP expandable I/O 3)

(GM sub unit 3)

(GX/GP expandable I/O 4)

(GM sub unit 4)

2001 int[2000] dint[2000] real[2000]

• • • • • • • • • • • •

2050 int[2049] dint[2049] real[2049]

2101 int[2050] dint[2050] real[2050]

• • • • • • • • • • • •

2150 int[2099] dint[2099] real[2099]

2201 int[2100] dint[2100] real[2100]

• • • • • • • • • • • •

2250 int[2149] dint[2149] real[2149]

2301 int[2150] dint[2150] real[2150]

• • • • • • • • • • • •

2350 int[2199] dint[2199] real[2199]

2401 int[2200] dint[2200] real[2200]

• • • • • • • • • • • •

2450 int[2249] dint[2249] real[2249]

2501 int[2250] dint[2250] real[2250]

• • • • • • • • • • • •

2550 int[2299] dint[2299] real[2299]

3001 int[2500] dint[2500] real[2500]

• • • • • • • • • • • •

3050 int[2549] dint[2549] real[2549]

3101 int[2550] dint[2550] real[2550]

• • • • • • • • • • • •

3150 int[2599] dint[2599] real[2599]

3201 int[2600] dint[2600] real[2600]

• • • • • • • • • • • •

3250 int[2649] dint[2649] real[2649]

3301 int[2650] dint[2650] real[2650]

• • • • • • • • • • • •

3350 int[2699] dint[2699] real[2699]

3401 int[2700] dint[2700] real[2700]

• • • • • • • • • • • •

3450 int[2749] dint[2749] real[2749]

3501 int[2750] dint[2750] real[2750]

• • • • • • • • • • • •

3550 int[2799] dint[2799] real[2799]

4001 int[3000] dint[3000] real[3000]

• • • • • • • • • • • •

4050 int[3049] dint[3049] real[3049]

4101 int[3050] dint[3050] real[3050]

• • • • • • • • • • • •

4150 int[3099] dint[3099] real[3099]

4201 int[3100] dint[3100] real[3100]

• • • • • • • • • • • •

4250 int[3149] dint[3149] real[3149]

4301 int[3150] dint[3150] real[3150]

• • • • • • • • • • • •

4350 int[3199] dint[3199] real[3199]

4401 int[3200] dint[3200] real[3200]

• • • • • • • • • • • •

4450 int[3249] dint[3249] real[3249]

4501 int[3250] dint[3250] real[3250]

• • • • • • • • • • • •

4550 int[3299] dint[3299] real[3299]

INT16

Datatype

INT32

Datatype

FLOAT

Continued on next page

14

IM 04L51B01-18EN

Page 23

Datatobeaccessed Tag name

Type Number Datatype

Input/Output channel

(GX/GP expandable I/O 5)

(GM sub unit 5)

(GX/GP expandable I/O 6)

(GM sub unit 6)

5001 int[3500] dint[3500] real[3500]

• • • • • • • • • • • •

5050 int[3549] dint[3549] real[3549]

5101 int[3550] dint[3550] real[3550]

• • • • • • • • • • • •

5150 int[3599] dint[3599] real[3599]

5201 int[3600] dint[3600] real[3600]

• • • • • • • • • • • •

5250 int[3649] dint[3649] real[3649]

5301 int[3650] dint[3650] real[3650]

• • • • • • • • • • • •

5350 int[3699] dint[3699] real[3699]

5401 int[3700] dint[3700] real[3700]

• • • • • • • • • • • •

5450 int[3749] dint[3749] real[3749]

5501 int[3750] dint[3750] real[3750]

• • • • • • • • • • • •

5550 int[3799] dint[3799] real[3799]

6001 int[4000] dint[4000] real[4000]

• • • • • • • • • • • •

6050 int[4049] dint[4049] real[4049]

6101 int[4050] dint[4050] real[4050]

• • • • • • • • • • • •

6150 int[4099] dint[4099] real[4099]

6201 int[4100] dint[4100] real[4100]

• • • • • • • • • • • •

6250 int[4149] dint[4149] real[4149]

6301 int[4150] dint[4150] real[4150]

