Page 1

User ’s

Manual

Model SKYD (Style S)

Alarm Unit

Yokogawa Electric Corporation

IM 01B04K01-02E

11th Edition

Page 2

Page 3

Contents

Chapter 1 Introduction

1.1 Inspection ............................................................................................................................ 1-2

1.2 Documentation Conventions ............................................................................................... 1-3

1.3 Notice .................................................................................................................................. 1-4

1.4 Compatibility with Previous Models .....................................................................................1-5

Chapter 2 General

2.1 Standard Specifications ......................................................................................................2-2

2.2 Model and Suffix Codes ......................................................................................................2-3

2.3 Accessories ......................................................................................................................... 2-4

1

1

2

2

3

3

App

4

Chapter 3 Installation

3.1 External Wiring .................................................................................................................... 3-2

3.2 Example of Alarm Wiring .....................................................................................................3-3

3.2.1 High-limit and High-high-limit Alarms .....................................................................................3-3

3.2.2 Three-position Alarm .............................................................................................................. 3-3

Chapter 4 Principles of Operation

4.1 Principle of Operation ..........................................................................................................4-1

4.2 Description of Functions ......................................................................................................4-2

4.2.1 SKYD-10x/20x Functions .......................................................................................................4-2

4.2.2 SKYD-30x Functions ..............................................................................................................4-5

4.3 Example of Alarm Function Setting .....................................................................................4-6

4.3.1 Condition of Alarm Function ...................................................................................................4-6

4.3.2 Parameters of Alarm Function ................................................................................................4-6

4.3.3 Operating Condition of Alarm Function ..................................................................................4-6

Chapter 5 Setting

5.1 Names of Components .......................................................................................................5-2

5.2 Setting Jumper .................................................................................................................... 5-3

5.2.1 Check of Setting Jumper and its Location ..............................................................................5-4

5.3 Setting of Parameters .........................................................................................................5-5

5.3.1 Parameter Change Disable Function .....................................................................................5-5

5.3.2 Setting of Parameters Using Display Setter (SKYD-x04) ....................................................... 5-5

5.3.3 Setting of Parameters Using Handy Terminal ........................................................................5-9

5.4 Parameter List ................................................................................................................... 5-10

5.4.1 SKYD-10x Parameter List ....................................................................................................5-10

5.4.2 SKYD-20x Parameter List ....................................................................................................5-14

5.4.3 SKYD-30x Parameter List ....................................................................................................5-19

5

6

7

8

Chapter 6 Maintenance

6.1 Test Equipment ...................................................................................................................6-2

6.2 Check of Input ..................................................................................................................... 6-3

6.2.1 Check for SKYD-10x and SKYD-20x .....................................................................................6-3

6.2.2 Check for SKYD-30x ..............................................................................................................6-4

6.3 Check of Alarm Set Point ....................................................................................................6-5

6.3.1 Check for SKYD-10x and SKYD-20x .....................................................................................6-5

6.3.2 Check for SKYD-30x ..............................................................................................................6-5

6.4 List of Replaceble Parts ......................................................................................................6-6

Chapter 7 Troubleshooting

7.1 Action in Fault Condition. ....................................................................................................7-2

IM 01B04K01-02E

Toc-1

Page 4

Contents

Chapter 8 Power Supply Terminal Connections (Option /TB, /A2TB, and /REK)

8.1 External View and Names of Components .........................................................................8-2

8.2 Power Supply and Ground Wiring ....................................................................................... 8-3

General Specifications

Toc-2

IM 01B04K01-02E

Page 5

Chapter 1 Introduction

Introduction

This manual describes the functions and operations of the SKYD Alarm Unit.

● IntendedReaders

This manual is intended for personnel in charge:

• Installation and wiring

• Instrumentation and setup of the function

• Operation and monitoring of the controller

• Maintenance of equipment

● RelatedDocuments

The following documents all relate to the SKYD Alarm Unit. Read them as necessary.

The codes enclosed in parentheses are the document numbers.

Manual Title Manual No. Description

Rack-Mounted Instruments IM 1B4F2-01E Describes mounting and wiring for the YS80 rack-mounted instruments.

Model JHT200 Handy Terminal IM 77J50H01-01EN Describes operation of JHT200.

1

1

Introduction

IM 01B04K01-02E

1-1

Page 6

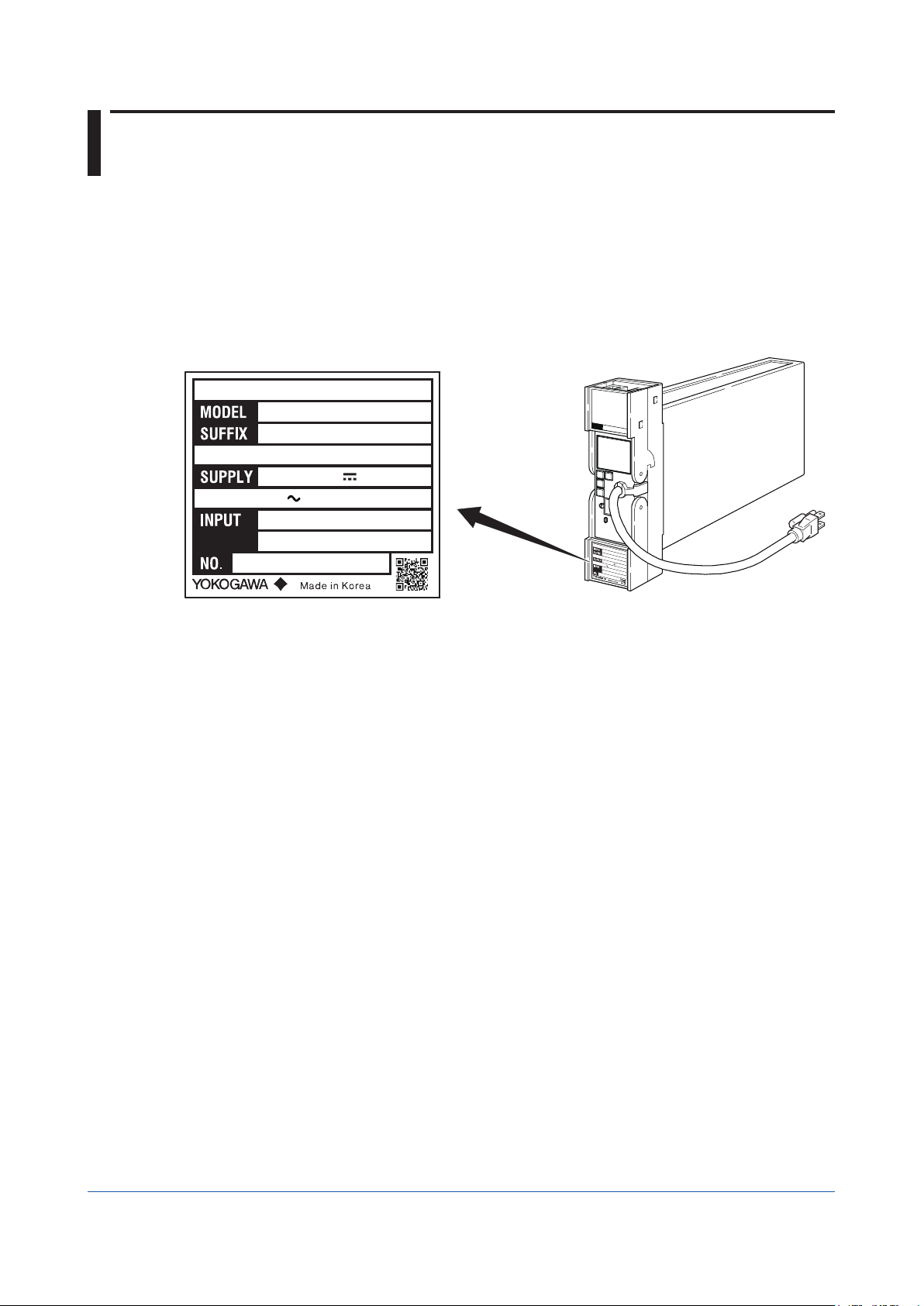

1.1 Inspection

The SKYD alarm unit is shipped only after stringent inspection at the factory. Visually inspect

the product upon delivery to make sure it is not damaged in any way.

Store the box and inner packing material of the package in a safe place / they may be

needed if there is a problem with the product and it needs to be sent back for repair.

Check of Model and Suffix Codes

The model and suffix codes are indicated on the Name plate attached to the front cover of

the instrument. Crosscheck this information with the model and suffix codes of Section 2.2

to ensure that the product is as specified in the order.

ALARM UNIT

SKYD

-204*S

24-110VDC

100-120VAC 50/60Hz

60mA

6.0VA

1-5VDC

ALARM UNIT

SKYD

-204*S

24-110VDC

100-120VAC 50/60Hz

60mA

1-5VDC

XXXXXXXXX

Figure 1-1 Name plate for Thermocouple Input (Description example)

6.0VA

XXXXXXXXX

Confirmation of the Package Contents

Check the package contents against the list below. If anything is missing or damaged,

immediately contact the sales office from which you purchased the product or your nearest

Yokogawa representative.

• SKYD Alarm Unit ..............................................................................................1

• Alarm Label (Parts No.: L4040JA) .....................................................................1

• Precautions on the Use of the YS80 Series ......................................................1

Downloadable Electronic Manuals

You can download the latest manuals from the following website:

http://www.yokogawa.com/ns/ys/

F0101.ai

1-2

IM 01B04K01-02E

Page 7

1.2 Documentation Conventions

This manual uses the following notational conventions

Symbols

The following symbols are used in this manual.

Markings

Indicates that operating the hardware or software in a particular

manner may damage it or result in a system failure.

Draws attention to information that is essential for understanding the

operation and/or features of the product.

1

1

Introduction

Description of Displays

Some of the representations of product displays shown in this manual may be exaggerated,

simplified, or partially omitted for reasons of convenience when explaining them.

QR Code

The product has a QR Code pasted for efficient plant maintenance work and asset

information management. It enables confirming the specifications of purchased products and

user’s manuals.

For more details, please refer to the following URL.

https://www.yokogawa.com/qr-code

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

Note

Gives additional information to complement the present topic and/or

describe terms specific to this document.

Gives reference locations for further information on the topic.

IM 01B04K01-02E

1-3

Page 8

1.3 Notice

This Instruction Manual

• This manual should be passed on to the end user. Keep at least one extra copy of the

manual in a safe place.

• Read this manual carefully to gain a thorough understanding of how to operate this

product before you start using it.

• This manual is intended to describe the functions of this product. Yokogawa Electric

Corporation (hereinafter simply referred to as Yokogawa) does not guarantee that these

functions are suited to the particular purpose of the user.

• Under absolutely no circumstances may the contents of this manual, in part or in whole,

be transcribed or copied without permission.

• The contents of this manual are subject to change without prior notice.

• Every effort has been made to ensure accuracy in the preparation of this manual. Should

any errors or omissions come to your attention however, please contact your nearest

Yokogawa representative or sales office.

