Page 1

SL1000

Acquisition Software

IM 720120-61E

10th Edition

Page 2

List of Manuals

Thank you for purchasing the SL1000 High-Speed Data Acquisition Unit. This user’s

manual explains the functions and operating procedures of the SL1000 Acquisition

Software. To ensure correct use, please read this manual thoroughly before beginning

operation.

After reading the manual, keep it in a convenient location for quick reference whenever a

question arises during operation.

The following manuals, including this one, are provided as manuals for the SL1000.

Please read all of them.

Manual Title Manual No. Description

SL1000

High-Speed Data Acquisition Unit

User’s Manual

SL1000 Acquisition Software

User’s Manual

SL1000 Input Module

User’s Manual

Precautions Concerning the

Modules

701992 Xviewer Install Manual IM 701992-02E This manual explains how to install the

SL1000

High-Speed Data Acquisition Unit

IM 720120-01E Explains all functions and procedures of

the SL1000 excluding the communication

functions.

IM 720120-61E This manual. Explains all functions and

procedures of the Acquisition Software used

to configure and control the SL1000.

IM 720120-51E Explains the specifications of the input

modules that can be installed in the SL1000.

IM 701250-04E The manual explains the precautions

concerning the modules.

*

Xviewer

IM 720120-92 Document for China

setup software.

The “E” in the manual numbers are the language codes.

* The Xviewer user’s manual is included in the Xviewer help.

Notes

Contact information of Yokogawa offices worldwide is provided on the following sheet.

Document No. Description

PIM 113-01Z2 List of worldwide contacts

• The contents of this manual are subject to change without prior notice as a result of

continuing improvements to the instrument’s performance and functions. The figures

given in this manual may differ from those that actually appear on your screen.

• Every effort has been made in the preparation of this manual to ensure the accuracy

of its contents. However, should you have any questions or find any errors, please

contact your nearest YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without

YOKOGAWA’s permission is strictly prohibited.

• The TCP/IP software of this product and the document concerning the TCP/IP

software have been developed/created by YOKOGAWA based on the BSD Networking

Software, Release 1 that has been licensed from University of California.

10th Edition: August 2018 (YMI)

All Rights Reserved, Copyright © 2007 Yokogawa Electric Corporation

All Rights Reserved, Copyright © 2012 Yokogawa Test & Measurement Corporation

IM 720120-61E

i

Page 3

Trademarks

Revisions

• Microsoft, Internet Explorer, Windows, Windows 7, Windows 8, and Windows 10 are

either registered trademarks or trademarks of Microsoft Corporation in the United

States and/or other countries.

• Adobe, Acrobat, and PostScript are trademarks of Adobe Systems Incorporated.

• MATLAB is a registered trademark of The MathWorks, Incorporated in the United

States.

• For purposes of this manual, the ® and TM symbols do not accompany their

respective registered trademark names or trademark names.

• Other company and product names are registered trademarks or trademarks of their

respective holders.

• 1st Edition: September 2007

• 2nd Edition: September 2008

• 3rd Edition: May 2009

• 4th Edition: July 2012

• 5th Edition: September 2013

• 6th Edition: June 2014

• 7th Edition: October 2015

• 8th Edition: July 2017

• 9th Edition: October 2017

• 10th Edition: August 2018

ii

IM 720120-61E

Page 4

Terms and Conditions of the Software License

Yokogawa Electric Corporation and Yokogawa Test & Measurement Corporation, Japanese corporations (hereinafter called “Yokogawa”), grants permission to use this

Yokogawa Software Program (hereinafter called the “Licensed Software”) to the Licensee on the conditions that the Licensee agrees to the terms and conditions stipulated

in Article 1 hereof.

You, as the Licensee (hereinafter called “Licensee”), shall agree to the following terms and conditions for the software license (hereinafter called the “Agreement”) based

on the use intended for the Licensed Software.

Please note that Yokogawa grants the Licensee permission to use the Licensed Software under the terms and conditions herein and in no event shall Yokogawa intend to

sell or transfer the Licensed Software to the Licensee.

Licensed Software Name: SL1000 Acquisition Software

Article 1 (Scope Covered by these Terms and Conditions)

1.1 The terms and conditions stipulated herein shall be applied to any Licensee who purchases the Licensed Software on the condition that the Licensee consents to agree

to the terms and conditions stipulated herein.

1.2 The “Licensed Software” herein shall mean and include all applicable programs and documentation, without limitation, all proprietary technology, algorithms, and knowhow such as a factor, invariant or process contained therein.

Article 2 (Grant of License)

2.1 Yokogawa grants the Licensee, for the purpose of single use, non-exclusive and non-transferable license of the Licensed Software.

2.2 The Licensee is, unless otherwise agreed in writing by Yokogawa, not entitled to copy, change, sell, distribute, transfer, or sublicense the Licensed Software.

2.3 The Licensed Software shall not be copied in whole or in part except for keeping one (1) copy for back-up purposes. The Licensee shall secure or supervise the copy

of the Licensed Software by the Licensee itself with great, strict, and due care.

2.4 In no event shall the Licensee dump, reverse assemble, reverse compile, or reverse engineer the Licensed Software so that the Licensee may translate the Licensed

Software into other programs or change it into a man-readable form from the source code of the Licensed Software. Unless otherwise separately agreed by Yokogawa,

Yokogawa shall not provide the Licensee the source code for the Licensed Software.

2.5 The Licensed Software and its related documentation shall be the proprietary property or trade secret of Yokogawa or a third party which grants Yokogawa the rights. In

no event shall the Licensee be transferred, leased, sublicensed, or assigned any rights relating to the Licensed Software.

2.6 Yokogawa may use or add copy protection in or onto the Licensed Software. In no event shall the Licensee remove or attempt to remove such copy protection.

2.7 The Licensed Software may include a software program licensed for re-use by a third party (hereinafter called “Third Party Software”, which may include any software

program from affiliates of Yokogawa made or coded by themselves.) In the case that Yokogawa is granted permission to sublicense to third parties by any licensors

(sub-licensor) of the Third Party Software pursuant to different terms and conditions than those stipulated in this Agreement, the Licensee shall observe such terms and

conditions of which Yokogawa notifies the Licensee in writing separately.

2.8 In no event shall the Licensee modify, remove or delete a copyright notice of Yokogawa and its licenser contained in the Licensed Software, including any copy thereof.

Article 3 (Restriction of Specific Use)

3.1 The Licensed Software shall not be intended specifically to be designed, developed, constructed, manufactured, distributed or maintained for the purpose of the

following events:

a) Operation of any aviation, vessel, or support of those operations from the ground;,

b) Operation of nuclear products and/or facilities;,

c) Operation of nuclear weapons and/or chemical weapons and/or biological weapons; or

d) Operation of medical instrumentation directly utilized for humankind or the human body.

3.2 Even if the Licensee uses the Licensed Software for the purposes in the preceding Paragraph 3.1, Yokogawa has no liability to or responsibility for any demand or

damage arising out of the use or operations of the Licensed Software, and the Licensee agrees, on its own responsibility, to solve and settle the claims and damages

and to defend, indemnify or hold Yokogawa totally harmless, from or against any liabilities, losses, damages and expenses (including fees for recalling the Products and

reasonable attorney’s fees and court costs), or claims arising out of and related to the above-said claims and damages.

Article 4 (Warranty)

4.1 The Licensee shall agree that the Licensed Software shall be provided to the Licensee on an “as is” basis when delivered. If defect(s), such as damage to the medium

of the Licensed Software, attributable to Yokogawa is found, Yokogawa agrees to replace, free of charge, any Licensed Software on condition that the defective

Licensed Software shall be returned to Yokogawa’s specified authorized service facility within seven (7) days after opening the Package at the Licensee’s expense. As

the Licensed Software is provided to the Licensee on an “as is” basis when delivered, in no event shall Yokogawa warrant that any information on or in the Licensed

Software, including without limitation, data on computer programs and program listings, be completely accurate, correct, reliable, or the most updated.

4.2 Notwithstanding the preceding Paragraph 4.1, when third party software is included in the Licensed Software, the warranty period and terms and conditions that apply

shall be those established by the provider of the third party software.

4.3 When Yokogawa decides in its own judgement that it is necessary, Yokogawa may from time to time provide the Licensee with Revision upgrades and Version upgrades

separately specified by Yokogawa (hereinafter called “Updates”).

4.4 Notwithstanding the preceding Paragraph 4.3, in no event shall Yokogawa provide Updates where the Licensee or any third party conducted renovation or improvement

of the Licensed Software.

4.5 THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES OF QUALITY AND PERFORMANCE, WRITTEN, ORAL, OR

IMPLIED, AND ALL OTHER WARRANTIES INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE

HEREBY DISCLAIMED BY YOKOGAWA AND ALL THIRD PARTIES LICENSING THIRD PARTY SOFTWARE TO YOKOGAWA.

4.6 Correction of nonconformity in the manner and for the period of time provided above shall be the Licensee’s sole and exclusive remedy for any failure of Yokogawa to

comply with its obligations and shall constitute fulfillment of all liabilities of Yokogawa and any third party licensing the Third Party Software to Yokogawa (including any

liability for direct, indirect, special, incidental or consequential damages) whether in warranty, contract, tort (including negligence but excluding willful conduct or gross

negligence by Yokogawa) or otherwise with respect to or arising out of the use of the Licensed Software.

Article 5 (Infringement)

5.1 If and when any third party should demand injunction, initiate a law suit, or demand compensation for damages against the Licensee under patent right (including utility

model right, design patent, and trade mark), copy right, and any other rights relating to any of the Licensed Software, the Licensee shall notify Yokogawa in writing to

that effect without delay.

5.2 In the case of the preceding Paragraph 5.1, the Licensee shall assign to Yokogawa all of the rights to defend the Licensee and to negotiate with the claiming party.

Furthermore, the Licensee shall provide Yokogawa with necessary information or any other assistance for Yokogawa’s defense and negotiation. If and when such a

claim should be attributable to Yokogawa, subject to the written notice to Yokogawa stated in the preceding Paragraph 5.1, Yokogawa shall defend the Licensee and

negotiate with the claiming party at Yokogawa’s cost and expense and be responsible for the final settlement or judgment granted to the claiming party in the preceding

Paragraph 5.1.

5.3 When any assertion or allegation of the infringement of the third party’s rights defined in Paragraph 5.1 is made, or when at Yokogawa’s judgment there is possibility of

such assertion or allegation, Yokogawa will, at its own discretion, take any of the following countermeasures at Yokogawa’s cost and expense.

a) To acquire the necessary right from a third party which has lawful ownership of the right so that the Licensee will be able to continue to use the Licensed Software;

b) To replace the Licensed Software with an alternative one which avoids the infringement; or

c) To remodel the Licensed Software so that the Licensed Software can avoid the infringement of such third party’s right.

5.4 If and when Yokogawa fails to take either of the countermeasures as set forth in the preceding subparagraphs of Paragraph 5.3, Yokogawa shall indemnify the Licensee

only by paying back the price amount of the Licensed Software which Yokogawa has received from the Licensee. THE FOREGOING PARAGRAPHS STATE THE

ENTIRE LIABILITY OF YOKOGAWA AND ANY THIRD PARTY LICENSING THIRD PARTY SOFTWARE TO YOKOGAWA WITH RESPECT TO INFRINGEMENT OF

THE INTELLECTUAL PROPERTY RIGHTS INCLUDING BUT NOT LIMITED TO, PATENT AND COPYRIGHT.

IM 720120-61E

iii

Page 5

Terms and Conditions of the Software License

Article 6 (Liabilities)

6.1 If and when the Licensee should incur any damage relating to or arising out of the Licensed Software or service that Yokogawa has provided to the Licensee under the

conditions herein due to a reason attributable to Yokogawa, Yokogawa shall take actions in accordance with this Agreement. However, in no event shall Yokogawa

be liable or responsible for any special, incidental, consequential and/or indirect damage, whether in contract, warranty, tort, negligence, strict liability, or otherwise,

including, without limitation, loss of operational profit or revenue, loss of use of the Licensed Software, or any associated products or equipment, cost of capital, loss

or cost of interruption of the Licensee’s business, substitute equipment, facilities or services, downtime costs, delays, and loss of business information, or claims of

customers of Licensee or other third parties for such or other damages. Even if Yokogawa is liable or responsible for the damages attributable to Yokogawa and to the

extent of this Article 6, Yokogawa’s liability for the Licensee’s damage shall not exceed the price amount of the Licensed Software or service fee which Yokogawa has

received. Please note that Yokogawa shall be released or discharged from part or all of the liability under this Agreement if the Licensee modifies, remodels, combines

with other software or products, or causes any deviation from the basic specifications or functional specifications, without Yokogawa’s prior written consent.

6.2 All causes of action against Yokogawa arising out of or relating to this Agreement or the performance or breach hereof shall expire unless Yokogawa is notified of the

claim within one (1) year of its occurrence.

6.3 In no event, regardless of cause, shall Yokogawa assume responsibility for or be liable for penalties or penalty clauses in any contracts between the Licensee and its

customers.

Article 7 (Limit of Export)

Unless otherwise agreed by Yokogawa, the Licensee shall not directly or indirectly export or transfer the Licensed Software to any countries other than those where

Yokogawa permits export in advance.

Article 8 (Term)

This Agreement shall become effective on the date when the Licensee receives the Licensed Software and continues in effect unless or until terminated as provided herein,

or the Licensee ceases using the Licensed Software by itself or with Yokogawa’s thirty (30) days prior written notice to the Licensee.

Article 9 (Injunction for Use)

During the term of this Agreement, Yokogawa may, at its own discretion, demand injunction against the Licensee in case that Yokogawa deems that the Licensed Software

is used improperly or under severer environments other than those where Yokogawa has first approved, or any other condition which Yokogawa may not permit.

Article 10 (Termination)

Yokogawa, at its sole discretion, may terminate this Agreement without any notice or reminder to the Licensee if the Licensee violates or fails to perform this Agreement.

However, Articles 5, 6, and 11 shall survive even after the termination.

Article 11 (Jurisdiction)

Any dispute, controversies, or differences between the parties hereto as to interpretation or execution of this Agreement shall be resolved amicably through negotiation

between the parties upon the basis of mutual trust. Should the parties fail to agree within ninety (90) days after notice from one of the parties to the other, both parties

hereby irrevocably submit to the exclusive jurisdiction of the Tokyo District Court (main office) in Japan for settlement of the dispute.

Article 12 (Governing Law)

This Agreement shall be governed by and construed in accordance with the laws of Japan. The Licensee expressly agrees to waive absolutely and irrevocably and to the

fullest extent permissible under applicable law any rights against the laws of Japan which it may have pursuant to the Licensee’s local law.