• • • • • • • • • • • •

6350 int[4199] dint[4199] real[4199]

6401 int[4200] dint[4200] real[4200]

• • • • • • • • • • • •

6450 int[4249] dint[4249] real[4249]

6501 int[4250] dint[4250] real[4250]

• • • • • • • • • • • •

6550 int[4299] dint[4299] real[4299]

INT16

Datatype

INT32

Explicit Message

Datatype

FLOAT

Continued on next page

IM 04L51B01-18EN

15

Page 24

Explicit Message

Datatobeaccessed Tag name

Type Number Datatype

Input/Output channel

(Continuous channel data

area)*

Computation channel A001 int[5000] dint[5000] real[5000]

Communication channel

(Read/Write)

“• • •” stands for data in numerical order.

* The “continuous channel data area” is a special area that enables continuous reading by limiting

the number of channels of each module to 10.

For only the I/O channels on a GX/GP main unit or I/O channels on a GM main unit, this area

can be used to read data consecutively.

0001 int[4500] dint[4500] real[4500]

• • • • • • • • • • • •

0010 int[4509] dint[4509] rea[4509]

0101 int[4510] dint[4510] rea[4510]

• • • • • • • • • • • •

0110 int[4519] dint[4519] rea[4519]

0201 int[4520] dint[4520] rea[4520]

• • • • • • • • • • • •

0210 int[4529] dint[4529] rea[4529]

0301 int[4530] dint[4530] rea[4530]

• • • • • • • • • • • •

0310 int[4539] dint[4539] rea[4539]

0401 int[4540] dint[4540] rea[4540]

• • • • • • • • • • • •

0410 int[4549] dint[4549] rea[4549]

0501 int[4550] dint[4550] rea[4550]

• • • • • • • • • • • •

0510 int[4559] dint[4559] rea[4559]

0601 int[4560] dint[4560] rea[4560]

• • • • • • • • • • • •

0610 int[4569] dint[4569] rea[4569]

0701 int[4570] dint[4570] rea[4570]

• • • • • • • • • • • •

0710 int[4579] dint[4579] rea[4579]

0801 int[4580] dint[4580] rea[4580]

• • • • • • • • • • • •

0810 int[4589] dint[4589] rea[4589]

0901 int[4590] dint[4590] rea[4590]

• • • • • • • • • • • •

0910 int[4599] dint[4599] rea[4599]

• • • • • • • • • • • •

A200 int[5199] dint[5199] real[5199]

C001 int[6000] dint[6000] real[6000]

• • • • • • • • • • • •

C500 int[6499] dint[6499] real[6499]

INT16

Datatype

INT32

Datatype

FLOAT

Data on the Recorder

16

DataType

For a PLC, you can specify the type of read or write data using a file number or tag name

in a command. However, the data type is fixed to INT16 for commands “PLC2 Unprotected

Read/Write” and “PLC5 Word Range Read/Write.”

The data count on the recorder is as follows:

Model Type(Suffixcode)

GX10,

GP10

GX20-1,

GX20-1

GX20-2,

GX20-2

GM10-1 Standard (-1) 100 0001 to 6650 100 A001 to A100 300 C001 to C300

GM10-2 Large Memory (-2) 500 0001 to 6650 200 A001 to A200 500 C001 to C500

Standard (-1) 100 0001 to 6650 50 A001 to A050 50 C001 to C050

Standard (-1) 100 0001 to 6650 100 A001 to A100 300 C001 to C300

Large Memory (-2) 500 0001 to 6650 200 A001 to A200 500 C001 to C500

Input/Outputchannel Computationchannel

Count Number Count Number Count Number

Communication

channel

IM 04L51B01-18EN

Page 25

Explicit Message

The following table shows the I/O channel assignments when a PID control module is

installed.