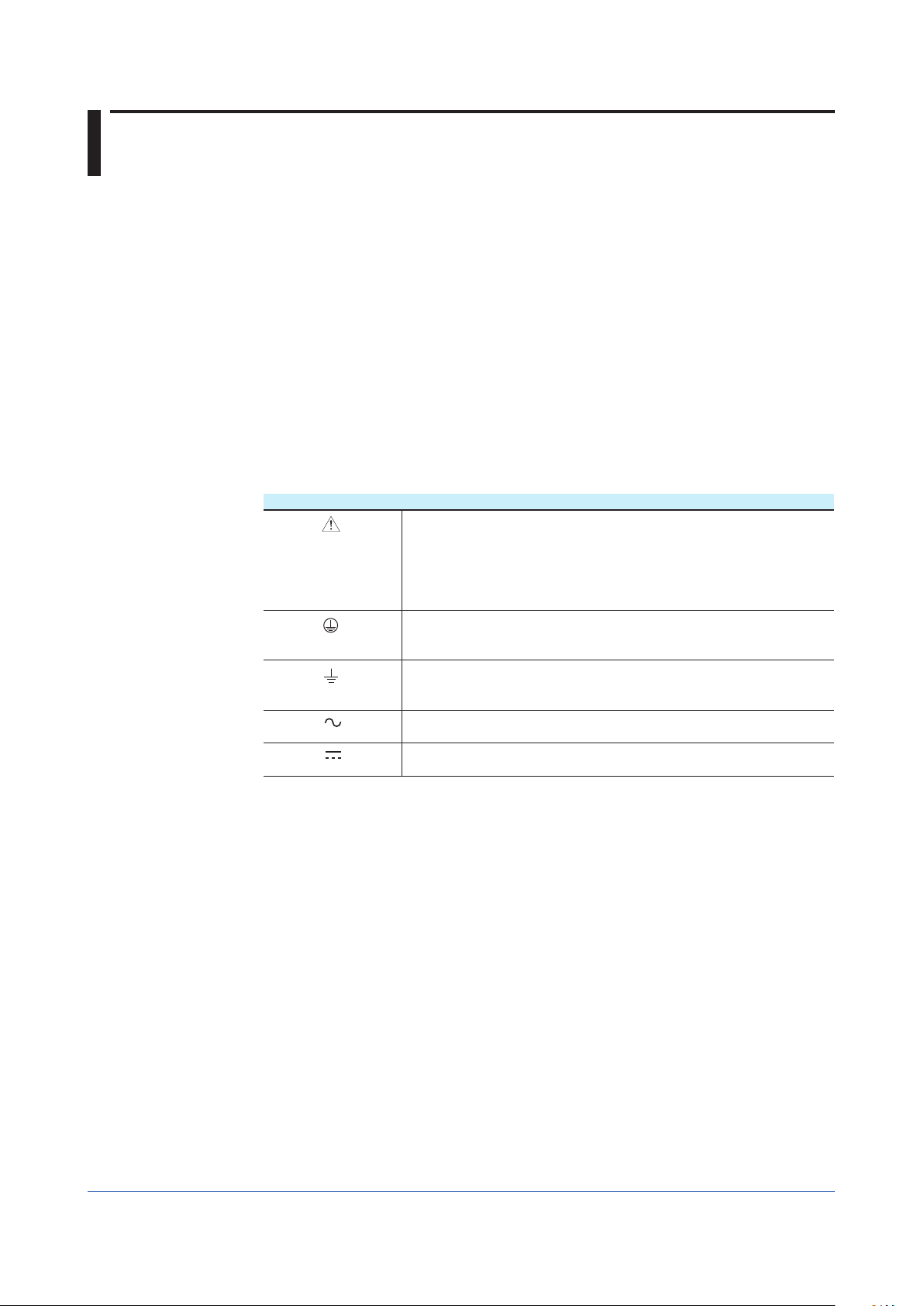

Protection, Safety, and Prohibition against Unauthorized Modification

• The following safety symbols are used on the product and in this manual.

Markings

CAUTION

• In order to protect the product and the system controlled by it against damage and ensure

its safe use, make certain that all of the instructions and precautions relating to safety

contained in this document are strictly adhered to. Yokogawa does not guarantee safety

if products are not handled according to these instructions.

• If protection/safety circuits are to be used for the product or the system controlled by it,

they should be externally installed on the product.

• Do not turn off the power of the product during adjustment and parameter setting.

• Be sure to confirm the parameters referring to ‘‘5.4 Parameter List’’ before installing the

product in a system or plant. After confirming them, install the product in a system or plant

and turn on the power.

• When you replace the parts or consumables of the product, only use those specified by

Yokogawa.

• If the product is to be used in systems with special requirements for human safety, such

in as nuclear power and radiation related equipment, railway facilities, aircraft facilities,

and medical devices, please consult with your sales representative.

• Do not modify the product.

Force Majeure

• Yokogawa does not make any warranties regarding the product except those mentioned

in the WARRANTY that is provided separately.

• Yokogawa assumes no liability to any party for any loss or damage, direct or indirect,

caused by the use or any unpredictable defect of the product.

If this symbol is indicated on the product, the operator should refer

to the explanation given in the instruction manual in order to avoid

personal injury or death to either themselves or other personnel, and/

or damage to the instrument. The manual describes that the operator

should exercise special care to avoid shock or other dangers that may

result in injury or loss of life.

Protective ground terminal:

This symbol indicates that the terminal must be connected to ground

prior to operating the equipment.

Function ground terminal:

This symbol indicates that the terminal must be connected to ground

prior to operating the equipment.

AC voltage:

This symbol indicates that AC voltage is present.

DC voltage:

This symbol indicates that DC voltage is present.

1-4

IM 01B04K01-02E

Page 9

1.4 Compatibility with Previous Models

Compatibility with style A

● Operation and settings differ from previous model (styles A). Please read this document

carefully before operating the product.

● Before installing this product in a system or plant, you must check the jumper settings and

parameters described in chapter 5, “Settings.” After checking settings and parameters,

install the product in the system or plant, and then turn ON the power.

Compatibility with style R

● Operation and settings are the same as for the previous model (style R). Please read this

document carefully before operating the product.

● Before installing this product in a system or plant, you must check the jumper settings and

parameters described in chapter 5, “Settings.” After checking settings and parameters,

install the product in the system or plant, and then turn ON the power.

1

1

Introduction

IM 01B04K01-02E

1-5

Page 10

Blank

Page 11

121

Chapter 2 General

General

The Model SKYD Alarm Unit provides two types of alarms : absolute alarm that is output

after comparison of one input signal with one or two alarm set points, and deviation alarm

that is output after comparison of the deviation between two inputs with two alarm set points.

Direct or reverse alarm action can be selected for each of the alarm output set points. The

front panel is provided with an alarm LED indicator lamp for confirming alarm relay action

(when relay is energized).

The JHT200 Handy Terminal (*1) is used for setting the SKYD parameters.

On the SKYD model with display setter (SKYD-x04), input indication (engineering unit) can

be displayed and alarm set points can be displayed / set on the front panel.

*1: The modular jack conversion adapter (E9786WH) is required for connecting the JHT200 Handy

Terminal to the Alarm Unit.

The 5 pin-connector type communication cable (F9182EE) and modular jack conversion adapter

(E9786WH) is required for connecting the BT200 BRAIN Terminal of YOKOGAWA ELECTRIC

Corporation

2

General

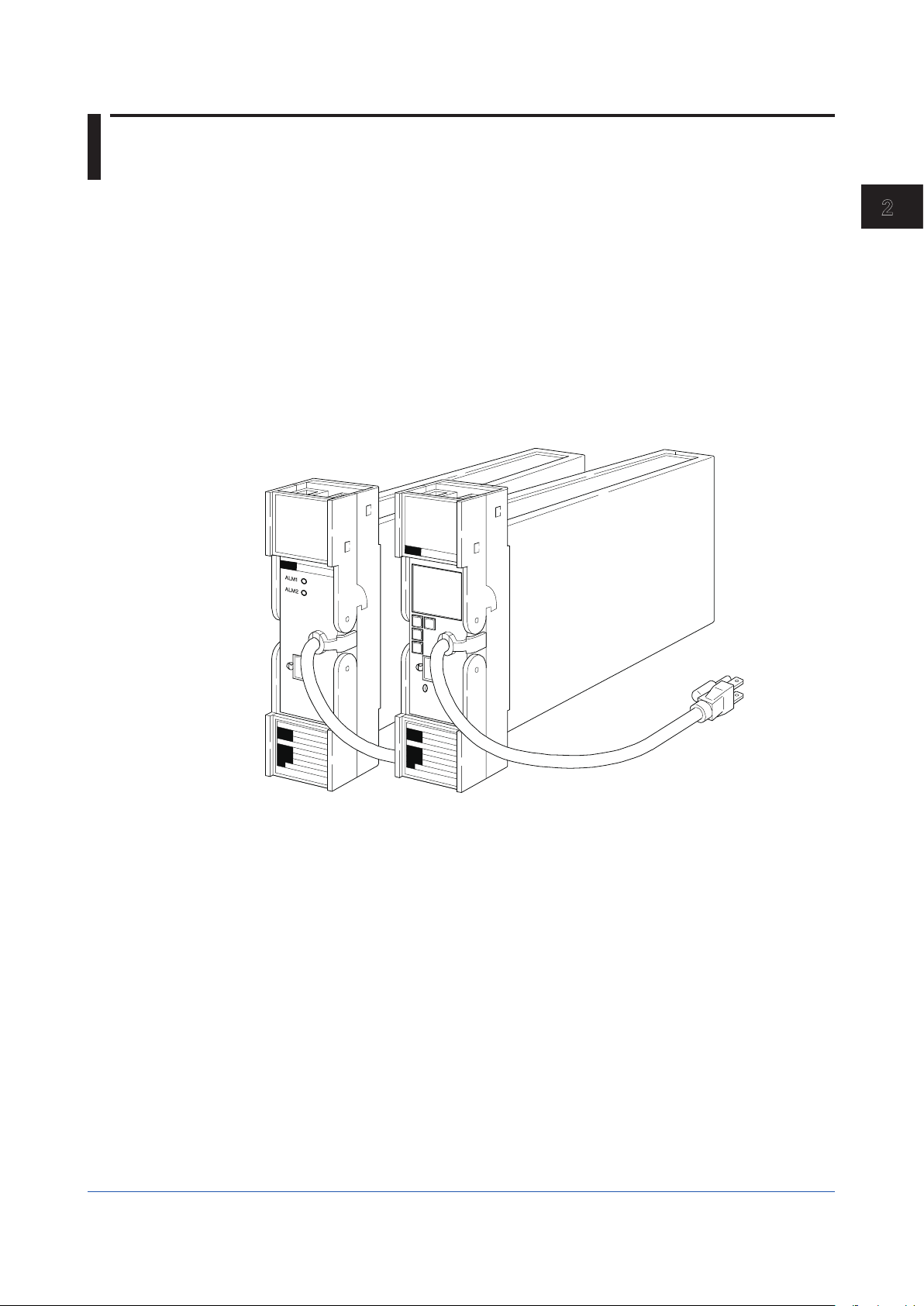

Figure 2-1 External View

IM 01B04K01-02E

F0201.ai

2-1

Page 12

2.1 Standard Specifications

Please see the General Specifications (GS 01B04K01-02E) at the end of this manual.