Article 13 (Severability)

In the event that any provision hereof is declared or found to be illegal by any court or tribunal of competent jurisdiction, such provision shall be null and void with respect

to the jurisdiction of that court or tribunal and all the remaining provisions hereof shall remain in full force and effect.

iv

IM 720120-61E

Page 6

How to Use This Manual

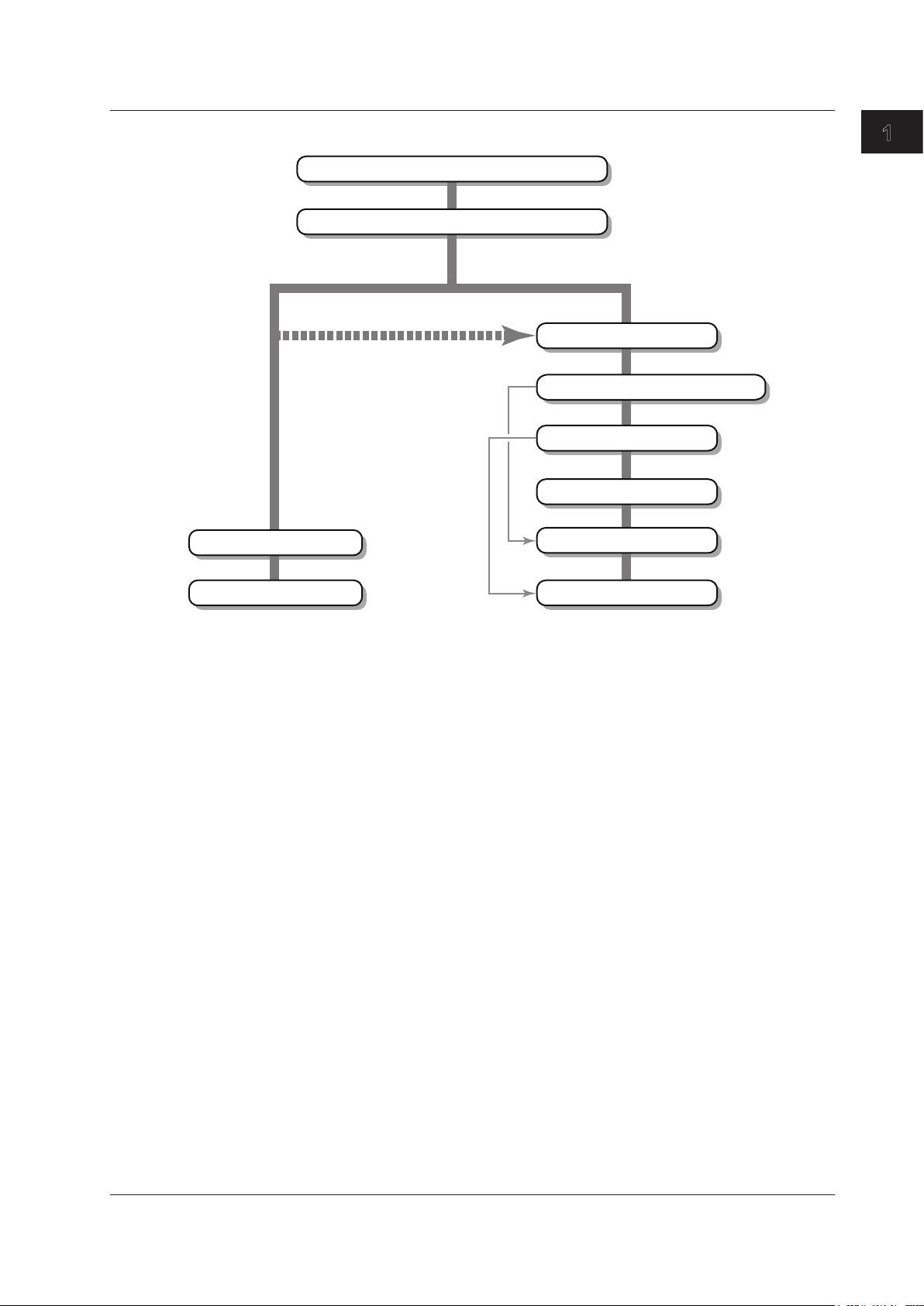

Structure of the Manual

This user’s manual consists of the following sections.

Chapter Title Description

1 What the Acquisition Software Can Do

Gives an overview of the Acquisition Software and the details of its functions.

2 Installation

Explains how to install and uninstall the Acquisition Software and how to

install the USB driver.

3 Connecting to an SL1000

Explains how to connect the SL1000 Data Acquisition Unit to your PC.

4. Setting the Measurement Conditions

Explains how to set the measurement conditions, trigger functions, GO/

NO-GO judgment functions, and alarm functions for each input module and

how to start measurements.

5 Recording Measured Data

Explains how to record the measured data.

6 Display

Explains how to display waveforms of measured data and how to set the

screen.

7 Analysis

Explains the automated measurement of waveform parameters and how to

read measured values using cursors.

8 Saving, Loading, and Transferring Data

Explains how to display waveforms of data measured in the past, how to save

the SL1000’s measured data to your PC, how to save setup data, how to

load previous setup data, how to save computed data and screen captures of

measured waveforms, how to average and save measured data, and how to

transfer files between the SL1000 and your PC.

9 Other Functions

Explains how to set the clock, the start-up and exit options, as well as how to

perform a self-test, key lock, initialization, calibration, and the like.

10 File Operation

Explains how to merge files, how to divide files, how to accelerate waveform

displaying, how to convert data to CSV files, and so on.

11 Error Messages

Lists various error messages.

12 Specifications

Lists the specifications of the Acquisition Software.

Appendix

Explains the relationship between the number of data points and acquisition

count, the relationship between the maximum number of measured points

and measuring time, and the relationship between the number of channels

and sample rate.

Index

IM 720120-61E

v

Page 7

Contents

List of Manuals ...................................................................................................................................i

Terms and Conditions of the Software License................................................................................ iii

How to Use This Manual ...................................................................................................................v

Chapter 1 What the Acquisition Software Can Do

1.1 Overview of This Software................................................................................................ 1-1

1.2 Connection & Group Settings ........................................................................................... 1-7

1.3 Measurement Settings ..................................................................................................... 1-9

1.4 Recording Settings ......................................................................................................... 1-22

1.5 Display Settings .............................................................................................................. 1-27

1.6 Triggering ....................................................................................................................... 1-28

1.7 Analysis Function ........................................................................................................... 1-33

1.8 Alarms ............................................................................................................................ 1-35

1.9 GO/NO-GO Judgment (for Triggered Mode) .................................................................. 1-37

1.10 X-Y Display ..................................................................................................................... 1-38

1.11 Screen Description ......................................................................................................... 1-39

1.12 Other Functions .............................................................................................................. 1-43

1.13 Basic Operation .............................................................................................................. 1-44

Chapter 2 Installation Procedure

2.1 Recommended PC System .............................................................................................. 2-1

2.2 Installing or Uninstalling the Acquisition Software ............................................................ 2-2

2.3 Installing the USB Driver .................................................................................................. 2-4

2.4 Starting and Exiting the Acquisition Software ................................................................... 2-7

Chapter 3 Connecting to the SL1000

3.1 Connecting Using the USB ............................................................................................... 3-1

3.2 Specifying Communication Settings (When Using the Optional Ethernet Interface) ........ 3-2

3.3. Connecting Using the Ethernet Interface (Option) ........................................................... 3-4

3.4 ConguringtheSystem .................................................................................................... 3-5

Chapter 4 Specifying Measurement Settings

4.1 Setting the Measuring Mode and Acquisition Mode ......................................................... 4-1

4.2 Measuring the Voltage and Current .................................................................................. 4-2

4.3 Measuring the Temperature.............................................................................................. 4-8

4.4 Measuring the Strain .......................................................................................................4-11

4.5 Measuring the Acceleration ............................................................................................ 4-16

4.6 Measuring the Frequency, Number of Rotations, Period, Duty Cycle, Power Supply

Frequency, Pulse Width, Pulse Integration, and Velocity ................................................... 4-18

4.7 Making Measurements Using an External Clock Signal ................................................. 4-34

4.8 Making Measurements Using Triggers ........................................................................... 4-35

4.9 Setting the Alarm ............................................................................................................ 4-44

4.10 Setting the GO/NO-GO Judgment (for Triggered Mode) ................................................ 4-48

4.11 Performing Auto Setup ................................................................................................... 4-51

4.12 Starting and Stopping the Measurement ........................................................................ 4-52

vi

IM 720120-61E

Page 8

Contents

Chapter 5 Recording Measured Data

5.1 Recording Measured Data Immediately as the Measurement Is Started (Free Run Mode) ..

5-1

5.2 RecordingMeasuredDatafromaSpeciedTime(FreeRunMode) ............................... 5-6

5.3 Recording Measured Data from When an Alarm Occurs (Free Run Mode) ..................... 5-8

5.4 Recording by Applying External Trigger Signals (in Free Run Mode) ............................ 5-10

5.5 Recording in Triggered Mode ......................................................................................... 5-12

5.6 Recording to Divided Files ............................................................................................. 5-14

Chapter 6 Display

6.1 Setting the Display Conditions ......................................................................................... 6-1

6.2 Operating the Screen ....................................................................................................... 6-6

6.3 Expanding and Reducing Waveforms ............................................................................ 6-14

6.4 Displaying the Measured Data That Has Been Saved (Excluding the /XV0 Option) ...... 6-16

6.5 Starting Xviewer (Excluding the /XV0 Option) ................................................................ 6-17

6.6 Displaying the Alarm Log (Free Run Mode) ................................................................... 6-18

6.7 Accumulating Waveforms and Displaying Snapshots .................................................... 6-20

6.8 Setting Marks ................................................................................................................. 6-22

6.9 Displaying X-Y Waveforms ............................................................................................. 6-24

Chapter 7 Analysis

7.1 Reading Measured Values Using Cursors........................................................................ 7-1

7.2 Computing Waveform Parameters (Triggered Mode)....................................................... 7-3

1

2

3

4

5

6

7

Chapter 8 Saving, Loading, and Transferring Data

8.1 Saving and Loading Measured Data ................................................................................ 8-1

8.2 Saving and Loading Setup Data ....................................................................................... 8-3

8.3 Saving the SL1000’s Data to Your PC .............................................................................. 8-4

8.4 Averaging and Saving History Data.................................................................................. 8-6

8.5 Saving Computed Data .................................................................................................... 8-8

8.6 Saving Waveform Screen Captures ................................................................................. 8-9

8.7 Transferring Files between the SL1000s and the PC ..................................................... 8-10

Chapter 9 Other Functions

9.1 Synchronizing the Clock with Your PC ............................................................................. 9-1

9.2 Automatically Merging Recorded Files (Only during synchronous operation) .................. 9-2

9.3 Setting the Software Start-up Options and Exit Options .................................................. 9-3

9.4 Adjusting the LCD ............................................................................................................ 9-5

9.5 Performing a Self-Test ...................................................................................................... 9-6

9.6 Display the SL1000 Information ....................................................................................... 9-8

9.7 Displaying the SL1000 System Information ..................................................................... 9-9

9.8 Locking the Keys on the SL1000 .................................................................................... 9-10

9.9 Initializing the SL1000 Settings .......................................................................................9-11

9.10 Calibrating the SL1000 ................................................................................................... 9-12

9.11 Specifying Communication Settings on SL1000s on the Network (Option) ................... 9-13

9.12 Displaying the Operating Status, Showing and Hiding the Toolbar and Status Bar, and

Undocking the Menu Bar and Toolbar ............................................................................ 9-14

9.13 Displaying the Software Version ..................................................................................... 9-15

8

9

10

11

12

App

Index

IM 720120-61E

vii

Page 9

Contents

Chapter 10 File Operation

10.1 Starting and Exiting the File Utility .................................................................................. 10-1

10.2 Common Operations ...................................................................................................... 10-2

10.3 Merging Files .................................................................................................................. 10-8

10.4 Dividing Files ................................................................................................................ 10-12

10.5 Accelerating Waveform Displaying ............................................................................... 10-17

10.6 Converting Waveform Data Files to CSV or Binary Files ............................................. 10-19

Chapter 11 Maintenance

11.1 Troubleshooting ...............................................................................................................11-1

11.2 Messages ........................................................................................................................11-2

Chapter 12 Specications

12.1 Connection to the SL1000 .............................................................................................. 12-1

12.2 Measurement Functions ................................................................................................. 12-1

12.3 Trigger Function ............................................................................................................. 12-2

12.4 Recording Function ........................................................................................................ 12-3

12.5 Functions ........................................................................................................................ 12-4

Appendix

Appendix 1 Number of Data Points and Acquisition Count .................................................. App-1

Appendix 2 Maximum Number of Measured Points and Measuring Time ........................... App-2

Appendix 3 Number of Channels and Measurement Group Sample Rate .......................... App-5

Index

viii

IM 720120-61E

Page 10

PC

Signal to be measured

Chapter 1 What the Acquisition Software Can Do

1.1 Overview of This Software

The Acquisition Software is used to connect to an SL1000 via the USB interface or the

optional Ethernet interface and record and display data that the SL1000 has measured.

The Acquisition Software allows you to do the following:

• Set measurement and record conditions of an SL1000.

• Start and stop measurements on an SL1000.

• Start and stop recording.

• Display waveforms of the measured data, cursor values, and waveform parameters.

• Synchronize the operation of up to eight linked SL1000s.