Datatobeaccessed Reading data Datatobeaccessed Reading data

Input/Output

channel

u: Unit number, m: Module number

Example: Loop number L651 OUT corresponds to I/O channel number 6503.

um01 Loop 1 PV Input/Output

um02 Loop 1 SP um20 DO2

um03 Loop 1 OUT um21 DO3

um04 Loop 2 PV um22 DO4

um05 Loop 2 SP um23 DO5

um06 Loop 2 OUT um24 DO6

um07 Loop 1 AI um25 DO7

um08 Loop 2 AI um26 DO8

um09 Loop 1 AO

um10 Loop 2 AO

um11 DI1

um12 DI2

um13 DI3

um14 DI4

um15 DI5

um16 DI6

um17 DI7

um18 DI8

channel

um19 DO1

IM 04L51B01-18EN

17

Page 26

I/O Messages

SystemConfigurationonPLC

An I/O message is also called an Implicit message. An I/O message is used to transmit prespecified I/O data at intervals. An I/O message is exchanged via a connection path which is

first set in RSLinx and read into RSLogix. A connection path defines the IP address of the

recorder, communication port of the PLC, and distinction of input/output.

A device, once configured in RSLinx, can be downloaded into an RSLogix project. The

recorder is configured as a “Generic Ethernet Module” in RSLogix.

Instance ID

Each data on the recorder corresponds to the instance ID of an Assembly object. Each data

value can be accessed as an INT32 or FLOAT type. In an I/O message, use an instance

ID to code the data on the recorder to be accessed. The following table lists instance IDs,

sizes, and data types.

• INT32

Type Number Operationtype Instance ID Size Datatype

Input/Output channel

(GX/GP main unit)

(GM main unit)

(GX/GP expandable I/O 1)

(GM sub unit 1)

(GX/GP expandable I/O 2)

(GM sub unit 2)

(GX/GP expandable I/O 3)

(GM sub unit 3)

(GX/GP expandable I/O 4)

(GM sub unit 4)

Input/Output channel

(GX/GP expandable I/O 5)

(GM sub unit 5)

0001 to 0050,

0101 to 0150

0201 to 0250,

0301 to 0350

0401 to 0450,

0501 to 0550

0601 to 0650,

0701 to 0750

0801 to 0850,

0901 to 0950

1001 to 1050,

1101 to 1150

1201 to 1250,

1301 to 1350

1401 to 1450,

1501 to 1550

2001 to 2050,

2101 to 2150

2201 to 2250,

2301 to 2350

2401 to 2450,

2501 to 2550

3001 to 3050,

3101 to 3150

3201 to 3250,

3301 to 3350

3401 to 3450,

3501 to 3550

4001 to 4050,

4101 to 4150

4201 to 4250,

4301 to 4350

4401 to 4450,

4501 to 4550

5001 to 5050,

5101 to 5150

5201 to 5250,

5301 to 5350

5401 to 5450,

5501 to 5550

Producer 101 400 (4 x 100) INT32

Producer 102 400 (4 x 100) INT32

Producer 103 400 (4 x 100) INT32

Producer 104 400 (4 x 100) INT32

Producer 105 400 (4 x 100) INT32

Producer 106 400 (4 x 100) INT32

Producer 107 400 (4 x 100) INT32

Producer 108 400 (4 x 100) INT32

Producer 111 400 (4 x 100) INT32

Producer 112 400 (4 x 100) INT32

Producer 113 400 (4 x 100) INT32

Producer 116 400 (4 x 100) INT32

Producer 117 400 (4 x 100) INT32

Producer 118 400 (4 x 100) INT32

Producer 121 400 (4 x 100) INT32

Producer 122 400 (4 x 100) INT32

Producer 123 400 (4 x 100) INT32

Producer 126 400 (4 x 100) INT32

Producer 127 400 (4 x 100) INT32

Producer 128 400 (4 x 100) INT32

Continued on next page

18

IM 04L51B01-18EN

Page 27

I/O Messages

Type Number Operationtype Instance ID Size Datatype

(GX/GP expandable I/O 6)

(GM sub unit 6)

Input/Output channel

(Continuous channel data

area)*

Computation channel A001 to A100 Producer 137 400 (4 x 100) INT32

Communication channel

(Read/Write)

- Configuration 195 0 -

- Producer /

* The “continuous channel data area” is a special area that enables continuous reading by limiting

the number of channels of each module to 10.

For only the I/O channels on a GX/GP main unit or I/O channels on a GM main unit, this area

can be used to read data consecutively.