2-2

IM 01B04K01-02E

Page 13

121

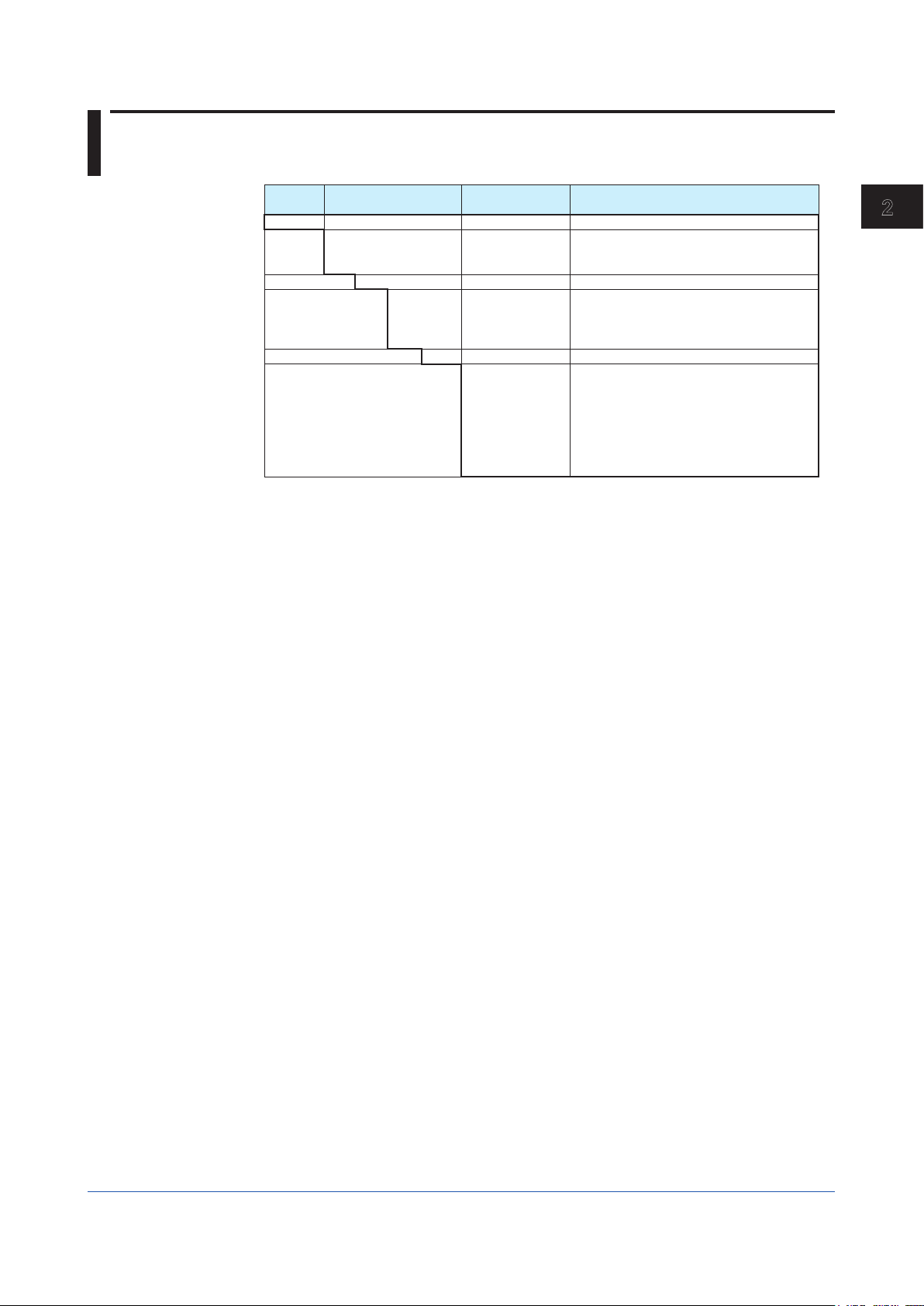

2.2 Model and Suffix Codes

Model Suffix Codes Optional

SKYD Alarm Unit

Alarm -1

Sux Code 0 Always 0

Setting Scale

Style Code *S Style S

Option Codes

-2

-3

(*1)

(*4) (*5)

*1: In the case of two set points, the setting ranges of one set point/two set points are the same.

*2: The value obtained by squaring the setting value functions as the alarm setting value.

*3: 2-input deviation alarm only

*4: /LOCK, /REK, /TB, /A2TB, and /A2ER cannot be specified together.

*5: /FBP, /A2TB, and /A2ER cannot be specified together.

0

1

2

4

Suffix Codes

/NHR

/FBP

/LOCK

/WSW

/REK

/TB

/A2TB

/A2ER

1 input, 1 setpoint absolute alarm

1 input, 2 setpoints absolute alarms

2 inputs, 2 setpoints deviation alarms

0 to 100 linear

0 to 10 square root

-100 to +100 linear (deviation alarm)

Actual scale (with display setter)

Without rack case

Power supply fuse bypass

Power supply plug with lock

With spring washer

Mount to same line with EK series rack

With power supply terminal

220V version with power supply terminal

220V version with power supply plug

Description

(*2)

2

General

(*3)

IM 01B04K01-02E

2-3

Page 14

2.3 Accessories

Alarm Label: 1 sheet

2-4

IM 01B04K01-02E

Page 15

1

2

1

2

Chapter 3 Installation

Installation

For details of the installation procedure and wiring precautions, refer to the instruction

manual “Installation of Rack-Mounted Instruments” (IM 1B4F2-01E).

3

3

Installation

IM 01B04K01-02E

3-1

Page 16

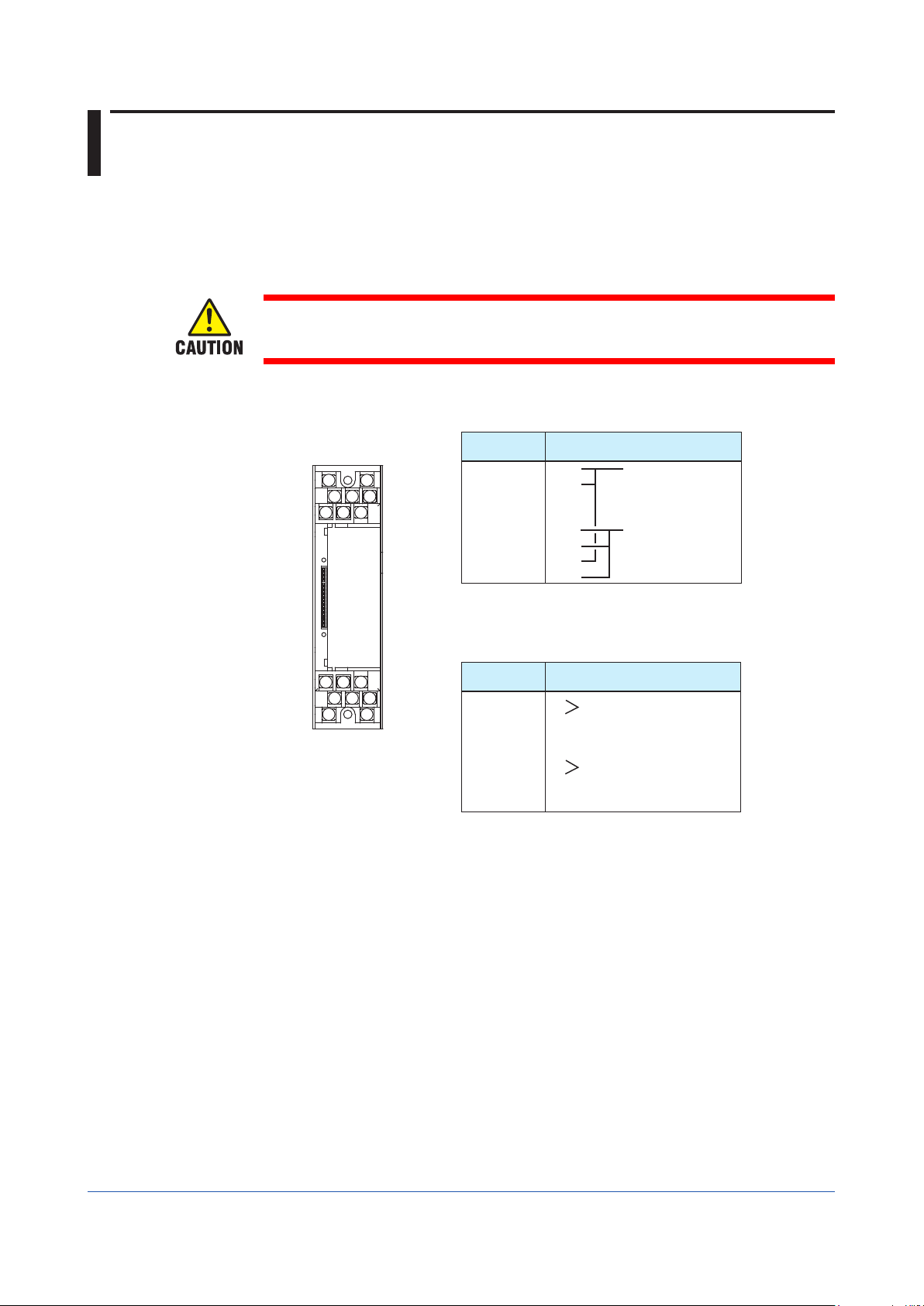

3.1 External Wiring

(a) All cable ends must be furnished with crimp-on type solderless lugs (for 4mm screws)..

(b) Draw out the internal unit from the rack case.

(c) Connect the cables to the correct terminals referring to Figure 3-1.

(d) Return the internal unit into the rack case after completing the wiring.

(e) Always return the terminal block cover to its original position after completing the wiring.

The terminal block cover cannot be returned to its original position if the internal

unit is not installed its original position in the rack case. Securely return the terminal

block cover because it also functions as lock for the internal unit.

Terminal arrangement

OUT

K

J

HFDCB

A

Terminal

Designation

A NC

Description

Alarm output 1

B COM

C

D

F NC Alarm output 2

(*1)

H COM

J NO

K NO

Do not connect to the output terminal when the terminal is not

in use.

*1: Except SKYD-1 type.

Terminal

Designation

1 +

2 3

4

3

5

1

2

4

6

8

7

IN

5 +

6 7

8

*2: For SKYD-3 type only.

Figure 3-1 Terminal Layout and Terminal Wiring

Input 1

Input 2

Description

(*2)

3-2

IM 01B04K01-02E

Page 17

1

2

1

2

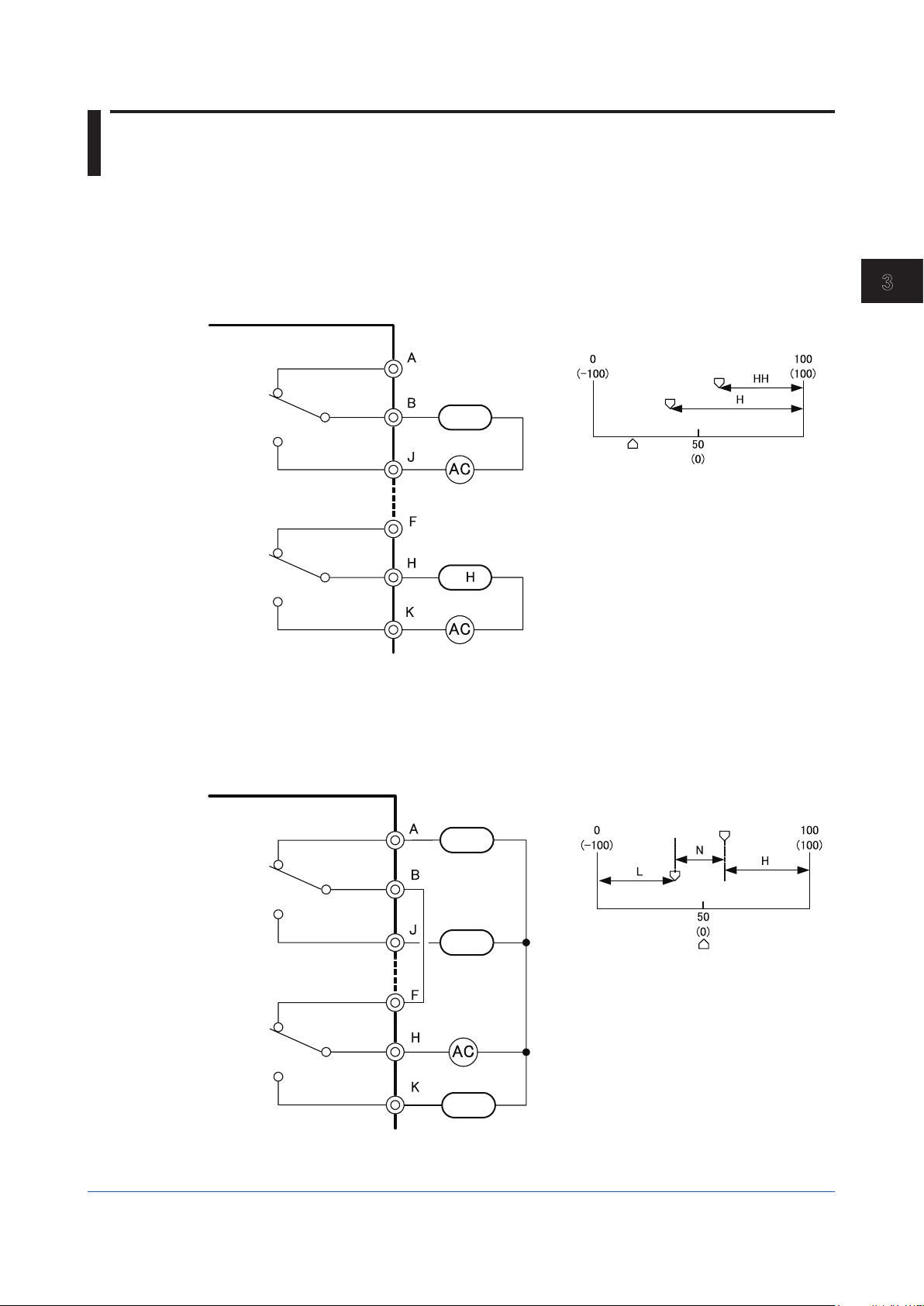

3.2 Example of Alarm Wiring

The SKYD alarm unit provides various types or alarms depending on the setting of the alarm

action or the method of connecting the alarm output terminals. Thus, the necessary wiring

should be made with reference to the following two examples:

3.2.1 High-limit and High-high-limit Alarms

Set the direct action (DIRECT) for the alarm actions of both alarms 1 and 2. Then wire the

terminals as illustrated in Figure 3-2.