• Start the Xviewer (accompanying software) and display waveforms of data saved in

the past (excluding the /XV0 option)

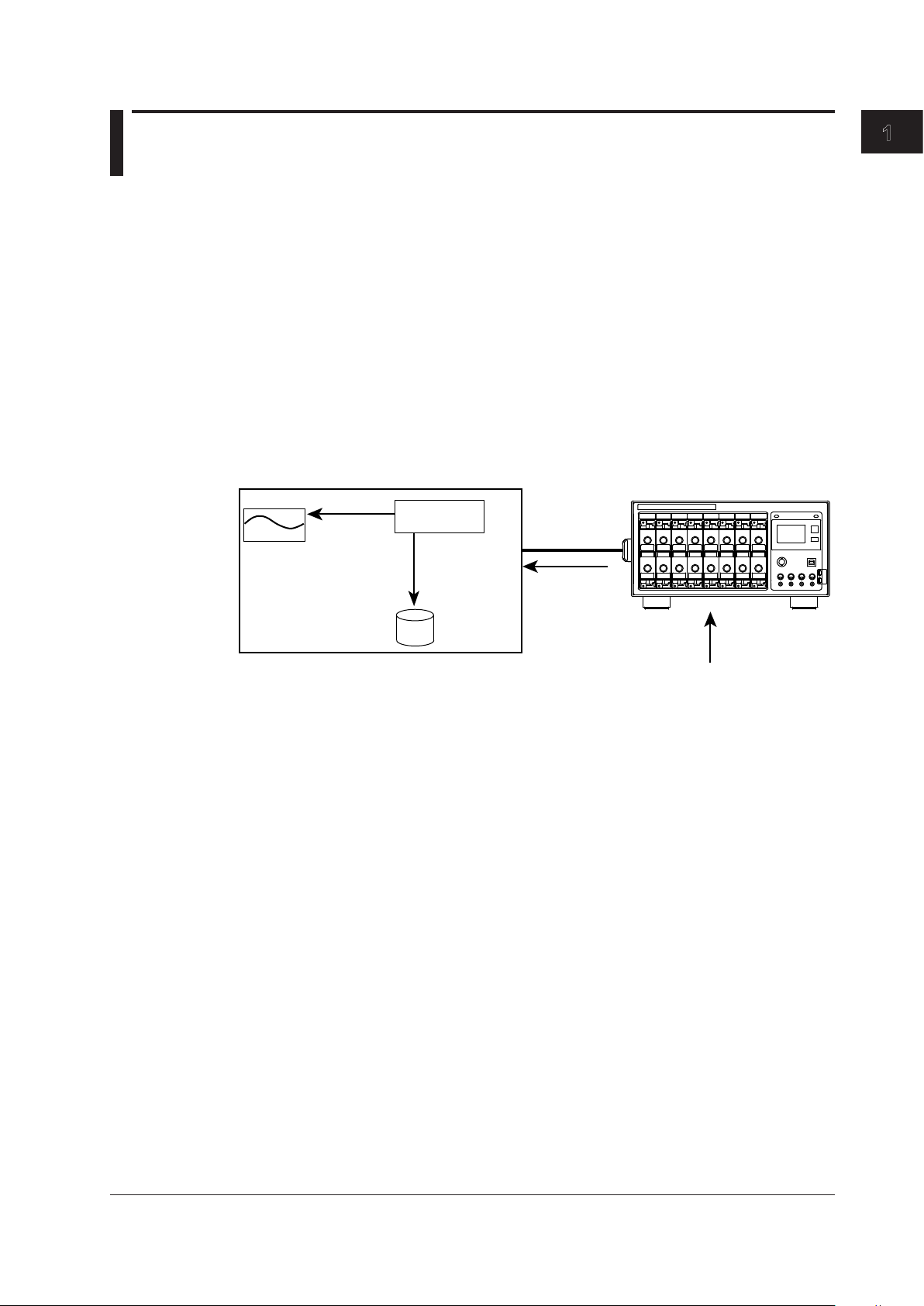

Signal and Data Flow

The signal and data flow between this software and the SL1000 is described below.

Display

Display data

Measured raw data

Current value data

Communication

process

Measured raw data

HDD

Display data

Measured raw data

Current value data

Measurement file

1

What the Acquisition Software Can Do

SL1000

Display Data

P-P compression data that the SL1000 creates for displaying waveforms. The data is

sent to your PC in unit of measuring groups. For a description of display groups, see

section 1.5.

Measured Raw Data

All the measured data that the SL1000 acquired. The data is sent to your PC in unit of

measuring groups to save the data on the hard disk of your PC. For a description of

measuring groups, see section 1.2.

The data is used in data analysis such as cursor measurements and waveform

parameter computations.

Current Value Data

The current values that the SL1000 calculated. The data is sent immediately upon a

request from your PC.

IM 720120-61E

1-1

Page 11

PC

Signal to be measured

1.1 Overview of This Software

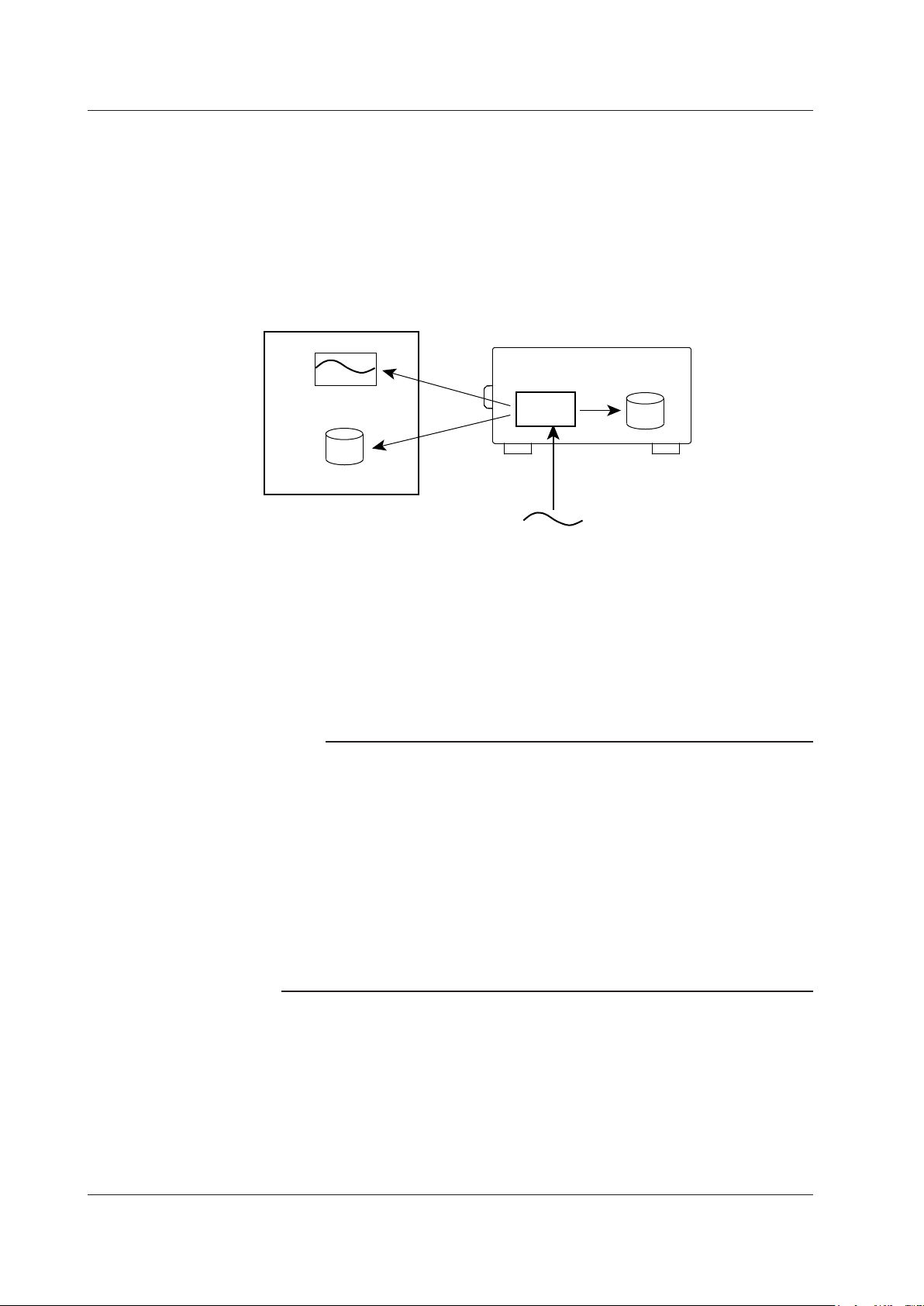

Measurement and Recording

This software refers to the task of acquiring measured data into the internal memory of

an SL1000 as measurement and the task of saving the measured data that has been

acquired to the internal memory of an SL1000 as files on your PC’s hard disk or the

internal hard disk of an SL1000 while making measurements as recording.

The measured data acquired in the internal memory of an SL1000 is cleared when the

power is turn ON/OFF or when measurement is resumed. The waveform screen of this

software displays waveforms of measured data acquired to the internal memory of an

SL1000 after applying P-P compression.

After the measurement stops, all the measured data acquired in the internal memory of

an SL1000 can be saved as a single file on your PC. This task is referred to as saving

not recording in which data is saved while the measurement is in progress.

Connecting to an SL1000

The USB can be used to connect your PC directly to an SL1000 or the optional Ethernet

interface can be used to connect to an SL1000 over the network.

Only a single SL1000 can be connected to a single PC.

Note

• Remove the USB or Ethernet cable that is connecting the SL1000 to the PC only after you

have exited the Acquisition Software or after you have disconnected the communication

between the SL1000 and the PC.

• In the default setting of the SL1000, the DHCP function is turned ON. You can immediately

connect an SL1000 to your PC by connecting the SL1000 to a network with a DHCP server.

• An exclusive driver is necessary to connect using the USB. If an SL1000 is connected

to your PC via the USB, an installation wizard starts. Install the driver according to the

instructions on the screen. For details, see section 2.3, “Installing the USB Driver.”

• You cannot connect both Ethernet and USB interfaces simultaneously to an SL1000.

You cannot connect to the SL1000 that this software is connected to via USB, using the

accompanying Xviewer (excluding /XV0) application nor using FTP.

• When connecting an SL1000 to the PC, disable the PC standby mode. If it is enabled, the

connection between the SL1000 and the PC may be disconnected.

Display

HDD

Record

Memory

SL1000

Record

HDD

Measure

1-2

IM 720120-61E

Page 12

Trigger sources and alarm sources can be combined between units (using AND or OR logic).

1.1 Overview of This Software

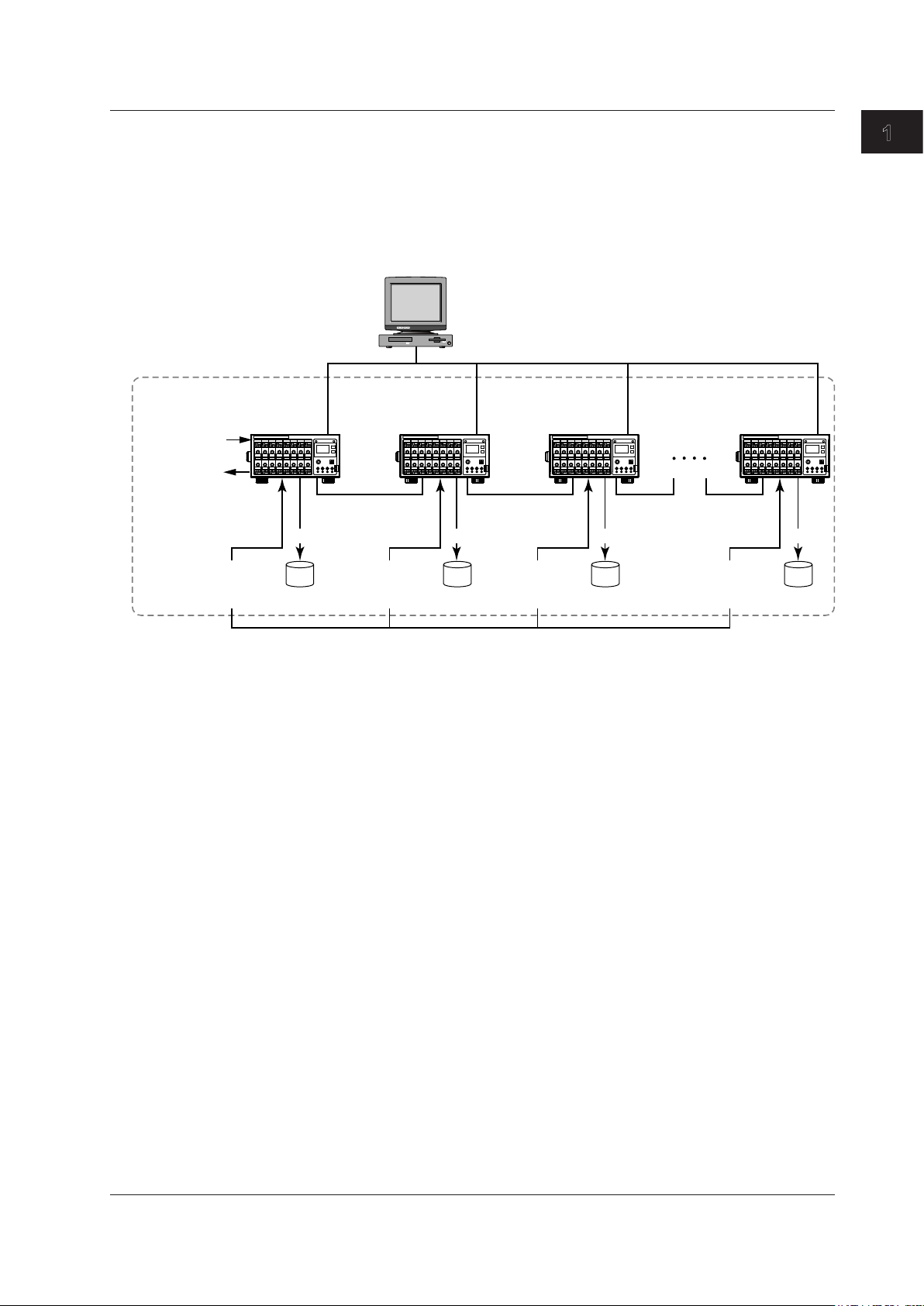

Synchronous Operation

You can synchronize the operation of up to eight SL1000s by connecting them using

the following synchronous connecting cable that are sold separately: 720901-01 (1 m in

length) or 720901-02 (3 m in length).

For instructions on how to connect the SL1000s to your PC for synchronous operation

and for details on the sync I/O connectors (SYNC IN and SYNC OUT), see the SL1000

High-Speed Data Acquisition Unit User’s Manual (IM 720120-01E).

Same GROUP ID (0 to F)

• External clock input

• External trigger

input

• Trigger output

• Alarm output

Signal input

(Trigger source,

Alarm source)

Master

UNIT-ID = 0

SYNC

OUT

HDD HDD HDD HDD

PC

Slave #1

UNIT-ID = 1

SYNC

IN

Signal input

(Trigger source,

Alarm source)

USB/Ethernet

SYNC

OUT

Signal input

(Trigger source,

Alarm source)

Slave #2

UNIT-ID = 2

SYNC

IN

SYNC

OUT

1

What the Acquisition Software Can Do

Slave #7

UNIT-ID = 7

SYNC

IN

RecordRecordRecordRecord

Signal input

(Trigger source,

Alarm source)

The external clock input and external trigger input synchronize with the signals from the

master unit. Trigger sources and alarm sources are combined using AND or OR logic

between units, and are transmitted from the master unit’s trigger output and alarm output.

The slave units’ external clock input, external trigger input, trigger output, and alarm

output are invalid.

Synchronized Items

• Measurement and recording start and stop

• Clock

Slave units synchronize to the master unit’s external or internal clock.

• Time (The time of the slave unit is synchronized with the time of the master unit.)

• Triggering

The AND or OR logic of the master unit’s external trigger input and slave units’ trigger

sources.

When the SL1000 triggers, the trigger signal is transmitted from the master unit’s

trigger output.

• Alarms

The AND or OR logic of the slave units’ channel alarm conditions or the OR logic of

the slave units’ system alarm conditions.