6001 to 6050,

6101 to 6150

6201 to 6250,

6301 to 6350

6401 to 6450,

6501 to 6550

0001 to 0010,

0101 to 0110,

0201 to 0210,

0301 to 0310,

0401 to 0410,

0501 to 0510,

0601 to 0610,

0701 to 0710,

0801 to 0810,

0901 to 0910

A101 to A200 147 400 (4 x 100)

C001 to C100 Producer /

C101 to C200 Producer /

C201 to C300 Producer /

C301 to C400 Producer /

C401 to C500 Producer /

Producer 131 400 (4 x 100) INT32

Producer 132 400 (4 x 100) INT32

Producer 133 400 (4 x 100) INT32

Producer 136 400 (4 x 100) INT32

138 400 (4 x 100) INT32

Consumer

139 400 (4 x 100) INT32

Consumer

140 400 (4 x 100) INT32

Consumer

141 400 (4 x 100) INT32

Consumer

142 400 (4 x 100) INT32

Consumer

196 0 -

Consumer

IM 04L51B01-18EN

19

Page 28

I/O Messages

•FLOAT

Type Number Operationtype Instance ID Size Datatype

Input/Output channel

(GX/GP main unit)

(GM main unit)

(GX/GP expandable I/O 1)

(GM sub unit 1)

(GX/GP expandable I/O 2)

(GM sub unit 2)

(GX/GP expandable I/O 3)

(GM sub unit 3)

(GX/GP expandable I/O 4)

(GM sub unit 4)

(GX/GP expandable I/O 5)

(GM sub unit 5)

(GX/GP expandable I/O 6)

(GM sub unit 6)

Input/Output channel

(Continuous channel data

area)*

Computation channel A001 to A100 Producer 184 400 (4 x 100) FLOAT

0001 to 0050,

0101 to 0150

0201 to 0250,

0301 to 0350

0401 to 0450,

0501 to 0550

0601 to 0650,

0701 to 0750

0801 to 0850,

0901 to 0950

1001 to 1050,

1101 to 1150

1201 to 1250,

1301 to 1350

1401 to 1450,

1501 to 1550

2001 to 2050,

2101 to 2150

2201 to 2250,

2301 to 2350

2401 to 2450,

2501 to 2550

3001 to 3050,

3101 to 3150

3201 to 3250,

3301 to 3350

3401 to 3450,

3501 to 3550

4001 to 4050,

4101 to 4150

4201 to 4250,

4301 to 4350

4401 to 4450,

4501 to 4550

5001 to 5050,

5101 to 5150

5201 to 5250,

5301 to 5350

5401 to 5450,

5501 to 5550

6001 to 6050,

6101 to 6150

6201 to 6250,

6301 to 6350

6401 to 6450,

6501 to 6550

0001 to 0010,

0101 to 0110,

0201 to 0210,

0301 to 0310,

0401 to 0410,

0501 to 0510,

0601 to 0610,

0701 to 0710,

0801 to 0810,

0901 to 0910

A101 to A200 194 400 (4 x 100)

Producer 148 400 (4 x 100) FLOAT

Producer 149 400 (4 x 100) FLOAT

Producer 150 400 (4 x 100) FLOAT

Producer 151 400 (4 x 100) FLOAT

Producer 152 400 (4 x 100) FLOAT

Producer 153 400 (4 x 100) FLOAT

Producer 154 400 (4 x 100) FLOAT

Producer 155 400 (4 x 100) FLOAT

Producer 158 400 (4 x 100) FLOAT

Producer 159 400 (4 x 100) FLOAT

Producer 160 400 (4 x 100) FLOAT

Producer 163 400 (4 x 100) FLOAT

Producer 164 400 (4 x 100) FLOAT

Producer 165 400 (4 x 100) FLOAT

Producer 168 400 (4 x 100) FLOAT

Producer 169 400 (4 x 100) FLOAT

Producer 170 400 (4 x 100) FLOAT

Producer 173 400 (4 x 100) FLOAT

Producer 174 400 (4 x 100) FLOAT

Producer 175 400 (4 x 100) FLOAT

Producer 178 400 (4 x 100) FLOAT

Producer 179 400 (4 x 100) FLOAT

Producer 180 400 (4 x 100) FLOAT

Producer 183 400 (4 x 100) FLOAT

Continued on next page

20

IM 04L51B01-18EN

Page 29

Type Number Operationtype Instance ID Size Datatype

Communication channel

(Read/Write)

- Configuration 195 0 -

- Producer /

Explanation

• The recorder data can be accessed using the INT32 or FLOAT type. Data can be

accessed by the type based on the specified instance ID.