SKYD Alarm Unit

H

H

Alarm 1 setting

Input (deviation)

value

Alarm 2 setting

3

3

Installation

Alarm output terminal

Figure 3-2 External Wiring - Example 1

F0302.ai

3.2.2 Three-position Alarm

Set the reverse action (REVERSE) for the alarm action of alarm 1, and the direct action

(DIRECT) for the alarm action of alarm 2. Then wire the terminals as illustrated in Figure 3-3.

SKYD Alarm Unit

N

L

H

Alarm output terminal

Figure 3-3 External Wiring - Example 2

Alarm

Alarm 2 setting

Alarm 1 setting

Input (deviation) value

F0302.ai

IM 01B04K01-02E

3-3

Page 18

3.2 Example of Alarm Wiring

Applicable Cables

(1) Signal circuit wiring

(2) Alarm circuit wiring

(3) Power supply wiring

• Cross-sectional area of the cable conductor: 0.5 to 0.75 mm

2

• Examples of applicable cables: Single core PVC insulated flexible cable (VSF)

stranded wires (JIS C 3306); heat-resistant vinyl-insulated cable (UL style 1007)

• Cross-sectional area of the cable conductor: 0.5 to 1.25 mm

2

• Examples of applicable cables: 600 V PVC insulated cable (IV) stranded wires (JIS C

3307); PVC insulated cable for electric appliances (KIV) stranded wires (JIS C 3316);

heat-resistant vinyl-insulated cable (UL style 1007)

• Cross-sectional area of the cable conductor: 1.25 to 2.00 mm

2

• Examples of applicable cables: 600 V PVC insulated cable (IV) stranded wires (JIS C

3307)

3-4

IM 01B04K01-02E

Page 19

1

2

3

1

2

3

Chapter 4 Principles of Operation

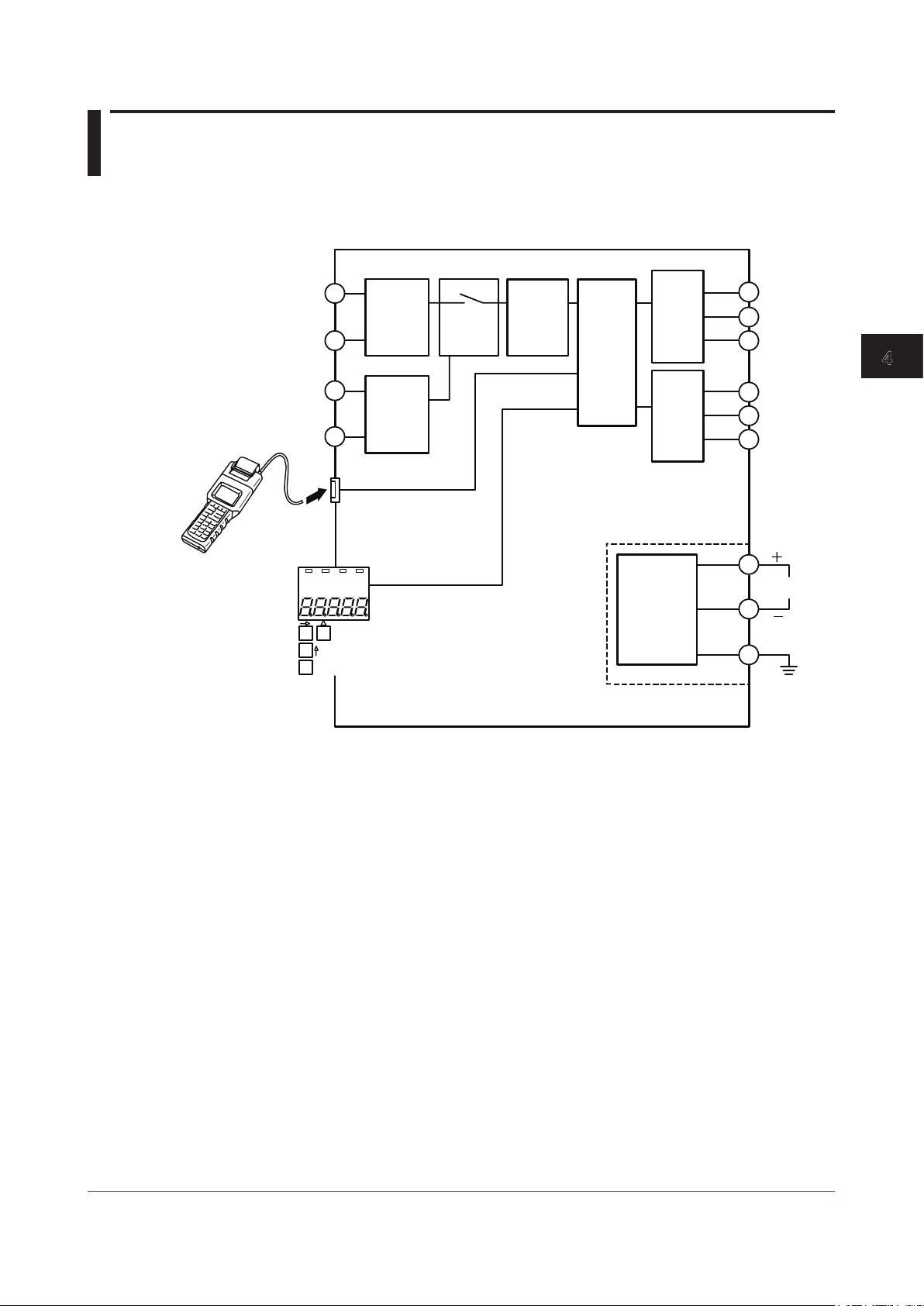

4.1 Principle of Operation

Input signals are converted to digital data by the A/D conversion circuit. The resulting digital

data is processed (square root calculation, etc.) by the microcomputer, and the alarm relay

is then energized/de-energized by alarm calculation processing (comparison, etc.).

1

2

5

6

Handy

Terminal

SET

Figure 4-1 Hardware Function Block Diagram

Input

processing

circuit 1

Input

processing

circuit 2

(*1)

Display setter (*2)

*1: SKYD-30x only

*2: SKYD-x04 only

*3: Except SKYD-10x

Multiplexer

conversion

A/D

circuit

Micro-

processor

Relay

output 1

Relay

output 2

(*3)

Power

supply circuit

A

B

J

F

H

K

L

Power

supply

N

GND

F0401.ai

App

4

Principles of Operation

IM 01B04K01-02E

4-1

Page 20

4.2 Description of Functions

The following describes the functions of the SKYD-10x/20x and SKYD-30x.

4.2.1 SKYD-10x/20x Functions

Input signal

A/D conversion

1 to 5 VDC

Normalization

INPUT1

Square root calculation

LINEARIZE1

LOW CUT1

Scaling (*1)

Bias (*1)

PV1

Alarm detection 1

Alarm relay connection 1

BIAS1

SET POINT1

HYSTERESIS1

ALM1 ACTION

ON DELAY1

OFF DELAY1

RLY1 ACTION

Relay output 1 Relay output 2

Figure 4-2 Software Function Block Diagram

The alphabet codes in the figure are the names of BRAIN communication parameters.

*1: SKYD- 04 only

RLY1 TEST

SCH1

SCL1

DP1

SKYD-20 only

Alarm detection 2

Alarm relay connection 2

SET POINT2

HYSTERESIS2

ALM2 ACTION

ON DELAY2

OFF DELAY2

RLY2 ACTION

RLY2 TEST

F0402.ai

4-2

IM 01B04K01-02E

Page 21

1

2

3

1

2

3

4.2 Description of Functions

●ExplanationofInputprocessingblock

• A/D conversion:

Performs A/D conversion on input signals.

• Normalization:

A/D-converted signals are converted to a scale of 1 to 5 V DC. (INPUT1)

• Square root calculation (LINEARIZE1):

When square root calculation is set to ON, the input processing block performs square

root calculation on the input signal.

The low-cut point (LOW CUT1) can be set to the square root calculation. The figure

below shows operation when the input signal is near the low-cut point. This low-cut

point is provided with a hysteresis of 0.2%.

Input after low-cut processing

App

4

Principles of Operation

When X

X - 1 + 1

≤1V: Y=X

Input (X)

F0403.ai

Y = 2 x

X =

Y Y,X: 1 to 5 (V)

Low-cut point

Hysteresis fixed at 8 mV (0.2%)

• Scaling (SKYD-x04 only):

The display in engineering unit is available according to the SCH1, SCL1 and DP1

parameter settings.

The value after scaling (or, when the bias function is used, the value obtained by

adding bias to this value) becomes PV1.

SCH1, SCL1, DP1 setting (default: 0.0 to 100.0)

<Setting Method>

(1) Set the decimal point position matched to the unit system actually in use at DP1.

(Example: two digits past the decimal point)

(2) Register the measuring input scale range at SCH1 and SCL1.

(Example: SCH1=20.00, SCL1=0.00)

(Example)

1V 5V

0.0 (SCL1) 100.0 (SCH1)

0.00 (SCL1) 20.00 (SCH1)

IM 01B04K01-02E

Decimal point position registered at DP1.

Default scale

Measuring input scale

(after scaling)

F0404.ai

4-3

Page 22

4.2 Description of Functions

Reverse scaling (SCH1 < SCL1) is also possible.

A setting error occurs when SCH1 is set to equal SCL1.

● ExplanationofAlarmdetectionblock

• Bias:

A bias value (BIAS1) can be added to scaling values.

This allows error to be compensated when there is an error between the input value

and the indicated value.

Bias can be set within the range ±10% [(SCH1 - SCL1) x 0.1] of the scaling width.

The input value displayed on the display setter on the front panel (PV1 in the BRAIN

communications parameter) is the value after addition of bias.

In the following description, n is "1" for SKYD-10x, and "1" or "2" for SKYD-20x.

• Alarm detection n:

Performs alarm detection.

• ALMn ACTION: Alarm action

Direct .................. The alarm state is entered when the input value is at the preset

alarm set point or higher.

Reverse...............The alarm state is entered when the input value is at the preset

alarm set point or lower.

• SET POINTn: Alarm set point

• HYSTERESISn: Alarm hysteresis (See Figure 4-4.)

• ON DELAYn: Alarm ON delay

Sets the dead time until the alarm turns ON.

An alarm state is entered when the input value is in the alarm range for the duration

set at ON DELAYn.

If input returns to the normal range before the time set at ON DELAYn is reached, the

alarm does not turn ON.

• OFF DELAYn: Alarm OFF delay

Sets the dead time until the alarm turns OFF.

A normal state is entered when the input value is in the normal range for the duration

set at OFF DELAYn.

If input returns to the alarm range before the time set at OFF DELAYn is reached, the

alarm does not turn OFF.

4-4

• For ON DELAY/OFF DELAY, if you change the time during a delay, cancel the delay

operation, and restart operation with the set delay time.

• The alarm function does not work for 3 seconds after power ON.

● Relayoutputblock

• RLYn ACTION: Alarm relay action

Energized at normal operation ............ The relay is energized when the alarm

detection result is a normal state.

De-energized at normal operation....... The relay is energized when the alarm detection

result is an alarm state.

• RLYn TEST: Relay action test

This function is for testing relay action.

Relays can be turned ON/OFF without influencing the currently alarm detection result.