When an alarm occurs, an alarm signal is transmitted from the master unit’s alarm

output.

• Detection of sync cable disconnection and of units powering-off

IM 720120-61E

1-3

Page 13

Set the repeat conditions (for Free Run mode, sections 5.1 to 5.4)

1.1 Overview of This Software

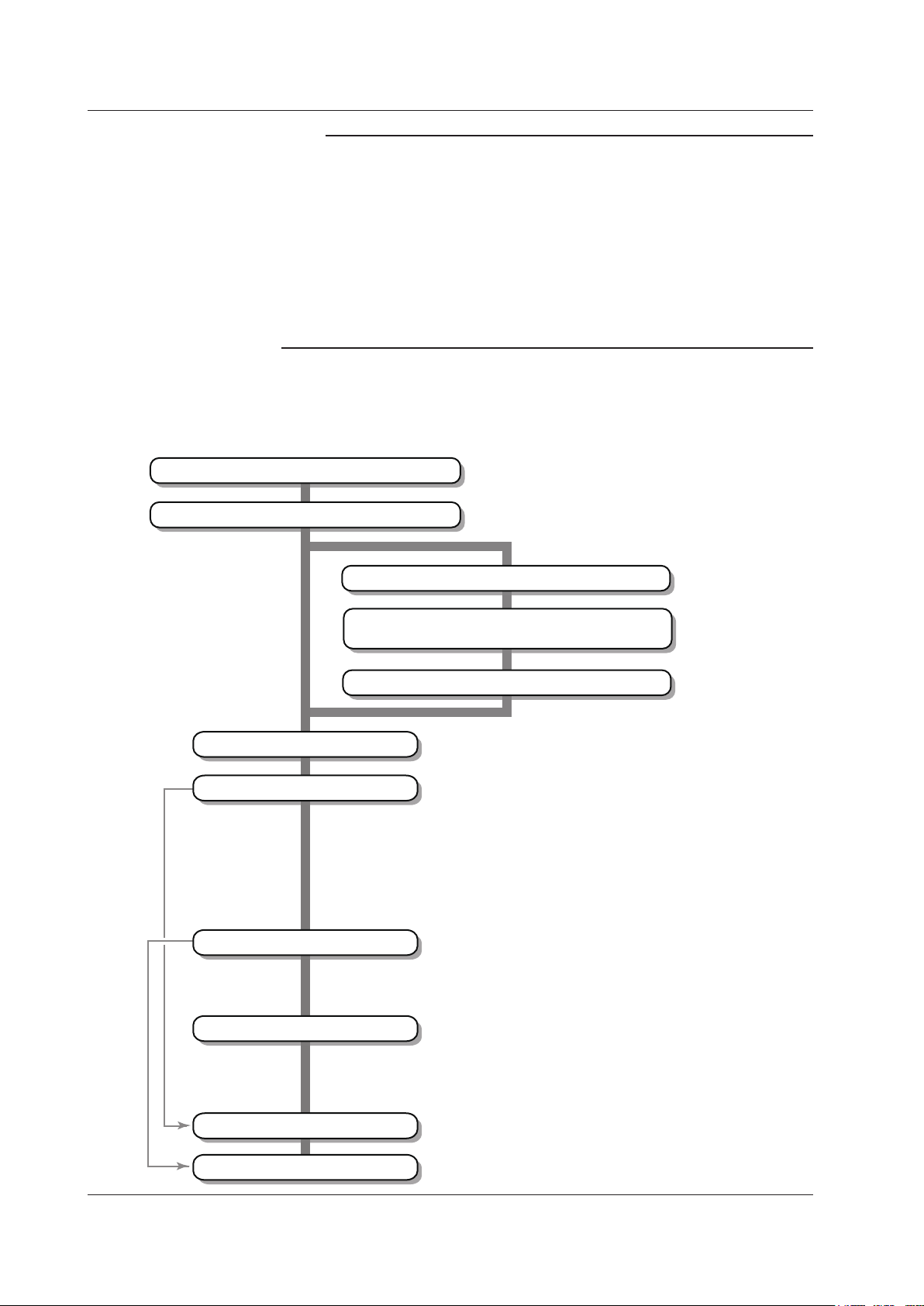

Workflow

The workflow to make measurements using the Acquisition Software varies depending

on whether it is the first time that you are connecting to the SL1000.

If Connecting to the SL1000 for the First Time

Note

• You cannot specify Single (N) of Triggered Mode.

• You cannot set the auto recording destination to PC HDD+Unit HDD.

• You cannot set the GO/NO-GO judgment output.

• When the save destination is set to Unit HDD, the recording files are saved to each unit’s

hard disk.

• To perform synchronous operation, set the master and slave units to the same group ID (from

0 to F). Set the master unit’s unit ID to 0, and slave units’ unit IDs in ascending order from

1 to 7. For details, see section 4.1 in the SL1000 High-Speed Data Acquisition Unit User’s

Manual (IM 720120-01E).

• Connect or disconnect the synchronous connecting cable only after (1) you have exited the

Acquisition Software or disconnected the communication between the SL1000 and PC and (2)

you have turn the SL1000 off.

Connect to the SL1000 via the USB

Install the USB driver

Connect via the USB

Set the communication parameters (TCP/IP)

Set the connection method to Ethernet on

the Connection & Group Settings screen

Connect to the SL1000 via the Ethernet network

Configure the system

Set the measurement conditions

Set the record conditions

(IM 720120-01E, a separate manual)

(section 2.3)

Connect via the Ethernet network (option)

(section 3.2)

(section 3.4)

(IM 720120-01E, a separate manual)

Set the measuring group

(Register the channels that will acquire measured data)

Set the measuring mode (section 4.1)

Set the acquisition mode (sections 4.1 and 4.8)

Set the clock source (sections 4.1 and 4.7)

Set the sample rate and sample interval (sections 4.2 to 4.6)

Set the measuring range, input coupling, and the like

(section 4.2 to 4.6)

Set the external clock (section 4.7)

Set the trigger (section 4.8)

Set the alarm (section 4.9)

Set GO/NO-GO (section 4.10)

Set the recording destination (chapter 5)

Set the recording start/stop conditions

(for Free Run mode, sections 5.1 to 5.4)

1-4

Set the display conditions

Start measurement

Start recording

Set file information (chapter 5)

Set the display group (section 6.1)

(Register the channels to be displayed on a waveform screen)

Set the scale (section 6.1)

Set the zone (section 6.1)

Set the waveform color and thickness (section 6.1)

Set the vertical and horizontal axes (section 6.1)

IM 720120-61E

Page 14

(IM 720120-01E, a separate manual)

1.1 Overview of This Software

If Reconnecting to the SL1000

Connect to the SL1000

Start the Acquisition Software

When the SL1000 is started with the

previous setup file (section 9.3)

Change the settings as necessary

Start measurement

1

What the Acquisition Software Can Do

(section 2.2)

When making measurements by changing

the measurement conditions

Configure the system

Set the measurement conditions

Set the record conditions

Set the display conditions

Start measurement

Start recording

* For details on each setup item, see the operation flow diagram “Connecting to the SL1000 for

the First Time.”

Start recording

IM 720120-61E

1-5

Page 15

1.1 Overview of This Software

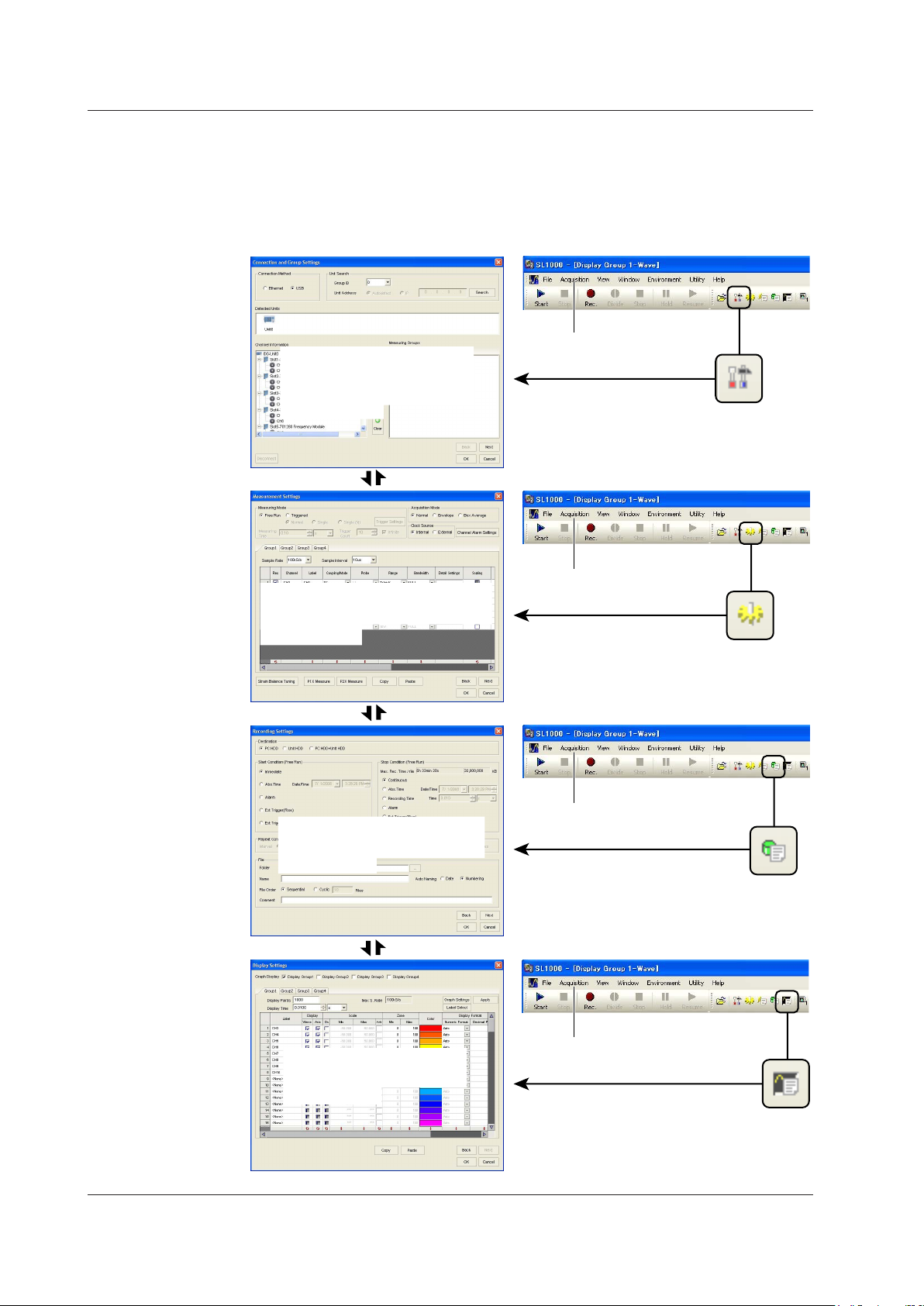

Setup in Wizard Format

The basic setup consisting of connection and group settings, measurement settings,

recording settings, and display settings can be specified easily using dialog boxes in

wizard format. You can also specify the connection and group settings, measurement

settings, recording settings, and display settings individually using the toolbar or menu

bar.

Acquisition menu

Connection & Group

Settings screen

For the operating procedure,

see chapter 3.

[NEXT]

[Back]

Acquisition menu

Measurement Settings screen

For the operating procedure,

see chapter 4.

[NEXT]

[Back]

Acquisition menu

Recording Settings screen

For the operating procedure,

see chapter 5.

1-6

[NEXT]

[Back]

Display Settings screen

For the operating procedure,

see chapter 6.

Acquisition menu

IM 720120-61E

Page 16

1.2 Connection & Group Settings

Unit ID = 0 Unit ID = 1 Unit ID = 7 Unit ID = 0 Unit ID = 1 Unit ID = 7 Unit ID = 0 Unit ID = 1 Unit ID = 7

Connection Method

Select USB or Ethernet for the interface used to communicate the SL1000. This software

can communicate with the SL1000 that is connected to the selected interface.

The Ethernet interface can be used on an SL1000 with the /C10 option.

Searching for an SL1000

Search for an SL1000 that is to communicate with your PC.

If connected using the USB, you can search for an SL1000 by specifying a group ID.

If connected using the Ethernet interface, you can search by specifying a group ID and

IP address.

Group ID

A number assigned to the SL1000. Group IDs are used to identify different SL1000s

connected to the network.

There are 16 group IDs: 0 to 9 and A to F.

You can also search for an SL1000 without specifying a group ID.

To perform synchronous operation, set the master and slave units to the same group ID.

Unit ID

A number assigned to the SL1000.

The unit ID cannot be specified when searching.

To perform synchronous operation, set the unit ID of the master unit to 0, and the unit ID

of the slave units to 1 to 7 in ascending order.

1

What the Acquisition Software Can Do

PC

USB/Ethernet

Group ID = 0 Group ID = 1 Group ID = F

SL1000 SL1000 SL1000

master

slave slave

master

slave slave

SL1000 SL1000 SL1000SL1000 SL1000 SL1000

master

slave slave

For details on the group ID and unit ID, see the SL1000 High-Speed Data Acquisition

Unit User’s Manual (IM 720120-01E).

IP Address

You can search by specifying an IP address assigned to the SL1000.