• The operation type “Producer” indicates a read-only instance and “Producer/Consumer”

indicates a read/write instance.

Data on the Recorder

See the explanation in the previous section on Explicit messages.

I/O Messages

C001 to C100 Producer /

Consumer

C101 to C200 Producer /

Consumer

C201 to C300 Producer /

Consumer

C301 to C400 Producer /

Consumer

C401 to C500 Producer /

Consumer

Consumer

* The “continuous channel data area” is a special area that enables continuous reading by limiting

the number of channels of each module to 10.

For only the I/O channels on a GX/GP main unit or I/O channels on a GM main unit, this area

can be used to read data consecutively.

185 400 (4 x 100) FLOAT

186 400 (4 x 100) FLOAT

187 400 (4 x 100) FLOAT

188 400 (4 x 100) FLOAT

189 400 (4 x 100) FLOAT

196 0 -

IM 04L51B01-18EN

21

Page 30

Communication Considerations

AboutCommunicationInterval

DataUpdate

The recorder data is updated in a scan interval. Even if a PLC accesses the data at shorter

intervals than the recorder scan intervals, the data is updated only at scan intervals.

Communication Interval

A PLC should access the recorder at intervals of 100 ms or longer.

* This is required to maintain compatibility with other protocols supported by the recorder

than EtherNet/IP.

AccesstoNon-existentData

If non-existent data is accessed, either of the following operations occur.

• 0 is read if non-existent data is read.

• Nothing is done if non-existent data is written.

Specialdata

Special data will have the following values:

Channel status Datatype

Integer (Int) Floating(Float)

+Over, +Burnout Maximum expressible value

–Over, –Burnout Minimum expressible value

+

–

Example: Channel status is “–Over”

Datatype Outputvalue

Int16 –32768 (0x8000)

Int32 –2147483648 (0x80000000)

Float

Writing Data to the Recorder

Inputvalue Recorder value

More than 99999999 +Over

–9999999 to 99999999 The data is written without change.

Less than –9999999 –Over

–

(0xff800000)

22

IM 04L51B01-18EN

Page 31

Specifications

The following table shows the basic specifications of the EtherNet/IP server function of the

recorder.

Specification Description

Implementation level Level 2 (Message Server + I/O Server)

Maximum number of connections 20 connections (10 sessions)

Ports used 44818/tcp, 44818/udp, 2222/udp

Supported protocols EIP/PCCC, EIP/native

Messaging Explicit (UCMM, Class 3) + I/O (Class 1)

Object Assembly, PCCC, Data Table

Authentication File No. 11246.01 (Jan 21, 2014) (GX/GP)

1, 2

3

4

5

1 A “session,” a framework of connection management in the encapsulation protocol layer

of EtherNet/IP, provides similar functions as a TCP connection to carry out message

communications.

2 Although multiple connections can be made in one session, the total number of connections

cannot exceed the maximum number of connections.

3 44818/tcp is used mainly for Explicit messages, 2222/udp for I/O messages, and 44818/udp for

communications of response to RSWho of RSLinx.

4 CSP/PCCC (Allen Bradley Ethernet) is not supported.

5 The description of common object is omitted.

IM 04L51B01-18EN

23

Page 32

ExampleofanExplicitMessageUsingRSLogix5000

MSG

...

This is an example of using RSLogix 5000 to configure an Explicit message to be sent to the

recorder by a PLC supporting the CIP Data Table Read/Write command.

This section assumes that the reader is familiar with the operations of RSLogix 5000 and

RSLinx and that RSLogix 5000 can communicate with the target recorder via RSLinx.