Direction of alarm relay action: De-energized at normal operation (Factory-shipped settings)

ALMn Direction of alarm action Input value < Set point Set point < Input value

DIR Direct (high-limit alarm) Output relay de-energized Output relay energized

RVS Reverse (low-limit alarm) Output relay energized Output relay de-energized

Direction of alarm relay action: Energized at normal operation

ALMn Direction of alarm action Input value < Set point Set point < Input value

DIR Direct (high-limit alarm) Output relay energized Output relay de-energized

RVS Reverse (low-limit alarm) Output relay de-energized Output relay energized

IM 01B04K01-02E

Page 23

1

2

3

1

2

3

4.2.2 SKYD-30x Functions

4.2 Description of Functions

Input signal 1

A/D conversion

1 to 5 VDC

Normalization

INPUT1

Square root calculation (*1)

Scaling (*1)

Bias (*1)

PV1

Deviation (subtraction)

INPUT DEV

Alarm detection 1

Alarm relay connection 1

*1: SKYD-304 only

LINEARIZE1

LOW CUT1

SCH1

SCL1

DP1

BIAS1

SET POINT1

HYSTERESIS1

ALM1 ACTION

ON DELAY1

OFF DELAY1

RLY1 ACTION

RLY1 TEST

Relay output 1 Relay output 2

Figure 4-3 Software Function Block Diagram

Input signal 2

A/D conversion

Normalization

INPUT2

Square root calculation (*1)

Scaling (*1)

Bias (*1)

PV2

Alarm detection 2

Alarm relay connection 2

1 to 5 VDC

BIAS2

*1: SKYD-304 only

HYSTERESIS2

ALM2 ACTION

OFF DELAY2

SET POINT2

ON DELAY2

RLY2 ACTION

RLY2 TEST

F0405.ai

App

4

Principles of Operation

The alphabet symbols in the figure are the names of BRAIN communication parameters.

In the following descriptions, n is "1" or "2".

● Input processing block

Functions are the same as SKYD-10x/20x except that there are two inputs.

• Input deviation processing block

Input deviation INPUT DEV is the value of "PV1 - PV2".

● Alarm detection block

Functions are the same as SKYD-20x except that the detection target is input deviation

INPUT DEV.

● Relay output block

Functions are the same as SKYD-20x.

IM 01B04K01-02E

4-5

Page 24

4.3 Example of Alarm Function Setting

This section describes the alarm function setting showing the example using the alarm

function parameters.

4.3.1 Condition of Alarm Function

Set the following conditions.

(1) Condition for Alarm 1

The alarm is output when the status where the input value is 80% or more continues for 1

second or more.

The alarm is released when the status where the input value is 70% or less continues for

2 seconds or more.

(2) Condition for Alarm 2

The alarm is output when the input value is 15% or less.

The alarm is released when the input value is 20% or more.

4.3.2 Parameters of Alarm Function

The table below shows the parameters the condition of alarm function described in 4.3.1 is

placed to.

Table 4-1 Table of Parameter Setting Example for Alarm 1 and Alarm 2 (SKYD-20x)

Item Alarm 1 Alarm 2

Alarm set point E01: SET POINT1 80% E02: SET POINT2 15%

Direction of alarm action E07: ALM1 ACTION DIRECT E08: ALM2 ACTION REVERSE

Alarm hysteresis E09: HYSTERESIS1 10% E10: HYSTERESIS2 5%

Alarm ON delay E15: ON DELAY1 1 s E16: ON DELAY2 0 s

Alarm OFF delay E17: OFF DELAY1 2 s E18: OFF DELAY2 0 s

Parameter Set point Parameter Set point

4.3.3 Operating Condition of Alarm Function

Refer to the following figure for operating condition of alarm 1 and alarm 2.

Alarm condition established

100

Alarm-1 set point >

Alarm-2 set point >

Alarm-1 Direct

action

Alarm-2 Reverse

action

80

60

40

20

Alarm-2 hysteresis (5%)

15

0

De-energized

Figure 4-4 Alarm Action

Alarm-released condition established

1 s 2 s

Energized

De-energized

Alarm-1 hysteresis (10%)

Alarm condition established

Alarm-released condition established

Elapsed time (s)

De-energized

Energized De-energized

F0406.ai

4-6

IM 01B04K01-02E

Page 25

1

2

3

App

1

2

3

4

Chapter 5 Setting

Setting

Items to Confirm before Start of Operation

Before you start operation, inspect and confirm the following items:

(1) Draw out the internal unit from the rack case, and make sure that the specified fuses are

properly mounted in the fuse holders at the rear of the internal unit.

(2) When inserting the internal unit into the rack case, firmly connect the multi-pin connectors

for connecting the internal unit and the case.

(3) Make sure that power plugs are properly connected to the power outlet.

(4) Make sure that external wiring to the terminal block is properly connected.

Refer to Section 7.1, “Action in Fault Condition” for how to detect device error by

alarm output.

5

Setting

IM 01B04K01-02E

5-1

Page 26

5.1 Names of Components

The following shows the names of SKYD components.

ALM SP

1

2

Alarm 1,2 relay action indicator lamps (ALM1,2)

Alarm 1,2 set point indicator lamps (SP1,2)

1 2

Display setter

Data digit feed key

Parameter selection key

Tag plate

Alarm 1,2 relay action indicator lamps (ALM1,2)

BRAIN connector (w/ cover)

Key setting enable switch

(ENBL switch)

Name plate

Other than SKYD-x04

SKYD-x04

Output terminal block

SET

Main board

Data change key

SET

Data setting fix key

Terminal block cover/handle

for drawing out internal unit

Rack case

Input terminal block

Multi-pin connector

Power plug

Figure 5-1 Names of Components

5-2

F0501.ai

IM 01B04K01-02E

Page 27

1

2

3

App

1

2

3

4

5.2 Setting Jumper

The SKYD is provided with the following jumpers.

Other SKYDs excluding the SKYD-x04 are not provided with the ALM1, 2 jumpers.

(Can be set by using the JHT200 Handy Terminal.)

Jumper Code Jumper Name Except SKYD-x04 SKYD-x04

W. P. Parameter Write Protect Available Available

ALM1 Alarm 1 action setting jumper Not available Available

ALM2 Alarm 2 action setting jumper

(except SKYD-10x)

• Parameter Write Protect jumper

When this jumper is set to ON, changing of parameters by the key switches and Handy

Terminal is disabled. “LOC” will be displayed on the display setter if the “→” switch is

pressed with the SP1 or SP2 parameter displayed on the display setter.

To cancel the “LOC” display and return to the previous display, press any key.

• Alarm action setting jumper

This jumper is for setting the direction of alarm action.

The table below shows the relationship between direction of alarm action and direction of

relay action.

Direction of alarm relay action: De-energized at normal operation

ALMn Direction of alarm action Input value < Set point Set point < Input value

DIR Direct (high-limit alarm) Output relay de-energized Output relay energized

RVS Reverse (low-limit alarm) Output relay energized Output relay de-energized

Not available Available

5

Setting

Direction of alarm relay action: Energized at normal operation

ALMn Direction of alarm action Input value < Set point Set point < Input value

DIR Direct (high-limit alarm) Output relay energized Output relay de-energized

RVS Reverse (low-limit alarm) Output relay de-energized Output relay energized

IM 01B04K01-02E

5-3

Page 28

5.2 Setting Jumper

5.2.1 Check of Setting Jumper and its Location

The setting jumpers are located on the main board of the internal unit.

Draw out the internal unit, and check the current jumper settings.

Current jumper settings can also be checked on the JHT200 Handy Terminal.

Parameter Write Protect A55: WRT PROTECT

Direction of alarm 1 action E07: ALM1 ACTION

Direction of alarm 2 action (except SKYD-10x) E08: ALM2 ACTION

Parameter Write

Protect

ON disables

changing of

parameters.

Jumper Name Parameter Name

Direction of alarm

action

Direct

action

selected

Reverse

action

selected

Setting jumpers

(factory-set default)

F0502.ai

Figure 5-2 Setting Jumper

Change of Setting Jumper

Follow the procedure below to change the setting jumpers:

(a) Pull the terminal block cover toward you to draw out the internal unit from the rack case.

(b) Check the jumpers on the main board of the internal unit, and change their settings as

desired. Use tweezers or another fine-tipped object to change the setting jumpers.

(c) Return the internal unit to the rack case.

(d) Return the terminal block cover to its original position.

5-4

F0502.ai

IM 01B04K01-02E

Page 29

1

2

3

App

1

2

3

4

5.3 Setting of Parameters

This instrument has BRAIN communication parameters for specifying functions and

adjusting input. Connect JHT200 Handy Terminal (*1) to the instrument to display or set

parameters (modular jack conversion adapter (E9786WH) is required )

On the SKYD model with display setter (SKYD-x04), input indication (engineering unit) can

be displayed and alarm set points can be display/set on the front panel.

For details on parameters, refer to the Parameter Lists.

*1: BT200 BRAIN Terminal of YOKOGAWA ELECTRIC Corporation can also be used.

When connecting the JHT200 Handy Terminal, the adapter for modular-jack (model E9786WH)

is required. When using the BT200 BRAIN Terminal of YOKOGAWA Electric Corporation, the

communication cable of 5-pin connector type (model F9182EE) and the adapter for modularjack

(model E9786WH) are required.

5.3.1 Parameter Change Disable Function

The SKYD is provided with a parameter change disable function for preventing parameter

settings from being changed by operator error.

Table 5-1 Parameter Change Disable Function

Disable Setting Method Disable Cancel

Parameter Write

Protect jumper

Enable switch

(SKYD-x04 only)

Set W.P. jumper on the main

board to “ON”.

Changes cannot be made if no

settings are made for 30 minutes

after operating any key switch

on the front panel in a setting

change enable state.

Method

Set W.P. jumper on

the main board to

“OFF”.

Press the Enable

switch.

5

Setting

Description of Disable

Operation

● Changing of parameter

setting by key switches.

● Changing of parameter

setting by Handy Terminal.

● Changing of parameter

setting by key switches.

5.3.2 Setting of Parameters Using Display Setter (SKYD-x04)

On the SKYD-x04, you can change alarm set point using the display setter on the front

panel.

Other parameters are changed using the JHT200 Handy Terminal.

The table below describes the relationship between key switch operations and migration of

display states.

Table 5-2 Relationship between Key Switch Operations and Migration of Display States

Key

Switch

∆ Displays the next

→ Advances to the setting

↑ Displays the previous

SET No operation Advances to the setting fix

ENBL Enters setting change enable state.

Display Mode Setting Change Mode Setting Fix Mode Indicator Out Mode

parameter.

change mode when a

settable or changeable

parameter is displayed in

the setting change enabled

state. (*1)

parameter.

Enable switch is disabled if the Parameter Write Protect jumper is set to “ON”.

*1: When the Parameter Write Protect jumper on the main board is set to “ON”, the SKYD will not

advance to the setting change mode. In this state, “LOC” is displayed on the display setter.

Cancels the newly changed

values, returns to the

display mode, and displays

the next parameter.

Moves setting digit. Returns to the setting

Changes the set point. No operation

mode.

Display Function

Cancels the newly changed

values, returns to the

display mode, and displays

the next parameter.

change mode, and moves

to the next digit.

Fixes the set point, and

advances to the display

mode.

This mode is entered if no

key switches are operated

for 30 minutes when the

display mode parameter is

set to “OFF”.

The display mode is

returned to if any key switch

is pressed in the indicator

out mode.

IM 01B04K01-02E

5-5

Page 30

5.3 Setting of Parameters

Indicator out mode is

entered if no key switch is

operated for 30 minutes

when display mode

parameter is "OFF".

Indicator out mode Display mode

Display mode is returned to

when any key switch is

pressed.

Moves to setting

Cancels new set point

value, returns to display

mode, and displays next

parameter.