IM 720120-61E

1-7

Page 17

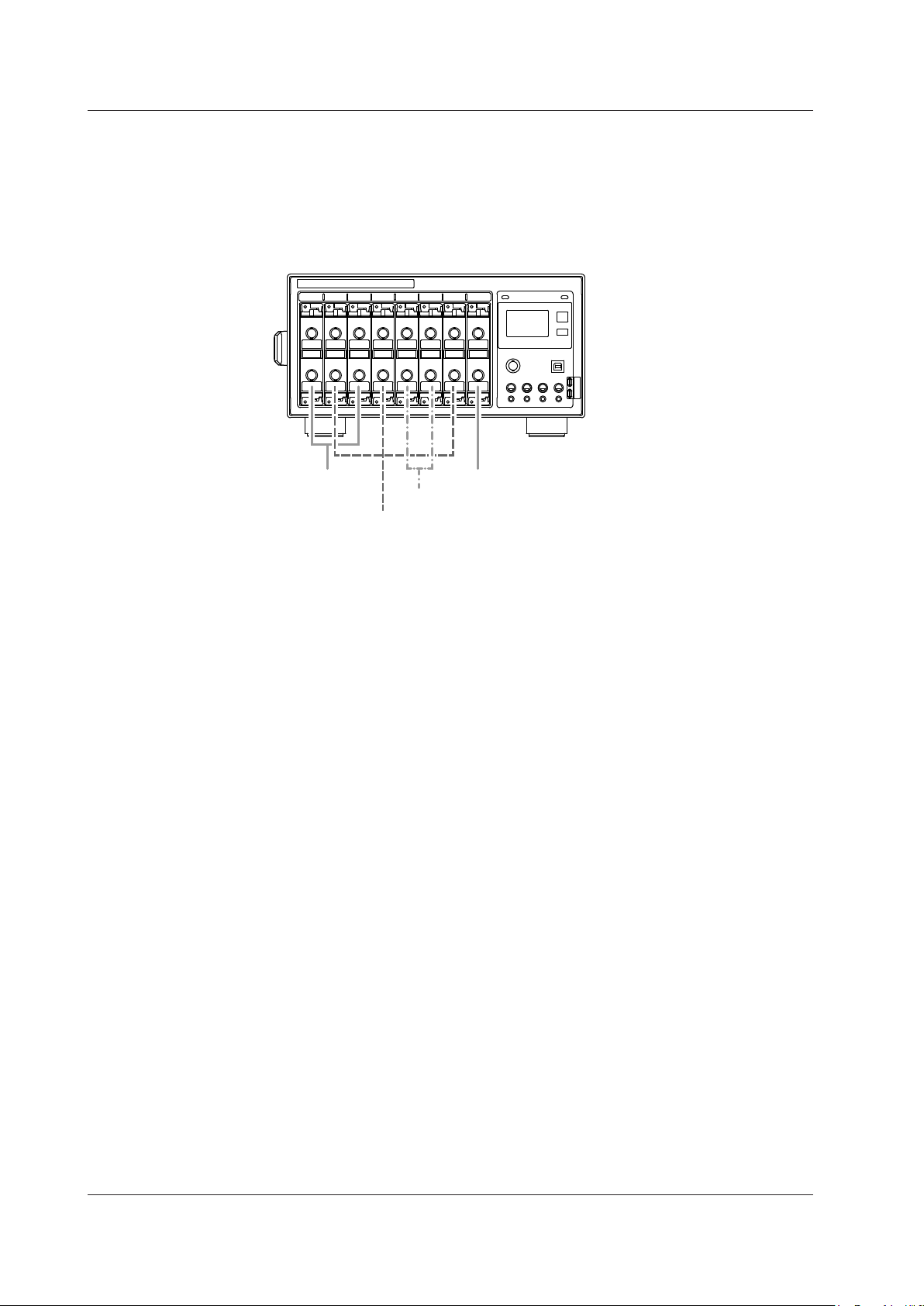

SL1000

Measuring group 1

Measuring group 2

1.2 Connection & Group Settings

Measuring Groups

Modules installed in a connected SL1000 are registered to measuring groups according

to the sample rate used to make measurements. Up to four measuring groups can be set

up.

Measurement is performed only on modules that are registered to measuring groups.

Below is an example of how modules can be registered to measuring groups.

Measuring group 4

Measuring group 3

1-8

IM 720120-61E

Page 18

1.3 Measurement Settings

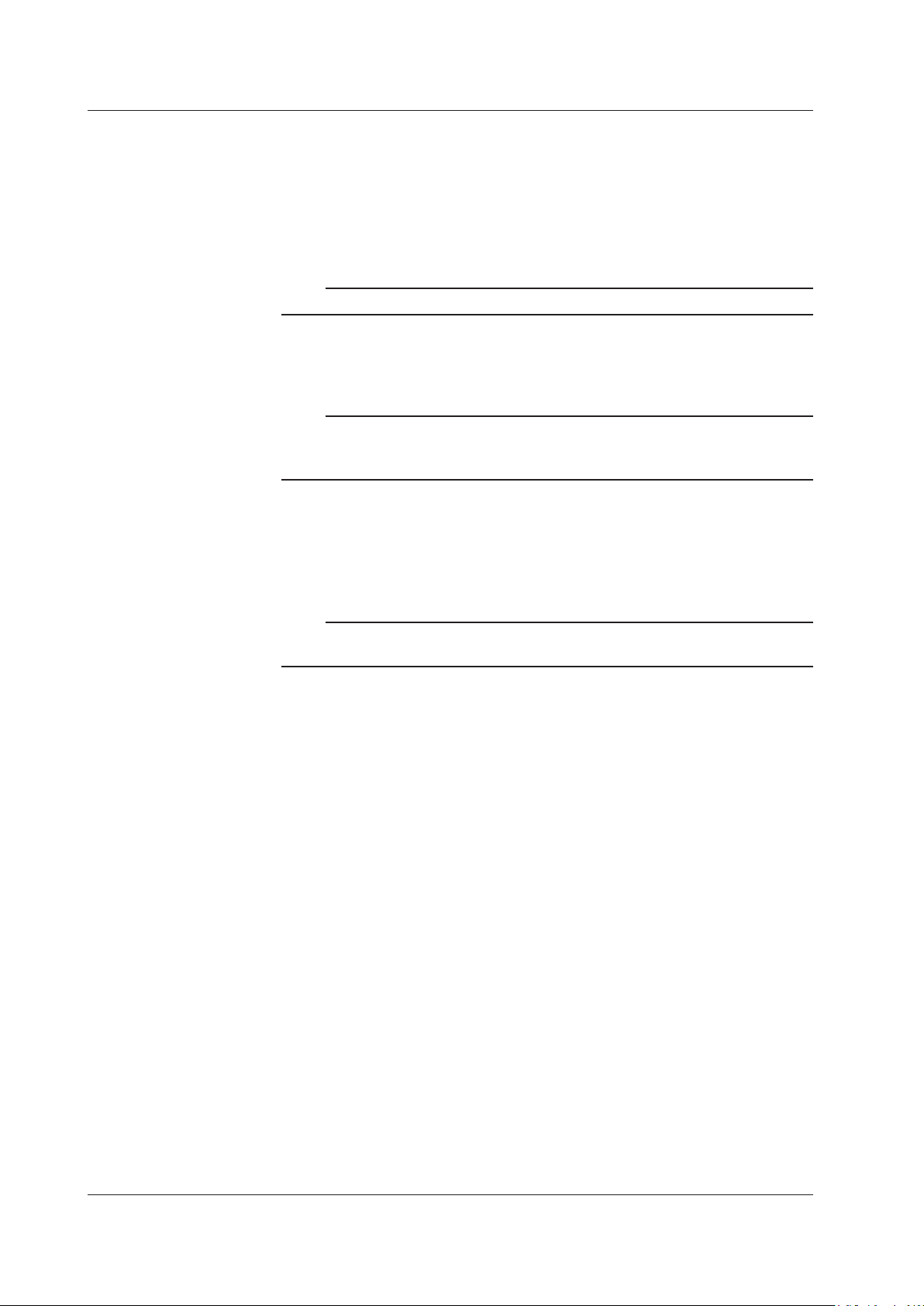

Normal mode

Envelope mode

Measurement points at the maximum sample rate of the module

Maximum value

Measuring Mode

There are two measuring modes: Free Run and Triggered.

Free Run Mode

Data is acquired immediately upon starting a measurement. The SL1000 continues to

acquire data until the measurement is stopped.

The measured data can also be recorded to the hard disk of the SL1000 or your PC at a

specified time or when an alarm occurs.

The following functions are not available in Free Run mode.

• GO/NO-GO function

• Automated measurement of waveform parameters

• Zoom on a particular section of the waveform

Triggered Mode

After starting the measurement, the SL1000 acquires data when a trigger condition is

met. After acquiring data over the specified measuring time, data acquisition stops. You

can also record the measured data acquired in Triggered Mode to the hard disk of the

SL1000 or your PC.

If Triggered Mode is used, you can perform automated measurement of waveform

parameters and zoom in on waveforms.

For details on triggers, see section 1.6, “Triggering.”

The following functions are not available in Triggered Mode.

• Channel alarm

• Recording start and end condition settings

1

What the Acquisition Software Can Do

Acquisition Mode

Normal Mode

Envelope Mode

When acquiring measured data in the internal memory of the SL1000, it is possible to

perform processing on data and display waveforms based on the processed data. The

following three types of data processing are available.

In this mode, measured data is acquired without special processing.

If measuring at a sample rate lower than the maximum sampling rate of each input

module, the SL1000 samples data at 100 S/s internally, determines the maximum and

minimum values among the measured values over each sample interval at the specified

sample rate, and acquires them as pairs.

This mode is effective when you want to avoid aliasing because the sample rate is

essentially kept high. It is also effective when you want to detect glitches (pulse signals

which rise very fast) or display an envelope of a modulating signal.

Input signal

B

A

b

a

Minimum value

IM 720120-61E

Measurement points at the specified sample rate

1-9

Page 19

Time

Input signal (500 kS/s)

Box averaged data

1.3 Measurement Settings

Box Average Mode

Input modules with a maximum sample rate less than 100 MS/s cannot acquire data

at certain points even if the internal sampling rate is 100 MS/s. The data at points that

cannot be sampled will take on the same value as the previous measured data.

Envelope Mode has no effect if measuring at a sample rate higher than the maximum

sample rate of the input module.

This mode is available on the 701250 (HS10M12), 701255 (NONISO_10M12), 720210

(HS100M12), 720211 (HS100M12), and 720250 (HS10M12). In this mode, the SL1000

determines the moving average of the data sampled at the maximum sample rate and

acquires and displays the resultant data. Box averaging is effective in eliminating small

amounts of noise from the input signal. It can also remove noise from a single-shot

signal.

Clock Source

Internal Clock

The sampling timing of the measured data is controlled using the clock signal (internal

clock) that is generated from the internal time-base circuit of the SL1000.

External Clock

The sampling timing of the measured data is controlled using a clock signal applied

externally. This mode is available when the acquisition mode is set to Normal.

The external clock input is useful for observing a signal whose period varies or for

observing waveforms by synchronizing to the clock signal of the signal being measured.

The maximum frequency that can be used for the external clock varies depending on the

module.

720210, 720211: 5 MHz

701250, 701251, 701255, 720250: 1 MHz

701267, 701270, 701271, 701275: 100 kHz

701281, 720281, 720268: 1 MHz

701261, 701262: 100 kHz when measuring voltage

500 Hz when measuring temperature

701265, 720266: 500 Hz

If an external clock that exceeds the maximum frequency is applied, the data is sampled

at the maximum frequency, and the measured data at times when data cannot be

sampled is set to the same value as the previous sampled data.

When using an external clock, the time axis unit becomes the number of measured

points, not time. Therefore, the measuring time is set and the cursor measurement

values are displayed in terms of the number of measured points.

Voltage

Voltage

• • • •

21

20

• • •

2

• • • •

1

•

a

36

• • • •

Time

b

1-10

IM 720120-61E

Page 20

sample rate of the module

Data that is not actually acquired

Aliasing signal Input signal Sampling point

1.3 Measurement Settings

Sample Rate and Sample Interval

You can set the sample rate or sample interval for each measuring group.

The sample rate (the number of samples per second in unit of S/s) is related to the

sample interval as follows:

Sample rate = 1/sample interval

The maximum sample rate varies depending on the module. If you set a sample rate that

exceeds the maximum sample rate of a module, data cannot be acquired at the specified

sample rate. The data at times when data cannot be acquired is set to the same value as

the previous acquired data.

Note

If the sample rate of measuring group 1 is set to 50 MS/s, 5 MS/s, 500 kS/s, 50 kS/s, 5 kS/s,

500 S/s, or 50 S/s, the sample rate of other groups cannot be set to the next lower sample rate.

For example, if the sample rate of measuring group 1 is set to 500 kS/s, the sample rate of

other measuring groups cannot be set to 200 kS/s (the next lower sample rate).

1

What the Acquisition Software Can Do

Input signal

Measured data

Data that is actually acquired

Sampling timing at the specified

sample rate

Sampling timing at the maximum

The SL1000 can display waveforms correctly for frequencies less than one-half the

sample rate as defined by the Nyquist sampling theorem.*

* If the sample rate is comparatively low with respect to the input signal frequency,

the harmonics contained in the signal are lost. In this case, some of the harmonics

will appear at low frequencies due to the effects described by the Nyquist sampling

theorem. This phenomenon is called aliasing. You can avoid aliasing by acquiring

waveforms with the acquisition mode set to envelope.

IM 720120-61E

1-11

Page 21

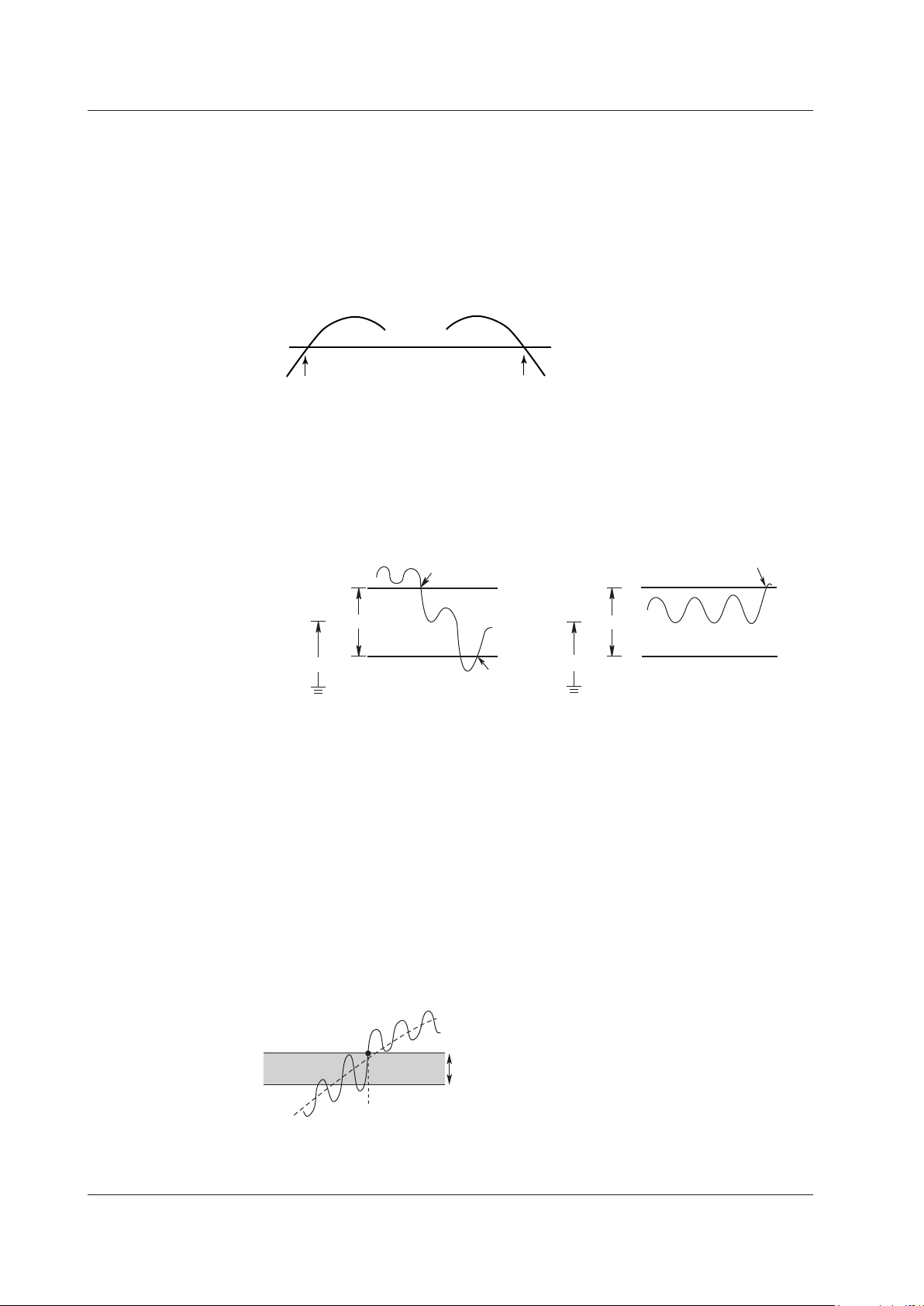

terminal

DC AC GND

terminal

DC-RMS AC-RMS

1.3 Measurement Settings

Input Coupling

If you want to measure only the amplitude of an AC signal, measurement is easier if the

DC component is removed from the input signal. On the other hand, there are times

when you want to check the ground level or measure the entire input signal (both the DC

and AC components). You can change the input coupling setting to meet your application

needs. By changing this setting, the way in which the vertical control circuit (voltage axis)

receives the input signal is switched. The following types of input coupling are available.