Tag

Making tags initially will be useful. Go to Controller Organizer (a tree on the left side of the

screen) and open Controller Tag to make a tag with Data Type of Message (Name the tag

as MSG1). Also, make a tag used to retain data to be written to the recorder (Name the tag

as DATATransfer and store 10 FLOAT values). Make a bit used to launch a message as

WriteMessageBit.

Controller Tags

Name DataType

DATATransfer REAL [10]

MSG1 Message

WriteMessageBit BOOL

MSGInstruction

Go to the Input/Output tab, then the Ladder Element toolbar to select MSG. The MSG block

is inserted as ladder output. Tag MSG1 is assigned to the MSG block.

(EN)

...

(DN)

(ER)

Message

Message Control

MSG1

Make the MSG block settings (Click the

button in the MSG block). The following shows

an example in which the PLC writes data to the communication channel data C001 to C010

on the recorder.

Set the Message Type as “CIP Data Table Write,” Source Element as “DATATransfer”

(a tag in the PLC described earlier), Number of Element as “10” (which can be set to a

larger value if more data should be read or written per message). Set the Destination

Element as “real [6000]. “This corresponds to communication channel data C001 on the

recorder.

MessageConfiguration

ConfigurationTab

MessageType CIP Data Table Write

SourceElement DATATransfer

NumberOfElement 10

Destination Element real [6000]

Next, go to the Communication tab and set a connection path to the recorder. The path

name should consist of the PLC Ethernet port name (LocalENB in this example), comma, 2,

comma, and the recorder IP address in this order.

MessageConfiguration

CommunicationTab

Path LocalENB,2,192.168.1.126

24

IM 04L51B01-18EN

Page 33

I/O Configuration

Ethernet

ETHERNET-MODULE GX

(U)

WriteMessageBit MSG1 EN

Example of an Explicit Message Using RSLogix 5000

If the connection path to the recorder is configured using RSLinx, the connection path is

changed to an automatically named pathname (GX of ETHERNET-MODULE GX shown in

the figure below in this example). If the recorder is not configured, the I/O Configuration tree

does not show ETHERNET-MODULE GX. The connection path in the Communication tab is

not replaced, either.

MessageLaunchLogic

Lastly, configure the message launch logic. In the example shown in the figure below, the

MSG block is launched and writes data to the recorder when the WriteMessageBit is On. At

the same time, the WriteMessageBit is changed to Off and writing is ended.

Message

Message Control

MSG

...

MSG1

WriteMessageBit

(EN)

(DN)

(ER)

IM 04L51B01-18EN

25

Page 34

ExampleofI/OMessageUsingRSLogix5000

ConnectionwithGX/GP

First, define the connection with recorder using RSLinx. Go to Communication on the menu

bar and select Configure Drivers.

Next, select Ethernet Devices and click Add New....

Enter a driver name. In this example, GX is entered but other names can also be

entered.

Enter the IP address of recorder and click OK.

GX is displayed on the RSWho list of RSLinx.

ConfigurationofCommunicationSettings

Open RSLogix 5000 and select a PLC used to communicate with recorder. Right-click

Ethernet in I/O Configuration and select New Module.

Click + to open the list. Select ETHERNET-MODULE and click OK. An ETHERNETMODULE

setup window will open.

The following shows an example of reading data in input/output channels 0001 to 0010 and

writing the data to communication channel data C001 to C020. Data can be accessed using

the INT32 type.

In the Name field, enter GX (or other communication connection name). Since data is

accessed using INT32, keep Comm Format as Data-DINT. In IP Address, enter the IP

address of recorder.

In Connection Parameter, define the input and output. In Input and Output, enter a

respective instance ID and size. In Configuration, enter an instance ID of 195 and a size

of 0.

NewModule

Name GX

Comm Format Data-DINT

Address/Host Name

IP Address 10.0.232.126

Connection Parameter

Input 101 10 (32-bit)

Output 138 20 (32-bit)

Configuration 195 0 (8-bit)

AssemblyInstance Size

Tag

In Controller Tag, the GX:I and GX:O tags to be used in control logic have been

made. Click + to expand the tag and see all the points of a size specified in the module

definition.

26

IM 04L51B01-18EN

Loading...

Loading...