Setting fix mode Setting change mode

(all digits flashing)

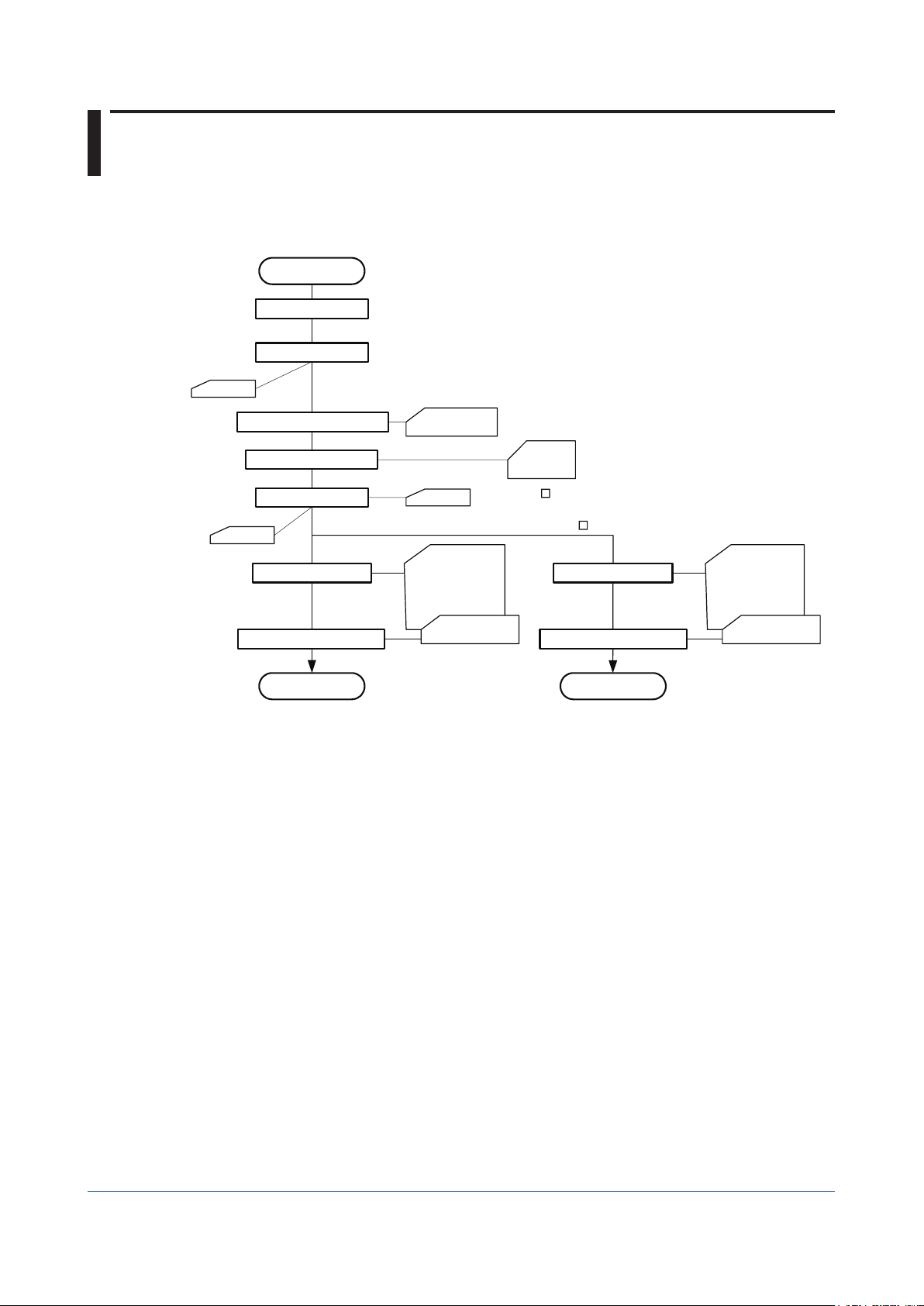

Figure 5-3 Key Switch Operations and Migration of Display States

Fixes set point, and moves

to display mode.

Moves to setting fix

mode.

Returns to setting change

mode, and moves to next digit.

change mode.

Displays previous parameter.

Displays next parameter.

Feeds digit.

Increments value.

Switching the Display

Each press of the ∆ key switches the display data.

Cancels new set point,

returns to display mode,

and displays next

parameter.

F0503.ai

Power on

Press key.

Input value (PV1) is

displayed.

SP1 /SP2 lamps out

In this example,

"40.00"

Figure 5-4 Progression of Display Screen

Alarm 1 set point (SP1)

is displayed.

SP1 lamp lit

In this example,

"50.00"

LED Indicator Lamps

The table below lists the type of LED indicator lamps on the front panel and their lighting

conditions.

LED Lamp Color Lighting Conditions Remarks

ALM1 Yellow Lit when alarm 1 output relay is energized

ALM2 Yellow Lit when alarm 2 output relay is energized SKYD-20x, -30x only

SP1 Green Lit when alarm 1 set point (SP1) is displayed on the

SP2 Green Lit when alarm 2 set point (SP2) is displayed on the

display setter

display setter

Press key.

Press key.

Alarm 2 set point (SP2)

is displayed.

SP2 lamp lit

In this example,

"30.00"

SKYD-x04 only

SKYD-204, -304 only

F0504.ai

5-6

IM 01B04K01-02E

Page 31

1

2

3

App

1

2

3

4

Setting Parameters

Display the desired parameter (e.g. alarm set point), and follow the procedure below to

change its set point.

AL M S P

1

2

1 2

SET

AL M S P

1

2

1 2

SET

5.3 Setting of Parameters

(1) Input value (60.00) is displayed at power ON.

Press the - key. The SP1 lamp lights, and the alarm 1 set point is displayed.

(2) The alarm 1 set point (80.00) is displayed.

Press the - key. In the case of the SKYD-104, the SP1 lamp goes out, and the

input value is displayed.

In the case of the SKYD-204/304, the SP2 lamp lights, and

the alarm 2 set point is displayed.

AL M SP

1

2 1 2

Alarm 2 set point (30.00) is

displayed. (SKYD-204/304 only)

5

Setting

(3) Press the ENBL switch to enter setting change enable state.

(4) Set the alarm set point. (Change the alarm 1 set point to "70.00" from "80.00".)

Alarm set points whose SP lamp is lit can be changed.

Press the - key.

Press the - key.

Press the - key.

Figure 5-5 Setting Parameters

SET

The uppermost digit on the display flashes.

Hold down the key to move the flashing section to the digit

on the right.

This increments the value at the flashing digit. Hold down the

key to feed the value to "7".

All parameter digits flash. Pressing the key again

causes "70.00" to light. (This fixes the new parameter

settings.).

SET

F0505.ai

● WhentheParameterWriteProtectjumperonthemainboardissetto“ON”,the

SKYD will not advance to the setting change mode. In this state, “LOC” is dis-

played on the display setter.

● Donotturnoffthepoweroftheinstrumentduringparametersetting.

IM 01B04K01-02E

5-7

Page 32

5.3 Setting of Parameters

Display at Power ON

The model with display setter displays REV NO. (revision number of software for the SKYD)

for about 2 seconds after power ON.

Example of display (REV NO.10)

LOC Display

When “LOC” is displayed, this indicates that parameter settings cannot be changed.

(The Parameter Write Protect jumper on the main board is set to “ON”.)

To cancel the “LOC” display and return to the previous display, press any key.

Indicator Out Mode Display

In this mode, only the decimal point is displayed on the display setter.

When the display mode parameter (DSP MODE) is set to “OFF”, and no key operation is

performed for 30 minutes, the SKYD moves to the indicator out mode.

To cancel this mode and return to the display mode, press any key switch.

I/O signal processing and calculations are performed as usual even in the indicator out

mode.

If the self check discovers an error (A/D conversion error, EEPROM error, EEPROMSUM

error) in the indicator out mode, this mode is canceled, and the error is displayed. Also,

the SKYD does not move to the indicator out mode when an error (A/D conversion error,

EEPROM error, EEPROMSUM error) occurs.

1 2 1 2

Moves to indicator

out mode if no key is

operated for 30

minutes.

Indicator out mode

Only decimal point is lit.

Figure 5-6 Indicator Out Mode

Press any key.

1 2 1 2

Normal operation

mode

F0506.ai

5-8

IM 01B04K01-02E

Page 33

1

2

3

App

1

2

3

4

5.3.3 Setting of Parameters Using Handy Terminal

For details of operation and adjusting procedures of JHT200 Handy Terminal, refer to

the instruction manual “JHT200 Handy Terminal” (IM 77J50H01-01EN).

<Connection>

Cable of 5-pin

connector type

(F9182EE)

JHT200

Handy Terminal

Figure 5-7 Connecting the Handy Terminal

5.3 Setting of Parameters

BRAIN connector

5

Setting

Adapter for modular jack

(E9786WH)

F0504.ai

IM 01B04K01-02E

5-9

Page 34

5.4 Parameter List

BRAIN communication parameters for SKYD are as follows.

On the SKYD-x04, only the input value can be displayed, and the alarm set point can be

displayed and set on the display setter on the front panel. Other, parameters are displayed

and set using the Handy Terminal.

5.4.1 SKYD-10x Parameter List

No.

Initial

display

01 Model Name MODEL Displays the model name. Displayed

02 Tag Number TAG NO Displays the tag number that is set.

03 Self Check SELF CHK Displays the result (GOOD/ERROR) of the self check.

A Display 1 DISPLAY1

A01

A03

A15

A54

A55

A56 REV NO. REV NO. Displays the device revision No.

A58 MENU REV MENU REV Displays the revision No. of the parameter group.

A60 Self Check SELF CHK Displays the result (GOOD/ERROR) of the self check.

B Display 2 DISPLAY2

B01 Analog Input 1 Same as item A

B03 PV1

B15 Alarm 1 Relay

B60 Self Check

Parameter

Name

Analog Input 1 INPUT1 Input value before input processing (square root or scaling)

PV1 PV1 Input value (engineering unit) after input processing (square

Alarm 1 Relay

Display

Status Display STATUS Displays the value added to the value (Hex) indicating the

Parameter Write

Protect

Display

Symbol Description Display

(unit: V)

root or scaling)

RLY1 STATUS Displays the state of the alarm 1 relay.

DE-ENERGIZED: De-energized

ENERGIZED: Energized

self check result.

0000: Normal

0001: EEPROM error

0002: EEPROMSUM error

0004: Low input cut state

0008: Input range exceeded

0010: Setting error

0040: Power interruption during operation

1000: A/D conversion error

WRT PROTECT Displays the state of the Parameter Write Protect jumper.

OFF: Setting of parameters enabled

ON: Setting of parameters disabled

Conditions

on all

Displayed

on all

Displayed on

SKYD-104

Displayed

on all

5-10

IM 01B04K01-02E

Page 35

1

2

3

App

1

2

3

4

5.4 Parameter List

No.

D Setting Parameters SET(I/O)

D01 Tag Number 1 TAG NO.1 8 alphanumerics can be

D02 Tag Number 2 TAG NO.2 8 alphanumerics can be

D03 Comment 1 COMMENT1 8 alphanumerics can be

D04 Comment 2 COMMENT2 8 alphanumerics can be

D17 Linearization 1 LINEARIZE1 Specifies square root

D19 Low Cut 1 LOW CUT1 Specifies low-cut point

D40 Input Decimal Point

D41 Input Scale L SCL1 Sets the display value at

D42 Input Scale H SCH1 Sets the display value at

D46 PV1 PV1 Displays the input value

D47 Input 1 Bias BIAS1 Adds the bias value to

D51 Display Mode DSP MODE Selects the display setter

D60 Self Check SELF CHK Result of self check (GOOD/ERROR) of the self check. Displayed on all

Parameter Name Symbol Description Setting Range Factory-set

entered.

entered.

entered.

Position

entered.

calculation ON/OFF.

during square root

calculation.

DP1 Sets the position of the

decimal point for the input

scale (SCH1, SCL1).

0% input

100% input

after input processing

(scaling).

the value after input

processing, and displays as

the PV1.

state after 30 minutes

elapses after a key switch

operation.

OFF: Power save mode

Only the decimal point

is displayed.

ON: Constant ON mode

Data is displayed at

all times regardless of

elapsed time.

*1: Initialized when changing SCH1, SCL1

OFF

SQR

0.3 to 100.0 % 1.0 % Displayed on

#####

####.#

###.##

##.###

-9999 to 9999

(engineering unit)

-9999 to 9999

(engineering unit)

±10% of scaled

span (EUS) *1

OFF

ON

Value

OFF Displayed on

####.# Displayed on

0.0

100.0

±0% of span

(EUS) *1

ON

Display

Conditions

Displayed on all

SKYD-100, -104

SKYD-100, -104

Displayed when

LINEARIZE1 =

SQR

SKYD-104

5

Setting

IM 01B04K01-02E

5-11

Page 36

5.4 Parameter List

No.