DC

The input signal is directly coupled to the attenuator of the vertical control circuit. Select

DC if you want to measure the entire input signal (DC and AC components).

AC (Only When Measuring the AC Voltage)

The input signal is coupled to the attenuator of the vertical control circuit through

a capacitor. Select AC if you want to measure only the amplitude of the AC signal,

eliminating the DC components from the input signal.

GND

Input signal is coupled to the ground not to the attenuator of the vertical control circuit.

Select GND to check the ground level on the screen.

Input

1 MΩ

Vertical

control

circuit

Input

terminal

1 MΩ

Vertical

control

circuit

Input

terminal

Vertical

control

circuit

TC (Only When Measuring the Temperature)

Select TC if you are measuring the temperature using the 701261 (UNIVERSAL), 701262

(UNIVERSAL (AAF)), 701265 (TEMP/HPV), or 720266 (TEMP/HPV).

DC-RMS

Using the 701267 (HV (with RMS)) or 720268 (HV (with RMS/AAF)), both the DC and AC

components of the signal are converted to rms values and displayed. An RMS conversion

circuit is connected to the vertical control circuit of the same input coupling circuit used

when the coupling is set to DC.

AC-RMS

Using the 701267 (HV (with RMS)) or 720268 (HV (with RMS/AAF)), only the AC

component of the signal is converted to rms values and displayed. An RMS conversion

circuit is connected to the vertical control circuit of the same input coupling circuit used

when the coupling is set to AC.

Input

1 MΩ

Vertical

control

circuit

RMS

conversion

circuit

AD

Input

terminal

1 MΩ

Vertical

control

circuit

RMS

conversion

circuit

AD

ACCL (Only When Measuring Acceleration)

Select ACCL when measuring acceleration on the 701275 (ACCL/VOLT).

1-12

IM 720120-61E

Page 22

1.3 Measurement Settings

Probe Attenuation and Current-to-Voltage Conversion Ratio

For voltage (current) measurement, a probe is normally used in connecting the circuit

being measured to the signal input terminal. Using a probe has the following advantages.

• Prevents disturbing the voltage and current of the circuit being measured.

• Applies the signal with no distortion.

• Expands the measurable voltage (current) range of the SL1000.

When using a probe, the attenuation setting on the SL1000 must be set equal to the

probe attenuation or current-to-voltage conversion ratio so that the measured voltage

(current) can be read directly.

Set the probe attenuation for the accessory probes (sold separately) as follows:

• Isolated probe (700929): 10:1

• Current probe (700937 and 701933): 10 A:1 V

• Current probe (701930 and 701931): 100 A:1 V

• 10:1 Passive Probe for the DL750/DL750P (701940): 10:1

The SL1000 has the following attenuation settings: 1:1, 10:1, 100:1, 1000:1, 1 A:1 V,

10 A:1 V,

accessories (sold separately), set the attenuation ratio on the SL1000 according to the

attenuation of the probe.

2

and 100 A:1 V.3 If you are using a probe other than the ones provided as

1 Output voltage rate: 1 V/A

2 Output voltage rate: 0.1 V/A

3 Output voltage rate: 0.01 V/A

1

What the Acquisition Software Can Do

1

Measuring Range

Bandwidth Limit

Note

Use a probe that matches the input capacity of each module. Otherwise, the capacity cannot

be adjusted.

Set the measuring range according to the input signal.

Select a TC type when measuring temperature.

You can set a upper bandwidth limit on the analog signal for each channel. This allows

you to observe waveforms with noise components above the specified frequency

removed.

IM 720120-61E

1-13

Page 23

Measured value

Scale value

Ground level or

strain balance level

Normal display Inverted display

1.3 Measurement Settings

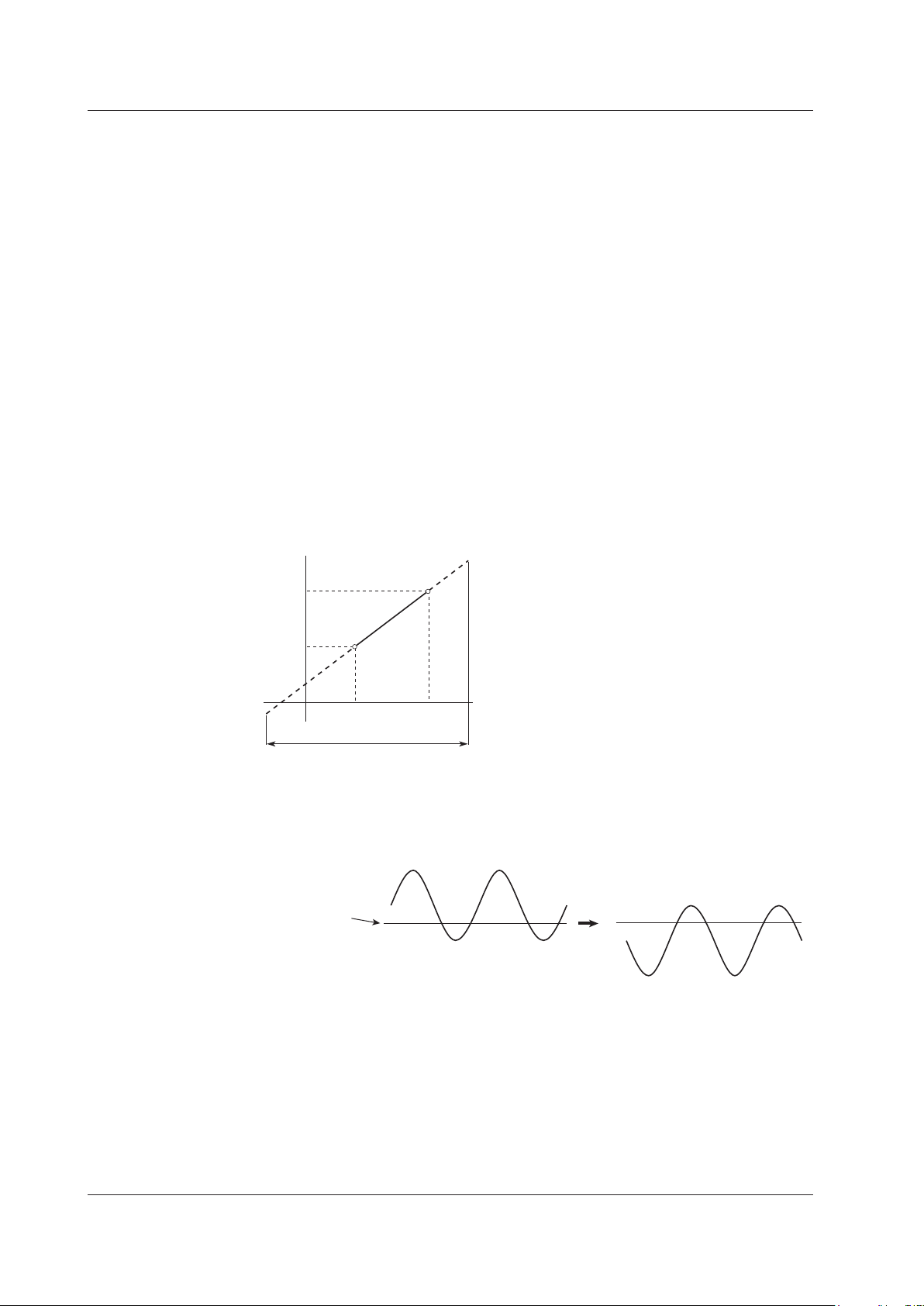

Linear Scaling

The measured data can be scaled to any physical value and displayed.

When measuring the voltage (current), strain, or frequency (number of rotations, period,

duty cycle, power supply frequency, pulse width, pulse integration, and velocity), there

are two methods of linear scaling: “aX+b” and “P1-P2.”

aX+b

The results obtained from the following computation based on the specified scaling

coefficient a and offset b are displayed as cursor measurement values and automated

measurement values of waveform parameters. You can also assign a unit to the result of

linear scaling.

Y = aX + b

P1-P2

Specify arbitrary scale values (P1Y and P2Y) for the measured values of two arbitrary

points (P1X and P2X). The scale conversion equation (y = ax + b) is derived from these

four values.

• Range of measured values (P1X and P2X): –9.99990E+25 to +9.99990E+25

• Range of scaled values (P1Y and P2Y): –9.99990E+25 to +9.99990E+25

• Initial setting of scale values: P1X +0.0000E+00, P1Y +0.0000E+00

P2X +1.0000E+00, P2Y +1.0000E+00

Inversion

y = ax + b

P2Y

P1Y

P1

P1X

Measuring range

P2

P2X

When measuring voltage or strain, the waveform can be displayed with the vertical axis

inverted around the ground level or the strain balance level as shown below.

1-14

IM 720120-61E

Page 24

0

where u(t) is the input signal and T is one period of the input signal.

V

0

V

0

2

1.3 Measurement Settings

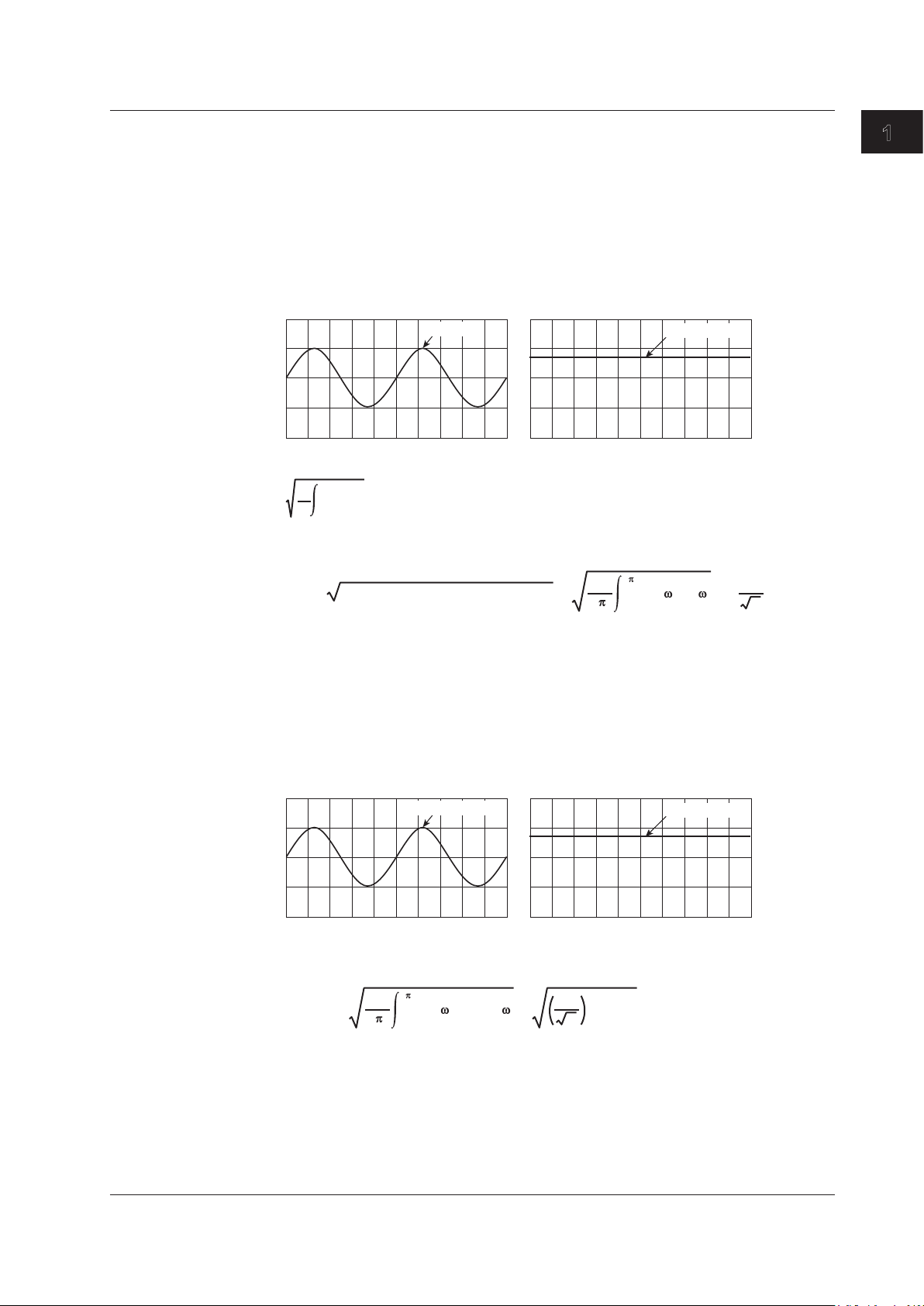

RMS Measurement

If the module is 701267 (HV (with RMS)) or 720268 (HV (with RMS/AAF)), you can

observer the RMS value of the input signal.

AC-RMS

This setting is used when you want to observe only the rms values of the AC signal,

eliminating the DC components from the input signal.

Example

If the rms value of a 2-Vpeak sinusoid input signal is measured, a DC waveform at

approximately 1.4 V is displayed (see right figure).

2 Vpeak

Approx. 1.4 V

The rms value is derived from the following equation:

T

1

u(t)2 dt

T

Givenu(t)=VmsinωtwhereVmisthepeakvalue,ωistheangularvelocity(whichis

equal to 2pf where f is the frequency of the sinusoid signal), the rms value, Vrms, is

2

rms

The average of u(t)2 over one cycle

=

1

= =

(Vmsin t)2 d t

2

Vm

2

1

What the Acquisition Software Can Do

As in the above example, when Vm is 2 V, the rms value, Vrms, is approximately 1.4 V.

DC-RMS

This setting is used when you want to observe the rms values of both the DC and AC

components of the input signal.

Example

If the rms value of a 2-Vpeak sinusoid input signal riding on top of a 1-V DC component

is measured, a DC waveform at approximately 1.7 V is displayed (see right figure).

2 Vpeak + 1 Vdc

Approx. 1.7 V

IftheDCcomponentisexpressedasVdcandtheACcomponentasu(t)=Vmsinωt,the

rms value, Vrms (+DC), of the sinusoid input signal riding on top of the DC component is

derived from the following equation:

2

rms(+DC)

1

= =

(Vmsin t+Vdc)2 d t

2

Vm

2

dc)

(V

+

2

As in the above example, when Vdc is 1 V and Vm is 2 V, the rms value, Vrms (+DC), is

approximately 1.7 V.

IM 720120-61E

1-15

Page 25

1.3 Measurement Settings

Temperature Measurement

Thermocouple Type

The following types of thermocouples are available.

K, E, J, T, L, U, R, S, B, N, W, and Au7Fe

Selectable Temperature Units

You can select °C or K.

Reference Junction Compensation (RJC)

The voltage generated by a thermocouple depends on the temperature of the point of

measurement and the reference junction temperature. In this case, the function used

to compensate the temperature on the measurement instrument to the cold junction is

referred to as reference junction compensation.

You can turn ON/OFF the internal RJC circuit of the SL1000.

ON: Use this setting to enable the reference junction compensation by the internal

OFF: Select this setting when checking the temperature measurement value or when

Burnout

Specify the behavior when the thermocouple input detects a burnout.

ON: Fix the measured value to the upper limit of the measurement range of each

OFF: Not detect burnouts.

RJC circuit.

using an external reference junction (0 °C).

thermocouple if a burnout is detected.

1-16

IM 720120-61E

Page 26

1.3 Measurement Settings

Strain Measurement

You can measure strain by connecting a strain gauge bridge (bridge head) or a strain

gauge transducer to the strain module (701270 (STRAIN_NDIS) or 701271 (STRAIN_

DSUB)).

Relationship between the Strain (μSTR) and the Transducer Output (mV/V)

TheSL1000allowstheunittobechangedbetween“thestrainunit(μSTR:×10

and “the output unit of the strain gauge transducer (mV/V)

(μSTR).”ThefollowingrelationshipexistsbetweenμSTRandmV/V.

(mV/V)=0.5×(μSTR)/1000

Example

500(μSTR)→0.5×500(μSTR)/1000=0.25(mV/V)

Gauge Factor If mV/V Is Selected

K = 2

You can set the gauge factor to any value on the SL1000. However, if there are no

specifications on the strain gauge transducer, set K to 2.

If K is not 2, e is derived in the SL1000 using the following equation.

e=(4/K)×(V/E)

If you switch the unit, the unit of all related parameters of the channel is switched

accordingly.

• Scale

• Trigger level

• Values of automated measurement of waveform parameters and cursor

In addition, the 701271 (STRAIN_DSUB) supports shunt calibration.

For a description of the basic defining equation of strain and shunt calibration, see the

SL1000 High-Speed Data Acquisition Unit User’s Manual (IM 720120-01E)

–6

1

.” The default setting is “strain

e: Measured value of the strain gauge transducer [mV/V]

V: Voltage measured on the bridge [V]

E: Voltage applied to the bridge [V]

K: Gauge factor

measurements, etc.

2

1 The unit corresponding to the output of the strain gauge transducer. A value expressing

the transducer output per volt applied to the bridge in mV. You can set the bridge voltage

(excitation: voltage applied to the bridge) from 2 V, 5 V, and 10 V on the SL1000. However,

since the mV/V value is a converted value, the measured value is basically constant.

2 Shunt calibration refers to the act of correcting the gain of the strain measurement by

connecting a known resistance (shunt calibration resistance) to the strain gauge in parallel.

1

What the Acquisition Software Can Do

strain)”

IM 720120-61E

1-17

Page 27

1.3 Measurement Settings

Acceleration Measurement

The Acceleration Module (with AAF) (701275 (ACCL/VOLT)) measures acceleration

using the output signal from an acceleration sensor. Direction connection is possible to

a built-in amplifier type acceleration sensor. (A charge output type acceleration sensor

that does not have a built-in amplifier cannot be connected directly to the 701275 (ACCL/

VOLT). For details on how to connect acceleration sensors, see the SL1000 High-Speed

Data Acquisition Unit User’s Manual (IM 720120-01E).)

Note

The 701275 (ACCL/VOLT) can also measure voltage.

Current Supply to Acceleration Sensors

The 701275 (ACCL/VOLT) can supply 4 mA of current to the acceleration sensor when

measuring acceleration.

Note

If you supply current to the acceleration sensor before it is connected to the item under

measurement, the internal circuit of the acceleration sensor may be damaged. Be sure to

supply current after connecting the acceleration sensor.

Filter

If you set the bandwidth limit to Auto, the anti-aliasing filter (AAF) and low-pass filter are

enabled depending on the sample rate to eliminate high-frequency noise from the input

signal. Using the anti-aliasing filter when measuring voltage allows elimination of aliasing

noise. For details on the bandwidth limit, see section 4.2.

Note

The filter is effective not only during acceleration measurement but also during voltage

measurement.

1-18

IM 720120-61E

Page 28

Tw(s)

F(Hz)

Nr: The number of

pulses per rotation

Tw(s)

Tw(s)

Thigh(s)

Tlow(s)

1.3 Measurement Settings

Frequency Measurement

The Frequency Module (701281 (FREQ) or 720281 (FREQ)) measures frequency,

number of rotations, period, duty cycle, power supply frequency, pulse width, pulse

integration, and velocity.

Measured Item

Frequency

Frequency F (Hz) = 1/Tw (s)

Measurable range: 0.01 Hz to 500 kHz

RPMs/RPSs

RPMs=Frequency(Hz)/thenumberofpulsesperrotation(Nr)×60

Measurable range: 0.01 rpm to 100000 rpm

RPSs = Frequency (Hz)/the number of pulses per rotation (Nr)

Measurable range: 0.001 rps to 2000 rps

1

What the Acquisition Software Can Do

Period

Period (s) = Tw (s)

Measurablerange: 2μsto50s

Duty

Duty cycle (%) = Thigh (s)/Tw (s) or

Duty cycle (%) = Tlow (s)/Tw (s)

Measurable range: 0% to 100%

Power Supply Frequency

Power supply frequency (Hz) = 1/Tw (s)

Resolution: 0.01 Hz

Measurable range: (50 Hz, 60 Hz, 400 Hz) ±20 Hz

Pulse Width

Pulse width (s) = Thigh (s) or

pulse width (s) = Tlow (s)

Measurablerange: 1μsto50s

Thigh(s)

Tlow(s)

IM 720120-61E

1-19

Page 29

N (count)

Tw(s)

Distance per

pulse (l)

Pulse input stop

Stop prediction

0

1.3 Measurement Settings

Pulse Integration (Distance/Flow Rate)

Pulseintegratedvalue=N(count)×physicalamountperpulse(I)

Set the physical amount per pulse (I) to distance or flow rate.

A suitable user-defined unit can be assigned to the specified physical amount.

Measurablerange: upto2×10

9

counts

Velocity

Velocity(km/h)=Distanceperpulsel(km)/Tw(s)×3600

Velocity (m/s) = Distance per pulse l (m)/Tw (s)

The distance and unit can be defined by the user (angular velocity, etc.).

Measurable range: F (=1/Tw) = 0.01 Hz to 500 kHz

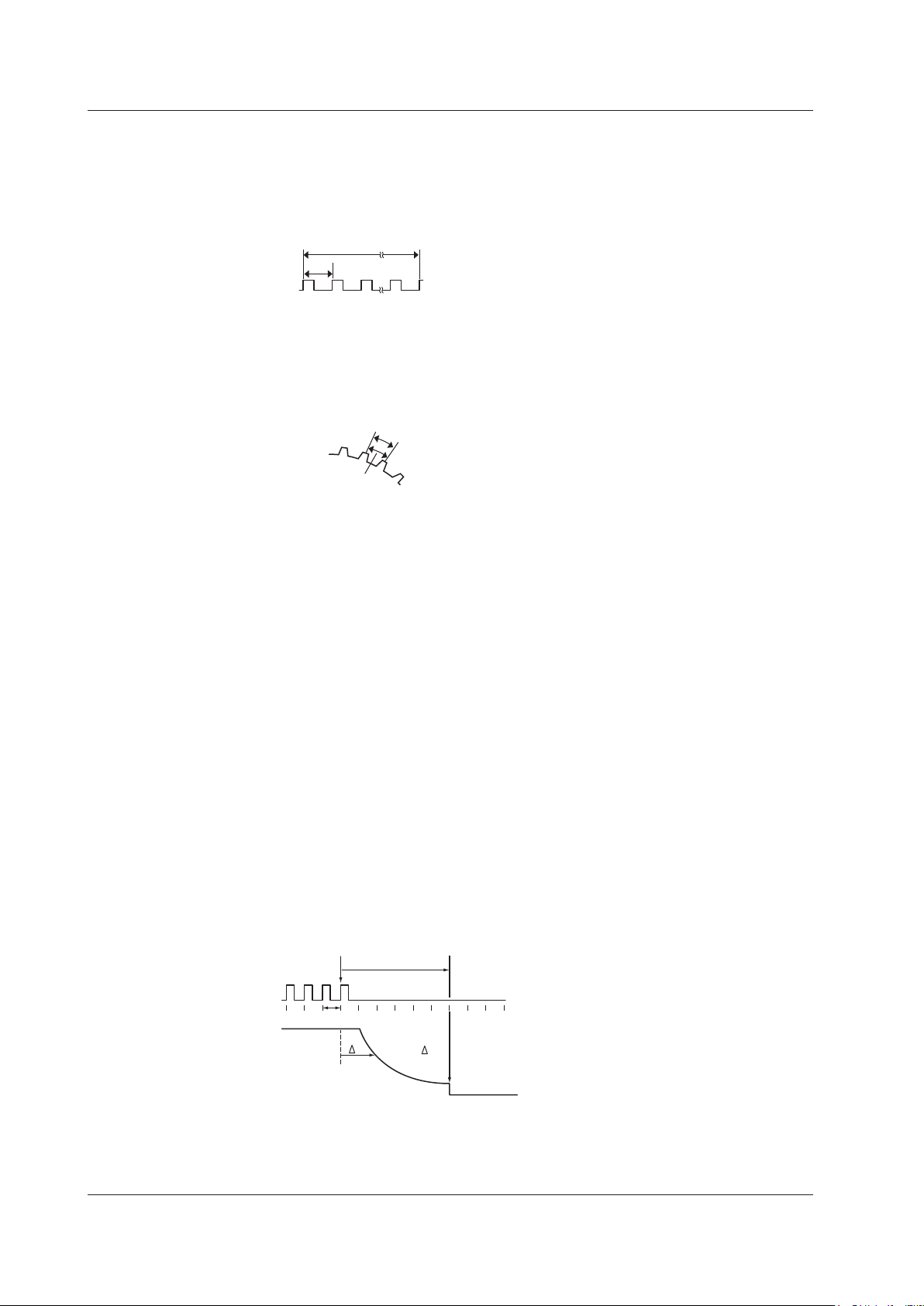

Decelerating Prediction and Stop Prediction

The 701281 (FREQ) or 720281 (FREQ) automatically performs internal computation and

displays waveforms by predicting the deceleration curve and stop point even when the

input pulse is suddenly cut off. This function allows the measurement of waveforms of

deceleration behavior that is close to the actual physical phenomenon in applications in

which the deceleration behavior of an object that have inertia is measured such as in the

brake test of automobiles.

Decelerating Prediction

The deceleration curve is computed according to the following equation using the

elapsed time after the pulse input stops (Δt).

Frequency (f) = 1/period (Δt)

The decelerating prediction starts after a pulse period (T) of the pulse one period

before the pulse input stopped elapses after the pulse input stopped.

l

Stop Prediction

The function determines the stop point at a constant time after the pulse input stops,

and the frequency is set to 0. The time from the point when the pulse input stops to

thepointwhenthefunctiondeterminesthattheobjecthasstoppedcanbesetto×1.5,

×2,×3,...,×9,and×10(10settings)ofthepulseperiod(T)ofthepulseoneperiod

before the pulse input stopped.