E Setting Alarm

E01 Alarm 1 Set Point SET POINT1 Alarm 1 set point

E03 Alarm 1 Set Point SET POINT1 Alarm 1 set point

E07 Alarm 1 Action ALM1 ACTION Displays the direction

E09 Alarm 1 Hysteresis

E15 Alarm 1 ON Delay ON DELAY1 Sets the dead time until the

E17 Alarm 1 OFF Delay OFF DELAY1 Sets the dead time until

E19 Alarm 1 Relay

D60 Self Check SELF CHK Displays the result

Parameter Name Symbol Description Setting Range Factory-set

Parameters

Action

SET(ALM)

Setting range SKYD-100: -999.9 to 999.9%

(*1) SKYD-104: -19999 to 32000 (decimal point position set at

DP1)

Default SKYD-100: 100.0%

SKYD-104: When ALM1 ACTION=DIRECT, SCH1

When ALM1 ACTION=REVERSE, SCL1

On the SKYD-104, this range is initialized when SCH1 and/or

SCL1 are changed.

Setting range (*1) SKYD-101: 0.0 to 100.0 (default: 10.0)

(direct/reverse) of action of

alarm 1.

The setting can be changed

on models except SKYD-

104.

On the SKYD-104, displays

the state of the jumpers on

HYSTERESIS1

RLY1 ACTION Specifies the direction of

*1: For details on the Alarm Setting and Accuracy Warranty Range, see "2.1 Standard

Specifications."

the main board.

Sets the hysteresis until the alarm 1 alarm state is canceled.

Setting range Except SKYD-104: 0.0 to 100.0%

SKYD-104: 0 to 100% of span (EUS) after scaling

Default Except SKYD-104: 2.0%

SKYD-104: 2.0% of span (EUS) after scaling

This range is initialized when SCH1 and/or SCL1 are changed.

alarm is output after alarm

1 enters the alarm state.

alarm output is stopped

after alarm 1 is released

from the alarm state.

alarm 1 relay action.

NRM DE-ENERGIZED:

De-energized during

normal operation

NRM ENERGIZED:

Energized during

normal operation

(GOOD/ERROR) of the self check.

Value

DIRECT

REVERSE

0 to 999 s 0 s

0 to 999 s 0 s

NRM

DE-ENERGIZED

NRM

ENERGIZED

DIRECT Displayed on all

NRM

DEENERGIZED

Display

Conditions

Displayed on

SKYD-100, -104

Displayed on

SKYD-101

5-12

IM 01B04K01-02E

Page 37

1

2

3

App

1

2

3

4

5.4 Parameter List

No.

P Adjustment

P03 Input 1 Zero

P04 Input 1 Span

P60 Self Check SELF CHK Displays the result (GOOD/ERROR) of the self check.

Q Test Parameters TEST

Q04 Alarm 1 Forced

Q60 Self Check SELF CHK Displays the result (GOOD/ERROR) of the self check.

Parameter Name Symbol Description Setting Range Factory-set

Parameters

Adjustment

Adjustment

Output

ADJUST

ZERO ADJ1 Performs zero adjustment (0% side) on input 1.

SPAN ADJ1 Performs span adjustment (100% side) on input 1.

RLY1 TEST Forcibly executes relay

*1: After the test ends, press the OK key to cancel the forced output state and set to the normal

operation state.

n.nnn V RST

n.nnn V INC

n.nnn V HINC

n.nnn V HDEC

n.nnn V DEC

n.nnn indicates the current input value.

Increase or decrease “n.nnn” until the target value is reached.

INC/DEC : Increase/decrease “n.nnn.”

HINC/HDEC : Increase/decrease “n.nnn” more rapidly than INC/

DEC.

RST : When a reset is made, the adjustment values return to their

factory settings.

The adjustment method is the same as ZERO ADJ1.

output regardless of the

input state. (*1)

DE-ENERGIZED

ENERGIZED

Value

Display

Conditions

Display on all.

Display on all.

5

Setting

IM 01B04K01-02E

5-13

Page 38

5.4 Parameter List

5.4.2 SKYD-20x Parameter List

No.

Initial

display

01 Model Name MODEL Displays the model name. Displayed

02 Tag Number TAG NO Displays the tag number that is set.

03 Self Check SELF CHK Displays the result (GOOD/ERROR) of the self check.

A Display 1 DISPLAY1

A01

A03

A15

A16

A54

A55

A56 REV NO. REV NO. Displays the device revision No.

A58 MENU REV MENU REV Displays the revision No. of the parameter group.

A60 Self Check SELF CHK Displays the result (GOOD/ERROR) of the self check.

B Display 2 DISPLAY2

B01 Analog Input 1 Same as item A

B03 PV1

B15 Alarm 1 Relay

B16 Alarm 2 Relay

B60 Self Check

Parameter

Name

Analog Input 1 INPUT1 Input value before input processing (square root or scaling)

PV1 PV1 Input value (engineering unit) after input processing (square

Alarm 1 Relay

Display

Alarm 2 Relay

Display

Status Display STATUS Displays the value added to the value (Hex) indicating the

Parameter Write

Protect

Display

Display

Symbol Description Display

(unit: V)

root or scaling)

RLY1 STATUS Displays the state of the alarm 1 relay.

DE-ENERGIZED: De-energized

ENERGIZED: Energized

RLY2 STATUS Displays the state of the alarm 2 relay.

DE-ENERGIZED: De-energized

ENERGIZED: Energized

self check result.

0000: Normal

0001: EEPROM error

0002: EEPROMSUM error

0004: Low input cut state

0008: Input range exceeded

0010: Setting error

0040: Power interruption during operation

1000: A/D conversion error

WRT PROTECT Displays the state of the Parameter Write Protect jumper.

OFF: Setting of parameters enabled

ON: Setting of parameters disabled

Conditions

on all

Displayed

on all

Displayed on

SKYD-204

Displayed

on all

5-14

IM 01B04K01-02E

Page 39

1

2

3

App

1

2

3

4

5.4 Parameter List

No.

D Setting Parameters SET(I/O)

D01 Tag Number 1 TAG NO.1 8 alphanumerics can be

D02 Tag Number 2 TAG NO.2 8 alphanumerics can be

D03 Comment 1 COMMENT1 8 alphanumerics can be

D04 Comment 2 COMMENT2 8 alphanumerics can be

D17 Linearization 1 LINEARIZE1 Specifies square root

D19 Low Cut 1 LOW CUT1 Specifies low-cut point

D40 Input Decimal Point

D41 Input Scale L SCL1 Sets the conversion

D42 Input Scale H SCH1 Sets the conversion

D46 PV1 PV1 Displays the input value

D47 Input 1 Bias BIAS1 Adds the bias value to

D51 Display Mode DSP MODE Selects the display setter

D60 Self Check SELF CHK Result of self check

Parameter Name Symbol Description Setting Range Factory-set

entered.

entered.

entered.

entered.

calculation ON/OFF.

during square root

calculation.

Position

DP1 Sets the position of the

decimal point for the input

scale (SCH1, SCL1).

standard value at 1V input

to scale and display the

input value in engineering

units.

standard value at 5V input

to scale and displays the

input value in engineering

units.

after input processing

(scaling).

the value after input

processing, and displays as

the PV1.

state after 30 minutes

elapses after a key switch

operation.

OFF: Power save mode

Only the decimal point

is displayed.

ON: Constant ON mode

Data is displayed at

all times regardless of

elapsed time.

(GOOD/ERROR) of the self check.

*1: Initialized when changing SCH1, SCL1

Value

OFF

SQR

0.3 to 100.0 % 1.0 % Displayed on

#####

####.#

###.##

##.###

-9999 to 9999

(engineering unit)

-9999 to 9999

(engineering unit)

±10% of scaled

span (EUS) *1

OFF

ON

OFF Displayed on

####.# Displayed on

0.0

100.0

±0% of span

(EUS) *1

ON

Display

Conditions

Displayed on all

SKYD-200, -204

SKYD-200, -204

Displayed when

LINEARIZE1=SQR

SKYD-204

Displayed on all

5

Setting

IM 01B04K01-02E

5-15

Page 40

5.4 Parameter List

No.

E Setting

E01 Alarm 1 Set Point SET POINT1 Alarm 1 set point

E02 Alarm 2 Set Point SET POINT2 Alarm 2 set point

E03 Alarm 1 Set Point SET POINT1 Alarm 1 set point

E04 Alarm 2 Set Point SET POINT2 Alarm 2 set point

E07 Alarm 1 Action ALM1 ACTION Displays the direction (direct/

Parameter Name Symbol Description Setting

SET(ALM)

Parameters(alarm)

Setting range SKYD-200: -999.9 to 999.9%

(*1) SKYD-204: -19999 to 32000 (decimal point position set at

DP1)

Default SKYD-200: 100.0%

SKYD-204: When ALM1 ACTION=DIRECT, SCH1

When ALM1 ACTION=REVERSE, SCL1

On the SKYD-204, this range is initialized when SCH1 and/or

SCL1 are changed.

Setting range SKYD-200: -999.9 to 999.9%

SKYD-204: -19999 to 32000 (decimal point position set at

DP1)

Default SKYD-200: 100.0%

SKYD-204: When ALM2 ACTION=DIRECT, SCH1

When ALM2 ACTION=REVERSE, SCL1

On the SKYD-204, this range is initialized when SCH1 and/or

SCL1 are changed.

Setting range SKYD-201: 0.0 to 100.0 (default: 10.0)

Setting range SKYD-201: 0.0 to 100.0 (default: 10.0)

reverse) of action of

alarm 1.

The setting can be changed on

models except SKYD-204.

On the SKYD-204, displays the

state of the jumpers on the main

board.

Range

DIRECT

REVERSE

Factory-set

Value

DIRECT Displayed on all

Display

Conditions

Displayed on

SKYD-200, -204

Displayed on

SKYD-200, -204

Displayed on

SKYD-201

Displayed on

SKYD-201

E08 Alarm 2 Action ALM2 ACTION Displays the direction (direct/

E09 Alarm 1 Hysteresis

E10 Alarm 2 Hysteresis

E15 Alarm 1 ON Delay ON DELAY1 Sets the dead time until the

E16 Alarm 2 ON Delay ON DELAY2 Sets the dead time until the

E17 Alarm 1 OFF Delay OFF DELAY1 Sets the dead time until alarm

E18 Alarm 2 OFF Delay OFF DELAY2 Sets the dead time until alarm

HYSTERESIS1

HYSTERESIS2

reverse) of action of

alarm 2.

The setting can be changed on

models except SKYD-204.

On the SKYD-204, displays the

state of the jumpers on the main

board.

Sets the hysteresis until the alarm 1 alarm state is canceled.

Setting range Except SKYD-204: 0.0 to 100.0%

SKYD-204: 0 to 100% of span (EUS) after scaling

Default Except SKYD-204: 2.0%

SKYD-204: 2.0% of span (EUS) after scaling

On the SKYD-204, this range is initialized when SCH1 and/or

SCL1 are changed.

Sets the hysteresis until the alarm 2 alarm state is canceled.

The setting range and default are the same as alarm 1

hysteresis.

On the SKYD-204, this range is initialized when SCH1 and/or

SCL2 are changed.

alarm is output after alarm 1

enters the alarm state.

alarm is output after alarm 2

enters the alarm state.

output is stopped after alarm 1

is released from the alarm state.

output is stopped after alarm 2

is released from the alarm state.

DIRECT

REVERSE

0 to 999 s 0 s

0 to 999 s 0 s

0 to 999 s 0 s

0 to 999 s 0 s

REVERSE

5-16

IM 01B04K01-02E

Page 41

1

2

3

App

1

2

3

4

5.4 Parameter List

No.

E19 Alarm 1 Relay

E20 Alarm 2 Relay

D60 Self Check SELF CHK Displays the result

Parameter Name Symbol Description Setting

Action

Action

RLY1 ACTION Specifies the direction of alarm

1 relay action.

NRM DE-ENERGIZED:

De-energized during normal

operation

NRM ENERGIZED:

Energized during normal

operation

RLY2 ACTION Specifies the direction of alarm

2 relay action.

NRM DE-ENERGIZED:

De-energized during normal

operation

NRM ENERGIZED:

Energized during normal

operation

(GOOD/ERROR) of the self check.

*1: For details on the Alarm Setting and Accuracy Warranty Range, see "2.1 Standard

Specifications."

Range

NRM

DEENERGIZED

NRM

ENERGIZED

NRM

DEENERGIZED

NRM

ENERGIZED

Factory-set

Value

NRM

DEENERGIZED

NRM

DEENERGIZED

Display

Conditions

Displayed on all

5

Setting

IM 01B04K01-02E

5-17

Page 42

5.4 Parameter List

No.