1-20

T×n

n: 1.5 to 10

T

f0

Decelerating

prediction

t

f = 1/ t

IM 720120-61E

Page 30

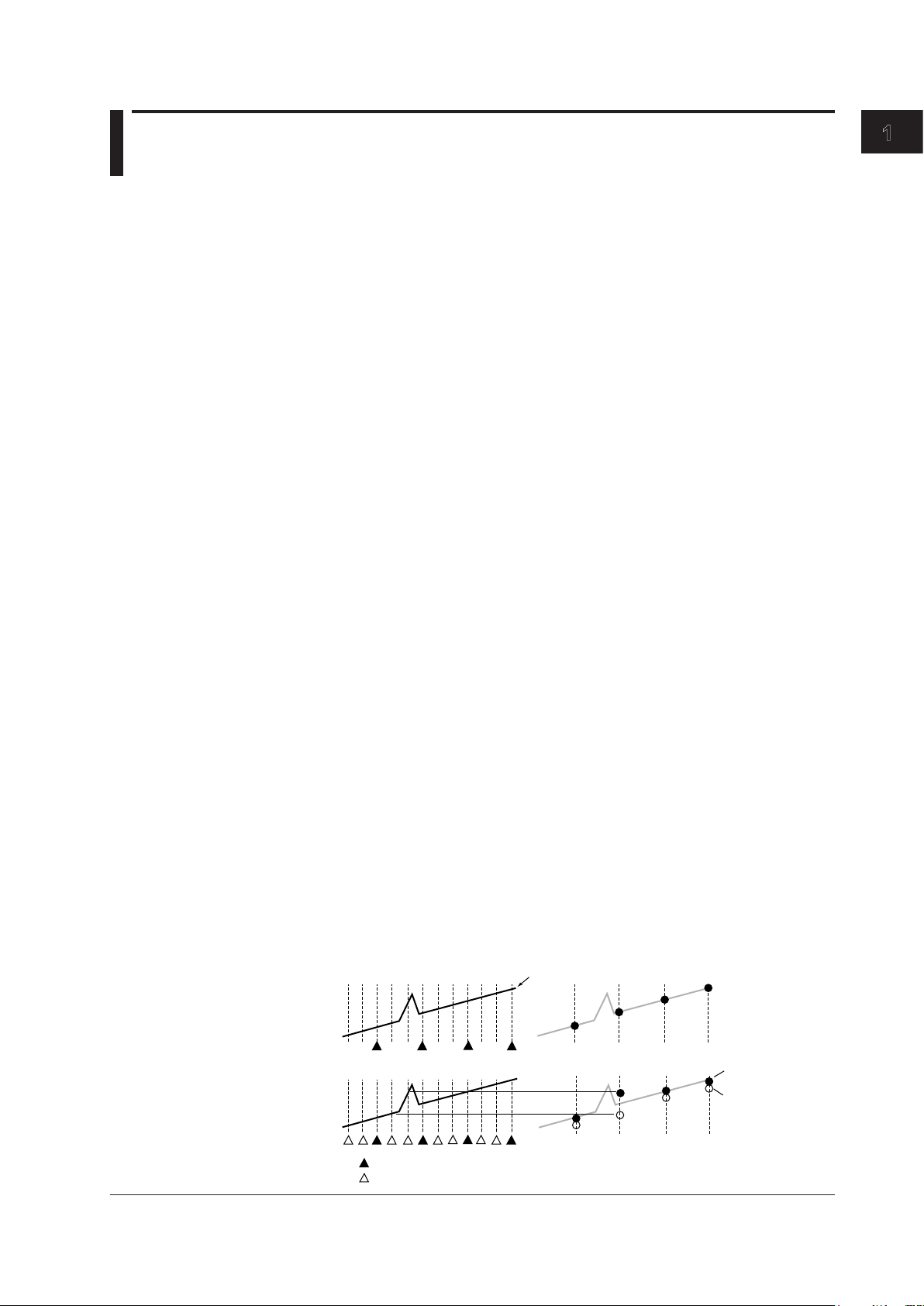

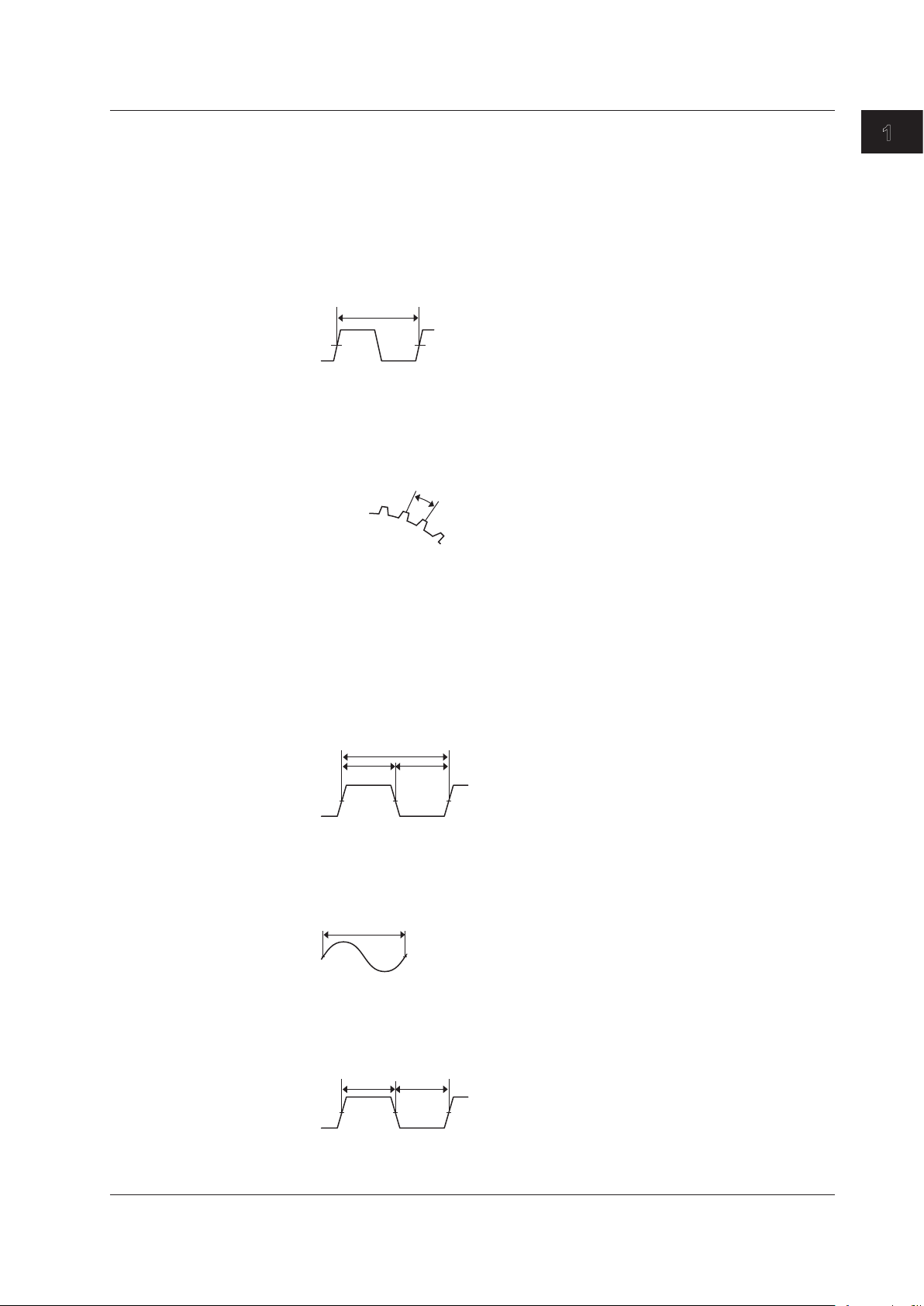

If the smoothing filter is used

If pulse average is used

If pulse average is not used

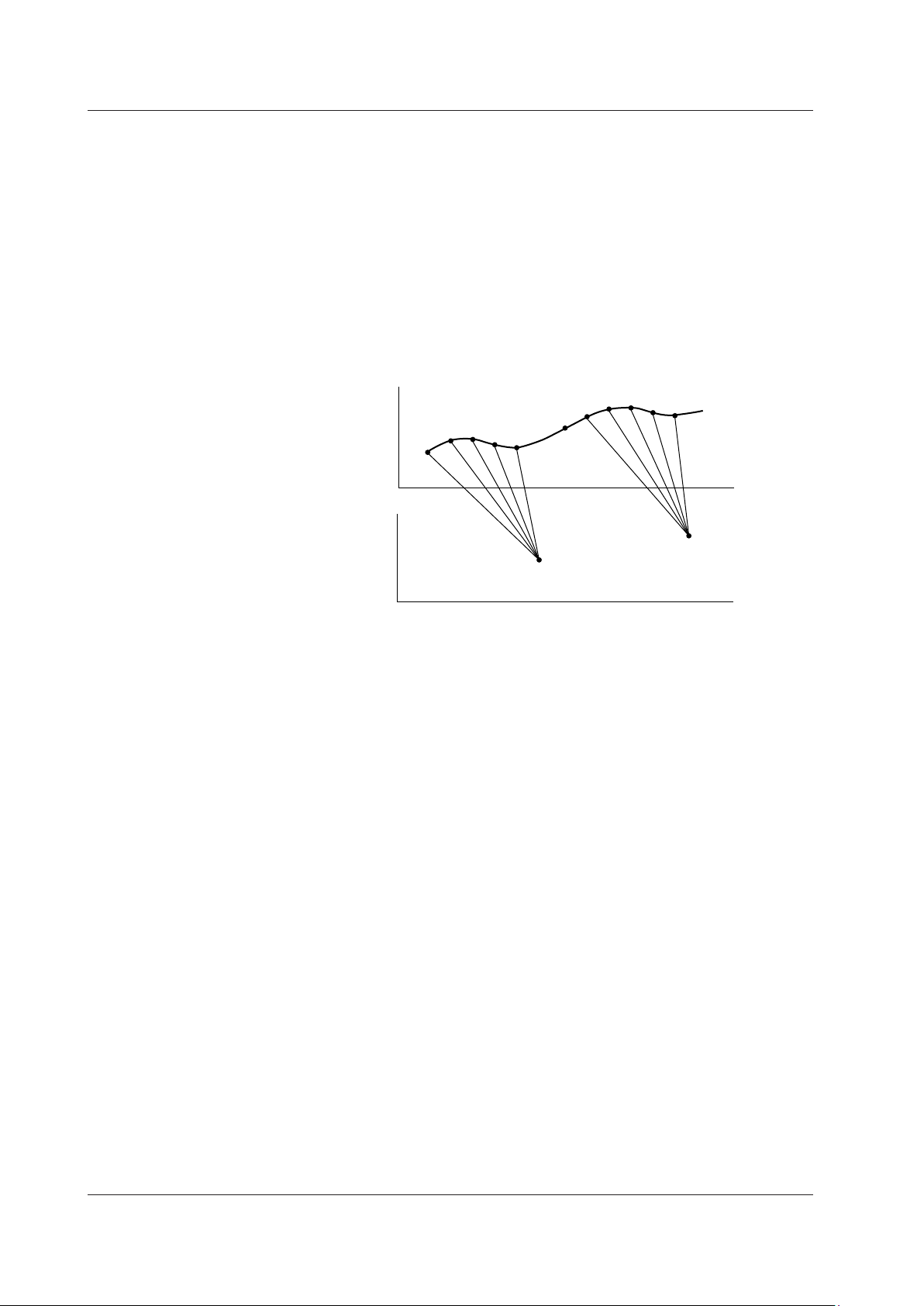

1.3 Measurement Settings

Filter

Smoothing filter (moving average)

The frequency module can display waveforms by taking the moving average of the data

in realtime. The order of moving average can be set in terms of time in the range of 0.0 ms

to 1 s (up to 25000th order). The order of moving average is equal to the specified time

dividedby40μs.

The smoothing filter has the following characteristics.

• Converts a waveform that changes in steps to a smooth waveform.

• Improves the resolution by reducing the measurement jitter. The resolution improves

especially when measuring high frequencies or when expanding the display using the

offset function. Consequently, highly accurate measurements can be made.

• Can be used on all measurement parameters of the frequency module.

Original waveform

1

What the Acquisition Software Can Do

Pulse Average

Measures the input pulse by dividing the pulse by the specified number of pulses (1 to

4096 pulses). The pulse average has the following characteristics.

• If pulse dropouts are present or pulse interval is fluctuating within a period,

measurements can be made by eliminating the effects from the dropout or fluctuation

(fluctuating component of the waveform used to measure the frequency or period).

• The measured result is displayed as a value per input pulse even when pulse average

is used. Therefore, there is no need to perform scaling again.

• Can be used when measuring frequency, number of rotations, period, power supply

frequency, pulse integration, and velocity.

N = 11

f1

f2

f3

Offset Function

The 701281 (FREQ) or 720281 (FREQ) allows you to set the center of observation (offset

value) and expand the area around the offset value for close observation. It allows you to

measure the fluctuation around a certain frequency. You can set an offset value up to 100

times the measuring range (500 kHz maximum).

IM 720120-61E

1-21

Page 31

1.4 Recording Settings

Recording Methods

There are two recording methods. One method is to record automatically according to

the specified conditions (auto recording). The other method is to save the measured

data that has been acquired in the memory of the SL1000 through file operation after the

measurement is finished (saving of waveform data).

Auto Recording

The measured data is automatically recorded to a specified hard disk.

You can select the recording destination from the following three destinations:

• PC HDD: Records to the hard disk of the PC in which this software was installed.

• Unit HDD: Records to the hard disk of the SL1000.

• PC HDD+Unit HDD: Records both to the hard disk of your PC and to the hard disk of

the SL1000.

The free space on the hard disk of your PC and the SL1000 can be displayed on the

screen.

Note

During synchronous operation, you cannot select PC HDD+Unit HDD.

Saving the Waveform Data

The measured data acquired in the internal memory of the SL1000 is saved to your PC.

All the measured data in the memory is saved as a single file.

The data saved to the hard disk of the SL1000 can be copied to the hard disk of your

PC using the accompanying Xviewer (except the /XV0 option) or the FTP function (/C10

option).

Averaging and Saving History Data

The measured data acquired in the internal memory of the SL1000 is averaged and

saved to your PC. From the measured data in the memory, you select the data (up to

5000 waveforms) to average, and the data is saved as a single file.

The saved averaged waveforms can also be displayed on the screen using the

accompanying Xviewer (except the /XV0 option).

Recording Start and Stop Conditions (Auto Recording)

The recording start and stop conditions vary depending on the measuring mode.

In Free Run Mode

You can select the following recording start and stop conditions.

Recording start condition

Immediate: Starts recording as soon as it is ready to record.

Abs.Time: Starts recording at a specified time if it is ready to record.

Alarm: Starts recording when an alarm occurs if it is ready to record.

External trigger: Starts recording when the SL1000 is ready to record and it receives

a recording control signal (edge signal or gate signal) through the

trigger input terminal. (Rise) indicates rising edge trigger, and (Fall)

indicates falling edge trigger.

* The SL1000 will be ready to record if you click the Start Recording button or choose

Start Recording from the Acquisition menu.

1-22

IM 720120-61E

Page 32

1.4 Recording Settings

Recording stop condition

Continuous: Continues to record until recording is manually stopped.

Abs.Time: Continues to record to a specified time.

Recording time: Continues to record for a specified time. When measuring with an

external clock, measurement is performed up to a specified number

of measured points.

Alarm: Continues to record until the alarm is cleared.

External trigger: Stops recording when the SL1000 receives a recording control signal

(edge signal or gate signal) through the trigger input terminal. (Rise)

indicates rising edge trigger, and (Fall) indicates falling edge trigger.

In Trigger Mode

The SL1000 will start measuring or recording if the trigger conditions are met when the

SL1000 is ready to record.

recording will stop. The SL1000 can also start measuring or recording after a given time

elapses from when the trigger condition is met.

* The SL1000 will be ready to record if you click the Start Recording button or choose

Start Recording from the Acquisition menu.

Repeat Condition (Auto Recording)

When recording the measured data repetitively, you can specify the repeat count and the

repeat interval.

*

When a specified measuring time arrives, measurement and

1

What the Acquisition Software Can Do

Record Interval

The record interval can be specified only if the recording start condition is set to

Immediate or Abs. Time and the recording stop condition is Recording Time. You can

specify the time (the number of measured points if measuring using an external clock

signal) from when the recording is started until the next recording is started. This is

available when the measuring mode is set to Free Run.

Record Count

The number of recordings. You can set it if

• The recording stop condition is set to Recording time.

• The recording start and stop conditions are set to Alarm.

• The recording start and end conditions are both External Trigger (Rise) or both

External Trigger (Fall).

The record count is valid when the measuring mode is set to Free Run.

IM 720120-61E