P Adjustment

P03 Zero Adjustment

P04 Span Adjustment

P60 Self Check SELF CHK Displays the result

Q Test Parameters TEST

Q04 Alarm 1 Forced

Q05 Alarm 2 Forced

Q60 Self Check SELF CHK Displays the result

Parameter Name Symbol Description Setting Range Factory-set

Parameters

(Input 1)

(Input 1)

Output

Output

ADJUST

ZERO ADJ1 Performs zero adjustment (0% side) on input 1.

SPAN ADJ1 Performs span adjustment (100% side) on input 1.

RLY1 TEST Forcibly executes relay

RLY2 TEST

*1: After the test ends, press the OK key to cancel the forced output state and set to the normal

operation state.

n.nnn V RST

n.nnn V INC

n.nnn V HINC

n.nnn V HDEC

n.nnn V DEC

n.nnn indicates the current input value.

Increase or decrease “n.nnn” until the target value is reached.

INC/DEC : Increase/decrease “n.nnn.”

HINC/HDEC : Increase/decrease “n.nnn” more rapidly than INC/

DEC.

RST : When a reset is made, the adjustment values return to their

factory settings.

The adjustment method is the same as ZERO ADJ1.

(GOOD/ERROR) of the self check.

output regardless of the

input state.(*1)

(GOOD/ERROR) of the self check.

DE-ENERGIZED

ENERGIZED

Value

Display

Conditions

Displayed

on all

Displayed

on all

5-18

IM 01B04K01-02E

Page 43

1

2

3

App

1

2

3

4

5.4.3 SKYD-30x Parameter List

5.4 Parameter List

No.

Initial

display

01 Model Name MODEL Displays the model name. Displayed

02 Tag Number TAG NO Displays the tag number that is set.

03 Self Check SELF CHK Displays the result (GOOD/ERROR) of the self check.

A Display 1 DISPLAY1

A01

A02

A08 Input Deviation INPUT DEV Deviation value (PV1-PV2) after input processing Displayed

A15

A16

A54

A55

A56 REV NO. REV NO. Displays the device revision No.

A58 MENU REV MENU REV Displays the revision No. of the parameter group.

A60 Self Check SELF CHK Displays the result (GOOD/ERROR) of the self check.

B Display 2 DISPLAY2

B01 Analog Input 1 Same as item A

B02 Analog Input 2

B08 Input Deviation

B15 Alarm 1 Relay

B16 Alarm 2 Relay

B60 Self Check

Parameter

Name

Analog Input 1 INPUT1 Input value before input processing (square root or scaling)

Analog Input 2 INPUT2 Input value before input processing (square root or scaling)

Alarm 1 Relay

Display

Alarm 2 Relay

Display

Status Display STATUS Displays the value added to the value (Hex) indicating the

Parameter Write

Protect

Display

Display

Symbol Description Display

(unit: V)

(unit: V)

RLY1 STATUS Displays the state of the alarm 1 relay.

DE-ENERGIZED: De-energized

ENERGIZED: Energized

RLY2 STATUS Displays the state of the alarm 2 relay.

DE-ENERGIZED: De-energized

ENERGIZED: Energized

self check result.

0000: Normal

0001: EEPROM error

0002: EEPROMSUM error

0004: Low input cut state

0008: Input range exceeded

0010: Setting error

0040: Power interruption during operation

1000: A/D conversion error

WRT PROTECT Displays the state of the Parameter Write Protect jumper.

OFF: Setting of parameters enabled

ON: Setting of parameters disabled

Conditions

on all

Displayed on

SKYD-304

on all

5

Setting

IM 01B04K01-02E

5-19

Page 44

5.4 Parameter List

No.

D Setting Parameters SET(I/O)

D01 Tag Number 1 TAG NO.1 8 alphanumerics can be

D02 Tag Number 2 TAG NO.2 8 alphanumerics can be

D03 Comment 1 COMMENT1 8 alphanumerics can be

D04 Comment 2 COMMENT2 8 alphanumerics can be

D17 Input 1 Square Root

D19 Input 1 Low-cut LOW CUT1 Specifies low-cut point

D40 Input Decimal Point

D41 Input Scale L SCL1 Sets the conversion

D42 Input Scale H SCH1 Sets the conversion

D46 PV1 PV1 Displays the input value

D47 Input 1 Bias BIAS1 Adds the bias value to

D48 PV2 PV2 Displays the input value

D49 Input 2 Bias BIAS2 Adds the bias value to

D51 Display Mode DSP MODE Selects the display setter

D60 Self Check SELF CHK Result of self check

Parameter Name Symbol Description Setting Range Factory-set

entered.

entered.

entered.

Calculation

LINEARIZE1 Specifies square root

DP1 Sets the position of the

Position

*1: Initialized when changing SCH1, SCL1

entered.

calculation ON/OFF.

during square root

calculation.

decimal point for the input

scale (SCH1, SCL1).

standard value at 1V input

to scale and display the

input value in engineering

units.

standard value at 5V input

to scale and displays the

input value in engineering

units.

after input processing

(scaling).

the value after input

processing, and displays as

the PV1.

after input processing

(scaling).

the value after input

processing, and displays as

the PV2.

state after 30 minutes

elapses after a key switch

operation.

OFF: Power save mode

Only the decimal point

is displayed.

ON: Constant ON mode

Data is displayed at

all times regardless of

elapsed time.

(GOOD/ERROR) of the self check.

Value

OFF

SQR

0.3 to 100.0 % 1.0 %

#####

####.#

###.##

##.###

-9999 to 9999

(engineering unit)

-9999 to 9999

(engineering unit)

±10% of scaled

span (EUS) *1

±10% of scaled

span (EUS) *1

OFF

ON

OFF Displayed on

####.# Displayed on

0.0

100.0

±0% of span

(EUS) *1

±0% of span

(EUS) *1

ON

Display

Conditions

Displayed on all

SKYD-304

Displayed on

SKYD-304

and when

LINEARIZE1=SQR

SKYD-304

Displayed on all

5-20

IM 01B04K01-02E

Page 45

1

2

3

App

1

2

3

4

5.4 Parameter List

No.

E Setting

E05 Alarm 1 Set

E06 Alarm 2 Set

E07 Alarm 1 Action ALM1 ACTION Displays the direction (direct/reverse)

E08 Alarm 2 Action ALM2 ACTION Displays the direction (direct/reverse)

E09 Alarm 1

E10 Alarm 2

E15 Alarm 1 ON

E16 Alarm 2 ON

E17 Alarm 1 OFF

E18 Alarm 2 OFF

E19 Alarm 1 Relay

E20 Alarm 2 Relay

E60 Self Check SELF CHK Displays the result (GOOD/ERROR) of the self check.

Parameter

Name

Parameters

(alarm)

Point

Point

Hysteresis

Hysteresis

Delay

Delay

Delay

Delay

Action

Action

Symbol Description Setting Range Factory-set

SET(ALM)

SET POINT1 Alarm 1 set point

SET POINT2 Alarm 2 set point

HYSTERESIS1

HYSTERESIS2

ON DELAY1 Sets the dead time until the alarm is

ON DELAY2 Sets the dead time until the alarm is

OFF DELAY1 Sets the dead time until alarm output

OFF DELAY2 Sets the dead time until alarm output

RLY1 ACTION Specifies the direction of alarm 1 relay

RLY2 ACTION Specifies the direction of alarm 2 relay

*1: For details on the Alarm Setting and Accuracy Warranty Range, see "2.1 Standard Specifications."

Setting range SKYD-302: -999.9 to 999.9%

(*1) SKYD-304: -19999 to 32000 (decimal point position set at DP1)

Default SKYD-302: 100.0%

SKYD-304: When ALM1 ACTION= DIRECT, SCH1-SCL1

When ALM1 ACTION= REVERSE, SCL1-SCH1

On the SKYD-304, this range is initialized when SCH1 and/or SCL1

are changed.

Setting range SKYD-302: -999.9 to 999.9%

(*1) SKYD-304: -19999 to 32000 (decimal point position set at DP1)

Default SKYD-302: -100.0%

SKYD-304: When ALM2 ACTION=DIRECT, SCH1-SCL1

When ALM2 ACTION=REVERSE, SCL1-SCH1

On the SKYD-304, this range is initialized when SCH1 and/or SCL1

are changed.

of action of alarm 1.

The setting can be changed on

models except SKYD-304.

On the SKYD-304, displays the state

of the jumpers on the main board.

of action of alarm 2.

The setting can be changed on

models except SKYD-304.

On the SKYD-304, displays the state

of the jumpers on the main board.

Sets the hysteresis until the alarm 1 alarm state is canceled.

Setting range SKYD-302: 0.0 to 100.0%

SKYD-304: 0 to 100% of span (EUS) after scaling

Default SKYD-302: 2.0%

SKYD-304: 2.0% of span (EUS) after scaling

On the SKYD-304, this range is initialized when SCH1 and/or SCL1

are changed.

Sets the hysteresis until the alarm 2 alarm state is canceled.

The setting range and default are the same as alarm 1 hysteresis.

On the SKYD-304, this range is initialized when SCH1 and/or SCL1

are changed.

output after alarm 1 enters the alarm

state.

output after alarm 2 enters the alarm

state.

is stopped after alarm 1 is released

from the alarm state.

is stopped after alarm 2 is released

from the alarm state.

action.

NRM DE-ENERGIZED: De-energized

during normal operation

NRM ENERGIZED: Energized during

normal operation

action.

NRM DE-ENERGIZED: De-energized

during normal operation

NRM ENERGIZED: Energized during

normal operation

DIRECT

REVERSE

DIRECT

REVERSE

0 to 999 s 0 s

0 to 999 s 0 s

0 to 999 s 0 s

0 to 999 s 0 s

NRM

DEENERGIZED

NRM

ENERGIZED

NRM

DEENERGIZED

NRM

ENERGIZED

Value

DIRECT Displayed on

REVERSE

NRM

DEENERGIZED

NRM

DEENERGIZED

Display

Conditions

Display on all

all

Displayed on

all

5

Setting

IM 01B04K01-02E

5-21

Page 46

5.4 Parameter List

No.

P Adjustment

P03 Zero Adjustment

P04 Span Adjustment

P05 Zero Adjustment

P06 Span Adjustment

P60 Self Check SELF CHK Displays the result (GOOD/ERROR) of the self check. Displayed

Q Test Parameters TEST

Q04 Alarm 1 Forced

Q05 Alarm 2 Forced

Q60 Self Check SELF CHK Displays the result (GOOD/ERROR) of the self check.

Parameter Name Symbol Description Setting Range Factory-set

Parameters

(Input 1)

(Input 1)

(Input 2)

(Input 2)

Output

Output

ADJUST

ZERO ADJ1 Performs zero adjustment (0% side) on input 1.

SPAN ADJ1 Performs span adjustment (100% side) on input 1.

SPAN ADJ2 Zero adjustment (0% side) of input 2

SPAN ADJ2 Span adjustment (100% side) of input 2

RLY1 TEST Forcibly executes relay output

RLY2 TEST

*1: After the test ends, press the OK key to cancel the forced output state and set to the normal

operation state.

n.nnn V RST

n.nnn V INC

n.nnn V HINC

n.nnn V HDEC

n.nnn V DEC

n.nnn indicates the current input value.

Increase or decrease “n.nnn” until the target value is reached.

INC/DEC : Increase/decrease “n.nnn.”

HINC/HDEC : Increase/decrease “n.nnn” more rapidly than INC/

DEC.

RST : When a reset is made, the adjustment values return to their

factory settings.

The adjustment method is the same as ZERO ADJ1.

Adjustment method is the same as ZERO ADJ1.

• On SKYD-304 only

Adjustment method is the same as ZERO ADJ1.

• On SKYD-304 only

regardless of the input state. (*1)

DEENERGIZED

ENERGIZED

Value

Display

Conditions

Displayed

on all

on all

Displayed

on all

5-22

IM 01B04K01-02E

Page 47

1

2

3

App

1

2

3

5

4

Chapter 6 Maintenance

Maintenance

This chapter describes the calibration procedures that can be done in the instrument room

or service shop.

6

Maintenance

IM 01B04K01-02E

6-1

Page 48

6.1 Test Equipment

For efficient maintenance of this alarm unit, it is recommended that the user have the

following test equipment manufactured by Yokogawa or their equivalent.